Page 1

KS150/190/215-SD Installation Guide

Package Contents

•

One 15", 19", or 21.5" Modular Touch Panel PC

•

3-pin Terminal Blcok Connector

•

SATA and Mini PCIe Installation Screws

DFI reserves the right to change the specications at any time prior to the

product's release. For the latest revision and more details of the installation

procedure, please refer to the user's manual on the website.

www.d.com

1

Page 2

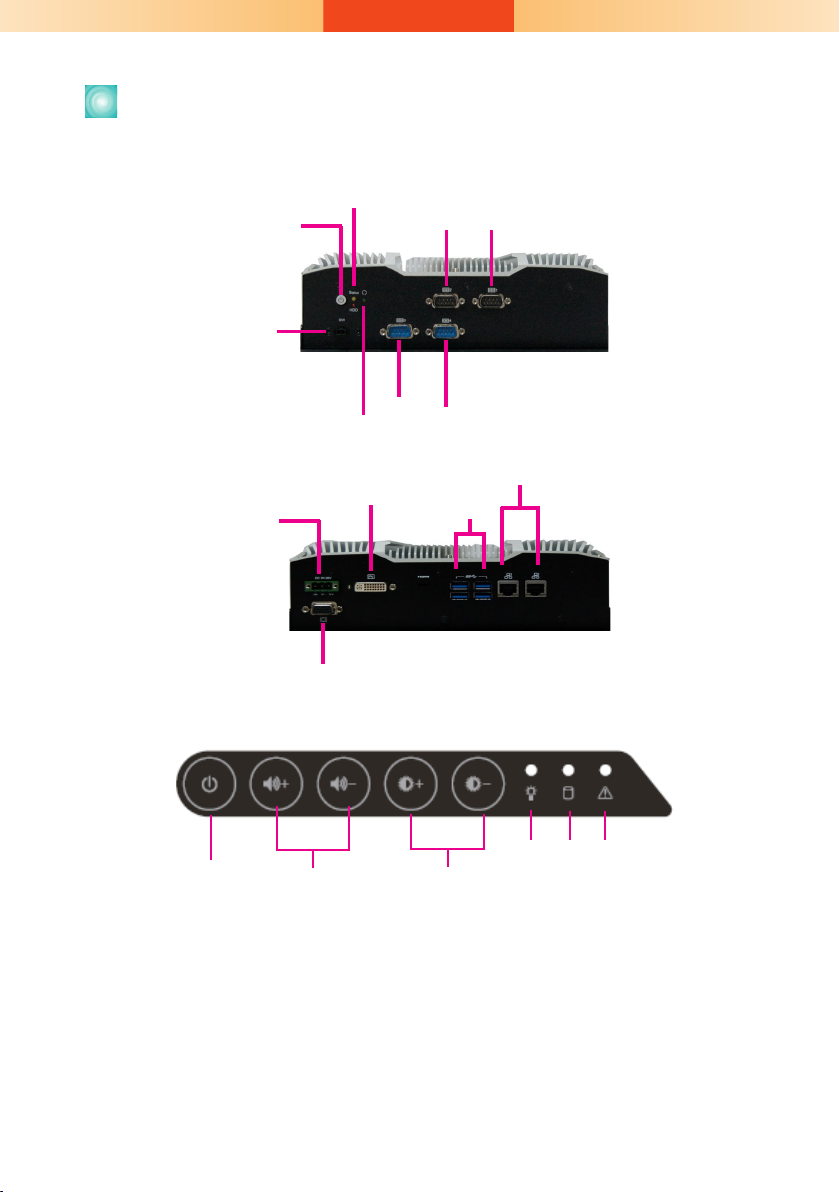

Panel

Bottom View

Power Button

Remote Power Switch

Status LED (Orange)

HDD LED (Red)

COM 2

COM 3

Reset Button

COM 1

COM 4

Top View

DC-in

Front OSD Functions (only for models with front OSD)

Backlight or Power

on/off

Notes on OSD Settings:

The front OSD is capable of controlling the system in the following ways in addition to

its explicit functions.

1. System Power On/Off: Press the Backlight on/off button for 3 seconds.

2. Light Sensor On/Off: Press the Brightness up arrow for 3 seconds.

3. OSD Lock/Unlock: Press the Brightness down arrow for 3 seconds.

4. The Alarm LED has no funtion for the KS-SD Series.

Volume

DVI-D

(DVI-I connector)

VGA

Brightness

USB 3.0

LAN 2

LAN 1

Power HDD Alarm LED

2

Page 3

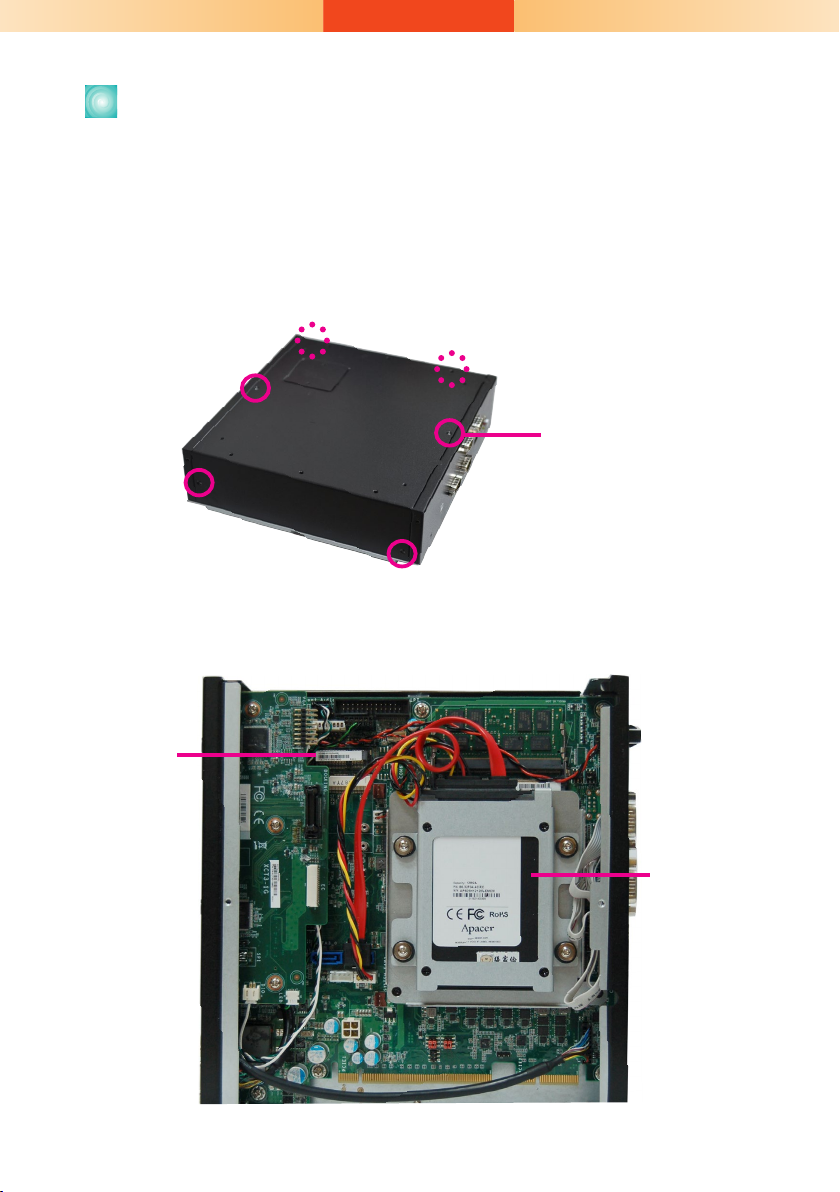

Removing the Chassis Cover

1. Make sure the system and all other peripheral devices connected to it

have been powered-off.

2. Disconnect all power cords and cables.

3. The 6 mounting screws on the rear side of the system are used to

secure the cover to the chassis. Remove these screws and put them in a

safe place for later use.

Mounting Screw

4. Lift the cover to open the system.

5. The Mini PCIe, M.2 and the SODIMM slots are readily accessible after

removing the chassis cover.

Mini PCIe

Sockets

SATA drive bay

3

Page 4

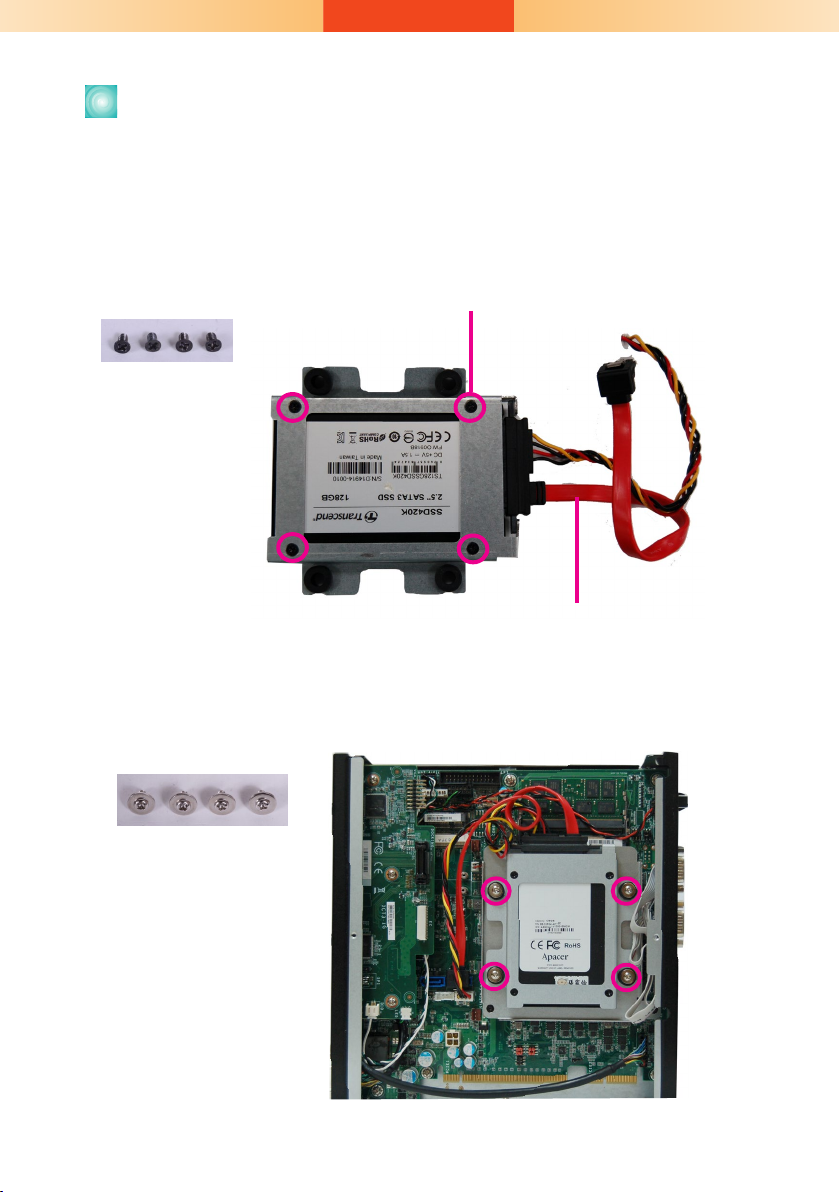

Installing a SATA Drive

The system can accommodate one SATA drive. Please use the following

procedure to install a SATA drive in the system.

1. Before installing the SATA drive, connect the SATA data/power cable

to the SATA data connector of the SATA drive. Then install the SATA

drive onto the HDD bracket with the provided mounting screws.

Mounting Screws

Mounting screws

SATA data and power cable

2. Place the SATA drive installed with the HDD bracket in the system.

Align the mounting holes on the HDD bracket with the mounting holes

on the drive bay and use the provided mounting screws to secure the

drive in place.

Mounting Screws

4

Page 5

3. Connect the other end of the SATA data/power cable to the SATA data

and power connectors on the system board respectively.

SATA data connector

SATA power connector

5

Page 6

Installing a SODIMM

The system supports two DDR4 SODIMM socket. To install a memory module, grasp the memory module by its edges and align the module’s notch

with the socket’s notch; then insert the memory into the socket at an

angle and push it down until you feel a click.

Insert the memory

at an angle

SODIMM module

installed into the socket

Notes:

1. The system supports dual-channel conguration. To enable dual-channel,

populate both SODIMM sockets.

2. If installing only one memory module, please install it on the memory socket

labeled DIMM 1 (the one closer to the edge of the board).

3. The SODIMM sockets can only accept DDR4 memory modules. Please do not

install other types of memory modules.

6

Page 7

Installing a Mini PCIe or mSATA Card

The system board is equipped with 2 Mini PCIe slots: one full-size and

(PCIe/USB signals) and one half-size slot (USB/mSATA signals). Here we will

demonstrate the installation of a full-size Mini PCIe card.

1. Grasp the Mini PCIe card by its edges and align the notch in the

connector of the Mini PCIe card with the notch in the connector on the

system board.

2. Push the Mini PCIe card down and use the provided mounting screw to

secure the card on the system board.

Mounting screw

Antenna hole

7

Page 8

Important:

The bottom side of a full-size Mini PCIe module should have a component height

restriction of 0.82 mm and will sit ush against the connected half-size Mini PCIe

module if such a component is used and the half-size slot is connected with a

module.

0.82mm

8

Page 9

Assemble the Modular Panel PC

The modular panel PC comprises two parts: a box module and a panel module.

1. Take off the cover of the ADP connector. Hold the box module with its

ADP connector (female) in line with the ADP connector (male) of the

panel module. Align the box module with the panel module using the

alignment posts.

ADP

connector

cover screw

Box Module

ADP

Connector

(female)

2. Hold the box module with its ADP connector (female) in line with the

ADP connector (male) of the panel module. Align the box module with

the panel module using the alignment posts.

Alignment

Post

Note:

If the orientation of the assembly is not correct, the box module will not seat evenly on top

of the panel module, which results in some space in between them and indicates that the

ADP connectors are not engaged. When this is the case, please turn the box module the

other way around.

Panel Module

9

Page 10

3. Seat the box module on top of the panel module with the alignment

post effortlessly sliping into the designated holes on the box module.

Press to install these two modules and secure the installation with 8

mouting screws.

Mounting Screw

Alignment

Post

Mounting Screw

Box + Panel Module

10

Page 11

Mounting Options

VESA mount

The VESA-mount specifications for this device is 100 x 100 (mm).

Please use a compatible VESA mount kit that can sustain the weight

and size of this device. The VESA mount kit includes the following:

• 2 VESA mount brackets

• Bracket screws

VESA mount bracket 1

VESA mount bracket 2

1. Before starting any installation procedures, attach the poron foam to

the Panel PC.

Poron foam

2. Select a place on the wall where you will mount the Panel PC.

3. Use the provided mounting screws to attach “VESA mount bracket 1” to

the wall.

Mounting screw

VESA mount bracket 1

11

Page 12

4. The system has designed Attach the other bracket (VESA mount

bracket 2) to the rear of the Panel PC.

Thumb screw

Hooks

VESA mount bracket 2

Mounting screw

5. Slide the Panel PC to "wall mount bracket 1" to attach the two brackets

with the hooks. Then tighten the thumb screw to secure the assembly

in place. Note that the following diagram is for illustration only and may

not resemble the actual product.

Thumb screw

12

Page 13

Panel mount

The panel mounting kit includes the following:

• 10 mounting clamps

1. Before starting any installation procedures, attach the poron foam to the

Panel PC.

2. Select a place on the panel (or wall) where you will mount the Panel PC.

3. Cut out a shape on the panel that corresponds to the Panel PC’s rear

dimensions (15": 367mm x 300mm; 19": 447mm x 380mm; 21.5":

526.2mm x 342.6mm) and ensure that the Panel PC can be tted into

the panel properly.

Mounting hole

Panel

300

272

367

169

4. Insert the Panel PC from the outside surface of the panel into the

mounting hole until it is properly tted against the panel.

5. Position the mounting clamps along the rear edges of the Panel PC and

insert them into the slits around the Panel PC. Note that the following

diagram is for illustration only and may not resemble the actual product.

13

Page 14

cap

Mounting clamp

Slit for mounting the clamp

6. The rst and second clamps must be positioned and secured diagonally

prior to mounting the rest of the clamps. Tighten the clamp’s screw

using an electric screwdriver by pressing the at cap onto the back of

the panel.

Note:

The maximum thickness of your panel’s mounting wall should be 10 mm for secure

panel mount.

14

Page 15

Communication Port Pin Assignments

The system is equipped with 4 COM ports that enable serial communication.

The COM 1 and COM 2 ports can be switched between typical RS232 or

RS232 with power on its Pin NO.1 (12V) and Pin No.9 (5V).

COM 2

COM 1

COM 3

COM 4

COM 1/COM 2 (RS232 with power/422/485)

COM 3~COM4 (RS232/422/485)

DCD

(or +12V)

RXD

TXD

DTR

1

2 3 4

7

6

RTS

DSR

RS232

GND

5

8

9

RI

CTS

(or +5V)

RXD-

RXD+

1

245

6 8

7

N.C.

RS422

3

N.C.

GND

TXD-

TXD+

9

N.C.

N.C.

DATA+

1

6 8

N.C.

N.C.

DATA-

245

3

7

N.C.

9

N.C.

N.C.

GND

N.C.

RS485

The system is also equipped with 3 display ports: DVI-D, HDMI, and VGA.

DVI-D

(DVI-I connector)

DC-in

VGA

Notes:

1. The DVI-D port can be in HDMI or DVI-D.

2. The HDMI is a DP/HDMI combo port but can only transmit HDMI signals (unless wired as a DP

port). Please plug in an HDMI cable with the right orientation and alignment to avoid damage to

the connector. You should feel resistance (due to a pin on the right) if the cable is not inserted

correctly. Please see a video at https://youtu.be/SUj07rfN5l8 for detailed instructions.

HDMI

Aligning side

(left)

Angled-corner

pin

Angled-corner

(up)

15

Align this edge with the

left side of the connector

Page 16

Buzzer

USB 3-4

USB 3.0

USB 1-2

USB 3.0

Power LED

HDD LED

J22

JP2

JP3

J21

HDMI (default)/DP

DVI

System

Fan 2

1

Front

Panel

51

2

1

10

9

1

1

1

1

4

SATA Power

-

DC-in

LAN 2

LAN 1

PCIe x16 (PCIE1)

SPI Flash

BIOS

9

1

2 10

COM 4

VGA

1

6

(JP4)

Clear CMOS

Data (JP1)

Auto Power-on

Select (JP11)

1

6

(JP9) (JP16)

1

6

6

1

(JP8) (JP15)

1

6

6

1

(JP10)

1

2 10

COM 3

1

(JP6)

6

6

9

1

2 10

COM 2

9

1

2

(JP7) (JP14)

6

6

1

2

1

2 10

COM 1

9

1

2

16

LPC

1

2

14

4-pin power

1

1

2

3

4

PCIe x4 (PCIE2)

Power Button

Reset

DDR4_2 SODIMM

DDR4_1 SODIMM

1

(JP5)

6

6

1

1

1

6

6

2 2

2

6

1

4

2

25

26

Parallel

1

DIO Power

DIO

S/PDIF

Front Audio

2

51

1

10

9

ECX

+

SATA 3.0

USB 11-12

USB 2.0

USB 2.0 13-14

(JP13)

1

1

(JP12)

COM 2

1

SATA 0

SATA 1

1

Mini PCIe

mSATA

System

Fan 1

1

1

bettery

1

1

1

2 12

USB 2.0 9

COM 1

Board Layout and Jumper Settings

Clear CMOS Data JP1

Normal (default) 1-2 On

Clear CMOS Data 2-3 On

RS232/Power Select: COM 1 (JP3), COM 2 (JP2)

RS232 (default) 1-3 (RI), 2-4 (DCD) On

RS232 with power 3-5 (+5V), 4-6 (+12V) On

RS232/422/485 Select: COM 1 (JP6), COM 2 (JP13)

RS232 (default) 1-2 On

RS422 Full Duplex 3-4 On

RS485 5-6 On

RS232/422/485 Select: COM 1 (JP5/JP12)

COM 2 (JP7/JP14)

RS232 (default) 1-3, 2-4 On

RS422 Full Duplex/RS485 3-5, 4-6 On

Auto Power-on Select JP11

Power-on via Power Button (default) 1-2 On

Power-on via AC Power 2-3 On

RS232/422/485 Select: COM 3 (JP9), COM 4 (JP4)

RS232 (default) 1-2 On

RS422 Full Duplex 3-4 On

RS485 5-6 On

RS232/422/485 Select: COM 3 (JP8/JP15)

COM 4 (JP10/JP16)

RS232 (default) 1-3, 2-4 On

RS422 Full Duplex/RS485 3-5, 4-6 On

16

Notes:

1. When COM1 RS232/422/485 is selected, JP5 and JP12 must be set

in accordance to JP6.

2. When COM2 RS232/422/485 is selected, JP7 and JP14 must be set

in accordance to JP13.

3. When COM3 RS232/422/485 is selected, JP8 and JP15 must be set

4. When COM4 RS232/422/485 is selected, JP10 and JP16 must be

in accordance to JP9.

set in accordance to JP4.

A56701937

Loading...

Loading...