Page 1

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW008

Cordless Reciprocating Saw

Scies alternatives à régulateur sans fil

Sierras reciprocantes in alámbrico

Questions? See us in the World Wide Web at www.dewalt.com

Page 2

moment of inattention while operating power tools may result in

serious personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothing, jewelry, or long hair can be caught

in moving parts.

Air vents often cover moving parts and should also

be avoided.

• Avoid accidental starting. Be sure switch is in the locked or off

position before inserting battery pack. Carrying tools with your

finger on the switch or inserting the battery pack into a tool with the

switch on invites accidents.

• Remove adjusting keys or switches before turning the tool on.

A wrench or key that is left attached to a rotating part of the tool

may result in personal injury.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be

used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to a loss of control.

• Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer and the rate for which it

is designed.

• Do not use tool if switch does not turn it on or off. Any tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect battery pack from tool or place the switch in the

locked or off position before making any adjustments, changing accessories, or storing the tool. Such preventative safety

measures reduce the risk of starting the tool accidentally.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Rules – For All Battery

Operated Tools

WARNING! Read and understand all instructions.

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Do not abuse the cord. Never use the cord to carry the tool.

Keep cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged cords may cre-

ate a fire.

• A battery operated tool with integral batteries or a separate bat-

tery pack must be recharged only with the specified charger

for the battery. A charger that may be suitable for one type of bat-

tery may create a risk of fire when used with another battery.

• Use battery operated tool only with the specifically designed

battery pack. Use of any other batteries may create a risk of fire.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

Page 3

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• When battery pack is not in use, keep it away from other metal

objects like: paper clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another. Shorting the battery terminals together may

cause sparks, burns, or a fire.

• Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely

to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufac-

turer for your model. Accessories that may be suitable for one

tool, may become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified person-

nel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

Additional Specific Safety Rules

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring.

Contact with a “live” wire will make exposed metal parts of the tool

“live” and shock the operator.

CAUTION: Wear appropriate personal hearing protection dur-

ing use. Under some conditions and duration of use, noise from this

product may contribute to hearing loss.

1

English

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with sawdust from treated lumber.

Do not allow dust to get into your mouth, eyes or lay on the skin.

Wear protective clothing whenever possible.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

Important Safety Instructions for

Battery Packs

Your tool uses a 24 Volt DEWALT battery pack. When ordering

replacement battery packs, be sure to include catalog number and

voltage. The battery pack is not fully charged out of the carton! First

read the safety instructions below. Then follow charging notes and

procedures.

CAUTION: The batteries in your battery pack are the nickel–cad-

mium type. Cadmium is considered to be a toxic material by the

Environmental Protection Agency. Before disposing of damaged or

worn out Nickel–Cadmium battery packs, check with your state

Environmental Protection Agency to find out about special restrictions

on the disposal of these battery packs or return them to a D

EWALT

certified service center for recycling.

Page 4

2

CAUTION: When not in use, place tool on its side on a stable

surface where it will not cause a tripping or falling hazard. Some

tools with large battery packs will stand upright on the battery pack but

may be easily knocked over.

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it is severely damaged or

is completely worn out.The battery pack can explode in a fire.

• A small leakage of liquid from the battery pack cells may occur

under extreme usage or temperature conditions. This does not

indicate a failure. However, if the outer seal is broken and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water

for a minimum of 10 minutes and seek immediate medical attention. (Medical note: The liquid is 25–35% solution of potassium

hydroxide.)

• Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, immediately discontinue use and do not recharge.

• Do not carry extra battery packs in aprons, pockets, or tool boxes

along with other metal objects. Battery pack could be short circuited causing damage to the battery pack and possibly causing

severe burns or fire.

• Charge the battery packs only in D

EWALT chargers.

• NOTE: Review and observe all of the “Important Charging Notes”

in the charger instruction section of this manual.

• DO NOT probe pack with conductive objects.

• DO NOT splash or immerse in water or other liquids.

• Maintain clean and open vent holes.

NOTE: Battery storage and carrying caps are provided

for use whenever the battery is out of the tool or charger.

Remove cap before placing battery in charger or tool.

English

WARNING: Do not store or carry battery so that metal objects

can contact exposed battery terminals. For example, do not place

battery in aprons, pockets, tool boxes, product kit boxes, drawers, etc.,

with loose nails, screws, keys, etc. without battery cap. Transporting

batteries can possibly cause fires if the battery terminals

inadvertently come in contact with conductive materials such as

keys, coins, hand tools and the like. The US Department of

Transportation Hazardous Material Regulations (HMR) actually prohibit

transporting batteries in commerce or on airplanes (i.e., packed in

suitcases and carry-on luggage) UNLESS they are properly protected

from short circuits. So when transporting individual batteries, make sure

that the battery terminals are protected and well insulated from

materials that could contact them and cause a short circuit.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling

Corporation) Seal on the nickel-cadmium battery (or battery pack) indicates that the costs to recycle the battery (or

battery pack) at the end of its useful life have already been

paid by D

EWALT. In some areas, it is illegal to place spent

nickel-cadmium batteries in the trash or municipal solid waste stream

and the RBRC program provides an environmentally conscious alternative.

RBRC in cooperation with D

EWALT and other battery users, has

established programs in the United States to facilitate the collection of

spent nickel-cadmium batteries. Help protect our environment and

conserve natural resources by returning the spent nickel-cadmium

battery to an authorized D

EWALT service center or to your local retail-

er for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery.

Introduction

Your charger is designed to use standard 120 volt AC, 60 Hz power.

Do not use DC or any other voltage. Charge time is approximately

one hour.

Page 5

3

English

Important Safety Instructions for Battery

Chargers

SAVE THESE INSTRUCTIONS: This manual contains important

safety and operating instructions.

• Before using charger, read all instructions and cautionary markings

on (1) charger, (2) battery pack, and (3) product using battery pack.

DANGER: 120 volts present at charging terminals. Do not probe

with conductive objects. Danger of electric shock or electrocution.

DANGER: If battery pack case is cracked or damaged, do not

insert into charger. Electric shock or electrocution may result.

• DO NOT attempt to charge the battery pack with any chargers

other than the ones in this manual. The charger and battery

pack are specifically designed to work together.

• Do not expose charger to rain or snow.

• These chargers are not intended for any uses other than

charging D

EWALT rechargeable batteries. Any other uses may

result in risk of fire, electric shock or electrocution.

• Pull by the plug rather than cord when disconnecting charger.

This will reduce the risk of damage to the cord.

• Make sure cord is located so that it will not be stepped on,

tripped over, or otherwise subjected to damage or stress.

• Do not use an extension cord unless absolutely necessary.

Use of improper extension cord could result in risk of fire, electric

shock, or electrocution.

• An extension cord must have adequate wire size (AWG or

American Wire Gauge) for safety. The smaller the gauge number

of the wire, the greater the capacity of the cable, that is 16 gauge

has more capacity than 18 gauge. When using more than one

extension to make up the total length, be sure each individual

extension contains at least the minimum wire size.

RECOMMENDED MINIMUM AWG SIZE FOR EXTENSION CORDS

Total Extension Cord Length (feet)

25 50 75 100 125 150 175

Wire Gauge

18 18 16 16 14 14 12

• Do not place any object on top of charger or place the charg-

er on a soft surface that might block the ventilation slots and

result in excessive internal heat. Place the charger in a position

away from any heat source. The charger is ventilated through slots

in the top and the bottom of the housing.

• Do not operate charger with damaged cord or plug — have

them replaced immediately.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way; take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service

center when service or repair is required. Incorrect reassembly

may result in a risk of electric shock, electrocution or fire.

• Unplug charger from outlet before attempting any cleaning.

This will reduce risk of electric shock. Removing the battery pack

will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• DO NOT store or use the tool and battery pack in locations

where the temperature may reach or exceed 105°F (such as

outside sheds or metal buildings in summer).

• The charger is designed to operate on standard household

electrical power (120 Volts). Do not attempt to use it on any

other voltage. This does not apply to the vehicular charger.

Charging Procedure

1. Plug the charger into an appropriate outlet.

2. Insert the battery pack into the charger. Be sure the pack is fully seated in the charger. The red (charging) light will blink continuously indicating that the charging process has started.

3. The completion of charge will be indicated by the red light remaining

ON continuously. The pack is fully charged and may be used at this

time or left in the charger.

WARNING: Don't allow any liquid to get inside charger. Electric

shock may result. To facilitate the cooling of the battery pack after

use, avoid placing the charger or battery pack in a warm environment

such as in a metal shed, or an uninsulated trailer.

Page 6

4

English

CAUTION: Never attempt to open the battery pack for any reason.

If the plastic housing of the battery pack breaks or cracks, return to a

service center for recycling.

Battery Packs

Your tool uses a 24 Volt DEWALT battery pack. When ordering replacement battery packs, be sure to include catalog number and voltage.

Extended Run-Time battery packs deliver more run-time than standard battery packs.

BATTERY PERFORMANCE

Some chargers have a tune-up feature that optimizes battery pack

performance. Your charger may provide Automatic Tune-Up™ Mode

or manual (i.e., push button) Tune-Up™ mode. For information on this

feature, please see the appropriate section below. Because batteries

slowly lose their charge when they are not on the charger, the best

place to keep your battery pack is on the charger at all times.

USING AUTOMATIC TUNE-UP™ MODE

The Automatic Tune-Up™ Mode equalizes or balances the individual

cells in the battery pack allowing it to function at peak capacity. Battery

packs should be tuned up after every 10th charge/ discharge cycle or

whenever the pack no longer delivers the same amount of work. To

use the automatic tune-up mode, simply place the battery pack in the

charger and leave it for at least eight hours. The charger will cycle

through the following modes.

1. The red light will blink continuously indicating that the 1-hour

charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will stay on

continuously and will no longer blink. This indicates that the pack

is fully charged and can be used at this time.

3. Whenever the pack is left in the charger after the initial 1-hour

charge, the charger will begin the Automatic Tune-Up™ Mode.

This mode continues up to 8 hours or until the individual cells in

the battery pack are equalized. The battery pack is ready for use

and can be removed at any time during the Tune-Up™ Mode.

4. Once the Automatic Tune-Up™ Mode is complete the charger will

transition to a maintenance charge; no indicator light shows the

completion of the Automatic Tune-Up™ Mode.

USING THE MANUAL TUNE-UP™ MODE

The manual Tune-Up™ mode equalizes or balances the individual

cells in the battery pack at its peak capacity. This mode takes up to 8

hours to complete. Battery packs should be tuned up weekly or after

10 charge/discharge cycles or whenever the pack no longer delivers

the same amount of work.

1. To tune up your battery pack, place the battery in the charger as

usual. The red light will blink continuously indicating that the

charge cycle has started.

2. Press the Tune-Up™ Mode button any time after the charge cycle

has started. The red light will stop blinking momentarily, blink

quickly 3 times, and then resume blinking continuously. The

charger is now tuning up the cells in your battery.

3. When the Tune-Up™ mode cycle is complete, the light will stay on

continuously. The pack is fully charged and may be used at this

time or left in the charger.

4. If you select Tune-Up™ Mode and then change your mind,

remove the battery from the charger. After 5 seconds, insert the

battery into the charger. The normal charge cycle will begin.

Charge Indicators

HOT/COLD PACK DELAY

When the charger detects a battery that is excessively hot or excessively cold, it automatically starts a Hot/Cold Pack Delay, suspending

charging until the battery temperature has normalized. After this happens, the charger automatically switches to the Pack Charging mode.

This feature ensures maximum battery life. The red light flashes long,

then short while in the Hot/Cold Pack Delay mode.

REPLACE PACK

These chargers are designed to detect certain problems that can arise

with battery packs which would be indicated by the red light flashing

at a fast rate. If this occurs, re-insert battery pack. If problem persists,

Page 7

5

English

try a different battery pack to determine if the charger is OK. If the new

pack charges correctly, then the original pack is defective and should

be returned to a service center for recycling. If the new battery pack

gives the same trouble indication as the original, have charger tested

at an authorized service center.

PROBLEM POWER LINE

When these chargers are used with some portable power sources

such as generators or sources that convert DC to AC, the chargers

may temporarily suspend operation, flashing the red light with two

fast blinks followed by a pause. This indicates the power source is

out of limits. Your power supply may need service.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light

glowing indefinitely. The charger will keep the battery pack fresh and

fully charged.

NOTE: A battery pack will slowly lose its charge when kept out of the

charger. If the battery pack has not been kept on maintenance charge,

it may need to be recharged before use. A battery pack may also slowly lose its charge if left in a charger that is not plugged into an appropriate AC source.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65°F and

75°F (18°- 24°C). DO NOT charge the battery pack in an air temperature below +40°F(+4.5°C), or above +105°F (+40.5°C). This is

important and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem.

3. If the battery pack does not charge properly — (1) Check current

at receptacle by plugging in a lamp or other appliance, (2) Check

to see if receptacle is connected to a light switch which turns

power off when you turn out the lights. (3) Move charger and battery pack to a location where the surrounding air temperature is

approximately 65°F - 75°F (18°- 24°C). (4) If charging problems

persist, take or send the tool, battery pack and charger to your

local service center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs which were easily done previously. DO NOT

CONTINUE to use under these conditions. Follow the charging

procedure. You may also charge a partially used pack whenever

you desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can be

shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, steel wool, aluminum foil, or any

buildup of metallic particles should be kept away from charger

cavities. Always unplug the charger from the power supply when

there is no battery pack in the cavity. Unplug charger before

attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING: Don't allow any liquid to get inside charger. Electric

shock may result. To facilitate the cooling of the battery pack after use,

avoid placing the charger or battery pack in a warm environment such

as in a metal shed, or an uninsulated trailer.

CAUTION: Never attempt to open the battery pack for any reason.

If the plastic housing of the battery pack breaks or cracks, return to a

service center for recycling.

Important

This product is not user servicable. There are no user servicable parts

inside the charger. Servicing at an authorized service center is

required to avoid damage to static sensitive internal components.

READ ALL OF THE INSTRUCTIONS IN THE BATTERY CHARGER

SECTION OF THIS MANUAL BEFORE ATTEMPTING TO CHARGE

THE BATTERY PACK FOR YOUR TOOL.

Always use correct battery pack (pack supplied with tool or replacement pack exactly like it.) Never install any other battery pack. It will

ruin your tool and may create a hazardous condition.

Page 8

6

English

Fan Cooling

This charger is equipped with an internal fan that provides rapid cooling of D

EWALT DW0242 battery packs. The fan operation is automatic

and will turn on when required during battery charging. The fan will

also cycle periodically when there is no battery in the charger in order

to blow dust from the fan vents.

WARNING: Fan may blow debris from vent area at any time. Keep

face and eyes away from area above vents. To minimize the risk of

eye injury, always use eye protection.

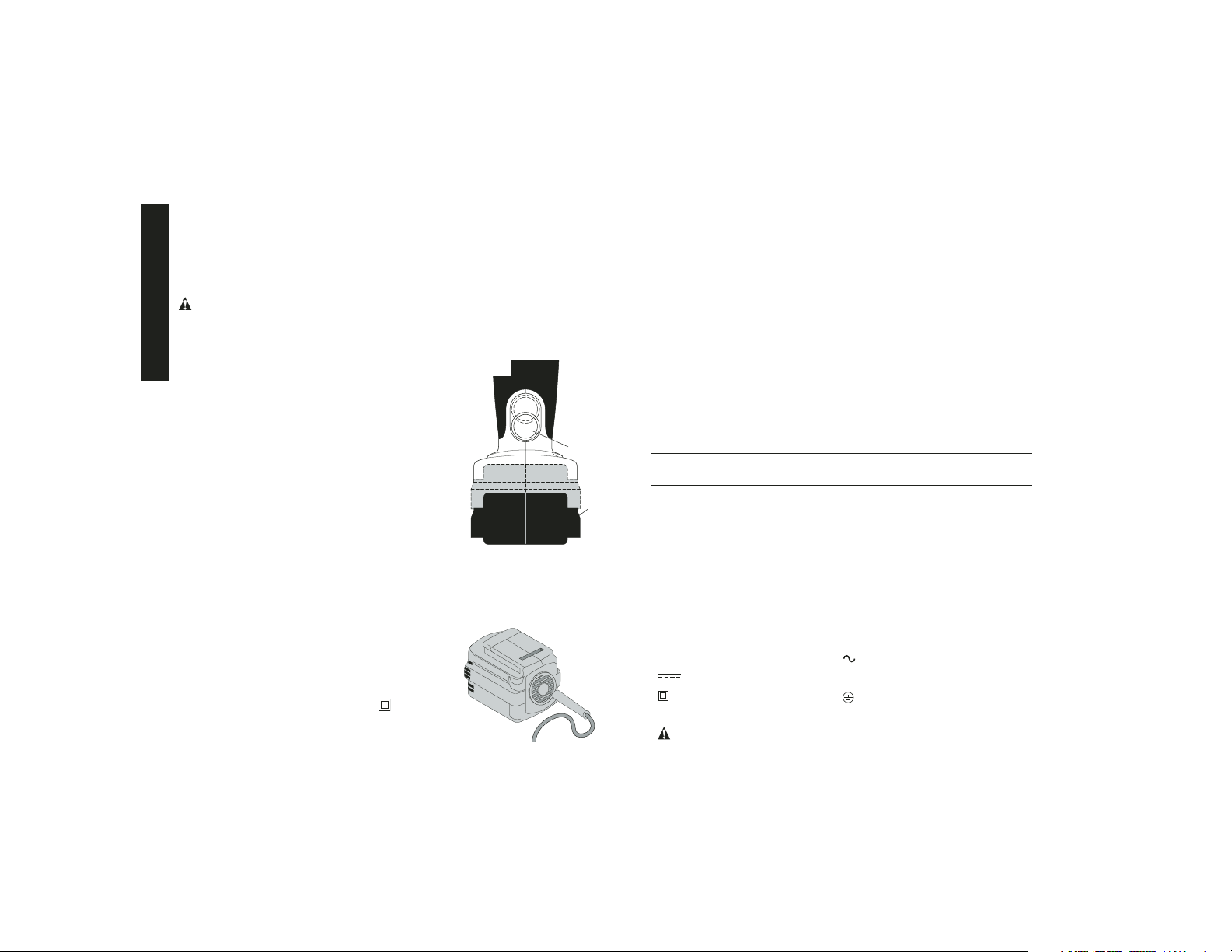

Installing and Removing

the Battery Pack

NOTE: Make sure your battery pack is fully

charged. To install the battery pack into the tool

handle, align the base of the tool with the notch

inside the tool’s handle and slide the battery

pack firmly into the handle until you hear the

lock snap into place as shown in FIG. 1.

To remove the battery pack from the tool, slide

the release button (A) away from the battery

pack (B) and the battery may be removed from

the tool handle. Insert it into the charger as

described in the charger section of this manual.

Additional Specific Safety Instructions

When Using DW0247 AC Adapter

• Double insulated tools are equipped with a polarized plug (one

blade is wider than the other.) This plug

will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit,

contact a qualified electrician to install a

polarized outlet. Do not change the plug

in any way. Double insulation eliminates

the need for the three wire grounded power

cord and grounded power supply system.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor exten-

sion cord marked “W-A” or “W.” These cords are rated for outdoor use and reduce the risk of electric shock.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• Avoid accidental starting. Be sure switch is off before plug-

ging in. Carrying tools with your finger on the switch or plugging in

tools that have the switch on invites accidents.

• Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventative safety measures reduce the risk of starting the

tool accidentally.

• The label on your tool may include the following symbols.

V ..........volts A..............amperes

Hz ........hertz W ............watts

min ......minutes ..........alternating current

......direct current

n

o ............no load speed

..........

Class II

..............

earthing terminal

..............Construction .../min ......revolutions per minute

........safety alert symbol

FIG. 1

A

B

Page 9

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your

power supply agrees with the nameplate markings.

Voltage decrease of more than 10% will cause loss of power and overheating. All D

EWALT tools are factory tested; if this tool does not oper-

ate, check your battery pack.

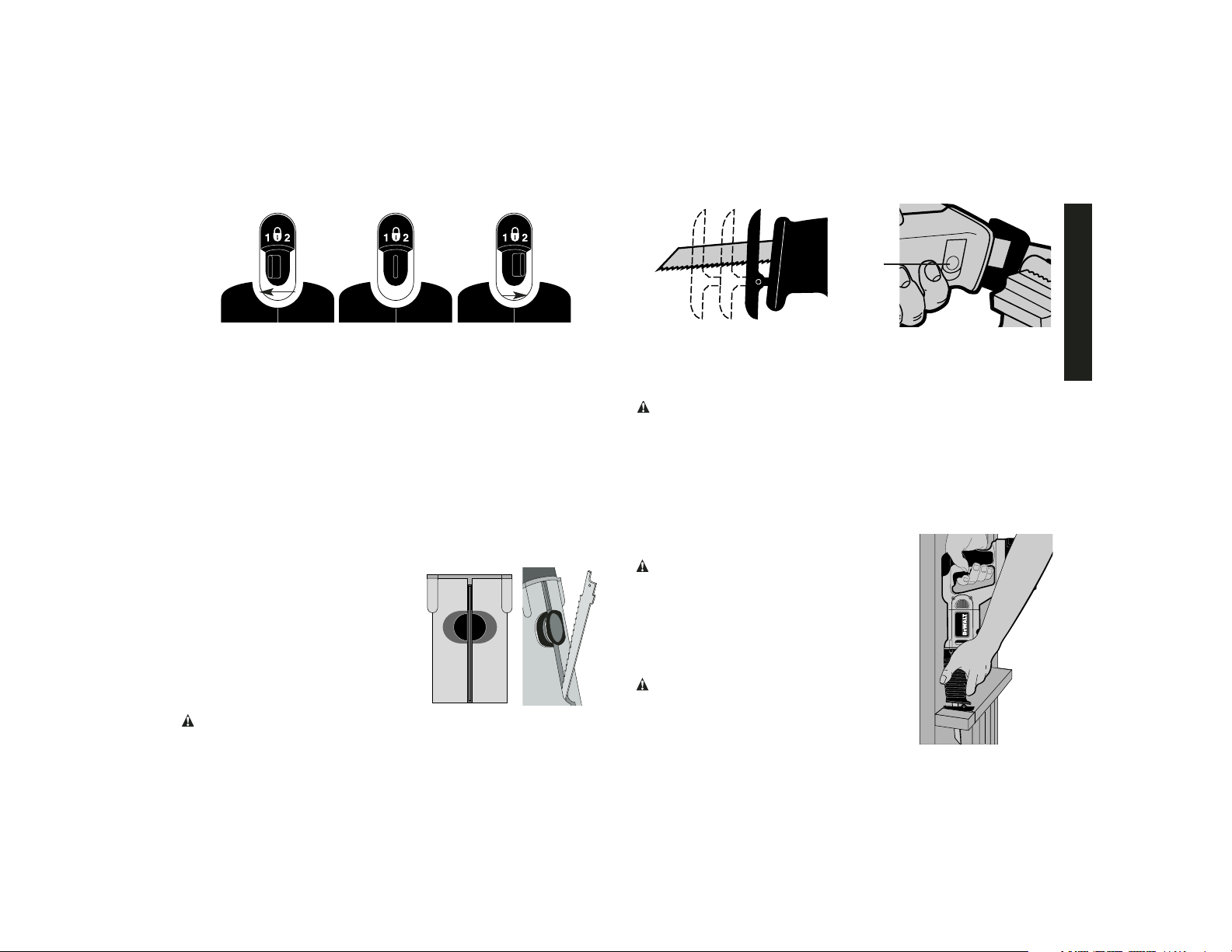

Dual Range Switch (Fig. 2)

This dual range saw offers a choice of speeds for greatly improved

cutting rates in various metals and a lock position. Note that the High

Range (2) setting is more efficient in softer materials such as wood,

while the Low Range (1) setting is best for cutting metals.

LOW RANGE - For cutting metal sheet, pipe, conduit, etc.

HIGH RANGE - For cutting wood, plastic, composition boards and

other similar materials.

Blade Storage (Fig. 3)

A slot has been provided for storage of

a spare blade. Be sure that the teeth

are facing in, as shown, when inserting

the blade. Press the blade all the way

in, so that the jaws will catch and hold

the blade.

Adjustable Shoe

(Fig. 4)

CAUTION: LOCK TRIGGER SWITCH AND REMOVE BATTERY.

The shoe will adjust to limit the depth of cut. Hold the saw with the

underside facing up. Push the button on the hand grip and slide the

shoe out to one of the three settings and release the button.

Blade Clamp Release Lever (Fig. 5)

CA

UTION: LOCK TRIGGER SWITCH AND REMOVE BATTERY.

To install blade into saw:

1. Open blade clamp release lever up.

2. Insert blade shank from the front.

3. Close blade clamp release lever down.

To Remove blade from saw:

1. Open up blade clamp release lever.

2. Remove blade.

OPERATION

CAUTION: Always wear eye protection

while operating this or any other power tool.

Flush-To Cutting (Fig. 6)

The compact design of the saw motor housing and spindle housing permits extremely

close cutting to floors, corners and other difficult areas.

CAUTION: When sawing into walls, floors

or wherever “live” electrical wires may be

encountered, DO NOT TOUCH ANY FRONT

METAL PARTS OF THE TOOL! Hold the tool

7

English

FIG. 3

FIG. 2

A

B

C

FIG. 4

A

FIG. 5

FIG. 6

Page 10

8

only by the plastic or rubber handle and housing to prevent electric

shock if you saw into a “live” wire.

Metal Cutting (Fig. 7)

This unit has different metal cutting capacities depending upon type of

blade used and the metal to be cut. Use a finer blade for ferrous metals and a coarse blade for non-ferrous materials. In thin gauge sheet

metals it is best to clamp wood to both sides of sheet. This will insure

a clean cut without excess vibration or tearing of metal. Always

remember not to force cutting blade as this reduces blade life and

causes costly blade breakage. To prolong blade life, use other areas

of the blade by adjusting the shoe position.

(See Adjustable Shoe,)

NOTE: It is generally recommended that when cutting metals you

should spread a thin film of oil or other coolant along the line ahead of

the saw cut for easier operation and longer blade life.

Wood Cutting (Fig.8)

Before cutting any type of wood, be sure it is firmly anchored or

clamped to prevent slipping. Place blade lightly against work to be cut,

switch on saw motor and allow it to obtain maximum speed before

applying pressure. Always hold saw firmly with both hands while cutting. Whenever possible, the saw shoe must be held firmly against the

material being cut. This will prevent the saw from jumping or vibrating

and minimize blade breakage.

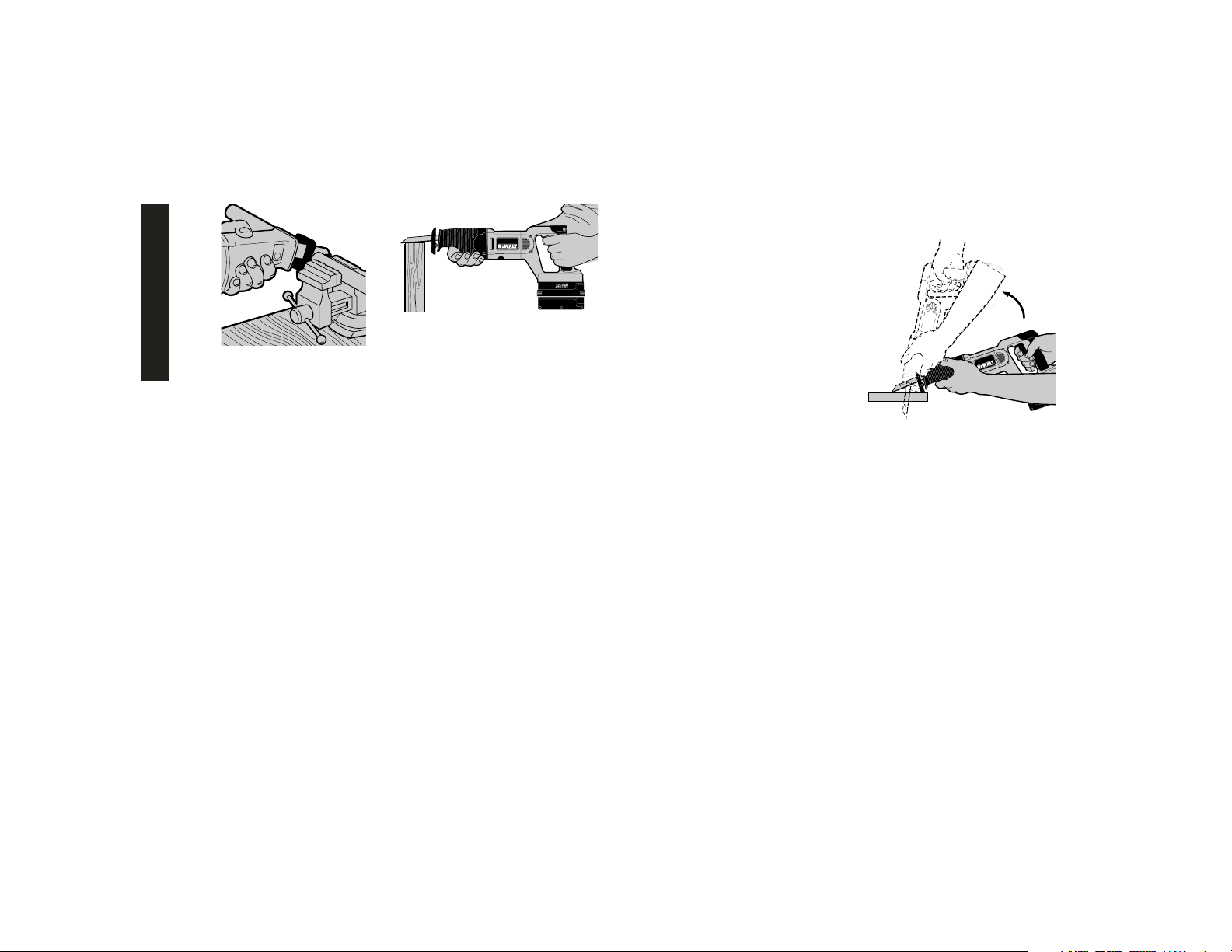

Pocket Cutting (Fig. 9) (Wood Only)

The initial step in pocket cutting is to

measure the surface area to be cut

and mark clearly with a pencil, chalk

or scriber. Insert pocket cutting blade

in blade clamp and tighten blade

clamp securely. Next, tip the saw

backward until the back edge of the

shoe is resting on the work surface.

Now switch motor on, always permitting blade to attain maximum speed.

Grip handle steadily and begin a

slow, deliberate upward swing with

the handle of the saw. Blade will

begin to feed into material. Always be sure blade is completely through

material before continuing with pocket cut.

NOTE: In areas where blade visibilty is limited, use the edge of the

saw shoe as a guide. Lines for any given cut should be extended

beyond edge of cut to be made.

MAINTENANCE

Lubrication

DEWALT tools are properly lubricated at the factory and are ready for

use. Tools should be relubricated regularly every sixty days to six

months, depending on usage. (Tools used constantly on production or

heavy-duty jobs and tools exposed to heat may require more frequent

lubrication.) This lubrication should only be attempted by trained power

tool repair persons, such as those at D

EWALT service centers or by

other qualified service personnel.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local retailer or service center.

English

FIG. 9

FIG. 7

FIG. 8

Page 11

CAUTION: The use of any non-recommended accessory may be

hazardous. A complete listing of service centers is included with

your tool.

If you need assistance in locating any accessory, please contact:

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286 or call 1-800-4 D

EWalt (433-9258).

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

personnel, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258).

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by nor-

mal use, for free, any time during the first year after purchase.

2 YEARS FREE SERVICE ON

XRP

™ BATTERY PACKS

DC9096, DC9091 and DC9071

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT Power Tool, Laser, or Nailer for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund

– no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT for a free

replacement.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

9

English

Page 12

10

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO :

1 800 4-DEWALT (1-800-433-9258)

Regles de sécurité générales pour tous

les outils à baterie

AVERTISSEMENT! Vous devez lire et comprendre toutes les

instructions. Le non-respect, même partiel, des instructions ci-

après entraîne un risque de choc électrique, d’incendie et/ou de

blessures graves.

CONSERVEZ CES INSTRUCTIONS.

AIRE DE TRAVAIL

• Veillez à ce que l’aire de travail soit propre et bien éclairée. Le

désordre et le manque de lumière favorisent les accidents.

• N’utilisez pas d’outils électriques dans une atmosphère explo-

sive, par exemple en présence de liquides, de gaz ou de poussières inflammables. Les outils électriques créent des étincelles

qui pourraient enflammer les poussières ou les vapeurs.

• Tenez à distance les curieux, les enfants et les visiteurs pen-

dant que vous travaillez avec un outil électrique. Ils pourraient

vous distraire et vous faire faire une fausse manoeuvre.

SÉCURITÉ ÉLECTRIQUE

• Ne maltraitez pas le cordon. Ne transportez pas l’outil par son

cordon et ne débranchez pas la fiche en tirant sur le cordon.

N’exposez pas le cordon à la chaleur, à des huiles, à des arêtes

vives ou à des pièces en mouvement. Remplacez immédiatement

un cordon endommagé. Un cordon endommagé augmente le

risque de choc électrique.

• Un outil à bloc-batterrie amovible ou à batterie intégrée ne doit

être rechargé qu’avec le chargeur prévu pour la batterie. Un

chargeur qui convient à tel type de batterie peut présenteer un

risque d’incendie avec tel autre type de batterie.

• N’utilisez un outil qu’avec un bloc-batterie conçu spécifique-

ment pour lui. L’emploi d’un autre bloc-batterie peut créerr un

risque d’incendie.

Français

SÉCURITÉ DES PERSONNES

• Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. N’utilisez pas un outil électrique si vous

êtes fatigué ou sous l’influence de drogues, d’alcool ou de

médicaments. Un instant d’inattention suffit pour entraîner des

blessures graves.

• Méfiez-vous d’un démarrage accidental. Avant d’insérer un

bloc-batterie, assurez-vous quee l’interrupteur de l’outil est sur

ARRÊT. Le fait de transporter un outil avec le doigt sur la détente

ou d’insérer un bloc-batterie alors que l’interrrupteur set en position

MARCHE peut mener tout droit à un accident.

• Enlevez les clés de réglage ou de serrage avant de démarrer

l’outil. Une clé laissée dans un pièce tournante de l’outil peut

provoquer des blessures.

• Ne vous penchez pas trop en avant. Maintenez un bon appui et

restez en équilibre en tout temps. Un bonne stabilité vous permet

de mieux réagir à une situation inattendue.

• Utilisez des accessoires de sécurité. Portez toujours des

lunettes ou une visière. Selon les conditions, portez aussi un

masque antipoussière, des bottes de sécurité antidérapantes, un

casque protecteur et/ou un appareil antibruit.

• Porter des vêtements appropriés; ne pas porter de vêtements

amples, de gants ni de bijoux, et couvrir ou attacher les cheveux

longs, car ceux-ci peuvent rester coincés dans les pièces mobiles.

Se tenir éloigné des évents puisque ces derniers pourraient camoufler des pièces mobiles.

UTILISATION ET ENTRETIEN DES OUTILS

• Immobilisez le matériau sur une surface stable au moyen de

brides ou de toute autre façon adéquate. Le fait de tenir la pièce

avec la main ou contre votre corps offre un stabilité insuffisante et

peut amener un dérapage de l’outil.

• Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche. L’outil

correct fonctionne mieux et de façon plus sécuritaire. Respectez

aussi la vitesse de travail qui lui est propre.

Page 13

• N’utilisez pas un outil si son interrupteur est bloqué. Un outil

que vous ne pouvez pas commander par son interrupteur est dangereux et droit être réparé.

• Retirez le bloc-batterie ou mettez l’interrupteur sur ARRÊT ou

en position verrouillée avant d’effectuer un réglage, de changer d’accessoire ou de ranger l’outil. De telled mesures préven-

tives réduisent le rrisque de démarrrage accidentel d l’outil.

• Rangez les outils hors de la portée des enfantes et d’autres

personnes inexpérimentées. Les outils sont dangereux dans les

mains d’utilisateurs novices.

• Lorsque le bloc-batterie n’est pas en service, tenez-le à l’écart

d’autres métalliques (trombones, pièces de monnaie. clés,

clous, vis, etc.) susceptibles d’établir un contact électrique

entre les deux bornes. La mise en court-circuit des bornes de la

batterie peut produire des éntincelles et constitue un risque de

brûlures ou d’incendie.

• Prenez soin de bien entretenir les outils. Les outils de coupe

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins susceptibles de coincer et plus faciles à diriger.

• Soyez attentif à tout désalignement ou coincement des pièces

en mouvement, à tout bris ou à toute autre condition préjudiciable au bon fonctionnement de l’outil. Si vous constatez qu’un

outil est endommagé, faites-le réparer avant de vous en servir. De

nombreux accidents sont causés par des outils en mauvais état.

• N’utilisez que des accessoires que le fabricant recommande

pour votre modèle d’outil. Certains accessoires peuvent convenir à un outil, mais être dangereux avec autre.

RÉPARATION

• La réparation des outils électriques doit être confiée à un

réparateur qualifié. L’entretien ou la réparation d’un outil élec-

trique par un amateur peut avoir des conséquences graves.

• Pour la réparation d’un outil, n’employez que des pièces de

rechange d’origine. Suivez les directives données à la section

« Réparation » de ce manuel. L’emploi de pièces non autorisées

ou le non-respect des instructions d’entretien peut créer un risque

de choc électrique ou de blessures.

Mesures de sécurité additionnelles

• Ne le saisir que par ses poignées en plastique afin de se protéger des secousses électriques que provoqueraient le contact

de la lame avec un fil sous tension. Lorsqu’on scie dans les murs,

les planchers ou tout autre endroit où peuvent se trouver des fils

sous tension, ne pas toucher à tout composant métallique de l’outil.

AVERTISSEMENT! Porter des lunettes de sécurité ou autre

dispositif de protection oculaire car le martelage peut faire projeter

des particules et entraîner des dommages irréversibles aux yeux.

AVERTISSEMENT : Certains outils, tels que les sableuses élec-

triques, les scies, les meules, les perceuses ou certains autres outils

de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le système reproductif.

Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la

fréquence avec laquelle on effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit bien ventilé et

utiliser l’équipement de sécurité approprié tel un masque anti-poussières spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par

cet outil ou autres outils électriques. Porter des vêtements de

protection et nettoyer les parties exposées du corps avec de

l'eau savonneuse. S'assurer de bien se protéger afin d'éviter d'ab-

sorber par la bouche, les yeux ou la peau des produits chimiques

nocifs.

11

Français

Page 14

12

AVERTISSEMENT : Cet outil peut produire et répandre de la pous-

sière susceptible de causer des dommages sérieux et permanents au

système respiratoire. Toujours utiliser un appareil respiratoire antipoussières approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé du visage et du corps

.

Importantes mesures de sécurité

relatives aux ensembles de piles

L’ensemble de piles n’est pas complètement chargé à sa sortie de

l’usine. Lire d’abord les instructions suivantes, puis se conformer aux

directives relatives au chargement.

MISE EN GARDE : Les piles de l’ensemble renferment du nickel-

cadmium. Le cadmium est un produit toxique. Avant de se débarrasser d’un ensemble de piles au nickel-cadmium, se renseigner sur les

règlements locaux à cet effet ou retourner l’ensemble de piles à un

centre de service D

EWALT autorisé pour qu’il y soit recyclé.

MISE EN GARDE : Quand pas en service, placez l'outil de son

côté sur une surface stable où il ne causera pas un risque de

déclenchement ou en chute. Quelques outils avec de grands

paquets de batterie se tiendront droits sur le paquet de batterie mais

peuvent être facilement frappés plus de.

LIRE TOUTES LES DIRECTIVES

• Ne pas incinérer l’ensemble de piles même s’il est très endommagé

ou complètement usé. La chaleur des flammes peut faire exploser

les piles.

• Il peut se produire une légère fuite du liquide excitateur des piles

dans des conditions d’utilisation et de chargement difficiles ou en

cas de température extrême, fuite qui ne serait pas nécessairement

un signe de panne. Toutefois, si ce liquide s’échappe par une rupture du joint étanche du boîtier et atteint la peau, il faut :

a. laver immédiatement à l’eau et au savon;

b. neutraliser à l’aide d’un acide doux (jus de citron ou vinaigre);

c. si le liquide excitateur atteint les yeux, il faut rincer à l’eau claire

pendant au moins dix minutes et consulter immédiatement un

médecin. (Avis au médecin : le liquide excitateur est une solution

d’hydrogène de potassium à 25-35 p. 100.)

• Ne pas tenter d’ouvrir le boîtier de l’ensemble de piles. Si le boîtier

en plastique se fend ou se brise, ne plus s’en servir et ne pas le

recharger.

• Ne pas transporter des ensembles de piles de rechange dans des

tabliers, des poches ou des coffres à outil avec d’autres objets

métalliques. L’ensemble de piles pourrait alors être court-circuité,

ce qui l’endommagerait et présenterait des risques de brûlures

importantes ou d’incendie.

• Les ensembles de piles doivent être chargés seulement à l’aide

d’un chargeur D

EWALT.

• NOTE : Relire et respecter toutes les notes importantes relatives

au chargement qu’on retrouve dans le présent guide.

• NE PAS toucher le bloc-piles au moyen d’objets conducteurs.

• NE PAS éclabousser, ou immerger dans l’eau ou dans quelque

liquide que ce soit.

• Maintenir propre et ouvrir les évents.

REMARQUE : un capuchon est fourni avec la pile en vue d’être utilisé

chaque fois qu’on retire cette dernière de l’outil ou du chargeur en vue

de la ranger ou de la transporter; enlever le capuchon avant de

remettre la pile dans le chargeur ou dans l’outil.

AVERTISSEMENT : S’assurer, au moment de ranger

ou de transporter un bloc-pile ou une pile, qu’aucun

objet métallique n’entre en contact avec leurs bornes à

découvert de celui-ci. Par exemple, il faut éviter de placer

un bloc-pile ou une pile sans capuchon dans un tablier, une

poche, une boîte à outils ou un tiroir (etc.) contenant des objets tels que

des clous, des vis ou des clés, car tout contact entre les bornes à

découvert et un objet métallique comme une clé, une pièce de

monnaie, un outil à main. etc. pourrait causer un incendie. En effet,

les règlements américains Hazardous Material Regulations (HMR) du

US Department of Transportation interdisent le transport d’un bloc-pile

ou d’une pile dans tout moyen de transport commercial ou aéronef (que

Français

Page 15

13

Français

ce soit dans une valise ou le bagage de cabine) SAUF s’ils sont bien

protégés contre les courts-circuits. On doit donc s’assurer, lorsqu’on

transporte un bloc-pile ou une pile séparément, de bien protéger et isoler

les bornes contre tout matériau qui risque d’entrer en contact avec eux

et de causer un court-circuit.

Le sceau RBRC

mc

Le sceau RBRCmcde l’ensemble de piles au nickelcadmium indique que D

EWALT participe volontairement à

un programme du monde industriel qui a pour objet de

ramasser et de recycler ces ensembles de piles à la fin

de leur vie utile, si on s’en débarrasse aux États-Unis. Le

programme RBRCmc offre une solution de rechange

pratique à la mise au rebut des ensembles de piles au nickel-cadmium

usés, que ce soit à la poubelle ou dans le système municipal car cette

mise au rebut est illégale dans certains endroits.

Grâce à la contribution de D

EWALT au RBRC

mc

, il suffit de laisser un

ensemble de piles usé chez les détaillants qui vendent des piles au

nickel-cadmium de rechange ou dans un centre de service D

EWALT

autorisé. On peut également se renseigner auprès de son centre

local de recyclage pour savoir comment se débarrasser d’un ensemble de piles usé. D

EWALT fait partie de ce programme en raison de

son engagement à protéger l’environnement et à préserver les

ressources naturelles.

RBRCmcest une marque de commerce de l’organisme américain

Rechargeable Battery Recycling Corporation.

Introduction

Le chargeur est conçu pour utiliser une alimentation domestique standard de 120 volts c.a., 60 Hz. Ne pas se servir d’une alimentation en

courant continu (c.c.) ni d’une alimentation sous toute autre tension.

Le temps de chargement dure environ une heure.

Importantes mesures de sécurité

relatives au chargeur

CONSERVER CES INSTRUCTIONS : Le présent guide contient des

conseils importants relatifs à la sécurité et à l’utilisation.

• Bien lire toutes les directives et tous les avertissements qui se trouvent sur (1) le chargeur, (2) l’ensemble de piles et (3) l’outil avant

d’utiliser le chargeur.

DANGER : Les bornes du chargeur sont sous une tension de

120 volts. Ne pas les examiner avec un objet conducteur; cela

présente des risques de secousses électriques.

DANGER : Ne pas placer dans le chargeur un ensemble de piles

craqué ou endommagé; cela présente des risques de secousses électriques.

• NE JAMAIS tenter de charger l’ensemble de piles à l’aide d’un

chargeur autre que ceux décrits dans le présent guide. Le

chargeur et l’ensemble de piles ont été conçus pour fonctionner

ensemble.

• Protéger le chargeur de la pluie ou de la neige.

• L’utilisation du chargeur pour tout ensemble de piles autre

que les ensembles rechargeables D

EWALT comporte des

risques d’incendie et de secousses électriques.

• Débrancher l’appareil en tirant sur la fiche plutôt que sur le

cordon pour minimiser les risques de dommages au cordon et à

sa fiche.

• Veiller à ce que le cordon soit rangé de sorte qu’on ne marche

pas dessus, qu’il ne présente pas de risques de blessures, et qu’il

ne soit pas autrement sujet aux dommages et aux contraintes.

• Ne jamais utiliser de cordon de rallonge sauf nécessité absolue.

L’utilisation d’un cordon de rallonge non conforme présente des

risques d’incendies et de secousses électriques.

• Les cordons de rallonge doivent être faits de conducteurs de

calibre approprié (AWG ou jauge américaine des fils) par

mesure de sécurité. Le numéro de calibre du fil est inversement

proportionnel à la capacité du cordon. Ainsi, un cordon de calibre

16 a une capacité supérieure à celle d’un cordon de calibre 18.

Lorsqu’il est nècessaire d’utiliser plus d’un cordon de rallonge,

veiller à ce que chaque cordon ait au moins le calibre minimal.

Page 16

14

Français

CALIBRE MINIMAL RECOMMANDÉ (AWG)

POUR LES CORDONS DE RALLONGE

Longueur totale de cordon de rallonge (en mètres)

7,6 15 30 50

Calibre (AWG) du cordon

18 18 16 14

• Ne rien déposer sur le chargeur et ne pas déposer ce dernier

sur une surface qui pourrait en bloquer les orifices car cela

risque de provoquer la surchauffe de l’appareil. La ventilation

du chargeur se fait par les fentes sur le dessus et le dessous de

l’appareil. Éloigner le chargeur des sources de chaleur.

• Ne jamais se servir du chargeur lorsque le cordon ou la fiche

sont endommagés. Les remplacer immédiatement.

• Ne jamais se servir d’un chargeur qui a encaissé un coup

brusque, qui est tombé ou qui est endommagé. Le faire vérifier

à un centre de service autorisé.

• Ne jamais démonter le chargeur. N’en confier la réparation ou

l’entretien qu’à un centre de service autorisé. Le remontage

non conforme du produit comporte des risques d’incendies ou de

secousses électriques.

• Débrancher le chargeur de la prise de courant avant de le net-

toyer pour minimiser les risques de secousses électriques. Le

risque n’est pas éliminé en enlevant l’ensemble de piles du

chargeur.

• NE JAMAIS raccorder deux chargeurs l’un à l’autre.

• NE PAS ranger le produit dans un endroit où la température

peut atteindre ou dépasser 40 °C (105 °F) (comme dans une

remise métallique en été).

• Le chargeur est conçu pour fonctionner sur une alimentation

domestique standard (120 volts). Ne pas essayer de s’en

servir sous toute autre tension. Ceci ne s'applique pas au

chargeur de vehicular.

Chargement

1. Brancher le chargeur dans une prise de courant appropriée.

2. Insérer l’ensemble de piles dans le chargeur. S’assurer que

l’ensemble de piles est bien installé dans le chargeur. Le témoin

rouge (de chargement) clignote continuellement pour indiquer le

processus de chargement.

3. Lorsque l’ensemble de piles est complètement chargé, le témoin

rouge reste ALLUMÉ. L’ensemble de piles est alors chargé et on

peut s’en servir ou le laisser dans le chargeur.

AVERTISSEMENT : Éviter de laisser tomber du liquide dans le

chargeur. Il pourrait en résulter une décharge électrique. Pour aider

au refroidissement de l’ensemble de piles après son utilisation,

éviter de placer le chargeur ou les piles dans un milieu réchauffé

comme une remise en métal ou une remorque isolée.

MISE EN GARDE : Ne jamais tenter d’ouvrir l’ensemble de piles

pour quelque raison que ce soit. Si le corps en plastique de l’ensemble

de piles est brisé ou fissuré, le retourner au centre après-vente pour

recyclage.

Ensemble de piles

L’outil nécessite un ensemble de piles DeWALT de 24 volts. Lorsqu’on

commande un ensemble de piles de rechange, bien indiquer le

numéro de modèle et la tension

Les ensembles de piles XR PACK

mc

à durée prolongée durent 25 p.

100 plus longtemps que les ensembles de piles standard.

L'EXÉCUTION de BATTERIE

L'EXÉCUTION de BATTERIE que quelques chargeurs ont un dispositif de mise au point optimalise l'exécution de paquet de batterie.

Votre chargeur peut fournir automatique Accordent-Up™ le mode ou

manuel (c.-à-d. bouton de poussée) Accordez-Up™ le mode. Pour

l'information sur ce dispositif, voir s'il vous plaît la section appropriée

ci-dessous. Puisque les batteries détruisent lentement leur charge

quand elles ne sont pas sur le chargeur, le meilleur endroit pour

garder votre paquet de batterie est sur le chargeur à tous les temps.

L'UTILISATION AUTOMATIQUE ACCORDENT-UP

mc

L'utilisation automatique Accordent-Up™ le mode que les automatiques Accordent-Vers le haut le mode égalisent ou équilibrent les dif-

Page 17

15

Français

férentes cellules dans le paquet de batterie lui permettant de fonctionner à la capacité maximale. Des paquets de batterie devraient être

accordés vers le haut après que chaque 10ème cycle de

charge/décharge ou toutes les fois que le paquet ne fournit plus la

même quantité de travail. Pour utiliser le mode automatique de mise

au point, placez simplement le paquet de batterie dans le chargeur et

laissez-le pendant au moins huit heures. Le chargeur fera un cycle par

les modes suivants.

1. La lumière rouge clignotera sans interruption indiquant que le

cycle d'une heure de charge a commencé.

2. Quand le cycle d'une heure de charge est complet, la lumière

restera en fonction sans interruption et ne clignotera plus. Ceci

indique que le paquet est entièrement chargé et peut être utilisé à

ce moment.

3. Toutes les fois que le paquet est laissé dans le chargeur après que

la charge d'une heure initiale, le chargeur commence l'automatique

Accordez-Vers le haut le mode. Ce mode continue jusqu'à 8

heures ou jusqu'aux différentes cellules dans le paquet de batterie

sont égalisés. Le paquet de batterie est opérationnel et peut être

retiré à tout moment pendant Accordent-Vers le haut le mode.

4. Une fois les automatiques Accordent-Vers le haut le mode sont

complets la transition de volonté de chargeur à une charge d'entretien; aucun voyant de signalisation ne montre l'accomplissement de l'Autom.

MODE RECHARGEMENT (TUNE-UP

mc

)

Le mode rechargement (Tune-Up

mc

) sert à égaliser ou à équilibrer

chaque cellule du bloc-piles lors de son cycle de capacité limite; le

cycle total dure 8 heures. Le bloc-piles doit être rechargé chaque

semaine, après 10 cycles de charge / de décharge ou lorsque la

capacité du bloc-piles commence à diminuer.

1. Pour recharger le bloc-piles, placer les piles dans le chargeur de

la manière habituelle. Le voyant rouge clignotera continuellement,

indiquant que le cycle de charge est amorçé.

2. On peut enfoncer le bouton Tune-Up

mc

à n’importe quel moment

une fois la charge amorçée. Le voyant rouge s’éteindra momen-

tanément, clignotera trois fois brièvement puis restera allumé,

indiquant que le chargeur est en mode rechargement.

3. Une fois le cycle de rechargement terminé, le voyant restera

allumé, indiquant que le bloc-piles est complètement rechargé; on

peut alors le réutiliser ou le laisser dans le chargeur.

4. Si on sélectionne le mode de rechargement mais qu’on change

d’idée par la suite, retirer les piles du chargeur. Attendre 5 secondes, puis réinsérer la pile afin d’amorcer le cycle de charge normal.

Indicateurs de chargement

TEMPORISATION POUR ENSEMBLE DE PILES CHAUD

OU FROID

Lorsque le chargeur détecte un ensemble de piles trop chaud ou trop

froid, il passe automatiquement en mode de temporisation. Le chargement de l’ensemble de piles reprend seulement lorsque ce dernier est

revenu à une température normale. Alors, le chargeur revient automatiquement en mode de chargement. Cette fonction optimise la durée de

l’ensemble de piles. En mode de temporisation, le témoin rouge émet

en alternance un clignotement long et un clignotement court.

REMPLACEMENT DE L’ENSEMBLE DE PILES

Les chargeurs sont conçus pour déceler certains problèmes d’ensembles de piles. Le cas échéant, le témoin rouge clignote vite. Il faut alors

remettre l’ensemble de piles dans le chargeur. Lorsque le problème

persiste, essayer un autre ensemble de piles afin de déterminer si le

chargeur est défectueux. Si le deuxième ensemble est chargé correctement, cela signifie que le premier ensemble est défectueux et qu’il

faut le retourner à un centre de service pour qu’il y soit recyclé. Par

contre, si le deuxième ensemble éprouve les mêmes difficultés que le

premier, faire vérifier le chargeur à un centre de service autorisé.

PROBLEME D’ALIMENTATION

Lorsque les chargeurs sont branchés sur une source de courant portative, comme une génératrice ou une source qui convertit le courant

continu en courant alternatif, les chargeurs peuvent s’arrêter momentanément. Le témoin rouge clignote alors deux fois, puis il s’éteint. Cela

indique que la source ne fournit pas le courant nécessaire.

Page 18

16

Français

ENSEMBLE DE PILES DANS LE CHARGEUR

On peut laisser l’ensemble de piles indéfiniment dans le chargeur

lorsque le témoin est allumé. De la sorte, l’ensemble de piles est toujours chargé et prêt à être utilisé.

NOTE : Un ensemble de piles perd lentement de sa charge lorsqu’il

n’est pas branché dans le chargeur. Il peut donc être nécessaire de

recharger un ensemble de piles qui n’est pas resté en mode d’entretien de la charge avant de s’en servir. Un ensemble de piles qui se

trouve dans un chargeur non branché dans une prise de courant alternatif appropriée peut également perdre sa charge.

Conseils importants relatifs à la charge

1. Pour optimiser la durée de vie et le rendement de l’ensemble de

piles, il est préférable de le charger à des températures variant

entre 18 et 24 ºC (65 et 75 ºF). NE PAS charger l’ensemble de

piles lorsque la température ambiante est inférieure à 4,5 ºC (40

ºF) ou supérieure à 40,5 ºC (105 ºF). Cette mesure est importante

et aide à prévenir les risques de graves dommages à l’ensemble

de piles.

2. Pendant la charge, l’ensemble de piles et le chargeur peuvent

devenir chauds au toucher. Il s’agit d’une situation normale qui ne

pose aucun problème.

3. Si l’ensemble de piles ne se charge pas bien, 1) vérifier l’alimentation de la prise en y branchant une lampe ou un autre appareil,

2) vérifier si la prise est commandée par un interrupteur pour

l’éclairage qui met la prise hors circuit lorsqu’on éteint les

lumières, 3) déplacer l’ensemble de piles et le chargeur dans une

pièce où la température ambiante se situe entre 18 et 24 ºC (65

et 75 ºF), 4) si le problème persiste, il faut confier l’outil, l’ensemble de piles et le chargeur au centre après-vente local.

4. Il faut recharger l’ensemble de piles lorsqu’il ne fournit plus le

courant nécessaire pour effectuer les tâches aussi facilement

qu’auparavant. NE PLUS S’EN SERVIR dans ces conditions.

Suivre les directives relatives à la charge. On peut également

charger n’importe quand un ensemble de piles partiellement

déchargé.

5. Dans certaines conditions, lorsque le chargeur est branché, des

corps étrangers peuvent court-circuiter les contacts de charge

exposés. Il faut donc garder à distance les corps étrangers conducteurs comme, entre autre, la laine d’acier, le papier d’aluminium

ou toute autre accumulation de particules métalliques des cavités

du chargeur. Toujours débrancher le chargeur avant de le nettoyer.

6. Ne pas congeler ou immerger le chargeur dans de l’eau ou dans

un autre liquide.

AVERTISSEMENT : Éviter de laisser tomber du liquide dans le

chargeur. Il pourrait en résulter une décharge électrique. Pour aider au

refroidissement de l’ensemble de piles après son utilisation, éviter de

placer le chargeur ou les piles dans un milieu réchauffé comme une

remise en métal ou une remorque isolée.

MISE EN GARDE : Ne jamais tenter d’ouvrir l’ensemble de piles

pour quelque raison que ce soit. Si le corps en plastique de l’ensemble de piles est brisé ou fissuré, le retourner au centre après-vente

pour recyclage.

Important

L’utilisateur ne peut réparer ni le chargeur ni les pièces qu’il renferme.

Il faut donc en confier la réparation à un centre de service autorisé afin

d’éviter d’endommager les composants internes du chargeur qui sont

sensibles à la statique.

BIEN LIRE TOUTES LES DIRECTIVES DU PRÉSENT GUIDE RELATIVES AU CHARGEUR AVANT DE CHARGER L’ENSEMBLE DE

PILES.

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’à un centre de sousses

électriques. Lorsqu’il faut utiliser une rallonge, s’assurer qu’elle est

conforme aux consignes suivantes.

Éventez le refroidissement

Ce chargeur est muni d’un ventilateur interne qui refroidit rapidement

les bloc-piles DW0242 de D

EWALT. Le ventilateur fonctionne automa-

Page 19

tiquement durant le chargement de la pile, au besoin, et se met en

marche périodiquement lorsqu’il n’y a aucune pile dans le chargeur

afin d’éliminer la poussière accumulée dans les évents.

AVERTISSEMENT : Le ventilateur se met aussi en marche péri-

odiquement lorsque le chargeur ne contient aucune pile afin d’éliminer la poussière qui s’est accumulée dans les évents.

Retrait et installation de l’ensemble

de piles

NOTE : S’ASSUREER QUE L’ENSEMBLE DE

PILES EST COMPLÈTEMENT CHARGÉ.

Pour installer l’ensemble de piles dans la

poignée de l’outil, aligner le socle de l’outil sur

l’encoche à l’intérieur de la poignée de l’outil et

faire glisser l’ensemble de piles fermement

dans la poignée jusqu’à ce qu’un déclic se

fasse entendre (fig. 1).

Pour retirer l’ensemble de piles de l’outil, glisser le bouton de relâchement (A) éloigné du tas

de pile (B) et la pile peut être enlevée de la

poignée d'outil. L'insérer dans le chargeur

comme décrit dans la section de chargeur de

ce manuel.

Consignes de sécurité additionnelles

Converteur courant alternatif DW0247

• Les outils à double isolation sont munis d’une fiche polarisée

(c’est-à-dire que l’une des lames est plus large que l’autre),

laquelle ne peut être raccordée qu’à une prise

polarisée et ce, dans un seul sens; on doit

l’inverser si on est incapable de l’enfoncer

complètement. Si la fiche ne s’adapte toujours

pas, on doit demander à un électricien qualifié

d’installer la prise appropriée. On ne doit jamais

modifier la fiche. La double isolation élimine le besoin d’installer un

cordon d’alimentation trifilaire et un système d’alimentation électrique pourvus d’une mise à la terre.

• Éviter tout contact entre le corps et les éléments mis à la terre,

comme les tuyaux, les radiateurs, les cuisinières et les

réfrigérateurs afin de réduire les risques de choc électrique.

• Ne pas utiliser l’outil électrique dans des endroits mouillés, ni

l’exposer à la pluie; l’infiltration d’eau à l’intérieur de l’outil augmente les risques de choc électrique.

• Ne pas utiliser le cordon de manière abusive; on ne doit pas

transporter l’outil en le tenant par le cordon, ou utiliser ce dernier

pour le débrancher. On doit tenir le cordon à l’écart des sources de

chaleur, de l’huile, des arêtes vives ou des pièces mobiles.

Remplacer immédiatement les cordons endommagés, car ces

derniers augmentent les risques de choc électrique.

• Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit

utiliser que des rallonges conçues pour cet usage, comme celles

de type « W-A » ou « W », afin de réduire les risques de choc

électrique.

Calibre minimal des cordons de rallonge

Longueur totale du cordon

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Intensité

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• Éviter les démarrages accidentels; s’assurer que l’interrupteur

soit en position arrêt avant de brancher l’outil. Ne pas transporter

ce dernier en laissant le doigt sur l’interrupteur ni le brancher

lorsque l’interrupteur est en position marche, car cela pourrait

causer un accident.

• Débrancher le cordon de la prise murale avant d’effectuer un

réglage, de changer les accessoires ou de ranger l’outil; ces

mesures de sécurité préventives réduisent les risques de démarrage accidentel.

• L’étiquette de l’outil peut comporter les symboles suivants.

17

Français

FIG. 1

A

B

Page 20

18

V ............volts A..............ampères

Hz ..........hertz W ............watts

min ........minutes ..........courant alternatif

......courant continu

n

o ............sous vide

..........Construction ............borne de mise à la

..............de classe II ................minute

..........symbole .../min ......tours à la minute

..............d´avertissement

Moteur

L’outil DEWALT fonctionne avec un moteur construit par DEWALT.

S’assurer que l’alimentation concorde avec les indications sur la

plaque signalétique.

Une baisse de tension de plus de 10 % provoquera une perte de puissance et une surchauffe. Tous les outils D

EWALT sont vérifiés en

usine; si cet outil ne fonctionne pas, vérifier l’alimentation.

Commutateur à deux gammes de vitesse

(Fig. 2)

La scie à deux gammes de vitesses offre une variété de vitesses augmentant grandement la coupe dans différents métaux. La gamme de

vitesses élevées convient mieux dans les matériaux tendres comme

le bois, tandis que la gamme de basses vitesses est idéale pour

couper des métaux.

GAMME DE BASSES VITESSES - Déplacer le commutateur à glissière vers le bas de sorte que le chiffre un s'aligne sur les flèches.

Pour couper de la tôle, des tuyaux et des conduits, entre autres.

GAMME DE VITESSES ÉLEVÉES - Déplacer le commutateur à glis-

sière vers le haut de sorte que le chiffre deux s'aligne sur les flèches.

Pour couper du bois des panneaux de composite et d'autres matériaux semblables.

L'Emmagasinage de lame (la fig. 3).

Une entaille a été pourvu à l'emmagasinage d'un épargne la lame.

Etre sûr que les dents font face à dans, comme indiqué, en insérant

la lame. Appuyer la lame complètement à l'intérieur, pour que les

mâchoires attraperont et tiendront la lame.

Patin réglable (Fig. 4)

MISE EN GARDE : METTRE LA SCIE HORS TENSION ET LA

DÉBRANCHER.

Le patin se règle afin de limiter la profondeur de coupe. Saisir la scie

en la renversant. Pousser le bouton de la prise et faire glisser le patin dans l'une des trois positions,

puis relâcher le bouton.

Levier de dégagement

du serre-lame (Fig. 5)

MISE EN GARDE : METTRE LA SCIE

HORS TENSION ET LA DÉBRANCHER.

Faire ce qui suit pour installer une

lame:

Français

FIG. 3

FIG. 4

FIG. 2

A

B

C

FIG. 5

A

Page 21

1. Soulever le levier de dégagement du serre-lame.

2. Insérer l'arbre de la lame à l'avant de l'outil.

3. Abaisser le levier de dégagement du serre-lame.

Faire ce qui suit pour retirer une lame:

1. Soulever le levier de dégagement du serre-lame.

2. Retirer la lame.

OPÉRATION

MISE EN GARDE : Toujours porter des lunettes de sécurité.

Coupe à ras (Fig. 6)

La conception compacte du carter du moteur et de

celui de l'arbre de la scie alternative permet de

couper au ras des planchers, des coins et d'autres

endroits d'accès difficile.

MISE EN GARDE : Lorsqu'on coupe dans les

murs, les planchers ou tout autre endroit où peuvent

se trouver des fils sous tension, NE PAS TOUCHER

À TOUT COMPOSANT MÉTALLIQUE DE L'OUTIL.

Ne le saisir que par la poignée et le boîtier en plastique ou en caoutchouc afin de se protéger des secousses électriques en cas de contact avec un fil sous

tension.

Coupe du métal (Fig. 7)

Cette scie alternative permet la coupe de

différents types de métaux selon la lame

utilisée et le métal à couper. Utiliser une

lame à dents fines pour les métaux ferreux et une lame à grosses dents pour

les métaux non ferreux. Lorsqu’on coupe

de la tôle mince, il est préférable d’y fixer

un morceau de bois de chaque côté afin

d’assurer une coupe précise sans vibrations excessives et éviter de déchirer la

tôle. Éviter de forcer la lame afin de prolonger sa durée de vie et de ne

pas briser ce coûteux accessoire.

REMARQUE : appliquer une mince couche d’huile ou d’autre liquide

de refroidissement le long de la ligne de coupe devant la scie pour

faciliter le travail et prolonger la durée de vie de la lame; en présence

d’aluminium, on recommande d’utiliser du kérosène.

Coupe du bois

(Fig. 8)

Avant de procéder, s’assurer

que l’ouvrage soit fermement

ancré ou fixé afin de l’empêcher

de glisser. Déposer doucement

la lame et le protège-lame sur le

matériau à couper. Mettre le

moteur en marche et le laisser atteindre sa vitesse maximale avant

d’exercer de la pression sur la scie. Toujours saisir fermement la scie

avec les deux mains durant la coupe et, dans la mesure du possible,

tenir fermement le protège-lame contre l’ouvrage afin d’empêcher la

scie de sauter ou de vibrer et d’éviter de la briser.

Coupe effectuee a partir de l’Iinterieur

du materiau - bois seulement (Fig. 9)

• Mesurer la surface de coupe et marquer celle-ci clairement au

moyen d’un crayon à mine, d’une craie ou d’une pointe à tracer.

• Insérer la lame prévue pour cette coupe dans la bride de serrage et serrer fermement cette dernière.

• Pencher la scie vers l’arrière jusqu’à ce

que le dos du protège-lame repose sur la

surface de travail.

• Mettre l’outil en marche et laisser la lame

atteindre sa vitesse maximale.

• Saisir fermement la poignée et remonter

lentement mais sûrement la scie jusqu’à ce

que la lame coupe le matériau. Avant de

19

Français

FIG. 7

FIG. 8

FIG. 6

FIG. 9

Page 22

20

faire avancer la scie le long de la ligne de coupe, s’assurer que la

lame ait complètement pénétré le matériau.

REMARQUE : lorsqu’il est difficile de voir la lame, se guider au moyen

du bord du protège-lame.

ENTRETIEN

Lubrification

Les outils DEWALT sont lubrifiés à l’usine et prêts à être utilisés. Il faut

lubrifier à nouveau les outils tous les deux à six mois selon l’utilisation.

(Les outils utilisés constamment dans les travaux continus ou à service

intense et ceux exposés à la chaleur nécessitent une lubrification plus

fréquente.) Seuls les réparateurs d’outils électriques compétents

peuvent effectuer cette lubrification, comme le personnel des centres de

service D

EWALT ou d’autres réparateurs qualifiés.

Accessoires

Des accessoires recommandés pour utilisation avec votre outil sont

disponibles à un coût supplémentaire à votre centre local de service.

MISE EN GARDE : L’utilisation de tout accessoire non recom-

mandé peut représenter un danger.

Si vous avez besoin d’aide pour trouver un accessoire, veuillez contacter la D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

MD 21286 ou appeler 1-800-4-DEWALT (1-800-433-9258).

Réparations

Afin d’assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations, l’entretien et le réglage (y compris l’inspection et le remplacement des balais) devraient être effectués par des centres de service

autorisés ou d’autres organismes de service qualifiés, en utilisant toujours des pièces de rechange identiques.

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un

défaut de matériel ou de fabrication pour une période de trois ans à

compter de la date d’achat. La présente garantie ne couvre pas les

pièces dont la défectuosité a été causée par une usure normale ou

l’usage abusif de l’outil. Pour obtenir de plus amples renseignements

sur les pièces ou les réparations couvertes par la présente garantie,

visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-D

EWALT). Cette garantie ne s’applique pas aux accessoires et ne

vise pas les dommages causés par des réparations effectuées par un

tiers. Cette garantie confère des droits légaux particuliers à l’acheteur,

mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un état

ou d’une province à l’autre.

En plus de la présente garantie, les outils D

EWALT sont couverts par

notre :

CONTRAT D’ENTRETIEN GRATUIT D’UN AN

D

EWALT entretiendra l’outil et remplacera les pièces usées au cours

d’une utilisation normale et ce, gratuitement, pendant une période

d’un an à compter de la date d’achat.

CONTRAT D’ENTRETIEN GRATUIT DE DEUX ANS

SUR LES BLOC-PILES

XRP

MC

DC9096, DC9091 et DC9071, et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque raison que

ce soit, du rendement de l’outil électrique, du laser ou de la cloueuse

D

EWALT, celui-ci peut le retourner, accompagné d’un reçu, dans les

90 jours à compter de la date d’achat pour obtenir un remboursement

intégral, sans aucun problème.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE : Si vos étiquettes

d'avertissement deviennent illisibles ou sont manquantes, composez

le 1-800-4-D

EWALT pour obtenir une étiquette de remplacement gra-

tuite.