Page 1

BT968

COM Express Compact Module

User’s Manual

A30600407

1

www.dfi .comChapter 1 Introduction

Page 2

Copyright

FCC and DOC Statement on Class B

This publication contains information that is protected by copyright. No part of it may be reproduced in any form or by any means or used to make any transformation/adaptation without

the prior written permission from the copyright holders.

This publication is provided for informational purposes only. The manufacturer makes no

representations or warranties with respect to the contents or use of this manual and specifically disclaims any express or implied warranties of merchantability or fitness for any particular

purpose. The user will assume the entire risk of the use or the results of the use of this document. Further, the manufacturer reserves the right to revise this publication and make changes

to its contents at any time, without obligation to notify any person or entity of such revisions

or changes.

Changes after the publication’s first release will be based on the product’s revision. The website

will always provide the most updated information.

© 2014. All Rights Reserved.

Trademarks

Product names or trademarks appearing in this manual are for identification purpose only and

are the properties of the respective owners.

COM Express Specification Reference

PICMG® COM Express ModuleTM Base Specification.

http://www.picmg.org/

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio TV technician for help.

Notice:

1. The changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

2. Shielded interface cables must be used in order to comply with the emission limits.

2

www.dfi .comChapter 1 Introduction

Page 3

Table of Contents

Copyright .............................................................................................................2

Trademarks ........................................................................................................2

FCC and DOC Statement on Class B .....................................................2

About this Manual ..........................................................................................4

Chapter 4 - BIOS Setup ............................................................... 32

Overview ..................................................................................................... 32

AMI BIOS Setup Utility .............................................................................33

Main ......................................................................................................... 33

Advanced .................................................................................................. 33

Chipset ..................................................................................................... 40

Security .................................................................................................... 45

Boot ......................................................................................................... 45

Save & Exit ...............................................................................................46

Updating the BIOS ....................................................................................46

Notice: BIOS SPI ROM .............................................................................47

Warranty ..............................................................................................................4

Static Electricity Precautions ......................................................................4

Safety Measures ..............................................................................................4

About the Package .........................................................................................5

Chapter 1 - Introduction .............................................................................6

Specifications ................................................................................................6

Features ........................................................................................................7

Chapter 2 - Concept .......................................................................8

COM Express Module Standards ..............................................................8

Specification Comparison Table ...............................................................9

Chapter 3 - Hardware Installation ...............................................10

Board Layout ...............................................................................................10

Block Diagram .............................................................................................10

Mechanical Diagram ..................................................................................11

System Memory ..........................................................................................12

Installing the DIMM Module ....................................................................... 13

Connectors ...................................................................................................14

CPU Fan Connector.................................................................................... 14

COM Express Connectors ........................................................................... 14

COM Express Connectors Signal Discription .................................................17

Standby Power LED ................................................................................... 25

Cooling Option ............................................................................................25

Installing BT968 onto a Carrier Board .................................................26

Installing the COM Express Debug Card .............................................29

Chapter 5 - Supported Software ...........................................................48

Chapter 6 - GPIO Programming Guide...............................................61

Appendix A - nLite and AHCI Installation Guide ...........................62

nLite ...............................................................................................................62

AHCI ..............................................................................................................66

Appendix B - Watchdog Sample Code ................................................68

Appendix C - System Error Message ...................................................69

Appendix D - Troubleshooting ................................................................70

3

www.dfi .comChapter 1 Introduction

Page 4

About this Manual

Static Electricity Precautions

An electronic file of this manual is included in the CD. To view the user’s manual in the CD, insert the CD into a CD-ROM drive. The autorun screen (Main Board Utility CD) will appear. Click

“User’s Manual” on the main menu.

Warranty

1. Warranty does not cover damages or failures that arised from misuse of the product, inability to use the product, unauthorized replacement or alteration of components and product specifications.

2. The warranty is void if the product has been subjected to physical abuse, improper installation, modification, accidents or unauthorized repair of the product.

3. Unless otherwise instructed in this user’s manual, the user may not, under any circumstances, attempt to perform service, adjustments or repairs on the product, whether in or

out of warranty. It must be returned to the purchase point, factory or authorized service

agency for all such work.

4. We will not be liable for any indirect, special, incidental or consequencial damages to the

product that has been modified or altered.

It is quite easy to inadvertently damage your PC, system board, components or devices even

before installing them in your system unit. Static electrical discharge can damage computer

components without causing any signs of physical damage. You must take extra care in handling them to ensure against electrostatic build-up.

1. To prevent electrostatic build-up, leave the system board in its anti-static bag until you are

ready to install it.

2. Wear an antistatic wrist strap.

3. Do all preparation work on a static-free surface.

4. Hold the device only by its edges. Be careful not to touch any of the components, contacts

or connections.

5. Avoid touching the pins or contacts on all modules and connectors. Hold modules or connectors by their ends.

Important:

Electrostatic discharge (ESD) can damage your processor, disk drive and other components. Perform the upgrade instruction procedures described at an ESD workstation only. If such a station is not available, you can provide some ESD protection by

wearing an antistatic wrist strap and attaching it to a metal part of the system chassis. If a wrist strap is unavailable, establish and maintain contact with the system

chassis throughout any procedures requiring ESD protection.

Safety Measures

To avoid damage to the system:

• Use the correct AC input voltage range.

To reduce the risk of electric shock:

• Unplug the power cord before removing the system chassis cover for installation or servicing. After installation or servicing, cover the system chassis before plugging the power

cord.

4

www.dfi .comChapter 1 Introduction

Page 5

About the Package

The package contains the following items. If any of these items are missing or damaged,

please contact your dealer or sales representative for assistance.

• One BT968 board

• One DVD

• One QR (Quick Reference)

Optional Items

• COM331-B carrier board kit

• COM101-BAT carrier board kit

• Heat sink

• Heat spreader with heat sink and fan

The board and accessories in the package may not come similar to the information listed

above. This may differ in accordance with the sales region or models in which it was sold. For

more information about the standard package in your region, please contact your dealer or

sales representative.

Before Using the System Board

Before using the system board, prepare basic system components.

If you are installing the system board in a new system, you will need at least the following

internal components.

• Storage devices such as hard disk drive, CD-ROM, etc.

You will also need external system peripherals you intend to use which will normally include at

least a keyboard, a mouse and a video display monitor.

5

www.dfi .comChapter 1 Introduction

Page 6

Chapter 1 - Introduction

Specifications

Chapter 1

Processor

System Memory

Graphics

Audio

Serial ATA

LAN

eMMC*

(optional)

Trusted

Platform

Module - TPM*

(optional)

• Intel® AtomTM/Intel® Celeron® processors

- E45: Intel

- E26: Intel

- J00: Intel

- N07: Intel

®

AtomTM E3845, Quad Core, 2M Cache, 1.91GHz, 10W

®

AtomTM E3826, Dual Core, 1M Cache, 1.46GHz, 7W

®

Celeron® J1900, Quad Core, 2M Cache, up to 2.42GHz, 10W

®

Celeron® N2807, Dual Core, 1M Cache, up to 2.16GHz, 4.3W

(The following specifi cations will be available upon request. Please contact

your sales representative for more information.)

- E27: Intel

- E25: Intel

- E15: Intel

- N30: Intel

®

AtomTM E3827, Dual Core, 1M Cache, 1.75GHz, 8W

®

AtomTM E3825, Dual Core, 1M Cache, 1.33GHz, 6W

®

AtomTM E3815, Single Core, 0.5M Cache, 1.46GHz, 5W

®

Celeron® N2930, Quad Core, 2M Cache, up to 2.16GHz, 7.5W

• BGA 1170 packaging technology

• 22nm process technology

• Two 204-pin DDR3L SODIMM sockets (-E45/-E27/-E26/-J00/-N30)

- up to 8GB system memory

- dual channel memory interface

One 204-pin DDR3L SODIMM socket (-E25/-E15/-N07)

- up to 4GB system memory

- single channel memory interface

• Supports DDR3L 1333MHz (-E45/-E27/-J00/-N30/-N07)

Supports DDR3L 1066MHz (-E26/-E25/-E15)

• DRAM device technologies: 1Gb, 2Gb and 4Gb DDR3L DRAM

technologies are supported for x8 and x16 devices, unbuffered, non-ECC

• Intel® HD Graphics

• Supports VGA, DDI, LVDS (default) or DDI* interfaces

• Supports 2 display interfaces at the same time

• VGA: 24-bit, resolution up to 2560x1600 @60Hz

• LVDS: NXP PTN3460, 24-bit, dual channel, resolution up to 1920x1200 @60Hz

• Digital Display Interface: HDMI, DVI and DP

• HDMI, DVI: resolution up to 1920x1080 @60Hz

• DP: resolution up to 2560x1600 @ 60Hz

• Supports hardware acceleration for DirectX 11, OCL 1.2, OGL 3.2, H.264,

MPEG2, MVC, VC-1, WMV9 and VP8

• Supports High Defi nition Audio interface

• Supports 2 Serial ATA interfaces

• SATA 2.0 with data transfer rate up to 3Gb/s

• Integrated Advanced Host Controller Interface (AHCI) controller

• Intel® I210AT Gigabit Ethernet Controller

• Integrated 10/100/1000 transceiver

• Fully compliant with IEEE 802.3, IEEE 802.3u, IEEE 802.3ab

• Supports 4GB, 8GB, 16GB and 32GB eMMC onboard

• Provides a Trusted PC for secure transactions

• Provides software license protection, enforcement and password protection

Expansion

Interfaces

Watchdog

• Supports 1 USB 3.0 port

• Supports 8 USB 2.0 ports

- 4 integrated USB 2.0 ports

- 1 USB HSIC for 4 USB 2.0 Ports

• Supports 3 PCIe x1 (default); or 1 PCIe x4 (PCIe port 3, by default, is shared

with the onboard LAN)*

• Supports LPC interface

• Supports I

• Supports SMBus interface

• Suppotrs 2 serial interfaces (TX/RX)

• Supports 8-bit Digital I/O

2

C interface

• Watchdog timeout programmable via software from 1 to 255 seconds

Timer

Damage Free

Intelligence

BIOS

Power

• Monitors CPU temperature

• Monitors Vcore/Vgfx/VDDR/1V0/VBAT voltages

• Monitors CPU/system fan speed

• Watchdog timer function

• AMI BIOS

- 64Mbit SPI BIOS

• 16W with E3845 at 1.91GHz and 2x 4GB DDR3L SODIMM

Consumption

OS Support

Temperature

Humidity

Power Input

PCB

• Windows 7 Ultimate x86 & SP1 (32-bit)

• Windows 7 Ultimate x64 & SP1 (64-bit)

• Windows 8 Enterprise x86 (32-bit)

• Windows 8 Enterprise x64 (64-bit)

• Windows 8.1 Enterprise x86 (32-bit)

• Windows 8.1 Enterprise x64 (64-bit)

• Operating

- Atom: 0

- Celeron: 0

• Storage: -40

o

C to 60oC, -20oC to 70oC, -40oC to 85oC

o

C to 60oC

o

C to 85oC

• 5% to 90%

• 12V, 5VSB, VCC_RTC (ATX mode)

12V, VCC_RTC (AT mode)

• Dimensions

- COM Express

- 95mm (3.74") x 95mm (3.74")

• Compliance

- PICMG COM Express

®

Compact

®

R2.1, Type 6

Note:

*Optional and is not supported in standard model. Please contact your sales representative for more information.

6

www.dfi .comChapter 1 Introduction

Page 7

Chapter 1

Features

• Watchdog Timer

The Watchdog Timer function allows your application to regularly “clear” the system at the set

time interval. If the system hangs or fails to function, it will reset at the set time interval so

that your system will continue to operate.

• DDR3L

DDR3L is a higher performance DDR3 SDRAM interface providing less voltage and higher

speed successor. DDR3L SDRAM modules support 1066/1333MHz for DDR modules. DDR3L delivers increased system bandwidth and improved performance to provide its higher bandwidth

and its increase in performance at a lower power.

• Graphics

The integrated Intel® HD graphics engine delivers an excellent blend of graphics performance

and features to meet business needs. It provides excellent video and 3D graphics with outstanding graphics responsiveness. These enhancements deliver the performance and compatibility needed for today’s and tomorrow’s business applications. Supports VGA, DDI, LVDS

(default) or DDI (optional) interfaces for up to 2 display outputs at the same time.

• Serial ATA

Serial ATA is a storage interface that is compliant with SATA 1.0a specification. With speed of

up to 3Gb/s (SATA 2.0), it improves hard drive performance faster than the standard parallel

ATA whose data transfer rate is 100MB/s.

• Gigabit LAN

The Intel® WGI210AT Gigabit LAN controller supports up to 1Gbps data transmission.

• USB

The system board supports the new USB 3.0. It is capable of running at a maximum transmission speed of up to 5 Gbit/s (625 MB/s) and is faster than USB 2.0 (480 Mbit/s, or 60 MB/s)

and USB 1.1 (12Mb/s). USB 3.0 reduces the time required for data transmission, reduces

power consumption, and is backward compatible with USB 2.0. It is a marked improvement

in device transfer speeds between your computer and a wide range of simultaneously

accessible external Plug and Play peripherals.

7

www.dfi .comChapter 1 Introduction

Page 8

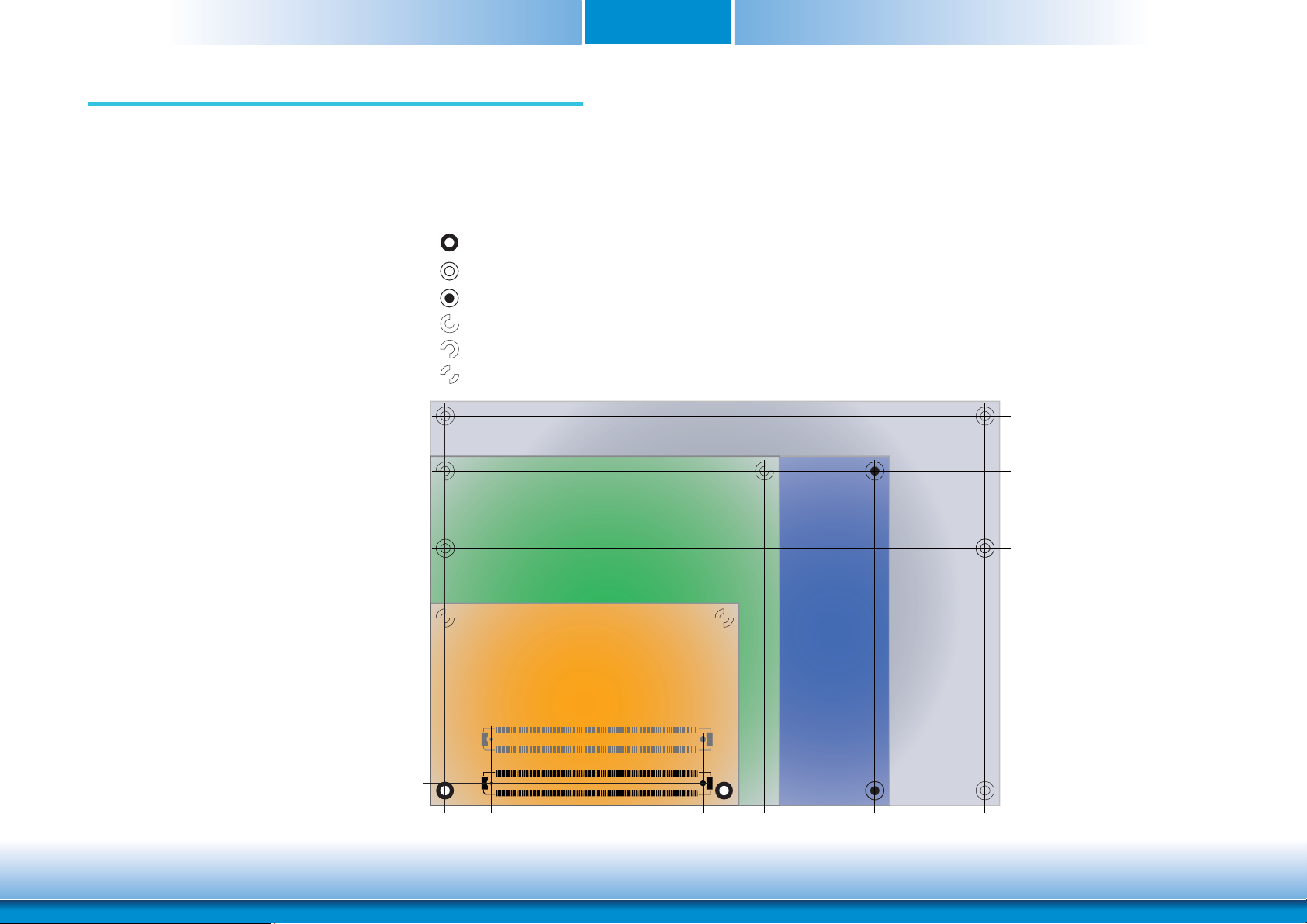

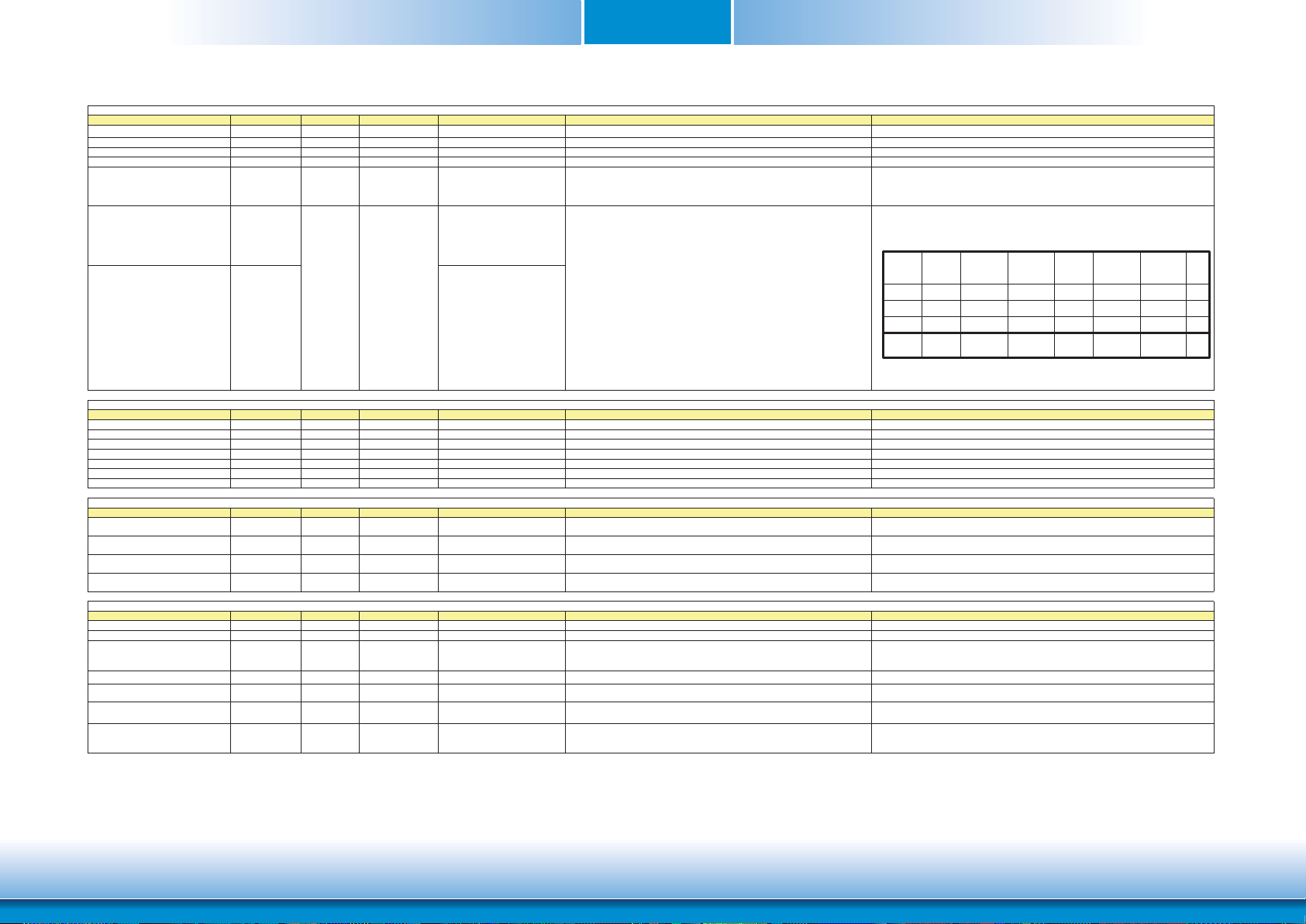

Chapter 2 - Concept

COM Express Module Standards

The figure below indicates the dimensions of the different types of COM Express modules.

BT968 is a COM Express Compact. The dimension is 95mm x 95mm.

Common for all Form Factors

Extended only

Basic only

Compact only

Compact and Basic only

Mini only

Chapter 2

106.00

Extended

91.00

18.00

6.00

0.00

4.00

0.00

16.50

Mini

8

74.20

80.00

91.00

BasicCompact

70.00

51.00

4.00

121.00

151.00

www.dfi .comChapter 2 Concept

Page 9

Chapter 2

/

)

A

T

ANA

ANA

t

ANA

)

p

t

/

/

A

A

A

A

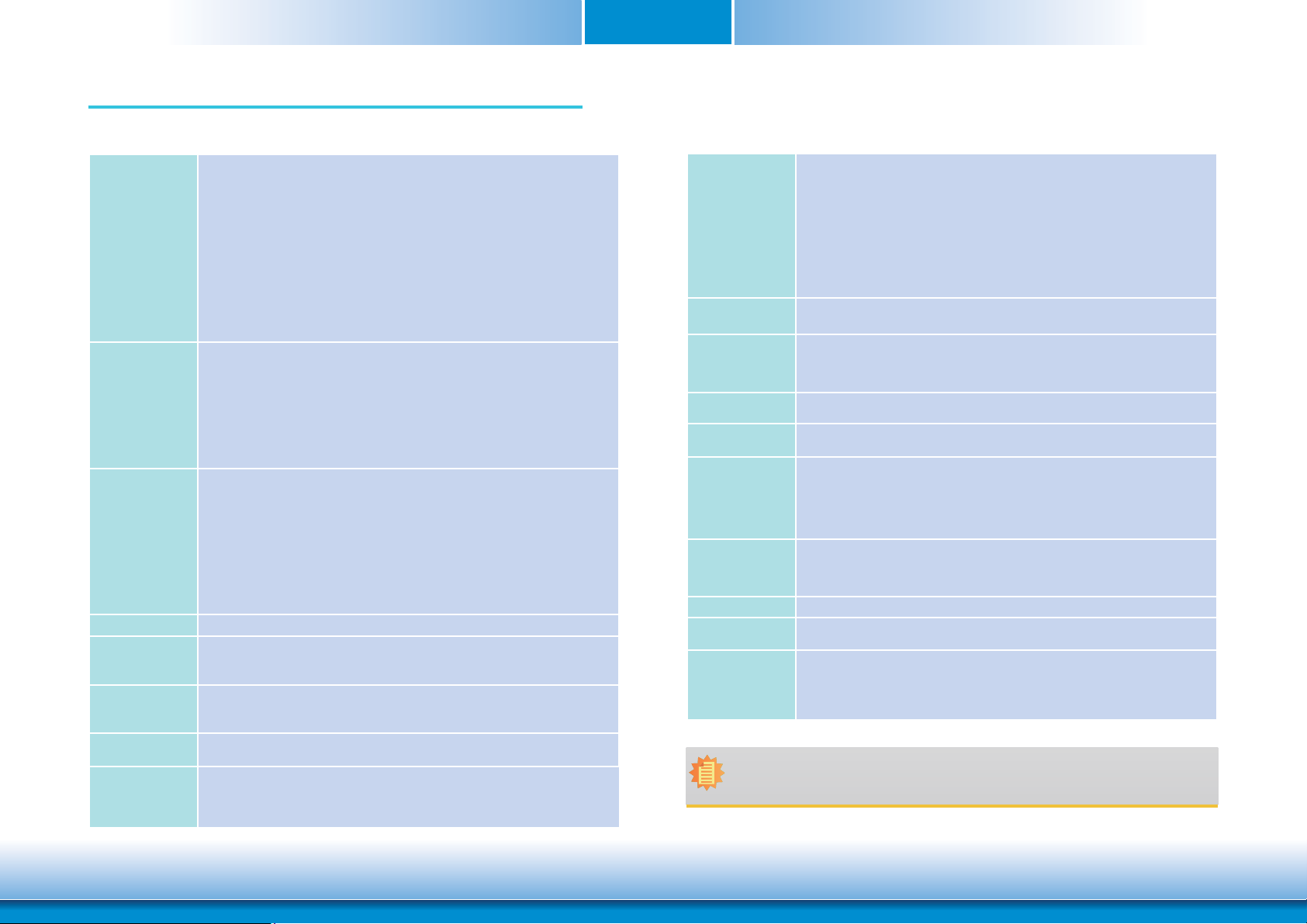

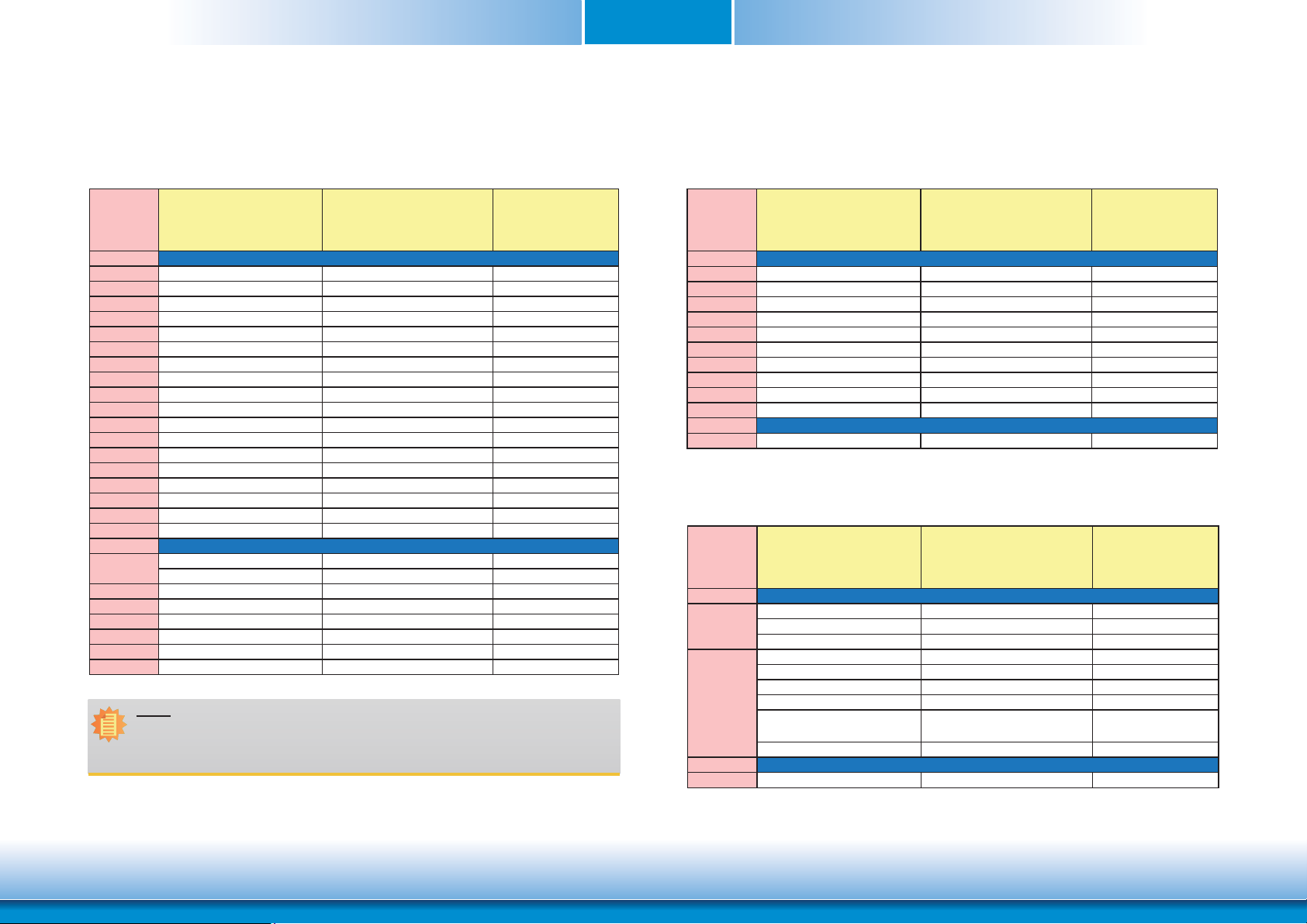

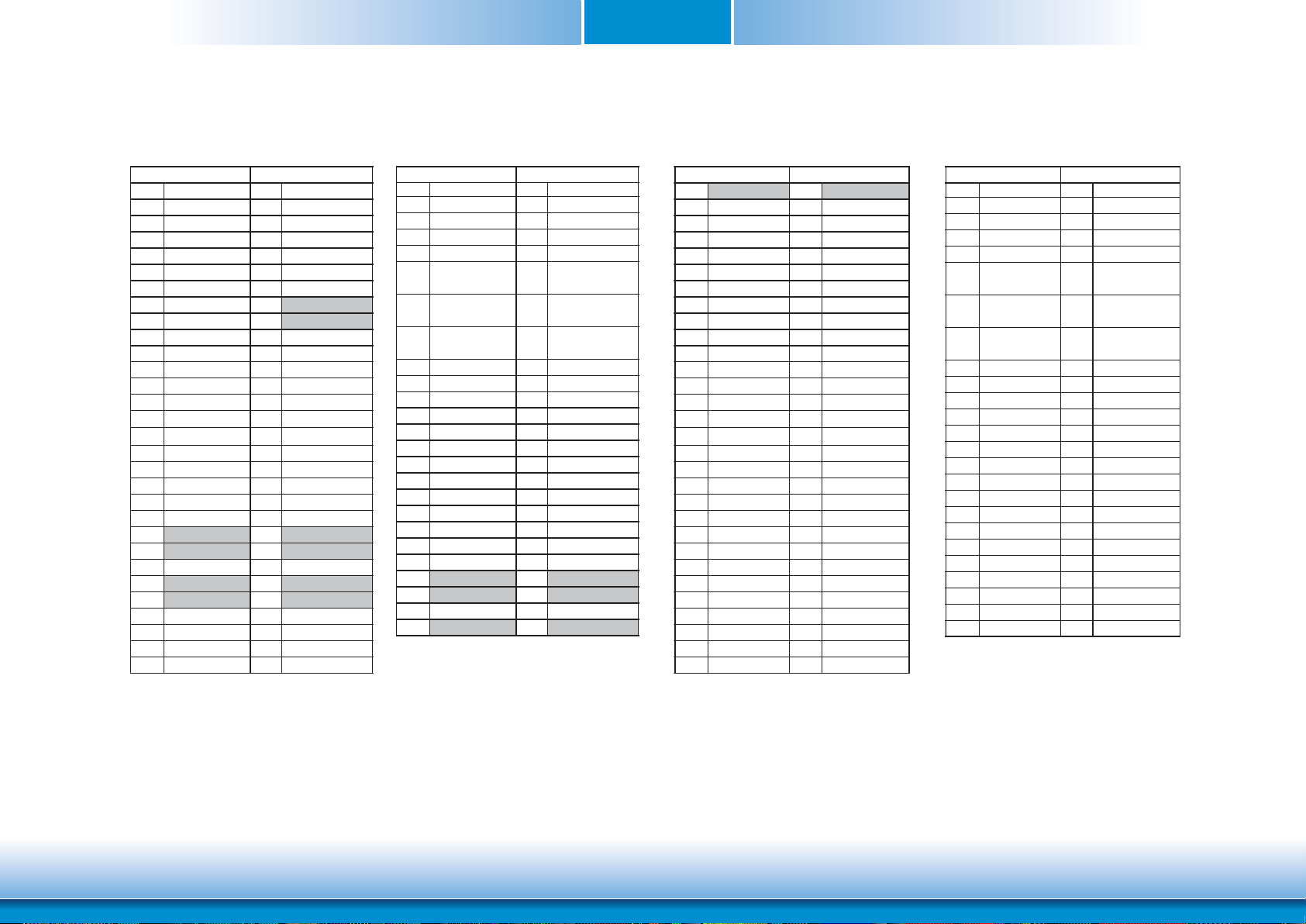

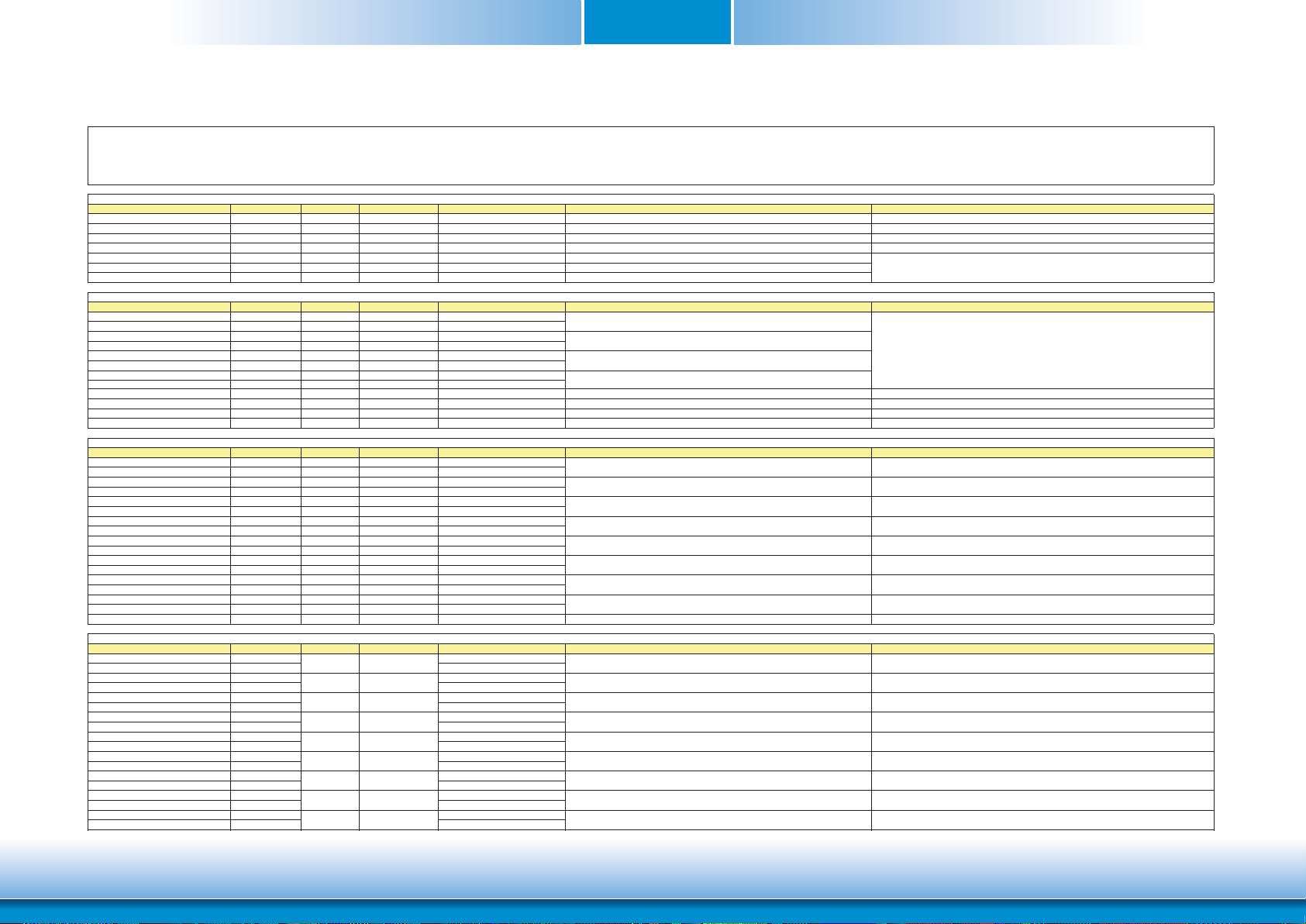

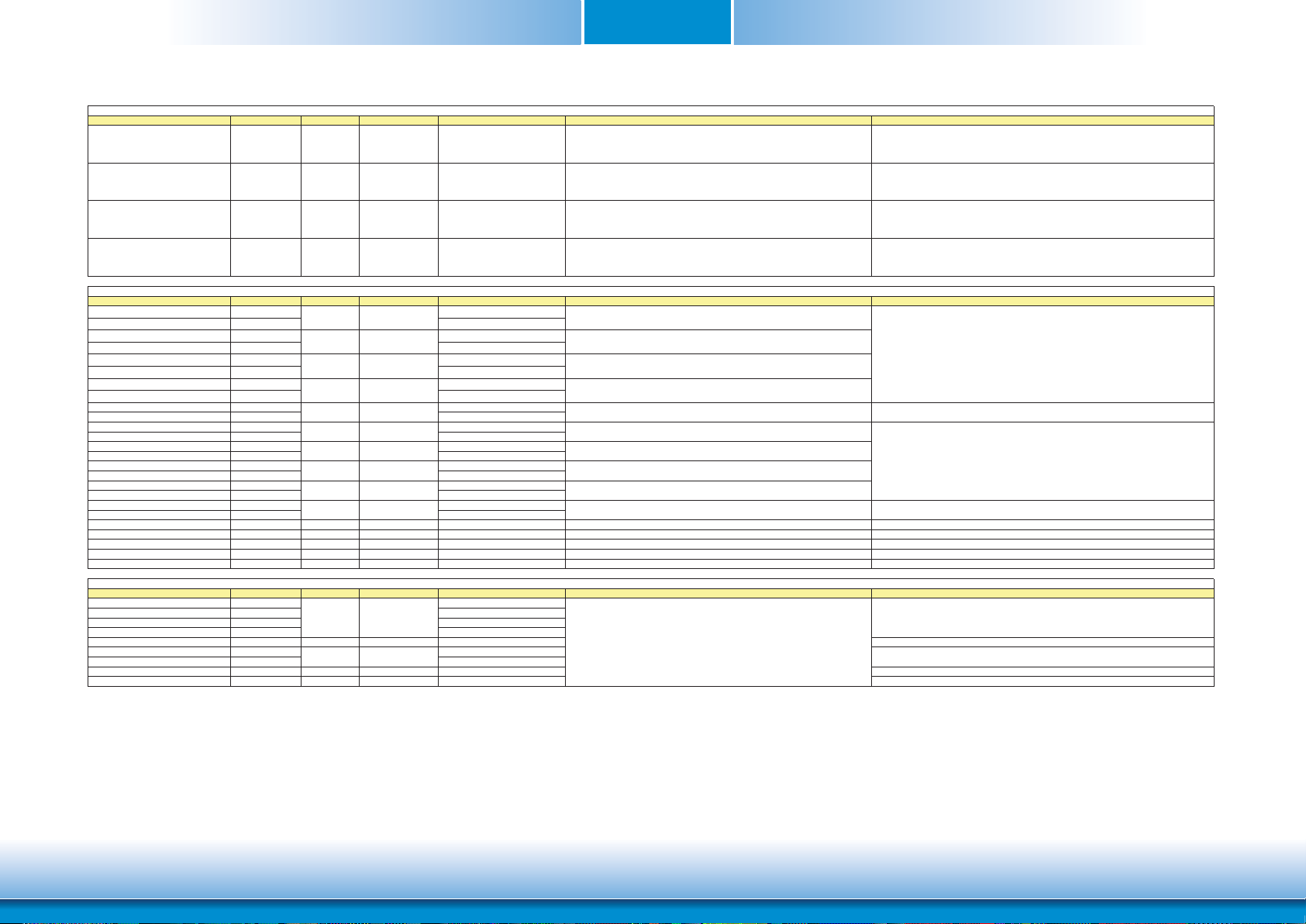

Specification Comparison Table

The table below shows the COM Express standard specifications and the corresponding specifications supported on the BT968 module.

Connector Feature

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

A-B

5

6

PCI Express Lanes 0 - 5 1 / 6 3 (4 for BOM Opt.

LVDS Channel

LVDS Channel B 0 / 1 1

eDP on LVDS CH A pins 0 / 1 0

VGA Port 0 / 1 1

V-Out N

DDI 0 N

Serial Ports 1 - 2 0 / 2 2

CAN interface on SER1 0 / 1 0

SATA / SAS Ports 1 / 4 2

AC’97 / HDA Digital Interface 0 / 1 1

USB 2.0 Ports 4 / 8 8

USB Clien

USB 3.0 Ports N

LAN Port 0 1 / 1 1

Express Card Support 1 / 2 2

LPC Bus 1 / 1 1

SPI 1 / 2 1

SDIO(muxed on GPIO

General Pur

SMBus 1 / 1 1

I2C 1 / 1 1

Watchdog Timer 0 / 1 1

Speaker Ou

External BIOS ROM Support0 / 2 1

Reset Functions 1 / 1 1

COM Express Module Base

Specification Type 6

(No IDE or PCI, add DDI+ USB3)

Max

Min

System I/O

0 / 1 1

0 / 1 0

System Management

0 / 1 0

ose I/O 8 / 8 8

1 / 1 1

DFI BT968

Type 6

Note:

• 5 Indicates 12V-tolerant features on former VCC_12V signals.

• 6 Cells in the connected columns spanning rows provide a rough approximation of

features sharing connector pins.

COM Express Module Base

Connector Feature

A-B

A-B Thermal Protection 0 / 1

A-B Battery Low Alarm 0 / 1

A-B Suspend/Wake Signals 0 / 3

A-B Power Button Support 1 / 1

A-B Power Good 1 / 1

A-B VCC_5V_SBY Contacts 4 / 4

5

A-B

5

A-B

5

A-B

A-B Trusted Platform Modules 0 / 1

A-B

A-B VCC_12V Contacts 12 / 12

Sleep Input 0 / 1

Lid Input 0 / 1

Fan Control Signals 0 / 2

Specification Type 6

(No IDE or PCI, add DDI+ USB3)

Min

Power Management

Max

Power

DFI BT968

Type 6

1

1

3

1

1

4

1

1

2

1

12

Module Pin-out - Required and Optional Features C-D Connector. PICMG® COM.0Revision 2.1

Connector Feature

C-D

C-D

C-D

6

6

PCI Express Lanes 16 - 31 0 / 16

PCI Express Graphics (PEG) 0 / 1

Muxed SDVO Channels 1 - 2 NA

PCI Express Lanes 6 - 15 0 / 2

PCI Bus - 32 Bit NA

PATA Port NA

LAN Ports 1 - 2 NA

DDIs 1 - 3 0 / 3

COM Express Module Base

Specification Type 6

(No IDE or PCI, add DDI+ USB3)

Max

Min

System I/O

DFI BT968

Type 6

0

0

N

0

N

N

N

2 (DDI 2 option with

onboard LVDS)

C-D

USB 3.0 Ports 0 / 4

C-D VCC_12V Contacts 12 / 12

Power

1

12

9

www.dfi .comChapter 2 Concept

Page 10

Chapter 3 - Hardware Installation

SATA 2.0 2x

USB 3.0 Port 1

)

)

VGA

PCIe GEN

2 (3

1

x4)

HD A

udio

LPC Bus

SLP/LID

USB 2.0 4x

(

SM

Bus

-

TCA6408A

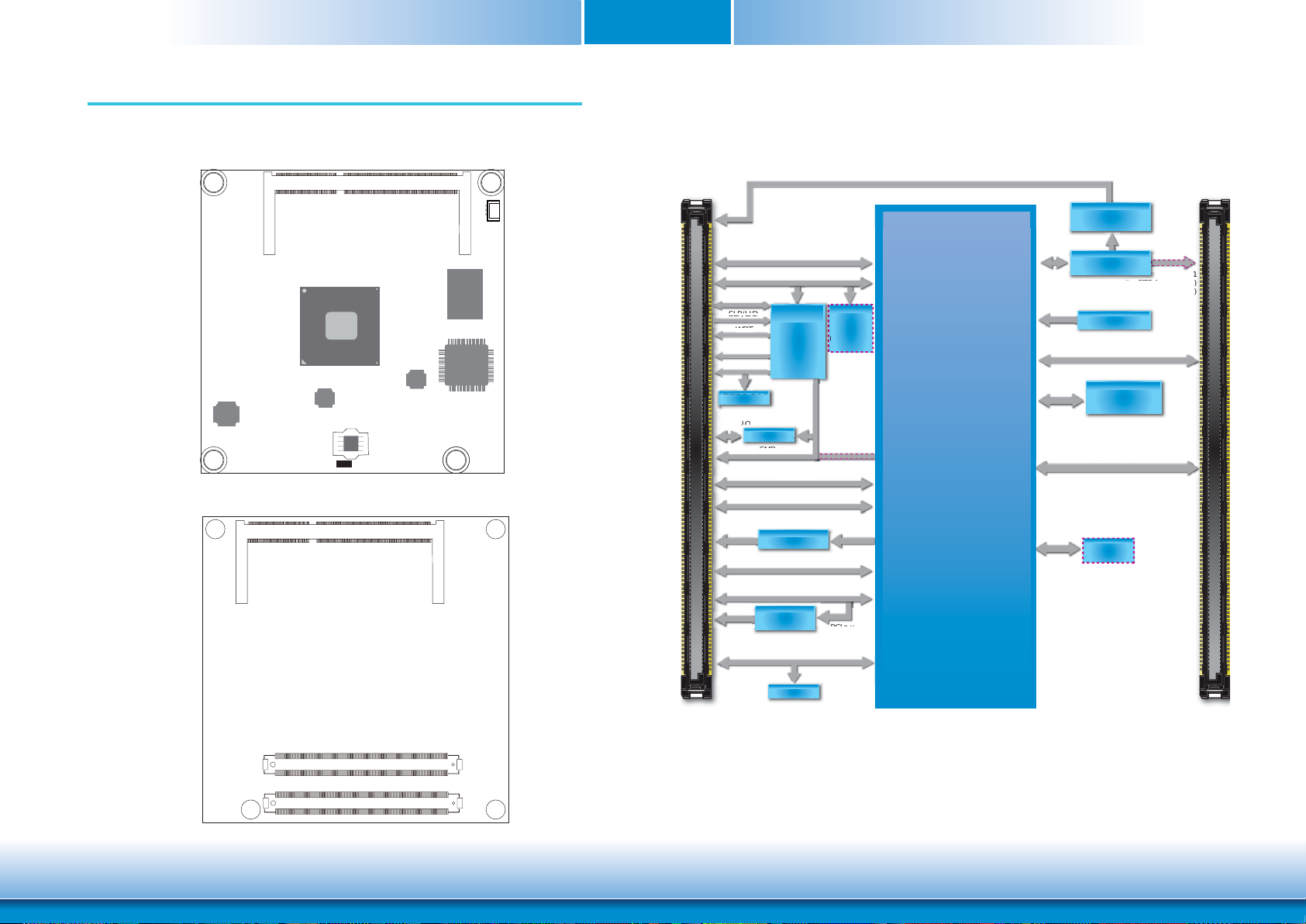

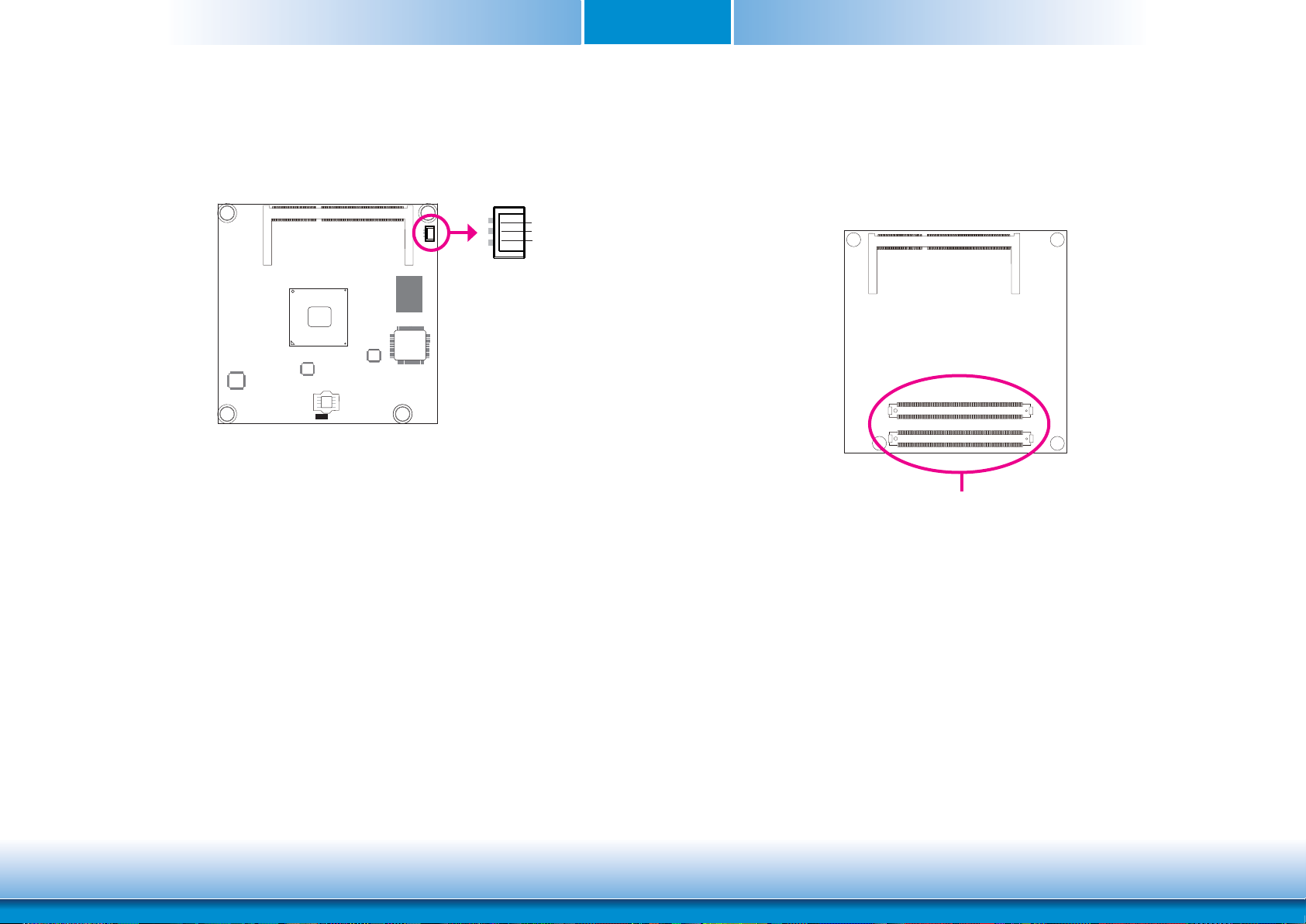

Board Layout

Chapter 3

Block Diagram

Intel I210AT

DDR3L_1 SODIMM

Intel

BGA 1170

SMSC USB4604

Top View

DDR3L_2 SODIMM

NXP PTN3460

SPI Flash BIOS

Standby Power LED

eMMC

(optional)

ITE

IT8528E

1

CPU Fan

Serial Port 0,1

8-bit DIO

8

A / B

USB 2.0 4x

SLP/LID

WDT

Embedded

Fan PWM/

TACH_IN

2

C Bus

I

Controller

EEPROM

TCA6408A

SMBus

USB4604

SATA 2.0 2x

PCIe GEN2 (3 x1 or 1 x4)

LAN

Intel® GLAN

I210AT

VGA

LPC Bus

IT8518E

HD Audio

USB 2.0 4x

x1 or

TPM 1.2

SLB9635

(optional)

USB HSIC

PCIe x1

LVDS Ports (Dual Channel)

Atom E3800 Series

/Celeron

eDP to LVDS

(PTN3460)

Default eDP (DDI) Port

DDI

Port 1

1:2 DP S/W

PI3VDP612A

IMVP7

DDI Port 0 (to BTB DDI Port1)

DDR3L Memory

DDR3

1066/1333MHz

Dual Channel

eMMC

Slot 2x

USB 3.0 Port 1

eMMC

(Optional)

DDI Port1

(to BTB DDI Port 2)

(co-lay with PTN3460)

C / D

SPI Bus

SPI Flash

D110

C110

B110

A110

COM Express connector

COM Express connector

D1

C1

B1

A1

Bottom View

10

www.dfi .comChapter 3 Hardware Installation

Page 11

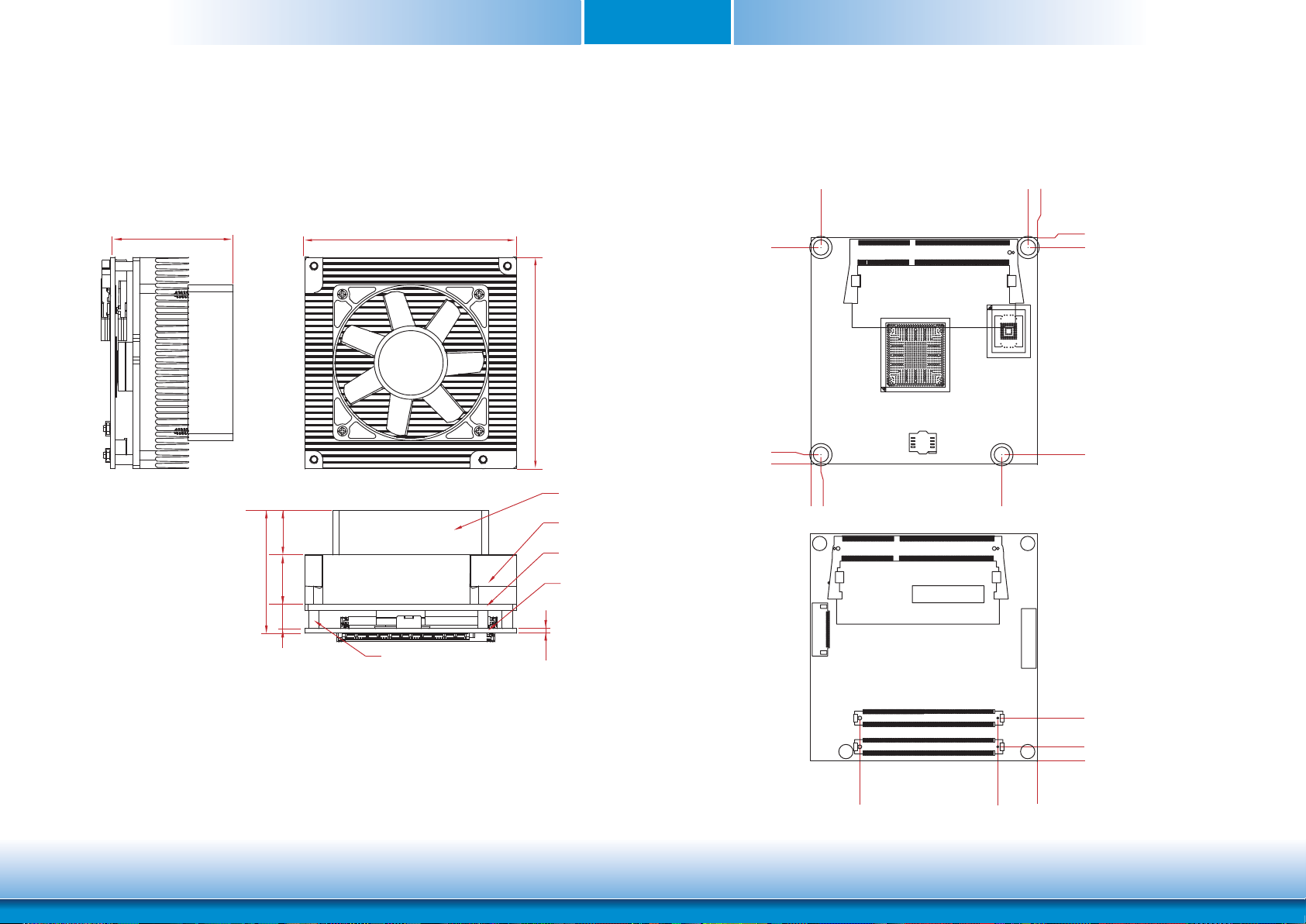

Mechanical Diagram

Chapter 3

53.00

BT968 Module with Heat Sink

95.00

20.00

55.00

95.00

Fan

Heat sink

Heatspreader

Module PCB

91.00

4.00

0.00

0.00

BT968 Module

91.00

4.00

4.00

95.00

95.00

91.00

Top View

4.00

80.00

11.00 22.00

Standoff

Side View of the Module with Heat Sink and Carrier Board

2.00

Bottom View

18.00

6.00

0.00

0.00

74.20

11

16.50

www.dfi .comChapter 3 Hardware Installation

Page 12

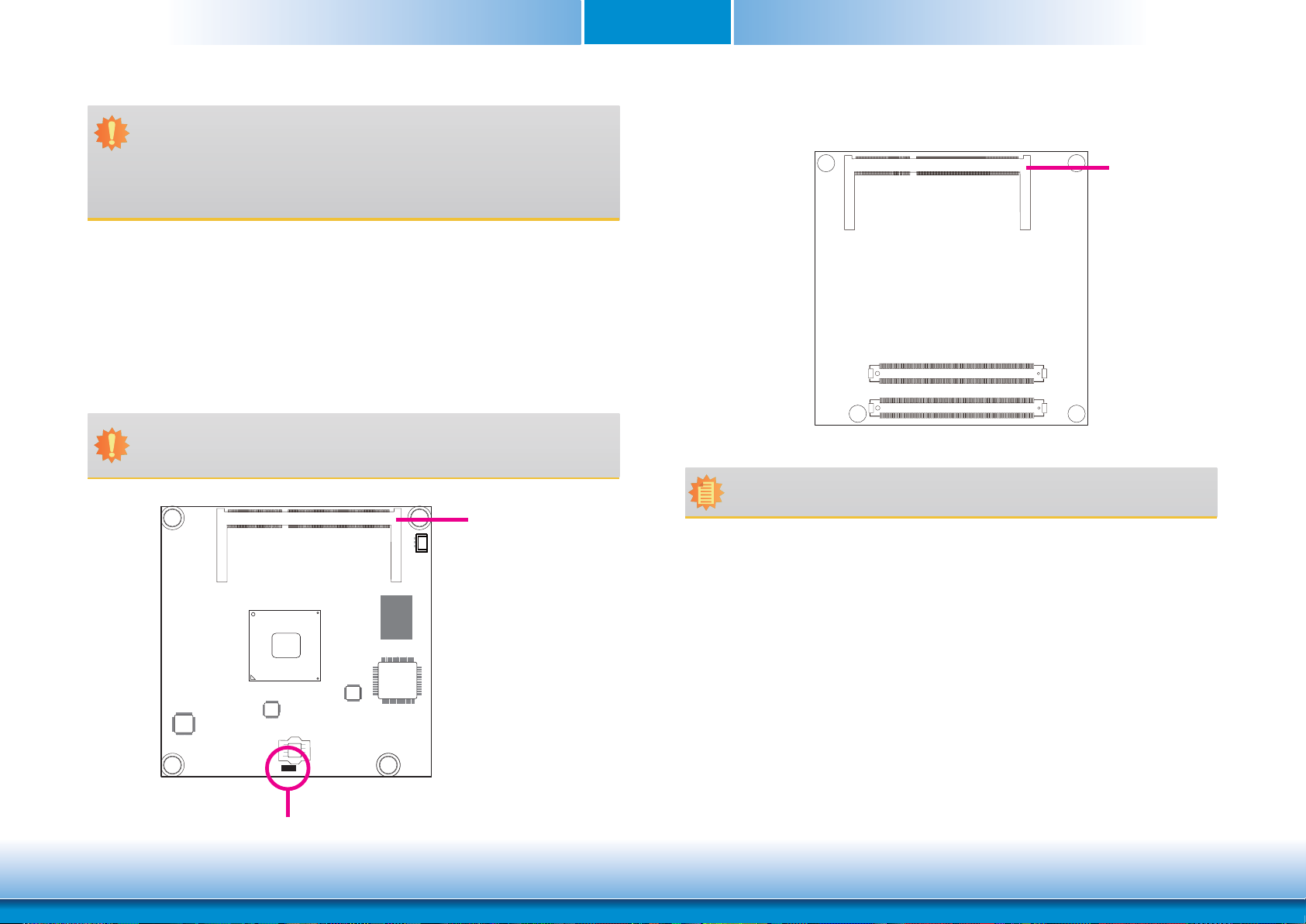

Important:

Electrostatic discharge (ESD) can damage your board, processor, disk drives, add-in

boards, and other components. Perform installation procedures at an ESD workstation

only. If such a station is not available, you can provide some ESD protection by wearing an antistatic wrist strap and attaching it to a metal part of the system chassis. If

a wrist strap is unavailable, establish and maintain contact with the system chassis

throughout any procedures requiring ESD protection.

System Memory

The system board is equipped with one or two 204-pin SODIMM sockets that support DDR3L

memory modules depending on the CPU processor supported.

• Two 204-pin DDR3L SODIMM sockets (-E45/-E27/-E26/-J00/-N30)

- up to 8GB system memory

- dual channel memory interface

One 204-pin DDR3L SODIMM socket (-E25/-E15/-N07)

- up to 4GB system memory

- single channel memory interface

Important:

When the Standby Power LED lights red, it indicates that there is power on the board.

Power-off the PC then unplug the power cord prior to installing any devices. Failure to

do so will cause severe damage to the board and components.

DDR3L_1

Chapter 3

DDR3L_2

Bottom View

Note:

When installing one DDR3L SODIMM only, make sure to install it on the socket (SODIMM 1) that is located on the top side of the module.

Standby

Power LED

Top View

12

www.dfi .comChapter 3 Hardware Installation

Page 13

Chapter 3

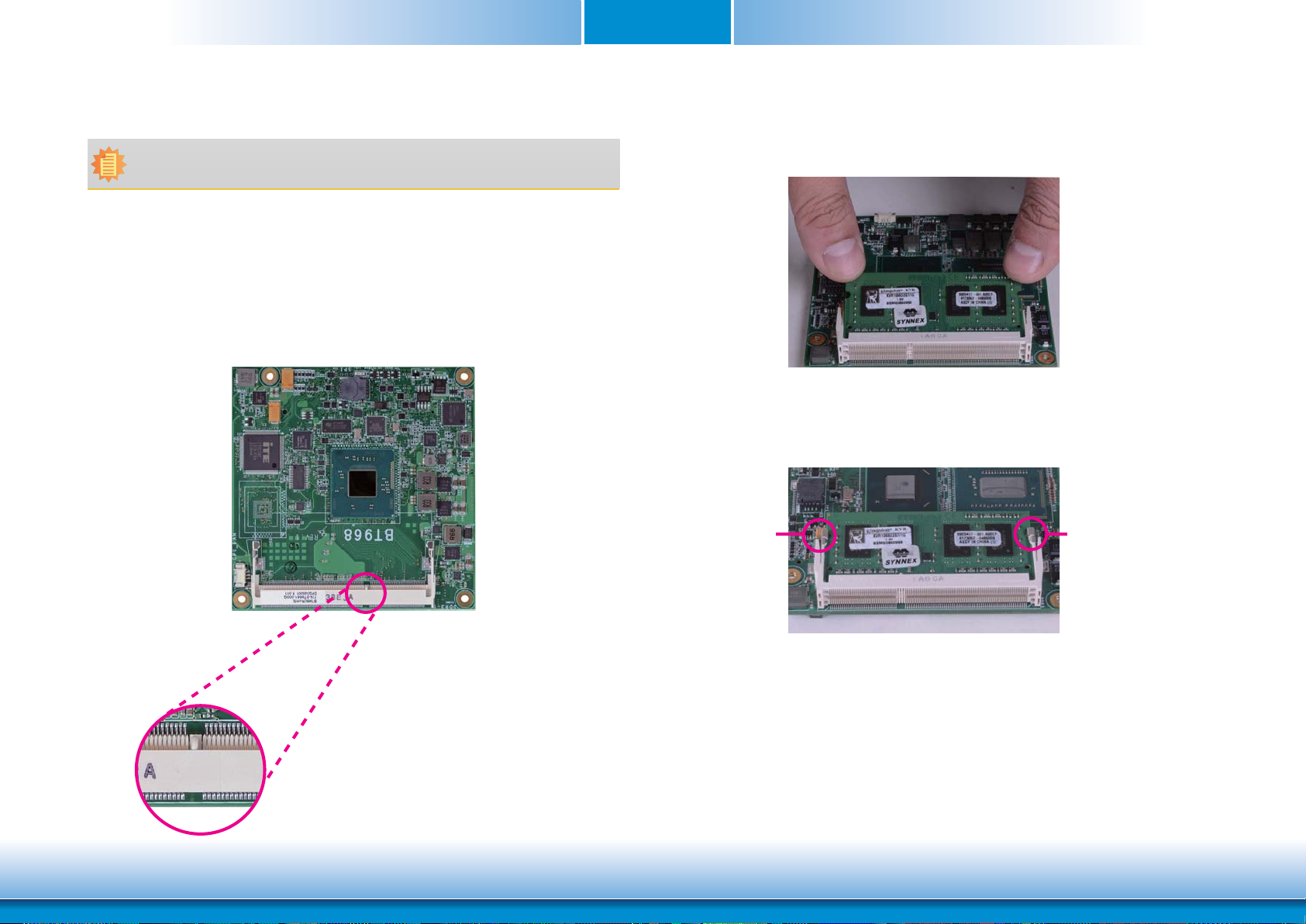

Installing the DIMM Module

Note:

The system board used in the following illustrations may not resemble the actual one.

These illustrations are for reference only.

1. Make sure the PC and all other peripheral devices connected to it has been powered down.

2. Disconnect all power cords and cables.

3. Locate the SODIMM socket on the system board.

4. Note the key on the socket. The key ensures the module can be plugged into the socket in

only one direction.

5. Grasping the module by its edges, align the module into the socket at an approximately 30

degrees angle. Apply firm even pressure to each end of the module until it slips down into

the socket. The contact fingers on the edge of the module will almost completely disappear

inside the socket.

6. Push down the module until the clips at each end of the socket lock into position. You will

hear a distinctive “click”, indicating the module is correctly locked into position.

ClipClip

13

www.dfi .comChapter 3 Hardware Installation

Page 14

Chapter 3

Connectors

CPU Fan Connector

3

1

Connect the CPU fan’s cable connector to the CPU fan connector on the board. The cooling fan

will provide adequate airflow throughout the chassis to prevent overheating the CPU and board

components.

BIOS Setting

“Module Board H/W Monitor” submenu in the Advanced menu of the BIOS will display the current speed of the cooling fan. Refer to chapter 4 of the manual for more information.

Ground

+12V

Sense

COM Express Connectors

The COM Express connectors are used to interface the BT968 COM Express board to a carrier

board. Connect the COM Express connectors (located on the solder side of the board) to the

COM Express connectors on the carrier board.

Refer to the “Installing BT968 onto a Carrier Board” section for more information.

COM Express Connectors

Refer to the following pages for the pin functions of these connectors.

14

www.dfi .comChapter 3 Hardware Installation

Page 15

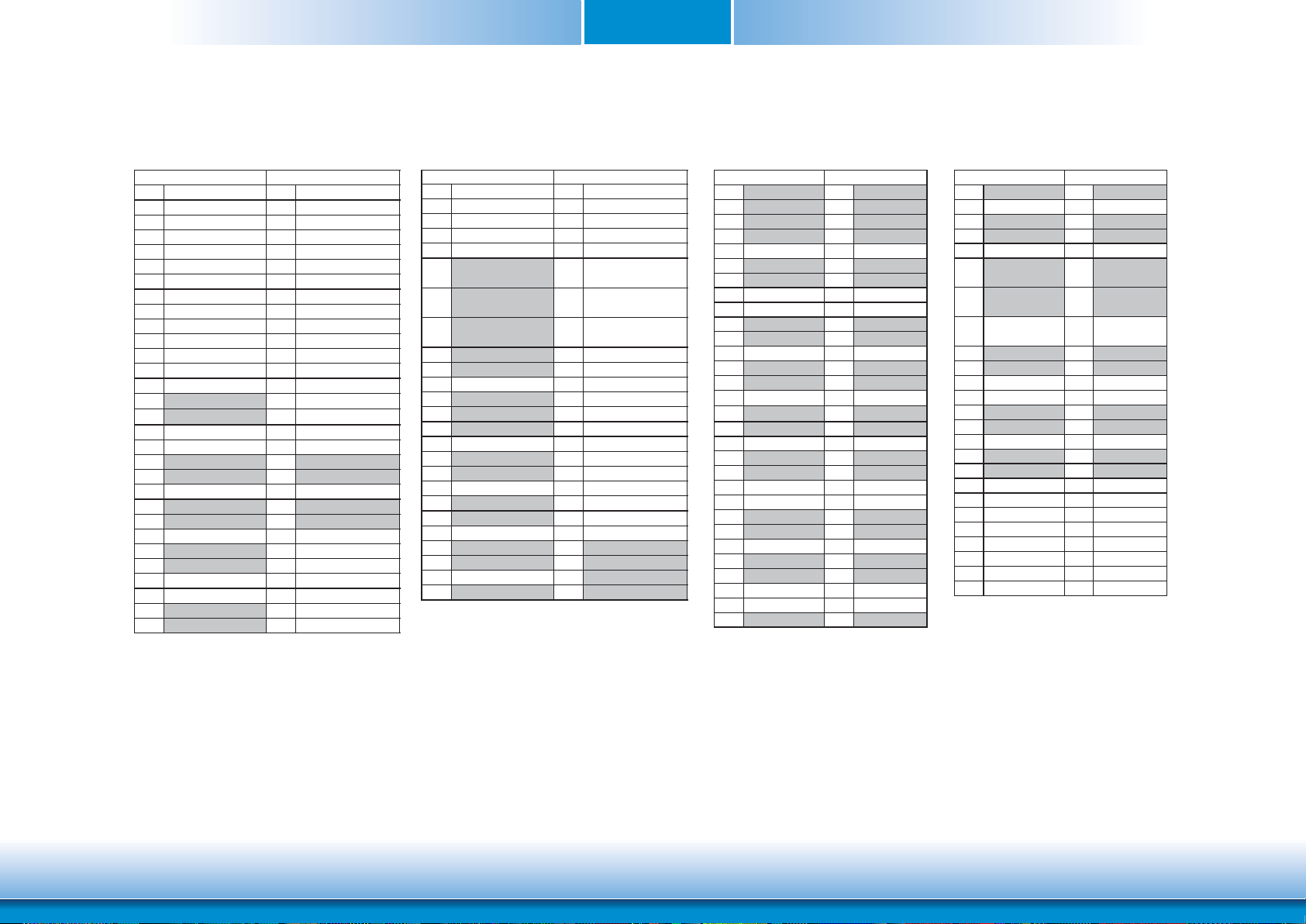

COM Express Connectors

Chapter 3

Row A Row B

A1 GND (FIXED) B1 GND (FIXED)

A2 GBE0_MDI3- B2 GBE0_ACT#

A3 GBE0_MDI3+ B3 LPC_FRAME#

A4 GBE0_LINK100# B4 LPC_AD0

A5 GBE0_LINK1000# B5 LPC_AD1

A6 GBE0_MDI2- B6 LPC_AD2

A7 GBE0_MDI2+ B7 LPC_AD3

A8 GBE0_LINK# B8 LPC_DRQ0# (NA)

A9 GBE0_MDI1- B9 LPC_DRQ1# (NA)

A10 GBE0_MDI1+ B10 LPC_CLK

A11 GND (FIXED) B11 GND (FIXED)

A12 GBE0_MDI0- B12 PWRBTN#

A13 GBE0_MDI0+ B13 SMB_CK

A14 GBE0_CTREF B14 SMB_DAT

A15 SUS_S3# B15 SMB_ALERT#

A16 SATA0_TX+ B16 SATA1_TX+

A17 SATA0_TX- B17 SATA1_TXA18 SUS_S4# B18 SUS_STAT#

A19 SATA0_RX+ B19 SATA1_RX+

A20 SATA0_RX- B20 SATA1_RXA21 GND (FIXED) B21 GND (FIXED)

A22 SATA2_TX+ (NA) B22 SATA3_TX+ (NA)

A23 SATA2_TX- (NA) B23 SATA3_TX- (NA)

A24 SUS_S5# B24 PWR_OK

A25 SATA2_RX+ (NA) B25 SATA3_RX+ (NA)

A26 SATA2_RX- (NA) B26 SATA3_RX- (NA)

A27 BATLOW# B27 WDT

A28 (S)ATA_ACT# B28 NA

A29 AC/HDA_SYNC B29 AC/HDA _SDIN1

A30 AC/HDA _RST# B30 AC/HDA _SDIN0

Row A Row B

A31 GND (FIXED) B31 GND (FIXED)

A32 AC/HDA _BITCLK B32 SPKR

A33 AC/HDA _SDOUT B33 I2C_CK

A34 BIOS_DIS0# B34 I2C_DAT

A35 THRMTRIP# B35 THRM#

A36 USB6- B36 USB7-

A37 USB6+ B37 USB7+

A38 USB_6_7_OC# B38 USB_4_5_OC#

A39 USB4- B39 USB5-

A40 USB4+ B40 USB5+

A41 GND (FIXED) B41 GND (FIXED)

A42 USB2- B42 USB3A43 USB2+ B43 USB3+

A44 USB_2_3_OC# B44 USB_0_1_OC#

A45 USB0- B45 USB1A46 USB0+ B46 USB1+

A47 VCC_RTC B47 EXCD1_PERST#

A48 EXCD0_PERST# B48 EXCD1_CPPE#

A49 EXCD0_CPPE# B49 SYS_RESET#

A50 LPC_SERIRQ B50 CB_RESET#

A51 GND (FIXED) B51 GND (FIXED)

A52 PCIE_TX5+(NA) B52 PCIE_RX5+(NA)

A53 PCIE_TX5-(NA) B53 PCIE_RX5-(NA)

A54 GPI0 B54 GPO1

A55 PCIE_TX4+(NA) B55 PCIE_RX4+(NA)

Row A Row B

A56 PCIE_TX4-(NA) B56 PCIE_RX4- (NA)

A57 GND B57 GPO2

A58 PCIE_TX3+ B58 PCIE_RX3+

A59 PCIE_TX3- B59 PCIE_RX3A60 GND (FIXED) B60 GND (FIXED)

A61 PCIE_TX2+ B61 PCIE_RX2+

A62 PCIE_TX2- B62 PCIE_RX2-

A63 GPI1 B63 GPO3

A64 PCIE_TX1+ B64 PCIE_RX1+

A65 PCIE_TX1- B65 PCIE_RX1A66 GND B66 WAKE0#

A67 GPI2 B67 WAKE1#

A68 PCIE_TX0+ B68 PCIE_RX0+

A69 PCIE_TX0- B69 PCIE_RX0-

A70 GND(FIXED) B70 GND (FIXED)

A71 LVDS_A0+ B71 LVDS_B0+

A72 LVDS_A0- B72 LVDS_B0-

A73 LVDS_A1+ B73 LVDS_B1+

A74 LVDS_A1- B74 LVDS_B1-

A75 LVDS_A2+ B75 LVDS_B2+

A76 LVDS_A2- B76 LVDS_B2-

A77 LVDS_VDD_EN B77 LVDS_B3+

A78 LVDS_A3+ B78 LVDS_B3-

A79 LVDS_A3- B79 LVDS_BKLT_EN

A80 GND (FIXED) B80 GND (FIXED)

A81 LVDS_A_CK+ B81 LVDS_B_CK+

A82 LVDS_A_CK- B82 LVDS_B_CKA83 LVDS_I2C_CK B83 LVDS_BKLT_CTRL

A84 LVDS_I2C_DAT B84 VCC_5V_SBY

A85 GPI3 B85 VCC_5V_SBY

Row A Row B

A86 RSVD B86 VCC_5V_SBY

A87 RSVD B87 VCC_5V_SBY

A88 PCIE0_CK_REF+ B88 BIOS_DIS1#

A89 PCIE0_CK_REF- B89 VGA_RED

A90 GND (FIXED) B90 GND (FIXED)

A91 SPI_POWER B91 VGA_GRN

A92 SPI_MISO B92 VGA_BLU

A93 GPO0 B93 VGA_HSYNC

A94 SPI_CLK B94 VGA_VSYNC

A95 SPI_MOSI B95 VGA_I2C_CK

A96 TPM_PP B96 VGA_I2C_DAT

A97 NC B97 SPI_CS#

A98 SER0_TX B98 RSVD

A99 SER0_RX B99 RSVD

A100 GND (FIXED) B100 GND (FIXED)

A101 SER1_TX B101 FAN_PWMOUT

A102 SER1_RX B102 FAN_TACHIN

A103 LID# B103 SLEEP#

A104 VCC_12V B104 VCC_12V

A105 VCC_12V B105 VCC_12V

A106 VCC_12V B106 VCC_12V

A107 VCC_12V B107 VCC_12V

A108 VCC_12V B108 VCC_12V

A109 VCC_12V B109 VCC_12V

A110 GND (FIXED) B110 GND (FIXED)

15

www.dfi .comChapter 3 Hardware Installation

Page 16

Chapter 3

Row C Row D

C1 GND (FIXED) D1 GND (FIXED)

C2 GND D2 GND

C3 USB_SSRX0- D3 USB_SSTX1C4 USB_SSRX0+ D4 USB_SSTX1+

C5 GND D5 GND

C6 NA D6 NA

C7 NA D7 NA

C8 GND D8 GND

C9 NA D9 NA

C10 NA D10 NA

C11 GND (FIXED) D11 GND (FIXED)

C12 NA D12 NA

C13 NA D13 NA

C14 GND D14 GND

C15 DDI1_PAIR6+ (NA) D15 DDI1_CTRLCLK_AUX+

C16 DDI1_PAIR6- (NA) D16 DDI1_CTRLDATA_AUXC17 RSVD D17 RSVD

C18 RSVD D18 RSVD

C19 PCIE_RX6+ (NA) D19 PCIE_TX6+ (NA)

C20 PCIE_RX6- (NA) D20 PCIE_TX6- (NA)

C21 GND (FIXED) D21 GND (FIXED)

C22 PCIE_RX7+ (NA) D22 PCIE_TX7+ (NA)

C23 PCIE_RX7- (NA) D23 PCIE_TX7- (NA)

C24 DDI1_HPD D24 RSVD

C25 DDI1_PAIR4+ (NA) D25 RSVD

C26 DDI1_PAIR4- (NA) D26 DDI1_PAIR0+

C27 RSVD D27 DDI1_PAIR0C28 RSVD D28 RSVD

C29 DDI1_PAIR5+ (NA) D29 DDI1_PAIR1+

C30 DDI1_PAIR5- (NA) D30 DDI1_PAIR1-

Row C Row D

C31 GND (FIXED) D31 GND (FIXED)

C32 DDI2_CTRLCLK_AUX+ D32 DDI1_PAIR2+

C33 DDI2_CTRLDATA_AUX- D33 DDI1_PAIR2C34 DDI2_DDC_AUX_SEL D34 DDI1_DDC_AUX_SEL

C35 RSVD D35 RSVD

DDI3_CTRLCLK_AUX+

C36

(NA)

DDI3_CTRLDATA_AUX-

C37

(NA)

DDI2_DDC_AUX_SEL

C38

(NA)

C39 DDI3_PAIR0+ (NA) D39 DDI2_PAIR0+

C40 DDI3_PAIR0- (NA) D40 DDI2_PAIR0C41 GND (FIXED) D41 GND (FIXED)

C42 DDI3_PAIR1+ (NA) D42 DDI2_PAIR1+

C43 DDI3_PAIR1- (NA) D43 DDI2_PAIR1C44 DDI3_HPD (NA) D44 DDI2_HPD

C45 RSVD D45 RSVD

C46 DDI3_PAIR2+ (NA) D46 DDI2_PAIR2+

C47 DDI3_PAIR2- (NA) D47 DDI2_PAIR2C48 RSVD D48 RSVD

C49 DDI3_PAIR3+ (NA) D49 DDI2_PAIR3+

C50 DDI3_PAIR3- (NA) D50 DDI2_PAIR3C51 GND (FIXED) D51 GND (FIXED)

C52 PEG_RX0+ (NA) D52 PEG_TX0+ (NA)

C53 PEG_RX0- (NA) D53 PEG_TX0- (NA)

C54 TYPE0# (NC) D54 PEG_LANE_RV# (NA)

C55 PEG_RX1+ (NA) D55 PEG_TX1+ (NA)

D36 DDI1_PAIR3+

D37 DDI1_PAIR3-

D38 RSVD

Row C Row D

C56 PEG_RX1- (NA) D56 PEG_TX1- (NA)

C57 TYPE1# (NC) D57 TYPE2# (GND)

C58 PEG_RX2+ (NA) D58 PEG_TX2+ (NA)

C59 PEG_RX2- D59 PEG_TX2- (NA)

C60 GND (FIXED) D60 GND (FIXED)

C61 PEG_RX3+ (NA) D61 PEG_TX3+ (NA)

C62 PEG_RX3- (NA) D62 PEG_TX3- (NA)

C63 RSVD D63 RSVD

C64 RSVD D64 RSVD

C65 PEG_RX4+ (NA) D65 PEG_TX4+ (NA)

C66 PEG_RX4- (NA) D66 PEG_TX4- (NA)

C67 NC D67 GND

C68 PEG_RX5+ (NA) D68 PEG_TX5+ (NA)

C69 PEG_RX5- (NA) D69 PEG_TX5- (NA)

C70 GND (FIXED) D70 GND (FIXED)

C71 PEG_RX6+ (NA) D71 PEG_TX6+ (NA)

C72 PEG_RX6- (NA) D72 PEG_TX6- (NA)

C73 GND D73 GND

C74 PEG_RX7+ (NA) D74 PEG_TX7+ (NA)

C75 PEG_RX7- (NA) D75 PEG_TX7- (NA)

C76 GND D76 GND

C77 RSVD D77 RSVD

C78 PEG_RX8+ (NA) D78 PEG_TX8+ (NA)

C79 PEG_RX8- (NA) D79 PEG_TX8- (NA)

C80 GND (FIXED) D80 GND (FIXED)

C81 PEG_RX9+ (NA) D81 PEG_TX9+ (NA)

C82 PEG_RX9- (NA) D82 PEG_TX9- (NA)

C83 RSVD D83 RSVD

C84 GND D84 GND

C85 PEG_RX10+ (NA) D85 PEG_TX10+ (NA)

Row C Row D

C86 PEG_RX10- (NA) D86 PEG_TX10- (NA)

C87 GND D87 GND

C88 PEG_RX11+ (NA) D88 PEG_TX11+ (NA)

C89 PEG_RX11- (NA) D89 PEG_TX11- (NA)

C90 GND (FIXED) D90 GND (FIXED)

C91 PEG_RX12+ (NA) D91 PEG_TX12+ (NA)

C92 PEG_RX12- (NA) D92 PEG_TX12- (NA)

C93 GND D93 GND

C94 PEG_RX13+ (NA) D94 PEG_TX13+ (NA)

C95 PEG_RX13- (NA) D95 PEG_TX13- (NA)

C96 GND D96 GND

C97 RSVD D97 RSVD

C98 PEG_RX14+ (NA) D98 PEG_TX14+ (NA)

C99 PEG_RX14- (NA) D99 PEG_TX14- (NA)

C100 GND (FIXED) D100 GND (FIXED)

C101 PEG_RX15+ (NA) D101 PEG_TX15+ (NA)

C102 PEG_RX15- (NA) D102 PEG_TX15- (NA)

C103 GND D103 GND

C104 VCC_12V D104 VCC_12V

C105 VCC_12V D105 VCC_12V

C106 VCC_12V D106 VCC_12V

C107 VCC_12V D107 VCC_12V

C108 VCC_12V D108 VCC_12V

C109 VCC_12V D109 VCC_12V

C110 GND (FIXED) D110 GND (FIXED)

16

www.dfi .comChapter 3 Hardware Installation

Page 17

Chapter 3

A

/

A

s

s

s

s

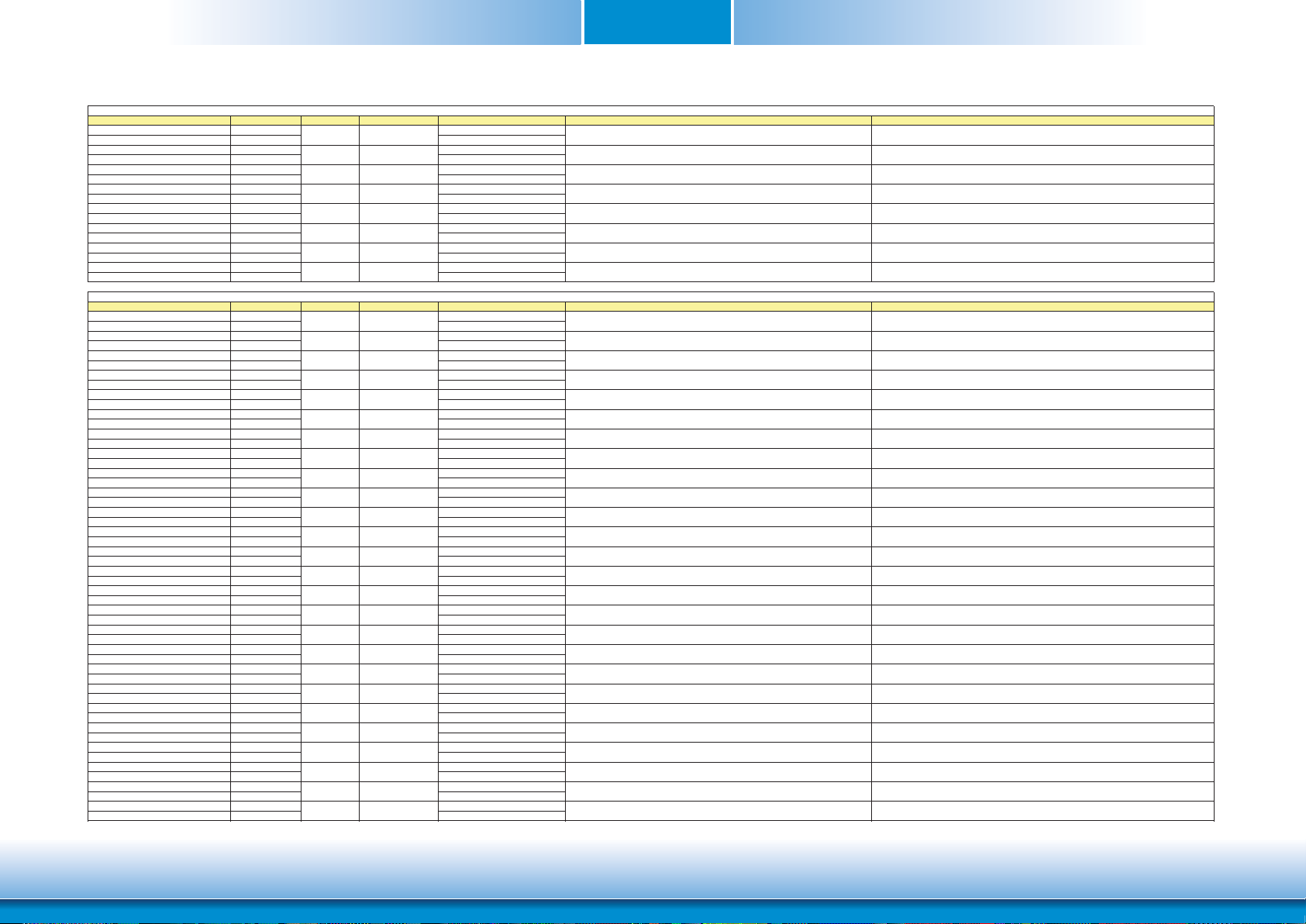

COM Express Connectors Signal Description

Pin Types

I Input to the Module

O Output from the Module

I/O Bi-directional input / output signal

OD Open drain output

C97/HDA Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

AC/HAD_RST# A30 O CMOS 3.3V Suspend/3.3V Connect to CODEC pin 11 RESET# Reset output to CODEC, active low.

AC/HDA_SYNC A29 O CMOS 3.3V/3.3V Connect to CODEC pin 10 SYNC Sample-synchronization signal to the CODEC(s).

AC/HDA_BITCLK A32 I/O CMOS 3.3V/3.3V Connect to CODEC pin 6 BIT_CLK Serial data clock generated by the external CODEC(s).

AC/HDA_SDOUT A33 O CMOS 3.3V/3.3V Connect to CODEC pin 5 SDATA_OUT Serial TDM data output to the CODEC.

AC/HDA_SDIN2 B28 I/O CMOS 3.3V Suspend/3.3V HDA_SDIN2 NA NC

AC/HDA_SDIN1 B29 I/O CMOS 3.3V Suspend/3.3V Connect 33 ƻ in series to CODEC1 pin 8 SDATA_IN

AC/HDA_SDIN0 B30 I/O CMOS 3.3V Suspend/3.3V Connect 33 ƻ in series to CODEC0 pin 8 SDATA_IN

Gigabit Ethernet Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

GBE0_MDI0+ A13 I/O Analog 3.3V max Suspend

GBE0_MDI0- A12 I/O Analog 3.3V max Suspend

GBE0_MDI1+ A10 I/O Analog 3.3V max Suspend

GBE0_MDI1- A9 I/O Analog 3.3V max Suspend

GBE0_MDI2+ A7 I/O Analog 3.3V max Suspend

GBE0_MDI2- A6 I/O Analog 3.3V max Suspend

GBE0_MDI3+ A3 I/O Analog 3.3V max Suspend

GBE0_MDI3GBE0_ACT# B2 OD CMOS 3.3V Suspend/3.3V Connect to LED and recommend current limit resistor 150 ȟ to 3.3VSB Gigabit Ethernet Controller 0 activity indicator, active low.

GBE0_LINK# A8 OD CMOS 3.3V Suspend/3.3V NC Gigabit Ethernet Controller 0 link indicator, active low.

GBE0_LINK100# A4 OD CMOS 3.3V Suspend/3.3V Connect to LED and recommend current limit resistor 150ȟ to 3.3VSB Gigabit Ethernet Controller 0 1000 Mbit / sec link indicator, active low.

GBE0_LINK1000# A5 OD CMOS 3.3V Suspend/3.3V Connect to LED and recommend current limit resistor 150ȟ to 3.3VSB Gigabit Ethernet Controller 0 1000 Mbit / sec link indicator, active low.

SATA Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

SATA0_TX+ A16 O SATA AC coupled on Module AC Coupling capacitor

SATA0_TX- A17 O SATA AC coupled on Module AC Coupling capacitor

SATA0_RX+ A19 I SATA AC coupled on Module AC Coupling capacitor

SATA0_RX- A20 I SATA AC coupled on Module AC Coupling capacitor

SATA1_TX+ B16 O SATA AC coupled on Module AC Coupling capacitor

SATA1_TX- B17 O SATA AC coupled on Module AC Coupling capacitor

SATA1_RX+ B19 I SATA AC coupled on Module AC Coupling capacitor

SATA1_RX- B20 I SATA AC coupled on Module AC Coupling capacitor

SATA2_TX+ A22 O SATA AC coupled on Module AC Coupling capacitor

SATA2_TX- A23 O SATA AC coupled on Module NA

SATA2_RX+ A25 I SATA AC coupled on Module NA

SATA2_RX- A26 I SATA AC coupled on Module NA

SATA3_TX+ B22 O SATA AC coupled on Module NA

SATA3_TX- B23 O SATA AC coupled on Module NA

SATA3_RX+ B25 I SATA AC coupled on Module NA

SATA3_RX- B26 I SATA AC coupled on Module NA

ATA_ACT# A28 I/O CMOS 3.3V / 3.3V PU 47K to 3.3V Connect to LED and recommend current limit resistor 220ƻ to 3.3V ATA (parallel and serial) or SAS activity indicator, active low.

PCI Express Lanes Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

PCIE_TX0+ A68 AC Coupling capacitor

PCIE_TX0- A69 AC Coupling capacitor

PCIE_RX0+ B68

PCIE_RX0- B69

PCIE_TX1+ A64 AC Coupling capacitor

PCIE_TX1- A65 AC Coupling capacitor

PCIE_RX1+ B64

PCIE_RX1- B65

PCIE_TX2+ A61 AC Coupling capacitor

PCIE_TX2- A62 AC Coupling capacitor

PCIE_RX2+ B61

PCIE_RX2- B62

PCIE_TX3+ A58 AC Coupling capacitor

PCIE_TX3- A59 AC Coupling capacitor

PCIE_RX3+ B58

PCIE_RX3- B59

PCIE_TX4+ A55 NA

PCIE_TX4- A56 NA

2I

O Analog3.3V max Suspend

O PCIE AC coupled on Module PCI Express Differential Transmit Pairs 0

I PCIE AC coupled off Module PCI Express Differential Receive Pairs 0

O PCIE

I PCIE AC coupled off Module

O PCIE AC coupled on Module PCI Express Differential Transmit Pairs 2

I PCIE AC coupled off Module

O PCIE AC coupled on Module

I PCIE AC coupled off Module

O PCIE AC coupled on Module

AC coupled on Module PCI Express Differential Transmit Pairs 1

Connect to Magnetics Module MDI0+/-

Connect to Magnetics Module MDI1+/-

Connect to Magnetics Module MDI2+/-

Connect to Magnetics Module MDI3+/-

Connect to SATA0 Conn TX pin

Connect to SATA0 Conn RX pin Serial ATA or SAS Channel 0 receive differential pair.

Connect to SATA1 Conn TX pin

Connect to SATA1 Conn RX pin Serial ATA or SAS Channel 1 receive differential pair.

NA (No support)

NA (No support) NA (No support)

NA (No support) NA (No support)

NA (No support) NA (No support)

Connect to PCIE device or slot

Device - Connect AC Coupling cap 0.1uF

Slot - Connect to PCIE Conn pin

Connect to PCIE device or slot

Device - Connect AC Coupling cap 0.1uF

Slot - Connect to PCIE Conn pin

Connect to PCIE device or slot

Device - Connect AC Coupling cap 0.1uF

Slot - Connect to PCIE Conn pin

Connect to PCIE device or slot (This Port is BOM Option with On board LAN)

Device - Connect AC Coupling cap 0.1uF (This Port is BOM Option with On board LAN)

Slot - Connect to PCIE Conn pin

NA (No support)

Serial TDM data inputs from up to 3 CODECs.

Gigabit Ethernet Controller 0: Media Dependent Interface Differential

Pairs 0,1,2,3. The MDI can operate in 1000, 100 and 10 Mbit / sec

modes. Some pairs are unused in some modes, per the following:

1000BASE-T 100BASE-TX 10BASE-T

MDI[0]+/- B1_DA+/- TX+/- TX+/ MDI[1]+/- B1_DB+/- RX+/- RX+/ MDI[2]+/- B1_DC+/ MDI[3]+/- B1_DD+/-

Serial ATA or SAS Channel 0 transmit differential pair.

Serial ATA or SAS Channel 1 transmit differential pair.

NA (No support)

PCI Express Differential Receive Pairs 1

PCI Express Differential Receive Pairs 2

PCI Express Differential Transmit Pairs 3 (This Port is BOM Option with On board LAN)

PCI Express Differential Receive Pairs 3 (This Port is BOM Option with On board LAN)

NA (No support)

17

www.dfi .comChapter 3 Hardware Installation

Page 18

Chapter 3

s

s

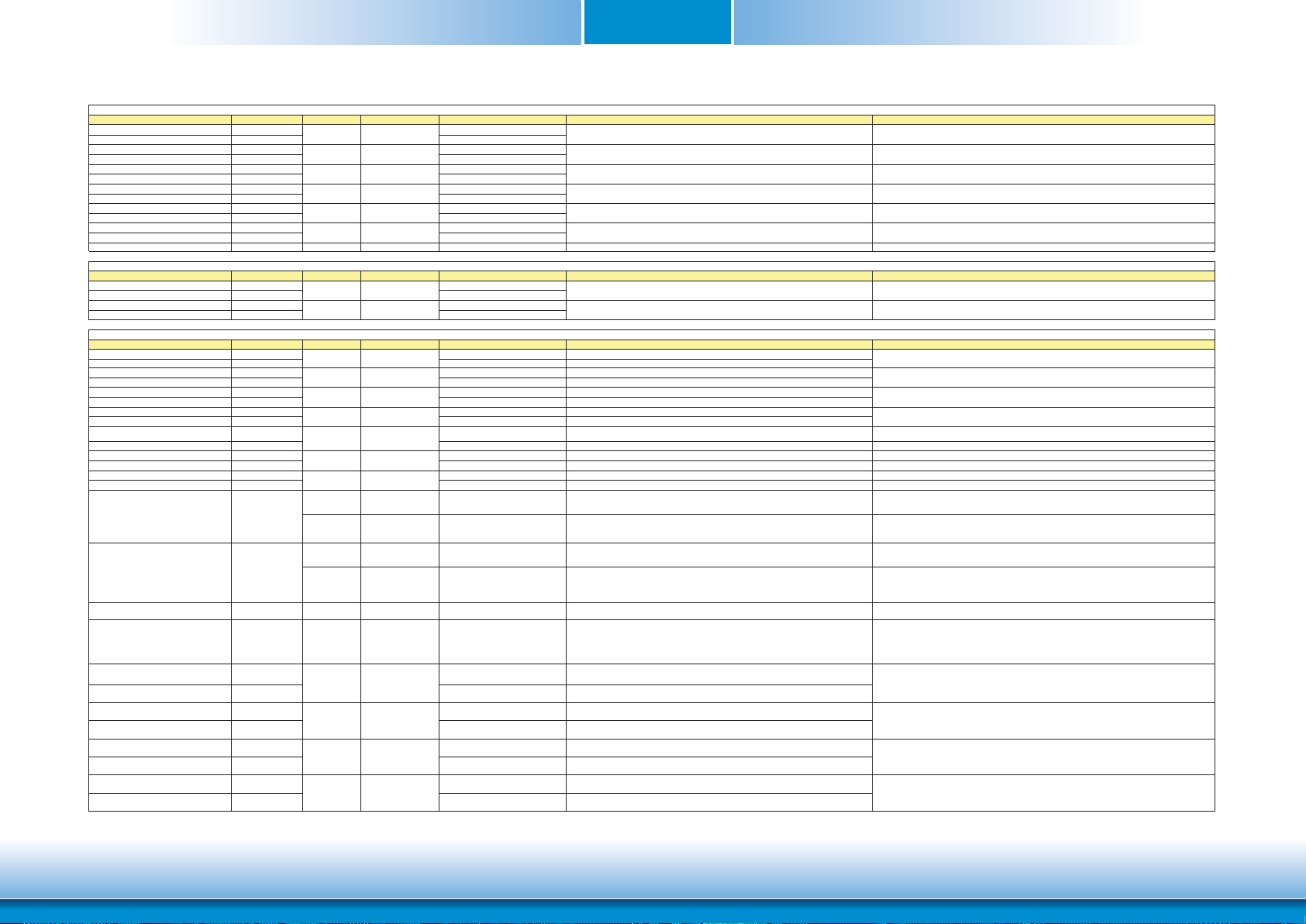

PCI Express Lanes Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

PCIE_RX4+ B55

PCIE_RX4- B56

PCIE_TX5+ A52 NA

PCIE_TX5- A53 NA

PCIE_RX5+ B52

PCIE_RX5- B53

PCIE_TX6+ D19 NA

PCIE_TX6- D20 NA

PCIE_RX6+ C19

PCIE_RX6- C20

PCIE_TX7+ D22 NA

PCIE_TX7- D23 NA

PCIE_RX7+ C22 NA

PCIE_RX7- C23 NA

PCIE0_CK_REF+ A88

PCIE0_CK_REF- A89

PEG Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

PEG_TX0+ D52 NA ==> (ALL PEG)

PEG_TX0- D53 NA ==> (ALL PEG)

PEG_RX0+ C52

PEG_RX0- C53

PEG_TX1+ D55 NA ==> (ALL PEG)

PEG_TX1- D56 NA ==> (ALL PEG)

PEG_RX1+ C55

PEG_RX1- C56

PEG_TX2+ D58 NA ==> (ALL PEG)

PEG_TX2- D59 NA ==> (ALL PEG)

PEG_RX2+ C58

PEG_RX2- C59

PEG_TX3+ D61 NA ==> (ALL PEG)

PEG_TX3- D62 NA ==> (ALL PEG)

PEG_RX3+ C61

PEG_RX3- C62

PEG_TX4+ D65 NA ==> (ALL PEG)

PEG_TX4- D66 NA ==> (ALL PEG)

PEG_RX4+ C65

PEG_RX4- C66

PEG_TX5+ D68 NA ==> (ALL PEG)

PEG_TX5- D69 NA ==> (ALL PEG)

PEG_RX5+ C68

PEG_RX5- C69

PEG_TX6+ D71 NA ==> (ALL PEG)

PEG_TX6- D72 NA ==> (ALL PEG)

PEG_RX6+ C71

PEG_RX6- C72

PEG_TX7+ D74 NA ==> (ALL PEG)

PEG_TX7- D75 NA ==> (ALL PEG)

PEG_RX7+ C74

PEG_RX7- C75

PEG_TX8+ D78 NA ==> (ALL PEG)

PEG_TX8- D79 NA ==> (ALL PEG)

PEG_RX8+ C78

PEG_RX8- C79

PEG_TX9+ D81 NA ==> (ALL PEG)

PEG_TX9- D82 NA ==> (ALL PEG)

PEG_RX9+ C81

PEG_RX9- C82

PEG_TX10+ D85 NA ==> (ALL PEG)

PEG_TX10- D86 NA ==> (ALL PEG)

PEG_RX10+ C85

PEG_RX10- C86

PEG_TX11+ D88 NA ==> (ALL PEG)

PEG_TX11- D89 NA ==> (ALL PEG)

PEG_RX11+ C88

PEG_RX11- C89

PEG_TX12+ D91 NA ==> (ALL PEG)

PEG_TX12- D92 NA ==> (ALL PEG)

PEG_RX12+ C91

PEG_RX12- C92

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module

I PCIE AC coupled off Module

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module

O PCIE PCIE Connect to PCIE device, PCIe CLK Buffer or slot

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE

O PCIE AC coupled on Module

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module

I PCIE AC coupled off Module

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)NA (No support)

AC coupled off Module NA (No support)

AC coupled on Module NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

Reference clock output for all PCI Express and PCI Express Graphics

lanes.

NA (No support)

NA (No support)

NA (No support)

NA (No support)NA (No support)

18

www.dfi .comChapter 3 Hardware Installation

Page 19

Chapter 3

s

S

(

)

)

/

p

(

))

p

(

))

p

(

))

p

(

))

p

(

))

p

(

))

p

(

))

s

s

PEG Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

PEG_TX13+ D94 NA ==> (ALL PEG)

PEG_TX13- D95 NA ==> (ALL PEG)

PEG_RX13+ C94

PEG_RX13- C95

PEG_TX14+ D98 NA ==> (ALL PEG)

PEG_TX14- D99 NA ==> (ALL PEG)

PEG_RX14+ C98

PEG_RX14- C99

PEG_TX15+ D101 NA ==> (ALL PEG)

PEG_TX15- D102 NA ==> (ALL PEG)

PEG_RX15+ C101

PEG_RX15- C102

PEG_LANE_RV# D54 I CMO

ExpressCard Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

EXCD0_CPPE# A49

EXCD1_CPPE# B48

EXCD0_PERST# A48

EXCD1_PERST# B47

DDI Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

DDI1_PAIR0+/SDVO1_RED+ D26 Connect AC Coupling Capacitors 0.1uF to Device

DDI1_PAIR0DDI1_PAIR1+/SDVO1_GRN+ D29 Connect AC Coupling Capacitors 0.1uF to Device

DDI1_PAIR1-/SDVO1_GRN- D30 Connect AC Coupling Capacitors 0.1uF to Device

DDI1_PAIR2+/SDVO1_BLU+ D32 Connect AC Coupling Capacitors 0.1uF to Device

DDI1_PAIR2-/SDVO1_BLU- D33 Connect AC Coupling Capacitors 0.1uF to Device

DDI1_PAIR3+/SDVO1_CK+ D36 Connect AC Coupling Capacitors 0.1uF to Device

DDI1_PAIR3-/SDVO1_CK- D37 Connect AC Coupling Capacitors 0.1uF to Device

DDI1_PAIR4+/SDVO1_INT+ C25

DDI1_PAIR4-/SDVO1_INT- C26 NA (No support) NA (No support)

DDI1_PAIR5+/SDVO1_TVCLKIN+ C29 NA (No support) NA (No support)

DDI1_PAIR5-/SDVO1_TVCLKIN- C30 NA (No support) NA (No support)

DDI1_PAIR6+/SDVO1_FLDSTALL+ C15 NA (No support) NA (No support)

DDI1_PAIR6-/SDVO1_FLDSTALL- C16

DDI1_CTRLCLK_AUX+/SDVO1_CTRLCLK D15

DDI1_CTRLCLK_AUX-/SDVO1_CTRLDATA D16

DDI1_HPD C24 I CMOS 3.3V / 3.3V PD 100K PD 1M and Connect to device Hot Plug Detect DDI Hot-Plug Detect

DDI1_DDC_AUX_SEL D34 I CMOS 3.3V / 3.3V PD 1M

DDI2_PAIR0+ D39

DDI2_PAIR0- D40

DDI2_PAIR1+ D42

DDI2_PAIR1- D43

DDI2_PAIR2+ D46

DDI2_PAIR2- D47

DDI2_PAIR3+ D49

DDI2_PAIR3- D50

SDVO1_RED- D27 Connect AC Coupling Capacitors 0.1uF to Device

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module

O PCIE AC coupled on Module NA (No support)

I PCIE AC coupled off Module NA (No support)

I CMOS 3.3V /3.3V

O CMOS 3.3V /3.3V PCI ExpressCard: reset, active low, one per card

O PCIE

O PCIE AC coupled off Module DDI 1 Pair 1 differential pairs/Serial Digital Video B green output differential pair

O PCIE

O PCIE AC coupled off Module DDI 1 Pair 3 differential pairs/Serial Digital Video B clock output differential pair.

I PCIE

I PCIE AC coupled off Module

I PCIE

I/O PCIE AC coupled on Module

I/O OD CMOS 3.3V / 3.3V

I/O PCIE AC coupled on Module

I/O OD CMOS 3.3V / 3.3V

O PCIE AC coupled off Module

O PCIE AC coupled off Module

O PCIE AC coupled off Module

O PCIE AC coupled off Module

3.3V / 3.3V

AC coupled off Module DDI 1 Pair 0 differential pairs/Serial Digital Video B red output differential pair

AC coupled off Module DDI 1 Pair 2 differential pairs/Serial Digital Video B blue output differential pair

AC coupled off Module

AC coupled off Module

PD 100K to GND

(S/W IC between Rpu/PCH)

PU 2.2K to 3.3V, PD 100K to GND

(S/W IC between Rpu/Rpd

resistor)

PU 100K to 3.3V

(S/W IC between Rpu/PCH)

PU 2.2K to 3.3V/PU 100K to 3.3V

(S/W IC between 2.2K/100K

resistor)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA (No support)

NA

No support

NA (No support) NA (No support)

NA (No support) NA (No support)

Connect to DP AUX+ DP AUX+ function if DDI1_DDC_AUX_SEL is no connect

Connect to HDMI/DVI I2C CTRLCLK HDMI/DVI I2C CTRLCLK if DDI1_DDC_AUX_SEL is pulled high

Connect to DP AUX- DP AUX- function if DDI1_DDC_AUX_SEL is no connect

Connect to HDMI/DVI I2C CTRLDATA HDMI/DVI I2C CTRLDATA if DDI1_DDC_AUX_SEL is pulled high

PU 100K to 3.3V for DDC(HDMI/DVI)

Connect AC Coupling Capacitors 0.1uF to Device

(This Port is BIOS Option with On board LVDS (DP to LVDS))

Connect AC Cou

This Port is BIOS Option with On board LVDS (DP to LVDS

Connect AC Cou

This Port is BIOS Option with On board LVDS (DP to LVDS

Connect AC Cou

This Port is BIOS Option with On board LVDS (DP to LVDS

Connect AC Cou

This Port is BIOS Option with On board LVDS (DP to LVDS

Connect AC Cou

This Port is BIOS Option with On board LVDS (DP to LVDS

Connect AC Cou

This Port is BIOS Option with On board LVDS (DP to LVDS

Connect AC Cou

This Port is BIOS Option with On board LVDS (DP to LVDS

ling Capacitors 0.1uF to Device

ling Capacitors 0.1uF to Device

ling Capacitors 0.1uF to Device

ling Capacitors 0.1uF to Device

ling Capacitors 0.1uF to Device

ling Capacitors 0.1uF to Device

ling Capacitors 0.1uF to Device

NA (No support)

NA (No support

PCI ExpressCard: PCI Express capable card request, active low, one per

card

Selects the function of DDI1_CTRLCLK_AUX+ and DDI1_CTRLDATA_AUX-.

DDI[n]_DDC_AUX_SEL shall be pulled to 3.3V on the Carrier with a 100K Ohm

resistor to configure the DDI[n]_AUX pair as the DDC channel.

Carrier DDI[n]_DDC_AUX_SEL should be connected to pin 13 of the DisplayPort

DDI 2 Pair 0 differential pairs

(This Port is BIOS Option with On board LVDS (DP to LVDS))

DDI 2 Pair 1 differential pairs

(This Port is BIOS Option with On board LVDS (DP to LVDS))

DDI 2 Pair 2 differential pairs

(This Port is BIOS Option with On board LVDS (DP to LVDS))

DDI 2 Pair 3 differential pairs

(This Port is BIOS Option with On board LVDS (DP to LVDS))

19

www.dfi .comChapter 3 Hardware Installation

Page 20

Chapter 3

s

s

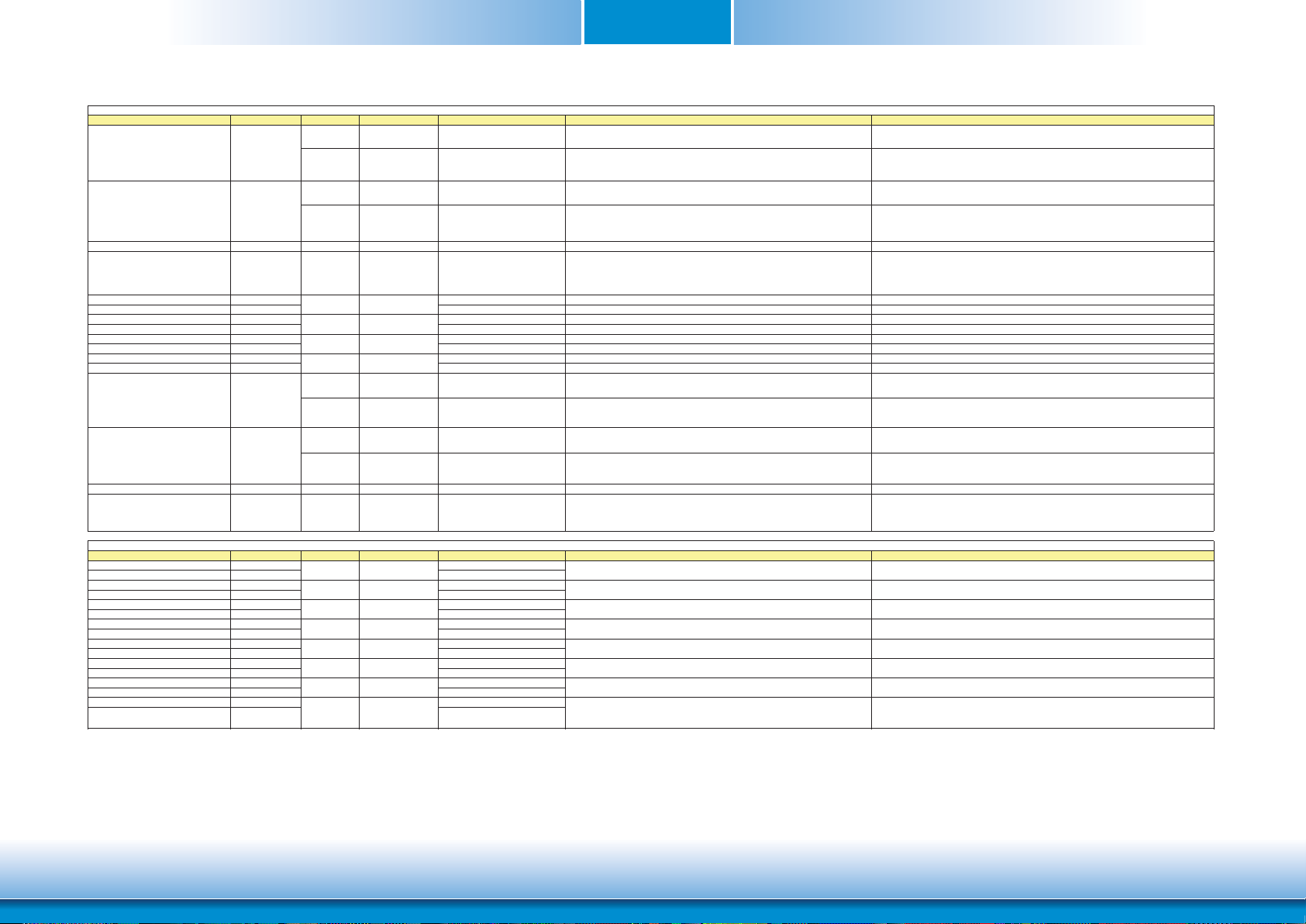

DDI Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

I/O PCIE AC coupled on Module

DDI2_CTRLCLK_AUX+ C32

DDI2_CTRLCLK_AUX- C33

DDI2_HPD D44 I CMOS 3.3V / 3.3V PD 100K PD 1M and Connect to device Hot Plug Detect DDI Hot-Plug Detect

DDI2_DDC_AUX_SEL C34 I CMOS 3.3V / 3.3V PD 1M to GND

DDI3_PAIR0+ C39 NA NA (No support) NA (No support)

DDI3_PAIR0- C40 NA NA (No support) NA (No support)

DDI3_PAIR1+ C42 NA NA (No support) NA (No support)

DDI3_PAIR1- C43 NA NA (No support) NA (No support)

DDI3_PAIR2+ C4 NA NA (No support) NA (No support)

DDI3_PAIR2- C47 NA NA (No support) NA (No support)

DDI3_PAIR3+ C49 NA NA (No support) NA (No support)

DDI3_PAIR3- C50 NA NA (No support) NA (No support)

DDI3_CTRLCLK_AUX+ C36

DDI3_CTRLCLK_AUX- C37

DDI3_HPD C44 I CMOS 3.3V / 3.3V NA (No support) NA (No support)

DDI3_DDC_AUX_SEL C38 I CMOS 3.3V / 3.3V NA

I/O OD CMOS 3.3V / 3.3V

I/O PCIE AC coupled on Module

I/O OD CMOS 3.3V / 3.3V

O PCIE AC coupled off Module

O PCIE

O PCIE AC coupled off Module

O PCIE AC coupled off Module

I/O PCIE AC coupled on Module NA

I/O OD CMOS 3.3V / 3.3V NA

I/O PCIE AC coupled on Module NA

I/O OD CMOS 3.3V / 3.3V NA

AC coupled off Module

PD 100K to GND

(S/W IC between Rpu/PCH)

PU 2.2K to 3.3V, PD 100K to GND

(S/W IC between Rpu/Rpd

resistor)

PU 100K to 3.3V

(S/W IC between Rpu/PCH)

PU 2.2K to 3.3V/PU 100K to 3.3V

(S/W IC between 2.2K/100K

resistor)

Connect to DP AUX+ DP AUX+ function if DDI2_DDC_AUX_SEL is no connect

Connect to HDMI/DVI I2C CTRLCLK HDMI/DVI I2C CTRLCLK if DDI2_DDC_AUX_SEL is pulled high

Connect to DP AUX- DP AUX- function if DDI2_DDC_AUX_SEL is no connect

Connect to HDMI/DVI I2C CTRLDATA HDMI/DVI I2C CTRLDATA if DDI2_DDC_AUX_SEL is pulled high

PU 100K to 3.3V for DDC(HDMI/DVI)

NA (No support) NA (No support)

NA (No support) NA (No support)

NA (No support) NA (No support)

NA (No support) NA (No support)

NA (No support) NA (No support)

Selects the function of DDI2_CTRLCLK_AUX+ and DDI2_CTRLDATA_AUX-.

DDI[n]_DDC_AUX_SEL shall be pulled to 3.3V on the Carrier with a 100K Ohm

resistor to configure the DDI[n]_AUX pair as the DDC channel.

Carrier DDI[n]_DDC_AUX_SEL should be connected to pin 13 of the DisplayPort

USB Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

USB0+ A46

USB0- A45

USB1+ B46

USB1- B45

USB2+ A43

USB2- A42

USB3+ B43

USB3- B42

USB4+ A40

USB4- A39

USB5+ B40

USB5- B39

USB6+ A37

USB6- A36

USB7+ B37

USB7- B36

I/O USB 3.3V Suspend/3.3V

I/O USB 3.3V Suspend/3.3V

I/O USB 3.3V Suspend/3.3V

I/O USB 3.3V Suspend/3.3V

I/O USB

I/O USB 3.3V Suspend/3.3V

I/O USB 3.3V Suspend/3.3V

I/O USB 3.3V Suspend/3.3V

3.3V Suspend/3.3V

Connect 90ಳ @100MHz Common Choke in series and ESD suppressors to GND to USB

connector

Connect 90ಳ @100MHz Common Choke in series and ESD suppressors to GND to USB

connector

Connect 90ಳ @100MHz Common Choke in series and ESD suppressors to GND to USB

connector

Connect 90ಳ @100MHz Common Choke in series and ESD suppressors to GND to USB

connector

Connect 90ಳ @100MHz Common Choke in series and ESD suppressors to GND to USB

connector

Connect 90ಳ @100MHz Common Choke in series and ESD suppressors to GND to USB

connector

Connect 90ಳ @100MHz Common Choke in series and ESD suppressors to GND to USB

connector

Connect 90ಳ @100MHz Common Choke in series and ESD suppressors to GND to USB

connector

USB differential pairs 0

USB differential pairs 1

USB differential pairs 2

USB differential pairs 3

USB differential pairs 4

USB differential pairs 5

USB differential pairs 6

USB differential pairs 7, USB7 may be configured as a USB client or as a host, or both, at the

Module designer's discretion.(CR901-B default set as a host)

20

www.dfi .comChapter 3 Hardware Installation

Page 21

Chapter 3

s

p

s

s

USB Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

USB_0_1_OC# B44 I CMOS 3.3V Suspend/3.3V PU 10k to 3.3VSB Connect to Overcurrent of USB Power Switch

USB_2_3_OC# A44 I CMOS 3.3V Suspend/3.3V PU 10k to 3.3VSB Connect to Overcurrent of USB Power Switch

USB_4_5_OC# B38 I CMOS 3.3V Suspend/3.3V PU 10k to 3.3VSB Connect to Overcurrent of USB Power Switch

USB_6_7_OC# A38 I CMOS 3.3V Suspend/3.3V PU 10k to 3.3VSB Connect to Overcurrent of USB Power Switch

LVDS Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

LVDS_A0+ A71

LVDS_A0- A72

LVDS_A1+ A73

LVDS_A1- A74

LVDS_A2+ A75

LVDS_A2- A76

LVDS_A3+ A78

LVDS_A3- A79

LVDS_A_CK+ A81

LVDS_A_CK- A82

LVDS_B0+ B71

LVDS_B0- B72

LVDS_B1+ B73

LVDS_B1- B74

LVDS_B2+ B75

LVDS_B2- B76

LVDS_B3+ B77

LVDS_B3- B78

LVDS_B_CK+ B81

LVDS_B_CK- B82

LVDS_VDD_EN A77 O CMOS 3.3V / 3.3V Connect to enable control of LVDS panel power circuit LVDS panel power enable

LVDS_BKLT_EN B79 O CMOS 3.3V / 3.3V Connect to enable control of LVDS panel backlight power circuit. LVDS panel backlight enable

LVDS_BKLT_CTRL B83 O CMOS 3.3V / 3.3V Connect to brightness control of LVDS panel backlight power circuit. LVDS panel backlight brightness control

LVDS_I2C_CK A83 I/O OD CMOS 3.3V / 3.3V PU 2.2K to 3.3V Connect to DDC clock of LVDS panel I2C clock output for LVDS display use

LVDS_I2C_DAT A84 I/O OD CMOS 3.3V / 3.3V PU 2.2K to 3.3V Connect to DDC data of LVDS panel I2C data line for LVDS display use

LPC Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

LPC_AD0 B4

LPC_AD1 B5

LPC_AD2 B6

LPC_AD3 B7

LPC_FRAME# B3 O CMOS 3.3V / 3.3V LPC frame indicates the start of an LPC cycle

LPC_DRQ0# B8

LPC_DRQ1# B9

LPC_SERIRQ A50 I/O CMOS 3.3V / 3.3V LPC serial interrupt

LPC_CLK B10 O CMOS 3.3V / 3.3V LPC clock output - 33MHz nominal

O LVDS LVDS

O LVDS

O LVDS LVDS

O LVDS LVDS

O LVDS LVDS

O LVDS LVDS

O LVDS LVDS

O LVDS LVDS

O LVDS LVDS

I/O CMOS 3.3V / 3.3V

I CMOS

LVDS

3.3V / 3.3V NA (No support)

Connect to LVDS connector LVDS Channel A differential pairs

Connect to LVDS connector

Connect to LVDS connector

Connect to LVDS connector

Connect to LVDS connector

Connect to LVDS connector

Connect to LVDS connector

Connect to LVDS connector

Connect to LVDS connector

Connect to LVDS connector

Connect to LPC device

USB over-current sense, USB channels 0 and 1. A pull-up for this line

shall be present on the Module. An open drain driver from a USB

current monitor on the Carrier Board may drive this line low. Do not

pull this line high on the Carrier Board.

USB over-current sense, USB channels 2 and 3. A pull-up for this line

shall be present on the Module. An open drain driver from a USB

current monitor on the Carrier Board may drive this line low. Do not

ull this line high on the Carrier Board.

USB over-current sense, USB channels 4 and 5. A pull-up for this line

shall be present on the Module. An open drain driver from a USB

current monitor on the Carrier Board may drive this line low. Do not

pull this line high on the Carrier Board.

USB over-current sense, USB channels 6 and 7. A pull-up for this line

shall be present on the Module. An open drain driver from a USB

current monitor on the Carrier Board may drive this line low. Do not

pull this line high on the Carrier Board.

Ther LVDS flat panel differential pairs (LVDS_A[0:3]+/-, LVDS_B[0:3]+/-. LVDS_A_CK+/-,

LVDS_B_CK+/-) shall have 100ƻ terminations across the pairs at the destination. These

terminations may be on the Carrier Board if the Carrier Board implements a LVDS deserializer

on-board

LVDS Channel A differential clockO LVDS LVDS

LVDS Channel B differential pairs

Ther LVDS flat panel differential pairs (LVDS_A[0:3]+/-, LVDS_B[0:3]+/-. LVDS_A_CK+/-,

LVDS_B_CK+/-) shall have 100ƻ terminations across the pairs at the destination. These

terminations may be on the Carrier Board if the Carrier Board implements a LVDS deserializer

on-board

LVDS Channel B differential clock

LPC multiplexed address, command and data bus

21

www.dfi .comChapter 3 Hardware Installation

Page 22

Chapter 3

ȟ

ȟ

ȟ

ȟ

(

)

(

)

(

)

(

)

p

(

)

s

V

s

s

s

SPI Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

SPI_CS# B97 O CMOS 3.3V Suspend/3.3V

SPI_MISO A92 I CMOS 3.3V Suspend/3.3V Connect a series resistor 33

SPI_MOSI A95 O CMOS 3.3V Suspend/3.3V Connect a series resistor 33

SPI_CLK A94 O CMOS 3.3V Suspend/3.3V Connect a series resistor 33

SPI_POWER A91 O 3.3V Suspend/3.3V

BIOS_DIS0# A34

I CMOS

BIOS_DIS1# B88

GA Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

VGA_RED B89 O Analog Analog PD 150R PD 150R,connect to VGA connector with EMI filter & ESD protect component. Red for monitor. Analog output

VGA_GRN B91 O Analog Analog PD 150R PD 150R,connect to VGA connector with EMI filter & ESD protect component. Green for monitor. Analog output

VGA_BLU B92 O Analog Analog PD 150R PD 150R,connect to VGA connector with EMI filter & ESD protect component. Blue for monitor. Analog output

VGA_HSYNC B93 O CMOS 3.3V / 3.3V Connect to VGA connector with a3.3V Buffer IC to isolate PCH & Display Device Horizontal sync output to VGA monitor

VGA_VSYNC B94 O CMOS 3.3V / 3.3V Connect to VGA connector with a 33V Buffer IC to isolate PCH & Display Device Vertical sync output to VGA monitor

VGA_I2C_CK B95 I/O OD CMOS 3.3V / 3.3V PD 2.2K to 3.3V Connect to VGA connector with a 3.3V to 5V Level shift circuit. DDC clock line (I2C port dedicated to identify VGA monitor capabilities)

VGA_I2C_DAT B96 I/O OD CMOS 3.3V / 3.3V PD 2.2K to 3.3V Connect to VGA connector with a 3.3V to 5V Level shift circuit. DDC data line.

Serial Interface Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

SER0_TX A98 O CMOS 3.3V/5V PD 4.7K

SER0_RX A99 I CMOS 3.3V/5V PU 47K to 3.3V

SER1_TX A101 O CMOS 3.3V/5V PD 4.7K

SER1_RX A102 I CMOS 3.3V/5V PU 47K to 3.3V

Miscellaneous Signal Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

I2C_CK B33 I/O OD CMOS 3.3V Suspend/3.3V PU 2.2K to 3.3VSB General purpose I2C port clock output

I2C_DAT B34 I/O OD CMOS 3.3V Suspend/3.3V PU 2.2K to 3.3VSB General purpose I2C port data I/O line

SPKR B32 O CMOS 3.3V / 3.3V

WDT B27 O CMOS 3.3V / 3.3V Output indicating that a watchdog time-out event has occurred.

FAN_PWNOUT B101 O OD CMOS 3.3V / 3.3V

FAN_TACHIN B102 I OD CMOS 3.3V / 3.3V

TPM_PP A96 I CMOS 3.3V / 3.3V PD 10K

NA

Connect a series resistor 33

to Carrier Board SPI Device CS# pin

to Carrier Board SPI Device SO pin Data in to Module from Carrier SPI

to Carrier Board SPI Device SI pin Data out from Module to Carrier SPI

to Carrier Board SPI Device SCK pin Clock from Module to Carrier SPI

Chip select for Carrier Board SPI - may be sourced from chipset SPI0 or SPI1

Power supply for Carrier Board SPI – sourced from Module – nominally

3.3V. The Module shall provide a minimum of 100mA on SPI_POWER.

Carriers shall use less than 100mA of SPI_POWER. SPI_POWER

shall only be used to power SPI devices on the Carrier

Selection straps to determine the BIOS boot device.

The Carrier should only float these or pull them low, please refer to

COM Express Module Base Specification Revision 2.1 for strapping options of BIOS disable signals.

Chipset

BIOS

BIOS

DIS1#

1

1

0

General purpose serial port 0 transmitter

Recommend add Protecting Logic Level Signals on Pins Reclaimed from VCC_12V

General purpose serial port 0 receiver

Recommend add Protecting Logic Level Signals on Pins Reclaimed from VCC_12V

General purpose serial port 1 transmitter

Recommend add Protecting Logic Level Signals on Pins Reclaimed from VCC_12V

General purpose serial port 1 receiver

Recommend add Protecting Logic Level Signals on Pins Reclaimed from VCC_12V

Output for audio enunciator - the "speaker" in PC-AT systems.

This port provides the PC beep signal and is mostly intended for

debugging purposes.

Fan s

eed control. Uses the Pulse Width Modulation (PWM) technique to control the fan's RPM.

Recommend add Protecting Logic Level Signals on Pins Reclaimed from VCC_12V

Fan tachometer input for a fan with a two pulse output.

(Recommend add Protecting Logic Level Signals on Pins Reclaimed from VCC_12V)

Trusted Platform Module (TPM) Physical Presence pin. Active high.

TPM chip has an internal pull down. This signal is used to indicate

Physical Presence to the TPM.

DIS0#

0

SPI CS1#

Destination

1

Module

1

Carrier

00

(Default)

Chipset

SPI CS0#

Destination

Carrier

SPI_CS#

ModuleModule SPI0/SPI1

High

High

ModuleModule

SPI0

SPI1

Module

(Default)

(Default)

SPI

Descriptor

Module

Module

CarrierCarrier

Module

(Default)

Bios

Entry

Carrier FWH

SPI0/SPI1

SPI0/SPI1

(Default)

Ref

Line

0

1

2

3

22

www.dfi .comChapter 3 Hardware Installation

Page 23

Chapter 3

(

)

s

s

Power and System Management Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

PWRBTN# B12 I CMOS 3.3V Suspend/3.3V PU 10K to 3.3VSB

SYS_RESET# B49 I CMOS 3.3V Suspend/3.3V PU 10K to 3.3VSB

CB_RESET# B50 O CMOS 3.3V Suspend/3.3V PD 100K

PWR_OK B24 I CMOS 3.3V / 3.3V

SUS_STAT# B18 O CMOS 3.3V Suspend/3.3V Indicates imminent suspend operation; used to notify LPC devices.

SUS_S3# A15 O CMOS 3.3V Suspend/3.3V

SUS_S4# A18 O CMOS 3.3V Suspend/3.3V Indicates system is in Suspend to Disk state. Active low output.

SUS_S5# A24 O CMOS 3.3V Suspend/3.3V Indicates system is in Soft Off state.

WAKE0# B66 I CMOS 3.3V Suspend/3.3V PU 10K to 3.3VSB PCI Express wake up signal.

WAKE1# B67 I CMOS 3.3V Suspend/3.3V PU 10K to 3.3VSB

BATLOW# A27 I CMOS 3.3V Suspend/ 3.3V

LID# A103 I OD CMOS 3.3V Suspend/12V PU 10K to 3.3VSB

SLEEP# B103 I OD CMOS 3.3V Suspend/12V PU 10K to 3.3VSB

THRM# B35 I CMOS 3.3V / 3.3V PU 10K to 3.3V Input from off-Module temp sensor indicating an over-temp situation.

THRMTRIP# A35 O CMOS 3.3V / 3.3V PU 10K to 3.3V Active low output indicating that the CPU has entered thermal shutdown.

SMB_CK B13 I/O OD CMOS 3.3V Suspend/3.3V PU 2.2K to 3.3VSB System Management Bus bidirectional clock line.

SMB_DAT B14 I/O OD CMOS 3.3V Suspend/3.3V PU 2.2K to 3.3VSB System Management Bus bidirectional data line.

SMB_ALERT# B15 I CMOS 3.3V Suspend/3.3V

GPIO Signals Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

GPO0 A93

GPO1 B54

GPO2 B57

GPO3 B63

GPI0 A54

GPI1 A63

GPI2 A67

GPI3 A85

O CMOS

I CMOS 3.3V / 3.3V

3.3V / 3.3V

A falling edge creates a power button event. Power button events can

be used to bring a system out of S5 soft off and other suspend states,

as well as powering the system down.

Reset button input. Active low request for Module to reset and reboot.

May be falling edge sensitive. For situations when SYS_RESET# is

not able to reestablish control of the system, PWR_OK or a power

cycle may be used.

Reset output from Module to Carrier Board. Active low. Issued by

Module chipset and may result from a low SYS_RESET# input, a low

PWR_OK input, a VCC_12V power input that falls below the minimum

specification, a watchdog timeout, or may be initiated by the Module

software.

Power OK from main power supply. A high value indicates that the

power is good. This signal can be used to hold off Module startup to

allow Carrier based FPGAs or other configurable devices time to be

programmed.

Indicates system is in Suspend to RAM state. Active low output. An

inverted copy of SUS_S3# on the Carrier Board may be used to

enable the non-standby power on a typical ATX supply.

General purpose wake up signal. May be used to implement wake-up

on PS2 keyboard or mouse activity.

Indicates that external battery is low.

This port provides a battery-low signal to the Module for orderly

transitioning to power saving or power cut-off ACPI modes.

LID switch. Low active signal used by the ACPI operating system for a LID switch.

Recommend add Protecting Logic Level Signals on Pins Reclaimed from VCC_12V

Sleep button. Low active signal used by the ACPI operating system to bring the

system to sleep state or to wake it up again.

(Recommend add Protecting Logic Level Signals on Pins Reclaimed from VCC_12V)

System Management Bus Alert – active low input can be used to

generate an SMI# (System Management Interrupt) or to wake the system.

General purpose output pins.

Upon a hardware reset, these outputs should be low.

General purpose input pins.

Pulled high internally on the Module.

23

www.dfi .comChapter 3 Hardware Installation

Page 24

Chapter 3

A

s

Power and GND Signal Description

Signal Pin# Module Pin Type Pwr Rail /Tolerance BT968 Carrier Board Description

VCC_12V

VCC_5V_SBY B84~B87 Power

VCC_RTC A47 Power Real-time clock circuit-power input. Nominally +3.0V.

GND

104~A109

B104~B109

C104~C109

D104~D109

A1, A11, A21, A31,

A41, A51, A57, A60,

A66, A70, A80, A90,

A100, A110, B1,

B11, B21 ,B31, B41,

B51, B60, B70, B80,

B90, B100, B110,

C1, C2, C5, C8, C11,

C14, C21, C31, C41,

C51, C60, C70, C73,

C76, C80, C84, C87,

C90, C93, C96,

C100, C103, C110,

D1, D2, D5, D8,

D11, D14, D21,

D31, D51, D60,

D67, D70, D73,

D76, D80, D84,

D87, D90, D93,

D96, D100, D103,

D110

Power Primary power input: +12V nominal. All available VCC_12V pins on the connector(s) shall be used.

Standby power input: +5.0V nominal. If VCC5_SBY is used, all

available VCC_5V_SBY pins on the connector(s) shall be used. Only

used for standby and suspend functions. May be left unconnected if

these functions are not used in the system design.

Power

Ground - DC power and signal and AC signal return path.

All available GND connector pins shall be used and tied to Carrier

Board GND plane.

24

www.dfi .comChapter 3 Hardware Installation

Page 25

Chapter 3

Standby Power LED

Standby

Power LED

This LED will light when the system is in the standby mode.

Cooling Option

Heat Sink with Cooling Fan

Note:

The system board used in the following illustrations may not resemble the actual

board. These illustrations are for reference only.

Top View of the Heat Sink

1

• “1” denotes the location of the thermal pad designed to contact the corresponding

components that are on BT968.

Important:

Remove the plastic covering from the thermal pad prior to mounting the heat sink

onto BT968.

25

Bottom View of the Heat Sink

www.dfi .comChapter 3 Hardware Installation

Page 26

Chapter 3

Installing BT968 onto a Carrier Board

Important:

The carrier board (COM331-B) used in this section is for reference purpose only and

may not resemble your carrier board. These illustrations are mainly to guide you on

how to install BT968 onto the carrier board of your choice.

• To download COM331-B datasheet and manual

1. Now install the module and heatsink assembly onto the carrier board. The photo below

shows the locations of the mounting holes on the carrier board.

2. Insert the provided mounting screws into the mounting holes - from the bottom through

the top of the carrier board.

Mounting hole

3. While supporting the mounting screw at the bottom, from the top side of the board, fasten

a bolt into the screw.

Bolts

4. The photo below shows the solder side of the board with the screws already fixed in place.

Mounting screw

Mounting screws

5. The photo below shows the component side of the board with the bolts already fixed in

place.

Bolts

26

www.dfi .comChapter 3 Hardware Installation

Page 27

Chapter 3

6. Grasping BT968 by its edges, position it on top of the carrier board with its mounting

holes aligned with the bolts on the carrier board. This will also align the COM Express

connectors of the two boards to each other.

COM Express connectors

on BT968

COM Express connectors

on the carrier board

7. Press BT968 down firmly until it is completely seated on the COM Express connectors of

the carrier board.

BT968

COM Express connectors

on the carrier board

Pressing

points

BIOS ROM socket

Note:

The illustrations above show the pressing points of the module onto the carrier board.

Be careful when pressing the module, it may damage the socket.

27

www.dfi .comChapter 3 Hardware Installation

Page 28

Chapter 3

8. Verify that the module is firmly seated onto the COM Express connectors of the carrier

board.

BT968

The module is completely

seated on the carrier board

BT968

9. Use the provided mounting screws to secure BT968 with heat sink to the carrier board

and then connect the cooling fan’s cable to the fan connector on BT968. The photo below

shows the locations of the long mounting screws.

Long screws