WAR

NING:

For your safety the

life.

POUR VOTRE SÉCURITÉ

AVERTISSEMENT. Assurez

-

vouz

COMMERCIAL DRYER

FOR YOUR SAFETY

MODEL T-30X2 & T-50X2 VENDED

C-SERIES CONTROL, NATURAL GAS/LP HEATED

OPERATOR’S MANUAL

INSTALLATION & OPERATION INSTRUCTIONS

The dryer must not be stored or installed where it will be exposed to water and/or weather.

information in this manual must be

followed to minimize the risk of fire

or explosion or to prevent property

damage, personal injury or loss of

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Clear the room, building or area of all

occupants.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

– Installation and service must be performed by

a qualified installer, service agency or the

gas supplier.

Post the following “For Your Safety” caution in a

prominent location:

de bien suivre les instructions

données dans cette notice pour

réduire au minimum le risque

d'incendie ou d'explosion ou pour

éviter tout dommage matérial,

toute blessure ou la mort.

Ne pas entreposer ni utiliser d'essence ni d'autres

vapeurs ou liquides inflammables dans le voisinage

de cet appareil ou de tout autre appareil.

– QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

• Ne pas tenter d'allumer d'appareil.

• Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones se trouvant

dans le bâtiment où vous vous trouvez.

• Évacuez la pièce, le bâtiment ou la zone.

• Appelez immédiatement votre

fournisseour de gaz depuis un voisin.

Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le service des incendies.

– L'installation et l'entretien doivent être assurés par

un installateur ou un service d'entretien qualifié

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

It is important that you read this Manual and retain it

for future reference. For service or replacement parts,

contact the distributor in your area or the

manufacturer.

8514-253-001 REV B page 1

Ne pas enteposer ni utiliser d'essence ni d'autres

vapeurs ou liquides inflammables dans le voisinage

de cet appareil ou de tout autre appareil.

You, the purchaser, must post in a prominent location instructions to be followed in the event the user

smells gas. Consult your local gas supplier for

procedure to be followed if the odor of gas is

present.

Dexter Laundry, Inc.

2211 W. Grimes

Fairfield, Iowa 52556

TABLE OF CONTENTS

Page No.

Warnings about use and operation 2

Dryer Specifications 3, 4

Dryer Dimensions 5- 10

Installation Instructions 11

Dryer Shutdown 15

Description of Dryer Control 16

Operating Instructions 16

Programming the Dryer Control 17

Servicing and Troubleshooting 28

Preventative Maintenance Instructions 29

Dual Voltage Conversion Instructions 31

WARNINGS ABOUT USE AND OPERATION

DO NOT MODIFY THIS APPLIANCE. KEEP SHIELDS, GUARDS, AND COVERS IN PLACE. These

safety devices are provided to protect everyone from injury.

It is ABSOLUTELY ESSENTIAL that the dryer be grounded to a known earth (zero) ground in accordance

with local codes or, in the absence of local codes, with the latest editions of the National Electric Code, ANSI//NFPA

70 or Standard CSA C22.1 Canadian Electrical Code Part 1. This is not only for personal safety, but is necessary

for proper operation of the controller. Failure to do so will void the warranty of the controller.

A DRYER SHOULD BE CONNECTED TO POWER FOR THREE (3) MINUTES before it is operated or

before a program change is made. Operation or program changes, which occur during this "power up" period, are

subject to loss in case of power interruption. After the initial three minutes, all programmed data is protected

from power interruptions of any length and the customer's individual cycle is protected up to 3 seconds. This is

done without batteries.

LEAVE THE ELECTRICAL POWER TO THE DRYER ON AT ALL TIMES except when necessary for service

or other similar activities. The hour meter function adds only full hours to its reading. If the power is shut off every night,

any fraction of an hour of time that is on the machine at that time will be lost. Turning the power off every night

could also have some effect on the long-term life of the memory after a number of years. Turning power off

occasionally won’t affect the unit.

THIS DRYER IS EQUIPPED WITH AN OVER-TEMPERATURE THERMOSTAT located on the end of

the burner housing above the gas valve. Should the dryer cease to operate, refer to your “Service Procedure and

Parts Data” book for instructions.

CHECK THIS THERMOSTAT WHEN INSTALLING DRYER to assure it is not tripped. Impacts such as

rough handling in shipment, may trip the thermostat. It may be reset by inserting a wooden pencil or dowel

through the bushing in the cover.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE while in operation.

THIS APPLIANCE SHALL NOT BE USED TO DRY OFF SOLVENTS OR DRY-CLEANING FLUIDS.

8514-253-001 REV B page 2

SPECIFICATIONS

30 lb. Commercial Stack Dryer: T-30X2 - DC30X2NC-15EC2X (60 Hz), DC30X2NC-39AC2X (50 Hz)

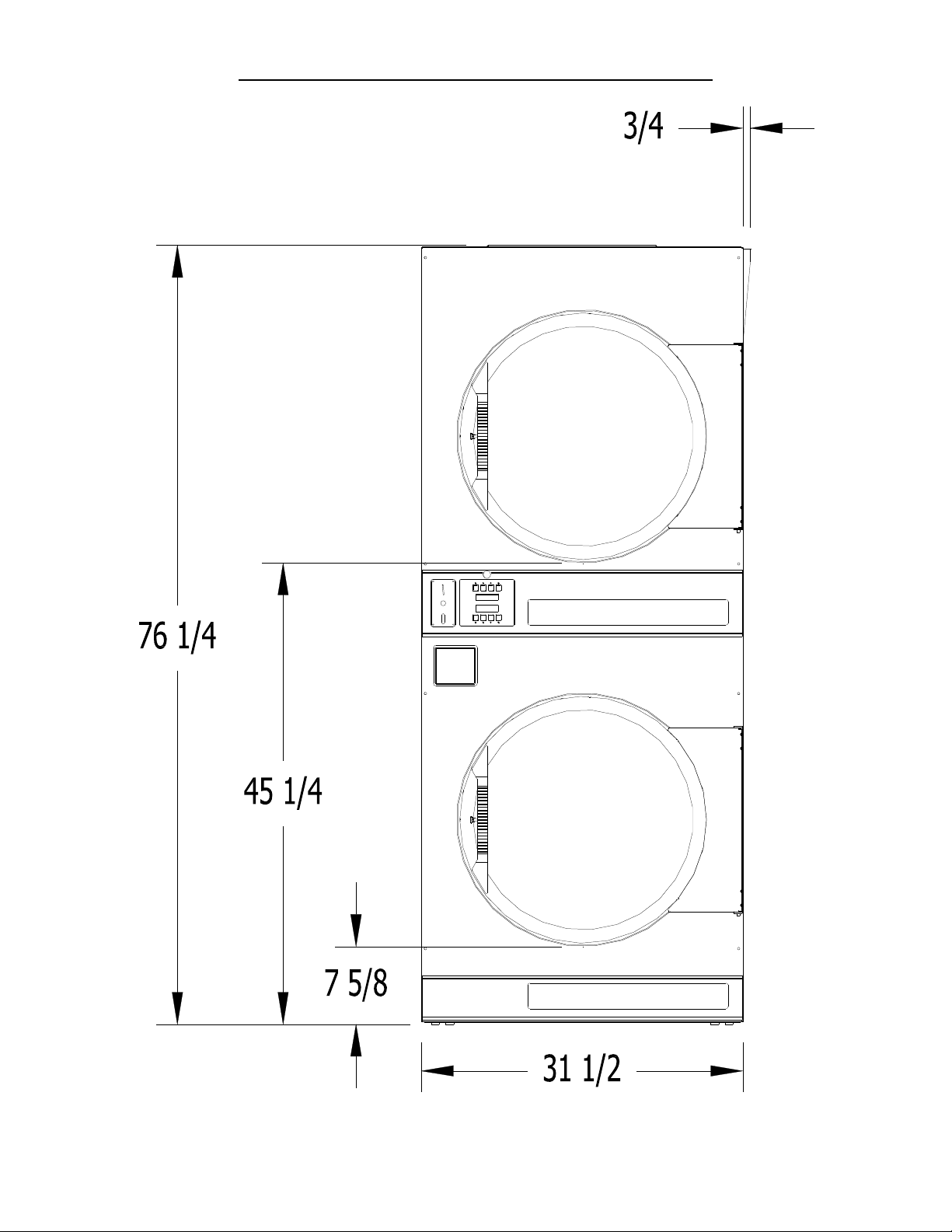

Cabinet Height 76 1/4” 1937 mm.

(Assumes minimum leveling leg adjustment)

Cabinet Width 31 1/2” 800 mm.

Cabinet Depth 49 1/2” 1257 mm.

Floor to Bottom of Door- Bottom Dryer 7 5/8” 194 mm.

Floor to Bottom of Door- Top Dryer 45 1/4” 1149 mm.

Door Opening 22 5/8” 575 mm.

Dry Wt. Capacity 30 x 2 lbs. 13.6 x 2 kg.

Cylinder Diameter 30” 762 mm.

Cylinder Depth 27 1/2” 699 mm.

Cylinder Volume 11.25 cu. ft. 319 liters

Lint Screen Area 453 sq. in. 2923 sq. cm.

Gas Input (per dryer- 60 hz) 90,000 Btu/hr 26.4 kW

Gas Input (per dryer- 50 hz) 74,000 Btu/hr 21.7 kW

Gas Supply Connection 1/2” 12.7 mm.

Natural Gas Supply (Water Column) 5-10” 127 mm. - 254 mm.

Natural Burner Manifold

(60 hz Water Column) 3.5” 88.9 mm

(50 hz Water Column) 3.4” 86.4 mm

L.P. Supply (Water Column) 11.5 -14” 292 mm. - 356 mm.

L.P. Burner Manifold Pressure

(60 hz Water Column) 11” 279 mm

(50 hz Water Column) 10” 254 mm

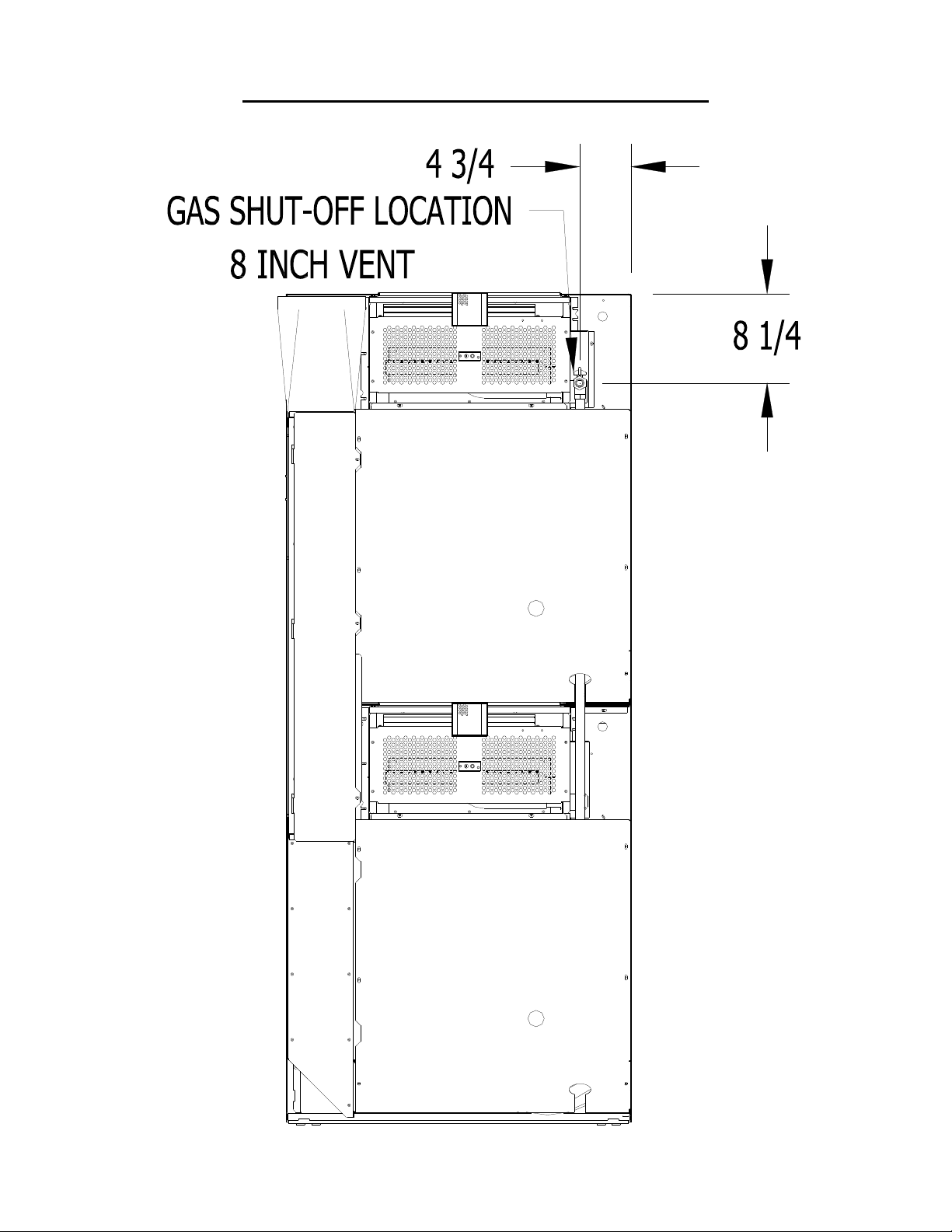

Exhaust Size 8” 203 mm.

Make-up Air 1.5 sq. ft. 1394 sq. cm.

Example: 1.5 sq. ft = 1 ft. long X 1.5 ft. wide

Motor Size 1/2 H.P. .373 kW

Airflow (60 hz) 600 CFM 17.0 m^3/min

Airflow (50 hz) 500 CFM 14.2 m^3/min

Electrical Specifications - 120/60/1

Voltage/Hz/Phase 120V/60Hz/1Phase

Running Amps 8.0

Circuit Protection Amps 20

Wire Size 12 gauge

Electrical Service 2 wire + ground

Electrical Specifications - 208-240/60/1

Voltage/Hz/Phase 208-240V/60Hz/1Phase

Running Amps 5.0

Circuit Protection Amps 15

Wire Size 12 gauge

Electrical Service 2 wire + ground

Electrical Specifications - 230/50/1

Voltage/Hz/Phase 230V/50Hz/1Phase

Running Amps 10.0

Circuit Protection Amps 15

Wire Size 12 gauge

Electrical Service 2 wire + ground

Shipping Weight 750 lbs. 340 kg.

Net Weight 699 lbs. 317 kg.

Clearance Behind Machines (min.) 18” 457 mm.

8514-253-001 REV B page 3

SPECIFICATIONS

50 lb. Commercial Stack Dryer: T-50X2 – DC50X2NC-15EC2X (60 Hz), DC50X2NC-49AC2X (50 Hz)

Cabinet Height 79 1/4” 2012 mm.

(Assumes minimum leveling leg adjustment)

Cabinet Width 34 1/2” 876 mm.

Overall Depth 56 3/4” 1441 mm.

Floor to Bottom of Door- Bottom Dryer 7” 178 mm.

Floor to Bottom of Door- Top Dryer 46” 1168 mm.

Door Opening 25 5/8” 651 mm.

Dry Wt. Capacity 50 x 2 lbs. 22.7 x 2 kg.

Cylinder Diameter 32 1/2” 826 mm.

Cylinder Depth 33” 838 mm.

Cylinder Volume 15.84 cu. ft. 448 liters

Lint Screen Area 544 sq. in. 3510 sq. cm.

Gas Input (per dryer- 60 hz) 108,000 Btu/hr 31.7 kW

Gas Input (per dryer- 50 hz) 96,500 Btu/hr 28.3 kW

Gas Supply Connection 1/2” 12.7 mm.

Natural Gas Supply (Water Column) 5-10” 127 mm. - 254 mm.

Natural Burner Manifold

(60 hz Water Column) 3.5” 88.9 mm

(50 hz Water Column) 3.5” 88.9 mm

L.P. Supply (Water Column) 11.5 -14” 292 mm. - 356 mm.

L.P. Burner Manifold Pressure

(60 hz Water Column) 11” 279 mm

(50 hz Water Column) 10” 254 mm

Exhaust Size 8” 203 mm.

Make-up Air 1.5 sq. ft. 1394 sq. cm.

Example: 1.5 sq. ft = 1 ft. long X 1.5 ft. wide

Motor Size 3/4 H.P. .560 kW

Airflow (60 Hz) 650 CFM 18.4 m^3/min

Airflow (50 hz) 510 CFM 14.4 m^3/min

Electrical Specifications - 120/60/1

Voltage/Hz/Phase 120V/60Hz/1Phase

Running Amps 24.0

Circuit Protection Amps 30

Wire Size 10 gauge

Electrical Service 2 wire + ground

Electrical Specifications - 208-240/60/1

Voltage/Hz/Phase 208-240V/60Hz/1Phase

Running Amps 12.0

Circuit Protection Amps 20

Wire Size 12 gauge

Electrical Service 2 wire + ground

Electrical Specifications - 240/50/1

Voltage/Hz/Phase 240V/50Hz/1Phase

Running Amps 12.0

Circuit Protection Amps 20

Wire Size 12 gauge

Electrical Service 2 wire + ground

Shipping Weight 917 lbs. 416 kg.

Net Weight 857 lbs. 389 kg.

Clearance Behind Machines (min.) 18” 457 mm.

8514-253-001 REV B page 4

T-30X2 DRYER DIMENSIONS- FRONT VIEW

8514-253-001 REV B page 5

T-30X2 DRYER DIMENSIONS - SIDE VIEW

8514-253-001 REV B page 6

T-30X2 DRYER DIMENSIONS - REAR VIEW

8514-253-001 REV B page 7

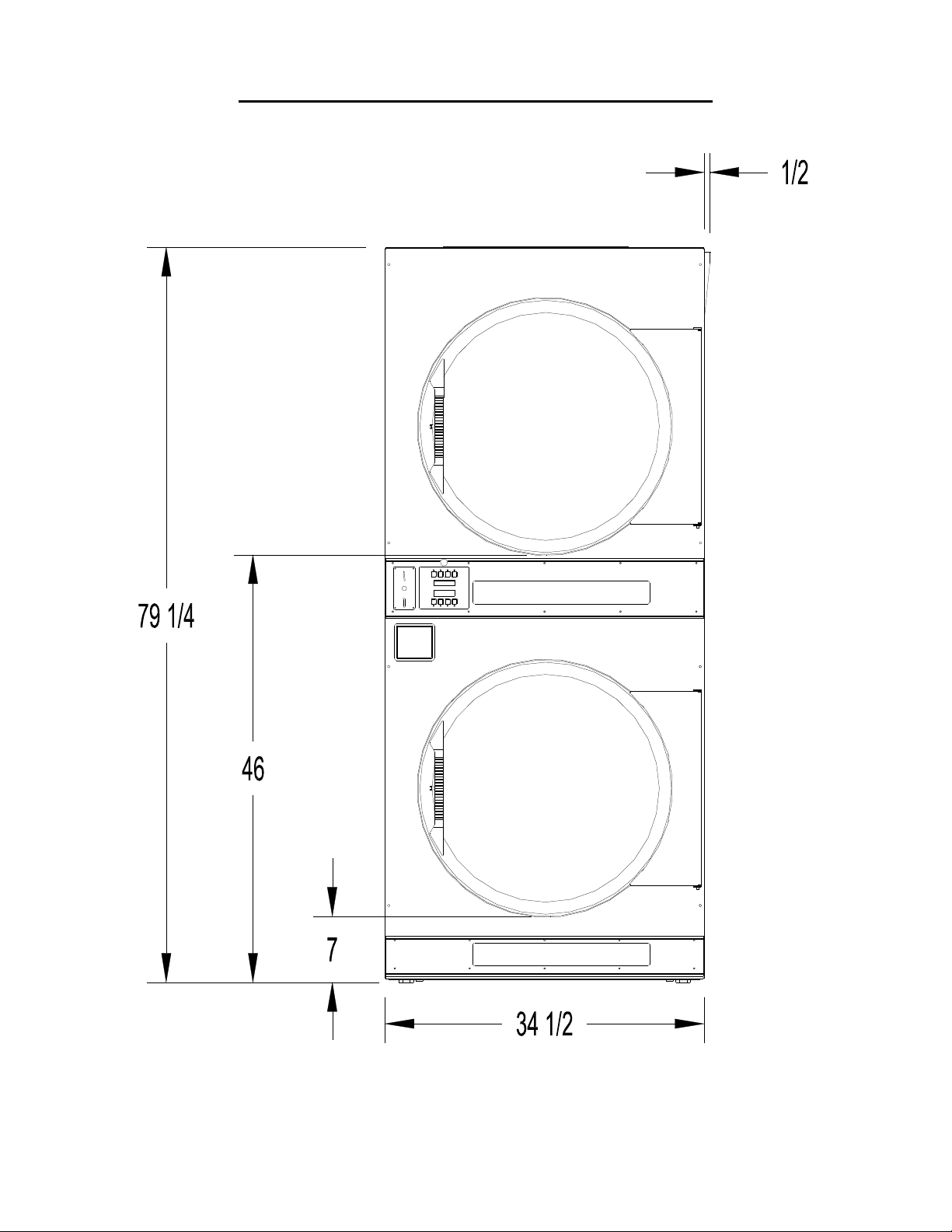

T-50X2 DRYER DIMENSIONS- FRONT VIEW

8514-253-001 REV B page 8

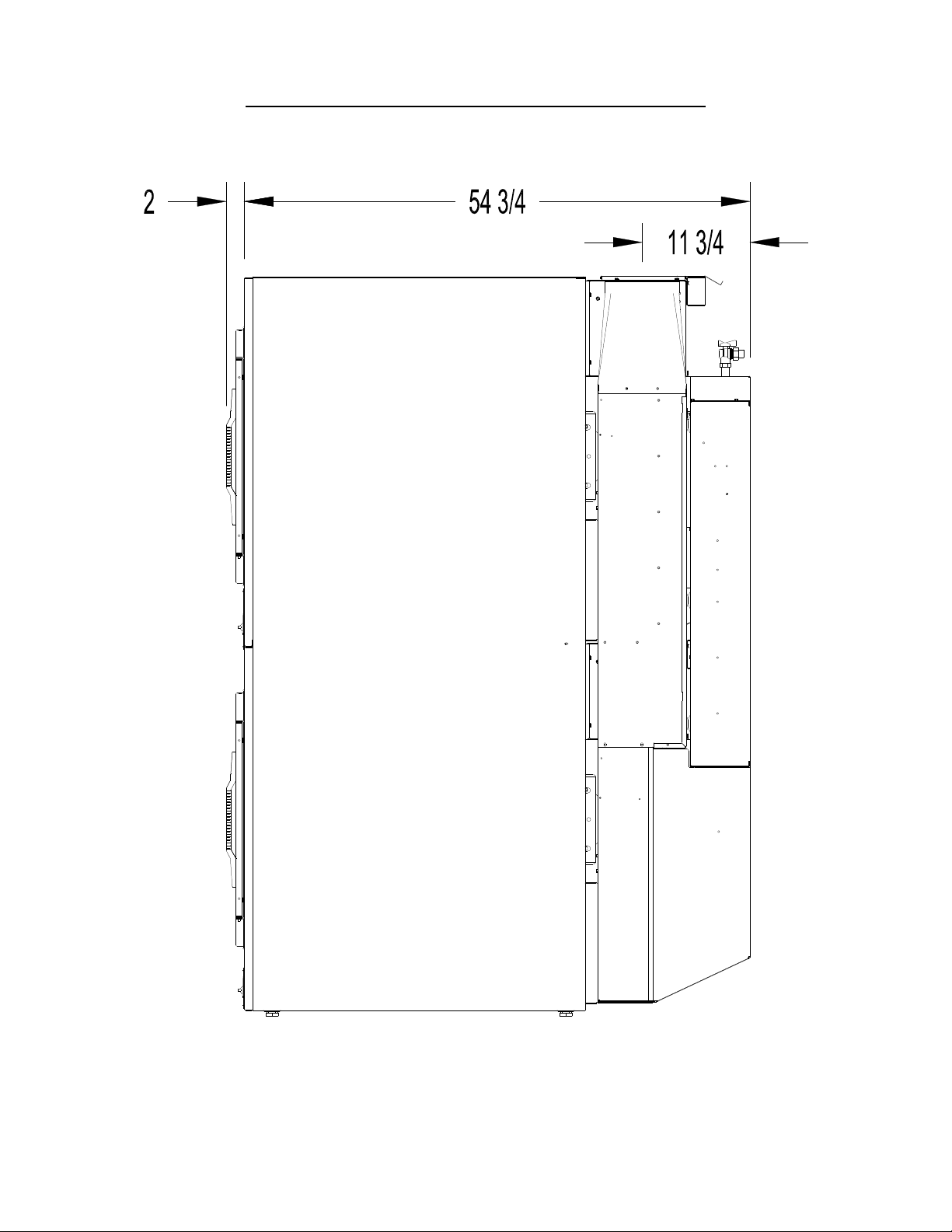

T-50X2 DRYER DIMENSIONS - SIDE VIEW

8514-253-001 REV B page 9

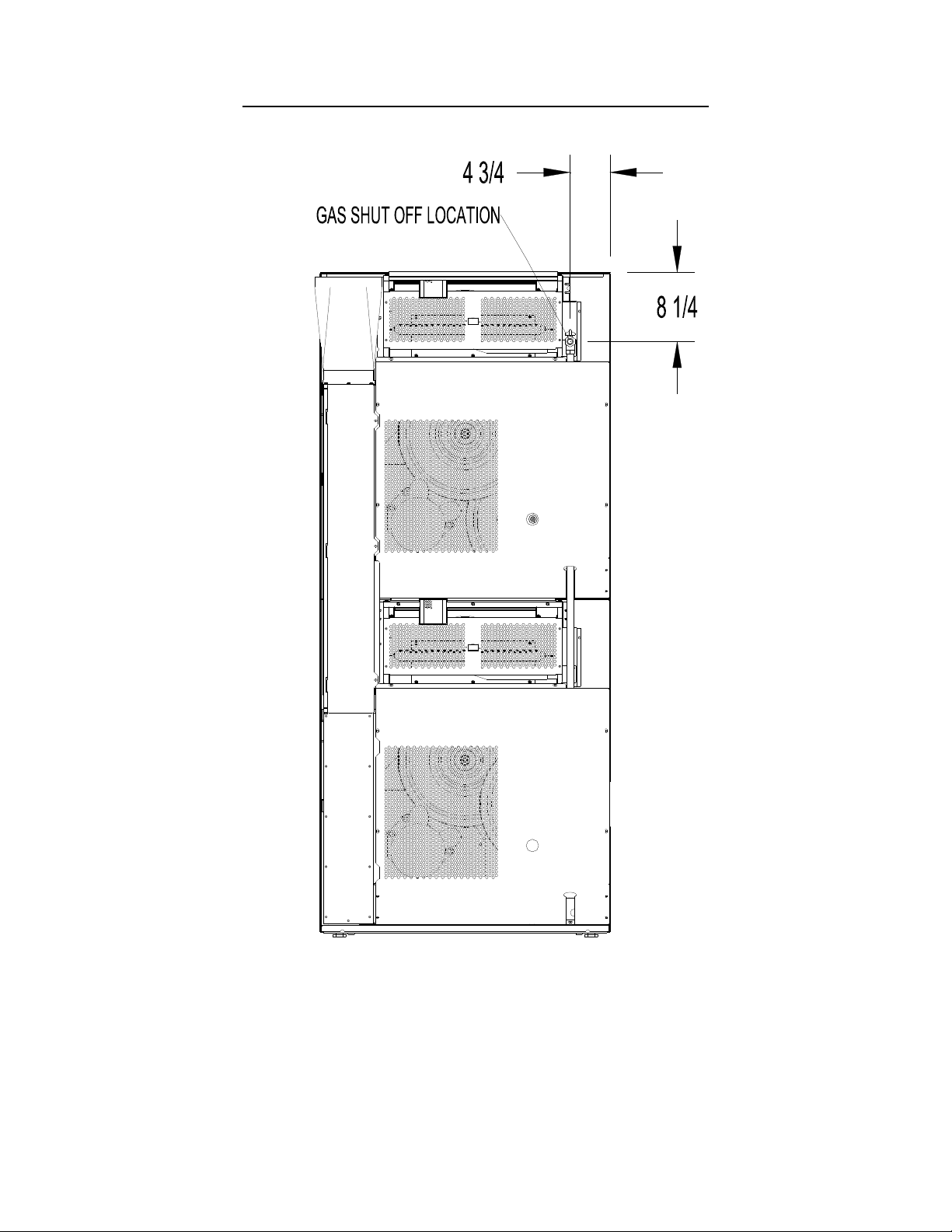

T-50X2 DRYER DIMENSIONS - REAR VIEW

8 INCH VENT

8514-253-001 REV B page 10

Loading...

Loading...