Page 1

DWV902L

www .

.eu

DWV902M

Page 2

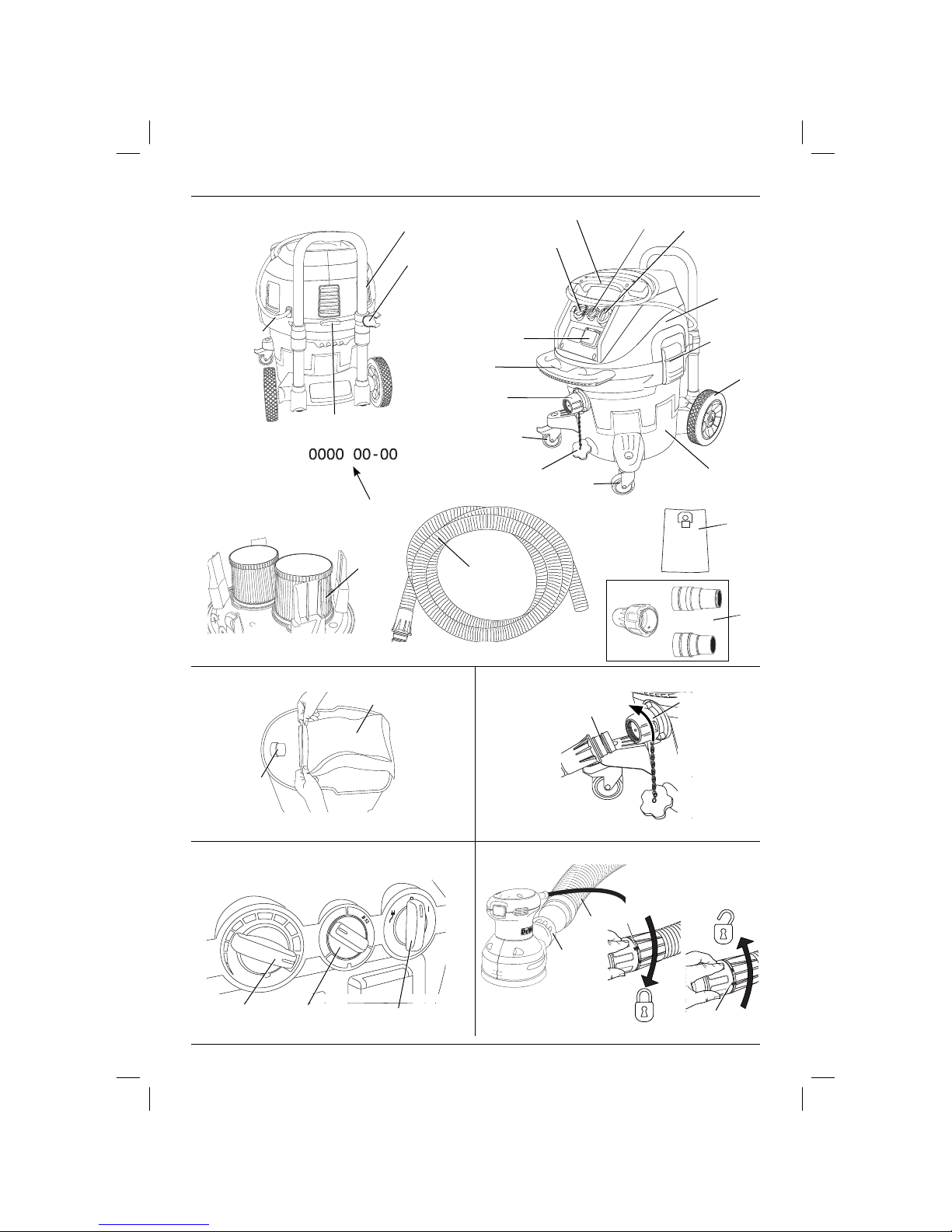

Figure 1

r

a

p

o

n

k

c

Figure 2

b

m

l

d

e

j

q

h

s

f

h

bb

t

i

g

u

Figure 3

t

g

j

j

Figure 4

n

p

Figure 5

v

Ø 20

g

w

o

v

1

Page 3

Figure 6 Figure 7

x

Figure 8 Figure 9

r

q

y

i

Figure 10 Figure 11

z

aa

2

b

s

j

Page 4

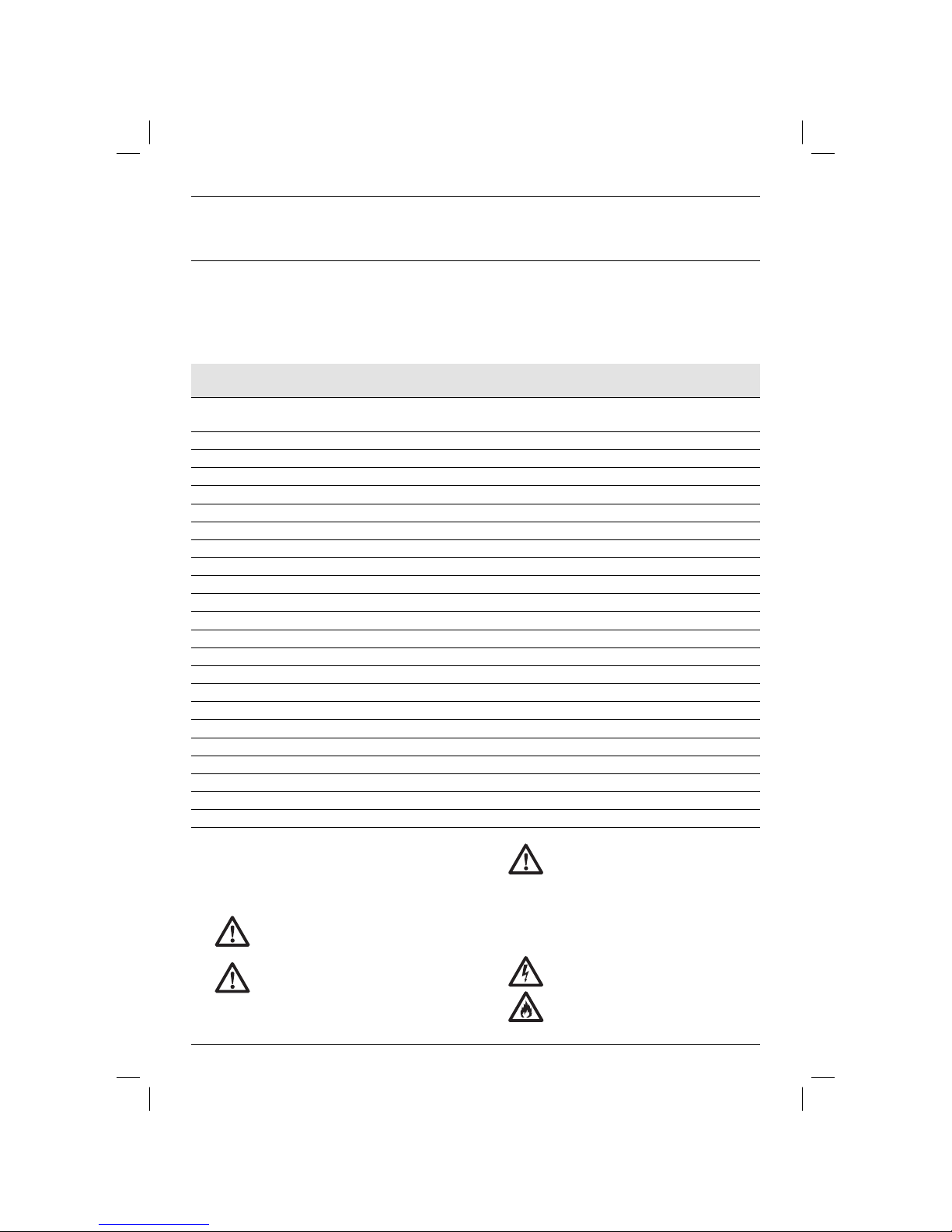

ENGLISH

HEAVY-DUTY CONSTRUCTION DUST EXTRACTOR

DWV902L, DWV902M

Congratulations!

You have chosen a DEWALT product. Years of experience, thorough product development and innovation

make DEWALT one of the most reliable partners for professional power tool users.

Technical Data

DWV902L DWV902L DWV902M DWV902M

QS/GB LX QS/GB LX

Voltage V 230 – 230 –

U.K. & Ireland V 230 115 230 115

Type 1 1 1 1

Rated power W 1400 1400 1400 1400

Max power W 3600 1840 3600 1840

Power, normal operation (EN 60335-2-69) W 1200 1065 1200 1065

Frequency Hz 50 50 50 50

Protective class IPX4 IPX4 IPX4 IPX4

Container capacity l 38 38 38 38

Filling quantity (liquid) l 18.4 18.4 18.4 18.4

Flow rate (max at blower) l/s 68 64 68 64

Negative pressure (max at blower) kPa 21 20 21 20

Flow rate (per EN 60335-2-69) l/s 32.6 31.3 32.6 31.3

Negative pressure (per EN 60335-2-69) kPa 18.6 16.8 18.6 16.8

Filter surface m² 0.4 0.4 0.4 0.4

Power connection data of power tool W 2200 440 2200 440

Hose length m 4.1 4.1 4.1 4.1

Hose diameter mm 32 32 32 32

Weight kg 15 15 15 15

LPA (sound pressure) dB(A)

KPA (sound pressure uncertainty) dB(A)

LWA (sound power) dB(A)

KWA (sound power uncertainty) dB(A)

73 73 73 73

3 3 3 3

87 87 87 87

3 3 3 3

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

24

CAUTION: Indicates a potentially

NOTICE: Indicates a practice not

Denotes risk of fire.

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

related to personal injury which, if

not avoided, may result in property

damage.

Denotes risk of electric shock.

Page 5

ENGLISH

Important Safety Instructions

EC-Declaration of Conformity

MACHINERY DIRECTIVE

DWV902L, DWV902M

DEWALT declares that these products described

under Technical Data are in compliance with:

2006/42/EC, EN 60335-2-69.

These products also comply with Directive

2004/108/EC and 2011/65/EU. For more

information, please contact DEWALT at the following

address or refer to the back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

DEWALT.

Horst Grossmann

Vice President Engineering and

Product Development

DEWALT, Richard-Klinger-Strasse 11,

D-65510, Idstein, Germany

13.06.2012

WARNING: To reduce the risk of injury,

Important Safety Instructions

WARNING! Read all safety warnings

SAVE ALL WARNINGS AND INSTRUCTIONS

BEFORE USING THIS APPLIANCE, READ AND FOLLOW ALL

INSTRUCTIONS.

WARNING: Operators shall be

WARNING: To reduce the risk of

• Before use, operators shall be provided with

information, instruction and training for the

use of the machine and the substances for

which it is to be used, including the safe

read the instruction manual.

and all instructions. Failure to follow

the warnings and instructions may result

in electric shock, fire and/or serious

injury.

FOR FUTURE REFERENCE

adequately instructed on the use of

these machines.

electric shock. Do not expose to rain.

Store indoors.

method of removal and disposal of the

material collected.

• Operators should observe any safety

regulations appropriate to the materials being

handled.

• Do not leave the appliance when it is

connected to a power source. Unplug it from

outlet when not in use and before servicing.

• Do not allow the appliance to be used as a

toy. Pay close attention when the appliance is

used by or near children.

• Use this appliance ONLY as described in the

manual. Use only D

attachments.

• Do not use this appliance with a damaged

cord or plug. If the appliance is not working

correctly, or if it has been dropped,

damaged, left outdoors, or dropped in water,

return it to a service center.

• Do not pull or carry this appliance by the

cord, use the cord as a handle, close a door

on the cord, or pull the cord around sharp

edges or corners. Do not run the appliance

over the cord. Keep cord away from heated

surfaces.

• Do not unplug this appliance by pulling on

the cord. To unplug, grasp the plug, not the

cord.

• Do not handle the plug or appliance with wet

hands.

• Do not put any objects into the openings of

the appliance. Do not use the appliance with

any opening blocked; keep free of dust, lint,

hair and anything else that may reduce air

flow.

• Keep hair, loose clothing, fingers, and all

body parts away from the openings and

moving parts.

• Turn off all controls before unplugging

appliance.

• Use extra care when cleaning on stairs.

• Do not use the appliance to pick up

flammable or combustible liquids, such as

gasoline, or use in areas where flammable or

combustible liquids are present.

• Static shocks are possible in dry areas or

when the relative humidity of the air is low.

This is only temporary and does not affect

the use of the vacuum. To reduce the

frequency of static shocks, add moisture to

the air with a console, installed humidifier or

use DWV9316-XJ non-static hose accessory.

• To avoid spontaneous combustion, empty

canister after each use.

EWALT recommended

SAVE THESE INSTRUCTIONS

25

Page 6

ENGLISH

Additional Safety Rules

• Do not pick up anything that is burning or

smoking, such as cigarettes, matches, or hot

ashes.

• Do not use to vacuum combustible explosive

materials, such as coal, grain, or other finely

divided combustible material.

• Do not use to vacuum hazardous, toxic or

carcinogenic materials, such as asbestos or

pesticide.

• Never pick up explosive liquids (e.g. gasoline,

diesel fuel, heating oil, paint thinner, etc.),

acids or solvents.

• Do not use vacuum without filters in place,

except as described under Wet Pickup

Applications.

• Some wood contains preservatives which

can be toxic. Take extra care to prevent

inhalation and skin contact when working

with these materials. Request and follow any

safety information available from your material

supplier.

• Do not use vacuum as a step ladder.

• Do not place heavy objects on vacuum.

Markings on Dust Extractor

The following pictograms are shown on the

appliance:

Read instruction manual before use.

WARNING: This appliance contains

harmful dust. The emptying and

maintenance, including the removal of

the dust bag, may only be executed

by trained personnel wearing suitable

protection equipment. Do not switch on

until the complete filter system has been

installed.

Class L dust extractors are suitable to extract dry,

non-combustable dusts with workpace limit values

of >1mg/m³.

Class M dust extractors are suitable to extract dry,

non-combustable dusts with workpace limit values

of ≥ 0.1 mg/m³.

DATE CODE POSITION (FIG. 1)

The date code (bb), which also includes the year of

manufacture, is printed into the housing.

Example:

2012 XX XX

Year of Manufacture

Package Contents

The package contains:

1 Dust extractor

1 Hose

1 DWV9210-XJ connector kit

2 Filters

1 Instruction manual

1 Exploded drawing

• Check for damage to the dust extractor, parts

or accessories which may have occurred

during transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Description (fi g. 1)

WARNING: Never modify the power

a. Top handle/cord wrap

b. Power cord

c. Vacuum head

d. Canister latch

e. Wheel

f. Canister

g. Suction hose

h. Casters (one equipped with parking brake)

i. Filters

j. Twist-lock hose inlet

k. Hose clip

l. Front handle

m. Outlet for power tools

n. Variable suction dial

o. On/off/tool control switch

p. Flow alarm adjustment (Class M models only)

q. Telescoping handle release button

r. Telescoping handle

s. Inlet plug (Class M models only)

t. Bag

appliance or any part of it. Damage or

personal injury could result.

26

Page 7

ENGLISH

u. DWV9210-XJ connector kit (includes DWV9000,

DWV9120, DWV9130)

ANTI-STATIC HOSE OPTION

The DWV902L and DWV902M are each equipped

with an anti-static grounding system. An anti-static

hose must be purchased at extra cost from your

authorised service center. This hose (DWV9316-XJ)

fits into the dust extractor system the same way as

the standard hose. To contact your seller or check

the location of your nearest authorised D

repair agent in the DEWALT catalogue or contact

your DEWALT office at the address indicated in this

manual.

INTENDED USE

These vacuums are used for fine particulate pick-up,

like wallboard, concrete or surface dust.

DWV902L

This appliance can be used as industrial vacuum

cleaner and dust extractor for mobile operations to

take up all types of dry, non-combustible dusts up

to dust Class L with limit values for occupational

exposure greater than 1 mg/m³.

DWV902M

This appliance can be used as industrial vacuum

cleaner and dust extractor for mobile operations to

take up all types of dry, non-combustible dusts up

to dust Class M with limit values for occupational

exposure greater than or equal to 0.1 mg/m³.

DO NOT use in rain or in presence of flammable

liquids or gases.

These heavy-duty vacuums are for professional

use. DO NOT let children come into contact

with this appliance. Supervision is required when

inexperienced operators use this appliance.

DO NOT use the dust extractor for combustible

dust.

DO NOT use the dust extractor in explosive

atmospheres.

NOTE: This appliance is suited for the commercial

use, e.g. in hotels, schools, hospitals, factories,

shops, offices, rental companies, and on

construction sites.

• This product is not intended for use by persons

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

EWALT

Electrical Safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

WARNING: 115 V units have to

If the supply cord is damaged, it must be replaced

by D

prepared cord which is available through the

DEWALT service organisation.

be operated via a fail-safe isolating

transformer with an earth screen

between the primary and secondary

winding.

EWALT service organisation by a specially

Mains Plug Replacement

(U.K. & Ireland Only)

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

• Connect the brown lead to the live terminal in

the plug.

• Connect the blue lead to the neutral terminal.

WARNING: No connection is to be

Follow the fitting instructions supplied with good

quality plugs. Recommended fuse: 13 A.

made to the earth terminal.

Using an Extension Cable

If an extension cable is required, use an approved

3–core extension cable suitable for the power

input of this appliance (see Technical Data).The

minimum conductor size is 1.5 mm2; the maximum

length is 30 m.

When using a cable reel, always unwind the cable

completely.

ASSEMBLY AND ADJUSTMENTS

(FIG. 1–3)

WARNING: To reduce the risk

of injury, turn appliance off and

disconnect appliance from power

source before installing and

removing accessories, before

adjusting or changing set-ups or

when making repairs. An accidental

start-up can cause injury.

27

Page 8

ENGLISH

WARNING: The filters (i) must always

1. If optional paper or fleece bag (t) is to be used,

NOTE: Be careful not to tear the bag. Place

2. Place the vacuum head (c) onto the canister

3. Insert end of hose (g) into twist-lock hose inlet (j)

be in place while vacuuming, except

as described under Wet Pick Up

Applications under Operation. When

vacuuming fine dust, you may also use

an additional paper bag or fleece bag to

make emptying the canister easier.

WARNING: Dust collection bags must

be used for dust Class M.

install as shown in figure 2.

bag securely onto inlet (j) to provide a tight seal

for maximum dust collection performance.

and secure it by closing the canister latches (d).

and rotate counterclockwise to lock in place.

OPERATION

Instructions for Use (fi g. 1, 4)

WARNING: Always observe the safety

1. Plug the power cord into an appropriate outlet.

2. Turn the on/off/tool control switch (o) to the ON

3. Set the variable suction dial (n) to the desired

NOTE: This setting also controls the level of

4. Follow the direction under Connecting to

FLOW ALARM ADJUSTMENT (FIG. 4)

Class M models only

Adjust the flow alarm adjustment control (p) to

the correct hose (or tube) inside diameter size or

accessory diameter referring to the largest section.

The chosen diameter of the adjustment control must

instructions and applicable regulations.

WARNING: To reduce the risk

of injury, turn appliance off and

disconnect appliance from power

source before installing and

removing accessories, before

adjusting or changing set-ups or

when making repairs. An accidental

start-up can cause injury.

position ( ).

position. This feature allows the user to control

the vacuum's power, suction and noise.

suction. This is very useful in applications where

the vacuum creates unacceptable levels of drag

to the work piece.

Power Tools to connect to the power tool to

be used.

be equal or bigger as the largest diameter of the

used hose/tube/ accessories. The hose supplied is

32mm inside diameter. An acoustic alarm will sound

if the flow rate falls below 20 m/s. The system has a

time delay to reduce unintended alarms.

CONNECTING TO POWER TOOLS (FIG. 1, 4, 5)

WARNING: Only use the outlet (m) for

1. Plug the vacuum power cord into an

2. Plug the power tool into the outlet (m).

NOTE: See Power connection data of

3. Turn on/off/tool control switch (o) to the

NOTE: The vacuum cleaner starts automatically

4. To switch back to manual mode, turn the on/

5. Your D

NOTE: If using an adapter ensure it is firmly

a. Ensure the collar on the AirLock connector

b. Push the AirLock connector onto the adapter

c. Rotate the collar to the locked position.

NOTE: The ball bearings inside collar lock

purposes specified in the instructions.

appropriate outlet.

power tool under Technical Data for the

power allowance of the tool to be plugged into

the outlet (m).

ACTIVATION position . This allows the

vacuum to be turned on and off automatically

by the power tool.

within 0.5 seconds and continues to run for

15seconds after the power tool has been

turned off.

off/tool control switch (o) to the ON position ( ).

In manual mode the tool and the vacuum are

turned on and off independent of each other.

EWALT construction dust extractor is

fitted with the D

system. The AirLock allows for a fast, secure

connection between the suction hose (g) and

power tool. The AirLock connector (w) connects

directly to DEWALT compatable tools or through

the use of an AirLock adapter (available from

your local DEWALT supplier). Refer to the

Accessories section for detail on available

adapters.

attached to the tool outlet before following the

steps below.

is in the unlock position. Align notches (v) on

collar and AirLock connector as shown for

unlock and lock positions.

connector point.

into slot and secure the connection.The

power tool is now securely connected to the

dust extractor.

EWALT AirLock connection

28

Page 9

ENGLISH

AUTOMATIC FILTER CLEANING SYSTEM

This vacuum has a highly effective filter cleaning

system which minimizes filter clogging. Every

30seconds, one of the two filters gets automatically

cleaned. The cleaning process alternates between

the filters and continues through the life of the unit.

NOTE: It is normal to hear a clicking sound during

this process.

NOTE: After many hours of operation the automatic

filter cleaning system may not be effective. When

this happens the filters will need to be cleaned or

replaced. Refer to Filter under Maintenance.

PARKING BRAKE (FIG. 1, 6)

The parking brake will lock one wheel in place to

prevent vacuum from rolling.

1. To engage parking brake, depress

the brake button (x) to snap the brake into the

locked position.

2. To disengage parking brake, depress the brake

button and brake will snap into the unlocked

position.

REMOVE / CHANGE USED DUST COLLECTION BAG (FIG. 1)

1. Turn off vacuum and unplug cord from outlet.

2. Close the twist-lock hose inlet (j) with the inlet

3. Unlatch canister latches (d) and remove vacuum

4. Pull the collection bag carefully from inlet (j).

5. Seal the collection bag opening tightly when

6. Dispose of collection bag in appropriate

WET PICK UP APPLICATIONS (FIG. 1, 7)

WARNING: DO NOT connect power

WARNING: Plug vacuum into residual

WARNING: If foam or liquid escapes

WARNING: Appropriate personal

protective equipment like dust mask and

gloves should be used while handling

used dust bags.

plug (s).

head (c)

removing it from the machine.

container according to statutory provisions.

tools to outlet (m) when using the

vacuum for wet pick up.

current device (RCD) protected outlet

when using the vacuum for wet pick up.

from the machine, switch off

immediately.

CAUTION: Clean the water level limiting

device regularly and examine it for signs

of damage.

NOTICE: DO NOT remove ball float

Before using the vacuum for wet pick up:

TO EMPTY CANISTER (FIG. 1, 7)

The ball float valve (y) will block air to the motor

when the canister is full and the sound of the motor

will change at once. When the motor has a high

pitched sound and air/water flow stops, empty the

canister.

1. Turn off vacuum and unplug cord from outlet.

2. Unlatch canister latches (d) and remove vacuum

3. Empty contents of canister (f) into a suitable

TO CONVERT BACK TO DRY VACUUM OPERATION (FIG. 1)

1. Empty Canister, refer to To Empty Canister

2. Place canister upside down position until dry.

3. Place vacuum head (c) on a level surface until

4. Reinstall filters when vacuum head is dry. See

5. When canister is dry place the vacuum head (c)

TELESCOPING HANDLE (FIG. 1, 8)

Press release button (q) to raise and lower the

telescoping handle (r).

(y), doing so will cause damage to the

vacuum. The ball float keeps water from

entering the motor.

• Ensure the canister is empty and free of

excessive dust.

• Remove filters (i).

• Plug vacuum into a RCD protected outlet.

WARNING: Do not use the machine

with this set up for dust Class L and M.

head (c).

container or drain.

instructions.

DO NOT use wet canister for dry pick up.

dry.

Filters under Maintenance.

onto the canister and secure it by closing the

canister latches (d).

Shut Down/Transportation

(fi g. 1, 11)

1. Turn on/off/tool control switch (o) to the OFF

position.

2. Unplug the unit.

3. Class M only: Close the twist-lock hose inlet (j)

with the inlet plug (s).

4. Store the power cord (b) as shown.

5. When transporting in vehicles, secure the

machine.

29

Page 10

ENGLISH

MAINTENANCE

Your DEWALT appliance has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper appliance care and regular

cleaning.

WARNING: For user servicing, the

• The manufacturer, or an instructed

• When carrying out service or repair

• For Class M machines the

WARNING: To reduce the risk

of injury, turn appliance off and

disconnect appliance from power

source before installing and

removing accessories, before

adjusting or changing set-ups or

when making repairs. An accidental

start-up can cause injury.

machine must be dismantled, cleaned

and serviced, as far as is reasonably

practicable, without causing risk to the

maintenance staff and others. Suitable

precautions include, decontamination

before dismantling, provision for local

filtered exhaust ventilation where the

machine is dismantled, cleaning of the

maintenance area and suitable personal

protection.

person, shall perform a technical

inspection at least annually, consisting

of, for example, inspection of filters for

damage, air tightness of the machine

and proper function of the control

mechanism.

operations, all contaminated items

which cannot be satisfactorily cleaned,

are to be disposed of; such items

shall be disposed of in impervious

bags in accordance with any current

regulation for the disposal of such

waste.

outside of the machine should be

decontaminated by vacuum cleaning

methods and wiped clean or treated

with sealant before being taken

out of a hazardous area. All the

machine parts shall be regarded as

contaminated when removed from the

hazardous area and appropriate action

taken to prevent dust dispersal.

• For dust extractors it is necessary to

provide for an adequate air change

rate L in the room if the exhaust air is

returned to the room.

(NOTE: Reference to National

Regulations is necessary.)

Filter (fi g. 1, 9, 10)

FILTER CARE

The filters included with this vacuum are long life

filters. To be effective in minimizing dust recirculation,

the filters MUST be installed correctly and in good

condition.

WARNING: Appropriate personal

protective equipment like dust mask

and gloves should be used while

handling the filters.

To Remove Filters

1. Turn on/off/tool control switch (o) to the OFF

position (O) and unplug cord from outlet.

2. Release canister latches (d) and remove

vacuum head (c) from canister. Place vacuum

head on a level surface upside down.

3. Turn each filter (i) counterclockwise by gripping

it on the plastic end cover as shown, and

carefully remove from head, ensuring debris

does not fall into mounting hole.

NOTE: Use care to not damage filter material.

4 If the bottom side of the vacuum head (c) needs

to be cleaned, use a cloth dampened with

water and mild soap and allow it to dry. Dispose

of cloth in an appropriate container.

5. Inspect filters for wear, tears or other damage.

NOTE: If there is any doubt on the condition

of the filters they MUST be replaced. DO NOT

continue use if filters are damaged.

WARNING: Never use compressed

air or a brush to clean filters, otherwise

damage to the filter membrane will

occur which will allow dust to pass

through the filter. If needed, gently tap

against a hard surface or rinse with

room temperature water and let air

dry. Cleaning of the filters is typically

unnecessary, even if the filter is

covered with dust. The automatic filter

cleaning system will maintain maximum

performance and continue to function.

If visual damage to the filter membrane

exists, replace filters. Filters typically

last between six and twelve months

depending on use and care.

30

Page 11

ENGLISH

To Install Filters

1. Ensure filter seal (aa) is in place and is secure

2. Line up filter threads (z) to vacuum head threads

and using moderate force, turn filter clockwise

until tight.

NOTE: Use care to not damage filter material.

3. Place the vacuum head (c) onto the container

and secure it by closing the canister latches (d).

Lubrication

Your appliance requires no additional lubrication.

Cleaning

WARNING: Never use solvents or other

harsh chemicals for cleaning the nonmetallic parts of the appliance. These

chemicals may weaken the materials

used in these parts. Never let any liquid

get inside the machine; never immerse

any part of the appliance into a liquid.

1. Vacuum the outside of the dust extractor. For

further cleaning use a cloth dampened only with

water and mild soap if necessary.

2. After use dispose of cloth in an appropriate

container.

Storage (fi g. 11)

1. Empty the canister, refer to To Empty Canister

under Operation.

2. Clean the vacuum inside and outside. Refer to

Cleaning.

3. Clean or replace filters, refer to Filters.

4. Store the suction hose and the power cord as

shown in the illustration. Place the unit in a dry

room and secure it from unauthorized use.

NOTE: Plug inlet plug (s) into inlet (j) to keep

debris inside canister when suction hose is

removed. You can also attach the ends of the

hose together and lock together with the twistlock end.

Optional Accessories

WARNING: Since accessories, other

SECURING THE POWER CORD TO THE HOSE (FIG. 1)

The power cord (b) can be secured to the suction

hose (g) using the D279058CL hose clip (available

from your local D

Consult your dealer for further information on the

appropriate accessories.

than those offered by DEWALT, have

not been tested with this product, use

of such accessories with this appliance

could be hazardous. To reduce the risk

of injury, only D

accessories should be used with this

product.

ACCESSORIES

DWV9310-XJ Filter

DWV9315-XJ Crush-proof hose

DWV9316-XJ Anti-static hose

DWV9401-XJ Paper bag

DWV9400-XJ Plastic liner

DWV9402-XJ Fleece bag

D

EWALT AirLock System

DWV9000 Twist-Lock

DWV9110 29-35mm tapered

DWV9120 35-38mm stepped

DWV9130 35mm OD adapter

DWV9150 35mm OD angle

EWALT supplier).

EWALT recommended

connection

rubber adapter

rubber adapter

adapter

Troubleshooting

PROBLEM SOLUTION

Motor

does not

run

Suction

capacity

decreases

Check power cord, plugs and outlet.

Ensure the on/off /tool control switch

is in the ON position ( ).

Remove blockages in the suction

nozzle, suction tube, suction hose

or filters.

Replace the paper or fleece bag.

Check for proper installation of the

filters.

Clean or replace the filters.

Empty canister, refer to Empty

Canister under Operation.

31

Page 12

ENGLISH

PROBLEM SOLUTION

Vacuum

stops

running

Dust

comes

out while

vacuuming

Automatic

filter

cleaning

is not

working

Power tool

does not

turn on.

Thermal overload has been tripped:

1. Turn the vacuum off and

disconnect vacuum cleaner from

power source.

2. Empty the canister, if needed.

3. Allow the unit to cool.

4. Plug the power cord into an

appropriate outlet and turn on/

off/tool control switch to the ON

position (

not restart contact your seller or

check the location of your nearest

authorised DEWALT repair agent

in the DEWALT catalogue or

contact your DEWALT office at the

address indicated in this manual.

Check for proper installation of the

filters.

Ensure filters are not damaged;

replace if necessary.

Ensure filter seals are in place and are

secure.

Listen for the solenoid clicking to

ensure the filter cleaning mechanism

is working.

Ensure the on/off/tool control switch is

in the ACTIVATION position

) to test. If vacuum will

.

D

EWALT provides a facility for the collection and

recycling of DEWALT products once they have

reached the end of their working life. To take

advantage of this service please return your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your local

EWALT office at the address indicated in this

D

manual. Alternatively, a list of authorised DEWALT

repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com.

Protecting the Environment

Separate collection. This product must

not be disposed of with normal

household waste.

Should you find one day that your DEWALT product

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products

and packaging allows materials to be

recycled and used again. Re-use of

recycled materials helps prevent

environmental pollution and reduces

the demand for raw materials.

Local regulations may provide for separate collection

of electrical products from the household, at

municipal waste sites or by the retailer when you

purchase a new product.

32

Page 13

GUARANTEE

DEWALT is confident of the quality of its

products and offers an outstanding guarantee

for professional users of the product. This

guarantee statement is in addition to and in

no way prejudices your contractual rights as a

professional user or your statutory rights as a

private non-professional user. The guarantee

is valid within the territories of the Member

States of the European Union and the

European Free Trade Area.

• 30 DAY NO RISK SATISFACTION GUARANTEE •

If you are not completely satisfied with the

performance of your D

simply return it within 30 days, complete

with all original components, as purchased,

to the point of purchase, for a full refund

or exchange. The product must have been

subject to fair wear and tear and proof of

purchase must be produced.

• ONE YEAR FREE SERVICE CONTRACT •

If you need maintenance or service for your

EWALT product, in the 12 months following

D

purchase, you are entitled to one service free

of charge. It will be undertaken free of charge

at an authorised DEWALT repair agent. Proof

of purchase must be produced. Includes

labour. Excludes accessories and spare parts

unless failed under warranty.

• ONE YEAR FULL WARRANTY •

EWALT product becomes defective

If your D

due to faulty materials or workmanship

within 12 months from the date of purchase,

DEWALT guarantees to replace all defective

parts free of charge or – at our discretion –

replace the unit free of charge provided that:

• The product has not been misused;

• The product has been subject to fair

wear and tear;

• Repairs have not been attempted by

unauthorised persons;

• Proof of purchase is produced;

• The product is returned complete with all

original components.

If you wish to make a claim, contact your

seller or check the location of your nearest

authorised DEWALT repair agent in the

D

EWALT catalogue or contact your DEWALT

office at the address indicated in this manual.

A list of authorised D

full details of our after-sales service is available

on the Internet at: www.2helpU.com.

EWALT product,

EWALT repair agents and

ENGLISH

33

Loading...

Loading...