Page 1

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (JUL04-CD-1)

Form No. 626676-00 DW378, DW378G, DW378GT Copyright © 1998, 2002, 2004 D

EWALT

The following are trademarks for one or more D

EWALT power tools: the yellow and black color scheme;

the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the

array of lozenge-shaped humps on the surface of the tool.

Questions? See us in the World Wide Web at www.dewalt.com

DW378, DW378G, DW378GT

7-1/4"(184 mm) Framing Saw

Scie circulaire pour la charpente de 184 mm (7 1/4 po)

Siera alternataiva de 184 mm (7-1/4")

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

General Safety Instructions

WARNING! Read and understand all instructions. Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while operating a power tool. Distractions

can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or modify the plug in any way. Do not use any adaptor plugs. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. If the tools should

electrically malfunction or break down, grounding provides a low resistance path to carry electricity away from the user. Applicable only to Class I (grounded) tools. The DW378G and

DW378GT are grounded tools.

• Double insulated tools are equipped with a polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to

install a polarized outlet. Do not change the plug in any way. Double insulation elim-

inates the need for the three wire grounded power cord and grounded power supply system.

Applicable only to Class II (double insulated) tools. The DW378 is a double insulated

tool.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A”

or “W.” These cords are rated for outdoor use and reduce the risk of electric shock. When

using an extension cord, be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

10- 12 16 16 14 12

12- 16 14 12 Not Recommended

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal

injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving parts. Loose clothing, jewelry, or long hair

can be caught in moving parts. Air vents often cover moving parts and should also be

avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss

of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the tool. Such preventative safety measures reduce the risk of

starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or mainte-

nance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Additional Safety Instructions for Circular Saws

DANGER! Keep hands away from cutting area and blade. Keep your second hand on

auxiliary handle, or motor housing. If both hands are holding the saw, they cannot be cut by

the blade.

CAUTION: Blades coast after turn off.

• Keep your body positioned to either side of the blade, but not in line with the saw

blade. KICKBACK could cause the saw to jump backwards (see Causes and Operator

Prevention of Kickback and KICKBACK).

• Do not reach underneath the work. The guard can not protect you from the blade below

the work.

• Check lower guard for proper closing before each use. Do not operate saw if lower

guard does not move freely and close instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally dropped, the lower guard may be bent. Raise

the lower guard with the retracting handle and make sure it moves freely and does not touch

the blade or any other part, at all angles and depth of cut.

• Check the operation and condition of the lower guard spring. If the guard and the

spring are not operating properly, they must be serviced before use. Lower guard may

operate sluggishly due to damaged parts, gummy deposits, or a buildup of debris.

• Lower guard should be retracted manually only for special cuts such as “pocket cuts”

and “compound cuts.” Raise lower guard by retracting handle. As soon as blade

enters the material, lower guard must be released. For all other sawing, the lower guard

should be allowed to operate automatically.

• Always observe that the lower guard is covering the blade before placing saw down

on bench or floor. An unprotected, coasting blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch

is released.

• NEVER hold piece being cut in your hands or across your leg. It is important to support

the work properly to minimize body exposure, blade binding, or loss of control.

• Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will also

make exposed metal parts of the tool “live” and shock the operator.

• When ripping, always use a rip fence or straight edge guide. This improves the accuracy of cut and reduces the chance for blade binding.

• Always use blades with correct size and shape (diamond vs. round) arbor holes.

Blades that do not match the mounting hardware of the saw will run eccentrically, causing

loss of control.

• Never use damaged or incorrect blade washers or bolts. The blade washers and bolt

were specially designed for your saw, for optimum performance and safety of operation.

• Avoid cutting nails. Inspect for and remove all nails from lumber before cutting.

CAUSES AND OPERATOR PREVENTION OF KICKBACK

• Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator.

• When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the

motor reaction drives the unit rapidly back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade

can dig into the top surface of the wood causing the blade to climb out of the kerf and jump

back toward operator.

• Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given below:

• Maintain a firm grip with both hands on the saw and position your body and arm to

allow you to resist kickback forces. Kickback forces can be controlled by the operator, if

proper precautions are taken.

• When blade is binding, or when interrupting a cut for any reason, release the trigger

and hold the saw motionless in the material until the blade comes to a complete stop.

Never attempt to remove the saw from the work or pull the saw backward while the

blade is in motion or kickback may occur. Investigate and take corrective actions to elim-

inate the cause of blade binding.

• When restarting a saw in the workpiece, center the saw blade in the kerf and check

that the saw teeth are not engaged into the material. If saw blade is binding, it may walk

up or kickback from the workpiece as the saw is restarted.

• Support large panels to minimize the risk of blade pinching and kickback. Large panels tend to sag under their own weight. Support must be placed under the panel on both

sides, near the line of cut and near the edge of the panel.

• Do not use dull or damaged blade. Unsharpened or improperly set blades produce narrow

kerf causing excessive friction, blade binding, and kickback.

• Blade depth and bevel adjusting locking levers must be tight and secure before mak-

ing cut. If blade adjustment shifts while cutting, it may cause binding and kickback.

• Use extra caution when making a “Pocket Cut” into existing walls or other blind areas.

The protruding blade may cut objects that can cause kickback.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con-

struction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Always use eye protection. All users and bystanders must wear eye protection

that conforms to ANSI Z87.1.

CAUTION: Wear appropriate personal hearing protection during use. Under some con-

ditions and duration of use, noise from this product may contribute to hearing loss.

CAUTION: When cutting into walls, floors or wherever live electrical wires may be encoun-

tered, DO NOT TOUCH ANY METAL PARTS OF THE TOOL! Hold the tool only by insulated

grasping surfaces to prevent electric shock if you cut into a live wire.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V..........volts A ..........amperes

Hz........hertz W ..........watts

min ......minutes ........alternating current

....direct current

n

o..........no load speed

........Class II Construction ..........earthing terminal

........safety alert symbol .../min....revolutions per minute

FEATURES

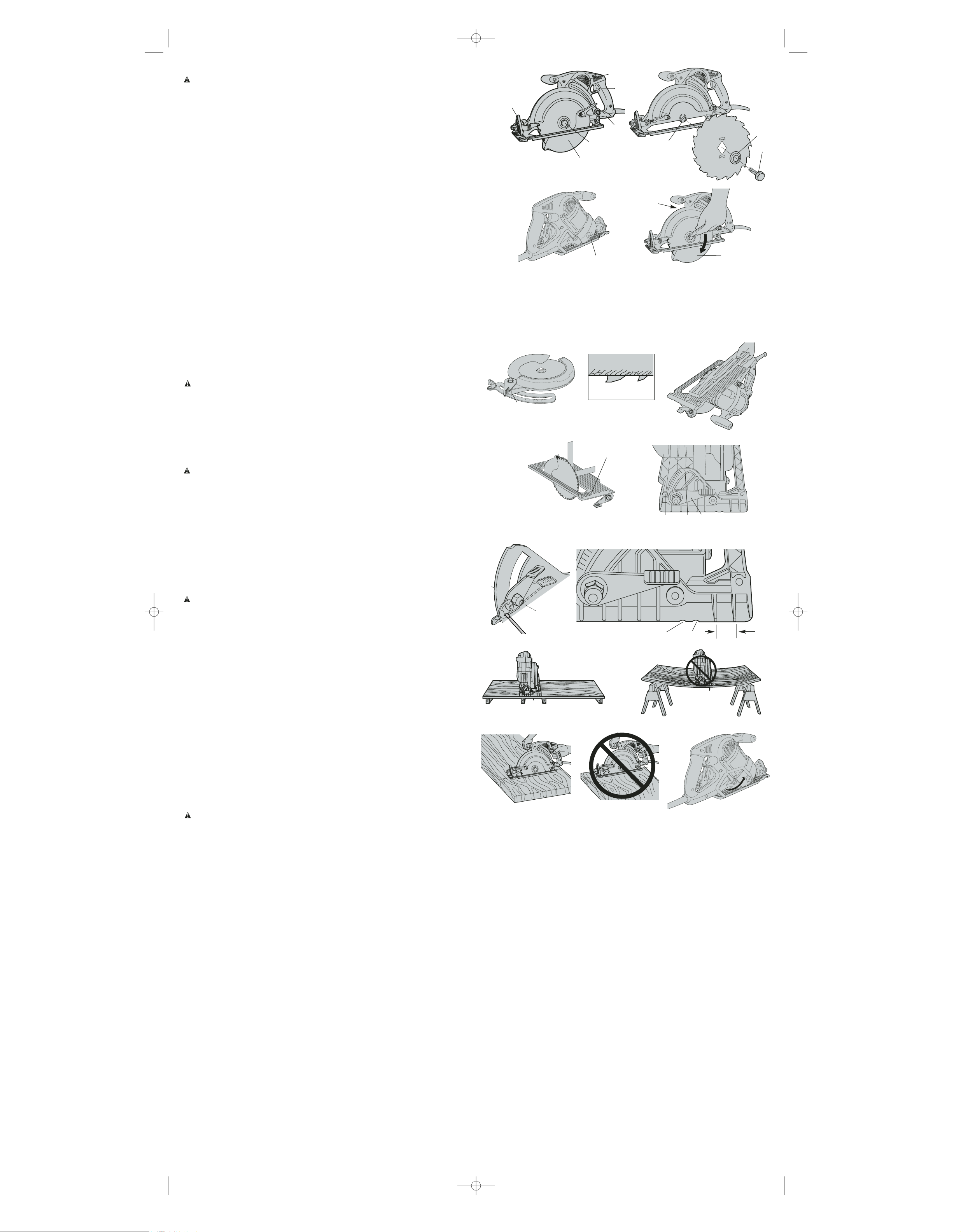

A. Brush inspection cover E. Shoe

B. Trigger switch F. Blade clamping screw

C. Cutting depth adjustment

D. Bevel angle adjustment

Motor

Your DEWALT tool is powered by a DEWALT motor. Be sure your power supply agrees with

nameplate marking. 120 Volts AC/DC means your saw will operate on alternating or direct current. As little as 10% lower voltage can cause loss of power and can result in overheating. All

D

EWALT tools are factory-tested; if this tool does not operate, check the power supply.

11x20,DW378 7/21/04 12:51 PM Page 1

Page 2

Changing Blades

CAUTION: Turn off and unplug the tool before making any adjustments or

removing/installing attachments or accessories.

TO INSTALL THE BLADE

1. Place inner clamp washer (G) on saw spindle with the large flat surface facing out toward

the blade (Fig. 1).

2. Retract the lower blade guard (H) and place blade on saw spindle against the inner clamp

washer, making sure that the blade will rotate in the proper direction (the direction of the rotation arrow on the saw blade and the teeth must point in the same direction as the direction

of rotation arrow on the saw). Do not assume that the printing on the blade will always be facing you when properly installed. When retracting the lower blade guard to install the blade,

check the condition and operation of the lower blade guard to assure that it is working properly. Make sure it moves freely and does not touch the blade or any other part, in all angles

and depths of cut.

3. Place outer clamp washer (I) on saw spindle with the large flat surface against the blade and

the wording on the outer clamp washer facing you.

4. Thread blade clamping screw (F) into saw spindle by hand (screw has left-hand threads and

must be turned counterclockwise to tighten).

5. Depress the blade lock (J) while turning the saw spindle with the blade wrench until the

blade lock engages and the blade stops rotating (Fig. 3).

6. Tighten the blade clamping screw firmly with the blade wrench.

NOTE: Never engage the blade lock while saw is running, or engage in an effort to stop the tool.

Never turn the saw on while the blade lock is engaged. Serious damage to your saw will result.

TO REPLACE THE BLADE

1. To loosen the blade clamping screw (F), depress the blade lock (J) and turn the saw spindle with the blade wrench until the blade lock engages and the blade stops rotating. With

the blade lock engaged, turn the blade clamping screw clockwise with the blade wrench

(screw has left-hand threads and must be turned clockwise to loosen).

2. Remove the blade clamping screw (F) and outer clamp washer (I) only. Remove old blade.

3. Clean any sawdust that may have accumulated in the guard or clamp washer area and check

the condition and operation of the lower blade guard as previously outlined. Do not lubricate

this area.

4. Select the proper blade for the application (see Blades). Always use blades that are the correct size (diameter) with the proper size and shape center hole for mounting on the saw

spindle. Always assure that the maximum recommended speed (rpm) on the saw blade

meets or exceeds the speed (rpm) of the saw.

5. Follow steps 2 through 6 under To Install the Blade, making sure that the blade will rotate

in the proper direction.

LOWER BLADE GUARD

WARNING: The lower blade guard is a safety feature which reduces the risk of serious

personal injury. Never use the saw if the lower guard is missing, damaged, misassembled

or not working properly. Do not rely on the lower blade guard to protect you under all circumstances. Your safety depends on following all warnings and precautions as well as

proper operation of the saw. Check lower guard for proper closing before each use as

outlined in Additional Safety Rules for Circular Saws. If the lower blade guard is missing

or not working properly, have the saw serviced before using. To assure product safety

and reliability, repair, maintenance and adjustment should be performed by an authorized service center or other qualified service organization, always using identical

replacement parts.

Cutting Depth Adjustment

CAUTION: Turn off and unplug the tool before making any adjustments or

removing/installing attachments or accessories.

Hold the saw firmly. Raise the depth adjustment lever (C) to loosen and move shoe to obtain

the desired depth of cut, as shown. Make sure the depth adjustment lever has been retightened

(lowered) before operating saw (Fig. 4).

Your saw is equipped with a carbide tipped saw blade for long life and efficient cutting.

Setting the saw at the proper cutting depth keeps blade friction to a minimum, removes saw-

dust from between the blade teeth, results in cooler, faster sawing and reduces the chance of

kickback. Align the appropriate mark on the depth adjustment strap with triangle on the upper

blade guard. Your depth is set.

For the most efficient cutting action using a carbide tipped saw blade, set the Depth Adjustment

so that about one half of a tooth projects below the surface of the wood to be cut (Figure 5).

A method of checking for the correct cutting depth is shown in Figure 6. Lay a piece of the material you plan to cut along the side of the blade, as shown in the figure, and observe how much

tooth projects beyond the material.

Bevel Angle Adjustment

CAUTION: Turn off and unplug the tool before making any adjustments or

removing/installing attachments or accessories.

The full range of the bevel adjustment is from 0 TO 50 DEGREES. The quadrant is graduated

in increments of 5 degrees.

On the front of the saw is a bevel angle adjustment mechanism (Fig. 8) consisting of a calibrated

quadrant (L) and a lever (M). To set the saw for a bevel cut, raise to loosen the Bevel Adjustment

lever and tilt shoe to the desired angle by aligning the pointer (N) with the desired angle mark.

Retighten lever firmly by lowering it.

KERF INDICATOR

The front of the saw shoe has a kerf indicator (Figure 10) for vertical and bevel cutting. This indicator enables you to guide the saw along cutting lines penciled on the material being cut. The

indicator lines up with the left (outer) side of the saw blade, which makes the slot or “kerf” cut

by the moving blade fall to the right of the indicator. The ribs on the front of the shoe are at 1/2"

(13mm) spacing.

OPERATION

Switch (Fig. 1)

Pull the trigger switch (B) to turn the motor ON. Releasing the trigger turns the motor OFF. This

tool has no provision to lock the switch in the ON position, and should never be locked ON in

any way.

Workpiece Support

Figure 11 and 13 show proper sawing position. Figure 12 and 14 show an unsafe condition.

Hands should be kept away from cutting area, and power cord is positioned clear of the cutting

area so that it will not get caught or hung up on the work.

To avoid kickback, DO support board or panel NEAR the cut, (Fig. 11, 13). DON’T support board

or panel away from the cut (Fig. 12, 14). When operating the saw, keep the cord away from the

cutting area and prevent it from becoming hung up on the work piece.

WARNING: It is important to support the work properly and to hold the saw firmly to prevent

loss of control which could cause personal injury; Figure 14 illustrates typical hand support of

the saw.

ALWAYS DISCONNECT SAW BEFORE MAKING ANY ADJUSTMENTS! Place the work with

its “good” side - the one on which appearance is most important - down. The saw cuts upward,

so any splintering will be on the work face that is up when you saw it.

Cutting

Support the work so that the waste will be on your left. Place the wider portion of the saw shoe

on that part of the work piece which is solidly supported, not on the section that will fall off when

the cut is made. As examples, Figure 13 illustrates the RIGHT way to cut off the end of a board,

and Figure 14 the WRONG way. Always clamp work. Don’t try to hold short pieces by hand!

Remember to support cantilevered and overhanging material. Use caution when sawing material from below.

Be sure saw is up to full speed before blade contacts material to be cut. Starting saw with blade

against material to be cut or pushed forward into kerf can result in kickback.

Push the saw forward at a speed which allows the blade to cut without laboring. Hardness and

toughness can vary even in the same piece of material, and knotty or damp sections can put a

heavy load on the saw. When this happens, push the saw more slowly, but hard enough to keep

it working without much decrease in speed.

Sawhook

Your saw has a convenient saw hook to allow you to hang the saw on a joist or rafter. The

sawhook folds flat against the tool handle when not in use.

To use the sawhook, push down on the hook and rotate it outwards from the handle. It will latch

into position. (Fig.15)

To return the sawhook to its stored position, push down on the hook and rotate it back towards

the handle. It will latch into position.

Kickback

When the saw blade becomes pinched or twisted in the cut, kickback can occur. The saw is

thrust rapidly back toward the operator. When the blade is pinched or bound tightly by the kerf

closing down, the blade stalls and the motor reaction drives the unit backward. When the blade

becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into

the top surface of the wood causing the blade to climb out of the kerf and jump back toward the

operator.

Kickback is more likely to occur when any of the following conditions exist.

1. IMPROPER WORKPIECE SUPPORT

A. Sagging or improper lifting of the cut off piece causing pinching of the blade. (Figure 12)

B. Cutting through material supported at the outer ends only (see Figure 12). As the mater-

ial weakens it sags, closing down the kerf and pinching the blade.

C.Cutting off a cantilevered or overhanging piece of material from the bottom up in a verti-

cal direction. The falling cut off piece can pinch the blade.(Figure 14)

D.Cutting off long narrow strips (as in ripping). The cut off strip can sag or twist closing the

kerf and pinching the blade.

FIG. 2

FIG. 3

FIG. 4

C

FIG. 7

FIG. 5

J

FIG. 6

FIG. 8

K

M

L

FIG. 9

N

FIG. 10

0˚

45˚

1/2”

13 mm

B

C

A

E

F

FIG. 12

FIG. 13

FIG. 14

FIG. 15

FIG. 11

TIGHTEN

(counterclockwise)

SERRER

(vers la gauche)

AJUSTAR

(dirección contraria

a las manillas

del reloj)

LOOSEN

(clockwise)

DESSERRER

(vers la droite)

AFLOJAR

(dirección de las

manillas del reloj)

FIG. 1

D

F

I

G

J

E. Snagging the lower guard on a surface below the material being cut momentarily reduc-

ing operator control. The saw can lift partially out of the cut increasing the chance of blade

twist.

2. IMPROPER DEPTH OF CUT SETTING ON SAW

Using the saw with an excessive depth of cut setting increases loading on the unit and susceptibility to twisting of the blade in the kerf. It also increases the surface area of the blade

available for pinching under conditions of kerf close down. See CUTTING DEPTH

ADJUSTMENT.

3. BLADE TWISTING (MISALIGNMENT IN CUT)

A. Pushing harder to cut through a knot, a nail, or a hard grain area can cause the blade to

twist.

B. Trying to turn the saw in the cut (trying to get back on the marked line) can cause blade

twist

C.Extended reach or operating saw with poor body control (out of balance), can result in

twisting the blade.

D.Changing hand grip or body position while cutting can result in blade twist.

E. Backing unit up to clear blade can lead to twist if not done carefully.

4. MATERIALS THAT REQUIRE EXTRA ATTENTION

A. Wet lumber

B. Green lumber (material freshly cut or not kiln dried)

C.Pressure treated lumber (material treated with preservatives or anti-rot chemicals)

5. USE OF DULL OR DIRTY BLADES

Dull blades cause increased loading of the saw. To compensate, an operator will usually

push harder which further loads the unit and promotes twisting of the blade in the kerf. Worn

blades may also have insufficient body clearance which increases the chance of binding and

increased loading.

6. LIFTING THE SAW WHEN MAKING BEVEL CUTS

Bevel cuts require special operator attention to proper cutting techniques - especially guidance of the saw. Both blade angle to the shoe and greater blade surface in the material

increase the chance for binding and misalignment (twist) to occur.

7. RESTARTING A CUT WITH THE BLADE TEETH JAMMED AGAINST THE MATERIAL

The saw should be brought up to full operating speed before starting a cut or restarting a cut

after the unit has been stopped with the blade in the kerf. Failure to do so can cause stalling

and kickback.

Any other conditions which could result in pinching, binding, twisting, or misalignment of the

blade could cause kickback. Refer to the sections on “Adjustments And Set-Up” and “Operation”

for procedures and techniques that will minimize the occurrence of kickback.

MAINTENANCE

Lubrication

Your saw has a sealed gear housing filled to the proper level with a high-performance gear lubricant. Adding excessive amounts of lubricant, or adding improper lubricant can cause leakage or

premature gear failure.

H

H

11x20,DW378 7/21/04 12:51 PM Page 2

Page 3

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET OUTIL OU TOUT AUTRE

OUTIL DEWALT, COMPOSER SANS FRAIS LE NUMÉRO SUIVANT : 1 800 4-DEWALT (1 800

433-9258)

Règles de sécurité – Généralités

AVERTISSEMENT! Lire et comprendre toutes les directives. Le non-respect

de toutes les directives suivantes présente des risques de secousses électriques, d'incendie ou de blessures graves.

CONSERVER CES MESURES

ZONE DE TRAVAIL

• S'assurer que la zone de travail est propre et bien éclairée. Des établis encombrés et

des endroits sombres présentent des risques d'accidents.

• Ne pas utiliser des outils électriques en présence de vapeurs explosives (comme

celles dégagées par des liquides, des gaz ou des poussières inflammables). Les étin-

celles générées par le moteur des outils électriques peuvent enflammer les poussières ou

les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de travail lorsqu'on utilise

un outil électrique. Une distraction peut entraîner la perte de maîtrise de l'outil.

MESURES DE SÉCURITÉ RELATIVES À L'ÉLECTRICITÉ

• Les outils mis à la terre doivent être branchés dans une prise bien installée et mise à

la terre conformément à tous les codes et règlements en vigueur. Ne jamais retirer la

broche de terre ni modifier la fiche. Ne pas utiliser d'adaptateur pour fiche. Vérifier

auprès d'un électricien certifié en cas de doute quant à la mise à la terre de la prise.

En cas de défaillance électrique ou de bris de l'outil, la mise à la terre procure un chemin de

faible résistance au courant qui autrement traverserait l'utilisateur. Valable seulement pour

les outils de classe I (mis à la terre). Les modèles DW378G et DW378GT sont mis à la

terre.

• Les outils à double isolation comportent une fiche polarisée (une lame plus large que

l'autre). La fiche n'entre que d'une façon dans une prise polarisée. Lorsque la fiche

n'entre pas à fond dans la prise, essayer de nouveau après avoir inversé les broches

de la fiche. Si la fiche n'entre toujours pas dans la prise, communiquer avec un électricien certifié afin de faire installer une prise polarisée. Ne modifier en aucune façon

la fiche. La double isolation élimine le besoin d'un cordon trifilaire mis à la terre et d'un

système d'alimentation mis à la terre. Valable seulement pour les outils de classe II (à

double isolation). Le modèle DW378 comporte une double isolation.

• Éviter de toucher à des surfaces mises à la terre comme des tuyaux, des radiateurs,

des cuisinières et des réfrigérateurs. Les risques de secousses électriques sont plus

élevés si le corps de l'utilisateur est mis à la terre.

• Protéger les outils électriques de la pluie ou des conditions mouillées. Une infiltration

d'eau dans l'outil augmente les risques de secousses électriques.

• Manipuler le cordon avec soin. Ne jamais se servir du cordon afin de transporter

l'outil ni tirer sur le cordon pour débrancher l'outil. Éloigner le cordon des sources de

Inspect your saw periodically for leakage. If you notice any leaks promptly return your saw to a

service center for inspection and relubrication.

Brushes

CAUTION: Turn off and unplug the tool before making any adjustments or

removing/installing attachments or accessories.

Inspect carbon brushes regularly by unplugging tool, removing the Brush Inspection Cover

and withdrawing the brush assembly. Keep brushes clean and sliding freely in their guides.

Always replace a used brush in the same orientation in the holder as it was prior to removal.

Carbon brushes have varying symbols stamped into their sides, and if either brush is worn

down to the line closest to the spring, they must be replaced. Use only identical D

EWALT

brushes. New brush assemblies are available at your local service center. The tool should be

allowed to “run in” (run at no load without a blade) for 10 minutes before use to seat new

brushes.

While “running in” DO NOT TIE, TAPE, OR OTHERWISE LOCK THE TRIGGER SWITCH ON.

HOLD BY HAND ONLY.

SHOE ADJUSTMENT

CAUTION: Turn off and unplug the tool before making any adjustments or

removing/installing attachments or accessories.

Your shoe has been factory set to assure that the blade is perpendicular to the shoe. If after

extended use, you need to re-align the blade as follows:

ADJUSTING FOR 90 DEGREE CUTS (FIG. 7, 8)

1. Return the saw to 0 degrees bevel.

2. Place the saw on its side, and retract the lower guard.

3. Loosen the Bevel Adjustment Lever (M). Place a square against the blade and the shoe.

4. Using an Allen wrench, turn the set screw on the underside of the shoe (K) until the blade

and the shoe are both in flush contact with the square. Retighten the Bevel Adjust Lever.

ADJUSTING DEPTH ADJUSTMENT AND BEVEL ADJUSTMENT LEVERS.

It may be desirable to adjust the the depth adjustment lever or the bevel adjustment lever. (They

may loosen in time and hit the shoe before tightening). To tighten either, follow the steps below.

CAUTION: Turn off and unplug the tool before making any adjustments or

removing/installing attachments or accessories.

1. Using a small screwdriver, pry the lock ring off, see Figure 9.

2. Remove the lever and rotate it in the desired direction about 1/8 of a revolution.

3. Reinstall the lock ring with the concave side against the lever to hold it in place.

Blades

A dull blade will cause slow, inefficient cutting, overload on the saw motor, excessive splintering

and increase the possibility of kickback. Change blades when it is no longer easy to push the

saw through the cut, when the motor is straining, or when excessive heat is built up in the blade.

It is a good practice to keep extra blades on hand so that sharp blades are available for immediate use. Dull blades can be sharpened in most areas; see SAWS-SHARPENING in the yellow

pages.

Hardened gum on the blade can be removed with trichlorethylene (nail polish remover),

kerosene, turpentine, or oven cleaner. Anti-stick coated blades can be used in applications

where excessive build-up is encountered, such as pressure treated and green lumber.

VISUALLY EXAMINE CARBIDE BLADES BEFORE USE. REPLACE IF DAMAGED.

COMBINATION FRAMING- All purpose fast rip and cross cuts.

PRESSURE TREATED/WET LUMBER- Coated - Resistant to build-up

EXTREME DURABILITY - Maximum impact resistance for longer life.

FINISHING - More teeth for finer finish cuts.

FAST CUT FRAMING - Fastest blade for rips and cross cuts

D

EWALT also offers a full line of steel blades for specialty jobs such as plywood, non-ferrous

metal, planing, and iron/steel.

NOTE: All D

EWALT blades offer a diamond knockout for use on this saw.

Accessories

WATER FEED ATTACHMENTS ARE NOT RECOMMENDED FOR THIS SAW.

Recommended accessories for use with your tool are available at extra cost from your local ser-

vice center.

CAUTION: The use of any non-recommended accessory may be hazardous.

If you need any assistance in locating any accessory, please contact DEWALT Industrial Tool

Co., 701 East Joppa Road, Baltimore, MD 21286 or call 1-800-732-4441.

Repairs

To assure product safety and reliability, repairs, maintenance and adjustment should be performed by D

EWALT Inc. Industrial Service Centers or other qualified service organizations,

These service organizations service D

EWALT tools always using DEWALT replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear

or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your D

EWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-DEWALT for a free replacement.

chaleur, des flaques d'huile, des arêtes tranchantes et des pièces mobiles. Remplacer

immédiatement les cordons endommagés. Les cordons endommagés augmentent les

risques de secousses électriques.

• Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit utiliser que des rallonges

conçues pour cet usage, comme celles de type « W-A » ou « W », afin de réduire les

risques de choc électrique. S’assurer que la rallonge est en mesure de porter le courant

nécessaire à l’outil. Une rallonge de calibre inférieur entraînera une chute de tension se

traduisant par une perte de puissance et une surchauffe. Le tableau ci-dessous illustre les

calibres que l’on doit utiliser selon la longueur de la rallonge et l’intensité nominale indiquée

sur la plaque signalétique. En cas de doute, utiliser le calibre suivant. Plus le calibre est petit,

plus la rallonge peut porter de courant.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

SÉCURITÉ PERSONNELLE

• Demeurer vigilant, prendre soin et faire preuve de jugement lorsqu'on utilise un outil

électrique. Ne pas s'en servir lorsqu'on est fatigué ou affaibli par des drogues, de l'alcool ou des médicaments. De graves blessures peuvent résulter d'un moment d'inattention

lors de l'utilisation d'un outil électrique.

• Porter des vêtements appropriés. Ne pas porter des vêtements amples ni des bijoux.

Attacher les cheveux longs. Tenir les cheveux, les vêtements et les gants à l’écart des

pièces mobiles. Les vêtements amples, les bijoux et les cheveux longs peuvent être hap-

pés par des pièces mobiles. Se tenir éloigné des évents puisque ces derniers pourraient

camoufler des pièces mobiles.

• Éviter les démarrages accidentels. S'assurer que l'interrupteur est en position hors

tension avant de brancher l'outil. Afin d'éviter les risques de blessures, ne pas transporter

l'outil avec le doigt sur l'interrupteur ni brancher un outil dont l'interrupteur est en position sous

tension.

• Enlever les clés de réglage avant de mettre l'outil sous tension. Une clé qui est laissée

sur une pièce rotative de l'outil présente des risques de blessures.

• Ne pas dépasser sa portée. Garder son équilibre en tout temps. On s'assure d'une

meilleure maîtrise de l'outil dans des situations imprévues grâce à une position stable et un

bon équilibre.

• Porter de l'équipement de sécurité. Toujours porter des lunettes de sécurité. Dans certaines conditions, il faut porter des masques respiratoires, des chaussures antidérapantes,

un casque de sécurité ou des protège-tympans.

UTILISATION ET ENTRETIEN DE L'OUTIL

• Utiliser des pinces de serrage ou de tout autre moyen pratique afin de fixer et de

soutenir la pièce à ouvrer sur une plate-forme stable. La pièce est instable lorsqu'elle est

retenue par la main ou le corps de l'utilisateur. Cela présente des risques de perte de maîtrise

de l'outil.

• Ne pas forcer l'outil. Utiliser l'outil approprié à la tâche. L'outil approprié fonctionne mieux

et sûrement lorsqu'on s'en sert à son rendement nominal.

• Ne pas se servir de l'outil lorsque l'interrupteur est défectueux. Le cas échéant, l'outil

est dangereux et il faut le réparer.

• Débrancher l'outil de la source d'alimentation avant de le régler, d'en remplacer les

accessoires ou de le ranger. On minimise de la sorte le risque de démarrage accidentel de

l'outil.

• Ranger l'outil hors de portée des enfants et de toute autre personne qui n'en connaît

pas le fonctionnement. L'outil est dangereux entre les mains de ces personnes.

• Prendre soin des outils. S'assurer que les outils de coupe sont tranchants et propres.

Des outils bien entretenus à arêtes tranchantes ont moins tendance à se coincer et ils se

maîtrisent mieux.

• Vérifier l'alignement et les attaches des pièces mobiles, le degré d'usure des pièces

ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l'outil. Faire

réparer un outil endommagé avant de s'en servir. Des outils mal entretenus sont la cause de

nombreux accidents.

• Utiliser seulement les accessoires recommandés par le fabricant pour le modèle. Des

accessoires qui conviennent à un outil peuvent présenter des risques avec un autre outil.

ENTRETIEN

• Confier l'entretien de l'outil seulement à du personnel qualifié. Le non-respect de la

présente directive présente des risques de blessures.

• Lors de l'entretien de l'outil, utiliser seulement des pièces de rechange identiques.

Respecter les consignes relatives à l'entretien du présent guide d'utilisation. Il y a

risque de secousses électriques ou de blessures lorsqu'on utilise des pièces non autorisées

ou lorsqu'on ne respecte pas les consignes relatives à l'entretien.

Mesures de sécurité relatives aux scies circulaires

DANGER! Garder les mains éloignées des zones de coupe et de la lame. Toujours tenir l’outil

en plaçant une main sur la poignée auxiliaire ou le carter du moteur; on protège ses mains en

les utilisant toutes les deux pour tenir l’outil.

MISE EN GARDE : les lames ne s’arrêtent pas immédiatement lorsque l’interrupteur est mis

en position d’arrêt.

• Toujours se placer d’un côté ou de l’autre de la lame en évitant de se tenir dans son

trajet, car la scie pourrait reculer brusquement par suite d’un REBOND. (Voir les sections

« Causes du rebond et mesures préventives » et « Effet de rebond ».

• Ne pas mettre les mains sous la pièce car il n’y a aucune protection contre la lame à cet

endroit.

• Vérifier le protège-lame inférieur afin de s’assurer qu’il soit bien fermé avant d’utiliser l’outil; ne pas faire fonctionner ce dernier si le protège-lame ne se déplace pas librement

ou s’il ne se ferme pas instantanément. Ne jamais le bloquer en position ouverte. Si on

laisse tomber la scie, soulever le protège-lame inférieur au moyen du levier d’escamotage

et le vérifier afin de s’assurer qu’il n’y ait aucun dommage, qu’il se déplace librement et qu’il

n’entre pas en contact avec la lame ou toute autre pièce de l’outil, quels que soient l’angle

et la profondeur de coupe.

• S’assurer que le ressort du protège-lame inférieur soit en bon état de fonctionnement; sinon, on doit lui faire subir un entretien avant d’utiliser l’outil. Le protège-

lame peut être difficile à déplacer en présence de pièces endommagées, de dépôts gommeux ou de débris accumulés.

• On ne doit escamoter manuellement le protège-lame inférieur que pour réaliser une

coupe spéciale, complexe ou à partir de l’intérieur d’un matériau. Pour ce faire, on doit

le soulever au moyen du levier d’escamotage, relâchant ce dernier dès que la lame mord

dans la pièce. Le protège-lame s’escamote automatiquement pour tous les autres types de

coupe.

• Toujours s’assurer que le protège-lame inférieur recouvre la lame avant de déposer la

scie sur le plancher ou sur un établi, car, sans protection, une lame qui tourne encore

fait reculer la scie, coupant tout ce qui se trouve sur son passage. Il est en outre bon de

savoir combien de temps la lame prend pour s’arrêter une fois l’interrupteur relâché.

• Ne JAMAIS tenir la pièce dans ses mains ou la placer sur ses jambes pour la couper.

Il est important de soutenir la pièce correctement afin d’éviter d’exposer des parties du corps

à la lame, de coincer cette dernière ou encore, de perdre la maîtrise de l’outil.

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en contact avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre les

pièces métalliques de l’outil sous tension, engendrant des risques de choc électrique.

• Toujours utiliser un guide de refend ou de bord droit lorsqu’on effectue une coupe en long

afin d’assurer la précision de cette dernière et d’éviter de coincer la lame.

• Toujours utiliser une lame munie d’un arbre dont les orifices sont de dimension et de

forme appropriées (ronds ou en losanges); les lames qui ne correspondent pas aux élé-

ments de fixation de la scie tourneront de manière excentrique, faisant perdre la maîtrise de

l’outil.

• Ne jamais utiliser de rondelles ou de boulons endommagés ou autres que ceux qui

ont été conçus pour la scie, afin d’obtenir un rendement optimal et de travailler en toute

sécurité.

• Éviter de couper des clous; s’assurer que le bois de sciage soit exempt de clous avant de

procéder à la coupe.

CAUSES DU REBOND ET MESURES PRÉVENTIVES

• Le rebond est une réaction soudaine de l’outil causée par une lame pincée, bloquée ou mal

alignée , occasionnant la perte de maîtrise de la scie, qui se soulève et se détache de la pièce

en direction de l’opérateur.

• Lorsque la lame reste coincée ou est immobilisée par une entaille qui se referme, l’arrêt de la

lame et la réaction du moteur entraîne un recul brusque de l’outil vers l’opérateur.

• Si la lame se tord ou est mal alignée, les dents arrière peuvent s’engager sur le dessus de la

pièce, faisant grimper la lame hors de l’entaille et rebondir l’outil en direction de l’opérateur.

• Le rebond découle d’une mauvaise utilisation ou du mauvais fonctionnement de l’outil; on peut

l’éviter en prenant les précautions suivantes.

• Tenir fermement l’outil des deux mains et placer le corps et les bras de manière à pou-

voir maîtriser les effets du REBOND; le rebond peut être maîtrisé si l’opérateur prend les

précautions nécessaires.

• Lorsque la lame se coince ou qu’on veut interrompre une coupe pour quelque raison

que ce soit, relâcher l’interrupteur à gâchette et maintenir la scie immobile dans la

pièce, jusqu’à ce que la lame s’arrête complètement. Ne jamais tenter de sortir la scie

hors de l’entaille ou de la tirer vers soi avant que la lame ne se soit immobilisée com-

11x20,DW378 7/21/04 12:51 PM Page 3

Page 4

plètement afin d’éviter le REBOND. Vérifier la pièce afin de déterminer la cause du coincement et de prendre les mesures correctives qui s’imposent.

• Lorsqu’on remet la scie en marche, centrer la lame dans l’entaille et s’assurer que les

dents ne soient pas engagées dans le matériau. Si la lame se coince, la scie peut grimper

hors de l’entaille ou faire un REBOND lorsqu’on la redémarre.

• Soutenir les grands panneaux afin d’éviter autant que possible de coincer la lame et

d’engendrer un REBOND. Les grands panneaux tendent à s’affaisser sous leur poids et

doivent être soutenus de chaque côté, près de la ligne de coupe et du bord du panneau.

• Ne pas utiliser de lames usées ou endommagées, car celles-ci produisent des entailles

plus étroites, ce qui peut causer une friction excessive, coincer la lame et engendrer un

REBOND.

• Bien verrouiller les leviers de réglage de profondeur et d’angle de biseau avant

d’amorcer une coupe ; si ces leviers se déplacent durant la coupe, la lame peut se coincer

et entraîner un REBOND.

• On doit faire particulièrement attention lorsqu’on effectue une coupe «interne» dans un

mur ou un endroit difficile à voir, car la lame peut couper des objets cachés qui risquent

d’occasionner un REBOND.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies, les meules,

les perceuses ou certains autres outils de construction, peuvent produire de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on

retrouve :

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (comme

l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on effectue ces

travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit bien aéré et

utiliser le matériel de sécurité approprié, tel un masque anti-poussières spécialement conçu

pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres outils

électriques. Porter des vêtements de protection et nettoyer les parties exposées du

corps à l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber par la

bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire anti-poussières approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé du visage et du corps

.

AVERTISSEMENT : Toujours porter des lunettes de sécurité. L’utilisateur et toute autre

personne se trouvant à proximité de la zone de coupe doit porter des lunettes de sécurité conformes à la norme ANSI Z87.1.

MISE EN GARDE : Porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation, le bruit

émanant de ce produit pourrait contribuer à la perte d’audition.

MISE EN GARDE : lorsqu’on effectue une coupe dans un mur, un plancher ou dans un

endroit où l’on risque d’entrer en contact avec des fils cachés, toujours tenir l’outil par les surfaces isolantes prévues à cette fin, car de tels contacts peuvent mettre les pièces métalliques

de l’outil sous tension et engendrer des risques de choc électrique. NE JAMAIS TOUCHER LES

PIÈCES MÉTALLIQUES DE L’OUTIL!

• L’étiquette apposée sur l’outil peut comprendre les symboles suivants. Voici les symboles et

leurs définitions :

V..........volts A ............ampères

Hz........hertz W ..........watts

min ......minutes ..........courant alternatif

....courant continu

n

o ..........aucune option à vide

........construction de classe II ..........borne de terre

........symbole d’avertissement .../min ....tours par minute

CARACTÉRISTIQUES

A. Couvercle d'inspection des balais E. Patin

B. Interrupteur à détente F. Vis de fixation de la lame

C. Dispositif de réglage de

la profondeur de coupe

D. Dispositif de réglage de l'angle de coupe

Moteur

Un moteur DEWALT entraîne l'outil DEWALT. Veiller à ce que la tension d'alimentation soit conforme aux exigences de la plaque signalétique de l'outil. La mention 120 volts c.a./c.c. signifie

que l'outil fonctionne également sur une alimentation en courant alternatif ou continu. Une

baisse de tension de 10 p. 100 entraîne une perte de puissance et la surchauffe. Tous les outils D

EWALT sont essayés avant de quitter l'usine. Lorsque celui-ci refuse de fonctionner, vérifi-

er la source de courant électrique.

Remplacement des lames

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retire/d’installer une pièce ou un accessoire.

INSTALLATION DE LA LAME

1. Placer la rondelle de bride de serrage interne (G) sur la broche de scie (la large surface

plane doit être orientée vers l’extérieur, face à la lame (fig. 1).

2. Escamoter le protège-lame inférieur (H) et placer la lame sur la broche, contre la rondelle

de bride de serrage interne, en s’assurant que la lame tourne dans le bon sens (le sens de

la flèche de rotation située sur la lame et les dents doivent pointer dans la même direction

que celle de la flèche indiquée sur la scie). Ne pas assumer que le côté imprimé de la lame

est toujours face à l’utilisateur lorsqu’elle est installée correctement. Lorsqu’on escamote le

protège-lame inférieur en vue d’installer la lame, le vérifier afin de s’assurer qu’il est en bon

état et qu’il fonctionne correctement, c’est-à-dire, qu’il se déplace librement et qu’il ne

touche pas à la lame ni à toute autre pièce quelconque, quel que soit l’angle ou la profondeur de coupe.

3. Placer la rondelle de bride de serrage externe (I) sur la broche de scie, en s’assurant de

placer la large surface plane contre la lame, et le côté imprimé de la rondelle face à l’utilisateur.

4. Fileter la vis de fixation de la lame (F) dans la broche et la serrer fermement avec les doigts

(cette vis à filetage inverse doit être serrée vers la gauche).

5. Appuyer sur le bouton de verrouillage de la lame (J) et tourner la broche au moyen de la clé

de réglage de la lame jusqu’à ce que le bouton de verrouillage s’engage et que la lame s’immobilise (fig. 3).

6. Serrer fermement la vis de fixation au moyen de la clé de réglage.

REMARQUE : Ne jamais engager le bouton de verrouillage de la lame lorsque la scie est en

marche pour tenter d’arrêter l’outil. Ne jamais mettre l’outil en marche lorsque le bouton de verrouillage est engagé afin d’éviter d’endommager gravement la scie.

REMPLACEMENT DE LA LAME

1. Pour desserrer la vis de fixation de la lame (F), appuyer sur son bouton de verrouillage (J)

et tourner la broche au moyen de la clé de réglage jusqu’à ce que le bouton de verrouillage

s’engage et que la lame s’immobilise. Une fois le bouton engagé, tourner la vis de fixation

de la lame vers la droite au moyen de la clé (cette vis à filetage inverse doit être desserrée

vers la droite).

2. Retirer la vis de fixation (F) et la rondelle de bride de serrage externe (I) seulement, puis

enlever l’ancienne lame.

3. Enlever la sciure qui aurait pu s’accumuler dans le protège-lame ou autour de la rondelle et

vérifier le protège-lame inférieur afin de s’assurer qu’il est en bon état et qu’il fonctionne correctement, tel que décrit précédemment. Ne pas lubrifier cette zone.

4. Choisir la lame qui convient à la tâche (voir la section « Lames » du présent guide). Toujours

utiliser une lame de dimension (diamètre) appropriés munie d’un orifice de dimension et de

forme appropriées en vue de leur installation sur la broche. Toujours s’assurer que la vitesse

maximale recommandée (tr/min) indiquée sur la lame est égale ou supérieure à la vitesse

(tr/min) de la scie.

5. Suivre les étapes de 2 à 6 décrites à la section « Installation de la lame » du présent guide,

en s’assurant que la lame tourne dans le bon sens.

PROTÈGE-LAME INFÉRIEUR

AVERTISSEMENT : Le protège-lame inférieur est un dispositif de sécurité qui réduit les

risques de blessure grave. Ne jamais utiliser la scie lorsque le protège-lame inférieur est

manquant, endommagé, mal assemblé ou en mauvais état de fonctionnement. Ne pas se

fier sur le protège-lame inférieur pour se protéger sous toutes les circonstances. Pour

assurer sa propre sécurité, on doit suivre toutes les mesures de précaution et consignes

de sécurité décrites ci-dessous et utiliser l’outil correctement. Vérifier le protège-lame

inférieur avant chaque utilisation afin de s’assurer qu’il se ferme correctement, tel que

décrit à la section « Règles de sécurité additionnelles concernant les scies circulaires »

du présent guide. Lorsque le protège-lame inférieur est manquant ou qu’il ne fonctionne

pas bien, apporter la scie à un centre de service autorisé avant de l’utiliser. Pour assurer la sécurité et la fiabilité de ce produit, toutes les opérations de réparation, d’entretien

et de réglage doivent être effectuées dans un centre de service autorisé ou par du personnel qualifié; on ne doit utiliser que des pièces de rechange identiques.

Réglage de la profondeur de coupe

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retire/d’installer une pièce ou un accessoire.

Saisir fermement la scie. Soulever le levier de réglage de la profondeur de coupe (C) et déplacer le patin de façon à obtenir la profondeur de coupe voulue, de la façon illustrée. Bien resserrer

(abaisser) le levier de réglage de la profondeur de coupe avant de se servir de la scie (Fig. 4).

La scie est munie d'une lame à dents au carbure qui en prolongent la durée et en rendent la

coupe des plus efficaces.

Un bon réglage de la profondeur de coupe minimise la friction de la lame, permet l'évacuation

de la sciure, assure une coupe rapide et en douceur tout en réduisant les risques de rebond.

Aligner la marque appropriée de la courroie de réglage de la profondeur sur le triangle du protecteur supérieur. La profondeur de coupe est alors réglée.

Pour optimiser les résultats de coupe lorsqu'on utilise une lame à dents au carbure, régler la

profondeur de coupe de sorte qu'une moitié de dent de la lame sorte du dessous du matériau

à découper (fig. 5).

La figure 6 illustre la marche à suivre pour vérifier le réglage de la profondeur. Déposer un

échantillon du matériau à découper le long de la lame. Remarquer comment la dent de la lame

sort de l'échantillon.

Réglage pour coupes en biseau débrancher la scie

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retire/d’installer une pièce ou un accessoire.

La gamme complète de réglage pour les coupes en biseau va de 0 À 50 DEGRÉS. Le secteur

est calibré en multiples de 5 degrés.

Le mécanisme de réglage de l'angle de coupe se trouve à l'avant de la scie (fig. 8) et il consiste

en un secteur calibré (L) et en un levier (M). Le réglage de la scie pour les coupes en biseau

se fait en soulevant le levier pour le desserrer, et en faisant basculer le patin jusqu'à ce qu'on

obtienne l'angle voulu en alignant l'indicateur (N) sur l'angle indiqué. Resserrer fermement le

levier en l'abaissant.

INDICATEUR DE VOIE

À l'avant du patin de la scie, il y a un indicateur de voie (fig. 10) servant aux coupes à la verticale et en biseau. L'indicateur permet de guider la scie le long de lignes de coupe tracées sur

le matériau à découper. L'indicateur s'aligne sur le côté gauche (externe) de la lame de la scie

permettant à la lame de couper la voie à droite de l'indicateur. Les rainures à l'avant du patin

sont espacées de 13 mm (1/2 po).

FONCTIONNEMENT

Interrupteur (fig. 1)

Enfoncer la détente pour mettre le moteur en marche et la relâcher pour arrêter le moteur. L'outil

ne peut pas être bloqué en mode de fonctionnement continu et il ne faudrait jamais essayer de

le bloquer dans cette position.

Soutien du matériau à découper

Les figures 11 et 13 illustrent la meilleure position de coupe. Les figures 12 et 14 illustrent une

position de coupe inappropriée. Il faut toujours éloigner les mains et le cordon électrique de la

zone de coupe de sorte que ce dernier ne puisse pas s'accrocher sur la surface de travail.

Pour éviter les risques de rebond, SOUTENIR le matériau PRÈS de la ligne de coupe (fig. 11

et 13). NE PAS soutenir le matériau loin de la ligne de coupe (fig. 12 et 14). Lorsqu'on se sert

de la scie, éloigner le cordon de la zone de coupe et l'empêcher de s'accrocher sur la surface

de travail.

AVERTISSEMENT : Il est essentiel de bien soutenir la pièce à découper et de bien saisir la

scie afin de prévenir les risques de blessures. La figure 13 montre la bonne façon de tenir l'outil.

TOUJOURS DÉBRANCHER LA SCIE AVANT DE LA RÉGLER. Placer le «bon» côté du matériau à découper (celui dont l'apparence importe le plus) vers le bas. En effet, la scie coupe vers

le haut de sorte que les éclats se trouvent sur la face supérieure de la pièce.

Coupe

Soutenir la pièce à découper de sorte que la ligne de coupe se trouve sur la gauche. Placer la

partie large du patin sur la partie soutenue du matériau et non sur la partie du matériau qui

tombera après la coupe. La figure 15, par exemple, illustre la BONNE façon de découper l'extrémité du matériau; tandis que le figure 14 montre la MAUVAISE façon. Toujours placer le

matériau dans un étau. Ne pas essayer de retenir les petites pièces à la main. Soutenir également les pièces en porte-à-faux ou en saillie. Prendre garde lorsqu'on scie des pièces par le

bas.

S'assurer que la scie tourne à plein régime avant d'insérer la lame dans la pièce à découper. Il

existe des risques de rebond lorsqu'on démarre la scie et que la lame est contre la pièce à

découper ou que la lame se trouve dans la voie.

Faire avancer la scie à une vitesse qui ne force pas la lame. La difficulté de la coupe peut varier dans une même pièce en raison de la teneur en humidité et en noeuds du bois. Lorsque l'humidité et les noeuds exercent une surcharge sur la scie, la faire avancer lentement mais assez

fermement pour que la scie maintienne son régime.

Crochet

La scie comporte un crochet des plus pratiques pour suspendre la scie sur une solive ou un

chevron. Le crochet se replie à plat sur la poignée de l'outil lorsqu'on ne s'en sert pas.

Pour s'en servir, appuyer sur le crochet et le faire tourner vers l'extérieur de la poignée. Il s'enclenche en place (fig. 15).

Pour rabaisser le crochet, l'abaisser et le faire tourner vers la poignée. Il s'enclenche en place.

Rebond

Lorsque la lame se coince dans la pièce à découper, il y a un rebond. La scie sort alors rapidement de la pièce à découper vers l'utilisateur. Lorsque la lame est coincée en raison de le fermeture de la voie, la lame se bloque et la réaction du moteur fait sortir la scie de la pièce à

découper vers l'arrière. Lorsque la lame est coincée ou n'est pas bien alignée sur la ligne de

coupe, les dents à l'arrière de la lame peuvent creuser la surface supérieure de la pièce faisant

sortir la lame de la voie, vers l'utilisateur.

Les situations suivantes présentent des risques de rebonds.

1. MAUVAIS SOUTIEN DE LA PIÈCE À DÉCOUPER

A. L'affaissement ou le mauvais soutien de la pièce découpée peut causer le blocage de la

lame (fig. 12).

B. Le découpage d'un matériau seulement soutenu à l'extrémité externe (voir la figure 12)

fait affaisser le matériau à mesure qu'il s'affaiblit, refermant ainsi la voie et bloquant la

lame.

C. Le découpage d'une pièce en porte-à-faux ou en saillie à partir du bas vers le haut, à la

verticale, provoque le blocage de la lame lorsque la pièce découpée tombe (fig. 14).

D. Le découpage de longues bandes étroites (coupes en refente) peut causer l'affaissement

ou la torsion de la bande bloquant ainsi la voie et coinçant la lame.

E. L'accrochage du protecteur inférieur sur la surface sous le matériau peut réduire momen-

tanément la maîtrise de l'utilisateur sur l'outil. La scie peut alors sortir en partie de la pièce

augmentant le risque de torsion de la lame.

2. RÉGLAGE INCORRECT DE LA PROFONDEUR DE COUPE

Lorsque le réglage de la profondeur de coupe dépasse la profondeur requise, la charge de

l'outil ainsi que les risques de torsion de la lame dans la voie augmentent. Le réglage incorrect augmente également la surface de coinçage de la lame dans le cas où la voie se

referme. Consulter la rubrique relative au réglage de la profondeur de coupe à la page 4.

3. TORSION DE LA LAME (COUPE MAL ALIGNÉE)

A. Le fait de pousser fort pour découper un noeud, un clou ou une section à grain dur peut

provoquer la torsion de la lame.

B. Lorsqu'on essaie de faire dévier la scie pendant le découpage (pour revenir dans la ligne

de coupe) peut également provoquer la torsion de la lame.

C. Le fait de s'étirer hors de sa portée ou de ne pas garder son équilibre peut causer la tor-

sion de la lame.

D. Le changement de position des mains ou du corps pendant la coupe peut provoquer la

torsion de la lame.

E. Le retrait de la scie pour dégager les copeaux de la lame peut faire tordre la lame si le

retrait ne se fait pas soigneusement.

4. MATÉRIAUX PRÉSENTANT DES RISQUES

A. Le bois qui est humide.

B. Le bois vert; qui est frais coupé ou qui n'a pas encore passé au séchoir.

C.Le bois qui est traité à la pression (traité avec des agents de conservation ou des pro-

duits chimiques contre la moisissure).

5. UTILISATION DES LAMES ÉMOUSSÉES OU SALES

Les lames émoussées augmentent la charge de la scie. Pour compenser, l'utilisateur

pousse habituellement fort ce qui charge un peu plus la scie et occasionne la torsion de la

lame dans la voie. Les lames usées n'ont pas suffisamment de jeu ce qui augmente les

risques de pliage et de surcharge.

6. RETRAIT DE LA SCIE PENDANT LES COUPES EN BISEAU

Les coupes en biseau doivent être faites en respectant un certain nombre de techniques,

particulièrement relatives au guidage de la scie. En effet, l'angle de la lame au patin et la

grande surface de la lame sur le matériau augmentent les risques de pliage et de torsion.

7. REDÉMARRAGE D'UNE COUPE AVEC LES DENTS DE LA LAME COINCÉES DANS LE

MATÉRIAU

Il faut attendre que la scie atteigne son plein régime avant de commencer à découper ou

avant de remettre la scie en marche. Autrement, la scie peut caler ou rebondir.

Toute autre condition qui peut occasionner le coincement, le pliage, la torsion ou l'alignement

incorrect de la lame peut également résulter en un rebond. Consulter les rubriques relatives aux

réglages et à l'installation ainsi qu'au fonctionnement de la scie afin de minimiser les risques de

rebond.

ENTRETIEN

Lubrification

La scie comporte un boîtier scellé des engrenages rempli au niveau approprié de lubrifiant à

haut rendement. L'ajout d'une quantité excessive ou de la mauvaise qualité de lubrifiant peut

entraîner des fuites ou la défaillance prématurée des engrenages.

11x20,DW378 7/21/04 12:51 PM Page 4

Page 5

Instrucciones de seguridad generales

ADVERTENCIA: Es indispensable sujetarse a las precauciones básicas de

seguridad, con la finalidad de reducir el peligro de incendio, choque eléctrico y

lesiones personales, en todas las ocasiones en que se utilicen herramientas eléctricas. Entre estas precauciones se incluyen las siguientes.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las bancas con objetos amonton-

ados y las zonas oscuras propician los accidentes.

• No opere herramientas eléctricas portátiles en atmósferas explosivas, como en pres-

encia de líquidos, gases o polvos inflamables. Las herramientas eléctricas producen

chispas que pueden originar la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados mientras opera una herramien-

ta eléctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas con conexión a tierra deben conectarse a una toma de corriente

instalada y aterrizada correctamente de conformidad con todos los códigos y regulaciones locales. Nunca elimine la pata de conexión a tierra ni modifique la clavija en

ninguna manera. No utilice clavijas adaptadoras. Consulte con un electricista calificado

si tiene dudas acerca de la conexión correcta a tierra de su toma de corriente. En el caso

que su herramienta tenga una falla eléctrica, el aterrizaje proporciona una vía de baja

resistencia para llevar la electricidad lejos del operador. Aplicable únicamente a her-

ramientas Clase I (con conexión a tierra). Los modelos DW378G y DW378GT son herramientas aterrizadas.

Vérifier régulièrement la scie pour en déceler des fuites d'huile. En cas de fuite, confier rapidement la scie aux préposés du centre de service de la région afin d'en remplacer les joints et d'en

assurer la lubrification appropriée.

Balais

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retire/d’installer une pièce ou un accessoire.

Inspecter régulièrement les balais en charbon en débranchant d'abord la scie, en retirant le couvercle d'inspection des balais et en sortant l'assemblage-balais. S'assurer que les balais sont

propres et qu'ils glissent bien dans leurs guides. Toujours remplacer les balais usés par des balais placés dans le même sens dans le porte-balai. Différents symboles sont inscrits sur les côtés

des balais en charbon. Lorsque le balai est usé jusqu'à la ligne la plus près du ressort, il faut le

remplacer. N'utiliser que des balais de rechange identiques D

EWALT. Le centre de service de

la région vend des balais de rechange. Il faut laisser l'outil fonctionner à vide (sans charge et

sans lame) pendant dix minutes avant de l'utiliser afin de permettre aux nouveaux balais de s'installer.

Pendant le fonctionnement à vide de la scie, NE PAS ATTACHER, COLLER NI BLOQUER DE

TOUTE AUTRE FAÇON L'INTERRUPTEUR À DÉTENTE. LE TENIR À LA MAIN SEULEMENT.

RÉGLAGE DU PATIN

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retire/d’installer une pièce ou un accessoire.

Le patin a été réglé en usine de façon à ce que la lame y soit perpendiculaire. Après une utilisation prolongée, il peut être nécessaire de le régler comme suit.

RÉGLAGE POUR COUPES À 90 DEGRÉS (FIG. 7, 8)

1. Régler la scie pour une coupe en biseau à 0 degré.

2. Déposer la scie sur son côté et en escamoter le protecteur inférieur.

3. Desserrer le levier de réglage pour coupes en biseau (M). Placer une équerre contre la lame

et le patin.

4. À l'aide d'une clé hexagonale, faire tourner la vis de pression qui se trouve sous le patin (K)

jusqu'à ce que la lame et le patin reposent contre l'équerre. Resserrer le levier de réglage

pour coupes en biseau.

RÉGLAGE DES LEVIERS DE RÉGLAGE DE LA PROFONDEUR DE COUPE ET POUR

COUPES EN BISEAU

Il peut être nécessaire de régler les leviers de réglage de la profondeur de coupe ou pour coupes

en biseau. (Ces leviers peuvent se desserrer avec le temps et frapper contre le patin avant de

se resserrer.) Faire ce qui suit pour resserrer l'un ou l'autre des leviers.

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retire /d’installer une pièce ou un accessoire.

1. À l'aide d'un petit tournevis, soulever et retirer la bague de retenue (fig. 9).

2. Retirer le levier et le faire tourner dans le sens voulu d'environ 1/8 tour.

3. Remettre la bague de retenue en place avec le côté concave vers le levier afin de retenir ce

dernier en place.

Lames

Une lame émoussée procure des coupes lentes et inefficaces qui augmentent la surcharge du

moteur, la production excessive d'éclats et les risques de rebond. Il faut remplacer la lame

lorsque celle-ci avance difficilement dans la voie, lorsque le moteur force ou lorsque la lame surchauffe. C'est pourquoi il est conseillé d'avoir à portée de la main quelques lames de rechange

qui sont utiles lorsque les lames émoussées se font affûtées (voir la rubrique «Scies - Aiguisage

et réparation» des Pages Jaunes).

La gomme durcie sur la lame peut être enlevée à l'aide de trichloréthylène (solvant pour vernis

à ongles), de kérosène, de térébenthine ou d'un produit nettoyant pour le four. On peut utiliser

des lames recouvertes d'un enduit antiadhésif pour effectuer des travaux présentant une surcharge (comme pour couper du bois traité ou du bois vert).

VÉRIFIER LES LAMES AU CARBURE AVANT DE S'EN SERVIR. REMPLACER LES LAMES

ENDOMMAGÉES.

UNIVERSELLE – Coupes universelles en travers et en refente.

POUR BOIS TRAITÉ ET BOIS VERT – Lame recouverte d'un enduit résistant aux

accumulations.

À DURÉE PROLONGÉE – Résistance maximale aux chocs en prolongeant la durée.

DE FINITION – Plus de dents améliorant la finition de la coupe.

DE COUPE RAPIDE – Coupes rapides en travers et en refente.

D

EWALT offre également une gamme complète de lames en acier pour travaux spécialisés

(comme la coupe du contreplaqué et des métaux non ferreux ainsi que du fer ou de l'acier, et le

rabotage).

NOTE : Toutes les lames D

EWALT comportent une forme poinçonnée en diamant afin de pou-

voir servir sur la présente scie.

Accessoires

IL EST DÉCONSEILLÉ D'UTILISER DES ACCESSOIRES POUR L'ALIMENTATION EN EAU

AVEC LA SCIE.

Les accessoires recommandés pour l'outil sont vendus séparément au centre de service de la

région.

MISE EN GARDE : L’utilisation de tout accessoire non recommandé peut être dangereuse.

Pour trouver un accessoire, prière de communiquer à l'adresse suivante, DEWALT Industrial

Tool Co., 701 East Joppa Road, Baltimore, MD 21286, É.-U. ou composer le numéro suivant, 1

(800) 732-4441.

Reparations

Pour assurer la SÉCURITÉ et la FIABILITÉ de cet outil, toutes les opérations de réparation,

d’entretien et de réglage doivent être effectuées dans un centre de service autorisé ou par du

personnel qualifié (cela comprend l’inspection et le remplacement du balai); on ne doit utiliser

que des pièces de rechange identiques.

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un défaut de matériel ou de fabrication pour une période de trois ans à compter de la date d’achat. La présente garantie ne couvre pas les pièces dont la défectuosité a été causée par une usure normale ou l’usage abusif

de l’outil. Pour obtenir de plus amples renseignements sur les pièces ou les réparations couvertes par la présente garantie, visiter le site www.dewalt.com ou composer le 1 800 433-9258

(1 800 4-D

EWALT). Cette garantie ne s’applique pas aux accessoires et ne vise pas les dom-

mages causés par des réparations effectuées par un tiers. Cette garantie confère des droits

légaux particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un

état ou d’une province à l’autre.

En plus de la présente garantie, les outils D

EWALT sont couverts par notre :

CONTRAT D’ENTRETIEN GRATUIT D’UN AN

D

EWALT entretiendra l’outil et remplacera les pièces usées au cours d’une utilisation normale et

ce, gratuitement, pendant une période d’un an à compter de la date d’achat, et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque raison que ce soit, du rendement de

l’outil électrique, du laser ou de la cloueuse D

EWALT, celui-ci peut le retourner, accompagné

d’un reçu, dans les 90 jours à compter de la date d’achat, pour obtenir un remboursement intégral, sans aucun problème.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE : Si vos étiquettes d'avertissement deviennent

illisibles ou sont manquantes, composez le 1-800-4-D

EWALT pour obtenir une étiquette de rem-

placement gratuite.

• Las herramientas con doble aislamiento están equipadas con una clavija polarizada

(con una pata más ancha que la otra.) Esta clavija se acoplará únicamente en una

toma de corriente polarizada de una manera. Si la clavija no se acopla al contacto,

inviértala. Si aún así no se ajusta, comuníquese con un electricista calificado para que le