Page 1

DEWALT Industrial Tool Company, P.O. Box 158, 626 Hanover Pike, Hampstead, MD 21074 Printed in U.S.A. (JULY97-CD-1) Form No. 384404

DW628 Copyright © 1997

Garantía completa

Las herramientas industriales DEWAL Testán garantizadas durante un

año a partir de la fecha de compra. Repararemos, sin cargos,

cualquier falla debida a material o mano de obra defectuosos. Para

obtener información sobre reparaciones en garantía, llame por favor al

326-7100. Esta garantía no se aplica a los accesorios ni a daños

causados por reparaciones efectuadas por terceras personas. Esta

garantía le otorga derechos legales específicos, y usted puede tener

otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas DEWALT están amparadas

por nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño

de su herramienta industrial D

EWALT, sencillamente devuélvala a los

vendedores participantes durante los primeros 30 días después de la

fecha de compra para que le efectúen un reembolso completo. Por

favor regrese la unidad completa, con el transporte pagado. Se puede

requerir prueba de compra.

384404/DW628 5/2/02 1:39 PM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW628

3.5 HP Router

Toupie de 3,5 HP

Rebajadora de 3,5 HP

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

384404/DW628 5/2/02 1:39 PM Page 3

Page 3

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

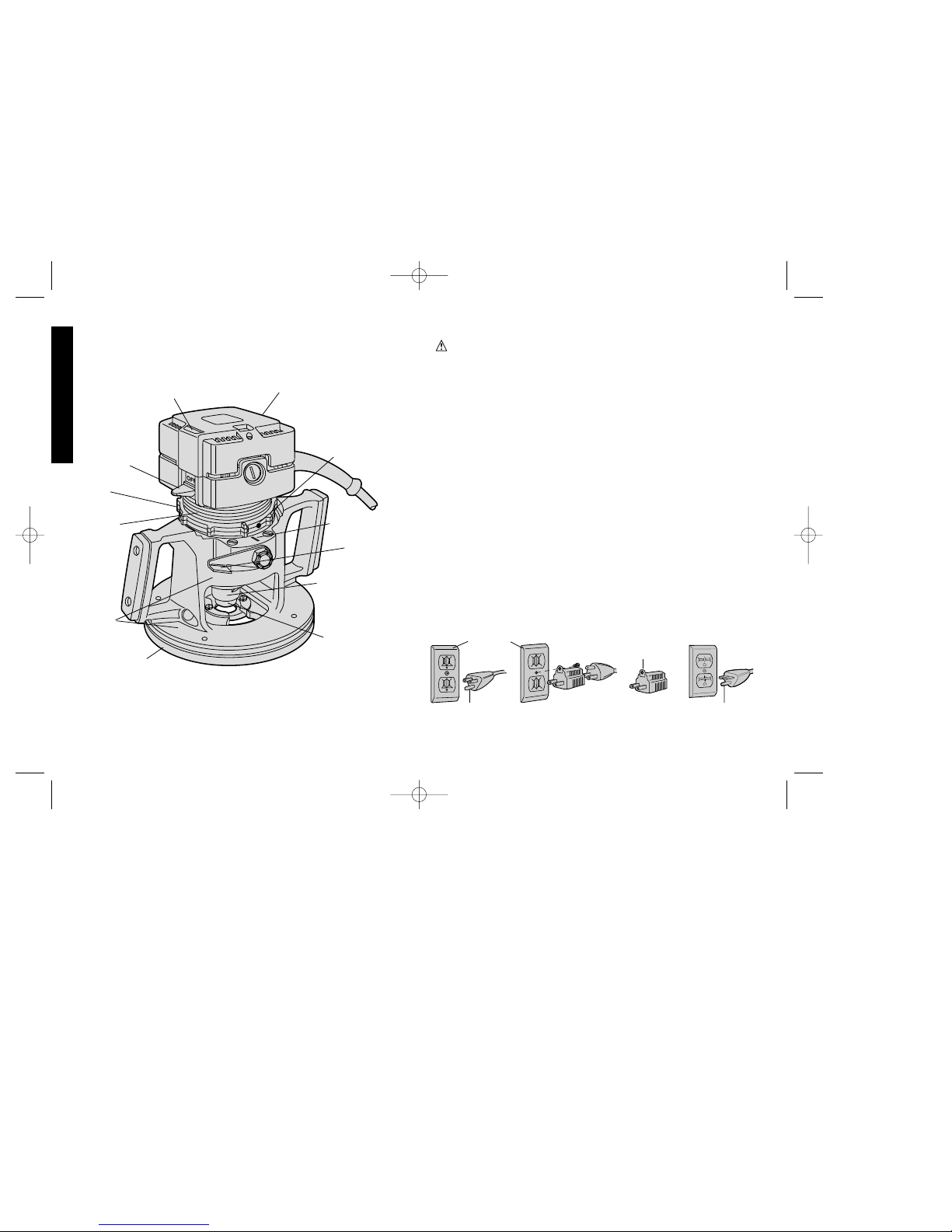

Grounding Instructions

This tool should be grounded while in use to protect the operator from

electric shock. The tool is equipped with a 3-conductor cord and 3prong grounding type plug to fit the proper grounding type receptacle.

The green (or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and yellow) wire

to a live terminal. If your unit is intended for use on less than 150 V,

it has a plug that looks like that shown in sketch A. If it is for use on

150 to 250 V, it has a plug that looks like that shown in sketch D. An

adapter, sketches B and C, is available for connecting sketch A type

plugs to 2-prong receptacles. The green-colored rigid ear, lug, or the

like, extending from the adapter must be connected to a permanent

ground, such as a properly grounded outlet box. No adapter is

available for a plug as shown in sketch D. ADAPTER SHOWN IN

FIGURES B and C IS NOT FOR USE IN CANADA.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

SWITCH PROBE

END CAP

RING LOCK

SCRIBE LINE

CLAMP

LEVER

COLLET

ADAPTER

COLLET NUT

SUB BASE

BASE

MOTOR

UNIT

SWITCH

ADJUSTING

RING

AB CD

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

GROUNDING PIN

ADAPTER

384404/DW628 5/2/02 1:39 PM Page 4

Page 4

Safety Instructions For All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces. For example; pipes, radiators, ranges, and

refrigerator enclosures.

• KEEP CHILDREN AWAY. Do not let visitors contact tool or

extension cord. All visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the

rate for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy-duty tool. Don’t use tool for purpose not intended.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

• USE SAFETY GLASSES. Also use face or dust mask if cutting

operation is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep

handles dry, clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger

on switch. Be sure switch is off when plugging in.

• EXTENSION CORDS. Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole receptacles that accept

the tool’s plug. Replace or repair damaged cords. Make sure your

extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The following table

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage (AWG)

Than Than

0- 6 18161614

6 - 10 18 16 14 12

10- 1216161412

12 - 16 14 12 Not Recommended

• OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

1

English

384404/DW628 5/2/02 1:39 PM Page 1

Page 5

removing the motor unit from the base. ALWAYS BE SURE THAT

THE CLAMP LEVER IS IN THE LOCKED (DOWN) POSITION

WHEN ROUTING.

The orientation of the lever can be changed if desired by loosening

the lock nut that fastens it to the router and rotating the lever to the

desired position. Retighten the lock nut.

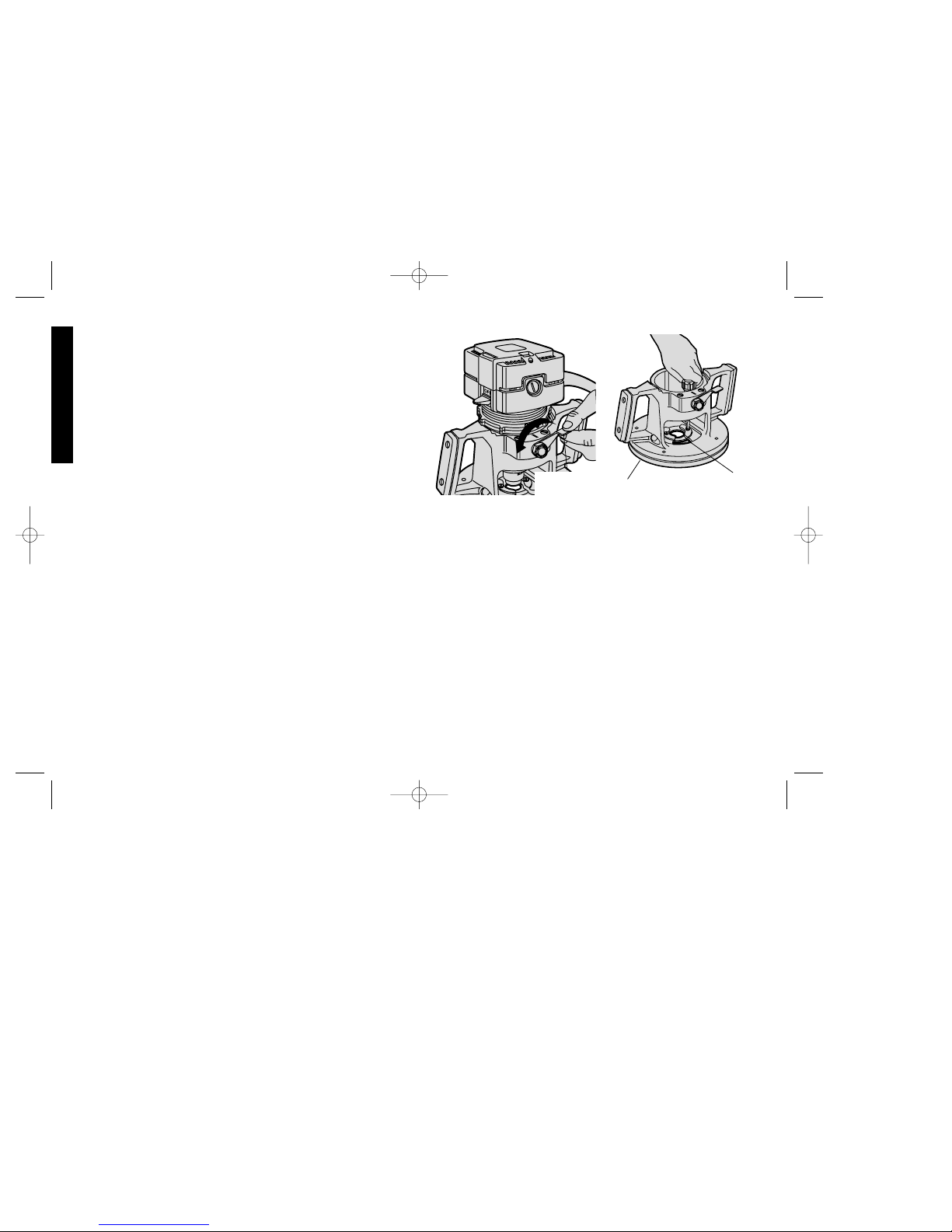

Sub Base

Turn Off and Unplug Router

The sub base on your router has been specifically designed to permit

better visibility than conventional routers but retain the ability to use

template guides. The guide adapter, if not needed, can be easily

removed for even more visibility. To remove the adapter raise the

Clamp Lever and lift the motor assembly out of the router base. This

will enable you to reach and remove the two screws in the base

which hold the guide adapter in place, as shown in Figure 2.

When you reinstall the motor unit, be sure to align the Guide Screw

(Figure 3) with the slot in the router base.

LOCKING

LEVER

2

so marked.

• STAY ALERT. Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

• CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

SAVE THESE INSTRUCTIONS

Motor

Your DEW ALT tool is powered by a DEWAL T-built motor . Be sure your

power supply agrees with the nameplate marking.

120 Volts 60Hz or “AC/DC” means your tool may be operating with

alternating or direct current.

Voltage decrease of more than 10% will cause loss of power and

overheating. All D

EWAL Ttools are factory tested; if this tool does not

operate, check the power supply.

Clamp Lever

Turn Off and Unplug Router.

In order to lock the position of the router motor unit in the router base,

a lever has been provided on the side of the tool, as shown in Figure

1.

To lock the motor unit in place, push the lever all the way down; to

release the motor, raise the lever up to about a right angle to the

tool. Use this loosened position for making depth adjustments and

English

FIG. 1 FIG. 2

SUB BASE

GUIDE

ADAPTER

384404/DW628 5/2/02 1:39 PM Page 2

Page 6

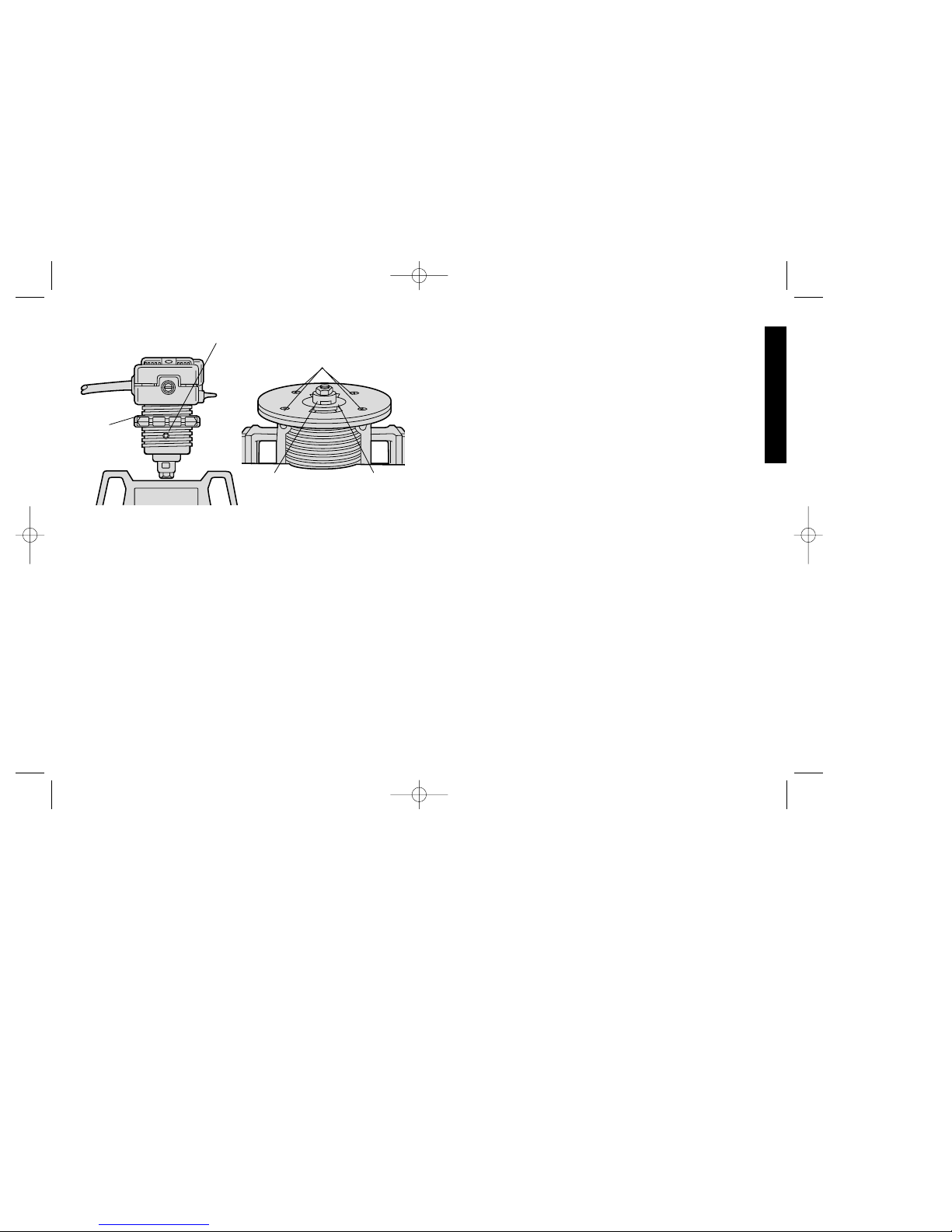

Sub Base Alignment For Template Routing

The guide adapter is aligned with the collet at the time of

manufacture, but the two may become misaligned during shipping

and handling, particularly if the tool is dropped. To properly align the

collet with the guide adapter follow the steps below.

1. Turn Off and Unplug Router.

2. Raise the Clamp Lever and remove the motor unit from the router

base.

3. Remove the Guide Screw and the Adjusting Ring shown in Figure 3.

4. Loosen the 4 screws in the Sub Base, as shown in Figure 4.

5. Re-insert the Guide Screw (not the Adjusting Ring) in the motor

unit and insert the motor unit into the router base. (Make sure

that you align the Guide Screw with the slot in the router base.)

6. Lower the motor unit until the collet adapter extends through the

guide adapter, as shown in Figure 4. Adjust the Sub Base until the

collet adapter fits through it.

7. Tighten the four screws in the Sub Base and remove the motor

unit from the router base.

8. Remove the Guide Screw and re-install the Adjusting Ring.

9. Install the Guide Screw and re-insert the motor unit into the router

base. (Be sure to align the guide screw with the slot in the base.)

10. The template guide is now aligned with the collet.

NOTE: When installing the guide screw in the above section

remember that it must be tightened firmly so that the head is flush

against the side of the motor unit.

Attaching Bits and Cutters

Turn Off and Unplug Router

Insert the shank of the desired bit or cutter into the collect as far as it

will go, then pull it out slightly (about 1/32”,.793 mm). Use the

wrenches provided to securely tighten the collet nut. One wrench

holds the collet adapter and the other tightens the collet nut.

A special coating has been put on the collet and collet nut to increase

the bit holding power. Use only the wrenches provided with your

router to tighten the collet nut. Other tools may damage the coating

through overtightening.

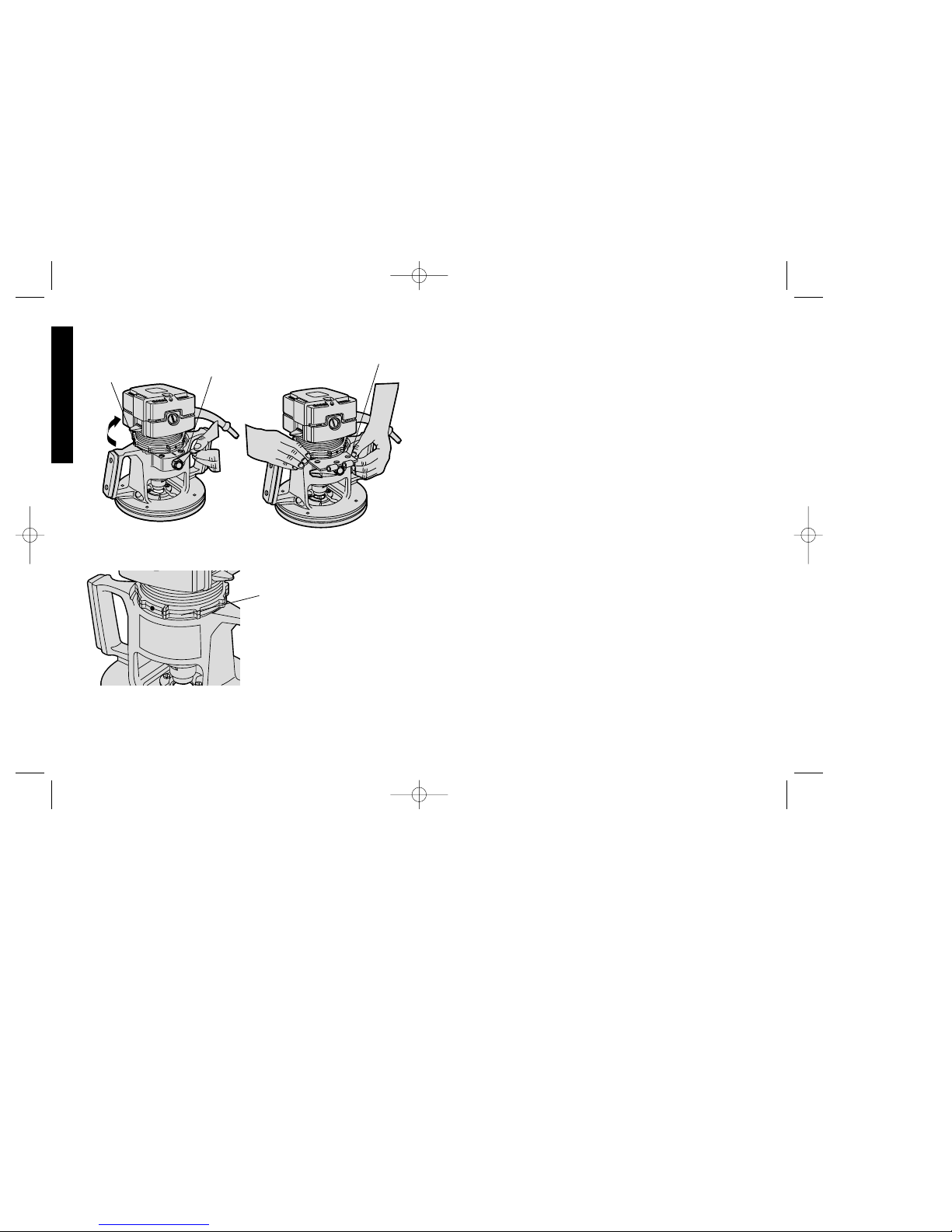

Depth Adjustment

Turn Off and Unplug Router

Loosen the Clamp Lever by raising it fully. Adjust the depth setting of

the router bit by turning the Adjusting Ring shown in Figure 5. To

raise the bit away from the work surface, turn the ring clockwise (as

viewed from the top of the tool) and to lower the bit into the work, turn

it counterclockwise.Directly over the Clamp Lever pivot point is a

line scribed into the aluminum housing, as shown in Figure 5. As the

ring is rotated, the raised lugs on the ring will pass over this line. Each

time a lug passes the line, the bit is raised or lowered 1/64" (.396

mm). Every full revolution of the Adjusting Ring accounts for

3

English

FIG. 3

GUIDE SCREW

ADJUSTING

RING

GUIDE

ADAPTER

COLLET

ADAPTER

FIG. 4

SCREWS

384404/DW628 5/2/02 1:39 PM Page 3

Page 7

1/8"(3.175 mm) of adjustment either up or down.

The lugs are consecutively numbered for convenience. For faster

adjustments, lift the motor housing slightly and spin the Adjusting

Ring.

Duplicating specific depths of cut, such as hinge butt mortises, can

be done quickly and accurately by following the steps below.

1. TURN OFF AND UNPLUG ROUTER.

2. Lower the router bit until it just touches the workpiece. (Refer to

preceding section on “DEPTH ADJUSTMENT.”)

3. Lock the Clamp Lever

4. Raise the Adjusting Ring by rotating it counterclockwise until the

hinge will just fit between the top edge of the router base and the

bottom of the Adjusting Ring, as shown in Figure 6.

5. Remove the hinge and invert the router to prevent the bit from

marring the work surface.

6. Unlock the Clamp Lever and allow the base to fall to the new

setting. Lock the Clamp Lever in place and the depth is set. The

router will now cut to the exact thickness of the hinge.

Adjusting Ring Lock

Turn Off and Unplug Router.

To prevent the Adjusting Ring from rotating due to vibration of the

router, a nylon set screw has been provided in the ring. When the ring

is set as desired, tighten this set screw, shown in Figure 7. Be careful

to avoid overtightening which will strip the soft nylon screw. The set

screw can be used whenever desired, or never at all.

On/Off Switch

The on/off switch is located on the side of the router, just above the

hand grip, Figure 8. T o turn on the router , raise the on/of f switch lever

with your thumb while gripping the tool. T o turn of f the router, pull the

switch lever down. When the router is running, you will notice a probe

4

English

FIG. 7

OFF

OFF

FIG. 5

FIG. 6

CLAMP

LEVER

ADJUSTING

RING

HINGE

NYLON RING

LOCK

384404/DW628 5/2/02 1:39 PM Page 4

Page 8

extending from the top of the router. This probe is connected to the

on/off switch lever and can be used to turn off the router by pushing

it down toward the end cap. This probe also prevents the router from

inadvertently being turned on while it is inverted and resting on its

end cap. The end cap is designed so that the router can be inverted

for temporary storage, when changing the work piece, and while

changing router bits. Figure 9.

CAUTION: Some wood contains preservatives such as copper

chromium arsenate (CCA) which can be toxic. When cutting or

sanding these materials extra care should be taken to avoid

inhalation and minimize skin contact.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, call us toll

free at: 1-800-4-D

EWALT (1-800-433-9258) or contact:

DEWALT Industrial Tool Company

626 Hanover Pike, P.O. Box 158

Hampstead, MD. 21074-0158

CAUTION: The use of any other accessory not recommended for

use with this tool could be hazardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

EWAL T. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWAL T heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

5

English

FIG. 9FIG. 8

ON/OFF

SWITCH

PROBE LOCATION

PROBE

384404/DW628 5/2/02 1:39 PM Page 5

Page 9

6

Français

Importantes mesures de sécurité

AVERTISSEMENT : Afin de réduire les risques d’incendie, de

secousses électriques ou de blessures lorsqu’on utilise des outils

électriques, il faut toujours respecter les mesures de sécurité

suivantes.

LIRE TOUTES LES DIRECTIVES.

Mise à la terre

L’outil doit être mis à la terre lorsqu’on s’en sert afin de protéger

l’utilisateur contre les secousses électriques. D’ailleurs, l’outil est

muni d’un cordon trifilaire et d’une fiche à trois broches convenant

aux prises mises à la terre. Le conducteur vert (ou vert et jaune) du

cordon constitue la mise à la terre. Ne jamais relier le conducteur

vert (ou vert et jaune) à une borne sous tension. Lorsque l’outil est

conçu pour être alimenté à une tension maximale de 150 volts, sa

fiche ressemble à celle illustrée à la figure A. Lorsque l’outil est

conçu pour être alimenté à une tension maximale de 150 à250 volts,

sa fiche ressemble à celle illustrée à la figure D. Il existe des

adaptateurs (figures B et C) pour brancher le type de fiche illustré à

la figure A dans des prises à deux trous. L’oreille ou la cosse rigide

et verte doit être reliée à une mise à la terre permanente, comme une

prise bien mise à la terre. Il n’y a pas d’adaptateur pour les fiches

semblables à celle illustrée à la figure

D. AU CANADA, ON NE PEUT

PAS SE SERVIR DE L’ADAPTATEUR ILLUSTRÉ AUX FIGURES B ET C.

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO:

1 800 4-DEWALT (1 800 433-9258)

BOUCHON D’EXTRÉMITÉ

DISPOSITIF DE

VERROUILLAGE

DE LA BAGUE

LIGNE

GRAVÉE

LEVIER DE

SERRAGE

ADAPTATEUR

POUR MANDRIN

À PINCE

ÉCROU DU

MANDRIN À

PINCE

SOUS-PLAQUE

PLAQUE

BLOC-

MOTEUR

BAGUE DE

RÉGLAGE

INTERRUPTEUR

POINTE DE

L’INTERRUPTEUR

AB CD

BROCHE DE PRISE

MISE À LA TERRE

BROCHE DE PRISE

MISE À LA TERRE

PRISE MISE

À LA TERRE

DISPOSITIF DE

MISE À LA TERRE

ADAPTATEUR

384404/DW628 5/2/02 1:39 PM Page 6

Page 10

7

Français

ou d’un étau. On peut alors se servir des deux mains pour faire

fonctionner l’outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres pour

qu’ils donnent un rendement supérieur et sûr. Suivre les directives

concernant la lubrification et le remplacement des accessoires.

Inspecter régulièrement le cordon de l’outil et le faire réparer au

besoin à un atelier d’entretien autorisé. Inspecter régulièrement

les cordons de rallonge et les remplacer lorsqu’ils sont

endommagés. S’assurer que les poignées sont toujours propres,

sèches et libres de toute tache d’huile ou de graisse.

• DÉBRANCHER OU VERROUILLER EN POSITION HORS

TENSION LES OUTILS NON UTILISÉS. Respecter cette mesure

lorsqu’on ne se sert pas de l’outil, ou qu’on doit le réparer ou en

changer un accessoire (comme une lame, un foret ou un couteau).

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de

vérifier si les clés de réglage ont été retirées avant de faire

démarrer l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur l’interrupteur lorsqu’on transporte l’outil. S’assurer que

l’interrupteur est à la position hors circuit lorsqu’on branche l’outil.

•

CORDONS DE RALLONGE. Utiliser seulement des cordons de

rallonge trifilaires ayant une fiche à 3 broches ainsi qu’une prise à

3 trous acceptant la fiche de l’outil. Remplacer ou réparer les

cordons de rallonge endommagés. S’assurer que le cordon de

rallonge est en bon état. Lorsqu’on se sert d’un cordon de

rallonge, s’assurer qu’il est de calibre approprié pour la tension

nécessaire au fonctionnement de l’outil. L’utilisation d’un cordon

de calibre inférieur occasionne une baisse de tension entraînant

une perte de puissance et la surchauffe. Le tableau suivant

indique le calibre approprié selon la longueur du cordon et les

mentions de la plaque signalétique de l’outil. En cas de doute,

utiliser un cordon de calibre supérieur. Le chiffre indiquant le

Mesures de sécurité pour tous les outils

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail. Ne pas

utiliser l’outil en présence de liquides ni de gaz inflammables.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES.

Éviter tout contact avec des objets mis à la terre, comme des

tuyaux, radiateurs, cuisinières, réfrigérateurs et autres objets du

genre.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail et il faut les empêcher de toucher à

l’outil ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans

un endroit sec, situé en hauteur ou fermé à clé, hors de la portée

des enfants.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr

et efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil

ou d’un accessoire le rendement d’un outil de fabrication plus

robuste. Se servir de l’outil selon l’usage prévu.

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples et des bijoux qui peuvent être happés par les

pièces en mouvement. Porter des gants de caoutchouc et des

chaussures à semelle antidérapante pour travailler à l’extérieur.

Protéger la chevelure si elle est longue.

• PORTER DES LUNETTES DE SÉCURITÉ. Porter également un

masque respiratoire si le travail de coupe produit de la poussière.

• NE PAS MANIPULER LE CORDON DE FAÇON ABUSIVE. Ne

pas transporter l’outil par le cordon ni tirer sur ce dernier pour le

débrancher de la prise. Éloigner le cordon des sources de chaleur,

des flaques d’huile et des arêtes tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides

384404/DW628 5/2/02 1:39 PM Page 7

Page 11

8

calibre est inversement proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil

moins plus

0- 6 18161614

6 - 10 18 16 14 12

10- 1216161412

12 - 16 14 12 Non recommandé

• CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR.

Lorsque l’outil est utilisé à l’extérieur, ne se servir que d’un cordon

de rallonge conçu pour l’extérieur et portant la mention appropriée.

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de l’outil lorsqu’on est fatigué.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à

utiliser l’outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré

d’usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l’outil. Faire

réparer ou remplacer tout protecteur ou toute autre pièce

endommagée dans un centre de service autorisé, sauf si le

présent guide fait mention d’un avis contraire. Confier le

remplacement de tout interrupteur défectueux à un centre de

service autorisé. Ne jamais se servir d’un outil dont l’interrupteur

est défectueux.

CONSERVER CES MESURES.

Moteur

Un moteur DEWALT alimente l’outil DEWALT. Veiller à ce que la

tension d’alimentation soit conforme aux exigences de la plaque

signalétique de l’outil.

La mention “120 volts, 60 Hz” ou “c.a./c.c.” signifie que l’outil peut

fonctionner à l’aide de courant alternatif ou continu.

Une baisse de tension de plus de 10 p. 100 entraîne une perte de

puissance et la surchauffe. Tous les outils D

EWALT sont essayés

avant de quitter l’usine. Lorsque celui-ci refuse de fonctionner,

vérifier la source de courant électrique.

Levier de blocage

Mettre la toupie hors tension et la débrancher.

Afin de bloquer le bloc-moteur dans la plaque de la toupie, il y a un

levier sur le côté de l’outil (fig. 1).

Pour bloquer le bloc-moteur en place, abaisser à fond le levier; pour

dégager le bloc-moteur, soulever le levier jusqu’à environ un angle

droit par rapport à l’outil. Utiliser cette position déverrouillée pour

Français

FIG. 1 FIG. 2

LEVIER DE

VERROUILLAGE

ADAPTATEUR

POUR GUIDE

SOUS-

PLAQUE

384404/DW628 5/2/02 1:39 PM Page 8

Page 12

régler la profondeur de coupe et pour retirer le bloc-moteur de la

plaque. TOUJOURS S’ASSURER QUE LE LEVIER DE BLOCAGE

EST EN POSITION VERROUILLÉE (ABAISSÉE) LORSQU’ON SE

SERT DE L’OUTIL.

On peut modifier le sens du levier au besoin en desserrant le contreécrou que retient le levier à la toupie et en faisant tourner le levier à

la position voulue. Resserrer le contre-écrou.

Sous-plaque

Mettre la toupie hors tension et la débrancher.

La sous-plaque de la toupie a été conçue spécifiquement pour

assurer une meilleure visibilité que celle des toupies

conventionnelles tout en acceptant des guides pour modèle. On

peut aisément retirer l’adaptateur pour guide lorsqu’il ne sert pas afin

d’accroître la visibilité. Pour retirer l’adaptateur, soulever le levier de

blocage et soulever le bloc-moteur hors de la plaque. On peut alors

atteindre et retirer les deux vis de la plaque qui retiennent le guide en

place (fig. 2).

Lorsqu’on réinstalle le bloc-moteur, bien aligner la vis du guide (fig.3)

sur la fente de la plaque.

Centrage de la sous-plaque pour

toupiller à l’aide de modèles

L’adaptateur pour guide est aligné sur le mandrin àpince au moment

de l’expédition. Ces deux composants peuvent se déplacer en cours

de transport et de manutention, surtout si on échappe l’outil. Faire ce

qui suit afin de bien aligner le mandrin à pince sur l’adaptateur pour

guide.

1. Mettre la toupie hors tension et la débrancher.

2. Soulever le levier de blocage et retirer le bloc-moteur de la

plaque.

3. Retirer la vis du guide et la bague de réglage (fig. 3).

4. Desserrer les 4 vis de la sous-plaque (fig. 4).

5. Remettre la vis du guide (sans la bague de réglage) dans le blocmoteur et insérer ce dernier dans la sous-plaque. (S’assurer de

bien aligner la vis du guide sur la fente de la plaque.)

6. Abaisser le bloc-moteur jusqu’à ce que l’adaptateur du mandrin

à pince dépasse de l’adaptateur pour guide (fig. 4). Régler la

sous-plaque jusqu’à ce que l’adaptateur du mandrin à pince

passe à travers de celle-ci.

7. Resserrer les 4 vis de la sous-plaque et retirer le bloc-moteur de

la plaque.

8. Retirer la vis du guide et réinstaller la bague de réglage.

9. Installer la vis du guide et insérer de nouveau le bloc-moteur dans

la plaque. (S’assurer de bien aligner la vis du guide sur la fente

de la plaque.)

10. Le guide pour modèle est alors aligné sur le mandrin à pince.

NOTE : Lorsqu’on installe la vis du guide dans la section précédente,

ne pas oublier de bien la serrer de sorte que sa tête affleure le côté

du bloc-moteur.

9

Français

FIG. 3

FIG. 4

VIS DU GUIDE

BAGUE DE

RÉGLAGE

VIS

ADAPTATEUR

POUR GUIDE

384404/DW628 5/2/02 1:39 PM Page 9

Page 13

10

Français

Installation de mèches et de fraises

Mettre la toupie hors tension et la débrancher.

Insérer la tige de la mèche ou de la fraise voulue à fond dans le

mandrin à pince, puis le retirer légèrement (environ 0,793 mm

(1/32 po)). Utiliser les clés fournies pour bien serrer l’écrou du

mandrin à pince. Retenir l’adaptateur du mandrin à pince à l’aide

d’une clé et, de l’autre, serrer l’écrou.

Un enduit spécial recouvre le mandrin à pince et l’écrou afin d’en

accroître la puissance de retenue de la mèche. Utiliser seulement

les clés fournies pour serrer l’écrou. D’autres outils pourraient en

abîmer l’enduit en serrant excessivement.

Réglage de la profondeur

Mettre la toupie hors tension et la débrancher.

Desserrer le levier de blocage en le soulevant complètement. Régler

la profondeur de la mèche en faisant tourner la bague de réglage

(fig. 5). Pour soulever la mèche et l’éloigner de la surface de travail,

faire tourner la bague dans le sens horaire (lorsqu’on regarde le

dessus de l’outil) et pour abaisser la mèche dans la pièce, la faire

tourner dans le sens antihoraire. Il y a une ligne gravée dans le

boîtier en aluminium juste au-dessus du point de pivot du levier de

blocage (fig. 5). Lorsqu’on fait tourner la bague, les oreilles de la

bague passent sur cette ligne. Chaque fois qu’oreille passe la ligne,

la mèche est soulevée ou abaissée de 396 mm (1/64 po). Chaque

tour complet de la bague de réglage équivaut à un réglage de

3,175 mm (1/8 po) vers le haut ou le bas.

Les oreilles sont numérotées en conséquence par souci de

commodité. Afin d’accélérer les réglages, soulever légèrement le

carter du moteur et faire tourner la bague de réglage.

On peut copier rapidement et précisément des profondeurs de

coupes spécifiques (comme des charnières, des assemblages à

plat joint et des mortaises) en faisant ce qui suit.

FIG. 7

OFF

OFF

FIG. 5

FIG. 6

LEVIER DE

BLOCAGE

BAGUE DE

RÉGLAGE

CHARNIERE

DISPOSITIF DE VERROUILLAGE

DE LA BAGUE EN NYLON

384404/DW628 5/2/02 1:39 PM Page 10

Page 14

11

Français

1. METTRE LA TOUPIE HORS TENSION ET LA DÉBRANCHER.

2. Abaisser la mèche jusqu’à ce qu’elle touche à la pièce. (Voir la

rubrique précédente sur le réglage de la profondeur.)

3. Verrouiller le levier de blocage.

4. Soulever la bague de réglage en la faisant tourner dans le sens

antihoraire jusqu’à ce que la charnière s’insère tout juste entre le

dessus de la plaque et le dessous de la bague de réglage (fig. 6).

5. Retirer la charnière et inverser la toupie afin d’empêcher la mèche

d’égratigner la surface.

6. Déverrouiller le levier de blocage et laisser retomber la plaque au

nouveau réglage. Verrouiller le levier de blocage en place et la

profondeur est réglée. La toupie coupe alors l’épaisseur exacte

de la charnière.

Réglage du dispositif de verrouillage de

la bague

Mettre la toupie hors tension et la débrancher.

Afin d’empêcher de tourner en raison des vibrations de la toupie, la

bague comporte une vis de pression en nylon. Lorsque la bague

est réglée, serrer la vis de pression (fig. 7). Éviter de trop la serrer au

risque d’en endommager le filetage en nylon. On peut se servir ou

non de la vis de pression.

Interrupteur

L’interrupteur se trouve sur le côté de la toupie près de la poignée

(fig. 8). Pour actionner l’outil, soulever l’interrupteur à l’aide du pouce

tout en saisissant l’outil. Pour l’arrêter, abaisser l’interrupteur.

Lorsque la toupie fonctionne, on peut remarquer une pointe qui

dépasse sur le dessus de la toupie. Cette pointe est reliée à

l’interrupteur et on peut s’en servir pour mettre l’outil hors tension en

l’abaissant vers le bouchon d’extrémité. La pointe sert également à

empêcher le démarrage par inadvertance de l’outil lorsque celui-ci

est renversé et qu’il repose sur son bouchon d’extrémité. Ce

bouchon est conçu de façon à soutenir temporairement la toupie en

position inversée lorsqu’on en remplace un accessoire ou qu’on

remplace la pièce à ouvrer (fig. 9).

MISE EN GARDE : Certaines essences de bois renferment des

agents de conservation (comme de l’arséniate de cuivre et de chrome)

qui peuvent être toxiques. Lorsqu’on doit couper ou poncer de tels

matériaux, prendre des mesures supplémentaires afin d’éviter d’inhaler

les vapeurs toxiques et de minimiser les contacts avec la peau.

Accessoires

Les accessoires recommandés pour l’outil sont vendus séparément

chez les détaillants et au centre de service de la région. Pour trouver

un accessoire, composer sans frais le 1 (800) 4-D

EWALT

(1 (800) 433-9258) ou communiquer à l’adresse suivante.

D

EWALT Industrial Tool Company

626 Hanover Pike, P.O. Box 158

Hampstead, MD 21074-0158

É.-U.

FIG. 9FIG. 8

INTERRUPTEUR

EMPLACEMENT DE

LA POINTE

POINTE

384404/DW628 5/2/02 1:39 PM Page 11

Page 15

12

MISE EN GARDE : L’utilisation de tout autre accessoire non

recommandé pour l’outil peut être dangereuse.

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’au personnel d’un

centre de service D

EWALT ou d’un atelier d’entretien autorisé

n’utilisant que les seules pièces de rechange D

EWALT.

Garantie complète

Les outils industriels de service intensif DEWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée sans frais. Pour obtenir de plus amples

renseignements relatifs à la garantie, composer le 1 (800) 94D

EWAL T(1 (800) 433-9258). La présente garantie ne couvre pas les

accessoires ni les avaries dues aux réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnent des droits légaux spécifiques. L’utilisateur peut également

se prévaloir d’autres droits selon l’état ou la province qu’il habite.

En outre, la garantie suivante couvre les outils D

EWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT

REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service intensif

D

EWALT ne donne pas entière satisfaction, il suffit de le retourner

chez le marchand participant dans les 30 jours suivant la date

d’achat afin d’obtenir un remboursement complet. Il faut retourner,

port payé, l’outil complet. On peut exiger une preuve d’achat.

Français

Imported by / Importé par

DeWALT Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

384404/DW628 5/2/02 1:39 PM Page 12

Page 16

Instrucciones importantes de seguridad

ADVERTENCIA: Siempre que utilice herramientas eléctricas

debe seguir algunas precauciones básicas de seguridad para reducir

los riesgos de incendio, choque eléctrico y lesiones personales.

entre estas precauciones se encuentran las siguientes:

LEA TODAS LAS INSTRUCCIONES

Instrucciones De Conexión A Tierra

Esta herramienta debe conectarse a tierra para proteger al operador

de choques eléctricos. Esta unidad está equipada con un cordón

eléctrico de tres hilos y una clavija de aterrizaje con tres patas para

conectarse a la toma de corriente adecuada. El conductor verde (o

verde y amarillo) es el cable de tierra. Nunca conecte el cable verde

(o verde y amarillo) a una terminal viva. Si su unidad está hecha para

funcionar con menos de 150 volts, tiene una clavija similar a la que

se muestra en la figura A. Si es para usarse con corriente de 150 a

250 volts, tiene una clavija como la que se muestra en la figura D.

Hay adaptadores, figuras B y C, para conectar clavijas del tipo de la

figura A a tomas de corriente para dos patas. La oreja de color verde

deberá conectarse a tierra permanente, tal como una toma de

corriente aterrizada adecuadamente. No hay adaptadores para

clavijas como la de la figura

D. EL ADAPTADOR MOSTRADO EN

LAS FIGURAS B Y C NO ESTA HECHO PARA USARSE EN CANADÁ

.

13

Español

CAJA DEL INTERRUPTOR

TAPA SUPERIOR

SEGURO

LÍNEA

GRABADA

PALANCA

DE

FIJACIÓN

ADAPTADOR

DE BOQUILLAS

TUERCA DE LA

BOQUILLA

SUB BASE

BASE

UNIDAD

DEL

MOTOR

INTERRUPTOR

ANILLO DE

AJUSTE

SI TIENE CUALQUIER PREGUNTA O COMENTARIO ACERCA DE

ESTA O CUALQUIER OTRA HERRAMIENTA D

EWAL T, POR FA VOR

LLÁMENOS AL: 326-7100

ESPECIFICAÇIONS:

120V CA/CD

60Hz 13A

24,000 RPM

AB CD

PATA DE CONEXION A TIERRA

TOMA DE

CORRIENTE

ATERRIZADA

MEDIO DE

ATERRIZAJE

PATA DE

CONEXION A TIERRA

ADAPTADOR

384404/DW628 5/2/02 1:39 PM Page 13

Page 17

14

Aléjelo de calor, aceite y bordes afilados.

• ASEGURE LAS PIEZAS DE TRABAJO. Utilice prensas para

sujetar su pieza de trabajo; es más seguro que usar su mano y le

deja ambas manos libres para operar la herramienta.

• NO SE SOBREEXTIENDA. Apoye bien los pies y conserve el

equilibrio siempre.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas

limpias y afiladas para un rendimiento mejor y más seguro. Siga

las instrucciones de lubricación y cambio de accesorios. Revise la

herramienta periódicamente y si está dañada, hágala reparar por

una estación de servicio autorizada. Revise los cables de

extensión periódicamente y reemplácelos si están dañados.

Conserve las empuñaduras secas, limpias y libres de aceite y

grasa.

• DESCONECTE LAS HERRAMIENTAS O ASEGÚRELAS EN

POSICIÓN DE APAGADO. Desconecte la herramienta cuando no

la utilice, cuando la cambie de lugar, antes de darle servicio y

cuando le cambie accesorios como brocas, puntas o cortadores.

• QUITE LAS LLAVES DE AJUSTE Y LAS HERRAMIENTAS DE

MANO. Acostúmbrese a verificar que se hayan retirado todas las

llaves antes de encender la unidad.

• EVITE EL ENCENDIDO ACCIDENTAL. No acarree la

herramienta con el dedo en el interruptor. Asegúrese que el

interruptor esté en posición de apagado antes de conectar la

unidad.

• CABLES DE EXTENSIÓN. Asegúrese que su extensión esté en

buenas condiciones. Cuando utilice una extensión, asegúrese que

tenga el calibre suficiente para conducir la corriente que su herramienta

necesita. Una extensión con calibre menor al necesario causará una

caída en el voltaje de la línea, resultando en pérdida de potencia y

sobre calentamiento.

La tabla siguiente muestra el calibre correcto para

usarse, de acuerdo con la longitud de la extensión y el amperaje en la placa

de identificación.

Si tiene dudas, utilice el calibre siguiente. Mientras

menor sea el número del calibre, mayor será la capacidad del cable.

Español

Instrucciones De Seguridad Para Todas

las Herramientas

• CONSERVE LIMPIA EL ÁREA DE TRABAJO. Las áreas y los

bancos con objetos acumulados en desorden propician los

accidentes.

• DELE PRIORIDAD AL AMBIENTE DE TRABAJO. No exponga

las herramientas eléctricas a la lluvia. No utilice herramientas

eléctricas en lugares húmedos o inundados. Ilumine bien la zona

de trabajo. No utilice las herramientas eléctricas en presencia de

líquidos o gases inflamables.

• PROTÉJASE CONTRA EL CHOQUE ELÉCTRICO. Evite el

contacto corporal con superficies aterrizadas, por ejemplo:

tuberías radiadores, hornos, gabinetes de refrigeración, etc.

• CONSERVE APARTADOS A LOS NIÑOS. No permita que niños

ni otros visitantes toquen la herramienta ni los cables de extensión.

Todos los visitantes deben apartarse del área de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Siempre

que no use las herramientas, debe guardarlas en un lugar seco y

elevado o bajo llave, fuera del alcance de los niños.

• NO FUERCE LA HERRAMIENTA. Esta hará el trabajo mejor y

de manera más segura bajo las especificaciones para las que se

diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta pequeña o a sus dispositivos en una tarea destinada

a una herramienta de alto rendimiento. No utilice la herramienta

para tareas para las que no ha sido diseñada.

• VÍSTASE DE MANERA ADECUADA. No utilice ropas sueltas ni

joyas, pueden quedar atrapadas en las partes móviles. Se

recomienda el uso de guantes y calzado antiderrapante cuando

trabaje a la intemperie. Cúbrase el cabello si lo tiene largo.

• UTILICE GAFAS DE SEGURIDAD.También utilice una mascarilla

contra polvo si la operación lo produce.

• NO MALTRATE EL CABLE. Nunca cargue la herramienta por el

cable ni tire de éste para desconectarlo de la toma de corriente.

384404/DW628 5/2/02 1:39 PM Page 14

Page 18

• CABLES DE EXTENSIÓN PARA INTEMPERIE. Cuando utilice

la herramienta a la intemperie, utilice únicamente extensiones

destinadas para este uso y marcadas así.

• ESTÉ ALERTA. Concéntrese en lo que hace. Utilice el sentido

común. No opere la herramienta si está cansado.

• REVISE LAS PARTES DAÑADAS. Antes de seguir usando la

herramienta, debe revisar las guardas y otras partes para

determinar realizarán su función adecuadamente. Revise la

alineación de las partes móviles, la manera en que están sujetas,

que no haya piezas o soportes rotos, y cualesquiera otras

condiciones que puedan afectar la operación. Una guarda u otra

pieza que esté dañada debe ser reparada o reemplazada en un

centro de servicio autorizado. No use la herramienta si el

interruptor no enciende y apaga.

CONSERVE ESTAS INSTRUCCIONES

Motor

Su herramienta DEWAL Tfunciona con un motor DEWALT. Asegúrese

que la alimentación concuerde con las indicaciones de la placa de

identificación.

15

Español

120 Volts 60 Hz o “AC/DC” significa que su herramienta puede

operarse con corriente alterna o con corriente directa.

Disminuciones en el voltaje de 10% o mayores causarán pérdida de

potencia y sobre calentamiento. T odas las herramientas D

EWALT se

prueban en la fábrica; si esta herramienta no funciona, revise la

alimentación de corriente.

Palanca De Fijación

Apague y desconecte la rebajadora.

Para fijar la posición de la unidad del motor de la rebajadora con

respecto a la base, se ha provisto una palanca a un lado de la

herramienta, como se ilustra en la Figura 1.

Para asegurar la unidad del motor en cierta posición, empuje la

palanca hacia abajo; para liberar el motor, suba la palanca hasta

quedar aproximadamente en ángulo recto con respecto a la

herramienta. Utilice esta posición suelta para hacer ajustes de

profundidad y para sacar la unidad del motor de la base.

ASEGÚRESE SIEMPRE QUE LA PALANCA DE FIJACIÓN ESTÉ

PALANCA

DE FIJACIÓN

FIG. 1 FIG. 2

SUB BASE

ADAPTADOR

PARA GUÍA

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7.62 7.63-15.24 15.25-30.48 30.49-45.72

240V 0-15.24 15.25-30.48 30.49-60.96 60.97-91.44

Amperaje

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

384404/DW628 5/2/02 1:39 PM Page 15

Page 19

16

EN LA POSICIÓN CERRADA (HACIA ABAJO) CUANDO CORTE.

Puede cambiarse la orientación de la palanca en caso que se desee

aflojando la tuerca de seguridad que la sujeta a la rebajadora y

girando la palanca a la posición deseada. Apriete de nuevo la tuerca

de seguridad.

Sub Base

Apague y desconecte la rebajadora

La sub base de su rebajadora se ha diseñado especialmente para

permitir mayor visibilidad que las rebajadoras convencionales pero

conserva la capacidad para usar plantillas guía. Si no se necesita el

adaptador de guías, puede desmontarse para tener aún mayor

visibilidad. Para quitar el adaptador suba la palanca de fijación y

levante el montaje del motor hacia fuera de la base de la rebajadora.

Esto le permitirá alcanzar y quitar los dos tornillos de la base que

sujetan al adaptador en su sitio, como se observa en la Figura 2.

Cuando reinstale la unidad del motor, asegúrese de alinear el tornillo

guía (Figura 3) con la ranura que se encuentra en la base de la

rebajadora.

Alineación de la Sub Base Para Corte

Con Plantillas

El adaptador de guías está alineado con la boquilla desde su

fabricación, pero ambos pueden perder la alineación durante el

embarque y el manejo, particularmente si la herramienta se cae.

Para linear de manera correcta la boquilla con respecto al adaptador

de guías, siga los pasos descritos a continuación.

1. Apague y desconecte la rebajadora.

2. Suba la palanca de fijación y saque la unidad del motor de la base

de la rebajadora.

3. Quite el tornillo de la guía y el anillo de ajuste ilustrados en la Figura 3.

4. Afloje los cuatro tornillos de la sub base, como se observa en la

figura 4.

5. Re inserte el tornillo de la guía (no el anillo de ajuste) en la unidad

del motor e inserte a continuación la unidad del motor en la base

de la rebajadora. (Asegúrese de alinear el tornillo de la guía con

la ranura de la base de la rebajadora.)

6. Baje la unidad del motor hasta que el adaptador de la boquilla se

extienda a través del adaptador de la guía, como se observa en la

figura 4. Ajuste la sub base hasta que el adaptador de boquillas

se acople a través de éste.

7. Apriete los cuatro tornillos de la sub base y saque la unidad del

motor de la base de la rebajadora.

8. Quite el tornillo de la guía y reinstale el anillo de ajuste.

9. Instale el tornillo de la guía y reinserte la unidad del motor en la

base de la rebajadora. (Asegúrese de alinear el tornillo de la guía

con la ranura de la base.)

10. La guía de plantillas está ahora alineada con la boquilla.

NOTA: Cuando instale el tornillo de la guía antes mencionado,

recuerde que deberá estar apretado firmemente de manera que la

cabeza esté al ras de la parte lateral de la unidad del motor.

Español

FIG. 3

TORNILLO GUÍA

ANILLO DE

AJUSTE

ADAPTADOR

DE GUÍAS

FIG. 4

TORNILLOS

384404/DW628 5/2/02 1:39 PM Page 16

Page 20

Instalación De Cuchillas y Cortadores

Apague y desconecte la rebajadora

Inserte el vástago de la cuchilla que desee en la boquilla tanto como

sea posible, a continuación tire ligeramente de ella

(aproximadamente 0,8 mm [1/32”]). Utilice las llaves que le

proporcionamos para apretar con firmeza la tuerca de la boquilla.

Con una llave sujete el adaptador de boquillas y con la otra apriete la

tuerca de la boquilla.

La boquilla y su tuerca tienen un recubrimiento especial para

aumentar la capacidad de retención de cortadores. Únicamente

utilice las llaves provistas con su rebajadora para apretar la tuerca de

la boquilla. Puede dañar el recubrimiento.

Ajuste De Profundidad

Apague y desconecte la rebajadora.

Afloje la palanca de fijación levantándola completamente. Ajuste la

profundidad de corte de la rebajadora girando el anillo de ajuste,

ilustrado en la figura 5. Para subir el cortador para alejarlo de la

superficie de trabajo, gire el anillo en el sentido de las manecillas

del reloj (Visto desde la parte superior de la unidad) y para bajar el

cortador hacia la superficie de trabajo, gírelo en sentido contrario a

las manecillas del reloj. Directamente sobre el eje de la palanca de

fijación se encuentra una línea grabada en la carcaza de aluminio,

como se observa en la figura 5. Al girar el anillo, las lengüetas

pasarán sobre esta línea. Cada vez que una de las lengüetas pase

por la línea, se sube o se baja el cortador 0,396 mm (1/64”). Una

revolución completa del anillo de ajuste equivale a 3,175 mm (1/8”)

de ajuste hacia abajo o hacia arriba.

Las lengüetas se han numerado consecutivamente para mayor

comodidad. Para ajustes más rápidos, levante ligeramente la unidad

del motor y gire el anillo de ajuste.

Para duplicar una profundidad de corte específica, como la de una

caja para bisagra, siga los pasos descritos a continuación.

17

Español

FIG. 7

OFF

OFF

FIG. 5

FIG. 6

PALANCA

DE FIJACIÓN

ANILLO DE

AJUSTE

BISAGRA

SEGURO DE

NYLON DEL

ANILLO

384404/DW628 5/2/02 1:39 PM Page 17

Page 21

18

1. APAGUE Y DESCONECTE LA REBAJADORA.

2. Baje el cortador hasta tocar apenas la superficie de trabajo.

(Consulte la sección anterior “Ajuste de profundidad”.)

3. Asegure la palanca de fijación.

4. Suba el anillo de ajuste girándolo en sentido contrario a las

manecillas del reloj hasta que la bisagra quede justo entre el

borde superior de la base de la rebajadora y la parte inferior del

anillo de ajuste, como se muestra en la Figura 6.

5. Saque la bisagra e invierta la rebajadora para evitar que el

cortador dañe la superficie de trabajo.

6. Desasegure la palanca de fijación y permita que la base caiga en

la nueva posición. Asegure la palanca de fijación en posición y

tendrá la profundidad ajustada. La rebajadora cortará ahora a la

profundidad exacta de la bisagra.

Español

Ajuste Del Seguro Del Anillo

Apague y desconecte la rebajadora.

Para evitar que el anillo de ajuste gire debido a las vibraciones de la

rebajadora, se le ha provisto con un prisionero de nylon. Cuando

haya ajustado el anillo en la posición deseada, apriete este

prisionero, como se observa en la figura 7. T enga cuidado para evitar

sobreapretar, ya que arruinaría el prisionero. Puede utilizar este

prisionero siempre que quiera, o nunca si así lo desea.

Interruptor De Encendido Y Apagado

El interruptor de encendido y apagado se encuentra a un lado de la

rebajadora, justo por arriba de la empuñadura, Figura 8. para

encender la rebajadora, suba la palanca del interruptor con el pulgar

al mismo tiempo que sujeta la herramienta. Para apagar la

rebajadora, empuje la palanca hacia abajo. Cuando la rebajadora

esté en funcionamiento, notará una caja que se extiende de la parte

superior de la rebajadora. Esta caja está conectada al interruptor de

encendido y apagado y puede utilizarse para apagar la unidad

empujándola hacia abajo, hacia la tapa. Esta caja también sirve para

evitar encender la rebajadora inadvertidamente mientras está

apoyada sobre la tapa. La tapa está diseñada de manera que pueda

colocar la rebajadora de cabeza para guardarla temporalmente, para

cambiar la pieza de trabajo y cambiar de cortadores, Figura 9.

PRECAUCIÓN: Algunos tipos de madera contienen

conservadores como el arsenato cúprico de cromo (CCA) que

pueden ser tóxicos. Cuando corte o lije estos materiales, deberá

tener precaución extrema para evitar la inhalación y minimizar el

contacto con la piel de estas sustancias.

FIG. 9FIG. 8

INTERRUPTOR

DE ENCENDIDO

Y APAGADO

LOCALIZACIÓN DE LA CAJA

CAJA

384404/DW628 5/2/02 1:39 PM Page 18

Page 22

Accesorios

Los accesorios recomendados para emplearse con su herramienta

se encuentran a su disposición con costo extra con su distribuidor o

centro de servicio locales. Si necesita ayuda para localizar algún

accesorio, comuníquese por favor al 1-800-4-D

EWALT o a:

D

EWALT Industrial Tool Company

626 Hanover Pike, P.O. Box 158

Hampstead, MD. 21074-0158

PRECAUCIÓN: El uso de cualquier accesorio no recomendado

puede ser peligroso.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros autorizados de servicio DeWAL T u otras organizaciones

autorizadas. Estas organizaciones prestan servicio a las herramientas

DeWALT y emplean siempre refacciones legitimas DeWALT.

19

Español

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av. Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

384404/DW628 5/2/02 1:39 PM Page 19

Page 23

20

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: __________ Mod./Cat.: _____________

Marca: _____________________ Núm. de serie:__________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: __________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

_____________________________________________________

Este producto está garantizado por un año a partir de la fecha de entrega,

contra cualquier defecto en su funcionamiento, así como en materiales y

mano de obra empleados para su fabricación. Nuestra garantía incluye la

reparación o reposición del producto y/o componentes sin cargo alguno para

el cliente, incluyendo mano de obra, así como los gastos de transportación

razonablemente erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta y esta

póliza sellada por el establecimiento comercial donde se adquirió el producto,

de no contar con ésta, bastará la factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

•Cuando el producto se hubiese utilizado en condiciones distintas a las

normales;

•Cuando el producto no hubiese sido operado de acuerdo con el

instructivo de uso que se acompaña;

•Cuando el producto hubiese sido alterado o reparado por personas

distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica,

centros de servicio autorizados y franquiciados en la República

Mexicana, donde podrá hacer efectiva su garantía y adquirir partes,

refacciones y accesorios originales.

Garantía Completa

Las herramientas industriales DEWalt están garantizadas durante un año a

partir de la fecha de compra. Repararemos, sin cargos, cualquier falla debida

a material o mano de obra defectuosos. Por favor regrese la unidad completa,

Español

con el transporte pagado, a cualquier Centro de Servicio para Herramientas

Industriales de DEWalt o a las estaciones de servicio autorizado enlistadas

bajo "Herramientas Eléctricas" en la Sección Amarilla. Esta garantía no se

aplica a los accesorios ni a daños causados por reparaciones efectuadas

por terceras personas. Esta garantía le otorga derechos legales específicos,

y usted puede tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas DEWALT están amparadas por

nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de

su herramienta industrial DEWalt, sencillamente devuélvala a los vendedores

participantes durante los primeros 30 días después de la fecha de compra

para que le efectúen un reembolso completo. Por favor regrese la unidad

completa, con el transporte pagado. Se puede requerir prueba de compra.

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 326-7100

SECCI N

AMARILLA

Si funciona…

y funciona muy bien.

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

384404/DW628 5/2/02 1:39 PM Page 20

Loading...

Loading...