Page 1

©

0

e-'l_

oO

•

L..O

U) L

"0 L

"='8

0") ,_-

•I" X

"0

,. "o

_,_ 0

&

DEWALTIndustrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(MAR07) Form No.651120-00 DW505, DW520

Copyright © 1997, 2002, 2004, 2006, 2007 DEWALT

The following are trademarks for one or more DEWALTpower tools: theyellow and black color scheme;

the "D"shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the

array of lozenge-shaped humps on the surface of the tool.

S Definitions: Safety Guidelines \

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

A DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

_ WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

A CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation

which, ff not avoided, may result in property damage.

1/

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

General Safety Rules

A WARNIN!! To reduce risk of injury, user must read instruction manual

F_ l t f_ll II t t L _ d b l, It [ t h k

aLure o o ow a ins ruc ions is e e ow may resu in e ec ric s oc, fire

and/or serious injury. The term "power tool" in all of the warnings listed below

refers to your mains-operated (corded) power tool or battery-operated (cordless)

power tool

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tool& Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock. Have damaged cords repaired

or replaced by an authorized service center. Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole receptacles that accept the tool's plug.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock. Make sure

your extension cord is in good condition. When using an extension cord, be sure to use

one heavy enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating. The following

table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the

heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

Mo_

Than

0

6

10

12

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before plugging

in. Carrying power tools with your finger on the switch or plugging in power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at at times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts. Air vents often cover moving parts and should also be avoided.

g) ff devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce

dust-related hazards.

4) POWERTOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool ff the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tools operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking

into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Not More

Than

6

10

12

16

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

18

18

16

14

AWG

16

16

16

12

16 14

14 12

14 12

Not Recommended

Additional Safety Rules for Hammerdrills

* Hold power tools by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Contact with a "live"

wire will make exposed metal parts of the tool "live" and shock the operator.

Be certain that the material being drilled does not conceal electric or gas service and that

their locations have been verified with the utility companies.

Wear ear protectors. Exposure to noise can cause hearing loss.

Use auxiliary handles supplied with the tool. Loss of control can cause personal injury.

Keep a firm grip on the tool at all times. Do not attempt to operate this tool without holding

it with beth hands. Operating this tool with one hand will result in loss of control Breaking

through or encountering hard materials such as re-bar may be hazardous as well. Tighten the

side handle securely before use.

° Use clamps or other practical way to secure and support the work'piece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control

* Wear safety goggles or other eye protection. Hammering operations cause chips to fly.

Flying particles can cause permanent eye damage. Wear a dust mask or respirator for appli-

cations that generate dust. Ear protection may be required for most applications.

. Keep a firm grip on the tool at all times. Do not attempt to operate this tool without

holding it with both hands. Operating this tool with one hand will result in loss of control.

Breaking through or encountering hard materials such as re-bar may be hazardous as well.

° Do not operate this tool for long periods of time. Vibration caused by hammer action may

be harmful to your hands and arms. Use gloves to provide extra cushion and limit exposure

by taking frequent rest periods.

° Do not recondition bits yourself. Chisel reconditioning should be done by an authorized

specialist. Improperly reconditioned chisels could cause injury.

° Wear gloves when operating tool or changing bits. Accessible metalparts on the tool and

bits may get extremely hot during operation. Small bits of broken material may damage bare

hands.

° Never lay the tool down until the bit has come to a complete stop. Moving bits could

cause injury.

° Do not strike jammed bits with a hammer to dislodge them. Fragments of metal or mate-

rial chips could dislodge and cause injury.

. Keep the power cord away from the rotating bit. Do not wrap the cord around any part

of your body. An electric cord wrapped around a spinning bit may cause personal injury and

loss of control

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

° ANSI Z87.1 eye protection (CAN/CSA Z94.3),

° ANSI $12.6 ($3.19) hearing protection,

° NIOSH/OSHA/MSHA respiratory protection.

Z&WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

° lead from lead-based paints,

° crystalline silica from bricks and cement and other masonry products, and

° arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

° Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other inju_ Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Alway_s_ff.ye _t!'et_z_t_ users and bystanders must wear eye protection

that conforms to AN_Z_7.1. o VSRSZON: Z

A WARNING: Alwa_r _YhY_i_,p_cTnal hearing_DtOtection that conforms to ANSI

$12.6 ($3.19) durin_ise. Un_f_F_ _'onditions and _u_k_n of use, noise from this product

may contribute to hearing loss.

Page 2

Thelabelonyourtoolmayincludethefollowingsymbols.Thesymbolsandtheirdefinitions

areasfollows:

V.................. volts

Hz................ hertz

min .............. minutes

--- ........... direct current

@ ................ Class I Construction

(grounded)

[] ................ Class II Construction

(double insulated)

BPM ............ beats per minute

COMPONENTS

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

A. Trigger switch E Side handle

B. Locking button G. Handle grip

C. Reversing lever

D. Shift knob

E. Hammer/drill selector

INTENDED USE

The DW505 and DW520 heavy-duty hammerdrills have been designed for professional drilling

and hammerdrilling, screwdriving and light chipping, chiselling, demolition applications and for

carbide-tipped core drilling at various work sites (i.e., construction sites). DO NOT use under

humid conditions or in presence of flammable liquids or gases.

The DW505 and DW520 heavy-duty hammerdrills are professional power tools. DO NOT let chil-

dren come into contact with the tool. Supervision is required for those under 16 years of age.

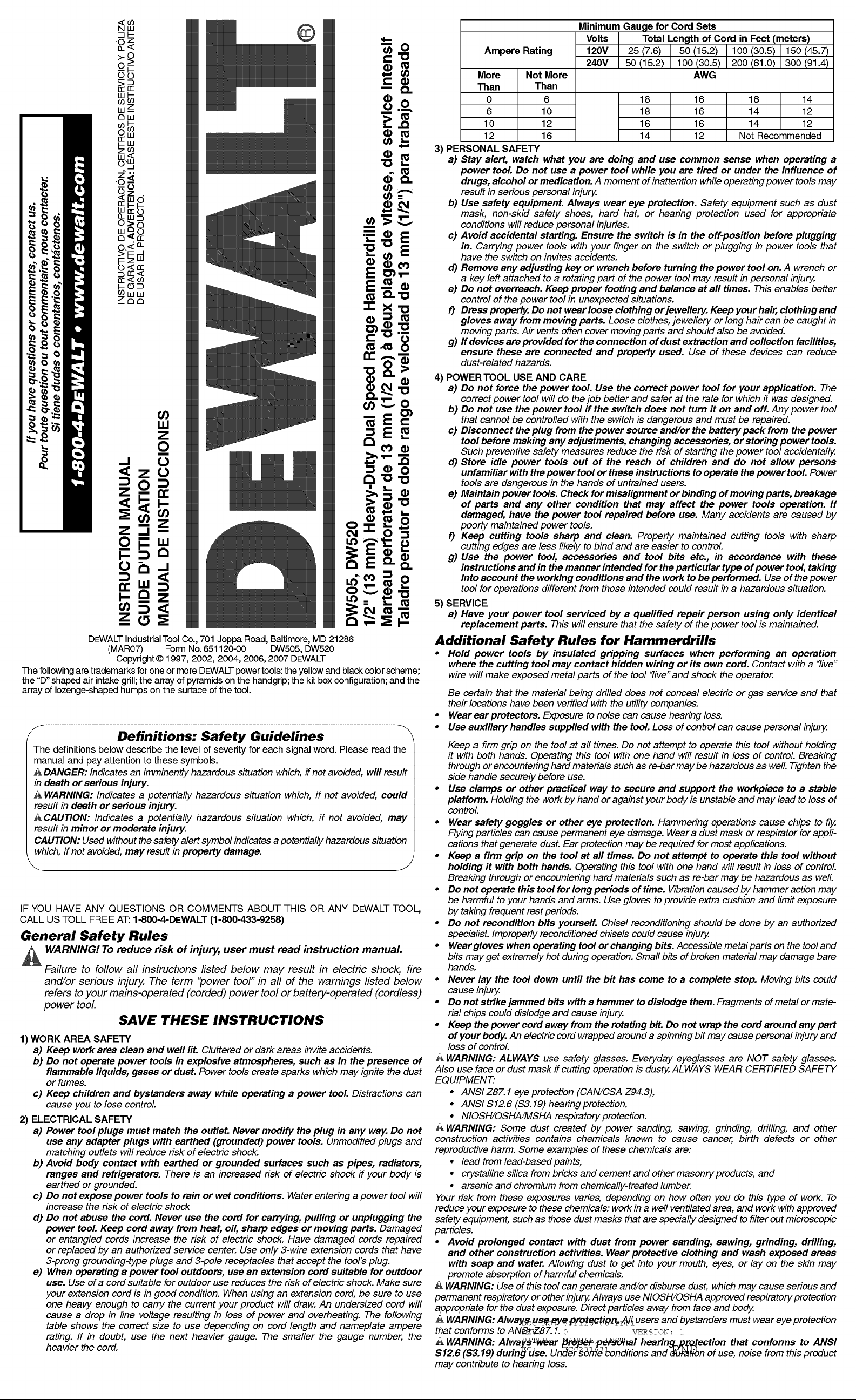

Side Handle (Fig. 1)

A WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side

handle properly installed. Failure to do so may result in the side handle slipping during tool

operation and subsequent loss of control Hold tool with both hands to maximize control.

A side handle (F) is supplied with this hammerdrill. It clamps to the front of the gear case as

shown in Figure 1 and can be rotated 360 °for right- or left- hand use.

After the side handle is rotated into position, it should be pushed rearward until the slots (H)

on the lip of the side handle are aligned and fully engaged with the projecting tabs (I) on the

underside of the gear case. The side handle is then securely clamped by turning the handle grip

(G) clockwise until tight.

Switch (Fig. 2)

To start hammerdrill, depress the trigger switch (A). To stop hammerdrill, release the trigger

switch.

A WARNING: Be sure to release the locking mechanism before disconnecting the plug from

the power supply, Failure to do so will cause the hammerdrill to start immediately the next time

it is plugged in. Damage or personal injury could result.

To lock the trigger switch in the ON position for continuous operation, depress the trigger switch

and push up the locking button (B). The tool will continue to run. To turn the tool OFF, from a

locked-on condition, squeeze and release the trigger once. Before using the tool (each time), be

sure that the locking button release mechanism is working freely.

DO NOT lock the switch on when drilling by hand so that you can instantly release the

trigger switch if the bit binds in the hole. The locking button is for use ONLY when the hammerdrill

is mounted in a drill press stand or other wise held stationary.

VARIABLE SPEED

The variable speed trigger switch permits speed control. The farther the trigger switch is

depressed, the higher the speed of the hammerdrill.

NOTE: Use lower speeds for starting holes without a centerpunch, drilling in metal, plastics or

ceramics, or driving screws. Higher speeds are better for drilling in wood and composition board

and for using abrasive and polishing accessories.

REVERSING LEVER

The reversing lever (C)is used to reverse the hammerdrill for backing out screws or jammed bits.

It is located above the trigger, shown in Figure 2. To reverse the hammerdrill, turn it off and push

the reversing lever to the left (when viewed from the chuck end).

To position the lever for forward operation, turn the hammerdrill off and push the lever to the right

(when viewed from the chuck end).

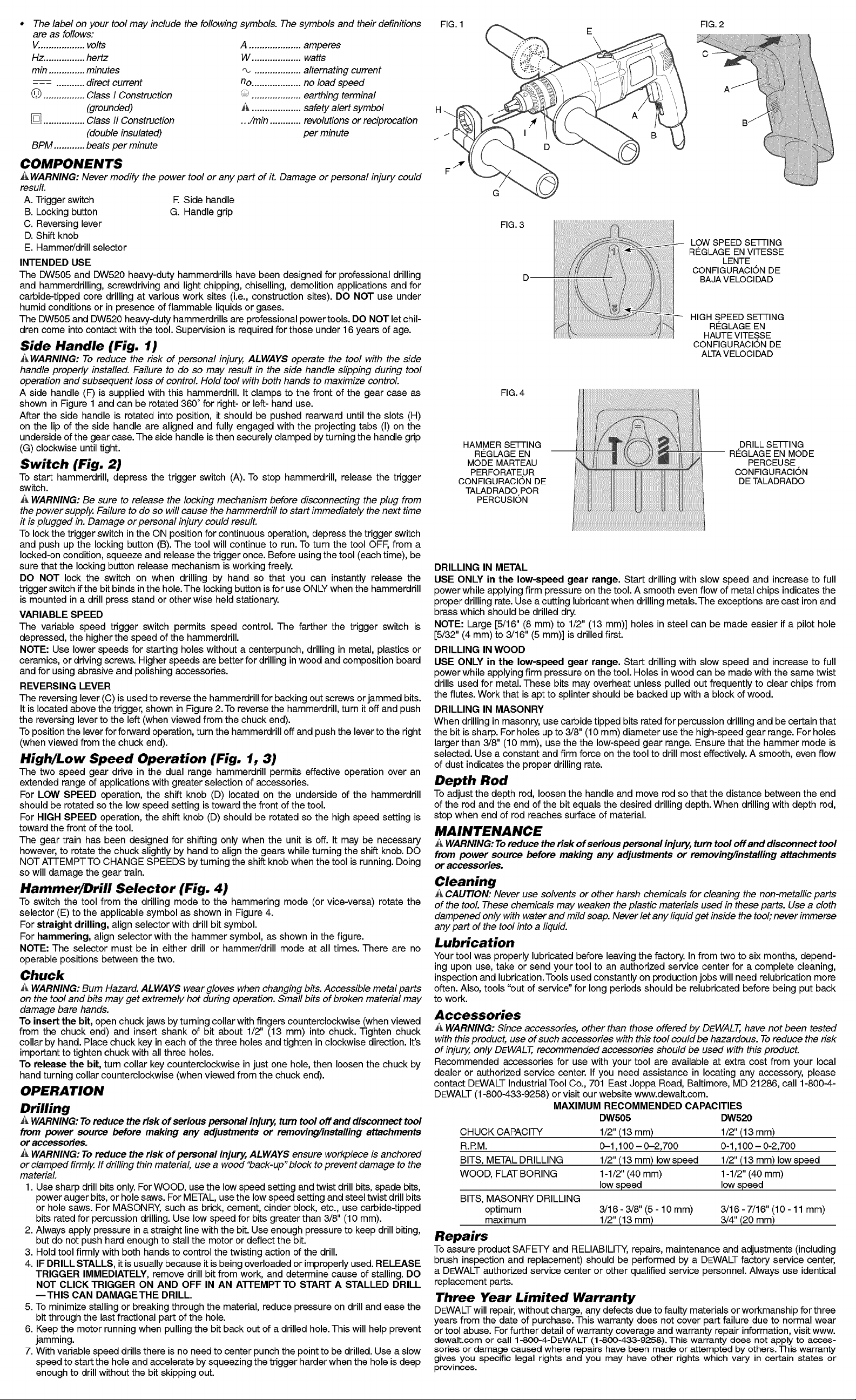

High/Low Speed Operation (Fig. 1, 3)

The two speed gear drive in the dual range hammerdrill permits effective operation over an

extended range of applications with greater selection of accessories.

For LOW SPEED operation, the shift knob (D) located on the underside of the hammerdrill

should be rotated so the low speed setting is toward the front of the tool.

For HIGH SPEED operation, the shift knob (D) should be rotated so the high speed setting is

toward the front of the tool.

The gear train has been designed for shifting only when the unit is off. It may be necessary

however, to rotate the chuck slightly by hand to align the gears while turning the shift knob. DO

NOT A-I-I-EMPTTO CHANGE SPEEDS by turning the shift knob when the tool is running. Doing

so will damage the gear train.

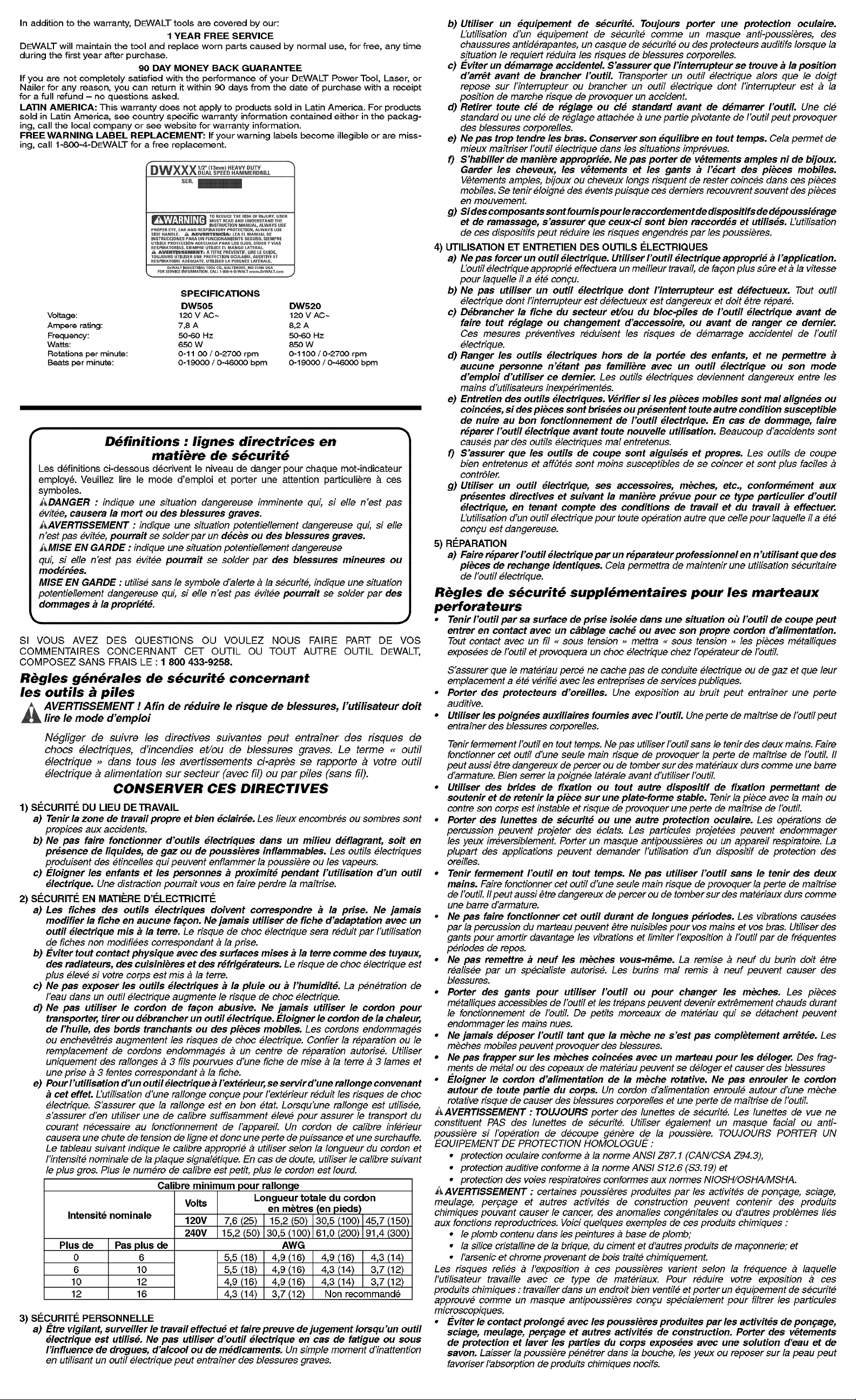

Hammer/Drill Selector (Fig. 4)

To switch the tool from the drilling mode to the hammering mode (or vice-versa) rotate the

selector (E) to the applicable symbol as shown in Figure 4.

For straight drilling, align selector with drill bit symbol.

For hammering, align selector with the hammer symbol, as shown in the figure.

NOTE: The selector must be in either drill or hammer/drill mode at all times. There are no

operable positions between the two.

Chuck

i_ WARNING: Burn Hazard. ALWAYS wear gloves when changing bits. Accessible metal parts

on the tool and bits may get extremely hot during operation. Small bits of broken material may

damage bare hands.

To insert the bit, open chuck jaws by turning collar with fingers counterclockwise (when viewed

from the chuck end) and insert shank of bit about 1/2" (13 mm) into chuck. Tighten chuck

collar by hand. Place chuck key in each of the three holes and tighten in clockwise direction. It's

important to tighten chuck with all three holes.

To release the bit, turn collar key counterclockwise in just one hole, then loosen the chuck by

hand turning collar counterclockwise (when viewed from the chuck end).

OPERATION

Drilling

WARNING: Toreduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments

or accessories.

A WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored

or clamped firmly, If drilling thin material, use a wood "back-up" block to prevent damage to the

material

1. Use sharp drill bits only. For WOOD, use the low speed setting and twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, usethe low speed setting and steel twist drill bits

or hole saws. For MASONRY, such as brick, cement, cinder block, etc., use carbide-tipped

bits rated for percussion drilling. Use low speed for bits greater than 3/8" (10 mm).

2. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting,

but do not push hard enough to stall the motor or deflect the bit.

3. Hold tool firmly with both hands to control the twisting action of the drill.

4. IF DRILL STALLS, it is usually because it is being overloaded or improperly used. RELEASE

TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO

NOT CLICK TRIGGER ON AND OFF IN AN AFFEMPT TO START A STALLED DRILL

mTHIS CAN DAIVlAGETHE DRILL.

5. To minimize stalling or breaking through the material, reduce pressure on drill and ease the

bit through the last fractional part of the hole.

6. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent

jamming.

7. With variable speed drills there is no need to center punch the point to be drilled. Use a slow

speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep

enough to drill without the bit skipping out.

A .................... amperes

W ................... watts

.................. alternating current

no ................... no load speed

................... earthing terminal

,& ................... safety alert symbol

.../min ............ revolutions or reciprocation

per minute

FIG. 2

C

FIG. 1

FIG. 3

LOW SPEED SE'Fi-ING

R#GLAGE EN VITESSE

FIG. 4

HAMMER SE'Fi-ING

R#GLAGE EN

MODE MARTEAU

PERFORATEUR

CONFIGURACI()N DE

TALADRADO POR

PERCUSI()N

DRILLING IN METAL

USE ONLY in the low-speed gear range. Start drilling with slow speed and increase to full

power while applying firm pressure on the tool. A smooth even flow of metal chips indicates the

proper drilling rate. Use a cutting lubricant when drilling metals. The exceptions are cast iron and

brass which should be drilled dry.

NOTE: Large [5/16" (8 mm) to 1/2" (13 mm)] holes in steel can be made easier if a pilot hole

[5/32" (4 mm) to 3/16" (5 mm)] is drilled first.

DRILLING IN WOOD

USE ONLY in the Iow-spead gear range. Start drilling with slow speed and increase to full

power while applying firm pressure on the tool. Holes in wood can be made with the same twist

drills used for metal. These bits may overheat unless pulled out frequently to clear chips from

the flutes. Work that is apt to splinter should be backed up with a block of wood.

DRILLING IN MASONRY

When drilling in masonry, use carbide tipped bits rated for percussion drilling and be certain that

the bit is sharp. For holes up to 3/8" (10 mm) diameter use the high-speed gear range. For holes

larger than 3/8" (10 mm), use the the low-speed gear range. Ensure that the hammer mode is

selected. Use a constant and firm force on the tool to drill most effectively. A smooth, even flow

of dust indicates the proper drilling rate.

LENTE

CONFIGURACI()N DE

BAJA VELOCI DAD

HIGH SPEED SE'Fi-ING

R#GLAGE EN

HAUTE VITESSE

CONFIGURACI()N DE

ALTA VELOCI DAD

DRILL SE'Fi-ING

-- R#GLAGE EN MODE

PERCEUSE

CONFIGURACI()N

DE TALADRADO

Depth Rod

To adjust the depth rod, loosen the handle and move rod so that the distance between the end

of the rod and the end of the bit equals the desired drilling depth. When drilling with depth rod,

stop when end of rod reaches surface of material.

MAINTENANCE

A WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments

or accessories.

C_anmg

A CAUTION: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Lubrication

Your tool was properly lubricated before leaving the factory. In from two to six months, depend-

ing upon use, take or send your tool to an authorized service center for a complete cleaning,

inspection and lubrication.Tools used constantly on production jobs will need relubrication more

often. Also, tools "out of service" for long periods should be relubricated before being put back

to work.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only DEWALT, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory, please

contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-

DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

MAXIMUM RECOMMENDED CAPACITIES

DWS05 DW520

CHUCK CAPACITY

R.RM.

BITS_ METAL DRILLING

WOOD, FLAT BORING

BITS, MASONRY DRILLING

optimum

maximum

1/2" (13 ram)

0-1 _100- 0-2_700

1/2" (13 mm) low speed

1-1/2" (40 mm)

low speed

3/16 - 3/8" (5 - 10 ram)

1/2" (13 mm)

1/2" (13 ram)

0-1_100 - 0-2_700

1/2" (13 mm)low speed

1-1/2" (40 mm)

low speed

3/16 - 7/16" (10- 11 ram)

3/4" (20 mm)

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a DEWALT factory service center,

a DEWALT authorized service center or other qualified service personnel. Always use identical

replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear

or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.

dewalt.com or call 1-8OO-4-DEWALT (1-800-433-9258). This warranty does not apply to acces-

sories or damage caused where repairs have been made or attempted by others. This warranty

gives you specific legal rights and you may have other rights which vary in certain states or

provinces.

Page 3

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the packag-

ing, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are miss-

ing, call 1-800-4-DEWALT for a free replacement.

VVV I/2" (13ram) HEAVY DUTY

AAz#_ DUAL SPEED HAMMERDRILL

SEB.

MUST READ AND UNDERSTAN[_ THE

T0 SEDUCETHERmSS0Fm_JURY,USER

PROPER EYE, EAR AND RESPIRATORY PRO £ECTRO_= ALWAYS USE

S_0E HANOLE= _ ADS_I_I'EN_A= LEA EL MANUAL DE

mNSTR#CCIONES PARS UN FUNCIONAMmENT0 $EGURO. SIEMPRE

U'flLISEPROTECS_ONA#ESUADAPARSLOS0JOS, 0iDeS ¥ viAs

RESPIRATORmA$= $1EMPRE L_TILBCE EL MANGO LATERAL

& AV_R_SSW_ENT: A TRRE PREVENTmF, ElSE LE GUmDE.

TOOJORRS UTILBSEA R_E PROTESTBON 0CULARRE, AS#UTIVE ET

RESPIRAT0mRE ADEQUATE= U31LISER LA POIG_EE _TERALE=

#EWA[TB_USTR_AL"roe[ CO.,BALTH_J_GRE,MD 21286 _JSA

_, FORSERVmCEmNFORMATm0t_,CALLI_e_#WALTwww=DEWALT,ce_ ,_

Voltage: 120 V AS~ 120 V AS~

Ampere rating: 7,8 A 8,2 A

Frequency: 50-60 Hz 50-60 Hz

Watts: 650 W 850 W

Rotations per minute: 0-11 O0 / 0-2700 rprn 0-1100 / 0-2700 rprn

Beats per minute: 0-19000 / 0-46000 bprn 0-19000 / 0-46000 bprn

INSTRUCTION MANUAL. ALWAYS USE

SPECIFICATIONS

DWS05 DW520

mati_re de sdcuritd

es d_finitions ci-dessous d_crivent le niveau de danger pour chaque mot-indicateur

I_ Ddfinitions : lignes directrices en

mploy& Veuillez life le mode d'emploi et porter une attention particuli_re &ces

ymboles.

I A DANGER : indique une situation dangereuse imminente qui, si ells n'est pas

l evitee, causera la mort ou des blessuros graves.

I AAVERTISSEMENT : indique une situation potentie//ement dangereuse qui, si ells

I n'est pas evitee, pourrait se solder par un d#c#s ou des blessures graves.

I AMISE EN GARDE : indique une situation potentie//ement dangereuse

I qui, si ells n'est pas evitee pourrait se solder par des blessures mineures ou

I modifies.

I MISE EN GARDE : uti/ise sans/e symbols d'a/erte _/a securite, indique une situation

I Potentie//ement dangereuse qui, si ells n'est pas evitee pourrait se solder par des

ommages _ la proprietY.

Sl VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE PART DE VOS

COMMENTAIRES CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL DEWALT,

COMPOSEZ SANS FRAIS LE • 1 800 433-9258.

R_gles gdndrales de sdcuritd concernant

les outils _ piles

AVERTISSEMENT ! Afin de r_duire le risque de blessures, I'utilisateur doit

life le mode d'emploi

N#gliger de suivre les directives suivantes peut entrafner des risques de

chocs #lectriques, d'incendies et/ou de blessures graves. Le terme _ outil

#lectrique R,clans tousles avertissements ci-apr#s se rapporte _ votre outil

#lectrique _ alimentation sur secteur (avec ill) ou par piles (sans ill).

CONSERVER CES DIRECTIVES

1) SECURITt DU LIEU DE TRAVAIL

a) Tenir la zone de travail propre et bien _clair_e. Les lieux encombres ou sombres sont

propices aux accidents.

b) Ne pas fairs fonctionner d'outils #lectriques clans un milieu d#flagrant, soit en

presence de liquides, de gaz ou de poussi#res inflammables. Les outils electriques

produisent des etincelles qui peuvent enflammer la poussi#re oules vapeurs.

c) Eloigner los enfants et los per_onnes _ proximit# pendant I'utilisation d'un outil

#lectrique. Une distraction pourrait vous en faire perdre la ma_trise.

2) SIsCURITI5 EN MATIISRE D'ISLECTRICITI5

a) Los fiches des outils #lectriques doivent correspondro _ la prise. Ne ]amais

modifier la fiche en aucune fa_on. Ne ]amais utiliser de fiche d'adaptation avec un

outil #lectrique mis _ la term. Le risque de choc electrique sera reduit par I'utilisation

de fiches non modifiees correspondant _ la prise.

b) _-viter tout contact physique avec des surfaces mises _ la term comme des tuyaux,

des radiateurs, des cuisinibres et des r_frig#rateurs. Le risque de choc electrique est

plus eleve si votre corps est mis _ la terre.

c) Ne pas exposer los outils #lectriques _ la pluie ou _ I'humidit#. La penetration de

I'eau darts un outil electrique augments le risque de choc electrique.

d) Ne pas utiliser le cordon de fa_on abusive. Ne _amais utiliser le cordon pour

transporter, tirer ou d#brancher un outil #lectrique. Eloigner le cordon de la chaleur,

de I'huile, des bords tranchants ou des pi#ces mobiles. Les cordons endommages

ou enchev#tres augmentent los risques de choc electrique. Confier la reparation ou le

remplacement de cordons endommages _ un centre de reparation autorise. Utiliser

uniquement des rallonges _ 3 ills pourvues d'une fiche de miss _ la terre _ 3 lames et

one prise _ 3 fentes correspondant _ la fiche.

e) Pour I'utilisation d'un outil _lectrique _ I'ext_rieur, se servir d'une rallonge convenant

_tcot effeL L'utilisation d'une rallonge concur pour I'exterieur reduit los risques de choc

electrique. S'assurer que la rallonge est en bon etat. Lorsqu'une rallonge est utilisee,

s'assurer d'en utiliser une de calibre suffisamment eleve pour assurer le transport du

courant necessaire au fonctionnement de l'appareiL Un cordon de calibre inferieur

causera une chute de tension de ligne et dons une perte de puissance etune surchauffe.

Le tableau suivant indique le calibre approprie a utiliser selon la longueur du cordon et

l'intensite nominale de la plaque signaletique. En cas de doute, utiliser le calibre suivant

le plus gros. Plus le numero de calibre est petit, plus le cordon est lourd.

Calibre minimumpour rallonge

Volts Longueurtotale du cordon

Intensitenominale

Plus de

0

6

10

12

Pas plus de

6

10

12

16

120V

240V

7,6 (25) 15,2 (50)

15,2 (50) 30,5 (100)

5,5 (18) 4,9 (16)

5,5 (18) 4,9 (16)

4,9 (16) 4,9 (16)

4,3 (14) 3,7 (12)

3) SF_CURITF_PERSONNELLE

a) Etre vigilant,surveil/erle travail effectu_et fairs preuve de jugement /orsqu'un outil

_/ectrique est utilis_. Ne pas utiliser d'outil _/ectrique en cas de fatigue ou sous

/'influence de drogues, d'a/coo/ou de m_dicaments.Un simple moment @inattention

en utilisant un outil electrique peut entra_nerdes blessures graves.

en metres (en pieds)

30,5 (100) 45,7 (150)

61,0 (200) 91,4 (300)

AWG

4,9 (16) 4,3 (14)

4,3 (14) 3,7 (12)

4,3 (14) 3,7 (12)

Non recommande

b) Utiliser un #quipement de s#curit#. Toujours porter une protection oculaire.

L'utilisation d'un equipement de securite comme un masque anti-poussi_res, des

chaussures antiderapantes, un casque de securite ou des protecteurs auditifs Iorsque la

situation le requiert reduira los risques de blessures corporelles.

c) Eviter un d#marrage accidentel. $'assurer que I'interrupteur se trouve _ la position

d'arr#t avant de brancher I'outil. Transporter un outil electrique alors que le doigt

repose sur I'interrupteur ou brancher un outil electrique dont I'interrupteur est _ la

position de marche risque de provoquer un accident.

d) Retirer toute cl_ de r_glage ou cl_ standard avant de d_marrer I'outil. Une cle

standard ou une cle de reglage attachee _ une partie pivotante de I'outil peut provoquer

des blessures corporelles.

e) Ne pas trop tendro los bros. Conserver son #quifibro en tout temps. Cela permet de

mieux ma_triser I'outil electrique darts los situations imprevues.

f) $'habiller de mani#re appropri#e. Ne pas porter de v#tements amples ni de bijoux.

Garder los cheveux, los v#tements et los gants _ I'#cart des pibces mobiles.

V#tements amples, bijoux ou cheveux longs risquent de rester coinces dans ces pi#ces

mobiles. Se tenir eloigne des events puisque ces derniers recouvrent souvent des pi#ces

en mouvement.

g) Sides composants sont fournis pour le raccordement dedispositifs de d_poussi_rage

et de ramassage, s'assurer que ceux-ci sont bien raccord#s et utilis#s. L'utilisation

de cos dispositifs pout reduire los risques engendres par los poussi_res.

4) UTILISATION ET ENTRETIEN DES OUTILS 15LEOTRIQUES

a) Ne pas forcer un outil #lectrique. Utiliser I'outil #lectrique appropri# _ I'application.

L'outil electrique approprie effectuera un meilleur travail, de facon plus sore et _ la w'tesse

pour laquelle il a ete con#u.

b) Ne pas utiliser un outil #lectrique dont I'interrupteur est d#fectueux. Tout outil

electrique dont I'interrupteur est defectueux est dangereux et dolt #tre repar&

c) D#brancher la fiche du secteur et/ou du bloc-piles de I'outil #lectrique avant de

fairs tout re'glage ou changement d'accessoire, ou avant de ranger ce dernier.

Cos mesures preventives reduisent los risques de demarrage accidentel de I'outil

electrique.

d) Ranger los outils #lectriques hor_ de la port#e des enfants, et ne permettre

aucune performs n'#tant pas familiars avec un outil #lectrique ou son mode

d'emploi d'utiliser ce demier. Los outils electriques deviennent dangereux entre los

mains d'utilisateurs inexperimentes.

e) Entrotien des outils #lectriques. V#rifier si los pi#ces mobiles sont real aligners ou

coinc_es, si des pi_ces sont bris_es ou pr_sentent toute autre condition susceptible

de nuire au bon fonctionnement de I'outil _lectrique. En cas de dommage, faire

r_parer I'outil _lectrique avant toute nouvelle utilisation. Beaucoup d'accidents sont

causes par des outils electriques mal entretenus.

f) S'assuror que les outils de coupe sont aiguis_s et propres. Les outils de coupe

bien entretenus et aff_ttes sont moins susceptibles de se coincer et sont plus faciles

contrSler.

g) Utiliser un outil #lectrique, sos accessoiros, mbches, etc., conform#ment aux

pr#sentes directives et suivant la mani#ro pr#vue pour ce type particulier d'outil

#lectrique, en tenant compte des conditions de travail et du travail _ effectuer.

L'utilisation d'un outil electrique pour toRte operation autre que celle pour laquelle il a ete

con#u est dangereuse.

5) RI5PARATION

a) Faire r_parer I'outil _lectrique par un r_parateur professionnel en n'utilisant que des

pibces de rechange identiques. Cola permettra de maintenir one utilisation securitaire

de I'outil electrique.

R_gles de s_curit_ suppl_mentaires pour les marteaux

perforateurs

• Tenir I'outil par sa surface de prise isol_e darts une situation ob I'outil de coupe peut

entrer en contact avec un c_blage cach_ ou avec son propre cordon d'alimentation.

Tout contact avec un fil _ sous tension ,, mettra _ sous tension ,, los pibces metalliques

exposees de I'outil et provoquera un choc electrique chez I'operateur de Ibutil.

S'assurer que le materiau perce ne cache pas de conduits electrique ou de gaz et que leur

emplacement a ete verifie avec les entreprises de services publiques.

Porter des protecteur_ d'oroilles. Une exposition au bruit peRt entratner one porte

auditive.

Utiliser los poign_es auxiliaires foumies avec I'outil. Une porte de maffrise de I'outil peRt

entratner des blessures corporelles.

Tenir fermement I'outilen tout temps. Ne pas utiliser I'outilsans le tenir des deux mains. Fairs

fonctionner cet outil d'une souls main risque de provoquer la porte de mattrise de I'outil. II

peRt aussi _tre dangereux de percer ou de tomber sur des materiaux durs comme one barre

d'armature. Bien serrer la poignee laterale avant d'utiliser I'outiL

• Utiliser des brides de fixation ou tout autre dispositif de fixation permettant de

soutenir et de retenir la pibce sur une plate-forms stable. Tenir la pibce avec la main ou

contre son corps est instable et risque de provoquer one porte de mattrise de Ibutil.

• Porter des lunettes de s_curit_ ou une autre protection oculairo. Los operations de

percussion peuvent projeter des eclats. Les particules projetees peuvent endommager

les yeux irreversiblement. Porter un masque antipoussibres ou un appareil respiratoire. La

plupart des applications peuvent demander I'utilisation d'un dispositif de protection des

oreilles.

• Tenir refinement I'outil en tout temps. Ne pas utiliser I'outil sans le tenir des deux

mains. Faire fonctionner cet outil d'une souls main risque de provoquer la porte de mattrise

de I'outiL IIpeRt aussi _tre dangereux de percer ou de tomber sur des materiaux durs somme

one barre d'armature.

• Ne pas fairs fonctionner cot outil durant de Iongues p_riodes. Los vibrations causers

par la percussion du marteau peuvent #tre nuisibles pour vos mains et vos bras. Utiliser des

gants pour amortir davantage los vibrations et limiter I'exposition _ I'outil par de frequentes

periodes de repos.

• Ne pas rome#re _t neuf les mbches vous-m_me. La remiss _ neuf du burin dolt _tre

rea/isee par un sp_cia/iste autorise. Les burins mal remis _ neuf peuvent causer des

blessures.

• Porter des gants pour utiliser I'outil ou pour changer los mbches. Les pibces

metalliques accessibles de I'outil et los trepans peuvent devenir extr#mement chaRds durant

le fonctionnement de Ibutil. De petits morceaux de materiau qui se detachent peuvent

endommager les mains nues.

• Ne jamais d#poser I'outil tant que la mbche ne s'est pas complbtement arr#t#e. Les

mbches mobiles peuvent provoquer des blessures.

• Ne pas frapper sur les mbches coinc_es avec un marteau pour les d_loger. Des frag-

ments de metal ou des copeaux de materiau peuvent se deloger et causer des blessures

• Eloigner le cordon d'alimentation de la mbche rotative. Ne pas enrouler le cordon

autour de touts partie du corps. Un cordon d'alimentation enroule autour d'une mbche

rotative risque de causer des blessures corporelles et one porte de maffrise de I'outil.

_AVERTISSEMENT : TOUJOUR$ porter des lunettes de securite. Los lunettes de vue ne

constituent PAS des lunettes de securite. Utiliser egalement un masque facial ou anti-

Roussiere si l'operation de decoupe genere de la poussiere. TOUJOURS PORTER UN

EQUIPEMENT DE PROTECTION HOMOLOGUE :

• protection oculaire conforme a la norme ANSI Z87.1 (CAN/CSA Z94.3),

• protection auditive conformea la norme ANSI $12.6 ($3.19) et

• protection des voles respiratoires conformes aux normes NIOSH/OSHA/MSHA.

AAVERTISSEMENT : certaines peussieres produites par les activites de pon¢age, sciage,

meulage, per¢age et autres activites de construction peuvent contenir des produits

chimiques pouvant causer le cancer, des anomalies congenitales ou d'autres problemes lies

aux fonctions reproductrices. Voici quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures a base de plomb;

• la silice cristalline de la brique, du ciment et d'autres produits de ma¢onnerie; et

• l'arsenic et chrome provenant de bois traite chimiquement.

Les risques relies a l'exposition aces poussieres varient selon la frequence a laquelle

l'utilisateur travaille avec ce type de materiaux. Pour reduire votre exposition aces

produits chimiques : travailler dans un endroit bien ventile et porter un equipement de securite

approuve somme un masque antipoussieres con¢u specialement pour filtrer les particules

microscopiques.

• _-viter le contact prolong_ avec les poussieres produites par les activit_s de pon_age,

sciage, meu/age, paryage et autres activit_s de construction. Porter des v#tements

de protection et laver/es parties du corps expos_es avec une solution d'eau et de

savon. Laisser /a poussiere penetrer dans /a bouche, /es yeux ou repeser sur /a peau peut

favoriser /'absorption de produits chimiques nocifs.

Page 4

AAVERTISSEMENT : I'utilisation de cet outil peut produire et/ou degager des poussieres qui

risqueraient de causer des problemes respiratoires graves et permanents ou d'autres problemes

medicaux. Toujours porter un appareil respiratoire approuve par la NIOSH/OSHA pour se prote-

ger de la poussiere. Diriger les particules loin du visage et du corps.

A AVERTISSEMENT: tou]oura utiliser une protection oculaira. Tousles utilisateurs et per-

sonnes _ proximite doivent porter une protection oculaire conforme _ la norme ANSI Z87.1.

I&AVERTISSEMENT : TOUJOURS porter une protection auditive appropri_e conformS-

merit _ la norme ANSI $12.6 ($3.19) Iora de I'utilisation du produit. Dans certaines condi-

tions et salon la duree d'utilisation, le bruit emis par ce produit peut contribuer _ une perte

auditive.

• L'etiquette apposee sur votre outil peut comprendre les symboles suivants. Les symboles et

leurs definitions sont indiques ci-apres :

V..................... volts

Hz................... hertz

min ................. minutes

---. ............. courant continu

@ ................... Construction de classe I

(mis _ la term)

[] ................... Construction de classe II

(_ double isolation)

BPM ............... coups par minute

A.................... amperes

W................... watts

_, ................. courant altematif

no .................. vitesse _ vide

................... borne de terre

Z&.................. symbole d'alerte _ la securite

.../min ............ rotations ou altemance

par minute

COMPOSANTS

i_AVERTISSEMENT : ne jamais modifier I'outil electrique ou I'une de ses parties. Une telle

pratique risque de provoquer des dommages materiels ou des blessures corporelles.

A. G&chette E Poignee lateralee

B. Bouton de verrouillage G. Prise ergonomique

C. Levier invereeurr

D. Bouton de changement de rapport

E. Selecteur de modes marteau perforateur/perceuse

UTILISATION PR#_.VUE

Les marteaux perforateurs, modules DW505 et DW520, de service intensif sont conqus pour

le per_age et le perqage au marteau perforateur professionnels, le vissage etles applications

legates de burinage, de gougeage et de demolition ainsi qua le carottage avec trepans & pointes

carburees & divers lieux de travail (p. ex., chantiers de construction). NE PAS utiliser sous des

conditions humides ou en presence de liquides ou de gaz inflammables.

Les marteaux perforateurs, modules DW505 et DW520, de service intensif, sont des outils elec-

triques pour professionnels. NE PAS mettre les enfants en contact avec routil. Les utilisateurs

de moins de 16 ans doivent _tre supervises.

Poign_e lat_rale (fig. 1)

AAVERTISSEMENT : pour reduire le risque de blessures corporelles, TOUJOURS utiliser

I'outil si la poignee laterale y est bien installee. Une mauvaise installation pourrait se solder par

un glissement de la poignee laterale en cours de fonctionnement, puis une perte de maFtrise

de I'outiL Tenir I'outil des deux mains pour obtenir une plus grande maFtrise de I'outiL

Le marteau perforateur est livre avec une poignee laterale (F). Elle se fixe & ravant du carter

d'engrenages comma il est illustre & la figure 1 et peut 6tre tournee sur 360 ° pour une utilisa-tion

de la main droite ou gauche.

Une fois la poignee laterale dans la position souhaitee, renfoncer jusqu'& ce qua les rainures

(H) du rebord de la poignee laterale soient alignees et bien enclenchees dans les languettes (I)

en saillie de la face inferieure du carter d'engrenages. Puis, tourner la prise ergonomique (G)

dans le sans horaire jusqu'& ce qu'elle soit bien settee. La poignee laterale est alors soil-dement

fixee.

G_chette (fig. 2)

Pour demarrer le marteau perforateur, enfoncer la g&chette (A). Pour I'arr_ter, la tel&char.

AAVERTISSEMENT : s'assurer de bien degager le mecanisme de verrouillage avant de

debrancher la fiche dans I'alimentation sur secteur. L'inobservation de cette mesure

provoquera le demarrage immediat du marteau perforateur des le prochain branchement. Une

telle pratique risque de provoquer des dommages materiels ou des blessures corporelles.

Pour bloquer la g&chette en position de marche pour un fonctionnement continu, enfoncer la

g&chette et pousser le bouton de verrouillage (B) vers le haut. I'outil maintiendra son regime.

Pour eteindre routil bloque en mode continu, presser une fois et tel&char la g&chette. Avant

la prochaine utilisation de I'outil (at ce & chaque utilisation), s'assurer qua le mecanisme de

degagement du bouton de verrouillage se deplace librement.

NE PAS verrouiller la g&chette lots de per_age & la main de sorte qu'il soit possible de tel&char

immediatement la g&chette si la m6che se coince dans le trou. Utiliser UNIQUEMENT le bouton

de verrouillage Ioreque le marteau perforateur est fixe sur un socle de perceuse & colonne ou

un autre dispcsitif de fixation.

VITESSE VARIABLE

La g&chette & vitesses variables offre la maftrise de lavitesse. Plus on enfonce la g&chette, plus

la vitesse du marteau perforateur augmente.

REMARQUE : utiliser les vitesses plus lentes pour debuter le per_age d'un trou sans pointeau,

percer le metal, les plastiques ou la ceramique et visser. Les vitesses plus elevees sont mieux

adaptees pour percer le bois et les planches de compose et pour rutilisation d'accessoires pour

le ponqage et le polissage.

LEVIER INVERSEUR

Le levier inverseur (C) du marteau perforateur s'utilise pour actionner la marche arri6re de routil

pour le retrait de vis ou de m6ches ceincees. II est Ioge au dessus de lag&chette comma indique

& la figure 2. Pour actionner la marche arri6re du marteau perforateur, d'abord I'eteindre puis

deplacer le levier inverseur vers la gauche (si on se place & I'extremite du mandrin).

Pour revenir en mode de marche avant, eteindre le marteau perforateur et deplacer le levier

inverseur vers la droite (si on se place & I'extremite du mandrin).

Fonctionnement _ vitesses _lev_e/lente (fig. 1, 3)

I'engrenage & deux vitesses du marteau perforateur & deux plages permet un fonctionnement

efficace de routil dans une gamme etendue d'applications avec un plus grand choix

d'accessoires.

Pour un fonctionnement &VITESSE LENTE, tourner le bouton de changement de rapport (D),

Ioge sur la face inferieur du marteau perforateur, de sorte que le reglage de vitesse lente pointe

vers ravant de routil.

Pour un fonctionnement & HAUTE VITESSE, tourner le m6me bouton (D) de sorte que le

reglage de vitesse elevee pointe vers ravant de routil.

De par sa conception, le train d'engrenages change de vitesse que Iorsque rappareil est eteint.

Toutefois, il sera peut-6tre necessaire de tourner leg_rement le mandrin & la main pour aligner

les engrenages tout en tournant le bouton de changement de rapport. NE PAS ESSAYER DE

CHANGER DE VlTESSES en tournant le bouton de changement de rapport avec routil en

marche. Une telle pratique endommagera le train d'engrenages.

Sdlecteur de modes marteau perforateur/perceuse

(fig. 4)

Pour passer du mode perceuse au mode marteau perforateur (et vice-versa), tourner le

selecteur (E) et le pointer sur le symbole applicable comme indique & la figure 4.

Pour un pergage droit, aligner le selecteur avec le symbole de la meche.

Pour la fonction de marteau perforateur, aligner le selecteur avec le symbole du marteau

perforateur comme indique & la figure.

REMARQUE : le selecteur de mode dolt se trouver en mode de perqage ou de perforateur en

tout temps. Aucune autre fonction n'est offerte entre celles-ci.

Mandrin

AAV£RTISS£M£NT : Risque de bKtlure. TOUJOURS porter les gants lors de changements

de meches ou burins. Les pieces metalliques accessibles de l'outil etles trepans peuvent

devenir extremement chauds durant le fonctionnement de l'outiL De petits morceaux de mate-

riau qui se detachent peuvent endommager les mains nues.

Pour inserer une m_he, tourner la bague du mandrin & la main, en sens antihoraire (si on

se place & I'extremite du mandrin) pour ouvrir les m&choires puis inserer la queue de la meche

dans le mandrin d'environ 13 mm (1/2 po). Puis setter le mandrin & la main. Inserer la cle de

mandrin darts les trois trous et setter en sens horaire. II est important de bien setter les trois

trous du mandrin.

Pour degager une meche, tourner la cle de la bague du mandrin en sens antihoraire dans un

seul des trous puis desserrer le mandrin & la main en tournant la bague en sens horaire (si on

se place & I'extremite du mandrin).

FONCTIONNEMENT

PerFage

i_AVERTISSEMENT : Pour r_duire le risque de blessures corporelles graves, _teindre

I'outil et le d_brancher avant d'effectuer tout r_glage, d'enlever ou d'installer tout

accessoiras.

i_AVERTISSEMENT : pour r_duire le risque de blessures corporelles, TOUJOURS

s'assurer qua la piece soit ancree ou fixee fermement. En cas de per_age dans un materiau

fin, utiliser un bloc en bois pour eviter tout dommage au materiau.

1. N'utiliser qua des m6ches bien aiguisees. Pour le BOIS, utiliser la vitesse lente et des

forets helicofdaux, & trois pointes, & bois pour outil electrique ou des scies-cloches. Pour

le METAL, utiliser la vitesse lente et des forets helicofdaux en acier ou des scies-cloches.

Pour la MAC,,ONNERIE, par example les briques, le ciment, les blocs de baton, etc., utiliser

des m_ches & pointe carburee pour perqage & percussion. Utiliser la vitesse lente pour les

m6ches de plus de 10 mm (3/8 po).

2. Toujours exercer une pression en ligne droite par rapport & la m6che. Exercer suffisamment

de pression pour faire mordre la m6che mais ne pas trop appuyer pour eviter de bloquer le

moteur ou de faire devier la m6che.

3. Tenir routil fermement des deux mains pour contr61er la torsion de la perceuse.

4. Sl LA PERCEUSE SE BLOQUE, leprobl6me est.generalement attribuable & une surcharge

ou une mauvaise utilisation. RELACHER IMMEDIATEMENT LA GAOHE'B'E, retirer la

m6che du trou perce et determiner la cause du blocage. NE PAS APPUYER DE FA(_ON

RP_.PP_.TP_.ESUR LA GACHE'I-rE POUR TENTER DE DISMARRER UNE PERCEUSE

BLOQUP_.ECAR CE'I-rE PRATIQUE PEUT ENDOMMAGER L'OUTIL.

5. Pour eviter les blocages ou un bris Iorsque vous effectuez un per_age, reduire la pression

sur la perceuse et percer en douceur la derni6re partie du trou.

6. Faire tourner la perceuse pour retirer la m6che du trou perc& Cette pratique emp6che la

m6che de se coincer.

7. Les perceuses & regime variable n'ont pas besoin d'un pointeau pour amorcer le trou.

Utiliser une vitesse lente pour commencer le trou et accelerer en appuyant davantage sur la

g&chette Iorsque le trou est assez profond pour percer sans qua la m6che n'en deborde.

PER(_AGE DANS LE M#_.TAL

UTILISER UNIQUEMENT la plage de vitesse lente. Amorcer le trou & faible vitesse puis pass-

er & plain regime tout en appuyant fermement sur routil. Une evacuation continue et reguli6re

de copeaux metalliques indique qua la vitesse de perqage est adequate. Utiliser un lubrifiant de

coupe pour percer les metaux. Seuls la fonte et le laiton doivent 6tre perces & sac.

REMARQUE :le per_age de grands trous [8 & 13 mm (5/16 & 1/2 po)] dans racier sara facilite

si on perce d'abord un avant-trou [4 &5 mm (5/32 & 3/16 po)].

PER(_AGE DANS LE BOIS

UTILISER UNIQUEMENT la plage de vitesse lente. Amorcer le trou & faible vitesse puis

passer &plain regime tout en appuyant fermement sur routil. II est possible d'utiliser les m6mes

forets helicofdaux qui percent le metal. Ces forets peuvent surchauffer s'ils ne sont pas frequem-

ment retires pour nettoyer les cannelures. Les pi6ces susceptibles de provoquer des eclats de

bois devraient 6tre soutenues avec un bloc de bois.

PER(_AGE DANS LA MA(_ONNERIE

Pour le perqage de la maqonnerie, utiliser des m6ches & pointes carburees prevues pour une

utilisation avec un marteau perforateur et s'assurer que la m6che soit bien affQtee. Pour les trous

jusqu'& concurrence de 10 mm (3/8 po) de diam6tre, utiliser la plage de haute vitesse. Pour

ceux de plus de 10 mm (3/8 po) de diam6tre, utiliser la plage de vitesse lente. S'assurer que le

mode marteau est selectionn& Utiliser une force ferme et constante sur routil pour un perqage

plus efficace. Une evacuation continue de poussi6re indique que votre vitesse de perqage est

adequate.

Tige de r_glage de profondeur

Pour regler la tige de reglage de profondeur, desserrer la poignee puis deplacer la tige de

mani_re & ce que la distance separant son extremite et I'extremite de la m_che corresponde &

la profondeur de perqage recherchee. Pour le perqage avec une tige de reglage de profondeur,

arr6ter routil Iorsque I'extremite de la tige atteint la surface du materiau.

ENTRETIEN

/_AVERTISSEMENT : Pour r_duire le risque de blessures corporelles graves, _teindre

I'outil et le d_brancher avant d'effectuer tout r_glage, d'enlever ou d'installer tout

accessoires.

Nettoyage

_AVERTISSEMENT: ne jamais utiliser de solvants ni d'autres produits chimiques puissants

pour nettoyer les pieces non metalliques de I'outiL Ces produits chimiques peuvent affaiblir les

materiaux de plastique utilises dans ces pieces. Utiliser un chiffon humecte uniquement d'eau

et de savon doux. Ne jamais laisser de liquide penetrer dans I'outil et n'immerger aucune par-

tie de I'outil dans un liquide.

Lubrification

I'outil a ete parfaitement lubrifie avant de quitter rusine. Dans deux & six mois, selon rutilisation,

amener ou envoyer routil & un centre de reparation autorise pour un nettoyage, une inspection

et une lubrification totale. Les outils utilises constamment pour des travaux doivent 6tre lubrifies

plus frequemment. De plus, les outils <,inutilises ,, pendant une Iongue periode doivent 6tre

lubrifies de nouveau avant d'6tre reutilises.

Accessoires

A AVERTISSEMENT : puisque les accessoires autres que ceux offerts par DEWALT n'ont pas

ete testes avec ce produit, leur utilisation pourrait s'averer dangereuse. Pour reduire le risque

de blessures, utiliser exclusivement les accessoires DEWALT recommandes avec ce produit.

Les accessoires recommandes pour utilisation avec routil sont disponibles, & un coQt supple-

mentaire, aupr6s du distributeur ou du centre de reparation autorise de votre region. Pour toute

demande d'assistance pour trouver un accessojre, veuillez contacter DEWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286, Etats-Unis, composer le 1-800-4-DEWALT (1-800-

4,33-9258) ou visiter notre site Web & www.dewalt.com.

MANDRIN 13 mm (1/2") 13 mm (1/2")

TR/MI N 0-1,100 - 0-2,700 0-1,100 - 0-2,700

MI_CHES, PERC,,AGEMEI-ALLIQUE 13 mm (1/2") 13 mm (1/2")

BOIS, FORETS/k, BOIS PLATS

MI_CHES, PERC,,AGEDE MAC,,ONNERIE

optimale 5 - 10 mm (3/16 - 3/8")

maximale 13 mm (1/2")

CAPACIT#_.SMAXlMALES RECOMMAND#_.ES

DW505 DW520

Vitesse lente Vitesse lente

40 mm (1-1/2")

Vitesse lente

40 mm(1-1/2")

Vitesselente

10- 11 mm (3/16- 7/16")

20 mm (3/4")

R_parations

Pour assurer la SI_CURITI_ et la FIABILITI_ du produit, les reparations, rentretien etles reglages

(y compris rinspection et le remplacement de la brosse) doivent ¢tre realises par un centre de

reparation en usine DEWAL% un centre de reparation autorise DEWALT ou par un personnel de

reparation professionnel. Toujours utiliser des pieces de rechange identiques.

Garantie limitde trois ans

DEWALT reparera gratuitement tousles problemes dus & des defauts de materiau ou de fabri-

cation pendant trois arts &compter de la date d'achat. Cette garantie ne couvre pas des defail-

lances de piece dues & une usure normale ou & une mauvaise utilisation de routil. Pour plus

de details relatifs & la couverture de la garantie et aux reparations sous garantie, visiter le site

Web www.dewalt.com ou composer le 1 (800) 4-DEWALT (1 (800) 433-9258). Cette garantie

ne s'applique pas aux accessoires ni aux dommages causes par des reparations realisees ou

tentees par des tiers. Cette garantie vous accor de des droits legaux specifiques et il est possible

que vous ayez d'autres droits qui varient d'un Etat ou d'une province & rautre.

En plus de la garantie, les outils DEWALT sont couverts par notre :

SERVICE D'ENTRETIEN GRATUIT DE 1 AN

DEWALT entretiendra routil et remplacera les pieces usees par une utilisation normale et ce,

gratuitement, & tout instant pendant la premiere annee & compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n'_tes pas entierement satisfait des performances de votre outil electrique, laser ou de

votre cloueuse DEWALT pour quelque raison que ce soit, vous pouvez le retourner accompagne

d'un requ darts les 90 jours suivant la date d'achat et nous vous rembourserons entierement

- sans poser de questions.

Page 5

AM#_.RIQUELATINE :cette garantie ne s'applique pas aux produits vendus en Am6rique latine.

Pour ceux-ci, veuillez consulter les informations relatives & la garantie sp6cifique pr6sente dans

remballage, appeler rentreprise locale ou consulter le site Web pour les informations relatives

&cette garantie.

REMPLACEMENT GRATUIT DES #_.TIQUE'B'ES D'AVERTISSEMENT : siles 6tiquettes

d'avertissement deviennent illisibles ou sont manquantes, composer le 1 (800) 4-DEWALT pour

en obtenir le remplacement gratuit.

f

DIAIVVV 1!z' (_3mm)HEAVY DUTY

W W A,_4_ DUAL SPEED HAMMEBDDJLL

SER.

TO REDUCETHE BruSKOFraNJURY, USERMUST BEN} AND UNOERSTAND THE

PROPER EYE,EARAND RESPIRATORY PROTECTION.ALWAYS USE

$_REHAf_RLE= _ ADVmW_rENC&_: LEA ELMANUAl, DE

INSTRURCIONE$ PARA ON FUNCmONAMIENTU SEGURO, SIEMPRE

OTILICEPROTERUm0N AOEUUARA PARA LOSR JR& OiOUSY ViAS

RESPIBATRRPAS.RIEMPREUTILIUEELMANGO LATERAL,

_, A_R'_SS_MENT_ A TmTREPHEVENTIF.LIRELEGUmDE.

TOUJOURS UTILISERUf_EPROTECTIR_JUUULAmRE AOOmTIVEET

RESPIRATRIREADEQUATE= UTILISERLA POmRNEE LATERALE=

DEWALTm_DUST_IALT00LCO,,BALTIMORE,MD 21_BUSA

mNRTRUUTmOI_MANUAL. ALWAYS USE

CARACTI_RISTIQUES

DWS05 DW520

Volts : 120 V AC ~ 120 V AC ~

Amperes : 7,8 A 8,2 A

Frequency : 50-60 Hz 50-60 Hz

Watts : 650 W 850 W

Rotations par minute : 0-1 1 00/0-2 700 rpm 0-1 100/0-2 700 rpm

Coups par minute : 0-19 000 / 046 000 cpm 0-19 000 / 046 000 cpm

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de

sepal. Lea el manual y preste atenci6n a estos simbolos.

APELIGRO: indica una situaci6n de peligro inminente que, si no se evita,

provocara la muerte o lesiones graves.

AADVERTENClA: indica una situaci6n de peligro potencial que, si no se

evita, podrfa provocar la muerte o lesiones graves.

APRECAUClON: indica una situaci6n de peligro potencial que, si no se evita,

posiblemente provocarfa lesiones leves o moderadas.

PRECAUClON: cuando se utiliza sin el sfmbolo de alerta de segufidad indica

una situaci6n de peligro potencial que, si no se evita, puede provocar dafios

en la propiedad.

J

Reglas de seguridad generales

Para reducir el riesgo de lesiones, el usuario debe leer el manual de

instrucciones.

El incumplimiento de todas las instrucciones enumeradas a continuaciSn puede

provocar una descarga el#ctrica, un incendio o lesiones graves. El t#rmino

"herramienta el#ctrica" incluido en todas las advertencias enumeradas a

continuaciSn hace referencia a su herramienta el#ctrica operada con

corriente (cable el#ctrico) o a su herramienta el#ctrica operada con baterfas

(inal#mbrica).

CONSERVE ESTAS INSTRUCCIONES

1) SEGURIDAD EN EL AREA DETRABAJO

a) Mantenga el #tea de trabajo limpia y bien iluminada. Las areas abarrotadas y oscuras

prop/c/an accidentes.

b) No opera las herramientas el6ctricas en atmSsferas explosivas, como ambientes

donde haya polvo, gases o Ifquidos inflamables. Las herramientas e/ectricas or/g/nan

chispas que pueden encender el po/vo o los vapores.

c) Mantenga alejados a los n/los y a los espectadores de la herramienta el6ctrica en

funcionamiento. Las distracciones puoden provocar /a perdida de control

2) SEGURIDAD ELISCTRICA

a) ) Los enchufes de la herramienta el6ctrica deben adaptarae al tomacorriente. Nunca

modifique el enchufe de ninguna manera. No utilice ning#n enchufe adaptador con

herramientas el#ctricas con conexiSn a tierra. Los enchufes no modificados y que se

adaptan a los tomacorrientes reduciran el riesgo de descarga electrica.

b. Evite el contacts corporal con superficies con descargas a tierra tales como

tuber(as, radiadores, estufas y refrigeradoras. Existe mayor riesgo de descarga

electrica si su cuerpo esta puesto a tierra.

c) No exponga las herramientas ele'ctricas a la Iluvia o a condiciones de humedad. Si

le entra agua a la herramienta electrica, aumentara el riesgo de descarga electrica.

d) No use el cable indebidamente. Nunca utilice el cable para transportar, t/rat o

desenchufar la herramienta el#ctrica. Mantenga el cable ale]ado del calor, el ace#e,

los bordes filosos o las piezas mSviles. Los cables daSados o enredados aumentan el

riesgo de descarga electric& Los cables dafiados deben ser reparados o reemplazados

en un centro de mantenimiento autorizado. Use solamente cables prolongadores de

3 conductores que tengan enchufes a tierra de 3 patas y receptaculos tripolares que se

adapten al enchufe de la herramienta.

e) AI operar una herramienta el6ctrica en el exterior, utilice un cable prolongador

adecuado para tal uso. Utilice un cable adecuado para uso en exteriores a fin de reducir

el riesgo de descarga electric& AsegEtrese de que el cable prolongador este en buenas

condiciones. Cuando utilice un cable prolongador, asegEtrese de que tenga la capacidad

para conducir la corriente que su products exige. Un cable de menor capacidad

provocara una disminuci6n en el voltaje de la Ifnea, Io cual producira una perdida de

potencia y sobrecalentamiento. La siguiente tabla muestra la medida correcta que debe

utilizar segEm la Iongitud de/cable y la capacidad nominal en amperios indicada en la

placa. En caso de duda, utilice el calibre inmediatamente superior. Cuanto menor sea el

nEtmero de calibre, mas grueso sera el cable..

Calibre m_nimoparajuegos de cables

Capacidad nominal

enamperios

120V 7,6 (25)

240V 15,2 (50)

Desde Hasta

0 6

6 10

10 12

12 16

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle /o que est_ haciendo y utilica el sent/do com_n

cuando emp/ee una herramienta e/_ctrica. No uti/ice una herramienta e/6ctrica si

est_ cansado o bajo el efecto de drogas, alcohol o medicamentos. Un moments de

descuido mientras se opera una herramienta e/ectrica puede provocar dafios persona/es

graves.

b) Use equips de seguridad. $iempre utilice protecciSn para los SIRS. El uso del equips

de seguridad, como las mascaras para polvo, el calzado de seguridad antideslizante,

los cascos o la proteccion auditiva, en las condiciones adecuadas reducira las lesiones

personales.

c) Evite el encendido accidental Aseg_rese de que el interruptor est_ en la posicidn

de apagado antes de enchufar /a herramienta. Transportar herramientas e/ectricas

con su dedo apoyado sobre el interruptor o enchufar herramientas e/ectricas con el

interruptor en /a posicion de encendido puede propiciar accidentes.

Voltios

Largototal del cableen metros (enpies)

18

18

16

14

15,2 (50)

30,5 (100)

16

16

16

12

30,5 (100) 45,7 (150)

61,0 (200) 91,4 (300)

AWG

16 14

14 12

14 12

No recomendado

d) Retire la ctavija de ajuste o la Ilave de tuercas antes de encender la herramienta

el6ctrica. Una /lave de tuercas o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta electrica puede provocar lesiones personales.

e) No se estire. Conserve el equilibrio y p#rese adecuadamente en todo moments.

Esto permite un me]or control de la herramienta electrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni ]oyas. Mantenga el cabello,

la ropa y los guantes ale]ados de las piezas en movimiento. Las ropas holgadas,

/as joyas o el cabello largo pueden quedar atrapados en /as piezas en movimiento. Los

orificios de ventilaci6n suelen cubrir piezas en movimiento, per Io que tambien se deben

evitar.

g) $i se suministran dispositivos para la conexiSn de accesorios con fines de

recolecciSn y extracciSn de polvo, aseg#rese de que est#n conectados y que

se utilicen correctamente. El uso de estos dispositivos puede reducir los peligros

relacionados con el polvo.

4) USOY CUIDADO DE LA MAQUINA HERRAMIENTA

a) No fuerce la herramienta el6ctrica. Utilice la herramienta el6ctrica correcta para

el trabajo que realizar_. Sise la uti/iza a la velocidad para la que rue dise_ada, la

herramienta electrica correcta permite trabajar me]or y de manera mas segura.

b) No utilice la herramienta el#ctrica si no puede encenderla o apagarla con el

interruptor. Toda herramienta electrica que no pueda ser controlada mediante el

interruptor es peligrosa y debe repararse.

c) Desconecte el enchufe de la fuente de energfa y/o el paquete de baterfa de la

herramienta el6ctrica antes de realizar ajustes, cambiar accesorios o almacenar

herramientas el6ctricas. Estas medidas de seguridad preventivas reducen el riesgo de

encender la herramienta electfica en forma accidental

d) Guarde la herramienta el#ctrica que no est6 en uso fuera del alcanca de los n/fiRS y

no permita que otras personas no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas electricas son peligrosas si son operadas por

usuarios no capacitados.

e) Real/ca el mantenimiento de las herramientas el#ctricas. Revise que no haya piezas

en movimiento mal alineadas o trabadas, piezas rotas o cualquier otra situaciSn

que pueda afectar el funcionamiento de las herramientas ele'ctricas. $i encuentra

dafios, haga reparar la herramienta el#ctrica antes de utflizarla. Se producen muchos

accidentes a causa de/as herramientas electricas que carecen de un mantenimiento

adecuado.

f) Mantenga las herramientas de corte afiladas y limp/as. Las herramientas de corte

con mantenimiento adecuado y con los bordes de corte afilados son menos propensas

a trabarse y son mas faciles de controlar.

g) Utilice la herramienta el#ctrica, los accesorios y las brocas de la herramienta, etc. de

acuerdo con estas instrucciones y de la forma prevista para el tips de herramienta

el#ctrica en particular, ten/ends en cuenta las condiciones de traba]o y el trabe]o

que debe realizarse. El uso de la herramienta electrica para operaciones diferentes de

aquellas para /as que fue disefiada podrfa originar una situaci6n peligrosa.

5) MANTENIMIENTO

a) Sol/cite a una persona calificada en reparaciones que realice el mantenimiento de

su herramienta el6ctrica y utilice sSIo piezas de repuesto id_nticas. Esto garantizara

la seguridad de la herramienta electrica

Normas de seguridad adicionales para taladros percutores

• Sostenga la herramienta pot las superficies de agarre aisladas cuando realice una

operaciSn en la que la herramienta de corte pueda tocar cables el_ctricos ocultos o el

cable de 6sta. El contacts con un cable con corriente electrica hara que /as partes expuestas

de la herramienta tengan corriente y que el operador reciba una descarga electfica.

AsegEtrese de que el material per taladrar no contenga cableados o tuberfas de gas ocultos,

cuyas ubicaciones deben haber s/do constatadas con/as empresas de servicios pEtblicos

correspondientes.

Use protectores audit/yRs. La exposici6n al ruido puede ocasionar la perdida de la

audici6n.

Use los mangos auxiliaras que se suministran con la herramienta. La perdida de/control

podrfa ocasionar lesiones personales.

Sujete la herramienta firmemente en todo moments. No intente hacer funcionar esta her-

ramienta sin sostenerla con ambas manos. Si intenta hacerla funcionar con una sola mano,

podrfa perder el control de la herramienta. Tambien podrfa ser peligroso perforar o encontrar

mater/ales duros, como barras de refuerzo. Ajuste firmemente el mango lateral antes de

utilizar la herramienta.

• Utilice abrazaderas u otra forma pr#ctica para asegurar y sostener la pieza de trabajo

en una plataforma estable. Sostener el trabajo con/a manoo contra el cuerpo no bfinda /a

estabi/idad requefida y puode //evar a/a perdida de/controL

• Use lentes de seguridad u otra protecciSn similar para los ojos. A/mart/liar se producen

astillas. Las partfculas vo/atiles puoden provocar lesiones oculares permanentes. Utilice una

mascara para po/vo o una mascafi//a de respiraci6n en ap/icaciones que generen po/vo. La

mayor(a de/as ap/icaciones puoden requefir protecci6n auditiva.

• Sujete la herramienta firmemente en todo moments. No intente hacer funcionar esta

herramienta sin sostenerla con ambas manos. Si intenta hacerla funcionar con una sola

mano, podrfa perder el control de la herramienta. Tambien podrfa ser peligroso perforar o

encontrar mater/ales duros, como barras de refuerzo.

• No haga funcionar esta herramienta durante perfodos prolongados. La vibraci6n

que produce la acci6n de percusi6n puede ser perjudicial para /as manos y los brazos.

Use guantes que provean amortiguaci6n extra y l/mite la exposici6n tomando descansos

frecuentes.

• No reacondicione las brocas usted mismo. El reacondicionamiento del cincel debe

ser realizado por un especialista autofizado. Los cinceles reacondicionados de manera

incorrecta pueden provocar lesiones.

• Use guantes cuando utilice la herramienta o cambie las brocas. Mientras la herramienta

se encuentra en funcionamiento, /as piezas metalicas accesibles de la misma y/as brocas

pueden sobrecalentarse. Los trozos pequefios de material rots pueden dafiar /as manos sin

guantes.

• Nunca apoye la herramienta hasta que la broca se haya detenido completamente. Las

brocas en movimiento podrfan provocar lesiones.

• No golpee las brocas atascadas con un martillo para desatascarlas. Pueden despren-

derse fragmentos de metal o astillas de/material que podrfan causar lesiones.

• Mantenga el cable el#ctrico ale]ado de la broca giratoria. No enrosque el cable

alradedor de ninguna parte del cuerpo. Un cable electrico enroscado alrededor de una

broca giratofia puede provocar lesiones personales y perdida de/control.

_,ADVERTENClA: Use $1EMPRE lentes de seguridad. Los anteojos de uso diario NO

son lentes de seguridad. Utilice tambien mascaras faciales o para polvo si el corte produce

polvillo. UTILICE SIEMPRE EQUIPOS DE SEGURIDAD CERTIFICADOS:

• protecci6n para los ojos ANSI Z87.1(CAN/USA Z94.3),

• protecci6n auditiva ANSI $12.6 ($3.19),

* proteccion respiratoria seg_tn/as normas NIOSH/OSHA/MSHA..

_,ADVERTENCIA: Algunas partfculas originadas al l/jar, aserrar, amolar, taladrar y realizar

otras actividades de construccion contienen productos qufmicos que producen cancer,

defectos de nacimiento y otros problemas reproductivos. Algunos ejemplos de estos productos

qufmicos son:

• el plomo de las pinturas de base plomo,

• la sflice cristalina de ladrillos, cements y otros productos de mamposterfa, y

• el arsenics y el cromo de la madera con tratamiento qufmico.

El riesgo derivado de estas expesiciones varfa seg_tn la frecuencia con la que se realice este

tips de trabajo. Para reducir la expos/c/on a estos productos qufmicos, se recomienda trabajar

en areas bien ventiladas y usar equipos de seguridad aprobados, como las mascaras para

polvo especialmente diseSadas para filtrar las partfculas microscopicas.

• Evite el contacts prolongado con las particulas de polvo originadas al l/jar, aserrar,

esmeri/ar, ta/adrar y rea/izar demos actividades de/a construccidn. Use indumentaria

protectora y lave/as Meas expuestas con agua y jabdn. Evite que el pe/vo entre en /a

boca yen los ojos ose depesite en /a p/el, para impedir /a absorcion de productos qufmicos

nocivos.

J_ADVERTENCIA: El uso de esta herramienta puede generar o dispersar partfcu/as de po/vo,

que pueden causar lesiones respirator/as permanentes y graves u otras lesiones. Use siempre

proteccion respiratona apropiada para la expos/c/on al pelvo aprobada per el Instituto Nacional

de Salud y Seguridad Ocupacional de EE.UU. y la Administracion de Salud y Seguridad

Ocupacional de EE.UU. (NIOSH y OSHA respectivamente, per sus siglas en ingles). Aleje la

cara y el cuerpe del contacts con las partfculas.

Page 6

A ADVERTENCIA: Utilice siempre protecci6n para los ojos. Todos los usuarios y especta-

dores deben utilizar protecci6n para los ojos conforme con las normas ANSI Z87.1.

i_ ADVERTENClA: Durante el uso, use siempre protecci6n auditiva adecuada qua cumpla

con la norma ANSI $12.6 ($3.19). Bajo ciertas circunstancias y segEm el periodo de uso, el

ruido producido por este producto puede contribuir a la perdida de audici6n.

• La etiqueta de su herramienta puede incluir los siguientes simbolos. Los simbolos y sus

de/in/c/ones son los siguientes:

V.................. voltios

Hz................ hertz

min .............. minutos

--- ........... corfiente d/recta

@ ................ Construcci6n Clase I

(con conexi6n a tierra)

[] ................ Construcci6n Clase II

(con aislamiento doble)

BPM ............ golpes por minuto

A ................. ampefios

W................ vatios

"_ ............... corriente altema

no................ velocidad sin carga

................ terminal a tierra

................ simbolo de alerta de seguridad

.../min ......... revoluciones o reciprocidad

por minuto

COMPONENTES