Page 1

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZADE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUC-

TIVO ANTES DE USAR ELPRODUCTO.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Instructions for All Tools

WARNING! Read and understand all instructions. Failure to follow all instructions listed

below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adaptor plugs. Check with a qualified

electician if you are in doubt as to whether the outlet is properly grounded. If the tools

should electrically malfunction or break down, grounding provides a low resistance path to

carry electricity away from the user. Applicable only to Class I (grounded) tools.

• Double insulated tools are equipped with a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician

to install a polarized outlet. Do not change the plug in any way. Double insulation

eliminates the need for the three wire grounded power cord and grounded power supply

system. Applicable only to Class II (double insulated) tools.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A”

or “W.” These cords are rated for outdoor use and reduce the risk of electric shock.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size

18 AWG 18 AWG 16 AWG 16 AWG 14 A WG 14 AWG 12 AWG

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal

injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing , and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

Air vents often cover moving parts and should also be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss

of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

•

Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool. Such preventative safety measures reduce the risk of starting

the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on another tool.

SERVICE

•Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Additional Specific Safety Instructions for Grinders

• Always use proper guard with grinding wheel. A guard protects operator from broken wheel

fragments. Do not use Type 1 abrasive or diamond wheels without proper guarding.

• Accessories must be rated for at least the speed recommended on the tool warning label.

Wheels and other accessories running over rated speed can fly apart and cause injury. NEVER

use Type II (Flaring Cup Wheels) on this tool.

• Hold tool by insulated gripping surfaces when performing an operation where the cutting

tool may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

• Before using, inspect recommended accessory for cracks or flaws. If such a crack or flaw

is evident, discard the accessory. The accessory should also be inspected whenever you think

the tool may have been dropped.

• When starting the tool (with a new or replacement wheel installed) hold the tool in a well

protected area and let it run for one minute. If the wheel has an undetected crack or flaw, it

should burst in less than one minute. Never start the tool with a person in line with the wheel. This

includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment. If this occurs, stop the

tool and inspect the wheel.

• Always use Side handle. The side handle should always be used to maintain control of the tool

at all times.

• Clean out your tool periodically. Dust and grit containing metal particles often accumulate on

interior surfaces and could create an electric shock hazard.

• Never depress the spindle lock pin when the tool is runnung or coasting. Damage to

the gear and lock pin will result.

• Always use guards with depressed center grinding wheels.

• Clean your tool out periodically.

CAUTION: Wear appropriate personal hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

• The label on your tool may include the following symbols.

V......................volts A ................amperes

Hz....................hertz W................watts

min ..................minutes ..............alternating current

................direct current

n

o ..............no load speed

......................

Class II Construction …/min ........revolutions or reciprocation

......................earthing terminal

..................per minute

SAVE THESE INSTRUCTIONS

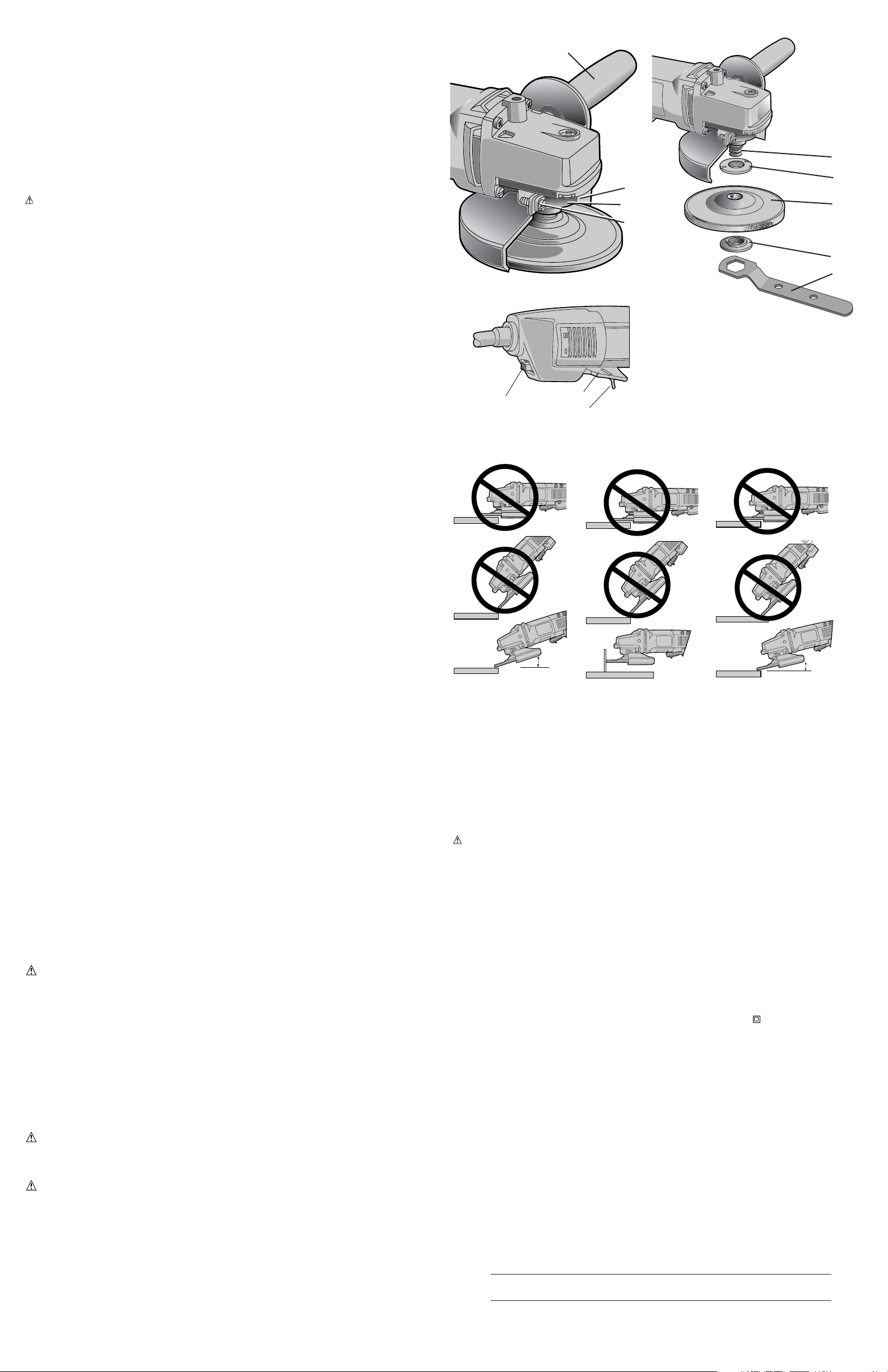

Fitting and Removing Guard (Fig. 1)

IMPORTANT:Unplug the tool before fitting or removing the guard. Use the tool without the guard

only when sanding or wire brushing.

FITTING GUARD:

1. Loosen screws (A), allowing the guard ring (B) to slide over the gear case hub (C).

2. Lugs on guard ring must align with groove in gear case hub.

3. Tighten screws to securely attach guard to gear case hub.

REMOVING GUARD:

Follow the above procedure n reverse order.

Installing Auxiliary Handle (Fig. 1)

The side handle (D) can be fitted to the left side, right side or top of the gear case in the threaded holes, as shown. The side handle should be used at all times to maintain complete control of

the tool.

Mounting Grinding Wheels (Fig. 2)

Grinding wheels are available as optional accessories. Before fitting a grinding wheel, disconnect

the plug from power source.

1. Locate the inner flange (A) on the machine spindle (B).

2. Place the wheel against the backing flange,(C) centering the grinding wheel on the backing

flange pilot.

3. Screw the threaded clamp nut onto the spindle (D).

4. Rotate the spindle by hand while pressing the spindle lock fully until it has found its locking

location and holds the spindle still (E).

5. Firmly tighten the threaded flange with the supplied hex wrench (F).

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

Printed in U.S.A. (MAR02-CD-1) Form No. 382900-01 DW402,402G Copyright © 2002

The following are trademarks for one or more D

EWALT power tools: the yellow and black color

scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box con-

figuration; and the array of lozenge-shaped humps on the surface of the tool.

DW402/DW402G

Heavy Duty Small Angle Grinders

Petites rectifieuses coudées de service intensif

Esmeriladoras de ángulo pequeño para trabajo pesado

Questions? See us in the World Wide Web at www.dewalt.com

Page 2

Mounting Edge Cutting Wheels (Fig. 2)

Type 27 Edge cutting wheels are available as optional accessories. Before fitting a cutting

wheel, unplug tool from the power source.

1. Locate the inner clamp nut (A) on the machine spindle (B).

2. Place the wheel against the flange,(C) centering the grinding wheel on the backing flange

pilot. (D).

4. Rotate the spindle by hand while pressing the spindle lock (E) fully until it has found its locking location and holds the the spindle still.

5. While depressing spindle lock button, firmly tighten the threaded flange with supplied hex

wrench (F).

Fitting a Sanding Backing Pad and Sanding Disc

Sanding backing pads are available as optional accessories. To fit the pad, unplug the tool, follow

instructions provided with the accessory.

CAUTION: Accessories must be rated for at least the speed recommended on the tool

warning label. Wheels and other accessories running over rated speed can fly apart and

cause injury.

Fitting Wire Cup Brushes

The wire cup brush or wire stringer bead wheel screws directly on the spindle of the machine

without the use of flanges.

Operation

Starting the Tool Fig. 3)

Always be sure the tool is not locked on before plugging it in.

1. To start the grinder, squeeze the paddle switch (A) after rotating the off-lock (B) out of the

way.

2. To turn the tool off, release the paddle.

3. The switch can be locked in the ON position by engaging the button (C) at the rear of the tool

after squeezing the paddle.

4. To turn the tool off while the lock-on feature is engaged, sqeeze and release the paddle.

For Grinding (Fig. 4)

Using a depressed center Type 27 wheel, use the tool at an angle of approximately 10-20

degrees to the work for grinding. Most type 27 wheels are not designed for cutting operations

Edge Cutting (Fig. 5)

Edge cutting can be performed only with Type 27 wheels that are designed and specified for

this purpose. Protect yourself during edge cutting by directing the open side of the guard away

from you and toward a surface.

Sanding With Abrasive Discs (Fig. 6)

When using an abrasive disc, hold the tool so that an angle of 5° to 15° exists between the

disc and the work, as shown. If only the outer edge of the sanding disc is pressed flat against

the work, the sanding action will be irregular and bumpy, and the tool will be difficult to control.

Precautions When Sanding Paint

Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the contaminated dust. The greatest danger of lead poisoning is to children and pregnant women.

Since it is difficult to identify whether or not a paint contains lead without a chemical analysis, we

recommend the following precautions when sanding any paint:

A. PERSONAL SAFETY

1. No children or pregnant women should enter the work area where the paint sanding is being

done until all clean up is completed.

2. A dust mask or respirator should be worn by all persons entering the work area. The filter

should be replaced daily or whenever the wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust and fumes should be

used. Ordinary painting masks do not offer this protection. See your local hardware dealer for

the proper (NIOSH approved) mask.

3. NO EATING, DRINKING or SMOKING should be done in the work area to prevent ingesting

contaminated paint particles. Workers should wash and clean up BEFORE eating, drinking or

smoking. Articles of food, drink, or smoking should not be left in the work area where dust would

settle on them.

B. ENVIRONMENTALSAFETY

1. Paint should be removed in such a manner as to minimize the amount of dust generated.

2. Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils

thickness.

3. Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

C. CLEANING AND DISPOSAL

1. All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the duration

of the sanding project. Vacuum filter bags should be changed frequently.

2. Plastic drop cloths should be gathered up and disposed of along with any dust chips or other

removal debris. They should be placed in sealed refuse receptacles and disposed of through

regular trash pick-up procedures. During clean up, children and pregnant women should be

kept away from the immediate work area.

3. All toys, washable furniture and utensils used by children should be washed thoroughly

before being used again.

Cleaning

Blowing dust and grit out of the motor housing using compressed air is a necessary regular

maintenance procedure. Dust and grit containing particles from metal grinding often accumulate

on interior surfaces and could create an electrical shock hazard if not frequently cleaned out.

CAUTION: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. Use clean, dry rag only.

Lubrication

DEWALT tools are properly lubricated at the factory and are ready for use. Tools should be relubricated regularly every sixty days to six months, depending on usage. (Tools used constantly

on production or heavy-duty jobs and tools exposed to heat may require more frequent lubrication.) This lubrication should only be attempted by trained power tool repairpersons.

Motor Brushes

DEWALT uses an advanced brush system which automatically stops the tool when the brushes

wear out. This prevents serious damage to the motor.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory for your

tool, please contact your local dealer or authorized service center.

CAUTION: The use of any other accessory not recommended for use with this tool could be

hazardous.

Depressed center grinding wheels must fit within the confines of the guard and must be rated

higher than the recommended speed as marked on the nameplate.

WARNING: To reduce the risk of injury, always use proper guards when grinding and wear

eye protection.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including

brush inspection and replacement) should be performed by authorized service centers or other

qualified service organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from date of purchase. We will

repair, without charge, any defects due to faulty materials or workmanship. For warranty repair

information, call 1-800-4-DEWALT. This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

FIG. 2

10° TO 20°

FIG. 4

A

B

FIG.1

FIG. 3

B

A

FIG. 5

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET OUTIL OU TOUT AUTRE

OUTIL D

E

WALT, COMPOSER SANS FRAIS LE NUMÉRO:

1-800-4-DEWALT (1-800-433-9258)

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT! Vous devez lire et comprendre toutes les instructions. Le nonrespect, même partiel, des instructions ci-après entraîne un risque de choc électrique, d’incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS.

AIRE DE TRAVAIL

• Veillez à ce que l’aire de travail soit propre et bien éclairée. Le désordre et le manque de

lumière favorisent les accidents.

• N’utilisez pas d’outils électriques dans une atmosphère explosive, par exemple en

présence de liquides, de gaz ou de poussières inflammables. Les outils électriques

créent des étincelles qui pourraient enflammer les poussières ou les vapeurs.

• Tenez à distance les curieux, les enfants et les visiteurs pendant que vous travaillez

avec un outil électrique. Ils pourraient vous distraire et vous faire faire une fausse

manoeuvre.

SÉCURITÉ ÉLECTRIQUE

• Les outils à double isolation sont équipés d’une fiche polarisée (une des lames est

plus large que l’autre), qui ne peut se brancher que d’une seule façon dans une prise

polarisée Ne modifiez pas la fiche de l’outil. La double isolation élimine le besoin d’un

cordon d’alimentation à trois fils avec mise à la terre ainsi que d’une prise de courant mise à

la terre.

• Évitez tout contact corporel avec des surfaces mises à la terre (tuyauterie, radiateurs,

cuisinières, réfrigérateurs, etc.). Le risque de choc électrique est plus grand si votre corps

est en contact avec la terre.

• N’exposez pas les outils électriques à la pluie ou à l’eau. La présence d’eau dans un outil

électrique augmente le risque de choc électrique.

• Ne maltraitez pas le cordon. Ne transportez pas l’outil par son cordon et ne débranchez

pas la fiche en tirant sur le cordon. N’exposez pas le cordon à la chaleur, à des huiles,

à des arêtes vives ou à des pièces en mouvement. Remplacez immédiatement un

cordon endommagé. Un cordon endommagé augmente le risque de choc électrique.

• Lorsque vous utilisez un outil électrique à l’extérieur, employez un prolongateur pour

l’extérieur marqué «W-A» ou «W». Ces cordons sont faits pour être utilisés à l’extérieur et

réduisent le risque de choc électrique. S’assurer que le cordon de rallonge est en bon état.

Lorsqu’on se sert d’un cordon de rallonge, s’assurer qu’il est de calibre approprié pour la

tension nécessaire au fonctionnement de l’outil. L’utilisation d’un cordon de calibre inférieur

occasionne une baisse de tension entraînant une perte de puissance et la surchauffe. Le

tableau suivant indique le calibre approprié selon la longueur du cordon et les mentions de la

plaque signalétique de l’outil. En cas de doute, utiliser un cordon de calibre supérieur. Le

chiffre indiquant le calibre est inversement proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0- 6 18 161614

6- 10 18 16 14 12

10 - 12 16161412

12 - 16 14 12 Non recommandé

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your D

EWALT heavy duty industrial

tool, simply return it to the participating seller within 30 days for a full refund. Please return the

complete unit, transportation prepaid. Proof of purchase may be required.

FREE WARNING LABELREPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-DEWALT for a free replacement.

C

C

D

A

B

C

D

E

FIG. 6

10° TO 15°

F

Page 3

SÉCURITÉ DES PERSONNES

• Restez alerte, concentrez-vous sur votre travail et faites preuve de jugement.

N’utilisez pas un outil électrique si vous êtes fatigué ou sous l’influence de drogues,

d’alcool ou de médicaments. Un instant d’inattention suffit pour entraîner des blessures

graves.

• Habillez-vous convenablement. Ne portez ni vêtements flottants ni bijoux. Confinez les

cheveux longs. N’approchez jamais les cheveux, les vêtements ou les gants des

pièces en mouvement. Des vêtements flottants, des bijoux ou des cheveux longs risquent

d’être happés par des pièces en mouvement. Se tenir éloigné des évents puisque ces

derniers pourraient camoufler des pièces mobiles.

• Méfiez-vous d’un démarrage accidentel. Avant de brancher l’outil, assurez-vous que

son interrupteur est sur ARRÊT. Le fait de transporter un outil avec le doigt sur la détente

ou de brancher un outil dont l’interrupteur est en position MARCHE peut mener tout droit à un

accident.

• Enlevez les clés de réglage ou de serrage avant de démarrer l’outil. Une clé laissée dans

un pièce tournante de l’outil peut provoquer des blessures.

• Ne vous penchez pas trop en avant. Maintenez un bon appui et restez en équilibre en

tout temps. Un bonne stabilité vous permet de mieux réagir à une situation inattendue.

• Utilisez des accessoires de sécurité. Portez toujours des lunettes ou une visière. Selon

les conditions, portez aussi un masque antipoussière, des bottes de sécurité antidérapantes,

un casque protecteur et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN DES OUTILS

• Immobilisez le matériau sur une surface stable au moyen de brides ou de toute autre

façon adéquate. Le fait de tenir la pièce avec la main ou contre votre corps offre un stabilité

insuffisante et peut amener un dérapage de l’outil.

• Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche. L’outil correct fonctionne mieux

et de façon plus sécuritaire. Respectez aussi la vitesse de travail qui lui est propre.

• N’utilisez pas un outil si son interrupteur est bloqué. Un outil que vous ne pouvez pas

commander par son interrupteur est dangereux et droit être réparé.

• Débranchez la fiche de l’outil avant d’effectuer un réglage, de changer d’accessoire ou

de ranger l’outil. De telles mesures préventives de sécurité réduisent le risque de démarrage

accidentel de l’outil.

• Rangez les outils hors de la portée des enfantes et d’autres personnes

inexpérimentées. Les outils sont dangereux dans les mains d’utilisateurs novices.

• Prenez soin de bien entretenir les outils. Les outils de coupe doivent être toujours bien

affûtés et propres. Des outils bien entretenus, dont les arêtes sont bien tranchantes, sont

moins susceptibles de coincer et plus faciles à diriger.

• Soyez attentif à tout désalignement ou coincement des pièces en mouvement, à tout

bris ou à toute autre condition préjudiciable au bon fonctionnement de l’outil. Si vous

constatez qu’un outil est endommagé, faites-le réparer avant de vous en servir. De

nombreux accidents sont causés par des outils en mauvais état.

• N’utilisez que des accessoires que le fabricant recommande pour votre modèle d’outil.

Certains accessoires peuvent convenir à un outil, mais être dangereux avec autre.

RÉPARATION

• La réparation des outils électriques doit être confiée à un réparateur qualifié. L’entretien

ou la réparation d’un outil électrique par un amateur peut avoir des conséquences graves.

• Pour la réparation d’un outil, n’employez que des pièces de rechange d’origine. Suivez

les directives données à la section «Réparation» de ce manuel. L’emploi de pièces non

autorisées ou le non-respect des instructions d’entretien peut créer un risque de choc

électrique ou de blessures.

• Tenez l’outil par ses surfaces de prise isolées pendant toute opération où l’outil de

coupe portrait venir en contact avec un câblage dissimulé ou avec son propre cordon.

En cas de contact avec un conducteur sous tension, les pièces métalliques à découvert de

l’outil transmettraient un choc électrique à l’utilisateur.

Règles de sécurité additionnelles concernant les

meules

·Toujours utiliser le dispositif de protection qui convient à la meule afin de protéger l’opérateur des fragments pouvant être projetés par une meule brisée.

• La vitesse des accessoires doit correspondre à la vitesse minimale recommandée

indiquée sur l’étiquette d’avertissement de l’outil, car les meules et les accessoires qui sont

réglés à une vitesse trop élevée peuvent se briser et occasionner des blessures lorsque des fragments de métal sont projetés. La vitesse des accessoires est réglée au-dessus de la vitesse à

vide de l’outil puisque la vitesse réelle de l’outil peut varier.

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en

contact avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre

les pièces métalliques de l’outil sous tension, engendrant des risques de choc électrique.

• Avant d’utiliser un accessoire recommandé, le vérifier afin de s’assurer qu’il n’y a ni

bris ni fissure. Si on y trouve de tels défauts, mettre l’accessoire au rebut. Inspecter

également l’accessoire chaque fois qu’il subit un choc.

• Lorsqu’on démarre l’outil (après y avoir installé une meule ou une brosse métallique

neuve ou de rechange), se tenir dans un endroit bien protégé et le faire fonctionner

pendant une minute, car si la meule est fissurée ou brisée, elle devrait éclater en

moins d’une minute. Si des brins se détachent de la brosse métallique, ils seront alors vis-

ibles. Ne jamais démarrer un outil lorsque quelqu’un, y compris l’opérateur, se tient directement devant lui.

• Éviter de faire rebondir la meule durant son fonctionnement ou de l’utiliser sans

ménagement. Si la meule subit de tels traitements, arrêter l’outil et inspecter cette dernière.

• Toujours utiliser la poignée latérale et s’assurer qu’elle est bien serrée afin de bien maîtris-

er l’outil en tout temps.

• Nettoyer périodiquement l’outil; la poussière et la saleté contenant des particules

métalliques tendent à s’accumuler sur les surfaces internes et peuvent entraîner des

risques de choc électrique.

MISE EN GARDE : porter un dispositif de protection personnel anti-bruit approprié durant

l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation, le bruit émanant

de ce produit pourrait contribuer à la perte d’audition.

AVERTISSEMENT : Certains outils, tels que les sableuses électriques, les scies, les meules,

les perceuses ou certains autres outils de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on

retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence avec laquelle on effectue

ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit bien ventilé et utiliser l’équipement de sécurité approprié tel un masque anti-poussières spécialement

conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres outils

électriques. Porter des vêtements de protection et nettoyer les parties exposées du

corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber

par la bouche, les yeux ou la peau des produits chimiques nocifs.

•L’étiquette de l’outil peut comporter les symboles suivants.

V ..................volts A................ampères

Hz ................hertz W ..............watts

.../min............minutes ..............courant alternatif

............courant continu

n

o..............sous vide

..................construction de classe II .../min ........tours ou courses à la minute

..................borne de mise à la terre ..............symbole d´avertissement

CONSERVER CES MESURES.

Interrupteur à palette (Fig. 1)

Pour mettre la rectifieuse en marche, enfoncer la palette. Pour l’arrêter, relâcher la palette.

L’interrupteur peut être verrouillé en mode de fonctionnement continu en appuyant sur le bouton

de verrouillage qui se trouve à l’arrière de l’outil tout en enfonçant la palette. Toujours s’assurer

que le bouton de verrouillage est dégagé avant de brancher l’outil. Pour arrêter l’outil lorsqu’il est

bloqué en mode de fonctionnement continu, appuyer une fois sur la palette et la relâcher.

Tige de verrouillage de l’arbre (Fig. 2)

Enfoncer la tige de verrouillage de l’arbre et faire tourner l’arbre jusqu’à ce que la tige de verrouillage s’enclenche dans l’arbre.

NOTE : Ne jamais enfoncer la tige de verrouillage de l’arbre lorsque l’outil fonctionne. Cela pourrait endommager les engrenages et la tige de verrouillage.

Poignée auxiliaire (Fig. 2)

La rectifieuse est dotée d’une poignée auxiliaire qui se visse d’un côté ou de l’autre de l’outil, ou

sur le dessus du boîtier avant. IL FAUT UTILISER CETTE POIGNÉE EN TOUT TEMPS afin

d’optimiser la maîtrise de l’outil.

Ponçage

Les accessoires de ponçage sont vendus séparément.

Installation des disques abrasifs : S’assurer que l’outil est débranché et que l’interrupteur est à

la position d’arrêt. Pousser à fond le moyeu de l’écrou du disque au centre du disque abrasif et

du disque d’appui.

Installer les disques assemblés sur l’arbre et fixer l’écrou du disque dans le moyeu. Visser dans

le sens horaire, jusqu’au fond de l’arbre. Enfoncer la tige pour verrouiller l’arbre. Lorsqu’on se

sert d’un disque abrasif, saisir l’outil de sorte qu’il y ait un angle d’environ 10 à 15° entre le

disque et la surface de travail, comme le montre la figure 4. Le ponçage sera irrégulier et l’outil

sera difficile à maîtriser si seulement le rebord extérieur du disque entre en contact avec la surface à poncer.

Retrait du disque

Mettre l’outil hors tension et le débrancher.

Se protéger la main avec un chiffon ou un gant, et faire tourner le disque dans le sens antiho-

raire pour le retirer de l’arbre. Saisir l’arbre en le bloquant à l’aide de la tige.

Meules à moyeu creux (arbre de

5/8 po — 11 po)

Les meules à moyeu creux peuvent servir pour enlever une quantité moyenne de métal de surfaces planes ou courbées.

MISE EN GARDE : Ne jamais utiliser les meules à moyeu creux sans le protecteur appro-

prié

Installation de la meule à moyeu creux

1. S’assurer que l’outil est débranché et que l’interrupteur est à la position d’arrêt.

2. Vérifier si le protecteur est bien fixé au boîtier d’engrenages.

3. Placer la bride d’appui sur l’arbre de l’outil de la façon illustrée à la figure 5.

4. Vérifier la vitesse nominale de la meule. Ne jamais utiliser une meule dont la vitesse nominale est inférieure à celle indiquée sur la plaque signalétique de l’outil.

5. Placer la meule à moyeu creux sur l’arbre de la façon illustrée.

6. Visser la rondelle de serrage sur l’arbre de l’outil de la façon illustrée. Saisir l’arbre en enclenchant la tige de verrouillage de l’arbre et serrer la rondelle à l’aide de la clé.

Lorsqu’on se sert de la meule à moyeu creux, saisir l’outil de sorte qu’il y ait un angle d’environ

10° entre la meule et la surface de travail.

Brosses boisseaux métalliques et brosses métalliques

torsadées

(arbre de 5/8 po —11 po)

La brosse boisseau métallique sert à nettoyer des soudures, des angles, des coins et à enlever

de la peinture.

La brosse boisseau métallique torsadée sert à effectuer les tâches précédentes ainsi qu’à finir

les surfaces et les coins rugueux.

Installation

1. Débrancher l’outil et s’assurer que l’interrupteur est en position d’arrêt. Déposer la rectifieuse

en plaçant l’arbre vers le haut.

2. S’assurer que la vitesse nominale de la brosse est égale ou supérieure à celle indiquée sur

la plaque signalétique de l’outil.

3. Visser à fond la brosse sur l’arbre.

Nettoyage

Il faut nettoyer régulièrement le carter du moteur en y soufflant de l’air comprimé pour en chasser la poussière et les charpies. Des particules métalliques s’accumulent souvent sur les parois

internes de l’outil et elles présentent des risques de secousses électriques si on ne les enlève

pas régulièrement.

MISE EN GARDE : Ne jamais nettoyer les composants non métalliques de l’outil à l’aide de

solvants ni de tout autre produit chimique. Utiliser seulement un chiffon sec et propre.

Mesures à prendre lors du ponçage de peinture

IL N’EST PAS RECOMMANDÉ de poncer de la peinture à base de plomb puisqu’il est difficile

d’en maîtriser la poussière contaminée. Ce genre de ponçage présente de sérieux risques

d’empoisonnement au plomb pour les femmes enceintes et les enfants.

Puisqu’il est difficile de déterminer si la peinture renferme du plomb sans en faire une analyse

chimique, il est conseillé de se conformer aux mesures suivantes lors du ponçage de tout type

de peinture.

A. SÉCURITÉ PERSONNELLE

1. Ne laisser aucun enfant ni aucune femme enceinte entrer dans la pièce où il y a ponçage de

peinture jusqu’à ce que la pièce soit nettoyée.

2. Toute personne entrant dans la pièce de travail devrait porter un masque ou un appareil respiratoire. L’utilisateur devrait remplacer le filtre chaque jour ou dès qu’il éprouve de la difficulté à respirer.

NOTE : Il faut seulement utiliser des masques conçus pour le travail en présence de poussières

ou de vapeurs de plomb. Les masques ordinaires ne sont pas conçus à cet effet. Consulter le

quincaillier pour choisir le masque approprié.

3. IL EST INTERDIT DE MANGER, DE BOIRE ET DE FUMER dans la pièce de travail afin de

ne pas ingérer des particules contaminées. L’utilisateur doit se laver et se nettoyer AVANTde

manger, de boire ou de fumer. Il ne faut pas laisser dans la pièce de travail de la nourriture,

des boissons ou des cigarettes car de la poussière pourrait se déposer sur ces articles.

B. PROTECTION DE L’ENVIRONNEMENT

1. Il faut enlever la peinture de manière à produire un minimum de poussière.

2. Il faut sceller la zone de travail à l’aide de feuilles de plastique d’une épaisseur minimale de

4mils.

3. Il faut poncer de façon à réduire la propagation de la poussière hors de la pièce de travail.

C. NETTOYAGE ET DÉCHETS

1. Il faut bien aspirer toutes les surfaces de la pièce de travail et les nettoyer à fond chaque jour

pendant la durée des travaux. Il faut remplacer fréquemment le filtre de l’aspirateur.

2. Ramasser les feuilles de plastique et les jeter avec la poussière et les autres débris dans des

contenants étanches à placer avec les ordures ménagères pour l’enlèvement. Tenir les

enfants et les femmes enceintes à l’écart de la zone de travail pendant les travaux de nettoyage.

3. Il faut nettoyer à fond les jouets, les meubles et les ustensiles des enfants avant de les utiliser de nouveau.

Lubrification

Les outils DEWALT sont bien lubrifiés en usine et ils sont prêts à servir. Il faut les lubrifier

régulièrement à des intervalles variant entre 60 jours et 6 mois, selon le degré d’utilisation. (Les

outils utilisés continuellement ou pour des travaux de service intensif, et ceux exposés à la

chaleur devraient être lubrifiés plus souvent.) Seul du personnel qualifié devrait effectuer les

travaux de lubrification.

Page 4

Balais du moteur

Les outils DEWALT sont dotés d’un système perfectionné de vérification des balais qui arrête

automatiquement l’outil lorsque les balais sont usés afin d’empêcher d’endommager le moteur.

Accessoires

Les accessoires recommandés pour l’outil sont vendus séparément chez les détaillants et aux

centres de service autorisés. La liste complète des centres de service se trouve dans l’emballage. Pour trouver un accessoire, communiquer avec le détaillant ou le centre de service de la

région.

MISE EN GARDE : L’utilisation de tout accessoire autre que ceux recommandés pour l’outil

peut être dangereuse.

Les meules à moyeu creux doivent s’insérer dans le protecteur et leur vitesse nominale doit être

supérieure à celle indiquée sur la plaque signalétique de l’outil.

AVERTISSEMENT: Afin de minimiser les risques de blessures, toujours utiliser le protecteur

approprié lors des travaux et porter des lunettes de sécurité.

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en confier la réparation, l’entretien et les rajustements (y compris l’inspection des balais) qu’à un centre de service ou à un

atelier d’entretien autorisé n’utilisant que des pièces de rechange identiques.

Garantie complète

Les outils industriels de service intensif D

EWALT sont garantis pendant un an à partir de la date

d’achat. Toute pièce d’un outil D

EWALT qui s’avérait défectueuse en raison d’un vice de matière

ou de fabrication sera réparée sans frais. Pour obtenir de plus amples renseignements sur les

réparations couvertes para garantie, composer le 1 (800)4-D

EWALT. Il suffit de retourner l’outil

complet à un centre de service D

EWALT. La présente garantie ne couvre pas les accessoires ni

les avaries dues aux réparations tentées ou effectuées par des tiers. Les modalités de la

présente garantie donnet des droits légaux spécifiques. L'utilisateur peut également se prévaloir d'autres droits selon l'état ou la province qu'il habite.

En outre, la garantie suivante couvre les outils D

EWALT .

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil ne donne pas entière satisfaction, il suffit de le retourner où il a été acheté dans les 30 jours suivant la date d’achat afin d’obtenir un remboursement

intégral. Prière de retourner l'outil complet port payé. Une preuve d'achat peut être requise.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE

Si vos étiquettes d'avertissement deviennent illisibles ou sont manquantes, composez le 1-8004-D

EWALT pour obtenir une étiquette de remplacement gratuite.

Reglas generales de seguridad

¡ADVERTENCIA! Lea y comprenda todas las instrucciones. No hacerlo puede originar

riesgos de choque eléctrico, incendio y lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las bancas amontonadas y las

zonas oscuras propician los accidentes.

• No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados mientras opera una her-

ramienta eléctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas con doble aislamiento están equipadas con una clavija polarizada

(con una pata más ancha que la otra.) Esta clavija se acoplará únicamente en una

toma de corriente polarizada de una manera. Si la clavija no se acopla al contacto,

inviértala. Si aún así no se ajusta, comuníquese con un electricista calificado para

que le instalen una toma de corriente polarizada apropiada. El doble aislamiento

elimina la necesidad de cables con tres hilos y sistemas de alimentación con conexión a

tierra.

• Evite el contacto corporal con superficies aterrizadas tales como tuberías, radi-

adores, hornos y refrigeradores. Hay un gran riesgo de choque eléctrico si su cuerpo

hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a condiciones de mucha

humedad. El agua que se introduce en las herramientas aumenta el riesgo de descargas

eléctricas.

• No maltrate el cable. Nunca tome el cable para transportar una herramienta ni para

desconectarla de la toma de corriente. Consérvelo alejado de calor aceite, bordes afilados o piezas móviles. Cambie inmediatamente los cables dañados. Los cables daña-

dos aumentan el riego de choque eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie, utilice una extensión mar-

cada “W-A” o “W”. Estas extensiones están clasificadas para uso a la intemperie y para

reducir el riesgo de choques eléctricos. Cuando utilice una extensión, asegúrese de

emplear una con el calibre suficiente para soportar la corriente necesaria para su herramienta. Una extensión con calibre inadecuado causará una caída en el voltaje de la línea

resultando en pérdida de potencia y sobrecalentamiento. La tabla siguiente muestra el calibre correcto para usarse, relativo a la longitud de la extensión y el amperaje mencionado

en la placa de identificación. Si tiene dudas, utilice el calibre siguiente. Mientras más

pequeño sea el número del calibre, mayor será su capacidad.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

Más No más Calibre del cordón A WG

de de

0- 618161614

6- 1018 16 14 12

10 - 12 16161412

12 - 16- 14 12 No recomendado

SEGURIDAD PERSONAL

• Esté alerta concéntrese en lo que está haciendo. Recurra al sentido común cuando

opere una herramienta eléctrica. No opere ninguna herramienta si se encuentra fatigado o bajo la influencia de drogas, alcohol o medicamentos. Un momento de desa-

tención mientras se operan herramientas eléctricas puede ocasionar lesiones graves.

• Vístase adecuadamente. No utilice ropa floja o joyas. Cubra su cabello. Conserve su

cabello, ropas y guantes alejados de las piezas móviles. Las piezas de vestir flojas, las joyas

y el cabello largo pueden resultar atrapados por las piezas móviles. Las rejillas de ventilación

cubren partes móviles y también deben evitarse.

• Evite el encendido accidental. Asegúrese que el interruptor esté en posición de apa-

gado antes de conectar. Sostener una herramienta con el dedo en el interruptor o conectarla sin fijarse si el interruptor está en posición de encendido propicia los accidentes.

• Retire las llaves de ajuste antes de encender la herramienta. Una llave que se deja en

una pieza giratoria puede ocasionar lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien apoyados, al igual que el equi-

librio. La posición correcta de los pies y el equilibrio permiten controlar mejor la herramienta en situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en los ojos. Se deben utilizar

mascarillas contra polvo, zapatos antiderrapantes, casco o protectores para los oídos para

tener las condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice prensas u otros medios prácticos para asegurar y apoyar la pieza de trabajo

en una plataforma estable. Sujetar las piezas con la mano o contra su cuerpo es inestable

y puede originar la pérdida de control.

• No fuerce la herramienta. Emplee la herramienta correcta para su aplicación. La her-

ramienta correcta hará el trabajo mejor y de manera más segura y bajo las especificaciones

para las que fue diseñada.

• No utilice la herramienta si el interruptor no enciende y apaga. Cualquier herramienta

que no pueda controlarse por medio del interruptores peligrosa y debe reemplazarse.

• Desconecte la clavija de la toma de corriente antes de hacer cualquier ajuste, cam-

bio de accesorios o de guardar la herramienta. Tales medidas de seguridad preventivas

reducirán el riesgo de que la herramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los niños y de otras personas no

capacitadas. Las herramientas son peligrosas en manos de personas no capacitadas.

• Cuide sus herramientas. Conserve las herramientas de corte afiladas y limpias. Las

herramientas que reciben un mantenimiento adecuado, con piezas de corte afiladas, difícilmente se atascan y son más fáciles de controlar.

• Verifique la alineación de las piezas móviles, busque fracturas en las piezas y cua-

lesquiera otras condiciones que puedan afectar la operación de las herramientas. Si

está dañada, lleve su herramienta a servicio antes de usarla de nuevo. Muchos acci-

dentes se deben a herramientas con mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende para su modelo de her-

ramienta. Los accesorios que estén diseñados para una herramienta, pueden volverse

peligrosos cuando se emplean con otra.

SERVICIO

• El servicio a las herramientas lo debe efectuar únicamente personal calificado. El ser-

vicio o mantenimiento realizado por personal no calificado puede originar riesgos de

lesiones.

• Cuando efectúe servicio a una herramienta, utilice únicamente refacciones idénticas.

Siga las instrucciones de la sección de Mantenimiento de este manual. El empleo de

piezas no autorizadas o no seguir las instrucciones de mantenimiento puede originar riegos

de choque eléctrico o lesiones.

• La etiqueta de su herramienta puede incluir los siguientes símbolos.

V..................volts A ....................amperes

Hz................hertz W....................watts

.../min ..........minutos ..................corriente alterna

............corriente directa

n

o ..................velocidad sin carga

................construcción Clase II /min ................revoluciones o reciprocaciones por

................erminales de ......................minuto

................conexión a tierre ......................símbolo de alerta de seguridad

Instrucciones de seguridad adicionales para

esmeriladores

• Utilice siempre la guarda apropiada con la piedra de esmeril. La guarda protege al operador

de los fragmentos que se desprenden de una piedra rota.

• Los accesorios deben estar clasificados por lo menos para la velocidad recomendada en

la etiqueta de advertencia de la herramienta. Los discos y otros accesorios que funcionan a

una velocidad mayor que la establecida para su funcionamiento pueden salir despedidos y

causar lesiones.

• Sujete la herramienta por las superficies aislantes cuando efectúe una operación en la que

la herramienta de corte pueda hacer contacto con cableado oculto o con su propio cable.

El contacto con un cable “vivo” hará que las partes expuestas de la herramienta “vivan” y descarguen en el operador.

•Antes de utilizar los accesorios recomendados, revíselos en busca de fallas o cuarteaduras.

Si hay fallas o cuarteaduras evidentes, descarte el accesorio. El accesorio también deberá

ser revisado cuando usted piense que la herramienta ha sido dejada caer.

• Cuando encienda la herramienta (con una rueda nueva o de repuesto instalada) sujétela en

un área bien protegida y déjela funcionar durante un minuto. Si la rueda tiene una cuarteadura o falla que no haya sido detectada, deberá estallar en menos de un minuto. Nunca

encienda la herramienta con una persona alineada con la rueda. Esto incluye al operador.

• Durante la operación, evite hacer que la rueda rebote así como darle tratamiento rudo. Si

esto ocurre, apague la herramienta y revise la rueda.

• Utilice siempre el mango lateral. Apriete el mango lateral con firmeza. El mango lateral debe

usarse siempre para conservar el control de la unidad en todo momento.

• Limpie la herramienta periódicamente. El polvo y el esmeril contienen partículas metálicas que

se acumulan con frecuencia en las superficies interiores y pueden ocasionar riesgos de choque

eléctrico.

• SIEMPRE UTILICE GUARDAS con las ruedas de centro hundido, o con piedras de copa.

• Limpie su herramienta periódicamente.

PRECAUCION: utilice la protección auditiva apropiada durante el uso. Bajo ciertas

condiciones de duración de uso, el ruido producido por este producto puede contribuir a la

pérdida auditiva.

ADVERTENCIA : Parte del polvo creado al lijar, aserruchar, moler o perforar con máquina,

así como al realizar otras actividades de la construcción, contiene substancias químicas que se

sabe producen cáncer, defectos congénitos u otras afecciones reproductivas. Algunos ejemplos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la frecuencia en que se haga este tipo

de trabajo. Para reducir la exposición a esas substancias químicas: trabaje en un área bien ventilada, y trabaje con equipos de seguridad aprobados, tales como máscaras contra el polvo

especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con polvos originados por lijar, aserrar, esmerilar, tal-

adrar y otras actividades constructivas. Vista ropas protectoras y lave las áreas

expuestas con agua y jabón. Permitir que el polvo se introduzca en su boca, ojos, o dejar-

lo sobre la piel promueve la absorción de químicos dañinos.

• La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutos ......................corriente alterna

......................corriente directa

n

o........................velocidad sin carga

..........................construcción clase II

........................terminales de

conexión a tierre

..........................símbolo de alerta seguridad .../min ..................revoluciones o

reciprocaciones por

minuto

CONSERVE ESTAS INSTRUCCIONES

Gatillo (fig. 1)

Para encender la esmeriladora, apriete al gatillo. Para apagar la herramienta, suelte el gatillo.

Botón de cierre de huso (fig. 2)

Empuje el cierre del huso y gire el huso hasta que se enganche, así cerrando el huso.

NOTA: Nunca apriete el cierre del huso con la herramienta en funcionamiento.

Manija auxiliar (fig. 2)

Una manija auxiliar viene con su esmeril y puede ser instalada en cualquier lado del bastidor

frontal. Utilice siempre la manija auxiliar para mantener el control completo de la herramienta.

Como lijar con discos abrasivos

Accesorios mostrados en este manual están disponibles a costo extra.

Para instalar discos de lijar:

Asegúrese de que que la herramienta está desenchufada. Apriete el centro de la arandela a

traves del centro del disco de lijar, al tope, y también a través del disco de respaldo. Ponga el

Page 5

centro del respaldo en el huso. Instale la arandela de presilla en el huso y enrosque hacia la

derecha, completamente sobre el huso. Ponga el botón de cierre.

Cuando use el disco de lijar, tenga la herramienta con un angulo de 10º a 15º entre el disco y

el trabajo. Si sólo se usa el extremo exterior del disco, resultará en un acabado de superficie

aspera. Si el disco se aprieta contra el trabajo, la superficie será irregular y rugosa y la herramienta será dificil de controlar.

Como quitar el disco

Desconecte y desenchufe la herramienta.

Usando un paño o guante para proteger su mano, gire el disco hacia la izquierda para quitarlo

del huso. Mantenga el huso bien sujeto enganchando el cierre del huso.

Muela de centro rebajado

(huso 5/8" - 11")

Se usan para quitar metal moderado en superficies lisas o contorneadas.

PRECAUCION: Nunca use ruedas de centro rebajado sin el protector adecuado. PARA

INSTALAR RUEDAS DE CENTRO REBAJADO:

1. Asegúrese que la herramienta está desconectada y que el botón interruptor está en la posición “OFF”.

2. Asegúrese de que el asemblaje del protector está sujeto con seguridad al bastidor del huso.

3. Ponga el respaldo en el huso.

4. Revise la velocidad en la rueda de centro rebajado. Nunca use la rueda a velocidades

menores de la que viene en el “aviso” de la etiqueta de la herramienta.

5. Ponga la rueda de centro rebajado en el huso.

6. Enrosque la arandela en el huso, mantenga el huso poniendo el botón de cierre y apretando la arandela con la llave.

Cuando use la rueda de centro rebajado, tenga la herramienta con un ángulo de 10º entre el

disco y el trabajo.

Cepillos engarzados y anudados cepillos de alambre (5/8"

– 11" huso)

Las aplicaciones normales para los cepillos de alambre incluyen la limpieza de soldaduras,

ángulos, esquinas y eliminación de pintura. El uso de cepillos engarzados y muelas de cable

trenzado es el mismo.

Se pueden usar para acabar superficies irregulares o esquinas.

Para instalar un cepillo acopado engarzado y muelas de cable trenzado.

1. Desconecte la herramienta y desenchúfela y asegúrese de que el botón interruptor está en

OFF. Ponga el esmeril boca abajo con el huso hacia arriba.

2. Procure que la velocidad clasificada del cepillo es igual o superior a la velocidad recomendada en la etiqueta del esmeril.

3. Enrosque el cepillo en el huso y apriételo.

Limpieza

Una tarea de mantenimiento regular y necesaria es la de usar aire comprimido para quitar el

polvo y la arenilla del bastidor del motor. El polvo y la arenilla que contienen partículas de metal

se acumula a menudo en las superficies interiores y pueden crear un peligro de electrocución

si no se limpia frecuentemente.

PRECAUCION: Nunca use disolventes o químicos fuertes para limpiar las partes no-metáli-

cas de la herramienta. Use un paño limpio y seco solamente.

Precauciones a tomar al lijar

NO SE RECOMIENDAlijar pintura con base de plomo debido a la dificultad de controlar el polvo

contaminante. Niños y mujeres embarazadas representan el grupo de mayor peligro de envenenamiento de plomo.

SEGURIDAD DEL MEDIO AMBIENTE

1. Se debe quitar la pintura de tal forma que se produzca la menor cantidad de polvo posible.

2. Las zonas en las que se lije pintura deben de estar protegidas con láminas de plástico de 4

milésimas de pulgada de grosor.

3. A la hora de lijar se debe de reducir el esparcimiento de polvo de pintura fuera de la zona de

trabajo.

LIMPIEZA Y ELIMINACION DE RESIDUOS

1. Todas las superficies de la zona de trabajo deben de ser aspiradas y limpiadas profundamente todos los días mientras dure el proyecto de lijado. Las bolsas del filtro de la aspiradora

deben de cambiarse frecuentemente.

2. La ropa de protección de plástico debe de juntarse y eliminarse con las virutas de serrín y

otros residuos. Se deben de colocar en contenedores cerrados y ponerse en el lugar normal

de recogida de basura. Ala hora de realizar la limpieza, niños y mujers embarazadas deben

estar fuera de la zona de trabajo inmediata.

3. Todo juguete, muebles lavables o utensilios usados por niños deben de lavarse en profundidad antes de usarse de nuevo.

Lubricación

Las herramientas D

EWALT están lubricadas de fábrica y están listas para usarse. Las her-

ramientas deben de ser relubricadas regularmente de cada sesenta días a seis meses, dependiendo de su uso. (Las herramientas usadas constantemente en trabajos pesados y las que

están expuestas al calor pueden requerir lubricación más frecuente). Esta lubricación debe de

ser realizada por personal calificado.

Carbones del motor

DEWALT usa un sistema avanzado de carbones que para la herramienta automaticamente

cuando los carbones se gasten, así evitando daños graves al motor.

Accesorios

Dispone usted de los accesorios recomendados para su herramienta con cargo adicional con

su distribuidor local o en los centros de servicio autorizado. Si necesita usted ayuda para encontrar algún accesorio, haga por favor contacto con:

PRECAUCION: El uso de cualquier accesorio no recomendado para emplearse con esta

herramienta puede ser peligroso.

Las muelas de centro rebajado deben de caber dentro de las dimensiones del protector y deben

de estar clasificadas para velocidades superiores a la velocidad recomendada en la etiqueta.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán hacerse reparaciones, mantenimiento y ajustes de esta herramienta en los centros de servicio para herramientas industriales de D

EWALT.u otras organizaciones calificadas. Estas organizaciones prestan servicio a las

herramientas D

EWALT y emplean siempre refacciones legítimas DEWALT.

Póliza de GarantÍía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: __________ Mod./Cat.: _____________

Marca: _____________________ Núm. de serie:__________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: __________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

_____________________________________________________

Este producto está garantizado por un año a partir de la fecha de entrega, contra cualquier

defecto en su funcionamiento, así como en materiales y mano de obra empleados para su fabricación. Nuestra garantía incluye la reparación o reposición del producto y/o componentes sin

cargo alguno para el cliente, incluyendo mano de obra, así como los gastos de transportación

razonablemente erogados derivados del cumplimiento de este certificado.

Epecificaciones (DW402, DW402G)

Tensión de alimentación 120 V CA/CD

Frecuencia de operación:60 Hz

Consumo de corriente: 7,5 A

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 326-7100

SECCI N

AMARILLA

Si funciona…

y funciona muy bien.

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

Para hacer efectiva esta garantía deberá presentar su herramienta y esta póliza sellada por

el establecimiento comercial donde se adquirió el producto, de no contar con ésta, bastará la

factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el instructivo de uso que se

acompaña;

• Cuando el producto hubiese sido alterado o reparado por personas distintas a las enlistadas

al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica, centros de servicio autorizados y franquiciados en la República Mexicana, donde podrá hacer efectiva su garantía y

adquirir partes, refacciones y accesorios originales.

Garantía Completa

Las herramientas industriales DEWALT están garantizadas durante un año a partir de la fecha

de compra. Repararemos, sin cargos, cualquier falla debida a material o mano de obra defectuosos. Por favor regrese la unidad completa, con el transporte pagado, a cualquier Centro de

Servicio para Herramientas Industriales de D

EWALT o a las estaciones de servicio autorizado

enlistadas bajo "Herramientas Eléctricas" en la Sección Amarilla. Esta garantía no se aplica a

los accesorios ni a daños causados por reparaciones efectuadas por terceras personas. Esta

garantía le otorga derechos legales específicos, y usted puede tener otros derechos que

pueden variar de estado a estado.

En adición a la garantía, las herramientas D

E

WALT están amparadas por nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de su herramienta

industrial DEWALT, sencillamente devuélvala a los vendedores participantes durante los

primeros 30 días después de la fecha de compra para que le efectúen un reembolso completo.

Por favor regrese la unidad completa, con el transporte pagado. Se puede requerir prueba de

compra.

REEMPLAZO DE LAS ETIQUETAS DE ADVERTENCIA GRATUITO: Si sus etiquetas de

advertencia se tornan ilegibles o se pierden, llame al 1-800-4-D

EWALT para que se las reem-

placen sin cost.

PARAREPARACION Y SERVICIO DE SUS HERRAMIENTAS ELECTRICAS FAVOR DE DIRIGIRSE

AL CENTRO DE SERVICIO MAS CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av. Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARAOTRAS LOCALIDADES LLAME AL: 326 7100

Loading...

Loading...