Page 1

DWE4001

www .

.eu

DWE4050

Page 2

English (original instructions) 3

Français (traduction de la notice d’instructions originale) 15

Copyright DEWALT

B

Page 3

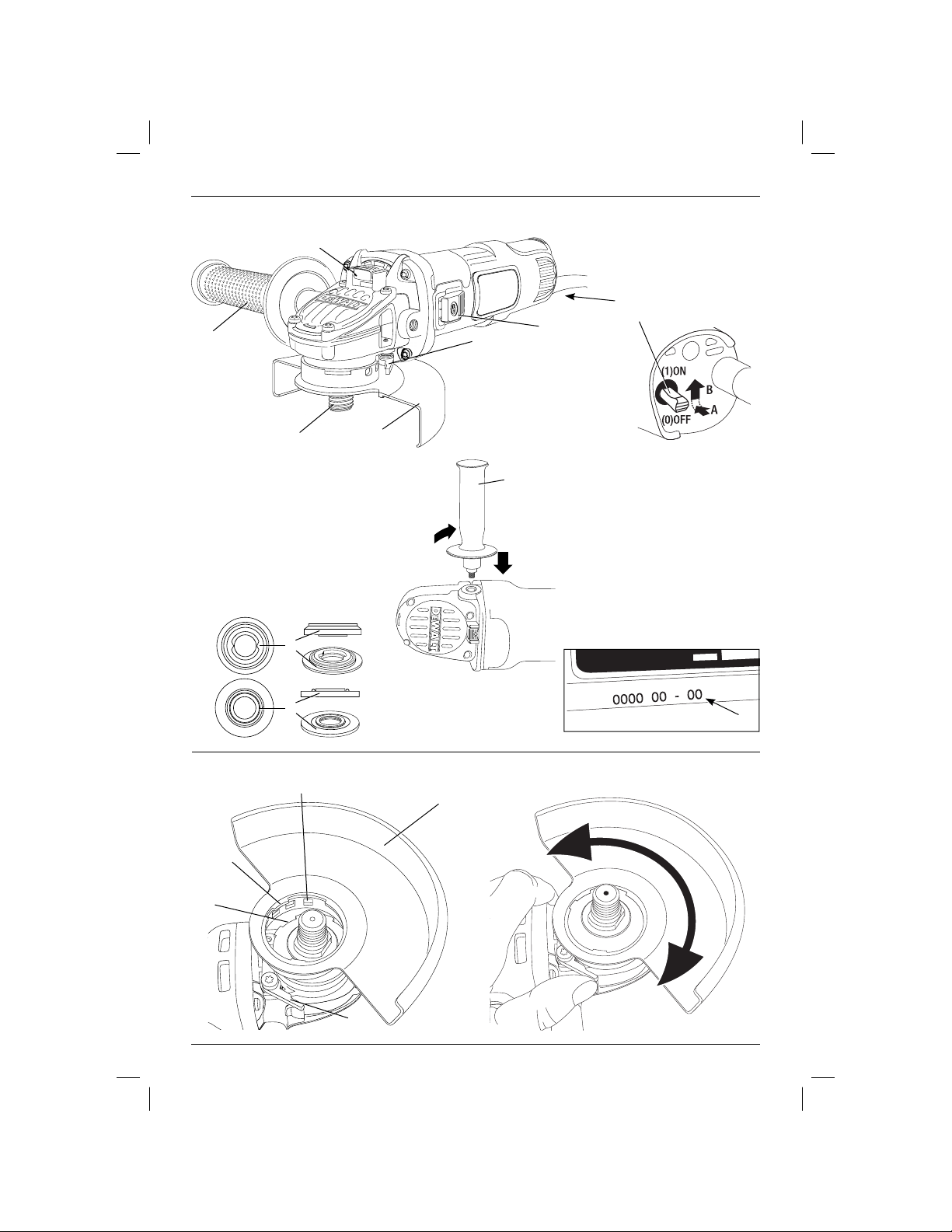

Figure 1

c

DWE4050

a

g1

h

g

DWE4001

Figure 2

b

d

e

k

i

f

c

p

f

j

h

1

Page 4

Figure 3

Figure 4

e

f

j

Figure 5

i

m

j

l

b

b

Figure 6

DWE4050

n

d

g

DWE4001

g1

2

Page 5

ANGLE GRINDERS

DWE4001, DWE4050

ENGLISH

Congratulations!

You have chosen a DEWALT tool. Years of

experience, thorough product development and

innovation make DEWALT one of the most reliable

partners for professional power tool users.

Technical Data

DWE4001 DWE4050

B4/B5 B4/B5

Voltage V 127/220–240 127/220–240

Type 1 1

Power input W 800 800

No-load/rated speed min-1 12000 12000

Wheel diameter mm 100 115

Spindle diameter M10 M14

Weight kg 1.72* 1.76*

* weight includes side handle and guard

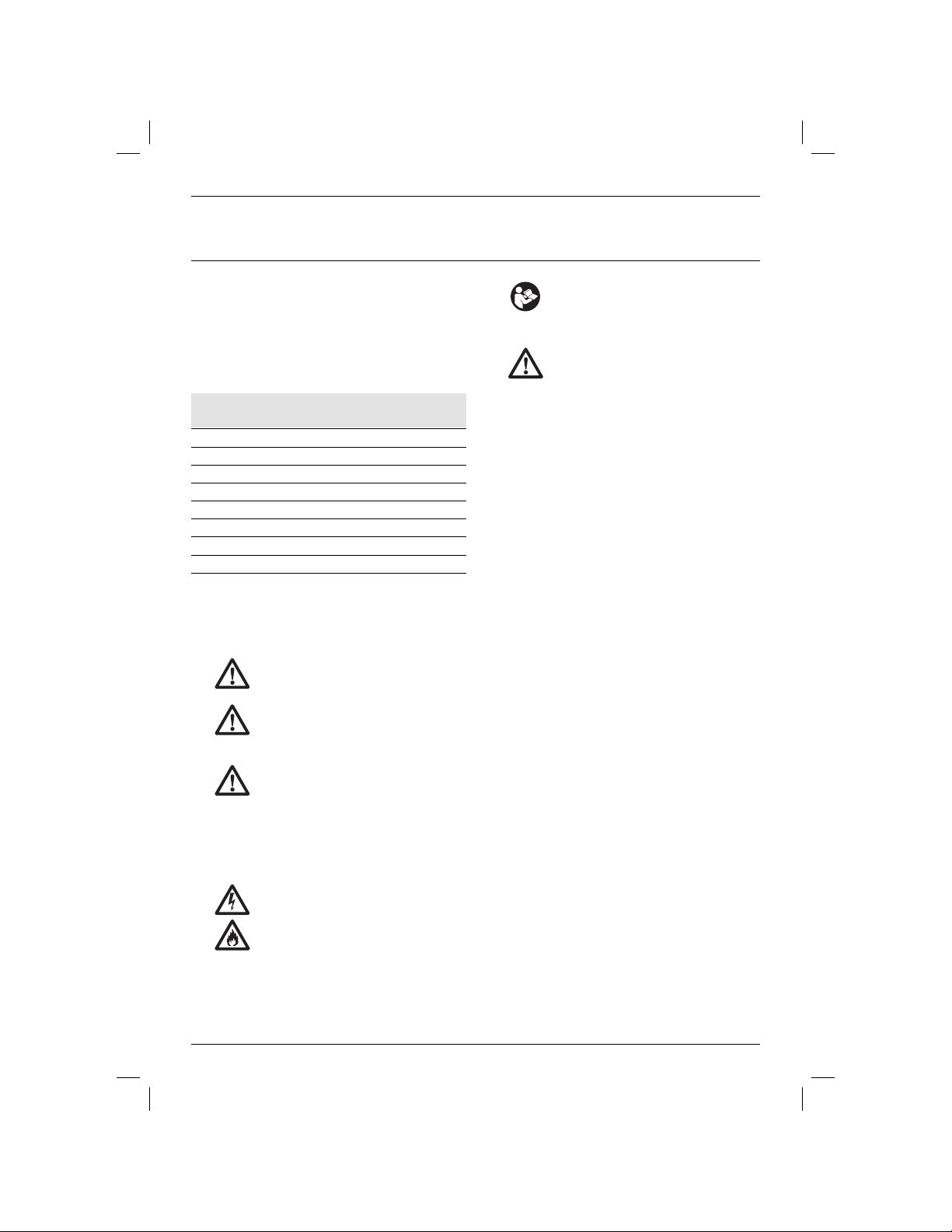

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

NOTICE: Indicates a practice not

related to personal injury which, if

not avoided, may result in property

damage.

Denotes risk of electric shock.

Denotes risk of fire.

WARNING: To reduce the risk of injury,

read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings

and all instructions. Failure to follow

the warnings and instructions may result

in electric shock, fire and/or serious

injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

3

Page 6

ENGLISH

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

ADDITIONAL SPECIFIC SAFETY RULES

Safety Instructions for All Operations

a) This power tool is intended to function

as a grinder, sander, wire brush, polisher

or cut-off tool. Read all safety warnings,

instructions, illustrations and specifications

provided with this power tool. Failure to follow

all instructions listed below may result in electric

shock, fire and/or serious injury.

b) Do not use accessories which are not

specifically designed and recommended

by the tool manufacturer. Just because the

accessory can be attached to your power tool,

it does not assure safe operation.

4

Page 7

ENGLISH

c) The rated speed of the accessory must be at

least equal to the maximum speed marked

on the power tool. Accessories running faster

than their rated speed can break and fly apart.

d) The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or

controlled.

e) The arbour size of wheels, flanges, backing

pads or any other accessory must properly

fit the spindle of the power tool. Accessories

with arbour holes that do not match the

mounting hardware of the power tool will run

out of balance, vibrate excessively and may

cause loss of control.

f) Do not use a damaged accessory. Before

each use inspect the accessory such as

abrasive wheel for chips and cracks, backing

pad for cracks, tear or excess wear, wire

brush for loose or cracked wires. If power

tool or accessory is dropped, inspect for

damage or install an undamaged accessory.

After inspecting and installing an accessory,

position yourself and bystanders away from

the plane of the rotating accessory and run

the power tool at maximum no-load speed

for one minute. Damaged accessories will

normally break apart during this test time.

g) Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye protection must

be capable of stopping flying debris generated

by various operations. The dust mask or

respirator must be capable of filtrating particles

generated by your operation. Prolonged

exposure to high intensity noise may cause

hearing loss.

h) Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken

accessory may fly away and cause injury

beyond immediate area of operation.

i) Hold power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. Cutting

accessory contacting a "live" wire may make

exposed metal parts of the power tool "live" and

could give the operator an electrical shock.

j) Position the cord clear of the spinning

accessory. If you lose control, the cord may be

cut or snagged and your hand or arm may be

pulled into the spinning accessory.

k) Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and

pull the power tool out of your control.

l) Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

m) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside

the housing and excessive accumulation of

powdered metal may cause electrical hazards.

n) Do not operate the power tool near

flammable materials. Sparks could ignite these

materials.

o) Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

FURTHER SAFETY INSTRUCTIONS

FOR ALL OPERATIONS

Causes and Operator Prevention

of Kickback

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging causes

rapid stalling of the rotating accessory which in turn

causes the uncontrolled power tool to be forced in

the direction opposite of the accessory’s rotation at

the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the

surface of the material causing the wheel to climb

out or kick out. The wheel may either jump toward

or away from the operator, depending on direction

of the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these

conditions.

Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be

avoided by taking proper precautions as given

below:

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control

5

Page 8

ENGLISH

over kickback or torque reaction during start

up. The operator can control torque reaction or

kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating

accessory. Accessory may kickback over your

hand.

c) Do not position your body in the area where

power tool will move if kickback occurs.

Kickback will propel the tool in direction

opposite to the wheel’s movement at the point

of snagging.

d) Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or

kickback.

e) Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of control.

Safety Warnings Specifi c for

Grinding and Abrasive Cutting-Off

Operations

a) Use only wheel types that are recommended

for your power tool and the specific guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot

be adequately guarded and are unsafe.

b) The guard must be securely attached

to the power tool and positioned for

maximum safety, so the least amount of

wheel is exposed towards the operator. The

guard helps to protect the operator from broken

wheel fragments, accidental contact with wheel

and sparks that could ignite clothing.

c) Wheels must be used only for recommended

applications. For example: do not grind with

the side of cut-off wheel. Abrasive cut-off

wheels are intended for peripheral grinding, side

forces applied to these wheels may cause them

to shatter.

d) Always use undamaged wheel flanges

that are of correct size and shape for your

selected wheel. Proper wheel flanges support

the wheel thus reducing the possibility of wheel

breakage. Flanges for cut-off wheels may be

different from grinding wheel flanges.

e) Do not use worn down wheels from larger

power tools. Wheel intended for larger power

tool is not suitable for the higher speed of a

smaller tool and may burst.

Additional Safety Warnings Specifi c

for Abrasive Cutting-Off Operations

a) Do not "jam" the cut-off wheel or apply

excessive pressure. Do not attempt to make

an excessive depth of cut. Overstressing the

wheel increases the loading and susceptibility to

twisting or binding of the wheel in the cut and

the possibility of kickback or wheel breakage.

b) Do not position your body in line with and

behind the rotating wheel. When the wheel,

at the point of operations, is moving away from

your body, the possible kickback may propel the

spinning wheel and the power tool directly at

you.

c) When wheel is binding or when interrupting

a cut for any reason, switch off the power

tool and hold the power tool motionless

until the wheel comes to a complete stop.

Never attempt to remove the cut-off wheel

from the cut while the wheel is in motion

otherwise kickback may occur. Investigate

and take corrective action to eliminate the cause

of wheel binding.

d) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed

and carefully reenter the cut. The wheel may

bind, walk up or kickback if the power tool is

restarted in the workpiece.

e) Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under

their own weight. Supports must be placed

under the workpiece near the line of cut and

near the edge of the workpiece on both sides of

the wheel.

f) Use extra caution when making a "pocket

cut" into existing walls or other blind areas.

The protruding wheel may cut gas or water

pipes, electrical wiring or objects that can cause

kickback.

Safety Warnings Specifi c for Sanding

Operations

a) Do not use excessively oversized sanding

disc paper. Follow manufacturer’s

recommendations, when selecting sanding

paper. Larger sanding paper extending beyond

the sanding pad presents a laceration hazard

and may cause snagging, tearing of the disc

or kickback.

6

Page 9

ENGLISH

Safety Warnings Specifi c for

Polishing Operations

a) Do not allow any loose portion of the

polishing bonnet or its attachment strings

to spin freely. Tuck away or trim any loose

attachment strings. Loose and spinning

attachment strings can entangle your fingers or

snag on the workpiece.

Safety Warnings Specifi c for Wire

Brushing Operations

a) Be aware that wire bristles are thrown by

the brush even during ordinary operation.

Do not overstress the wires by applying

excessive load to the brush. The wire bristles

can easily penetrate light clothing and/or skin.

b) If the use of a guard is recommended for

wire brushing, do not allow any interference

of the wire wheel or brush with the guard.

Wire wheel or brush may expand in diameter

due to work and centrifugal forces.

Additional Safety Rules for Grinders

• Threaded mounting of accessories must match

the grinder spindle thread. For accessories

mounted by flanges, the arbor hole of the

accessory must fit the locating diameter of

the flange. Accessories that do not match the

mounting hardware of the power tool will run

out of balance, vibrate excessively and may

cause loss of control.

• The grinding surface of the centre depressed

wheels must be mounted below the plane of

the guard lip. An improperly mounted wheel

that projects through the plane of the guard lip

cannot be adequately protected.

• Do not use Type 11 (flaring cup) wheels on

this tool. Using inappropriate accessories can

result in injury.

• Always use side handle. Tighten the handle

securely. The side handle should always be

used to maintain control of the tool at all times.

Residual Risks

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

– Impairment of hearing.

– Risk of personal injury due to flying particles.

– Risk of burns due to accessories becoming hot

during operation.

– Risk of personal injury due to prolonged use.

– Risk of dust from hazardous substances.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual before use.

Wear ear protection.

Wear eye protection.

DATE CODE POSITION (FIG. 1)

The date code (p), which also includes the year of

manufacture, is printed into the housing.

Example:

2012 XX XX

Year of Manufacture

Package Contents

The package contains:

1 Angle grinder

1 Guard

1 Side handle

1 Flange set

1 Wrench

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Description (fi g. 1)

WARNING: Never modify the power

tool or any part of it. Damage or

personal injury could result.

a. Spindle lock button

b. Spindle

c. Side handle

d. Backing flange

e. Threaded clamp nut

f. Guard

g. Slider switch (DWE4050)

7

Page 10

ENGLISH

g1. On/off switch (DWE4001)

h. Guard release lever

INTENDED USE

The DWE4001, DWE4050 heavy-duty angle grinders

have been designed for professional grinding,

sanding, wire brushing, polishing and cutting

applications.

DO NOT use grinding wheels other than centre

depressed wheels and flap discs.

DO NOT use under wet conditions or in the

presence of flammable liquids or gases.

These heavy-duty angle grinders are professional

power tools.

DO NOT let children come into contact with the

tool. Supervision is required when inexperienced

operators use this tool.

• This product is not intended for use by persons

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

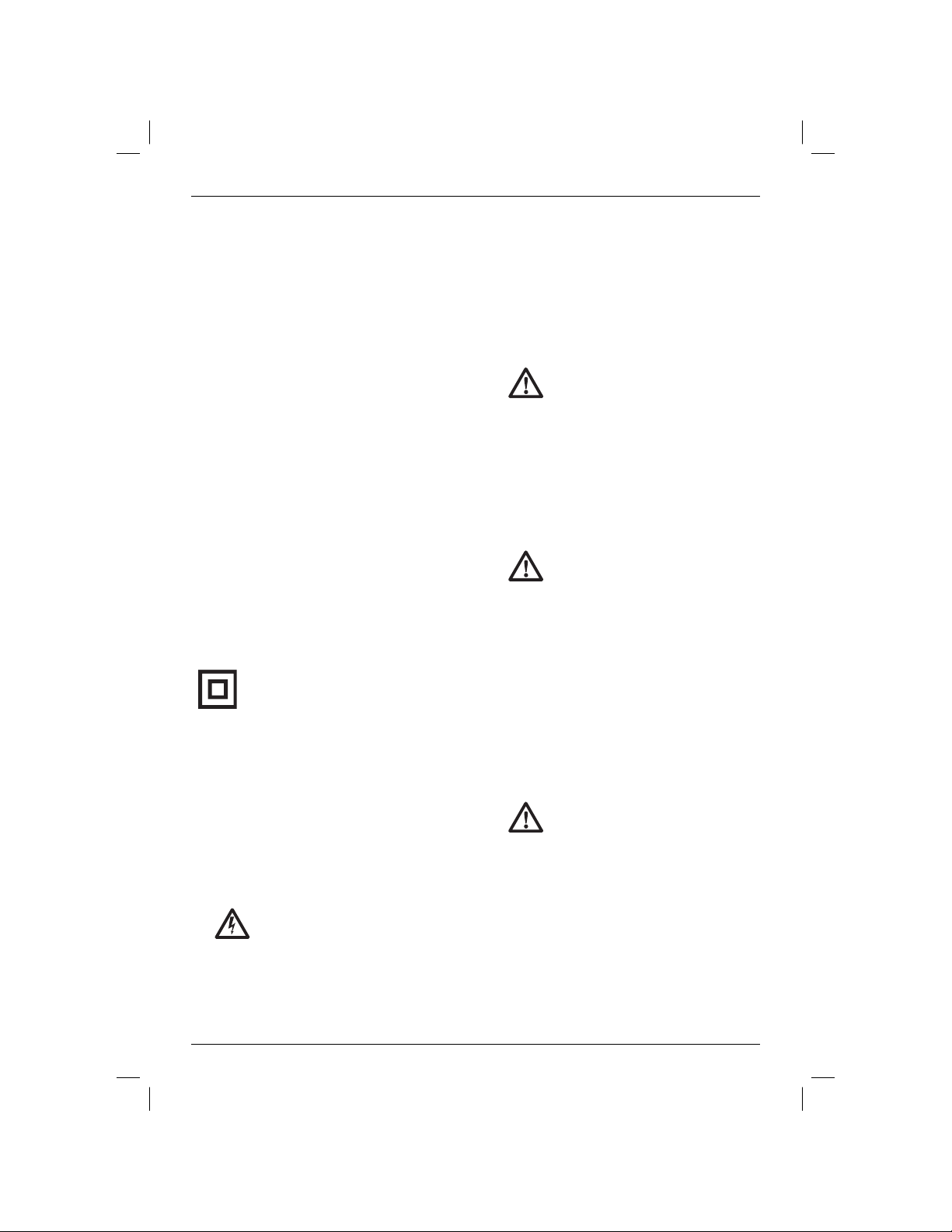

Electrical Safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Your DEWALT tool is double insulated in

accordance with IEC60745; therefore no

earth wire is required.

If the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

DEWALT service organisation.

Mains Plug Replacement

(Middle East and Africa)

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

• Connect the brown lead to the live terminal in

the plug.

• Connect the blue lead to the neutral terminal.

WARNING: No connection is to be

made to the earth terminal.

Follow the fitting instructions supplied with good

quality plugs. Recommended fuse: 13 A.

Using an Extension Cable

If an extension cable is required, use an approved

3–core extension cable suitable for the power input

of this tool (see Technical Data).The minimum

conductor size is 1.5 mm

is 30 m.

When using a cable reel, always unwind the cable

completely.

2

; the maximum length

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories. Before

reconnecting the tool, depress and

release the trigger switch to ensure that

the tool is off. An accidental start-up can

cause injury.

Attaching Side Handle (fi g. 1)

WARNING: Before using the tool,

Screw the side handle (c) tightly into one of the holes

on either side of the gear case. The side handle

should always be used to maintain control of the

tool at all times.

check that the handle is tightened

securely.

Accessories and Attachments

It is important to choose the correct guards, backing

pads and flanges to use with grinder accessories.

Refer to chart at the end of this section for

information on choosing the correct accessories.

NOTE: Edge grinding and cutting can be performed

with Type 27 wheels designed and specified for this

purpose.

WARNING: Accessories must be rated

If it does not, it may have been designed for a

circular saw and should not be used. Use only

the accessories shown in chart at the end of this

section. Accessory ratings must be above listed

minimum wheel speed as shown on tool nameplate.

for at least the speed recom mended

on the tool warning label. Wheels and

other accessories running over rated

accessory speed may burst and cause

injury. Threaded accessories must have

a M14 (DWE4050) or M10 (DWE4001)

hub. Every unthreaded accessory must

have a 22 mm (DWE4050) or 16 mm

(DWE4001) arbor hole.

8

Page 11

ENGLISH

Mounting Guards

WARNING: To reduce the risk

NOTE: Please refer to the Grinding and Cutting

Accessory Chart at the end of this section to

see other accessories that can be used with these

grinders.

MOUNTING AND REMOVING (TYPE 27)

ONE-TOUCH GUARD (FIG. 2)

NOTE: If your grinder is supplied with a keyless

One-Touch guard ensure the screw and spring are

fitted correctly before mounting the guard

1. Press the guard release lever (h).

2. While holding the guard release lever open, align

3. Keeping the guard release lever open, push the

4. With the spindle facing the operator, rotate

5. For easy adjustment, the guard can be rotated

NOTE: The guard release lever should snap

6. To remove the guard, follow steps 1–3 of these

MOUNTING AND REMOVING THE FIXED SCREW GUARD

(FIG. 3)

DWE4001

1. Place the angle grinder on a table, spindle (b)

2. Align the lugs (i) with the notches (j).

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories. Before

reconnecting the tool, depress and

release the trigger switch to ensure that

the tool is off. An accidental start-up can

cause injury.

CAUTION: Guards must be used with

this grinder.

the lugs (i) on the guard (f) with the slots on the

gear case (j).

guard down until engage the lugs and rotate

them into the groove on the gear case hub.

Release the guard release lever.

the guard clockwise into the desired working

position. The guard body should be positioned

between the spindle and the operator to provide

maximum operator protection.

in the clockwise direction.

into one of the alignment holes (k) on the guard

collar. This insures that the guard is secure.

The guard can be repositioned the opposite

direction by depressing the guard release lever.

instructions in reverse.

up.

3. Press the guard (f) down and rotate it to the

required position.

4. Securely tighten the screw (l).

5. To remove the guard, slacken the screw.

CAUTION: If the guard cannot be

tightened by the adjusting screw (l), do

not use the tool. To reduce the risk of

personal injury, take the tool and guard

to a service center to repair or replace

the guard.

Fitting and Removing a Grinding Disc

(fi g. 1, 4)

WARNING: Do not use a damaged

1. Place the tool on a table, guard up.

2. Fit the backing flange (d) correctly onto the

3. Place the disc (n) on the backing flange (d).

4. Screw the threaded clamp nut (e) onto the

The ring on the threaded clamp nut (e) must

5. Press the spindle lock button (a) and rotate the

6. Tighten the threaded clamp nut (e) with the hex

7. Release the spindle lock.

8. To remove the disc, loosen the threaded clamp

NOTE: Edge grinding can be performed with Type

27 wheels designed and specified for this purpose;

6 mm thick wheels are designed for surface grinding

while 3 mm wheels are designed for edge grinding.

disc.

spindle (b) (fig. 4).

When fitting a disc with a raised centre, make

sure that the raised centre (m) is facing the

backing flange (d).

spindle (b) (fig. 4):

face towards the disc when fitting a grinding

disc.

spindle (b) until it locks in position.

key provided or a two pin spanner.

nut (e) with the hex key provided or a two pin

spanner.

Mounting Wire Brushes

andWire Wheels

Wire cup brushes or wire wheels screw directly on

the grinder spindle without the use of flanges. Use

only wire brushes or wheels provided with a M14

(DWE4050) or M10 (DWE4001) threaded hub. A

Type 27 guard is required when using wire brushes

and wheels.

9

Page 12

ENGLISH

CAUTION: Wear work gloves when

handling wire brushes and wheels.

They can become sharp.

CAUTION: Wheel or brush must not

touch guard when mounted or while

in use. Undetectable damage could

occur to the accessory, causing wires to

fragment from accessory wheel or cup.

1. Thread the wheel on the spindle by hand.

2. Depress spindle lock button and use a wrench

on the hub of the wire wheel or brush to tighten

the wheel.

3. To remove the wheel, reverse the above

procedure.

NOTICE: Failure to properly seat the

wheel hub before turning the tool on

may result in damage to tool or wheel.

Fitting and Removing a

Backing pad/Sanding sheet (fi g. 1)

1. Place the tool on a table or flat surface, with the

guard facing up.

2. Remove the backing flange (d).

3. Place the rubber backing pad correctly onto the

spindle (b).

4. Place the sanding sheet on the rubber backing

pad.

5. Screw the threaded clamp nut (e) onto the

spindle. The ring on the threaded clamp nut

must face towards the rubber backing pad.

6. Press the spindle lock button (a) and rotate the

spindle (b) until it locks in position.

7. Tighten the threaded clamp nut (e) with the hex

key provided or a two pin spanner.

8. Release the spindle lock.

9. To remove the rubber backing pad, loosen

the threaded clamp nut (e) with the hex key

provided or a two pin spanner.

Fitting a Wire Cup Brush

Screw the wire cup brush directly onto the spindle

without the use of the spacer and threaded flange.

Prior to Operation

• Install the guard and appropriate disc or wheel.

Do not use excessively worn discs or wheels.

• Be sure the inner and outer flanges are

mounted correctly.

10

• Make sure the disc or wheel rotates in the

direction of the arrows on the accessory and

the tool.

OPERATION

Instructions for Use

WARNING: Always observe the safety

instructions and applicable regulations.

WARNING: To reduce the risk

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories. Before

reconnecting the tool, depress and

release the trigger switch to ensure that

the tool is off.

WARNING:

• Ensure all materials to be ground or

cut are secured in place.

• Secure and support the workpiece.

Use clamps or a vice to hold and

support the workpiece to a stable

platform. It is important to clamp and

support the workpiece securely to

prevent movement of the workpiece

and loss of control. Movement of

the workpiece or loss of control may

create a hazard and cause personal

injury.

• Apply only a gentle pressure to the

tool. Do not exert side pressure on the

disc.

• Avoid overloading. Should the tool

become hot, let it run a few minutes

under no load condition.

Proper Hand Position (fi g. 1, 6)

WARNING: To reduce the risk of

serious personal injury, ALWAYS use

proper hand position as shown.

WARNING: To reduce the risk of

serious personal injury, ALWAYS hold

securely in anticipation of a sudden

reaction.

Proper hand position requires one hand on the side

handle (c), with the other hand on the body of the

tool, as shown in figure 1.

Switches

CAUTION: Hold the side handle and

body of the tool firmly to maintain

control of the tool at start up and during

Page 13

ENGLISH

use and until the wheel or accessory

stops rotating. Make sure the wheel has

come to a complete stop be fore laying

the tool down.

NOTE: To reduce unexpected tool movement,

do not switch the tool on or off while under load

conditions. Allow the grinder to run up to full speed

before touching the work surface. Lift the tool from

the surface before turning the tool off. Allow the tool

to stop rotating before putting it down.

SWITCHING ON AND OFF DWE4001

(FIG. 5)

To run the tool press the switch (g1) in before

moving it completely forward.

To stop the tool move the switch (g1) back the

opposite way.

To stop the tool in continuous operation, press on

the back part of the switch.

WARNING: Do not switch the tool on

SLIDER SWITCH DWE4050

(FIG. 5)

WARNING: Before connecting the tool

To start the tool, slide the ON/OFF slider switch (g)

toward the front of the tool. To stop the tool, release

the ON/OFF slider switch.

For continuous operation, slide the switch toward

the front of the tool and press the forward part of

the switch inward. To stop the tool while operating

in continuous mode, press the rear part of the slider

switch and release.

WARNING: Before using the tool,

check that the handle is tightened

securely.

or off when under load.

to a power supply, be sure the slider

switch is in the off position by pressing

the rear part of the switch and releasing.

Ensure the slider switch is in the off

position as described above after any

interruption in power supply to the tool,

such as the activation of a ground fault

interrupter, throwing of a circuit breaker,

accidental unplugging, or power failure.

If the slider switch is locked on when the

power is connected, the tool will start

unexpectedly.

Spindle Lock (fi g. 1)

The spindle lock (a) is provided to prevent the

spindle from rotating when installing or removing

wheels. Operate the spindle lock only when the tool

is turned off, unplugged from the power supply, and

has come to a complete stop.

NOTICE: To reduce the risk of damage

to the tool, do not engage the spindle

lock while the tool is operating. Damage

to the tool will result and attached

accessory may spin off possibly

resulting in injury.

To engage the lock, depress the spindle lock button

and rotate the spindle until you are unable to rotate

the spindle further.

Metal Applications

When using the tool in metal applications, make

sure that a residual current device (RCD) has been

inserted to avoid residual risks caused by metal

swarf.

If the power supply is shut off by the RCD, take the

tool to authorised DEWALT repair agent.

WARNING: In extreme working

conditions, conductive dust can

accumulate inside the machine housing

when working with metal. This can

result in the protective insulation in the

machine becoming degraded with a

potential risk of an electrical shock.

To avoid build-up of metal swarf inside the machine,

we recommend to clear the ventilation slots on a

daily basis. Refer to Maintenance.

Using Flap Discs

WARNING: Metal dust build-up.

Extensive use of flap discs in metal

applications can result in the increased

potential for electric shock. To reduce

this risk, insert an RCD before use

and clean the ventilation slots daily by

blowing dry compressed air into the

ventilation slots inaccordance with the

below maintenance instructions.

MAINTENANCE

Your DEWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories. Before

reconnecting the tool, depress and

11

Page 14

ENGLISH

release the trigger switch to ensure that

the tool is off. An accidental start-up can

cause injury.

Pop-off Brushes

The motor will be automatically shut off indicating

that the carbon brushes are nearly worn out and

that the tool needs servicing. The carbon brushes

are not user-serviceable. Take the tool to an

authorised D

EWALT repair agent.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING: Blow dirt and dust out of

WARNING: Never use solvents or

the main housing with dry air as often as

dirt is seen collecting in and around the

air vents. Wear approved eye protection

and approved dust mask when

performing this procedure.

other harsh chemicals for cleaning the

non-metallic parts of the tool. These

chemicals may weaken the materials

used in these parts. Use a cloth

dampened only with water and mild

soap. Never let any liquid get inside the

tool; never immerse any part of the tool

into a liquid.

Protecting the Environment

Separate collection. This product must

not be disposed of with normal

household waste.

Should you find one day that your D

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products and

packaging allows materials to be

recycled and used again. Re-use of

recycled materials helps prevent

environmental pollution and reduces

the demand for raw materials.

Local regulations may provide for separate collection

of electrical products from the household, at

municipal waste sites or by the retailer when you

purchase a new product.

DEWALT provides a facility for the collection and

recycling of DEWALT products once they have

reached the end of their working life. To take

advantage of this service please return your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your local

DEWALT office at the address indicated in this

manual. Alternatively, a list of authorised DEWALT

repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com.

EWALT product

Optional Accessories

WARNING: Since accessories, other

Consult your dealer for further information on the

appropriate accessories.

12

than those offered by DEWALT, have

not been tested with this product, use

of such accessories with this tool could

be hazardous. To reduce the risk of

injury, only DEWALT recommended

accessories should be used with this

product.

Page 15

GRINDING AND CUTTING ACCESSORY CHART

Guard Type Accessory Description How to Fit Grinder

Depressed

centre grinding

disc

TYPE 27

GUARD

Flap wheel

Type 27 guard

Backing flange

ENGLISH

Wire wheels

Wire wheels

with threaded

nut

Wire cup with

threaded nut

Backing pad/

sanding sheet

Type 27 depressed

centre wheel

Threaded clamp nut

Type 27 guard

Wire wheel

Type 27 guard

Wire brush

Type 27 guard

Rubber backing pad

Sanding disc

Threaded clamp nut

13

Page 16

ENGLISH

GRINDING AND CUTTING ACCESSORY CHART (cont.)

Guard Type Accessory Description How to Fit Grinder

Diamond

cutting wheels

TYPE 27

GUARD

NO

GUARD

Polishing

bonnet

Type 27 guard

Backing flange

Cutting wheel

Threaded clamp nut

14

Page 17

MEULEUSES ANGULAIRES

DWE4050, DWE4051

FRANÇAIS

Félicitations!

Vous avez choisi un outil DEWALT. Des années

d’expertise dans le développement et l’innovation

de ses produits ont fait de DEWALT, le partenaire

privilégié des utilisateurs professionnels d’outils

électriques.

Caractéristiques techniques

DWE4001 DWE4050

B4/B5 B4/B5

Tension V 127/220–240 127/220–240

Type 1 1

Puissance absorbée W 800 800

Vitesse à vide/nominale min-1 12000 12000

Diamètre de meule mm 100 115

Diamètre de broche M10 M14

Poids kg 1,72* 1,76*

* le poids inclus la poignée latérale et le carter

Défi nitions: consignes de sécurité

Les définitions ci-après décrivent le degré de risques

associé à chaque balise. Lire soigneusement la

notice d’instructions et respecter ces symboles.

DANGER: indique une situation

de danger imminent qui, si rien

n’est fait pour l’éviter, aura comme

conséquences la mort ou des

dommages corporels graves.

AVERTISSEMENT: indique une

situation de danger potentiel qui, si

rien n’est fait pour l’éviter, pourra avoir

comme conséquences la mort ou des

dommages corporels graves.

ATTENTION: indique une situation

de danger potentiel qui, si rien n’est

fait pour l’éviter, pourrait avoir comme

conséquences des dommages

corporels mineurs ou moindres.

AVIS: indique une pratique ne posant

aucun risque de dommages

corporels, mais qui par contre, si rien

n’est fait pour l’éviter, pourrait poser

des risques de dommages matériels.

Indique des risques de décharges

électriques.

Indique des risques d’incendie.

AVERTISSEMENT: pour réduire tout

risque de dommages corporels, lire la

notice d’instructions

Consignes de sécurité générales

propres aux outils électriques

AVERTISSEMENT! lire toutes les

Le terme «outil électrique» mentionné dans les

avertissements ci-après se rapporte aux outils

alimentés sur secteur (avec fil) ou par piles (sans fil).

1) SÉCURITÉ - AIRE DE TRAVAIL

a) Maintenir l’aire de travail propre et bien

b) Ne pas utiliser un outil électrique dans un

c) Maintenir à l’écart les enfants, ou toute

2) SÉCURITÉ – ÉLECTRICITÉ

a) La fiche électrique de l’outil doit

b) Éviter tout contact corporel avec des

directives et consignes de sécurité.

Tout manquement aux directives et

consignes ci-incluses comporte des

risques de décharges électriques,

d’incendie et/ou de dommages

corporels graves.

CONSERVER TOUTES CES DIRECTIVES ET

CONSIGNES À TITRE DE RÉFÉRENCE

éclairée. Les lieux sombres ou encombrés

sont propices aux accidents.

milieu déflagrant, comme en présence de

liquides, gaz ou poussières inflammables.

Les outils électriques peuvent produire des

étincelles qui pourraient enflammer toute

émanation ou poussière ambiante.

autre personne, lors de l’utilisation d’un

outil électrique. Toute distraction pourrait

faire perdre la maîtrise de l’appareil.

correspondre à la prise murale. Ne

modifier la fiche en aucune façon. Ne

pas utiliser de fiche d’adaptation avec

un outil électrique mis à la terre (masse).

L’utilisation de fiches d’origine et de prises

appropriées réduira tout risque de décharges

électriques.

éléments mis à la terre comme: tuyaux,

radiateurs, cuisinières ou réfrigérateurs.

Les risques de décharges électriques

augmentent lorsque le corps est mis à la

terre.

15

Page 18

FRANÇAIS

c) Ne pas exposer les outils électriques à

la pluie ou à l’humidité. Tout contact d’un

outil électrique avec un liquide augmente les

risques de décharges électriques.

d) Ne pas utiliser le cordon de façon

abusive. Ne jamais utiliser le cordon

pour transporter, tirer ou débrancher un

outil électrique. Protéger le cordon de

toute source de chaleur, de l’huile, et

de tout bord tranchant ou pièce mobile.

Les cordons endommagés ou emmêlés

augmentent les risques de décharges

électriques.

e) En cas d’utilisation d’un outil électrique à

l’extérieur, utiliser systématiquement une

rallonge conçue à cet effet. Cela diminuera

tout risque de décharges électriques.

f) Si on ne peut éviter d’utiliser un outil

électrique en milieu humide, utiliser

un circuit protégé par un dispositif de

courant résiduel (RCD). Cela réduira tout

risque de décharges électriques.

3) SÉCURITÉ INDIVIDUELLE

a) Rester systématiquement vigilant et faire

preuve de jugement lorsqu’on utilise un

outil électrique. Ne pas utiliser d’outil

électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de

médicaments. Tout moment d’inattention

pendant l’utilisation d’un outil électrique

comporte des risques de dommages

corporels graves.

b) Porter un équipement de protection

individuel. Porter systématiquement un

dispositif de protection oculaire. Le fait

de porter un masque anti-poussières, des

chaussures antidérapantes, un casque

de sécurité ou un dispositif de protection

auditive, lorsque la situation le requiert,

réduira les risques de dommages corporels.

c) Prévenir tout démarrage accidentel.

S’assurer que l’interrupteur est en

position d’arrêt avant de brancher l’outil

sur le secteur et/ou à la batterie, ou de le

ramasser ou le transporter. Transporter un

outil le doigt sur l’interrupteur ou brancher un

outil électrique alors que l’interrupteur est en

position de marche invite les accidents.

d) Retirer toute clé de réglage avant de

démarrer l’outil. Une clé laissée sur une

pièce rotative d’un outil électrique comporte

des risques de dommages corporels.

e) Adopter une position stable. Maintenir les

pieds bien ancrés au sol et conserver son

équilibre en permanence. Cela permettra

de mieux maîtriser l’outil électrique en cas de

situations imprévues.

f) Porter des vêtements appropriés. Ne

porter aucun vêtement ample ou bijou.

Maintenir cheveux, vêtements et gants

à l’écart des pièces mobiles, car ils

pourraient s’y faire prendre.

g) Lorsqu’un dispositif de connexion

à un système de dépoussiérage ou

d’élimination est fourni, s’assurer qu’il est

branché et utilisé correctement. L’utilisation

de ces dispositifs peut réduire les risques

engendrés par les poussières.

4) UTILISATION ET ENTRETIEN DES OUTILS ÉLECTRIQUES

a) Ne pas forcer un outil électrique. Utiliser

l’outil approprié au travail en cours. L’outil

approprié effectuera un meilleur travail, de

façon plus sûre et à la vitesse pour laquelle il

a été conçu.

b) Ne pas utiliser un outil électrique dont

l’interrupteur est défectueux. Tout appareil

dont l’interrupteur est défectueux est

dangereux et doit être réparé.

c) Débrancher la fiche du secteur et/ou

la batterie de l’outil électrique avant

d’effectuer tout réglage, de changer tout

accessoire, ou avant de le ranger. Ces

mesures préventives réduiront tout risque de

démarrage accidentel de l’appareil.

d) Après utilisation, ranger les outils

électriques hors de portée des enfants

et ne permettre à aucune personne non

familière avec son fonctionnement (ou sa

notice d’instructions) de l’utiliser. Les outils

peuvent être dangereux entre des mains

inexpérimentées.

e) Entretenir les outils électriques. Vérifier

les pièces mobiles pour s’assurer qu’elles

sont bien alignées et tournent librement,

qu’elles sont en bon état et ne sont

affectées d’aucune condition susceptible

de nuire au bon fonctionnement de l’outil.

En cas de dommage, faire réparer l’outil

électrique avant toute nouvelle utilisation.

De nombreux accidents sont causés par des

outils mal entretenus.

f) Maintenir tout organe de coupe propre

et bien affûté. Les outils de coupe bien

entretenus et affûtés sont moins susceptibles

de se coincer et sont plus faciles à contrôler.

g) Utiliser un outil électrique, ses

accessoires, mèches, etc., conformément

aux présentes directives et suivant la

manière prévue pour ce type particulier

d’outil électrique, en tenant compte des

16

Page 19

FRANÇAIS

conditions de travail et de la tâche à

effectuer. L’utilisation d’un outil électrique

à des fins autres que celles prévues est

potentiellement dangereuse.

5) RÉPARATION

a) Faire entretenir les outils électriques par

un réparateur qualifié en n’utilisant que

des pièces de rechange identiques. Cela

permettra de préserver l’intégrité de l’outil

électrique et la sécurité de l’utilisateur.

RÈGLES PARTICULIÈRES DE

SÉCURITÉ ADDITIONNELLES

Consignes générales de sécurité

a) Cet outil électrique a été conçu pour le

meulage, ponçage, brossage métallique,

polissage ou le tronçonnage. Lire toute

directive de sécurité, consigne, illustration et

spécification fournie avec l’outil électrique.

Tout manquement aux directives suivantes

pose des risques de décharges électriques,

d’incendie et/ou de blessures graves.

b) Ne pas utiliser des accessoires qui n’ont pas

été spécifiquement conçus et recommandés

par le fabricant de l’outil. Le fait que

l’accessoire peut être rattaché à l’outil électrique

ne veut pas automatiquement dire que son

utilisation ne posera aucun risque.

c) La vitesse nominale des accessoires

doit être équivalente ou supérieure

à celle recommandée sur l’étiquette

d’avertissement de l’outil. Les accessoires

utilisés à une vitesse plus rapide que leur vitesse

nominale peuvent éclater ou se détacher de

l’outil.

d) Le diamètre externe et l’épaisseur de

l’accessoire utilisé doivent se conformer

aux spécifications de la plaque signalétique

de l’outil électrique. Les accessoires aux

spécifications incorrectes ne peuvent être ni

maintenus ni contrôlés de façon adéquate.

e) L’alésage des meules, brides, tampons de

soutien, ou de tout autre accessoire, doit

correspondre parfaitement à la taille de la

broche de l’outil électrique. Les accessoires

dont l’alésage ne correspond pas au dispositif

d’installation de l’outil électrique ne tourneront

pas correctement, vibreront de façon excessive

et pourront causer la perte de contrôle de l’outil.

f) Ne pas utiliser d’accessoires endommagés.

Avant toute utilisation, vérifier tous les

accessoires, par exemple que les meules

abrasives ne sont ni ébréchées ni fendues,

les tampons de soutien ne sont ni fendus ni

usés excessivement, les brosses métalliques

ne comportent aucun élément brisé ou

lâche. En cas de chute, vérifier que l’outil

n’a pas été endommagé et remplacer tout

accessoire abîmé. Après avoir inspecté

et installé un accessoire, se situer, soimême et tout individu présent, hors du

plan de rotation de l’accessoire et laisser

tourner l’outil une minute à sa vitesse à

vide maximale. En général, tout accessoire

endommagé se brisera lors du temps d’essai.

g) Porter un équipement de protection

individuel. Selon l’application, utiliser une

protection faciale et des lunettes ou un

masque de protection. Si approprié, porter

un masque anti-poussières, une protection

auditive, des gants et un tablier d’atelier

capables de vous protéger contre toute

projection abrasive ou tout fragment. La

protection oculaire doit être capable d’arrêter

toute projection de débris engendrés par des

opérations diverses. Le masque anti-poussières

doit être capable de filtrer les particules

engendrées par l’opération en cours. Toute

exposition prolongée à un haut niveau de

décibels peut occasionner une perte de l’acuité

auditive.

h) Maintenir à distance toute personne

étrangère au travail en cours. Toute

personne à l’intérieure de l’aire de travail

doit porter un équipement de protection

individuel. Des débris provenant de la pièce

à travailler ou d’un accessoire brisé pourraient

être éjectés et causer des dommages corporels

au-delà de l’aire de travail immédiate.

i) Tenir l’outil par les surfaces isolées

prévues r cet effet pendant toute utilisation

ou l’organe de coupe pourrait entrer en

contact avec des fils électriques cachés ou

son propre cordon. Tout contact de l’organe

de coupe avec un fil sous tension peut mettre

les parties métalliques exposées de l’outil sous

tension et électrocuter l’utilisateur.

j) Maintenir le cordon électrique éloigné de la

partie rotative de l’outil. En cas de perte de

contrôle, le cordon pourrait être sectionné ou

abîmé, et les bras ou mains pourraient entrer en

contact avec l’organe rotatif.

k) Attendre systématiquement l’arrêt complet

de l’outil avant de le déposer. L’organe rotatif

pourrait s’accrocher à la surface utilisée et

rendre l’outil dangereusement imprévisible.

17

Page 20

FRANÇAIS

l) Ne pas laisser l’outil électrique en marche

alors qu’il est accroché à votre côté. Tout

contact accidentel de l’organe rotatif pourrait

faire que ce dernier s’accroche aux vêtements

et qu’un accessoire entre en contact avec le

corps.

m) Nettoyer régulièrement les orifices

d’aération de l’outil. Le ventilateur du moteur

attirera de la poussière à l’intérieur du boîtier

et une accumulation excessive de poussières

métalliques pourrait poser des risques

d’électrocution/incendie.

n) Ne pas utiliser cet outil électrique à

proximité de matériaux inflammables, car

des étincelles pourraient les enflammer.

o) Ne pas utiliser d’accessoires nécessitant

l’utilisation d’un réfrigérant fluide. L’utilisation

d’eau ou de tout autre réfrigérant fluide pourrait

poser des risques d’électrocution ou de

décharges électriques.

CONSIGNES GÉNÉRALES DE

SÉCURITÉ COMPLÉMENTAIRES

Causes et prévention anti-rebonds

Les rebonds sont la conséquence du grippage

ou coinçage d’une meule, d’un tampon de

soutien, d’une brosse en rotation ou de tout autre

accessoire. Tout grippage ou coinçage causera

rapidement le blocage de l’accessoire en rotation,

ce qui lancera l’outil non contrôlé dans la direction

opposée à l’accessoire en rotation au point du

grippage.

Par exemple, si une meule abrasive reste accrochée

ou pincée dans une pièce à travailler, le bord

de la meule engagée au point de grippage peut

s’enfoncer dans la surface du matériau et faire

tressauter ou rebondir la meule. La meule peut alors

rebondir vers ou à l’opposé de l’utilisateur, selon la

direction du mouvement de la meule au point de

grippage. Dans ces conditions, il peut aussi arriver

que les meules abrasives se brisent.

Les rebonds proviennent d’une utilisation impropre

de l’outil ou de conditions ou procédures

d’exécution incorrectes, et peuvent être évités

en prenant les précautions adéquates énoncées

ci-dessous:

a) Maintenir la scie fermement en positionnant

le corps et les bras de façon à pouvoir

résister à toute force de rebonds. Utiliser

systématiquement la poignée latérale,

si fournie avec l’outil, pour un contrôle

maximal de l’outil en cas de rebonds ou

retour de couple au démarrage. L’utilisateur

peut contrôler le retour de couple ou les forces

de rebonds si des précautions adéquates sont

prises.

b) Ne jamais approcher les mains de l’organe

rotatif. L’accessoire pourrait rebondir sur les

mains.

c) Ne pas positionner le corps dans l’espace

que pourrait occuper l’outil en cas de

rebonds. Les rebonds projetteront l’outil dans

la direction opposée au mouvement de la meule

au point de grippage.

d) Prendre des précautions supplémentaires

pour travailler des coins, des bords acérés,

etc. Éviter que l’accessoire sursaute ou

reste accroché. Les coins, bords acérés ou les

sursauts ont tendance à retenir l’accessoire en

rotation et causer la perte de contrôle de l’outil,

ou des rebonds.

e) Ne pas rattacher une lame à chaîne

coupante, à sculpter ou une lame dentée.

Ces lames posent des risques de rebonds

fréquents et de perte de contrôle de l’outil.

Consignes spécifi ques de sécurité

propres au polissage et au

tronçonnage abrasif

a) Utiliser uniquement des types de meules

recommandés pour votre outil électrique

ainsi que le carter spécifiquement conçu

pour la meule choisie. Les meules non

conçues pour un outil électrique ne peuvent être

adéquatement protégées et sont dangereuses.

b) Le carter doit être soigneusement arrimé à

l’outil électrique et installé pour optimiser

la sécurité, de façon à ce que l’utilisateur

soit le moins possible exposé à la meule.

Le carter doit protéger l’utilisateur contre des

fragments de roue cassés, le contact accidentel

et des étincelles qui pourraient enflammer les

vêtements.

c) Les meules ne doivent être utilisées que

pour les applications recommandées. Par

exemple: ne pas meuler avec la partie

latérale d’une meule à tronçonner. Les

meules à tronçonner ont été conçues pour

le meulage périphérique, toute force latérale

appliquée sur ces meules pourrait les faire

éclater.

d) Utiliser systématiquement des brides de

meules en parfait état, de taille et forme

adaptées à la meule choisie. Les brides

18

Page 21

FRANÇAIS

de meules servent de support aux meules,

réduisant ainsi les possibilités que la meule

se brise. Les brides de meules à tronçonner

peuvent différer des brides de disques à meuler.

e) Ne pas utiliser de meules émoussées lors

de leur utilisation sur des outils électriques

plus gros. Les meules conçues pour des outils

électriques plus gros ne sont pas adéquates

pour les vitesses plus rapides des outils plus

petits, et risqueraient d’éclater.

Consignes spécifi ques de

sécurité additionnelles propres au

tronçonnage abrasif

a) Ne pas gripper la meule à tronçonner ou lui

appliquer une pression excessive. Ne pas

tenter d’effectuer des profondeurs de coupe

excessives. Pousser excessivement la meule

augmente la charge imposée à l’outil, et les

possibilités de torsion ou grippage de la meule

dans la coupe, et par conséquent les rebonds

et bris.

b) Ne pas aligner le corps avec la meule en

rotation ou se placer derrière elle. Lorsque la

meule, au point d’exécution, s’éloigne du corps,

tout rebond possible pourrait propulser la meule

en rotation et l’outil électrique directement sur

l’utilisateur.

c) En cas de grippage de meule, ou si une

coupe est interrompue pour quelque raison

que ce soit, arrêter l’outil électrique et le

maintenir immobile jusqu’à arrêt complet

de la meule. Ne jamais tenter de retirer une

meule à tronçonner de la coupe alors qu’elle

est en rotation, pour prévenir tout rebond.

Vérifier la pièce à travailler et prendre les

mesures adéquates pour éliminer toute cause

de grippage.

d) Ne pas reprendre l’opération de coupe

dans la pièce. Laisser la meule tourner à

plein régime puis ré-entrer dans la coupe

prudemment. La meule pourrait se gripper,

sortir de la coupe ou effectuer un rebond si

l’outil électrique était remis en marche dans la

pièce à travailler.

e) Soutenir les panneaux, ou toute pièce

surdimensionnée, pour minimiser tout risque

de grippage ou rebond de la meule. Les

pièces larges ont tendance à s’affaisser sous

leur propre poids. Un support doit être installé

sous la pièce à travailler, près de la ligne de

coupe, et près des bords, de chaque côté de la

meule.

f) Prenez des précautions supplémentaires

lors de «coupes de poche» dans des

murs existants ou dans toute zone à

visibilité limitée. La meule pourrait couper

des canalisations de gaz ou d’eau, des fils

électriques ou des objets pouvant causer en

retour des rebonds.

Consignes spécifi ques de sécurité

propres au ponçage

a) Ne pas utiliser des disques de papier

abrasif de taille excessive. Suivre les

recommandations du fabricant lors de la

sélection du papier à poncer. Les feuilles

de papier abrasif de grande taille, dépassant

du tampon ponceur, posent des risques de

lacération, et peuvent faire que le disque

s’accroche ou se déchire, ou causer des

rebonds.

Consignes spécifi ques de sécurité

propres au polissage

a) Ne laisser aucune portion flottante du

bonnet de polissage ou de ses cordons

de fixation tourner librement. Ranger ou

couper toute partie excessive des cordons

de fixation. Des cordons trop longs, en rotation

libre, pourraient se prendre dans les doigts ou

dans la pièce à travailler.

Consignes spécifi ques de sécurité

propres au brossage métallique

a) Prendre des précautions, car des fibres

métalliques sont éjectées par la brosse

pendant le cours normal des opérations.

Ne pas surcharger les fils en appliquant une

pression excessive sur la brosse. Les fibres

métalliques peuvent facilement pénétrer les

vêtements légers et/ou la peau.

b) Si l’utilisation d’un carter est recommandée

pour le brossage métallique, protéger la

brosse métallique circulaire ou la brosse de

toute interférence avec ce carter. Le diamètre

des brosses métalliques circulaires ou des

brosses, peut se dilater. C" est dû au travail et

aux forces centrifuges.

Consignes de sécurité

supplémentaires pour les meuleuses

• Le fi letage de montage des accessoires

doit correspondre à celui du mandrin de la

meuleuse. Pour les accessoires montés avec

des brides, l’alésage de l’accessoire doit

19

Page 22

FRANÇAIS

correspondre au diamètre de positionnement

de la bride. Les accessoires qui ne

correspondent pas au dispositif d’installation

de l’outil électrique ne tourneront pas

correctement, vibreront de façon excessive et

pourront causer la perte de contrôle de l’outil.

• La surface de meulage des meules à moyeu

déporté doit être montée au-dessous du

plan de la lèvre du carter de protection. Une

meule mal montée qui dépasse du plan de la

lèvre du carter de protection ne peut pas être

correctement protégée.

• Ne pas utiliser les meules de type 11 (à

moyeu déporté) sur cet outil. L’utilisation

d’accessoires inappropriés peut causer des

blessures.

• Toujours utiliser la poignée latérale. Serrez

fermement la poignée. La poignée latérale

doit toujours être utilisée pour conserver le

contrôle de l’outil en permanence.

Risques résiduels

En dépit de l’application des normes de sécurité en

vigueur et de l’installation de dispositifs de sécurité,

certains risques résiduels sont inévitables. Il s’agit

de:

– Diminution de l’acuité auditive;

– Risques de dommages corporels dus à des

projections de particules;

– Risques de brûlures provoquées par des

accessoires ayant surchauffé pendant leur

fonctionnement;

– Risques de dommages corporels dus à un

usage prolongé;

– Risques posés par les poussières de

substances dangereuses.

Étiquettes sur l’appareil

On trouve les diagrammes suivants sur l’outil:

Lire la notice d’instructions avant toute

utilisation.

Porter un dispositif de protection auditive.

Porter un dispositif de protection oculaire.

EMPLACEMENT DE LA DATE CODÉE DE FABRICATION

(FIG. 1)

La date codée de fabrication (p), qui comprend aussi

l’année de fabrication, est imprimée sur le boîtier.

Exemple:

2012 XX XX

Année de fabrication

Contenu de l’emballage

Ce carton comprend:

1 Meuleuse angulaire

1 Carter

1 Poignée latérale anti-vibrations

1 Dispositif de bride

1 Clé plate

1 Notice d’instructions

1 Dessin éclaté

• Vérifier que l’appareil et ses pièces ou

accessoires n’ont pas été endommagés lors du

transport.

• Prendre le temps de lire attentivement et

comprendre cette notice d’instructions avant

toute utilisation de l’appareil.

Description (fi g. 1, 4)

AVERTISSEMENT: ne jamais modifier

l’outil ni aucun de ses composants, car

cela pose des risques de dommages

corporels ou matériels.

a. Bouton de blocage de l’arbre

b. Arbre

c. Poignée latérale

d. Bride de soutien

e. Écrou de blocage fileté

f. Carter

g. Commutateur coulissant (DWE4050)

g1. Interrupteur marche/arrêt (DWE4001)

h. Levier de déblocage du carter

USAGE PRÉVU

Les modèles de meuleuses angulaires industrielles

DWE4001 et DWE4050 ont été conçus pour le

meulage, le ponçage, le brossage métallique, le

polissage et le tronçonnage professionnels.

NE PAS utiliser de meules autres que des meules à

moyeu déporté ou des disques à lamelles.

NE PAS utiliser ces outils en milieu ambiant humide

ou en présence de liquides ou de gaz inflammables.

Ces meuleuses angulaires industrielles sont des

outils électriques de professionnels.

20

Page 23

FRANÇAIS

NE PAS les laisser à la portée des enfants. Une

supervision est nécessaire auprès de tout utilisateur

non expérimenté.

• Ce produit n’est pas prévu pour être utilisé par

des personnes (y compris les enfants) dont les

capacité physiques, sensorielles ou mentales

sont réduites ou qui manquent d’expérience

ou d’aptitudes, sauf si ces personnes sont

surveillées par une autre personne responsable

de leur sécurité. Ne jamais laisser les enfants

seuls avec ce produit.

Sécurité électrique

Le moteur électrique a été conçu pour fonctionner

sur une tension unique. Vérifier systématiquement

que la tension du secteur correspond bien à la

tension indiquée sur la plaque signalétique.

Votre outil DEWALT à double isolation

est conforme à la norme IEC60745; un

branchement à la terre n’est donc pas

nécessaire.

Si le cordon fourni est endommagé, le remplacer

par un cordon spécialement conçu à cet effet, et

disponible auprès du service après-vente DEWALT.

Toujours utiliser la fiche prescrite lors du

CH

remplacement du câble d’alimentation.

Type 11 pour la classe II

(Isolation double) – outils

Type 12 pour la classe I

(Conducteur de terre) – outils

En cas d’utilisation à l’extérieur, connecter les

CH

outils portatifs à un disjoncteur FI.

Remplacement de la fi che

d’alimentation

(Moyen-Orient et Afrique)

Si une nouvelle fiche d’alimentation doit être montée:

• Mettre soigneusement au rebut l’ancienne fiche.

• Raccorder le fil marron à la borne de phase

dans la fiche.

• Raccorder le fil bleu à la borne de neutre.

AVERTISSEMENT: Aucun

Suivez les instructions de montage fournies avec

des fiches de bonne qualité. Fusible recommandé:

13 A.

branchement ne doit être fait à la borne

de terre.

Uso de un alargador

En caso de que sea necesario utilizar un alargador,

use uno de 3 conductores aprobado y apto para

la potencia de esta herramienta (véanse los Datos

técnicos). El tamaño mínimo del conductor es

1,5 mm2; la longitud máxima es 30 m.

Si utiliza un carrete de cable, desenrolle siempre el

cable completamente.

ASSEMBLAGE ET RÉGLAGES

AVERTISSEMENT: pour réduire

tout risque de dommages corporels

graves, arrêter et débrancher l’outil

du secteur avant tout réglage ou

avant de retirer ou d’installer toute

pièce ou tout accessoire. Avant de

rebrancher l’outil, presser puis relâcher

la gâchette pour s’assurer que l’outil est

bien à l’arrêt. Tout démarrage accidentel

pourrait causer des dommages

corporels.

Installation de la poignée latérale

AVERTISSEMENT: avant toute

utilisation, vérifier que la poignée est

solidement arrimée.

Vissez fermement la poignée latérale (c) dans

l’un des trous situés de chaque côté du carter

d’engrenage. La poignée latérale doit toujours

être utilisée pour conserver le contrôle de l’outil en

permanence.

Accessoires et pièces de rechange

Il est important de choisir les carters, les tampons

support et les brides appropriés pour utiliser

les accessoires de la meuleuse. Référez-vous

au tableau à la fin de cette section pour des

informations sur le choix d’accessoires appropriés.

REMARQUE: Le meulage et le tronçonnage de

bords peuvent être effectués avec des meules de

type 27 conçues et spécifiées à cet effet.

AVERTISSEMENT: La vitesse des

accessoires doit être au moins égale

à celle recommandée sur l’étiquette

d’avertissement de l’outil. Les roues et

d’autres accessoires fonctionnant sur

la vitesse nominale peuvent exploser et

causer des blessures. Les accessoires

filetés doivent avoir un moyeu M14

(DWE4050) ou M10 (DWE4001).

Chaque accessoire non fileté doit avoir

un alésage de 22mm (DWE4005) ou de

16mm (DWE4001).

21

Page 24

FRANÇAIS

Si ce n’est pas le cas, il peut avoir été conçu

pour une scie circulaire et ne doit pas être utilisé.

Utilisez uniquement les accessoires illustrés dans

le tableau à la fin de cette section. La vitesse

nominale des accessoires doit être supérieure à la

vitesse minimale de la roue indiquée sur la plaque

signalétique de l’outil.

Protections de montage

AVERTISSEMENT: pour réduire

tout risque de dommages corporels

graves, arrêter et débrancher l’outil du

secteur avant tout réglage ou avant de

retirer ou d’installer toute pièce ou tout

accessoire. Avant de rebrancher l’outil,

presser puis relâcher la gâchette pour

s’assurer que l’outil est bien à l’arrêt. Un

démarrage accidentel peut provoquer

des blessures.

ATTENTION: cette meuleuse à disque

doit être utilisée avec un carter.

REMARQUE: Veuillez vous reporter au Tableau

d’accessoires de meulage et de tronçonnageen

fin de section pour voir la liste des accessoires

pouvant être utilisés avec ces meuleuses.

MONTAGE ET DÉMONTAGE

DU CARTER ONE-TOUCH (TYPE 27) (FIG. 2)

REMARQUE: Si votre meuleuse est fournie avec

un carter sans clé One-Touch, assurez-vous que la

vis et le ressort sont installés correctement avant de

monter le carter

1. Appuyez sur le levier de déverrouillage du carter

(h).

2. Tout en tenant le levier de déverrouillage du

carter ouvert, alignez les patins (i) sur le carter (f)

avec des fentes sur le boîtier d’engrenages (j).

3. Garder le levier de déverrouillage du carter

ouvert, appuyez sur la garde jusqu’à ce que les

patins s’enclenchent , et faites-les tourner dans

la rainure sur le moyeu du carter d’engrenage.

Relâchez le levier de déverrouillage du carter.

4. Avec le verrou du carter en face de l’opérateur,

faites pivoter le carter en sens horaire dans la

position de travail désirée. Le corps du carter

doit être positionné entre l’arbre et l’opérateur

pour offrir une protection maximale de

l’opérateur.

5. Pour un réglage facile, le carter peut être tourné

dans le sens horaire.

REMARQUE: Le levier de déverrouillage du

carter doit s’enclencher dans l’un des trous

d’alignement (k) sur le col du carter. Ceci

garantit que le carter est sécurisé. Le carter

peut être repositionné en sens opposé en

appuyant sur le levier de déverrouillage du

carter.

6. Pour retirer le carter, suivez les étapes 1-3 de

ces instructions dans l’ordre inverse.

MONTAGE ET DÉMONTAGE DU CARTER DE PROTECTION À

VIS FIXE (FIG. 3)

DWE4001

1. Disposer la meuleuse angulaire sur une table,

avec la broche (b) sur le dessus.

2. Alignez les pattes (i) sur les encoches (j).

3. Poussez sur le carter (f) et tournez-le dans la

position requise.

4. Vissez soigneusement la vis (l).

5. Pour retirer le carter, dévissez la vis.

ATTENTION: si le carter ne peut pas

être resserré correctement à l’aide de la

vis (l), ne pas utiliser l’outil. Pour réduire

tout risque de dommages corporels,

amener l’outil et le carter dans un centre

de réparation pour faire réparer ou

remplacer le carter.

Montage et démontage d’un disque

de meulage (fi g. 1, 4)

AVERTISSEMENT: ne pas utiliser de

disque endommagé.

1. Disposez l’outil sur une table, avec le carter sur

le dessus.

2. Installez correctement la bride de soutien (d) sur

la broche (b), (fig. 4).

3. Placez le disque (n) sur la bride de soutien (d).

Lors de l’installation d’un disque avec un centre

en relief, assurez-vous que ce centre en relief

(m) soit positionné face à la bride de soutien (d).

4. Vissez l’écrou de blocage fileté (e) sur la broche

(b) (fig. 4):

L’anneau sur l’écrou de blocage fileté (e) doit

se trouver contre le disque lorsqu’on utilise un

disque de meulage.

5. Appuyez sur le bouton de blocage de l’arbre

(a) puis faites pivoter la broche (b) jusqu’à ce

qu’elle se verrouille en place.

6. Serrer l’écrou de serrage filetée (e) avec la clé

hexagonale fournie ou une clé à deux broches.

7. Libérez le verrouillage de l’arbre.

8. Pour retirer le disque, desserrez l’écrou de

serrage filetée (e) avec la clé hexagonale fournie

ou une clé à deux broches.

22

Page 25

FRANÇAIS

REMARQUE: Le meulage de bords peut être

effectué avec des meules de type 27 conçues et

spécifiées à cet effet; les meules d’une épaisseur

de 6mm sont conçues pour le meulage de surface

tandis que les meules de 3mm sont conçues pour

le meulage des bords.

Montage des brosses métalliques

et brosses métalliques à mèches

Les brosses métalliques soucoupes ou les brosses

métalliques à mèches se montent directement sur

le mandrin de la meuleuse sans utiliser de brides.

Utilisez uniquement des brosses métalliques ou

brosses métalliques à mèches dotées d’un moyeu

fileté M14 (DWE4050) ou M10 (DWE4001). Un

carter type 27 est nécessaire lors de l’utilisation

des brosses métalliques ou des brosses

métalliques à mèches.

ATTENTION: Portez des gants de

travail lors de la manipulation des

brosses métalliques et des meules. Elles

peuvent devenir tranchantes.

ATTENTION: La meule ou la brosse

ne doit pas toucher le carter quand

il est monté ou en cours d’utilisation.

Des dégâts indétectables peuvent se

produire sur l’accessoire, entraînant