Dialogic® SS7G2x Signaling Server

SGW Mode User Manual

www.dialogic.com

Copyright© 2005-2007 Dialogic Corporation. All Rights Reserved. You may not reproduce this document in

whole or in part without permission in writing from Dialogic Corporation.

All contents of this document are furnished for informational use only and are subject to change without notice and do not represent a commitment on the part

of Dialogic Corporation or its subsidiaries (“Dialogic”). Reasonable effort is made to ensure the accuracy of the information contained in the document.

However, Dialogic does not warrant the accuracy of this information and cannot accept responsibility for errors, inaccuracies or omissions that may be

contained in this document.

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH DIALOGIC

BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED

IN A SIGNED AGREEMENT BETWEEN YOU AND DIALOGIC, DIALOGIC ASSUMES NO LIABILITY WHATSOEVER, AND DIALOGIC

DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF DIALOGIC PRODUCTS INCLUDING LIABILITY

OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY

INTELLECTUAL PROPERTY RIGHT OF A THIRD PARTY.

Dialogic products are not intended for use in medical, life saving, life sustaining, critical control or safety systems, or in nuclear facility applications.

It is possible that the use or implementation of any one of the concepts, applications, or ideas described in this document, in marketing collateral produced by

or on web pages maintained by Dialogic may infringe one or more patents or other intellectual property rights owned by third parties. Dialogic does not

provide any intellectual property licenses with the sale of Dialogic products other than a license to use such product in accordance with intellectual property

owned or validly licensed by Dialogic and no such licenses are provided except pursuant to a signed agreement with Dialogic. More detailed information

about such intellectual property is available from Dialogic’s legal department at 9800 Cavendish Blvd., Montreal, Quebec, Canada H4M 2V9. Dialogic

encourages all users of its products to procure all necessary intellectual property licenses required to implement any concepts or applications and

does not condone or encourage any intellectual property infringement and disclaims any responsibility related thereto. These intellectual property

licenses may differ from country to country and it is the responsibility of those who develop the concepts or applications to be aware of and comply

with different national license requirements.

Dialogic is a registered trademark of Dialogic Corporation. Dialogic's trademarks may be used publicly only with permission from Dialogic. Such permission

may only be granted by Dialogic’s legal department at 9800 Cavendish Blvd., 5th Floor, Montreal, Quebec, Canada H4M 2V9. Any authorized use of

Dialogic's trademarks will be subject to full respect of the trademark guidelines published by Dialogic from time to time and any use of Dialogic’s trademarks

requires proper acknowledgement.

Windows is a registered trademark of Microsoft Corporation in the United States and/or other countries. Other names of actual companies and products

mentioned herein are the trademarks of their respective owners.

®

PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED,

Publication Date: September 2007

Document Number: 05-2304-004

2

Dialogic® SS7G2x Signaling Server SGW Mode User Manual Issue 4

Contents

1Overview.................................................................................................................. 8

1.1 General Description............................................................................................. 8

1.2 Related Information............................................................................................ 8

1.3 Applicability ....................................................................................................... 9

1.4 Hardware Overview....................... .. .. .................................................................. 9

1.4.1 Part Numbers.......................................................................................... 9

1.5 Connectivity....................................................................................................... 9

1.6 User Interface.................................................................................................... 9

1.7 Configuration and Program Storage......................................................................10

1.8 IP Security........................................................................................................10

1.9 Functional Summary ..........................................................................................10

1.9.1 Signaling...............................................................................................10

1.9.2 Configuration Model................................................................................11

1.9.3 Cross Connections ..................................................................................11

1.9.4 Monitoring .............................................................................................11

1.9.5 Remote Data Centres..............................................................................12

1.9.6 Alarm Log..............................................................................................12

1.9.7 M3UA Backhaul Operation........................................................................12

1.9.8 M2PA Longhaul Operation ........................................................................13

1.9.9 Default Routing ......................................................................................13

1.9.10 Resilience..............................................................................................13

2 Specification ............................................................................................................15

2.1 Hardware Specification........... .. ................................ .. ................................ .. ......15

2.2 System Capacity................................................................................................15

2.3 System Capabilities............................................................................................15

2.4 Signaling Capabilities (Per System) ......................................................................15

2.5 Physical Interfaces (Per Signaling Board) ..............................................................15

2.6 TDM Signaling Capabilities (Per Signaling Board)....................................................15

3 Installation and Initial Configuration .......................................................................16

3.1 Installation .......................................................................................................16

3.2 Connecting a VT100 Terminal ..............................................................................16

3.3 Software Download............................................................................................16

3.4 Initial Configuration ..... .. ............................... .. ................................ .. .................17

3.5 Configuration Procedure .....................................................................................19

4Operation.................................................................................................................20

4.1 General............................................................................................................20

4.2 Log On/Off Procedure.........................................................................................20

4.3 Command Character Set and Syntax ....................................................................21

4.4 Command Formats........................................................................ .....................21

4.5 Command Entry ............ ....................................................................................21

4.6 Dangerous Commands .......................................................................................22

4.7 Changing Configuration Data...............................................................................22

4.8 Command Responses...................... .. .. ...............................................................22

4.9 FTP Access........................................................................................................23

4.10 Backing Up System Software...............................................................................24

4.10.1 Software Backup to a Remote Data Centre.................................................24

4.11 Updating System Software..................................................................................24

4.11.1 Software Update from a Remote Data Centre .............................................24

4.11.2 Software Update from CD-ROM.................................................................24

4.11.3 Software Update from Startup..................................................................25

4.12 Backing Up Configuration Data ............................................................................25

4.12.1 Configuration Backup to Remote Data Centre .............................................25

4.13 Updating Configuration Data ...............................................................................26

3

Contents

4.13.1 Configuration Update from a Remote Data Centre .......................................26

4.13.2 Configuration Update from CD ROM...........................................................26

4.13.3 Configuration Update from Startup............................................................26

4.14 System Licenses................................................................................................27

4.14.1 Purchasing System License s........................................................... .. .. ......27

4.14.2 Installing System Licenses.......................................................................28

4.14.3 License Update from Remote Data Centre ..................................................28

4.14.4 License Update by FTP.............................................................................29

5 Parameter Definitions..............................................................................................30

5.1 Parameter Table ................................................................................................30

5.2 Remote Operations ............................................................................................37

5.3 Signaling Gateway Timers...................................................................................38

5.3.1 Signaling Gateway-Specific Timers............................................................38

5.3.2 MTP3-Specific Timers ..............................................................................38

5.3.3 SCTP-Specific Timers........ .. .. ................................ ................................ ...39

5.4 Board Types......................................................................................................39

6 Command Definitions...............................................................................................40

6.1 Command Groups........................................ .. .. ..................................................40

6.2 Command Notation....................... .. .. ................................ .. ...............................40

6.3 Command Attributes .................................. .. .. ................................ ....................40

6.4 Alarm Commands ........................................ ................................ ......................41

6.4.1 ALCLS – Alarm Class Set..........................................................................42

6.4.2 ALCLP – Alarm Class Print........................................................................42

6.4.3 ALFCP – Alarm Fault Code Print ................................................................43

6.4.4 ALLIP – Alarm List Print...........................................................................44

6.4.5 ALLOP – Alarm Log Print............................................. .............................45

6.4.6 ALREI – Alarm Reset Initiate ....................................................................46

6.4.7 ALTEI – Alarm Test Initiate.......................................................................46

6.4.8 ALTEE – Alarm Test End............................... ................................ .. ..........47

6.5 Configuration Commands....................................................................................48

6.5.1 CNBOI – Configuration Board Initiate.........................................................49

6.5.2 CNBOE – Configuration Board End.............................................................49

6.5.3 CNBOP – Configuration Board Print ...........................................................50

6.5.4 CNBUI – Configuration Back Up Initiate .......................... .. ... .. ....................50

6.5.5 CNMOI – Configuration Monitor Initiate......................................................51

6.5.6 CNMOE – Configuration Monitor End..........................................................51

6.5.7 CNMOP – Configuration Monitor Print....................................... .. ................52

6.5.8 CNPCI – Configuration PCM Initiate...........................................................52

6.5.9 CNPCC – Configuration PCM Change........................... .. .. .. .........................53

6.5.10 CNPCE – Configur ation PCM End ............. ................................ .. .. ..............53

6.5.11 CNPCP – Configuration PCM Print ..............................................................54

6.5.12 CNRDI – Configuration Remote Data Centre Initiate ....................................54

6.5.13 CNRDC – Configuration Remote Data Centre Change...................................55

6.5.14 CNRDE – Configuration Remote Data Centre End.........................................55

6.5.15 CNRDP – Configuration Remote Data Centre Print .......................................56

6.5.16 CNSWP – Configuration Software Print.......................................................56

6.5.17 CNSYS – Configuration System Set ...........................................................57

6.5.18 CNSYP – Configuration System Print..........................................................59

6.5.19 CNTDS – Configuration Time and Date Set.................................................60

6.5.20 CNTDP – Configuration Time And Date Print ...............................................60

6.5.21 CNTOS – Configuration Timeout Value Set..................................................61

6.5.22 CNTOP – Configuration Timeout Value Print................................................61

6.5.23 CNTSP – Configuration Timeslot Print ........................................................62

6.5.24 CNUPI – Configuration Update Initiate .......................................................63

6.5.25 CNXCI – Configuration Cross Conne ct Initiate.............................................64

6.5.26 CNXCE – Configuration Cross Connect End.................................................64

6.5.27 CNXCP – Configuration Cross Connect Print................................................65

6.6 SS7 Signaling Commands...................................................................................66

6.6.1 C7LSI – CCS SS7 Link Set Initiate.............................................................67

6.6.2 C7LSC – CCS SS7 Link Set Change ...........................................................68

6.6.3 C7LSE – CCS SS7 Link Set End.................................................................69

4

Dialogic® SS7G2x Signaling Server SGW Mode User Manual Issue 4

6.6.4 C7LSP – CCS SS7 Link Set Print................................................................69

6.6.5 C7RTI – CCS SS7 Route Initiate................................................................70

6.6.6 C7RTC – CCS SS7 Route Change...............................................................71

6.6.7 C7RTE – CCS SS7 Route End....................................................................72

6.6.8 C7RTP – CCS SS7 Route Print...................................................................72

6.6.9 C7SLI – CCS SS7 Signaling Link Initiate.....................................................73

6.6.10 C7SLC – CCS SS7 Signaling Link Change ...................................................74

6.6.11 C7SLE – CCS SS7 Signaling Link End.........................................................75

6.6.12 C7SLP – CCS SS7 Signaling Link Print........................................................75

6.7 IP Commands ...................................................................................................76

6.7.1 IPEPS – Set Ethernet Port Speed...............................................................77

6.7.2 IPEPP – Display Ethernet Port Speed .........................................................77

6.7.3 IPGWI – Internet Protocol Gateway Initiate ................................................78

6.7.4 IPGWE – Internet Protocol Gateway End ....................................................78

6.7.5 IPGWP – Internet Protocol Gateway Print...................................................79

6.8 MML Commands................................................................................................80

6.8.1 MMLOI – MML Log Off Initiate...................................................................81

6.8.2 MMLOP – MML Log Off Print......................................................................81

6.8.3 MMLOS – MML Log Off Set .......................................................................82

6.8.4 MMPTC – MML Port Change ......................................................................82

6.8.5 MMPTP – MML Port Print ..........................................................................83

6.9 Maintenance Commands.....................................................................................84

6.9.1 MNBLI – Maintenance Blocking Initiate ......................................................85

6.9.2 MNBLE – Maintenance Blocking End ..........................................................86

6.9.3 MNINI – Maintenance Inhibit Initiate .........................................................87

6.9.4 MNINE – Maintenance Inhibit End .............................................................87

6.9.5 MNRSI – Maintenance Restart System Initiate ............................................88

6.10 Measurement Commands....................................................................................89

6.10.1 MSC7P – Measurements SS7 Print.............................................................90

6.10.2 MSEPP – Measurement Ethernet Port Print .................................................92

6.10.3 MSPCP – Measurements PCM Print ............................................................94

6.10.4 MSSLP – Measurements SIGTRAN Link Print...............................................95

6.10.5 MSSYP – Measuremen ts System Print......................................... .. .............96

6.11 Remote Data Centre Commands ..........................................................................97

6.11.1 RDCRI – Remote Data Centre Continuous Record Initiate .............................98

6.11.2 RDCRC – Remote Data Centre Continuous Record Change......................... ...99

6.11.3 RDCRE – Remote Data Centre Continuous Record End ...............................100

6.11.4 RDCRP – Remote Data Centre Continuous Record Print ..............................100

6.11.5 RDPDI – Remote Data Centre Periodic Data Initiate...................................101

6.11.6 RDPDE – Remote Data Centre Periodic Data End.......................................101

6.11.7 RDPDP – Remote Data Centre Periodic Data Print......................................102

6.11.8 RDPRI – Remote Data Centre Periodic Report Initiate.................................103

6.11.9 RDPRC – Remote Data Centre Periodic Report Change ...............................104

6.11.10RDPRE – Remote Data Centre Periodic Report End.....................................104

6.11.11RDPRP – Remote Data Centre Periodic Report Print....................................105

6.12 Signaling Gateway Commands...........................................................................106

6.12.1 SGDPI – Signaling Gateway Destination Point Initiate ................................107

6.12.2 SGDPC – Signaling Gateway Destination Point Change...............................107

6.12.3 SGDPE – Signaling Gateway Destination Point End ....................................108

6.12.4 SGDPP – Signaling Gateway Destination Point Print...................................108

6.12.5 SGIRI – Signaling Gateway Incoming Route Initiate...................................109

6.12.6 SGIRC – Signaling Gateway Incoming Route Change ................................110

6.12.7 SGIRE – Signaling Gateway Incoming Route End.......................................110

6.12.8 SGIRP – Signaling Gateway Incoming Route Print......................................111

6.12.9 SGRKI – Signaling Gateway Routing Key Initiate.......................................112

6.12.10SGRKE – Signaling Gateway Routing Key End...........................................113

6.12.11SGRKP – Signaling Gateway Routing Key Print..........................................113

6.13 SIGTRAN Commands........................................................................................114

6.13.1 SNALI – SIGTRAN Application Server List Initiate ......................................115

6.13.2 SNALE – SIGTRAN Application Server List End........................... .. .. ...........115

6.13.3 SNALP – SIGTRAN Application Server List Print.........................................116

6.13.4 SNAPI – SIGTRAN Application Server Initiate............................................116

6.13.5 SNAPE – SIGTRAN Application Server End................................................117

6.13.6 SNAPP – SIGTRAN Application Server Print............................................... 117

6.13.7 SNNAI – SIGTRAN Network Appearance Initiate.................................. .. .. ..118

5

Contents

6.13.8 SNNAE – SIGTRAN Network Appearance End............................................118

6.13.9 SNNAP – SIGTRAN Network Appearance Print...........................................119

6.13.10 SNSLI – SIGTRAN Signaling Link Initiate..................................................120

6.13.11 SNSLC – SIGTRAN Signaling Link Change.................................................121

6.13.12 SNSLE – SIGTRAN Signaling Link End......................................................121

6.13.13SNSLP – SIGTRAN Signaling Link Print.....................................................122

6.14 Status Commands ...........................................................................................123

6.14.1 STALP – Status Alarm Print ....................................................................124

6.14.2 STAPP – Status Application Server Print ..................................... .. .. ..........125

6.14.3 STBOP – Status Board Print....................................................................126

6.14.4 STCRP – Status C7 Route Print ...............................................................127

6.14.5 STC7P – Status C7 Link Print..................................................................128

6.14.6 STEPP – Status Ethernet Port Print..........................................................129

6.14.7 STIPP – Status IP Print ..........................................................................130

6.14.8 STPCP – Status PCM Print ......................................................................131

6.14.9 STRDP – Status Remote Data Centre Print ...............................................132

6.14.10STSLP – Status SIGTRAN Link Print.............................. ...........................133

6.14.11STSYP – Status System Print..................................................................134

7 Configuration Overview .........................................................................................135

7.1 System, Hardware and Signaling Configuration....................................................135

7.1.1 System Configuration............................................................................135

7.1.2 Boards and PCMs........................................................................ ..........136

7.2 Signaling Configuration.....................................................................................136

7.2.1 SS7 Configuration.................................................................................136

7.2.2 M3UA Configuration ..............................................................................138

7.3 Routing Configuration.......................................................................................139

7.4 Management and Operations.............................................................................141

7.5 Default Routing ...............................................................................................141

7.5.1 Configuring Default Routing ...................................................................141

7.6 Resilience .......................................................................................................142

7.6.1 IP Port Bonding ....................................................................................142

7.6.2 Dual Resilient Operation ........................................................................143

7.6.3 Multihoming.........................................................................................145

8 Alarm Fault Code Listing ........................................................................................146

9 Remote Data Centre Operation...............................................................................151

9.1 Local Data Centres...........................................................................................151

9.2 Continuous Records .........................................................................................151

9.3 Periodic Reporting............................................................................................151

9.3.1 C7 Link Traffic Measurements.................................................................151

9.3.2 PCM Traffic Measurements ........................................ .............................151

9.3.3 SIGTRAN Link Traffic Measurements........................................................152

9.3.4 Ethernet Port Traffic Measurements.........................................................152

9.3.5 System Measurements ..........................................................................152

9.4 RDC File Formats......................................... .. .. ................................ ................152

9.4.1 Alarm Record File Format...................................................................... .152

9.4.2 Ethernet Port Measurements File Format ..................................................153

9.4.3 PCM Measurements File Format ..............................................................153

9.4.4 SS7 Link Measurements File Format ........................................................154

9.4.5 SIGTRAN Link Measurements File Format.................................................155

9.4.6 System Measurements File Format..........................................................155

9.5 RDC Configuration and Usage.............................. .. .. ... ............................... .. .. ... .155

9.5.1 RDC Initialization........................................ ................................ .. ........155

9.5.2 Continuous Records ..............................................................................156

9.5.3 Periodic Reports....................................................................................156

9.5.4 Software Update...................................................................................157

9.5.5 Configuration Backup ............................................................................157

9.5.6 Configuration Update ............................................................................157

6

Dialogic® SS7G2x Signaling Server SGW Mode User Manual Issue 4

9.5.7 Software Option Installation...................................................................157

10 SS7G2x SNMP MIB.................................................................................................158

11 Worked Configuration Examples ............................................................................160

11.1 Backhaul Configuration............................................. ................................ .. .. ....160

11.2 M2PA Longhaul Configuration ............................................................................160

11.3 Dual Resilient Configuration ..............................................................................161

11.3.1 SG 1 Configuration................................................................................162

11.3.2 SG 2 Configuration................................................................................162

12 Command Summary...............................................................................................163

Glossary.................................................................................................................166

Index.....................................................................................................................168

Figures

1 M3UA Backhaul Configuration........................ .. ................................ .. .. .. .....................13

2 M2PA Longhaul Configur ation............................................................ .. .......................13

3 Dual Resilient Configuration.......................................................................................14

4 Multiple IP Networks..................... .. .. ................................ .. .. ................................ ..135

5 Physical Configuration.............................................................................................136

6 SS7 Signaling Example............................................................................................137

7 M2PA Example........................... ............................................................................138

8 M3UA Backhaul Example ....... .. .. .. ................................ .. ............................... ... ........139

9 Routing Configuration Example.................................................................................140

10 System Using Default Routing ..................................................................................142

11 Dual Resilient Operation..........................................................................................144

12 Example Back-Haul Co nfig uration ........................................... .. .. ... ...........................160

13 M2PA Longhaul Configuration.............................. ................................ .. .. .................161

14 Example Dual Resilient Configuration ........................................................................161

Tables

1 Command Rejection Responses ..................................................................................22

2 Parameter Definitions................................................................................................30

3 Remote Operation Types....................................... .. ................................ ...................37

4 Signaling Gateway Specific Timers..............................................................................38

5 MTP3 ITU Timers......................................................................................................38

6 MTP3 ANSI Timers....................................................................................................38

7 SCTP-Specific Timers................................................................................................39

8 Board Types.............................................................................................................39

9 Alarm Fault Codes ..................................................................................................146

Revision History

Date Part Number Issue Description of Changes

September 2007 05-2304-004 4 Updates for brand changes, web sites, and other minor corrections.

December 2005 05-2304-003 3

May 2005 05-2304-001 2 Supports the first production release.

March 2005 05-2304-001-01 1 Field Trial release.

Note: The latest released issue of this guide can be found at:

http://www.dialogic.com/support/helpweb/signaling

Updates to include support for resilient IP connectivity, additional

measurement and status commands (STSYP, MSSYP and MSEPP) and

other minor enhancements and corrections.

7

Chapter 1 Overview

Chapter 1: Overview

1.1 General Description

®

The Dialogic

SS7G21 and SS7G22 products," individually as "SS7G21" and "SS7G22," respectively, or individually or

interchangeably as "SS7G2x"), with the Dialogic® SS7SBG20SGW SGW Mode software license installed and

enabled, operate as SIGTRAN Signaling Gateways (hereinafter sometimes referred to as "Signaling

Gateway"). They provide an interface between SS7 and IP networks, allowing SS7 information to be carried

over IP to either IP resident signaling points and applications (for example, a soft switch) or to another

Signaling Gateway. IETF SIGTRAN protocols are used to ensure interoperability with third party equipment.

The Signaling Server may be purchased as one of two equipment types; SS7G21 and SS7G22. Each

equipment type uses the same chassis and operates with the same software, but uses different signaling

boards. See Section 1.4, “Hardware Overview” on page 9 for a fuller description of the Signaling Server

hardware.

The Signaling Gateway uses the SIGTRAN M3UA protocol to "backhaul" SS7 signaling messages to IP

resident Application Servers, removing the need for Application Hosts to have dedicated SS7 MTP services or

hardware. Application Servers using the Signalling Gateway may be part of a single point code or multiple

point codes.

The Signaling Gateway M3UA architecture uses open standards interfaces, providing flexibility , scalability and

resilience. It is easy to add or reconfigure M3UA Application Servers and Signaling Gateways to meet

demands for new services or increased capacity.

SS7G21 and SS7G22 Signaling Servers, (hereinafter sometimes referred to collectively as "the

The Signaling Gateway also supports SIGTRAN M2PA protocol to talk to other Point Codes over IP links,

rather than TDM. M2PA may be used to connect within the central office, or for longhaul links over IP.

The SIGTRAN Signaling Gateway (SGW) functionality is provided as a software option on the SS7G21 and

SS7G22 Signaling Servers. To enable this functionality, order and install the SS7SBG20SGW software

license. A unit with the SGW Mode license installed and enabled is referred to as a “Signaling Gateway”

throughout this manual.

When the software license is either not installed or deactivated, the SS7G21 and SS7G22 act as SS7

Signaling Interface Units (SIUs), providing an interface to SS7 networks for a number of distributed

application platforms via TCP/IP LAN. In this mode, the units implement the SS7 Message Transfer Part

(MTP) and a number of User Parts (ISUP, SCCP, TCAP, MAP, IS41 and INAP). See the SS7G2x SIU Mode User

Manual for a detailed description of this mode of operation.

The SS7G21 and SS7G22, when fitted with the DSC Mode software license, operate as a protocol converter.

It provides protocol interworking between any pair of telephony protocols for both network protocols and

access protocols. Description and use of the system acting as a protocol converter is outside the scope of this

manual. See the SS7G2x DSC Mode User Manual for a detailed description of this mode of operation.

The SS7G21 and SS7G22 are shipped without the SGW Mode Software License installed and therefore start

up initially as SS7 Signaling Interface Units (SIUs). The procedures for the purchase and installation of the

SGW and other software options are described in Section 4.14, “System Licenses” on page 27. The

procedures required to configure a unit for SGW operation as well as those for initial system configuration

are described in Chapter 3, “Installation and Initial Configuration”.

1.2 Related Information

®

This user manual, together with the Dialogic

SS7G21 and SS7G22 Hardware Manual forms the

documentation set for the SGW mode of operation of an SS7G2x. The Dialogic® SS7G21 and SS7G22

Hardware Manual addresses the hardware-specific aspects of the product including: hardware variants,

installation, specification, module replacement and a full description of the hardware modules. This user

manual describes the user interface together with all parameters and configuration commands.

The full title of the hardware manual is:

• Dialogic

®

SS7G21 and SS7G22 Signaling Servers Hardware Manual –

(05-2300-xxx)

8

®

Dialogic

SS7G2x Signaling Server SGW Mode User Manual Issue 4

The latest software and documentation supporting SS7G2x products is available on the web at

http://www.dialogic.com/support/helpweb/signaling.

The product data sheet is available at

http://www.dialogic.com/support/helpweb/signaling.

®

For more information on Dialogic

SS7 products and solutions, visit

http://www.dialogic.com/support/helpweb/signaling.

When used for M3UA backhaul operation, the Signaling Gateway may operate with an ASP operating either

an Dialogic M3UA Application Server or an Application Server provided by a third party vendor. See the

Dialogic

®

SS7 Protocols Programmer’s Manual for SIGTRAN Host Software for documentation on the

configuration and use of a Dialogic M3UA Application Server.

1.3 Applicability

This manual is applicable to SS7G2x units with software V3.02 and later installed. This manual is not

applicable when operating as a Signaling Interface Unit (SIU) or as a DSC Protocol Converter (DSC). See the

Dialogic

®

SS7G2x SIU Mode User Manual and the Dialogic® SS7G2x DSC Mode User Manual for descriptions

use of these modes of operation.

1.4 Hardware Overview

The Signaling Gateway may be purchased as one of two equipment types; SS7G21 and SS7G22. Each

equipment type uses the same chassis and operates with the same software, but differ in the type of preinstalled SS7 Signaling boards. This provides options in the numbers and types of links and ports available.

An SS7G21 may be purchased with one, two, or three SPCI2S boards (where each board provides four SS7

links, two T1/E1 interfaces and two V.11 serial ports per board) or one, two or three SPCI4 boards (where

each board provides four SS7 links and four T1/E1 interfaces per board).

An SS7G22 may be purchased with one, two or three SS7HDP boards (where each board provides 64 SS7

links and four T1/E1 interfaces per board) with a system maximum of 128 SS7 links.

When T1 or E1 is selected, the Signaling Gateway may be configured to pass the bearer channels from one

PCM port to another, effectively “dropping out” the signaling in line.

See Chapter 2, “Specification” for a full definition of the capabilities of the system.

1.4.1 Part Numbers

®

See the Dialogic

SS7G21 and SS7G22 Hardware Manual for a full list of the ordering codes and definitions

of all of the hardware variants of the two equipment types.

1.5 Connectivity

TDM SS7 signaling can interface to the Signaling Gateway using balanced 1544 kbit/sec (T1) balanced

connections in accordance with G.733 or 2048 kbit/sec (E1) connections in accordance with G.703. SS7

signaling can also be presented on a V.11 (56/64 kbit/sec) synchronous serial interface.

MP2A signaling used for communication between paired Signaling Gateways can be received at the conveter

using 4 x 1 Gbit/sec RJ45 Ethernet™ interfaces.

1.6 User Interface

The Signaling Gateway provides serial port and telnet connections for configuration and management. All

ports provide identical functionality and operate using text-based MML (Man Machine Language) commands

in accordance with CCITT recommendations.

The serial and telnet ports allow the user to configure the Signaling Gateway for operation and to carry out

subsequent modifications to the configuration. They allow the user to read the current status of the various

signaling entities and to view the current active alarms and a history of past alarm events.

9

Chapter 1 Overview

The Signaling Gateway provides SNMP V1 support to allow the reporting of alarms to an SNMP manager. See

Chapter 10, “SS7G2x SNMP MIB” for more information.

The Signaling Gateway has alarm indicators on the front panel and alarm relays for connection to an

integrated management system.

1.7 Configuration and Program Storage

All configuration data is stored on hard disk and is automatically recovered after system restart.

Configuration data may optionally be backed up to a remote computer, previously backed-up configurations

can be reloaded.

All operating software is stored on hard disk and is automatically initiated after system restart. The oper ating

software can be updated either by reading a new software release from CD ROM or by FTP transfer from a

remote computer. In both cases, software update is initiated by MML command. See Section 4.11, “Updating

System Software” on page 24 for details. Following a software update, the Signaling Gateway automatically

uses the saved configuration data so that there is no need to reenter the configuration parameters.

1.8 IP Security

The Signaling Gateway offers a number of security features to protect it from unwarranted access on its IP

interface. It is recommended that the user always enable the optional password protection on the

management interface port and on the FTP server port (if used).

For additional security, the Signaling Gateway is also equipped to support

Secure Shell (SSH).

Unused ports are disabled to increase security against unintentional or malicious interference.

Additional security may be gained by separating management and signaling IP traffic. This can be achieved

by configuring specific Ethernet ports for traffic and utilizing other Ethernet ports for system management.

It should be understood that while the Signaling Gateway has been designed with security in mind, it is

recommended that Signaling Gateway accessibility over IP is restricted to as small a network as possible. If

the unit is accessible by third parties, the use of a third-party firewall should be considered.

1.9 Functional Summary

The functional summary is described in the following topics:

telnet and FTP access using a

• Signaling

• Configuration Model

• Cross Connections

• Monitoring

• Remote Data Centres

• Alarm Log

• M3UA Backhaul Operation

• M2PA Longhaul Operation

• Dual Operation

• Default Routing

1.9.1 Signaling

The Signaling Gateway supports the Message Transfer Part (MTP) in accordance with ITU Recommendations

Q.700, Q.704 and Q.707 and ANSI operation in accordance with ANSI T1.111.

When a link set contains two or more signaling links, the Signaling Gateway supports load sharing and the

full changeover and changeback procedures in accordance with ITU-T Q.704.

10

®

Dialogic

SS7G2x Signaling Server SGW Mode User Manual Issue 4

The Signaling Gateway supports up to 128 TDM SS7 signaling links allowing the Signaling Gateway to

interface over TDM to a maximum of 64 other signaling points.

If required, each signaling link in a link set can be terminated on a separate signaling board providing

additional resilience.

The Signaling Gateway can have a presence in up to four separate IP subnets.

The Signaling Gateway supports up to 32 M2PA SS7 signaling links, allowing the Signaling Gateway to

interface over IP to a maximum of 32 other signaling points.

M2PA is supported in accordance with the IETF SS7 MTP2-User Peer-to-Peer Adaptation Layer specification.

SCTP is supported in accordance with IETF RFC 2960 and RFC 3309 Stream Control Transmission Protocol.

The Signaling Gateway supports communication with up to 200 Application Servers Processes (ASPs) for

backhaul operation over M3UA.

M3UA is supported in accordance with the IETF RFC 3332 SS7 MTP3 User Adaptation Layer.

1.9.2 Configuration Model

MTP data messages are considered to arrive at either an MTP3 link set or an M3UA SIGTRAN link. The link

set or M3UA SIGTRAN link identifies the network and SS7 format of the message. MTP3 link sets can exist

above a TDM MTP2 signaling link or a signaling link utilizing a M2PA SIGTRAN link for communication over IP.

The decision as to how to process the data message is performed by the incoming route. The incoming

route is identified by the network and domain (either MTP or IP) that a message arrives from.

The incoming route then determines whether the message requires further analysis of the data prior to

destination selection by looking up a routing key table or whether a destination can immediately be

selected.

If the Signaling Gateway determines that a routing key table be looked up, the data from the data message

is compared with routing keys in a routing key table. If a match is found, and the destination for that routing

key is in service, that destination is used. Otherwise, if the incoming route also has a destination associated

with it, that default destination is used. If no routing key table is associated with it, the default destination is

used.

A destination can route a data message to either an Application Server (AS) or to MTP (MTP over MTP2 or

MTP over M2PA). Selection of whether MTP or IP routing is used is determined by the availability of the data

messages point code in the MTP or IP domain and whether MTP or IP has priority.

If MTP routing is selected, the data message is sent out on an MTP SS7 route that matches the point code of

the data message. It is possible to configure MTP3 with a default route for use when it is undesirable to

preconfigure all routes that are used.

See Chapter 7, “Configuration Overview” for a more detailed configuration discussion and Chapter 11,

“Worked Configuration Examples” for some examples.

1.9.3 Cross Connections

The Signaling Gateway allows the user to set up cross connections (semi-permanent connections) between

an incoming timeslot on one PCM port and an outgoing timeslot on any PCM port. These connections can

either be simplex or duplex.

1.9.4 Monitoring

The Signaling Gateway allows the user to monitor TDM signaling links by dropping a copy of the signaling to

a spare PCM port. This allows for a protocol analyzer to be left connected to one PCM port and gives the user

the ability to control remotely which signaling links are monitored. Each monitored signaling link requires

two timeslots on the spare PCM port, one to monitor the send direction and the other for the receive

direction.

11

Chapter 1 Overview

1.9.5 Remote Data Centres

The Signaling Gateway supports the transfer of software updates, configuration files, alarm reports and

periodic measurements over Ethernet to/from a remote location, the Remote Data Centre (RDC).

Multiple RDCs can be configured by specifying an IP address and a user name and password for the Signaling

Gateway to use to “logon” to the RDC.

Data transfer to the RDC uses the File Transfer Protocol (FTP).

Measurement reports are made on a configurable periodic basis.

Optionally, since it can be configured as an FTP server, the Signaling Gateway itself can be configured to act

as an RDC, thus allowing RDC operation to be performed locally on the Signaling Gateway itself.

See Chapter 9, “Remote Data Centre Operation” for a more detailed description of the capabilities and

configuration of an RDC.

1.9.6 Alarm Log

®

The Dialogic

hardware or the operation of the protocols. Each alarm condition is assigned a severity/class (3 = Critical,

2 = Major , 1 = Minor) and a category and ID, which give more detail about the alarm. There are a number of

mechanisms described below, by which these conditions can be communicated to management systems, and

ultimately to the system operator (see Chapter 8, “ Alarm F ault Code Listing” for a full list of alarm t ypes, and

their reporting parameters):

• Active alarms are indicated on the front panel of the unit by three LEDs showing the severity; CRT, MJR

and MNR. See the Dialogic

these indicators.

SS7G2x product is able to detect a number of events or alarm conditions relating to either the

®

SS7G21 and SS7G22 Hardware Manual for information on the location of

• Active alarms may be indicated remotely from the unit, by connecting to relay outputs provided by the

SS7G2x. There are contacts for each severity; Critical, Major and Minor. See the SS7G21 and SS7G22

Hardware Manual for information on the location, pinout and rating of the Alarms connector.

• Alarm events (class, category and ID) may be reported to an SNMP manager. Activation of SNMP V1

support and the SNMP MIB are described in Chapter 10, “SS7G2x SNMP MIB”.

• A system operator can obtain a listing of the current alarm status (ID, class, fault title, occurrence time

and title) using the ALLIP management terminal command described in Section 6.4.4, “ALLIP” on

page 44.

• A system operator can access a log of the current and previous alarms using the ALLOP management

terminal command described in Section 6.4.5, “ALLOP” on page 45. The Alarm Log has the capacity for

up to 200 entries, each entry detailing the ID, title, alarm class, fault title, occurrence time, status

(active or cleared), and cleared time (if appropriate). If a new fault occurs when the log is full, the oldest

entry that is either cleared, of lower class, or equal class is overwritten, in that order of preference. The

operator may request a display of the log at any time and ma y remo ve entries that have cleared status.

• The alarm log may also be reported to a Remote Data Centre (RDC). See Section 9, “Remote Data

Centre Operation” on page 151 for the configuration and operation of an RDC and for the format of the

alarm log records.

1.9.7 M3UA Backhaul Operation

The Signaling Gateway can use the SIGTRAN protocol M3UA to “backhaul” SS7 information to an IP resident

Application Server (AS) operating on one or more Application Server Processes (ASPs). Examples of

Application Servers are Media Gateway Controllers or IP resident databases. In both cases, the Application

Server can operate as a Signaling End Point (SEP), where SS7 User Part Protocols, such as SCCP or ISUP,

operate above a M3UA layer on the host.

12

®

Dialogic

SS7G2x Signaling Server SGW Mode User Manual Issue 4

Figure 1. M3UA Backhaul Configuration

SEP

SS7 Links

SS7G2x

M3UA Links

ASP1

Application

Server (AS)

ASP2

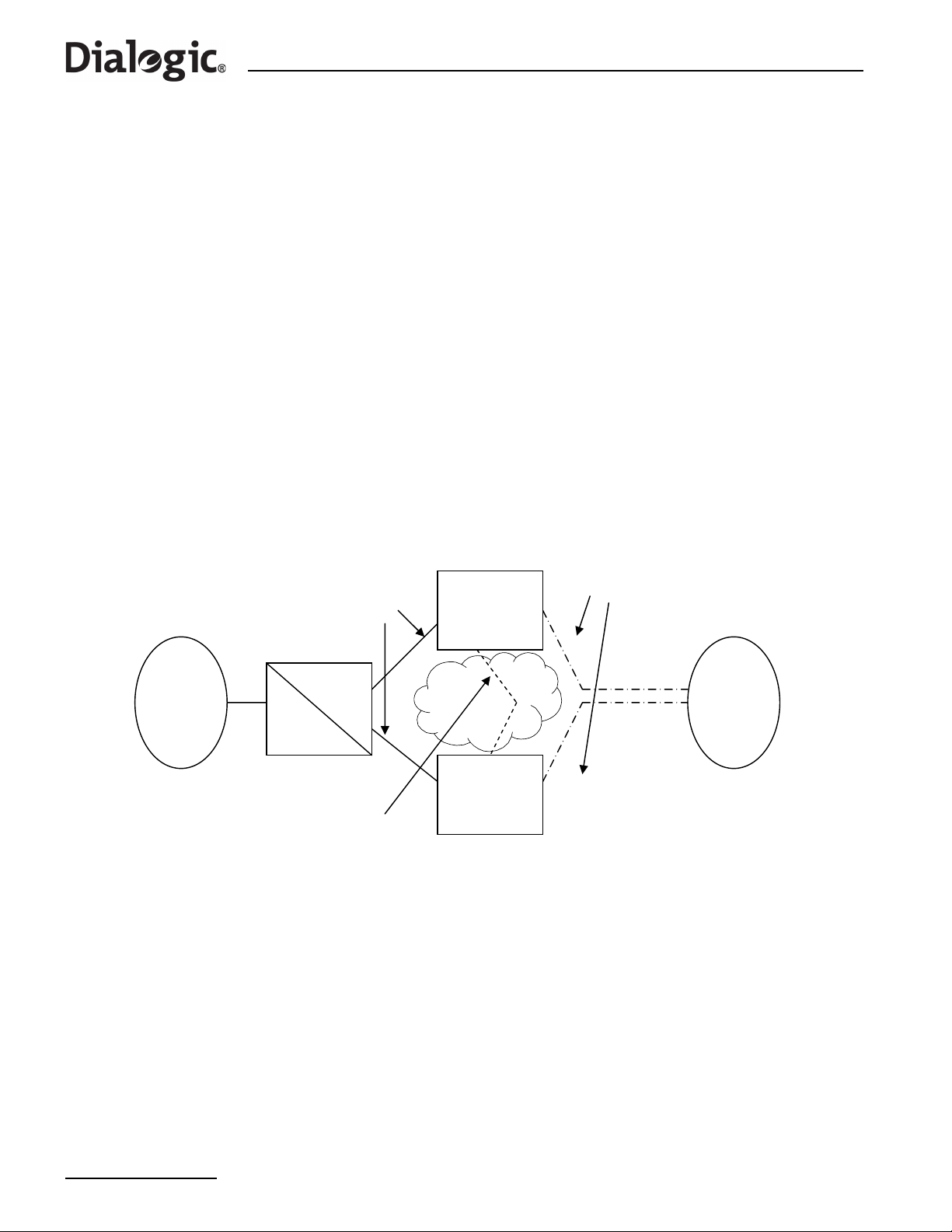

1.9.8 M2PA Longhaul Operation

The Signaling Gateway is capable of replacing TDM SS7 links with signaling links operating over IP providing

the equivalent functionality to MTP Layer 2 by using the SIGTRAN M2P A protocol. One use of M2P A signaling

links would be for the low cost longhaul of signaling traffic possibly inv olving SS7/SS7 protocol conversion.

T wo Signaling Gateways would be required, one either side of the IP connection translating between M2P A << MTP2. See Chapter 11, “Worked Configuration Examples” for an M2PA Longhaul configuration example.

Figure 2. M2PA Longhaul Configuration

MTP2

Signaling

Links

SEP

SG1

M2PA

Signaling

Links

SG2

MTP2

Signaling

Links

SEP

Bearer

Channels

1.9.9 Default Routing

The Signaling Gateway may be configured to use default routing. This is designed to allow greater routing

flexibility. See Section 6.5, “Configuration Commands” on page 48 for further information regarding default

routing.

1.9.10 Resilience

1.9.10.1 IP Resilience

The Signaling Gateway has four IP ports. These ports may be configured with IP addresses in separate IP

networks to allow greater IP resilience on the Signaling Gateway. IP addresses are configured using the

CNSYS command. The CNSYS command also allows the user to configure the default IP gateway for the unit,

while the IPGWI command allows the user to configure additional IP gateways.

13

Chapter 1 Overview

As the Signaling Gateway supports static, rather th an dynamic IP routing, the Signaling Gatew ay may not be

configured with different IP addresses within the same IP network. Instead, resilience between two IP ports

within the same network can be achieved by using IP port bonding, which allows two physical IP ports to be

bonded together in an active/standby configuration under a single IP address. See Section 7.6.1, “IP Port

Bonding” on page 142 for more information.

1.9.10.2 Dual Operation

The Signaling Gateway may be configured as part of a Dual-Resilient pair; that is, two SS7G2x units

appearing to the network as a single point code. If the SS7 network loses accessibility of one unit, the point

code status remains unaffected.

®

Figure 3 shows a dual resilient system with two Dialogic

network and an M3UA ASP. To achieve this configuration, the following additions to the normal configuration

must be made:

1. The configuration of an inter -S S7G2x link set. This has the same DPC and OPC. This link set may consist

of MTP2 links, M2PA links or a combination of both.

2. Each C7Route must be configured to use a preferred link set LS1 and a backup link set LS2.

3. Each SS7G2x must be configured with a C7Route to the other SS7G2x using only LS2.

Note: Since both SS7G2xs have C7Links that are part of the same link set (from the perspective of the

adjacent point code), care must be taken in the assignment of SLCs.

SS7G2xs products connected to an STP in the SS7

Figure 3. Dual Resilient Configuration

M3UA Links

LS1

SS7G2x 1

PC 1

PC 3

STP

PC 2

ASP

SS7G2x 1

PC 1

LS2

Inter SS7G2x

Linkset

(shown as M2PA)

See Chapter 7, “Configuration Overview” for a more in depth discussion of Dual Resilient configuration.

14

®

Dialogic

SS7G2x Signaling Server SGW Mode User Manual Issue 4

Chapter 2: Specification

2.1 Hardware Specification

®

Full details of the Signaling Gateway hardware specification are given in the Dialogic

Hardware Manual.

2.2 System Capacity

The maximum capacity is dependent on the number and type of signaling boards installed. The numbers

given in this section are for a single unit. Use of Signaling Gateways in dual pairs or in clusters proportionally

increases the capacity of the overall system while still acting as a single SS7 point code.

2.3 System Capabilities

SS7G21 and SS7G22

• Maximum number of signaling boards: 3

• Number of 10/100/1000 Mbit/sec Ethernet interfaces: 4

2.4 Signaling Capabilities (Per System)

• Maximum number of SS7 Signaling Links (including M2PA): 128

• Maximum number of M2PA Signaling Links: 32

Note: A system supports up to 128 SS7 links, where each link can be used for either M2PA or MTP2.

The number of SS7 links used for M2 PA reduces the number of links available for MTP2 and viceversa. For example, if 32 SS7 links are used for M2PA, 96 links are available for MTP2.

• Maximum number of SS7 link sets: 64

• Maximum number of SS7 routes: 128 per network

• Maximum number of Networks: 4

• Maximum number of Application Servers: 200

• Maximum number of Application Servers: 200

• Maximum number of M3UA routes: 200

• Maximum number of Network Contexts: 4

2.5 Physical Interfaces (Per Signaling Board)

• SPCI2S T1/E1 PCM interfaces: 2

• SPCI2S SS7 V.11 serial interfaces: 2

• SPCI4 T1/E1 PCM interfaces: 4

• SS7HDP T1/E1 PCM interfaces: 4

2.6 TDM Signaling Capabilities (Per Signaling Board)

• Maximum number of SS7 Signaling Links (SPCI4 / SPCI2S): 4

• Maximum number of SS7 Signaling Links (SS7HDP): 64

Note: The system limit for a Signaling Gateway is still 128 SS7 Signaling Links even when three

SS7HDP boards are installed.

15

Chapter 3 Installation and Initial Configuration

Chapter 3: Installation and Initial Configuration

3.1 Installation

Note: The Signaling Gateway should only be installed by suitably qualified service personnel. Important

safety and technical details, required for installation, are given in the Dialogic

®

SS7G21 and

SS7G22 Hardware Manual.

In order to complete the installation of the Signaling Gateway unit, follow the steps below:

1. Connect a VT100 terminal to the unit (see Section 3.2).

2. Check whether a software download and upgrade is required (see Section 3.3).

3. Install any additional software option licenses that may have been purchased (see Section 4.14.2,

“Installing System Licenses” on page 28).

4. Change the system type to act as a SIGTRAN Signaling Gateway (see Section 3.4).

5. Set the IP addresses of the unit (see Section 3.4).

6. Apply the configuration to the unit (see Section 3.5).

3.2 Connecting a VT100 Terminal

A VT100 compatible terminal can be connected, using a DKL29 cable, to the serial port (COM2) on the rear of

the unit. After pressing the carriage return (Enter) key, the Signaling Gateway interface prompt is displayed.

Default serial port settings are 9600 baud, 8 data bits, 1 stop bits and no parity bits.

The output on the VT100 screen is one of the following:

SS7G20(SIU) logged on at 2004-01-20 14:52:29

<

to indicate SIU operation

OR

SS7G20(SGW) logged on at 2004-01-20 14:52:29

<

to indicate SGW operation

OR

SS7G20(DSC) logged on at 2004-01-20 14:52:29

<

to indicate DSC operation.

3.3 Software Download

®

Up-to-date information and software downloads for the Dialogic

SS7G2x products can be found at the

following URL:

http://www.dialogic.com/support/helpweb/signaling

The product leaves the factory with fully-functional software installed. We recommend you check the above

URL for any recent revisions, and install them before putting the product into service.

Since it is possible to source units from multiple supply channels, we recommend that each is verified to

ensure that all units in a delivery are at the same software revision.

Follow the steps below:

1. Check the current software version running in the system using the CNSWP command.

2. Check the latest distribution file from the “SS7G2x Signaling Gateway” section on the SS7 Products

download web site:

http://www.dialogic.com/support/helpweb/signaling

16

®

Dialogic

SS7G2x Signaling Server SGW Mode User Manual Issue 4

3. If a download is required, store the distribution file in an empty directory on the hard drive of the

downloading machine.

4. Follow the steps detailed in Section 4.11, “Updating System Software” on page 24 in order to carry out

the update of the system software.

3.4 Initial Configuration

By default, the Signaling Gateway is shipped configured to operate in SIU mode. Once an SGW license has

been applied, the system must be restarted using the MNRSI MML command requesting that the unit operate

in SGW mode. Connect a VT100 terminal to identify the mode of operation (See Section 3.2, “Connecting a

VT100 Terminal” on page 16).

The MNRSI restart command should be used to restart the system in a different mode. MNRSI should be

used together with the mode in which the Signaling Gateway is expected to operate in after restart. For SGW

operation this is:

MNRSI:SYSTYPE=SGW;

The Signaling Gateway is configured with a default IP address of 192.168.0.1. If this address is not unique,

or not suitable for the existing network configuration, it is necessary to change this value to a unique IP

address in the Ethernet network to which it is connected. Instructions for making this change are given

below.

Using the VT100-compatible terminal, the IP address is set by entering the system configuration command,

CNSYS. For example, to set the IP address to 123.124.125.126, the following command should be entered:

CNSYS:IPADDR=123.124.125.126;

It is also possible to configure a subnet mask if the unit is a member of a subnet. The default subnet mask is

255.255.255.0. To set the subnet mask to a different value, the following command should be used (the

example here sets a subnet mask of 255.255.255.192):

CNSYS:SUBNET=255.255.255.192;

The management interface also allows an IP gateway address to be specified using the GATEWAY parameter.

This is set by default to 0.0.0.0, indicating that no gateway is present. For example, to set the gateway

address to 123.124.125.250, the following command is used:

CNSYS:GATEWAY=123.124.124.250;

The current settings can be displayed by entering the CNSYP command.

CNSYP;

The configuration is displayed in the format shown below:

System Configuration

UNITID: 0004238734ef

SYSID:

SYSREF: 0

PASSWORD: ********

FTPPWD: N

FTPSER: Y

SECURE: N

PER: 0

IPADDR: 172.28.148.99

SUBNET: 255.255.255.0

IPADDR2: 170.28.148.100

SUBNET2: 255.255.255.0

IPADDR3: 170.28.148.101

SUBNET3: 255.255.255.0

IPADDR4: 0.0.0.0

SUBNET4: 255.255.255.0

GATEWAY: 172.28.148.1

SNMP: N

SGW: Y

DSC: N

SIU: N

EXECUTED

17

Chapter 3 Installation and Initial Configuration

Note: The protocol and mode parameters are only present if licensed. When a protocol or mode is

active, the parameter shows the value “Y”, and when inactive, the parameter shows the value

“N”.

The new IP address parameters is initialized with immediate effect . If the IP address used to login to the unit

for the telnet session is changed, the user is automatically logged out of the session. However, the user can

log in again without delay using the new IP address.

The Ethernet connection should be verified by attempting to “ping” the SGW from a computer connected to

the same Ethernet network, using the following command:

ping 123.124.125.126

If the Signaling Gateway has been configured correctly, it responds to the ping and the host machine displays

a message confirming communication with the Signaling Gateway (the exact format and response of this

message is operating system dependant).

If ping fails, the user should check that the IP address was entered correctly and that there is no fault with

the cabling to the Signaling Gateway.

Once the ping command shows that the Ethernet connection is valid, it should be possible to access the

management interface previously used on the VT100 compatible terminal via telnet. This is achieved by

establishing a telnet session to port 8100 or 8101.

Note: It is not possible to telnet to the standard telnet port 23.

For example, on a typical host console, the following command starts a telnet session to a Signaling Gateway

with an IP address of 123.124.125.126:

telnet 123.124.125.126 8100

The telnet terminal displays the MML interface prompt:

SS7G20(SGW) logged on at 2004-01-20 14:52:29

<

An optional password can be set to control remote access to the MML. This is also done using the CNSYS

command:

CNSYS:PASSWORD=password,CONFIRM=password;

If set, a user opening a telnet session to the MML is prompted to enter a password, for example:

SS7G20(SGW) logged on at 2004-01-20 14:52:29

password:

Password access can be removed by specifying “null” values for the PASSWORD and CONFIRM parameters,

that is:

CNSYS:PASSWORD=,CONFIRM=;

For additional security, the units support the use of Secure Shell (SSH) tunnelling for telnet and secure FTP

operation. The user should use the CNSYS command to restrict telnet access to "telnet via SSH tunnelling"

only. For example:

18

CNSYS:SECURE=Y;

Note: The unit does not provide a Secure Shell session connection. Your SSH client may need additional

configuration to allow SSH tunnelling without a session connection.

®

Dialogic

SS7G2x Signaling Server SGW Mode User Manual Issue 4

Once activated, a future user is required to set up an SSH tunnel prior to telnet access. For a client on a

Linux® or Solaris™ like operating system, login for telnet using the ssh application. The ssh application should

be invoked using a shellscript of the following form:

#!/bin/sh

ssh -l siuftp -C -f $1 -L 2323:$1:8101 sleep 5

telnet localhost 2323

3.5 Configuration Procedure

Once the system architecture and protocol configuration is known, it is necessary to set this configuration

within the Signaling Gateway. Configuration is achieved using MML commands as described in Chapter 6,

“Command Definitions”. An overview of configuration is provided in Chapter 7, “Configuration Overview” and

example configurations are described in Chapter 11, “Worke d Conf iguration Examples”.

19

Chapter 4 Operation

Chapter 4: Operation

4.1 General

The Signaling Gateway can be configured by the user from either serial port 2 (COM2, on the rear panel) or

by using telnet over the Ethernet interface. The serial port can be configured over a range of baud rates and

parity. The default configuration for the port is 9600 bits/s, 8 data bits, 1 stop bit, and no parity. Serial port

1 (COM1, on the front panel) is not supported on the SS7G2x. Flow control can be set to either NONE or

XON/XOFF on the terminal used to communicate with the serial interface of the SS7G2x.

The commands that make up the Signaling Gateway Man-Machine Interface Language (MML) are based on

the CCITT blue book recommendations Z.311 to Z.317.

In the following description, input text, numerals and characters that th e user is expected to enter are shown

in bold text and responses displayed on the screen are shown in fixed width text. S yntax elements that are

further defined are shown in angle brackets, for example, <time of day>.

4.2 Log On/Off Procedure

To initiate a dialog with the Signaling Gateway, the operator must “log on” to one of the MML interfaces.

T o log on to the serial port when it is configured to use DTR/DSR, the connected terminal should assert DSR.

The Signaling Gateway asserts DTR in response and the user can then enter into a dialog with the Signaling

Gateway. The session is ended by operator command to the Signaling Gateway, or by the terminal

deasserting DSR or at the expiry of an auto log off timer. The Signaling Gateway deasserts DTR in response

to any one of these three. To log on again, DSR must first be deasserted.

To log on to the serial port when it is not configured to use DTR/DSR, the carriage return key should be

entered. The session is ended by operator command to the Signaling Gateway or at the expiry of an auto log

off timer.

The two telnet connections provided are accessed using a standard telnet utility . Only ports 8100 and 8101 can

be used. The default port 23 should not be used.

If a password is specified for the system, when logging on, the password is required before being allowed to

continue. If an incorrect password is entered, the system again prompts for a password. If an incorrect

password is entered three times, the port is disconnected. For safety, the password is never required on the

serial port.

When the connection is established, a message consisting of the system identity followed by:

logged on at <calendar date> <time of day>

is displayed, followed by the command prompt, which is the less than symbol (<). The logon session is

ended either by operator command or at the end of an auto log off time out.

The system maintains two timers during the log on session: an “auto log off warning” timer and a “auto log

off” timer. Both are restarted each time a new command is input. When the auto log off warning time out

expires, an auto log off warning message is output to the terminal and any partially entered command is

discarded. The system then outputs a command prompt to the terminal. If no command is input before the

auto log off time out expires, the log on session is ended. The duration of both these timers is userconfigurable and can even be disabled completely.

When log off is initiated, a message consisting of the system identity followed by:

logged off at <calendar date> <time of day>

is output to the operator’s terminal. The Signaling Gateway then initiates the appropriate procedure to end

the connection to the operator’s terminal.

20

®

Dialogic

SS7G2x Signaling Server SGW Mode User Manual Issue 4

4.3 Command Character Set and Syntax

The only characters used for commands and parameters are:

• The letters A to Z and a to z, referred to as <letter>. The case of characters in command names and

parameter names is not significant.

• The digits 0 to 9, referred to as <digit>

• - (hyphen), CR (FE5), SP (space), $(dollar), & (ampersand), * (asterisk),

: (colon), ; (semicolon) / (solidus), . (full stop/period) and = (equals sign)

• The DEL (Delete) character or the BS (Backspace) character is used to delete characters on the current

line.

• The CAN character (Ctrl X) is used as an abort character.

It is possible to indicate several simple values for the same parameter by grouping parameter arguments

using the operators & or &&. For example, 3&6 indicates the simple parameter arguments 3 and 6. A

sequence of consecutive simple parameter arguments is indicated by writing the lower and upper simple

parameter arguments separated by &&, hence 4&&8 indicates the simple parameter arguments 4, 5, 6, 7

and 8.

Comments are allowed in command input, and can appear in any position on the command line. A comment

is defined as a character string enclosed between the separators /* (solidus asterisk) and */ (asterisk

solidus), where the character string can contain any characters except the format effector characters (HT –

Horizontal Tab, LF – Line Feed, VT – Vertical Tab, FF – Form Feed and CR – Carriage Return) and the

sequence */.

4.4 Command Formats

To allow easy command recognition and familiarization, all the commands share a common five character

format:

XXYYZ

where:

• XX = Command group

• YY = Function within group

• Z = Operation code

The following operation codes are used:

• C = Change

• E = End

• I = Initiate

• P = Print

• S = Set

Note: The term “print” refers to output to the serial port in use for the dialog procedure.

4.5 Command Entry

Each character entered is echoed to the operator’s terminal. The BS (backspace) or DEL (delete) character

can be used to delete characters entered within the current line. This causes the Signaling Gateway to output

the sequence BS space BS. On a visual display terminal, this has the effect of deleting the last character

entered from the display.

Commands can be entered whenever the command prompt has been output. Commands are terminated by

a semicolon (;) followed by CR. Commands may exceed one line on the terminal, but may not exceed 100

characters.

If a command takes parameters, a colon is used to separate the command from the parameters. A comma

(,) is used to separate multiple parameters.

21

Chapter 4 Operation

To ensure correct operation of the character deletion, the maximum number of characters entered on a

single command line should be no greater than the number of characters that can be displayed on a single

line of the terminal (to prevent text “wrap around”). If a command is longer than one line, each line before

the last should be terminated with a complete parameter value followed by a comma and CR. The command

can then continue on the next line. If the user wishes to specify more parameters than can be entered on a

single initiate command, they should use the initiate command to enter mandatory parameters, then use a

change command to specify additional parameters.

A partially entered command can be aborted using the CAN character. The system outputs an indication that

the command has been aborted, followed by a prompt for new command input. The CAN character can also

be used to abort an output listing on the operators terminal.

4.6 Dangerous Commands

Commands that affect the Signaling Gateway operation are considered DANGEROUS commands. When a

DANGEROUS command is entered the Signaling Gateway outputs the following on a new line:

Are you sure? [Y/N]

The operator must enter Y followed by CR to continue the execution of the command. Any other valid input

character apart from SP or CR, followed by CR, causes the command to be aborted.

4.7 Changing Configuration Data

Many configuration commands require that certain other commands have been entered first (for example to

block a link before removing a boards configuration). These rules are described on a per-command basis as

prerequisites.

4.8 Command Responses

The Signaling Gateway does not, in general, produce output unless in response to an operator command.

The only exception to this is the auto log off warning message and the log off message (when log off is

initiated automatically).

The auto log off warning message is as follows:

WARNING: Auto log off imminent!

When a syntactically correct command has been issued to the Signaling Gateway, acceptance is indicated by

the Command Executed output as follows:

EXECUTED

An invalid command is not acted upon. The Signaling Gateway indicates command rejection by issuing one of

the responses in Table 1. Onl y the fi rst error detected in a command is indicated.

Table 1. Command Rejection Responses

Response Reason for Rejection

UNACCEPTABLE COMMAND

UNKNOWN COMMAND The command is not recognized.

NO SYSTEM RESOURCES

INVALID PARAMETER NAME A parameter name has been entered that is not v alid for this command.

EXTRA PARAMETERS Too many parameters have b een entered.

MISSING PARAMETER A required parameter has not been input.

INCONSISTENT PARAMETER The parameters input are not valid together for the command.

MISSING DATA A parameter has no data.

INCONSISTENT DATA

RANGE ERROR The value assigned to a numeric parameter is outside the valid range.

The command is valid but not in the current state of the equipment (for

example, changing a signaling link configuration without blocking).

The requested command cannot be execu ted due to unav ailable system

resources.