Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (MAY04 - 1) Form No. 154725-01

DW501, DW505, DW515 Copyright © 1997, 2002, 2004

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the

array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW501/DW505/DW515

1/2" (13mm) and 5/8" (16mm) Heavy Duty Dual Speed Range Hammerdrills

Perceuse à percussion de 13 mm (1/2 po) et 16mm (5/8 po) à deux gammes de vitesses

Rotomartillo de 13 mm (1/2") y 16mm (5/8") para trabajo pesado con doble velocidad

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us on the World Wide Web at www.dewalt.com

Page 3

English

1

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Rules

WARNING! READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below may result in electric

shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adapter plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user. Applicable only to

Class I (grounded) tools.

• Double insulated tools are equipped with a polarized plug

(one blade is wider than the other.) This plug will fit in a

polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact

a qualified electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation eliminates

the need for the three wire grounded power cord and grounded

power supply system. Applicable only to Class II (double

insulated) tools.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W.” These cords are rated

for outdoor use and reduce the risk of electric shock. When

using an extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gage. The smaller the gage number,

the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Not Recommended

Page 4

English

2

Such preventative safety measures reduce the risk of starting

the tool accidentally.

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and

clean. Properly maintained tools, with sharp cutting edges are

less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may affect

the tools operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained

tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool, may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this

manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or

injury.

Additional Safety Rules for Hammer

Drills

• Hold tool by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock the operator.

• Wear safety goggles or other eye protection. Hammering and

drilling operations cause chips to fly. Flying particles can cause

permanent eye damage.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool while

tired or under the influence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may result

in serious personal injury,

• Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves away

from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts.

Air vents often cover moving parts and

should also be avoided.

• Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or switches before turning the tool

on. A wrench or key that is left attached to a rotating part of the

tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the

tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to a loss of

control.

• Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer and the rate for

which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and must

be repaired.

• Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Page 5

English

3

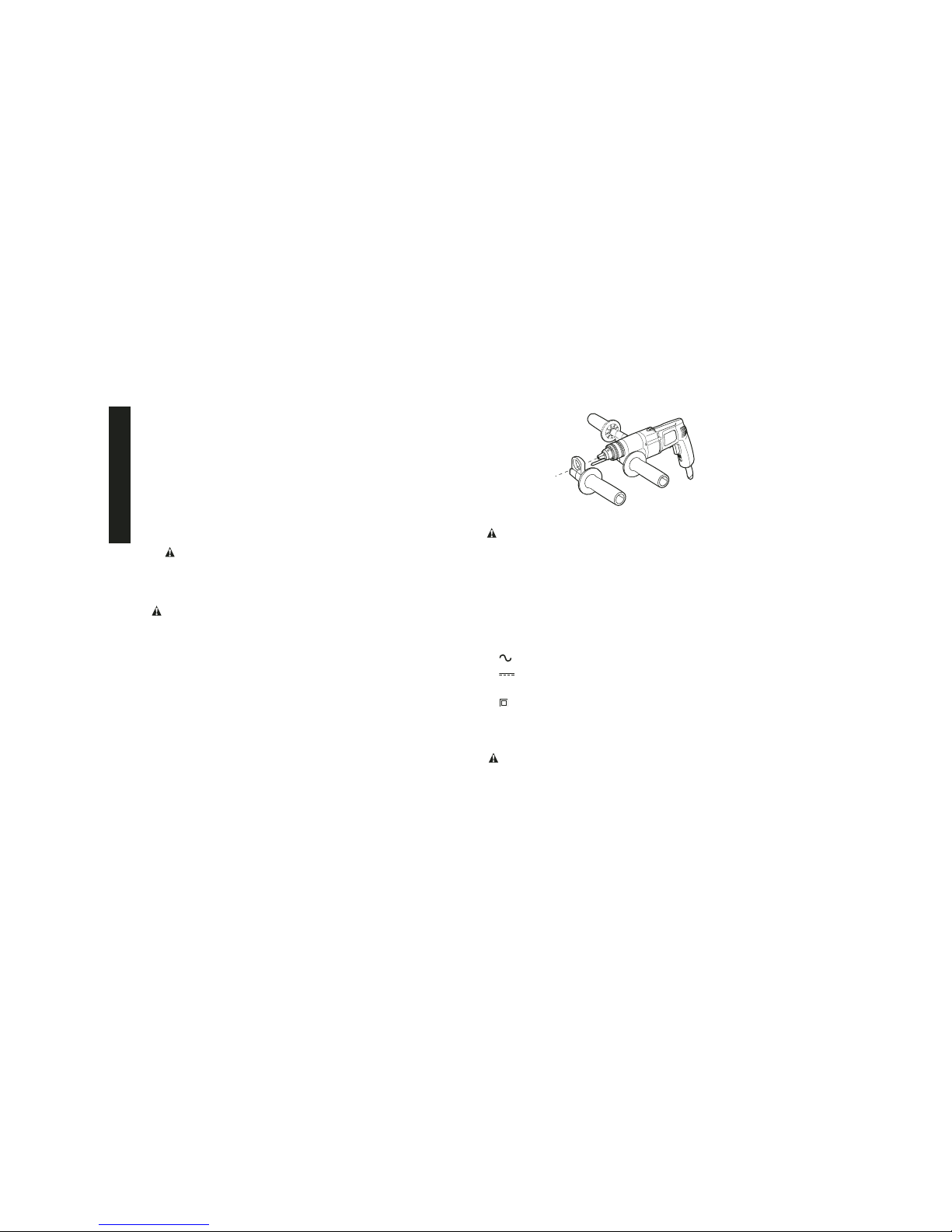

FIGURE 1

• Wear ear protectors when hammering for extented periods

of time. Temporary hearing loss or serious ear drum damage

may result from high sound levels generated by hammer drilling.

• Always use the side handle supplied with the tool. Keep a

firm grip on the tool at all times. Do not attempt to operate this

tool without holding it with both hands.

• Do not overreach while operating the tool. Maintain a

balanced working stance at all times. When necessary, use only

properly postioned, safe, platforms and scaffolding. WORK

SAFE.

• Hammer bits and tools get hot during operation. Wear gloves

when touching them.

•

CAUTION:DO NOT TOUCH ANY METAL PARTS OF THE

TOOL when drilling or driving into walls, floors or wherever

live electrical wires may be encountered! Hold the tool only by

insulated grasping surfaces to prevent electric shock if you drill or

drive into a live wire.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

CAUTION: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

•

The label on your tool may include the following symbols.

V ........................volts

A ........................amperes

Hz ........................hertz

W ........................watts

min ........................minutes

........................alternating current

........................direct current

n

o ........................no load speed

........................Class II Construction

…/min ......................revolutions or reciprocation per minute

BPM ........................beats per minute

Side Handle

CAUTION: Always use side handle when provided and hold

hammerdrill with both hands.

A side handle is supplied with this hammerdrill. It clamps to the front

of the gear case as shown in Figure 1 and can be rotated 360˚ to

permit right or left hand use.

Page 6

English

4

NOTE: Use lower speeds for starting holes without a centerpunch,

drilling in metal, plastics or ceramics, or driving screws. Higher

speeds are better for drilling in wood and composition board and for

using abrasive and polishing accessories.

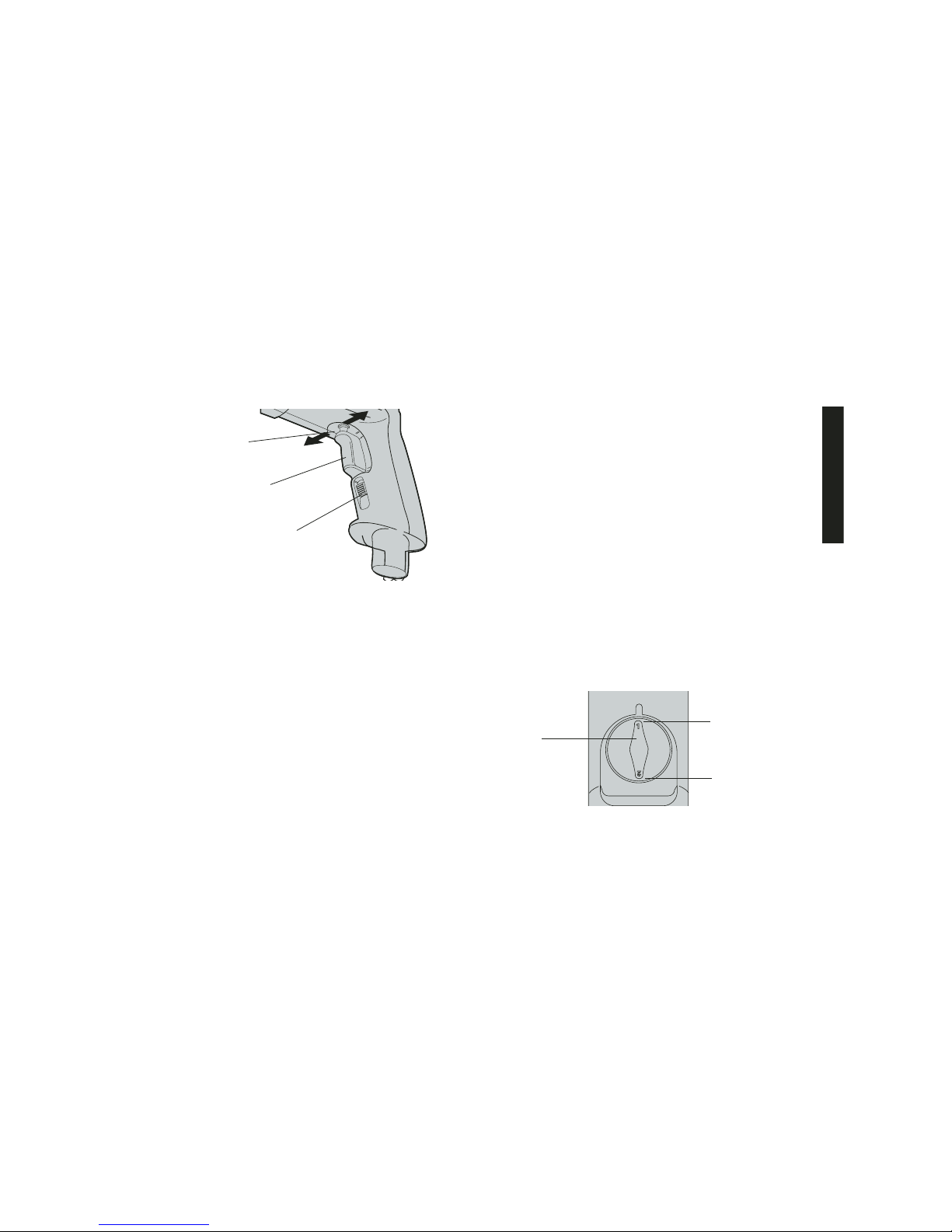

The

reversing lever

is used to reverse the hammerdrill for backing

out screws or jammed bits. It is located above the trigger, shown in

Figure 2. To reverse the hammerdrill, turn it OFF and push the

reversing lever to the left (when viewed from the chuck end). To

position the lever for forward operation, turn the hammerdrill OFF

and push the lever to the right.

High/Low Speed Operation

The two speed gear drive in the dual range hammer drill permits

effective operation over an extended range of applications with

greater selection of accessories.

For

LOW SPEED

operation, the shift knob (see Figure 3) located

on the underside of the hammerdrill should be rotated so the “low

speed” graphic is toward the front of the tool.

For

HIGH SPEED

operation, should be rotated so the “high speed”

graphic is toward the front of the tool.

FIGURE 3

LOW SPEED

SETTING

SHOFT

KNOB

Switch

To start hammerdrill, depress the trigger switch (Figure 2). To stop

hammerdrill, release the switch. To lock the trigger switch in the ON

position for continuous operation, depress the trigger switch and

push up the

locking button

. The tool will continue to run. To turn the

tool OFF, from a locked ON condition, squeeze and release the

trigger once. Before using the tool (each time), be sure that the

locking button release mechanism is working freely.

Do not lock the switch ON when drilling by hand so that you can

instantly release the trigger switch if the bit binds in the hole. The

locking button is for use only when the hammerdrill is mounted in a

drill press stand or other wise held stationary. Be sure to release the

locking mechanism before disconnecting the plug from the power

supply. Failure to do so will cause the hammerdrill to start

immediately the next time it is plugged in. Damage or injury could

result.

The

variable speed trigger switch

permits speed control. The

farther the trigger switch is depressed, the higher the speed of the

hammerdrill.

REVERSING

LEVER

TRIGGER

SWITCH

LOCKING

BUTTON

FIGURE 2

FRONT OF TOOL

HIGH SPEED

SETTING

Page 7

English

5

The gear train has been designed for shifting only when the unit is

off. It may be necessary however, to rotate the chuck slightly by hand

to align the gears while turning the shift knob. DO NOT ATTEMPT

TO CHANGE SPEEDS by turning the shift knob when the tool is

running. Doing so will damage the gear train.

Hammer/Drill Selector

To switch the tool from the drilling mode to the hammering mode (or

vice-versa) rotate the dial on the applicable symbol shown in Figure

4. For straight drilling, align the drill bit symbol toward the chuck. For

hammering, align the hammer symbol with the chuck, as shown in

the figure.NOTE: The selector must be in either drill, or hammer/drill

mode at all times. There are no operable positions between the two.

Chuck

To insert bit,

open chuck jaws by turning collar with fingers and

insert shank of bit about 3/4" (19mm) into chuck. Tighten chuck collar

by hand. Place chuck key in each of the three holes and tighten in

clockwise direction. It’s important to tighten chuck with all three

holes.

To release bit

, turn chuck key counterclockwise in just one

hole, then loosen the chuck by hand.

Operation

DRILLING

1. Always unplug the drill when attaching or changing bits or

accessories.

2. Use sharp drill bits only. For WOOD, use the low speed setting

and twist drill bits, spade bits, power auger bits, or hole saws.

For METAL, use the low speed setting and steel twist drill bits or

hole saws. For MASONRY, such as brick, cement, cinder block,

etc., use carbide-tipped bits rated for percussion drilling. Use

low speed for bits greater than 3/8”.

3. Be sure the material to be drilled is anchored or clamped firmly.

If drilling thin material, use a wood “back-up” block to prevent

damage to the material.

4. Always apply pressure in a straight line with the bit. Use enough

pressure to keep drill biting, but do not push hard enough to stall

the motor or deflect the bit.

5. Hold tool firmly to control the twisting action of the drill.

6. IF DRILL STALLS, it is usually because it is being overloaded or

improperly used. RELEASE TRIGGER IMMEDIATELY, remove

drill bit from work, and determine cause of stalling. DO NOT

CLICK TRIGGER OFF AND ON IN AN ATTEMPT TO START A

STALLED DRILL — THIS CAN DAMAGE THE DRILL.

7. To minimize stalling or breaking through the material, reduce

pressure on drill and ease the bit through the last fractional part

of the hole.

8. Keep the motor running when pulling the bit back out of a drilled

hole. This will help prevent jamming.

9. With variable speed drills there is no need to center punch the

point to be drilled. Use a slow speed to start the hole and

accelerate by squeezing the trigger harder when the hole is

deep enough to drill without the bit skipping out.

DRILLING IN METAL

USE ONLY in the “low speed” gear range. Start drilling with slow

speed and increase to full power while applying firm pressure on the

tool. A smooth even flow of metal chips indicates the proper drilling

rate. Use a cutting lubricant when drilling metals. The exceptions are

cast iron and brass which should be drilled dry. The cutting lubricants

that work best are sulphurized cutting oil or lard oil; bacon-grease will

also serve the purpose.

NOTE: Large (5/16” to 1/2”) holes in steel can be made easier if a

pilot hole (5/32” to 3/16”) is drilled first.

DRILLING IN WOOD

USE ONLY in the “low speed” gear range. Start drilling with slow

speed and increase to full power while applying firm pressure on

the tool. Holes in wood can be made with the same twist drills used

Page 8

English

6

Self-lubricating bearings are used in the tool and periodic

relubrication is not required. In the unlikely event that service is ever

needed, take your tool to an authorized service location.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

MAXIMUM RECOMMENDED CAPACITIES

DW505 DW515

CHUCK CAPACITY 1/2" 5/8”

R.P.M. 0–1,100 0–2,700 0-900 - 0-2,200

BITS, METAL DRILLING 3/8" – Low speed 3/4” Low speed

WOOD, FLAT BORING 1 1/2" – Low speed 1-1/2” Low

speed

BITS, MASONRY DRILLING 3/4" Soft materials 5/8” Soft

Materials

Low speed Low speed

1/2" Concrete 5/8” Concrete

Low speed Low speed

HOLE SAWS 2-1/8" – Low speed 4” Low speed

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of purchase.

This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

FIGURE 4

DRILL

SETTING

HAMMER

SETTING

for metal. These bits may overheat unless pulled out frequently to

clear chips from the flutes. Work that is apt to splinter should be

backed up with a block of wood.

DRILLING IN MASONRY

When drilling in masonry, use carbide tipped bits rated for

percussion drilling and be certain that the bit is sharp. For holes up

to 3/8” diameter use the “high speed”gear range. For holes larger

than 3/8”, use the the “low speed” gear range. Ensure that the

hammer mode is selected. Use a constant and firm force on the tool

to drill most effectively. A smooth, even flow of dust indicates the

proper drilling rate.

Depth Rod

To adjust the depth rod, loosen the handle and move rod so that the

distance between the end of the rod and the end of the bit equals the

desired drilling depth. When drilling with depth rod, stop when end of

rod reaches surface of material.

Maintenance

CLEANING & LUBRICATION

Use only mild soap and damp cloth to clean the tool. Never let any

liquid get inside the tool; never immerse any part of the tool into a

liquid.

Page 9

English

7

information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other

rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT Power Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund – no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT for a free

replacement.

Page 10

Français

8

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO :

1 800 4-DEWALT (1 800 433-9258)

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT! Vous devez lire et comprendre toutes les

instructions. Le non-respect, même partiel, des instructions ci-

après entraîne un risque de choc électrique, d’incendie et/ou de

blessures graves.

CONSERVEZ CES INSTRUCTIONS.

AIRE DE TRAVAIL

• Veillez à ce que l’aire de travail soit propre et bien éclairée.

Le désordre et le manque de lumière favorisent les accidents.

• N’utilisez pas d’outils électriques dans une atmosphère

explosive, par exemple en présence de liquides, de gaz ou

de poussières inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières ou les

vapeurs.

• Tenez à distance les curieux, les enfants et les visiteurs

pendant que vous travaillez avec un outil électrique. Ils

pourraient vous distraire et vous faire faire une fausse

manoeuvre.

SÉCURITÉ ÉLECTRIQUE

• Les outils à double isolation sont équipés d’une fiche

polarisée (une des lames est plus large que l’autre), qui ne

peut se brancher que d’une seule façon dans une prise

polarisée Ne modifiez pas la fiche de l’outil. La double

isolation élimine le besoin d’un cordon d’alimentation à trois

fils avec mise à la terre ainsi que d’une prise de courant mise à

la terre.Valable seulement pour les outils de classe I (mis à

la terre).

• Évitez tout contact corporel avec des surfaces mises à la

terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs,

etc.). Le risque de choc électrique est plus grand si votre corps

est en contact avec la terre. Valable seulement pour les outils

de classe II (à double isolation).

• N’exposez pas les outils électriques à la pluie ou à l’eau. La

présence d’eau dans un outil électrique augmente le risque de

choc électrique.

• Ne maltraitez pas le cordon. Ne transportez pas l’outil par

son cordon et ne débranchez pas la fiche en tirant sur le

cordon. N’exposez pas le cordon à la chaleur, à des huiles,

à des arêtes vives ou à des pièces en mouvement.

Remplacez immédiatement un cordon endommagé. Un

cordon endommagé augmente le risque de choc électrique.

• Lorsque vous utilisez un outil électrique à l’extérieur,

employez un prolongateur pour l’extérieur marqué «W-A»

ou «W». Ces cordons sont faits pour être utilisés à l’extérieur et

réduisent le risque de choc électrique. S’assurer que le cordon

de rallonge est en bon état. Lorsqu’on se sert d’un cordon de

rallonge, s’assurer qu’il est de calibre approprié pour la tension

nécessaire au fonctionnement de l’outil. L’utilisation d’un cordon

de calibre inférieur occasionne une baisse de tension entraînant

une perte de puissance et la surchauffe. Le tableau suivant

indique le calibre approprié selon la longueur du cordon et les

mentions de la plaque signalétique de l’outil. En cas de doute,

utiliser un cordon de calibre supérieur. Le chiffre indiquant le

calibre est inversement proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Non recommandé

Page 11

Français

9

SÉCURITÉ DES PERSONNES

• Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. N’utilisez pas un outil électrique si

vous êtes fatigué ou sous l’influence de drogues, d’alcool

ou de médicaments. Un instant d’inattention suffit pour

entraîner des blessures graves.

• Habillez-vous convenablement. Ne portez ni vêtements

flottants ni bijoux. Confinez les cheveux longs. N’approchez

jamais les cheveux, les vêtements ou les gants des pièces

en mouvement. Des vêtements flottants, des bijoux ou des

cheveux longs risquent d’être happés par des pièces en

mouvement.

• Méfiez-vous d’un démarrage accidentel. Avant de brancher

l’outil, assurez-vous que son interrupteur est sur ARRÊT. Le

fait de transporter un outil avec le doigt sur la détente ou de

brancher un outil dont l’interrupteur est en position MARCHE

peut mener tout droit à un accident.

• Enlevez les clés de réglage ou de serrage avant de démarrer

l’outil. Une clé laissée dans un pièce tournante de l’outil peut

provoquer des blessures.

• Ne vous penchez pas trop en avant. Maintenez un bon appui

et restez en équilibre en tout temps. Un bonne stabilité vous

permet de mieux réagir à une situation inattendue.

• Utilisez des accessoires de sécurité. Portez toujours des

lunettes ou une visière. Selon les conditions, portez aussi un

masque antipoussière, des bottes de sécurité antidérapantes, un

casque protecteur et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN DES OUTILS

• Immobilisez le matériau sur une surface stable au moyen de

brides ou de toute autre façon adéquate. Le fait de tenir la

pièce avec la main ou contre votre corps offre un stabilité

insuffisante et peut amener un dérapage de l’outil.

• Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche.

L’outil correct fonctionne mieux et de façon plus sécuritaire.

Respectez aussi la vitesse de travail qui lui est propre.

• N’utilisez pas un outil si son interrupteur est bloqué. Un outil

que vous ne pouvez pas commander par son interrupteur est

dangereux et droit être réparé.

• Débranchez la fiche de l’outil avant d’effectuer un réglage,

de changer d’accessoire ou de ranger l’outil. De telles

mesures préventives de sécurité réduisent le risque de

démarrage accidentel de l’outil.

• Rangez les outils hors de la portée des enfantes et d’autres

personnes inexpérimentées. Les outils sont dangereux dans

les mains d’utilisateurs novices.

• Prenez soin de bien entretenir les outils. Les outils de coupe

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

• Soyez attentif à tout désalignement ou coincement des

pièces en mouvement, à tout bris ou à toute autre condition

préjudiciable au bon fonctionnement de l’outil. Si vous

constatez qu’un outil est endommagé, faites-le réparer

avant de vous en servir. De nombreux accidents sont causés

par des outils en mauvais état.

• N’utilisez que des accessoires que le fabricant recommande

pour votre modèle d’outil. Certains accessoires peuvent

convenir à un outil, mais être dangereux avec autre.

RÉPARATION

• La réparation des outils électriques doit être confiée à un

réparateur qualifié. L’entretien ou la réparation d’un outil

électrique par un amateur peut avoir des conséquences graves.

• Pour la réparation d’un outil, n’employez que des pièces de

rechange d’origine. Suivez les directives données à la

section «Réparation» de ce manuel. L’emploi de pièces non

autorisées ou le non-respect des instructions d’entretien peut

créer un risque de choc électrique ou de blessures.

• Tenez l’outil par ses surfaces de prise isolées pendant toute

opération où l’outil de coupe portrait venir en contact avec

un câblage dissimulé ou avec son propre cordon. En cas de

Page 12

Français

10

contact avec un conducteur sous tension, les pièces métalliques

à découvert de l’outil transmettraient un choc électrique à

l’utilisateur.

Mesures de sécurité additionnelles

• Saisir les surfaces isolées de l’outil lorsqu’on s’en sert là où

il pourrait y avoir des fils sous tension et lorsqu’il pourrait

entrer en contact avec son propre fil. En cas de contact avec

un fil sous tension, les composantes métalliques à découvert

de l’outil deviendraient sous tension et l’utilisateur subirait des

secousses électriques.

• S’assurer que les poignées sont propres, libres de toute

tache d’huile et de graisse. Il est conseillé de porter des gants

en caoutchouc afin d’optimiser la maîtrise de l’outil.

• Lorsqu’on perce ou on visse dans les murs, les planchers

ou tout autre endroit où peuvent se trouver des fils sous

tension, NE PAS TOUCHER À TOUT COMPOSANT

MÉTALLIQUE DE L’OUTIL. Ne le saisir que par ses surfaces

de prise en plastique afin de se protéger des secousses

électriques que provoqueraient le contact du foret ou de la lame

avec un fil sous tension.

AVERTISSEMENT : Certains outils, tels que les sableuses

électriques, les scies, les meules, les perceuses ou certains autres

outils de construction, peuvent soulever de la poussière contenant

des produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits

de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la

fréquence avec laquelle on effectue ces travaux. Pour réduire

l’exposition à de tels produits, il faut travailler dans un endroit bien

ventilé et utiliser l’équipement de sécurité approprié tel un masque

anti-poussières spécialement conçu pour filtrer les particules

microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par

cet outil ou autres outils électriques. Porter des vêtements

de protection et nettoyer les parties exposées du corps

avec de l’eau savonneuse. S’assurer de bien se protéger afin

d’éviter d’absorber par la bouche, les yeux ou la peau des

produits chimiques nocifs.

MISE EN GARDE : porter un dispositif de protection

personnel anti-bruit approprié durant l’utilisation. Sous

certaines conditions et pendant toute la durée de l’utilisation, le bruit

émanant de ce produit pourrait contribuer à la perte d’audition.

• L’étiquette de l’outil peut comporter les symboles suivants.

V ..............volts A ..............ampères

Hz ............hertz W ............watts

min ..........minutes ..........courant alternatif

........courant continu

n

o ............sous vide

............construction de …/min ......tours ou courses

................classe II ................à la minute

............borne de mise à la terre

Poignée latérale

MISE EN GARDE : Toujours utiliser la poignée latérale le cas

échéant et saisir la perceuse à percussion des deux mains.

La perceuse à percussion comporte une poignée latérale. Celle-ci

se fixe au boîtier d’engrenages à l’avant de l’outil (fig. 1) et on peut

la faire tourner sur 360° de façon à être utile autant aux gauchers

qu’aux droitiers.

Interrupteur

Enfoncer l’interrupteur à détente pour mettre l’outil en marche

(fig. 2). Pour l’arrêter, il suffit de relâcher l’interrupteur. Pour assurer

le fonctionnement continu de l’outil, il suffit d’enfoncer la détente et

de pousser le

bouton de verrouillage

vers le haut. L’outil continue

Page 13

Français

11

INVERSEUR DE

MARCHE

INTERRUPTEUR

À DÉTENTE

BOUTON DE

VERROUILLAGE

FIGURE 2

FIGURE 3

FIGURE 4

DEVANT DE L’OUTIL

VITESSES ÉLEVÉES

CADRAN DE

SÉLECTION

PERÇAGE

PERÇAGE À

PERCUSSION

VITESSES BASSES

alors de fonctionner. Pour arrêter l’outil lorsqu’il est en mode de

fonctionnement continu, enfoncer l’interrupteur à fond et le relâcher.

Toujours s’assurer que le bouton de verrouillage fonctionne bien

avant d’utiliser l’outil (chaque fois).

Ne pas verrouiller l’interrupteur lorsqu’on effectue des travaux de

perçage manuels de manière à relâcher instantanément

l’interrupteur si le foret reste coincé. Il faut seulement utiliser le

bouton de verrouillage lorsque la perceuse est installée sur un établi

ou fixée de toute autre façon. Veiller à ce que le bouton de

verrouillage soit dégagé avant de débrancher l’outil, sinon celui-ci se

remettra immédiatement en marche la prochaine fois qu’on s’en

servira et cela présente des risques de dommages et de blessures.

Le

régulateur de vitesse

permet de contrôler la vitesse de l’outil.

Plus on enfonce l’interrupteur à détente, plus l’outil fonctionne

rapidement.

NOTE : Afin de maximiser la durée de l’outil, se servir des basses

vitesses uniquement pour l’amorçage de trous sans utiliser un

poinçon au préalable, pour percer les métaux, les plastiques et la

céramique ou pour enfoncer des vis. Les vitesses élevées

conviennent mieux au perçage du bois et des panneaux ainsi que

pour utiliser des accessoires de ponçage et de polissage.

L’inverseur de marche

sert à sortir les vis ou les forets bloqués. Il se

trouve au-dessus de l’interrupteur à détente, comme le montre la

figure 2. Pour actionner la marche arrière, il faut mettre l’outil hors

tension et faire glisser l’inverseur de marche vers la gauche

(lorsqu’on regarde le mandrin). Remettre l’inverseur à la marche

avant en arrêtant d’abord l’outil et en faisant glisser l’inverseur vers

la droite.

Fonctionnement à vitesses basses ou

élevées

Les deux gammes de vitesses de la perceuse à percussion

procurent un fonctionnement efficace pour une gamme complète

d’utilisations avec un grand choix d’accessoires.

Page 14

Français

12

Pour utiliser les VITESSES BASSES, faire tourner le cadran de

sélection (fig. 3) qui se trouve sous la perceuse à percussion de sorte

que le symbole des vitesses basses se trouve à l’avant de l’outil.

Pour utiliser les VITESSES ÉLEVÉES, faire tourner le cadran de

sélection de sorte que le symbole des vitesses élevées se trouve à

l’avant de l’outil.

On peut seulement modifier la position des engrenages lorsque l’outil

est hors tension. Il peut toutefois être nécessaire de faire tourner le

mandrin légèrement à la main afin d’aligner les engrenages lorsqu’on

fait tourner le cadran de sélection. NE PAS TENTER DE MODIFIER

LE RÉGIME DE L’OUTIL en actionnant le cadran de sélection

lorsque l’outil fonctionne au risque d’endommager les engrenages.

Sélecteur du mode de fonctionnement

Pour passer du mode de perçage à celui de perçage à percussion

(ou vice versa), faire tourner le cadran qui se trouve sur le dessus de

l’outil (fig. 4) en choisissant le symbole approprié. Pour percer, aligner

le symbole du foret sur le mandrin. Pour percer à percussion, aligner

celui du marteau sur le mandrin (voir la figure).

NOTE : Le sélecteur doit être dans l’une ou l’autre de ces positions

en tout temps. Il n’y a aucun mode de fonctionnement entre ces deux

positions.

Mandrin

Pour insérer un foret

, ouvrir les mâchoires du mandrin en faisant

tourner la bague à la main et y insérer environ 3/4 po de l’arbre du

foret. Resserrer la bague du mandrin à la main. Placer la clé du

mandrin dans chacun des trois trous et serrer dans le sens horaire. Il

est essentiel de bien serrer les trois trous du mandrin afin de prévenir

le glissement du foret.

Pour dégager le foret

, il suffit de faire tourner

la clé du mandrin dans le sens antihoraire dans l’un des trous, puis de

desserrer le mandrin à la main.

Fonctionnement

PERÇAGE

1. Toujours débrancher l’outil lorsqu’on en change les forets ou les

accessoires.

2. N’utiliser que des forets bien affûtés. Pour le BOIS : utiliser les

vitesses basses et des forets hélicoïdaux, à langue d’aspic, de

tarière ou des emporte-pièce; pour le MÉTAL : utiliser les

vitesses basses et des forets hélicoïdaux en acier de coupe

rapide ou des emporte-pièce; pour la MAÇONNERIE (brique,

ciment et béton, etc.) : forets au carbure pour le perçage à

percussion. Utiliser les vitesses basses pour les forets de plus

de 3/8 po de diamètre.

3. Veiller à ce que la pièce à percer soit solidement retenue ou

fixée en place. Afin d’éviter les avaries aux matériaux minces,

les adosser à un bloc de bois épais.

4. Toujours exercer la pression en ligne directe avec le foret.

N’user que de la force qu’il faut pour que le foret continue de

percer; éviter de trop forcer, ce qui pourrait faire caler le moteur

ou dévier le foret.

5. Saisir fermement la perceuse afin de contrer l’effet de torsion de

l’outil en marche.

6. LA PERCEUSE S’ÉTOUFFE habituellement lorsqu’elle est

surchargée ou utilisée de façon inappropriée. RELÂCHER

IMMÉDIATEMENT L’INTERRUPTEUR À DÉTENTE, retirer le

foret du matériau et déterminer la cause du blocage. ÉVITER

DE METTRE EN MARCHE ET HORS CIRCUIT L’OUTIL À

L’AIDE DE L’INTERRUPTEUR À DÉTENTE DANS LE BUT

DE FAIRE DÉMARRER LA PERCEUSE BLOQUÉE, CELA

POURRAIT L’ENDOMMAGER.

7. Afin de minimiser l’étouffement du moteur ou le défoncement de

la pièce, réduire la pression et faire avancer plus doucement le

foret vers la fin de sa course.

Page 15

Français

13

8. Laisser le moteur en marche lorsqu’on retire le foret d’un trou

afin d’éviter qu’il se coince.

9. Il n’est pas nécessaire de pratiquer un creux de guidage avec

les perceuses à régulateur de vitesse. Utiliser plutôt une basse

vitesse pour commencer le trou, puis accélérer en enfonçant

plus profondément l’interrupteur à détente lorsque le foret est

suffisamment inséré dans la pièce.

PERÇAGE DANS LE MÉTAL

UTILISER SEULEMENT à la gamme de vitesses basses.

Commencer à percer à basse vitesse et augmenter jusqu’à la pleine

puissance tout en exerçant une pression ferme sur l’outil. Une

production uniforme de copeaux métalliques à débit moyen indique

un perçage convenable. Utiliser de l’huile de coupe pour percer dans

les métaux, sauf la fonte et le laiton qui se percent à sec. L’huile de

coupe la plus efficace est l’huile sulfurisée ou l’huile de lard; la

graisse de bacon est parfois suffisante.

NOTE : Il peut être plus facile de percer de gros trous dans l’acier

(de 5/16 po à 1/2 po) lorsqu’on perce un trou de guidage (de 5/32 po

à 3/16 po) au préalable.

PERÇAGE DANS LE BOIS

UTILISER SEULEMENT à la gamme de vitesses basses.

Commencer à percer à basse vitesse et augmenter jusqu’à la pleine

puissance tout en exerçant une pression ferme sur l’outil. Les forets

hélicoïdaux à métal peuvent servir à percer le bois, mais il faut les

retirer souvent du trou pour chasser les copeaux et rognures des

goujures afin d’éviter qu’ils ne surchauffent. Pour percer de gros

trous, utiliser les forets à bois d’une perceuse électrique. Adosser les

matériaux friables à un bloc de bois quelconque.

PERÇAGE DANS LA MAÇONNERIE

Lorsqu’on perce de la maçonnerie, utiliser des forets à pointe de

carbure conçus pour le perçage à percussion et s’assurer qu’ils sont

bien affûtés. Pour percer des trous d’un diamètre maximal de 3/8 po,

utiliser la gamme de vitesses élevées. Pour percer des trous d’un

diamètre de plus de 3/8 po, utiliser la gamme de vitesses basses. Ne

pas oublier de choisir le mode de fonctionnement à percussion.

Exercer une pression constante et ferme sur l’outil afin d’en

optimiser le rendement. Une production uniforme de poussière à

débit moyen indique un perçage convenable.

Jauge de profondeur

Afin de régler la jauge de profondeur, desserrer la poignée et

déplacer la jauge de sorte que la distance entre son extrémité et le

bout du foret égale la profondeur voulue. Lors du perçage avec la

jauge de profondeur, arrêter de percer lorsque l’extrémité de la jauge

atteint la surface du matériau percé.

Entretien

NETTOYAGE ET LUBRIFICATION

Nettoyer l’outil seulement à l’aide d’un savon doux et d’un linge

humide. Ne laisser aucun liquide s’infiltrer dans l’outil et ne jamais

immerger l’outil.

L’outil est muni de roulements autolubrifiés qui ne nécessitent

aucune lubrification périodique. Dans l’éventualité peu probable où

l’outil nécessiterait de l’entretien, le confier au personnel d’un centre

de service autorisé.

Accessoires

Les accessoires recommandés pour l’outil sont vendus séparément

chez les détaillants ou au centre de service autorisé de la région.

MISE EN GARDE : L’utilisation de tout accessoire non

recommandé peut être dangereuse.

Page 16

Français

14

CAPACITÉS MAXIMALES RECOMMANDÉES

DW505 DW515

CAPACITÉ DU MANDRIN

17mm (5/8 po) 13 mm (1/2 po)

RÉGIME (trs/min) De 0 à 1 100 De 0 à 2 700 De 0 à 900 De 0

à 2 200

FORETS À MÉTAUX 10 mm (3/8 po) 10mm (3/8 po)

Basses vitesses Basses vitesses

FORETS À BOIS 38 mm (1 1/2 po) 38mm (1 1/2 po)

Basses vitesses Basses vitesses

FORETS À MAÇONNERIE Matériaux tendres

22mm (7/8 po) de 19 mm

(3/4 po) – Basses vitesses Basses vitesses

Béton de 13 mm Béton de 16 mm

(1/2 po) (5/8 po)

Basses vitesses Basses vitesses

EMPORTE-PIÈCE 53 mm (2 1/8 po) 100mm (4 po)

Basses vitesses Basses vitesses

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil,

n’en confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’au personnel d’un

centre de service D

EWALT ou d’un atelier d’entretien autorisé

n’utilisant que des pièces de rechange identiques.

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un

défaut de matériel ou de fabrication pour une période de trois ans à

compter de la date d’achat. La présente garantie ne couvre pas les

pièces dont la défectuosité a été causée par une usure normale ou

l’usage abusif de l’outil. Pour obtenir de plus amples renseignements

sur les pièces ou les réparations couvertes par la présente garantie,

visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1

800 4-D

EWALT). Cette garantie ne s’applique pas aux accessoires

et ne vise pas les dommages causés par des réparations effectuées

par un tiers. Cette garantie confère des droits légaux particuliers à

l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits

variant d’un état ou d’une province à l’autre.

En plus de la présente garantie, les outils D

EWALT sont couverts par

notre :

CONTRAT D’ENTRETIEN GRATUIT D’UN AN

D

EWALT entretiendra l’outil et remplacera les pièces usées au cours

d’une utilisation normale et ce, gratuitement, pendant une période

d’un an à compter de la date d’achat, et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque raison que

ce soit, du rendement de l’outil électrique, du laser ou de la cloueuse

D

EWALT, celui-ci peut le retourner, accompagné d’un reçu, dans les

90 jours à compter de la date d’achat, pour obtenir un

remboursement intégral, sans aucun problème.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE : Si vos étiquettes

d'avertissement deviennent illisibles ou sont manquantes,

composez le 1-800-4-D

EWALT pour obtenir une étiquette de

remplacement gratuite. En outre, les produits D

EWALT sont

couverts par la garantie suivante.

Page 17

Español

15

Reglas generales de seguridad

¡ADVERTENCIA! Lea y comprenda todas las instrucciones.

No hacerlo puede originar riesgos de choque eléctrico, incendio y

lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las

bancas amontonadas y las zonas oscuras propician los

accidentes.

• No opere herramientas eléctricas en atmósferas explosivas,

como en presencia de líquidos, gases o polvos inflamables.

Las herramientas eléctricas producen chispas que pueden

originar la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados

mientras opera una herramienta eléctrica. Las distracciones

pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

Las herramientas con tierra deben conectarse a una toma

de corriente instalada y aterrizada correctamente de

conformidad con todos los códigos y regulaciones locales.

Nunca elimine la pata de conexión a tierra ni modifique la

clavija en ninguna manera. No utilice clavijas adaptadoras.

Consulte con un electricista calificado si tiene dudas acerca

de la conexión correcta a tierra de su toma de corriente. En

el caso que su herramienta tenga una falla eléctrica, el aterrizaje

proporciona una vía de baja resistencia para llevar la electricidad

lejos del operador. Aplicable únicamente a herramientas Clase

I (aterrizadas)

• Las herramientas con doble aislamiento están equipadas

con una clavija polarizada (con una pata más ancha que la

otra.) Esta clavija se acoplará únicamente en una toma de

corriente polarizada de una manera. Si la clavija no se

acopla al contacto, inviértala. Si aún así no se ajusta,

comuníquese con un electricista calificado para que le

instalen una toma de corriente polarizada apropiada. El

doble aislamiento elimina la necesidad de cables con tres hilos

y sistemas de alimentación con conexión a tierra. Aplicable a

herramientas Clase II (con doble aislamiento).

• No exponga las herramientas eléctricas a la lluvia o a

condiciones de mucha humedad. El agua que se introduce en

las herramientas aumenta el riesgo de descargas eléctricas.

• No maltrate el cable. Nunca tome el cable para transportar

una herramienta ni para desconectarla de la toma de

corriente. Consérvelo alejado de calor aceite, bordes

afilados o piezas móviles. Cambie inmediatamente los

cables dañados. Los cables dañados aumentan el riego de

choque eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie,

utilice una extensión marcada “W-A” o “W”. Estas

extensiones están clasificadas para uso a la intemperie y para

reducir el riesgo de choques eléctricos.

• Cuando utilice una extensión, asegúrese de emplear una

con el calibre suficiente para soportar la corriente necesaria

para su herramienta. Una extensión con calibre inadecuado

causará una caída en el voltaje de la línea resultando en pérdida

de potencia y sobrecalentamiento. La tabla siguiente muestra el

calibre correcto para usarse, relativo a la longitud de la extensión

y el amperaje mencionado en la placa de identificación. Si tiene

dudas, utilice el calibre siguiente. Mientras más pequeño sea el

número del calibre, mayor será su capacidad.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

Más No más Calibre del cordón AWG

de de

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16- 14 12 No recomendado

Page 18

Español

16

SEGURIDAD PERSONAL

• Esté alerta concéntrese en lo que está haciendo. Recurra

al sentido común cuando opere una herramienta eléctrica.

No opere ninguna herramienta si se encuentra fatigado o bajo la

influencia de drogas, alcohol o medicamentos. Un momento de

desatención mientras se operan herramientas eléctricas puede

ocasionar lesiones graves.

• Vístase de manera adecuada. No tenga puestas ropas o

artículos de joyería flojos. Cubra su cabello si lo tiene largo.

Conserve su cabello, sus ropas y guantes alejados de las

piezas móviles. Las piezas de vestir flojas, las joyas y el cabello

largo pueden resultar atrapados por las piezas móviles.

• Evite el encendido accidental. Asegúrese que el interruptor

esté en posición de apagado antes de conectar. Sostener

una herramienta con el dedo en el interruptor o conectarla sin

fijarse si el interruptor está en posición de encendido propicia los

accidentes.

• Retire las llaves de ajuste antes de encender la herramienta.

Una llave que se deja en una pieza giratoria puede ocasionar

lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien

apoyados, al igual que el equilibrio. La posición correcta de

los pies y el equilibrio permiten controlar mejor la herramienta en

situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en

los ojos. Se deben utilizar mascarillas contra polvo, zapatos

antiderrapantes, casco o protectores para los oídos para tener

las condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Conserve los mangos secos, limpios y libres de aceite y

grasa. Es recomendable utilizar guantes de goma, esto le

permitirá controlar mejor la herramienta.

• Utilice prensas u otros medios prácticos para asegurar y

apoyar la pieza de trabajo en una plataforma estable. Sujetar

las piezas con la mano o contra su cuerpo es inestable y puede

originar la pérdida de control.

• No utilice la herramienta si el interruptor no enciende y

apaga. Cualquier herramienta que no pueda controlarse por

medio del interruptores peligrosa y debe reemplazarse.

• Desconecte la clavija de la toma de corriente antes de hacer

cualquier ajuste, cambio de accesorios o de guardar la

herramienta. Tales medidas de seguridad preventivas reducirán

el riesgo de que la herramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los niños y de

otras personas no capacitadas. Las herramientas son

peligrosas en manos de personas no capacitadas.

• Cuide sus herramientas. Conserve las herramientas de

corte afiladas y limpias. Las herramientas que reciben un

mantenimiento adecuado, con piezas de corte afiladas,

difícilmente se atascan y son más fáciles de controlar.

• Verifique la alineación de las piezas móviles, busque

fracturas en las piezas y cualesquiera otras condiciones

que puedan afectar la operación de las herramientas. Si está

dañada, lleve su herramienta a servicio antes de usarla de

nuevo. Muchos accidentes se deben a herramientas con

mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende

para su modelo de herramienta. Los accesorios que estén

diseñados para una herramienta, pueden volverse peligrosos

cuando se emplean con otra.

SERVICIO

• El servicio a las herramientas lo debe efectuar únicamente

personal calificado. El servicio o mantenimiento realizado por

personal no calificado puede originar riesgos de lesiones.

• Cuando efectúe servicio a una herramienta, utilice

únicamente refacciones idénticas. Siga las instrucciones de

la sección de Mantenimiento de este manual. El empleo de

piezas no autorizadas o no seguir las instrucciones de

mantenimiento puede originar riegos de choque eléctrico o

lesiones.

• Tome la herramienta por las superficies aislantes de

sujeción cuando realice una operación en que la

Page 19

Español

17

herramienta de corte pueda hacer contacto con cables

ocultos o con su propia extensión. El contacto con un cable

“vivo” hará que las partes metálicas de la herramienta queden

“vivas” y descarguen hacia el operador.

Reglas adicionales de seguridad

• Tome la herramienta por las superficies aislantes de

sujeción cuando realice una operación en que la

herramienta de corte pueda hacer contacto con cables

ocultos o con su propia extensión. El contacto con un cable

“vivo” hará que las partes metálicas de la herramienta queden

“vivas” y descarguen hacia el operador.

• Conserve los mangos secos, limpios, libres de aceite y

grasa. Se recomienda el uso de guantes de goma. Esto le

permitirá controlar mejor la herramienta.

• NO TOQUE NINGUNA PARTE METÁLICA DE LA

HERRAMIENTA cuando perfore o atornille en muros, pisos

o dondequiera que pueda encontrar cables eléctricos vivos.

Tome la herramienta solamente por las superficies de sujeción

aislantes para evitar el choque eléctrico en caso que perfore o

atornille un cable eléctrico vivo.

ADVERTENCIA : Parte del polvo creado al lijar, aserruchar,

moler o perforar con máquina, así como al realizar otras actividades

de la construcción, contiene substancias químicas que se sabe

producen cáncer, defectos congénitos u otras afecciones

reproductivas. Algunos ejemplos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de

albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la

frecuencia en que se haga este tipo de trabajo. Para reducir la

exposición a esas substancias químicas: trabaje en un área bien

ventilada, y trabaje con equipos de seguridad aprobados, tales

como máscaras contra el polvo especialmente diseñadas para filtrar

las partículas microscópicas.

• Evite el contacto prolongado con polvos originados por

lijar, aserrar, esmerilar, taladrar y otras actividades

constructivas. Vista ropas protectoras y lave las áreas

expuestas con agua y jabón. Permitir que el polvo se

introduzca en su boca, ojos, o dejarlo sobre la piel promueve la

absorción de químicos dañinos.

PRECAUCION: utilice la protección auditiva apropiada durante

el uso. Bajo ciertas condiciones de duración de uso, el ruido

producido por este producto puede contribuir a la pérdida auditiva.

• La etiqueta de su herramienta puede incluir los siguientes

símbolos.

V ............volts A ..............amperes

Hz ..........hertz W ............watts

min..........minutos ............corriente alterna

........corriente directano ............velocidad sin carga

............construcción …/min......revoluciones o

................Clase II ................reciprocaciones por

..........terminales de ................minuto

................conexión a tierra BPM ........golpes por minuto

Mango lateral

PRECAUCION: Utilice el mango lateral siempre que se le

proporcione y sujete el rotomartillo con ambas manos. Se suministra

un mango lateral con este rotomartillo. Se sujeta al frente de la caja

de engranes como se muestra en la figura 1 y se puede girar 360°

para permitir el uso a mano izquierda.

Interruptor

Para encender el rotomartillo, oprima el gatillo interruptor (figura 2).

Para detener el rotomartillo, suelte el gatillo. Para dejar fijo el

interruptor en la posición de encendido (“ON”) para operación

continua, oprímalo y presione el

botón del seguro.

La herramienta

Page 20

Español

18

PALANCA DE

REVERSA

GATILLO

INTERRUPTOR

BOTON DEL

SEGURO

FIGURA 2

FIG. 3

CAMBIE DE PUESTO

LA PERILLA

FRENTE DE LA HERRAMIENTA

CONFIGURACION

BAJA DE LA

VELOCIDAD

CONFIGURACION

DE ALTA

VELOCIDAD

continuará en funcionamiento. Para APAGAR la herramienta desde

la posición de operación continua, oprima y suelte el gatillo una

vez. Antes de usar la herramienta (cada vez), asegúrese de que el

mecanismo de liberación del seguro funciona libremente.

No asegure el interruptor en posición de ENCENDIDO cuando

taladre a mano para poder soltar el gatillo en caso que la broca se

atasque en el orificio. El botón de trabado se debe utilizar solamente

cuando el taladro se encuentra montado en una base de columna

de alguna otra manera. Asegúrese de montar el mecanismo de

seguridad antes de desconectar la clavija de la toma de corriente.

No hacerlo propiciará que el taladro se encienda en el momento de

volver a conectarlo, con el peligro consecuente de daños o lesiones.

El

interruptor de gatillo de velocidad variable

permite controlar la

velocidad. Cuanto más a fondo se oprima el gatillo, más elevada

será la velocidad del rotomartillo.

NOTA: Utilice velocidades bajas para perforar sin haber marcado

el “punto” de centro, taladrar en metal o plásticos, atornillar y

perforar cerámica. Las altas velocidades son mejores para barrenar

madera y aglomerados de ésta, y cuando se van a utilizar los

accesorios abrasivos y de pulido.

La

palanca de reversa

se utiliza para invertir la marcha del

rotomartillo sacar las brocas atascadas en barrenos muy apretados

y para destornillar. Se encuentra situada por arriba del interruptor de

gatillo como se observa en la figura 2. Para activar el motor en

reversa, apague el rotomartillo y mueva la palanca hacia la izquierda

(mirándola desde el portabrocas). Para operar la unidad hacia

adelante APAGUE el rotomartillo y cambie la posición de la palanca

hacia la derecha.

Operación a velocidad Alta/Baja

El engranaje de dos velocidades del rotomartillo de doble acción

permite una buena operación en gran variedad de aplicaciones, a

la vez que una capacidad muy aumentada para utilizar diversos

accesorios.

Para la operación en BAJA VELOCIDAD, debe girar la perilla de

cambios (fig. 3) de modo que el gráfico de baja velocidad quede

orientado hacia el frente de la herramienta.

Para la operación en ALTA VELOCIDAD, la perilla de cambios debe

girarse para que el gráfico correspondiente quede orientado hacia el

frente de la herramienta.

El tren de engranajes se ha diseñado para efectuar los cambios sólo

cuando está apagada la unidad. Sin embargo, quizá sea necesario

Page 21

Español

19

FIGURE 4

MODO DE

TALADRO

MODO DE

ROTOMARTILLO

girar ligeramente el broquero a mano para alinear los engranajes

mientras se da vuelta a la perilla de cambios. NO INTENTE

CAMBIAR VELOCIDADES girando la perilla de cambios si la

herramienta se encuentra activada. Hacer lo contrario dañará el tren

de engranajes.

Selector de modo Rotomartillo/Taladro

Para cambiar la herramienta de modo de taladro a modo de

rotomartillo (o viceversa) gire la perilla que se encuentra en la parte

superior de la unidad, ilustrada en la figura 4, hasta la posición que

desee. Para taladrado simple, apunte el gráfico de la broca hacia el

broquero. Para utilizar la unidad en modo de rotomartillo, apunte el

gráfico del martillo hacia el broquero, como se muestra en la figura.

NOTA: El selector deberá estar siempre en alguna de las dos

posiciones siempre. No hay posiciones de operación entre ambas.

Broquero

Para insertar la broca,

abra las mordazas del broquero haciendo

girar el collar con los dedos, e inserte el vástago de la broca a una

profundidad aproximada de 19 mm (3/4”) en el interior del broquero.

Apriete el collar con la mano. A continuación coloque la llave en cada

uno de los tres orificios, y apriete cada vez en el sentido de las

manecillas del reloj. Es importante que apriete las mordazas sobre la

broca en los tres orificios.

Para quitar la broca,

gire el broquero con la llave en sentido

contrario a las manecillas del reloj valiéndose de solamente uno de

los orificios. Afloje a continuación el broquero con la mano.

Operación

TALADRADO

1. Siempre desconecte el taladro cuando instale o cambie brocas

o accesorios.

2. Utilice exclusivamente brocas afiladas. PARA MADERA utilice

la posición de velocidad baja y brocas helicoidales, brocas de

horquilla, brocas de poder o brocas sierra. PARA METAL utilice

la posición de velocidad baja y brocas helicoidales de alta

velocidad o brocas sierra. PARA MAMPOSTERIA utilice brocas

con punta de carburo de tungsteno. Utilice la posición de

velocidad baja con brocas mayores a 3/8”.

3. Asegúrese que el material que va a barrenar esté firmemente

anclado o asegurado. Si perforará material delgado, utilice un

trozo de madera como “respaldo” para evitar dañarlo.

4. Aplique presión al taladro en línea recta con la broca. Haga

suficiente presión para que la broca siga perforando paro no

tanta para que el motor se atasque o la broca se desvíe.

5. Sujete el taladro firmemente para controlar la fuerza de torsión

de la broca.

6. SI EL TALADRO SE ATASCA, esto se deberá probablemente a

que está sobrecargado, o a que se usa de manera incorrecta.

SUELTE EL GATILLO DE INMEDIATO y determine la causa

del atascamiento. Retire la broca de la pieza de trabajo y

comience de nuevo. NO APRIETE EL GATILLO PARA HACER

PRUEBAS DE ENCENDIDO Y APAGADO CUANDO LA

BROCA ESTA ATORADA, ESTO PUEDE DAÑAR EL

TALADRO.

7. Para reducir el peligro de que se atasque el taladro, reduzca la

presión y deje ir suavemente la broca hacia el final del barreno.

Page 22

Español

20

8. Conserve el motor trabajando al retirar la broca del interior del

barreno, de esta manera evitará que se atasque.

9. Con los taladros con velocidad con velocidad variable no hay

necesidad de hacer una marca de centro. utilice una velocidad

baja para comenzar el barreno y acelere al oprimir el gatillo con

mayor fuerza cuando el orificio tenga la profundidad suficiente

para evitar que la broca se salga.

TALADRADO EN METAL

SOLAMENTE USE EL TALADRO en “velocidad baja”. Inicie la

perforación a baja velocidad y vaya aumentándola a la potencia

completa mientras aplica presión firme en la herramienta. El flujo

uniforme y suave de rebabas indica que se taladra a la velocidad

adecuada. Emplee un lubricante para corte cuando taladre en

metales. Las excepciones son hierro el colado y el latón, que deben

barrenarse en seco. Los lubricantes que mejor funcionan son el

aceite sulfúrico y la manteca.

NOTA: Los barrenos grandes (5/6” a 1/2”) en acero se pueden

hacer con mayor facilidad si se barrena un orificio piloto (5/32” a

3/16”) primero.

TALADRADO EN MADERA

SOLAMENTE USE EL TALADRO en “velocidad baja”. Inicie la

perforación a baja velocidad y vaya aumentándola a la potencia

completa mientras aplica presión firme en la herramienta. Se puede

perforar madera con las mismas brocas helicoidales que se utilizan

para metal. Estas deben estar afiladas y deben sacarse

frecuentemente para limpiarlas de virutas. Los trabajos susceptibles

de astillarse deben respaldarse con un bloque de madera.

TALADRADO EN MAMPOSTERIA

Cuando taladre en mampostería, utilice brocas con punta de carburo

de tungsteno, clasificadas para percusión, y asegúrese que la punta

tenga filo. Para barrenos hasta de 9,5 mm (3/8”) de diámetro, utilice

el engrane de velocidad alta. Para barrenos mayores, emplee el

engrane de velocidad baja. Asegúrese de haber seleccionado el

modo de rotomartillo. Utilice fuerza constante y firme en la

herramienta para taladrar con mayor efectividad. El flujo uniforme

de polvo indica que la velocidad de perforación es adecuada.

Varilla de profundidad

Para ajustar la varilla de profundidad, afloje el mango, coloque la

varilla de manera que la longitud proyectada de la broca por delante

del extremo de la varilla sea igual a la profundidad deseada para el

barreno. Cuando utilice la varilla de profundidad, deténgase cuando

el extremo de la varilla alcance la superficie del material.

Mantenimiento

LIMPIEZA Y LUBRICACION

Solamente utilice jabón suave y agua para limpiar la herramienta.

Nunca permita que ningún líquido se introduzca en la herramienta;

nunca sumerja ninguna parte de la herramienta en ningún líquido.

Se han empleado balero autolubricantes en la herramienta y por

tanto no requieren lubricación periódica. En el remoto caso que su

herramienta llegue a requerir servicio, llévela a un centro de servicio

autorizado.

Accesorios

Los accesorios recomendados para esta herramienta están a su

disposición con costo extra con su distribuidor local o en los centros

de servicio.

PRECAUCION: El empleo de cualquier otro accesorio puede ser

peligroso.

CAPACIDADES MAXIMAS RECOMENDADAS

DW505 DW515

CAPACIDAD DEL BROQUERO12,7 mm (1/2”) 17mm (5/8”)

R.P.M. 0-1,100 0-2,700 0-900 - 0-2200

BROCAS PARA METAL 9,5 mm (3/8”) 9,5mm (3/8”)–

Baja velocidad Baja velocidad

BROCAS PARA MADERA 38 mm (1 1/2”) 38mm (1 1/2”)

Baja velocidad Baja velocidad

Page 23

Español

21

BROCAS PARA 19mm (3/4”) 17mm (5/8”)

MAMPOSTERIA Materiales suaves Materiales suaves

Baja velocidad Baja velocidad

12,7 mm (1/2”) Concreto17mm (5/8”)

Baja velocidad Baja velocidad

BROCAS SIERRA Hasta 53,9 mm 100mm (4”0)

(2 1/8”) – Baja Baja velocidad

velocidad

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto,

deberán hacerse reparaciones, mantenimiento y ajustes

(incluyendo revisión y cambio de los carbones) por centros

autorizados de servicio u otras organizaciones calificadas que

empleen siempre refacciones idénticas

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELÉCTRICAS, FAVOR DE DIRIGIRSE AL CENTRO DE

SERVICIO MAS CERCANO

CULIACAN, SIN

Av. Nicolás Bravo #1063 Sur - Col. Industrial Bravo (667) 7 12 42 11

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juarez (33) 3825 6978

MEXICO, D.F.

Eje Central Lázaro Cardenas No. 18

Local D, Col. Obrera (55) 5588 9377

MERIDA, YUC

Calle 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L.

Av. Francisco I. Madero No.831 - Col. Centro (81) 8375 2313

PUEBLA, PUE

17 Norte #205 - Col. Centro (222) 246 3714

QUERETARO, QRO

Av. Madero 139 Pte. - Col. Centro (442) 214 1660

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis (444) 814 2383

TORREON, COAH

Blvd. Independencia, 96 Pte. - Col. Centro (871) 716 5265

VERACRUZ, VER

Prolongación Díaz Mirón #4280 - Col. Remes (229) 921 7016

VILLAHERMOSA, TAB

Constitución 516-A - Col. Centro (993) 312 5111

PARA OTRAS LOCALIDADES LLAME AL: (55) 5326 7100

Accesorios

Dispone usted de los accesorios para su herramienta por un cargo

adicional con su distribuidor local autorizado Se incluye una lista

completa de los centros de servicio con su herramienta..Si necesita

ayuda para encontrar cualquier accesorio, por favor comuníquese

con D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

MD 21286 o llame al teléfono 1-800-732-4441.

Garantía limitada por tres años

DEWALT reparará, sin cargo, cualquier falla que surja de defectos en

el material o la fabricación del producto, por hasta tres años a contar

de la fecha de compra. Esta garantía no cubre fallas de las piezas

causadas por su desgaste normal o abuso a la herramienta. Para

mayores detalles sobre la cobertura de la garantía e información

acerca de reparaciones realizadas bajo garantía, visítenos en

www.dewalt.com o llámenos al 1 800 433-9258 (1-800-4-D

EWALT).

Esta garantía no aplica a accesorios o a daños causados por

reparaciones realizadas o intentadas por terceros. Esta garantía le

otorga derechos legales específicos, además de los cuales puede

tener otros dependiendo del estado o provincia en que se

encuentre.

Page 24

Español

22

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

Epecificaciones DW505 DW515

Tensión de alimentación 120 V CA 120 V CA

Frecuencia de operación: 50/60 Hz 50/60 Hz

Consumo de corriente: 7,2 A 8,2 A

Además de la garantía, las herramientas DEWALT están cubiertas

por:

1 AÑO DE SERVICIO GRATUITO

DEWALT mantendrá la herramienta y reemplazará las piezas

gastadas por su uso normal, sin cobro, en cualquier momento

durante un año a contar de la fecha de compra.

GARANTÍA DE REEMBOLSO DE SU DINERO POR 90 DÍAS

Si no está completamente satisfecho con el desempeño de su

máquina herramienta, láser o clavadora DEWALT, cualquiera sea el

motivo, podrá devolverlo hasta 90 días de la fecha de compra con

su recibo y obtener el reembolso completo de su dinero – sin

necesidad de responder a ninguna pregunta.

REEMPLAZO DE LAS ETIQUETAS DE ADVERTENCIA

GRATUITO: Si sus etiquetas de advertencia se tornan ilegibles o

se pierden, llame al 1-800-4-D

EWALT para que se las reemplacen

sin cost.

IMPORTADOR: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS, 3A. SECCIÓN, CP 05120

DELEGACIÓN CUAJIMALPA, MÉXICO, D.F

TEL. 5 326 7100

R.F.C.: BDE810626-1W7

Loading...

Loading...