Page 1

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Rules

WARNING! READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to

follow all instructions listed below may result in electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of flam-

mable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while operating a power tool. Distractions

can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adaptor plugs. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. If the tools

should electrically malfunction or break down, grounding provides a low resistance path to

carry electricity away from the user. Applicable only to Class I (grounded) tools.

• Double insulated tools are equipped with a polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to

install a polarized outlet. Do not change the plug in any way. Double insulation elim-

inates the need for the three wire grounded power cord and grounded power supply system.

Applicable only to Class II (double insulated) tools.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A”

or “W.” These cords are rated for outdoor use and reduce the risk of electric shock. When

using an extension cord, be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18 16 16 14

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts. Air vents often cover moving parts and should also be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and bal-

ance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments, chang-

ing accessories, or storing the tool. Such preventative safety measures reduce the risk of

starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Additional Specific Safety Instructions for Cut-Out Tools

• Hold tool by insulated gripping surfaces when performing an operation where the tool

may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

WARNING: After changing bits or making any adjustments, make sure the collet nut is

securely tightened to avoid injury.

WARNING: Do not press spindle lock or collet lock buttons while motor is running. The oper-

ator may lose control and drop the tool. Personal injury or serious tool damage may result.

WARNING: Shut off all live electric circuits to any areas where cut outs will be made, to avoid

fire or serious personal injury.

CAUTION: Wear appropriate personal hearing protection during use. Under some con-

ditions and duration of use, noise from this product may contribute to hearing loss.

CAUTION: Do not touch the bit or collet nut during or immediately after cutting material. The

bit and collet nut may be hot enough to burn bare skin.

• Always wear eye protection. Dust mask or hearing protection must be used for appropriate conditions. Using personal safety devices is recommended. WORK SAFE.

• Always operate the tool with the depth guide in place. The guide keeps the bit from

plunging too deeply through the material. A minimum of penetration should be maintained to

eliminate the danger of cutting into electric wiring.

• Do not use this tool with drill or screwdriver bits. This tool is not intended to be used as

a drill or screwdriver.

• Be sure your cutting bits are sharp and in good condition. Damaged bits can cause the

tool to jump, injuring the operator.

• Be sure that the motor has stopped completely before you lay the cut-out tool down. If

the cutter head is still spinning when the tool is layed down, it could cause injury or damage.

• Be sure that the cutting bit is clear of the workpiece before starting motor. If the bit is

in contact with the workpiece when the motor starts it could make the tool jump, causing

damage or injury.

• If your tool fails to function properly, take it to an authorized service center. There are

no user serviceable parts inside this tool and it should only be opened by trained service

personnel.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con-

struction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may pro-

mote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

• The label on your tool may include the following symbols.

V ......................volts A ......................amperes

Hz ....................hertz W......................watts

min ..................minutes ....................alternating current

..................direct current no....................no load speed

......................Class II Construction ......................earthing terminal

....................safety alert symbol .../min ..............revolutions per minute

To Maintain Safe Tool Control

• Make sure the work surface is free of nails or screws. Cutting into a nail or screw may

cause the tool to jump, damaging the bit.

• Never operate the tool with one hand while holding the workpiece with the other hand.

Always clamp the material and guide the tool with both hands.

• Do not cut material lying on a hard surface. Clearance behind material to be cut must be

allowed for protruding bit.

• Disconnect plug from power supply before making adjustments, changing bits or cleaning

tool.

• Do not start the tool with bit engaged in the material. The bit may grab the material.

Motor

Be sure your power supply agrees with nameplate marking. 120 volts AC means your tool may

be operated only with alternating current and never with direct current.

Switch

To start the motor, slide the switch (A) to “I” position. To stop the motor, slide the switch to “O”

position (Fig. 1).

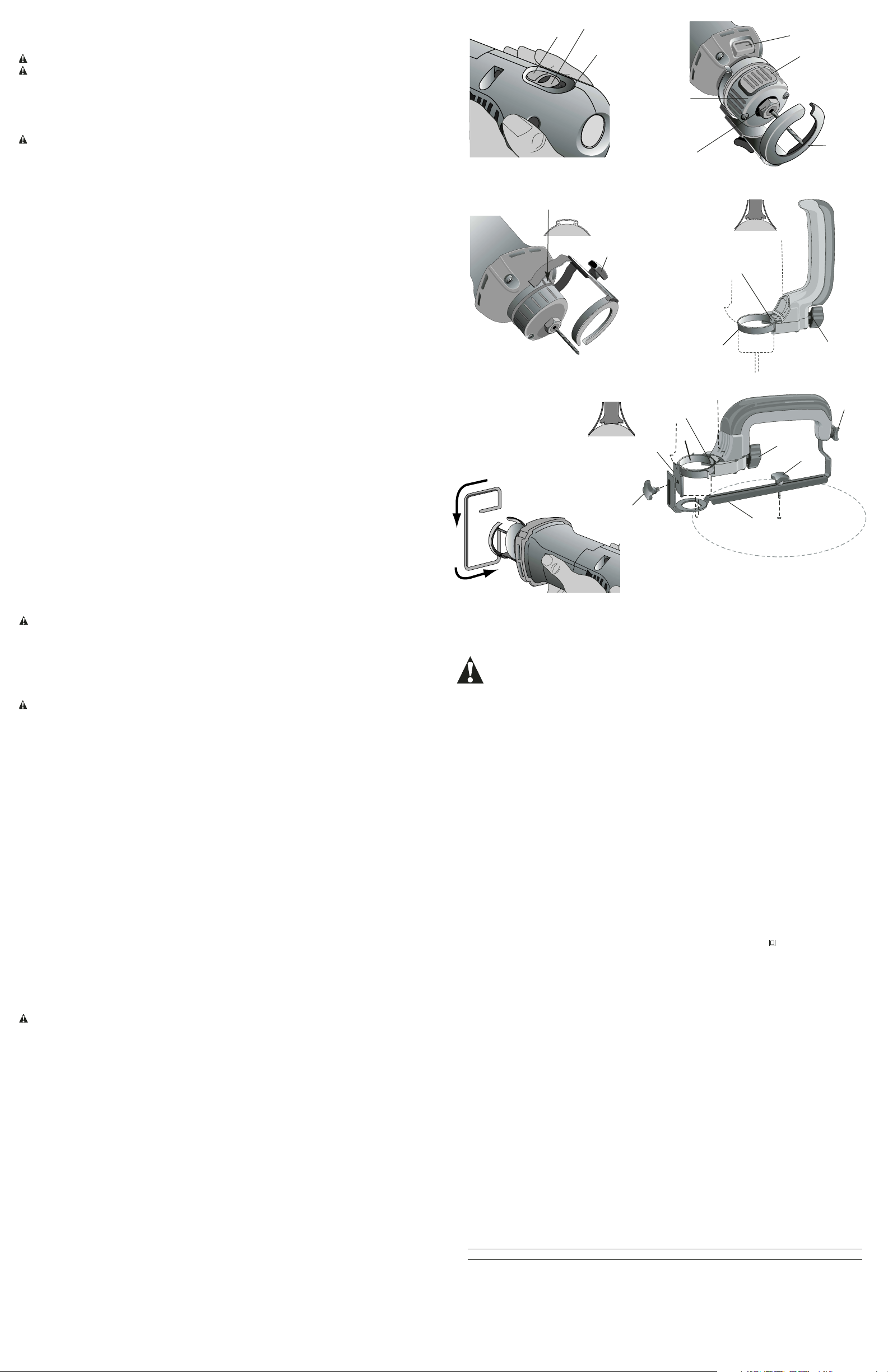

Installing and Removing the Bit (Fig. 2)

This tool has a tool-free bit change system. To change bits, FIRST turn off the tool and disconnect from power supply. Remove the guide.

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

(OCT04-CD-1) Form No. 626760-00 DW660 Copyright © 2000, 2004 D

EWALT

The following are trademarks for one or more D

EWALT power tools: the yellow and black color scheme;

the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the

array of lozenge-shaped humps on the surface of the tool.

DW660

Heavy-Duty Cut-Out Tool

Outil a Decouper à Service Intensif

Recortadora industrial

Questions? See us in the World Wide Web at www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Page 2

FIG. 5

H

L

M

N

FIG. 6

1. To replace bit, depress both spindle lock (C) and collet lock (B) and turn collet grip counterclockwise.

2. Insert bit.

WARNING: The bits are sharp and should be handled with great care.

CAUTION: When replacing bits, do not insert cutting flutes into the collet. This may result in

broken bits.

3. While depressing both spindle and collet locks, turn the collet grip clockwise to firmly tighten

the collet. For some heavy duty applications, it may be necessary to use a wrench to further

tighten the nut (D) while depressing the spindle lock (C).

4. Attach guide.

CAUTION: Never tighten the collet without a bit installed.

This tool comes with both 1/8" and 1/4" collets. To change collets, remove the collet nut and

insert the desired collet.

Depth Guide (Fig. 3)

To attach depth guide to the motor unit,

TURN OFF TOOL AND DISCONNECT FROM POWER

SUPPLY.

Depth guide snaps onto locators as shown. Keep depth guide in place at all times during operation of the tool. For best results, adjust the guide using knob (E) to allow the bit to protrude

about 1/8" past the material to be cut.

Side Handle DW6619 (Fig. 4)

When operating the tool, use the side handle for optimum control. To attach the side handle to

the motor unit,

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

1. Remove depth guide.

2. Loosen knob (F) until the collar of the tool is able to fit into the strap (G) of the side handle.

3. Align the locator on the tool with the locator on the side handle. (Detail) Tighten knob (F).

4. Snap the depth guide over the side handle strap (G) from the opposite side. Keep the depth

guide in place at all times during operation of the tool.

5. For best results, adjust the guide using knob (E) to allow the bit to protrude about 1/8"

through the material to be cut.

6. To remove the side handle, remove the depth guide, loosen the knob (F) until the tool can

come off the locator and slip out of the strap (G).

7. Reattach the depth guide.

Circle Cutter DW6621 (Fig. 5)

To attach the circle cutter to the motor unit,

TURN OFF THE TOOL AND DISCONNECT FROM

POWER SUPPLY.

1. Remove the depth guide.

2. Loosen knob (H) until the collar of the tool is able to fit into the strap (J) of the circle cutter.

3. Align the locator on the tool with the locator on the circle cutter. (Detail) Tighten knob (H).

4. Disassemble the depth guide collar. Snap the upper half (M) onto the strap (J).

5. Loosen knob (L) and extend circle cutter frame to the limit of travel.

6. Insert knob (E) through the frame (N).

7. Set depth of cut for your material and tighten knobs (E) and (L).

8. Measure to the center of the circle you wish to cut and adjust the length of the guide to that

radius.

9. Tighten the knob (O) holding the centerpoint in position.

10. Drill a 5/32" hole in the material to be cut at the center of the radius.

11. Plug in the tool, start the motor and allow the tool to spin up to speed.

12. Position the center point into the hole and plunge the cutter into the material.

13. With firm pressure, hold the center point in place and move the cutter counterclockwise

around to the finish.

CAUTION: At the finish of the circle, the material may drop out. Hold the tool with both hands

to maintain control.

14.To remove the circle cutter, loosen knob (H) until the tool can come off the locator and slip

out of the strap (J).

15.Reassemble the depth guide and reattach.

Operation

CUTTING A HOLE FOR AN ELECTRICAL OUTLET (FIG. 6)

WARNING: Shut off all live electric circuits to any areas where cut outs will be made.

1. Push any wiring deeply into the outlet box to avoid damage from the cutting bit.

2. Before hanging the sheet covering the outlet, mark the approximate location of the center of

the outlet on the wall board. Check the cutting bit depth against the side of the board to be

sure it will cut entirely through the material.

3. Tack the sheet in place with a few fasteners avoiding the stud holding the outlet. This allows

the wall board to flex slightly around the protruding fixture box.

4. Turn the cut-out tool on. Holding the tool firmly with both hands, (Fig. 6) plunge the bit

straight into the center of the outlet.

5. Cut to the right until the edge of the box is touched. Pull out just enough for the bit to clear

the edge of the box. Plunge in again holding the bit gently against the outside of the box.

6. Follow the outside of the box as shown keeping slight pressure against the box. This will

minimize wandering and give you a clean precise cut.

7. Remove the waste and dust from the outlet. Finish fastening the sheet of wall board.

Maintenance

The tool should be cleaned with a blast of air at least once a week, to eject as much dust as

possible. This will increase the life of the brushes and bearings inside the motor. Always use

appropriate safety equipment when using compressed air to clean a tool.

Although the tool’s plastic case is solvent resistant, you should never use solvents or harsh

chemicals to clean it. Wipe the non-metallic parts of the tool with a dry cloth.

Lubrication

All bearings are factory lubricated for the life of the tool.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory for your

tool, contact: D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286.

CAUTION: Do not use double ended bits. The use of any other accessory not recommended

for use with this tool could be hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including

brush inspection and replacement) should be performed by authorized service centers or other

qualified service organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear

or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your D

EWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-D

EWALT for a free replacement.

FIG. 1 FIG. 2

D

C

B

A

“O”

“I”

COLLET GRIP

DOUILLE DE

SERRAGE

ABRAZADERA

DEL COLLAR

GUIDE

GUIDE

GUÍA

FIG. 3

FIG. 4

E

LOCATOR

POSITIONNEUR

LOCALIZADOR

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU DE TOUT

AUTRE OUTIL D

EWALT, COMPOSER LE NUMÉRO SANS FRAIS : 1 800 4-DEWALT

(1 800 433-9258)

Directives de sécurité d’ordre général

AVERTISSEMENT! S’assurer de lire et de bien comprendre toutes les

directives. Le non-respect des directives décrites ci-après pourrait être la

cause de chocs électriques, d’incendies et/ou de blessures graves.

CONSERVER CES DIRECTIVES

AIRE DE TRAVAIL

• L’aire de travail doit être propre et bien éclairée. Les établis encombrés et le manque de

lumière peuvent entraîner des accidents.

• Ne pas faire fonctionner des outils électriques dans des atmosphères explosives,

comme en présence de liquides, de gaz et de poussières inflammables. Les outils électriques produisent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

• Tenir les spectateurs, les enfants et les visiteurs à l’écart lorsqu’on utilise l’outil. Les

distractions peuvent entraîner une perte de maîtrise.

RÈGLES DE SÉCURITÉ RELATIVES À L’ÉLECTRICITÉ

• Les outils mis à la terre doivent être branchés dans une prise correctement installée

et mise à la terre tel que l’indiquent les codes et règlements en vigueur. Ne jamais retirer la broche de mise à la terre ou modifier la prise en aucune façon. Ne pas utiliser de

fiche d’adaptation. Consulter un électricien qualifié s’il y a un doute en ce qui concerne la mise à la terre de la prise. En cas de mauvais fonctionnement ou de bris des out-

ils, la mise à la terre offre un chemin de faible résistance afin d’empêcher l’électrocution de

l’utilisateur. S’applique uniquement aux outils de classe I (mis à la terre).

• Les outils à double isolation sont pourvus d’une fiche polarisée (une lame est plus

large que l’autre). Cette fiche ne peut être branchée dans une prise polarisée que dans

un seul sens. Si la fiche ne peut être branchée dans la prise, inverser la fiche. Si on

n’arrive pas à la brancher, communiquer avec un électricien qualifié afin qu’il installe

une prise polarisée. Ne pas modifier la fiche. La double isolation élimine le besoin du

système de rallonge d’alimentation à trois fils et de bloc d’alimentation avec mise à la terre.

S’applique uniquement aux outils de classe II (à double isolation).

• Éviter tout contact corporel avec des surfaces mises à la terre, comme des tuyaux,

des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc électrique aug-

mente si le corps est mis à la terre.

• Ne pas exposer les outils électriques à la pluie ou à l’eau. L’infiltration d’eau dans un outil

électrique augmente le risque de choc électrique.

• Manipuler le cordon avec soin. Ne jamais s’en servir pour transporter l’outil ou pour

tirer la fiche hors de la prise. Tenir le cordon à l’écart de la chaleur, de l’huile, des arêtes

vives ou des pièces mobiles. Remplacer immédiatement les cordons endommagés, car ils

augmentent le risque de choc électrique.

• Lorsqu’on utilise un outil électrique à l’extérieur, il faut employer une rallongeportant

l’inscription “W-A” ou “W.” Ces rallonges sont conçues pour l’utilisation à l’extérieur et

réduisent le risque de choc électrique. S’il y a lieu d’utiliser une rallonge, s’assurer que celleci est de calibre suffisamment élevé pour acheminer le courant nécessaire au fonctionnement

de l’outil. Une rallonge de calibre trop faible pourrait causer une chute de tension se traduisant

par une perte de courant et une surchauffe. Le tableau qui suit indique le calibre approprié

selon la longueur de la rallonge et l’intensité indiquée sur la plaque signalétique. En cas de

doute, utiliser le calibre supérieur suivant. Plus le numéro de calibre est petit, plus le calibre

de la rallonge est élevé.

Calibre minimal des cordons de rallonge

TensionLongueur totale du cordon en meters

120 V De 0 à 7 De 7 à 15 De 15 à 30 De 30 à 45

240 V De 0 à 7 De 7 à 15 De 15 à 39 De 30 à 45

Intensité (A)

Au Au Calibre moyen de fil

moins plus

0-6 18 16 16 14

SÉCURITÉ PERSONNELLE

• Demeurer alerte, prêter attention à ce que l’on fait et faire preuve de bons sens

lorsqu’on utilise un outil électrique. Ne pas utiliser un outil lorsqu’on ressent de lafatigue ou après avoir consommé des drogues, de l’alcool, ou des médicaments. Un

moment d’inattention durant l’utilisation d’outils électriques peut entraîner de graves blessures.

• Porter des vêtements appropriés. Ne pas porter des vêtements amples ou des bijoux.

Les cheveux longs doivent être retenus. Tenir les cheveux, les vêtements et les gants

F

G

LOCATOR

POSITIONNEUR

LOCALIZADOR

LOCATOR

POSITIONNEUR

LOCALIZADOR

J

E

O

Page 3

à l’écart des pièces mobiles. Les vêtements amples, les bijoux et les cheveux longs peuvent être happés par des pièces mobiles. Il faut également se tenir à l’écart des évents qui

recouvrent souvent les pièces mobiles.

• Éviter le démarrage accidentel. S’assurer que l’interrupteur est en position d’arrêt

avant de brancher l’outil. Le fait de transporter un outil en appuyant sur la gâchette ou de

le brancher lorsque l’interrupteur se trouve en position de marche peut causer des accidents.

• Déposer les clés de réglage ou de serrage avant de mettre l’outil en marche. Une clé

laissée fixée à une pièce rotative de l’outil peut entraîner des blessures.

• Ne pas tendre le bras trop loin. Il faut demeurer en équilibre en tout temps. Un bon

équilibre permet une meilleure maîtrise de l’outil dans les situations inattendues.

• Utiliser du matériel de sécurité. Toujours porter des lunettes de protection. Il faut utilis-

er, au besoin, un masque antipoussières, des chaussures de sécurité antidérapantes, un

casque de sécurité ou des protecteurs d’oreilles.

UTILISATION DES OUTILS ET PRÉCAUTIONS

• Utiliser des pinces ou un autre moyen pratique de fixer et de soutenir la pièce à travailler sur une plateforme stable. Le fait de tenir la pièce avec la main ou de l’appuyer

contre le corps ne permet pas de la stabiliser et cela risque de causer une perte de maîtrise.

• Ne pas forcer l’outil. Utiliser celui qui convient au travail à effectuer. L’outil adéquat

permet de faire le travail de façon plus convenable et sûre lorsqu’il est employé suivant

l’utilisation pour laquelle il a été conçu.

• Ne pas utiliser l’outil si l’interrupteur ne permet pas de le mettre sous ou hors tension.

Tout outil impossible à commander au moyen de l’interrupteur est dangereux et doit être

réparé.

• Débrancher la fiche de la source d’alimentation avant d’effectuer des réglages, de

changer d’accessoire ou de ranger l’outil. De telles mesures préventives réduisent le

risque de le mettre en marche accidentellement.

• Ranger les outils hors de la portée des enfants et des autres personnes non qualifiées.

Les outils sont dangereux entre les mains d’utilisateurs non qualifiés.

• Veiller à entretenir correctement les outils. Les accessoires de coupe doivent être

maintenus bien affûtés et propres. Des outils bien entretenus, et dont les arêtes sont

coupantes, sont moins susceptibles de se coincer et sont plus faciles à manier.

• Vérifier la présence de pièces mobiles mal alignées ou coincées, de pièces brisées ou

de toute autre condition pouvant altérer le fonctionnement de l’outil. Si l’outil est

endommagé, il faut le faire réparer avant de l’utiliser. De nombreux accidents sont

causés par des outils mal entretenus.

• Utiliser seulement des accessoires recommandés par le fabricant du modèle. Des

accessoires convenant à un outil peuvent être dangereux lorsqu’on les installe sur un autre

outil.

RÉPARATION

• Seules des personnes qualifiées peuvent réparer les outils. Une réparation ou un entre-

tien effectué par une personne non qualifiée risque d’entraîner des blessures.

• Il faut utiliser uniquement des pièces de rechange identiques pour réparer un outil.

Suivre les directives figurant dans la section Entretien du présent manuel. L’emploi de

pièces inadéquates ou le non-respect des directives d’entretien peut provoquer un choc électrique ou des blessures.

Régles de sécurité additionelles concernant l’outil à

decouper

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en contact avec des fils cachés, car de tels contacts peuvent mettre les pièces métalliques de

l’outil sous tension, engendrant des risques de choc électrique.

AVERTISSEMENT : après avoir changé une mèche ou avoir fait quelque réglage que ce

soit, s’assurer que l’écrou de la douille de serrage soit bien serré.

AVERTISSEMENT : ne pas appuyer sur les boutons de verrouillage de la broche et de la

douille de serrage lorsque le moteur est en marche; l’utilisateur pourrait perdre la maîtrise de

l’outil et l’échapper, risquant ainsi de subir des blessures ou d’endommager gravement l’outil.

AVERTISSEMENT : couper le courant de tous les circuits électriques situés à proximité de

la zone où on prévoit effectuer des découpes.

MISE EN GARDE : Porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation, le bruit

émanant de ce produit pourrait contribuer à la perte d’audition.

MISE EN GARDE : ne pas toucher à la mèche ni à l’écrou de la douille de serrage pen-

dant l’utilisation de l’outil ni immédiatement après; ces pièces peuvent être suffisamment

chaudes pour causer des brûlures sur la peau.

• Toujours porter des lunettes de protection; on recommande à l’utilisateur de porter les

dispositifs de sécurité appropriés, comme un protecteur auditif ou un masque anti-poussières,

si la situation le requiert afin QU’IL PUISSE TRAVAILLER EN TOUTE SÉCURITÉ.

• On doit toujours s’assurer que le guide de profondeur soit en place avant d’utiliser

l’outil; ce dispositif empêche la mèche de trop s’enfoncer dans l’ouvrage, éliminant les

risques d’entrer en contact avec un fil électrique.

• Ne pas utiliser l’outil avec des mèches pour perceuses ou tournevis; l’outil n’est pas

conçu pour cet usage.

• Toujours s’assurer que les mèches soient bien aiguisées et en bon état; une mèche

endommagée pourrait faire sauter l’outil et causer des blessures.

• Attendre que le moteur s’arrête complètement avant de déposer l’outil à decouper. Si

l’arête tranchante tourne encore lorsqu’on dépose l’outil, on risque de causer des dommages

ou des blessures.

• S’assurer que la mèche n’est pas en contact avec la pièce avant de démarrer le

moteur, afin d’éviter de faire bondir l’outil et de causer des dommages ou des blessures.

• Cet outil ne contient aucune pièce pouvant être réparée par l’utilisateur. Si l’outil ne

fonctionne pas correctement, on doit l’emporter à un centre de service D

E

WALT qualifié afin

qu’il puisse y être réparé.

AVERTISSEMENT : Certains outils, tels que les sableuses électriques, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit

bien ventilé et utiliser l’équipement de sécurité approprié tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres outils

électriques. Porter des vêtements de protection et nettoyer les parties exposées du

corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber par

la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire anti-poussières approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé du visage et du corps.

• L’étiquette apposée sur l’outil peut comprendre les symboles suivants.Voici les symboles et

leurs définitions :

V................volts A ..................ampères

Hz..............hertz W ................watts

min ............minutes ................courant alternatif

..........courant direct

n

o ................régime sans charge

..............construction de classe II …/min..........tours ou va-et-vient par minute

..............borne de mise à la terre ................symbole d’alerte relatifs à la sécurité

Pour maintenir le contrôle de l’outil

• S’assurer que la surface de travail soit exempte de clou ou de vis; si l’outil passe sur

une ferrure de ce genre, cela pourrait le faire sauter et endommager la mèche.

• Ne jamais tenir l’outil d’une main et l’ouvrage de l’autre; l’ouvrage doit être maintenu

au moyen de dispositifs de serrage permettant ainsi de guider l’outil des deux mains.

S’assurer de toujours garder la maîtrise de l’outil.

• Ne jamais couper un ouvrage lorsque ce dernier est appuyé contre une surface

rigide; on doit prévoir derrière l’ouvrage un espace suffisamment grand pour permettre à

la mèche de sortir librement.

• Toujours débrancher la fiche de l’outil avant d’effectuer un réglage, de changer une

mèche ou de nettoyer l’outil.

• NE JAMAIS serrer l’écrou de la douille de serrage sans y avoir d’abord inséré une

mèche afin d’éviter d’endommager la douille.

• Ne jamais faire démarrer l’outil lorsque la mèche est déjà engagée dans un ouvrage;

celle-ci pourrait mordre dans le matériau et provoquer la perte de maîtrise de l’outil.

Moteur

S’assurer que la prise employée corresponde à celle de la plaque signalétique.

La présence d’une étiquette comportant la mention «120 V c.a.» signifie qu’on doit toujours

brancher l’outil dans une prise de courant alternatif et jamais dans une prise de courant continu.

Interrupteur

Pour faire démarrer le moteur, faire glisser l’interrupteur (A) à la position «I» et pour l’arrêter, à

la position «O» (fig.1).

Installation et Retrait des Méches (fig. 2)

L’outil est muni d’un système permettant de changer les mèches sans aucun outil additionnel.

AVANT de procéder, arrêter et débrancher l’outil, puis retirer le guide.

1. Pour installer une mèche, enfoncer le bouton de verrouillage de la broche (C) et celui de la

douille de serrage (B), puis tourner la douille de serrage vers la gauche.

2. Insérer la mèche.

AVERTISSEMENT : les mèches sont coupantes et doivent donc être manipulées avec

soin.

MISE EN GARDE : s’assurer de ne pas insérer les cannelures tranchantes de la mèche

dans la douille de serrage; cela pourrait briser la mèche.

3. Les boutons de verrouillage de la broche et de la douille de serrage étant toujours enfoncés, tourner la douille vers la droite afin de bien la serrer. Pour les gros travaux, il peut

s’avérer nécessaire d’utiliser une clé pour serrer l’écrou (D). Pour ce faire, on doit maintenir

enfoncé le bouton de verrouillage de la broche (C).

4. Fixer le guide

MISE EN GARDE : ne jamais serrer la douille sans y avoir d’abord inséré une mèche. Cet

outil est fourni avec deux douilles de serrage, soit une de 3,2 mm (1/8 po) et une de 6,4 mm

(1/4 po). Pour remplacer la douille de l’outil, retirer d’abord l’écrou qui la retient puis installer

la douille voulue.

Guide de profondeur (fig. 3)

Pour fixer le guide de profondeur au bloc moteur,

ARRÊTER ET DÉBRANCHER L’OUTIL

AVANT DE PROCÉDER.

Le guide s’enclenche sur les positionneurs (voir l’illustration). Le guide doit toujours rester fixé

sur l’outil lorsqu’on utilise ce dernier. Pour obtenir de meilleurs résultats, régler le guide au

moyen du bouton prévu à cet effet (E), de manière à laisser dépasser la mèche d’environ 3 mm

(1/8 po) derrière l’ouvrage.

Poignée latérale, modèle DW6619 (fig. 4)

Lorsqu’on utilise l’outil, le tenir au moyen de la poignée latérale afin de bien le maîtriser. Pour

fixer la poignée au bloc moteur,

ARRÊTER LÕOUTIL ET LE DÉBRANCHER DE LA SOURCE

D’ALIMENTATION ÉLECTRIQUE.

1. Retirer le guide de profondeur.

2. Desserrer le bouton (F) afin de pouvoir insérer le collier de l’outil dans la courroie (G) de la

poignée latérale.

3. Aligner le positionneur de l’outil avec celui de la poignée latérale. (Détail) Serrer le bouton (F).

4. Enclencher le guide de profondeur par-dessus la courroie de la poignée latérale (G), à partir du côté opposé. Maintenir le guide de profondeur en place en tout temps durant le fonctionnement de l’outil.

5. Pour obtenir de meilleurs résultats, régler le guide au moyen du bouton (E) pour sortir la

mèche d’environ 1/8 po du matériau à couper.

6. Pour retirer la poignée latérale, enlever le guide de profondeur, desserrer le bouton (F) afin

de détacher l’outil du positionneur et la glisser hors de la courroie (G).

7. Fixer à nouveau le guide de profondeur.

Coupe-cercle, modèle DW6621 (fig. 5)

Pour fixer le coupe-cercle au bloc moteur,

ARRÊTER L’OUTIL ET LE DÉBRANCHER DE LA

SOURCE D’ALIMENTATION ÉLECTRIQUE.

1. Retirer le guide de profondeur.

2. Desserrer le bouton (H) afin de pouvoir insérer le collier de l’outil dans la courroie (J) du

coupe-cercle.

3. Aligner le positionneur de l’outil avec celui du coupe-cercle. (Détail) Serrer le bouton (H).

4. Démonter le collier du guide de profondeur, puis enclencher la partir supérieure (M) sur la

courroie (J).

5. Desserrer le bouton (L) et sortir le bâti du coupe-cercle jusqu’à sa fin de course.

6. Insérer le bouton (E) à travers le bâti (N).

7. Régler la profondeur de coupe voulue, puis serrer les boutons (E) et (L).

8. Mesurer jusqu’au centre du cercle à découper, puis régler la longueur du guide jusqu’au

rayon obtenu.

9. Serrer le bouton (O) qui retient la pointe de centrage en place.

10. Percer un orifice de 5/32 po dans le matériau à couper, au centre du rayon.

11. Brancher l’outil, démarrer le moteur et attendre qu’il atteigne sa vitesse maximale.

12. Positionner la pointe de centrage dans l’orifice et amorcer la coupe.

13. En exerçant une pression ferme, maintenir la pointe de centrage en place et déplacer le

coupe-cercle vers la gauche, jusqu’à ce que la coupe soit terminée.

MISE EN GARDE : une fois la coupe terminée, le matériau peut se détacher; tenir l’outil des

deux mains afin de bien le maîtriser.

14. Pour retirer le coupe-cercle, desserrer le bouton (H) afin de détacher l’outil du positionneur,

puis le glisser hors de la courroie (J).

15. Assembler et fixer à nouveau le guide de profondeur.

Fonctionnement

DÉCOUPE D’UN TROU POUR UNE PRISE ÉLECTRIQUE (FIG. 6)

AVERTISSEMENT : couper le courant de tous les circuits électriques situés à proximité de

la zone où on prévoit effectuer une découpe.

1. Pousser les fils électriques au fond de la boîte à prises afin d’éviter de les endommager, le

cas échéant.

2. Avant d’installer la plaque de plâtre sur la boîte à prises, indiquer l’emplacement approximatif du centre de la boîte sur la plaque. Vérifier l’épaisseur du matériau afin de s’assurer

que la mèche utilisée soit suffisamment longue pour le traverser complètement.

3. Fixer la plaque au moyen de quelques attaches, en prenant soin d’éviter le goujon retenant

la boîte à prises, afin de permettre à la plaque de plâtre de fléchir légèrement autour de la

boîte en saillie.

4. Mettre l’outil en marche puis, en le tenant fermement des deux mains (fig. 4), enfoncer la

mèche directement au centre de la boîte à prises.

5. Diriger la mèche vers la droite, jusqu’à ce qu’elle atteigne le côté de la boîte; retirer la mèche

suffisamment pour passer par dessus la boîte, puis l’enfoncer de nouveau dans le matériau

en l’accotant légèrement sur l’extérieur de la boîte.

6. Suivre le contour de la boîte, tel qu’illustré, en exerçant une légère pression contre celle-ci

afin d’éviter de faire dévier l’outil et de s’assurer d’obtenir une coupe précise.

7. Retirer les retailles et la poussière de la boîte. Fixer la plaque de plâtre de façon définitive.

Entretien

L’outil doit être nettoyé au moyen d’un jet d’air comprimé au moins une fois par semaine de

manière à en retirer le plus de poussière possible et d’améliorer la durée de vie des balais et

des roulements du moteur. On doit toujours porter le matériel de sécurité approprié lorsqu’on

nettoie un outil à l’air comprimé.

Bien que le boîtier en plastique de l’outil soit résistant aux solvants, ne jamais utiliser ce produit,

ni toute autre solution chimique, pour le nettoyer. Essuyer les pièces non métalliques de l’outil

au moyen d’un linge sec.

TOUS LES ROULEMENTS ONT ÉTÉ LUBRIFIÉS EN USINE POUR LA DURÉE DE VIE DE

L’OUTIL.

Page 4

Accessoires

Les accessoires recommandés pour l’outil sont vendus séparément chez les dépositaires

locaux ou les centres de service autorisés. Pour obtenir de l’aide concernant l’achat d’un

accessoire, communiquer avec D

EWALT Industrial Tool Company, 701 East Joppa Road,

Baltimore, MD 21286 aux États-Unis.

MISE EN GARDE : ne pas utiliser de mèches à deux bouts. L’usage d’un accessoire non

recommandé peut présenter un danger.

Reparations

Pour assurer la SÉCURITÉ et la FIABILITÉ de ce produit, l’outil doit être réparé, entretenu et

réglé par un centre de service autorisé ou qualifié (cela comprend l’inspection et le remplacement du balai); seules des pièces de rechange identiques doivent être utilisées.

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un défaut de matériel ou de fabrication pour une période de trois ans à compter de la date d’achat. La présente garantie ne couvre pas les pièces dont la défectuosité a été causée par une usure normale ou l’usage abusif

de l’outil. Pour obtenir de plus amples renseignements sur les pièces ou les réparations couvertes par la présente garantie, visiter le site www.dewalt.com ou composer le 1 800 433-9258

(1 800 4-D

EWALT). Cette garantie ne s’applique pas aux accessoires et ne vise pas les dom-

mages causés par des réparations effectuées par un tiers. Cette garantie confère des droits

légaux particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un

état ou d’une province à l’autre.

En plus de la présente garantie, les outils D

EWALT sont couverts par notre :

CONTRAT D’ENTRETIEN GRATUIT D’UN AN

D

EWALT entretiendra l’outil et remplacera les pièces usées au cours d’une utilisation normale et

ce, gratuitement, pendant une période d’un an à compter de la date d’achat, et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque raison que ce soit, du rendement de

l’outil électrique, du laser ou de la cloueuse D

EWALT, celui-ci peut le retourner, accompagné

d’un reçu, dans les 90 jours à compter de la date d’achat, pour obtenir un remboursement intégral, sans aucun problème.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE : Si vos étiquettes d'avertissement deviennent

illisibles ou sont manquantes, composez le 1-800-4-D

EWALT pour obtenir une étiquette de rem-

placement gratuite.

Instrucciones de seguridad generales

¡ADVERTENCIA! Lea todas las instrucciones hasta comprenderlas. No

ajustarse a las instrucciones siguientes puede ser causa de choque eléctrico,

incendio o lesiones graves.

CONSERVE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

• Mantenga el área de trabajo limpia y bien iluminada. Las bancadas desordenadas y las

zonas oscuras propician los accidentes.

• No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición del polvo o los vapores.

•Mientras opere una herramienta eléctrica, mantenga lejos a los observadores, niños y

visitantes. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELÉCTRICA

• Las herramientas con toma de tierra deben conectarse a un enchufe apropiadamente

instalado y con conexión a tierra, de acuerdo con todas las normas y ordenanzas

jurídicas. No quite la pata de conexión a tierra ni realice ninguna modificación en la

clavija. No emplee adaptadores para clavijas. Si tiene alguna duda acerca de si el

enchufe está correctamente conectado a tierra, consulte a un electricista cualificado.

Si la herramienta presentase disfunciones eléctricas o averías, la toma de tierra ofrece

una vía de baja resistencia que garantiza la seguridad del usuario. Sólo es aplicable a las

herramientas de Clase I (con toma de tierra).

• Las herramientas con doble aislamiento están equipadas con una clavija polarizada

(una pata es más ancha que la otra). Esta clavija se acoplará a un enchufe polarizado

de una sola manera. Si la clavija no se acopla al contacto, inviértala. Si aún así no se

ajusta, comuníquese con un electricista cualificado para que instale un enchufe polarizado apropiado. Nunca cambie la clavija. El doble aislamiento elimina la necesidad de

cables con tres hilos y sistemas de suministro eléctrico con conexión a tierra. Sólo es aplicable a las herramientas de Clase II (con doble aislamiento).

• Evite el contacto del cuerpo con superficies conectadas a tierra, tales como tuberías,

radiadores, registros y refrigeradores. El riesgo de choque eléctrico aumenta si su cuerpo

hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a condiciones de mucha humedad.

Si entra agua en una herramienta eléctrica, aumenta el riesgo de choque eléctrico

• No maltrate el cable. Nunca tome el cable para transportar la herramienta ni para

desconectarla del enchufe. Mantenga el cable alejado de las fuentes de calor, el aceite,

las orillas afiladas o las piezas en movimiento. Cambie inmediatamente los cables

dañados. Los cables dañados aumentan el peligro de choque eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie, utilice una extensión marcada “W-A” o “W”. Estas extensiones están clasificadas para uso a la intemperie y para

reducir el riesgo de choque eléctrico. Al usar una extensión, asegúrese de que sea bastante

resistente para llevar la corriente que su producto requerirá. Una extensión de calibre insuficiente causará una caída en la línea de voltaje dando por resultado la pérdida de energía

y un sobrecalentamiento. La tabla siguiente muestra el tamaño correcto para utilizar dependiendo de la longitud de la extensión y del amperaje de la placa de identificación. En caso

de duda, utilice el de mayor calibre. Cuanto más pequeño es el número del calibre, más

resistente es la extensión.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

Amperaje

Más No más Calibre del cordón AWG

de de

0-6 18 16 16 14

SEGURIDAD PERSONAL

• Al utilizar una herramienta eléctrica, esté atento, concéntrese en lo que hace y aplique

el sentido común. No utilice la herramienta si se encuentra fatigado o bajo la influencia de drogas, alcohol, o fármacos. Mientras se utilizan herramientas eléctricas, basta un

instante de distracción para sufrir lesiones graves.

• Lleve ropa adecuada. No utilice ropa suelta ni joyas. Recójase el cabello largo.

Mantenga el cabello, la ropa y los guantes apartados de las piezas en movimiento. Las

partes móviles pueden atrapar las prendas de vestir sueltas, las joyas y el cabello. Los orificios de ventilación suelen cubrir piezas en movimiento, por lo que también se deben evitar.

• Evite puestas en marcha accidentales. Asegúrese de que el interruptor esté apagado

antes de enchufar la máquina. Transportar las herramientas con el dedo sobre el interruptor o enchufarlas con el interruptor encendido favorece los accidentes.

• Antes de poner en marcha la herramienta, retire las llaves de ajuste. Una llave que se

deje en una pieza giratoria de la herramienta puede provocar lesiones.

• No ponga en peligro su estabilidad. Manténgase siempre bien apoyado y equilibrado.

Un buen apoyo y equilibrio permiten controlar mejor la herramienta si se produce algún

imprevisto.

• Utilice el equipo de seguridad. Lleve siempre lentes protectores. Cuando sea adecua-

do, también se debe usar mascarilla antipolvo, zapatos de suela antideslizante, casco o protectores auditivos.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice abrazaderas u otro elemento adecuado para sujetar y apoyar la pieza de trabajo en una plataforma estable. Sujetar la pieza con la mano o contra el cuerpo es inestable

y facilita la pérdida de control.

• No fuerce la herramienta. Emplee la herramienta correcta para cada aplicación. La her-

ramienta correcta hace el trabajo mejor y más seguro dentro del rango para el que ha sido

diseñada.

• No utilice la herramienta si el interruptor no la enciende y apaga. Cualquier herramien-

ta que no pueda controlarse con el interruptor es peligrosa y se debe reparar.

• Desconecte la clavija del enchufe antes de proceder a cualquier ajuste, cambiar un

accesorio o guardar la herramienta. Estas medidas de seguridad preventiva reducen el

riesgo de poner en marcha la herramienta accidentalmente.

• Cuando no las utilice, guarde las herramientas fuera del alcance de los niños o de

cualquier persona no capacitada. Las herramientas son peligrosas en manos de usuarios

no capacitados.

• Cuide las herramientas. Conserve las herramientas de corte afiladas y limpias. Unas

herramientas adecuadamente cuidadas y con los bordes de corte afilados se deforman

menos y son más fáciles de controlar.

• Compruebe si las piezas móviles se desalinean o deforman, si hay alguna pieza rota

y cualquier otra circunstancia que pueda afectar al funcionamiento de la máquina. Si

la herramienta está dañada, hágala reparar antes de usarla. Muchos accidentes los

provocan unas herramientas mal cuidadas.

• Utilice únicamente los accesorios recomendados por el fabricante para su modelo. Un

mismo accesorio puede ser adecuado para una herramienta, pero peligroso si se usa en

otra.

SERVICIO

• El servicio a la herramienta sólo debe realizarlo personal cualificado. El servicio o man-

tenimiento realizados por personal no calificado puede dar como resultado un riesgo de

lesiones.

• Al proceder al mantenimiento de una herramienta, utilice únicamente refacciones

idénticas. Siga las instrucciones de la sección “Mantenimiento” de este manual. La utilización de piezas no autorizadas, o no respetar las instrucciones de mantenimiento, puede

suponer un peligro de choque eléctrico o de lesiones.

inar riegos de choque eléctrico o

lesiones.

Reglas adicionales de seguridad para recortadoras

• Cuando realice un trabajo en el cual la herramienta de corte pueda tener contacto con

cables ocultos o con su propio cable, tome la herramienta por las superficies aislantes de

sujeción. El contacto con un cable “vivo” hará que las partes metálicas de la herramienta

puedan transmitir una descarga eléctrica al operario.

ADVERTENCIA: Después de cambiar las brocas o realizar cualquier ajuste, asegúrese de

que la tuerca del collar se encuentre firmemente asegurada.

ADVERTENCIA: No apriete el botón del seguro del eje o del seguro de collar mientras el

motor se encuentre en marcha. El usuario podría perder el control y dejar caer la herramienta.

Esto puede causar lesiones personales o serias averías en la herramienta.

ADVERTENCIA: Apague todos los circuitos eléctricos de todas las áreas donde vaya a

realizar un corte.

PRECAUCIÓN: Utilice la protección auditiva adecuada durante el uso de esta unidad. Bajo

ciertas condiciones y duración de uso, el ruido producido por este producto puede contribuir a

la pérdida auditiva.

PRECAUCIÓN: No toque la broca o la tuerca del collar durante que realiza un corte o inmedi-

atamente después de hacerlo. Éstos puede estar suficientemente calientes para producirle una

seria quemadura en la piel.

• Utilice siempre protección para sus ojos. Si las condiciones lo exigen, utilice una máscara para el polvo o un protector auditivo. Es recomendable utilizar dispositivos para su

seguridad personal. TRABAJE BAJO CONDICIONES DE SEGURIDAD.

• Utilice siempre la herramienta con ayuda de la guía de profundidad. La guía evita que

la broca se introduzca con demasiada profundidad dentro del material. Con el fin de eliminar

el peligro de cortar un cable eléctrico, debe mantenerse una penetración mínima.

• No utilice esta herramienta con brocas para taladro o destornillador. Esta herramienta

no ha sido diseñada como taladro o destornillador.

• Asegúrese de que sus brocas de corte se encuentren afiladas y en buenas condiciones. Las brocas averiadas pueden hacer que la herramienta salte y cause lesiones al

usuario.

• Asegúrese que el motor haya parado por completo antes de poner la herramienta. Si

el cabezal de corte aún está en movimiento, podría ocasionar daño o lesiones personales.

• Antes de encender el motor asegúrese que la brocas de corte no esté en contacto con

el material de trabajo. Si la broca está haciendo contacto con la pieza de trabajo, podría

hacer saltar la rebajadora y ocasionar daño o lesiones personales.

• En caso de que la herramienta no funcione adecuadamente, llévela al centro D

E

WALT

de servicio certificado más cercano para su reparación. Esta herramienta no contiene

partes utilizables por el usuario.

ADVERTENCIA : Parte del polvo creado al lijar, aserruchar, moler o perforar con máquina,

así como al realizar otras actividades de la construcción, contiene substancias químicas que se

sabe producen cáncer, defectos congénitos u otras afecciones reproductivas. Algunos ejemplos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la frecuencia en que se haga este tipo

de trabajo. Para reducir la exposición a esas substancias químicas: trabaje en un área bien ventilada, y trabaje con equipos de seguridad aprobados, tales como máscaras contra el polvo

especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con polvos originados por lijar, aserrar, esmerilar, tal-

adrar y otras actividades constructivas. Vista ropas protectoras y lave las áreas

expuestas con agua y jabón. Permitir que el polvo se introduzca en su boca, ojos, o dejar-

lo sobre la piel promueve la absorción de químicos dañinos.

ADVERTENCIA: La utilización de esta herramienta puede originar polvo o dispersarlo, lo que

podría causar daños graves y permanentes al sistema respiratorio, así como otras lesiones.

Siempre use protección respiratoria aprobada por NIOSH/OSHA, apropiada para su uso en

condiciones de exposición al polvo. Procure que las partículas no se proyecten directamente

sobre su rostro o su cuerpo.

• La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ..................volts A ....................amperes

Hz ................hertz W ..................watts

min................minutos ..................corriente alterna

..............corriente directa

n

o ..................velocidad sin carga

..................construcción clase II ..................terminales de conexión a tierre

................símbolo de alerta seguridad .../min ............revoluciones o minuto

Para mantener el control seguro de la herramienta

• Asegúrese de que la superficie de trabajo se encuentre libre de puntillas o tornillos.

Si usted corta una puntilla o tornillo puede hacer que la herramienta salte y dañe la broca.

• Nunca haga funcionar la herramienta con una sola mano mientras sostiene la pieza de

trabajo con la otra mano. Sujete siempre el material y guíe la herramienta con las dos

manos. Mantenga siempre el control de su herramienta.

• No corte material que se encuentre sobre una superficie dura. Es necesario prever un

espacio detrás del material que va a ser cortado para permitir el movimiento sobresaliente

de la broca.

• Desconecte el clavijero de la toma de corriente antes de realizar cualquier ajuste,

cambiar las brocas o limpiar la herramienta.

• No inicie el funcionamiento de la herramienta cuando la broca se encuentre dentro del

material. La broca puede atascarse causando la pérdida de control

Page 5

• En caso de que la herramienta no funcione adecuadamente, llévela al centro DEWALT

de servicio certificado más cercano para su reparación. Esta herramienta no contiene

partes utilizables por el usuario.

Motor

Asegúrese de que el suministro de energía eléctrica corresponde a la indicada en la placa de

seguridad. 120 volt AC indica que su herramienta funciona tan sólo con corriente alterna y

nunca con corriente directa.

Interruptor

Para dar arranque al motor deslice el interruptor (A) hacia la posición “I”. Para detener el motor,

lleve el interruptor a la posición “O” (Ver FIG. 1).

Instalación y remoción de la broca (Fig. 2)

Esta herramienta cuenta con un sistema automático para el cambio de broca. Para cambiar

las brocas, PRIMERO apague la herramienta y desconéctela del suministro de energía eléctrica. Retire la guía.

1. Para reemplazar la broca, suelte el seguro del eje (C), el seguro del collar (B) y gire la

abrazadera del collar en el sentido opuesto al de las manecillas del reloj.

2. Inserte la broca.

ADEVERTENCIA: Las brocas son afiladas y deben ser manejadas con mucho cuidado.

PRECAUCIÓN: Cuando reemplace las brocas, no inserte brocas para corte dentro del col-

lar. Esto puede provocar la rotura de las brocas.

3. Mientras presiona los seguros del eje y del collar, gire la abrazadera del collar en el sentido de las manecillas del reloj para apretar firmemente el collar. Para algunos usos de tipo

industrial, quizás resulte necesario utilizar una llave con el fin de apretar más fuerte la tuerca (D) mientras presiona el eje dl seguro (C).

4. Asegure la guía.

PRECAUCIÓN: nunca apriete el collar sin tener una broca instalada.

Esta herramienta viene con collares de 1/8" y 1/4". Para cambiar los collares, retire la tuerca

del collar e inserte el collar deseado.

Guía de profundidad (Fig. 3)

Cómo sujetar la guía de profundidad a la unidad del motor,

APAGUE LA HERRAMIENTA Y

DESCONÉCTELA.

La guía de profundidad se inserta a presión como se muestra en la figura. Mantenga la guía

de profundidad permanentemente instalada mientras la herramienta esté en funcionamiento.

Para mejores resultados, ajuste la guía por medio de la agarradera (E) con el fin de permitir

que la broca sobresalga cerca de 1/8" del material que va a ser cortado.

Mango lateral DW6619 (Fig. 4)

Cuando opere la herramienta, use el mango lateral para tener óptimo control. Para instalar el

mango lateral a la unidad del motor, APAGUE LA HERRAMIENTA Y DESCONÉCTELA DE LA

TOMA DE CORRIENTE.

1. Retire la guía de profundidad.

2. Afloje la perilla (F) hasta que el collarín de la herramienta entre en la banda (G) del mango

lateral.

3. Haga coincidir el localizador de la herramienta con el localizador del mango lateral.

(Detalle) apriete la perilla (F).

4. Presione la guía de profundidad sobre la banda del mango lateral (G) desde el lado

opuesto. Conserve la guía de profundidad en su sitio en todo momento durante la

operación de la herramienta.

5. Para obtener mejores resultados, ajuste la guía con la ayuda de la perilla (E) para permitir que la broca sobresalga aproximadamente 3mm (1/8”) a través del material a cortar.

6. Para retirar el mango lateral, retire la guía de profundidad, afloje la perilla (F) hasta que la

herramienta puede desunirse del localizador y la banda se deslice hacia fuera (G).

7. Instale de nuevo la guía de profundidad.

Cortador de círculos DW6621 (Fig. 5)

Para instalar el cortador de círculos a la unidad del motor. APAGUE LA HERRAMIENTA Y

DESCONÉCTELA DE LA TOMA DE CORRIENTE.

1. Retire la guía de profundidad.

2. Afloje la perilla (H) hasta que el collarín de la herramienta entre en la banda (J) del cortador de círculos.

3. Haga coincidir el localizador de la herramienta con el localizador cortador de círculos.

(Detalle) apriete la perilla (H).

4. Desensamble el collarín de la guía de profundidad. Presione la mitad superior (M) en la

banda (J).

5. Afloje la perilla (L) y extienda el marco del cortador de círculos a la mitad de la carrera.

6. Inserte la perilla (E) a través del marco (N).

7. Ajuste la profundidad para el corte del material y apriete las perillas (E) y (L).

8. Mida al centro del círculo que desea cortar y ajuste la longitud de la guía para el radio que

desea.

9. Apriete la perilla (O) sujetando la punta central en posición.

10. Haga una perforación de 5/32" (4 mm) en el centro del radio en el material por cortar.

11. Conecte la herramienta, encienda el motor y espere a que la herramienta alcance la velocidad de trabajo.

12. Coloque la punta central en el orificio y haga que el cortador penetre el material.

13. Con presión firme, sujete la punta central en posición y mueva el cortador en sentido

opuesto a las manecillas del reloj alrededor hasta el final.

PRECAUCIÓN: Al final del círculo, el material puede desprenderse, sujete la herramienta

con ambas manos para conservar el control.

14. Para remover el cortador de círculos, afloje la perilla (H) hasta que la unidad pueda salirse

del localizador y se deslice fuera de la banda (J).

15. Ensamble de nuevo la guía de profundidad y reinstálela.

Funcionamiento

PARA REALIZAR UNA PERFORACIÓN PARA UNA TOMA DE CORRIENTE ELÉCTRICA

(FIG. 4)

ADVERTENCIA: Apague todos los circuitos eléctricos de todas las áreas donde vaya a

realizar un corte

1. Empuje con profundidad todos los cables al interior de la toma de corriente con el fin de

evitar dañarlos con la broca de corte.

2. Antes de fijar la lámina que cubre la toma de corriente, marque en el panel de la pared la

localización aproximada del centro de la toma de corriente. Verifique la profundidad de la

broca de corte contra el borde del panel de la pared, con el fin de asegurarse de que podrá

cortar a través del material.

3. Fije el panel en su lugar con unos cuantos sujetadores evitando la columna que sostiene

la toma de corriente. Esto permite que el panel se flexione ligeramente alrededor de la caja

eléctrica que sobrepasa el panel.

4. Encienda la recortadora. Sostenga la herramienta firmemente con las dos manos (FIG 4)

e introduzca la broca directamente en el centro de la toma de corriente.

5. Inicie el corte hacia la derecha hasta alcanzar el borde de la caja. Tire la broca hacia

afuera, justo lo necesario para pasar por encima del borde de la caja. Introduzca nuevamente la broca, apoyándola cuidadosamente contra el exterior de la caja.

6. Siga el contorno de la caja como se muestra en la figura, manteniendo una ligera presión

contra la caja. Esto evitará que la broca se desvíe y le permitirá obtener un corte preciso.

7. Retire la basura y el polvo de la toma de corriente. Termine de fijar el panel del muro.

Mantenimiento

La herramienta debe ser limpiada con un chorro de aire al menos una vez por semana, para

expulsar la mayor cantidad de polvo posible. Esto aumentará la vida de las escobillas y de los

cojinetes que se encuentran al interior del motor. Cuando utilice aire comprimido para limpiar

la herramienta, utilice siempre un equipo de seguridad adecuado. Aunque el cuerpo de plástico de la herramienta es resistente a los disolventes, nunca utilice disolventes o químicos

fuertes para limpiarla. Limpie las partes no metálicas de la herramienta con un paño seco.

Lubricación

Todos los cojinetes cuentan con una lubricación permanente durante la vida útil de la herramienta.

Accesorios

Usted puede adquirir los accesorios recomendados para su herramienta en su Centro local de

servicio, por medio de un pago adicional. En caso de requerir asistencia para localizar cualquier

accesorio para su herramienta, tome contacto con nosotros en: D

EWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286.

PRECAUCIÓN: No utilice brocas de doble filo. La utilización de cualquier accesorio no

recomendado para ser utilizado con esta herramienta, puede ser peligrosa.

Reparaciones

Para garantizar la SEGURIDAD y la FIABILIDAD del producto, las reparaciones, el mantenimiento y los ajustes (incluyendo la revisión y el cambio de escobillas), deberán ser realizados

en los centros autorizados de servicio u otras organizaciones de servicio calificadas que utilicen

siempre accesorios originales.

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: _________________________ Mod./Cat.: ______________________

Marca: __________________________________ Núm. de serie:_____________________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: _______________________________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

__________________________________________________________________________

Este producto está garantizado por un año a partir de la fecha de entrega, contra cualquier

defecto en su funcionamiento, así como en materiales y mano de obra empleados para su fabricación. Nuestra garantía incluye la reparación o reposición del producto y/o componentes sin

cargo alguno para el cliente, incluyendo mano de obra, así como los gastos de transportación

razonablemente erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta y esta póliza sellada por

el establecimiento comercial donde se adquirió el producto, de no contar con ésta, bastará la

factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el instructivo de uso que se

acompaña;

• Cuando el producto hubiese sido alterado o reparado por personas distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica, centros de servicio autorizados y franquiciados en la República Mexicana, donde podrá hacer efectiva su garantía y

adquirir partes, refacciones y accesorios originales.

Garantía limitada por tres años

DEWALT reparará, sin cargo, cualquier falla que surja de defectos en el material o la fabricación

del producto, por hasta tres años a contar de la fecha de compra. Esta garantía no cubre fallas

de las piezas causadas por su desgaste normal o abuso a la herramienta. Para mayores

detalles sobre la cobertura de la garantía e información acerca de reparaciones realizadas bajo

garantía, visítenos en www.dewalt.com o dirígase al centro de servicio más cercano. Esta

garantía no aplica a accesorios o a daños causados por reparaciones realizadas o intentadas

por terceros. Esta garantía le otorga derechos legales específicos, además de los cuales puede

tener otros dependiendo del estado o provincia en que se encuentre.

Además de la garantía, las herramientas D

EWALT están cubiertas por:

1 AÑO DE SERVICIO GRATUITO

D

EWALT mantendrá la herramienta y reemplazará las piezas gastadas por su uso normal, sin

cobro, en cualquier momento durante un año a contar de la fecha de compra.

GARANTÍA DE REEMBOLSO DE SU DINERO POR 90 DÍAS

Si no está completamente satisfecho con el desempeño de su máquina herramienta, láser o

clavadora D

EWALT, cualquiera sea el motivo, podrá devolverlo hasta 90 días de la fecha de

compra con su recibo y obtener el reembolso completo de su dinero – sin necesidad de responder a ninguna pregunta.

REEMPLAZO DE LAS ETIQUETAS DE ADVERTENCIA GRATUITO: Si sus etiquetas de

advertencia se tornan ilegibles o se pierden, llame al 1-800-4-D

EWALT para que se las reem-

placen sin cost.

PARA REPARACIÓN Y SERVICIO DE SUS HERRAMIENTAS ELÉCTRICAS, FAVOR DE

DIRIGIRSE AL CENTRO DE SERVICIO MÁS CERCANO

CULIACAN, SIN

Av. Nicolás Bravo #1063 Sur - Col. Industrial Bravo (667) 7 12 42 11

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juárez (33) 3825 6978

MEXICO, D.F.

Eje Central Lázaro Cárdenas No. 18

Local D, Col. Obrera (55) 5588 9377

MERIDA, YUC

Calle 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L.

Av. Francisco I. Madero No.831 - Col. Centro (81) 8375 2313

PUEBLA, PUE

17 Norte #205 - Col. Centro (222) 246 3714

QUERETARO, QRO

Av. Madero 139 Pte. - Col. Centro (442) 214 1660

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis (444) 814 2383

TORREON, COAH

Blvd. Independencia, 96 Pte. - Col. Centro (871) 716 5265

VERACRUZ, VER

Prolongación Díaz Mirón #4280 - Col. Remes (229) 921 7016

VILLAHERMOSA, TAB

Constitución 516-A - Col. Centro (993) 312 5111

PARA OTRAS LOCALIDADES LLAME AL: (55) 5326 7100

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

Información Técnica

DW660

Tensión de alimentación 120 V CA

Consumo de corriente: 5,0 A

Frecuencia de operación: 60 Hz

Revoluciones o porminuto 30,000

IMPORTADOR: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS, 3A. SECCIÓN, CP 05120

DELEGACIÓN CUAJIMALPA, MÉXICO, D.F

TEL. 5 326 7100

R.F.C.: BDE810626-1W7

Loading...

Loading...