Page 1

DW45RN

Roofing Coil Nailer

Cloueuse Pour Toiture À Clous En Bobine

Clavadora Para Techado A Resorte

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DeWALT • www.dewalt.com

Page Size: 8.5 x 5.5"

Page 2

Page 3

BEFORE OPERATING THIS TOOL, CAREFULLY READ AND

UNDERSTAND ALL INSTRUCTIONS IN THE IMPORTANT

SAFETY INSTRUCTIONS SECTION.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DeWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DeWALT

(1-800-433-9258)

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

Important Safety Instructions

WARNING: Do not operate this unit until you read this instruction

manual for safety, operation and maintenance instructions.

WARNING: This product contains chemicals known to the State

of California to cause cancer, and birth defects or other reproductive

harm. Wash hands after handling.

WARNING: Some dust contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm such

as asbestos and lead in lead based paint.

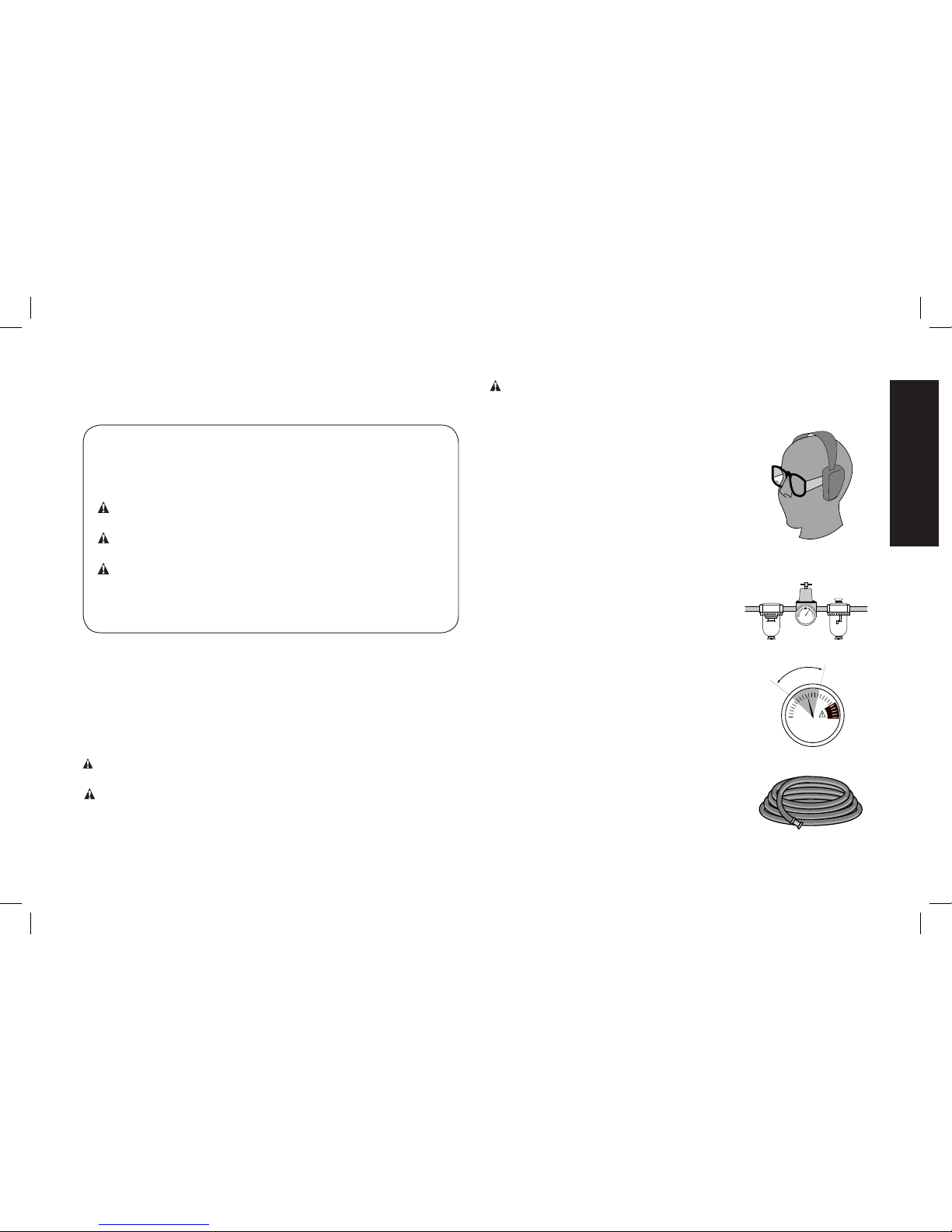

• Actuating tool may result in flying

FIG. A

FIG. B

FIG. C

FIG. D

debris, collation material, or dust

which could harm operator’s eyes.

The operator and all those persons in the

general area should wear safety glasses

with permanently attached side shields.

Approved safety glasses are imprinted

with the characters “Z87.1”. It is the

employer’s responsibility to enforce the

use of eye protection equipment by the

tool operator and other people in the work

area. (Fig. A)

• Always wear appropriate personal

hearing and other protection during

use. Under some conditions and duration

of use, noise from this product may

contribute to hearing loss. (Fig. A)

• Use only clean, dry, regulated air.

Conden sation from an air compressor can

rust and damage the internal workings of

the tool. (Fig. B)

• Regulate air pressure. Use air

pressure compatible with ratings on

the nameplate of the tool. (Not to

exceed 120 psi, 8.3 bar) Do not connect

the tool to a compressor rated at over

200 psi. The tool operating pressure must

never exceed 200 psi even in the event of

regulator failure. (Fig. C)

English

1

Page 4

• Only use air hose that is rated for a maximum working

pressure of at least 150 PSI (10.3 BAR) or 150% of the

maximum system pressure, which ever is greater. (Fig. D)

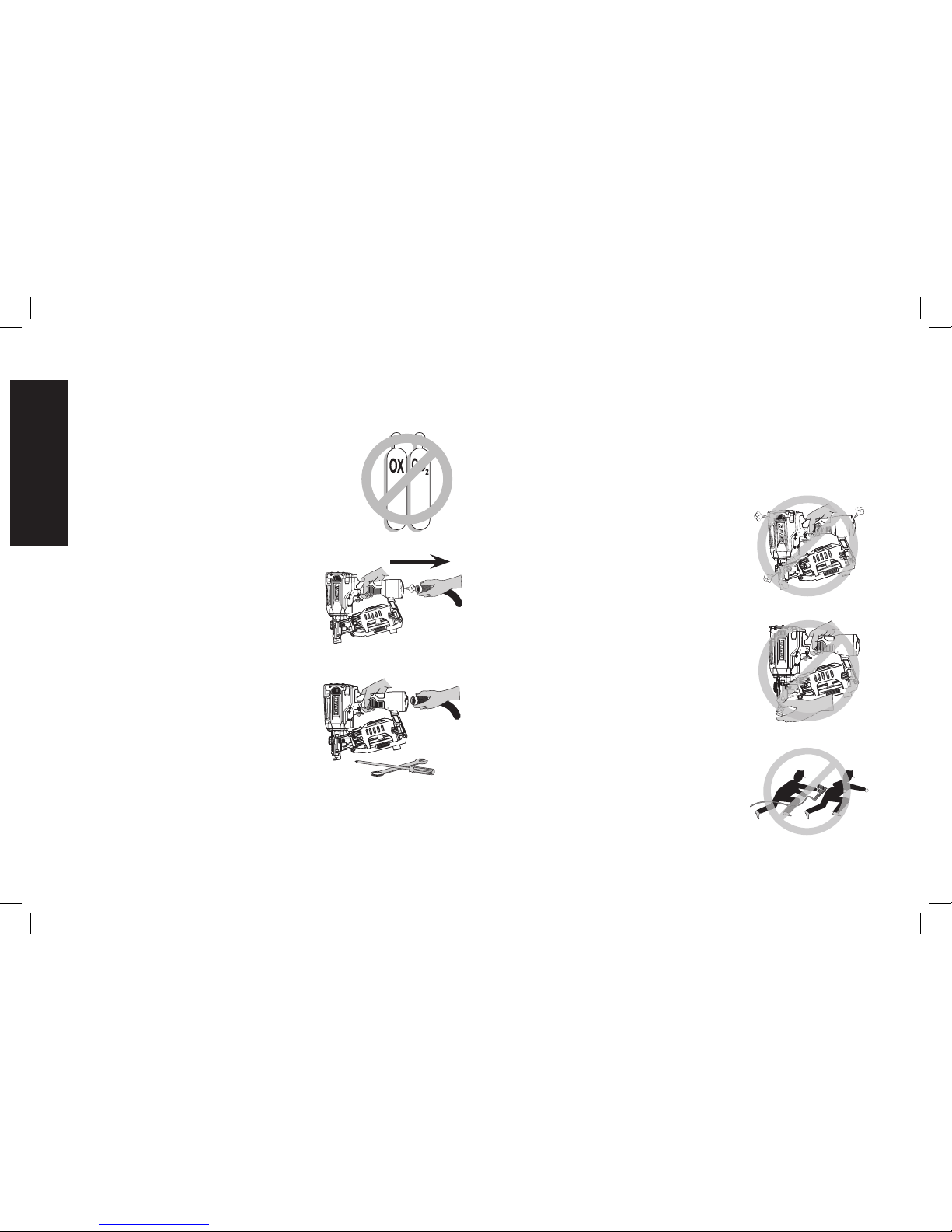

• Do not use bottled gases to power this

FIG. E

FIG. F

FIG. G

tool. Bottled compressed gases such as

oxygen, carbon dioxide, nitrogen,

hydrogen, propane, acetylene or air are

not for use with pneumatic tools. Never

use combustible gases or any other

reactive gas as a power source for this

tool. Danger of explosion and/or serious

personal injury may result. (Fig. E)

• Use couplings that relieve all

pressure from the tool when it is

disconnected from the power supply.

Use hose connectors that shut off air

supply from compressor when the tool is

disconnected. (Fig. F)

• Disconnect tool from air supply

when not in use. Always disconnect

tool from air supply and remove

fasteners from magazine before

leaving the area or passing the tool

to another operator. Do not carry

tool to another work area in which

changing location involves the use

of scaffoldings, stairs, ladders, and

the like, with air supply connected.

Do not make adjustments, remove magazine, perform

maintenance or clear jammed fasteners while connected

to the air supply. If the contact trip is adjusted when the tool

is connected to the air supply and nails are loaded, accidental

discharge may occur. (Fig. G)

• Connect tool to air supply before loading fasteners, to

prevent a fastener from being fired during connection. The

tool driving mechanism may cycle when tool is connected to

the air supply. Do not load fasteners with trigger or contact trip

depressed, to prevent unintentional firing of a fastener.

• Do not remove, tamper with, or

otherwise cause the tool, trigger, or

contact trip to become inoperable. Do

not tape or tie trigger or contact trip in the

ON position. Do not remove spring from

contact trip. Make daily inspections for

free movement of trigger and contact trip.

Uncontrolled discharge could result.

• Inspect tool before use. Do not

operate a tool if any portion of the tool,

trigger, or contact trip is inoperable,

disconnected, altered, or not working

properly. A tool that is not in proper

working order must not be used. Tags

and physical segregation shall be used

for control. Leaking air, damaged parts

or missing parts should be repaired or

replaced before use. (Fig.H)

• Do not alter or modify the tool in any

way. (Fig. I)

• Always assume that the tool contains

fasteners.

FIG. H

FIG. I

FIG. J

English

2

Page 5

• Do not point the tool at co-workers or yourself at any time.

No horseplay! Work safe! Respect the tool as a working implement.

(Fig. J)

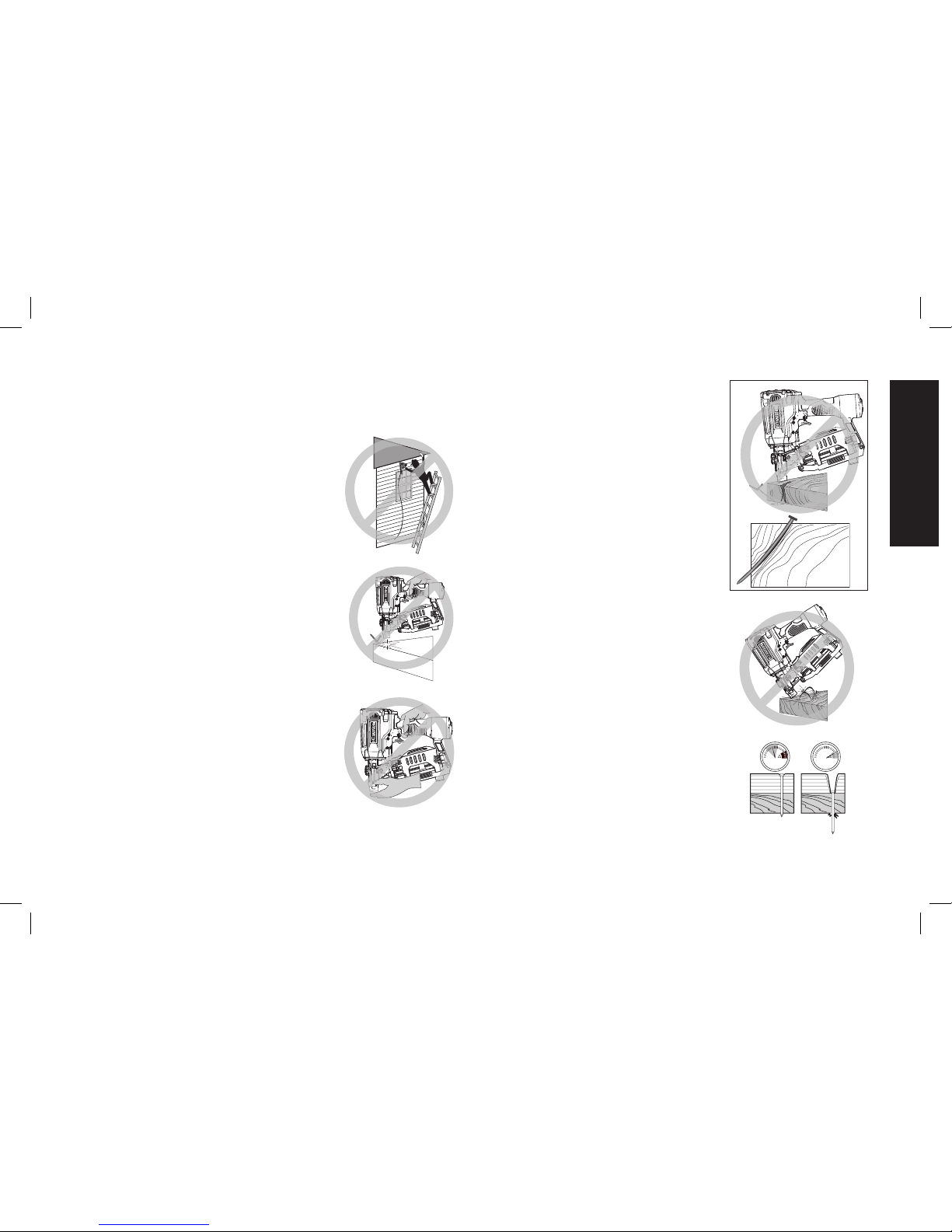

• Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can cause you

to lose control. When tool is not in use, it

should be locked in a safe place, out of

the reach of children.

• Remove finger from trigger when

not driving fasteners. Never carry

tool with finger on trigger. Accidental

discharge could result.

• Do not lift, pull or lower tool by the

hose.

• Do not overreach. Maintain proper

footing and balance at all times. Loss of

balance may cause cause personal injury.

(Fig. K)

• Make sure hose is free of obstructions

or snags. Entangled or snarled hoses

can cause loss of balance or footing.

• Use the tool only for its intended use.

Do not discharge fasteners into open

air, concrete, stone, extremely hard

woods, knots or any material too

hard for the fastener to penetrate.

Do not use the body of the tool or

top cap as a hammer. Discharged

fasteners may follow unexpected path

and cause injury. (Fig. L)

• Always keep fingers clear of

contact trip to prevent injury

from inadvertent release of nails.

(Fig.M)

• Refer to the Maintenance and

Repairs sections for detailed

information on the proper

maintenance of the tool

• Always operate the tool in a clean,

lighted area. Be sure the work

surface is clear of any debris and

be careful not to lose footing when

working in elevated environments

such as rooftops.

• Do not drive fasteners near edge

of material. The workpiece may

split causing the fastener to ricochet,

injuring you or a co-worker. Be aware

that the nail may follow the grain

of the wood (shiner), causing it to

protrude unexpectedly from the side

of the work material. Drive the nail

perpendicular to the grain to reduce

risk of injury. (Fig. N)

• Do not drive nails onto the heads

of other fasteners or with the tool

at too steep an angle. Personal

injury from strong recoil, jammed

fasteners, or ricocheted nails may

result. (Fig. O)

FIG. K

FIG. L

FIG. M

FIG. N

FIG. O

FIG. P

English

3

Page 6

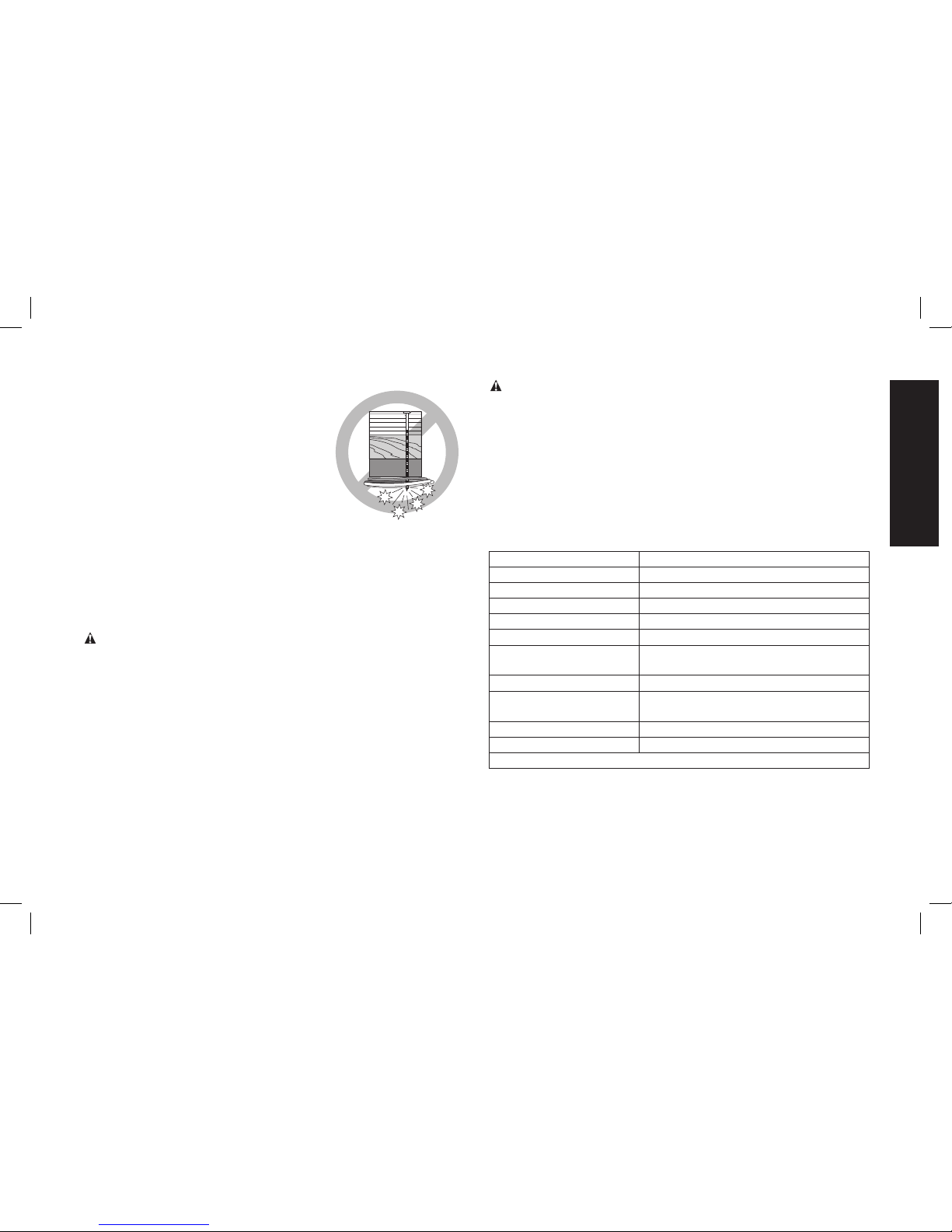

• Be aware of material thickness

when using the nailer. A protruding

nail may cause injury.

• Be aware that when the tool is being

utilized at pressures on the high

end of its operating range, nails can

be driven completely through thin

or very soft work material. Make sure

the pressure in the compressor is set so

that nails are set into the material and

not pushed completely through. (Fig. P)

• Keep hands and body parts clear

of immediate work area. Hold

workpiece with clamps when necessary

to keep hands and body out of potential

harm. Be sure the workpiece is properly

secured before pressing the nailer

against the material. The contact trip

may cause the work material to shift

unexpectedly. (Fig.Q)

• Do not use tool in the presence of

flammable dust, gases or fumes. The

tool may produce a spark that could

ignite gases causing a fire. Driving a nail

into another nail may also cause a spark.

(Fig.R)

• Keep face and body parts away

from back of the tool cap when

working in restricted areas. Sudden recoil can result in impact

to the body, especially when nailing into hard or dense material.

(Fig. S)

• Grip tool firmly to maintain control

while allowing tool to recoil away

from work surface as fastener is

driven. With the contact trip (black)

trigger assembled, if contact trip is

allowed to recontact work surface

before trigger is released an unwanted

fastener will be driven.

• Choice of triggering is important.

Check the manual for triggering options.

Refer to Trigger Operation under the Operation section.

CONTRACT TRIP (BLACK TRIGGER)

• When using the contract trip trigger, be careful of

unin tentional double fires resulting from tool recoil.

Unwanted fasteners may be driven if the contact trip is

allowed to accidentally re-contact the work surface. (Fig. T)

TO AVOID DOUBLE FIRES:

• Do not engage the tool against the work surface with a

strong force.

• Allow the tool to recoil fully after each actuation.

• Use sequential trip trigger (gray trigger).

•

When contact actuating the nailer, always keep tool

in control. Inaccurate placement of tool can result in

misdirected discharge of a fastener.

SEQUENTIAL TRIP (GRAY TRIGGER)

• When using the sequential trip trigger, do not actuate

the tool unless the tool is placed firmly against the

workpiece.

FIG. Q

FIG. R

FIG. S

FIG. T

English

4

Page 7

• Do not drive nails blindly into walls,

FIG. U

floors or other work areas. Fasteners

driven into live electrical wires, plumbing,

or other types of obstructions can result

in injury. (Fig.U)

• Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use tool while tired or under

the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools

may result in serious personal injury.

• DEPTH ADJUSTMENT: To reduce risk of serious injury

from accidental actuation when attempting to adjust depth,

ALWAYS:

• Disconnect air supply.

• Avoid contact with trigger during adjustments.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

WARNING: ALWAYS USE SAFETY GLASSES. Everyday

eyeglasses are NOT safety glasses. Also use face or dust mask

if operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA/Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

Specifications

MODEL DW45RN

HEIGHT 9.8" (249mm)

WIDTH 5" (127 mm)

LENGTH 11" (280mm)

WEIGHT 5.2 lb (2.4 kg)

OPERATING PRESSURE

70 – 120 psig (4.9 – 8.43kg/cm2)

AIR CONSUMPTION

PER 100 CYCLES *

3.7 cfm @ 80 psi (5.62 kg/cm2)

LOADING CAPACITY

120 Nails

FASTENER 0.120" (3mm) diameter,

15º wire collated roofing nails

FASTENER LENGTHS 3/4" (19 mm) - 1-3/4" (44.5 mm)

AIR INLET 1/4" NPT (6.4mm)

NOTE: Use only DeWALT approved fasteners

English

5

Page 8

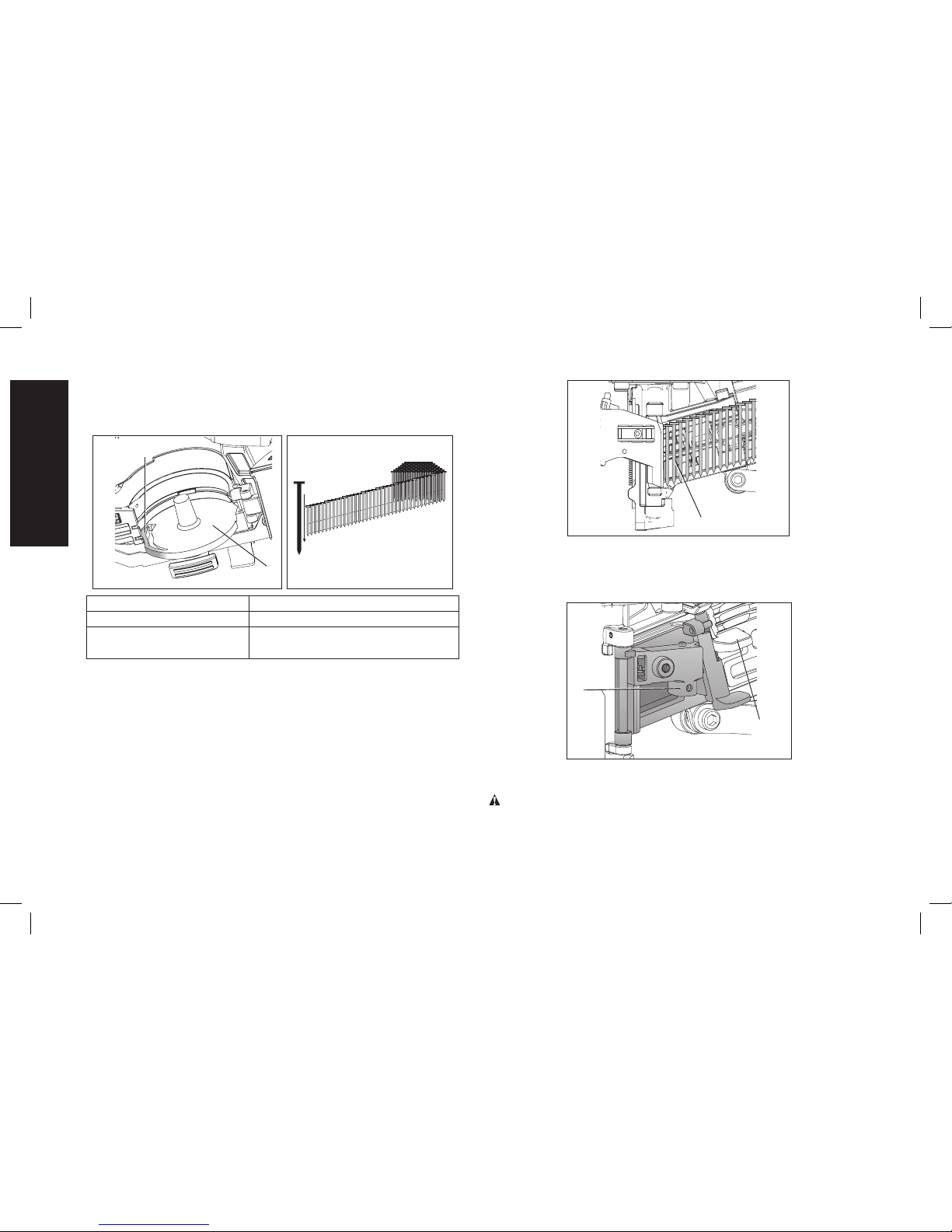

COMPONENTS (FIG. 1)

A. Top cap

B. Trigger

C. Canister cover

D. Door latch

E. Contact trip

F. Depth adjustment wheel

G. Nail guide door

H. Shingle guide

FIG. 1

A

E

F

B

C

H

D

G

ASSEMBLY

WARNING: Disconnect air line from tool and remove fasteners

from magazine before making adjustments or personal injury may

result.

Trigger

WARNING: Keep fingers AWAY from the trigger when not

driving fasteners to avoid accidental actuation. Never carry a

tool with finger on the trigger. With the contact trip trigger (black)

assembled, the tool will drive a fastener if the contact trip is bumped

while the trigger is depressed.

In accordance with the ANSI Standard SNT-101-2015, the DeWA LT

coil nailers are assembled with a black contract trip trigger. However,

a gray sequential trip trigger kit is available. For a replacement trigger

contact your authorized service center or call 1-800-4-DeWALT.

Air Fitting

This tool uses a 1/4" N.P.T. male plug. The inside diameter should be

0.180" (4.6 mm) or larger. The fitting must be capable of discharging

tool air pressure when disconnected from the air supply. A 3/8"

(9.5 mm) male quick connector coupling is available from DeWA LT

and may be used when a 1/4" (6.4mm) supply line is not available.

NOTE: A 3/8" (9.5 mm) supply line (and fittings) are required for

maximum tool performance.

WARNING: Always use couplings that relieve all pressure

from the tool when it is disconnected from the power supply.

Always use hose connectors that shut off air supply from compressor

when the tool is disconnected.

TO INSTALL AN AIR FITTING

1. Wrap the male end of the fitting with thread seal tape prior to

assembly to eliminate air leaks.

2. To install a 1/4" (6.4mm) fitting: screw it directly into the air inlet

and tighten firmly. NOTE: If an adapter is in the air inlet, remove it

prior to inserting the fitting.

English

6

Page 9

3. To install a 3/8" (9.5mm) fitting: screw the fitting into the 3/8"

(9.5mm) adapter and then into the air inlet of the tool and tighten

firmly.

OPERATION

Preparing the Tool

WARNING: Read the section titled Important Safety Instructions

at the beginning of this manual. Always wear eye and ear protection

when operating this tool. Keep the nailer pointed away from yourself

and others. For safe operation, complete the following procedures

and checks before each use of the nailer.

NOTICE: To reduce the risk of damage to the tool, only use DeWALT

pneumatic tool oil or a non-detergent SAE 20 weight oil. Oil with

additives or detergent will damage tool parts.

1. Before you use the nailer, be sure that the compressor tanks

have been properly drained.

2. Lubricate the tool following these directions:

a. Use DeWALT pneumatic tool oil or a non-detergent S.A.E. 20

weight oil. DO NOT use detergent oil or additives as they will

damage o-rings and rubber parts.

b. Use a filter-regulator-lubricator in the air line between the

compressor and the tool when possible.

c. If a lubricator is not available, add 5 to 7 drops of oil in the air

fitting a least twice a day or every 4 hours of use.

3. Wear proper eye, hearing and respiratory protection.

4. Ensure canister is empty of all fasteners.

5. Check for smooth and proper operation of contact trip and

pusher assemblies. Do not use tool if either assembly is not

functioning properly. NEVER use a tool that has the contact trip

restrained in the up position.

6. Check air supply. Ensure that air pressure does not exceed

recommended operating limits, refer to Tool Specifications.

7. Keep tool pointed away from yourself and others.

8. Connect air hose.

9. Check for audible leaks around valves and gaskets. Never use a

tool that leaks or has damaged parts.

WARNING: To reduce the risk of personal injury, disconnect tool

from air supply before performing maintenance, clearing a jammed

fastener, leaving work area, moving tool to another location or

handing the tool to another person.

Loading the Tool (Fig. 2–4)

WARNING: Keep the tool pointed away from yourself and others.

Serious personal injury may result.

WARNING: Never load nails with the contact trip or trigger

activated. Personal injury may result.

1. Read all Safety Warnings before using tool.

2. Connect the air supply to the tool.

3. Push the door latch

FIG. 2

D

G

C

(D) to open the nail

guide door (G).

4. Rotate the canister

cover (C) open.

5. Adjust the nail

platform (I) to properly

accommodate the nail

length being used.

• Push the platform

lever (J).

English

7

Page 10

• Rotate the platform (I) out.

• Slide platform to the desired position.

• Push platform in to engage platform lever.

FIG. 3

J

FIG. 4

I

PLATFORM POSITION NAIL LENGTH

lowest position 1-1/4" (32mm) - 1-3/4" (44.5mm)

upper position 3/4" (19mm) -1-1/4" (32mm)

- 1-3/4" (44.5mm)

6. Place the coil on the nail platform (I). Insert fasteners with

points down. IMPORTANT: Fasteners must point in the same

direction as they will be driven.

7. Uncoil enough nails [approximately 3" (76 mm)] to reach the

nose of the tool.

8. Insert the first nail into the nose and the second nail (M) between

the two rails of the feed pawl as shown in Fig. 5.

NOTE: Be careful not to deform the coil of nails during the loading

process. Otherwise, the nail guide door will not close and the nails

might not feed consistently.

FIG. 5

M

9. Close the canister cover (C) completely.

10. Close the nail guide door (G) making sure the door latch (D)

is completely engaged as shown in Fig. 6.

FIG. 6

D

G

Trigger Operation

WARNING: Always wear proper eye [ANSI Z87.1 (CAN/CSA

Z94.3)] and hearing protection [ANSI S12.6 (S3.19)] when operating

this tool.

English

8

Page 11

WARNING: The operator must not hold the trigger pulled on

contact trip tools except during fastening operation, as serious injury

could result if the trip accidentally contacted someone or something,

causing the tool to cycle.

WARNING: Keep hands and body away from the discharge area

of the tool. A contact trip tool may bounce from the recoil of driving a

fastener and an unwanted second fastener may be driven, possibly

causing injury.

WARNING: Never use rafter hook to hang tool from body, clothing

or belt.

CONTACT TRIP (BLACK TRIGGER)

The common operating procedure on “Contact Trip” tools is for the

operator to contact the work to actuate the trip mechanism while

keeping the trigger pulled, thus driving a fastener each time the work

is contacted. This will allow rapid fastener placement on many jobs,

such as sheathing, decking and pallet assembly. All pneumatic tools

are subject to recoil when driving fasteners. The tool may bounce,

releasing the trip, and if unintentionally allowed to recontact the work

surface with the trigger still actuated (finger still holding trigger pulled)

an unwanted second fastener will be driven.

SEQUENTIAL TRIP (GRAY TRIGGER)

The Sequential Trip requires the operator to hold the tool against

the work before pulling the trigger. This makes accurate fastener

placement easier, for instance on framing, toe nailing and crating

applications.

The Sequential Trip allows exact fastener location without the

possibility of driving a second fastener on recoil, as described under

Contact Trip.

The Sequential Trip Tool has a positive safety advantage because it

will not accidentally drive a fastener if the tool is contacted against

the work – or anything else – while the operator is holding the trigger

pulled.

CONTACT TRIP OPERATION (BLACK TRIGGER)

When using the contact trip (black) trigger the tool contains a contact

trip that operates in conjunction with the trigger to drive a fastener.

There are two methods of operation to drive fasteners with a contact

trip tool.

SINGLE FASTENER PLACEMENT: To operate the tool in this

manner, first position the contact trip on the work surface, WITHOUT

PULLING THE TRIGGER. Depress the contact trip until the nose

touches the work surface and then pull the trigger to drive a fastener.

Do not press the tool against the work with extra force. Instead, allow

the tool to recoil off the work surface to avoid a second unwanted

fastener. Remove your finger from the trigger after each operation.

RAPID FASTENER OPERATION: To operate the tool in this manner,

hold the tool with the contact trip pointing towards but not touching

the work surface. Pull the trigger and then tap the contact trip against

the work surface using a bouncing motion. Each depression of the

contact trip will cause a fastener to be driven.

SEQUENTIAL TRIP OPERATION (GRAY TRIGGER)

When using the sequential trip (gray) trigger the tool contains a

contact trip that operates in conjunction with the trigger to drive a

fastener. To operate a sequential trip tool, first position the contact

trip on the work surface

WITHOUT PULLING THE TRIGGER. Depress the contact trip and

then pull the trigger to drive a fastener. As long as the contact trip

is contacting the work and is held depressed, the tool will drive a

English

9

Page 12

fastener each time the trigger is depressed. If the contact trip is

allowed to leave the work surface, the sequence described above

must be repeated to drive another fastener.

Tool Operation Check (Fig.1)

WARNING: Remove all fasteners from tool before performing tool

operation check.

CONTACT TRIP OPERATION (BLACK TRIGGER)

A. With finger off the trigger (A), press the contact trip against the

work surface.

THE TOOL MUST NOT CYCLE.

B. Hold the tool off the work surface, and pull the trigger.

THE TOOL MUST NOT CYCLE.

C. With the tool off the work surface, pull the trigger. Press the

contact trip against the work surface.

THE TOOL MUST CYCLE.

D. Without touching the trigger, press the contact trip against the

work surface, then pull the trigger.

THE TOOL MUST CYCLE.

SEQUENTIAL TRIP OPERATION (GRAY TRIGGER)

A. Press the contact trip against the work surface, without touching

the trigger.

THE TOOL MUST NOT CYCLE.

B. Hold the tool off the work surface and pull the trigger.

THE TOOL MUST NOT CYCLE.

Release the trigger. The trigger must return to the trigger stop on

the frame.

C. Pull the trigger and press the contact trip against the work

surface.

THE TOOL MUST NOT CYCLE.

D. With finger off the trigger, press the contact trip against the work

surface. Pull the trigger.

THE TOOL MUST CYCLE.

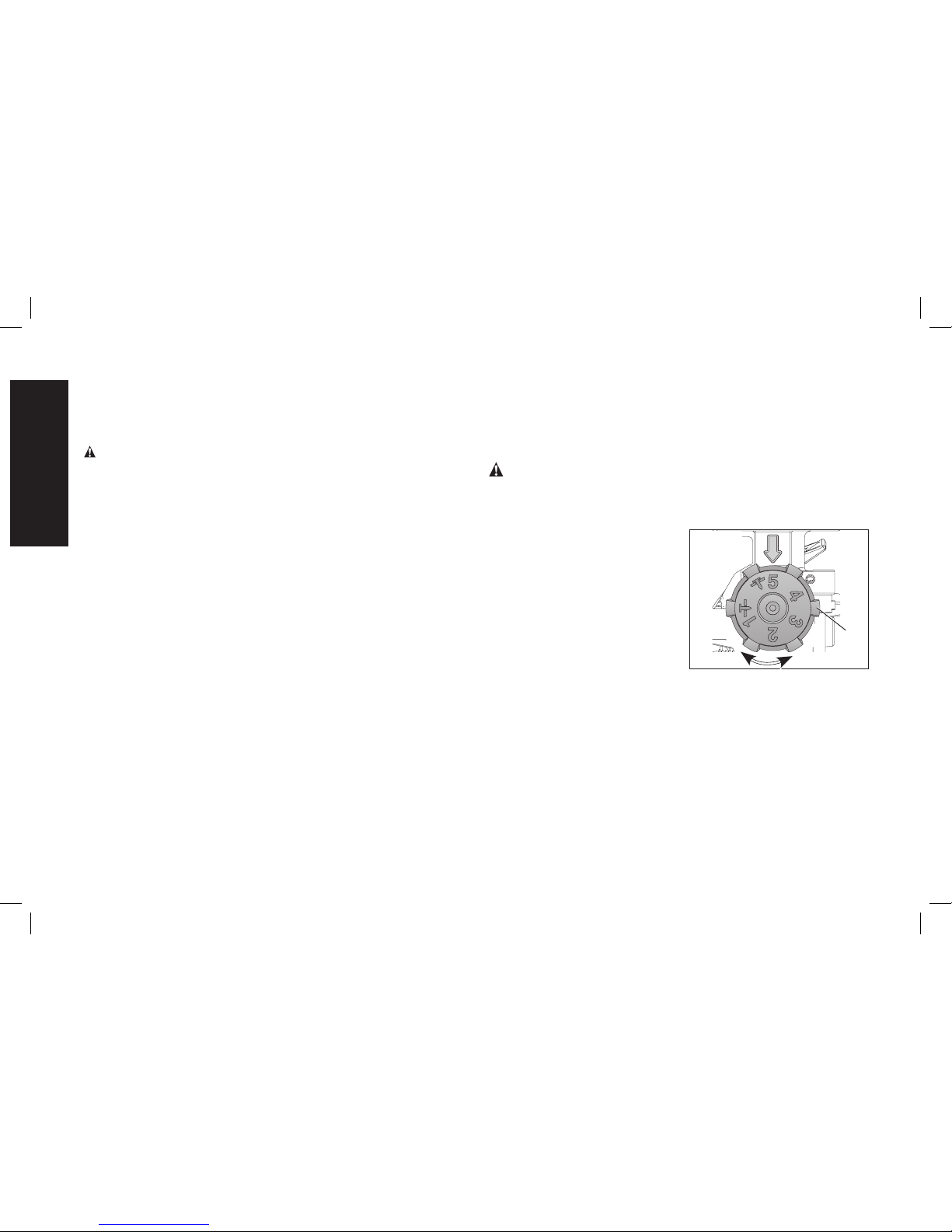

Adjusting Depth (Fig. 7)

WARNING: To reduce risk of serious injury from accidental

actuation when attempting to adjust depth, ALWAYS:

• Disconnect air supply.

• Avoid contact with trigger during adjustments.

The depth that the fastener is driven

F

FIG. 7

can be adjusted using the depth

adjustment wheel on the nose of

the tool. The depth of drive is

factory adjusted to a nominal

setting. Test fire a fastener and

check depth. If a change is

desired:

1. To drive the nail deeper, rotate

the depth adjustment wheel

(F) to the right. Setting 5 is the

deepest.

2. To drive a nail shallower, rotate the depth adjustment wheel (F) to

the left. Setting 1 is the shallowest.

Test drive another fastener and check depth. Repeat as necessary

to achieve desired results. The amount of air pressure required will

vary depending on the size of the fastener and the material being

fastened. Experiment with the air pressure setting to determine

the lowest setting that will consistently perform the job at hand. Air

pressure in excess of that required can cause premature wear and/

or damage to the tool.

English

10

Page 13

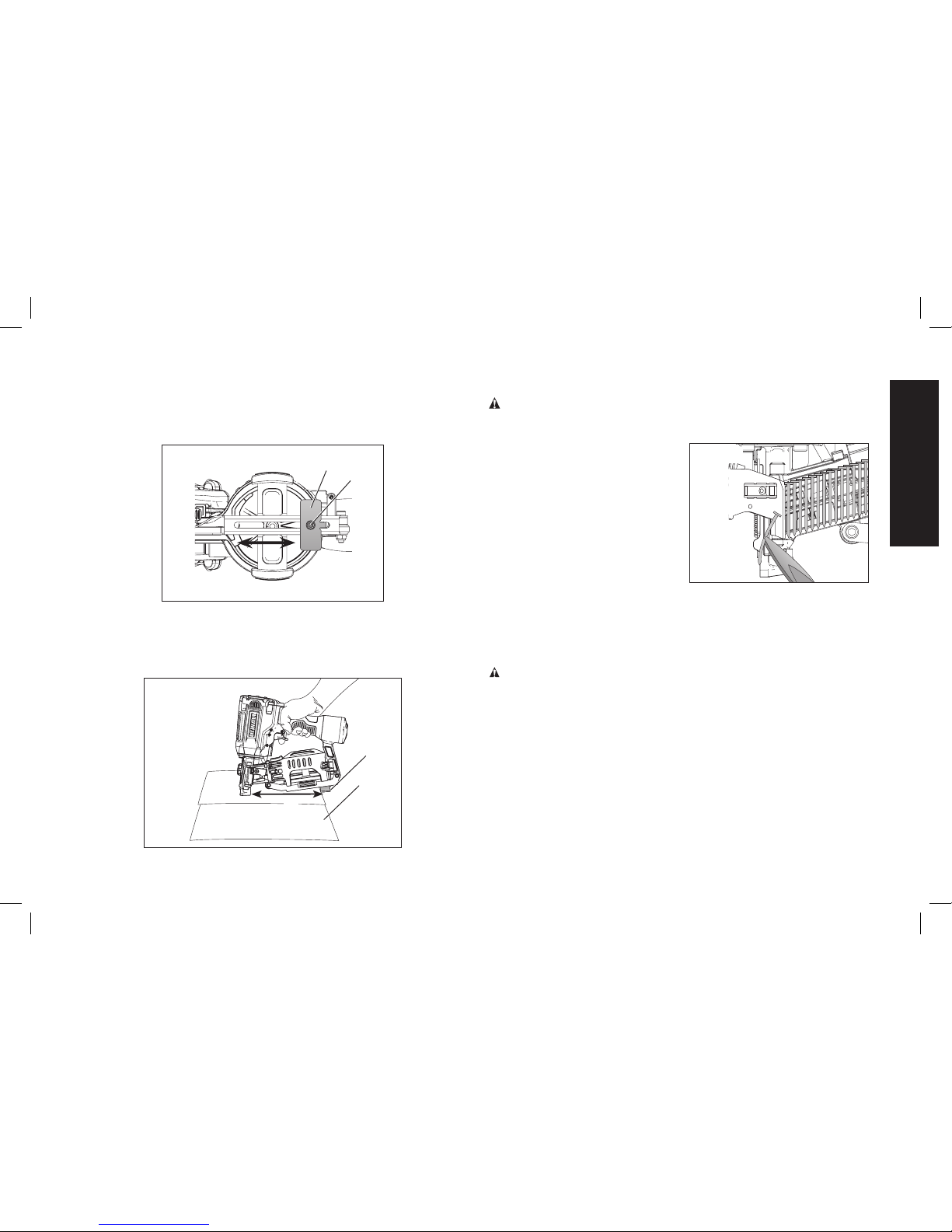

Shingle Guide (Fig. 8, 9)

Adjust shingle guide (H):

1. Loosen the adjusting screw (N) and slide the guide (H) to desired

position.

FIG. 8

H

N

2. Tighten adjusting screw firmly.

The guide (H) can be used as an aid to position the shingle being

nailed a specific distance (O) from the front edge of the previous row

of shingles (Q) as shown.

FIG. 9

H

Q

O

Clearing a Jammed Nail (Fig. 1, 10)

WARNING: Disconnect air line from tool and remove fasteners

from magazine before making adjustments or personal injury may

result..

If a nail becomes jammed in the

FIG. 10

nosepiece, keep the tool pointed

away from you and follow these

instructions to clear:

1. Disconnect the air supply

from the tool.

2. Push the door latch (D) to

open the nail guide door (G)

3. Open the canister cover (C).

4. Remove the jammed nail.

5. Correct any deformation that may have occurred to the nail coil.

NOTE: Should nails continue to jam frequently in nosepiece, have

tool serviced by an authorized DeWALT service center.

Cold Weather Operation

WARNING: Read the section titled Important Safety Instructions

at the beginning of this manual. Always wear eye and ear protection

when operating this tool. Keep the nailer pointed away from yourself

and others. For safe operation, complete the following procedures

and checks before each use of the nailer.

When operating tools at temperatures below freezing, complete

preparation procedures outlined above and follow the directions

below.

1. Make sure compressor tanks have been properly drained prior

to use. Always drain the compressor tanks at least once daily

while using the nailer. This is especially important in cold weather

because any moisture in the air in the tanks will condense in the

cold temperature.

English

11

Page 14

2. Keep the tool as warm as possible prior to use.

3. Make certain all fasteners have been removed from canister.

4. Put 5 to 7 drops of DeWALT Pneumatic Tool Oil or winter weight

pneumatic oil containing ethylene glycol in the end cap.

5. Lower air pressure to 80 psi (5.5 bar) or less.

6. Reconnect air and load nails into canister.

7. Actuate the tool 5 or 6 times into scrap lumber to lubricate o-rings.

8. Turn pressure up to operating level (not to exceed 120 psi) and

use tool as normal.

9. Re-lubricate with DeWALT Pneumatic Tool Oil or winter weight

pneumatic oil containing ethylene glycol in the end cap at least

twice a day or after 4 hours of use.

Hot Weather Operation

Tool should operate normally. However, keep tool out of direct sunlight

as excessive heat can damage bumpers, o-rings and other rubber

parts.

MAINTENANCE

WARNING: Disconnect air line from tool and remove fasteners

from magazine before making adjustments or personal injury may

result.

Daily Maintenance Chart

ACTION Lubricate tool with 5-7 drops of DeWALT Pneumatic

Tool Oil

WHY Prevents failure of o-rings

HOW Insert drops into air fitting on end cap of tool

ACTION Drain compressor tanks and hoses daily

WHY Prevents accumulation of moisture in compressor and

nailer

HOW Open petcocks or other drain valves on compressor

tanks. Allow any accumulated water to drain from

hoses

ACTION Clean canister, feed piston area and contact trip

mechanism.

WHY Permits smooth operation of magazine, reduces wear

and prevents jams

HOW Blow clean with compressed air. The use of oils or

solvents is not recommended as they tend to attract

debris

ACTION Before each use, check to ensure all screws, nuts and

fasteners are tight and undamaged

WHY Prevents jams, leaks and premature failure of tool

parts

HOW Tighten loose screws or other fasteners using the

appropriate hex wrench or screwdriver

Cleaning

WARNING: DO NOT use gasoline or similar highly flammable

liquids to clean the nailer. Vapor could be ignited by a spark, causing

and explosion.

Tar and dirt may build up on the nose and trip lever preventing correct

operation. Remove any buildup with kerosene, #2 fuel oil or diesel fuel.

Do not dip the nailer into these solvents beyond the height of the nail

heads, to avoid solvent getting into the drive cylinder.

Dry off the nailer before use. Any oil film left after cleanup will

accelerate the tar build up and the nailer will require more frequent

cleaning.

English

12

Page 15

NOTE: Solvents sprayed on the nose to clean and free up the trip

may have the opposite effect! The solvent may soften the tar on the

shingles and cause tar buildup to be accelerated. Dry operation is

better.

Repairs

WARNING: To reduce the risk of serious personal injury, remove

nails from magazine before making any adjustments or servicing this

tool.

WARNING: To assure product SAFETY and RELIABILITY, repairs

should be performed by a DeWALT factory service center or a

DeWALT authorized service center. Always use identical replacement

parts.

Accessories

WARNING: Since accessories, other than those offered by

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only DEWALT, recommended accessories should be used with

this product.

Recommended accessories for use with your tool are available

at extra cost from your local dealer or authorized service center.

If you need assistance in locating any accessory, please contact

DEWALT Industrial Tool Co., 701 East Joppa Road, Towson, MD

21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our website

www.dewalt.com.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you

obtain more efficient warranty service in case there is a problem

with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance

loss, such as fire, flood or theft, your registration of ownership will

serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to

contact you in the unlikely event a safety notification is required

under the Consumer Product Safety Act.

Register online at www.dewalt.com/register.

Seven Year Limited Warranty

DeWA LT will repair, without charge, any defects due to faulty materials

or workmanship for seven years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-DeWALT (1-800-

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights

which vary in certain states or provinces.

In addition to the warranty, DeWALT tools are covered by our:

1 YEAR FREE SERVICE

DeWA LT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

Nailer wear items, such as o-rings and driver blades, are not covered.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DeWA LT Power Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund – no questions asked.

English

13

Page 16

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the

local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DeWALT (1-800-433-

9258) for a free replacement. DO NOT use a tool with missing or

damaged safety warning label(s).

English

14

Page 17

TROUBLESHOOTING GUIDE

MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART BELOW.

FOR MORE SERIOUS OR PERSISTENT PROBLEMS, CONTACT A DeWALT SERVICE CENTER OR CALL 1-(800)-4-DeWALT.

WARNING: To reduce the risk of serious personal injury, remove

fasteners from magazine before making any adjustments or servicing this tool.

SYMPTOM PROBLEMS SOLUTIONS

Air leak near top of tool or in trigger area Loose screws. Tighten screws.

Worn or damaged o-rings or seals. Install overhaul kit.

Tool does nothing or operates sluggishly Inadequate air supply. Verify adequate air supply.

Inadequate lubrication. Put 5 or 7 drops of oil into air inlet.

Worn or damaged valve. Install valve kit.

Air leak near bottom of tool Loose screws. Tighten screws.

Worn or damaged o-rings or bumper. Install Overhaul Kit.

Tool jams or skips frequently Incorrect fasteners. Verify approved fasteners of correct size and 15°

collation angle.

Fasteners loaded incorrectly Verify fasteners are loaded in the correct platform

position.

Damaged fasteners. Bent collation wire. Replace with undamaged fasteners.

Canister or nose screws loose Tighten screws.

Canister is dirty. Clean magazine.

Driver tip is worn or damaged. Install Driver Maintenance Kit.

Worn piston seal. Install overhaul kit.

Worn valve. Install valve kit.

Other Contact a DeWALT Authorized Warranty Service

Center

English

15

Page 18

AVANT DE FAIRE FONCTIONNER CET OUTIL, LIRE

ATTENTIVEMENT ET COMPRENDRE TOUTES LES DIRECTIVES

DE LA SECTION “CONSIGNES DE SÉCURITÉ IMPORTANTES”

Définitions: lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour

chaque mot-indicateur employé. Lire le mode d’emploi et porter

une attention particulière à ces symboles.

DANGER: indique une situation dangereuse imminente qui,

si elle n’est pas évitée, entraînera la mort ou des blessures

graves.

AVERTISSEMENT : indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner la

mort ou des blessures graves.

ATTENTION : indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner des

blessures légères ou modérées.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n’est fait

pour l’éviter, pourrait poser des risques de dommages

matériels.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET

OUTIL OU DE TOUT AUTRE OUTIL DeWALT, COMPOSEZ LE

NUMÉRO SANS FRAIS : 1 800 4-DEWALT (1 800 433-9258)

CONSERVER TOUS LES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTÉRIEUR

Directives de sécurité importantes

AVERTISSEMENT: ne pas utiliser cet appareil avant d’avoir lu

le mode d’emploi ainsi que l’intégralité des directives de sécurité,

d’utilisation et d’entretien.

AVERTISSEMENT: ce produit contient des produits chimiques

reconnus par l’État de la Californie comme étant cancérigènes et

pouvant entraîner des anomalies congénitales ou d’autres problèmes

liés aux fonctions reproductrices. Se laver les mains après toute

manipulation.

AVERTISSEMENT: certaines poussières contiennent des produits

chimiques reconnus par l’État de la Californie comme cancérigènes et

pouvant entraîner des anomalies congénitales et d’autres problèmes liés

aux fonctions reproductrices, te

• La mise en marche de l’outil peut

FIG. A

FIG. B

projeter des débris, du matériel

amalgamé ou de la poussière

pouvant causer des blessures

oculaires à l’opérateur. L’opérateur et

toutes les personnes dans la zone

environnante doivent porter des lunettes

de sécurité avec écrans latéraux fixes.

Les lunettes de sécurité approuvées sont

estampillées avec la mention “Z87.1”.

L’employeur a la responsabilité d’imposer

à l’opérateur et à toutes autres personnes

dans la zone de travail le port

d’équipement de protection des yeux.

(fig. A)

• Toujours porter des protecteurs

d’oreilles appropriés et autres dispositifs de protection

durant l’utilisation. Selon les conditions et la durée d’utilisation,

le bruit émis par cet outil peut causer une perte auditive. (fig. A)

Français

16

Page 19

• Utiliser uniquement de l’air propre, sec et régulé. La conden

sation provenant d’un compresseur d’air peut faire rouiller et

endommager les composantes internes de l’outil. (fig. B)

• Réguler la pression d’air. Utiliser une

FIG. F

FIG. E

FIG. C

FIG. D

pression compatible avec la pression

nominale indiquée sur la fiche

signalétique de l’outil. (Ne doit pas

excéder 120 psi, 8,3 bars.) Ne pas

raccorder l’outil à un compresseur d’une

puissance nominale supérieure à 200

psi. La pression de fonctionnement de

l’outil ne doit jamais excéder 200 psi

même dans l’éventualité d’une

défaillance du régulateur. (fig. C)

• Utiliser exclusivement un tuyau

d’air prévu pour une pression de

fonctionnement maximale d’au moins

10,3 bars (150 psi) ou 150 % de la

pression maximale du système, selon

la pression la plus élevée. (Fig. D)

• Ne pas utiliser de gaz en bouteille

pour faire fonctionner cet outil. Les

gaz comprimés en bouteille comme

l’oxygène, le bioxyde de carbone, l’azote,

l’hydrogène, le propane, l’acétylène ou

l’air ne doivent pas être utilisés avec les

outils pneumatiques. Ne jamais utiliser

de gaz combustibles ou tout autre type

de gaz réactif comme source d’énergie

pour cet outil. Leur utilisation représente

un danger d’explosion et peut se solder

par des blessures corporelles. (fig. E)

• Utiliser des raccords qui libèrent toute

FIG. G

FIG. H

FIG. I

FIG. J

la pression de l’outil lorsqu’il est

débranché de la source d’alimentation.

Utiliser des connecteurs de tuyau qui

coupent l’alimentation d’air du

compresseur quand l’outil est débranché.

(fig. F)

• Débrancher l’outil de la source

d’alimentation en air lorsqu’il n’est

pas utilisé. Toujours débrancher l’outil

de la source d’alimentation en air et

retirer les attaches qui se trouvent

dans le magasin avant de quitter la

zone de travail ou de remettre l’outil à

un autre opérateur. Ne pas transporter

l’outil vers une autre zone de travail

qui comprend des échafaudages, des

marches, des échelles etc., avec la

source d’alimentation en air raccordée.

Ne pas effectuer de réglages, retirer

le magasin, effectuer l’entretien ou

débloquer des attaches coincées

pendant que l’outil est raccordé à

la source d’alimentation en air. Une

décharge accidentelle pourrait se produire

si le déclencheur est réglé alors que l’outil

est raccordé à la source d’alimentation en

air et que des clous sont chargés. (fig. G)

• Brancher l’outil à la source

d’alimentation en air avant de charger

les attaches afin de prévenir qu’une

attache soit éjectée au cours du

Français

17

Page 20

branchement. Le mécanisme d’entraînement de l’outil peut être

mis en cycle lorsque l’outil est branché à la source d’alimentation en

air. Ne pas enfoncer la détente ou le déclencheur lors du chargement

des attaches pour prévenir un clouage par inadvertance.

• Ne pas retirer, modifier ou rendre non fonctionnel, l’outil, la

détente ou le déclencheur de l’outil de quelque façon que

ce soit. Ne pas fixer de ruban ou d’attache sur la détente ou le

déclencheur pour le maintenir en position de MARCHE. Ne pas

retirer le ressort du déclencheur. Inspecter quotidiennement le bon

fonctionnement de la détente et du déclencheur. Une décharge

non contrôlée pourrait survenir.

• Inspecter l’outil avant de l’utiliser. Ne pas faire fonctionner un

outil si une partie de l’outil, de la détente ou du déclencheur

n’est pas fonctionnelle, est débranchée, modifiée ou ne

fonctionne pas correctement. Ne pas utiliser un outil ne

fonctionnant pas correctement. Repères et limites physiques

doivent être utilisés pour maintenir le contrôle. Les fuites d’air

ainsi que les pièces endommagées ou manquantes doivent être

réparées ou remplacées avant utilisation. (fig. H)

• Ne pas transformer ou modifier l’outil de quelque façon que

ce soit. (fig. I)

• Toujours considérer que l’outil contient des attaches.

• Ne jamais pointer l’outil en direction d’un collègue de

travail ou de soi-même. Pas de chamaillerie! Toujours travailler

prudemment! Respecter l’outil en tant qu’élément essentiel au

travail. (fig. J)

• Tenir les spectateurs, les enfants et les visiteurs à l’écart

durant l’utilisation d’un outil mécanique. Les distractions

peuvent entraîner une perte de maîtrise. Verrouiller l’outil dans un

endroit sûr, hors de la portée des enfants lorsqu’il n’est pas utilisé.

• Enlever le doigt de la détente lorsque vous ne clouez pas. Ne

jamais transporter l’outil avec le doigt sur la détente. Cette

pratique pourrait se solder par une décharge intempestive.

• Ne pas soulever, tirer ou abaisser l’outil par son tuyau.

• Ne pas tendre le bras trop loin. Il faut

FIG. K

FIG. L

FIG. M

demeurer bien campé sur ses pieds et en

équilibre en tout temps. Une perte

d’équilibre risquerait d’entraîner une

blessure corporelle. (fig. K)

• S’assurer que le tuyau est exempt

d’obstructions ou d’emmêlements.

Des tuyaux entremêlés ou vrillés peuvent

faire perdre l’équilibre ou perdre pied.

• N’utiliser l’outil que pour les travaux

pour lesquels il a été conçu; ne pas

décharger les attaches à l’air libre ni

dans des matériaux durs, comme le

béton, la pierre, le bois ou les noeuds

ou tout autre matériel trop difficile à

pénétrer. Ne pas utiliser le corps de

l’outil ou le couvercle supérieur en

guise de marteau. Les attaches éjectées

peuvent suivre une trajectoire inattendue et

causer des blessures. (fig. L)

• Toujours garder les doigts éloignés

du déclencheur par contact afin

d’éviter une décharge accidentelle

et les risques de blessure. (fig. M)

Français

18

Page 21

• Consulter les sections Entretien

et Réparations pour obtenir les

renseignements détaillés sur

l’entretien approprié de l’outil.

• Toujours utiliser l’outil dans un

endroit propre et bien éclairé;

s’assurer que la surface de travail est

exempte de débris et prendre soin de ne

pas perdre l’équilibre lorsqu’on travaille

dans un endroit surélevé, tel un toit.

• Ne pas enfoncer les attaches

près des bords de la pièce; celle-ci

pourrait se fractionner, ce qui risque

de faire ricocher l’attache et de blesser

quelqu’un, y compris l’utilisateur ou un

collègue de travail. S’assurer de ne pas

enfoncer l’attache en direction du fil du

bois afin qu’il ne dépasse pas le bord de

la pièce. Enfoncer le clou perpendiculaire

au fil du bois afin de réduire les risques

de blessure. (fig. N)

• Ne pas enfoncer de clous sur les

têtes d’autres attaches ou à un

angle trop aigu. Cette pratique peut

se solder par une blessure corporelle

provoquée par un recul, un coincement

d’attache ou un ricochet de clou. (fig. O)

• S’informer de l’épaisseur du

matériau lorsque vous utilisez une

cloueuse. Un clou en saillie peut causer

des blessures.

• Être conscient que lorsque l’outil est

utilisé à des pressions du côté élevé

de sa gamme de fonctionnement, les

clous peuvent passer complètement

à travers un matériau mince ou très

souple. S’assurer que la pression dans le

compresseur est réglée de sorte que les

clous sont fixés dans le matériau et non

poussés entièrement dans celui-ci. (Fig. P)

• Garder les mains et les parties du

corps éloignées de la zone de travail

immédiate. Au besoin, maintenir la pièce

à travailler avec des serres afin de garder

les mains et les parties du corps éloignées

du danger potentiel. S’assurer que la

pièce à travailler est adéquatement fixée

avant de pousser la cloueuse contre sa

surface. Le déclencheur peut entraîner

le déplacement inopiné de la pièce à

travailler. (fig. Q)

• Ne pas utiliser l’outil en présence de

poussières, de gaz ou d’émanations

inflammables. L’outil peut générer

une étincelle qui risque d’enflammer les

gaz, provoquant ainsi un incendie. Une

étincelle peut également survenir si un

clou est enfoncé sur un autre clou. (fig. R)

• Garder le visage et les parties du

corps éloignés de l’arrière du couvercle de l’outil lorsque

le travail est effectué dans des endroits restreints. Un recul

soudain peut entraîner un impact au corps, particulièrement durant

un clouage dans des matériaux durs ou denses. (fig. S)

FIG. N

FIG. O

FIG. P

FIG. Q

FIG. R

FIG. S

Français

19

Page 22

• Tenir fermement l'outil pour garder le contrôle tout en

permettant l'éloignement de l'outil de la surface de travail

pendant l'enfoncement de l'attache. Lorsque la gâchette

de déclenchement par contact (noire) est assemblée, si on

laisse le déclencheur par contact entrer en contact avec une

surface avant que la gâchette ne soit relâchée, une attache sera

enfoncée.

• Le choix de la méthode de déclenchement est important.

Vérifier le guide d’utilisation pour

connaître les options de déclenchement.

Se reporter à Utilisation de la gâchette

sous la section Fonctionnement.

DÉCLENCHEUR PAR CONTACT

(GÂCHETTE NOIRE)

• Lors de l’utilisation de la détente

par coup, prendre garde aux

doubles déclenchements

intempestifs provoqués par le

recul de l’outil. On peut enfoncer involontairement des

clous si le déclencheur touche de nouveau la pièce

inopinément. (fig. T)

POUR ÉVITER LES DOUBLES DÉCLENCHEMENTS:

• Ne pas presser l’outil contre la pièce avec trop de force.

• Permettre à l’outil d’effectuer complètement son mouvement

de recul après chaque actionnement.

• Utiliser la gâchette de déclenchement séquentiel (gâchette

grise).

•

En mode de déclenchement par contact, maintenir

systématiquement le contrôle de la cloueuse. Une

position incorrecte de l’outil pourra provoquer la libération

accidentelle d’un clou.

DÉCLENCHEMENT SÉQUENTIEL (GÂCHETTE GRISE)

• Avec la gâchette de déclenchement séquentiel, ne pas

activer la gâchette à moins que l’outil ne soit fermement

appliqué contre la pièce à travailler.

• Ne pas enfoncer de clous à l’aveugle

FIG. U

dans les murs, les planchers ou

autres zones de travail. Des attaches

enfoncées dans des fils électriques sous

tension, de la plomberie ou d’autres

types d’obstacles peuvent entraîner des

blessures. (fig. U)

• Demeurer alerte, prêter attention

au travail à effectuer et faire preuve

de bons sens pendant l’utilisation

d’un outil mécanique. Ne pas utiliser

un outil lorsqu’on ressent de la fatigue ou après avoir

consommé des drogues, de l’alcool ou des médicaments.

Un moment d’inattention durant l’utilisation d’outils mécaniques

peut entraîner de graves blessures.

• RÉGLAGE DE PROFONDEUR�: Afin de réduire les risques

de blessure grave causée par le démarrage accidentel

de l’outil lorsqu’on tente de régler la profondeur, on doit

TOUJOURS :

• débrancher l’alimentation d’air.

• éviter tout contact avec la gâchette durant l’ajustement

AVERTISSEMENT: Les scies, meules, ponceuses, perceuses

ou autres outils de construction peuvent produire des poussières

contenant des produits chimiques reconnus par l’État californien

pour causer cancers, malformations congénitales ou être nocifs au

système reproducteur. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb ;

FIG. T

Français

20

Page 23

• la silice cristallisée dans les briques et le ciment ou autres

articles de maçonnerie ; et

• l’arsenic et le chrome dans le bois ayant subi un traitement

chimique.

Le risque associé à de telles expositions varie selon la fréquence à

laquelle on effectue ces travaux. Pour réduire toute exposition à ces

produits : travailler dans un endroit bien aéré, en utilisant du matériel

de sécurité homologué tel un masque les microscopiques.

AVERTISSEMENT: TOUJOURS PORTER DES LUNETTES

DE SÉCURITÉ. Les lunettes optiques ne constituent PAS des

lunettes de sécurité. Utiliser également un masque facial

ou anti-poussières si l’opération génère de la poussière.

TOUJOURS PORTER UN ÉQUIPEMENT DE PROTECTION

HOMOLOGUÉ :

• protection oculaire conforme à la norme ANSI Z87.1 (CAN/

CSA Z94.3),

• protection auditive conforme à la norme ANSI S12.6 (S3.19) et

• protection des voies respiratoires conformes aux normes

NIOSH/OSHA/MSHA.

CONSERVER TOUS LES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTÉRIEUR

Fiche technique

MODÈLE DW45RN

HAUTEUR 249mm (9,8po)

LARGEUR 127mm (5po)

LONGUEUR 280mm (11po)

POIDS 2,4kg (5,2lb)

PRESSION DE SERVICE 4,9 – 8,43kg/cm2 (70 – 120 psig)

CONSOMMATION D’AIR

PAR 100 CYCLES*

0,1048 m3 (3,7 pi3/min) à 5,62 kg/cm

2

(80 psi)

CAPACITÉ DU

CHARGEUR

120clous

FIXATIONS Clous de toiture retenus à 15° par

fils d’acier, d’un diamètre de 3mm

(0,120po)

LONGUEUR DES

FIXATIONS

19mm - 44,5 mm

(3/4po – 1-3/4po)

PORT D’ADMISSION

D’AIR

6,4mm (1/4po NPT)

REMARQUE : n’utiliser que des attaches approuvées par

DeWALT.

COMPOSANTS (FIG. 1)

A. Couvercle supérieur

B. Gâchette

C. Couvercle du réservoir

D. Verrou

E. Déclencheur par contact

F. Molette de réglage de

profondeur

G. Portillon de guidage des

clous

H. Guide-bardeau

Français

21

Page 24

FIG. 1

A

E

F

B

C

H

D

G

ASSEMBLAGE

AVERTISSEMENT: afin d’éviter les risques de blessures,

débrancher le tuyau à air de l’outil et retirer les fixations du chargeur

avant de procéder au réglage.

Détente

AVERTISSEMENT : éloigner SYSTÉMATIQUEMENT les

doigts de la gâchette hors utilisation de l’outil pour éviter tout

déclenchement accidentel. Ne jamais transporter l’outil avec

le doigt sur la gâchette. Lorsque la gâchette de déclenchement

par contact (noire) est assemblée, l’outil libérera une attache si le

déclencheur par contact entre en contact avec une surface alors

que l’on appuie sur la gâchette.

Conformément aux standards ANSI SNT-101-2015, les cloueuses

DeWALT sont assemblées avec la gâchette noire de déclenchement

par contact. Il existe cependant une gâchette de déclenchement

séquentiel grise. Pour tout remplacement de la gâchette de

déclenchement par contact, veuillez contacter votre centre de

réparation agréé ou appeler le 1-800-4- DeWA LT.

Raccord d’air

Cet outil fonctionne avec une fiche mâle avec un pas de tuyauterie

de 1/4 po. Le diamètre interne doit mesurer au moins (4,6 mm

(0,180"). Le raccord doit être en mesure d’évacuer la pression

pneumatique lorsque l’outil est débranché de l’alimentation d’air.

DeWALT tiene disponible un acoplamiento con conector rápido

macho de 9,5mm (3/8po), que se puede utilizar cuando no hay

una línea de suministro de 6,4mm (1/4po) disponible

REMARQUE: une ligne d’alimentation (et des raccords) de 9,5mm

(3/8po) sont nécessaires pour que le rendement de l’outil soit optimal.

AVERTISSEMENT : toujours utiliser des raccords qui libèrent

toute la pression de l’outil lorsqu’il est débranché de

l’alimentation. Toujours utiliser des raccords de tuyau qui coupent

l’alimentation en air dès que l’outil est débranché.

POUR INSTALLER UN RACCORD D’AIR

1. Envelopper le bout mâle du raccord de ruban d’étanchéité pour

filetage avant d’assembler pour éliminer les fuites d’air.

2. Pour installer un raccord de 6,4 mm (1/4 po) : le visser

directement dans le port d’admission d’air et serrer fermement.

REMARQUE: s’il y a un adaptateur dans le port d’admission

d’air, il faut le retirer avant d’insérer le raccord.

Français

22

Page 25

3. Pour installer un raccord de 9,5mm (3/8po): visser le raccord

dans l’adaptateur de 9,5 mm (3/8 po), puis dans le port

d’admission d’air de l’outil et serrer fermement.

FONCTIONNEMENT

Préparation de l’outil

AVERTISSEMENT: lire la section intitulée Directives de sécurité

importantes début ce manuel. Toujours porter une protection

oculaire et auditive durant l’utilisation de cet outil. Toujours porter

une protection oculaire et une protection auditive lors de l’utilisation

de l’outil. Ne pas pointer la cloueuse dans votre direction ou celle

d’autres personnes. Pour une utilisation sécuritaire, effectuer toutes

les procédures et vérifier tous les points qui suivent avant chaque

utilisation de la cloueuse.

AVIS : pour réduire le risque d’endommager l’outil, utiliser uniquement

de l’huile pour outil pneumatique DeWALT ou une huile SAE

d’indice20 non détergente. Les huiles détergentes ou qui contiennent

des additifs risqueraient d’endommager les pièces de l’outil.

1. Avant d’utiliser la cloueuse, s’assurer que les réservoirs du

compresseur ont été correctement purgés.

2. Lubrifier l’outil comme suit:

a. Utiliser de l’huile pour outil pneumatique DEWALT ou une huile

S.A.E. de grade 20 non détergente. NE PAS utiliser une huile

détergente ou des additifs pour éviter d’endommager les joints

toriques et les pièces en caoutchouc.

b. Lorsque c’est possible, utiliser un ensemble filtre-régulateur-

lubrificateur avec le tuyau d’air, entre le compresseur et l’outil.

c. Si un lubrificateur n’est pas disponible, ajouter 5 à 7 gouttes

d’huile dans le raccord d’air au moins deux fois par jour ou

après toutes les quatre heures d’utilisation.

3. Porter une protection oculaire, auditive et respiratoires adéquates.

4. S’assurer que le réservoir est effectivement vide.

5. Vérifier le bon fonctionnement régulier du déclencheur et des

ensembles du poussoir. Ne pas utiliser l’outil si un des ensembles

ne fonctionne pas correctement. NE JAMAIS utiliser un outil dont

le déclencheur est coincé en position de marche.

6. Vérifier la source d’alimentation en air. Vérifier que la pression ne

dépasse pas les limites recommandées (se reporter à la fiche

technique de l’outil).

7. Ne pas pointer la cloueuse dans votre direction ou celle d’autres

personnes.

8. Raccorder le tuyau d’air.

9. Vérifier la présence de fuites audibles autour des soupapes et des

joints. Ne jamais utiliser un outil qui présente des fuites ou dont

certaines pièces sont endommagées.

AVERTISSEMENT: pour réduire les risques de blessures

corporelles, débrancher l’outil de la source d’alimentation en air avant

d’effectuer l’entretien, de dégager une attache bloquée, de quitter la

zone de travail, de déplacer l’outil dans un autre endroit ou de donner

l’outil à une autre personne.

Chargement de l’outil (fig. 2–4)

AVERTISSEMENT : ne pas pointer l’outil dans votre direction ou

celle d’autres personnes. Autrement, il pourrait survenir un accident

entraînant des blessures graves.

AVERTISSEMENT : ne jamais charger les clous lorsque le

déclencheur par contact ou la détente sont actionnés. Risque de

blessures corporelles.

1. Lire tous les Avertissements de sécurité avant d’utiliser l’outil.

2. Raccorder la source d’alimentation d’air à l’outil.

Français

23

Page 26

3. Poussez le verrou (D)

FIG. 2

D

G

C

pour ouvrir le portillon

de guidage des clous

(G).

4. Faites pivoter le

couvercle du réservoir

(C) pour l’ouvrir.

5. Ajustez la plateforme de

clous (l) à la longueur

des clous utilisés.

• Poussez le levier de

plateforme (J).

• Faites pivoter la plateforme (I) pour la sortir.

• Insérez la plateforme dans la position désirée.

• Poussez la plateforme pour activer le levier de plateforme.

FIG. 3

J

FIG. 4

I

POSITION DE LA

PLATEFORME

LONGUEUR DU CLOU

position la plus basse

1-1/4" (32mm) - 1-3/4" (44,5mm)

position la plus haute

3/4" (19mm) -1-1/4" (32mm) - 1-3/4"

(44,5mm)

6. Placer la bobine sur la plateforme de clous (I). Insérer les attaches

avec les pointes vers le bas. IMPORTANT: les attaches doivent

pointer dans la direction où elles seront enfoncées.

7. Dérouler assez de clous [environ 76mm (3po)] pour attendre le

bec de l’outil.

8. Insérer le premier clou dans le bec et le deuxième clou (M) entre

les deux rails du cliquet d’alimentation, comme l’illustre la fig. 5.

REMARQUE: prendre soin de ne pas déformer la bobine de clous

lors du chargement. Sinon, la porte du guide-clou ne fermera pas, et

l’alimentation en clous risque d’être irrégulière.

FIG. 5

M

9. Refermez complètement le couvercle du réservoir (C).

10. Fermer la porte du guide-clou (G) en vérifiant que le loquet de la

porte (D) s’engage complètement, comme l’illustre la fig. 6.

Français

24

Page 27

FIG. 6

D

G

Utilisation de la gâchette

AVERTISSEMENT : toujours porter une protection oculaire

(ANSI Z87.1 [CAN/CSA Z94.3]) ainsi qu’une protection auditive

appropriées (ANSIS12.6 [S3.19]) lors de l’utilisation de cet outil.

AVERTISSEMENT : sauf lors du clouage, l’utilisateur ne doit

pas maintenir la gâchette de l’outil à déclenchement par contact

enfoncée, car il existe un risque de blessures graves si la gâchette

entre accidentellement en contact avec une personne ou un objet et

provoque le déclenchement de l’outil.

AVERTISSEMENT : éloigner les mains et le corps de la zone

d’expulsion des clous. Le recul peut provoquer le rebond de l’outil

à déclencheur par contact et libérer une deuxième fixation, ce qui

risque de provoquer des blessures.

AVERTISSEMENT: ne jamais utiliser un crochet à chevron pour

suspendre l’outil sur le corps, sur un vêtement ou à la ceinture.

DÉCLENCHEMENT PAR CONTACT (GÂCHETTE NOIRE)

En règle générale, les outils à déclenchement par contact s’utilisent

en créant un contact avec la surface de travail pour actionner le

mécanisme de déclenchement tout en gardant la gâchette enfoncée.

Ainsi, une fixation est libérée à chaque contact avec la surface. Cette

méthode favorise le positionnement rapide des fixations dans de

nombreux travaux comme l’application de revêtement, la pose de

platelage ou l’assemblage de palettes.

Un recul se produit sur tous les outils pneumatiques lors de la

libération de fixations. Il peut arriver que le rebond qui s’ensuit libère le

déclencheur. En cas de contact involontaire avec la surface de travail

alors que la gâchette est toujours actionnée (doigt sur la gâchette

enfoncée), une deuxième fixation sera libérée.

DÉCLENCHEMENT SÉQUENTIEL (GÂCHETTE GRISE)

L’utilisateur doit maintenir l’outil contre la surface de travail avant

d’appuyer sur la gâchette. Il est ainsi plus facile de placer les fixations

lors, par exemple, de la pose de charpente, de clouage en biais ou

de la construction de caisses.

Le déclenchement séquentiel permet de positionner la fixation de

manière précise sans risquer d’en libérer une deuxième sous l’effet

du recul (se reporter à Déclenchement par contact).

L’outil à déclenchement séquentiel constitue un avantage sur le plan

de la sécurité, puisqu’il interdit tout déclenchement accidentel si

l’outil heurte la surface de travail ou quoi que ce soit d’autre alors que

l’utilisateur appuie sur la gâchette.

FONCTIONNEMENT DU DÉCLENCHEMENT PAR CONTACT

(GÂCHETTE NOIRE)

Les modèles à déclencheur par contact (gâchette noire) sont équipés

d’un déclencheur qui fonctionne en collaboration avec la gâchette

pour libérer une fixation. Il existe deux méthodes pour libérer des

fixations avec un outil à déclencheur par contact.

POSE D’UNE SEULE FIXATION: Pour utiliser l’outil afin de poser une

seule fixation, commencer par positionner le déclencheur par contact

Français

25

Page 28

sur la surface de travail, SANS APPUYER SUR LA GÂCHETTE.

Enfoncer le déclencheur par contact jusqu’à ce que le nez touche

la surface de travail, puis appuyer sur la gâchette pour libérer une

fixation. Ne pas exercer de force excessive pour appuyer l’outil contre

la surface. Prévoir plutôt une distance de recul pour éviter qu’une

deuxième fixation ne soit libérée. Retirer le doigt de la gâchette après

chaque action.

MODE DE FIXATION RAPIDE: Pour utiliser l’outil avec déclencheur

par contact en mode rapide, le pointer vers la surface de travail sans

toutefois la toucher. Appuyer sur la gâchette, puis toucher la surface

de travail avec le déclencheur par contact en donnant un à-coup. À

chaque fois que le déclencheur par contact est enfoncé, une fixation

est libérée.

FONCTIONNEMENT DU DÉCLENCHEMENT SÉQUENTIEL

(GÂCHETTE GRISE)

Les modèles à déclencheur séquentiel (gâchette grise) sont équipés

d’un déclencheur qui fonctionne en collaboration avec la gâchette

pour libérer une fixation. Pour actionner un outil à déclenchement

séquentiel, commencer par positionner le déclencheur par contact

sur la surface de travail

SANS APPUYER SUR LA GÂCHETTE. Enfoncer le déclencheur par

contact puis appuyer sur la gâchette pour libérer une fixation. Tant

que le déclencheur est en contact avec la surface et reste enfoncé,

l’outil envoie une fixation chaque fois que vous appuyez sur la

gâchette. Si le déclencheur s’écarte de la surface de travail, il faut

répéter la séquence ci-dessus pour libérer une autre fixation.

Vérification du fonctionnement de l’outil

(fig.1)

AVERTISSEMENT: toujours sortir toutes les fixations de l’outil

avant d’en vérifier le fonctionnement.

FONCTIONNEMENT DU DÉCLENCHEMENT PAR CONTACT

(GÂCHETTE NOIRE)

A. Sans toucher la gâchette (A), appuyer le déclencheur par contact

contre la surface de travail.

L’OUTIL NE DOIT PAS SE DÉCLENCHER.

B. Écarter l’outil de la surface de travail et appuyer sur la gâchette.

L’OUTIL NE DOIT PAS SE DÉCLENCHER.

C. Une fois l’outil écarté de la surface de travail, appuyer sur la

gâchette. Appuyer le déclencheur par contact contre la surface

de travail.

L’OUTIL DOIT SE DÉCLENCHER.

D. Sans toucher la gâchette, appuyer le déclencheur par contact

contre la surface de travail, puis appuyer sur la gâchette.

L’OUTIL DOIT SE DÉCLENCHER.

FONCTIONNEMENT DU DÉCLENCHEMENT SÉQUENTIEL

(GÂCHETTE GRISE)

A. Appuyer le déclencheur par contact contre la surface de travail,

sans toucher la gâchette.

L’OUTIL NE DOIT PAS SE DÉCLENCHER.

B. Tenir l’outil à l’écart de la surface de travail et appuyer sur la

gâchette.

L’OUTIL NE DOIT PAS SE DÉCLENCHER.

Relâcher la gâchette. Elle doit revenir à l’arrêt se trouvant sur le

châssis de l’outil.

C. Appuyer sur la gâchette et presser le déclencheur par contact

contre la surface de travail.

L’OUTIL NE DOIT PAS SE DÉCLENCHER.

D. Sans toucher la gâchette, appuyer sur déclencheur par contact

contre la surface de travail. Appuyer sur la gâchette.

L’OUTIL DOIT SE DÉCLENCHER.

Français

26

Page 29

Réglage de la profondeur (Fig. 7)

AVERTISSEMENT : pour réduire les risques de blessures graves

par actionnement accidentel de l’outil lorsqu’on tente de régler la

profondeur, TOUJOURS:

• Débranchez l'alimentation d'air.

• Éviter tout contact avec la détente lors des réglages.

La profondeur à laquelle une

F

FIG. 7

attache est enfoncée peut être

réglée à l’aide de la molette de

réglage de profondeur sur le nez

de l’outil. La profondeur

d’enfoncement est ajustée d’usine

sur un tarage nominal. Effectuez

un essai en tirant une attache pour

vérifier la profondeur. Si vous

désirez en changer:

1. Pour enfoncer un clou plus profondément, tournez la molette de

réglage de profondeur (F) vers la droite. Le paramètre5 est le plus

profond.

2. Pour enfoncer le clou moins profondément, tournez la molette de

réglage de profondeur (F) vers la gauche. Le paramètre1 est le

moins profond.

Tirer une autre attache et vérifier la profondeur. Répéter si nécessaire

pour obtenir les résultats désirés. La quantité de pression d'air

nécessaire variera selon la dimension de l'attache et le matériau

d'installation. Faire l'expérience avec un réglage de pression d'air

afin de déterminer le réglage de pression le plus faible pouvant offrir

une performance stable pendant la durée du travail. Une pression

d'air plus élevée que celle nécessaire peut entraîner une usure

prématurée et des dommages à l'outil.

Guide-bardeau (Fig. 8, 9)

Réglage du guide-bardeau (H):

1. Desserrez la vis de réglage (N) et poussez le guide (H) sur la

position désirée.

FIG. 8

H

N

2. Resserrez la vis de réglage fermement.

Le guide (H) peut être utilisé pour faciliter le positionnement du

bardeau à clouer à une longueur spécifique (O) de la lisière du rang

précédent de bardeaux (Q), comme illustré.

FIG. 9

H

Q

O

Français

27

Page 30

Dégagement des clous coincés

(Fig. 1, 10)

AVERTISSEMENT : afin d’éviter les risques de blessures,

débrancher le tuyau à air de l’outil et retirer les fixations du chargeur

avant de procéder au réglage.

Si un clou se coince dans le bec

FIG. 10

de l’outil, l’utilisateur doit pointer

l’outil dans la direction opposée à

son corps et procéder comme suit

pour dégager le clou:

1. Débrancher la source

d’alimentation d’air de l’outil.

2. Poussez le verrou (D) pour

ouvrir le portillon de guidage

des clous (G).

3. Faites pivoter le couvercle du réservoir (C) pour l’ouvrir.

4. Enlever le clou coincé.

5. Corriger toute déformation éventuelle de la bobine de clous.

REMARQUE: dans le cas de coincements répétés des clous dans

le bec, confier la réparation de l’outil à un centre de réparation agréé

DeWA LT .

Fonctionnement par temps froid

AVERTISSEMENT: Lire la section intitulée Directives de sécurité

importantes début ce manuel. Toujours porter une protection

oculaire et auditive durant l’utilisation de cet outil. Garder la cloueuse

pointée en direction opposée de l’opérateur et des autres personnes.

Pour un fonctionnement sécuritaire, effectuer toutes les procédures

et vérifications suivantes avant chaque utilisation de la cloueuse.

Lorsque les outils sont utilisés à des températures inférieures au point

de congélation, effectuer les procédures de préparation ci-dessus et

suivre les directives ci-dessous.

1. S’assurer que les réservoirs du compresseur ont été purgés

adéquatement avant l’utilisation. Toujours purger les réservoirs

du compresseur au moins une fois par jour durant l’utilisation de

la cloueuse. Ceci est particulièrement important par temps froid

parce que l’humidité dans l’air des réservoirs se condensera.

2. Garder l’outil le plus chaud possible avant l’utilisation.

3. S’assurer que toutes les attaches ont été retirées du réservoir.

4. Ajouter dans le capuchon d’extrémité 5 à 7 gouttes d’huile pour

outil pneumatique DEWALT ou d’huile pneumatique de grade

d’hiver contenant de l’éthylène glycol.

5. Abaisser la pression d’air à 5,5 bar (80 psi )ou moins.

6. Actionner l’outil à 5 ou 6 reprises dans du bois non utilisable pour

lubrifier les joints toriques.

7. Rebrancher la source d’alimentation en air et recharger les clous

dans le réservoir.

8. Augmenter la pression jusqu’au niveau de fonctionnement (sans

excéder 120 psi) et utiliser l’outil normalement.

9. Lubrifier le capuchon d’extrémité de nouveau avec de l’huile pour

outil pneumatique DeWALT ou de l’huile pneumatique de grade

d’hiver contenant de l’éthylène glycol au moins deux fois par jour

ou toutes les quatre heures d’utilisation.

Fonctionnement par temps chaud

L’outil devrait fonctionner normalement. Cependant, garder l’outil

à l’abri de la lumière directe du soleil étant donné que la chaleur

excessive peut endommager les amortisseurs, les joints toriques et

les autres pièces de caoutchouc.

Français

28

Page 31

ENTRETIEN

AVERTISSEMENT : afin d’éviter les risques de blessures,

débrancher le tuyau à air de l’outil et retirer les fixations du chargeur

avant de procéder au réglage.

Tableau d’entretien journalier

ACTION Lubrifier l’outil avec 5 à 7 gouttes d’huile pour outils

pneumatiques DEWALT

POURQUOI Prévenir la défaillance des joints toriques

COMMENT Introduire les gouttes dans le raccord d’air de

l’embout de l’outill

ACTION Vider les réservoirs et les tuyaux du compresseur

quotidiennement

POURQUOI Prévenir l’accumulation d’humidité dans le

compresseur et le clouer

COMMENT Ouvrir les robinets de purge ou les autres robinets

des réservoirs du compresseur

ACTION Nettoyer le réservoir, la zone du piston

d’alimentation et le déclencheur par contact

POURQUOI Permet un fonctionnement en souplesse du

chargeur, réduit l’usure et prévient les coincements.

COMMENT Nettoyer à l’air comprimé. L’utilisation d’huiles ou

de solvants n’est pas recommandée car ils ont

tendance à retenir les particules

ACTION Avant chaque utilisation, vérifier si les écrous,vis et

attaches sont serrés et intacts

POURQUOI Prévenir les blocages, les fuites et la défaillance

prématurée des pièces de l’outil

COMMENT Utiliser la clé hexagonale ou le tournevisapproprié(D)

pour serrer les vis ou autres attaches.

Nettoyage

AVERTISSEMENT: NE PAS utiliser d’essence ou tout autre liquide

hautement inflammable pour nettoyer la cloueuse. Les émanations

pourraient enflammer une étincelle et causer une explosion.

Du goudron et de la saleté pourront s’accumuler sur le nez et le levier

de déclenchement et empêcher le bon fonctionnement de l’outil.

Retirez toute accumulation avec du kérosène, du fioul nº2 ou du

diesel. Ne trempez pas la cloueuse dans ces solvants au-delà de la

hauteur de la tête des clous, pour éviter que ces solvants ne pénètrent

dans le tambour de commande.

Séchez soigneusement la cloueuse avant toute réutilisation. Tout

dépôt d’huile demeurant après le nettoyage accélèrera l’accumulation

de goudron, et la cloueuse nécessitera des nettoyages plus fréquents.

REMARQUE: les solvants vaporisés sur le nez pour nettoyer et libérer

le déclenchement pourront avoir l’effet inverse! Les solvants pourront

ramollir le goudron sur les bardeaux et en accélérer l’accumulation sur

l’outil. Une opération à sec est plus appropriée.

Réparations

AVERTISSEMENT : afin d’éviter les risques de blessures,

débrancher le tuyau à air de l’outil et retirer les fixations du chargeur

avant de procéder au réglage.

Se reporter à la rubrique Guide de dépannage à la fin de cette

section.

AVERTISSEMENT : pour assurer la SÉCURITÉ et la FIABILITÉ du

produit, les réparations réalisés par un centre de réparation en usine

DeWALT ou un centre de réparation agréé DeWALT. Toujours utiliser

des pièces de rechange identiques.

Français

29

Page 32

Garantie à vie limitée de sept (7) ans

DeWALT réparera gratuitement tous les problèmes dus à des défauts

de matériau ou de fabrication pendant sept (7) ans à compter de la

date d’achat. Cette garantie ne couvre pas des défaillances de pièce

dues à une usure normale ou à une mauvaise utilisation de l’outil.

Pour en savoir plus sur la protection et les réparations sous garantie,

visiter le site Web www.dewalt.com ou composer le 1 800 433-9258

(1 800 4-DeWA LT ). Cette garantie ne s’applique pas aux accessoires

ni aux dommages causés par des réparations réalisées ou tentées

par des tiers. Cette garantie vous accorde des droits légaux précis et

il est possible que vous ayez d’autres droits qui varient d’un État ou

d’une province à l’autre.

En plus de la garantie, les outils DeWA LT sont couverts par notre:

SERVICE D’ENTRETIEN GRATUIT DE 1 AN

DeWA LT entretiendra l’outil et remplacera les pièces usées par une

utilisation normale et ce, gratuitement, à tout moment pendant la

première année à compter de la date d’achat. L’usure de pièces

comme les joints toriques ou les mécanismes de lames n’est pas

couverte.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n’êtes pas entièrement satisfait des performances de votre