Page 1

LULU

An

-Jl_

"0 Z

8_<{

>-o

o_>

@

--b

wz

c23--

o,<

z

w,,, d

,,o,,,=,b

o,<o

F-<_o-

o'_

_z w

F_<rr

co<

z_<co

_@D

7

_ ,-- >

DEWALT Industrial ToolCo., 701 East Joppa Road, Baltimore, MD 21286

(MAR14) Part No. N391690 DW303, DW303M, DW304P, DWE304

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the

"D" shaped air intake gril; the array of pyramids on the handgrip; the kit box configuration; and the array of

lozenge-shaped humps on the surface of the tool.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

_DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

_WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

J_CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not avoided, may

result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL

US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-g258}.

WARNING: To reduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

_ ARNING! Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-

operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified p/ugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock ifyour body is earthed

or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tooL Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

0 If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury,

Copyright © 2004, 2012,2014

J

FOR FUTURE REFERENCE

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tooL

Carrying power tools with your finger on the switch or energizing power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury,

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tooL Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source andlor the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally,

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tooL

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool's operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control

g) Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result

in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Specific Safety Rules

• Hold power tool by insulated gripping surfaces when performing an operation where

the cutting accessory may contact hidden wiring or its own cord. Cutting accessory

contacting a "live" wire may make exposed metal parts of the tool "live" and could give the

operator an electric shock

• Use clamps or another practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body leaves it unstable and may lead to

loss of control.

• Do not operate this tool for long periods of time. Vibration caused by the operating action

of this tool may cause permanent injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

• Air vents often cover moving parts and should be avoided. Loose clothes, jewelry or long

hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is

16gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using more than one extension to make up

the total length, be sure each individual extension contains at least the minimum wire size. The

following table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0

6

10

12

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use

face or dust mask if cutting operation is dusty, ALWAYS WEAR CERTIFIED SAFETY EQUIPMENX

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3. 19)hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

_WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are."

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. Toreduce

your exposure to these chemicals." work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

_WARNING: Use of this tool can generate and/or disperse dust, which may cause serious and

permanent respiratory or other injury, Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body,

_WARNING: Always wear proper personal hearing protection that conforms to ANSI

$12.6 ($3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions are

as follows."

V..................... volts

Hz................... hertz

min ................. minutes

--- or DC..... direct current

(_)................... Class I Construction

[] ................... Class II Construction

.../min ............ per minute

IPM ................. impacts per minute

SPM ............... strokes per minute

Not More

Than

6

10

12

16

(grounded)

(double insulated)

120V 25 (7.6) 50 (15.2) 100 (30.5) I 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) I 300 (91.4)

AWG

18

18

16

14

A......................... amperes

W........................ watts

'_ or AC ............. alternating current

or AC/DC ...... alternating or direct current

no....................... no load speed

n......................... rated speed

@ ....................... earthing terminal

t_........................ safety alert symbol

BPM ................... beats per minute

RPM ................... revolutions per minute

sfpm ................... surface feet per minute

16

16

16

12

16 14

14 12

14 12

Not Recommended

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Page 2

Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than

10% will cause loss of power and overheating. DEWALT tools are factory tested; if this tool does

not operate, check power supply.

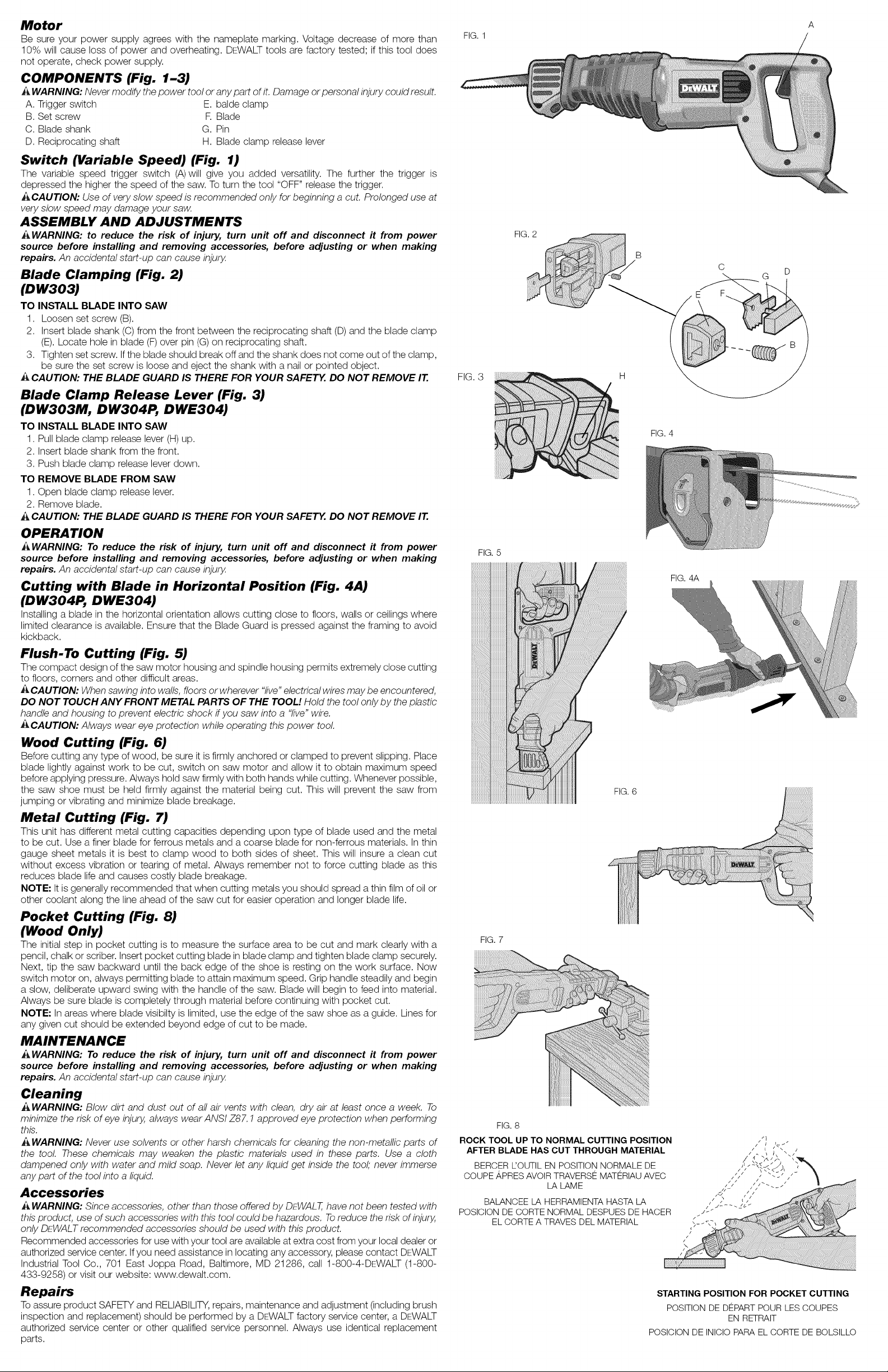

COMPONENTS (Fig. 1-3)

,_i,WARNING: Never modify the power tool or any part of it. Damage or personal injury could result.

A. Trigger switch E. balde clamp

B. Set screw F. Blade

C. Blade shank G. Pin

D. Reciprocating shaft H. Blade clamp release lever

Switch (Variable Speed) (Fig. 1)

The variable speed trigger switch (A)will give you added versatility The further the trigger is

depressed the higher the speed of the saw. To turn the tool "OFF" release the trigger.

A CAUTION: Use of very slow speed is recommended only for beginning a cut. Prolonged use at

very slow speed may damage your saw.

ASSEMBLY AND ADJUSTMENTS

_WARNING: to reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury,

Blade Clamping (Fig. 2)

(DW303)

TO INSTALL BLADE INTO SAW

1. Loosen set screw (B).

2. Insert blade shank (C) from the front between the reciprocating shaft (D) and the blade clamp

(E). Locate hole in blade (F)over pin (G) on reciprocating shaft.

3. Tighten set screw. Ifthe blade should break off and the shank does not come out of the clamp,

be sure the set screw is loose and eject the shank with a nail or pointed object.

A CAUTION: THE BLADE GUARD IS THERE FOR YOUR SAFETY. DO NOT REMOVE IT.

Blade Clamp Release Lever (Fig. 3)

(DW303M, DW304P, DWE304)

TO INSTALL BLADE INTO SAW

1. Pull blade clamp release lever (H) up.

2. Insert blade shank from the front.

3. Push blade clamp release lever down.

TO REMOVE BLADE FROM SAW

1 Open blade clamp release lever

2. Remove blade.

A CAUTION: THE BLADE GUARD IS THERE FOR YOUR SAFETY. DO NOT REMOVE IT.

OPERATION

_ WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury,

Cutting with Blade in Horizontal Position (Fig. 4A)

(DW304P, DWE304)

Installing a blade in the horizontal orientation allows cutting close to floors, walls or ceilings where

limited clearance is available. Ensure that the Blade Guard is pressed against the framing to avoid

kickback.

Flush-To Cutting (Fig. 5)

The compact design of the saw motor housing and spindle housing permits extremely close cutting

to floors, corners and other difficult areas.

A CAUTION: When sawing into walls, floors or wherever "live" electrical wires may be encountered,

DO NOT TOUCH ANY FRONT METAL PARTS OF THE TOOL! Hold the tool only by the plastic

handle and housing to prevent electric shock if you saw into a "live" wire.

,&CAUTION: Always wear eye protection while operating this power tool

Wood Cutting (Fig. 6)

Before cutting any type of wood, be sure it is firmly anchored or clamped to prevent slipping. Place

blade lightly against work to be cut, switch on saw motor and allow it to obtain maximum speed

before applying pressure. Always hold saw firmly with both hands while cutting. Whenever possible,

the saw shoe must be held firmly against the material being cut. This will prevent the saw from

jumping or vibrating and minimize blade breakage.

Metal Cutting (Fig. 7)

This unit has different metal cutting capacities depending upon type of blade used and the metal

to be cut. Use a finer blade for ferrous metals and a coarse blade for non-ferrous materials. In thin

gauge sheet metals it is best to clamp wood to both sides of sheet. This will insure a clean cut

without excess vibration or tearing of metal. Always remember not to force cutting blade as this

reduces blade life and causes costly blade breakage.

NOTE: It is generally recommended that when cutting metals you should spread a thin film of oil or

other coolant along the line ahead of the saw cut for easier operation and longer blade life.

Pocket Cutting (Fig. 8)

(Wood Only)

The initial step in pocket cutting is to measure the surface area to be cut and mark clearly with a

pencil, chalk or scriber. Insert pocket cutting blade in blade clamp and tighten blade clamp securely.

Next, tip the saw backward until the back edge of the shoe is resting on the work surface. Now

switch motor on, always permitting blade to attain maximum speed. Grip handle steadily and begin

a slow, deliberate upward swing with the handle of the saw. Blade will begin to feed into material.

Always be sure blade is completely through material before continuing with pocket cut.

NOTE: In areas where blade visibilty is limited, use the edge of the saw shoe as a guide. Lines for

any given cut should be extended beyond edge of cut to be made.

MAINTENANCE

_ WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury,

Cleaning

_, WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To

minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing

this.

,_,WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of

the tool These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool,"never immerse

any part of the tool into a liquid.

Accessories

i_,WARNING: Since accessories, other than those offered by DEWALT,have not been tested with

this product, use of such accessories with this tool could be hazardous. Toreduce the risk of injury,

only DEWALT recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local dealer or

authorized service center. Ifyou need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-

433-9258) or visit our website: www.dewalt.com.

Repairs

Toassure product SAFETYand RELIABILITY, repairs, maintenance and adjustment (including brush

inspection and replacement) should be performed by a DEWALT factory service center, a DEWALT

authorized service center or other qualified service personnel. Always use identical replacement

parts.

FIG. 1

FIG.2

FIG. 3

FIG. 7

FIG. 8

ROCK TOOL UP TO NORMAL CUTTING POSITION

AFTER BLADE HAS CUT THROUGH MATERIAL

BERCER L'OUTIL EN POSITION NORMALE DE

COUPE _,PRES AVOIR TRAVERSI_ MATI_RIAU AVEC

LA LAME

BALANCEE LA HERRAMIENTA HASTA LA

POSICION DE CORTE NORMAL DESPUES DE HACER

EL CORTE A TRAVES DEL MATERIAL

H

FIG. 4

STARTING POSITION FOR POCKET CUTTING

POSICION DE INICIO PARA EL CORTE DE BOLSILLO

C

FIG. 4A

POSITION DE DEPART POUR LES COUPES

EN RETRAIT

Page 3

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you obtain more efficient warranty

service in case there is a problem with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance loss, such as fire, flood or theft,

your registration of ownership will serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to contact you in the unlikely event

a safety notification is required under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DEWALTwill repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.

com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by others. This warranty gives you

specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DFWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

Ifyou are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer

for any reason, you can return it within 90 days from the date of purchase with a receipt for a full

refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained inthe packaging, call the

local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: Ifyour warning labels become illegible or are missing,

call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

bWxxxxvsREC,..OC..,N..W

" " _ TO REDUCETHE RiSK OF

iNJURY, USER MUST READ iNSTRUCTiON MANUAL

ALWAYS USE PROPER EYE AND RESPIRATORY

PROTECTION.

OEWALT INOOSTRJAL TOOL CO., SALT|MORE, •0 21285 U.S.A,

F0R SERWRE INEORMAT•N, CALL1-•0-4-DEWALT W_.O_NALT.com

DW303 v,..o,...c..,.o..w

|_[][_][_ JNSTRUCTIO NMANUAL ALWAYS USE PROPEREYE

AND RESPIRATORY PROTECTJ0N. _, _tdDVi-=Rlt Z_JC_: PARA OJS•IN UIR EL

RIESO0 DE LE•ONES, EL OSUARI0 DEBER/_ LEER ELMANUAL DE JNSTRUCCIONES.

SiEMPRE SE OEBERA LLEVAR LA PROTECCJf]N APROPJAOA PARA LA VISTA Y

PARA LAS VJASRESPJRATORIAS, _ AVER_$$EM_'r:/_ TITRE PREVENTIF,

tiRE LE GUIDE D'UTILISA"rBON. IL FAUT TOUJOURS PORTER DE L'EOOiPEME•r DE

PROTECTION OCULAJRE ET RESPJRAT•RE APPROP•E.

0EWALT IIIIOOS_IAL TOOL S0., 8AL]IMORE, MO 21286 U.S.A,

F0R SERVICE INFORMAEJ0• SAL!* 1-800-4-OEWALT w_.OEWA LT.com

11/8" STROKE (29rnm)

SER.

11/8" STROKE (29ram)

SER.

TO REDUCE THE RISK OF iNJURY, USER •UST READ

[& AD_I_It_•_: PASA •S•INOiS ELRIESOO OE LESi0NES, EL _

USUARm0OEBERALEERELMANUAL0EINSTRUCCIONES,SIEMPRESE

0EOEP_LLEVARLA P_0TECCiO_PROPiAOAPARAL_VISTAYPASAL_S

ViASSESRISATORiAS__ AVF_I_SS_M_mT_ AEiN03 •I_iMiSES

LESRiS_ES_E_LESS_RES_L_U_SATEURD0_TOU_RS L_E LE

_U_E 0_U_L_SA]]O__LFAUTTOUJOURSPORTER0__U_PE_E_T DE

_PROTECT_O_0C0LA_RE_T0ESP_RA_O_0EAPP_0_R_E_

Ddfinitions : lignes directrices en

mati_re de sdcuritd

Les definitions ci-dessous decrivent le niveau de danger pour chaque

mot-indicateur employe, Lirele mode d'emploi et porter une attention particuliere

a.ces symboles.

i_,DANGER : indique une situation dangereuse imminente qui, si elle n'est pas

evitee, entra_nera la mort ou des blessures graves.

_AVERTISSEMENT : indique une situation potentiel/ement dangereuse qui, si

ellen' est pas evitee, pourrait entra_ner la mort ou des blessures graves.

_ATTENTION : indique une situation potentie//ement dangereuse qui, si e//e

n'est pas evitee, pourrait entra_nerdes blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de dommages corporels

mais qui par contre, si rien n'est fait pour I'eviter, pourrait poser des risques de

dommages materiels.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU DE TOUT AUTRE

OUTIL DEWALT, COMPOSEZ LE NUMFt:ROSANS FRAIS ' 1-800-4-DEWALT (1-800-433-9258}.

AVERTISSEMENT : afin de reduire le risque de blessures, life le mode d'emploi de I'outil.

Avertissements de sdcuritd gdndraux pour les outils

dlectriques

Le non-respect des avertissements et des directives pourrait se solder par un choc

A AVERTISSEMENT ! Life tousles avertissements de s_curit_ et toutes les directives.

dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES LES

DIRECTIVES POUR UN USAGE ULTERIEUR

Le terme _ outil dectrique _ cite dans les avertissements se rapporte a votre outil electrique

alimentation sur secteur (avec ill) ou par piles (sans fil).

1) S#CURIT# DU LIEU DE TRAVAIL

a) Tenir I'aire de travail propre et bien _clair_e. Les Iieux encombres ou sombres sont

propices aux accidents.

b) Ale pas faire fonctionner d'outils _lectriques clans un milieu d_flagrant, tel qu'en

presence de liquides, de gaz ou de poussi_res inflammables. Les outils electriques

produisent des etincelles qui pourraient enflammer lapoussiere ou les vapeurs.

c) E:loigner les enfants et les personnes a proximit_ pendant rutilisation d'un outil

_lectrique. Une distraction pourrait en faire perdre la ma_trisea I'utilisateur.

2) SI_CURITI_ EN MATIERE D'I_LECTRICITI_

a) Les fiches des outils _lectriques doivent correspondre a la prise. Ne jamais modifier

la fiche d'aucune faqon. Ne jamais utiliser de fiche d'adaptation avec un outil

_lectrique mis a la terre. Le risque de choc dectrique sera reduit par I'utilisation de fiches

non modifiees correspondant a laprise.

b) E:viter tout contact physique avec des surfaces mises a la terre comme des tuyaux,

des radiateurs, des cuisini_res et des r_frig_rateurs. Le risque de choc dectrique est

plus deve si votre corps est mis a la terre.

c) Ne pas exposer les outils _lectriques a la pluie ou a I'humidit_. La penetration de I'eau

dans un outil dectrique augmente le risque de choc dectrique.

d) Ne pas utiliser le cordon de fa_on abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou d_brancher un outil _lectrique. Tenir le cordon _loign_ de

la chaleur, de I'huile, des bords tranchants et des pi_ces mobiles. Les cordons

endommages ou enchev_tres augmentent les risques de choc dectrique.

e) Pour I'utilisation d'un outil _lectrique a I'ext_rieur, se servir d'une rallonge

convenant a cette application. L'uti/isation d'une ra//onge conque pour/'exterieur reduira

les risques de choc dectrique.

f) S'il est impossible d'_viter I'utilisation d'un outil _lectrique clans un endroit

humide, brancher I'outil clans une prise ou sur un circuit d'alimentation dot_s d'un

disjoncteur de fuite a la terre (GFCI). L'utilisation de ce type de disjoncteur reduit les

risques de choc dectrique.

3) S#CURIT# PERSONNELLE

a) Etre vigilant, surveiller le travail effectu_ et faire preuve de jugement Iorsqu'un outil

_lectrique est utilis_. Ne pas utiliser d'outil _lectrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de m_dicaments. Un simple moment d'/nattent/on

en utilisant un outil dectrique peut entra_nerdes blessures corporelles graves.

b) Utiliser des _quipements de protection individuelle. Toujours porter une protection

oculaire. L'utilisation d'equipements de protection comme un masque antipoussiere, des

chaussures antiderapantes, un casque de securite ou des protecteurs auditifs Iorsque la

situation le requiert reduira les risques de blessures corporelles.

c) Emp_cher les d_marrages intempestifs. S'assurer que I'interrupteur se trouve a la

position d'arr_t avant de relier I'outil a une source d'alimentation et/ou d'ins_rer un

bloc-piles, de ramasser ou de transporter I'outil. Transporter un outi/ e/ectrique a/ors

que le doigt repose sur I'interrupteur ou brancher un outil dectrique dont I'interrupteur est

la position de marche risque de provoquer un accident.

d) Retirer toute cl_ de r_glage ou cl_ avant de d_marrer I'outil. Une cle ou une cle de

reglage attachee a une pattie pivotante de I'outil dectrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son _quilibre en tout temps. Cela permet de

mieux ma_triserI'outil dectrique dans les situations imprevues.

S'habiller de mani_re appropri_e. Ne pas porter de v_tements amples ni de bijoux.

Garder les cheveux, les v_tements et les gants a I'_cart des pi_ces mobiles. Les

v_tements amples, les bijoux ou les cheveux longs risquent de rester coinces dans les pieces

mobiles.

g) Sides composants sent fournis pour le raccordement de dispositifs de d_poussi_rage

et de ramassage, s'assurer que ceux-ci sent bien raccord_s et utilis_s. L'uti/isation

d'un dispositif de depoussierage peut reduire les dangers engendres par les poussieres.

4} UTILISATION ET ENTRETIEN D'UN OUTIL #LECTRIQUE

a) Ne pas forcer un outil _lectrique. Utiliser I'outil _lectrique appropri_ a I'application.

L'outil dectrique approprie effectuera un mei/leur travail, de faqon plus sore eta la vitesse

pour laquelle il a ete conqu.

b) Ne pas utiliser un outil _lectrique dont I'interrupteur est d_fectueux. Tout outil

dectrique dont /'interrupteur est defectueux est dangereux et doit _tre repar&

c) D_brancher la fiche de la source d'alimentation et/ou du bloc-piles de I'outil

_lectrique avant de faire tout r_glage ou changement d'accessoire ou avant de

ranger I'outil. Ces mesures preventives reduisent les risques de demarrage accidentel de

I'outil dectrique.

d) Ranger les outils _lectriques hers de la pottle des enfants et ne permettre

aucune personne n'_tant pas famili_re avec un outil _lectrique ou son mode

d'emploi d'utiliser cet outil. Les outi/s dectriques deviennent dangereux entre/es mains

d'utilisateurs inexperimentes.

e) Entretien des outils _lectriques. V_rifier si les pi_ces mobiles sent mal align_es ou

coinc_es, si des pi_ces sent bris_es ou pr_sentent toute autre condition susceptible

de nuire au ben fonctionnement de I'outil _lectrique. En cas de dommage, faire

r_parer I'outil _lectrique avant toute nouvelle utilisation. Beaucoup d'accidents sont

causes par des outils dectriques mal entretenus.

S'assurer que les outils de coupe sent aiguis_s et propres. Les outils de coupe bien

entretenus et affOtes sont moins susceptibles de se coincer et sont plus faciles a ma_triser.

g) Utiliser I'outil _lectrique, les accessoires, les forets, etc. conform_ment aux

pr_sentes directives en tenant compte des conditions de travail et du travail

effectuer. L'utilisation d'un outil dectrique pour toute operation autre que celle pour laquelle

ila ete conquest dangereuse.

5) RI_PARATION

a) Faire r_parer I'outil _lectrique par un r_parateur professionnel en n'utilisant que

des pi_ces de rechange identiques. Celapermettra de maintenir une utilisation securitaire

de I'outil dectrique.

Mesures de s_curit_ additionnelles et sp_cifiques _ I'outil

• Tenir I'outil _lectrique par les surfaces isol_es pr_vues a cet effet pendant toute

utilisation ob I'organe de coupe pourrait entrer en contact avec des ills _lectriques

caches ou son propre cordon. Tout contact de I'organe de coupe avec un fil sous tension

mettra les parties metalliques exposees de I'outil dectrique sous tension et dectrocutera

I'utilisateur.

• Utiliser des serre-joints, ou tout autre moyen, pour fixer et immobiliser le mat_riau sur

une surface stable. Tenir la piece a la main ou contre son corps offre une stabi/ite insuffisante

qui pourrait vous en faire perdre le contr_le.

• Ne pas utiliser cet outil pendant des p_riodes prolong_es. Les vibrations causees par

I'action de fonctionnement de I'outil peuvent blesser en permanence les doigts, les mains et les

bras. Porter des gants pour amortir les vibrations, faire des pauses frequentes et limiter le temps

d'utilisation quotidien de I'outiL

• Prendre des precautions a proximit_ des _vents, car ils cachent des pi_ces mobiles.

V_tements amples, bijoux ou cheveux longs risquent de rester coinces dans ces pieces mobiles.

• Pour la s_curit_ de I'utilisateur, utiliser une rallonge de calibre ad_quat (AWG,

American Wire Gauge [calibrage am_ricain normalis_ des ills _lectriques]). Plus le

calibre est petit, et plus sa capacite est grande. Un calibre 16, par exemple, a une capacite

superieure a un calibre 18. L'usage d'une rallonge de calibre insuffisant causera une chute de

tension qui entra_neraperte de puissance et surchauffe. Si plus d'une rallonge est utilisee pour

obtenir une certaine Iongueur, s'assurer que chaque rallonge presente au moins le calibre de

fil minimum. Le tableau ci-dessous illustre les calibres a utiliser selon la Iongueur de rallonge

et I'intensite nominale indiquee sur la plaque signaletique. En cas de doute, utiliser le calibre

suivant. Plus le calibre est petit, plus la rallonge peut supporter de courant.

Calibres minimaux des rallonDes

Intensit_ (en ampbres)

Sup_rieur

0

6

10

12

Inf_rieur

6

10

12

16

_AVERTISSEMENT : porter SYSTEMATIQUEMENT des lunettes de protection. Les lunettes

courantes NE sont PAS des lunettes de protection. Utiliser aussi un masque antipoussieres si la

decoupe dolt en produire beaucoup. PORTER SYSTEMATIQUEMENT UN EQUIPEMENT DE

SECURITE HOMOLOGUE :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) ;

• Protection auditive ANSI $12.6 ($3.19) ;

• Protection des voles respiratoires NIOSH/OSHA/MSHA.

,_AVERTISSEMENT : les scies, meules, ponceuses, perceuses ou autres outils de construction

peuvent produire des poussieres contenant des produits chimiques reconnus par I'Etat califomien

pour causer cancers, malformations congenitales ou _tre nocifs au systeme reproducteur. Parmi

ces produits chimiques, on retrouve :

• Le plomb dans les peintures a base de plomb ;

• La silice cristallisee dans les briques et le ciment, ou autres produits de maqonnerie ; et

• L'arsenic et le chrome dans le bois ayant subi un traitement chimique.

Le risque associe a de telles expositions varie selon la frequence a laquelle on effectue ces travaux.

Pour reduire toute exposition a ces produits : travailler dans un endroit bien aere, en utilisant du

materiel de securite homologue, tel un masque antipoussieres specialement conqu pour filtrer les

particules microscopiques.

• Limiter toute exposition prolong_e avec les poussi_res provenant du pon_age, sciage,

meulage, perqage ou toute autre activit_ de construction. Porter des v_tements de

protection et nettoyer a I'eau savonneuse les parties du corps expos_es. Le fait de

laisser la poussiere penetrer dans la bouche, les yeux ou la peau peut favoriser I'absorption de

produits chimiques dangereux.

_AVERTISSEMENT : cet outil peut produire et/ou repandre de la poussiere susceptible de

causer des dommages serieux et permanents au systeme respiratoire. Utiliser systematiquement

un appareil de protection des voles respiratoires homologue par le NIOSH ou I'OSHA. Diriger les

particules dans le sens oppose au visage et au corps.

volts LonDueur totale de cordon en mbtres (pieds)

120 V 7,6 (25) 30,5 (100) 45,7 (150)

240 V 15,2 (50) 61,0 (200) 91,4 (300)

15,2 (50)

30,5 (100)

AWG

18

18

16

14

16

16

16

12

16 14

14 12

14 12

Non recommande

Page 4

J_AVERTISSEMENT : pendant I'utilisation, porter syst_matiquement une protection

auditive individuelle adequate homologu_e ANSI $12.6 ($3.19). Sous certaines conditions et

suivant la duree d'utilisation, le bruit emanant de ce produit pourrait contribuer a une perte de

I'acuite auditive.

• L'etiquette apposee sur votre outil peut inclure les symboles suivants. Les symboles et leur

definition sont indiques ci-apres :

V.................... volts

Hz.................. hertz

min ................ minutes

--- ou DC.... courant continu

_) .................. classe I fabrication

(misa la terre)

[] .................. fabrication classe II

(double isolation)

.../min ........... par minute

IPM ................ impacts par minute

sfpm .............. pieds lineaires par minute (plpm)

A....................... amperes

W...................... watts

"_ ou AC .......... courant altematif

ou AC/DC... courant altematif ou

continu

no ..................... vitesse a vide

n ....................... vitesse nominale

..................... borne de terre

A ...................... symbole d'avertissement

BPM ................. battements par minute

r/min ................. tours par minute

SPM (FPM).... frequence par minute

CONSERVER CES CONSIGNES POUR

UTILISATION ULTERIEURE

Moteur

S'assurer que le bloc d'alimentation est compatible avec I'inscription de la plaque signaletique.Une

diminution de tension de plus de 10 % provoquera une perte de puissance et une surchauffe. Les

outils DEWALT sont testes en usine; si cet outil ne fonctionne pas, verifier ralimentation electrique.

DESCRIPTION (Fig. 1-3)

_AVERTISSEMENT : ne jamais modifier I'outil dectrique ni aucun de ses composants, car il y a

risques de dommages corporels ou materiels.

A. Gb.chette E. Serre-lame

B. Vis de pression F. Lame

C. Tige de la lame G. Goupille

D. Arbre tournant H. Levier de deverrouillage du serre-lame

Interrupteur _ d_tente (Fig. 1)

Le regulateur de vitesse (A) offre une grande souplesse d'utilisation. Plus on enfonce rinterrupteur a.

detente, plus la vitesse de la scie augmente. Pour rarr_ter, ilsuffit de relb.cher rinterrupteur.

_,ATTENTION : IIest recommande de se servir de la basse vitesse seulement pour commencer

une coupe. La scie peut _tre endommagee par une utilisation prolongee a tres basse vitesse.

ASSEMBLAGE ET AJUSTEMENTS

AAVERTISSEMENT :pour r_duire le risque de blessures, _teindre I'appareil et le

d_brancher avant d'installer ou de retirer tout accessoire et avant d'effectuer des r_glages

ou des r_parations. Un demarrage accidentel peut provoquer des blessures.

Serre-lame (Fig. 2)

(DW303)

POUR INSTALLER LA LAME SUR LA SCIE

1. Desserrez lavis de pression (B).

2. Inserez la tige de la lame (C)par ravant entre rarbre tournant (D) et le serre-lame (E). Placez le

trou sur la lame (F)sur la goupille (G) de I'arbre tournant.

3. Resserrez la vis de pression. Si la lame venait a.se casser et que sa tige refuse de sortir de la

bride, assurez-vous que la vis de pression est desserree puis ejectez latige a.raide d'un clou

ou d'un objet pointu.

_ATTENTION : LE PROTEGE-LAME EST INSTALLE PAR MESURE DE SECURITE. NE

PAS L'ENLEVER.

Levier de Degagement du Serre-Lame (Fig. 3)

(DW303M, DW304P, DWE304)

FAIRE CE QUI SUIT POUR INSTALLER UNE LAME

1. Soulever le levier de degagement du serre-lame (H).

2. Inserer rarbre de la lame a. I'avant de routil.

3. Abaisser le levier de degagement du serre-lame.

FAIRE CE QUI SUIT POUR RETIRER LA LAME

1. Soulever le levier de degagement du serre-lame.

2. Retirer la lame.

AATTENTION : LE PROTEGE-LAME EST INSTALLE PAR MESURE DE SECURITE. NE PAS

L'ENLEVER.

UTILISATION

AA VERTISSEMENT :pour r_duire le risque de blessures, _teindre I'appareil et le d_brancher

avant d'installer ou de retirer tout accessoire et avant d'effectuer des r_glages ou des

r_parations. Un demarrage accidentel peut provoquer des blessures.

Coupe avec la Lame en Position Horizontale (Fig. 4A)

(DW304P DWE304)

Le fait d'installer la lame horizontalement permet de couper a.raz du sol, d'un mur ou d'un plafond,

la.ou la liberte de manoeuvre est limitee. S'assurer de bien presser le protege-lame contre la

structure pour eviter les rebonds.

Coupe _ ras (Fig. 5)

La conception compacte du carter du moteur et de celui de rarbre de la scie alternative permet de

couper auras des planchers, des coins et d'autres endroits d'acces difficile.

_ATTENTION : Lorsqu'on coupe dans lesmurs, les .planchersou tout autre endroit DOpeuvent se

trouver des ills sous tension, NE PAS TOUCHER A TOUT COMPOSANT ME'TALLIQUE DE

L'OUTIL. Ne le saisir que par la poignee et le bo_tier en plastique ou en caoutchouc afin de se

proteger des secousses dectriques en cas de contact avec un fil sous tension.

_ATTENTION : Toujours porter des lunettes de securite Iorsqu'on utilise un outil dectrique.

Coupe du bois (Fig. 6)

Avant de couper une piece de bois quelconque, s'assurer qu'elle est solidement assujettie ou

immobilisee afin d'emp_cher qu'elle ne glisse. Consulter le tableau de selection des lames du

present guide afin de choisir la Iongueur et le type appropries de lame dans le but d'optimiser

les resultats. Appuyer legerement la lame contre la piece a.couper, mettre le moteur de la scie en

marche et attendre qu'il ait atteint sa vitesse maximale avant d'exercer de la pression. Toujours

saisir la scie fermement des deux mains pendant le travail. Dans la mesure du possible, appuyer

fermement le patin de la scie contre la piece pendant la coupe. Cette mesure emp_che la scie de

sauter ou de vibrer, et reduit les risques de bris de la lame.

posterieur du patin repose contre la surface de travail. Mettre le moteur en marche et attendre que la

lame ait atteint la vitesse maximale de coupe. Saisir fermement la poignee et redresser lentement la

poignee de la scie. La scie commence alors a.s'avancer dans la piece a.couper. Toujours s'assurer

que la scie transperce le materiau avant de poursuivre la coupe.

NOTE : Dans les endroits DOil est difficile de voir la lame pendant la coupe, utiliser le rebord du

patin de la scie comme guide. On conseille de prolonger les lignes tracees au crayon au-dela, de

la limite de la coupe a.executer.

MAINTENANCE

_A VERTISSEMENT :pour r_duire le risque de blessures, _teindre I'appareil et le d_brancher

avant d'installer ou de retirer tout accessoire et avant d'effectuer des r_glages ou des

r_parations. Un demarrage accidentel peut provoquer des blessures.

Nettoyage

_AVERTISSEMENT : enlever les saletes et la poussiere hors des events au moyen d'air

comprime propre et sec, au moins une lois par semaine. Pour minimiser le risque de blessure aux

yeux, toujours porter une protection oculaire conforme a la norme ANSI Z87.1 lots du nettoyage.

_AVERTISSEMENT : nejamais utiliser de solvants ni d'autres produits chimiques puissants pour

nettoyer les pieces non metalliques de I'outil. Ces produits chimiques peuvent affaiblir les materiaux

de plastique utilises dans ces pieces. Utiliser un chiffon humecte uniquement d'eau et de savon

doux. Nejamais laisser de liquide penetrer dans I'outil et n'immerger aucune partie de I'outil dans

un liquide.

Accessoires

_AVERTISSEMENT : puisque les accessoires autres que ceux offerts par DEWALT n'ont pas ete

testes avec ce produit, leur utilisation pourrait s'averer dangereuse. Pour reduire le risque de

blessures, utiliser exclusivement les accessoires DEWALT recommandes avec le present produit.

Les accessoires recommandes pour cet outil sont vendus separement au centre de service

de votre region. Pour obtenir de raide concernant I'achat d'un accessoire, communiquer avec

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 aux Etats-Unis;

composer le 1 800 433-9258 (1 800 4-DEWALT) ou visiter notre site Web : www.dewalt.com.

Rdparations

Pour assurer la SECURIT¢: et la FIABILIT¢: du produit, les reparations, I'entretien et les reglages

doivent _tre realises (cela comprend rinspection et le remplacement du balai) par un centre de

reparation en usine DEWALT, un centre de reparation agree DEWALT ou par d'autres techniciens

qualifies. Toujours utiliser des pieces de rechange identiques.

Registre en ligne

Merci pour votre achat. Enregistrez des maintenant votre produi:

• RI_PARATIONS SOUS GARANTIE: cette carte remplie vous permettra de vous prevaloir du

service de reparations sous garantie de faoon plus efficace dans le cas d'un probleme avec le

produit.

• CONFIRMATION DE PROPRII_TI_: en cas de perte provoquee par un incendie, une

inondation ou un vol, cette preuve de propriete vous servira de preuve aupres de votre

compagnie d'assurances.

• SI_CURITI_: I'enregistrement de votre produit nous permettra de communiquer avec vous dans

I'eventualite peu probable de renvoi d'un avis de securite regi par la Ioi federale americaine de

la protection des consommateurs.

Registre en ligne a.www.dewalt.com/register.

Garantie limit_e de trois ans

DEWALT reparera, sans frais, tout produit defectueux cause par un defaut de materiel ou de

fabrication pour une periode de trois ans a.compter de la date d'achat. La presente garantie ne

couvre pas les pieces dont la defectuosite a ete causee par une usure normale ou I'usage abusif

de I'outil. Pour obtenir de plus amples renseignements sur les pieces oules reparations couvertes

par la presente garantie, visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-DEWALT).Cette garantie ne s'applique pas aux accessoires et ne vise pas les dommages causes

par des reparations effectuees par un tiers. Cette garantie confere des droits legaux particuliers a.

I'acheteur, mais celui-ci pourrait aussi beneficier d'autres droits variant d'un etat ou d'une province

a.I'autre.

En plus de la presente garantie, les outils DEWALTsont couverts par notre :

CONTRAT D'ENTRETIEN GRATUlT D'UN AN

D_WALT entretiendra I'outil et remplacera les pieces usees au cours d'une utilisation normale et ce,

gratuitement, pendant une periode d'un an a.compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si racheteur n'est paR entierement satisfait, pour quelque raison que ce soit, du rendement de

I'outil electrique, du laser ou de la cloueuse DEWALT, celui-ci peut le retourner, accompagne d'un

reou, dans les 90 jours a.compter de la date d'achat pour obtenir un remboursement integral, sans

aucun probleme.

AMI_RIQUE LATINE : cette garantie ne s'applique aux produits vendus en Amerique latine.

Pour ceux-ci, veuillez consulter les informations relatives a. la garantie specifique presente dans

I'emballage, appeler I'entreprise locale ou consulter le site Web pour les informations relatives a.

cette garantie.

REMPLACEMENT GRATUIT DES I_TIQUETTES D'AVERTISSEMENT : si les etiquettes

d'avertissement deviennent illisibles ou sont manquantes, composer le 1 800 433-9258 (1 800

4-DEWALT) pour en obtenir le remplacement gratuit.

I 1/8" STROKE (29ram)

SER,

_TO REDUCETHERISE OF

iNJURY, USERMMUSTREADiNSTRUCTiON MANUAL,

ALWAYS USEPROPEREYEANDRESPIRATORY

PROTECTION,

OEWALT INDDSTMAL TOOL CO., BALTIMORE, MO 21286 U.S.A.

FOR SERVICE ]NFORMATJ0N, CALL 1-800-#-D_WALY www.D_WALT.com

11/8" STROKE (29ram)

SER.

_ iNSTRUCTiON MANUAL ALWAYS USE PROPER EYE

AND RESPIRATORY PROTECTION. _ _VN_lrlEEIC_: PARA BISMiNUiR EL

RiERGO DE LESiONES, ELUSUAMO DEOER._ LEER EL MANUAL DE iNSTRUCRiONER.

SIEMPRE SE DEBERA LLEVAR LA PROTECCJ()N APROPIAOA PARA LA VISTA Y

PARA LAS ViAS RESPiRATORJAS. _. AVEI_TiI_SI_M_I_r;/_ TITDE PREVEN_F

LIRE LE GUIDE O'OTILISATION. IL FAOT TODJODRS PORTER DE L'END JPEMERT DE

PROTECTION OCDLAiRE ET RESPIRATOiRE APPOOPME.

OEWALT iNDUSTRiAL TOOL CO. BALTIMORE, MD 21286 U.S.A.

FOR SERVICE INFORMATION, CALL 1-80_-4-OEWALT www.OEWALT.com

TO DEDUCE TOE RiSK OF INJURY, USER MUST READ

f& ADVNRTNN_A PARAOSM ND RELRERGODELEOONES,EL

USDAOmORRBERALEERELMANUALREINSTRUOCIONES.SIRMPDERE

DEOERALLEVARLAPROTECCON PROPADOPARALAV STAYPAP_LOS

ViASRESPIRATORIAS. A AVNR'C_SEMEMT: AFIRDEMINIMISER

LEOMSQUESOROLESSOOEO,L'UTlUSATEDRBOlTTOUJ_)UOSDOELE

GUIDEU'UTI_SATION.IL EAUTTODJOURRPORTERU_ L'ENUIPEMENT0_

PROTEO_ONOOOLAIREET RRSPIDATOIREAPPOOPRIE.

Coupe des mdtaux (Fig. 7)

Le rendement de cette scie depend du type de lame utilise et du metal a.couper. Se servir d'une

lame a.dents fines pour couper les metaux ferreux, et d'une lame a. dents grossieres pour couper

les metaux non ferreux. Lorsqu'on coupe une feuille de tOle mince, il est preferable d'immobiliser

la feuille de metal entre deux pieces de bois. On elimine ainsi les vibrations et les risques de

dechirement de la tOle. II ne faut jamais forcer I'outil en le poussant trop energiquement car on

reduirait la duree de la lame tout en risquant d'endommager la scie.

NOTE : IIest generalement conseille, pour la coupe des metaux, d'enduire la ligne de coupe d'une

mince pellicule d'huile ou d'une substance semblable afin de faciliter la manoeuvre de I'outil et de

prolonger la duree de la lame.

Coupe en retrait (Fig. 8)

(Bois seulement)

La premiere etape de la coupe en retrait consiste a.mesurer la superficie de la piece a.couper et a.la

marquer a.I'aide d'un trait de crayon ou de craie, ou d'un traooir. Inserer ensuite la lame de coupe en

retrait dans le serre-lame et bien la serrer. Incliner alors la scie vers I'arriere jusqu'a, ce que le rebord

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de sepal. Lea

el manual y preste atenciOn a estos simbolos.

J_PELIGRO: indica una situacidn de peligro inminenteque, si no se evita, provocara la

muerte o lesiones graves.

_ADVERTENCIA: indica una situacidn de peligro potencial que, si no se evita, podria

provocar la muerte o lesiones graves.

_,ATENCI(_N: indica una situacidn de peligro potencial que, si no se evita,

posiblemente provocarfa lesiones leves o moderadas.

AVISO: se refiere a una practica no relacionada a lesiones corporales que de no

evitarse puede resultar en dahos a la propiedad.

SI TIENE ALGUNA DUDA O ALGON COMENTARIO SOBRE ESTA U OTRA HERRAMIENTA

DEWALT,LL_,MENOS AL NOMERO GRATUITO: 1-800-4-DEWALT (1-800-433-9258}.

Page 5

O ADVERTENCIA: Para reducir el riesgo de lesiones, lea el manual de instrucciones.

Advertencias generales de seguridad para herramientas

eldctricas

iADVERTENCIA! Lea todas las advertencias de seguridad e instrucciones. El

incumplimiento de las advertencias e instrucciones puede provocar descargas electricas,

incendios o lesiones graves.

CONSERVE TODAS LAS ADVERTENCIAS E INSTRUCCIONES

PARA FUTURAS CONSULTAS

El t&mino "herramienta electrica" incluido en las advertencias hace referencia alas herramientas

electricas operadas con corriente (con cable electrico) o alas herramientas electricas operadas

con baterfas (inalambricas).

1) SEGURIDAD EN EL AREA DE TRABAJO

a) Mantenga el area de trabajo limpia y bien iluminada. Las areas abarrotadas y oscuras

propician accidentes.

b) No opere las herramientas el_ctricas en atmosferas explosivas, come ambientes

donde haya polvo, gases o liquidos inflamables. Las herramientas e/ectricas originan

chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los nifios y a los espectadores de la herramienta el_ctrica en

funcionamiento. Las distracciones pueden provocar la perdida de control.

2) SEGURIDAD EL#CTRICA

a) Los enchufes de la herramienta el_ctrica deben adaptarse al tomacorriente. Nunca

modifique el enchufe de ninguna manera. No utilice ningEm enchufe adaptador con

herramientas el_ctricas con conexion a tierra. Los enchufes no modiflcados y que se

adaptan a los tomacorrientes reduciran el riesgo de descarga electrica.

b) Evite el contacto corporal con superficies con descargas a tierra come, per

ejemplo, tuberias, radiadores, cocinas el_ctricas y refrigeradores. Existe mayor riesgo

de descarga electrica si su cuerpo esta puesto a tierra.

c) No exponga las herramientas el_ctricas a la Iluvia o a condiciones de humedad. Si

entra agua a una herramienta electrica, aumentara el riesgo de descarga electrica.

d) No maltrate el cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta el_ctrica. Mantenga el cable alejado del calor, el aceite, los bordes

filosos y las piezas moviles. Los cables dahados o enredados aumentan el riesgo de

descarga electrica.

e) AI operar una herramienta el_ctrica en el exterior, utilice un cable prolongador

adecuado para tal use. Utilice un cable adecuado para uso en exteriores a fin de reducir

el riesgo de descarga electrica.

Si el use de una herramienta el_ctrica en un lugar hE/merle es imposible de evitar,

utilice un suministro protegido con un interrupter de circuffo per falla a tierra

(GFCI). Eluso de un GFC/ reduce el riesgo de descargas electricas.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle Io que esta haciendo y utilice el sentido comEm

cuando emplee una herramienta el_ctrica. No utilice una herramienta el_ctrica si

esta cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta electrica puede provocar lesiones personales

graves.

b) Utilice equipos de proteccion personal. Siempre utilice proteccion para los ojos. En

las condiciones adecuadas, el uso de equipos de proteccidn, como mascaras para polvo,

calzado de seguridad antideslizante, cascos o proteccidn auditiva, reducira las lesiones

personales.

c) Evite el encendido pot accidente. Aseg(wese de que el interruptor est_ en la

posicidn de apagado antes de conectarlo a la fuente de energia o paquete de

baterias, o antes de levantar o transportar la herramienta. Transportar herramientas

electricas con el dedo apoyado en el interruptor o enchufar herramientas electricas con el

interruptor en la posicidn de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la Ilave de tuercas antes de encender la herramienta

el_ctrica. Una Ilave de tuercas o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta electrica puede provocar lesiones personales.

e) No se estire. Conserve el equilibrio y parese adecuadamente en todo memento.

Esto permite un mejor control de la herramienta electrica en situaciones inesperadas.

Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el cabello,

la ropa y los guantes alejados de las piezas en movimiento. Las ropas ho/gadas, /as

joyas o el cabel/o largo pueden quedar atrapados en las piezas en movimiento.

g) Si se suministran dispositivos para la conexion de accesorios con fines de

recoleccidn y extraccion de polvo, asegEwese de que est_n conectados y que se

utilicen correctamente. Eluso de dispositivos de recoleccidn de polvo puede reducir los

peligros relacionados con el polvo.

4} USO Y MANTENIMIENTO DE LA HERRAMIENTA EL#CTRICA

a) No fuerce la herramienta el_ctrica. Utilice la herramienta el_ctrica correcta para el

trabajo que realizara. Si se la utiliza a la velocidad para la que rue disehada, la herramienta

electrica correcta permite trabajar mejor y de manera mas segura.

b) No utilice la herramienta el_ctrica si no puede encenderla o apagarla con el

interrupter. Toda herramienta electrica que no pueda set controlada mediante el interruptor

es peligrosa y debe repararse.

c) Desconecte el enchufe de la fuente de energia o el paquete de baterias de la

herramienta el_ctrica antes de realizar ajustes, cambiar accesorios o almacenar

la herramienta el_ctrica. Estas medidas de seguridad preventivas reducen el riesgo de

encender la herramienta electrica en forma accidental.

d) Guarde la herramienta el_ctrica que no est_ en use fuera del alcance de los nifios y

no permffa que otras personas no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas electricas son peligrosas si son operadas pot

usuarios no capacitados.

e) Realice el mantenimiento de las herramientas el_ctricas. Revise que no haya piezas

en movimiento mal alineadas o trabadas, piezas rotas o cualquier otra situacion

que pueda afectar el funcionamiento de la herramienta el_ctrica. Si encuentra

dafios, haga reparar la herramienta el_ctrica antes de utilizarla. Se producen muchos

accidentes a causa de las herramientas electricas que carecen de un mantenimiento

adecuado.

Mantenga las herramientas de corte afiladas y limpias. Las herramientas de corte

con mantenimiento adecuado y con los bordes de corte afilados son menos propensas a

trabarse y son mas faciles de controlar.

g) Utilice la herramienta el_ctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de /a herramienta e/ectrica para

operaciones diferentes de aqudlas para las que rue disehada podrfa originar una situacidn

peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona calificada en reparaciones que realice el mantenimiento

de su herramienta el_ctrica y que solo utilice piezas de repuesto id_nticas. Esto

garantizara la seguridad de la herramienta electrica.

Reglas de seguridad adicionales

• Sujete la herramienta el_ctrica per las superficies aisladas cuando realice una

operacion en la cual el accesorio de corte pudiera entrar en contacto con instalaciones

el_ctricas ocultas o su propio cable. Si el accesorio de corte entra en contacto con un cable

bajo tensidn, las partes metalicas expuestas de la herramienta pueden cargarse y producir una

descarga electrica al operador.

• Use abrazaderas u otra forma practica de asegurar y apoyar la pieza de trabajo a

una plataforma estable. El sujetar la pieza de trabajo con la mano o contra su cuerpo no

proporciona estabilidad y puede causar una perdida de control

• No opere esta herramienta durante periodos largos de tiempo. La vibracidn causada

pot la accidn de operacidn de la herramienta puede causar lesiones permanentes a sus dedos,

manos y brazos. Use guantes para un mejor amortiguamiento, descanse con frecuencia y limite

el tiempo diario de uso.

Los orificios de ventilacidn suelen cubrir piezas en movimiento, per Io que tambi_n se

deben evitar. Las piezas en movimiento pueden atrapar prendas de vestir sueltas, joyas o el

cabello largo.

E1 cable de extension deben set de un calibre apropiado para su seguridad. Mientras

menor sea el calibre del hilo, mayor la capacidad del cable. Es decir, un hi/o calibre 16 tiene

mayor capacidad que uno de 18. Un cable de un calibre insuficiente causara una cafda en la

tensidn de la Ifnea dando pot resultado una p&dida de energfa y sobrecalentamiento. Cuando

se utilice mas de un alargador para completar el largo total, asegdrese que los hilos de cada

alargador tengan el calibre mfnimo. La tabla siguiente muestra el tamaho correcto a utilizar,

dependiendo de la Iongitud del cable y del amperaje nominal de la placa de identificacidn. Si

tiene dudas sobre cual calibre usar, use un calibre mayor. Cuanto mas pequeho sea el ndmero

del calibre, mas resistente sera el cable.

Calibre minimo para cables de alimentaciOn

Voltios Largo total del cordbn en metros (pies)

Amperaje

Mas de

0

6

10

12

_ADVERTENCIA: Use SIEMPRE lentes de seguridad. Los anteojos de diario NO SON lentes de

seguridad. Utilice ademas una cubrebocas o mascarilla antipolvo si la operacidn de corte genera

demasiado polvo. SIEMPRE LLEVE EQUIPO DE SEGURIDAD CERTIFICADO:

• Proteccidn ocularANSI Z87.1 (CAN/CSA Z94.3),

• Proteccidn auditiva ANSI $12.6 ($3. 19),

• Proteccidn respiratoria NIOSH/OSHA/MSHA.

_ADVERTENCIA: Algunas partfculas de polvo generadas al lijar, serrar, esmerilar y taladrar con

herramientas electricas, asf como al realizar otras actividades de construccidn, contienen

qufmicos que el Estado de California sabe que pueden producir cancer, defectos congenitos u

otras afecciones reproductivas. Ejemplos de estos qufmicos son."

• plomo de algunas pinturas en base a plomo,

• polvo de sflice proveniente de ladrillos y cemento y otros productos de albahilerfa, y

• arsenico y cromo provenientes de madera tratada qufmicamente.

Su riesgo de exposicidn a estos qufmicos varfa, dependiendo de la frecuencia con la cual realiza

usted este tipo de trabajo. Para reducir su exposicidn a estas sustancias qufmicas: trabaje en

una zona bien ventilada y Ilevando equipos de seguridad aprobados, como mascarillas antipolvo

especialmente disehadas para filtrar partfculas microscdpicas.

• Evite el contacto prolongado con polvo generado per el lijado, aserrado, pulido,

taladrado y otras actividades de construccion. Vista ropas protectoras y lave las areas

de la piel expuestas con agua y jabon. Si perm/te que el polvo se /ntroduzca en la boca u

ojos o quede sobre la piel, puede favorecer la absorcidn de productos qufmicos peligrosos.

_ADVERTENCIA: La utilizacidn de esta herramienta puede generar polvo o dispersarlo, Io que

podrfa causar dahos graves y permanentes al sistema respiratorio, asf como otras lesiones.

Siempre use proteccidn respiratoria aprobada pot NIOSH (Instituto Nacional de Seguridad y Salud

en el Trabajo) u OSHA (Administracidn de Seguridad y Salud en el Trabajo) apropiada para la

exposicidn al polvo. Dirija laspartfculas en direccidn contraria a la cara y el cuerpo.

_ADVERTENCIA: Siempre Ileve la debida proteccion auditiva personal en conformidad

con ANSI $12.6 ($3.19) durante el use de esta herramienta. Bajo algunas condiciones y

duraciones de uso, el ruido producido pot este producto puede contribuir a la p&dida auditiva.

• La etiqueta de su herramienta puede incluir los siguientes sfmbolos. A continuacidn se indican

los sfmbolos y sus definiciones:

V................... voltios

Hz................. hertz

min ............... minutos

--- o DC.... corriente directa

@ ................. Construccidn de Clase I

[] ................. Construccidn de Clase II)

.../min ..........pot minuto

IPM .............. impactos pot minuto

sfpm ............. pies de superficie por minuto

SPM ............. pasadas pot minuto

No mas de

6

10

12

16

(tierra)

(doble aislamiento)

120 V 7,6 (25) 30,5 (100) 45,7 (150)

240 V 15,2 (50) 61,0 (200) 91,4 (300)

18

18

16

14

A....................... amperios

no ..................... velocidad sin carga

n ....................... velocidad nominal

15,2 (50)

30,5 (100)

AWG

16

16

16

12

W...................... vatios

•"_ o AC ........... corriente altema

_-, oAC/DC ....corriente altema o directa

¢_ ..................... terminal de conexidn a tierra

,_...................... sfmbolo de advertencia de

seguridad

BPM ................. golpes por minuto

RPM ................. revoluciones pot minuto

16 14

14 12

14 12

No recomendado

GUARDE ESTAS INSTRUCCIONES

PARA FUTURAS CONSULTAS

Motor

Aseg0rese de que la fuente de energia concuerde con Io que se indica en la placa. Un descenso

en el voltaje de m_.s del 10% producir_, una p&dida de potencia y sobrecalentamiento. Todas

las herramientas DEWALT son probadas en f_.brica; siesta herramienta no funciona, verifique el

suministro electrico.

COMPONENTES (Fig. 1-3)

_ADVERTENCIA: Nunca modifique la herramienta electrica, ni tampoco ninguna de sus piezas.

Podrfa producir lesiones corporales o dahos.

A. Interruptor de gatillo E. Abrazadera de la hoja

B. Tornillo de fijaci6n F. Hoja

C. Base de la hoja G. Clavija

D. Eje alternativo H. Palanca de liberaci6n de la abrazadera de la hoja

Interruptor (velocidad variable) (Fig. 1)

El interruptor de gatillo de velocidad variable (A) le ofrece versatilidad afiadida. Cuanto m_.s se

oprima el gatillo, mayor ser_. la velocidad de la sierra. Para apagar la herramienta suelte el gatillo.

_ATENCION: El empleo de muy bajas velocidades sdlo se recomienda al iniciar un corte. El uso

prolongado de velocidades muy bajas puede dahar su herramienta.

MONTAJE Y AJUSTES

_ADVERTENCIA: Para reducir el riesgo de lesiones personales graves, apague la

herramienta y descon_ctela de la fuente de alimentacidn antes de instalar y retirar

accesorios, ajustar o cambiar configuraciones o realizar reparaciones. Un arranque

accidental podrfa causar lesiones.

Sujeci6n de la hoja (Fig. 2)

(DW303)

PARA INSTALAR LA HOJA EN LA SIERRA

1. Afloje el tornillo de fijaciOn (B).

2. Introduzoa labase de lahoja (C) por la parte delantera entre el eje alternativo (D)y la abrazadera

de la hoja (E). Ubique el orificio en la hoja (F) por encima de la clavija (G) en el eje alternativo.

3. Apriete el tornillo de fijaci6n. Si la hoja se rompiera y la base no sale de la abrazadera,

aseg0rese de que el tornillo de fijaci6n este aflojado y extraiga la base con un clavo u objeto

con punta.

J_ATENCION: LA GUARDA DE LA SEGUETA ESTA ALLI PAPA SU PROTECCION. NO LA

QUITE.

Palanca de Liberaci6n del Sujetador de Seguetas (Fig. 3)

(DW303M, DW304P, DWE304)

PARA INSTALAR LA SEGUETA EN LA SIERRA

1. Tire hacia arriba la palanca de liberaciOn del sujetador de seguetas (H).

2. Inserte la espiga de la segueta desde el frente.

3. Empuje hacia abajo la palanca de liberaciOn del sujetador de seguetas.

Page 6

PARA SACAR LA SEGUETA DE LA SIERRA

1. Abra la palanca de liberaci6n del sujetador de seguetas.

2. Saque la segueta.

J_4TENCION: LA GUARDA DE LA SEGUETA ESTA AHi PARA SU PROTECCION. NO LA

QUITE.

OPERACION

_ADVERTENCIA: Para reducir el riesgo de lesiones personales graves, apague la

herramienta y descon_ctela de la fuente de alimentacidn antes de instalar y retirar

accesorios, ajustar o cambiar configuraciones o realizar reparaciones. Un arranque

accidental podrfa causar lesiones.

Corte con la Segueta en Posici6n Horizontal (Fig. 4A)

(DW304P, DWE304)

La instalaciOn de una segueta en posiciOn horizontal permite cortar cerca de pisos, paredes o

techos donde existe poco espacio libre. Aseg0rese que la guarda de la segueta este presionada

contra el marco para evitar que rebote.

Cortes al hilo (Fig. 5)

El dise_o compacto de la cubierta del motor de la sierra y de la cubierta del eje, permite hacer

cortes extremadamente cercanos al piso, esquinas y otras 6,reas dificiles.

_ ATENCION: Cuando corte en paredes, pisos o dondequiera que se puedan encontrar cables

electricos "vivos", NO TOQUE NINGUNA PARTE METALICA FRONTAL DE LA

HERRAMIENTA. Sujete la sierra solamente del mango de plastico y de la cubierta para

prevenir descargas electricas si corta un cable "vivo".

J_,4TENCI(_N: Utilice siempre proteccidn en los ojos cuando opere esta herramienta electrica.

Corte de madera (Fig. 6)

Antes de cortar cualquier tipo de madera, aseg0rese que la pieza que va a cortar este sujeta y

asentada con firmeza para evitar patinaduras. Coloque la segueta contra la pieza sobre la que se

va a trabajar, encienda la herramienta y permita que alcance sumO,xima velocidad antes de aplicar

presi6n. Siempre sujete firmemente la sierra con ambas manos mientras este cortando. Siempre

que sea posible, la zapata debe colocarse firmemente contra la pieza de trabajo. Esto evitarO,que

la sierra salteo vibre y minimizarO,las fracturas de las seguetas.

Corte de metales (Fig. 7)

Esta unidad tiene diferentes capacidades de corte en metal dependiendo del tipo de segueta que

se emplee y del metal a ser cortado. Recuerde siempre que debe emplear una segueta de dientes

mO,s finos para los metales ferrosos (los que tienen un gran contenido de hiero), y de recurrir a una

de dientes mO,s gruesos para cortar los materiales no ferrosos. Cuando se va a cortar una Ib,mina

delgada de metal, Io mejor es sujetarla sobre otra Ib,mina de madera o madera contra choupada;

esto garantizarO,un corte limpio sin el peligro de vibraci6n o de que se desgarre el metal. Recuerde

siempre no forzar la herramienta de corte, pues esto reducirO,la vida 0til de la segueta y ocasiona

costosas fracturas de las seguetas.

NOTA: Se recomienda que cuando corte metales unte una delgada pelfcula de aceite o alg0n otro

refrigerante a Io largo de la Ifnea de corte para una operaci6n mO,s sencilla y una mayor duraci6n

de las seguetas.

Corte de bolsillo (Fig. 8) (solamente madera)

El paso inicial para el corte de bolsillo es medir el 6,rea que se va a cortar y marcarla claramente

con 16,piz,gis o un marcador de tinta. Introduzca la segueta para cortes de bolsillo en el sujetador

de seguetas y apriete firmemente. Enseguida, empuje la parte trasera de la herramienta hacia atrO,s

hasta que la orilla trasera de la zapata descanse sobre la superficie de trabajo. Ahora, encienda

el motor, permitiendo siempre que la segueta alcance su velocidad mO,xima. Sujete el mango

firmemente e inicie un balanceo hacia arriba con el mango de la sierra. La segueta comenzarb, a

introducirse en el material. Aseg0rese siempre de que la segueta ha traspasado el material por

completo antes de continuar con el corte de bolsillo.

NOTA: En b,reas donde la visibilidad hacia la segueta es escasa, utilice la orilla de la zapata como

gu[a. Las Ifneas para cualquier corte deben extenderse mO,s allO,de la zona donde se va a cortar.

MANTENIMIENTO

_ADVERTENCIA: Para reducir el riesgo de lesiones personales graves, apague la

herramienta y descon_ctela de la fuente de alimentacidn antes de instalar y retirar

accesorios, ajustar o cambiar configuraciones o realizar reparaciones. Un arranque

accidental podrfa causar lesiones.

Limpieza

i_ADVERTENCIA: Sople la suciedad y el polvo de todos los conductos de ventilacidn con aire

seco, al menos una vez pot semana. Para reducir el riesgo de lesiones, utilice siempre proteccidn

para los ojos aprobada ANSI Z87.1 al realizar esta tarea.

AADVERTENCIA: Nunca utilice solventes ni otros qufmicos abrasivos para limpiar las piezas no

metalicas de la herramienta. Estos productos qufmicos pueden debilitar los materiales plasticos

utilizados en estas piezas. Utilice un paho humedecido sdlo con agua y jabdn neutro. Nunca

permita que penetre Ifquido dentro de la herramienta ni sumerja ninguna de las piezas en un Ifquido.

Accesorios

AADVERTENCIA: Debido a que no se han probado con este producto otros accesorios que no

sean los que ofrece DEWALT, el uso de dichos accesorios con esta herramienta podrfa set

peligroso. Para reducir el riesgo de lesiones, con este producto deben usarse sdlo los accesorios

recomendados pot DEWALT.

Los accesorios que se recomiendan para utilizar con la herramienta estO,n disponibles a un

costo adicional en su distribuidor local o en un centro de mantenimiento autorizado. Si necesita

ayuda para Iocalizar alg0n accesorio, p6ngase en contacto con DEWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286, Ilame al 1-800-4-DEWALT (1-800-433-9258) o

visite nuestro sitio Web: www.dewalt.com.

Reparaciones

Para asegurar la SEGURIDAD y laCONFIABILIDAD delproducto, las reparaciones, el mantenimiento

y los ajustes deben (inclusive inspecci6n y cambio de carbones) ser realizados en un centro de

mantenimiento en la fO,brica DEWALT,en un centro de mantenimiento autorizado DEWALT u por

otro personal de mantenimiento calificado. Utilice siempre piezas de repuesto identicas.

PARA REPARACI(_N Y SERVICIO DE SOS HERRAMIENTAS ELI_CTRICAS, FAVOR DE

CULIACAN, SIN

Blvd.Emiliano Zapata 5400-1 Poniente

Col. San Rafael

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector JuO,rez

MEXICO, D.F.

Eje Central Lb,zaro CO,rdenas No. 18

Local D, Col. Obrera

MERIDA, YUC

Calle 63 #459-A - Col. Centro

MONTERREY, N.L.

Av. Francisco I. Madero 831 Poniente - Col. Centro

PUEBLA, POE

17 Norte #205 - Col. Centro

QUERETARO, QRO

Av. San Roque 274 - Col. San Gregorio

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis

TORREON, COAH

Blvd. Independencia, 96 Pte. - Col. Centro

VERACRUZ, VER

ProlongaciOn Diaz Mir0n #4280 - Col. Remes

VILLAHERMOSA, TAB

ConstituciOn 516-A- Col. Centro

DIRIGIRSE AL CENTRO DE SERVICIO MAS CERCANO

(667) 717 89 99

(33) 3825 6978

(55) 5588 9377

(999) 928 5038

(818) 375 23 13

(222) 246 3714

(442) 2 17 63 14

(444) 814 2383

(871) 716 5265

(229) 921 7016

(993) 312 5111

PARA OTRAS LOCALIDADES:

Si se encuentra en M_xico, por favor Ilame al (55) 5326 7100

Si se encuentra en U.S., por favor Ilame al

1-800-433-9258 (1-800 4-DEWALT)

POliza de Garantia

IDENTIFICACION DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: Mod./Cat.:

Marca: N0m. de serie:

(Dabs para ser Ilenados por el distribuidor)

Fecha de compra y/o entrega del producto:

Nombre y domicilio del distribuidor donde se adquiri6 el producto:

Este producto estO,garantizado por un a_o a partir de la fecha de entrega, contra cualquier defecto

en su funcionamiento, as[ como en materiales y mano de obra empleados para su fabricaci6n.

Nuestra garant[a incluye la reparaci6n o reposici6n del producto y/o componentes sin cargo alguno

para el cliente, incluyendo mano de obra, as[ como los gastos de transportaci6n razonablemente

erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garant[a deberO,presentar su herramienta y esta p61izasellada por el

establecimiento comercial donde se adquiri6 el producto, de no contar con esta, bastarO,la factura

de compra.

EXCEPCION ES

Esta garantia no serO,vO,lida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas alas normales;

• Cuando el producto no hubiese sido operado de acuerdo con el instructivo de uso que se

acompaha;

• Cuando el producto hubiese sido alterado o reparado pot personas distintas alas enlistadas

al final de este certificado.

Anexo encontrarO,una relaci6n de sucursales de servicio de fO,brica, centros de servicio autorizados

y franquiciados en la Rep0blica Mexicana, donde podrO,hacer efectiva su garant[a y adquirir partes,

refacciones y accesorios originales.

Registro en linea

Gracias por su compra. Registre su producto ahora para:

M SERVICIO EN GARANT|A: Si completa esta tarjeta, podrO, obtener un servicio en garant[a

mO,s eficiente, en caso de que exista un problema con su producto.

• CONFIRMATCION DE PROPIEDAD: En caso de una perdida que cubra el seguro, como

un incendio, una inundacbn oun robo, el registro de propiedad servirO,como comprobante de

compra.

• PARA SU SEGURIDAD: Si registra el producto, podremos comunicarnos con usted en el

caso improbable que se deba enviar una notificaciOn de seguridad conforme a la Federal

Consumer Safety Act (Ley Federal de Seguridad de Productos para el Consumidor).

Registro en linea en www.dewalt.com/register.

Garantia limitada por tres a_os

DFTWALTrepararO,,sin cargo, cualquier falla que surja de defectos en el material o la fabricacion del

producto, por hasta tres a_os a contar de la fecha de compra. Esta garant[a no cubre fallas de las

piezas causadas por su desgaste normal o abuso a la herramienta. Para mayores detalles sobre la

cobertura de la garant[a e informaciOn acerca de reparaciones realizadas bajo garant[a, vidtenos en

www.dewalt.com o dir[gase al centro de servicio mO,s cercano. Esta garant[a no aplica a accesorios

o a da_os causados por reparaciones realizadas o intentadas por terceros. Esta garant[a le otorga

derechos legales espec[ficos, adem_,s de los cuales puede tener otros dependiendo del estado o

la provincia en que se encuentre.

Adem_,s de la garant[a, las herramientas DfiiiWALTest_,ncubiertas por:

1 AI_IO DE SERVICIO GRATUITO

DEWALT mantendr_, la herramienta y reemplazar_, las piezas gastadas por su uso normal, sin

cobro, en cualquier momento durante un a_o a contar de la fecha de compra. Los art[culos

gastados por la clavadora, tales como la unidad de hoja y retorno del impulsador, no est_,n