Page 1

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW441, DW442, DW443, DW444

Right Angle Random Orbit Sanders

Ponceuses orbitales excentriques à angle droit

Lijadoras orbitales de movimiento múltiple de ángulo recto

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

Page 2

English

Important Safety Instructions

(For all tools)

WARNING: When using electric tools, basic safety precautions should always be followed to reduce risk of fire, electric

shock, and personal injury, including the following:

READ ALL INSTRUCTIONS

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces; for example, pipes, radiators, ranges, and

refrigerator enclosures.

• KEEP CHILDREN AWAY. All visitors should be kept away from

work area. Do not let visitors contact tool or extension cord.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE A TOOL. It will do the job better and safer at the

rate for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy duty tool. Don’t use tool for purpose not intended; for

example, don’t use circular saw for cutting tree limbs or logs.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear protective hair covering to contain long hair.

Air vents often cover moving

parts and should also be avoided.

• USE SAFETY GLASSES. Also use face or dustmask if operation

is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to dis-

connect from receptacle. Keep cord from heat, oil, and sharp

edges.

1

R

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

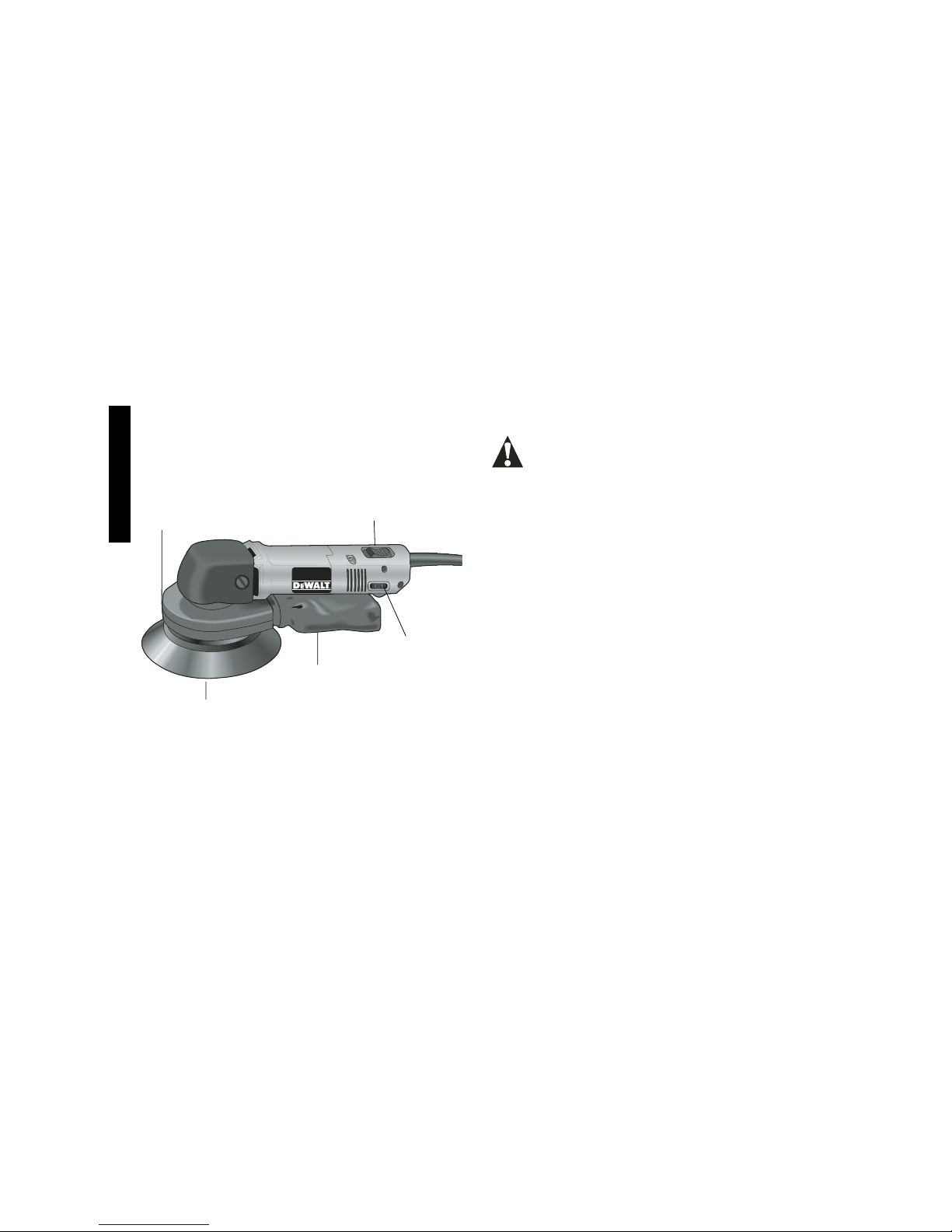

SANDING PAD

(HOOK AND LOOP - DW442 AND DW443)

(PSA- PRESSURE SENSITIVE ADHESIVE - DW441 AND DW444)

DUST BAG

SPEED CONTROL DIAL

(DW443 AND DW444)

ON/OFF SWITCH

SHROUD

Page 3

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safe performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged have repaired by authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep handles dry,

clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry plugged-in tool

with finger on the switch. Be sure the switch is off when plugging

in.

• OUTDOOR USE EXTENSION CORDS. When tool is used out-

doors, use only extension cords intended for use outdoors and so

marked.

• STAY ALERT. Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard

or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions that may

affect its operation. A guard or other part that is defective should be

properly repaired or replaced by an authorized service center

unless otherwise indicated elsewhere in this instruction manual.

Have defective switches replaced by authorized service center. Do

not use tool if switch does not turn it on and off.

1

English

• DO NOT OPERATE portable electric tools near flammable liquids

or in gaseous or explosive atmospheres. Motors in these tools normally spark, and the sparks might ignite fumes.

Special Safety Instructions For Sanders

• Always wear eye protection and a respirator when sanding.

• Sanding of lead based paint is not recommended. See page 5 for

additional precautions when sanding paint.

• Do not operate the unit without the dust shroud.

• Do not operate this tool for long periods of time. Vibration

caused by the operating action of this tool may cause permanent

injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, saw-

ing, grinding, drilling, and other construction activities. Wear

protective clothing and wash exposed areas with soap and

water. Allowing dust to get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Page 4

English

2

Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

Double Insulation

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one double thickness of insulation

between you and the tool’s electrical system. Tools built with this insulation system are not intended to be grounded. As a result, your tool

is equipped with a two prong plug which permits you to use extension

cords without concern for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety precautions when operating this tool. The insulation system is for added

protection against injury resulting from a possible electrical insulation

failure within the tool.

CAUTION: When servicing all tools, USE IDENTICAL REPLACE-

MENT PARTS. Repair or replace damaged cords.

Polarized Plug

This product is supplied with a polarized plug (one blade is wider than

the other). This plug will fit into a polarized outlet (receptacle) only one

way. If the plug does not fit fully into your outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install a proper polarized outlet. Do not modify or change this plug in any way.

Extension Cords

Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. The table shows

the correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller the

gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Motor

Be sure your power supply agrees with nameplate marking.120 AC

means your tool may be operated only with alternating current and

never with direct current. Voltage decrease of more than 10% will

cause loss of power and overheating. All tools are factory tested; if this

tool does not operate, check the power supply.

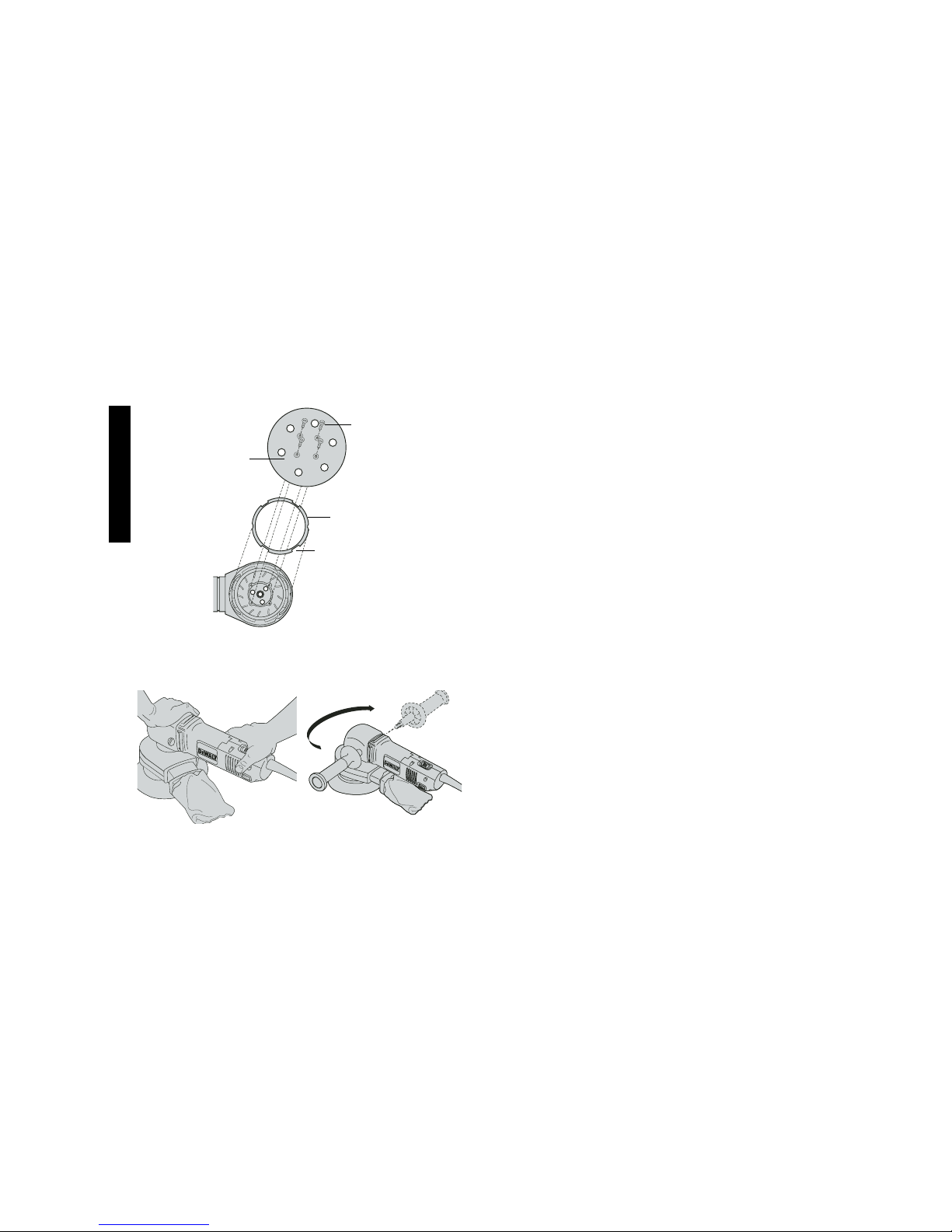

Attaching Sanding Discs

Your sander is designed to use 6" sanding discs with the 6 hole dust

extraction pattern.

Hook and Loop

(DW442 and DW443)

PSA - Pressure Sensitive Adhesive

(DW441 and DW444)

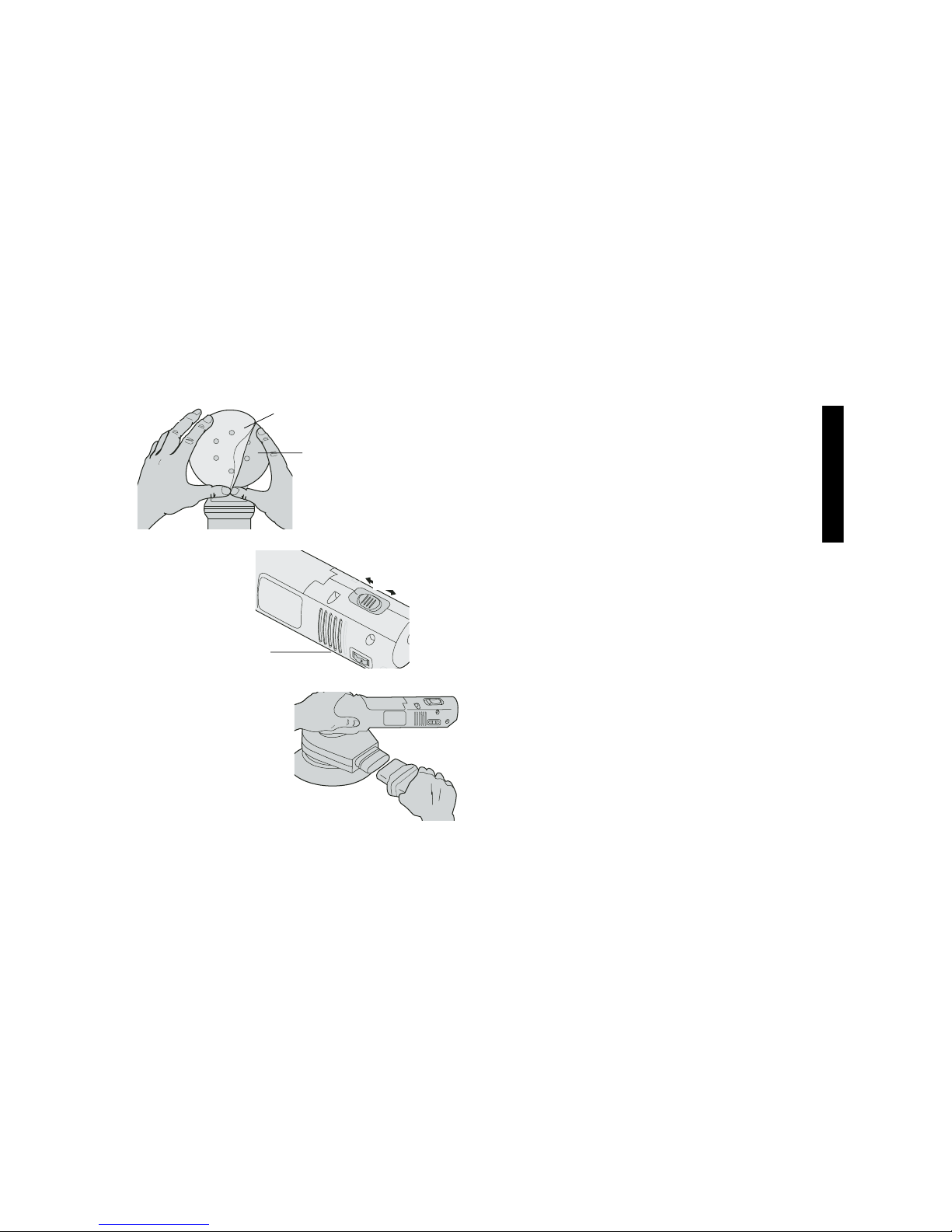

To attach paper to the sanding pad:

1. Turn off and unplug tool.

2. Turn the sander over so that the sanding pad is facing upward.

3. (DW441 and DW444 only) Clean dust from vinyl pad face.

4. Hold the pad with one hand to keep it from rotating.

5. With the other hand, align the holes and place the disc directly on

top of the pad (see FIG. 1).

Page 5

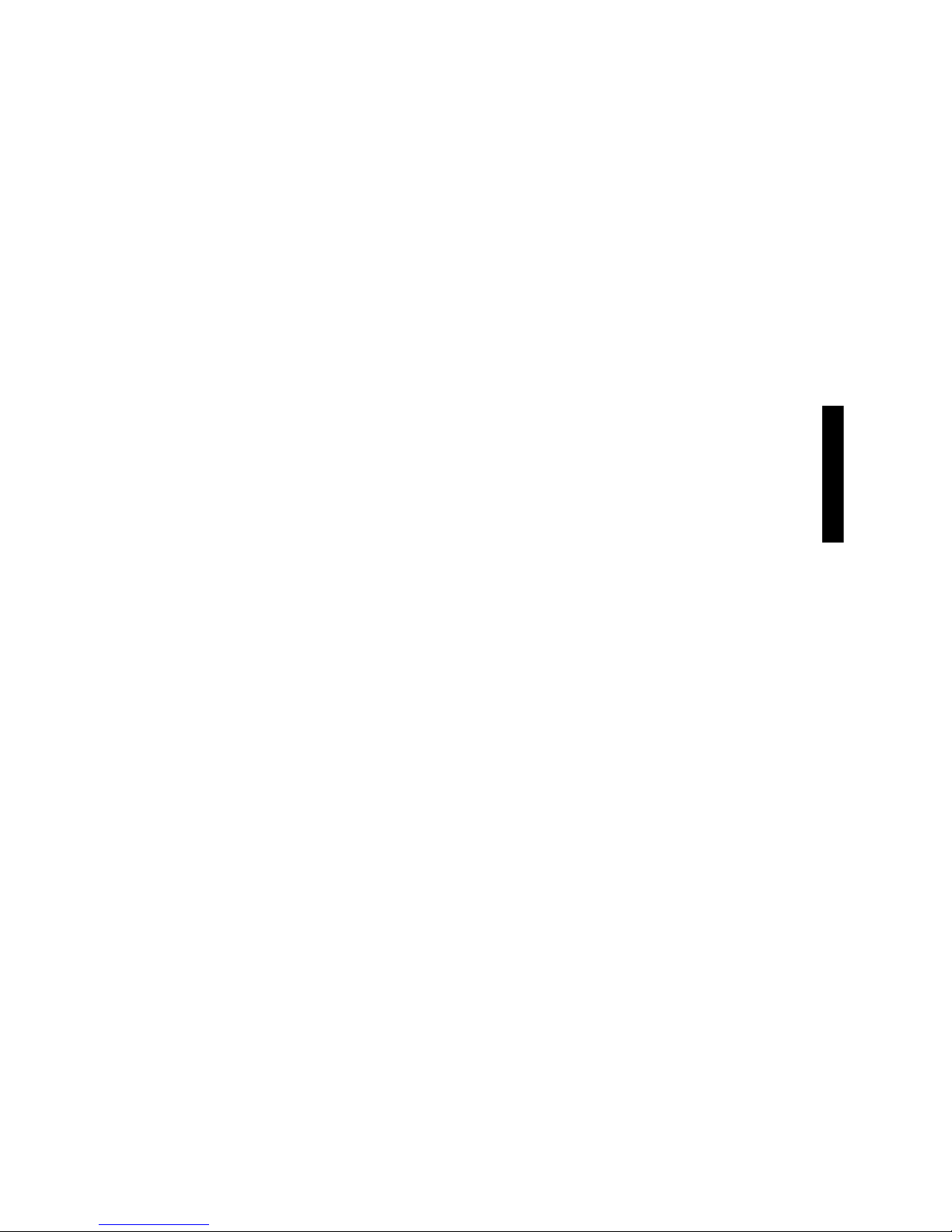

Switch

(See FIG. 2)To turn the unit on, slide the switch forward (the symbol

“I” will be visible.) To turn the unit off, slide the switch back (the symbol “O” will be visible). Before plugging in the unit, make sure the

switch is in the off position.

Speed Control Dial

(DW443 & DW444 Only)

The speed control dial (5 incremental settings) allows you to increase

or decrease speed from 4000 - 6800 Orbits Per Minute. The optimal

speed setting for each application is very much dependent on personal preference. You may want to experiment on a piece of scrap to

determine what gives you the best combination of finish quality and

material removal rate for your application. Generally, you will want to

use a higher setting on harder materials and a lower setting on softer

materials. Material removal rate increases as speed increases.

Dust Collection

Your sander comes equipped with a cloth filter bag to collect the dust

generated during sanding. To empty the dust bag, first turn off and

unplug tool. Firmly pull the bag off while holding the rubber boot

(FIG. 3). Empty the bag (you may want to turn it inside out.)

NOTE: Never operate this tool unless the dust collection bag is in

place.

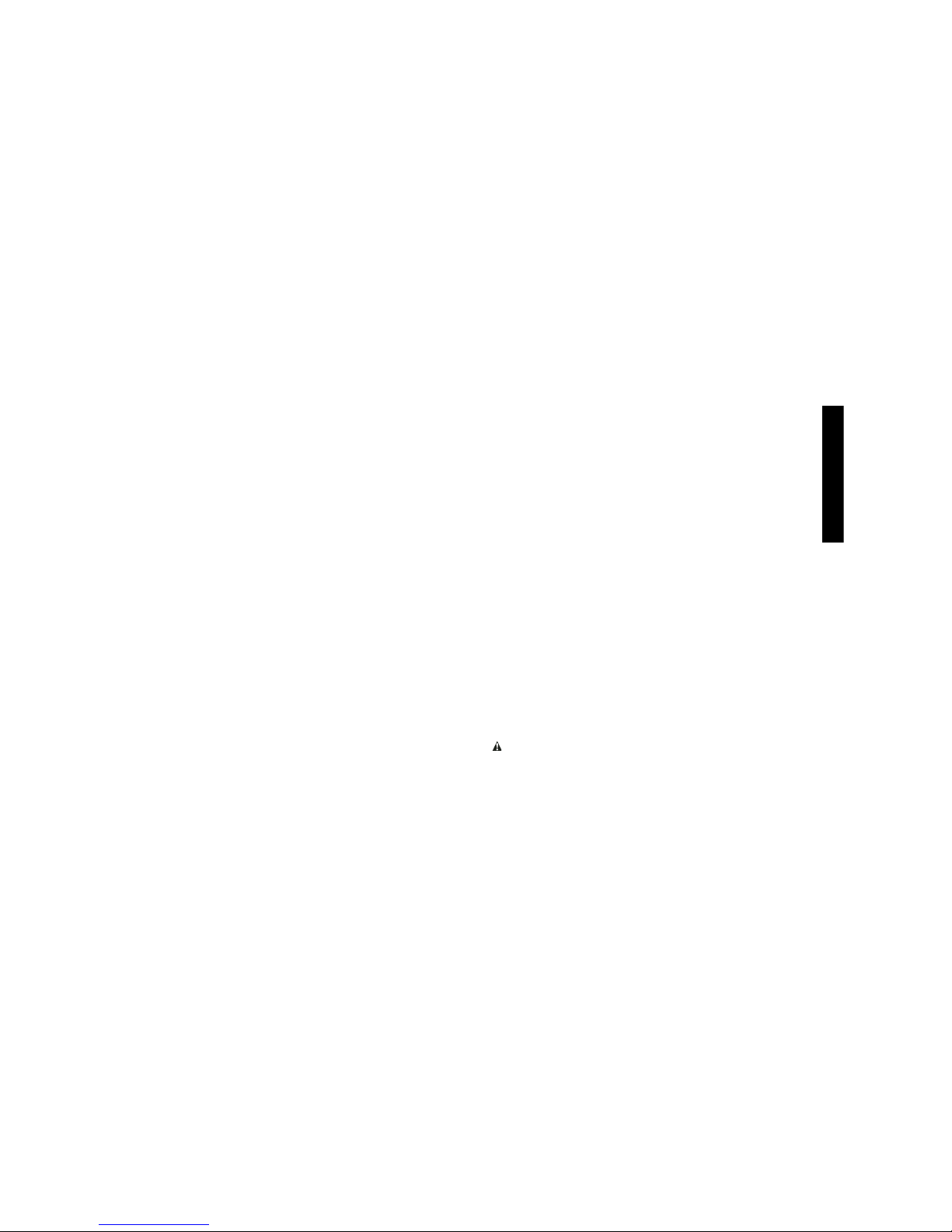

Replacing Sanding Pad

When the pad becomes worn out, use the following procedure to

replace pad. (See FIG. 4)

1. Turn off and unplug tool.

2. Remove 4 torx head screws from the bottom of the tool and

remove the pad.

3. Replace the pad and screws, making sure the CFS disc is aligned

properly.

3

English

1

FIG. 1

SANDING DISC

PAD

FIG. 2

ON

OFF

SPEED CONTROL DIAL

(SETTINGS 1 - 5)

FIG. 3

Page 6

4

Operation

To operate your sander, grasp it as shown in FIG. 5 and turn it on.

Move the unit in long, sweeping strokes along the surface being sanded, letting the sander do the work.

NOTE: Excessive downward pressure on the tool while sanding actually slows the removal rate and produces an inferior quality surface.

A side handle has been provided with your unit and can be used if

desired. The side handle can be screwed into either side of tool by first

removing the plastic screw, as shown in FIG. 6.

NOTE: Be sure to check your work often, this sander is capable of

removing material rapidly, especially with coarse paper.

The random orbital action of your sander allows you to sand with the

grain or at any angle across it for most sanding jobs. To produce the

best finish possible, start with coarse grit sandpaper and change gradually to finer and finer paper. Vacuum and wipe surface with a tack

cloth between grit steps.

The rate at which the dust bag fills up will vary with the type of material being sanded and the coarseness of the sandpaper. For best

results, empty the bag frequently.

When sanding painted surfaces, (see page 5 for additional precautions when sanding paint) you may find that the sandpaper loads up

and clogs with paint. A heat gun will work much better to remove paint

before sanding. FOLLOW ALL SAFETY INSTRUCTIONS IN HEAT

GUN INSTRUCTION MANUAL.

NOTE: (DW441 and DW444 only): When using PSA sanding discs, it

is necessary to remove the disc soon after operation. PSA papers, if

left on during tool storage, sometimes become difficult to remove. To

aid in the removal of old PSA paper, sand for a few minutes to soften

adhesive backing prior to changing disc.

Precautions To Take When Sanding Paint

1. Sanding of lead based paint is NOT RECOMMENDED due to the

difficulty of controlling the contaminated dust. The greatest danger

of lead poisoning is to children and pregnant women.

English

FIG. 5

FIG. 6

FIG. 4

TORX HEAD

SCREWS

CFS DISC

PAD

ALIGN NOTCHES

TO THOSE IN

SHROUD

Page 7

2. Since it is difficult to identify whether or not a paint contains lead

without a chemical analysis, we recommend the following precautions when sanding any paint:

PERSONAL SAFETY

a. No children or pregnant women should enter the work area where

the paint sanding is being done until all clean up is completed.

b. A dust mask or respirator should be worn by all persons entering

the work area. The filter should be replaced daily or whenever the

wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint

dust and fumes should be used. Ordinary painting masks do not

offer this protection. See your local hardware dealer for the proper N.I.O.S.H. approved mask.

c. NO EATING, DRINKING or SMOKING should be done in the work

area to prevent ingesting contaminated paint particles. Workers

should wash and clean up BEFORE eating, drinking or smoking.

Articles of food, drink, or smoking should not be left in the work

area where dust would settle on them.

ENVIRONMENTAL SAFETY

a. Paint should be removed in such a manner as to minimize the

amount of dust generated.

b. Areas where paint removal is occurring should be sealed with

plastic sheeting of 4 mils thickness.

c. Sanding should be done in a manner to reduce tracking of paint

dust outside the work area.

CLEANING AND DISPOSAL

a. All surfaces in the work area should be vacuumed and thorough-

ly cleaned daily for the duration of the sanding project. Vacuum filter bags should be changed frequently.

b. Plastic drop cloths should be gathered up and disposed of along

with any dust particles or other removal debris. They should be

placed in sealed refuse receptacles and disposed of through regular trash pick-up procedures.

During clean up, children and pregnant women should be kept

away from the immediate work area.

c. All toys, washable furniture and utensils used by children should

be washed thoroughly before being used again.

Lubrication

Self lubricating bearings are used in the tool and periodic relubrication

is not required. However, it is recommended that, once a year, you

take or send the tool to a service center for a thorough cleaning and

inspection.

Cleaning

Keep your machine as clean as possible by wiping with a clean cloth

and blowing through it with air after every 5 hours of use. Don’t use

harsh chemicals or solvents to clean the tool. These chemicals could

seriously damage the engineering polymers used to construct your

sander. If you typically wrap the cord around the tool when you store

it, leave a generous loop of cord such that the strain relief does not

bend. This helps prevent premature cord failure.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by a D

EWALT factory service center, a DEWALT autho-

rized service center or other qualified service personnel. Always use

identical replacement parts.

Application Notes

SANDPAPER - GRIT TYPES

Natural Abrasives

Flint is the softest (Mohs’ Scale 7)* of the common natural abrasives.

It has a tan color and is very inexpensive.

Garnet paper is harder than flint (Mohs’ Scale 7.5) and is easily identified by its bright orange color. Even though it is not the hardest, the

way the abrasive fractures gives you a good cutting edge for woodworking.

5

English

Page 8

6

Emery, even though harder than garnet (Mohs’ Scale 9), has blunt

edges making it a poor sanding abrasive. Its primary use is for polishing metal.

* Mohs’ Scale is the mineral hardness scale. It rates diamond at 15,

the hardest, and talc at 1.

Manufactured Abrasives

White Aluminum Oxide (AlO) is extremely hard (Mohs’ Scale 12) and

durable which makes it a great abrasive for use with the Random Orbit

Sander. “White” describes the particular way the abrasive is manufactured, not its color. This abrasive is widely available and comes in a

variety of colors due to the increasing use of dyes. Stearate lubricants

on the paper also enhance performance by reducing heat and the rate

at which the paper clogs.

Silicon Carbide (SiC) is the hardest abrasive (Mohs’ Scale 13) commonly available next to industrial diamond but is not as tough as

Aluminum Oxide abrasives. This abrasive easily fractures and provides sharp faces to the work throughout the life of the sanding paper.

This “self-sharpening” feature makes SiC an outstanding abrasive for

material removal but limits its life.

OPEN COAT VERSUS CLOSED COAT

Abrasives are applied to the paper with glue. When the grit is large

(say 60 or 80 grit) the percent of coverage is usually reduced to 60%

to 70% of the backing paper surface.This increases the life of the

paper by reducing the rate at which the paper clogs. This is called an

open coat and almost the only way you can buy sandpaper in heavier

grits. With finer grits the grit is applied at rates of 90% or more and

are labeled closed coat. Since the dust particle is much smaller the

tendency of the paper to load up and clog is greatly reduced.

GRIT SIZES

There are several grading systems used. The system most popular

today is sieve size. The number on the back of your sandpaper disc

refers to the screen size the particle can pass through. 120 grit paper

for example will sift through a screen with 120 holes per linear inch.

Every square inch of screen has 14,400 holes (120 x 120). The higher the number the finer the particle size. Common sizes are from 36

to 600 with the recent introduction of grit sizes up to 1200.

PAPER AND FILM: THE BACKING

Paper: The material most commonly used to carry the abrasive is

paper. Paper is graded by weight. “A” weight paper which is the most

prevalent is the lightest paper used and gives good durability and flexibility in most sanding applications. Other paper weights that are available are C, D, E, and F weight. The disadvantage of paper is its low

mechanical stiffness. Since the paper fiber gives during sanding, the

abrasive doesn’t stand up and some of the cutting edges do not

engage the work. The advantage is cost.

Film: Film backed sanding discs address the disadvantage of paper.

The film is mechanically stiffer than paper. Film is also more expensive but when all other things are held constant improves the cutting

performance of the abrasive.

Cloth and Vulcanized Fiber: These backings are typically hard to

find and are used in specialty applications. Most sandpaper you will

use will have the paper or film backing.

HOOK AND LOOP AND PSA: WHAT HOLDS THE SANDING

DISK TO THE PAD.

Hook & Loop

: The sanding disk as backed with a fabric nap (loops)

that interlocks with a grid of posts (hooks) on the sander’s pad. The

advantages are paper reusability and cooler interface between paper

and work.

PSA:

Pressure Sensitive Adhesive is applied to the back of the sanding disc and adheres to the sanding pad (Not the same pad that carries Hook & Loop paper). The advantage is cost. The major disadvantage is the tendency of PSA backed papers to adhere permanently to the pad if left on after sanding. Why does this happen? The main

culprit is heat. During sanding the pad and paper heat up. This causes the adhesive to flow into all the ridges on the vinyl pad and form a

English

Page 9

tight bond. If you remove the paper soon after you are finished sanding you don’t allow the adhesive to set. If you leave it on for a couple

of days the adhesive sets and has more strength than the paper carrier, causing the paper to tear and leaving you with a difficult clean up

job. One more disadvantage: If you do small sanding jobs and don’t

wear out the paper you cannot reuse it and tend to waste more paper.

SANDING

THE BASIC RULES: Which ones to break and which ones not to.

Always start with the coarsest grit first. Don’t break this rule. The

scratches get smaller as the grit number gets larger and the quality of

the finish generally improves. When you change grits be particular

about cleaning the surface that you are finishing. An 80 grit particle

floating on your work under your 220 grit paper will leave 80 grit

scratches. The best way to avoid this is to vacuum the work and then

carefully wipe down the work with a tack rag.

The random orbit sander action is equally applied across the grain and

with the grain. Since the scratch mark is small and random in all directions, the ability of the eye to see a scratch is greatly reduced.

Always wear a mask to avoid breathing the dust. NEVER BREAK

THIS RULE. We have engineered the tool to collect a majority of the

dust created in the sanding process but the tool does not capture it all.

To improve the capture rate use a vacuum but ALWAYS wear a dust

mask.

SOME OTHER HINTS FOR A BETTER FINISH

A random orbit sander is much more aggressive than other similarly

sized orbital tools so you may want to consider the next finer grit when

you start to sand your project.

Since the random orbit action makes a short scratch, you may find that

a project doesn’t require as many grit steps. A lot of professional cabinet makers only use 80, 120, and 150 grit on their work with satisfactory results. If in doubt about how the finish will take to your sanded

surface, wipe the surface with some paint thinner. Defects will show

up darker than the surrounding wood.

Careful inspection of the work prior to the finishing operation may

reveal dents. Try to correct these problems by raising the dent (a

hot iron and wet rag will do this) or carefully sand a large area

around the dent. If you vigorously sand the dent, you may create a

cupped surface.

When you are satisfied with the sanding job and you have finished

sanding with your finest grit, raise the grain by dampening the wood

with a wet rag. When the wood has dried and you are ready to apply

the finish, resand lightly to take off the wood fibers raised by the water.

Vac and tack the surfaces and immediately apply the first coat of finish before the wood gets dirty.

WOOD: Some important characteristics of wood

Hard grain and soft grain

Wood has hard grain and soft grain. Hard grain is typically the product of summer growth and soft grain the product of spring. All sanders

will remove more soft grain than hard grain and since the random

orbit sander is more aggressive, it will remove it that much more

quickly. Extended sanding on a piece of fir for example, will produce

a noticeably uneven finish. This is a good reason to correct flaws

before sanding.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, please contact D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286, call 1-800-4-D

EWALT (1-800-433-9258) or visit our website

www.dewalt.com.

CAUTION: The use of any other accessory not recommended for

use with this tool could be hazardous.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

7

English

Page 10

8

For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258).

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by nor-

mal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT Power Tool, Laser, or Nailer for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund

– no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in

Latin America. For products sold in Latin America, see country specific warranty information contained either in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

EWALT for a free

replacement.

English

Page 11

9

1

R

Français

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO :

1 800 4-DEWALT (1 800 433-9258)

Importantes mesures de sécurité

(pour tous les outils)

AVERTISSEMENT : Afin de réduire les risques d’incendie, de

secousses électriques ou de blessures lorsqu’on utilise des

outils électriques, il faut toujours respecter les mesures de sécurité

suivantes.

LIRE TOUTES LES DIRECTIVES

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES.

Éviter tout contact avec des objets mis à la terre, comme des

tuyaux, radiateurs, cuisinières, réfrigérateurs et autres objets du

genre.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail et il faut les empêcher de toucher à l’outil

ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans

un endroit sec, situé en hauteur ou fermé à clé, hors de la portée

des enfants.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr et

efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil

ou d’un accessoire le rendement d’un outil de fabrication plus

robuste. Se servir de l’outil selon l’usage prévu (par exemple, ne

pas se servir d’une scie circulaire pour couper des branches

d’arbres ou des bûches).

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples et des bijoux qui peuvent être happés par les

pièces en mouvement. Porter des gants de caoutchouc et des

chaussures à semelle antidérapante pour travailler à l’extérieur.

Protéger la chevelure si elle est longue. Se tenir éloigné des évents

puisque ces derniers pourraient camoufler des pièces mobiles.

DISQUE DE PONÇAGE

(DE TYPE BOUCLES ET CROCHETS - MODÈLES DW442 ET DW443)

(AUTOCOLLANT - MODÈLES DW441 ET DW444)

SAC À POUSSIÈRE

RÉGULATEUR DE

VITESSE

(MODÈLES DW443

ET DW444)

INTERRUPTEUR

ÉCRAN ANTIPOUSSIÈRE

Page 12

10

Français

• PORTER DES LUNETTES DE SÉCURITÉ. Porter également un

masque respiratoire si le travail de coupe produit de la poussière.

• NE PAS MANIPULER LE CORDON DE FAÇON ABUSIVE. Ne

pas transporter l’outil par le cordon ni tirer sur ce dernier pour le

débrancher de la prise. Éloigner le cordon des sources de chaleur,

des flaques d’huile et des arêtes tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides ou

d’un étau. On peut alors se servir des deux mains pour faire fonctionner l’outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres pour

qu’ils donnent un rendement supérieur et sûr. Suivre les directives

concernant la lubrification et le remplacement des accessoires.

Inspecter régulièrement le cordon de l’outil et le faire réparer au

besoin à un atelier d’entretien autorisé. Inspecter régulièrement

les cordons de rallonge et les remplacer lorsqu’ils sont endommagés. S’assurer que les poignées sont toujours propres, sèches

et libres de toute tache d’huile ou de graisse.

• DÉBRANCHER LES OUTILS NON UTILISÉS. Respecter cette

mesure lorsqu’on ne se sert pas de l’outil, ou qu’on doit le réparer

ou en changer un accessoire (comme une lame, un foret ou un

couteau).

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de véri-

fier si les clés de réglage ont été retirées avant de faire démarrer

l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur l’interrupteur lorsqu’on transporte l’outil. S’assurer que

l’interrupteur est à la position hors circuit lorsqu’on branche l’outil.

• CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR.

Lorsque l’outil est utilisé à l’extérieur, ne se servir que d’un cordon

de rallonge conçu pour l’extérieur et portant la mention appropriée.

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de l’outil lorsqu’on est fatigué.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Vérifier l’alignement

et les attaches des pièces mobiles, le degré d’usure des pièces et

leur montage, ainsi que tout autre facteur susceptible de nuire au

bon fonctionnement de l’outil. Faire réparer ou remplacer tout protecteur ou toute autre pièce endommagée dans un centre de service autorisé, sauf si le présent guide fait mention d’un avis contraire. Confier le remplacement de tout interrupteur défectueux à

un centre de service autorisé. Ne jamais se servir d’un outil dont

l’interrupteur est défectueux.

• NE PAS UTILISER les outils portatifs électriques dans des endroits

où l’atmosphère contient des vapeurs combustibles ou explosives.

Les étincelles que produit le moteur en marche pourraient enflammer ces produits.

Mesures de sécurité propres aux

ponceuses

• Toujours porter des lunettes de sécurité ainsi qu’un respirateur

lorsqu’on effectue des travaux de ponçage.

• Il n’est pas conseillé de poncer des surfaces recouvertes de pein-

ture à base de plomb. Consulter la page 15 pour connaître les

directives particulières portant sur le ponçage des surfaces recouvertes de peinture.

• Ne pas utiliser l’outil sans l’écran antipoussière.

• Ne pas utiliser cet outil pendant des périodes prolongées. Les

vibrations causées par l’action de fonctionnement de l’outil peuvent

blesser en permanence les doigts, les mains et les bras. Porter des

gants pour amortir les vibrations, faire des pauses fréquentes et

limiter le temps d’utilisation quotidien de l’outil.

AVERTISSEMENT : Certains outils, tels que les sableuses élec-

triques, les scies, les meules, les perceuses ou certains autres outils

de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le système reproductif.

Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

Page 13

11

Français

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la

fréquence avec laquelle on effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit bien ventilé et

utiliser l’équipement de sécurité approprié tel un masque anti-poussières spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par

cet outil ou autres outils électriques. Porter des vêtements de

protection et nettoyer les parties exposées du corps avec de

l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la pous-

sière susceptible de causer des dommages sérieux et permanents au

système respiratoire. Toujours utiliser un appareil respiratoire antipoussières approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé du visage et du corps.

MISE EN GARDE : Porter un dispositif de protection person-

nel anti-bruit approprié durant l’utilisation. Sous certaines condi-

tions et pendant toute la durée de l’utilisation, le bruit émanant de ce

produit pourrait contribuer à la perte d’audition.

Double isolation

Les outils à double isolation comportent deux couches distinctes

d’isolant électrique ou une double épaisseur d’isolant qui protègent

l’utilisateur contre les risques de blessures provenant du système

électrique de l’outil. Ce système de double isolation élimine le besoin

de mettre les outils à la terre. En effet, l’outil est muni d’une fiche à

deux broches, ce qui permet d’utiliser une rallonge ordinaire sans

avoir à se soucier d’assurer la mise à la terre.

NOTE : La double isolation ne dispense pas des mesures de sécurité

normales lors de l’utilisation de l’outil. Elle vise à procurer une pro-

tection supplémentaire contre les blessures que peut entraîner une

défectuosité de l’isolant électrique à l’intérieur de l’outil.

MISE EN GARDE : Pour réparer tout outil, N’UTILISER QUE DES

PIÈCES DE RECHANGE IDENTIQUES. Réparer ou remplacer les

cordons endommagés.

Fiche polarisée

Le produit est muni d’une fiche polarisée (une lame plus large que

l’autre) afin de minimiser les risques de secousses électriques. Ce

genre de fiche n’entre que d’une façon dans une prise polarisée.

Lorsqu’on ne peut insérer la fiche à fond dans la prise, il faut tenter de

le faire après avoir inversé les lames. Si la fiche n’entre toujours pas

dans la prise, il faut communiquer avec un électricien certifié qui

installera une prise polarisée appropriée. Il ne faut pas modifier ni

remplacer cette fiche.

Cordons de rallonge

S’assurer que le cordon de rallonge est en bon état. Lorsqu’on se sert

d’un cordon de rallonge, s’assurer qu’il est de calibre approprié pour

la tension nécessaire au fonctionnement de l’outil. L’utilisation d’un

cordon de calibre inférieur occasionne une baisse de tension entraînant une perte de puissance et la surchauffe. Le tableau indique le

calibre approprié selon la longueur du cordon et les mentions de la

plaque signalétique de l’outil. En cas de doute, utiliser un cordon de

calibre supérieur. Le chiffre indiquant le calibre est inversement proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à

150

240 V De 0 à 50 De 51 à 100 De 101 à 200 De 201 à 300

Intensité

Au Au Calibre de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

Page 14

12

CONSERVER CES MESURES

À TITRE DE RÉFÉRENCE

Moteur

Veiller à ce que la tension d’alimentation soit conforme aux exigences

de la plaque signalétique de l’outil. La mention 120 volts c.a. signifie

que l’outil fonctionne seulement sur une alimentation en courant alternatif, jamais en courant continu.

Une baisse de tension de plus de 10 p. 100 entraîne une perte de

puissance et la surchauffe. Tous les outils sont essayés avant de quitter l’usine. Lorsque celui-ci refuse de fonctionner, vérifier la source de

courant électrique.

Installation des disques de ponçage

La ponceuse est conçue pour utiliser des disques de ponçage de 6 po

percés de 6 trous pour le dépoussiérage.

Type boucles et crochets (Modèles DW442 et DW443)

Autocollants (Modèles DW441 et DW444)

Faire ce qui suit pour installer le papier sur le tampon de ponçage:

1. Mettre la ponceuse hors tension et la débrancher.

2. Retourner la ponceuse de sorte que le tampon de ponçage se

trouve sur le dessus.

3. (Modèles DW441 et DW444 seulement) Enlever la poussière des

surfaces en vinyle du tampon.

4. Retenir le tampon d’une main pour l’empêcher de tourner.

5. De l’autre main, aligner le disque sur le tampon et le placer

directement sur ce dernier (fig. 1).

Interrupteur

(Voir la fig. 2.) Pour mettre l’outil en marche, il suffit de faire glisser

l’interrupteur vers l’avant (pour découvrir le symbole «|»). Pour mettre l’outil hors tension, il suffit de faire glisser l’interrupteur vers l’arrière

(pour découvrir le symbole «O»). Avant de brancher l’outil, s’assurer

que l’interrupteur est en position d’arrêt.

Français

1

FIG. 1

DISQUE DE PONÇAGE

FIG. 2

MARCHE

ARRÊT

RÉGULATEUR DE VITESSE

( RÉGLAGES DE 1 À 5)

FIG. 3

TAMPON DE PONÇAGE

Page 15

Régulateur de vitesse

(Modèles DW443 et

DW444 seulement)

Le régulateur de vitesse (constitué de cinq réglages consécutifs) permet à l’utilisateur d’augmenter ou de diminuer la vitesse de l’outil sur

une gamme de 4 000 à 6 800 orbites à la minute. La vitesse optimale

à utiliser pour chaque application dépend des goûts personnels de

l’utilisateur. Il est conseillé d’essayer cette fonction sur des échantillons afin de déterminer la meilleure combinaison en vue de l’obtention

du fini et du taux de ponçage voulus. Habituellement, on utilise un

régime élevé pour poncer des matériaux durs et un faible régime, pour

les matériaux mous. Le taux de ponçage augmente avec le régime.

Système de dé poussiérage

La ponceuse est munie d’un sac à poussière qui ramasse la poussière

généreé par les travaux de ponçage. Pour vider le sac, il faut d’abord

mettre l’outil hors tension et le débrancher. Tirer fermement sur le sac

tout en retenant la gaíne en caoutchouc (fig. 3). Vider le sac (il peut

être nécessaire de le retourner à l’envers).

NOTE: Ne jamais utiliser l’outil si le sac à poussière n’est pas en

place.

Remplacement du tampon de ponçage

Lorsque le tampon est usé, le remplacer comme suit (fig. 4).

1. Mettre l’outil hors tension et le débrancher.

2. Enlever les 4 vis à tête Torx qui se trouvent sous l’outil (utiliser un

tournevis Torx T20 ou un tournevis à lame plate).

3. Retirer le tampon.

4. Remettre en place le tampon et les vis en s’assurant que le disque

à système de finition contrôlé est bien aligné.

Fonctionnement

Pour utiliser la ponceuse, la saisir de la façon illustrée à la figure 5,

puis la mettre en marche. Déplacer l’outil en lui imprimant de longs

mouvements de va-et-vient le long de la surface à poncer et sans le

forcer.

13

Français

FIG. 4

4 VIS À TÊTE

TORX

DISQUE À SYSTÈME

DE FINITION CON-

TRÔLÉ

ALIGNER LES

ENCOCHES SUR

CELLES DE L’ÉCRAN

ANTIPOUSSIÈRE

TAMPON DE PONÇAGE

FIG. 5

Page 16

14

NOTE : Lorsqu’on appuie sur la ponceuse pendant la tâche, on minimise le taux de ponçage et on obtient une surface de qualité moindre.

L’emballage comprend une poignée latérale qui peut être utilisée avec

la ponceuse. Il suffit de la visser d’un côté ou de l’autre de l’outil en

enlevant au préalable la vis de plastique (fig. 6).

NOTE : Vérifier souvent la surface de travail, car la ponceuse enlève

rapidement les matériaux (surtout avec du papier abrasif à gros

grains).

Le mouvement orbital excentrique de la ponceuse permet de poncer

dans le sens du grain ou dans tout autre angle dans la plupart des

cas. Pour optimiser le rendement, commencer à poncer avec du papier abrasif à gros grains et le remplacer graduellement par du papier

de plus en plus fin. Passer l’aspirateur et essuyer la surface avec un

chiffon entre chaque remplacement de papier.

Le taux de remplissage de la sac à poussière varie selon le type de

matériau poncé et la rugosité du papier abrasif. Pour optimiser les

résultats, vider souvent la sac.

Lorsqu’on ponce une surface peinte (voir les mesures supplémentaires à prendre lors du ponçage de peinture à la page 15), il se peut

que le papier abrasif se charge de peinture et bloque. Il est préférable

Français

FIG. 6

d’utiliser un pistolet chauffant pour enlever la peinture avant de sabler.

SE CONFORMER AUX MESURES DE SÉCURITÉ DU GUIDE

D’UTILISATION DU PISTOLET CHAUFFANT.

NOTE : (Modèles DW441 et DW444 seulement): Lorsqu’on utilise des

disques de ponçage autocollants, il faut enlever le disque peu après

les travaux. En effet, le disque autocollant est difficile à enlever si on

le laisse sur l’outil lorsqu’on range ce dernier. Le cas échéant, poncer

pendant quelques minutes afin de ramollir l’adhésif avant de remplacer le disque.

Mesures à prendre lors du ponçage de

peinture

1. IL N’EST PAS RECOMMANDÉ de poncer de la peinture à base de

plomb puisqu’il est difficile d’en maîtriser la poussière contaminée. Ce

genre de ponçage présente de sérieux risques d’empoisonnement au

plomb pour les femmes enceintes et les enfants.

2. Puisqu’il est difficile de déterminer si la peinture renferme du plomb

sans en faire une analyse chimique, il est conseillé de se conformer

aux mesures suivantes lors du ponçage de tout type de peinture.

SÉCURITÉ PERSONNELLE

a. Ne laisser aucun enfant ni aucune femme enceinte entrer dans la

pièce où il y a ponçage de peinture jusqu’à ce que la pièce soit nettoyée.

b. Toute personne entrant dans la pièce de travail devrait porter un

masque ou un respirateur. L’utilisateur devrait en remplacer le filtre

chaque jour ou dès qu’il éprouve de la difficulté à respirer.

NOTE : Il faut seulement utiliser des masques conçus pour le travail

en présence de poussières ou de vapeurs de plomb. Les masques

ordinaires ne sont pas conçus à cet effet. Consulter le quincaillier pour

choisir le masque approprié.

c. IL EST DÉCONSEILLÉ DE MANGER, DE BOIRE ET DE FUMER

dans la pièce de travail afin de ne pas ingérer de particules contaminées. L’utilisateur doit se laver et se nettoyer AVANT de manger, de

boire ou de fumer. Il ne faut pas laisser dans la pièce de travail de la

Page 17

15

Français

nourriture, des boissons ou des cigarettes car de la poussière pourrait

se déposer sur ces articles.

PROTECTION DE L’ENVIRONNEMENT

a. Il faut enlever la peinture de manière à produire un minimum de pous-

sière.

b. Il faut sceller la zone de travail à l’aide de feuilles de plastique d’une

épaisseur minimale de 4 mils.

c. Il faut poncer de façon à réduire la propagation de la poussière hors

de la pièce de travail.

NETTOYAGE ET DÉCHETS

a. Il faut bien aspirer toutes les surfaces de la pièce de travail et les net-

toyer à fond chaque jour pendant la durée des travaux. Il faut remplacer fréquemment le filtre de l’aspirateur.

b. Ramasser les feuilles de plastique et les jeter avec la poussière et les

autres débris dans des contenants étanches à placer avec les ordures

ménagères pour l’enlèvement.Tenir les enfants et les femmes

enceintes à l’écart de la zone de travail pendant les travaux de nettoyage.

c. Il faut nettoyer à fond les jouets, les meubles et les ustensiles des

enfants avant de les utiliser de nouveau.

Lubrification

L’outil comporte des roulements autolubrifiants qui ne nécessitent

aucune lubrification périodique. Il est toutefois conseillé de porter

l’outil, une fois l’an, à un centre de service pour une inspection et un

nettoyage complets.

Nettoyage

S’assurer que l’outil est toujours propre en l’essuyant avec un chiffon

propre et en y soufflant de l’air après chaque 5 heures d’utilisation. Ne

pas utiliser de produits chimiques puissants ni de solvants pour nettoyer l’outil. Ce genre de produits peut grandement endommager les

polymères utilisés dans la fabrication de l’outil. Lorsqu’on enroule sys-

tématiquement le cordon autour de l’outil au moment du rangement,

faire des boucles lâches de façon à ne pas faire plier la bague antitraction. On prévient de la sorte la défaillance prématurée du cordon.

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations,

l'entretien et les réglages (y compris l'inspection et le remplacement de

la brosse) doivent être réalisés par un centre de réparation en usine

D

EWALT, un centre de réparation autorisé DEWALT ou par un person-

nel de réparation professionnel. Toujours utiliser des pièces de

rechange identiques.

Utilisation

PAPIER ABRASIF - TYPES DE GRAINS

Abrasifs naturels

Le silex est le plus malléable (7 à l’échelle de Mohs*) des abrasifs

naturels communs. Il est de teinte ocre et très bon marché.

Le grenat est plus dur que le silex (7,5 à l’échelle de Mohs) et on le

reconnaît facilement à sa couleur orangée claire. Même s’il ne s’agit

pas de l’abrasif le plus dur, son type de fracture procure un très bon

tranchant pour le travail du bois.

L’émeri, même s’il est plus dur que le grenat (9 à l’échelle de Mohs),

a des rebords émoussés qui en font un abrasif de moindre qualité

pour le ponçage. On s’en sert essentiellement pour le polissage des

métaux.

Abrasifs fabriqués

L’oxyde d’aluminium blanc est extrêmement dur (12 à l’échelle de

Mohs) et durable ce qui en fait un bon abrasif à utiliser avec la ponceuse orbitale excentrique. Le terme «blanc» ne décrit pas la couleur

de l’abrasif mais la façon dont il est fabriqué. On en retrouve partout

et il est offert dans une vaste gamme de couleurs en raison de l’utilisation répandue des teintures. Les lubrifiants au stéarate du papier

améliorent également le rendement en minimisant le dégagement de

chaleur et le taux de blocage du papier. Le carbure de silicium con-

Page 18

stitue l’abrasif le plus dur (13 à l’échelle de Mohs) qu’on retrouve sur

le marché, après le diamant industriel, mais il n’est pas aussi résistant

que l’oxyde d’aluminium. Il casse facilement et offre des arêtes tranchantes pour toute la durée du papier abrasif. Cette caractéristique

d’«autoaffûtage» fait du carbure de silicium un abrasif remarquable

pour le ponçage mais en limite la durée.

* L’échelle de Mohs sert à mesurer la dureté des minéraux. On y

classe le diamant à 15 (le plus dur) et le talc à 1.

COUCHE OUVERTE OU FERMÉE

Les abrasifs sont fixés au papier à l’aide de colle. Lorsque les grains

sont gros (60 ou 80), le pourcentage de l’enduit est habituellement

réduit entre 60 et 70 p. 100 de la surface du papier. On augmente ainsi

la durée du papier en en réduisant le blocage. Il s’agit alors d’une

couche ouverte; forme sous laquelle on retrouve la plupart des

papiers abrasifs à gros grains sur le marché. Dans le cas des grains

fins, on fixe au moins 90 p. 100 d’abrasifs sur le papier. C’est ce qu’on

appelle une couche fermée. Puisque les particules sont plus fines, le

papier a moins tendance à se charger et à bloquer.

GROSSEUR DES GRAINS

Il existe plusieurs systèmes de classement. Le système le plus utilisé

consiste en celui qui mesure la dimension des éléments (déterminée

par tamisage). Le nombre qui apparaît à l’arrière du disque de

ponçage correspond à la dimension du tamis. Par exemple, un papier à grain 120 est constitué des grains qui passent dans un tamis

ayant 120 trous par pouce linéaire. Il y a 14 400 trous (120 sur 120)

par pouce carré. Plus le nombre accompagnant le terme «grain» est

élevé, plus la particule est fine. On trouve des papiers de grain 35

à 600, et depuis peu, il s’en fait jusqu’à 1 200.

PAPIER ET PELLICULE

Papier - Le matériau le plus élevé pour soutenir les abrasifs est le

papier. Celui-ci est classé en fonction de son poids. Du papier de

classe A, le plus commun, est le plus léger utilisé et il offre une bonne

durabilité et une bonne souplesse dans la plupart des utilisations. Il y

16

Français

a également du papier de classes C, D, E et F. Le désavantage du

papier consiste en sa faible rigidité mécanique. Puisque les fibres du

papier cèdent au cours du ponçage, l’abrasif ne tient pas en place et

certains tranchants ne s’engagent pas dans la pièce à ouvrer. L’avantage tient dans le prix.

Pellicule

- Les disques de ponçage sur pellicule parent aux désavantages du papier. La pellicule est plus rigide que le papier. Mais elle est

également plus chère, tout en offrant un rendement supérieur des

abrasifs.

Tissu et fibre vulcanisée

- Ces matériaux sont assez difficiles à trouver et servent dans des applications particulières. On trouve surtout

des abrasifs sur papier ou sur pellicule.

Disques à boucles et crochets et disques autocollants

- Systèmes

de fixation du disque

Boucles et crochets

- L’arrière du disque consiste en un tissu à

boucles qui se fixe sur le tissu à crochets du tampon. Ce système est

avantageux puisqu’on peut réutiliser le papier. De plus, l’interface

entre le papier et la pièce à poncer est plus fraîche.

Disque autocollant

- L’arrière du disque de ponçage est enduit d’un

adhésif sensible à la pression pour adhérer à la surface du tampon

(pas celui qui accepte un disque à boucles). L’avantage réside dans

le coût. Le principal désavantage est la tendance des disques autocollants à adhérer en permanence au tampon si on oublie de les

enlever après le ponçage. Quelle en est la raison? Il s’agit de la

chaleur. Pendant le ponçage, le tampon et le papier se réchauffent.

L’adhésif du disque coule alors dans les fissures du tampon en vinyle

et forme un lien solide. Si on enlève le papier peu après les travaux,

l’adhésif n’a pas le temps de prendre. Par contre, si on oublie

d’enlever le papier, l’adhésif a le temps de prendre. Le papier risque

alors de déchirer et le nettoyage de la ponceuse sera difficile. Un

autre désavantage : lorsqu’on effectue de petits travaux de ponçage

et qu’on n’utilise pas tout le papier, on ne peut pas le réutiliser. On

gaspille alors plus de papier.

Page 19

17

Français

PONÇAGE

MESURES FONDAMENTALES

Toujours commencer avec l’abrasif à gros grains. Ne pas déroger à

cette règle. Plus le numéro de grain est élevé, plus les égratignures

sont fines; ce qui améliore généralement la qualité du fini. Lorsqu’on

change de grosseur de grains, il ne faut pas oublier de nettoyer la surface de travail. En effet, s’il reste de l’abrasif à grain 80 sur la surface

lorsqu’on ponce cette dernière avec du papier 220, on risque

d’égratigner la surface avec les grains 80.

C’est pourquoi il est conseillé de passer l’aspirateur sur la surface puis

de bien l’essuyer avec un chiffon.

La ponceuse à mouvement orbital excentrique agit uniformément sur

le grain. Puisque les égratignures sont tellement fines et excentriques,

il est difficile de les voir à l’œil nu.

Toujours porter un masque afin de ne pas respirer la poussière. NE

JAMAIS DÉROGER À CETTE RÈGLE. La ponceuse est conçue

pour ramasser la plupart de la poussière générée par les travaux mais

elle ne capture pas toute la poussière. Pour améliorer le dépoussiérage, utiliser un aspirateur. Il faut également TOUJOURS porter un

masque.

AUTRES CONSEILS PRATIQUES POUR OPTIMISER LES

RÉSULTATS

La ponceuse orbitale excentrique agit plus rapidement qu’une ponceuse orbitale ordinaire, il vaut mieux choisir un abrasif plus fin qu’à

l’habitude pour commencer les travaux.

Puisque le mouvement orbital excentrique fait de courtes

égratignures, il se peut que la tâche nécessite moins de changement

de grosseur de grain. Un bon nombre d’ébénistes professionnels

n’utilise que du papier 80, 120 et 150 pour obtenir des résultats satisfaisants. En cas de doute sur la qualité du fini, essuyer la surface avec

du solvant. Les défauts apparaissent alors plus foncés que le reste de

la surface.

Avant la finition, on peut déceler des entailles grâce à une bonne

inspection. Essayer de corriger les défauts (à l’aide d’un fer chaud et

d’un chiffon humide) ou poncer avec soin une grande surface autour

de l’entaille. Si on ponce l’entaille avec vigueur, la surface risque de

se creuser.

À la fin des travaux de ponçage, soulever le grain en humectant le

bois avec un chiffon humide. Lorsque le bois est sec et qu’on est prêt

à l’enduire de fini, poncer légèrement pour enlever les fibres

soulevées par l’eau. Passer l’aspirateur, essuyer les surfaces et

enduire sans tarder la première couche de fini avant que le bois se

salisse.

BOIS : Caractéristiques importantes

Grain dur et tendre

Le bois comporte des grains durs et tendres. Le grain dur résulte de

la croissance estivale et le grain tendre est le produit de la croissance

printanière. Toutes les ponceuses retirent plus de grains tendres que

de grains durs. Puisque la ponceuse orbitale excentrique agit plus

rapidement, elle en enlève beaucoup plus. C’est pourquoi un ponçage

prolongé sur une pièce de résineux donne un fini inégal. Il s’agit d’une

bonne raison de corriger les défauts avant les travaux de ponçage.

Accessoires

Les accessoires recommandés pour être utilisés avec votre outil sont

disponibles chez votre concessionnaire ou le centre de réparation

autorisé de votre région. Si vous avez besoin d'assistance pour

trouver tout accessoire, veuillez communiquer avec D

EWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

États-Unis, composer le 1(800) 4-D

EWALT (1-800-433-9258) ou

visiter notre site Web à www.dewalt.com.

MISE EN GARDE : L’utilisation de tout autre accessoire non

recommandé pour l’outil peut être dangereuse.

MISE EN GARDE : NE PAS UTILISER DE COIFFE À POLIR À

FICELLE AVEC LA PONCEUSE. LA FICELLE EN MOUVEMENT

PRÉSENTE DES RISQUES DE BLESSURES GRAVES AUX

DOIGTS.

Page 20

18

Français

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un

défaut de matériel ou de fabrication pour une période de trois ans à

compter de la date d’achat. La présente garantie ne couvre pas les

pièces dont la défectuosité a été causée par une usure normale ou

l’usage abusif de l’outil. Pour obtenir de plus amples renseignements

sur les pièces ou les réparations couvertes par la présente garantie,

visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-D

EWALT). Cette garantie ne s’applique pas aux accessoires et ne

vise pas les dommages causés par des réparations effectuées par un

tiers. Cette garantie confère des droits légaux particuliers à l’acheteur,

mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un état

ou d’une province à l’autre.

En plus de la présente garantie, les outils D

EWALT sont couverts par

notre :

CONTRAT D’ENTRETIEN GRATUIT D’UN AN

D

EWALT entretiendra l’outil et remplacera les pièces usées au cours

d’une utilisation normale et ce, gratuitement, pendant une période

d’un an à compter de la date d’achat, et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque raison que

ce soit, du rendement de l’outil électrique, du laser ou de la cloueuse

D

EWALT, celui-ci peut le retourner, accompagné d’un reçu, dans les

90 jours à compter de la date d’achat, pour obtenir un remboursement intégral, sans aucun problème.

AMÉRIQUE LATINE : Cette garantie ne s'applique aux produits vendus en Amérique latine. Pour ceux-ci, veuillez consulter les informations relatives à la garantie spécifique présente dans l'emballage,

appeler l'entreprise locale ou consulter le site Web pour les informations relatives à cette garantie.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE : Si vos étiquettes

d'avertissement deviennent illisibles ou sont manquantes, composez le

1-800-4-D

EWALT pour obtenir une étiquette de remplacement gratuite.

Page 21

19

Español

1

R

BASE DE LIJADO

(GANCHO Y ABRAZADERA - DW442 Y DW443)

(PSA: ADHESIVO SENSIBLE A LA PRESIÓN - DW441 Y DW444)

BOLSA

RECOLECTORA

DE POLVO

CONTROL DE VELOCIDAD

(DW443 Y DW444)

INTERRUPTOR DE ENCEN-

DIDO Y APAGADO

CUBIERTA

ESPECIFICACIONES

Tension de alimentación: 120 V/CA~

Potencia nominal: 192 W

Frecuencia de operación: 60 Hz

Consumo de corriente: 2,0A

Instrucciones importantes de seguridad

(Para todas las herramientas)

ADVERTENCIA: Es indispensable sujetarse a las precau-

ciones básicas de seguridad, con la finalidad de reducir el peligro de incendio, choque eléctrico y lesiones personales, en todas

las ocasiones en que se utilicen herramientas eléctricas. Entre estas

precauciones se incluyen la siguientes:

LEA TODAS LAS INSTRUCCIONES

• CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

• OTORGUE PRIORIDAD A LA ZONA DE TRABAJO. No deje las

herramientas eléctricas expuestas a la lluvia. No las utilice en

lugares inundados o mojados. Conserve bien iluminada la zona de

trabajo.

• PROTÉJASE CONTRA EL CHOQUE ELÉCTRICO. Evite el con-

tacto corporal con superficies aterrizadas, por ejemplo, tuberías,

radiadores, antenas y gabinetes de refrigeración.

• CONSERVE APARTADOS A LOS NIÑOS. Los visitantes deben

estar alejados de la zona de trabajo. No permita que los visitantes

toquen las herramientas o los cables de extensión.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las her-

ramientas que no se están utilizando deben guardarse en un lugar

seco y elevado o bajo llave fuera del alcance de los niños.

• NO FUERCE LA HERRAMIENTA. Esta cumplirá su función mejor

y con más seguridad a la velocidad y la presión para las que se

diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una her-

ramienta pequeña o a sus dispositivos de montaje en un trabajo de

tipo pesado. No emplee la herramienta en una tarea para la que

no se diseñó; por ejemplo, no recurra a una sierra circular para cortar ramas o troncos de árbol.

• VÍSTASE DE LA MANERA ADECUADA. No use ropas o artícu-

Page 22

con el dedo en el interruptor. Asegúrese que el interruptor está en

posición de “apagado” antes de conectar la unidad.

• CORDONES DE EXTENSIÓN PARA INTEMPERIE. Cuando

opere su herramienta a la intemperie, utilice únicamente cordones

de extensión diseñados y marcados para este fin. Encontrará información más detallada en el interior del manual.

• NO SE DISTRAIGA. Concéntrese en lo que está haciendo.

Recurra al sentido común. No opere ninguna herramienta si está

fatigado.

• VERIFIQUE LAS PARTES DAÑADAS. Antes de seguir emplean-

do cualquier herramienta, es indispensable verificar con mucho

cuidado que las guardas u otras partes dañadas puedan operar de

la manera adecuada para cumplir con su función. Verifique la alineación de las partes móviles, la firmeza con que deben encontrarse sujetas a sus montaduras, las partes rotas, las propias montaduras y cualesquiera otros detalles que pudieran afectar la

operación de la herramienta. Las guardas y otras partes que se

encuentren dañadas deberán cambiarse o repararse en un centro

de servicio autorizado, a menos que se diga otra cosa en el manual del usuario. Haga que se cambien los interruptores dañados en

un centro de servicio autorizado. No emplee ninguna herramienta

que tenga estropeado o inutilizado el interruptor.

• NO OPERE ninguna herramienta eléctrica portátil cerca de líqui-

dos inflamables ni atmósferas cargadas con gases explosivos. Los

motores de estas herramientas descargan chispazos en condiciones normales, y éstos pueden desencadenar la ignición de

gases y vapores combustibles.

Instrucciones especiales de seguridad

para lijadoras

• Siempre que lije utilice protección para los ojos y respirador.

• No se recomienda lijar pinturas con base de plomo. Vea en la pág

24 las precauciones adicionales que se deben tomar cuando lije

pintura.

• No opere la unidad sin la cubierta para polvo.

20

Español

los de joyería flojos, pues podrían quedar atrapados por las partes

móviles de las herramientas. Se recomienda el empleo de guantes

de caucho y calzado antiderrapante cuando se trabaje al aire libre.

Cúbrase bien la cabeza para sujetarse el cabello si lo tiene largo.

Las rejillas de ventilación cubren partes móviles y también deben

evitarse.

• COLÓQUESE ANTEOJOS DE SEGURIDAD. Póngase también

una mascarilla contra el polvo si lo produce la operación que va

a efectuar.

• TENGA CUIDADO CON EL CORDÓN ELÉCTRICO. Nunca lev-

ante la herramienta tomándola por el cordón, ni tire de éste para

desconectarlo del enchufe. Apártelo del calor y los objetos

calientes, las substancias grasosas y los bordes cortantes.

• SUJETE LOS OBJETOS SOBRE LOS QUE TRABAJE. Utilice

prensas o tornillos de banco para sujetar los objetos sobre los que

va a trabajar. Esto ofrece mayor seguridad que sujetar los objetos

con la mano, y además deja libres ambas manos para operar la

herramienta.

• MANTENGA EL EQUILIBRIO. Conserve en todo momento bien

apoyados los pies, lo mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas afi-

ladas y limpias para que funcionen mejor y con mayor seguridad.

Siga las instrucciones para lubricación y cambio de accesorios de

su unidad. Revise periódicamente el cordón eléctrico y hágalo

reparar o reemplazar por un centro de servicio si está dañado.

Cambie los cordones de extensión si están dañados. Conserve las

empuñaduras secas, limpias y libres de aceite y grasa.

• DESCONECTE Y APAGUE LAS HERRAMIENTAS cuando no las

use, antes de darles servicio y cuando cambie accesorios, tales

como discos, brocas y otros dispositivos de corte.

• RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera el

hábito de asegurarse que se han retirado las llaves de ajuste de

las herramientas antes de accionarlas.

• EVITE QUE LA HERRAMIENTA SE ACCIONE ACCIDENTAL-

MENTE. Nunca sostenga una herramienta que está conectada

Page 23

• No opere esta herramienta durante períodos largos de tiempo.

La vibración causada por la acción de operación de la herramienta

puede causar lesiones permanentes a sus dedos, manos y brazos.

Use guantes para un mejor amortiguamiento, descanse con

frecuencia y limite el tiempo diario de uso.

ADVERTENCIA: Parte del polvo creado al lijar, aserruchar, moler

o perforar con máquina, así como al realizar otras actividades de la

construcción, contiene substancias químicas que se sabe producen

cáncer, defectos congénitos u otras afecciones reproductivas.

Algunos ejemplos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de

albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la frecuencia

en que se haga este tipo de trabajo. Para reducir la exposición a esas

substancias químicas: trabaje en un área bien ventilada, y trabaje con

equipos de seguridad aprobados, tales como máscaras contra el polvo

especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con polvos originados por lijar,

aserrar, esmerilar, taladrar y otras actividades constructivas.

Vista ropas protectoras y lave las áreas expuestas con agua y

jabón. Permitir que el polvo se introduzca en su boca, ojos, o

dejarlo sobre la piel promueve la absorción de químicos dañinos.

ADVERTENCIA: La utilización de esta herramienta puede originar

polvo o dispersarlo, lo que podría causar daños graves y permanentes

al sistema respiratorio, así como otras lesiones. Siempre use protección respiratoria aprobada por NIOSH/OSHA, apropiada para su uso

en condiciones de exposición al polvo. Procure que las partículas no

se proyecten directamente sobre su rostro o su cuerpo.

PRECAUCION: Utilice la protección auditiva apropiada

durante el uso. Bajo ciertas condiciones de duración de uso, el ruido

producido por este producto puede contribuir a la pérdida auditiva.

21

Español

Doble Aislamiento

Las herramientas DOBLEMENTE aisladas se han elaborado de manera integral con dos capas separadas de aislamiento eléctrico o una

capa doble de aislamiento entre usted y el sistema eléctrico que contienen. Las herramientas construidas con este sistema de aislamiento

no requieren conectarse a tierra. Como resultado su herramienta está

equipada con una clavija de dos patas que le permite emplear cordones de extensión sin preocuparse por tener una conexión a tierra.

NOTA: El doble aislamiento no substituye a las precauciones normales

de seguridad cuando se opera esta herramienta. La finalidad de este

sistema de aislamiento es ofrecer a usted protección añadida contra

lesiones resultantes de fallas en el aislamiento eléctrico interno de la

herramienta.

PRECAUCIÓN: UTILICE SOLAMENTE REFACCIONES ORIGI-

NALES cuando haga servicio a cualquier herramienta. Repare o

reemplace los cordones eléctricos dañados.

Clavija polarizada

Este producto se suministra con una clavija polarizada (una de las

patas es más ancha que la otra). Esta clavija se ajusta a tomas de

corriente polarizadas (contactos) sólo de una manera. Si la clavija no

se ajusta completamente a su toma de corriente, cambie las patas de

lado. Si aún así no se ajusta, llame a un electricista calificado para

que le instale una toma de corriente polarizada. No modifique o cambie esta clavija de ninguna manera.

Cordones de extensión

Asegúrese que su cordón de extensión esté en buenas condiciones.

Cuando utilice un cordón de extensión, asegúrese de usar uno con el

calibre necesario para soportar la corriente que su producto necesita.

Un cordón de extensión de menor calibre al necesario ocasionará una

caída en el voltaje de la línea, produciendo pérdida de potencia y

sobrecalentamiento. La tabla muestra el calibre correcto para utilizarse de acuerdo de la longitud del cordón y el amperaje nominal

que se encuentra en la placa de identificación del producto. Si tiene

dudas, utilice el calibre inmediato superior. Mientras más pequeño es

el número del calibre, mayor capacidad tiene el cordón.

Page 24

22

Español

figura 1

DISCO DE LIJA

figura 2

ENCENDIDO

APAGADO

CONTROL DE VELOCIDAD

(5 POSICIONES PROGRESIVAS)

figura 4

4 TORNILLOS

HEXAGONALES

ANILLO

CFS

HAGA COINCIDIR LAS

MUESCAS CON LAS DE LA

CUBIERTA

BASE DE LIJADO

BASE

1

figura 3

figura 5

figura 6

Page 25

23

Español

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7.6 7.7-15.2 15.3-30.4 30.5-45.7

240V 0-15.2 15.3-30.4 30.5-60.9 70-91.4

Amperaje

Más No más AWG

de de

0 - 6 18 16 16 14

6- 10 18 16 14 12

GUARDE ESTAS INSTRUCCIONES

PARA FUTURAS REFERENCIAS

Motor

Asegúrese que su toma de corriente concuerde con las especificaciones

de la placa de identificación.120 CA significa que su herramienta solamente se puede operar con corriente alterna y nunca con corriente directa. Disminuciones en el voltaje mayores al 10% causarán pérdida de

potencia y sobrecalentamiento. Todas las herramientas se prueban en la

fábrica; si esta herramienta no funciona, verifique la toma de corriente.

Colocación de los discos de lija

Su lijadora está diseñada para usar discos de lija de 15 cm (6") con

seis perforaciones para extracción de polvo.

Gancho y abrazadera (DW442 y DW443)

ASP - Adhesivo Sensible a la Presión (DW441 y DW444)

Para colocar la lija en la base de lijado:

1. Apague y desconecte la herramienta.

2. De la vuelta a la lijadora de manera que la base de lijado quede

boca arriba.

3. (Sólo DW441 y DW444) Elimine el polvo de la superficie de vinil

de la base.

4. Sujete la base con una mano para evitar que gire.

5. Con la otra mano, haga coincidir las perforaciones y coloque el

disco directamente sobre la base (figura 1).

Interruptor

(Ver figura 2) Para encender la unidad, deslice el interruptor hacia

adelante (el símbolo “I” quedará visible). Para apagar la unidad,

deslice el interruptor hacia atrás (el símbolo “O” quedará descubierto).

Antes de conectar la herramienta, asegúrese que el interruptor está

en la posición de apagado.

Control de velocidad

(sólo DW443 y DW444)

El control de velocidad (5 posiciones progresivas) le permite incrementar o disminuir la velocidad desde 4000 hasta 6800 órbitas por

minuto. La posición óptima para cada aplicación depende en gran

parte de las preferencias personales. Quizá usted desee experimentar en una pieza de desperdicio para determinar la velocidad que le

proporcione la mejor combinación de calidad de acabados y velocidad de remoción de material para su aplicación. Generalmente, usted

utilizará una posición más alta en materiales con mayor dureza y una

posición más baja en materiales suaves. La cantidad de material

removido aumenta proporcionalmente a la velocidad.

Recolección de Polvo

Su lijadora está equipada con una bolsa-filtro de tela para recolectar

el polvo generado durante el lijado. Para vaciar la bolsa recolectora,

primero apague y desconecte la herramienta. Tire firmemente de la

bolsa mientras sostiene la unidad por el protector de goma (figura 3).

Vacíe la bolsa (puede voltear el interior hacia afuera si gusta.)

NOTA: Nunca opere esta herramienta a menos que la bolsa recolectora de polvo esté en su posición.

Reemplazo de la base de lijado

Cuando la base se haya desgastado, siga este procedimiento para

reemplazarla. (Vea la figura 4)

1. Apague y desconecte la herramienta.

2. Quite los 4 tornillos hexagonales que se encuentran en la parte

inferior de la herramienta. (utilice un dado T20 o un destornillador

de punta plana.)

Page 26

NOTE: Cuando utilice discos de lija con ASP (adhesivo sensible a la

presión) es necesario remover el disco lo más pronto posible despues

de la operación. Es más difícil remover los papeles ASP si se dejan

en la herramienta cuando se guarda. Para facilitar la remoción de lijas

ASP, lije durante algunos minutos para suavizar el adhesivo del

respaldo antes de cambiar este último.

Precauciones a tomar en cuenta cuando

lije pintura

1. NO SE RECOMIENDA el lijado de pinturas con base de plomo

debido a la dificultad para controlar el polvo contaminado. El

mayor peligro de envenenamiento por plomo es para niños y

mujeres embarazadas.

2. Ya que es difícil identificar si una pintura contiene plomo o no sin

efectuar un análisis químico, recomendamos que tenga en cuenta las siguientes precauciones cuando lije cualquier tipo de pintura:

SEGURIDAD PERSONAL

a. No permita que entren al área de trabajo niños ni mujeres

embarazadas cuando lije pintura hasta que haya terminado de

asear el lugar.

b. Se recomienda el uso de máscaras o respiradores para todas las

personas que entren al área de trabajo. El filtro se debe reemplazar diariamente o cuando el usuario tenga dificultad para respirar.

NOTA: Sólo deben utilizarse mascaras adecuadas para trabajo

con polvo y vapores de pintura. Las mascaras ordinarias para pintura no ofrecen esta protección. Vea a su distribuidor de herramienta local para conseguir la máscara adecuada.

c. NO COMA, BEBA O FUME en la zona de trabajo para evitar

ingerir partículas de pintura contaminadas. Los usuarios deberán

lavarse y limpiarse ANTES de comer, beber o fumar. No deben

dejarse artículos para comer beber o fumar en el área de trabajo

donde el polvo se asentaría en ellos.

24

Español

3. Quite la base.

4. Reemplace la base y coloque los tornillos, asegurándose que el

disco quede bien alineado.

Operación

Para operar su lijadora, tómela como se muestra en la figura 5 y

enciéndala. Haga movimientos largos y consistentes sobre la superficie que esté lijando, permitiendo que la lijadora haga el trabajo.

NOTA: Aplicar presión excesiva a la herramienta únicamente disminuye la cantidad de material removido y da como resultado una superficie de calidad inferior.

Se suministra una empuñadura lateral con su unidad para que la

emplee si lo desea. La empuñadura lateral puede atornillarse en

cualquiera de los lados de la herramienta quitando primero el tornillo

de plástico (figura 6).

NOTA: Asegúrese de revisar su trabajo constantemente, ya que su

lijadora es capaz de remover el material rápidamente, especialmente

con papel de grano grueso.

La acción orbital de su lijadora le permite lijar en cualquier ángulo en

relación con el hilo de la madera en la mayor parte de los trabajos.

Para producir el mejor acabado posible, comience con lija de grano

grueso (burdo) y cámbielo gradualmente por lijas con grano más fino.

Aspire y limpie la superficie con una franela entre los cambios de tipo

de lija.

El tiempo que tarda en llenarse el recolector de polvo varía según el

tipo de material que se lije y el tipo de grano de la lija. Para obtener

mejores resultados, vacíe el recolector frecuentemente.