Page 1

INSTALLATION AND MAINTENANCE MANUAL

SAFESITE

LINEAR LED LIGHT

Document No: 9100-127-1402-99 Rev A

October 2010

MODELS

LSC3C4D2GEX

LSC3C4D3GEX

LSC3C4M2GEX

LSC3C4M3GEX

Figure 1.

Page 2

Document No: 9100-127-1402-99 Rev A

1: Introduction

This Linear LED light is designed for illumination of hazardous areas in industrial locations. It uses

the latest in solid state lighting technology for long life, low maintenance, and high efficiency.

The unique optical design focuses light downward to where it is needed, giving improved efficiency

over a conventional HID luminaire.

An internal, universal input, power-factor-corrected switch-mode supply allows it to be used from

any nominal 100V-277V, 50/60Hz AC supply without any variation in light output.

Models LSC3C4D2GEX, LSC3C4D3GEX, LSC3C4M2GEX and LSC3C4M3GEX

are suitable for use in the following locations:

• HAZARDOUS LOCATIONS: CLASS I DIV 1 & 2 GROUPS C, D

Ta - Ambient Temp: -40 TO +65°C

Temp Rating – T5 (2 ft), T4A (4’)

• SUITABLE FOR WET LOCATIONS

Note: Save these instructions for future reference.

Page 2 of 7

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 3

Document No: 9100-127-1402-99 Rev A

2: Installation

Warning:

To avoid the risk of fire, explosion, or electric shock, this product should be installed, inspected,

and maintained by a qualified electrician only, in accordance with all applicable electrical codes.

Warning:

To avoid electric shock:

• Be certain electrical power is OFF before and during installation and maintenance.

• Luminaire must be connected to a wiring system with an equipment-grounding conductor.

Warning:

To avoid explosion:

• Make sure the supply voltage is within the luminaries’ voltage rating.

• Ensure the marked T Rating is less than the ignition temperature of the Hazardous Atmosphere.

• Do not operate in ambient temperatures above those indicated on the luminaire nameplate.

• Do not operate if the lens is cracked or damaged. All fasteners should be properly seated.

Warning:

To prevent ignition of group C and D atmospheres conduit runs must have a sealing fitting

connected within 0.75 inches of the fixture. Note: Two ¾” NPT plugs are supplied for any

unused ¾ NPT openings and must be in place to ensure fixture integrity.

For supply connections use wire rated for at least 90ºC

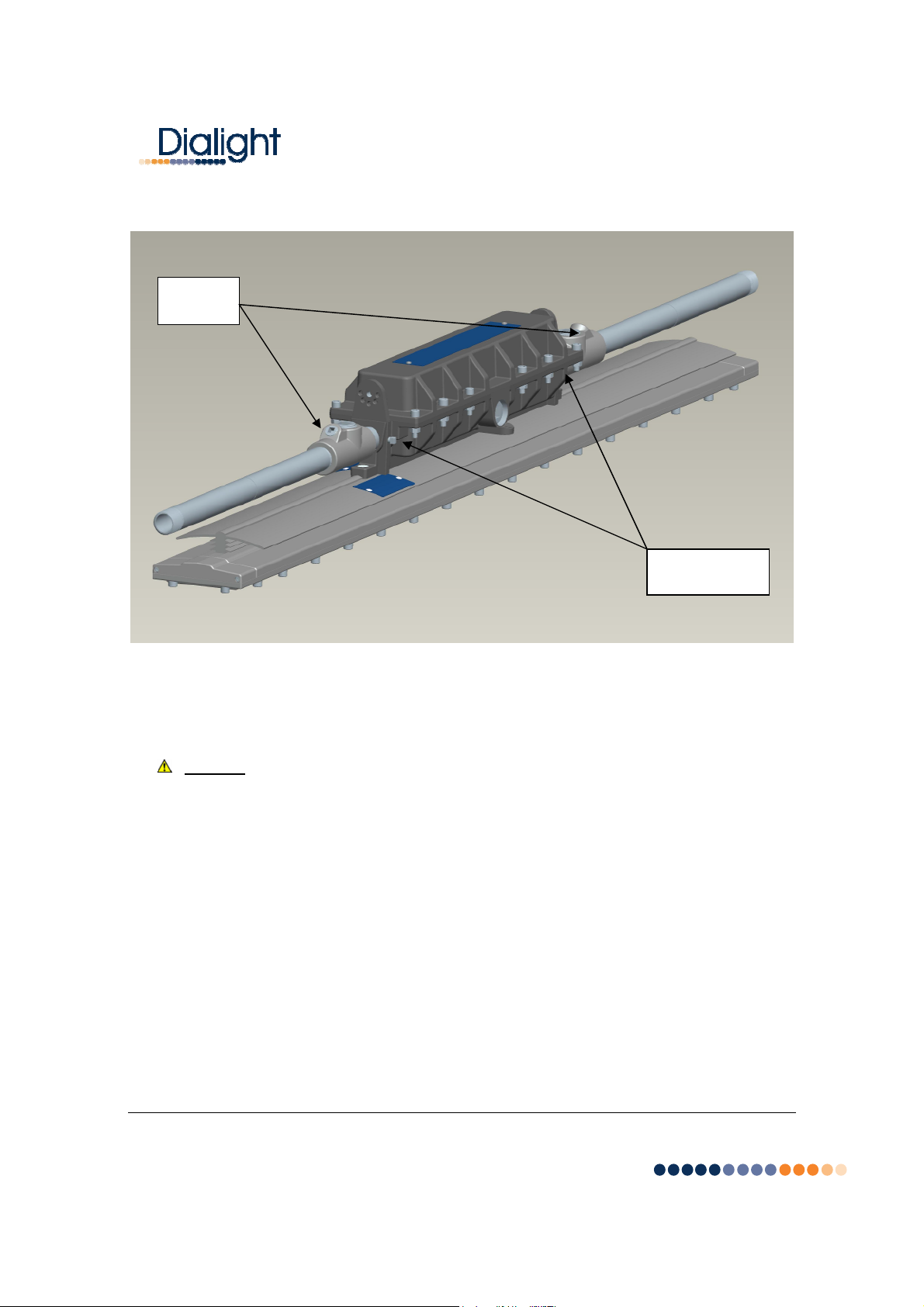

Pendent Mount

(Figure 2) Installation Steps:

• For maximum long term reliability and light output, the light must be installed in free air.

o The Linear fixture design incorporates an over-temperature control circuit that

reduces input power should internal temperatures reach a maximum level. In this

event, light output may be reduced.

• The Linear fixture is threaded for 3/4” NPT, at the center and each end of the Power

Supply Housing, in order to be assembled to conduit.

o Attach conduit and sealing fitting as shown in figure 2. Sealing fitting must be

located within .75” of the Power Supply Housing. Use conductive pipe sealant for

all fittings and conduit.

o Remove the Power Supply Cover to attach incoming power to the fixture. Ensure

that the o-ring is properly seated in the groove, reattach the Cover using the

screws and lock washers previously removed. Tighten all screws to 15 in/lbs.

o Tighten 1/4-20 anti-rotational screw in order to secure the fixture to the conduit.

• Connect incoming power as follows:

o Green to Safety Ground using green screw supplied in housing.

o Neutral to white

o Line to black

Page 3 of 7

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 4

• Restore power and verify operation.

fitting

screw

Sealing

Anti-rotation

Document No: 9100-127-1402-99 Rev A

Power

Supply

Cover

Figure 2.

Conduit through Mount

(Figure 3) Installation Steps:

• For maximum long term reliability and light output, the light must be installed in free air.

o The Linear fixture design incorporates an over-temperature control circuit that

reduces input power should internal temperatures reach a maximum level. In this

event, light output may be reduced.

• The Linear fixture is threaded for 3/4” NPT, at the center and each end of the Power

Supply Housing, in order to be assembled to conduit.

o Attach conduit and sealing fittings within .75” of the Housing as shown in figure 3.

Use conductive pipe sealant for all fittings and conduit.

o Remove the Power Supply Cover to attach incoming power to the fixture.

o Prior to replacing the Cover ensure that the o-ring seal is properly seated in the o-

ring groove. Reattach the Cover using the screws and lock washers previously

removed. Tighten all screws to 15 in/lbs.

o Tighten 1/4-20 anti-rotational screw in order to secure the fixture to the conduit.

• Connect power cable conductors as follows:

o Green to Safety Ground using green screw supplied in housing.

o Neutral to White

o Line to Black

• Restore power and verify operation.

Page 4 of 7

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 5

Document No: 9100-127-1402-99 Rev A

Sealing

Fittings

Anti-rotation

Screws

Figure 3.

3: Maintenance

• To avoid personal injury, disconnect power to the light and allow the unit to cool down

before performing maintenance.

Warning: No user serviceable parts inside of fixture. Risk of electric shock. Removal of the

lens will void the warranty.

1) Perform visual, mechanical and electrical inspections on a regular basis. We recommend

routine checks to be made on a yearly basis. Frequency of use and environment should

determine this. It is recommended to follow an Electrical Preventive Maintenance Program

as described in NFPA 70B: Recommended Practice for Electrical Equipment.

2) The lens (Figure 4) should be cleaned periodically as needed to ensure continued

photometric performance. Clean the lens with a damp, non-abrasive, lint-free cloth. If not

sufficient, use mild soap or a liquid cleaner.

3) Inspect the outside of the luminaire housing to ensure that they are free of any obstructions

or contamination (i.e. excessive dust build-up). Clean with a non-abrasive cloth if needed.

4) Do not operate if the lens is cracked or damaged. All fasteners should be properly seated.

Page 5 of 7

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 6

Document No: 9100-127-1402-99 Rev A

Glass Lens

Figure 4.

Specifications

Nominal AC Supply Voltage 100-277VAC, 50-60Hz

Power consumption:

2’ version 50W nominal

4’ version 100W nominal

Operating temperature range -40°F to +149°F [-40°C to +65°C]

T5 @ 149°F [65°C]

Power factor >0.9

ATHD <20%

Dimensions (L x W x H) See Figure 5.

Weight 22 lbs [9.98 kg] (4’), 14 lbs [6.35 kg] (2’)

Intertek Certified to UL-844 and C22.2 No. 137

Page 6 of 7

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 7

Figure 5.

Document No: 9100-127-1402-99 Rev A

DIMENSIONS ARE FOR REFERENCE ONLY.

All statements, technical information and recommendations contained herein are based on

information and tests we believe to be reliable. The accuracy or completeness thereof is not

guaranteed. In accordance with Dialight Corporation “Terms and Conditions of Sale”, and since

conditions of use are outside our control, the purchaser should determine the suitability of the

product for his intended use and assumes all risk and liability whatsoever in connection therewith.

REV. ECO No. DRN CHK APP QA CM DATE

A 2366 WSL KH KZ RL JB 10/28/10

Page 7 of 7

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Loading...

Loading...