Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter. Llámenos si tiene alguna pregunta o comentario.

855-805-5745 • www.dewalt.com

INSTRUCTION MANUAL

GUIDE DE’UTILISATION

MANUAL DE INSTRUCCIONES

SAVE THESE INSTRUCTIONS

CONSERVEZ CES INSTRUCTIONS

GUARDE ESTAS INSTRUCCIONES

DXH50KTHC, DXH75KTHC, DXH135KTHC, DXH175KTHC, DXH210KTHC

Kerosene Forced-aid Heater

Appareil de chauffage à air pulsé au Kérosène

Calentador Caldeo a aire forzado a Kerosene

READ INSTRUCTIONS CAREFULLY: Read

and follow all instructions. Place instructions

in a safe place for future reference. Do

not allow anyone who has not read these

instructions to assemble, adjust or operate

the heater.

VEUILLEZ LIRE ATTENTIVEMENT LES INSTRUCTIONS :

Lisez et observez toutes les instructions. Conservez

ces instructions dans un endroit sécuritaire pour vous

y référer ultérieurement. Interdisez à quiconque n’ayant

pas lu les présentes directives d’assembler, de régler

ou de faire fonctionner cette fournaise.

LEA CUIDADOSAMENTE LAS INSTRUCCIONES:

Lea y siga todas las instrucciones. Conserve

estas instrucciones en un lugar seguro para futura

referencia. No permita que nadie que no haya

leído estas instrucciones arme, ajuste o use el

calentador.

Page 2

English

2

WARNING: NOT FOR HOME OR RECREATIONAL VEHICLE USE.

Denitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in property damage.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS

PROVIDED WITH THIS HEATER, CAN RESULT IN DEATH, SERIOUS

BODILY INJURY AND PROPERTY LOSS OR DAMAGE FROM HAZARDS

OF FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON MONOXIDE

POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE

INSTRUCTIONS SHOULD USE OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH

AS AN INSTRUCTIONS MANUAL, LABELS, ETC. CONTACT THE

MANUFACTURER.

WARNING: FIRE BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING MATERIALS, PAPER,

OR CARDBOARD, A SAFE DISTANCE AWAY FROM THE HEATER AS

RECOMMENDED BY THE INSTRUCTIONS. NEVER USE THE HEATER IN

SPACES WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE, SOLVENTS, PAINT

THINNER, DUST PARTICLES OR UNKNOWN CHEMICALS.

WARNING: CARBON MONOXIDE CAN KILL YOU

USING A PORTABLE HEATER IN AN ENCLOSED AREA CAN PRODUCE

DEADLY CARBON MONOXIDE.

WARNING: This product can expose you to chemicals including lead

and lead compounds, which are known to the State of California to cause

cancer and birth defects or other reproductive harm. For more information

visit www.P65Warnings.ca.gov

This is an unvented gas-fired portable heater. It uses air (oxygen) from the

area in which it is used. Adequate combustion and ventilation air must be

provided. Refer to page 4.

WARNINGS

WARNING:

• DO NOT USE GASOLINE, NAPHTHA OR VOLATILE FUELS.

• STOP HEATER BEFORE ADDING FUELS.

• ALWAYS FILL OUTDOORS AWAY FROM OPEN FLAME.

• DO NOT USE EXTERNAL FUEL SOURCE.

• DO NOT OPERATE HEATER WHERE FLAMMABLE LIQUIDS OR VAPORS

MAY BE PRESENT.

• DO NOT START HEATER WHEN CHAMBER IS HOT.

• DO NOT START HEATER WHEN EXCESS FUEL HAS ACCUMULATED IN

THE CHAMBER.

• DO NOT PLACE COOKING UTENSILS ON TOP OF THE HEATER.

• PLUG ELECTRICAL CORD INTO A PROPERLY GROUNDED THREE-

PRONG RECEPTACLE.

Page 3

3

English

CONTENTS

WARNINGS 2

HEATER SPECIFICATIONS 3

OPERATING & SAFETY PRECAUTIONS 4

LIGHTING/OPERATING INSTRUCTIONS 5

MAINTENANCE 5

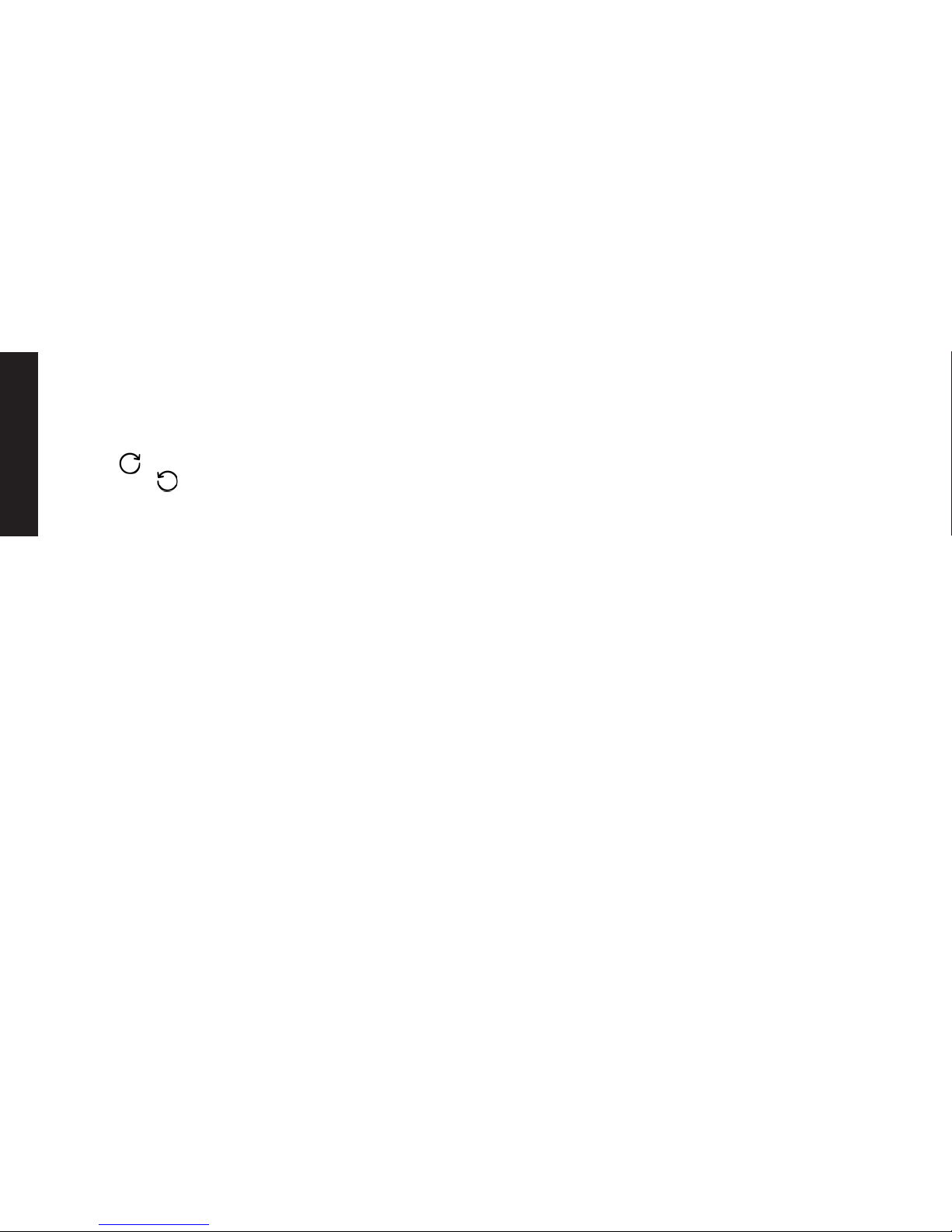

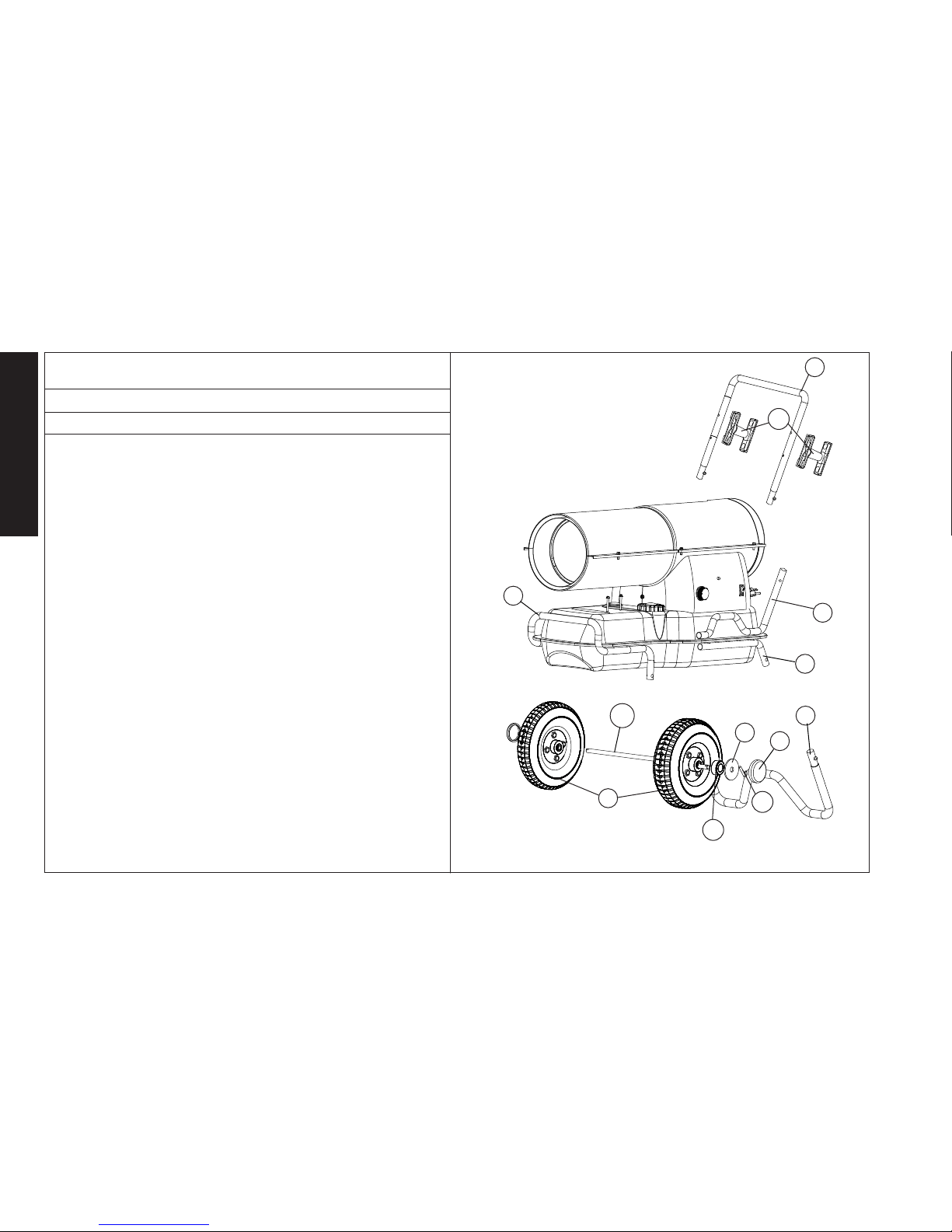

EXPLODED VIEW AND PARTS LIST 8

WIRING DIAGRAM 11

Model DXH50KTHC DXH75KTHC DXH135KTHC DXH175KTHC DXH210KTHC

Burn Rate: 50,000 BTU/hr (14.7 kW) 75,000 BTU/hr (22 kW) 125,000 BTU/hr (37 kW) 175,000 BTU/hr (51 kW) 210,000 BTU/hr (61.5 kW)

Fuel Rate: 0.37 gal/hr (1.5 L/hr) 0.55 gal/hr (2.1 L/hr) 0.96 gal/hr (3.5 L/hr) 1.3 gal/hr (5.0 L/hr) 1.6 gal/hr (6.0 L/hr)

Electrical Input

115 V, 60 HZ, 1 Ø, 3.5 A 1115 V, 60 HZ, 1 Ø, 4 A 115 V, 60 HZ, 1 Ø, 5.5 A 115 V, 60 HZ, 1 Ø, 5.5 A 115 V, 60 HZ, 1 Ø, 5.5 A

Min. operating voltage

110 V 110 V 110 V 110 V 110 V

Pressure Setting 3.5 psig (24 kPa) 4.2 psig (24 kPa) 5.1 psig (38 kPa) 6.8 psig (40 kPa) 8.2 psig (58.6 kPa)

Max. Outlet Temp. 1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C)

Fuel Tank Capacity 4 gallons (15.1 L) 6 gallons (22.7 L) 8.45 gallons (32 L) 13.5 gallons (51 L) 13.5 gallons (51 L)

Ignition Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous

Spark Generator Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma

Primary Safety Control Solid State Control Solid State Control Solid State Control Solid State Control Solid State Control

Certification

Heater Specications

WARNING: If the information in this manual is not followed

exactly, a fire or explosion may result causing injury or loss of

life.

- Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

- Service must be performed by a qualified service agency.

DXH50KTHC & DXH75KTHC WARNING

Not suitable for use on wood floors or other combustible materials. When

used the heater should rest on a suitable insulating material at least 1 inch

thick and extending 3 feet or more beyond the heater in all directions.

CAUTION: CSA certied for use with only No. 1-K kerosene fuel.

Factory Tested: Kerosene, Diesel #1 and #2, Fuel Oil #1 and #2, JP8 (Jet A Fuel)

Page 4

English

4

Operating Precautions

This is a kerosene, direct-fired, forced air heater. It’s intended use is primarily

temporary heating of buildings under construction, alteration or repair.

Direct-Fired means that all of the combustion products enter the heated space. Even

though this heater operates very close to 100 percent combustion efficiency, it still

produces small amounts of carbon monoxide. Carbon monoxide (called CO) is toxic.

CO can build up in a heated space and failure to provide adequate ventilation could

result in death. The symptoms of inadequate ventilation are:

• headache

• dizziness

• burning eyes and nose

• nausea

• dry mouth or sore throat

Be sure to follow advice about ventilation in the Safety Precautions section.

Forced Air means that a blower or fan pushes the air through the heater. Proper

combustion depends upon this air flow; therefore, the heater must not be revised,

modified or operated with parts removed or missing. Likewise, safety systems must

not be circumvented or modified in order to operate the heater.

When the heater is to be operated in the presence of other people the user is

responsible for properly acquainting those present with the safety precautions and

instructions, and of the hazards involved.

Safety Precautions

THIS IS A HEATING APPLIANCE. DO NOT ATTEMPT TO WARM OR COOK

FOOD ON THIS HEATER.

1. Recommended for use with No.1-K kerosene fuel. Factory tested for use with No.2-K

kerosene, No.1 or No.2 Diesel, No.1 or No.2 fuel oil or JP8 Jet A fuel and these fuels may

be used as well. Never use gasoline, biodiesel, oil drained from crank cases, naphtha, paint

thinners, alcohol or any other highly flammable fuels.

2. Check the heater thoroughly for damage. DO NOT operate a damaged heater.

3. DO NOT modify the heater or operate a heater which has been modified from its

original condition.

4. Suitable for either outdoor or indoor use where adequate ventilation is provided. Never

use in areas normally for habitation. Not for use where exposed to weather.

5. Use in well ventilated areas, provide at least 2 sq. ft. (0.19 sq. m.) of opening near

the floor and 2 sq. ft. (0.19 sq. m.) near the ceiling directly to outdoors. Increase air

openings as marked for each additional heater.

6. Always keep combustibles, like paper and wood at least 8 ft. (2.4 m) from the

heater outlet and 3 ft. (1.0 m) from the top, sides and inlet. Locate 10 ft. (3.0 m)

from canvas or plastic coverings and secure them to prevent flapping movement.

7. Caution: Due to the high surface and exhaust temperatures, adults and children

must observe clearances to avoid burns or clothing ignition. Do Not Touch. Keep

children, clothing, and combustible away.

8. Install the heater such that it is not directly exposed to water spray, rain and / or

water.

9. Never use in areas normally for habitation and /or where children may be present.

10. Operate only on a stable, level surface.

(DXH50KTHC & DXH75KTHC – See wood floor warning on page 3).

11. Do not use with duct work. Do not restrict inlet or exit.

12. Use only with electrical power specified. The electrical connection and grounding

must comply with National Electrical Code – ANSI/NFPA 70 (USA) and CSA

C22.1 Canadian Electrical Code, Part 1 (Canada).

13. Use only a properly grounded 3-prong receptacle or extension cord.

14. Do not move, handle, or service while hot or in operation.

15. Use only in accordance with local, state (provincial) or national requirements,

ordinances and codes.

Operating Instructions

UNPACKING

1. Remove heater from carton.

2. Remove all protective material which may have been applied to the heater for shipment.

3. Check the heater for possible shipping damage. If any damage is found immediately

contact the manufacturer at 855-805-5745.

ASSEMBLY

(FOR 135,000, 175, AND 210 BTU/hr models only see page 10)

Wheels and handles are found in the shipping carton along with mounting hardware. The

wheels, axle and mounting hardware are in a package. Tools required are a 5/16” nut driver,

3/8” open or adjustable wrench and standard pliers.

1. Assemble the wheels onto the wheel support as shown.

2. Install one of the cotter pins into the hole on one end of axle.

3. Slide the large washer, then wheel onto the axle next to the cotter pin.

4. Slide the spacer onto the axle next to the wheel.

5. Slide the partially assembled axle through the wheel support frame.

6. Slide the spacer onto the axle next to the wheel support.

Page 5

5

English

7. Slide the wheel, then large washer onto the axle and hold in place with the remaining

cotter pin.

8. Install the caps over the larger washers to finish the wheel assembly.

PREPARATION FOR OPERATION

1. Check the heater for possible shipping damage. If any is found, immediately contact

the manufacturer at 855-805-5745.

2. Follow all of the “Precautions”.

3. Fill the fuel tank with clean kerosene. In extremely cold weather, condensation may

develop in the tank and it is recommended that a tablespoon of de-icer be added

for each gallon (4 liters) of fuel in the tank. When filling the heater, use at least 2

gallons (8 liters) of fuel. Be sure heater is level and do not overfill. Use a funnel or

can with a long fill spout.

IMPORTANT: Before lling fuel tank the rst time or after extended storage

periods, drain the fuel tank of any moisture or condensation.

4. Locate heater at a safe distance from combustible materials. Models DXH50K &

DXH75K are not suitable for use on wood floors or other combustible materials.

When used, the heater should rest on suitable insulating material at least 1 inch

thick and extending 3 ft. or more beyond the heater in all directions.

HEATER START UP

DXH50KTHC

1. Plug the heater into a grounded 115V, 60 Hz, 1 Ø outlet.

DXH75KTHC, DXH135KTHC, DXH175KTHC, DXH210KTHC

1. Turn thermostat to lowest setting and make sure “On/Off” switch is “Off”.

2. Plug the heater into a grounded 115V, 60 Hz, 1 Ø outlet.

3. Start heater by pushing toggle switch to “On” position (light signifies switch is in

“On” position.)

4. Adjust thermostat to desired setting. Heater will cycle on/off as heat is required.

NOTES FOR ALL MODELS:

• In cold weather (below 10 °F [-12.2 °C] ) starting may be improved by holding a nger over the vent hole of the pump adjustment screw cap until the

heater starts.

• This unit is equipped with an interrupt circuit. The reset is integrated into

the “On/Off” switch. If the unit does not start, toggle the switch to “Off”,

wait 5 min, and toggle the switch to “On”

• EXTENSION CORD REQUIREMENTS: Up to 100’ (30.5 M) use 16 awg conductor. 101’ - 200’ (30.5 - 61.0 m) use 14 awg conductor.

HEATER SHUT DOWN

DXH50KTHC

1. Unplug the heater from power source.

DXH75KTHC, DXH135KTHC, DXH175KTHC, DXH210KTHC

1. Push “On/Off” switch to “Off” position. For extended shutdown, unplug heater

from power source.

HEATER RESTART AFTER SAFETY SHUTDOWN

DXH50KTHC

1. Unplug the heater from power source.

2. Wait 5 minutes.

3. Plug the heater back into power source.

DXH75KTHC, DXH135KTHC, DXH175KTHC, DXH210KTHC

1. Toggle switch to “OFF” position

2. Wait 5 minutes

3. Restart

Maintenance and Storage

WARNING: To prevent personal injury, unplug the heater from the wall outlet

before servicing.

For maximum efficiency and trouble-free service, make the following periodic

maintenance, cleaning and inspections.

ADJUSTING PUMP PRESSURE

Due to varying fuel viscosities and normal component wear the pump pressure on

this heater may need to be adjusted.

FUEL PRESSURE ADJUSTMENT SCREW

(located at the rear of the heater)

PRESSURE GAGE

(not included on DXH50KTHC

or DXH75KTHC)

Page 6

English

6

ADJUSTMENT PROCEDURE

1. Fill fuel tank.

2. Start heater.

3. Locate the pressure adjustment screw, located on the back of the power pack assembly

and accessible by the handle of the heater.

4. Remove the rubber cap over the fuel pressure adjustment screw.

5. Using a flat bladed screw driver, turn the pump pressure adjustment screw:

• clockwise

to increase pump pressure

• counter-clockwise

to decrease pump pressure

By using the installed pressure gage (not included on DXH50KTHC) you may quantitatively

calibrate the pressure. The manufacturer’s recommended pump pressures are in the

specifications chart on page 3.

6. The desired qualitative burner characteristics are that the nose cone in the combustion

chamber should be cherry red with no dark spots and the flame should not extend

beyond the nose cone.

IMPROPER PRESSURE ADJUSTMENT

Problem: Heater does not have a strong consistent flame.

Heater smokes and spits raw fuel.

Nose cone does not get cherry red.

Adjustment: Pump pressure is too low.

Turn adjustment screw clockwise to increase pump pressure

Problem: Flame extends beyond the end of the heater.

Adjustment: Pump pressure is too high.

Turn adjustment screw counter clockwise to decrease pump pressure.

Daily Maintenance Schedule

1. GENERAL. Make general visual inspection of heater for loose or damaged parts.

Check nuts and bolts to insure against looseness caused by vibration or rough

handling. Damaged parts should be repaired or replaced before using heater

again. Check heater operation to be sure it is operating normally (See “Servicing”

section for description of normal operation).

2. FILTERS. Dirty air or fuel filters will cause an imbalance in the air-fuel mixture. The

best indication that this condition exists is an increase in odors or difficulty getting

your heater to ignite. This heater should never be operated without the filters

in place. If required, clean filters as described under “500 Hours” and “Annual

Schedules”.

500 Hour Maintenance Schedule

1. AIR INTAKE FILTER. Remove and wash the filter element with a mild detergent,

dry thoroughly and replace. Do not oil the filter element. If your heater is

used where there is considerable dust or dirt, clean as often as necessary

(approximately every 50 hrs.).

2. REMOVE DUST. Clean heater twice a season (more often under dusty conditions).

Remove accumulated dust from the transformer, burner, motor and fan blades

with compressed air. Wipe area clean with a clean dry cloth. Inspect area to insure

all foreign materials are removed, especially around the burner and combustion

area.

3. CAD CELL. Clean the glass portion of the cad cell with a soft dry cloth.

4. NOZZLE. Accumulation of dirt from fuel and carbon from the compressor vanes

will eventually fill up the passages in the nozzle, resulting in reduction of fuel and

air flow. Pressure will gradually increase giving improper fuel-air mixture and

excess odor and smoke. If this occurs, replace the fuel nozzle.

5. FUEL TANK. Clean twice a season (during frequently used periods, clean twice a

month). Drain and flush the fuel tank with clean fuel oil.

Annual Maintenance Schedule

1. AIR OUTPUT FILTER. Remove the air output filter and tap the contaminated side

gently on a solid object to remove contaminates. Compressed air or liquids should

not be used to clean this filter. Reinstall cleaned filter in filter body in the same

position as it was when removed. If the filter appears extremely dirty, replace it

with a new filter of the same type. When replacing the filter cover, be sure the

gasket is firmly in place and the screws in the filter cover are tight to prevent air

leaks.

2. FUEL FILTER. Remove the fuel filter from fuel line and direct compressed air

through the filter in the opposite direction of fuel flow. Safety glasses should be

worn when using compressed air.

3. AIR AND FUEL LINES. If the air or fuel lines are removed during cleaning, be sure

all connections are tight before operating unit.

Page 7

7

English

Storage

Store the heater in a dry location free from fumes or dust.

At the end of each heating season, clean the heater as described in the MAINTENANCE section. Drain and flush the fuel tank with clean fuel. The manufacturer

recommends completely filling the tank with fuel for extended storage to minimize

condensation inside the tank.

It is recommended to only store kerosene in containers that are marked

“KEROSENE”.

Servicing

A hazardous condition may result if a heater is used that has been modified or is not

functioning properly.

When the heater is working normally:

* The flame is contained within the heater.

* The flame is essentially yellow.

* There is no strong disagreeable odor, eye burning or other physical discomfort.

* There is not smoke or soot internal or external to the heater.

* There are no unplanned or unexplained shutdowns of the heater.

Troubleshooting

High limit switch open circuit

1. Make sure heater is cooled off, toggle switch to “OFF” position, wait 5 minutes and retry.

Sparks, calling for ame, but no or slow motor operation

1. Check wiring to motor (per wiring schematic in manual)

2. Make sure that the pressure gauge is in place and not damaged

3. Adjust pressure for proper heater operation per manual

4. With heater disconnected from AC source, rotate fan clockwise to verify motor is free

5. Remove air filter housing from motor and inspect the pump rotor for damage. If damaged,

replace rotor assembly.

6. If wiring is correct, pump rotor is okay, and motor is not rotating freely, replace motor or

power-pack assembly.

7. If problem persists, replace oil flame control assembly.

8. Check for spark arching from the electrode assembly, to the combustion cylinder.

9. Check the cad cell for continuity.

No Spark

1. Check length and gage of extension cord for proper amp. draw (check page 5)

2. Check wiring to igniter (per wiring schematic in manual)

3. Check gap between electrode probes (2.3 - 3mm)

4. Still no spark, replace igniter assembly

5. Replace oil flame control assembly

Abnormal Motor Operation - Motor overheats or Stops

1. Motor speed too low (Motor should operate at 3450 rpm) - Replace motor

2. With heater disconnected from AC source, rotate fan clockwise to verify motor is free

3. Remove air filter housing from motor and inspect the pump rotor for damage. If damaged,

replace rotor assembly

4. If wiring is correct, pump rotor is okay, and motor is not rotating freely, replace motor or

power-pack assembly

5. Replace oil flame control assembly

Unable to Detect Flame

1. Check wiring to cad cell (per wiring schematic in manual)

2. Clean cad cell photo cell

a) Slide cad cell out of cad cell holder

b) Push the photo cell out of the black rubber cad cell housing by pushing on the 2 purple

wires

c) Clean the photo cell with a soft cloth and rubbing alcohol

d) Pull the photo cell back into the cad cell housing and reinstall into holder

e) Test heater

3. If the heater still does not operate, replace cad cell

4. Replace oil flame control assembly

Flame Control Failure

1. Check wiring in heater (per wiring schematic in manual).

2. Replace oil flame control assembly.

Page 8

English

8

1

2

3

4

5

6

7

9

10

11

13

14

15

16

17

18

19

20

21

24

25

26

53

28

29

30

31

32

34

35

36

37

38

39

40

41

42

43

44

45

46

47

51

52

8

12

22

23

33

48

49

50

27

Filter Kit

51

52

Page 9

9

English

# 50K 75K 135K 175K 210K Description

1 21036 21036 21036 21036 21036 Power Cord

2 26958 26970 26974 27112 27112 Fuel Tank Assembly

3 **** 21883 21884 21885 21886 RadiationShield Ass’y

4 26960 26967 26975 26975 26975 Power Pac Ass’y

5 21686 24343 24346 24346 24346 Fuel Tube

6 21835 21836 21837 21837 21837 Grille Assembly

7 24011 24011 24011 24011 24011 Oil cad cell Bracket

8 28779 28779 28792 28793 28793 Fuel Filter

9 23449 23449 23449 23449 23449 Motor Cord Sleeve

10 26957 27144 26973 27111 27111 Bottom Shell

11 21844 27143 26972 27110 27110 Top Shell, Burner

12 21854 26966 26971 27109 27109 Top Shell, Insp. Cover

13 21864 21864 21865 21865 21865 Motor Mounting Brkt

14 **** 28788 28735 28735 28735 Start Capacitor

15 23725 23725 24345 24345 24345 Air Tube

16 26225 26225 26225 26225 26225 Snap Bushing

17 26962 21794 26901 22105 22105 High Limit Control

18 F226831 F226831 F226831 F226831 F226831 Kit, Rotor

19 **** 26898 26898 26898 26898 Receptacle, 110V

20 **** 22104 22104 22104 22104 AC Receptacle Cover

21 26833 26833 26833 26833 26833 Air Pump Cylinder

22 21810 21810 21810 21810 21810 Outlet Housing

23 21812 21812 21812 21812 21812 Inlet Housing

24 **** **** 22257 22257 22257 Burner Head Ass’y

25 F221887 F221887 F221887 F221887 F221887 Kit, Filter

26 21814 21814 21814 21814 21814 Outlet Filter

27 21815 21815 21815 21815 21815 Inlet Filter

28 F266842 F266842 F266842 F266842 F266842 Kit, Pump Adjustment

29 21866 21866 21867 21867 21867 Flame Control Ass’y

30 21816 21816 21816 21816 21816 Flame Control Bracket

31 F226865 F226865 F226865 F226865 F226865 cad cell Flame Sensor

32 21882 21868 21869 21870 21871

Comb.Chamber Cyl.

Ass’y

# 50K 75K 135K 175K 210K Description

33 26959 26959 26959 26959 26959 Fuel Cap

34 26910 26910 26910 26910 26910 Fuel Cap Gasket

35 27339 21817 21818 21818 21818 Motor

36 27790 27790 28739 28739 28739 Nozzle Adapter

37 27421 28740 26885 26866 26866 Fan

38 22142 22142 22142 22142 22142 Igniter Assembly

39

F227416 F221878 F221879 F221889 F221891

Fuel Air Aspir. Nozzle

40 26223 26223 26223 26223 26223 Strain Relief Bushing

41

F221857 F221857 F221857 F221857 F221857

Electrode Assembly

42 21820 21820 21820 21820 21820

Electrode Insulated

Cover

43 21821 21821 21821 21821 21821 Hose Barb Adapter

44 **** 21822 21822 21822 21822 Thermostat Knob

45 **** 21734 21734 21734 21734 Thermostat Assembly

46 28785 28785 28785 28785 28785 ON/OFF Switch

47 **** 28791 28778 22185 22185 Fuel Gauge

48 26964 21888 27107 27116 27116 Control Panel

49 26965 26968 27108 27117 27117 Control Panel Back

50 28786 28786 28786 28786 28786 Pressure Gauge, Round

51 40801 40801 **** **** **** Handle

52 21813 21813 21813 21813 21813 Gasket, Outlet Filter

* 24171 24171 **** **** **** Nozzle mtg. plate

* 26227 26227 26227 Snap Bushing

* 27429 27429 27429 27429 27429

Nozzle Ext. Retaining

Ring

* 28745 28745 **** **** **** Fuel Line Bushing

* **** 22146 22146 22146 22146 Bracket Thermostat Mtg.

* **** 26070 26070 26070 26070 Clamp Loop

REPLACEMENT PARTS LIST

* Not shown in Figure **** Not applicable to model

Page 10

English

10

* Not shown in drawing

Handle and wheel assembly for

DXH135KTHC, DXH175KTHC & DXH210KTHC only.

Ref. Item # Item # Item # Description

135K 175k 210K

1 40981 40981 40981 Wheel Assembly, 10”

2 27127 27129 27129 Upper Handle w/Spring Clips

* 27121 27121 27121 Lower Handle, Right

3 22173 22173 22173 Lower Handle, Left

* 27105 27105 27105 Leg Support, Right

4 27105 27105 27105 Leg Support, Left

5 27104 27132 27133 Support Leg

6 27128 27130 27131 Front Handle

7 28749 28749 28749 Large Retainer Washer

8 28750 28750 28750 Cotter Pin

9 28751 28751 28751 Hub Cap

10 28754 28754 28754 Extension Cord Caddy

11 21897 21897 21897 Wheel Spacer

12 22168 22184 22184 Axel

* 28787 28787 28787 Hardware Package

PARTS LIST

1

2

3

4

6

5

9

7

8

10

11

12

Page 11

11

English

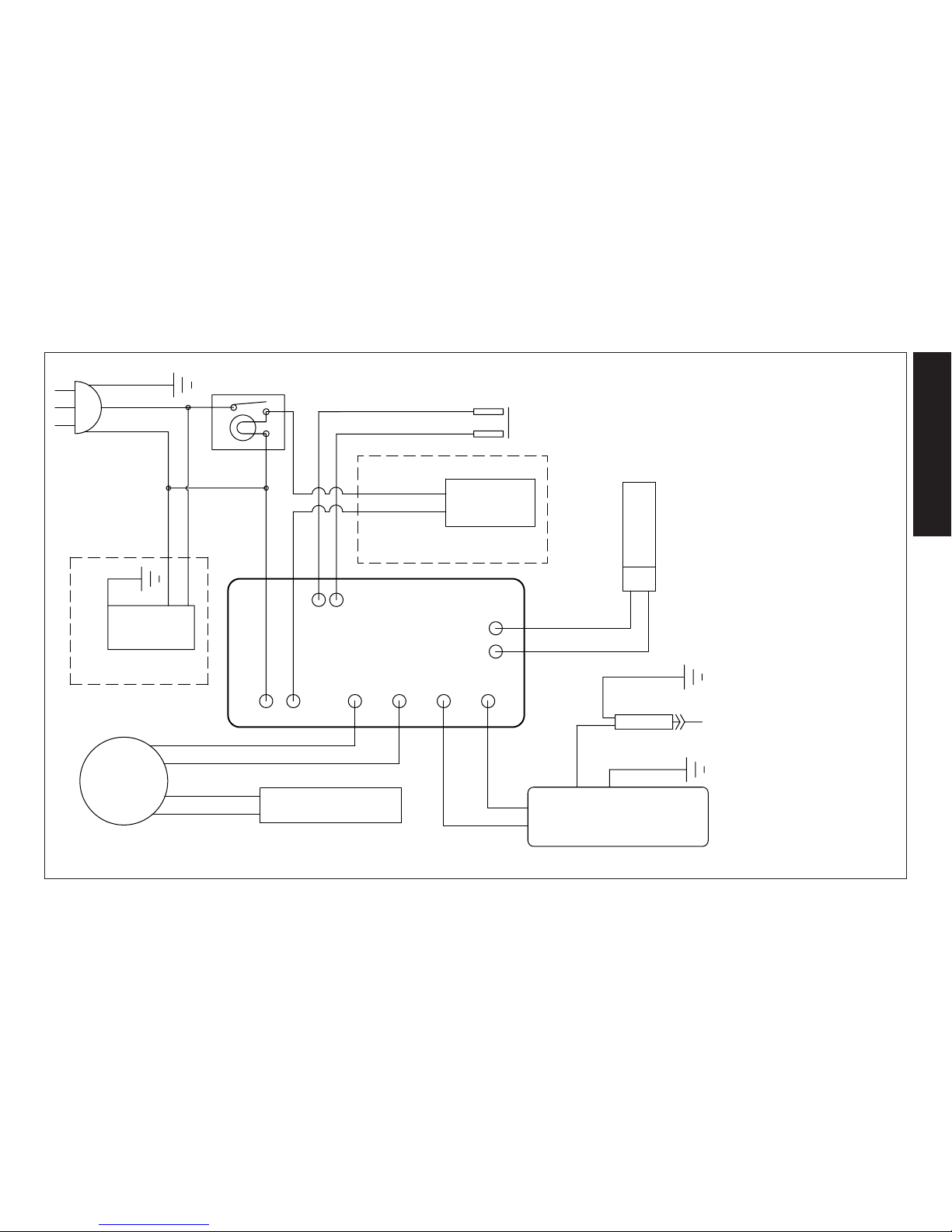

WIRING DIAGRAMS

DXH50KTHC

DXH75KTHC

18AWG BLUE

THERMOSTAT

18AWG PURPLE

COM1

I2

I1

M2

M1

L

N

18AWG PURPLE

18AWG GRN

18AWG BLK

18AWG WHT

18AWG YELL

18AWG YELL

FLAME CONTROL SCHEMATIC

(connections may not be in same

position on circuit board)

CORD SET

CAD CELL

HI-LIMIT

SWITCH

1

3

2

18AWG GRN

AC OUTLET

ON/OFF SWITCH

125KT,175KT,

210KT ONLY

75KT,125KT,175KT,210KT ONLY

18AWG PINK

18AWG PINK

MOTOR CAPACITOR

MOTOR

18AWG ORG

18AWG ORG

18AWG RED

18AWG RED

IGNITION TRANSFORMER

17AWG BLK

18AWG GRN

ELECTR0DE

17AWG BLK

18AWG BLK

18AWG WHT

H2

H1

The parts lists and wiring diagram show

the heater as it was constructed. Do not

use a heater which is different from that

shown. Heater performance is effected

by air pressure setting. If there is any

uncertainty about the air pressure setting,

have it checked. A heater which is not

working right must be repaired, but only by

a trained, experienced service person.

Page 12

English

12

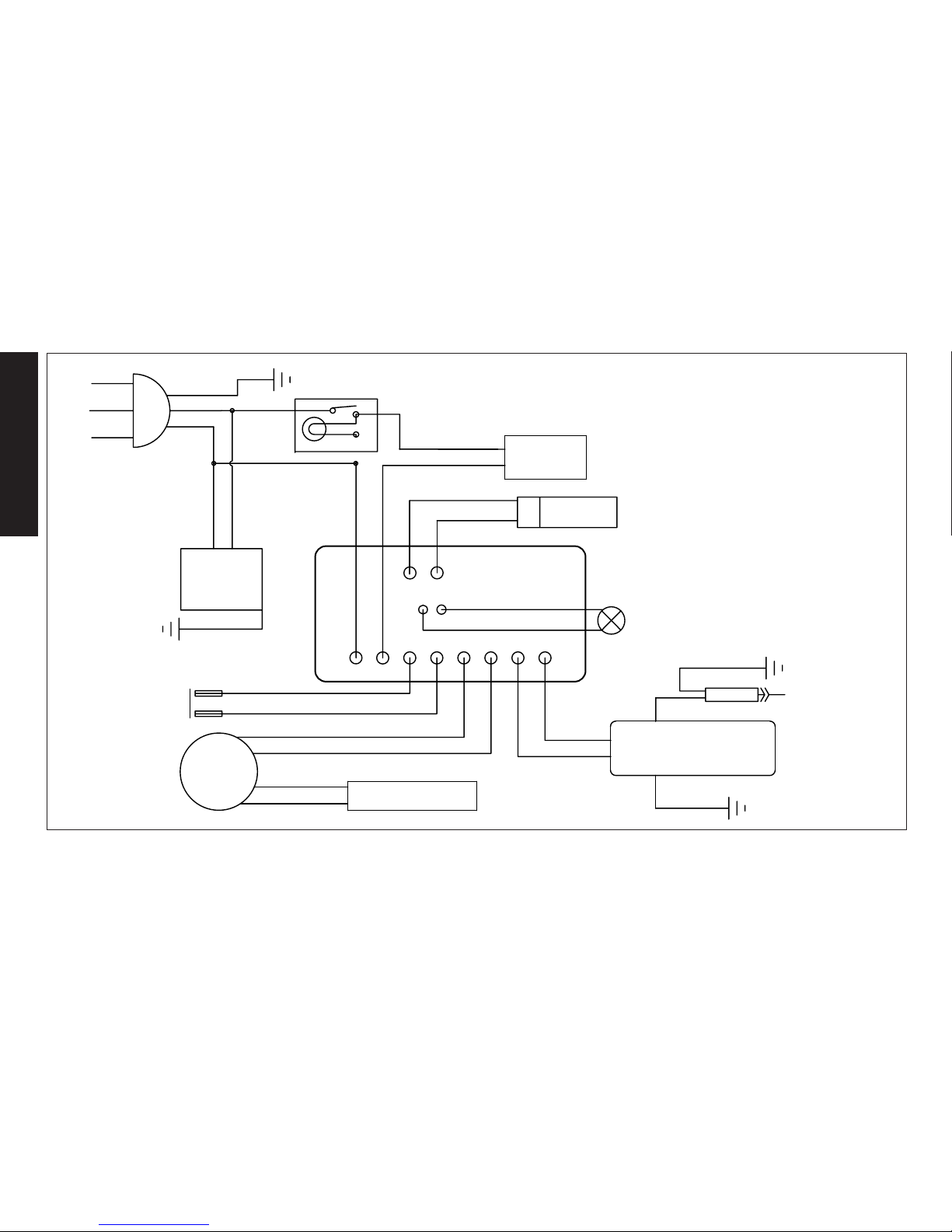

WIRING DIAGRAMS

The parts lists and wiring diagram show the heater as it was constructed. Do not use a heater which is different from that shown. Heater performance is effected by air

pressure setting. If there is any uncertainty about the air pressure setting, have it checked. A heater which is not working right must be repaired, but only by a trained,

experienced service person.

ON/OFF SWITCH

AC OUTLET

18AWG GRN

18AWG ORG

18AWG ORG

2

3

1

IGNITION TRANSFORMER

MOTOR

HI-LIMIT

SWITCH

CORD SET

MOTOR CAPACITOR

CIRCUIT BOARD

18AWG YELL

18AWG YELL

18AWG RED

18AWG RED

18AWG WHT

18AWG BLK

18AWG GRN

18AWG PURPLE

18AWG PINK

18AWG PINK

1

2

3

4

5

6

18AWG PURPLE

THERMOSTAT

18AWG BLUE

7

8

ELECTR0DE

18AWG GRN

17AWG BLK

9

10

RED LED

11 12

18AWG BLUE

17AWG BLK

24AWG BLK

24AWG RED

18AWG BLK

18AWG WHT

CAD CELL

DXH135KTHC

DXH175KTHC

DXH210KTHC

Page 13

13

English

INSTRUCTION MANUAL

Kerosene Forced Air Heater

DXH50KTHC

DXH75KTHC

DXH135KTHC

DXH175KTHC

DXH210KTHC

DEWALT®, GUARANTEED TOUGH® and the

yellow and black color scheme are trademarks

of the DEWALT Industrial Tool Co., used under

license. ©2017 DEWALT. EGI/Enerco Group Inc.

Under license from Dewalt Industrial Tool Co

Warning

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY

OTHER PARTS COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS

ARE ONLY AVAILABLE DIRECT FROM THE FACTORY AND MUST BE

INSTALLED BY A QUALIFIED SERVICE AGENCY.

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any Dewalt® local dealer or

direct from the factory

FOR INFORMATION REGARDING SERVICE:

Please call Toll-Free 855-805-5745

www.dewalt.com

Our office hours are 8:00 AM – 5:00 PM, EST, Monday through Friday.

Please include the model number, date of purchase, and description of

problem in all communication.

LIMITED WARRANTY

DeWalt® warrants its heaters and accessories to be free from defects in material and workmanship for a period of 2 years from date of purchase.

DeWalt® will repair or replace this product free of charge if it has been prove

to be defective within the 2 years period, and is returned at customer expense

with proof of purchase to DeWalt® within the warranty period.

UL733, CSA B140.8, CSA B140.9.3

Page 14

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter. Llámenos si tiene alguna pregunta o comentario.

855-805-5745 • www.dewalt.com

INSTRUCTION MANUAL

GUIDE DE’UTILISATION

MANUAL DE INSTRUCCIONES

SAVE THESE INSTRUCTIONS

CONSERVEZ CES INSTRUCTIONS

GUARDE ESTAS INSTRUCCIONES

DXH50KTHC, DXH75KTHC, DXH135KTHC, DXH175KTHC, DXH210KTHC

Kerosene Forced-aid Heater

Appareil de chauffage à air pulsé au Kérosène

Calentador Caldeo a aire forzado a Kerosene

READ INSTRUCTIONS CAREFULLY: Read

and follow all instructions. Place instructions

in a safe place for future reference. Do

not allow anyone who has not read these

instructions to assemble, adjust or operate

the heater.

VEUILLEZ LIRE ATTENTIVEMENT LES INSTRUCTIONS :

Lisez et observez toutes les instructions. Conservez

ces instructions dans un endroit sécuritaire pour vous

y référer ultérieurement. Interdisez à quiconque n’ayant

pas lu les présentes directives d’assembler, de régler

ou de faire fonctionner cette fournaise.

LEA CUIDADOSAMENTE LAS INSTRUCCIONES:

Lea y siga todas las instrucciones. Conserve

estas instrucciones en un lugar seguro para futura

referencia. No permita que nadie que no haya

leído estas instrucciones arme, ajuste o use el

calentador.

Page 15

Français

2

AVERTISSEMENT: NON CONÇU POUR ÊTRE UTILISÉ DANS UNE

HABITATION OU UN VÉHICULE RÉCRÉATIF.

AVERTISSEMENT G

ÉNÉRAL DE DANGER

:

LE NON-RESPECT DES MESURES DE PRÉVENTION ET INSTRUCTIONS

FOURNIES AVEC CET APPAREIL DE CHAUFFAGE RISQUE DE CAUSER LA MORT,

DES BLESSURES GRAVES ET DES DOMMAGES OU DES PERTES MATÉRIELLES

RÉSULTANT D’INCENDIE, D’EXPLOSION, DE BRÛLURE, D’ASPHYXIE,

D’INTOXICATION AU MONOXYDE DE CARBONE OU D’ÉLECTROCUTION.

SEULES LES PERSONNES APTES À COMPRENDRE ET À RESPECTER LES

INSTRUCTIONS DEVRAIENT UTILISER OU EFFECTUER L’ENTRETIEN DE CET

APPAREIL DE CHAUFFAGE.

SI VOUS AVEZ BESOIN D’AIDE OU D’INFORMATION AU SUJET DE L’APPAREIL

DE CHAUFFAGE (MANUEL D’INSTRUCTIONS, ÉTIQUETTES, ETC.), VEUILLEZ

COMMUNIQUER AVEC LE FABRICANT.

AVERTISSEMENT:

DANGER D’INCENDIE, D’EXPLOSION ET D’INHALATION.

CONSERVEZ LES MATÉRIAUX COMBUSTIBLES TELS QUE LES MATÉRIAUX DE

CONSTRUCTION, LE PAPIER ET LE CARTON À UNE DISTANCE SÉCURITAIRE DE

L’APPAREIL DE CHAUFFAGE COMME LE RECOMMANDENT LES INSTRUCTIONS.

N’UTILISEZ JAMAIS L’APPAREIL DE CHAUFFAGE DANS UN LOCAL QUI CONTIENT

OU RISQUE DE CONTENIR DES PARTICULES COMBUSTIBLES EN SUSPENSION

DANS L’AIR OU DES PRODUITS TELS QUE DE L’ESSENCE, DES SOLVANTS, DU

DILUANT À PEINTURE, DES PARTICULES DE POUSSIÈRE OU DES PRODUITS

CHIMIQUES INCONNUS.

AVERTISSEMENT: LE MONOXYDE DE CARBONE PEUT VOUSTUER

UTILISATION D’UN CHAUFFE PORTABLE DANS UN ESPACE CLOS PEUT PRODUIRE

AU MONOXYDE DE CARBONE MORTEL.

Cet appareil de chauffage portatif n’est pas ventilé. Il utilise l’oxygène de l’air

ambiant. Une circulation d’air adéquate doit être assurée pour la combustion et

la ventilation. Voir page3.

WARNINGS

AVERTISSEMENT:

• N’EMPLOYEZ PAS D’ESSENCE, DE NAPHTE OU DE PRODUITS

COMBUSTIBLES VOLATILS.

• ARRÊTEZ L’APPAREIL DE CHAUFFAGE AVANT D’Y AJOUTER DU

COMBUSTIBLE.

• REMPLISSEZ TOUJOURS LE RÉSERVOIR À L’EXTÉRIEUR, LOIN D’UNE

FLAMME NUE.

• N’UTILISEZ PAS DE SOURCE DE COMBUSTIBLE EXTERNE.

• NE FAITES PAS FONCTIONNER L’APPAREIL DE CHAUFFAGE SI DES VAPEURS

OU DES LIQUIDES INFLAMMABLES RISQUENT D’ÊTRE PRÉSENTS.

• NE DÉMARREZ PAS L’APPAREIL DE CHAUFFAGE SI LA CHAMBRE DE

COMBUSTION EST CHAUDE.

• NE DÉMARREZ PAS L’APPAREIL DE CHAUFFAGE SI UN SURPLUS DE

COMBUSTIBLE S’EST ACCUMULÉ DANS LA CHAMBRE DE COMBUSTION.

• NE PLACEZ PAS D’USTENSILES DE CUISSON SUR L’APPAREIL DE

CHAUFFAGE.

• BRANCHEZ LE CORDON ÉLECTRIQUE DANS UNE PRISE À TROIS BROCHES

ADÉQUATEMENT MISE À LA TERRE.

Dénitions : Directives de sécurité

Les dénitions ci-dessous décrivent le niveau de sévérité pour chaque mot signalétique. Veuillez lire le manuel et faire attention à ces symboles.

DANGER : Indique « une situation à risque imminent, laquelle, si elle n’est pas évitée, entraînera des blessures sérieuses ou la mort ».

AVERTISSEMENT :

Indique « une situation à risque potentiel, laquelle si elle n’est pas évitée, pourrait entraîner des blessures sérieuses ou la mort ».

MISE EN GARDE : Indique une situation dangereuse potentielle, laquelle, si elle n’est pas évitée, peut causer des blessures mineures ou des blessures légères.

AVIS : Indique une pratique non reliée à une blessure personnelle, laquelle, si elle n’est pas évitée, peut entraîner des dommages aux biens.

AVERTISSEMENT: LES SOUS-PRODUITS DE COMBUSTION ÉMIS LORS DE

L’UTILISATION DE CET APPAREIL CONTIENNENT DU MONOXYDE DE CARBONE, UN PRODUIT CHIMIQUE RECONNU PAR L’ÉTAT DE CALIFORNIE COMME

POUVANT CAUSER LE CANCER ET DES MALFORMATIONS CONGÉNITALES (OU

AUTRES DOMMAGES AU SYSTÈME REPRODUCTEUR). Pour plus d’informations,

visitez www.P65Warnings.ca.gov

Page 16

3

Français

TABLE DES MATIÈRES

AVERTISSEMENTS 2

SPÉCIFICATIONS DE CHAUFFAGE 3

PRÉCAUTIONS DE FONCTIONNEMENT ET DE SÉCURITÉ 4

INSTRUCTIONS D’ÉCLAIRAGE ET D’EXPLOITATION 5

ENTRETIEN 5

VUE ÉCLATÉE ET LISTE DES PIÈCES 8

SCHÉMA DE CÂBLAGE 11

Modèles

DXH50KTHC DXH75KTHC DXH135KTHC DXH175KTHC DXH210KTHC

Taux de combustion

: 50,000 BTU/hr (14,7 kW) 75,000 BTU/hr (22 kW) 125,000 BTU/hr (37 kW) 175,000 BTU/hr (51 kW) 210,000 BTU/hr (61,5 kW)

Consommation de combustible

: 0,37 gal/hr (1,5 L/hr) 0,55 gal/hr (2,1 L/hr) 0,96 gal/hr (3,5 L/hr) 1,3 gal/hr (5,0 L/hr) 1,6 gal/hr (6,0 L/hr)

Consommation électrique

115 V, 60 HZ, 1 Ø, 3,5 A 1115 V, 60 HZ, 1 Ø, 4 A 115 V, 60 HZ, 1 Ø, 5,5 A 115 V, 60 HZ, 1 Ø, 5,5 A 115 V, 60 HZ, 1 Ø, 5,5 A

Courant maximal 110 V 110 V 110 V 110 V 110 V

Pression 3,5 psig (24 kPa) 4,2 psig (24 kPa) 5,1 psig (38 kPa) 6,8 psig (40 kPa) 8,2 psig (58,6 kPa)

Température de sortie maximale:

1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C)

Capacité du réservoir

4 gallons (15,1 L) 6 gallons (22,7 L) 8,45 gallons (32 L) 13,5 gallons (51 L) 13,5 gallons (51 L)

Allumage

Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous

Générateur d’étincelle

Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma

Appareil de commande

Solid State Control Solid State Control Solid State Control Solid State Control Solid State Control

Certification

Spécications

AVERTISSEMENT: Le non-respect des instructions, telles

u’indiquées dans le présent guide, risque d’entraîner une explosion

ou un incendie entraînant des dommages matériels ou des blessures

graves, voire mortelles.

- N’entreposez pas et n’utilisez pas d’essence ou d’autres liquides ou vapeurs

inflammables àproximité de ce type d’appareil.

- L’entretien doit être effectué par un fournisseur de services d’entretien qualifié.

AVERTISSEMENT RELATIF AUX MODÈLES DXH50KTHC ET DXH75KTHC

Non conçu pour être utilisé sur des planchers de bois ou d’autres matériaux

combustibles. Lors de son fonctionnement, l’appareil de chauffage doit reposer sur un matériau isolant adéquat d’au moins 2,5 cm (1 po) d’épaisseur et

dépassant l’appareil d’au moins 90 cm (3 pi) de tous les côtés.

PRUDENCE : CSA certié pour l’utilisation avec seulement No. 1-K le combustible de pétrole.

L’usine évaluée: No.2-K, No. 1 ou le gazole de No. 2, No. 1 ou le fuel de No. 2 ou le Jet de JP8

Page 17

Français

4

Précautions Liées au Fonctionnement

Cet appareil de chauffage à air pulsé et à feu direct fonctionne au kérosène. Il est

destiné principalement à chauffer temporairement des édifices en construction, en

rénovation ou en réparation.

Le fonctionnement à feu direct de cet appareil signifie que tous les produits de

combustion se retrouvent dans l’air ambiant. Même si la combustion de l’appareil de

chauffage est presque complète, il produit quand même de petites quantités de monoxyde de carbone. Le monoxyde de carbone (appelé CO) est toxique. Il est possible

que le CO s’accumule dans le local à chauffer. Une ventilation inadéquate pourrait

ainsi causer la mort. Les symptômes ressentis en cas de ventilation inadéquate sont

les suivants:

• mal de tête

• étourdissement

• sensation de brûlure au nez et aux yeux

• nausée

• mal de gorge ou bouche sèche

Assurez-vous de respecter les conseils au sujet de la ventilation mentionnés dans la

section Précautions liées à la sécurité.

Un appareil à air pulsé signifie que l’air est soufflé dans l’appareil de chauffage par une

soufflerie. La qualité de la combustion dépend du débit d’air. Par conséquent, l’appareil

de chauffage ne doit pas être modifié ni être utilisé si des pièces sont manquantes. De

même, les systèmes de sécurité ne doivent pas être contournés ni modifiés pour faire

fonctionner l’appareil.

Lorsque l’appareil de chauffage doit fonctionner en présence d’autres personnes,

l’utilisateur est responsable d’informer ces dernières des instructions et précautions liées

à la sécurité et de les avertir des dangers inhérents.

Précautions Liées au Fonctionnement À La Sécurité

CECI EST UN APPAREIL DE CHAUFFAGE. N’ESSAYEZ PAS DE CHAUFFER

OU DE CUIRE DES ALIMENTS SUR CE RADIATEUR.

1. Recommandé pour l’utilisation avec le combustible de pétrole No.1-K. L’usine évaluée pour

l’utilisation avec le pétrole No.2-K, No. 1 ou le gazole de No. 2, No. 1 ou le fuel de No. 2

ou le Jet de JP8. Un combustible et ces combustibles peuvent être utilisés aussi. N’utilisez

jamais de l’essence, le pétrole égoutté des cas de fanatique, le naphte, du diluant pour

peintures, de l’alcool ou autres combustibles extrêmement inflammables.

2. Vérifiez attentivement si l’appareil de chauffage a subi des dommages. NE FAITES PAS

fonctionner un appareil endommagé.

3. NE MODIFIEZ PAS l’appareil de chauffage et ne le faites pas fonctionner s’il n’est plus

dans son état d’origine.

4. Convient pour une utilisation en extérieur ou à l’intérieur lorsque la ventilation est

adéquate. Ne jamais utiliser dans des zones normalement habitables. Ne pas utiliser

lorsqu’il est exposé aux intempéries.L’appareil ne doit pas être exposé aux intempéries.

5. Faites fonctionner l’appareil dans des endroits bien aérés en laissant une ouverture

d’au moins 0,19m² (2pi²) près du plancher et une autre d’au moins 0,19m² (2pi²)

près du plafond, qui donnent directement sur l’extérieur. Augmentez la dimension de

ces ouvertures tel qu’indiqué pour chaque appareil de chauffage additionnel.

6. Gardez tous les matériaux combustibles, comme le papier et le bois, à au moins

2,4m (8pi) de la sortie de l’appareil de chauffage et à 1,0m (3pi) du dessus et des

côtés de l’appareil ainsi que de la prise d’air. Placez l’appareil à 3m (10pi) des toiles

et des revêtements plastiques, et fixez-les afin d’empêcher tout battement.

7. Attention : En raison des températures élevées à la surface et à la sortie, les adultes

et les enfants doivent respecter les distances de sécurité pour éviter les brûlures et

l’inflammation des vêtements. Ne touchez pas à l’appareil. Gardez les enfants, les

vêtements et les produits combustibles à bonne distance de l’appareil.

8. Placez l’appareil de chauffage de façon à ce qu’il ne soit pas exposé directement à

l’eau.

9. Ne l’utilisez jamais dans des endroits qui servent normalement à l’habitation ni où

sont présents des enfants.

10. Utilisez uniquement sur des surfaces stables et de niveau. (Modèles DXH50KTHC &

DXH75KTHC – Voir l’avertissement au sujet des planchers de bois.)

11. N’utilisez pas l’appareil avec des conduits d’air. N’obstruez pas l’entrée et la sortie

d’air.

12. Utilisez uniquement avec l’alimentation électrique spécifiée. Le raccordement

électrique et la mise à la terre doivent être conformes au Code national de

l’électricité – ANSI/NFPA 70 (É.-U.) – et au Code canadien de l’électricité – CSA

C22.1 – partie 1 (Canada).

13. N’utilisez qu’avec une fiche ou une rallonge mise à la terre munie de trois broches.

14. Ne déplacez pas l’appareil, ne lui touchez pas et n’essayez pas d’en faire l’entretien

lorsqu’il est chaud.

15. Utilisez-le uniquement en conformité avec les codes, les ordonnances et les

exigences de la province, de l’État ou de la municipalité concernés.

Intructions de Fonctionnement

Déballage

1. Retirez l’appareil de chauffage de la boîte.

2. Enlevez tout le matériel de protection installé sur l’appareil pour le transport.

3. Vérifiez soigneusement tout dommage qu’aurait pu subir l’appareil de chauffage pendant

l’expédition. Si vous constatez quelque dommage, avisez immédiatement le fabricant au

855-805-5745.

ASSEMBLAGE (Pour modèles de 135k, 175k, et 210k BTU/hr uniquement, voir page 10)

Les roues et les poignées se trouvent dans la boîte avec les pièces servant à l’assemblage.

Les roues, l’essieu et les pièces servant à l’assemblage se trouvent dans un emballage. Les

outils nécessaires sont une clé de 5/16 po, une clé ou une clé à molette de 3/8 po et une pince

ordinaire.

1. Assemblez les roues sur le cadre de support tel qu’illustré.

2. Insérez l’une des goupilles fendues dans le trou situé au bout de l’essieu.

3. Insérez la grande rondelle sur l’essieu, à côté de la goupille fendue, puis la roue.

4. Insérez un séparateur sur l’essieu jusqu’à côté de la roue.

Page 18

5

Français

5. Insérez l’essieu partiellement assemblé dans le cadre de support des roues.

6. Insérez un séparateur sur l’essieu jusqu’à côté du support de roue.

7. Insérez la roue sur l’essieu, puis la grande rondelle et fixez-les en place avec l’autre goupille

fendue.

8. Installez les capuchons sur les grandes rondelles pour terminer l’assemblage des roues.

AVANT LE FONCTIONNEMENT

1. Vérifiez soigneusement tout dommage qu’aurait pu subir l’appareil de chauffage

pendant l’expédition. Si vous constatez des dommages, avisez immédiatement le

fabricant au 855-805-5745.

2. Respectez toutes les «Précautions».

3. Remplissez le réservoir de kérosène propre. Dans des conditions de froid intense,

il est possible que de la condensation se forme dans le réservoir. Il est donc

recommandé d’ajouter une cuillère à table de liquide antigivrant par 4 litres (1

gallon) de combustible. Utilisez au moins 8litres (2gallons) de combustible lors du

remplissage du réservoir. Assurez-vous que l’appareil de chauffage est de niveau

et que le réservoir ne déborde pas. Servez-vous d’un entonnoir ou d’un contenant

muni d’un long bec verseur.

IMPORTANT : Avant de remplir le réservoir la première fois ou après des

périodes d’entreposage prolongées, enlevez-en la condensation.

4. Placez l’appareil de chauffage à une distance sécuritaire des matériaux

combustibles. Les modèles MH50KR et MH75KTR ne sont pas conçus pour être

utilisés sur des planchers de bois ni d’autres matériaux combustibles. Lors de

son fonctionnement, l’appareil de chauffage doit reposer sur un matériau isolant

adéquat d’au moins 2,5cm (1po) d’épaisseur et dépassant l’appareil d’au moins

90cm (3pi) ou plus de tous les côtés.

DÉMARRAGE DE L’APPAREIL

DXH50KTHC

1. Branchez le câble d’alimentation dans une prise mise à la terre de 115V, 60 Hz, 1Ø.

DXH75KTHC, DXH135KTHC, DXH180KTHC, DXH210KTHC

1. Réglez le thermostat au minimum et assurez-vous que l’interrupteur est à«OFF ».

2. Branchez le cordon de l’appareil de chauffage dans une prise mise à la terre de 115

V, 60 Hz, 1 Ø.

3. Démarrez l’appareil de chauffage en mettant l’interrupteur à « ON » (Marche) (La

lumière s’allume à la position « ON »)

4. Réglez le thermostat à la température désirée. L’appareil de chauffage s’arrêtera et

redémarrera au besoin.

Pour tous les modèles:

• Lorsque la température est inférieure à -12 °C (10 °F), le démarrage sera

facilité si l’on met un doigt sur l’orice de ventilation de la vis de réglage de

pression jusqu’à ce que l’appareil de chauffage démarre.

ARRÊT DE L’APPAREIL

DXH50KTHC

1. Débranchez l’appareil.

DXH75KTHC, DXH135KTHC, DXH175KTHC, DXH210KTHC

1. Placez l’interrupteur à« OFF ». Pour un arrêt prolongé, débranchez l’appareil de

chauffage de sa source d’alimentation.

HEATER RESTART AFTER SAFETY SHUTDOWN

DXH50KTHC

Débranchez l’appareil, attendez cinq minutes puis rebranchez l’appareil.

DXH75KTHC, DXH135KTHC, DXH175KTHC, DXH210KTHC

Placez l’interrupteur à«OFF», attendez 5minutes puis démarrez l’appareil.

Entretien et Entreposage

AVERTISSEMENT: Pour éviter toute blessure, débranchez l’appareil de

chauffage de la prise murale avant d’en effectuer l’entretien.

Pour optimiser le fonctionnement et éviter les problèmes, effectuez régulièrement les

inspections, le nettoyage et l’entretien suivants.

RÉGLAGE DE PRESSION DE LA POMPE

En raison des variations de viscosité des combustibles et de l’usure normale des

pièces, il peut devenir nécessaire de régler la pression de la pompe.

Réglage pression vis

(située à l’arrière de l’appareil de chauffage)

JAUGE DE PRESSION

(non inclus sur DXH50KTHC ou

DXH75KTHC)

• Cet appareil est équipé d’un disjoncteur intégré à l’interrupteur

marche-arrêt. Si l’appareil ne démarre pas, placez l’interrupteur à«OFF »,

attendez 5minutes et placez-le à « ON ».

• CONDITIONS POUR UTILISER UNE RALLONGE ÉLECTRIQUE: pour une

rallonge jusqu’à 30,5m (100pi), conducteurs de calibre16; pour une rallonge de 30,5 à 61m (101-200pi), conducteurs de calibre14.

Page 19

Français

6

POUR RÉGLER LA PRESSION

1. Remplissez le réservoir.

2. Démarrez l’appareil.

3. Repérez la vis du régulateur de pression de combustible. Cette vis est située à l’arrière,

sous le couvercle du boîtier de filtre à air (à environ 2 po à partir de la gauche et 1 po à partir

du haut).

4. Retirer et le capuchon en caoutchouc sur la vis de réglage de la pression du carburant.

5. À l’aide d’un tournevis plat, serrez la vis pour augmenter la pression ou desserrez-la

pour réduire la pression. Les pressions nominales sont indiquées dans le tableau des

spécifications à la page3 du Guide d’utilisation et instructions de fonctionnement.

• dans le sens horaire

augmente la pression de la pompe

• dans le sens antihoraire

diminue la pression de la pompe

6. Pour une efficacité maximale, le cône avant de la chambre de combustion doit être rouge

cerise sans présenter de taches foncées, et la flamme ne doit pas se prolonger au-delà du

cône.

SYMPTÔMES DE RÉGLAGE DE PRESSION INCORRECT

Problème: L’appareil ne produit pas une flamme forte et homogène.

L’appareil émet de la fumée et éjecte du combustible brut.

Le cône avant ne devient pas rouge cerise.

Ajustement La pression est trop faible.

Serrez la vis de réglage pour augmenter la pression de la pompe.

Problème: La flamme dépasse l’extrémité du tube de sortie.

Ajustement: La pression est trop forte.

Desserrez la vis pour réduire la pression de la pompe.

Programme Quotidien

1. GÉNÉRAL. Faites une inspection visuelle générale de l’appareil de chauffage

pour déceler les pièces endommagées ou desserrées. Inspectez les boulons et

les écrous pour vous assurer que les vibrations et les manipulations brusques

ne les ont pas desserrés. Les pièces endommagées doivent être réparées ou

remplacées avant d’utiliser à nouveau l’appareil de chauffage. Vérifiez si l’appareil

fonctionne normalement (consultez la section «Réparation» pour une description

du fonctionnement normal).

2. FILTRES. Les filtres à air et à combustible doivent être propres pour assurer

l’équilibre du mélange air-combustible. À défaut de quoi, l’odeur augmentera et

l’appareil de chauffage démarrera difficilement. Ne faites pas fonctionner l’appareil

sans les filtres. Si nécessaire, nettoyez les filtres tel qu’il est décrit aux sections

«Programme 500 heures» et «Programme annuel»

Programme 500 Heures

1. FILTRE D’ADMISSION D’AIR. Enlevez le filtre et lavez-le à l’aide d’un détergent

doux. Séchez-le à fond et remettez-le en place. Ne huilez pas l’élément filtrant. Si

vous utilisez l’appareil dans un endroit contenant beaucoup de poussières et de

saletés, nettoyez le filtre aussi souvent que requis (aux 50 heures environ).

2. ENLÈVEMENT DE LA POUSSIÈRE. Nettoyez l’appareil de chauffage deux fois

par saison (plus souvent dans les endroits poussiéreux). Enlevez la poussière

accumulée sur le transformateur, le brûleur, le moteur et les pales du ventilateur à

l’aide d’un jet d’air comprimé. Essuyez les surfaces avec un chiffon sec et propre.

Inspectez ces endroits pour vous assurer que toute matière étrangère a été

enlevée, particulièrement autour du brûleur et de la zone de combustion.

3. CELLULE AU CADMIUM. Nettoyez la partie vitrée de la cellule au cadmium à

l’aide d’un chiffon doux et sec.

4. GICLEUR. L’accumulation de saleté de combustible et de carbone causée par

l’aube d’entrée obstruera éventuellement les conduits du gicleur et entraînera

une diminution du débit d’air et de combustible. La pression augmentera

graduellement, ce qui déséquilibrera le mélange air-combustible et produira un

surplus de fumée et d’odeur. Dans un tel cas, remplacez le gicleur.

5. RÉSERVOIR DE COMBUSTIBLE. Nettoyez-le deux fois par saison (au cours des

périodes d’utilisation intensive, nettoyez-le deux fois par mois). Rincez et vidangez

le réservoir à l’aide de mazout propre.

Programme Annuel

1. FILTRE DE SORTIE D’AIR. Enlevez le filtre de sortie d’air et frappez-en doucement

le côté sale sur un objet dur pour enlever les saletés. N’utilisez pas d’air comprimé

ni de liquide pour nettoyer le filtre. Replacez le filtre propre dans son réceptacle

dans la position où il était. Si le filtre paraît extrêmement sale, remplacez-le par un

autre du même type. En remettant le couvercle du filtre en place, assurez-vous

que le joint d’étanchéité est solidement en place et que les vis du couvercle sont

assez serrées pour empêcher des fuites d’air.

2. FILTRE À COMBUSTIBLE. Enlevez le filtre de la canalisation de combustible

et dirigez de l’air comprimé à travers le filtre dans le sens contraire du débit

du combustible. Veuillez porter des lunettes protectrices en utilisant de l’air

comprimé.

3. CANALISATIONS D’AIR ET DE COMBUSTIBLE. Si ces canalisations sont

enlevées au cours du nettoyage, assurez-vous de bien serrer les raccords avant

de faire fonctionner l’appareil.

Page 20

7

Français

Entreposage

Entreposez l’appareil de chauffage dans un endroit sec exempt de vapeurs et de

poussières.

À la fin de chaque saison, nettoyez l’appareil de chauffage tel qu’indiqué dans la

section ENTRETIEN. Rincez et vidangez le réservoir à l’aide de combustible propre. Le

fabricant recommande de remplir complètement le réservoir de combustible avant un

entreposage prolongé pour diminuer les risques de condensation.

Il est recommandé de stocké le kérosène uniquement dans des conteneurs portant la

mention «KÉROSÈNE».

Entretien

Un appareil de chauffage qui a été modifié ou qui ne fonctionne pas correctement

risque d’être une cause de dangers.

Lorsque l’appareil de chauffage fonctionne normalement:

* La flamme reste dans l’appareil de chauffage.

* La flamme est vraiment jaune.

* Il n’y a pas de forte odeur désagréable, pas de sensation de brûlure aux yeux, ni de

malaise physique général.

* Il n’y a pas de fumée ni de suie à l’intérieur ou à l’extérieur de l’appareil de chauffage.

* Il ne se produit pas d’arrêts imprévus ou inexpliqués de l’appareil.

DIAGNOSTIC D’ARRÊT DE SÉCURITÉ ET DÉPANNAGE

Circuit ouvert d’interrupteur de limite élevée

1. Assurez-vous que la fournaise soit refroidie, basculez l’interrupteur à la position « OFF »,

attendez 5 minutes et essayez de nouveau.

Des étincelles se produisent cherchant une amme, mais il n’y a aucun

fonctionnement du moteur ou bien un fonctionnement lent de ce dernier

1. Vérifiez le câblage au moteur (selon le schéma de câblage dans le manuel).

2. Assurez-vous que le bouchon de la jauge de pression soit en place et non endommagé.

3. Réglez la pression pour un bon fonctionnement de la fournaise selon le manuel.

4. Avec la fournaise débranchée de la source CA, tournez le ventilateur dans le sens des

aiguilles d’une montre pour vérifier que le moteur soit libre.

5. Enlevez le bâti du filtre d’air du moteur et inspectez le rotor de la pompe pour tout dommage.

Si endommagé, remplacez l’assemblage du rotor.

6. Si le câblage est correct, que le rotor de la pompe est correct, et que le moteur ne tourne

pas librement, remplacez le moteur ou l’assemblage du bloc d’alimentation.

7. Si le problème persiste, remplacez l’assemblage du contrôle de la flamme d’huile.

8. Vérifiez pour toute étincelle arquant de l’assemblage de l’électrode au cylindre de

combustion.

9. Vérifiez la cellule au sulfure de cadmium pour la continuité.

Aucune étincelle

1. Vérifiez la longueur et la jauge de la rallonge électrique pour un ampérage correcte. (Voir les

exigences à la page 5.)

2. Vérifiez le câblage pour l’allumeur (selon le schéma de câblage dans le manuel).

3. Vérifiez l’espace entre les sondes d’électrodes (2,3 à 3,0 mm).

4. Toujours aucune étincelle, remplacez l’assemblage de l’allumeur.

5. Remplacez l’assemblage du contrôle de la flamme d’huile.

Fonctionnement anormal du moteur - Surchauffes ou arrêts du moteur

1. Vitesse du moteur trop basse (Moteur doit fonctionner à 3 450 RPM, sauf le 50K à 1 550

RPM) - Remplacez le moteur.

2. Avec la fournaise débranchée de la source CA, tournez le ventilateur dans le sens des

aiguilles d’une montre pour vérifier que le moteur soit libre.

3. Enlevez le bâti du filtre d’air du moteur et inspectez le rotor de la pompe pour tout

dommage. Si endommagé, remplacez l’assemblage du rotor.

4. Si le câblage est correct, que le rotor de la pompe est correct, et que le moteur ne tourne

pas librement, remplacez le moteur ou l’assemblage du bloc d’alimentation.

5. Remplacez l’assemblage du contrôle de la flamme d’huile.

Incapable de détecter la amme

1. Vérifiez le câblage à la cellule au sulfure de cadmium (selon le schéma de câblage dans le

manuel).

2. Nettoyez la cellule photovoltaïque de la cellule au sulfure de cadmium.

a) Glissez la cellule au sulfure de cadmium hors du support de la cellule au sulfure de

cadmium.

b) Poussez la cellule photovoltaïque hors du bâti en caoutchouc noir de la cellule au

sulfure de cadmium en poussant sur les 2 fils pourpres.

c) Nettoyez la cellule photovoltaïque avec un chiffon doux et de l’alcool à friction.

d) Remettez la cellule photovoltaïque dans le bâti de la cellule au sulfure de cadmium et

installez de nouveau dans le support.

e) Testez la fournaise.

3. Si la fournaise ne fonctionne pas, remplacez la cellule au sulfure de cadmium.

4. Remplacez l’assemblage du contrôle de la flamme d’huile.

Échec du contrôle de la amme

1. Vérifiez le câblage dans la fournaise (selon le schéma de câblage dans le manuel).

2. Remplacez l’assemblage du contrôle de la flamme d’huile.

Page 21

Français

8

1

2

3

4

5

6

7

9

10

11

13

14

15

16

17

18

19

20

21

24

25

26

53

28

29

30

31

32

34

35

36

37

38

39

40

41

42

43

44

45

46

47

51

52

8

12

22

23

33

48

49

50

27

Filter Kit

51

52

Page 22

9

Français

# 50K 75K 135K 175K 210K Description

1 21036 21036 21036 21036 21036 Cordon d’alimentation

2 26958 26970 26974 27112 27112 Réservoir de combustible

3 **** 21883 21884 21885 21886 Bouclier thermique

4 26960 26967 26975 26975 26975 Boîtier d’alimentation

5 21686 24343 24346 24346 24346

Canalisation du combustible

6 21835 21836 21837 21837 21837 Grille

7 24011 24011 24011 24011 24011

Support de cellule au cadmium

8 28779 28779 28792 28793 28793 Filtre à combustible

9 23449 23449 23449 23449 23449 Gaine du cordon moteur

10 26957 27144 26973 27111 27111 Coque inférieure

11 21844 27143 26972 27110 27110

Coque supérieure, brûleur

12 21854 26966 26971 27109 27109

Coque supérieure, inspection

13 21864 21864 21865 21865 21865 Support de moteur

14 **** 28788 28735 28735 28735

Condensateur de démarrage

15 23725 23725 24345 24345 24345 Canalisation d’air

16 26225 26225 26225 26225 26225 Bague pression

17 26962 21794 26901 22105 22105 Commande à maximum

18 F226831 F226831 F226831 F226831 F226831 Ensemble de rotor

19 **** 26898 26898 26898 26898 Réceptacle, 110V

20 **** 22104 22104 22104 22104 Couvercle de réceptacle

21 26833 26833 26833 26833 26833 Cylindre de pompe à air

22 21810 21810 21810 21810 21810 Boîtier de sortie

23 21812 21812 21812 21812 21812 Boîtier d’admission

24 **** **** 22257 22257 22257 Tête de brûleur

25 F221887 F221887 F221887 F221887 F221887 Ensemble de rotor

26 21814 21814 21814 21814 21814 Filtre de sortie

27 21815 21815 21815 21815 21815 Filtre d’entrée

28 F266842 F266842 F266842 F266842 F266842

Ensemble de réglage de pompe

29 21866 21866 21867 21867 21867 Commande de flamme

30 21816 21816 21816 21816 21816

Support de commande

de flamme

31 F226865 F226865 F226865 F226865 F226865 Capteur de flamme

32 21882 21868 21869 21870 21871

Cyl. chambre combustion

# 50K 75K 135K 175K 210K Description

33 26959 26959 26959 26959 26959 Bouchon de réservoir

34 26910 26910 26910 26910 26910 Joint de bouchon

35 27339 21817 21818 21818 21818 Moteur

36 27790 27790 28739 28739 28739 Adaptateur gicleur

37 27421 28740 26885 26866 26866 Ventilateur

38 22142 22142 22142 22142 22142 Allumeur

39

F227416 F221878 F221879 F221889 F221891

Embout entrée d’air

40 26223 26223 26223 26223 26223 Bague réd. tension

41

F221857 F221857 F221857 F221857 F221857

Électrode

42 21820 21820 21820 21820 21820 Couv. isolé d’électrode

43 21821 21821 21821 21821 21821 Adaptateur à barbelures

44 **** 21822 21822 21822 21822 Bouton thermostat

45 **** 21734 21734 21734 21734 Thermostat

46 28785 28785 28785 28785 28785 Interrupteur

47 **** 28791 28778 22185 22185 Jauge à combustible

48 26964 21888 27107 27116 27116 Panneau de commande

49 26965 26968 27108 27117 27117

Panneau de comm.,

arrière

50 28786 28786 28786 28786 28786 Manomètre

51 40801 40801 **** **** **** Poignée

52 21813 21813 21813 21813 21813 Joint de filtre de sortie

* 24171 24171 **** **** **** Plaque de gicleur

* 26227 26227 26227 Bague pression

* 27429 27429 27429 27429 27429 Bague de retenue ext.

* **** 22146 22146 22146 22146

Support de thermostat

de parenthèse

* **** 26070 26070 26070 26070 Boucle de serrage

* 28745 28745 **** **** **** Bague filtre combustible

REPLACEMENT PARTS LIST

* Non représenté sur la figure

**** Ne s’applique pas au modèle

Page 23

Français

10

* Not shown in drawing

Assemblage de la poignée et des roues – Modèles

DXH135KTHC, DXH175KTHC & DXH210KTHC

seulement.

Ref. Item # Item # Item # Description

135K 175k 210K

1 40981 40981 40981 Roues de 10 po

2 27127 27129 27129 Poignée supérieure

* 27121 27121 27121 Poignée inférieure, droite

3 22173 22173 22173 Poignée inférieure, gauche

* 27105 27105 27105 Support de patte, droit

4 27105 27105 27105 Support de patte, gauche

5 27104 27132 27133 Béquille

6 27128 27130 27131 Poignée avant avec essieu

7 28749 28749 28749 Grande rondelle

8 28750 28750 28750 Goupille fendue

9 28751 28751 28751 Chapeau de moyeu

10 28754 28754 28754 Support de rallonge électr.

11 21897 21897 21897 Séparateur

12 22168 22184 22184 Axe

* 28787 28787 28787 Ensemble de quincaillerie

PARTS LIST

1

2

3

4

6

5

9

7

8

10

11

12

Page 24

11

Français

SCHÉMA DE CÂBLAGE

DXH50KTHC

DXH75KTHC

La liste des pièces et le

schéma de câblage présentent

l’appareil de chauffage tel qu’il

a été construit. N’utilisez pas

un appareil de chauffage qui

diffère de ce qui est illustré.

Le rendement de l’appareil de

chauffage dépend du réglage de

la pression d’air. Si vous avez un

doute au sujet de la pression d’air,

faites-la vérifier.

Si l’appareil de chauffage ne

fonctionne pas correctement, il

doit être réparé uniquement par

un technicien qualifié.

COM1

I2

I1

M2

M1

L

N

1

3

2

H2

H1

VRT AWG 18

JAUNE AWG 18

INTERRUPTEUR COM

-

MANDE MAX.

JAUNE AWG 18

BLEU AWG 18

MODÈLES 75KT, 125KT, 175KT ET

210KT UNIQUEMENT

THERMOSTAT

VIOLET AWG 18

VIOLET AWG 18

NOIR AWG 17

VRT AWG 18

TRANSFORMATEUR D’AL

-

LUMAGE

NOIR AWG 17

ÉLECTRODE

RGE AWG 18

RGE AWG 18

CELLULE AU

CADMIUM

SCHÉMA DE LA COMMANDE

DE FLAMME

(la position des connexions peut

différer sur le circuit imprimé)

INTERRUPTEUR

MARCHE-ARRÊT

NOIR AWG 18

BLC AWG 18

VRT AWG 18

MODÈLES 125KT,175KT

ET 210KT UNIQUEMENT

PRISE C.A.

ORG AWG 18

CONDENSATEUR

DU MOTEUR

ORG AWG 18

ROSE AWG 18

ROSE AWG 18

MOTEUR

CORDON D’ALIMEN

-

TATION

Page 25

Français

12

La liste des pièces et le schéma de câblage présentent l’appareil de chauffage tel qu’il a été construit. N’utilisez pas un appareil de chauffage qui diffère de ce qui est

illustré. Le rendement de l’appareil de chauffage dépend du réglage de la pression d’air. Si vous avez un doute au sujet de la pression d’air, faites-la vérifier.

Si l’appareil de chauffage ne fonctionne pas correctement, il doit être réparé uniquement par un technicien qualifié.

DXH135KTHC

DXH175KTHC

DXH210KTHC

BLC AWG 18

NOIR AWG 18

2

3

1

1

2

3

4

5

6

7

8

9

10

11 12

VRT AWG 18

NOIR AWG 18

BLC AWG 18

CORDON D’ALI

-

MENTATION

INTERRUPTEUR

MARCHE-ARRÊT

JAUNE AWG 18

JAUNE AWG 18

THERMOSTAT

VIOLET AWG 18

VIOLET AWG 18

CELLULE AU

CADMIUM

VRT AWG 18

PRISE C.A.

ORG AWG 18

CONDENSATEUR

DU MOTEUR

ORG AWG 18

ROSE AWG 18

ROSE AWG 18

MOTEUR

RGE AWG 18

RGE AWG 18

TRANSFORMATEUR D’AL

-

LUMAGE

NOIR AWG 17

NOIR AWG 17

ÉLECTRODE

COMMUTATEUR

LIMITE HAUTE

JAUNE AWG 18

JAUNE AWG 18

VRT AWG 18

NOIR AWG 24

RGE AWG 24

CARTE DE CIRCUIT

IMPRIMÉ

LED ROUGE

SCHÉMA DE CÂBLAGE

Page 26

13

Français

GUIDE DE’UTILISATION

Appareil de chauffage à air pulsé au Kérosène

DXH50KTHC

DXH75KTHC

DXH135KTHC

DXH175KTHC

DXH210KTHC

Avertissement

UTILISER UNIQUEMENT LES PIÈCES DE RECHANGE D’ORIGINE

DU FABRICANT. L’UTILISATION D’AUTRES PIÈCES PEUT CAUSER

DES BLESSURES OU LA MORT. LES PIÈCES DE RECHANGE SONT

DISPONIBLES SEULEMENT DIRECTEMENT DU FABRICANT ET ELLES

DOIVENT ÊTRE INSTALLÉES PAR UNE AGENCE DE SERVICE QUALIFIÉE.

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any Dewalt® local dealer or

direct from the factory

INFORMATION POUR LA COMMANDE DE PIÈCES:

APPROVISIONNEMENT : Il est possible d’acheter les accessoires auprès de

tout détaillant local DewaltMD ou alternativement, directement de l’usine

POUR DE L’INFORMATION CONCERNANT LE SERVICE:

Appeler sans frais au 855-805-5745

www.dewalt.com

Nos heures d’ouverture sont de 8h00 à 17h00, H.N.E, du lundi au vendredi.

Veuillez inclure votre numéro de modèle, la date d’achat, et une description

du problème dans toutes vos communications.

GARANTIE LIMITÉE

DeWalt® garantit que ses radiateurs et ses accessoires sont exempts de tout

défauts de matériaux et de fabrication pour une période de deux (2) ans à

compter de la date achat.

DeWalt® réparera ou remplacera ce produit sans les dépenses, si elles sont

jugées défectueuses au cours de cette période de deux (2) ans, et qu’il est retourné, aux frais du client, avec une copie de la preuve d’achat chez DeWalt®

pendant la période de garantie.

UL733, CSA B140.8, CSA B140.9.3

DEWALTMD, GUARANTEED TOUGHMD ainsi

que le schème jaune et noir sont des marques

déposées de DEWALT Industrial Tool Co., utilisés

sous licence. © DEWALT, 2017. EGI/Enerco Group

Inc. Sous licence de Dewalt Industrial Tool Co

Page 27

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter. Llámenos si tiene alguna pregunta o comentario.

855-805-5745 • www.dewalt.com

INSTRUCTION MANUAL

GUIDE DE’UTILISATION

MANUAL DE INSTRUCCIONES

SAVE THESE INSTRUCTIONS

CONSERVEZ CES INSTRUCTIONS

GUARDE ESTAS INSTRUCCIONES

DXH50KTHC, DXH75KTHC, DXH135KTHC, DXH175KTHC, DXH210KTHC

Kerosene Forced-aid Heater

Appareil de chauffage à air pulsé au Kérosène

Calentador Caldeo a aire forzado a Kerosene

READ INSTRUCTIONS CAREFULLY: Read

and follow all instructions. Place instructions

in a safe place for future reference. Do

not allow anyone who has not read these

instructions to assemble, adjust or operate

the heater.

VEUILLEZ LIRE ATTENTIVEMENT LES INSTRUCTIONS :

Lisez et observez toutes les instructions. Conservez

ces instructions dans un endroit sécuritaire pour vous

y référer ultérieurement. Interdisez à quiconque n’ayant

pas lu les présentes directives d’assembler, de régler

ou de faire fonctionner cette fournaise.

LEA CUIDADOSAMENTE LAS INSTRUCCIONES:

Lea y siga todas las instrucciones. Conserve

estas instrucciones en un lugar seguro para futura

referencia. No permita que nadie que no haya

leído estas instrucciones arme, ajuste o use el

calentador.

Page 28

Español

2

ADVERTENCIA: NO APTO PARA USAR EN EL HOGAR NI EN CASAS

RODANTES.

ADVERTENCIA GENERAL DE PELIGRO:

EL NO CUMPLIR CON LAS PRECAUCIONES E INSTRUCCIONES QUE VIENEN

CON ESTE CALENTADOR PUEDE CAUSAR LA MUERTE, LESIONES GRAVES Y

PÉRDIDAS Y DAÑOS MATERIALES DERIVADOS DEL PELIGRO DE INCENDIO,

EXPLOSIÓN, QUEMADURAS, ASFIXIA, ENVENENAMIENTO CON MONÓXIDO DE

CARBONO, Y/O DESCARGAS ELÉCTRICAS.

SOLO LAS PERSONAS QUE ENTIENDAN Y PUEDAN SEGUIR LAS

INSTRUCCIONES DEBEN USAR O MANTENER ESTE CALENTADOR.

SI NECESITA AYUDA O INFORMACIÓN ACERCA DEL CALENTADOR, COMO UN

MANUAL DE INSTRUCCIONES, ETIQUETAS, ETC., PÓNGASE EN CONTACTO

CON EL FABRICANTE.

ADVERTENCIA:

PELIGRO DE INCENDIO, QUEMADURAS, INHALACIÓN Y

EXPLOSIÓN. MANTENGA LOS COMBUSTIBLES SÓLIDOS, TALES COMO MATERIALES DE CONSTRUCCIÓN, PAPEL O CARTÓN, A UNA DISTANCIA SEGURA

DEL CALENTADOR. COMO SE RECOMIENDA EN LAS INSTRUCCIONES, NUNCA

USE EL CALENTADOR EN ESPACIOS QUE CONTENGAN O PODRÍAN CONTENER

COMBUSTIBLES VOLÁTILES O GASEOSOS, NI PRODUCTOS COMO GASOLINA,

SOLVENTES, DILUYENTES DE PINTURA, PARTÍCULAS DE POLVO O PRODUCTOS

QUÍMICOS DESCONOCIDOS.

ADVERTENCIA: EL MONÓXIDO DE CARBONO PUEDE CAUSARLE

LA MUERTE EL USO DE CALENTADORES PORTÁTILES EN UN LUGAR CERRA-

DO PUEDE PRODUCIR MORTAL MONÓXIDO DE CARBONO.

Este es un calentador portátil a gas sin fuente propia de ventilación. Utiliza

el aire (oxígeno) del área en la cual se emplea. Debe suministrarse el aire

necesario para la ventilación y la combustión. Ver página 3.

WARNINGS

ADVERTENCIA:

• NO UTILICE GASOLINA, NAFTA NI COMBUSTIBLES VOLÁTILES.

• APAGUE EL CALENTADOR ANTES DE AGREGAR COMBUSTIBLES.

• SIEMPRE LLÉNELO EN EL EXTERIOR LEJOS DE LLAMAS EXPUESTAS.

• NO UTILICE UNA FUENTE DE COMBUSTIBLE EXTERNA.

• NO UTILICE EL CALENTADOR DONDE HAYA LÍQUIDOS O VAPORES

INFLAMABLES.

• NO ENCIENDA EL CALENTADOR CUANDO LA CÁMARA ESTÉ CALIENTE.

• NO ENCIENDA EL CALENTADOR CUANDO SE HAYA ACUMULADO

COMBUSTIBLE EN EXCESO EN LA CÁMARA.

• NO COLOQUE UTENSILIOS DE COCINA SOBRE EL CALENTADOR.

• ENCHUFE EL CABLE ELÉCTRICO EN UN TOMACORRIENTE DE TRES

CLAVIJAS CORRECTAMENTE CONECTADO A TIERRA. EL USO DE

CALENTADORES PORTÁTILES EN UN LUGAR CERRADO PUEDE

PRODUCIR MORTAL MONÓXIDO DE CARBONO.

ADVERTENCIA: UNA DE LAS SUSTANCIAS QUE SE DESPRENDE EN LA

COMBUSTIÓN AL USAR ESTE EQUIPO ES EL MONÓXIDO DE CARBONO, UN

PRODUCTO QUÍMICO QUE DE ACUERDO CON EL ESTADO DE CALIFORNIA

PRODUCE CÁNCER Y DEFECTOS DE NACIMIENTO (U OTROS DAÑOS REPRODUCTIVOS). Para obtener más información, visite www.P65Warnings.ca.gov

Deniciones: Indicaciones de seguridad

Las siguientes definiciones describen el nivel de severidad para cada una de estas señales. Lea el manual y preste atención a estos símbolos.

PELIGRO: Indica una situación inminente de peligro, la que si no se evita, causará heridas graves o la muerte.

ADVERTENCIA: Indica una situación potencial de peligro, la que si no se evita, podría causar heridas graves o la muerte.

CUIDADO: Indica una situación potencial de peligro, la que si no se evita, podría resultar en heridas menores o moderadas.

AVISO: Indica una práctica no relacionada con heridas personales que, si no se evita, podría causar daños materiales.

Page 29

3

Español

CONTENTS

ADVERTENCIAS 2

ESPECIFICACIONES DEL CALENTADOR 3

PRECAUCIONES DE OPERACIÓN Y SEGURIDAD 4

ILUMINACIÓN Y INSTRUCCIONES DE OPERACIÓN 5

MANTENIMIENTO, ALMACENAMIENTO Y REPARACIÓN 5

LISTA DE PIEZAS 8

DIAGRAMA DE CABLEADO 11

Modelo DXH50KTHC DXH75KTHC DXH135KTHC DXH175KTHC DXH210KTHC

Tasa de combustión: 50,000 BTU/hr (14.7 kW) 75,000 BTU/hr (22 kW) 125,000 BTU/hr (37 kW) 175,000 BTU/hr (51 kW) 210,000 BTU/hr (61.5 kW)

Tasa de combustible: 0.37 gal/hr (1.5 L/hr) 0.55 gal/hr (2.1 L/hr) 0.96 gal/hr (3.5 L/hr) 1.3 gal/hr (5.0 L/hr) 1.6 gal/hr (6.0 L/hr)

Entrada de corriente:

115 V, 60 HZ, 1 Ø, 3.5 A 1115 V, 60 HZ, 1 Ø, 4 A 115 V, 60 HZ, 1 Ø, 5.5 A 115 V, 60 HZ, 1 Ø, 5.5 A 115 V, 60 HZ, 1 Ø, 5.5 A

Mín. Voltaje de operación:

110 V 110 V 110 V 110 V 110 V

Configuración de la presión:

3.5 psig (24 kPa) 4.2 psig (24 kPa) 5.1 psig (38 kPa) 6.8 psig (40 kPa) 8.2 psig (58.6 kPa)

Máx. Temperatura de salida:

1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C) 1450 °F (787 °C)

Capacidad del tanque de

combustible:

4 gallons (15.1 L) 6 gallons (22.7 L) 8.45 gallons (32 L) 13.5 gallons (51 L) 13.5 gallons (51 L)

Ignición Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous Direct Spark, Continuous

Generador de chispas: Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma Igniter 13 kV, 10 ma

Control de seguridad

primario:

Solid State Control Solid State Control Solid State Control Solid State Control Solid State Control

Certificación

Especicaciones

ADVERTENCIA: si no se siguen al pie de la letra las instrucciones

de este manual, podría producirse un incendio o una explosión

que provocaría daños materiales, lesiones o muertes.

- No almacene ni utilice gasolina ni ningún otro vapor o líquido inflamable cerca

de este o de cualquier otro artefacto.

- El mantenimiento debe realizarlo una agencia de servicio calificada.

DXH50KTHC Y DXH75KTHC ADVERTENCIA

No es adecuado para usar sobre pisos de madera ni sobre otros materiales

combustibles. Cuando usa el calentador debe colocarlo sobre un material

aislante adecuado de al menos 1 pulgada de espesor y que sobresalga 3 pies

o más del calentador en todas las direcciones.

CUIDADO: certicación por CSA para uso únicamente con el combustible a base de kerosene n.° 1-K.