Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in U.S.A. (FEB00-CD-1) Form No. 384286-01

Copyright © 1997,2000

DEWALT Battery and Charger Systems

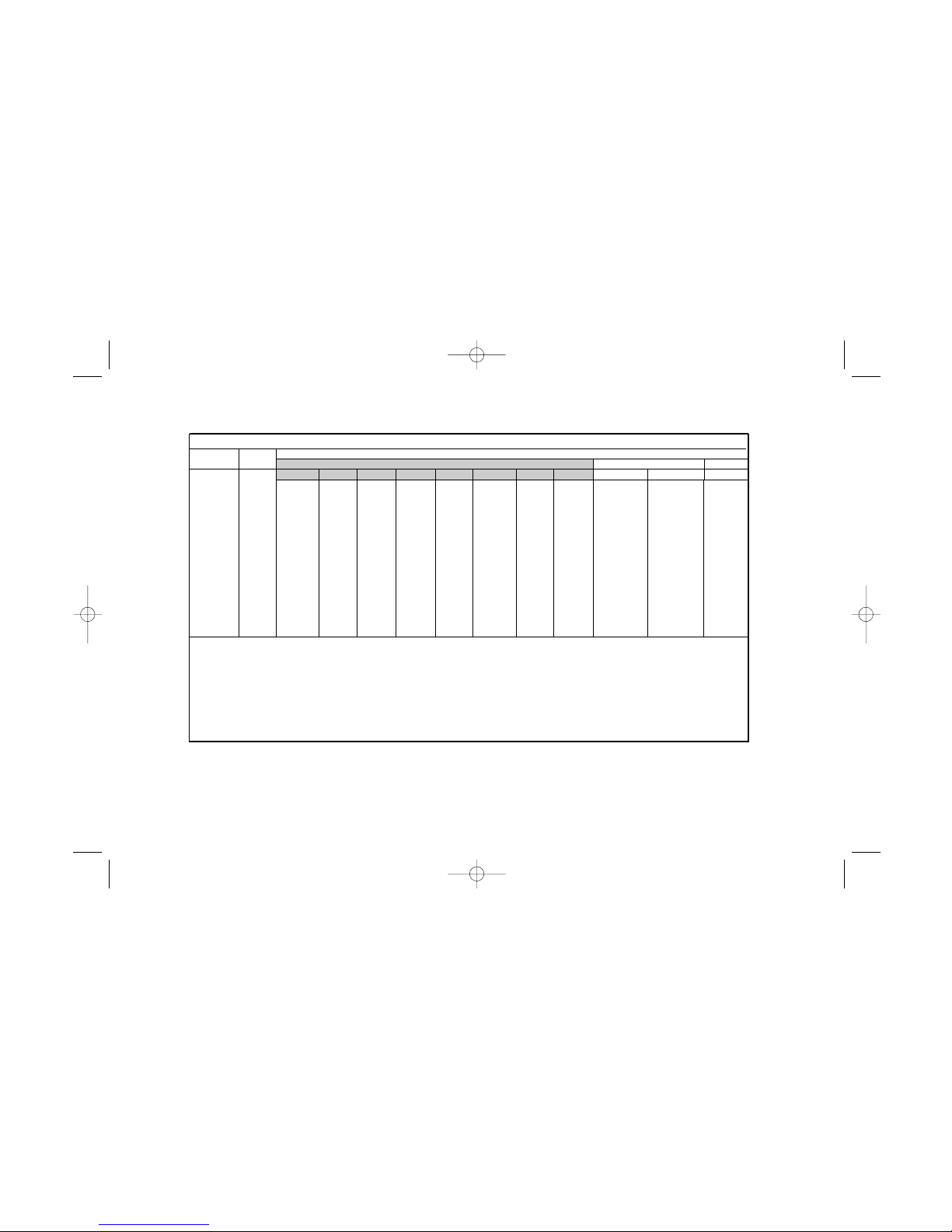

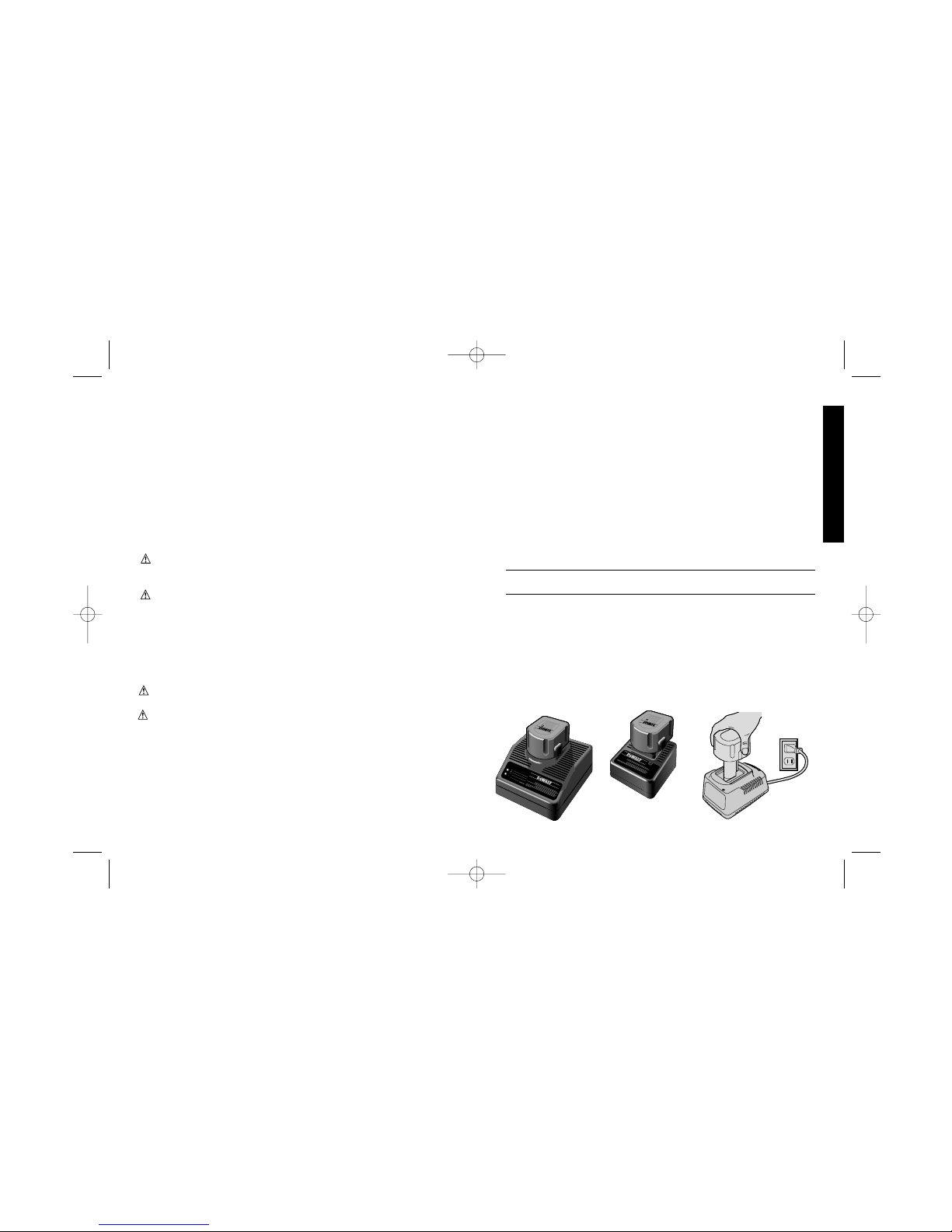

Batt. Output Chargers/Charge Time - Chargeurs/Durée de charge (Minutes) - Cargadores de pilas/Tiempo de carga (Minutos)

Model# Volts 120 Volts 230 Volts 12 Volts

DW9106 DW9118 DW9107 DW9108 DW9116 DW9117 DW911 DW0245 DW9108220 DW9116220 DW9109

DW0240 24 X X X X X X X 60 X X X

DW9096 18 X X X 60 60 22 60 X X X X

DW9095 18 X X X 45 45 15 45 X 45 45 45

DW9098 18 X X X 30 30 12 30 X 30 30 30

DW9091 14.4 60 90 45 45 45 15 45 X 45 45 45

DW9094 14.4 42 60 30 30 30 12 30 X 30 30 30

DW9051 13.2 43 X X X X X X X X X X

DW9071 12 60 90 45 45 45 15 45 X 45 45 45

DW9072 12 42 60 30 30 30 12 30 X 30 30 30

DW9050 12 43 X X X X X X X X X X

DW9061 9.6 60 90 45 45 45 15 45 X 45 45 45

DW9062 9.6 42 60 30 30 30 12 30 X 30 30 30

DW9048 9.6 40 X X X X X X X X X X

DW9057 7.2 42 60 30 30 30 12 30 X 30 30 30

DW9046 7.2 40 X X X X X X X X X X

X Indicates that the battery pack is not compatible with that specific charger.

X indique que le bloc-piles n’est pas compatible avec ce chargeur.

Una “X” indica que el paquete de pilas no es compatible con ese cargador.

All charge times are approximate. Actual charge time may vary. Read the instruction manual for more specific information.

Les durÈes de charge sont approximatives; la durÈe de charge rÈelle peut varier. Lire le manuel d’utilisation pour obtenir des renseigne-

ments plus prÈcis.

Los tiempos de carga son aproximados. La duraciÛn de carga real puede variar. Para obtener una informaciÛn m·s precisa, lea el manual

de utilizaciÛn.

DW936/384286-01 3/15/00 8:25 AM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

DW930/DW935/DW936

Cordless Trim Saws

Ébouteuses sans fil

Sierras circulares inalámbricas

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

DW936/384286-01 3/15/00 8:25 AM Page 3

Page 3

IF YOU HA VE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Rules – For All Battery

Operated Tools

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Do not abuse the cord. Never use the cord to carry the tool. Keep

cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords may create a fire.

• A battery operated tool with integral batteries or a separate

battery pack must be recharged only with the specified

charger for the battery. A charger that may be suitable for one

type of battery may create a risk of fire when used with another

battery.

• Use battery operated tool only with the specifically

designated battery pack. Use of any other batteries may create

a risk of fire.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

R

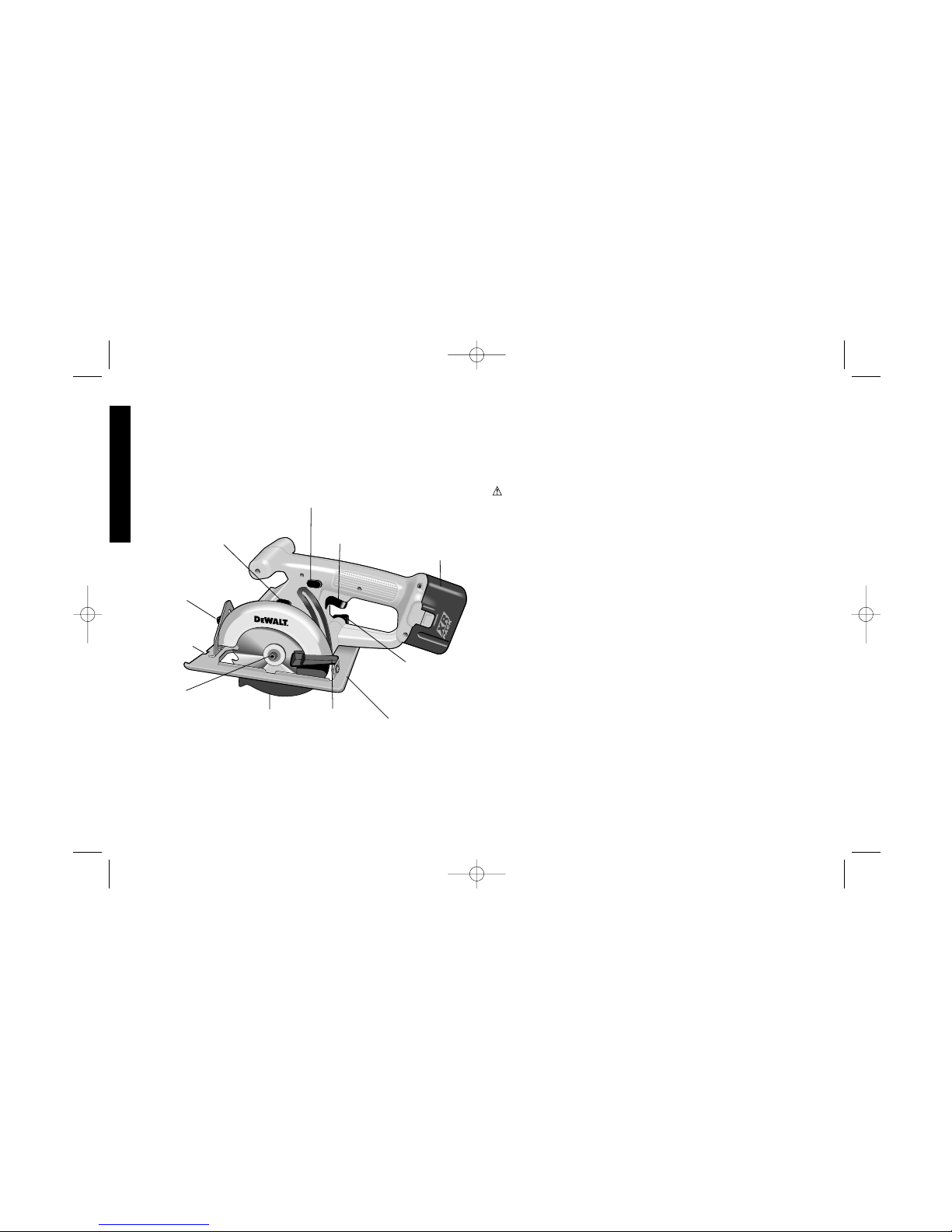

SWITCH LOCK OFF

BUTTON

BATTERY

PACK

SHOE

TRIGGER

SWITCH

DEPTH

ADJUSTMENT

KNOB

LOWER

GUARD

RETRACTING

LEVER

LOWER

GUARD

BLADE LOCK

BUTTON

BEVEL

ADJUSTMENT

KNOB

KERF

INDICATOR

BLADE CLAMPING

SCREW

DW930 12.0 Volt Cordless Trim Saw 2500 RPM

DW935 14.4 Volt Cordless Trim Saw 3000 RPM

DW936 18.0 Volt Cordless Trim Saw 3200 RPM

DW935 shown

DW936/384286-01 3/15/00 8:25 AM Page 4

Page 4

1

English

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or under

the influence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious

personal injury,

• Dress properly. Do not wear loose clothing or jewelry .Contain

long hair. Keep your hair, clothing, and gloves away from moving

parts. Loose clothing, jewelry, or long hair can be caught in moving

parts.

• Avoid accidental starting. Be sure switch is in the locked or

off position before inserting battery pack. Carrying tools with

your finger on the switch or inserting the battery pack into a tool

with the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool

on. A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in

unexpected situations.

• Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection must

be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to a loss of control.

• Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer at the rate for which it is

designed.

• Do not use tool if switch does not turn it on or off. A tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect battery pack from tool or place the switch in the

locked or off position before making any adjustments,

changing accessories, or storing the tool. Such preventative

safety measures reduce the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• When battery pack is not in use, keep it away from other

metal objects like: paper clips, coins, keys, nails, screws, or

other small metal objects that can make a connection from

one terminal to another. Shorting the battery terminals together

may cause sparks, burns, or a fire.

• Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely

to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be suitable

for one tool, may create a risk of injury when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel may result in a risk of injury.

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual. Use

of unauthorized parts or failure to follow Maintenance Instructions

may create a risk of shock or injury.

Additional Safety Rules

• Hold tool by insulated gripping surfaces when performing an

operation where the tool may contact hidden wiring. Contact

with a “live” wire will also make exposed metal parts of the tool

“live” and shock the operator.

DW936/384286-01 3/15/00 8:25 AM Page 1

Page 5

2

• When working on a ladder or on scaffolding be sure to lay the

tool down on its side when not in use. Some tools with large

battery packs will stand upright but may be easily knocked over.

• The label on your tool may include the following symbols.

V....................volts

A....................amperes

Hz..................hertz

W ..................watts

min ................minutes

................alternating current

..............direct current

n

o..................no load speed

..................

Class II Construction

…/min............revolutions or reciprocation per minute

..................earthing terminal

..................safety alert symbol

WARNING: Use of this tool can generate dust containing

chemicals known to cause cancer, birth defects or other

reproductive harm. Use appropriate respiratory protection.

Important Safety Instructions for Battery

Packs

The battery pack is not fully charged out of the carton! First

read the safety instructions below. Then follow charging notes

and procedures.

READ ALL INSTRUCTIONS.

• Do not incinerate the battery pack even if it is severely damaged or is

completely worn out.The battery pack can explode in a fire.

• A small leakage of liquid from the battery pack cells may occur under

extreme usage or temperature conditions. This does not indicate a

failure. However, if the outer seal is broken and this leakage gets on

your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water for

a minimum of 10 minutes and seek immediate medical attention.

(Medical note: The liquid is 25-35% solution of potassium hydroxide.)

• Do not carry extra battery packs in aprons, pockets, or tool boxes along

with other metal objects. Battery pack could be short circuited causing

damage to the battery pack and possibly causing severe burns or fire.

• Charge the battery packs only in D

E

WALTchargers.

• NOTE: The batteries in your battery pack are the nickel–cadmium

type. Cadmium is considered to be a toxic material by the

Environmental Protection Agency. Before disposing of damaged or

worn out Nickel–Cadmium battery packs, check with your state

Environmental Protection Agency to find out about special restrictions

on the disposal of these battery packs or return them to a D

EWALT

certified service center for recycling.

• DO NOT store or use the tool and battery pack in locations where the

temperature may reach or exceed 105°F (such as outside sheds or

metal buildings in summer).

DANGER: Never attempt to open the battery pack for any reason.

If battery pack case is cracked or damaged, do not insert into

charger. Danger of electric shock or electrocution. Damaged battery

packs should be returned to service center for recycling.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Corp

oration) Seal on the nickel-cadmium battery (or battery

pack) indicates that the costs to recycle the battery (or

battery pack) at the end of its useful life have already

been paid by D

EWALT. In some areas, it is illegal to

place spent nickel-cadmium batteries in the trash or

municipal solid waste stream and the RBRC program provides an

environmentally conscious alternative.

RBRC in cooperation with D

EWALT and other battery users, has

English

DW936/384286-01 3/15/00 8:25 AM Page 2

Page 6

established programs in the United States to facilitate the collection

of spent nickel-cadmium batteries. Help protect our environment

and conserve natural resources by returning the spent nickelcadmium battery to an authorized D

EWALTservice center or to your

local retailer for recycling. You may also contact your local recycling

center for information on where to drop off the spent battery.

Important Safety Instructions for Battery

Chargers

SAVE THESE INSTRUCTIONS - This manual contains important

safety instructions for D

EWAL T battery chargers.

• Before using battery charger, read all instructions and cautionary

markings on battery charger, battery and product using battery.

CAUTION:To reduce the risk of injury, charge only D

EWAL T nickel

cadmium rechargeable batteries. Other types of batteries may

burst causing personal injury and damage.

CAUTION: Under certain conditions, with the charger plugged in to

the power supply, the exposed charging contacts inside the charger

can be shorted by foreign material. Foreign materials of a

conductive nature such as, but not limited to, steel wool, aluminum

foil, or any buildup of metallic particles should be kept away from

charger cavities. Always unplug the charger from the power supply

when there is no battery pack in the cavity. Unplug charger before

attempting to clean.

DANGER: 120 volts present at charging terminals. Do not probe

with conductive objects. Danger of electric shock or electrocution.

WARNING: Don’t allow any liquid to get inside charger. Electric

shock may result.

• The charger and battery pack are specifically designed to work

together. DO NOTattempt to charge the battery pack with any chargers

other than the ones in this manual.

• These chargers are not intended for any uses other than charging

D

EWALT rechargeable batteries. Any other uses may result in risk of

fire, electric shock or electrocution.

• To reduce risk of damage to electric plug and cord, pull by plug rather

than cord when disconnecting charger.

• Make sure cord is located so that it will not be stepped on, tripped over,

or otherwise subjected to damage or stress.

• An extension cord should not be used unless absolutely necessary.

Use of improper extension cord could result in risk of fire, electric shock,

or electrocution.

• An extension cord must have adequate wire size (AWG or American

Wire Gauge) for safety. The smaller the gauge number of the wire, the

greater the capacity of the cable, that is 16 gauge has more capacity

than 18 gauge. When using more than one extension to make up the

total length, be sure each individual extension contains at least the

minimum wire size.

Recommended Minimum AWG Size for Extension Cords

Total Extension Cord Length (feet)

25 50 75 100 125 150 175

Wire Gauge

18 18 16 16 14 14 12

• The charger is ventilated through slots in the top and the bottom of the

housing. Do not place any object on top of charger or place the charger

on a soft surface that might block the ventilation slots and result in

excessive internal heat. Place the charger in a position away from any

heat source.

• Do not operate charger with damaged cord or plug — have them

3

English

• CHARGING

• CHARGED

• DELAY

DW9115

DANGER:

WARNING:

15 MINUTE CHARGER

FLASHING

ON

FAST FLASH•DEFECTIVE PACK

ON

9.0v

E

X

T

E

N

D

E

D

R

U

N

T

I

M

E

12.0v

E

X

T

E

N

D

E

D

R

U

N

T

I

M

E

DW9115

DANGER:

WARNING:

R

R

R

R

15 MINUTE CHARGER

1 HOUR CHARGERS

DW936/384286-01 3/15/00 8:25 AM Page 3

Page 7

continuously. The pack is fully charged and may be used at this time

or left in the charger.

4. If you select Tune-up™ and then change your mind, remove the

battery from the charger. After 5 seconds, insert the battery into the

charger. The normal charge cycle will commence.

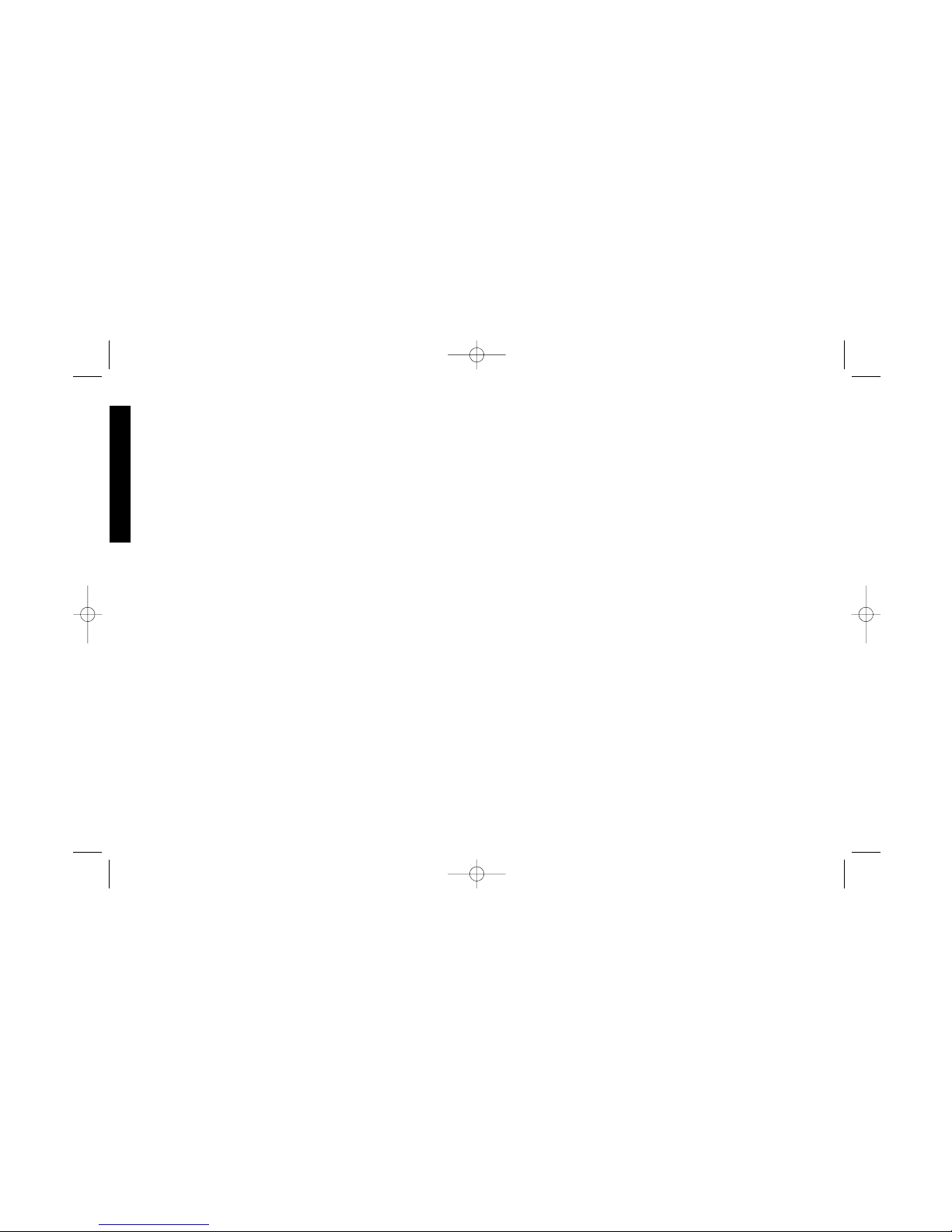

Charging Procedure

1 HOUR CHARGERS

1. Plug the charger into an appropriate power outlet.

2. Insert the battery pack into the charger, as shown in FIG.1,

making sure the pack is fully seated in the charger. The red

(charging) light will blink continuously indicating that the charging

process has started.

3. The battery pack will be fully charged in about 1 hour. The

completion of charge will be indicated by the red light remaining

ON continuously. The pack is fully charged and may be used at

this time or left in the charger.

TROUBLE INDICATORS: These chargers are designed to detect

certain problems that can arise with battery packs which would be

indicated by the red light flashing at a fast rate (and continuous

beeping for 15 Minute Chargers). If this occurs, re-insert battery

pack. If problem persists, try a different battery pack to determine if

the charger is OK. If the new pack charges correctly, then the original

pack is defective and should be returned to a service center for

recycling. If the new battery pack elicits the same trouble indication

as the original, have charger tested at an authorized service center.

PROBLEM POWER LINE

If your charger has a Problem Power Line indicator: When the charger

‘is used with some portable power sources such as generators or

sources that convert DC to AC, the charger may temporarily suspend

operation, flashing the red light with two fast blinks followed by a

pause. This indicates the power source is out of limits.

HOT PACK DELAY

If your charger has a Hot Pack Delay feature: When the charger

4

English

replaced immediately.

• Do not operate charger if it has received a sharp blow, been dropped, or

otherwise damaged in any way; take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service center

when service or repair is required. Incorrect reassembly may result in a

risk of electric shock, electrocution or fire.

• To reduce risk of electric shock, unplug charger from outlet before

attempting any cleaning. Removing the battery pack will not reduce this

risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household electrical

power (120 Volts AC). Do not attempt to use it on any other voltage!

This does not apply to vehiculat charger.

Chargers

Your battery can be charged in DEWALT 1 Hour Chargers, 15 Minute

Chargers or Vehicular 12 volt charger. Be sure to read all safety

instructions before using your charger.

Consult chart on back cover for compatibility of chargers and battery

packs.

Using Tune-Up™ Mode

The Tune-up™ mode will equalize or balance the individual cells in

the battery pack at its peak capacity. This cycle takes up to 8 hours to

complete. Battery packs should be tuned up weekly or after 10 to 20

charge/discharge cycles or whenever the pack no longer delivers the

same amount of work.

1. To tune up your battery pack, place the battery in the charger as

usual. The red light will blink continuously indicating that the charge

cycle has started.

2. The Tune-up™Button may be pressed at any time after the charge

has started. The red light will stop blinking momentarily, blink quickly

3 times, and then resume blinking continuously. The charger is

now giving your batteries a tune-up.

3. When the charge cycle has completed, the light will stay on

DW936/384286-01 3/15/00 8:25 AM Page 4

Page 8

detects a battery that is hot, it automatically starts a Hot Pack Delay,

suspending charging until the battery has cooled. After the battery has

cooled, the charger automatically switches to the Pack Charging

mode. This feature ensures maximum battery life. The red light

flashes long, then short while in the Hot Pack Delay mode.

15 MINUTE CHARGERS

1. Plug the charger into an appropriate power outlet. The charger will

beep twice, the red light will blink and go off.

2. Insert the battery pack into the charger, as shown in FIG. 1,

making sure the pack is fully seated in the charger. The red light

will blink and the charger will beep once indicating the charging

process has started.

3. The battery pack will be fully charged in less than 15 minutes

under most conditions. This will be indicated by the red light

remaining ON and 3 beeps. The pack is fully charged and may

be used at this time or left in the charger.

WEAK BATTERY PACKS: The charger can also detect a weak

battery. Such batteries are still usable but should not be expected to

perform as much work. In such cases, about 10 seconds after battery

insertion, the charger will beep rapidly 8 times to indicate a weak

battery condition. The charger will then go on to charge the battery to

the highest capacity possible.

ALL CHARGERS

Leaving the battery pack in the charger: When the red light

remains ON, the charger has switched to its "equalize charge" mode

which lasts approximately 4 hours, after which the charger will switch

to "maintenance charge" mode. The battery pack can be removed at

any time during these charge cycles, but will only be fully charged if

the red light is continuously ON. The charger and battery pack can be

left connected with the red light glowing indefinitely. The charger will

keep the battery pack fresh and fully charged. A battery pack will

slowly lose its charge when kept out of the charger. If the battery pack

has not been kept on maintenance charge, it may need to be

recharged before use. A battery pack may also slowly lose its charge

5

English

if left in a charger that is not plugged into an appropriate AC source.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65°F and 75°F

(18°- 24°C). DO NOT charge the battery pack in an air temperature

below +40°F(+4.5°C), or above +105°F (+40.5°C). This is important

and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem.

3. If the battery pack does not charge properly — (1) Check current at

receptacle by plugging in a lamp or other appliance, (2) Check to see

if receptacle is connected to a light switch which turns power off

when you turn out the lights. (3) Move charger and battery pack to a

location where the surrounding air temperature is approximately

65°F - 75°F (18°- 24°C). (4) If charging problems persist, take or

send the tool, battery pack and charger to your local service center.

4. The battery pack should be recharged when it fails to produce

sufficient power on jobs which were easily done previously. DO NOT

CONTINUE to use under these conditions. Follow the charging

procedure. You may also charge a partially used pack whenever you

• CHARGING

• CHARGED

• DELAY

15 MINUTE CHARGER

FLASHING

ON

FAST FLASH•DEFECTIVE PACK

ON

DW9115

DANGER:

WARNING:

R

FIG. 1

DW936/384286-01 3/15/00 8:25 AM Page 5

Page 9

• GUARD AGAINST KICKBACK. Kickback occurs when the saw

begins to stall rapidly and is driven back towards the operator. Release

the switch immediately if blade binds or saw stalls. Keep blades sharp.

Don’t force tool. Stay alert. Exercise control. Don’t remove saw from

work during a cut while the blade is moving. A more detailed

explanation of kickback follows in the operation section of this manual.

• LOWER GUARD when necessary for accurate starts, or when pocket

cutting, raise lower guard with the retracting lever.

• ADJUSTMENTS. Before cutting be sure depth and bevel adjustments

are tight.

• USE ONLY CORRECT BLADES. Use only blades with 10mm

diameter arbor. Do not use blades with incorrect size holes. Never

use defective or incorrect blade washers or bolts.

• AVOID CUTTING NAILS. Inspect for and remove all nails from lumber

before cutting.

• CAUTION: When sawing into walls, floors, or wherever “live”

electrical wires may be encountered, DO NOT TOUCH ANY METAL

PARTS OF THE TOOL! Hold the saw only by its plastic handles to

prevent electric shock if you accidentally saw into a live wire.

CAUTION: Some wood contains preservatives such as copper

chromium arsenate (CCA) which can be toxic. When cutting these

materials, extra care should be taken to avoid inhalation and minimize

skin contact.

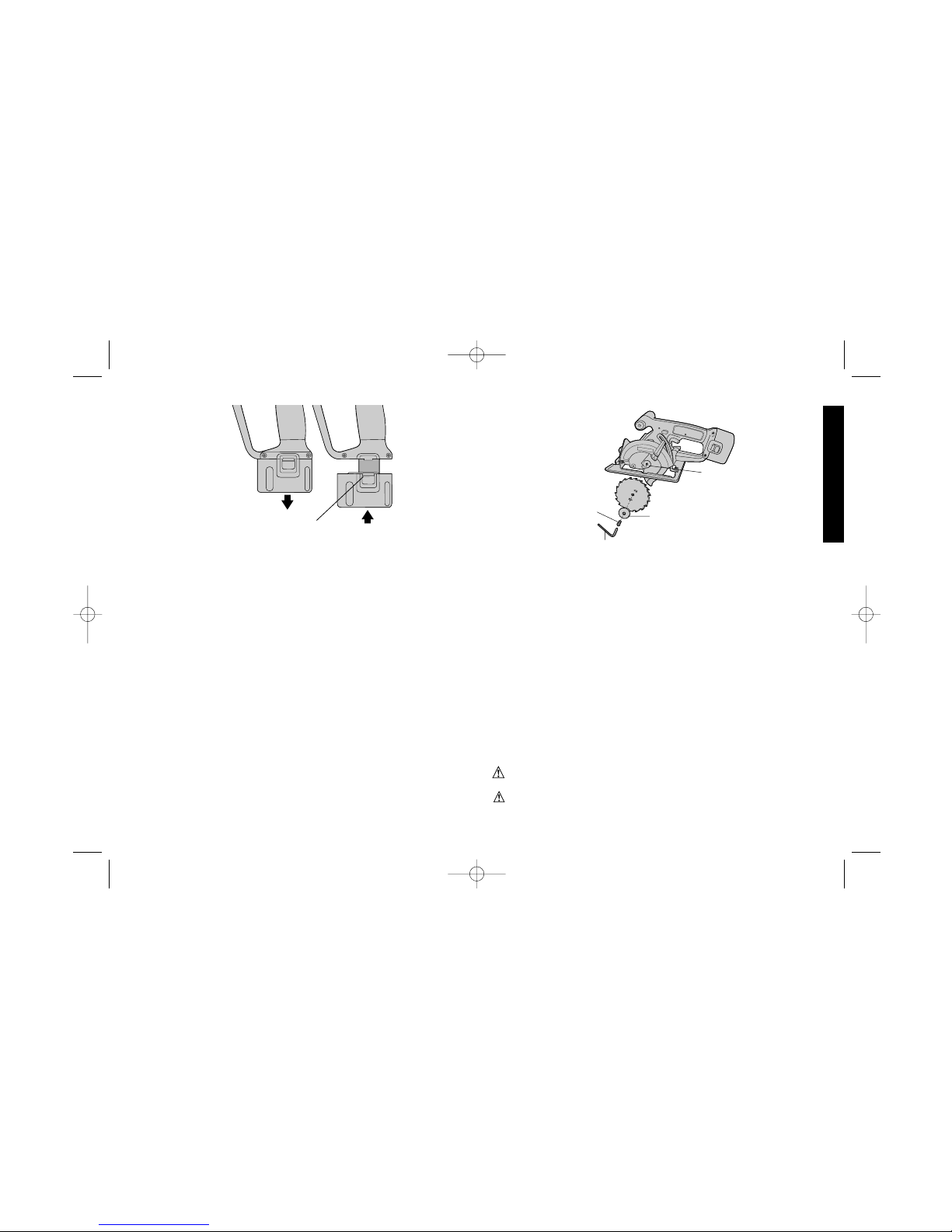

Installing and Removing the Battery Pack

NOTE: Make sure your battery pack is fully charged. To install the

battery pack into the tool handle, align the base of the tool with the

notch inside the tool’s handle and slide the battery pack firmly into the

handle until you hear the lock snap into place as shown in FIG. 2.

To remove the battery pack from the tool, press the release buttons

and firmly pull the battery pack out of the tool handle. Insert it into

the charger as described in the charger section of this manual.

6

English

desire with no adverse affect on the battery pack.

6. Do not immerse charger in water or any other liquid.

WARNING: Don't allow any liquid to get inside charger. Electric

shock may result. To facilitate the cooling of the battery pack after

use, avoid placing the charger or battery pack in a warm

environment such as in a metal shed, or an uninsulated trailer.

CAUTION: Never attempt to open the battery pack for any reason.

If the plastic housing of the battery pack breaks or cracks, return to

a service center for recycling.

Operation

Additional Safety Instructions

(For Circular Saws)

• Remove battery pack before changing blades, making cutting

depth or bevel adjustments, inspecting, and cleaning.

• KEEP GUARDS IN PLACE AND IN WORKING ORDER. Never

wedge or tie lower guard open. Check operation of lower guard before

each use. Do not use if lower guard does not close briskly and

completely over saw blade.

CAUTION: If saw is dropped, lower guard may be bent, restricting

full return. Do not use saw until the lower guard is returned to the

proper working order.

• KEEP BLADES CLEAN AND SHARP. Sharp blades minimize stalling,

overload, kickback, and give a cleaner cut.

• DANGER: Keep hands away from cutting area. Keep hands away

from blades. Do not reach underneath work while blade is rotating. Do

not attempt to remove cut material when blade is moving.

CAUTION: Blades continue to coast after trigger is released. Never

place your hand on the work surface in front of or behind the saw.

• SUPPORT LARGE PANELS. Large panels must be supported as

shown in FIG. 8 to minimize the risk of overload and kickback from

blade pinching. Resting the saw on the work piece should be done on

the larger portion of the work and the smaller piece should be cut off.

DW936/384286-01 3/15/00 8:25 AM Page 6

Page 10

Important!

This product is not user servicable. There are no user servicable

parts inside the charger. Servicing at an authorized service center is

required to avoid damage to static sensitive internal components.

READ ALL OF THE INSTRUCTIONS IN THE BATTER Y CHARGER

SECTION OF THIS MANUAL BEFORE ATTEMPTING TO

CHARGE THE BATTERY PACK FOR YOUR TOOL.

Always use correct battery pack (pack supplied with tool or

replacement pack exactly like it.) Never install any other battery pack.

It will ruin your tool and may create a hazardous condition.

Changing Blades

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. To attach blade, retract lower blade guard and place blade over

spindle and against the inner clamp washer. Place outer clamp

washer against the blade. (Blade must go on with the printed side

out- teeth at bottom of blade pointing forward—FIG. 3).

3. Thread on blade clamping screw firmly by hand to hold washer in

position. (Screw has left hand threads and must be turned

counterclockwise to tighten).

4. Lightly depress the blade lock (FIG. 4) while turning the spindle

7

English

INNER CLAMP

WASHER

OUTER

CLAMP

WASHER

BLADE

CLAMPING

SCREW

WRENCH

FIG. 3

RELEASE BUTTON

FIG. 2

until the blade stops rotating.

5. Tighten blade clamping screw (counterclockwise) firmly with the

blade wrench.

6. To remove blade, TURN OFF TOOL AND REMOVE BATTERY

PACK. Engage the blade lock and unscrew the blade clamping

screw by turning it clockwise with the blade wrench.

NOTE: Never engage blade lock while saw is running, or engage in

an effort to stop the tool. Never turn switch on when blade lock is

engaged. Serious damage to your saw will result.

Blades

A dull blade will cause slow, inefficient cutting overload on the saw

motor, excessive splintering, and could increase the possibility of

kickback. Recommended blades for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance regarding blades, please call 1-800-4-D

EWALT

(1-800-433-9258).

CAUTION: Do not use abrasive discs or blades for cutting ferrous

(steel) materials, glass or tile.

WARNING: To minimize the risk of eye injury, always use eye

protection. Carbide is a hard but brittle material. Foreign objects in

DW936/384286-01 3/15/00 8:25 AM Page 7

Page 11

the work piece such as wire or nails can cause tips to crack or break.

Only operate saw machine when proper saw blade guard is in place.

Mount blade securely in proper rotation before using, and always use

a clean, sharp blade.

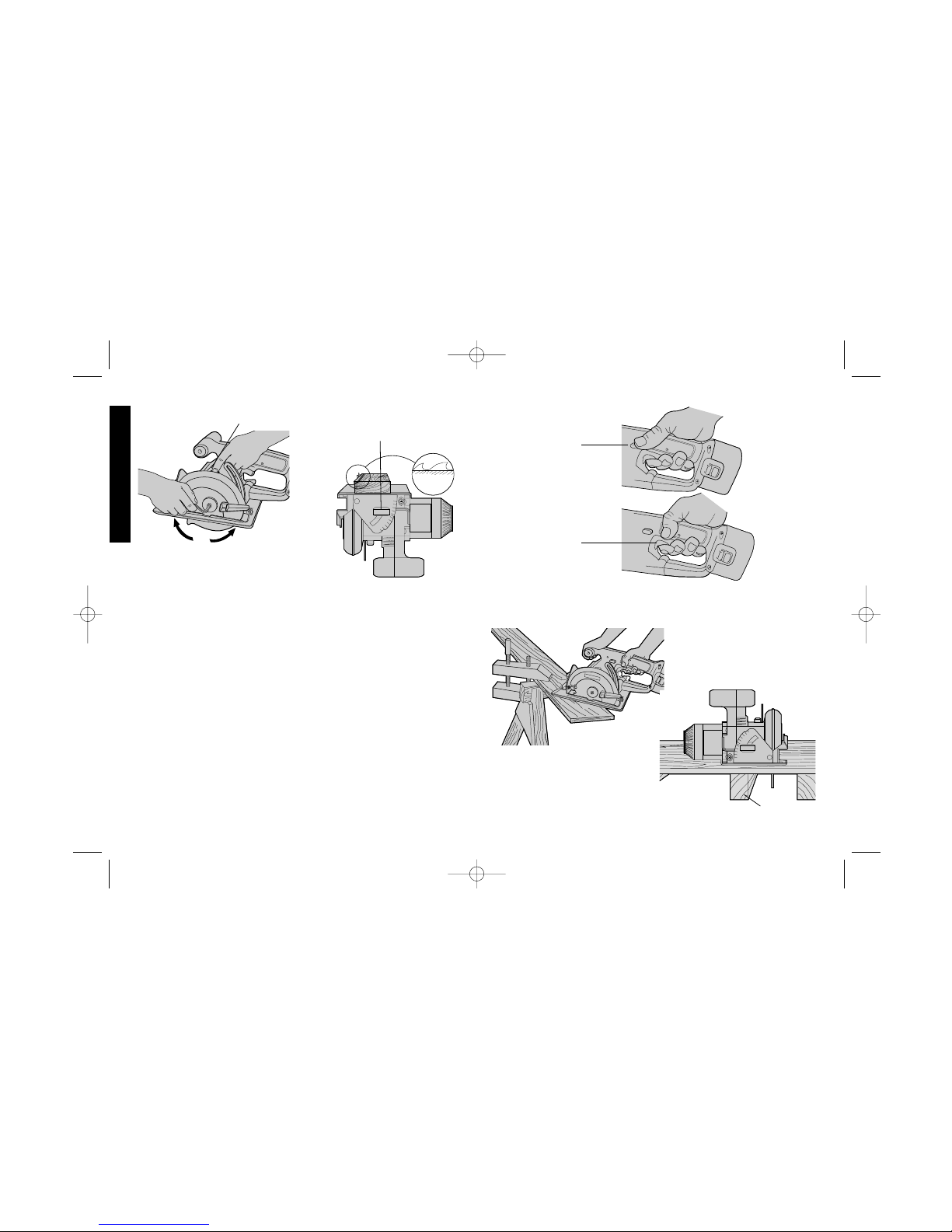

Cutting Depth Adjustment

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. Hold the saw firmly and loosen (counterclockwise) the depth

adjustment knob and move shoe to obtain the desired depth of

cut.

3. Make sure the depth adjustment knob has been retightened

(clockwise) before operating saw.

For the most efficient cutting action, set the depth adjustment so that

one tooth of the blade will project below the material to be cut. This

distance is from the tip of the tooth to the bottom of the gullet in front

of it. This keeps blade friction at a minimum, removes sawdust from

8

English

0

1

5

20

30

40

5

0

SWITCH LOCK

OFF RELEASE

BUTTON

TRIGGER

SWITCH

SUPPORT

DO support board or

panel NEAR the cut.

FIG. 6

FIG. 7

FIG. 8

0

1

5

2

0

3

0

40

50

LOOSEN

clockwise

TIGHTEN

counterclockwise

BEVEL

ADJUSTMENT

KNOB

FIG. 4

FIG. 5

BLADE LOCK

BUTTON

DW936/384286-01 3/15/00 8:25 AM Page 8

Page 12

the cut, results in cooler, faster sawing and reduces the chance of

kickback. A method for checking for correct cutting depth is shown

in FIG. 5. Lay a piece of the material you plan to cut along the side

of the blade, as shown, and observe how much tooth projects beyond

the material.

NOTE: When using carbide-tipped blades, make an exception to the

above rule and allow only one-half of a tooth to project below the

material to be cut.

Bevel Angle Adjustment

The full range of the bevel adjustment is from 0˚ to 50˚. The quadrant

is graduated in increments of 5˚. On the front of the saw is a bevel

angle adjustment mechanism (FIG. 5) consisting of a calibrated

quadrant and a knob. To set the saw for a bevel cut:

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

9

English

0

1

5

2

0

3

0

40

50

DON’T support board or

panel AWAY from the cut.

FIG. 9

FIG. 10

2. Loosen (counterclockwise) the quadrant knob and tilt shoe to the

desired angle by aligning the pointer with the desired angle mark.

Retighten knob firmly (clockwise).

NOTE: The quadrant pointer, located between the quadrant knob

and the quadrant, can be adjusted after loosening its screw.

Retighten firmly after adjustment.

Shoe Adjustment for 90˚ Cuts

If additional adjustment is needed:

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. Adjust the saw to 0˚ bevel.

3. Retract blade guard. Place the saw on blade side.

4. Loosen bevel adjustment knob. Place a square against the blade

and shoe to adjust the 90˚ setting.

5. Move the adjustment screw so that the shoe will stop at the proper

angle.

6. Confirm the accuracy of the setting by checking the squareness of

an actual cut on a scrap piece of material.

Kerf Indicator

The front of the saw shoe has a kerf indicator for vertical and bevel

cutting. This indicator enables you to guide the saw along cutting

lines penciled on the material being cut. The indicator lines up with

the left (outer) side of the saw blade, which makes the slot or “kerf”

cut by the moving blade fall to the right of the indicator. Guide along

the penciled cutting line so that the kerf falls into the waste or surplus

material.

Switch

Release lock off by pressing button as shown in FIG. 6. Pull the

trigger switch to turn the motor ON. Releasing the trigger turns the

motor OFF . Releasing the trigger also automatically actuates lock of f

button.

DW936/384286-01 3/15/00 8:25 AM Page 9

Page 13

10

English

NOTE: This tool has no provision to lock the switch in the ON

position, and should never be locked ON by any other means.

Work Piece Support

FIG. 7 shows proper sawing position. Note that hands are kept away

from cutting area. To avoid kickback, DO support board or panel

NEAR the cut, (FIG. 8). DON’T support board or panel away from the

cut, (FIG. 9).

WARNING: It is important to support the work properly and to

hold the saw firmly to prevent loss of control which could cause

personal injury. FIG. 7 illustrates typical hand support of the saw.

ALWAYS TURN OFF TOOL AND REMOVE BATTERY BEFORE

MAKING ANY ADJUSTMENTS!

Place the work with its “good” side–the one on which appearance is

most important–down. The saw cuts upward, so any splintering will

be on the work face that is up when you cut it.

Cutting

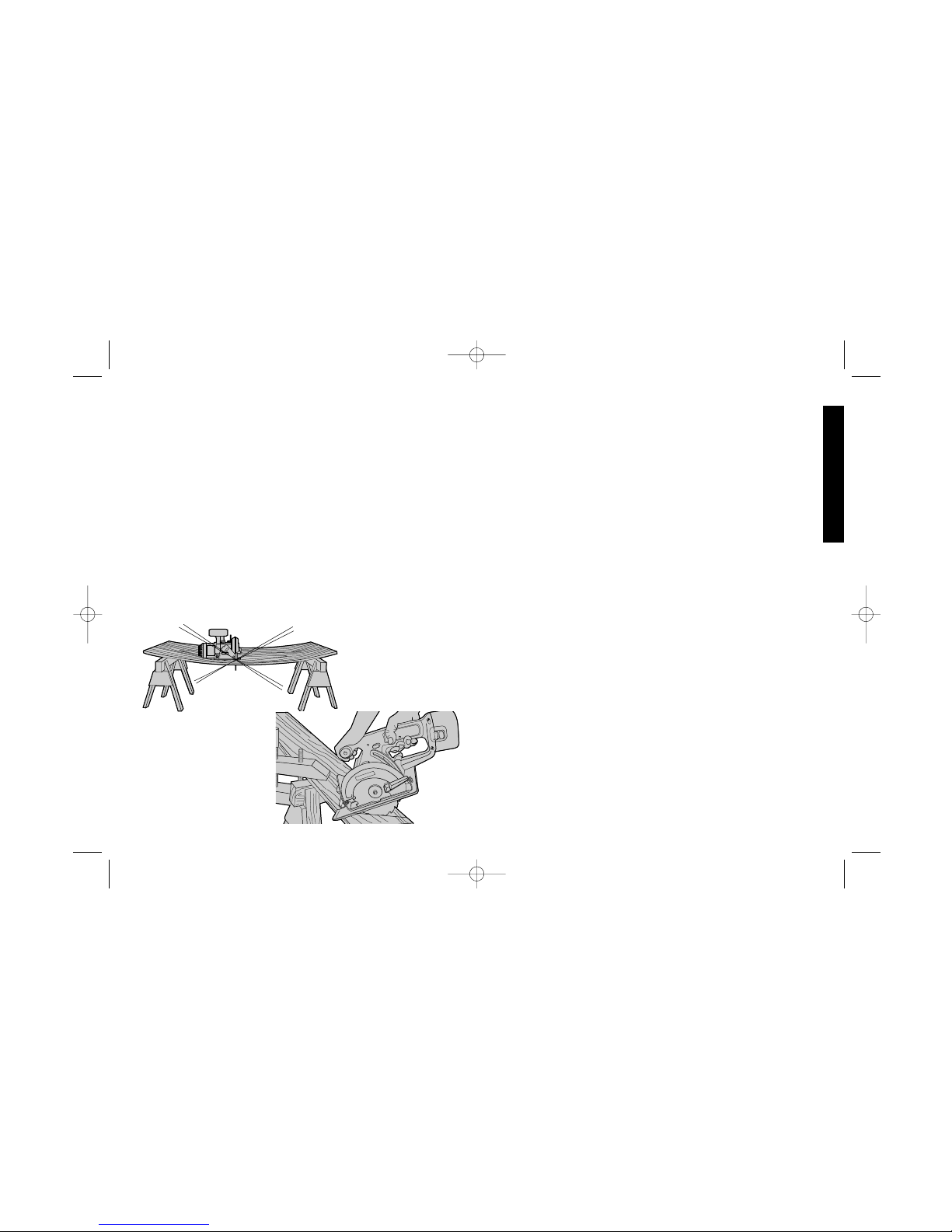

Place the wider portion of the saw shoe on that part of the work piece

which is solidly supported, not on the section that will fall off when the

cut is made. As examples, FIG. 7 illustrates the RIGHT way to cut

off the end of a board. Always clamp work. Don’t try to hold short

pieces by hand! Remember to support cantilevered and overhanging

material. Use caution when sawing material from below.

Be sure saw is up to full speed before blade contacts material to be

cut. Starting saw with blade against material to be cut or pushed

forward into kerf can result in kickback. Push the saw forward at a

speed which allows the blade to cut without laboring. Hardness and

toughness can vary even in the same piece of material, and knotty or

damp sections can put a heavy load on the saw. When this happens,

push the saw more slowly, but hard enough to keep it working without

much decrease in speed. Forcing the saw can cause rough cuts,

inaccuracy, kickback, and over-heating of the motor. Should your cut

begin to go off the line, don’t try to force it back on. Release the switch

and allow blade to come to a complete stop. Then you can withdraw

the saw, sight anew , and start a new cut slightly inside the wrong one.

In any event, withdraw the saw if you must shift the cut. Forcing a

correction inside the cut can stall the saw and lead to kickback.

IF SAW STALLS, RELEASE THE TRIGGER AND BACK THE SAW

UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN THE CUT

AND CLEAR OF THE CUTTING EDGE BEFORE RESTARTING.

As you finish a cut, release the trigger and allow the blade to stop

before lifting the saw from the work. As you lift the saw, the springtensioned telescoping guard will automatically close under the blade.

Remember the blade is exposed until this occurs. Never reach under

the work for any reason. When you have to retract the telescoping

guard manually (as is necessary for starting pocket cuts) always use

the retracting lever.

NOTE: When cutting thin strips, be careful to ensure that small cutoff

pieces don’t hang up on inside of lower guard.

RIPPING

Ripping is the process of cutting wider boards into narrower stripscutting grain lengthwise. Hand guiding is more difficult for this type

of sawing and some type of guide should be used.

POCKET CUTTING (FIG. 10)

TURN OFF TOOL AND REMOVE BATTERY PACK BEFORE

ADJUSTING.

A pocket cut is one that is made in a floor, wall, or other flat surface.

Adjust saw shoe so blade cuts at desired depth. Tilt saw forward

and rest front of the shoe on material to be cut. Using the retracting

lever, retract blade guard to an upward position. Lower rear of shoe

until blade teeth almost touch cutting line. Now release the blade

guard (its contact with the work will keep it in position to open freely

as you start the cut). Start the motor and gradually lower the saw until

its shoe rests flat on the material to be cut. Advance saw along the

DW936/384286-01 3/15/00 8:25 AM Page 10

Page 14

11

English

cutting line until cut is completed. Release trigger and allow blade to

stop completely before withdrawing the blade from the material.

When starting each new cut, repeat as above. Never tie the blade

guard in a raised position. Never move the saw backwards when

pocket cutting. This may cause the unit to raise up off of the work

surface which could cause injury.

Kickback

When the saw blade becomes pinched or twisted in the cut, kickback

can occur. The saw is thrust rapidly back toward the operator. When

the blade is pinched or bound tightly by the kerf closing down, the

blade stalls and the motor reaction drives the unit backward. When

the blade becomes twisted or misaligned in the cut, the teeth at the

back edge of the blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and jump back toward the

operator. Kickback is more likely to occur when any of the following

conditions exist.

Improper work piece support

• Sagging or improper lifting of the cutoff piece causing pinching of

the blade.

• Cutting through material supported at the outer ends only (FIG. 9).

As the material weakens it sags, closing down the kerf and

pinching the blade.

• Cutting off a cantilevered or overhanging piece of material from the

bottom up in a vertical direction. The falling cut off piece can pinch

the blade.

• Cutting off long narrow strips (as in ripping). The cutoff strip can

sag or twist closing the kerf and pinching the blade.

• Snagging the lower guard on a surface below the material being

cut, momentarily reducing operator control. The saw can lift

partially out of the cut, increasing the chance of blade twist.

Improper depth of cut setting on saw

Using the saw with an excessive depth of cut setting increases

loading on the unit and susceptibility to twisting of the blade in the kerf.

It also increases the surface area of the blade available for pinching

under conditions of kerf close down.

Blade twisting (Misalignment in Cut)

• Pushing harder to cut through a knot, or hard grain area can cause

blade to twist.

• Trying to turn the saw in the cut (trying to get back on the marked

line) can cause blade twist.

• Extended reach or operating saw with poor body control (out of

balance) can result in twisting the blade.

• Changing grip or body position while cutting can result in blade

twist.

• Backing unit up to clear blade can lead to twist if not done carefully.

Insufficient allowance for particularly tough materials

Materials that require extra attention: wet lumber, green lumber

(material freshly cut or not kiln dried), pressure treated lumber

(material treated with preservatives or anti-rot chemicals)

Use of dull or dirty blades

Dull blades cause increased loading of the saw. To compensate, an

operator will usually push harder which further loads the unit and

promotes twisting of the blade in the kerf. Worn blades may also have

insufficient body clearance which increases the chance of binding and

increased loading.

Lifting the saw when making bevel cuts

Bevel cuts require special operator attention to proper cutting

techniques - especially guidance of the saw. Both blade angle to the

shoe and greater blade surface in the material increase the chance for

binding and misalignment (twist) to occur.

Restarting a cut with the blade teeth jammed against the

material

The saw should be brought up to full operating speed before starting

a cut or restarting a cut after the unit has been stopped with the blade

in the kerf. Failure to do so can cause stalling and kickback.

Any other conditions which could result in pinching, binding, twisting,

or misalignment of the blade could cause kickback. Refer to sections

DW936/384286-01 3/15/00 8:25 AM Page 11

Page 15

Full One Y ear W arranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1-800-4 D

EWALT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have

other rights which vary from state to state.

In addition to the warranty, D

EWALTtools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALTheavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

12

on “Adjustments and Set-Up” and “Operation” for procedures and

techniques that will minimize the occurrence of kickback.

Cleaning

Use only mild soap and a damp cloth to clean the tool. Many

household cleaners contain chemicals which could seriously damage

plastic. Also, do not use gasoline, turpentine, lacquer or paint thinner,

dry cleaning fluids or similar products. Never let any liquid get inside

the tool; never immerse any part of the tool into a liquid.

Lubrication

Self lubricating ball and roller bearings are used in the tool and

relubrication is not required. However, it is recommended that, once a

year, you take or send the tool to a certified service center for a

thorough cleaning, inspection, and lubrication of the gear case.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by certified service centers or other qualified service

organizations, always using identical replacement parts.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, contact:

DEWALT Industrial Tool Co., 70 East Joppa Road, Baltimore, MD

21286. 1-800-4-DEWALT

CAUTION: The use of any other accessory not recommended

for use with this tool could be hazardous.

English

DW936/384286-01 3/15/00 8:26 AM Page 12

Page 16

13

Français

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE

PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU

TOUT AUTRE OUTIL D

E

WALT, COMPOSEZ SANS FRAIS LE : 1

800 433-9258.

Règles générales de sécurité - Outils à

piles

AVERTISSEMENT! Lire et comprendre toutes les directives, car le

non-respect des directives suivantes peut entraîner un choc électrique,

un incendie ou des blessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

· Garder la zone de travail propre et bien éclairée; les établis

encombrés et les endroits sombres sont propices aux accidents.

· Ne pas utiliser les outils électriques dans une atmosphère

explosive, comme à proximité de liquides, de gaz ou de

poussières inflammables; le moteur peut créer des étincelles et

enflammer les vapeurs ou les poussières environnantes.

· Tenir les enfants, les visiteurs ou toute autre personne à l’écart

lorsqu’on utilise un outil électrique; les distractions peuvent faire

perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ : ÉLECTRICITÉ

· Ne pas utiliser le cordon de manière abusive; on ne doit pas

transporter l’outil en le tenant par le cordon. On doit tenir le cordon à

l’écart des sources de chaleur, de l’huile, des bords tranchants ou des

pièces mobiles. Remplacer immédiatement les cordons endommagés,

car ces derniers augmentent les risques d’incendie.

· Un outil à piles intégrées ou à bloc-piles externe doit être

rechargé seulement au moyen du chargeur approprié, car un

chargeur destiné à une pile particulière peut entraîner un risque

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

E

WALT, COMPOSER SANS

FRAIS LE NUMÉRO :

1 800 4-DEWALT (1-800-433-9258)

R

BOUTON DE

VERROUILLAGE DE

L’INTERRUPTEUR

ENSEMBLE

DE PILES

PATIN

INTERRUPTEUR

À DÉTENTE

BOUTON DE

RÉGLAGE DE LA

PROFONDEUR DE

COUPE

RESSORT DE

RAPPEL DU

PROTÈGE-

LAME

INFÉRIEUR

PROTÈGE-

LAME

INFÉRIEUR

BOUTON DE

VERROUILLAGE

DE LA LAME

BOUTON DE

RÉGLAGE

DES COUPES

EN BISEAU

INDICATEUR

DE VOIE

VIS DE FIXATION

DE LA LAME

DW930 Ébouteuse sans fil de 12,0 volts 2 500 trs/min

DW935 Ébouteuse sans fil de 14,4 volts 3 000 trs/min

DW936 Ébouteuse sans fil de 18,0 volts 3 200 trs/min

DW936/384286-01 3/15/00 8:26 AM Page 13

Page 17

14

Français

pour lesquels il a été conçu. Pour obtenir de meilleurs résultats et

prévenir les risques de blessure, laisser l’outil couper à la vitesse pour

laquelle il a été conçu.

· Ne pas utiliser l’outil lorsque l’interrupteur de marche-arrêt ne

fonctionne pas; tout outil qui ne peut être commandé au moyen de

l’interrupteur est dangereux et doit être réparé.

· Débrancher le bloc-piles de l’outil ou mettre l’interrupteur en

position de verrouillage ou d’arrêt avant d’effectuer un réglage,

de changer les accessoires ou de ranger l’outil; ces mesures de

sécurité préventives réduisent les risques de démarrage accidentel.

· Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des

enfants ou des personnes non qualifiées; les outils sont dangereux

entre les mains de personnes inexpérimentées.

· Lorsqu’on n’utilise pas le bloc-piles, le ranger à l’écart des objets

métalliques tels que les trombones, les pièces de monnaie, les

clés, les clous, les vis ou autres petits objets susceptibles de

conduire l’électricité entre les bornes et d’occasionner ainsi des

étincelles, des brûlures ou un incendie.

· Bien entretenir l’outil; s’assurer qu’il soit toujours bien propre et

aiguisé. Les outils bien entretenus et dont les bords sont bien

tranchants sont moins susceptibles de rester coincés et sont plus

faciles à maîtriser.

· Vérifier les pièces mobiles afin de s’assurer qu’elles soient bien

alignées et qu’elles ne restent pas coincées; vérifier également les

pièces afin de s’assurer qu’il n’y ait aucun bris ni aucune autre

condition susceptible de nuire au bon fonctionnement de l’outil. Faire

réparer l’outil si ce dernier est endommagé avant de s’en servir à

nouveau, car les accidents sont souvent causés par des outils mal

entretenus.

· N’utiliser que les accessoires recommandés par le fabricant pour

le modèle concerné; un accessoire destiné à un outil particulier peut

devenir dangereux lorsqu’il est utilisé avec un autre.

ENTRETIEN

· L’outil doit être entretenu ou réparé par le personnel qualifié

d’incendie lorsqu’il est utilisé avec une autre.

· N’utiliser l’outil à piles qu’avec le bloc-piles désigné, car l’utilisation

d’un autre type de piles peut entraîner un risque d’incendie.

SÉCURITÉ PERSONNELLE

· Rester vigilant en tout temps et faire preuve de jugement

lorsqu’on utilise un outil électrique; ne pas utiliser l’outil lorsqu’on

est fatigué ou sous l’influence de drogues, d’alcool ou de

médicaments, car un moment d’inattention peut entraîner des

blessures graves.

· Porter des vêtements appropriés; ne pas porter de vêtements

amples ni de bijoux. Couvrir ou attacher les cheveux longs. Garder

les cheveux, les vêtements, les bijoux et les gants éloignés des pièces

mobiles, car ceux-ci peuvent s’y coincer.

· Éviter les démarrages accidentels; s’assurer que l’interrupteur soit

placé en position de verrouillage ou d’arrêt avant d’insérer le bloc-piles.

Ne pas transporter l’outil en laissant le doigt sur l’interrupteur ni insérer

le bloc-piles lorsque l’outil est en position de marche, car cela pourrait

causer un accident.

· Retirer les clés de réglage avant de démarrer l’outil; une clé

laissée sur une pièce rotative peut entraîner des blessures.

· Ne pas trop étendre les bras; les pieds doivent rester ancrés

fermement sur le sol afin de maintenir son équilibre en tout temps et de

mieux maîtriser l’outil dans des situations imprévues.

· Utiliser le matériel de sécurité approprié; toujours porter des lunettes

de protection. Porter un masque anti-poussières, des chaussures

antidérapantes, un casque de sécurité ou des protecteurs auditifs

lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

· Fixer et soutenir l’ouvrage sur une plate-forme stable au moyen

d’un étau ou de tout autre dispositif semblable; l’ouvrage est

instable lorsqu’on le retient manuellement ou qu’on l’appuie contre le

corps, ce qui peut faire perdre la maîtrise de l’outil.

· Ne pas forcer l’outil ni l’utiliser pour des travaux autres que ceux

DW936/384286-01 3/15/00 8:26 AM Page 14

Page 18

15

Français

seulement; toute maintenance effectuée par une personne non

qualifiée peut entraîner des risques de blessure.

· Lors de l’entretien, n’utiliser que des pièces de rechange identiques et

suivre les directives de la section «Entretien» du présent manuel afin

de prévenir les risques de choc électrique ou de blessure.

Règles de sécurité additionnelles

· Tenir l’outil par les surfaces isolées prévues à cette fin lorsque

l’outil risque d’entrer en contact avec des fils cachés, car de tels

contacts peuvent mettre les pièces métalliques de l’outil sous tension,

engendrant des risques de choc électrique.

· Lorsqu’on est installé sur une échelle ou un échafaudage pour

travailler, on doit déposer l’outil sur le côté lorsqu’on ne s’en sert

plus. Bien que certains outils munis d’un gros bloc-piles puissent être

placés à la verticale, dans cette position, ils peuvent facilement être

renversés.

• L’étiquette de l’outil peut comporter les symboles suivants.

V..............volts A ............ampères

Hz............hertz W ..........watts

min ..........minutes . . courant

alternatif

........courant continu

n

o ..........sous vide

............

Construction de classe II

............borne de mise

à la minute

............symbole d´avertissement .../min ....tours ou

courses à la minute

AVERTISSEMENT : puisque cet outil peut soulever de la poussière

contenant des produits chimiques susceptibles d’entraîner le

cancer, des malformations congénitales ou pouvant être nocifs sur le

plan reproductif, on recommande le port d’un appareil de protection

respiratoire approprié.

• CHARGING

• CHARGED

• DELAY

DW9115

DANGER:

WARNING:

15 MINUTE CHARGER

FLASHING

ON

FAST FLASH•DEFECTIVE PACK

ON

9

.0

v

E

X

T

E

N

D

E

D

R

U

N

T

I

M

E

1

2

.0

v

E

X

T

E

N

D

E

D

R

U

N

T

I

M

E

DW9115

DANGER:

WARNING:

R

R

R

R

CHARGEUR EN 15 MINUTES

• CHARGING

• CHARGED

• DELAY

15 MINUTE CHARGER

FLASHING

ON

FAST FLASH•DEFECTIVE PACK

ON

DW9115

DANGER:

WARNING:

R

FIG. 1

CHARGEURS EN UNE HEURE

CHARGEURS EN UNE HEURE

DW936/384286-01 3/15/00 8:26 AM Page 15

Page 19

16

Français

Importantes consignes de sécurité

concernant les bloc-piles

Les piles ne sont pas complètement chargées au moment de leur

livraison! Avant de les charger, lire attentivement toutes les

consignes de sécurité énumérées ci-dessous, ainsi que les

remarques, les notes et les méthodes de chargement.

LIRE TOUTES LES DIRECTIVES

· Ne pas incinérer les bloc-piles, même s’ils ont subi des dommages

importants ou ils sont usés complètement, car ils peuvent exploser en

présence de flammes.

· Les cellules des bloc-piles peuvent subir une fuite légère par suite d’un

usage extrême ou d’une exposition à certaines températures; ceci

n’indique pas un problème. Cependant, si le scellant externe est percé

et le liquide entre en contact avec la peau, on doit :

a) se laver rapidement la partie du corps touchée avec de l’eau

savonneuse;

b) neutraliser l’effet au moyen d’un acide doux tel que du jus de citron ou

du vinaigre;

c) si les yeux sont touchés, les rincer à fond avec de l’eau propre pendant

au moins 10 minutes et consulter immédiatement un médecin.

(Remarque aux fins médicales : ce liquide contient une solution

composée de 25 à 35 % d’hydroxyde de potassium.)

· Ne pas transporter des bloc-piles supplémentaires dans un tablier, une

poche ou une boîte à outils contenant des objets métalliques, car le

bloc-pile pourrait causer un court-circuit et s’endommager, ou risquer

de provoquer de graves brûlures ou un incendie.

· Ne charger les bloc-piles qu’au moyen des chargeurs D

EWALT .

· REMARQUE : le bloc-piles contient des piles au nickel-cadmium. Le

cadmium est considéré comme une substance toxique par les

agences de protection de l’environnement, dont le ministère de

l’Environnement; on recommande donc de vérifier auprès de l’agence

concernée avant de mettre au rebut des bloc-piles au nickel-cadmium

usés ou endommagés afin de se renseigner sur les dispositions

particulières qui s’appliquent dans votre région à ce sujet, ou de

retourner les bloc-piles usés ou endommagés à un centre de service

qualifié D

E

WALT afin qu’ils puissent être recyclés.

· NE PAS ranger ni utiliser l’outil ou le bloc-piles dans des endroits où la

température peut atteindre ou dépasser 40,5 ºC (105 ºF), comme les

cabanons ou les bâtiments en revêtement métallique durant l’été.

· DANGER : Ne jamais tenter d’ouvrir le bloc-piles pour quelle que

raison que ce soit. Si le compartiment se rupture ou subit des

dommages, ne pas l’insérer dans le chargeur afin d’éviter les risques

de choc électrique ou d’électrocution. On doit retourner les bloc-piles

endommagés à un centre de service afin qu’ils puissent être recyclés.

Bloc-piles

L'outil fonctionne sur un bloc-piles DEWALT de 18 volts. Lorsqu’on

commande des bloc-piles de rechange, on doit indiquer le numéro de

catalogue et la tension requise. Les bloc-piles à durée prolongée

durent 25 % plus longtemps que les bloc-piles standard.

REMARQUE : bien que l’outil puisse fonctionner au moyen de l’un ou

l’autre des deux types de bloc-piles, on doit s’assurer d’en choisir un

de tension appropriée.

FIG. 2

BOUTONS DE

DÉGAGEMENT

DW936/384286-01 3/15/00 8:26 AM Page 16

Page 20

17

Français

Sceau RBRC

MC

Le sceau RBRCMC de la Rechargeable Battery Recycling Corporation

apposé sur la pile au nickel-cadmium (ou le bloc-piles)

indique que les coûts de recyclage de ce dernier à la fin

de sa vie utile ont déjà été payés par D

EWALT. En

certains endroits, la mise au rebut ou aux ordures

municipales des piles au nickel-cadmium est illégale; le

programme de «RBRC» constitue donc une solution des plus

pratiques et écologiques.

La «RBRC», en collaboration avec D

EWALT et d’autres utilisateurs de

piles, a mis sur pied des programmes aux États-Unis dans le but de

faciliter la collecte des piles déchargées. D

EWALT encourage ses

utilisateurs à participer à son programme de protection de

l'environnement et de conservation des ressources naturelles en

retournant les piles usagées à un centre de service D

E

WALT ou chez

un dépositaire local afin qu’elles puissent être recyclées. On peut en

outre se renseigner auprès d’un centre de recyclage local pour

connaître d'autres sites les acceptant.

Importantes consignes de sécurité

concernant les chargeurs

CONSERVER CES DIRECTIVES – Le présent manuel contient

d’importantes consignes de sécurité concernant les chargeurs

D

EWALT .

· Avant d’utiliser le chargeur, lire toutes les directives et étiquettes de

mise en garde apposées sur le chargeur, la pile et le produit utilisant

la pile.

· Ne pas utiliser les outils électriques dans une atmosphère explosive,

comme à proximité de liquides, de gaz ou de poussières inflammables;

le moteur peut créer des étincelles et enflammer les vapeurs ou les

poussières environnantes.

· MISE EN GARDE : afin de réduire les risques de blessure, ne

charger que des piles au nickel-cadmium rechargeables D

EWALT, car

les autres peuvent éclater et entraîner des blessures ou des

dommages matériels.

· MISE EN GARDE : dans certaines conditions, lorsque le chargeur

est enfiché, les raccords de charge à nu situés à l’intérieur du chargeur

peuvent subir un court-circuit lorsqu’ils entrent en contact avec une

matière étrangère. Les matières conductives comme la laine d’acier, la

feuille d’aluminium ou les particules métalliques, mais sans toutefois

s’y limiter, doivent être tenus à l’écart des cavités du chargeur.

Toujours débrancher celui-ci lorsque le bloc-piles n’y est pas inséré

ou avant de le nettoyer.

· DANGER : les bornes du chargeur conduisent une haute tension;

on ne doit pas les toucher au moyen d’objets conducteurs afin d’éviter

les risques de choc électrique ou d’électrocution.

· AVERTISSEMENT : ne jamais laisser de liquide s’infiltrer à

l’intérieur du chargeur ni l’exposer à la pluie ou à la neige afin d’éviter

les risques de choc électrique.

· Le chargeur et le bloc-piles sont conçus spécialement pour être utilisés

ensemble; NE PAS charger le bloc-piles au moyen d’un chargeur autre

que ceux décrits dans le présent manuel.

· N’utiliser ces derniers que pour charger les piles rechargeables

D

EWALT; tout autre usage peut entraîner des risques d’incendie, de

choc électrique ou d’électrocution.

· Afin de réduire les risques de dommage à la fiche ou au cordon

électrique, débrancher le chargeur en saisissant la fiche, non le

cordon.

· S’assurer que le cordon soit placé de manière à éviter qu’il ne subisse

des dommages ou des contraintes ou que les personnes s’y prennent

les pieds et trébuchent.

· Ne pas utiliser de rallonge à moins que cela ne soit absolument

nécessaire, car l’usage d’une rallonge ayant une puissance

inadéquate pourrait causer des risques d’incendie, de choc électrique

ou d’électrocution.

· Afin d’assurer la sécurité de l’utilisateur, la rallonge doit être de calibre

AWG approprié. Plus le calibre est petit, plus la capacité est grande;

autrement dit, une rallonge de calibre 16 est plus puissante qu’une

DW936/384286-01 3/15/00 8:26 AM Page 17

Page 21

rallonge de calibre 18. Lorsqu’on utilise plusieurs rallonges pour

obtenir la longueur voulue, s’assurer que chacune d’elles présente les

valeurs minimales requises.

Calibre minimal recommandé des rallonges

Longueur totale de la rallonge (en pieds)

25 50 75 100 125 150

175

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m

45.7 m 53.3 m

Calibre AWG

18 18 16 16 14 14 12

· Le chargeur s’aère par l’entremise de fentes situées sur le dessus et le

dessous du logement; ne jamais mettre un objet sur le dessus du

chargeur ni placer celui-ci sur une surface molle risquant d’obstruer les

fentes de ventilation, ce qui pourrait causer une chaleur interne

excessive. Tenir le chargeur éloigné de toute source de chaleur.

· Ne pas faire fonctionner le chargeur lorsque le cordon ou la fiche est

endommagé. Si tel est le cas, les remplacer immédiatement.

· Ne pas faire fonctionner le chargeur s’il a subi un coup important, une

chute ou des dommages quelconques. Si cela se produit, l’emporter à

un centre de service autorisé.

· Ne pas démonter le chargeur, car un mauvais assemblage pourrait

occasionner des risques de choc électrique, d’électrocution ou

d’incendie. Le chargeur doit être retourné à un centre de service

autorisé aux fins d’une réparation ou d’un entretien, le cas échéant.

· Afin de réduire les risques de choc électrique, débrancher le chargeur

de la prise murale avant de procéder au nettoyage; le seul fait

d’enlever le bloc-piles ne réduit pas ce risque.

· Ne JAMAIS brancher deux chargeurs ensemble.

· Ne pas alimenter le chargeur au moyen d’une source autre que celles

indiquées sur la plaque signalétique.

Chargeurs

Les piles DeWALT peuvent être chargées au moyen d’un chargeur

18

Français

DEWALT d ’une heure ou de 15 minutes, ou d’un chargeur pour

véhicules de 12 volts. S’assurer de lire toutes les consignes de

sécurité avant d’utiliser le chargeur.

Consulter le diagramme apparaissant sur le couvercle arrière afin

de vérifier la compatibilité du chargeur avec le bloc-piles.

Mode rechargement (Tune-UpMC)

Le mode rechargement (Tune-UpMC) sert à égaliser ou à équilibrer

chaque cellule du bloc-piles lors de son cycle de capacité limite; le

cycle total dure 8 heures. Le bloc-piles doit être rechargé chaque

semaine, après 10 ou 20 cycles de charge / de décharge ou lorsque

la capacité du bloc-piles commence à diminuer.

1. Pour recharger le bloc-piles, placer les piles dans le chargeur de

la manière habituelle. Le voyant rouge clignotera continuellement,

indiquant que le cycle de charge est amorçé.

2. On peut enfoncer le bouton Tune-UpMC à n’importe quel moment

une fois la charge amorçée. Le voyant rouge s’éteindra

momentanément, clignotera trois fois brièvement puis restera

allumé, indiquant que le chargeur est en mode rechargement.

3. Une fois le cycle de rechargement terminé, le voyant restera

allumé, indiquant que le bloc-piles est complètement rechargé; on

peut alors le réutiliser ou le laisser dans le chargeur.

4. Si on sélectionne le mode de rechargement mais qu’on change

d’idée par la suite, retirer les piles du chargeur. Attendre 5

secondes, puis réinsérer la pile afin d’amorcer le cycle de charge

normal.

Méthode de chargement

CHARGEURS D’UNE HEURE

1. Enficher le chargeur dans une prise appropriée.

2. Insérer le bloc-piles dans le chargeur, tel qu’illustré à la FIG. 1,

en s’assurant de bien l’enfoncer. Le voyant (de charge) rouge

clignotera continuellement, indiquant que le cycle de charge est

amorcé.

DW936/384286-01 3/15/00 8:26 AM Page 18

Page 22

19

Français

3. Le bloc-piles est complètement chargé après environ une heure.

Le voyant rouge restera allumé, indiquant que le bloc-piles est

complètement rechargé; on peut alors le réutiliser ou le laisser

dans le chargeur.

4. PROBLÈMES RELIÉS À LA SOURCE DE COURANT : les

chargeurs munis d’un voyant d’indication de problème au niveau

de la source de courant peuvent suspendre temporairement le

chargement s’il est branché dans une source d’alimentation

portative, comme une génératrice ou un convertisseur de courant

continu en courant alternatif. En présence d’un tel problème, le

voyant rouge émet deux clignotements rapides, suivis d’une

pause, indiquant que le problème se situe au niveau de la source

de courant.

5. DISPOSITIF DE DÉTECTION DE PILES CHAUDES : si le

chargeur est muni d’un dispositif visant à détecter les piles

chaudes, le chargement sera retardé jusqu’à ce que la pile se

soit refroidie et le chargeur se placera automatiquement en

FIG. 3

FIG. 4

RONDELLE

DE

FIXATION

INTERNE

VIS DE FIXATION

DE LA LAME

CLÉ

RONDELLE

DE FIXATION

EXTERNE

DESSERRER

SENS

HORAIRE

SERRER

SENS

ANTIHORAIRE

BOUTON DE

VERROUILLAGE

DE LA LAME

position de chargement; ce dispositif sert à maximiser la durée

de vie des piles. Le voyant rouge s’allume longuement, et ensuite

brièvement lorsque ce dispositif est en marche.

CHARGEURS DE 15 MINUTES

1. Enficher le chargeur dans une prise appropriée; une fois alimenté,

il émet deux signaux sonores et le voyant rouge clignote puis

s’éteint.

2. Insérer le bloc-piles dans le chargeur, tel qu’illustré à la FIG. 1, en

s’assurant de bien l’enfoncer. Le voyant rouge clignotera

continuellement et le chargeur émettra un seul signal sonore pour

indiquer que le cycle de charge est amorcé.

3. Dans la plupart des cas, le bloc-piles requiert moins de 15 minutes

pour se charger complètement. Le voyant rouge reste allumé et le

chargeur émet trois signaux sonores pour indiquer que le bloc-piles

est complètement rechargé; on peut alors le réutiliser ou le laisser

dans le chargeur.

4. BLOC-PILES FAIBLE : on peut aussi utiliser le chargeur de 15

minutes pour déterminer si une pile est faible. Bien qu’on puisse

continuer à utiliser une pile faible, elle ne procurera pas un plein

rendement. Si tel est le cas, 10 secondes après l’insertion de la pile,

le chargeur émettra rapidement huit signaux sonores pour indiquer

qu’il s’agit d’une pile faible, puis chargera la pile jusqu’à sa pleine

capacité.

CHARGEURS DE TOUT TYPE

Bloc-piles laissé dans le chargeur. Lorsque le voyant rouge reste

allumé, cela signifie que le chargeur s’est placé en mode d’égalisation

de charge, lequel peut rester ainsi pendant environ 4 heures. Après

ce délai, le chargeur se placera en mode de tenue de charge. Bien que

le bloc-piles puisse être retiré pendant n’importe quel de ces cycles, il

n’est complètement chargé que lorsque le voyant rouge reste allumé

continuellement. On peut laisser le chargeur (avec un bloc-piles

inséré) raccordé à une prise tant que le voyant rouge reste allumé; le

DW936/384286-01 3/15/00 8:26 AM Page 19

Page 23

chargeur maintient alors la charge du bloc-piles afin que ce dernier soit

prêt à être utilisé. Un bloc-piles perd graduellement sa charge s’il n’est

pas gardé dans le chargeur. Un bloc-piles n’étant pas maintenu en

mode de tenue de charge devra être rechargé avant son utilisation. Un

bloc-piles peut graduellement perdre sa charge s’il est laissé dans un

chargeur qui n’est pas enfiché dans une source d’alimentation à

courant alternatif appropriée.

INDICATEURS D’ANOMALIE : les chargeurs sont conçus pour

détecter certains problèmes pouvant être reliés aux bloc-piles. Ces

problèmes sont indiqués par le clignotement rapide du voyant rouge et,

dans le cas des chargeurs de 15 minutes, par un signal sonore

continu. Si un tel problème survient, réinsérer le bloc-piles dans le

chargeur. Si le problème persiste, remplacer le bloc-piles afin de

déterminer si le chargeur fonctionne bien. Si le bloc-piles de rechange

se charge correctement, cela signifie que le bloc initial est défectueux

et qu’on doit le retourner à un centre de service afin qu’il puisse être

recyclé. Si le bloc neuf affiche le même problème que le bloc initial, on

doit faire vérifier le chargeur à un centre de service autorisé.

Notes importantes concernant le

chargement

1. Afin de maximiser la durée de vie du bloc-piles et d’assurer son

rendement optimal, le charger à la température ambiante, soit

entre 18 et 24 °C (65 et 75 °F). Afin d’éviter d’endommager le

bloc-piles, il est important de NE PAS le charger à des

températures inférieures à +4,5 °C (+40 °F) ou supérieures à

+40,5 °C (105 °F).

2. Le chargeur et le bloc-piles peuvent devenir chauds au toucher lors

du chargement. Ceci est normal et n’indique pas la présence d’un

problème.

3. Si le bloc-piles ne se charge pas normalement, il faut : (1) vérifier

l’alimentation de la prise en y enfichant une lampe ou un appareil,

(2) s’assurer que la prise ne soit pas raccordée à un interrupteur qui

coupe le courant lorsqu’on éteint les lumières, (3) placer le chargeur

et le bloc-piles dans un endroit où la température ambiante est

environ 18 à 24 °C (65 et 75 °F) ou, si le problème persiste, (4)

retourner l’outil, le bloc-piles et le chargeur au centre de service de

sa région.

4. Le bloc-piles doit être rechargé lorsqu’il ne produit pas suffisamment

de courant pour permettre à l’utilisateur de travailler normalement.

On doit CESSER de l’utiliser dans de telles conditions et suivre la

méthode de chargement. On peut aussi charger en tout temps un

bloc-piles partiellement déchargé sans nuire à son fonctionnement.

5. Dans certaines conditions, lorsque le chargeur est enfiché, les

raccords de charge à nu situés à l’intérieur du chargeur peuvent

subir un court-circuit lorsqu’ils entrent en contact avec une matière

étrangère. Les matières conductives comme la laine d’acier, la

feuille d’aluminium ou les particules métalliques, mais sans

toutefois s’y limiter, doivent être tenus à l’écart des cavités du

chargeur. Toujours débrancher celui-ci lorsque le bloc-piles n’y est

pas inséré ou avant de le nettoyer.

AVERTISSEMENT : ne jamais laisser de liquide s’infiltrer à

l’intérieur du chargeur afin d’éviter les risques de choc électrique.

Pour faciliter le refroidissement du bloc-piles après son utilisation,

éviter de placer ce dernier ou le chargeur dans un environnement

chaud comme un cabanon en métal ou une remorque non isolée.

MISE EN GARDE : ne jamais ouvrir le bloc-piles pour quelle que

raison que ce soit. Si le compartiment en plastique se rupture

ou se fissure, le retourner au centre de service afin qu’il puisse être

recyclé.

Important

L’utilisateur ne peut pas réparer le chargeur ni les pièces qu’il

renferme. Il faut donc en confier la réparation à un centre de service

autorisé afin d’éviter d’endommager les composants internes du

chargeur qui sont sensibles à la statique.

BIEN LIRE TOUTES LES DIRECTIVES RELATIVES AU

20

Français

DW936/384286-01 3/15/00 8:26 AM Page 20

Page 24

21

Français

0

1

5

20

3

0

4

0

50

FIG. 5

BOUTON DE

RÉGLAGE DES

COUPES EN BISEAU

FIG. 6

BOUTON DE DÉGAGEMENT DU

DISPOSITIF DE VERROUILLAGE DE

L’INTERRUPTEUR

INTERRUPTEUR À

DÉTENTE

CHARGEUR DU PRÉSENT GUIDE AVANT DE CHARGER

L’ENSEMBLE DE PILES.

Toujours utiliser l’ensemble de piles approprié (comme celui fourni

avec l’outil ou un ensemble de rechange identique). Ne jamais utiliser

un autre ensemble de piles; cela peut endommager l’outil et présente

des risques.

Lames

Une lame émoussée procure une coupe lente et inefficace, elle

entraîne la surchauffe du moteur et la production excessive d’éclats,

et elle peut augmenter les risques de rebond. On peut se procurer en

sus des lames recommandées pour l’outil chez les détaillants et au

centre de service de la région. Pour obtenir de plus amples

renseignements sur les lames, composer le 1 (800) 433-9258.

ATTENTION: Ne pas utiliser de lames ni de disques abrasifs pour

couper des matériaux ferreux (comme de l’acier), du verre ou de la

céramique.

AVERTISSEMENT : Pour réduire les risques de blessures,

toujours porter des lunettes de sécurité. Le carbure est un matériau

dur mais friable. Les bouts de lames peuvent craquer ou casser s’ils

entrent en contact avec des corps étrangers se trouvant dans la pièce

à découper (comme des fils ou des clous). Utiliser la scie seulement

avec le protecteur approprié en place. Bien installer la lame dans le

bon sens avant d’utiliser la scie et toujours se servir d’une lame

propre et bien affûtée.

Remplacement de la lame

1. METTRE L’OUTIL HORS TENSION ET ENLEVER L’ENSEMBLE

DE PILES.

2. Pour installer la lame, escamoter le protège-lame inférieur et

placer la lame sur l’arbre contre la rondelle de fixation interne.

Placer la rondelle de fixation externe contre la lame (la face

imprimée de la lame doit s’orienter vers l’extérieur; les dents du

bas de la lame pointant vers l’avant) (figure 3).

3. Serrer fermement à la main la vis de fixation de la lame de

manière à retenir la rondelle en place (la vis a des filets à gauche

et il faut la faire tourner dans le sens antihoraire pour la serrer).

4. Enfoncer légèrement le dispositif de verrouillage de la lame

(figure 4) en faisant tourner l’arbre jusqu’à ce que la lame

s’immobilise.

5. Serrer fermement (dans le sens antihoraire) la vis de fixation de la

lame avec la clé de la lame.

6. Pour retirer la lame, METTRE L’OUTIL HORS TENSION ET

ENLEVER L’ENSEMBLE DE PILES. Mettre le dispositif de

verrouillage de la lame en place et desserrer la vis de fixation de

la lame en la faisant tourner dans le sens horaire à l’aide de la

clé de la lame.

DW936/384286-01 3/15/00 8:26 AM Page 21

Page 25

22

NOTE : Ne jamais engager le dispositif de verrouillage de la lame

lorsque la scie fonctionne ni pour immobiliser l’outil. Ne jamais mettre

la scie en marche lorsque le dispositif de verrouillage de la lame est

en place; cela risque d’endommager la scie irrémédiablement.

Réglage de la profondeur de coupe

1. METTRE L’OUTIL HORS TENSION ET ENLEVER L’ENSEMBLE

DE PILES.

2. Saisir fermement la scie et desserrer (dans le sens antihoraire) le

bouton de réglage de la profondeur de coupe. Déplacer le patin