Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contactenos.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA DE

GARANT[A. ADVERTENOIA: LEASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

DWD450, DWD460

VSR Stud and Joist Drill

Perceuse pour charpente VSR

Taladro RVS (Rango de Velocidad Variable) para Vigas

®

Page 2

F

Definitions: Safety Guidelines

The definitions below describe the level of severity br each

signal word. Please read the manual and pay attention to these

symbols.

_DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

h_,WARNING: Indicates apotentially hazardous situation which,

if not avoided, could result in death or serious injury.

i_ CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258}.

_ ARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

_ WARNING! Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tooL Distractions can cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tooL Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating apowertool in adamp location is unavoidable,

use a ground fault circuff interrupter (GFCl) protected

supply. Use of a GFCI reduces the risk of electric shock.

Page 3

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power tools

are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment orbinding

of moving parts, breakage of parts and any other

condition that may affect the power toors operation. If

damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind and

are easier to control

g) Use the power tool, accessories and tool bits, etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Page 4

Additional Specific Safety Instructions

• Use auxiliary handle(s), if supplied with the tool. Loss of

control can cause personal injury.

• Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory may

contact hidden wiring or its own cord. Cutting accessory

contacting a "live" wire may make exposed metal parts of the

power tool "live" and could give the operator an electric shock.

• Wear ear protectors with impact drills. Exposure to noise can

cause hearing loss.

• Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

• Wear safety goggles or other eye protection. Hammering and

drilling operations cause chips to fly. Flying particles can cause

permanent eye damage.

• Keep handles dry, clean, and free from oil and grease. This

will enable better control of the tool

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewel/ery or long hair can be caught inmoving parts.

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. When using more than one extension to make up the

total length, be sure each individual extension contains at least the

minimum wire size. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

Minimum Gauge for Cord Sets

Not

More

6

10

12

16

Volts Total Length of Cord in Feet (meters)

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

Ampere

Rating

More

Than

Than

0 18 16 16 14

6 18 16 14 12

10 16 16 14 12

12 14 12 Not Recommended

AWARNING: ALWAYS use safety glasses. Everyday eyeglasses

are NOT safety glasses. Also use face or dust mask if cutting

operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT"

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

AWARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

Page 5

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

i_,WARNING: Use of this tool can generate and/or disperse dust,

which may cause serious and permanent respiratory or other

injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

WARNING: Always wear proper personal hearing protection

that conforms to ANSI $12.6 ($3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V................... volts A...................... amperes

Hz................. hertz

min ............... minutes

.... or DC... direct current

(_)................. Class I Construction

(grounded)

[] ................. Class II Construction

(double insulated)

.../min .......... per minute

BPM ............. beats per minute

IPM ............... impacts per minute

RPM ............. revolutions per

minute

W..................... watts

"_ or AC .......... alternating

current

or AC/DC... altemating

or direct

current

no .................... no load

speed

n...................... rated

speed

@..................... earthing

terminal

sfpm ............. surface feet A ..................... safety alert

per minute symbol

SPM ............. strokes per minute

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Motor

Be sure your power supply agrees with the nameplate marking. Voltage

decrease of more than 10% will cause loss of power and overheating.

DEWALT tools are factory tested; if this tool does not operate, check

power supply.

COMPONENTS (Fig. 1, 5)

A WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Bail handle

B. Speed selector lever

C. Forward/reverse button

D. Trigger switch

E. Bail handle bolt

INTENDED USE

The DWD450 and DWD460 heavy-duty stud and joist drills are

designed for professional drilling at various work sites (i.e., construction

sites). DO NOT use under wet conditions or in presence of flammable

liquids or gases.

These heavy-duty stud and joist drills are professional power tools.

DO NOT let children come into contact with the tool. Supervision is

required when inexperienced operators use this tool.

R 1/2" (13 mm) keyed chuck

G. E-ClutchTM indicator

(DWD460)

H. Knuckle guard (DWD460)

I. Side handle (two positions)

Page 6

FIG. 1

E

E

B

DWD450

DWD460

ASSEMBLY AND ADJUSTMENTS

_WARNING: To reduce the risk of injury, turn unit off

and disconnect ff from power source before installing and

removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

C

C

Torque

_WARNING: This is a high-torque drill. To reduce the risk of serious

personal injury, ALWAYS hold tool firmly with both hands in the

proper position for operation as shown.

Torque is the twisting action the drill produces in regards to the rotating

bit. As the drill bit meets resistance in the material being drilled, the

motor responds byadjusting the output torque to meet the requirement

up to the maximum capacity of the motor and gear system.

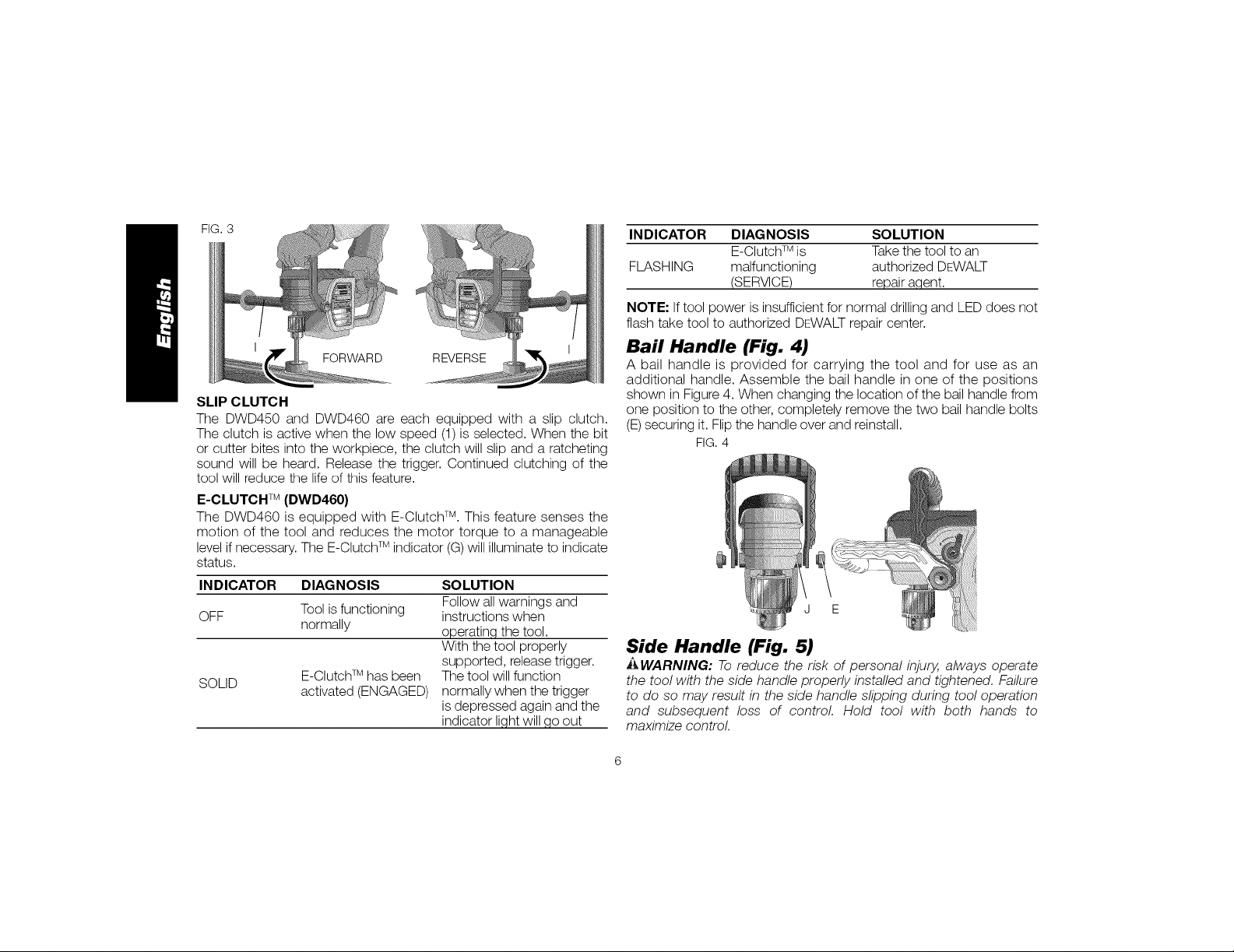

BRACING THE TOOL (FIG. 2, 3}

_J,WARNING: Toreduce the risk of serious personal injury,ALWAYS

use proper hand position as shown in Figure 2.

FIG.2

_ WARNING: To reduce the risk of serious personal injury. ALWAYS

hold or brace the tool securely in anticipation of a sudden reaction.

With hands in the proper hand position, brace the tool as shown in

Figure 3.

Page 7

FIG. 3

FORWARD REVERSE

SLIP CLUTCH

The DWD450 and DWD460 are each equipped with a slip clutch.

The clutch is active when the low speed (1)is selected. When the bit

or cutter bites into the workpiece, the clutch will slip and a ratcheting

sound will be heard. Release the trigger. Continued clutching of the

tool will reduce tile lifeof this feature.

E-CLUTCH TM (DWD460)

The DWD460 is equipped with E-Clutch TM. This feature senses the

motion of the tool and reduces the motor torque to a manageable

level if necessary. The E-ClutchTM indicator (G) will illuminate to indicate

status.

INDICATOR DIAGNOSIS SOLUTION

OFF Tool is functioning instructions when

Follow allwarnings and

normally operating the tool.

With the tool properly

supported, release trigger.

SOLID

E-ClutchTM has been The tool will function

activated (ENGAGED) normally when the trigger

is depressed again and the

indicator liqht will go out

INDICATOR DIAGNOSIS SOLUTION

E-ClutchTM is Take the tool to an

FLASHING malfunctioning authorized DEiWALT

(SERVICE) repair aqent.

NOTE: If tool power is insufficient for normal drilling and LED does not

flash take tool to authorized DEWALTrepair center.

Bail Handle (Fig. 4)

A bail handle is provided for carrying the tool and for use as an

additional handle. Assemble the bail handle in one of the positions

shown in Figure 4. When changing the location of the bail handle from

one position to the other, completely remove the two bail handle bolts

(E)securing it. Flip the handle over and reinstall.

FIG. 4

J E

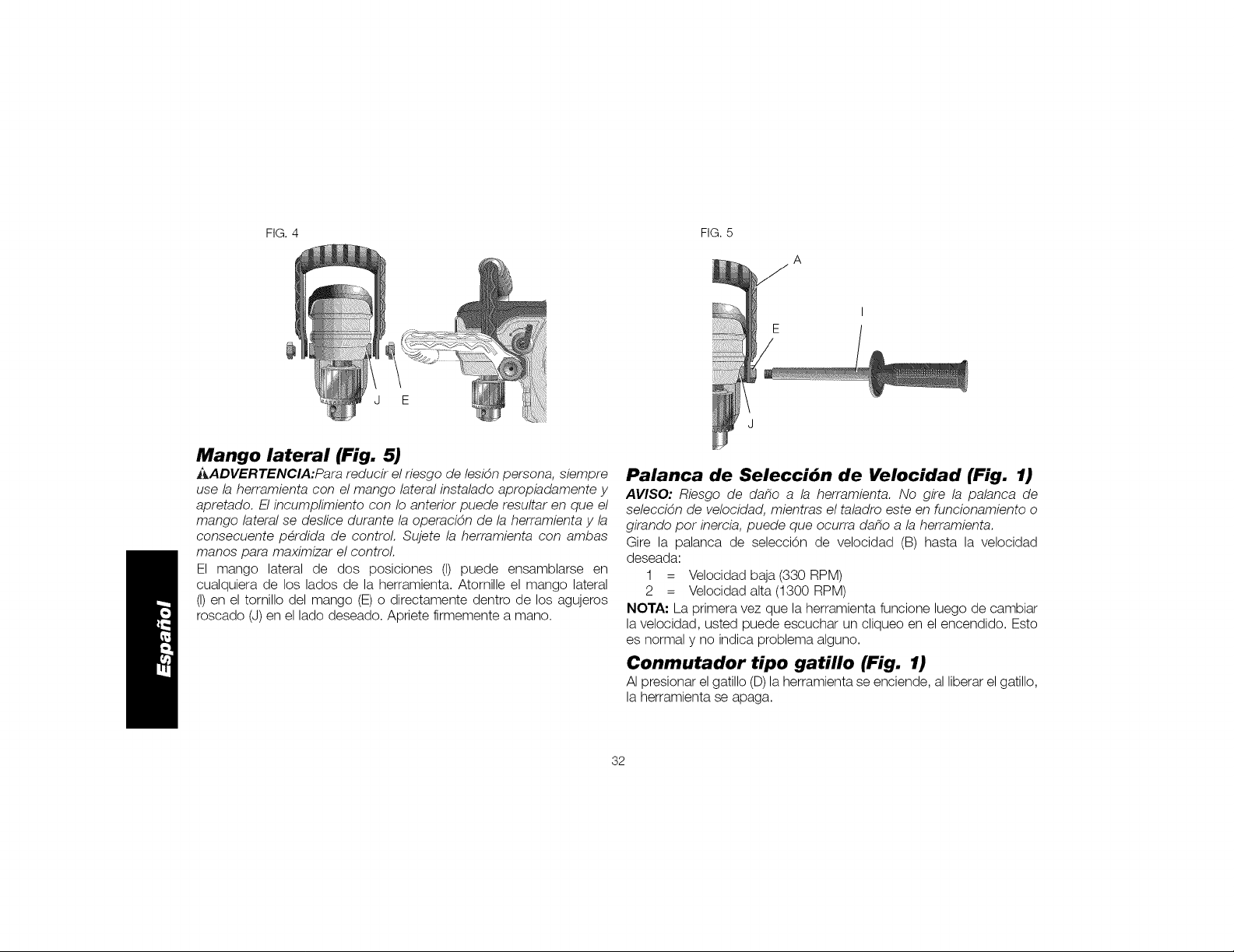

Side Handle (Fig. 5)

_WARNING: To reduce the risk of personal injury, always operate

the tool with the side handle properly installed and tightened. Failure

to do so may result in the side handle slipping during tool operation

and subsequent loss of control Hold tool with both hands to

maximize control

Page 8

The two position side handle (I) can be assembled into either side of

tool. Thread the side handle (I)into the bail handle bolt (E)or directly

into threaded holes (J) on desired side. Tighten securely by hand.

FIG.5

I

E

Speed Selector (Fig. 1)

NOTICE: Risk of tool damage. Do not rotate the speed selector lever

while the drill is running or coasting, damage may occur to the tool

Rotate the speed selector lever (B)to the desired speed:

1 = low speed (330 RPM)

2 = high speed (1300 RPM)

NOTE" The first time the tool is run after changing speeds, you may

hear a click on start up. This is normal and does not indicate a problem.

Trigger Switch (Fig. 1)

Depressing the trigger switch (D)turns the tool on, releasing the trigger

switch turns the tool off.

VARIABLE SPEED

A variable speed trigger switch permits speed control--the farther the

trigger is depressed, the higher the speed of the drill.

NOTE" Use lower speeds for starting holes without a center punch,

drilling in metal, plastics or ceramics. Higher speeds are better for

drilling wood and composition boards.

Forward/Reverse Button (Fig. 1)

A forward/reverse button (C) determines the direction of the tool. It is

located in front of the trigger switch.

To select forward rotation, release the trigger switch (D) and depress

the forward/reverse button on the right side of the tool.

Toselect reverse, depress the forward/reverse button on the left side

of the tool. When changing the position of the button, be sure the

trigger is released.

NOTE" The first time the tool is run after changing the direction of

rotation, you may hear a click on start up. This is normal and does not

indicate a problem.

OPERATION

_WARNING: To reduce the risk of injury, turn unit off

and disconnect ff from power source before installing and

removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

The bit rotates clockwise when the tool is in the forward position and

counterclockwise when the tool is in the reverse position. If the bit

binds, the tool will slow to a manageable level. Using proper hand

position, brace the side handle (I)or tool body against a stud for better

support (Fig. 3).

Page 9

Drilling

/_ WARNING: To reduce the risk of personal injury, ALWAYS

ensure workpiece is anchored or clamped firmly. If drilling thin

material, use a wood "back-up" block to prevent damage to the

material

1. Use sharp drill bits only. For WOOD, use twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use steel twist drill bits

or hole saws.

2. Always apply pressure in a straight line with the bit. Use enough

pressure to keep drill biting, but do not push hard enough to stall

the motor or deflect the bit.

3. Hold tool firmly with both hands to control the twisting action of the

drill.

4. IF DRILL STALLS, it is usually because it is being overloaded or

improperly used. RELEASE TRIGGER IMMEDIATELY, remove

drill bit from work, and determine cause of stalling. DO NOT

CLICK TRIGGER ON AND OFF IN AN ATTEMPT TO START

A STALLED DRILL -- THIS CAN DAMAGE THE DRILL.

5. To minimize stalling or breaking through the material, reduce

pressure on drill and ease the bit through the last fractional part of

the hole.

6. Keep the motor running when pulling the bit back out of a drilled

hole. This will help prevent jamming.

7. With variable speed drills there is no need to center punch

the point to be drilled. Use a slow speed to start the hole and

accelerate by squeezing the trigger harder when the hole is deep

enough to drill without the bit skipping out.

DRILLING IN METAL

Start drilling with slow speed and increase to full power while applying

firm pressure on the tool. A smooth even flow of metal chips indicates

the proper drilling rate. Use a cutting lubricant when drilling metals.

The exceptions are cast iron and brass which should be drilled dry.

NOTE: Large [5/16" (8 mm) to 1/2" (13 mm)] holes in steel can be

made easier ifa pilot hole [5/32" (4 mm) to 3/16" (5 mm)] is drilled first.

DRILLING IN WOOD

Start drilling with slow speed and increase to full power while applying

firm pressure on the tool. Holes in wood can be made with the same

twist drills used for metal. These bits may overheat unless pulled out

frequently to clear chips from the flutes. Work that is apt to splinter

should be backed up with a block of wood.

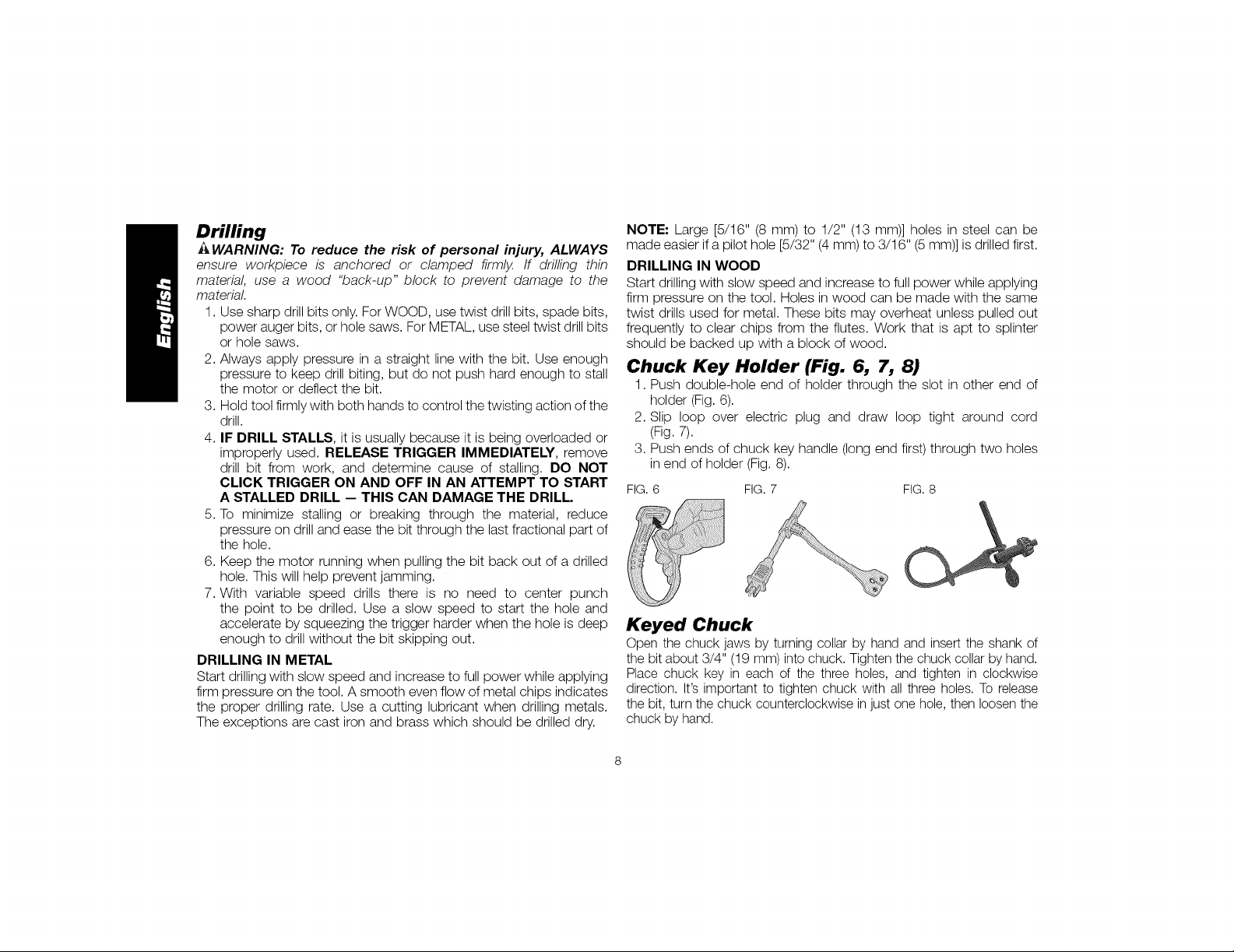

Chuck Key Holder (Fig. 6, 7, 8)

1. Push double-hole end of holder through the slot in other end of

holder (Fig. 6).

2. Slip loop over electric plug and draw loop tight around cord

(Fig. 7).

3. Push ends of chuck key handle (long end first) through two holes

in end of holder (Fig. 8).

FIG. 6 FIG. 7

FIG. 8

Keyed Chuck

Open the chuck jaws by turning collar by hand and insert the shank of

the bit about 3/4" (19 mm) into chuck. Tighten the chuck collar by hand.

Place chuck key in each of the three holes, and tighten in clockwise

direction. It's important to tighten chuck with all three holes. To release

the bit, turn the chuck counterclockwise in just one hole, then loosen the

chuck by hand.

Page 10

NOTE: When using hex shank or three sided shank bits be sure to align

the flat sides of the bit with the chuck jaws to ensure the bit is properly

engaged by the jaws.

REMOVAL OF KEYED CHUCK (FIG. 9)

Remove the left-handed clutch screw using a T25 torx wrench,

rotating clockwise to loosen.Tighten the chuck around the shorter

end of a hex wrench (not supplied) of 3/8" (10 mm) size. With the tool

braced securely, use a soft hammer and strike the hex wrench sharply

in the counterclockwise direction when viewed from the front of the

tool. This will loosen the chuck so that it can be removed by hand.

KEYED CHUCK INSTALLATION (FIG. 10)

Screw the chuck on by hand as far as it will go. Insert the shorter end

of a hex wrench (not supplied) of 3/8" (10 mm) size and strike it in

the clockwise direction with a soft hammer. Reinstall the left handed

clutch screw.

FIG. 9 FIG. 10

MAINTENANCE

_WARNING: To reduce the risk of injury, turn unit off

and disconnect R from power source before installing and

removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

Motor Brushes

DEiWALTuses an advanced brush system which automatically stops

the drill when the brushes wear out. This prevents serious damage to

the motor. New brush assemblies are available at authorized DEWALT

service centers. Always use identical replacement parts.

Lubrication

Your tool was properly lubricated before leaving the factory. In from

two to six months, depending upon use, take or send your tool to a

DEWALT Service Center or other qualified service organization for a

complete cleaning, inspection and relubrication.

Tools used constantly on production or heavy duty jobs or exposed

to heat may require more frequent lubrication. Tools "out of service"

for long periods should be relubricated before being put back into

service.

Cleaning

i_ WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

A WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tooL These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool,"never immerse any part of the tool into a liquid.

Accessories

i_WARNING: Since accessories, other than those offered by

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only DEWALT recommended accessories should be used with

this product.

Page 11

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call

1-800-4-DEWALT (1-800-433-9258) or visit our website: www.dewalt.

com.

MAXIMUM RECOMMENDED CAPACITIES

LOW SPEED HIGH SPEED

R.RM. 330 1300

WOOD, FLAT BORING - 1-1/2" (38 mm)

HOLE SAWS 6" (152.4 mm)

SHIP AUGER - 1-1/2" (38 mm)

SELF-FEED BITS 4-5/8" (102 mm) 2-9/16" (65 mm)

CLUTCH OPERATIVE YES NO

E-CLUTCH TM (DWD460) YES YES

NOTE: For holes in metal larger than 1/2" (13 mm) use hole saws.

Repairs

Toassure product SAFETY and RELIABILITY,repairs, maintenance and

adjustment (including brush inspection and replacement) should be

performed by a DEiWALTfactory service center, a DE:WALTauthorized

service center or other qualified service personnel. Always use

identical replacement parts.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you

obtain more efficient warranty service in case there is a problem

with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance

loss, such as fire, flood or theft, your registration of ownership will

serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to

contact you in the unlikely event a safety notification is required

under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DEWALTwill repair,without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-DEiWALT (1-800-433-9258).

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEiWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DE-:WALTPower Tool, Laser, or Nailer for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund

- no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local

company or see website for warranty information.

10

Page 12

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT (1-800-433-

9258) for a free replacement.

DWD450w,........_............

ANOR_SPIRATORYPROT_CTION.P_REOUCIREL_IES_OO_LESIONES_E_MANUAL ANDRESFI_ATOSYP80TE_TION.PA_REDU_IREL_IES_ODELESI_NESLFAELMA_UA_

--_ O\ EI_STRU_IO_ES.UTIIICE SlEMPREL_$ MA_IJASL_TE_LES. _11LICESIEMP_

_/_' (13mm) VSR STUD AND 3OlST [}RILL 1/2"(13mm) VSR STUD ANO ,JOIST OeILL

L__OTECClONAOECU_ P_A L_ VlST_y P_A L_SViAS_ESpI_ATO_IAS. L_e_OT_ClON AO_UADAPA_ L_ VISTAYPA_ L_SViAS_SPIRATO_IAS.

TOU_O_S _ItlSE_ LE_ POI_NEES_TE_AtES. TO_JO_RSPO_TE_DEgEOUIpEMEm DEp_OTEC_ON

AFINDEMINIMISE_EES_ISQ_ES DEBLESSURESU_E LEGUIDF-

11

Page 13

D_finitions : lignes directrices en

mati_re de s_curit_

Lesdefinitionsci-dessousdecriventle niveaudedanger pourchaque

mot-indicateur employe. Lire le mode d'emploi et porter une

attention particuliere a. ces symboles.

_DANGER : indique une situation dangereuse imminente qui,

si elle n'est pas evitee, entraTnera la mort ou des blessures

graves.

i_AVERTISSEMENT : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourrait entra_ner /a

mort ou des blessures graves.

AATTENTION : indique une situation potentie//ement

dangereuse qui, si elle n'est pas evitee, pourrait entra_ner des

blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n'est fair

pour /'eviter, pourrait poser des risques de dommages

materiels.

\

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL

OU DE TOUT AUTRE OUTIL DEWALT, COMPOSE LE NUMC:RO

SANS FRAIS : 1-800-4-DEWALT {1-800-433-9258}.

_ VERTISSEMENT afin de reduire le risque de blessures, life

le mode d'emploi de I'outil.

Avertissements de s_curit_ g_n_raux pour

les outils _lectriques

s_curit_ et toutes les directives. Le non-respect des

_k AVERTISSEMENT! life tous les avertissements de

avertissements et des directives pourrait se solder par un

choc dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTERIEUR

Le terme _outil dectrique _ cite dans les avertissements se rapporte

votre outil dectrique a alimentation sur secteur (avec ill) ou par piles

(sansfi/).

1) S#CURIT# DU LIEU DE TRAVAIL

a) Tenir I'aire de travail propre et bien _clair_e. Les /ieux

encombres ou sombres sont propices aux accidents.

b) Ne pas faire fonctionner d'outils _lectriques clans un

milieu d_flagrant, tel qu'en presence de liquides, de

gaz ou de poussi_res inflammables. Les outi/s e/ectriques

produisent des etincelles qui pourraient enflammer lapoussiere

ou les vapeurs.

c) E-Ioigner les enfants et les personnes a proximit_ pendant

I'utilisation d'un outil _lectrique. Une distraction pourrait en

faire perdre la ma_trise a I'utilisateur.

2) SI_CURITI_ EN MATI#RE D'I_LECTRICITI_

a) Les fiches des outils _lectriques doivent correspondre

la prise. Ne jamais modifier la fiche d'aucune faqon.

Ne jamais utiliser de fiche d'adaptation avec un outil

_lectrique mis a la terre. Le risque de choc dectrique sera

reduit par I'utilisation de fiches non modifiees correspondant

la prise.

12

Page 14

b) Eviter tout contact physique avec des surfaces mises a la

terre comme des tuyaux, des radiateurs, des cuisini_res

et des r_frig_rateurs. Le risque de choc electrique est plus

deve si votre corps est mis a la terre.

c) Ne pas exposer les outils _lectriques a la pluie ou

rhumidit_. La penetration de /'eau dans un outi/ e/ectrique

augmente le risque de choc dectrique.

d) Ne pas utiliser le cordon de fa_on abusive. Ne jamais

utiliser le cordon pour transporter, tirer ou d_brancher

un outil _lectrique. Tenir le cordon _loign_ de la chaleur,

de I'huile, des bords tranchants et des pi_ces mobiles.

Les cordons endommages ou enchev_tres augmentent les

risques de choc dectrique.

e) Pour rutilisation d'un outil _lectrique a I'ext_rieur, se

servir d'une rallonge convenant a cette application.

L'utilisation d'une rallonge conque pour I'exterieur reduira les

risques de choc dectrique.

f) S'il est impossible d'_viter rutilisation d'un outil

_lectrique clans un endroit humide, brancher routil clans

une prise ou sur un circuit d'alimentation dot_s d'un

disjoncteur de fuite a la terre (GFCl). L'uti/isation de ce type

de disjoncteur reduit les risques de choc dectrique.

3) SI_CURITI_ PERSONNELLE

a) Etre vigilant, surveiller le travail effectu_ et faire preuve

de jugement Iorsqu'un outil _lectrique est utilis_. Ne

pas utiliser d'outil _lectrique en cas de fatigue ou sous

rinfluence de drogues, d'alcool ou de m_dicaments. Un

simple moment d'inattention en utilisant un outil dectrique peut

entra_ner des blessures corporelles graves.

b) Utiliser des _quipements de protection individuelle.

Toujours porter une protection oculaire. L'uti/isation

d'equipements de protection comme un masque antipoussiere,

des chaussures antiderapantes, un casque de securite ou des

protecteurs auditifs Iorsque la situation le requiert reduira les

risques de blessures corporelles.

c) Emp_cher les d_marrages intempestifs. S'assurer que

rinterrupteur se trouve a la position d'arr_t avant de

relier routil a une source d'alimentation et/ou d'ins_rer

un bloc-piles, de ramasser ou de transporter routil.

Transporter un outil dectrique alors que le doigt repose sur

I'interrupteur ou brancher un outil dectrique dont I'interrupteur

est a la position de marche risque de provoquer un accident.

d) Retirer toute cl_ de r_glage ou cl_ avant de d_marrer

routil. Une c/e ou une c/e de reg/age attachee a une pattie

pivotante de I'outil dectrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son _quilibre en

tout temps. Ce/a permet de mieux ma_triser /'outi/ dectrique

dans les situations imprevues.

f) S'habiller de mani_re appropriee. Ne pas porter de

v_tements amples ni de bijoux. Garder les cheveux, les

v_tements et les gants a I'_cart des pi_ces mobiles. Les

v_tements amp/es, /es bijoux ou /es cheveux longs risquent de

rester coinces dans les pieces mobiles.

g) Si des composants sont fournis pour le raccordement de

dispositifs de d_poussi_rage et de ramassage, s'assurer

que ceux-ci sont bien raccord_s et utilis_s. L'uti/isation

d'un dispositif de depoussierage peut reduire les dangers

engendres par les poussieres.

4) UTILISATION E'r ENTRETIEN D'UN OUTIL CLECTRIQUE

a) Ne pas forcer un outil _lectrique. Utiliser routil _lectrique

appropri_ a rapplication. L'outi/ dectrique approprie

effectuera un mei/leur travail, de faqon plus sore eta la vitesse

pour laquelle il a ete conqu.

13

Page 15

b) Ne pas utiliser un outil _lectrique dont I'interrupteur

est d_fectueux. Tout outil dectrique dont I'interrupteur est

defectueux est dangereux et dolt _tre repare.

c) D_brancher la fiche de la source d'alimentation et/ou du

bloc-piles de I'outil _lectrique avant de faire tout r_glage

ou changement d'accessoire ou avant de ranger I'outil.

Ces mesures preventives reduisent les risques de demarrage

accidentel de I'outil dectrique.

d) Ranger /es outils _lectriques hors de la port_e des

enfants et ne permettre a aucune personne n'_tant

pas famili_re avec un outil _lectrique ou son mode

d'emploi d'utiliser cet outil. Les outils dectriques deviennent

dangereux entre les mains d'utilisateurs inexperimentes.

e) Entretien des outils _lectriques. V_rifier si les pi_ces

mobiles sont mal align_es ou coinc_es, si des pi_ces sont

bris_es ou pr_sentent toute autre condition susceptible

de nuire au bon fonctionnement de I'outil electrique.

En cas de dommage, faire r_parer I'outil _lectrique

avant toute nouvelle utilisation. Beaucoup d'accidents sont

causes par des outils dectriques mal entretenus.

f) S'assurer que /es outils de coupe sont aiguis_s et

propres. Les outils de coupe bien entretenus et affOtes

sont moins susceptibles de se coincer et sont plus faciles

ma_triser.

g) Utiliser I'outil _lectrique, /es accessoires, /es forets,

etc. conform_ment aux pr_sentes directives en tenant

compte des conditions de travail et du travail a effectuer.

L'utilisation d'un outil dectrique pour toute operation autre que

celle pour laquelle il a ete conquest dangereuse.

5) RI_PARATION

a) Faire r_parer I'outil _lectrique par un r_parateur

professionnel en n'utilisant que des pi_ces de rechange

identiques. Cela permettra de maintenir une utilisation

securitaire de I'outil dectrique.

Consignes de s_curit_ particuli_res

additionnelles

• Utiliser la/les poign_e(s) auxiliaire(s) si fournie(s) avec

I'outil. Une perte de contr61e de I'outil pourrait occasionner des

dommages corporels.

• Tenir I'outil par les surfaces isol_es pr_vues a cet effet

pendant toute utilisation ob I'organe de coupe pourraH

entrer en contact avec des ills _lectriques caches ou son

propre cordon. Tout contact de I'organe de coupe avec un fil

sous tension mettra les parties metalliques exposees de I'outil sous

tension et dectrocutera I'utilisateur.

• Pendant I'utilisation d'une perceuse a percussion, porter un

prot_ge-oreille. Le bruit en resultant pourrait occasionner une

perte de I'oui'e.

• Utiliser des serre-joints ou tout autre moyen pour fixer et

immobiliser le mat_riau sur une surface stable. Tenir la piece

la main ou contre son corps offre une stabilite insuffisante qui

pourrait vous en faire perdre le contr61e.

• Porter des lunettes de protection ou toute autre protection

oculaire. Le martelage et le perqage peuvent faire voltiger

des eclats. Ces particules volantes pourraient occasionner des

dommages oculaires permanents.

• Maintenir les poign_es propres et s_ches, exempts d'huile

ou de graisse. Cela permettra un meilleur contr6le de I'outil.

• Prendre des precautions b proximit_ des _vents, car ils

cachent des pi_ces mobiles. V_tements amp/es, bijoux ou

cheveux longs risquent de rester coinces dans ces pieces mobiles.

• Pour la s_curit_ de I'utilisateur, utiliser une rallonge de

calibre ad_quat (AWG, American Wire Gauge [calibrage

14

Page 16

am_ricain normalis_ des fils _lectriques]). Plus le calibre est

petit, et plus sa capacite est grande. Un calibre 16, par exemple,

a une capacite superieure a un calibre 18. L'usage d'une rallonge

de calibre insuffisant causera une chute de tension qui entra_nera

perte de puissance et surchauffe. Si plus d'une rallonge est

utilisee pour obtenir une certaine Iongueur, s'assurer que chaque

rallonge presente au moins le calibre de fil minimum. Le tableau

ci-dessous illustre les calibres a utiliser selon la Iongueur de rallonge

et I'intensite nominale indiquee sur la plaque signaletique. En cas

de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la

rallonge peut supporter de courant.

Calibres minimaux des rallonges

volts Longueur totale de

cordon en mbtres (pieds)

Intensitb (en 120 V 7,6 15,2 30,5 45,7

ampbres) (25) (50) (100) (150)

240V 15,2 30,5 61,0 91,4

(50) (100)(200) (300)

Sup_rieur Inf_rieur

0 6

6 10

10 12

12 16 14 12

AWG

18 16 16 14

18 16 14 12

16 16 14 12

Non

recommande

_A VERTISSEMENT : porter SYSTEMA TIQUEMENT des lunettes

de protection. Les lunettes courantes NE sont PAS des lunettes de

protection. Utiliser aussi un masque antipoussieres si la decoupe

doit en produire beaucoup. PORTER SYSTEMATIQUEMENT UN

EQUIPEMENT DE SECURITE HOMOLOGUE :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) ;

• Protection auditive ANSI $12.6 ($3.19) ;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

_,AVERTISSEMENT : les scies, meules, ponceuses, perceuses

ou autres outils de construction peuvent produire des poussieres

contenant des produits chimiques reconnus par I'Etat califomien

pour causer cancers, malformations congenitales ou _tre nocifs au

systeme reproducteur. Parmi ces produits chimiques, on retrouve :

• Le plomb clans les peintures a base de plomb ;

• La silice cristallisee dans les briques et le ciment, ou autres

produits de maqonnerie ; et

• L'arsenic et le chrome dans le bois ayant subi un traitement

chimique.

Le risque associe a de telles expositions varie selon la frequence

laquelle on effectue ces travaux. Pour reduire toute exposition a ces

produits : travailler dans un endroit bien aere, en utilisant du materiel

de securite homologue, tel un masque antipoussieres specialement

conqu pour filtrer les particules microscopiques.

• Limiter toute exposition prolong_e avec les poussi_res

provenant du ponqage, sciage, meulage, perqage ou toute

autre activit_ de construction. Porter des v_tements de

protection et nettoyer a I'eau savonneuse /es parties du

corps expos_es. Le far de laisser la poussiere penetrer clans la

bouche, les yeux ou la peau peut favoriser I'absorption de produits

chimiques dangereux.

AAVERTISSEMENT : cet outil peut produire et/ou repandre

de la poussiere susceptible de causer des dommages serieux et

permanents au systeme respiratoire. Utiliser systematiquement un

appareil de protection des voies respiratoires homologue par le

NIOSH ou I'OSHA. Diriger les particules dans le sens oppose au

visage et au corps.

15

Page 17

J_AVERTISSEMENT : pendant I'utilisation, porter

syst_matiquement une protection auditive individuelle

adequate homologu_e ANSI $12.6 ($3.19). Sous certaines

conditions et suivant la duree d'utilisation, le bruit emanant de ce

produit pourrait contribuer a une perte de I'acuite auditive.

• L'etiquette apposee sur votre outil peut inclure les symboles

suivants. Les symboles et leur definition sont indiques ci-apres :

V................... volts

Hz................. hertz

min ............... minutes

.... ou DC... courant continu

_) ................. classe I

fabrication

(mis a la terre)

[] ................. fabrication

classe II

(double isolation) nominale

.../min .......... par minute @ ..................... borne de terre

IPM ............... impacts par _ ...................... symbole

minute d'avertissement

BPM ............. battements par r/min ................. tours par

minute minute

sfpm ............. pieds lineaires SPM (FPM) ....... frequence par

par minute (plpm) minute

A....................... amperes

W...................... watts

"_ ou AC.......... courant

altematif

ou AC/DC... courant

altematif

ou continu

no ..................... vitesse a vide

n....................... vitesse

CONSERVER CES CONSIGNES

POUR UTILISATION ULTERIEURE

Moteur

S'assurer que le bloc d'alimentation est compatible avec I'inscription

de la plaque signaletique.Une diminution de tension de plus de 10 %

provoquera une perte de puissance et une surchauffe. Les outils

DEWALT sont testes en usine ; si cet outil ne fonctionne pas, verifier

I'alimentation electrique.

DESCRIPTION (Fig. 1, 5)

J_AVERTISSEMENT : Ne jamais modifier I'outil dectrique ni aucun

de ses composants, fly a risques de dommage corporel ou materiel

A. Poignee etrier

B. Selecteur de vitesse

C. Bouton marche

avant/arriere

D. Gb,chette

E. Boulon de poignee etrier

USAGE PR#VU

Les perceuses industrielles pour charpente DWD450 et DWD460

ont et6 congues pour le pergage professionnel sur differents lieux de

travail (ex. : chantiers de construction). NE PAS utiliser I'outil en milieu

ambiant humide ou en presence de liquides ou de gaz inflammables.

Ces perceuses industrielles pour charpente sont des outils de

professionnels. NE PAS laisser I'outil a, la portee des enfants. Une

supervision est necessaire aupres de tout utilisateur non experimente.

F. Mandrin a,cle de

13 mm (1/2 po.)

G. Voyant E-Clutch MD(DWD460)

H. Protege-doigts (DWD460)

I. Poignee laterale (deux positions)

16

Page 18

FIG.1

E

E

B

DWD450

DWD460

ASSEMBLAGE ET AJUSTEMENTS

_AVERTISSEMENT : pour r_duire le risque de blessures,

_teindre I'appareil et le d_brancher avant d'installer ou de

retirer tout accessoire et avant d'effectuer des r_glages ou des

r_parations. Un demarrage accidentel peut provoquer des blessures.

C

Couple

AAVERTISSEMENT : Cette perceuse dispose d'un couple eleve.

Pour reduire tout risque de dommages corporels graves, maintenir

SYSTE'MATIQUEMENT I'outil fermement, a deux mains, dans la

position adequate, comme illustre.

Le couple est raction de torsion produite par la perceuse Iors de la

rotation de la meche. Alors que la meche rencontre de la resistance

dans le materiau perce, le moteur repond en ajustant le couple de

sortie de fa_on a.remplir les besoins suivant la capacite maximale du

moteur et de rengrenage.

PRI_HENSION DE L'OUTIL (FIG. 2, 3)

AAVERTISSEMENT : Pour reduire tout risque de dommages

corporels graves, maintenir SYST£-MATIQUEMENT I'outil en

respectant la position des mains illustree en figure 2.

FIG.2

D

H

17

Page 19

AAVERTISSEMENT : Pour reduire tout risque de dommages

corporels graves, saisir et maintenir SYSTE'MATIQUEMENT I'outil

fermement pour anticiper toute reaction soudaine,

En respectant la position des mains, saisir I'outil comme illustre en

figure 3.

FIG.3

AVANT ARRIERE

LIMITEUR DE COUPLE .,_FRICTION

Les DWD450 et DWD460 sont toutes les deux equipees d'un limiteur

de couple a,friction. Ce limiteur est active Iorsque la vitesse reduite

(1) est choisie. Lorsque la meche ou le couteau mord dans la piece

a,travailler, le limiteur glisse et un cliquetis se fait entendre. Rel_,chez

alors la gb,chette. La frequence de la recurrence de ce processus

reduira la duree de vie du dispositif.

E-CLUTCH M° (DWD460)

Le modele DWD460 est equip6 d'un embrayage anti-blocage

E-Clutch MD.Ce dispositif detecte le niveau d'activite de I'outil et

ramene le couple du moteur a,un taux raisonnable si necessaire. Le

voyant E-Clutch MD(G) s'allumera pour indiquer le statut.

VOYANT DIAGNOSTIC SOLUTION

Suivre les directives

ETEINT L'outil fonctionne

normalement et consignes pendant

I'utilisation de I'outil.

En s'assurant que I'outil

est correctement maintenu,

L'embrayage rel_,cherlagb,chette. L'outil

CONTINU E-Clutch MDa et6 active fonctionnera normalement

(ENGAGED) Iorsqu'on reappuiera sur

la gb,chette et le voyant

s'eteindra.

Dysfonctionnement Amener I'outil dans un

CLIGNOTANT de I'embrayage centre de reparation

E-Clutch MD(SERVICE) a,qreeDEWALT.

REMARQUE : Si I'alimentation est insuffisante pour le fonctionnement

normal de la perceuse, et que le DEL ne clignote pas, amener I'outil

dans un centre de reparation agree DEWALT.

18

Page 20

Poign_e _trier (Fig. 4)

L'outil est equipe d'une poignee etrier supplementaire pour son

transport ou son utilisation. Installez la poignee etrier en choisissant

I'une des positions illustrees en figure 4. Pour changer la position de

la poignee etrier, retirez completement les deux boulons de poignee

etrier (E)qui la fixe au boTtier.Faites basculer la poignee et reinstallez-la.

FIG.4

J E

Poign_e lat_rale (Fig. 5)

AAVERTISSEMENT : Pour reduire tout risque de dommages

corporels, utiliser systematiquement I'outil avec sa poignee laterale

installee correctement et solidement. Tout manquement a cette

directive pourrait faire que la poignee laterale glisse pendant

I'utilisation de I'outil et entra_ner la perte du contr61e de celui-cL

Maintenir I'outil fermement a deux mains pour un contr61e maximum.

La poignee laterale a, deux positions (I) peut _tre indifferemment

installee sur I'un ou I'autre des c6tes de I'outil. Vissez la poignee

laterale (I)dans le boulon de poignee (E)ou directement dans les trous

filetes (J)sur le c6te choisi. Serrez ensuite fermement manuellement.

FIG. 5

S_lecteur de vitesse (Fig. 1)

AVIS : Risques de dommage materiel. Ne pas tourner le selecteur de

vitesse alors que la perceuse fonctionne ou n'est pas completement

arr_tee, des dommages materiels pourraient en resulter.

Ajustez le selecteur de vitesse (B)a,la vitesse desiree :

1 = vitesse reduite (330 r/min)

2 = vitesse elev6e (1300 r/min)

REMARQUE • Lorsque I'outil est remis en marche apres un

changement de vitesse, un clic pourra se faire entendre. C'est normal

et ne represente nullement une defaillance du produit.

G_chette (Fig. 1)

Appuyer sur la gb,chette (D), met I'outil en marche. Rel_,cher la

gb,chette, arr_te I'outil.

19

Page 21

VITESSE VARIABLE

La gb,chette a,vitesse variable permet de contrOler la vitesse. Plus on

appuie a,fond sur la gb,chette, plus lavitesse de la perceuse est elev6e.

REMARQUE : Utiliser une vitesse reduite pour commencer un trou

sans pointeau, pour percer le metal, les plastiques ou la ceramique.

Les vitesses elev6es sont recommandees pour percer le bois et les

panneaux d'agglomere.

Bouton marche avant/arri_re (Fig. 1)

Le bouton marche avant/arriere (C) determine la direction de I'outil. II

se trouve devant la gb,chette.

Pour choisir la marche avant, relb,chez la gb,chette (D)puis appuyez sur

le bouton marche avant/arriere sur le cOte droit de I'outil.

Pour choisir la marche arriere, appuyez sur le bouton marche avant/

arriere sur le cOte gauche de I'outil. Avant de changer la position du

bouton, assurez-vous que la gb,chette est bien rel_,ch6e.

REMARQUE : Lorsque I'outil est remis en marche apres un

changement de direction, un clic pourra se faire entendre. C'est

normal et ne represente nullement une defaillance du produit.

UTILISATION

_AVERTISSEMENT : pour r_duire le risque de blessures,

_teindre I'appareil et le d_brancher avant d'installer ou de

retirer tout accessoire et avant d'effectuer des r_glages ou des

r_parations. Un demarrage accidentel peut provoquer des blessures,

La meche tourne vers la droite Iorsque I'outil est en marche avant,

et vers la gauche Iorsque I'outil est en marche arriere. Si la meche

se coince, I'outil ralentira jusqu'a, une vitesse raisonnable. Disposez

vos mains dans la position adequate, agrippez la poignee laterale

(I) ou appuyez le corps de I'outil contre un chevron pour plus de

support (fig. 3).

Perfage

AAVERTISSEMENT : Pour r_duire tout risque de dommages

corporels, s'assurer SYSTEMATIQUEMENT que /a piece est

ancree ou arrimee solidement, Pour percer des materiaux fins, utiliser

un morceau de bois _ de renfort _pour eviter de les endommager,

1. Utilisez seulement des meches bien affutees. Pour le BOIS,

utilisez : meches helicdl'dales, forets a, trois pointes, meches

torsadees ou emporte-piece. Pour le MC:TAL, utilisez : meches

helicoTdalesen acier ou emporte-piece.

2. Appliquez systematiquement une certaine pression sur la meche

tout en restant dans I'alignement. Utilisez assez de pression pour

que la perceuse avance, mais sans pousser trop fort pour eviter

de bloquer le moteur ou devier la meche.

3. Maintenez fermement I'outil a,deux mains pour contrOler I'action

de torsion de la perceuse.

4. SI LA PERCEUSE SE BLOQUE, c'est en general parce qu'elle

est surchargee ou utilisee incorrectement. RELACHEZ ALORS

LA GACHETTE IMMI_DIATEMENT, retirez la meche de la piece

puis determinez quelle est la cause du blocage. N'APPUYEZ PAS

R#P#TITIVEMENT SUR LA G.,&,CHETTE POUR TENTER

DE RED#MARRER UNE PERCEUSE BLOQU#E. CELA

POURRAIT ENDOMMAGER LA PERCEUSE.

5. Pour minimiser tout blocage ou rupture du materiau, reduisez la

pression sur la perceuse pour faciliter le passage de la meche

dans la partie finale du trou.

6. Gardez le moteur en marche alors que vous retirez la meche du

trou pour eviter qu'elle y reste coincee.

7. Les pointeaux sont inutiles Iorsqu'on utilise une perceuse a,vitesse

variable. Utilisez une vitesse reduite pour commencer un trou, puis

accelerez en appuyant plus fort sur la gb,chette Iorsque le trou est

assez profond pour que la meche ne ressorte pas.

2O

Page 22

PERqAGE DU MI_TAL

Commencez a percer a une vitesse reduite puis passez a pleine

puissance tout en maintenant une pression ferme sur I'outil. Un jet

fluide et regulier de debris metalliques sera indicateur d'une vitesse

adequate. Utilisez un lubrifiant de coupe pour percer les metaux, &

I'exception de la fonte et du laiton qui doivent _tre perces & sec.

REMARQUE • Les trous larges [de 8 mm (5/16 po.) a, 13 mm

(1/2 po.)] dans I'acier peuvent _tre facilites si I'on perce d'abord un trou

pilote [de 4 mm (5/32 po.) & 5 mm (3/16 po.)],

PER(_AGE DU BOIS

Commencez a percer a une vitesse reduite puis passez a pleine

puissance tout en maintenant une pression ferme sur I'outil. Les

trous dans le bois peuvent _tre effectues avec les m_mes meches

helico'l'dalesque pour le metal. Ces meches peuvent surchauffer si on

ne les retire pas frequemment du trou pour eliminer les debris. Tout

materiau risquant d'eclater doit _tre renforce par un morceau de bois.

Sangle de la cld de mandrin (Fig. 6, 7, 8)

1. Inserez I'un des bouts de la sangle & deux trous dans sa fente &

I'autre bout (fig. 6).

2. Glissez le cordon electrique dans la boucle puis resserrez

fermement la boucle autour du cordon (fig. 7).

3. Inserez les extremites de la poignee de lacle de mandrin (le bout

long en premier) au travers des deux trous en bout de sangle

(fig. 8).

FIG.6 FIG.7 FIG.8

Mandrin _ cld

Ouvrez les m&choires du mandrin en faisant tourner la bague

manuellement puis inserez-y rarbre de la meche sur une Iongueur

d'environ 19 mm (3/4 po.). Resserrez le collier du mandrin

manuellement. Inserez la cle de mandrin dans chacun des trois

trous puis serrez vers la droite. II est important de serrer le mandrin a,

I'aide des trois trous. Pour rel&cher la meche, faites tourner la cle du

mandrin vers lagauche dans un seul trou, puis desserrez le mandrin

manuellement.

REMARQUE • Lorsqu'on utilise une queue de for_t hexagonale ou

une meche trilaterale, s'assurer de bien aligner les cOtes plats de la

meche avec les m&choires du mandrin pour s'assurer que la meche

est bien engagee dans celles-ci.

RETRAIT DU MANDRIN .ACLI_ (FIG. 9)

Retirez la vis de mandrin de gauche & I'aide de la cle m&le pour

empreinte hexalobee T25, en tournant vers la droite pour la desserrer.

Resserrez le mandrin autour de I'extremite la plus courte d'une cle

hexagonale (non fournie) de 10 mm (3/8 po.). Unefois routil fermement

arrime, utilisez un marteau souple pour donner un coup sec sur la

cle hexagonale vers la gauche (par rapport a, ravant de I'outil). Cela

desserrera le mandrin et permettra de le retirer manuellement.

INSTALLATION DU MANDRIN ._ CLI_ (FIG. 10)

Vissez a, fond le mandrin manuellement. Inserez I'extremite courte

d'une cle hexagonale (non fournie) de 10 mm (3/8 po.) et, & I'aide

d'un marteau souple, donnez un coup sec sur la cle vers la droite.

Reinstallez la vis de gauche du mandrin.

21

Page 23

FIG.9 FIG.10

MAINTENANCE

_AVERTISSEMENT : pour r_duire le risque de blessures,

_teindre I'appareil et le d_brancher avant d'installer ou de

retirer tout accessoire et avant d'effectuer des r_glages ou des

r_parations. Un demarrage accidentel peut provoquer des blessures.

Balais de moteur

DEWALTutilise unsysteme de balais qui immobilisentautomatiquement

la perceuse Iorsqu'ils sont uses. Cela protege le moteur de tout

dommage serieux. Des modules de balai sont disponibles dans les

centres de service agrees DEWALT. Utilisez systematiquement des

pieces de rechange d'origine.

Lubrification

Votre outil & et6 parfaitement lubrifie avant son depart d'usine. Entre

deux & six mois, selon la frequence d'utilisation, amenez ou envoyez

votre outil dans un centre de reparation DEWALT, ou chez tout autre

organisme de reparation qualifie pour un entretien complet, y compris

inspection et lubrification.

Les outils utilises constamment pour des travaux industriels ou

intensifs, ou qui sont exposes a.la chaleur peuvent necessiter d'etre

lubrifies plus souvent. Les outils inutilises pendant des periodes

prolongees doivent _tre relubrifies avant toute reutilisation.

Nettoyage

AAVERTISSEMENT : enlever les saletes et la poussiere hors des

events au moyen d'air comprime propre et sec, au moins une lois

par semaine. Pour minimiser le risque de blessure aux yeux, toujours

porter une protection oculaire conforme a la norme ANSI Z87. 1 Iors

du nettoyage.

ikAVERTISSEMENT : ne jamais utiliser de solvants ni d'autres

produits chimiques puissants pour nettoyer les pieces non metalliques

de I'outil. Ces produits chimiques peuvent affaiblir les materiaux

de plastique utilises dans ces pieces. Utiliser un chiffon humecte

uniquement d'eau et de savon doux. Ne jamais laisser de liquide

penetrer clans I'outil et n'immerger aucune pattie de I'outil clans un

liquide.

Accessoires

_,AVERTISSEMENT : puisque les accessoires autres que ceux

offerts par DEWALTn'ont pas ete testes avec ce produit, leur utilisation

pourrait s'averer dangereuse. Pour reduire le risque de blessures,

utiliser exclusivement les accessoires DEWALT recommandes avec

le present produit.

Les accessoires recommandes pour cet outil sont vendus separement

au centre de service de votre region. Pour obtenir de I'aide concernant

I'achat d'un accessoire, communiquer avec DEWALT Industrial Tool

Co., 701 East Joppa Road, Baltimore, MD 21286 aux Etats-Unis;

composer le 1 800 433-9258 (1 800 4-DEWALT) ou visiter notre site

Web : www.dewalt.com.

22

Page 24

AATTENTION : pour reduire tout risque de dommage corporel,

utiliser les accessoires suivants seulement dans les Iimites de

capacite illustrees par le tableau ci-dessous,

CAPACITIES MAXIMALES RECOMMANDIEES

VITESSE RE_DUITE VITESSE €:LEVEE

REGIME (r/min) 330 1300

BOIS, ALESAGE PLAT - 38 mm (1-1/2 po.)

EMPORTE-PIECE 152,4 mm (6 po.)

Mt_OHE _,SIMPLE

SPIRALE

Mt_CHE _, ALIMENTATION 102 mm 65 mm

AUTOMATIQUE (4-5/8 po.) (2-9/16 po.).

EMBRAYAGE ACTIONNI:t: OUI NON

VOYANT E-CLUTCH MD

(DWD460)

REMARQUE : Pour des trous dans le metal superieurs a, 13 mm

(1/2 po.), utiliser un emporte-piece.

- 38 mm (1-1/2 po.)

OUI OUI

Rdparations

Pour assurer la S¢:CURITEet la FIABILITE du produit, les reparations,

I'entretien et les reglages doivent _tre realises (cela comprend

I'inspection et le remplacement du balai) par un centre de reparation

en usine DEWALT, un centre de reparation agree DEWALT ou par

d'autres techniciens quali%s. Toujours utiliser des pieces de rechange

identiques.

Registre en ligne

Merci pour votre achat. Enregistrez des maintenant votre produi:

• RIEPARATIONS SOUS GARANTIE: cette carte remplie vous

permettra de vous prevaloir du service de reparations sous

garantie de fagon plus efficace dans le cas d'un probleme avec le

produit.

• CONFIRMATION DE PROPRIIETIE: en cas de perte provoquee

par un incendie, une inondation ou un vol, cette preuve de

propriet6 vous servira de preuve aupres de votre compagnie

d'assurances.

• SIECURITIE: I'enregistrement de votre produit nous permettra

de communiquer avec vous dans I'eventualit6 peu probable de

I'envoi d'un avis de securit6 regi par la Ioi federale americaine de

la protection des consommateurs.

Registre en ligne a,www.dewalt.com/register.

Garantie limitee de trois ans

DEWALT reparera, sans frais, tout produit defectueux cause par un

defaut de materiel ou de fabrication pour une periode de trois ans a,

compter de la date d'achat. La presente garantie ne couvre pas les

pieces dont la defectuosite a et6 causee par une usure normale ou

I'usage abusif de I'outil. Pour obtenir de plus amples renseignements

sur les pieces ou les reparations couvertes par la presente garantie,

visiter le site www.dewalt.com ou composer le 1800 433-9258 (1 800

4-DEWALT). Cette garantie ne s'applique pas aux accessoires et ne

vise pas les dommages causes par des reparations effectuees par un

tiers. Cette garantie confere des droits legaux particuliers a,I'acheteur,

mais celui-ci pourrait aussi beneficier d'autres droits variant d'un etat

ou d'une province a,I'autre.

En plus de la presente garantie, les outils DEWALTsont couverts par

notre :

Page 25

CONTRAT D'ENTRETIEN GRATUIT D'UN AN

DEWALT entretiendra I'outil et remplacera les pieces usees au cours

d'une utilisation normale et ce, gratuitement, pendant une periode

d'un an a,compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si I'acheteur n'est pas entierement satisfait, pour quelque raison que

ce soit, du rendement de I'outil electrique, du laser ou de la cloueuse

Dr:WALT, celui-ci peut le retourner, accompagne d'un re,u, dans les

90 jours a,compter de la date d'achat pour obtenir un remboursement

integral, sans aucun probleme.

AMI_RIQUE LATINE • cette garantie ne s'applique aux produits

vendus en Amerique latine. Pour ceux-ci, veuillez consulter les

informations relatives a, la garantie specifique presente dans

I'emballage, appeler I'entreprise locale ou consulter le site Web pour

les informations relatives a,cette garantie.

REMPLACEMENT GRATUIT DES I:!:TIQU ETTES

D'AVERTISSEMENT : si les etiquettes d'avertissement deviennent

illisibles ou sont manquantes, composer le 1 800 433-9258 (1 800

4-DEWALT) pour en obtenir le remDlacement gratuit.

1/'£' (13mini VSR STUD AND JOIST DRILL 1/Z'l13mmt VSR STUD ANO ,JOIST [tRILl,

DWD450w,........_............

! I ._ I l l '. | i l *= INJURY, USERMUSTREA B

ANO _[SPI_AT{)Ry PROTE_r 10N. pA/_ _EDUCIFt EL _IES_0 BE LESIONES LEA E_MANUAL

0[ INSTRUC_10_[S. I_TIII_E SlEMPRE tA$ MANIJA$ tATEP_ALES. UII[ICE SI£MPR£

LA _0TECCIIiN ADECIIADA pAPA LA VISTA Y pAPA LAS ViAS _tESPIRATI_RIAS.

--_INST_IJCilO_ MANUAL HIGt_ TORQIJE ALWAYS IJSE Sffi£ tlA_DLE. ALWilys USE pFIOPE_ EYE L

k

ARIN DE MINIMISEA EES _]SQIJES DE BLESSURES LI_E LEGUIDE.

24

Page 26

f

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada palabra de sepal. Lea el manual y preste atenciOn a estos

dmbolos.

PELIGRO: indica una situacidn de peligro inminente que, si

no se evita, provocara la muerte o lesiones graves.

h_.ADVERTENCIA: indica una situacidn de peligro potencial

que, si no se evita, podria provocar la muerte o lesiones

graves.

_ATENClON: indica una situacidn de peligro potencial que,

si no se evita, posiblemente provocarfa lesiones leves o

moderadas.

AVlSO: se refiere a una practica no relacionada a lesiones

corporales que de no evitarse puede resu/tar en da_os a la

propiedad.

SI TIENE ALGUNA DUDA O ALGON COMENTARIO SOBRE FI:STA

U OTRA HERRAMIENTA DEWALT, LL_,MENOS AL NOMERO

GRATUITO: 1-800-4-DEWALT (1-800-433-9258}.

_ ADVERTENCIA: Para reducir el riesgo de lesiones, lea el

manual de instrucciones.

Advertencias generales de seguridad para

herramientas el_ctricas

seguridad e instrucciones. El /ncump//m/ento de /as

_ iADVERTENCIA! Lea todas las advertencias de

advertencias e instrucciones puede provocar descargas

electricas, incendios o lesiones graves.

CONSERVE TODAS LAS ADVERTENCIAS

E INSTRUCCIONES PARA FUTURAS

CONSULTAS

El termino "herramienta electrica" incluido en las advertencias hace

referencia alas herramientas electricas operadas con corriente (con

cable electrico) o alas herramientas electricas operadas con baterfas

(inalambricas).

1) SEGURIDAD EN EL AREA DE TRABAJO

a) Mantenga el area de trabajo limpia y bien iluminada. Las

areas abarrotadas y oscuras propician accidentes.

b) No opere las herramientas el_ctricas en atmdsferas

explosivas, come ambientes donde haya polvo, gases

o liquidos inflamables. Las herramientas electricas originan

chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los ni_os y a los espectadores

de la herramienta el_ctrica en funcionamiento. Las

distracciones pueden provocar la perdida de control

2) SEGURIDAD EL#CTRICA

a) Los enchufes de la herramienta el_ctrica deben

adaptarse al tomacorriente. Nunca modifique el

enchufe de ninguna manera. No utilice ningEm enchufe

adaptador con herramientas el_ctricas con conexion a

tierra. Los enchufes no modificados y que se adaptan a los

tomacorrientes reduciran el riesgo de descarga electrica.

b) Evite el contacto corporal con superficies con descargas

a tierra como, per ejemplo, tuberias, radiadores, cocinas

el_ctricas y refrigeradores. Existe mayor riesgo de descarga

electrica si su cuerpo esta puesto a tierra.

25

Page 27

c) No exponga las herramientas el_ctricas a la Iluvia o a

condiciones de humedad. Si entra agua a una herramienta

electrica, aumentara el riesgo de descarga electrica.

d) No maltrate el cable. Nunca utilice el cable para

transportar, tirar o desenchufar la herramienta el_ctrica.

Mantenga el cable alejado del calor, el aceite, los

berries filosos y las piezas moviles. Los cables dahados o

enredados aumentan el riesgo de descarga electrica.

e) AI operar una herramienta el_ctrica en el exterior, utilice

un cable prolongador adecuado para tal use. Uti/ice un

cable adecuado para uso en exteriores a fin de reducir el

riesgo de descarga electrica.

f) Si el use de una herramienta el_ctrica en un lugar

h(/medo es imposible de evitar, utilice un suministro

protegido con un interrupter de circuito per falla a tierra

(GFCI). El uso de un GFC/ reduce el riesgo de descargas

electricas.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle Io que esta haciendo y

utilice el sentido com(m cuando emplee una herramienta

el_ctrica. No utilice una herramienta el_ctrica si

esta cansado o bajo el efecto de drogas, alcohol o

medicamentos. Un momento de descuido mientras se opera

una herramienta electrica puede provocar lesiones personales

graves.

b) Utilice equipos de proteccion personal. Siempre utilice

proteccion para los ojos. En las condiciones adecuadas, el

uso de equipos de proteccidn, como mascaras para polvo,

calzado de seguridad antideslizante, cascos o proteccidn

auditiva, reducira las lesiones personales.

c) Evite el encendido per accidente. Aseg(/rese de que

el interrupter est_ en la posicidn de apagado antes de

conectarlo a la fuente de energia o paquete de baterias,

o antes de levantar o transportar la herramienta.

Transportar herramientas electricas con el dedo apoyado en el

interruptor o enchufar herramientas electricas con el interruptor

en la posicidn de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la Ilave de tuercas antes de

encender la herramienta el_ctrica. Una Ilave de tuercas

o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta electrica puede provocar lesiones

personales.

e) No se estire. Conserve el equilibrio y parese

adecuadamente en todo memento. Esto permite un mejor

control de la herramienta electrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas

ni joyas. Mantenga el cabello, la ropa y los guantes

alejados de las piezas en movimiento. Las ropas ho/gadas,

las joyas o el cabello largo pueden quedar atrapados en las

piezas en movimiento.

g) Si se suministran dispositivos para la conexidn de

accesorios con fines de recoleccidn y extraccidn de

polvo, aseg(/rese de que est_n conectados y que se

utilicen correctamente. Eluso de dispositivos de reco/eccidn

de polvo puede reducir los peligros relacionados con el polvo.

4} USO Y MANTENIMIENTO DE LA HERRAMIENTA

ELleCTRICA

a) No fuerce la herramienta el_ctrica. Utilice la herramienta

el_ctrica correcta para el trabajo que realizara. Si se /a

utiliza a la velocidad para la que rue disehada, la herramienta

electrica correcta permite trabajar mejor y de manera mas

segura.

b) No utilice la herramienta el_ctrica si no puede encenderla

o apagarla con el interruptor. Toda herramienta e/ectrica

26

Page 28

que no pueda set controlada mediante el interruptor es

peligrosa y debe repararse.

c) Desconecte el enchufe de la fuente de energia o el

paquete de baterias de la herramienta el_ctrica antes

de realizar ajustes, cambiar accesorios o almacenar

la herramienta el_ctrica. Estas medidas de seguridad

preventivas reducen el riesgo de encender la herramienta

electrica en forma accidental

d) Guarde la herramienta el_ctrica que no est_ en uso fuera

del alcance de los nibos y no permita que otras personas

no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas electricas son

peligrosas si son operadas por usuarios no capacitados.

e) Realice el mantenimiento de las herramientas

el_ctricas. Revise que no haya piezas en movimiento

mal alineadas o trabadas, piezas rotas o cualquier otra

sfuacidn que pueda afectar el funcionamiento de la

herramienta el_ctrica. Si encuentra dabos, haga reparar

la herramienta el_ctrica antes de utilizarla. Se producen

muchos accidentes a causa de las herramientas electricas que

carecen de un mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias.

Las herramientas de corte con mantenimiento adecuado y con

los bordes de corte afilados son menos propensas a trabarse

y son mas faciles de controlar.

g) Utilice la herramienta el_ctrica, los accesorios y las

brocas de la herramienta, etc. de acuerdo con estas

instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de /a

herramienta electrica para operaciones diferentes de aquellas

para las que rue disehada podrfa originar una situacidn

peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona calificada en reparaciones que

realice el mantenimiento de su herramienta el_ctrica

y que solo utilice piezas de repuesto id_nticas. Esto

garantizara la seguridad de la herramienta electrica.

Instrucciones Especificas de Seguridad

Adicionales

• Utilice el (los) mango(s) auxiliares, si alguno viene con la

herramienta. Perder el control de la herramienta podrfa causar

lesiones corporales.

• Sujete la herramienta el_ctrica de sus superficies aislan-

tes cuando Ileve a cabo una operacidn en que el accesorio

de corte pudiera entrar en contacto con un hilo el_ctrico

oculto o con su propio cable. Los accesorios de corte que

entren en contacto con un hilo electrico activo podrfan hacer

que las partes metalicas de la herramienta electrica tambien se

activen con electricidad y que el operador sulfa una descarga

electrica.

• Use proteccion auditiva cuando utilice taladros de impacto.

La exposicidn al ruido puede causar perdida de la audicidn.

• Use abrazaderas u otra manera practica de fijar y sujetar

la pieza de trabajo a una plataforma estable. No sujete su

trabajo en forma manual o contra su cuerpo pues no quedara

estable y podrfa perder el control

• Use lentes de seguridad u otra proteccion ocular. Las

operaciones de martilleo y taladro producen astillas en vuelo. Las

partfculas en vuelo pueden provocar daho permanente a los ojos.

• Mantenga las empu_aduras secas, limpias, libres de aceite

y grasa. Esto permitira un mejor control de la herramienta.

• Los orificios de ventilacion suelen cubrir piezas en

movimiento, pot Io que tambi_n se deben evitar. Las piezas

27

Page 29

en movimiento pueden atrapar prendas de vestir sueltas, joyas o

el cabello largo.

• E1 cable de extension deben ser de un calibre apropiado

para su seguridad. Mientras menor sea el calibre del hi/o, mayor

la capacidad del cable. Es decir, un hilo calibre 16 tiene mayor

capacidad que uno de 18. Un cable de un calibre insuficiente

causara una cafda en la tensidn de la Ifnea dando pot resultado

una perdida de energfa y sobrecalentamiento. Cuando se utilice

mas de un alargador para completar el largo total, asegdrese que

los hilos de cada alargador tengan el calibre mfnimo. La tabla

siguiente muestra el tamaho correcto a utilizar, dependiendo

de la Iongitud del cable y del amperaje nominal de la placa de

identificacidn. Si tiene dudas sobre cual calibre usar, use un

calibre mayor. Cuanto mas pequeho sea el ndmero del calibre,

mas resistente sera el cable.

Calibre minimo para cables de alimentacibn

Voltios Largo total del cordon

en metros (pies)

Amperaje

120 V 7,6 15,2 30,5 45,7

(25) (50) (100) (150)

240 V 15,2 30,5 61,0 91,4

(50) (100) (200) (300)

No

Mas

mas

de

de

0 6

6 10

10 12

12 16

18 16 16 14

18 16 14 12

16 16 14 12

14 12 No recomendado

AWG

AADVERTENCIA: Use SIEMPRE lentes de seguridad. Los

anteojos de diario NO SON lentes de seguridad. Utilice ademas

una cubrebocas o mascari/la antipolvo si la operacidn de corte

genera demasiado polvo. SIEMPRE LLEVE EQUIPO DE SEGURIDAD

CERTIFICADO:

• Proteccidn ocularANSI Z87.1 (CAN/CSA Z94.3),

• Proteccidn auditiva ANSI $12.6 ($3.19),

• Proteccidn respiratoria NIOSH/OSHA/MSHA.

AADVERTENCIA: Algunas partfculas de polvo generadas al lijar,

serrar, esmerilar y taladrar con herramientas electricas, asf como al

realizar otras actividades de construccidn, contienen qufmicos que

el Estado de California sabe que pueden producir cancer, defectos

congenitos u otras afecciones reproductivas. Ejemplos de estos

qufmicos son:

• plomo de algunas pinturas en base a plomo,

• polvo de sflice proveniente de ladrillos y cemento y otros

productos de albahilerfa, y

• arsenico y cromo provenientes de madera tratada

qufmicamente.

Su riesgo de exposicidn a estos qufmicos varfa, dependiendo de la

frecuencia con la cual realiza usted este tipo de trabajo. Para reducir

su exposicidn a estas sustancias qufmicas: trabaje en una zona

bien ventilada y Ilevando equipos de seguridad aprobados, como

mascarillas antipolvo especialmente disehadas para filtrar partfculas

microscdpicas.

• Evite el contacto prolongado con polvo generado per el

lijado, aserrado, pulido, taladrado y otras actividades de

construccion. Vista ropas protectoras y lave las areas de

la piel expuestas con agua y jabdn. Si permite que el polvo

se introduzca en la boca u ojos o quede sobre la piel, puede

favorecer la absorcidn de productos qufmicos peligrosos.

AADVERTENCIA: La utilizacidn de esta herramienta puede

generar polvo o dispersarlo, Io que podrfa causar dahos graves