Page 1

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DWE574, DWE575, DWE575SB

7-1/4" (184 mm) Circular Saws

Scies circulaires de 184 mm (7-1/4 po)

Sierras circulares de 184 mm (7-1/4")

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DeWALT • www.dewalt.com

FINAL PRINT SIZE: 8.5 x 5.5"

Page 2

Page 3

1

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DeWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DeWALT

(1-800-433-9258).

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

Definitions: Safety Guidelines

The definitions below describe the level of severity for

each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury.

NOTICE: Indicates a practice not related to personal

injury which, if not avoided, may result in property

damage.

Page 4

2

English

f) If operating a power tool in a damp location is unavoidable,

use a ground fault circuit interrupter (GFCI) protected

supply. Use of a GFCI reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind and

are easier to control.

g) Use the power tool, accessories and tool bits, etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

Page 5

3

English

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Safety Instructions for All Saws

CUTTING PROCEDURES

a) DANGER: Keep hands away from cutting area and the

blade. Keep your second hand on auxiliary handle, or

motor housing. If both hands are holding the saw, they cannot

be cut by the blade.

b) Do not reach underneath the workpiece. The guard cannot

protect you from the blade below the workpiece.

c) Adjust the cutting depth to the thickness of the workpiece.

Less than a full tooth of the blade teeth should be visible below

the workpiece.

d) Never hold piece being cut in your hands or across

your leg. Secure the workpiece to a stable platform. It

is important to support the work properly to minimize body

exposure, blade binding, or loss of control.

e) Hold the power tool by insulated gripping surfaces only,

when performing an operation where the cutting tool

may contact hidden wiring or its own cord. Contact with a

"live" wire will also make exposed metal parts of the power tool

"live" and could give the operator an electric shock.

f) When ripping, always use a rip fence or straight edge

guide. This improves the accuracy of cut and reduces the

chance of blade binding.

g) Always use blades with correct size and shape (diamond

versus round) of arbor holes. Blades that do not match the

mounting hardware of the saw will run eccentrically, causing

loss of control.

h) Never use damaged or incorrect blade washers or bolt.

The blade washers and bolt were specially designed for your

saw, for optimum performance and safety of operation.

Further Safety Instructions for All Saws

KICKBACK CAUSES AND RELATED WARNINGS:

– Kickback is a sudden reaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw to lift up

and out of the workpiece toward the operator;

– When the blade is pinched or bound tightly by the kerf closing

down, the blade stalls and the motor reaction drives the unit

rapidly back toward the operator;

– If the blade becomes twisted or misaligned in the cut, the teeth

at the back edge of the blade can dig into the top surface of the

wood causing the blade to climb out of the kerf and jump back

toward the operator.

Kickback is the result of saw misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

a) Maintain a firm grip with both hands on the saw and

position your arms to resist kickback forces. Position

your body to either side of the blade, but not in line with

the blade. Kickback could cause the saw to jump backwards,

but kickback forces can be controlled by the operator, if proper

precautions are taken.

b) When blade is binding, or when interrupting a cut for any

reason, release the trigger and hold the saw motionless

in the material until the blade comes to a complete

stop. Never attempt to remove the saw from the work

or pull the saw backward while the blade is in motion or

kickback may occur. Investigate and take corrective actions to

eliminate the cause of blade binding.

Page 6

4

English

Raise lower guard by retracting handle and as soon

as blade enters the material, the lower guard must be

released. For all other sawing, the lower guard should operate

automatically.

d) Always observe that the lower guard is covering the

blade before placing saw down on bench or floor.

An unprotected, coasting blade will cause the saw to walk

backwards, cutting whatever is in its path. Be aware of the time

it takes for the blade to stop after switch is released.

Additional Specific Safety Instructions for

Circular Saws

WARNING: Do not use abrasive wheels or blades.

WARNING: Do not use water feed attachments.

• Use clamps or another practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body leaves it unstable and may lead to loss of

control.

• Keep your body positioned to either side of the blade, but

not in line with the saw blade. Kickback could cause the saw to

jump backwards (Refer to Causes and Operator Prevention of

Kickback and KICKBACK).

• Avoid cutting nails. Inspect for and remove all nails from

lumber before cutting.

• Accessories must be rated for at least the speed

recommended on the tool warning label. Wheels and other

accessories running over rated speed can fly apart and cause

injury. Accessory ratings must always be above tool speed as

shown on tool nameplate.

• Always make sure the saw is clean before using.

• Stop using this saw and have it properly serviced if any unusual

noise or abnormal operation occcurs.

c) When restarting a saw in the workpiece, center the

saw blade in the kerf and check that saw teeth are not

engaged into the material. If saw blade is binding, it may walk

up or kickback from the workpiece as the saw is restarted.

d) Support large panels to minimize the risk of blade

pinching and kickback. Large panels tend to sag under their

own weight. Supports must be placed under the panel on both

sides, near the line of cut and near the edge of the panel.

e) Do not use dull or damaged blades. Unsharpened or

improperly set blades produce narrow kerf causing excessive

friction, blade binding and kickback.

f) Blade depth and bevel adjusting locking levers must be

tight and secure before making cut. If blade adjustment

shifts while cutting, it may cause binding and kickback.

g) Use extra caution when sawing into existing walls or

other blind areas. The protruding blade may cut objects that

can cause kickback.

LOWER GUARD FUNCTION

a) Check lower guard for proper closing before each use.

Do not operate the saw if lower guard does not move

freely and close instantly. Never clamp or tie the lower

guard into the open position. If saw is accidentally dropped,

lower guard may be bent. Raise the lower guard with the

retracting handle and make sure it moves freely and does not

touch the blade or any other part, in all angles and depths of

cut.

b) Check the operation of the lower guard spring. If the

guard and the spring are not operating properly, they

must be serviced before use. Lower guard may operate

sluggishly due to damaged parts, gummy deposits, or a buildup of debris.

c) Lower guard should be retracted manually only for

special cuts such as “plunge cuts” and “compound cuts.”

Page 7

5

English

• Always be sure all components are mounted properly and securely

before using tool.

• Always handle the saw blade with care when mounting or

removing it.

• Always wait until the motor has reached full speed before starting

a cut.

• Always keep handles dry, clean and free of oil and grease. Hold the

tool firmly with both hands when in use.

• Always be alert at all times, especially during repetitive, monotonous

operations. Always be sure of position of your hands relative to the

blade.

• Stay clear of end pieces that may fall after cutting off. They may be

hot, sharp and/or heavy. Serious personal injury may result.

• Replace or repair damaged cords. Make sure your extension cord

is in good condition. Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole receptacles that accept

the tool’s plug.

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewelry or long hair can be caught in moving parts.

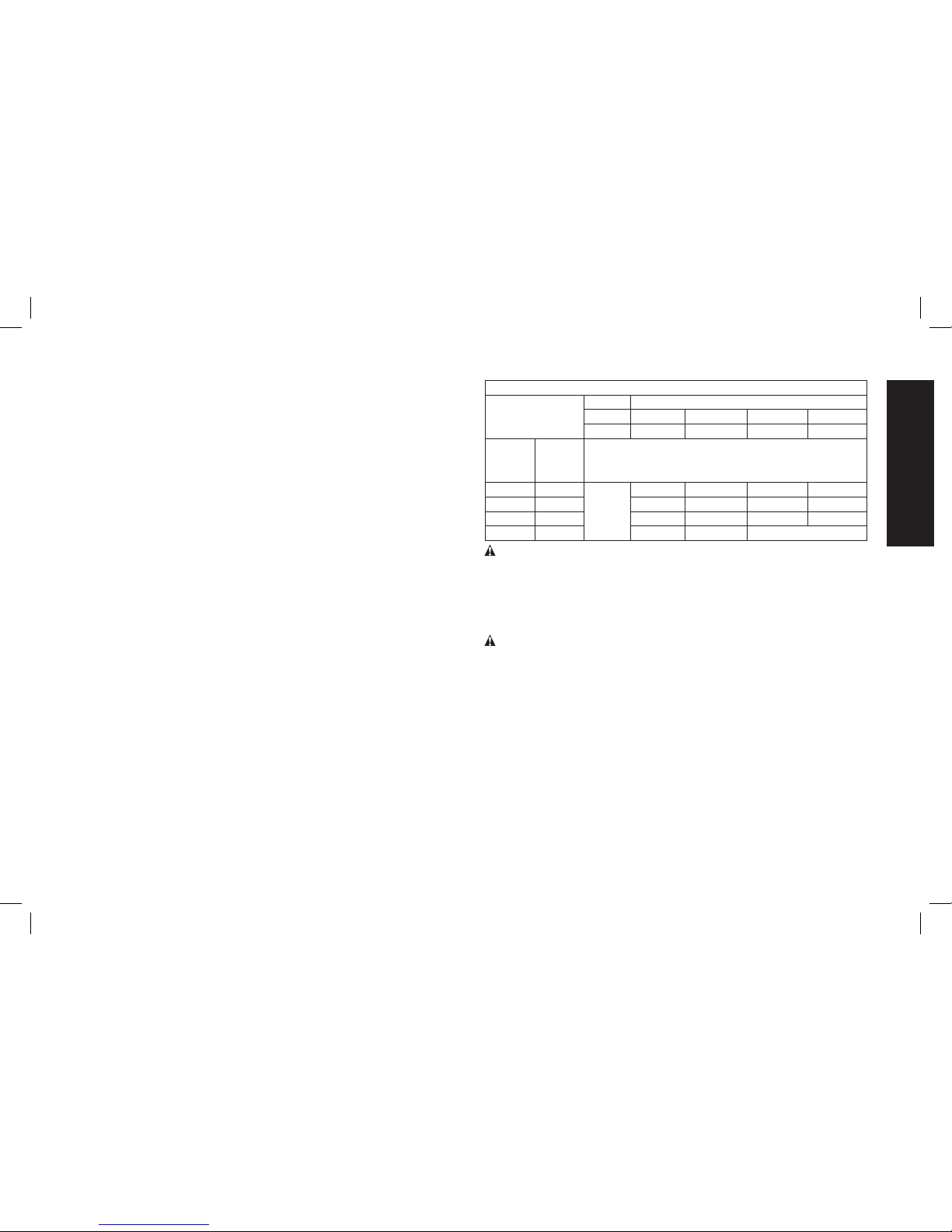

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. When using more than one extension to make up the

total length, be sure each individual extension contains at least the

minimum wire size. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

Minimum Gauge for Cord Sets

Ampere Rating

Volts Total Length of Cord in Feet (meters)

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

More

Than

Not

More

Than

AWG

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are

NOT safety glasses. Also use face or dust mask if cutting operation is

dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Page 8

6

English

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on

the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate

for the dust exposure. Direct particles away from face and body.

WARNING: Always wear proper personal hearing protection

that conforms to ANSI S12.6 (S3.19) during use. Under some

conditions and duration of use, noise from this product may contribute

to hearing loss.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V .....................volts A ....................... amperes

Hz...................hertz W ...................... watts

min .................minutes or AC ........... alternating

or DC ....direct current current

...................Class I Construction or AC/DC ...alternating

(grounded) ..........................or direct

..................Class II Construction current

(double insulated)

n

o .....................no load

…/min ............per minute speed

BPM ...............beats per minute n........................rated

IPM ................impacts per minute ..........................speed

RPM ...............revolutions per ...................... earthing

minute terminal

sfpm ...............surface feet ...................... safety alert

.......................per minute symbol

SPM ...............strokes per minute ..................... visible radiation

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

Motor

Be sure your power supply agrees with the nameplate marking.

Voltage decrease of more than 10% will cause loss of power and

overheating. DeWALT tools are factory tested; if this tool does not

operate, check power supply.

E

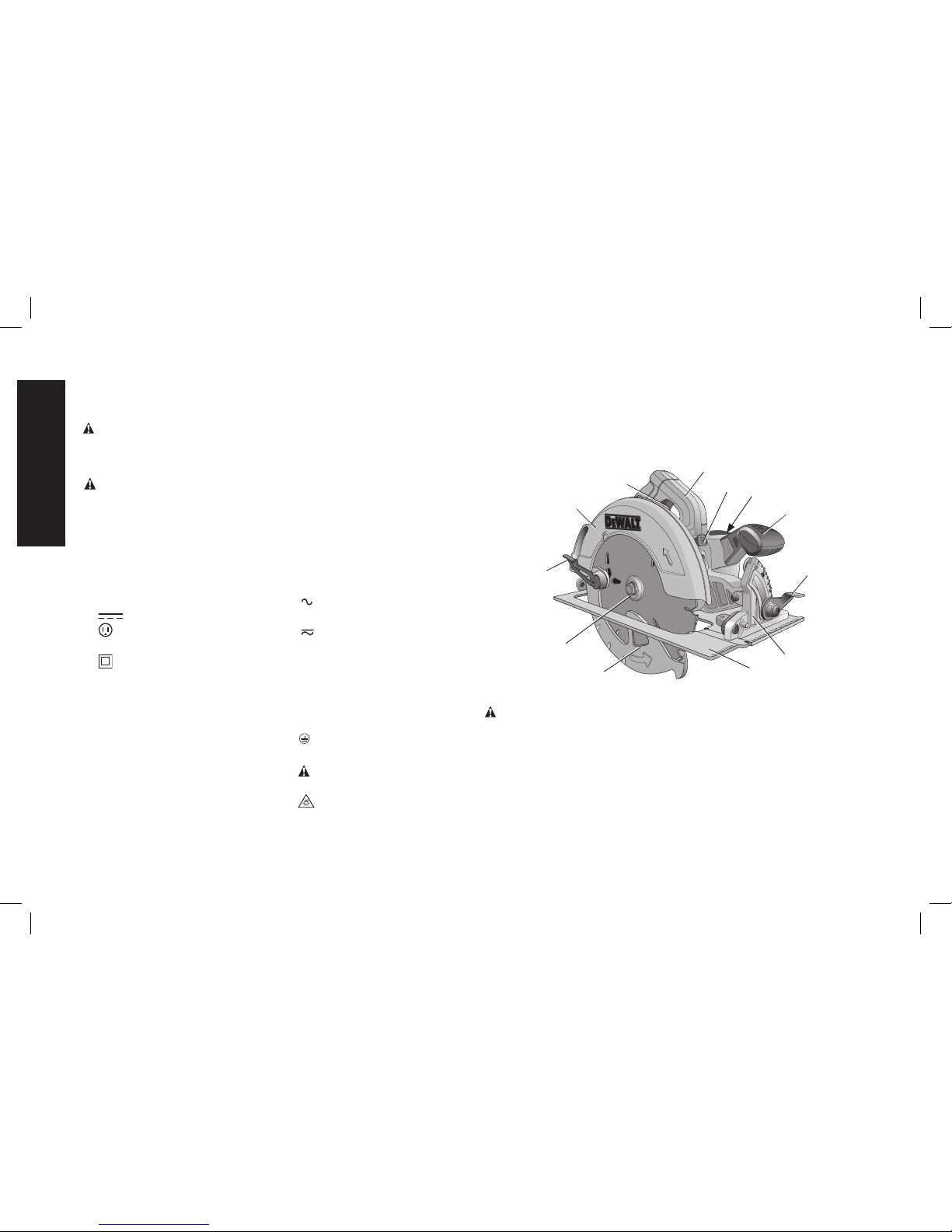

D

B

A

J

I

FIG. 1

H

G

F

C

L

K

COMPONENTS (Fig. 1)

WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Trigger switch H. Foot plate

B. Main handle I. Lower blade guard

C. Blade lock J. Blade clamping screw

D. End cap K. Lower guard lever

E. Auxiliary handle L. Upper blade guard

F. Bevel adjustment lever

G. Bevel angle adjustment mechanism

Page 9

7

English

INTENDED USE

These heavy-duty circular saws are designed for professional wood

cutting applications. DO NOT use water feed attachments with this

saw. DO NOT use abrasive wheels or blades. DO NOT use under wet

conditions or in presence of flammable liquids or gases.

These heavy-duty saws are professional power tools. DO NOT let

children come into contact with the tool. Supervision is required when

inexperienced operators use this tool.

ADJUSTMENTS

Changing Blades

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

M

J

N

FIG. 2

FIG. 3

K

I

TO INSTALL THE BLADE (FIG. 2–5)

1. Using the lower guard lever (K), retract the lower blade guard (I) and

place blade on saw spindle against the inner clamp washer (M),

making sure that the blade will rotate in the proper direction (the

direction of the rotation arrow on the saw blade and the teeth must

point in the same direction as the direction of rotation arrow on the

saw). Do not assume that the printing on the blade will always be

facing you when properly installed. When retracting the lower blade

guard to install the blade, check the condition and operation of the

lower blade guard to assure that it is working properly. Make sure

it moves freely and does not touch the blade or any other part, in

all angles and depths of cut.

2. Place outer clamp washer (N) on

C

FIG. 4

saw spindle with the large flat

surface against the blade and the

wording on the outer clamp

washer facing you.

3. Thread blade clamping screw (J)

into saw spindle by hand (screw

has right-hand threads and must

be turned clockwise to tighten).

4. Depress the blade lock (C)

FIG. 5

O

FIG. 5

B

while turning the saw spindle

with the blade wrench (O)

stored underneath the main

handle (B) (Fig. 5), until the

blade lock engages and the

blade stops rotating.

5. Tighten the blade clamping

screw firmly with the blade

wrench.

NOTE: Never engage the blade

lock while saw is running, or

engage in an effort to stop the

tool. Never turn the saw on while

the blade lock is engaged. Serious

damage to your saw will result.

Page 10

8

English

TO REPLACE THE BLADE (FIG. 2, 4, 5)

1. To loosen the blade clamping screw (J), depress the blade lock

(C) and turn the saw spindle with the blade wrench (O), stored

underneath the main handle (B), until the blade lock engages

and the blade stops rotating. With the blade lock engaged,

turn the blade clamping screw counterclockwise with the blade

wrench (screw has right-hand threads and must be turned

counterclockwise to loosen).

2. Remove the blade clamping screw (J) and outer clamp washer (N).

Remove old blade.

3. Clean any sawdust that may have accumulated in the guard or

clamp washer area and check the condition and operation of the

lower blade guard as previously outlined. Do not lubricate this area.

4. Select the proper blade for the application (refer to Recommended

Blade Types under Blades). Always use blades that are the

correct size (7-1/4" [178mm] diameter) with the proper size and

shape center hole for mounting on the saw spindle. Always assure

that the maximum recommended speed (rpm) on the saw blade

meets or exceeds the speed (rpm) of the saw.

5. Follow steps 1 through 5 under To Install the Blade, making sure

that the blade will rotate in the proper direction.

LOWER BLADE GUARD

WARNING: The lower blade guard is a safety feature which

reduces the risk of serious personal injury. Never use the saw if

the lower guard is missing, damaged, misassembled or not

working properly. Do not rely on the lower blade guard to

protect you under all circumstances. Your safety depends on

following all warnings and precautions as well as proper

operation of the saw. Check lower guard for proper closing

before each use as outlined in Additional Safety Rules for

Circular Saws. If the lower blade guard is missing or not

working properly, have the saw serviced before using. To

assure product safety and reliability, repair, maintenance and

adjustment should be performed by an authorized service

center or other qualified service organization, always using

identical replacement parts.

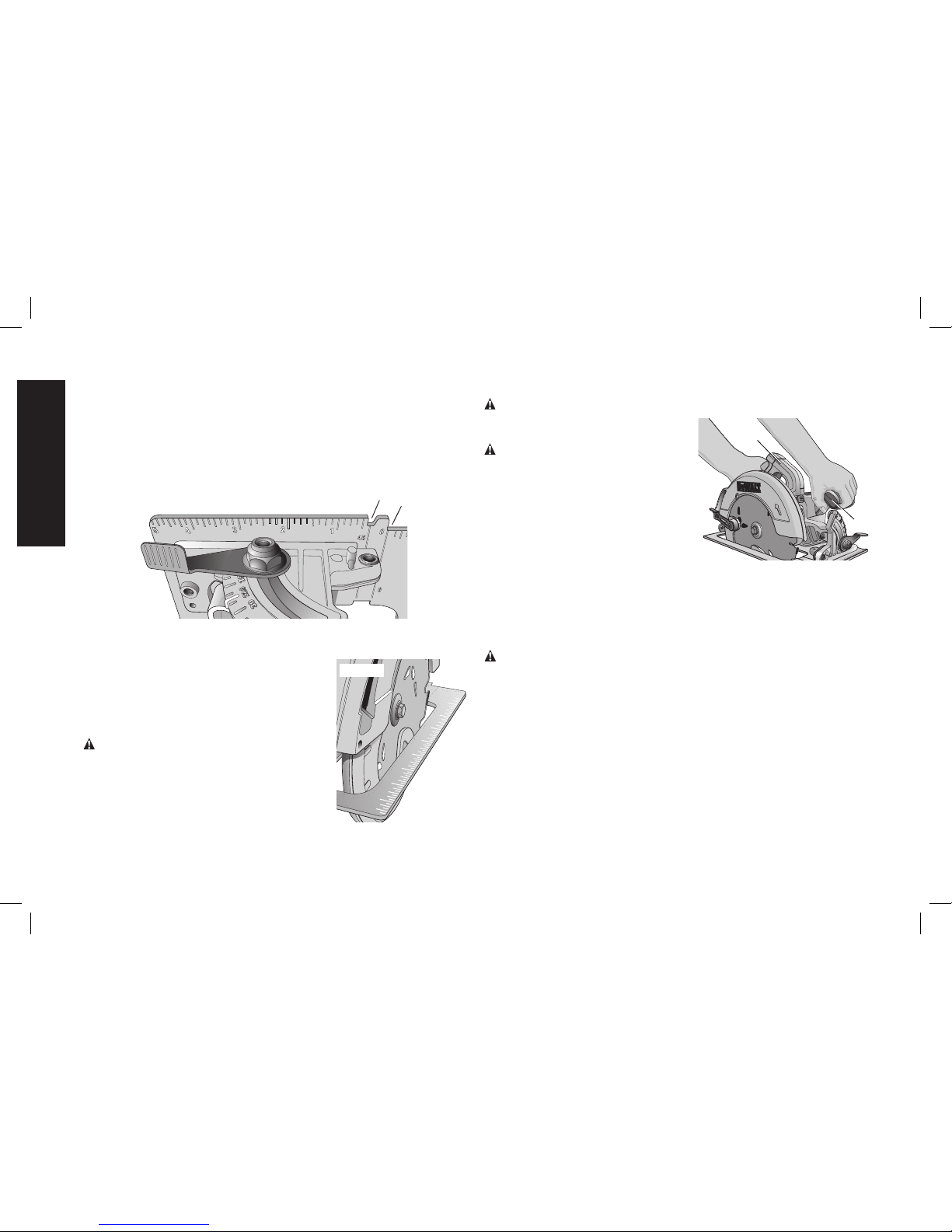

Cutting Depth Adjustment (Fig. 6–8)

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

Your saw is equipped with a

LOOSEN

TIGHTEN

P

FIG. 6

carbide tipped saw blade for

long life and efficient cutting.

Setting the saw at the proper

cutting depth keeps blade

friction to a minimum, removes

sawdust from between the

blade teeth, results in cooler,

faster sawing and reduces the

chance of kickback.

1. Hold the saw firmly. Raise the

FIG. 7

R

Q

P

S

depth adjustment lever (P) to

loosen and move foot plate to

obtain the desired depth of

cut, as shown. Make sure the

depth adjustment lever has

been retightened (lowered)

before operating the saw.

2. Align the appropriate mark on

the depth adjustment strap (R)

with notch (Q) on the upper

blade guard. Your depth is set.

Page 11

9

English

FIG. 8

3. For the most efficient cutting action using a carbide tipped saw

blade, set the depth adjustment so that about one half of a tooth

projects below the surface of the wood to be cut.

4. A method of checking for the correct cutting depth is shown in

Figure 8. Lay a piece of the material you plan to cut along the side

of the blade, as shown in the figure, and observe how much tooth

projects beyond the material.

ADJUSTING DEPTH ADJUSTMENT LEVER (FIG. 7)

It may be desirable to adjust the depth adjustment lever (P). It may

loosen in time and hit the foot plate before tighten ing.

To tighten the lever, follow the steps below.

1. Hold depth adjustment lever (P) and loosen the locknut (S).

2. Adjust the depth adjustment lever by rotating it in the desired

direction about 1/8 of a revolution.

3. Retighten nut.

Bevel Angle Adjustment (Fig. 9)

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

On the front of the saw is a bevel angle adjustment mechanism (G)

which consists of an angle quadrant with a pointer (T) and a bevel

adjustment lever (F). The angle

F

G

TIGHTEN

LOOSEN

T

U

V

FIG. 9

quadrant allows for coarse

adjustment. To achieve better

accuracy in cutting, use the fine

adjustment markings located

on the pivot bracket (U). The full

range of bevel adjustment for

the DWE574 is 0 to 50 degrees

and for the DWE575 and

DWE575SB it is 0 to 57

degrees. The pivot bracket is

graduated in increments of

1degree.

1. To set the saw for a bevel

cut, raise the bevel adjustment lever (F) to loosen the bevel

adjustment.

2. Tilt the foot plate to the desired angle by aligning the pointer (T)

with the desired angle mark on the pivot bracket (U).

3. Retighten the bevel adjustment by lowering the lever.

Bevel Detent (Fig.9)

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

These circular saws are equipped with a bevel detent feature. As you

tilt the foot plate you will hear a click and feel the foot plate stop at both

22.5 and 45 degrees. If either of these is the desired angle, retighten

the lever (F) by lowering it. If you desire another angle, continue tilting

the foot plate until the coarse bevel pointer (V) or the fine pointer (T)

aligns with the desired mark.

Page 12

10

English

Kerf Indicator (Fig. 10)

The front of the saw foot plate has a kerf indicator for vertical and bevel

cutting. This indicator enables you to guide the saw along cutting lines

penciled on the material being cut. The indicator lines up with the left

(inner) side of the saw blade which makes the slot or “kerf” cut by the

moving blade, fall to the right of the indicator. The markings on the

front of the foot plate are in increments of 1/8"(3.2mm).

FIG. 10

45˚

0˚

Cut Length Indicator (Fig. 11)

The markings on the side of the foot plate

FIG. 11

show the length of the slot being cut into

the material at the full depth of the cut. The

markings are in increments of 1/8" (3.2mm).

OPERATION

WARNING: To reduce the risk of

injury, turn unit off and disconnect it

from power source before installing

and removing accessories, before

adjusting or when making repairs. An

accidental start-up can cause injury.

Proper Hand Position (Fig.12)

WARNING: To reduce the risk of

FIG. 12

B

E

serious personal injury, ALWAYS use

proper hand position as shown.

WARNING: To reduce the risk of

serious personal injury, ALWAYS hold

securely in anticipation of a sudden

reaction.

Proper hand position requires one

hand on the main handle (B), with

the other hand on the auxiliary

handle (E).

Switch (Fig. 1)

Pull the trigger switch (A) to turn the motor on. Releasing the trigger

turns the motor off. This tool has no provision to lock the switch in the

on position, and the tool should never be locked on in any way.

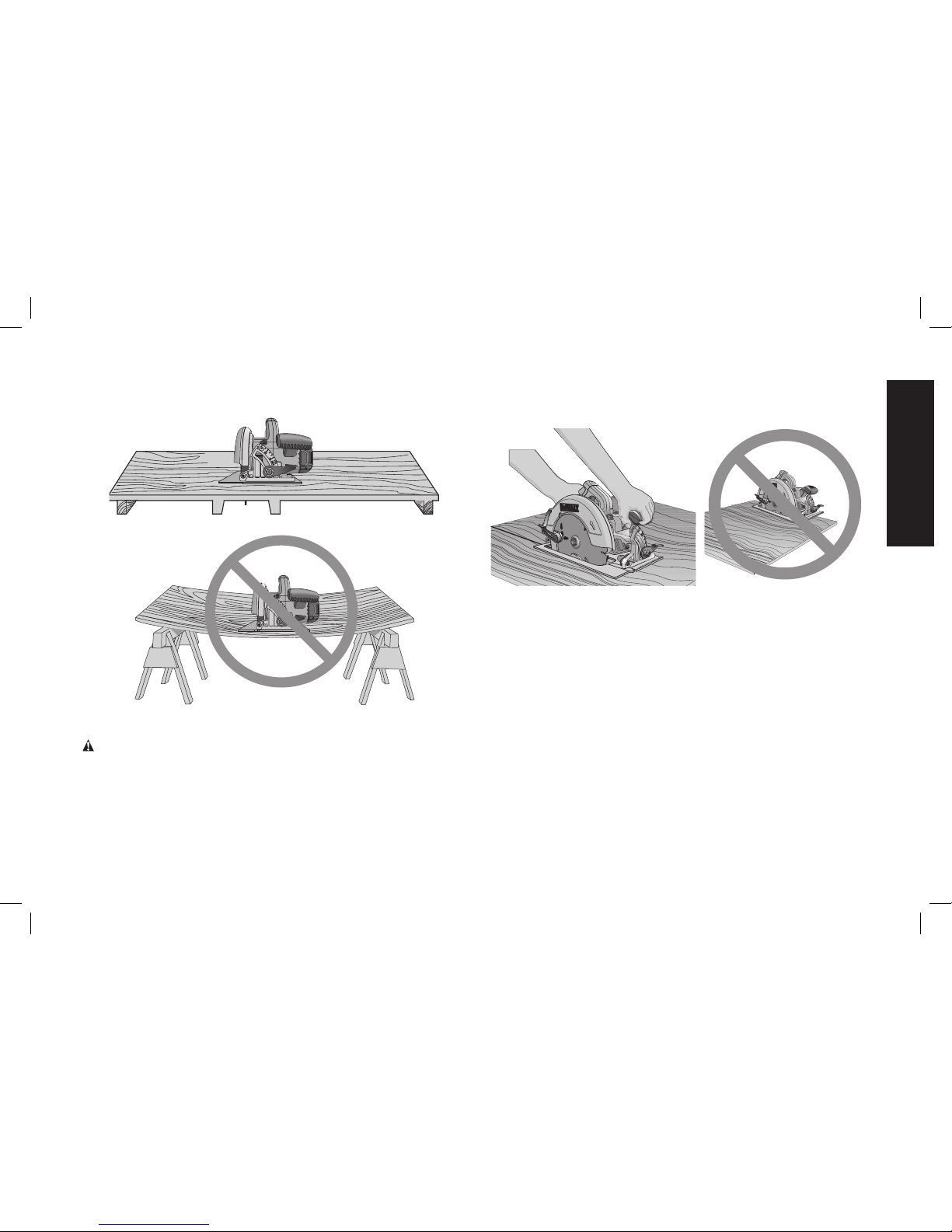

Workpiece Support (Fig. 13–16)

WARNING: To reduce the risk of serious personal injury, support

the work properly and hold the saw firmly to prevent loss of control.

Figures 13 and 15 show proper sawing position. Figures 14 and 16

show an unsafe condition. Hands should be kept away from cutting

area, and power cord is positioned clear of the cutting area so that it

will not get caught or hung up on the work.

To avoid kickback, ALWAYS support board or panel NEAR the cut,

(Fig. 13 and 15). DON’T support board or panel away from the cut

(Fig.14 and 16). When operating the saw, keep the cord away from

the cutting area and prevent it from becoming hung up on the work

piece.

ALWAYS DISCONNECT SAW BEFORE MAKING ANY ADJUST MENTS!

Place the work with its “good” side—the one on which appearance is

Page 13

11

English

most important—down. The saw cuts upward, so any splintering will be

on the work face that is up when you saw it.

FIG. 13

FIG. 14

Cutting

WARNING: Never attempt to use this tool by resting it upside

down on a work surface and bringing the material to the tool. Always

securely clamp the workpiece and bring the tool to the workpiece,

securely holding the tool with two hands as shown in Figure 15.

Place the wider portion of the saw foot plate on that part of the work

piece which is solidly supported, not on the section that will fall off when

the cut is made. As examples, Figure15 illustrates the RIGHT way to

cut off the end of a board. Always clamp work. Don’t try to hold short

pieces by hand! Remember to support cantilevered and overhanging

material. Use caution when sawing material from below.

FIG. 15 FIG. 16

Be sure saw is up to full speed before blade contacts material to be cut.

Starting saw with blade against material to be cut or pushed forward

into kerf can result in kickback. Push the saw forward at a speed which

allows the blade to cut without laboring. Hardness and toughness can

vary even in the same piece of material, and knotty or damp sections

can put a heavy load on the saw. When this happens, push the saw

more slowly, but hard enough to keep working without much decrease

in speed. Forcing the saw can cause rough cuts, inaccuracy, kickback,

and over-heating of the motor. Should your cut begin to go off the line,

don’t try to force it back on. Release the switch and allow blade to come

to a complete stop. Then you can withdraw the saw, sight anew, and

start a new cut slightly inside the wrong one. In any event, withdraw the

saw if you must shift the cut. Forcing a correction inside the cut can stall

the saw and lead to kickback.

IF SAW STALLS, RELEASE THE TRIGGER AND BACK THE SAW

UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN THE CUT

AND CLEAR OF THE CUTTING EDGE BEFORE RESTARTING.

Page 14

12

English

As you finish a cut, release the trigger and allow the blade to stop

before lifting the saw from the work. As you lift the saw, the springtensioned telescoping guard will automatically close under the blade.

Remember the blade is exposed until this occurs. Never reach under

the work for any reason. When you have to retract the telescoping

guard manually (as is necessary for starting pocket cuts) always use

the retracting lever.

NOTE: When cutting thin strips, be careful to ensure that small cutoff

pieces don’t hang up on inside of lower guard.

RIPPING (FIG. 17)

FIG. 17

W

Ripping is the process of cutting

wider boards into narrower

strips – cutting grain lengthwise.

Hand guiding is more difficult for

this type of sawing and the use

of DeWALT DW3278 rip guide

(W) is recommended.

POCKET CUTTING (FIG. 18)

WARNING: Never tie the

blade guard in a raised position.

Never move the saw backwards

FIG. 18

E

when pocket cutting. This may

cause the unit to raise up off the

work surface which could cause

injury.

A pocket cut is one that is made in

a floor, wall or other flat surface.

1. Adjust the saw foot plate so the

blade cuts at desired depth.

2. Tilt the saw forward and rest

front of the foot plate on

material to be cut.

3. Using the lower guard lever, retract lower blade guard to an

upward position. Lower rear of foot plate until blade teeth almost

touch cutting line.

4. Release the blade guard (its contact with the work will keep it

in position to open freely as you start the cut). Remove hand

from guard lever and firmly grip auxiliary handle (E), as shown in

Figure 18. Position your body and arm to allow you to resist

kickback if it occurs.

5. Make sure blade is not in contact with cutting surface before

starting saw.

6. Start the motor and gradually lower the saw until its foot plate rests

flat on the material to be cut. Advance saw along the cutting line

until cut is completed.

7. Release trigger and allow blade to stop completely before

withdrawing the blade from the material.

8. When starting each new cut, repeat as above.

Kickback

When the saw blade becomes pinched or twisted in the cut, kickback

can occur. The saw is thrust rapidly back toward the operator. When

the blade is pinched or bound tightly by the kerf closing down, the

blade stalls and the motor reaction drives the unit backward. When the

blade becomes twisted or misaligned in the cut, the teeth at the back

edge of the blade can dig into the top surface of the wood causing

the blade to climb out of the kerf and jump back toward the operator.

Kickback is more likely to occur when any of the following conditions

exist.

1. IMPROPER WORKPIECE SUPPORT

A. Sagging or improper lifting of the cut off piece can cause

pinching of the blade and lead to kickback (Fig. 14).

Page 15

13

English

B. Cutting through material supported at the outer ends only can

cause kickback. As the material weakens it sags, closing down

the kerf and pinching the blade.

C. Cutting off a cantilevered or overhanging piece of material from

the bottom up in a vertical direction can cause kickback. The

falling cut off piece can pinch the blade.

D. Cutting off long narrow strips (as in ripping) can cause kickback.

The cut off strip can sag or twist closing the kerf and pinching

the blade.

E. Snagging the lower guard on a surface below the material

being cut momentarily reduces operator control. The saw can

lift partially out of the cut increasing the chance of blade twist.

2. IMPROPER DEPTH OF CUT SETTING ON SAW

To make the most efficient cut, the blade should protrude only far

enough to expose 1/2 of a tooth as shown in Figure 9. This allows

the foot plate to support the blade and minimizes twisting and

pinching in the material. Refer to Cutting Depth Adjustment.

3. BLADE TWISTING (MISALIGNMENT IN CUT)

A. Pushing harder to cut through a knot, a nail, or a hard grain

area can cause the blade to twist.

B. Trying to turn the saw in the cut (trying to get back on the

marked line) can cause blade twist.

C. Over-reaching or operating the saw with poor body control (out

of balance), can result in twisting the blade.

D. Changing hand grip or body position while cutting can result in

blade twist.

E. Backing up the saw to clear blade can lead to twist if it is not

done carefully.

4. MATERIALS THAT REQUIRE EXTRA ATTENTION

A. Wet lumber

B. Green lumber (material freshly cut or not kiln dried)

C. Pressure treated lumber (material treated with preservatives or

anti-rot chemicals)

5. USE OF DULL OR DIRTY BLADES

Dull blades cause increased loading of the saw. To compensate,

an operator will usually push harder which further loads the unit

and promotes twisting of the blade in the kerf. Worn blades may

also have insufficient body clearance which increases the chance

of binding and increased loading.

6. LIFTING THE SAW WHEN MAKING BEVEL CUTS

Bevel cuts require special operator attention to proper cutting

techniques – especially guidance of the saw. Both blade angle to

the foot plate and greater blade surface in the material increase the

chance for binding and misalignment (twist) to occur.

7. RESTARTING A CUT WITH THE BLADE TEETH JAMMED

AGAINST THE MATERIAL

The saw should be brought up to full operating speed before

starting a cut or restarting a cut after the unit has been stopped

with the blade in the kerf. Failure to do so can cause stalling and

kickback.

Any other conditions which could result in pinching, binding, twisting,

or misalignment of the blade could cause kickback. Refer to

Additional Safety Instructions and Operation for procedures and

techniques that will minimize the occurrence of kickback.

MAINTENANCE

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

Page 16

14

English

Cleaning

WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning

the non-metallic parts of the tool. These chemicals may weaken the

plastic materials used in these parts. Use a cloth dampened only with

water and mild soap. Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid.

Lubrication

Self lubricating ball and roller bearings are used in the tool and

relubrication is not required. However, it is recommended that, once

a year, you take or send the tool to a service center for a thorough

cleaning, inspection and lubrication of the gear case.

Electric Brake (DWE575SB)

Your saw has an automatic electric brake which is designed to stop

the blade from coasting in about two seconds, after you release the

trigger switch. It is useful when making certain cuts in wood where a

coasting blade would result in a wide, imprecise cut.

Occasionally, the brake will not function properly and won’t stop the

saw in the 2 seconds discussed above. If this condition persists, turn

the saw on and off four or five times. If the brake still does not stop

the blade in about 2 seconds, the problem may be worn brushes.

Have the brushes replaced at a DeWALT authorized service center.

Repairs

WARNING: To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment (including brush inspection and

replacement) should be performed by a DeWALT factory service

center or a DeWALT authorized service center. Always use identical

replacement parts..

Refer to Brushes for brush replacement information.

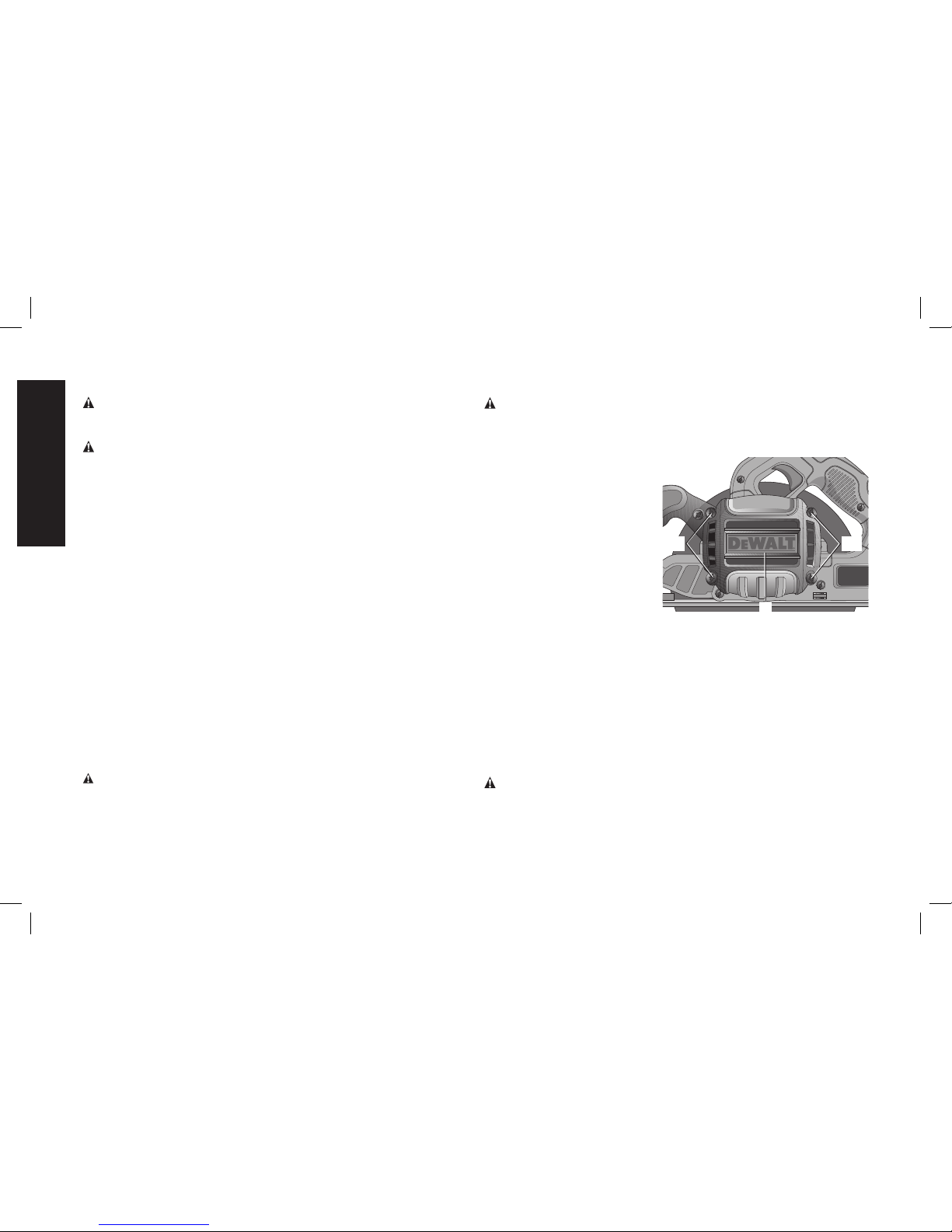

Brushes (Fig. 19)

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

Inspect carbon brushes

D

X

X

FIG. 19

regularly by disconnecting the

tool from the power source,

removing the four end cap

screws (X) with a screwdriver,

then removing the end

cap (D).

Keep brushes clean and

sliding freely in their guides.

Always replace a used brush

in the same orientation in

the holder as it was prior to

removal. Carbon brushes have varying symbols stamped into their

sides, and if either brush is worn down to the line closest to the

spring, take the tool to a DeWALT authorized service center for brush

assembly replacement. Use only identical DeWALT brushes. Always

replace the end cap after inspecting or servicing brushes. The tool

should be allowed to “run in” (run at no load without a blade) for 5

minutes before use to seat new brushes.

While “running in” DO NOT TIE, TAPE, OR OTHERWISE LOCK THE

TRIGGER SWITCH ON. HOLD BY HAND ONLY.

Foot Plate Adjustment

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

Page 17

15

English

Your foot plate has been factory set to assure that the blade is

perpendicular to the foot plate. If after extended use you need to

re-align the blade, follow the directions below:

ADJUSTING FOR 90 DEGREE CUTS (FIG. 1, 20)

1. Return the saw to

FIG. 20

Y

0degrees bevel.

2. Place the saw on its

side, and retract the

lower guard.

3. Set the depth of cut

at approximately 2"

(51mm).

4. Loosen the bevel

adjustment lever (F).

Place a square against

the blade and the

foot plate as shown in

Figure20.

5. Using a hex wrench, turn the set screw (Y) on the underside of the

foot plate until the blade and the foot plate are both in flush contact

with the square. Retighten the bevel adjustment lever.

ADJUSTING BEVEL ADJUSTMENT LEVER

It may be desirable to adjust the

FIG. 21

Z

F

bevel adjustment lever. It may

loosen in time and hit the foot plate

before tighten ing.

To tighten the lever, follow the

steps below.

1. Hold bevel adjustment lever (F)

and loosen the locknut (Z).

2. Adjust the bevel adjustment lever by rotating it in the desired

direction about 1/8 of a revolution.

3. Retighten nut.

Blades

A dull blade will cause inefficient cutting, overload on the saw motor,

excessive splintering and increase the possibility of kickback. Change

blades when it is no longer easy to push the saw through the cut,

when the motor is straining, or when excessive heat is built up in the

blade. It is a good practice to keep extra blades on hand so that sharp

blades are available for immediate use. Dull blades can be sharpened

in most areas; see SAWS-SHARPENING in the yellow pages.

Hardened gum on the blade can be removed with kerosene,

turpentine, or oven cleaner. Anti-stick coated blades can be used

in applications where excessive build-up is encountered, such as

pressure treated and green lumber.

RECOMMENDED BLADE TYPES

COMBINATION FRAMING 5/8" Round arbor, 24 teeth

All purpose fast rip and cross cuts.

PRESSURE TREATED/ 5/8" Round arbor, 20 teeth

WET LUMBER Coated - Resistant to gum build-up

EXTREME DURABILITY 5/8" Round arbor, 18 teeth

Coated, rock carbide

FINISHING 5/8" Round arbor, 36 teeth

More teeth for finer finish cuts.

FAST CUT FRAMING 5/8" Round arbor, 18 teeth

Fastest blade for rips and cross cuts

Page 18

16

English

Accessories

WARNING: Since accessories, other than those offered by DeWALT,

have not been tested with this product, use of such accessories with

this tool could be hazardous. To reduce the risk of injury, only DeWALT,

recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact DeWALT

Industrial Tool Co., 701 East Joppa Road, Towson, MD 21286, call

1-800-4-DeWALT (1-800-433-9258) or visit our website www.dewalt.

com.

DO NOT USE WATER FEED ATTACHMENTS WITH THIS SAW.

VISUALLY EXAMINE CARBIDE BLADES BEFORE USE. REPLACE IF

DAMAGED.

Three Year Limited Warranty

DeWA LT will repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-DeWALT (1-800-433-9258).

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, DeWALT tools are covered by our:

1 YEAR FREE SERVICE

DeWA LT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DeWA LT Power Tool, Laser, or Nailer for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund

– no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in

Latin America. For products sold in Latin America, see country specific

warranty information contained either in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DeWALT (1-800-433-

9258) for a free replacement.

Page 19

Français

17

Définitions: lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour

chaque mot-indicateur employé. Lire le mode d’emploi et

porter une attention particulière à ces symboles.

DANGER: indique une situation dangereuse imminente

qui, si elle n’est pas évitée, entraînera la mort ou des

blessures graves.

AVERTISSEMENT: indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner la

mort ou des blessures graves.

ATTENTION: indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner

des blessures légères ou modérées.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n’est fait

pour l’éviter, pourrait poser des risques de dommages

matériels.

IPOUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET

OUTIL OU DE TOUT AUTRE OUTIL DeWALT, COMPOSEZ LE

NUMÉRO SANS FRAIS : 1-800-4-DeWALT (1-800-433-9258).

AVERTISSEMENT : afin de réduire le risque de blessures, lire

le mode d’emploi de l’outil.

Avertissements de sécurité généraux

pour les outils électriques

AVERTISSEMENT ! Lire tous les avertissements de

sécurité et toutes les directives. Le non-respect des

avertissements et des directives pourrait se solder par un choc

électrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTÉRIEUR

Le terme « outil électrique » cité dans les avertissements se rapporte

à votre outil électrique à alimentation sur secteur (avec fil) ou par piles

(sans fil).

1) SÉCURITÉ DU LIEU DE TRAVAIL

a) Tenir l’aire de travail propre et bien éclairée. Les lieux

encombrés ou sombres sont propices aux accidents.

b) Ne pas faire fonctionner d’outils électriques dans un

milieu déflagrant, tel qu’en présence de liquides, de

gaz ou de poussières inflammables. Les outils électriques

produisent des étincelles qui pourraient enflammer la poussière

ou les vapeurs.

c) Éloigner les enfants et les personnes à proximité pendant

l’utilisation d’un outil électrique. Une distraction pourrait en

faire perdre la maîtrise à l’utilisateur.

2) SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a) Les fiches des outils électriques doivent correspondre

à la prise. Ne jamais modifier la fiche d’aucune façon.

Ne jamais utiliser de fiche d’adaptation avec un outil

électrique mis à la terre. Le risque de choc électrique sera

réduit par l’utilisation de fiches non modifiées correspondant à

la prise.

Page 20

Français

18

b) Éviter tout contact physique avec des surfaces mises à la

terre comme des tuyaux, des radiateurs, des cuisinières

et des réfrigérateurs. Le risque de choc électrique est plus

élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à

l’humidité. La pénétration de l’eau dans un outil électrique

augmente le risque de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais

utiliser le cordon pour transporter, tirer ou débrancher un

outil électrique. Tenir le cordon éloigné de la chaleur, de

l’huile, des bords tranchants et des pièces mobiles. Les

cordons endommagés ou enchevêtrés augmentent les risques

de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se

servir d’une rallonge convenant à cette application.

L’utilisation d’une rallonge conçue pour l’extérieur réduira les

risques de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil électrique

dans un endroit humide, brancher l’outil dans une prise

ou sur un circuit d’alimentation dotés d’un disjoncteur de

fuite à la terre (GFCI). L’utilisation de ce type de disjoncteur

réduit les risques de choc électrique.

3) SÉCURITÉ PERSONNELLE

a) Être vigilant, surveiller le travail effectué et faire preuve

de jugement lorsqu’un outil électrique est utilisé. Ne

pas utiliser d’outil électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Un

simple moment d’inattention en utilisant un outil électrique peut

entraîner des blessures corporelles graves.

b) Utiliser des équipements de protection individuelle.

Toujours porter une protection oculaire. L’utilisation

d’équipements de protection comme un masque antipoussière,

des chaussures antidérapantes, un casque de sécurité ou des

protecteurs auditifs lorsque la situation le requiert réduira les

risques de blessures corporelles.

c) Empêcher les démarrages intempestifs. S’assurer que

l’interrupteur se trouve à la position d’arrêt avant de

relier l’outil à une source d’alimentation et/ou d’insérer

un bloc-piles, de ramasser ou de transporter l’outil.

Transporter un outil électrique alors que le doigt repose sur

l’interrupteur ou brancher un outil électrique dont l’interrupteur

est à la position de marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé avant de démarrer

l’outil. Une clé ou une clé de réglage attachée à une partie

pivotante de l’outil électrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son équilibre en

tout temps. Cela permet de mieux maîtriser l’outil électrique

dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de

vêtements amples ni de bijoux. Garder les cheveux, les

vêtements et les gants à l’écart des pièces mobiles. Les

vêtements amples, les bijoux ou les cheveux longs risquent de

rester coincés dans les pièces mobiles.

g) Si des composants sont fournis pour le raccordement de

dispositifs de dépoussiérage et de ramassage, s’assurer

que ceux-ci sont bien raccordés et utilisés. L’utilisation d’un

dispositif de dépoussiérage peut réduire les dangers engendrés

par les poussières.

4) UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique

approprié à l’application. L’outil électrique approprié

effectuera un meilleur travail, de façon plus sûre et à la vitesse

pour laquelle il a été conçu.

Page 21

Français

19

b) Ne pas utiliser un outil électrique dont l’interrupteur

est défectueux. Tout outil électrique dont l’interrupteur est

défectueux est dangereux et doit être réparé.

c) Débrancher la fiche de la source d’alimentation et/ou du

bloc-piles de l’outil électrique avant de faire tout réglage

ou changement d’accessoire ou avant de ranger l’outil.

Ces mesures préventives réduisent les risques de démarrage

accidentel de l’outil électrique.

d) Ranger les outils électriques hors de la portée des enfants

et ne permettre à aucune personne n’étant pas familière

avec un outil électrique ou son mode d’emploi d’utiliser

cet outil. Les outils électriques deviennent dangereux entre les

mains d’utilisateurs inexpérimentés.

e) Entretien des outils électriques. Vérifier si les pièces

mobiles sont mal alignées ou coincées, si des pièces sont

brisées ou présentent toute autre condition susceptible

de nuire au bon fonctionnement de l’outil électrique.

En cas de dommage, faire réparer l’outil électrique

avant toute nouvelle utilisation. Beaucoup d’accidents sont

causés par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et

propres. Les outils de coupe bien entretenus et affûtés sont

moins susceptibles de se coincer et sont plus faciles à maîtriser.

g) Utiliser l’outil électrique, les accessoires, les forets,

etc. conformément aux présentes directives en tenant

compte des conditions de travail et du travail à effectuer.

L’utilisation d’un outil électrique pour toute opération autre que

celle pour laquelle il a été conçu est dangereuse.

5) RÉPARATION

a) Faire réparer l’outil électrique par un réparateur

professionnel en n’utilisant que des pièces de rechange

identiques. Cela permettra de maintenir une utilisation

sécuritaire de l’outil électrique.

Consignes de sécurité propres à toutes

les scies

PROCÉDURES DE COUPE

a) DANGER : éloigner les mains des zones et organes

de coupe. Maintenir la deuxième main sur la poignée

auxiliaire ou le boîtier du moteur. Lorsque les deux mains

maintiennent la scie, la lame ne peut les couper.

b) N’essayez pas de tenir le dessous de l’ouvrage. Le

protège-lame ne peut pas vous protéger de la lame en dessous

de l'ouvrage.

c) Ajustez la profondeur de coupe à l’épaisseur de l’ouvrage.

Moins d’une dent entière de lame devrait être visible en dessous

de l’ouvrage.

d) Ne tenez jamais dans vos mains ou sur vos genoux un

ouvrage qui est en cours de coupe. Fixez votre ouvrage

sur une plateforme stable. Il est important de soutenir

correctement l’ouvrage afin de minimiser l’exposition du corps

à la lame, le risque de coincement de la lame ou la perte de

contrôle de l’outil.

e) Tenez l’outil électrique uniquement par les parties

isolées prévues à cet effet pendant toute utilisation où

l’organe de coupe pourrait entrer en contact avec des

fils électriques ou son propre cordon d’alimentation. Tout

contact avec un fil « sous tension » risque de mettre « sous

tension» les pièces métalliques exposées de l’outil et de causer

une décharge électrique à l’opérateur.

f) Pendant les coupes de refente, utilisez toujours un guide

de refente ou un guide à bord droit. Ceci augmente toujours

l’exactitude de la coupe et diminue la possibilité de coincement

de la lame.

g) Utilisez toujours des lames dont l’alésage central est

de la taille et de la forme appropriées (soit en forme

Page 22

Français

20

b) En cas de coincement de la lame ou d’interruption d'une

coupe pour une raison quelconque, relâchez la gâchette

et tenez la scie immobile dans l’ouvrage jusqu’à ce que la

lame se soit immobilisée complètement. Ne tentez jamais

de retirer la scie de l’ouvrage ou de la tirer vers l’arrière

pendant que la lame est en mouvement, car un rebond

risquerait de se produire. Évaluez la situation et prenez les

mesures correctives nécessaires pour éliminer la cause du

coincement de la lame.

c) Lorsque vous remettez une scie en marche quand

l’ouvrage est présent, centrez la lame de scie dans le trait

de scie et vérifiez que les dents de la lame ne sont pas

engagées dans le matériau de l’ouvrage. Si la lame de scie

se coince, elle peut grimper hors de l’ouvrage ou rebondir sur

celui-ci quand la scie est remise en marche.

d) Soutenez les panneaux de grande taille de façon à

minimiser le risque de pincement et de rebond de la

lame. Les panneaux de grande taille ont tendance à s’affaisser

sous leur propre poids. Des supports doivent être placés des

deux côtés sous le panneau, à proximité de la ligne de coupe et

à proximité du rebord du panneau.

e) N’utilisez pas de lame émoussée ou endommagée. Des

lames non aiguisées ou mal installées produisent un trait de scie

étroit qui cause une friction excessive, le coincement de la lame

et un effet de rebond.

f) Les leviers de réglage de la profondeur et de l’angle de

coupe de la lame doivent être bien serrés et assujettis

avant de réaliser une coupe. Une modification du réglage de

la lame pendant la coupe risque d’entraîner un coincement et

un rebondissement de la lame.

g) Faites preuve d’une extrême prudence au moment de

scier dans un mur ou à tout autre endroit où la visibilité

est réduite. La lame en saillie est susceptible de couper des

objets pouvant causer des effets de rebonds.

de diamant, soit en forme de rond). Les lames qui ne

correspondent pas aux pièces de montage de la cie tourneront

de façon excentrique, ce qui causera une perte de contrôle de

l’outil.

h) Ne vous servez jamais de rondelles ou de boulons

de lames qui sont endommagés ou inappropriés. Les

rondelles et le boulon de lame ont été conçus spécifiquement

pour votre scie dans le but d'assurer une performance optimale

et un fonctionnement sans danger.

Consignes additionnelles de sécurité

propres à toutes les scies

CAUSES DE REBONDS ET AVERTISSEMENTS AFFÉRENTS:

– Le rebond est une réaction subite (causée par une lame de

scie pincée, coincée ou mal alignée) qui peut entraîner le

soulèvement d’une scie non contrôlée, sa sortie de l’ouvrage et

sa projection en direction de l'utilisateur.

– Si la lame est pincée ou coincée fortement pendant l’abaissement

de la scie, la lame se cale et le moteur réagit en entraînant

rapidement l’outil vers l’arrière dans la direction de l’opérateur.

– Si la lame se tord ou perd son alignement correct au cours

de la coupe, les dents sur le bord arrière de la lame peuvent

entamer la surface supérieure du bois, forçant ainsi la lame à

sortir du trait de scie et à « sauter » vers l’arrière en direction de

l’opérateur.

Le rebond est la conséquence d’une mauvaise utilisation de la scie et/

ou de procédures ou de conditions incorrectes, et il peut être évité en

prenant les précautions qui sont décrites ci-dessous :

a) Maintenez fermement la scie avec vos deux mains et

positionnez vos bras de façon à résister aux forces de

rebond. Les forces de rebond peuvent être contrôlées par

l’utilisateur quand les précautions appropriées sont prises.

Page 23

Français

21

FONCTION DU CARTER INFÉRIEUR

a) Inspectez le protège-lame inférieur avant chaque

utilisation pour vous assurer qu’il se ferme correctement.

Ne faites pas fonctionner la scie si le protège-lame

inférieur ne se déplace pas librement et ne se ferme

pas instantanément. Ne forcez jamais le protège-lame

inférieur dans la position ouverte à l’aide d’un collier de

serrage ou d’une attache. Il est possible que le protège-

lame inférieur se torde en cas de chute accidentelle de la

scie. Soulevez le protège-lame inférieur à l’aide de la poignée

rétractable et assurez-vous qu’il se déplace sans problème et

qu’il ne touche pas la lame ou une autre pièce, quel que soit

l’angle ou la profondeur de la coupe.

b) Vérifiez le fonctionnement du ressort du protège-lame

inférieur. Si le protège-lame inférieur et le ressort ne

fonctionnent pas correctement, ils doivent être réparés

avant l’emploi. Le protège-lame inférieur peut parfois mal

fonctionner à cause de pièces endommagées, d’accumulation

de résine ou de débris.

c) Le protège-lame inférieur doit être rétracté à la main

uniquement à l’occasion de coupes spéciales telles que

les « coupes en plongée » ou les « coupes composées ».

Soulevez le protège-lame inférieur à l’aide la poignée

rétractable et relâchez-le dès que la lame pénètre dans le

matériau de l’ouvrage. Pour toute autre opération de sciage,

le protège-lame inférieur doit fonctionner automatiquement.

d) Vérifiez toujours que le protège-lame inférieur couvre

la lame avant de placez la scie sur un banc ou sur le

sol. Une lame non protégée qui tourne librement entraînera le

mouvement de la scie en marche arrière, ce qui provoquera

la coupe de tout se qui se trouve sur sa trajectoire. Soyez

conscient du temps nécessaire à la lame pour s'arrêter une fois

que la gâchette est relâchée.

Consignes spécifiques additionnelles de

sécurité propres aux scies circulaires

AVERTISSEMENT: ne pas utiliser de meules ou de lames

abrasives.

AVERTISSEMENT : ne pas utiliser des dispositifs

d’alimentation en eau.

• Utilisez des serres de fixation ou un autre dispositif de

fixation permettant de soutenir et de retenir la pièce sur

une plate-forme stable. Tenir la pièce avec la main ou contre son

corps n’est pas suffisamment stable et risque de provoquer une

perte de maîtrise de l’outil.

• Se placer à gauche ou à droite de la lame de scie et non

dans sa trajectoire. L'effet de rebond risque de faire rebondir la

scie vers l’arrière (consulter les rubriques Causes des rebonds

et méthodes de prévention pouvant être utilisées par

l’utilisateur et REBOND).

• Éviter de couper des clous. Inspecter le bois et retirer les

clous présents avant toute coupe.

• La vitesse nominale des accessoires doit être équivalente

ou supérieure à celle recommandée sur l’étiquette

d’avertissement de l’outil. Une meule ou tout autre accessoire

tournant à une vitesse supérieure à sa vitesse nominale peut

se désintégrer et poser des risques de dommages corporels.

L’intensité nominale des accessoires utilisés doit être supérieure à

la vitesse minimum des outils, indiquée sur la plaque signalétique.

• Avant toute utilisation, s’assurer systématiquement que la scie est

propre.

• En cas de bruit inhabituel ou de fonctionnement anormal, arrêter

l’utilisation de la scie et la faire vérifier.

• S’assurer systématiquement que tous les composants sont

installés correctement et solidement avant toute utilisation de l’outil.

Page 24

Français

22

• Prendre systématiquement des précautions lors de l’installation et

du retrait de la lame de la scie.

• Attendre systématiquement que le moteur tourne à plein régime

avant d’entamer une coupe.

• Maintenir les poignées propres et sèches, exemptes d’huile ou

de graisse. Pendant l’utilisation, maintenir fermement l’outil à

deux mains.

• Rester constamment vigilant, particulièrement lors d’opérations

répétitives et monotones. Rester systématiquement conscient de

la position des mains par rapport à la lame.

• Se protéger de la chute de tout rebut pendant la coupe. Ils

pourraient être brûlants, coupants et/ou lourds et poser des

risques de dommages corporels sérieux.

• Remplacer ou faire réparer tout cordon endommagé. S’assurer

que la rallonge est en bon état. N’utiliser que des rallonges trifilaires

munies de fiches tripolaires, et des prises tripolaires acceptant la

fiche de l’outil.

• Prendre des précautions à proximité des évents, car ils

cachent des pièces mobiles. Vêtements amples, bijoux ou

cheveux longs risquent de rester coincés dans ces pièces mobiles.

• Pour la sécurité de l’utilisateur, utiliser une rallonge de

calibre adéquat (AWG, American Wire Gauge [calibrage

américain normalisé des fils électriques]). Plus le calibre est

petit, et plus sa capacité est grande. Un calibre16, par exemple,

a une capacité supérieure à un calibre18. L’usage d’une rallonge

de calibre insuffisant causera une chute de tension qui entraînera

perte de puissance et surchauffe. Si plus d’une rallonge est utilisée

pour obtenir une certaine longueur, s’assurer que chaque rallonge

présente au moins le calibre de fil minimum. Le tableau ci-dessous

illustre les calibres à utiliser selon la longueur de rallonge et

l’intensité nominale indiquée sur la plaque signalétique. En cas

de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la

rallonge peut supporter de courant.

Calibres minimaux des rallonges

Intensité (en

ampères)

volts Longueur totale de cordon en mètres

(pieds)

120 V 7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

240 V 15,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

Supérieur àInférieur

à

AWG

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Non recommandé

AVERTISSEMENT: porter SYSTEMATIQUEMENT des lunettes

de protection. Les lunettes courantes NE sont PAS des lunettes de

protection. Utiliser aussi un masque antipoussières si la découpe

doit en produire beaucoup. PORTER SYSTÉMATIQUEMENT UN

ÉQUIPEMENT DE SÉCURITÉ HOMOLOGUÉ:

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3);

• Protection auditive ANSI S12.6 (S3.19);

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

AVERTISSEMENT : les scies, meules, ponceuses, perceuses

ou autres outils de construction peuvent produire des poussières

contenant des produits chimiques reconnus par l’État californien pour

causer cancers, malformations congénitales ou être nocifs au système

reproducteur. Parmi ces produits chimiques, on retrouve:

• Le plomb dans les peintures à base de plomb;

• La silice cristallisée dans les briques et le ciment, ou autres

produits de maçonnerie; et

• L’arsenic et le chrome dans le bois ayant subi un traitement

chimique.

Le risque associé à de telles expositions varie selon la fréquence à

laquelle on effectue ces travaux. Pour réduire toute exposition à ces

Page 25

Français

23

produits: travailler dans un endroit bien aéré, en utilisant du matériel

de sécurité homologué, tel un masque antipoussières spécialement

conçu pour filtrer les particules microscopiques.

• Limiter toute exposition prolongée avec les poussières

provenant du ponçage, sciage, meulage, perçage ou toute

autre activité de construction. Porter des vêtements de

protection et nettoyer à l’eau savonneuse les parties du

corps exposées. Le fait de laisser la poussière pénétrer dans la

bouche, les yeux ou la peau peut favoriser l’absorption de produits

chimiques dangereux.

AVERTISSEMENT : cet outil peut produire et/ou répandre de

la poussière susceptible de causer des dommages sérieux et

permanents au système respiratoire. Utiliser systématiquement un

appareil de protection des voies respiratoires homologué par le NIOSH

ou l’OSHA. Diriger les particules dans le sens opposé au visage et au

corps.

AVERTISSEMENT : pendant l’utilisation, porter

systématiquement une protection auditive individuelle

adéquate homologuée ANSI S12.6 (S3.19). Sous certaines

conditions et suivant la durée d’utilisation, le bruit émanant de ce

produit pourrait contribuer à une perte de l’acuité auditive.

• L’étiquette apposée sur votre outil peut inclure les symboles

suivants. Les symboles et leur définition sont indiqués ci-après:

V ................... volts A ....................... ampères

Hz ................. hertz W ...................... watts

min ............... minutes ou AC .......... courant

ou DC ... courant continu ......................... alternatif

................. classe I ou AC/DC ... courant

..................... fabrication ......................... alternatif

(mis à la terre) ou continu

................. fabrication

n

o ..................... vitesse à vide

classe II n ....................... vitesse

(double isolation) ........................ nominale

…/min .......... par minute .....................borne de terre

IPM ............... impacts par ...................... symbole

minute ......................... d’avertissement

BPM ............. battements par r/min ................. tours par

minute minute

sfpm ............. pieds linéaires SPM (FPM) ....... fréquence par

par minute (plpm) minute

................ radiation visible

CONSERVER CES CONSIGNES POUR

UTILISATION ULTÉRIEURE

Moteur

S’assurer que le bloc d’alimentation est compatible avec l’inscription

de la plaque signalétique. Une diminution de tension de plus de 10 %

provoquera une perte de puissance et une surchauffe. Les outils

DeWALT sont testés en usine; si cet outil ne fonctionne pas, vérifier

l’alimentation électrique.

Page 26

Français

24

DESCRIPTION (Fig. 1)

AVERTISSEMENT: ne jamais modifier l’outil électrique ni aucun

de ses composants, car il y a risques de dommages corporels ou

matériels.

A. Gâchette H. Plaque d’assise

B. Poignée principale I. Protège-lame inférieur

C. Verrouillage de lame J. Vis de serrage de lame

D. Capot K. Levier du protège-lame inférieur

E. Poignée auxiliaire L. Protège-lame supérieur

F. Levier de réglage de biseau

G. Mécanisme de réglage

d’angle de biseau

E

D

B

A

J

I

FIG. 1

H

G

F

C

L

K

USAGE PRÉVU

Ces scies circulaires industrielles ont été conçues pour la découpe

professionnelle du bois. NE PAS utiliser d’accessoires d’alimentation

en eau avec cette scie. NE PAS utiliser de meules ou de lames

abrasives. NE PAS utiliser l’outil en milieu ambiant humide ou en

présence de liquides ou de gaz inflammables.

Ces scies industrielles sont des outils de professionnels. NE PAS les

laisser à la portée des enfants. Une supervision est nécessaire auprès

de tout utilisateur non expérimenté.

AJUSTEMENTS

Remplacement des lames

AVERTISSEMENT: pour réduire le risque de blessures, éteindre

l’appareil et le débrancher avant d’installer ou de retirer tout

accessoire et avant d’effectuer des réglages ou des réparations.

Un démarrage accidentel peut provoquer des blessures.

M

J

N

FIG. 2

FIG. 3

K

I

Page 27

Français

25

INSTALLATION DE LA LAME (FIG. 2–5)

1. À l’aide du levier du protège-lame inférieur (K), rétractez le protègelame inférieur (I) et placez la lame sur la broche de scie contre la

rondelle de serrage interne (M) en

C

FIG. 4

vous assurant que la lame

tournera dans le bon sens (le sens

de la flèche de rotation sur la lame

et les dents doit pointer dans la

même direction que celle de la

flèche de rotation sur la scie). Ne

pas assumer que le côté imprimé

de la lame est toujours face à

l’utilisateur lorsqu’elle est installée

correctement. Lorsqu’on escamote le protège-lame inférieur en

vue d’installer la lame, le vérifier afin de s’assurer qu’il est en bon

état et qu’il fonctionne correctement, c’est-à-dire, qu’il se déplace

librement et qu’il ne touche pas à la lame ni à toute autre pièce

quelconque, quel que soit l’angle ou la profondeur de coupe.

2. Placer la rondelle de bride de

FIG. 5

O

FIG. 5

B

serrage externe (N) sur la

broche de scie, en s’assurant

de placer la large surface

plane contre la lame, et le

côté imprimé de la rondelle

face à l’utilisateur.

3. Vissez manuellement la vis

de serrage de lame (J) sur la

broche de scie (la vis possède

un filetage vers la droite et

doit être tournée vers la droite

pour être resserrée).

4. Appuyez sur le bouton de

verrouillage de lame (C) tout

en tournant la broche de scie avec la clé pour lame (O) entreposée

sous la poignée principale (B), (fig.5), jusqu’à ce que le verrouillage

de lame s’enclenche et que la lame cesse de tourner.

5. Serrer fermement la vis de fixation au moyen de la clé de réglage.

REMARQUE : ne jamais engager le bouton de verrouillage de la lame

lorsque la scie est en marche pour tenter d’arrêter l’outil. Ne jamais

mettre l’outil en marche lorsque le bouton de verrouillage est engagé

afin d’éviter d’endommager gravement la scie.

REMPLACEMENT DE LA LAME (FIG. 2, 4, 5)

1. Pour desserrer la vis de serrage de lame (J), appuyez sur le bouton

de verrouillage de lame (C) et tournez la broche de scie avec la clé

pour lame (O) entreposée sous la poignée principale (B), jusqu’à

ce que le verrouillage de lame s’enclenche et que la lame cesse

de tourner. Alors que le verrouillage de lame est activé, tournez la

vis de serrage de lame vers la gauche avec la clé pour lame (la vis

a un filetage vers la droite et doit être tournée vers la gauche pour

être desserrée).

2. Retirer la vis de fixation (J) et la rondelle de bride de serrage

externe (N) seulement, puis enlever l’ancienne lame.

3. Enlever la sciure qui aurait pu s’accumuler dans le protège-lame

ou autour de la rondelle et vérifier le protège-lame inférieur afin de

s’assurer qu’il est en bon état et qu’il fonctionne correctement, tel

que décrit précédemment. Ne pas lubrifier cette zone.

4. Sélectionnez la lame adaptée à l’application désirée (se reporter

à la section Type de lames recommandées sous Lames).

Toujours utiliser une lame de dimension (178 mm [7-1/4"]

diamètre) appropriés munie d’un orifice de dimension et de forme