Page 1

Page 2

IF YOU

HAVE ANY

QUESTIONS OR COMMENTS ABOUT THIS,

OR

ANY

DeWALT

TOOL, CALL

US

TOLL FREE

AT I{üF+DE\IVALT

(1۾43}925S).

Serial Numberfrom Nameplate

Date of Purchase

Save this information forfdure

reference.

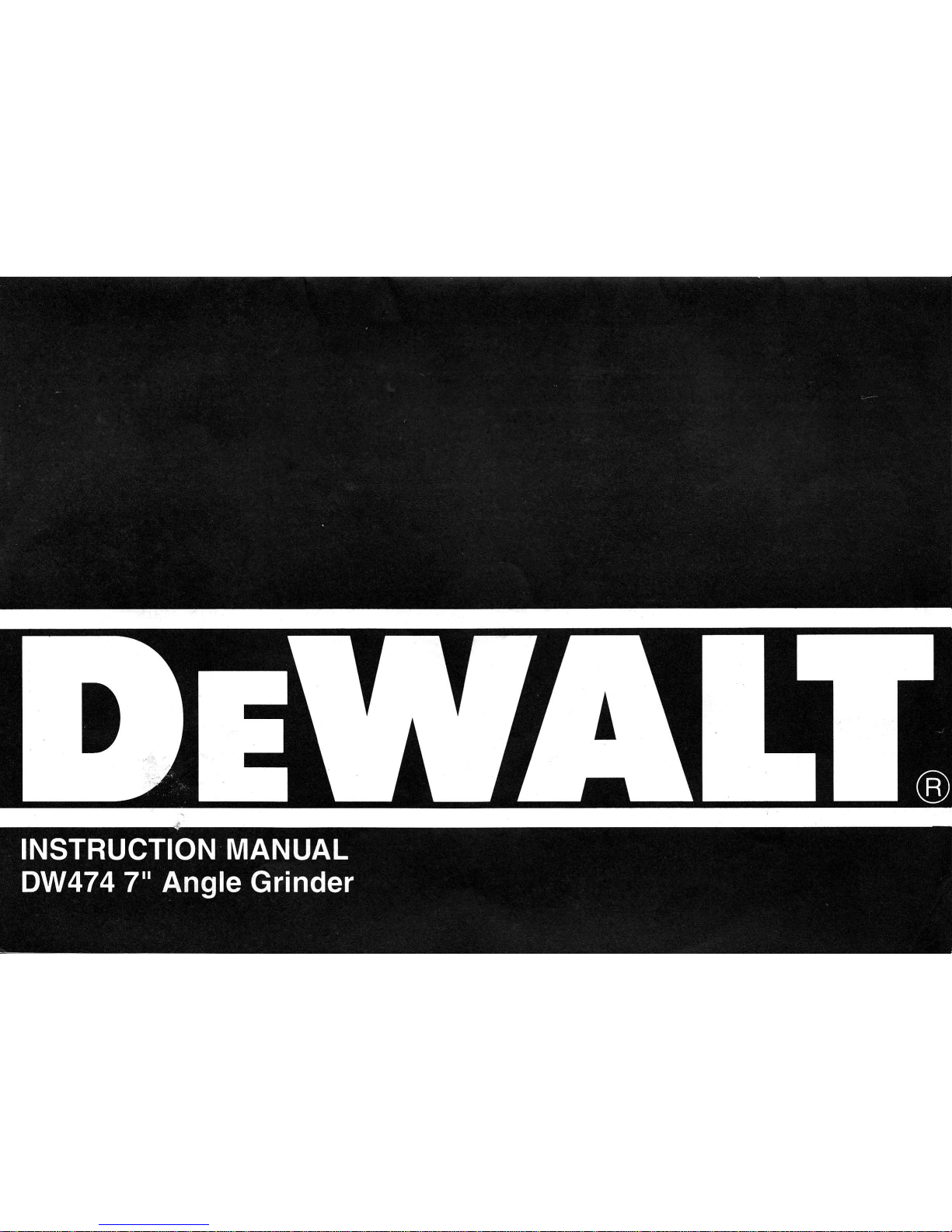

ROTATABLE'

STEEL GUARD

DgWALT...BU,

LT

J O

BSIT

E TO

U Grl

DeWALT high

performance

industrial

tools are made lor America's

toughest industrial and

construction applications. The design

of every

tool in the line

-

from

drills to sanders to

grinders

-

is the resuli

of

rigorous use on

jobsites

and throughout industry. Each

tool is

produced

with

painstaking precision

using advanced manufacturing

systems and intense

qualiÿ

control. Every tool is

checked before it

leaves

the

factory

to make

sure

that it

meets

your

standards for

durabiliÿ, reliabiliÿ

and

power.

DeWALT

Built Jobsite Tough...WE

GUARANTEE lT.

.-':r.:,.

:-r1,,-+;-Ë.4§*æ++

lmportant Salety

lnstructions

WARNING: When using electric

tools, basic safety

precautions

should always be

followed to reduce risk of

fire, electric shock, and

personal

inlury, including the

following:

READ ALL INSTRUCTIONS

Double

lnsulation

Double insulated tools are constructed

throughout with

two

separate

layers of electrical

insulation

or one double

thickness of

insulation

between

you

and the tool's electrical

system.

Tools

built

with this

insulation system are

not intended to be

grounded.

As

a

result,

your

tool is equipped

with a two

prong plug

which

permits you

to use

extension cords

without concem for maintaining

a

ground

connection.

NOTE: Double

insulation does not take the

place

of normal safeÿ

precautions

when operating

this tool. The

insulation system is for

added

protection

against

injury resulting from a

possible

electrical

insulation

failure within the tool.

CAUTION:

WHEN SERVICING USE

ONLY

IDENTICAL

REPLACEMENT

PARTS.

Repair

or

replace damaged cords.

Polarized

Plugs

Polarized

plugs (one

blade is

wider

than

the other) are used on

equipment

to reduce the risk of electric shock.

When

provided,

this

plug

will fit into

a

polarized

outlet only one

way. lf the

plug

does not fit

fully in the outlet, reverse the

plug.

lf it

still

does not fit, contact a

qualified

electrician

to install the

proper

outlet.

Do not change the

plug

in

any

way.

Salety

Instruclions

For All Tools

.

KEEP

WORK AREA CLEAN. Cluttered areas and benches

invite injuries.

.

CONSIDER

WORK AREA ENVIRONMENT.

Don't

expose

power

tools to rain. Don't use

power

tools

in

damp or

wet

locations.

Keep

work area

well lit. Do not use tool

in

presence

of flammable

liquids or

gases.

GUARD

AGAINST

ELECTRIC

SHOCK

Prevent boÜ contact

with

grounded

surtaces.

For example;

pipes,

radiators,

ranges,

and

ref rige rator enclosu

re s.

KEEP CHILDREN

AWAY. Do

not let visitors contact

tool or

extension

cord.

All visitors should be

kept away

from work

area.

STORE

IDLE TOOLS.

When not in use,

tools

should

be stored

in

dry,

and high or

locked-up

plaæ

-

out of

reach

of children.

DON'T

FORCE TOOL.

lt will do

the

iob

better and safer

at the

rate for which

it was

intended.

llSE RIGHT

TOOL. Don't

torce small

tool or attachment

to do

the

iob

of

a

heavy-duty tool.

Don't use tool

for

purpose

not

intended.

DRESS

PROPERLY.

Do

not wear loose clothing

or

iewelry.

They can be caught

in moving

parts.

Rubber

gloves

and

non-

skid tootwear

are

recommended

when working outdoors.

Wear

protective

hair

covering

to contain

long

hair.

USE SAFETy

GLASSES.

Also use

face

or

dust

mask if

operation

is dusÿ.

DON'T

ABUSE CORD.

Never carry

tool by cord or

yank

it to

disconnect

from receptacle.

Keep cord

from heat, oil, and

sharp

edges.

SECURE

WORK.

Use clamps or a

vise to hold

work. lt's safer

than using

your

hand and

it frees both

hands to operate tool.

DON'T OVERREACH.

Keep

proper

footing and balance

at all

times.

MAINTAIN

TOOLS WITH CARE.

Keep tools sharp and

clean

for better and

safer

pertormance.

Follow

instructions

for

lubricating and changing

accessories.

lnspect tool cords

periodically

and

if damaged,

have repaired by

authorized

1

I

_.1

Page 3

seruice

facilÿ. lnspæt

ertension

ærds

peiodically

and

replace if

damaged.

Keep handles

dry, clean, and lree from

oil and

grease.

DISCONNECT

OR LOCK

OFF TOOLS when

not in use,

before

seruicing,

and

when

changing

accessories,

such as blades, bits,

cutters.

REMOVE

ADJUSTING KEYS

AND WRENCHES.

Form habit

of

checking

to see that keys

and adjusting wrenches

are removed from

tool

before tuming it

on.

AVOID

UN,NTENTIONAL

STARTING. Don't

carry tool with finger

on switch. Be

sure switch is

off

when

plugging

in.

EXTENSION

CORDS. Make

sure

your

ertension cord is in

good

condition. When

using

an ertension cord,

be sure to uæ one heavy

enough to

cany the cunent

your product

will draw. An

undersized

cord will

cause a drop in line

voltage resulting in lo*s

of

power

and

overheating.

The following table

shows the correct

size to use

depending on

cord

length

and nameplate

ampere rating. lt in doubt,

use

the next heavier

gage.

The

smaller the

gage

number,

the

heavier the

cord.

OUTDOOR USE EXTENSION

CORDS. When

tool is used

outdoors,

use onÿ

ertension cords intended lor

use outdoors and

so marked.

STAY ALERT. Watch

what

you

are

doing. Use common

sense.

Do

not

operate tool when

you

are tired.

.

CHECK DAMAGED

PARTS.

Before

tufircr

use

of thë tool,

a

guard

or

other

part

that is

damaged

should

be carefully

cheçked

to

determine

that

it will

operate

properly

and

pertorm

its intended

function.

Check for

alignment

of moving

pails,

binding

of moving

parts,

breakage

of

pafts,.

mounting,

and

any other

conditions

that

may

atfect its

operation.

A

guard

or other

part

that is

damaged

should

be

properly

repaired

or replaced

by

an authorized

seruice

center

unless

otherwise indicated

elsewhere

in

this instruction

manual.

Have

defective

switches replaced

by authorized

service

center.

Do not

use tool if switch

does not

tum it

on and off.

.

ALWAYS

WEAR EYE PNOTECNON.

.

KEEP

GIIARDS lN

PLACE.

.

Use only

grinding

wheels

having a maximum

operating speed

at

least

high as

"No

Load RPM" marked

on the

tool's nameplate.

.

Before

using, inspect reæmmended

accessory

for cracks

or flaws. lf

such

a crack

or

flaw is

evident,

discard

the accessory. The

accessory

should

also be inspected

whenever

you

think the

tool

may have

been

dropped.

When

btaiing

the tool

(with

a new

or

replacement

wheel installed)

hold

the tool in

a well

protected

area

and let it run for

one minute. lf

the wheel

has

an undetected

crack or ftaw,

it shoutd

burst in tess

than

one minute.

Never stan the

tæl with

a

person

in line

with the

wheel.

This includes

the

operator.

ln

operation,

avoid bouncing the

wheel or

giving

rt rough

treatment.

lf this

occurs,

stop the tool

and inspect

the wheet.

ALWAYS

USE GUARDS with

depressed

center

wheels

or

flaring

cup

ginding

wheels.

Clean

your

tool out

periodically.

CAUTION:

Some wood

contains

preservatives

such as

copper

chromium

arsenate

(CCA)

which

can be toxic.

When

sanding these

materials

extra care

should be taken

to avoid inhalation

and

minimize

skin

contact.

SAVE THESE INSTRUCTIONS

FOR

FUTURE USE

Volts

r20v

I hon

Minimum

Goge

for

Cond Sets

Totul tengrh

of Cond in Feet

o-25 26-50

5t

-l

00 I 0t

-150

Not more

Thon

Americon

Wire Goge

0

6

l0

12

6 t8

10

t8

12

16

t6

l6

l6

l6

14

1À

14

12

12

16 14 12 Not Recommenderl

COUNTER CLOCKWISE

Ftc.s

-

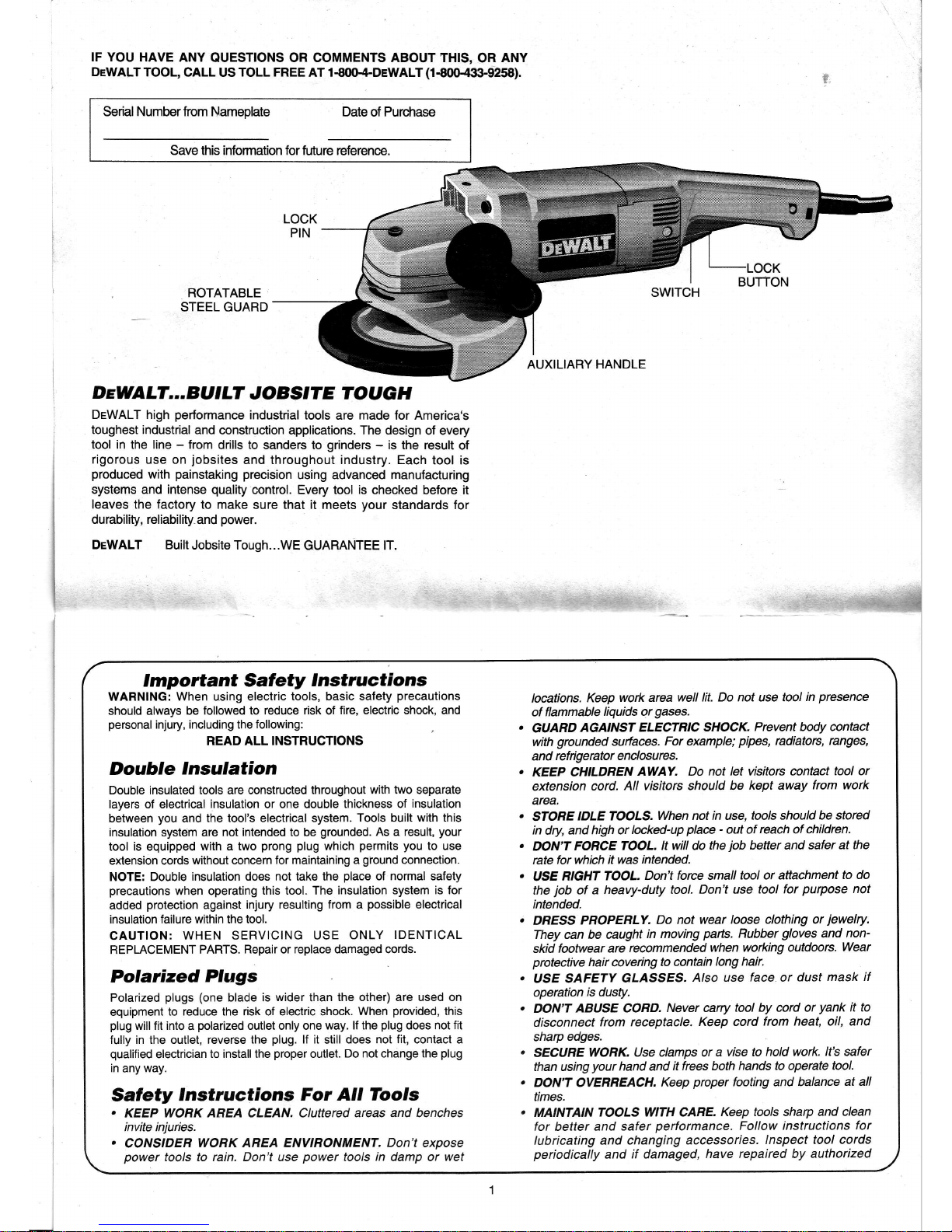

FIG.1

NOTE:

The

Guard

will fit in

one

position.

lf the holes

are

not

aligned,

rotate

Guard

until they are.

FlG. 4

LOCK

BUTTON

BACKING

HUB

FIBRE

Guard lnstallation

(FlG.l

)

Turn

off

and unplug

grinder.

A wheel

guard

is

packed

with

your grinder

that must

be used

whenever

using

a depressed

center

grinding

wheel.

NOTE: A

special

guard

is

required for

use with a Flaring

Cup

Wheel.

Do not

attempt

to use a flaring

cup wheel

with the wheel

guard

supplied with

your grinder.

(See page

4.)

To install

the

guard

to the

grinder,

place

it over the

spindle, as shown

in Figure

1, and install

the

provided

three

socket head screws

(5/32"

hex)

and

lock

washers in

the three holes in

the housing

adjacent

to the spindle.

Tighten these

screws

securely.

NOTE:

The

guard

will

only fit in one

position.

lf the holes

are not

aligned,

loosen

the

hex

nut, rotate

guard

until they

are and

retighten

the hex nut.

An

adjustable

skirt

guard

is

available

at extra cosl lor

use with flaring

cup wheels

only.

(wheels

also

available at

extra cost) The

adjustable

skirt

guard

installs

to the

same center three

holes

used to mount

the

wheel

guard

included

with

the tool. The

depressed

center wheèl

guard

must

be

removed

before mounting

the adjustable

skirt

guard.

NOTE:

NEVER

ATTEMPT

TO

USE ANY TYPE

OF GRINDING

WHEEL

WITHOUT

THE PROPER

GUARD. TO

DO

SO

WOULD

BE

EXTREMELY

HMARDOUS.

Swr'tch

Operation

(FIG.

2,

To

start tool

press

buttons A

and B at the

same time. For continuous

operation

with

switch locked

ON

press

only button B. To release

switch

press

button A and release.

LOGK

BUTTON

SANDING

DISC

BACKING

CLOCKWISE

Page 4

Auxiliary llandle

(FIG.

3l

An auxiliary handle

is fumished

with

your grinder

and can

be installed

on either

side of the

front housing, as shown

in Figure 3.

This handle

SHOULD BE USED

AT ALL

TIMES to maintain

complete control

of

the tool.

Spindle

Lock Button

(FtG.

3)

Turn off and unplug

grinder.

ln order to

prevent

the spindle

of the tool

lorm rotating

while installing

or

removing accessories,

a spindle

lock button

has been

provided

in

the

gear

head

of

the machine,

as shown

in Figure

4. To lock

the

spindle, depress

and

hold the lock button.

NEVER

DEPRESS

THE

LOCK BUTTON

WITH

THE TOOL

RUNNING OR COASTING.

Sanding

Discs

(FIG,

4)

NOTE:

The

guard

need

not be used

with sanding

discs.

TO INSTALL SANDING

DISCS:

Be sure that the

tool is unplugged.

Push the hub of the

clamp

washer

through the center oI

the sanding disc,

as far as

it will

go,

and also

through

ûre backing

disc.

Pr.i the

backing

hub

on

the tool spindle.

lnstall

the clamp

washer

on

the tool spindle

and thread the assembly

clockwise,

completeÿ

down on

the

spindle.

Engaç

the lock button.

When using a sanding

disc,

hold the tool so that an

angle of

10'to 15"

exists beùreen

the disc and

the work.

lf

onÿ

the outer edge

of the disc

is

used a rough crÎ surlace

will

result. lf the disc is

pressed

flat against

the

work the surface

will be inegular

and bumpy, and

the tool

will be difficult

to

control.

See

page

7 for a æmplete

descripüon

of usage and

mounüng altematives.

Removing

Disc

(FIG.

5l

Using

a cloth or

glove

to

protect your

hand, turn

the disc assembly

counterclockwise

to remove

it from the tool spindle.

Engage

lock button.

Depressed Center

Wheels

(FtG.

6t

Depressed center

wheels may be used lor

moderate metal removal on

flat or contoured surfaces.

CAUTION:

Never use depressed center

wheels without the

proper

guard.

TO INSTALL DEPRESSED CENTER

WHEELS:

1. Be sure tool is disconnected

from

power

supply and switch

is in

OFF

position.

2. Be sure the

guard

assembly

is securely attached to

the spindle

housing.

BACKING HUB

i;rry

SCREWS

FLARING

CUP

WHEEL

CLAMP

FIG.7

3.

Put

the backing

hub onto

the tool spindle.

4. Check

rated speed on depressed

center

wheel. Never use

wheel

with

rated speed lower

than the speed

in the'WARNING'

statement

on

the

nameplate of

the tool

5.

Place

the

depressed

center

wheel on

the tool spindle.

6.

Thread the clamp

washer on tool

spindle,

hold the tool spindle

by

engaging

the lock button,

and tighten

clamp

washer with

ppanner

wrench.

See

page

T lor a complete

description

ol usage

and

mounting alternatives.

When using a depressed

center

wheel,

hold the tool so

that an angle

of

approximately

30o exists

between

the wheel and

the work.

Wire Brushing

1. Disconnect tool

from

power

source.

Rest

grinder

on its back

with

spindle

facing up.

2. Thread wire cup brush onto

spindle and

tighten.

3. Common

applications

for wire cup brushes

include cleaning

welds,

angles, corners and

removal of

paint.

4. Always wear eye

protection

and appropriate

protective

clothing.

Flaring Cup

Wheels

(FIG.

fl

Use

flaring cup

wheels for smoothing

welds, casting

ridges, or

large

metal

areas, cutting

off studs, bolts,

rivets, etc.

A

5/8'

-

11

thread bushing

in the

wheel threads

directly on

the tool spindle.

Flaring Cup

Wheels should

only

be used

in

conjunction

with the correct size

adjustable skirt

guard.

Disconnect the tool

from the

power

supply.

Attach

guard

with the open

paft

of

the

guard

facing

away

from the operator.

Tighten mounting

screws

to sêcure

guard

in

place.

Hold down

the

spindle

lock button and

thread the flaring cup

wheel

onto

the spindle.

Be

sure

that the

wheel is

firmly

and completely

threaded onto

the spindle.

Loosen screws

holding the adjustable skirt

part

of the

guard

and slide

the skirt down

until about

1/4"

of

the llaring cup

wheel is exposed.

Tighten screws.

When using tool, tilt tool slightly-do

not

hold wheel

perfectly

flat

against the

work. Avoid bouncing

the wheel or

giving

it rough

treatment, since cracks

might develop

which would cause the

wheel

to fly apart. Always check

the wheel

for

cracks

before using

it,

and

always

use a wheel

guard.

Maintenance ol

Tool

Cleaning

Blowing dust and

grit

out oI the

motor housing using compressed

air is

a

necessary regular maintenance

procedure.

Dust and

grit

containing

metal

particles

often accumulate on

interior surfaces and

could create

an electrical shock hazard

if not frequently

cleaned

out.

CAUTION:

Never use solvenls or other

harsh

chemicals

for

cleaning

the

non-metallic

parts

of

the tool.

Use

clean, dry rag only.

Lubrication

DeWALT tools are

properly

lubricated at the

factory

and

are

ready for

use.

Tools should be

relubricated regularly every sixÿ days

to six

months,

depending on

usage.

(Tools

used constantly

on

production

or

heavy-duÿ

iobs

and

tools exposed to

heat may require more

frequent

lubrication.) This lubrication should only be attempted

by trained

power

tool repairpersons.

Page 5

lmportant

To

assure

product

SAFEIY

and RELIABILITY,

repairs, maintenanc€,

and adjustment should be

performed

by DeWALT certilied service

centers or other

qualified

service organizations.

These service

organizations service

DEWALT tools

always using

DeWALT

replacement

parts.

Black

&

Decker

(U.S.)

lnc., industrial tool service centers

are certified

for

serving DeWALT

industrial tools.

Aceessorr'es

AccessoryType Notes Usage

DEPRESSED

CENTER

WHEEL

Use Guard

Supplied

with

Tool

Use

for moderate

metal & mÉsonry

removal on

flat or

contoured surfaces

FLARING

CUP

GRINDING

WHEELS

Use

Flaring

Cup

Wheel

Guard

of size

to

match wheel

Use for smoothing

welds, and

sharp

edges,

and automotive

body

parts

W|RE

CUP

BRUSHES

Always wear

eye

protection

and

appropriate clothing

Use

lor rust removal

and surface

preparation

before

painting

*

Depressed

center

grinding

wheels

must fit within

the cpnfines

of the

guard

and must be rated higher than the recommended speed

as

marked on the nameplate.

**

When

using

flaring

cup

wheels,

always use

skirt

guard (4"

only).

Guards are available at

Black & Decker

(U.S.)

lnc., industrial service

centers.

WARNING-To reduce the risk ol injury, always use

proper guards

when

grinding

and

wear

eye

protection.

"'

CAUTIOI{: S:trands of

wire

anp brushes rnay break

and

fly oft whlle

in

use.

Users and oüprs

in ths

area should wear

adegueb

qn,

lace

and

body

protection.

Use onÿ wire

cup brush€s

thet

aro

ratêd

at or

gr€ater

than the RPM

shovn on the tool's nameplate.

lf

you

need

any assistrarrce

in locating

any acoessory,

pleass

oontact

DEWALT lndustrial Tool Cornpany,

626

Hanorrer Pike, P.O. Box 158,

Hampstead, MD

21 074 or call

1

-8ü)-4-DEWALT

(1

-80G.til3-9258).

Full Wananÿ

DEWALT heavy duÿ industrial tools

are

warranted for

one

year

from

date of

purchase.

We will repair, without charge, any defects due to

faulÿ

materials or wgrkmanship. Arrangements have

been

made with

the industrial tool

division of

Black

& Decker

(U.S.)

lnc. to

provide

warranty

repairs for DeWALT tools.

Please retum

the complete unit,

transportation

prepaid,

to any Black

&

Decker

(U.S.)

lnc. industrial

service center or authorized service station

listed

under

"Tools,

Electric" in the

yellow

pages.

This warranty

does

not apply to

accessories or damaç caused where repairs have been made or

attempted

by others.

This warranÿ

gives you

specific

legal rights

and

you

may have

other

rights which vary from

state to state.

ln addition to the warranty, DeWALT tools

are covered

by our:

30 DAY NO RISK SATISFACTTON

GUARANTEE

lf

you

are not

completely satisfied with the

performance

of

your

DeWALT heavy duty industrial tool,

simply

return it to

the

participatlng

seller within 30 days for a full refund. Please return

the

complete unit, transportation

prepaid.

Proof of

purchase

may

be

required.

See

'Tools-Electric'

-Yellow

Pages-

for Service & Sales

For Sandlng Applicatlons For Sanding

Applicâtlons

For use with all 7' Itlodels For usê

with

all

7" Models

For Grinding

Appllcations

For Grinding

Applications

For use

with

all

7"

Models

For

llllire Brush

Applications

For use with all

T" Models

For use with all 7' Models

l----

I

@@

I

ffi."**GDs#vq,"rd

ffi

t, * wlt,

+''narf rg wtê€b

I

s"FbirgG+Salblyqltd

.

brewihs'iâringwm

'

g'tu

irrsG.psâftryclârd

|

furæwitro'flaiEufræb

I

@

HffiFHHH",

gtÊ'oldCrchang3

RûÈbrPâd

I

(l/bcseRPMô000)

ùu.roop"o"-tu*'*r,pr*rc

^d6&»

ebrlmilmfsÔiny.

*3§@8ry

I

or

I

HtrÆiitffi*p***Æffi

@

§

4il.-ptm;;"pis

SWWz6/r'q1ickchilgpFtsb

WW

(i/hxsdeRPMdno)

I

sidFæFù&rBecldngPad

I

Uswitlrubbs@andôV1'

I

0üarsæRPM86æ)

I

Phsdicdsctormimmrigidity.

or

lrdtdæ@nut

I

a./a"

Oui*ClmgE

RrËber Pâd

(lra(

sde

RPM60æ)

6r/a"

Plsrclic Dis

(lüaxsæRPM6(m)

Usewih 3ÿr'QrickChange

Rubbs Pad

lor

mimum

flexibility

orllvr' Quick Change

Rubber Pad

forlsflext

lity.

6P/.'PiHElic

Di$

(Àrax

sæ RPM 6000)

Psfomæfundim æ

regulil

piHolic

d$ wih mE

flenbility

andffi@ler.

T"SandingDitcs

(tÉ"

Arbor)

WhedAdæ

(toræwihmh'-ù)

7' Depr€s6ed CenÈr

wheels

(t{oHü)

TlDeZl n

eialGrindirE

7 xllaxTlè I Tlfi

xtlqxtle I 85m

I

*

€sffiffit

.Wry

I

z's"ncnsDio

|

('r!"

atôoÔ

G eit MarRPil

w

24 8560

padNur

-æ-------@-

T\pe27 ÀrasnryGrindng

7 xllaxTlo

I

Tlæ

Orùr(Clügp7'DeprËsed

C$brfryhe*(Wrth

Hû)

Tlpez/ iretal Grin&rg

xr/6x

x1ÂxVell

Masry BslMl

(S;iliil

Carti&)

,À iT* EPiT

5.

6" 6m

GllrFedwhEq+B.rdE

(%ï1'IhEd)

KnoGd

Whs

qp

BnEtEs

FÂLllffæad)

qlt

illilRPM

24 8560

s6 8560

I

I

-!,!@*

ffiffi

W

,k

c@

PadNln

50

8560

_æ---_________!550_

80

8550

1æ 8550

I

I

I

I

I

I

I

I

I

I

I

I

I

l

I

I

I

I

**

ÉwÀ

ffi

I

or

;

*

ffi

W

Oiâ"Odd(CllarlsEFloôb

*-%-

ffi ffirs*rycilâd

iro,rU*p"Or,t

V

a

\8FÙ@GssedHte{wtEds'

I

@

I

or

I

@

I

I

I

@

I

I

Æw*ffi

-qiË#Éffiffi;,,

I

or

I

**.@*

4IF@

W

I

I

I 17

xllnxTle

I

Tlæ

-Fr

lcro I

Y

c*nnpNut

,dÆffiM.

ffiiffiT.s*yq,d

v

| §

or@r&eoererurces

60

8550

80 8560

Page 6

?

1

:--l

Other DIWÂLT

Heatry

Duly

lndustrial

Tools Available

From Your

Local Dealer

DW944K

9.6V Heavy Duty Versa-Clutch

Cordless

3/8"

Driver/Drill

Kit with

Keyless Chuck:

High

performance

industrial Versa-Clutch

cordless

Driver/Drill has

two variable speed ranges

and

reversing to

perform

well in

a wide variety of metals and wood. The

extremely versatile

cordless DriveriDrill has 11

clutch

settings, a keyless

chuck and delivers more

power

and

torque than

any cordless drill in its class. Also available:

DW945K

12.0V Heavy Duty Versa-Clutch

Cordless 3/8"

Driver/Drill

Kit with Keyless

Chuck

DW942R 7.2V

Heavy Duty Cordless 3/8" VSR Drill

DW360 Heavy

Duly 7-114" Circular

Saw

with Electric Brake:

High

pedormance

industrial saw has

a

13

amp

rating and a 2

second

electric brake.

lt has

a 50 degree bevel capacity and

steel helical

gears

to assure

long

term reliability" lt delivers

more watts

out and more torque

than other saws

in its

class.

Other DaWALT Heavy

Duty lndustrial

Tools

Available From

Your Local Dealer

DWl00l;leavy

Duty 3/8" VSR Drill:

High

performance

industrial

quality

variable

speed

reversing

drill

is

designed for long

life in heavy-duty

professional

use.

High

speed

(0-2500

RPM)

and

4.0

amps

enable the drill to

perform

well

in

a wide variety

of

metals,

wood, masonry

and composite materials. lt

also has a built-

in 2-way bubble level for

drilling accuracy.

DW411

Heavy Duty 1/4

Sheet Palm

Grip Sander:

High

performance

industrial

palm

grip

sander has

efficient

through-the-pad

dust

collection. Low vibration

design

delivers

less

than half

the vibration

of other

palm

sanders

for

greater

comfort

and durability. The

sander

gives

fast

and efficient material

removal.

DW3O4K Heavy

Duty VS

Reciprocating

Saw Kit:

High

performance

industrial

reciprocating

saw has low

vibration

design to reduce

user fatigue.

High

power

(6.0

amps and 1-118"

stroke Iength)

allows increased

productivity.

Lightweight

and comfortable.

DWI20K

Heavy

Duty 1/2" Right

Angle Drill Kit:

High

performance

industrial

right

angle drill is reversing

and

has

three speeds

(400/600/900

RPM) for

plumbing

and

electrical

applications. Powerful

7.0 amp motor

easily

handles

popular

2-9116"

self-feed

bits.

DW411

Page 7

Loading...

Loading...