Page 1

Questions? See us on the World Wide Web at www.dewalt.com

¿Dudas? Visítenos en Internet: www.dewalt.com

Dúvidas? Visite-nos na Internet em www.dewalt.com.br

INSTRUCTION MANUAL

MANUAL DE INSTRUÇÕES

MANUAL DE INSTRUCCIONES

DW366

7-1/4" (184 mm) Circular Saw

Serra Circular 7-1/4" (184 mm)

Sierra Circular de 184 mm (7-1/4")

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Page 2

Page 3

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases or dust.

Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable,

use a residual current device (GFCI) protected supply. Use

of an GFCI reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power tool

while you are tired or under the influence of drugs, alcohol

or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

English

1

Page 4

c) Prevent unintentional starting. Ensure the switch is in the

off position before connecting to power source and/or

battery pack, picking up or carrying the tool. Carrying power

tools with your finger on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating part

English

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction

and collection facilities, ensure these are connected and

properly used. Use of dust collection can reduce dust-related

hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for

your application. The correct power tool will do the job better

and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on

and off. Any power tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind and

are easier to control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into account the

working conditions and the work to be performed. Use of

the power tool for operations different from those intended could

result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person

using only identical replacement parts. This will ensure that

the safety of the power tool is maintained.

Additional Safety Instructions for

Circular Saws

DANGER! Keep hands away from cutting area and blade. Keep

your second hand on auxiliary handle, or motor housing. If both

hands are holding the saw, they cannot be cut by the blade.

• Keep your body positioned to either side of the saw blade, but

not in line with the saw blade. KICKBACK could case the saw to

jump backwards. (See “Causes and Operator Prevention of Kickback,

page 3 and ”KICKBACK” page 8)

• Do not reach underneath the work. The guard can not protect

you from the blade below the work.

• Check lower guard for proper closing before each use. Do not

operate saw if lower guard does not move freely and close

instantly. Never clamp or tie the lower guard into the open

2

Page 5

position. If saw is accidentally dropped, the lower guard may be

bent. Raise the lower guard with the Retracting Handle and make

sure it moves freely and does not touch the blade or any other part,

at all angles and depth of cut.

• Check the operation and condition of the lower guard spring.

If the guard and the spring are not operating properly,

they must be serviced before use. Lower guard may operate

sluggishly due to damaged parts, gummy deposits, or a buildup of

debris.

• Lower guard should be retracted manually only for special

cuts such as “Pocket Cuts” and “Compound Cuts.” Raise

lower guard by Retracting Handle. As soon as blade enters

the material, lower guard must be released. For all other

sawing, the lower guard should operate automatically.

• Always observe that the lower guard is covering the blade

before placing saw down on bench or floor. An unprotected,

coasting blade will cause the saw to walk backwards, cutting

whatever is in its path. Be aware of the time it takes for the blade

to stop after switch is released.

• NEVER hold piece being cut in your hands or across your

leg. It is important to support the work properly to minimize body

exposure, blade binding, or loss of control.

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring

or its own cord. Contact with a “live” wire will also make exposed

metal parts of the tool “live” and shock the operator.

• When ripping, always use a rip fence or straight edge guide.

This improves the accuracy of cut and reduces the chance for

blade binding.

• Always use blades with correct size and shape (diamond

vs. round) arbor holes. Blades that do not match the mounting

hardware of the saw will run eccentrically, causing loss of control.

• Never use damaged or incorrect blade washers or bolts. The

blade washers and bolt were specially designed for your saw, for

optimum performance and safety of operation.

CAUSES AND OPERATOR PREVENTION OF KICKBACK

• Kickback is a sudden reaction to a pinched, bound or misaligned

saw blade, causing an uncontrolled saw to lift up and out of the

workpiece toward the operator.

• When the blade is pinched or bound tightly by the kerf closing

down, the blade stalls and the motor reaction drives the unit rapidly

back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth at

the back edge of the blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and jump back toward

operator.

• Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below.

a. Maintain a firm grip with both hands on the saw and position

your body and arm to allow you to resist KICKBACK forces.

Kickback forces can be controlled by the operator, if proper

precautions are taken.

b. When blade is binding, or when interrupting a cut for any

reason, release the trigger and hold the saw motionless in

the material into the blade comes to a complete stop. Never

attempt to remove the saw from the work or pull the saw

backward while the blade is in motion or KICKBACK may

occur. Investigate and take corrective actions to eliminate the

cause of blade binding.

c. When restarting a saw in the workpiece, center the saw

blade in the kerf and check that the saw teeth are not

engaged into the material. If saw blade is binding, it may walk

up or KICKBACK from the workpiece as the saw is restarted.

d. Support large panels to minimize the risk of blade pinching

and KICKBACK. Large panels tend to sag under their own

weight. Support must be placed under the panel on both sides,

near the line of cut and near the edge of the panel.

3

English

Page 6

e. Do not use dull or damaged blade. Unsharpened or improperly

set blades produce narrow kerf causing excessive friction, blade

binding, and KICKBACK.

f. Blade depth and bevel adjusting locking levers must be

tight and secure before making cut. If blade adjustment shifts

while cutting, it may cause binding and KICKBACK.

g. Use extra caution when making a “Pocket Cut” into existing

English

walls or other blind areas. The protruding blade may cut

objects that can cause KICKBACK.

Additional Specific Instructions

CAUTION: When cutting into walls, floors or wherever live electrical

wires may be encountered, DO NOT TOUCH ANY METAL PARTS

OF THE TOOL! Hold the tool only by insulated grasping surfaces to

prevent electric shock if you cut into a live wire.

• KEEP BLADES CLEAN AND SHARP. Sharp blades minimize

stalling and kickback.

DANGER: KEEP HANDS AWAY FROM CUTTING AREA. Keep

hands away from blades. Do not reach underneath work while blade

is rotating. Do not attempt to remove cut material when blade is

moving.

CAUTION: Blades coast after turn off.

• SUPPORT LARGE PANELS. Large panels must be supported

as shown in Figure 10 to minimize the risk of blade pinching and

kickback. When cutting operation requires the resting of the saw

on the work piece, the saw shall be rested on the larger portion and

the smaller piece cut off.

• GUARD AGAINST KICKBACK. Kickback occurs when the saw

stalls rapidly and is driven back towards the operator. Release

switch immediately if blade binds or saw stalls. Keep blades sharp.

Support large panels as shown in Figure 10. Use fence or straight

edge guide when ripping. Don’t force tool. Stay alert-exercise

control. Don’t remove saw from work during a cut while the blade

is moving.

• ADJUSTMENTS. Before cutting be sure depth and bevel

adjustments are tight.

• AVOID CUTTING NAILS. Inspect for and remove all nails from

lumber before cutting.

• NEVER use abrasive cut-off wheels.

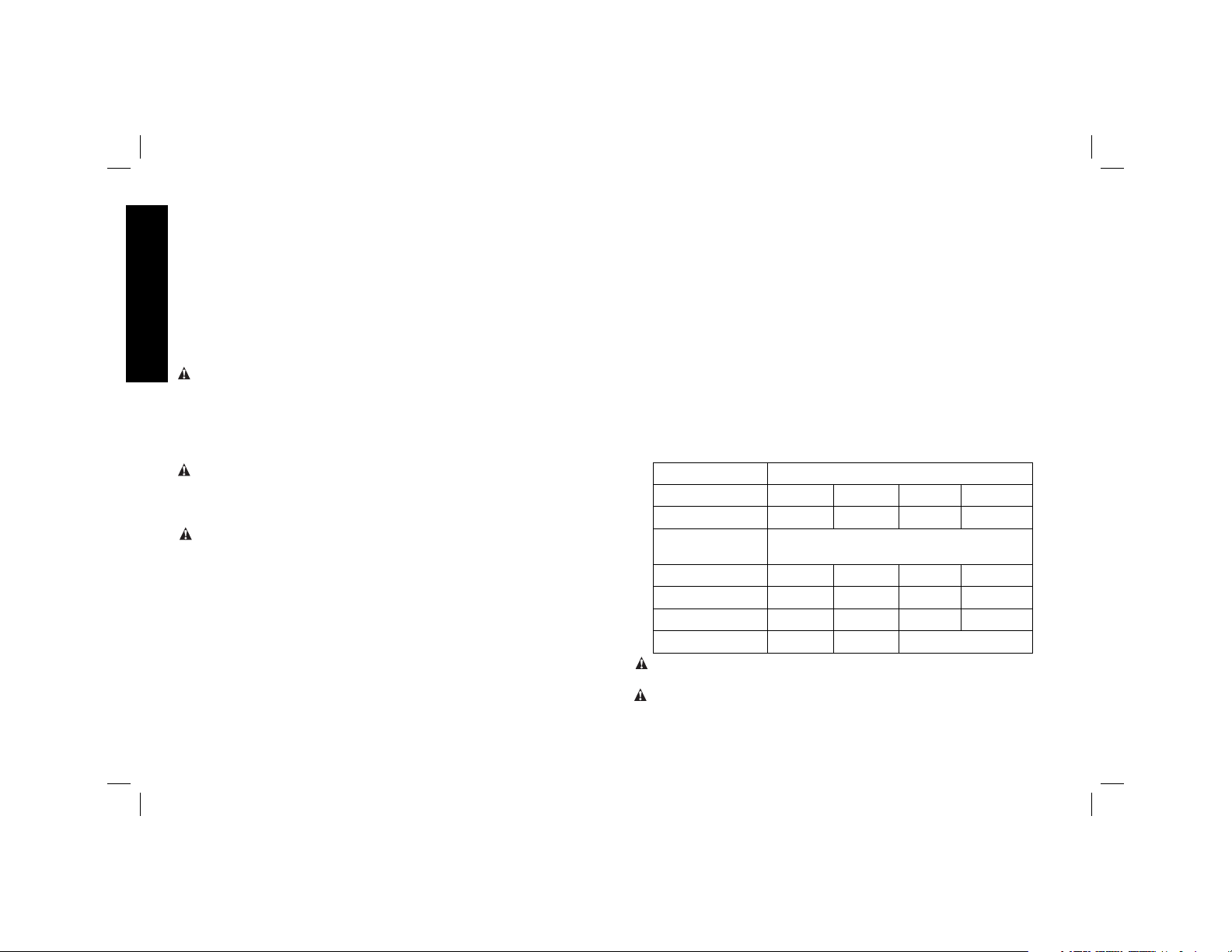

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. When using more than one extension to make up the

total length, be sure each individual extension contains at least the

minimum wire size. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

Voltage (Volts) Total length of cord in meters (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Rated Ampere

range

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Not Recommended

Minimal cross-sectional area of the

cord in meters (mm2 )

WARNING: Always use eye protection. All users and bystanders

must wear eye protection that conforms to ANSI Z87.1.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

4

Page 7

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• The label on your tool may include the following symbols.

V ..................volts A ................ amperes

Hz ................hertz W ............... watts

min ..............minutes

.............. alternating current

................alternating or .......... direct current

....................direct current

................

Class II …/min ......... revolutions or

n

o .............. no load speed

..................... Construction ................... reciprocation per

.................earthing terminal ................... minutes

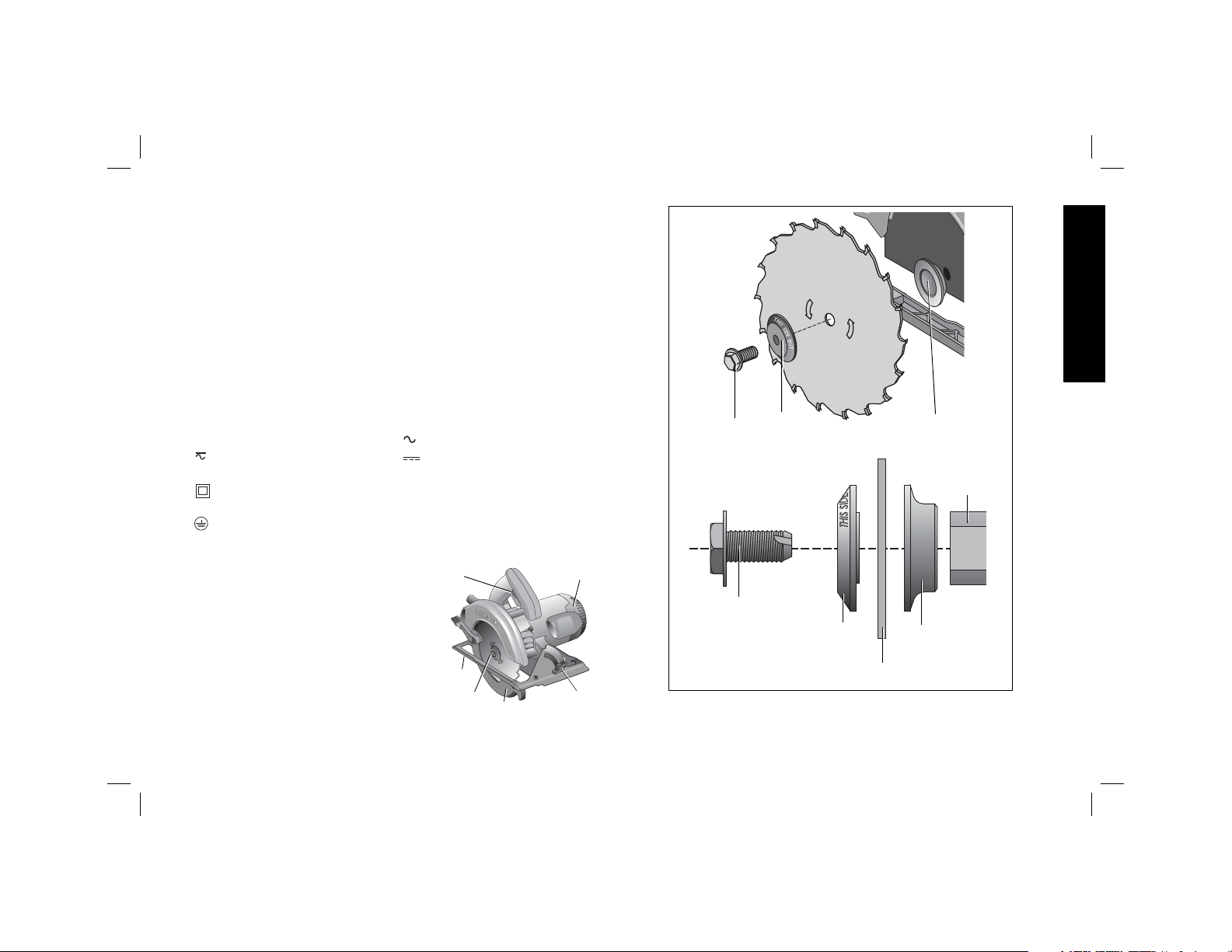

Features (Fig. 1)

A. End cap

FIG. 1

B

A

B. Trigger switch

C. Bevel angle adjustment knob

D. Shoe

E. Blade bolt

F. Lower blade guard

Motor

Your DEWALT tool is powered by a

D

EWALT motor. Be sure your power

D

E

F

C

supply agrees with name plate marking.

FIG. 2

English

E

H

E

H

BLADE

G

SPINDLE

G

5

Page 8

As little as 10% lower voltage can cause loss of power and can result

in overheating. All D

not operate, check the power supply.

EWALT tools are factory-tested; if this tool does

ADJUSTMENTS AND SETUP

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

making any adjustments or removing/installing attachments or

English

accessories.

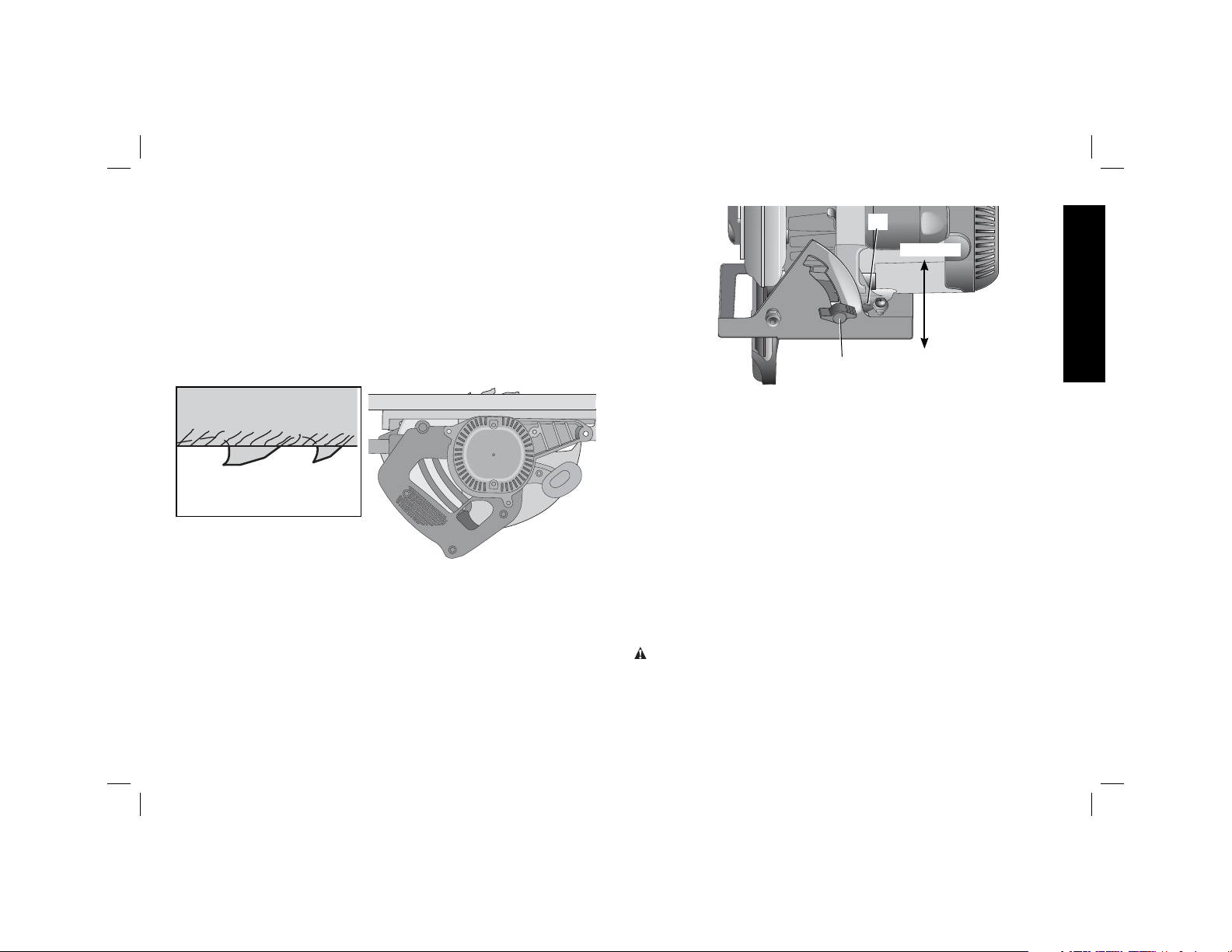

Attaching And Removing Blades (Fig. 1–4)

To attach the blade, retract lower blade guard (F) and place inner

clamp washer (G) and blade on saw spindle with printed side of

blade out. [Teeth at bottom of blade pointing forward, Fig. 2]. Place

outer clamp washer (H) on saw spindle. The larger surfaces of both

washers must face the blade. Thread on blade clamping bolt (E) firmly

by hand to hold both blade washers in position. Depress the lock pin

(I, Fig. 3) and turn the saw spindle until lock pin engages the shaft.

Tighten blade bolt clockwise with blade wrench.

FIG. 4FIG. 3

I

making any adjustments or removing/installing attachments or

accessories.

EWALT saw is equipped to accept blades with 5/8" (16 mm)

Your D

round arbor holes.

1. Depress LOCK PIN, (I, Fig. 3) and turn blade until the LOCK PIN

locks firmly into the saw shaft.

2. With blade wrench, loosen and remove the blade bolt (E) by

turning it in a counterclockwise direction when facing blade (right

hand thread). Retract lower blade guard (F) and remove blade.

3. When mounting new blade, the teeth must point in the direction

of blade rotation. Replace outer clamp washer (H). Replace and

tighten the blade bolt as much as possible with the fingers, then

tighten firmly with the blade wrench.

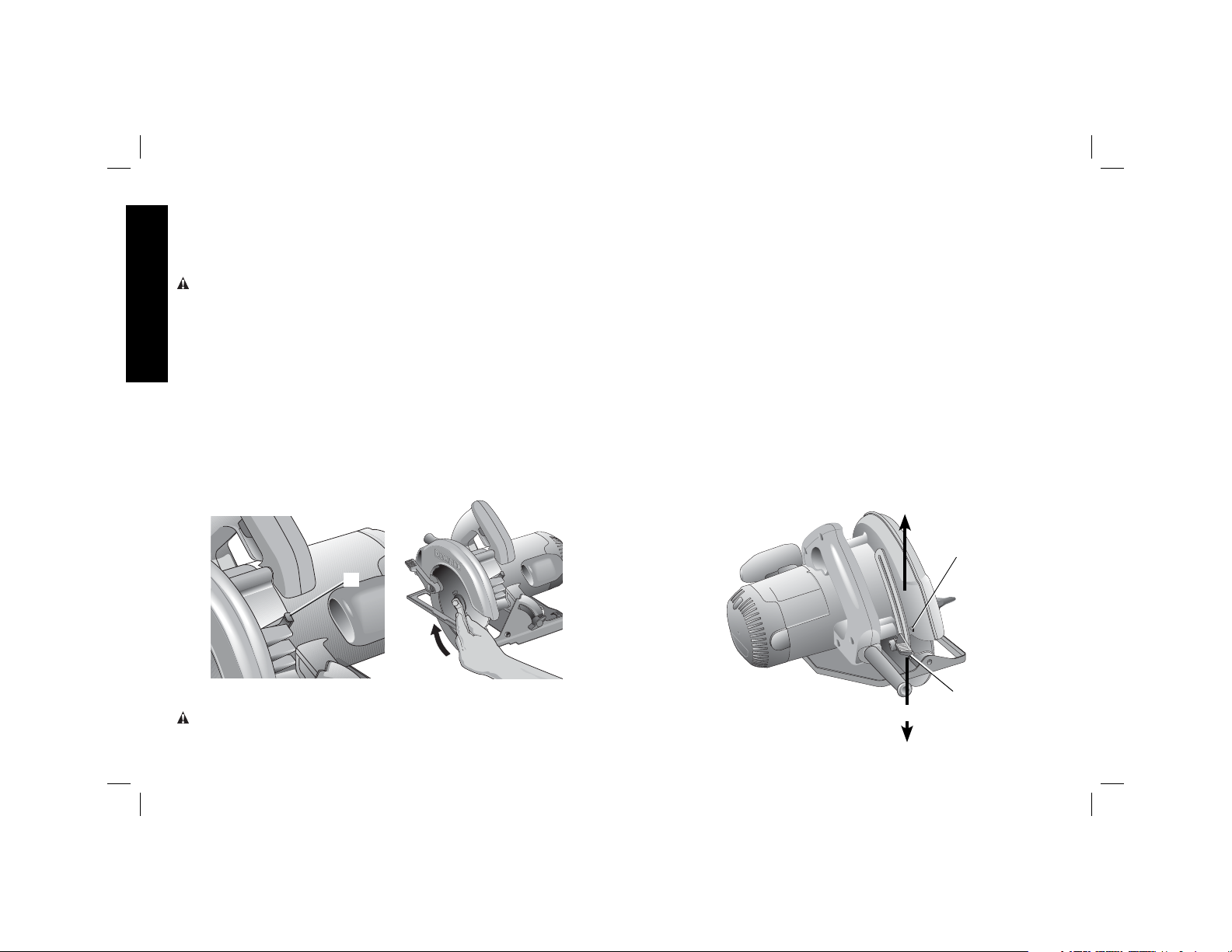

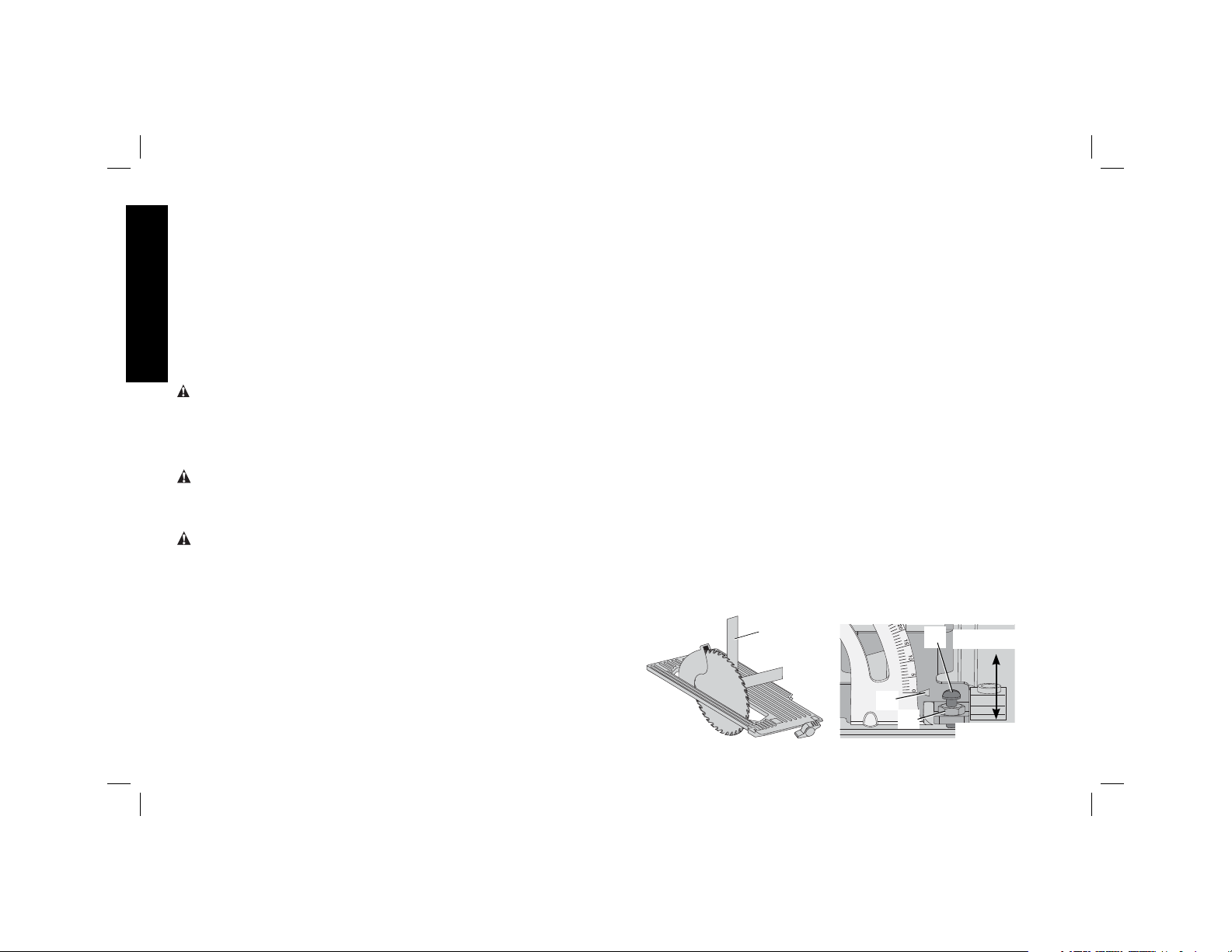

Cutting Depth Adjustment (Fig. 5–7)

Hold the saw firmly. Raise the depth adjustment lever (J, Fig. 5) to

loosen and move shoe to obtain the desired depth of cut, as shown.

Make sure the depth adjustment lever has been retightened (lowered)

before operating saw.

FIG. 5

LOOSEN

K

Changing Blades (Fig. 1–4)

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

J

TIGHTEN

6

Page 9

Your saw is equipped with a carbide tipped saw blade for long life and

efficient cutting.

Setting the saw at the proper cutting depth keeps blade friction to a

minimum, removes sawdust from between the blade teeth, results

in cooler, faster sawing and reduces the chance of kickback. Align

the appropriate mark on the depth adjustment strap with triangle

(K, Fig. 5) on the upper blade guard. Your depth is set.

For the most efficient cutting action using a carbide tipped saw blade,

set the depth adjustment so that about one half of a tooth projects

below the surface of the wood to be cut (Fig. 6).

FIG. 6

A method of checking for the correct cutting depth is shown in

Figure 7. Lay a piece of the material you plan to cut along the side

of the blade, as shown in the figure, and observe how much tooth

projects beyond the material.

FIG. 7

Bevel Angle Adjustment (Fig. 8)

The full range of bevel adjustment is from 0 to 50º. The pivot bracket

is graduated in increments of 1º.

On the front of the saw is a bevel angle adjustment mechanism

consisting of a quadrant with a pointer (L) and a knob (C).

FIG. 8

1. To set the saw for a bevel cut, turn the knob (C) to loosen the

bevel adjustment.

2. Tilt the shoe to the desired angle by aligning the pointer (L) with

the desired angle mark on the pivot bracket.

3. Retighten the bevel adjustment by turning the knob (C).

L

LOOSEN

C

TIGHTEN

Bevel Detent (Fig. 8)

The saw has a bevel stop at 45º. To set the bevel at an angle greater

than 45º, tilt the shoe to 45º, then slide the knob (C) into the upper

slot. When you reach the desired angle, tighten the knob.

Kerf Indicator

The front of the saw shoe has a kerf indicator for vertical and bevel

cutting. This indicator enables you to guide the saw along cutting lines

penciled on the material being cut.

OPERATION

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

making any adjustments or removing/installing attachments or

accessories.

English

7

Page 10

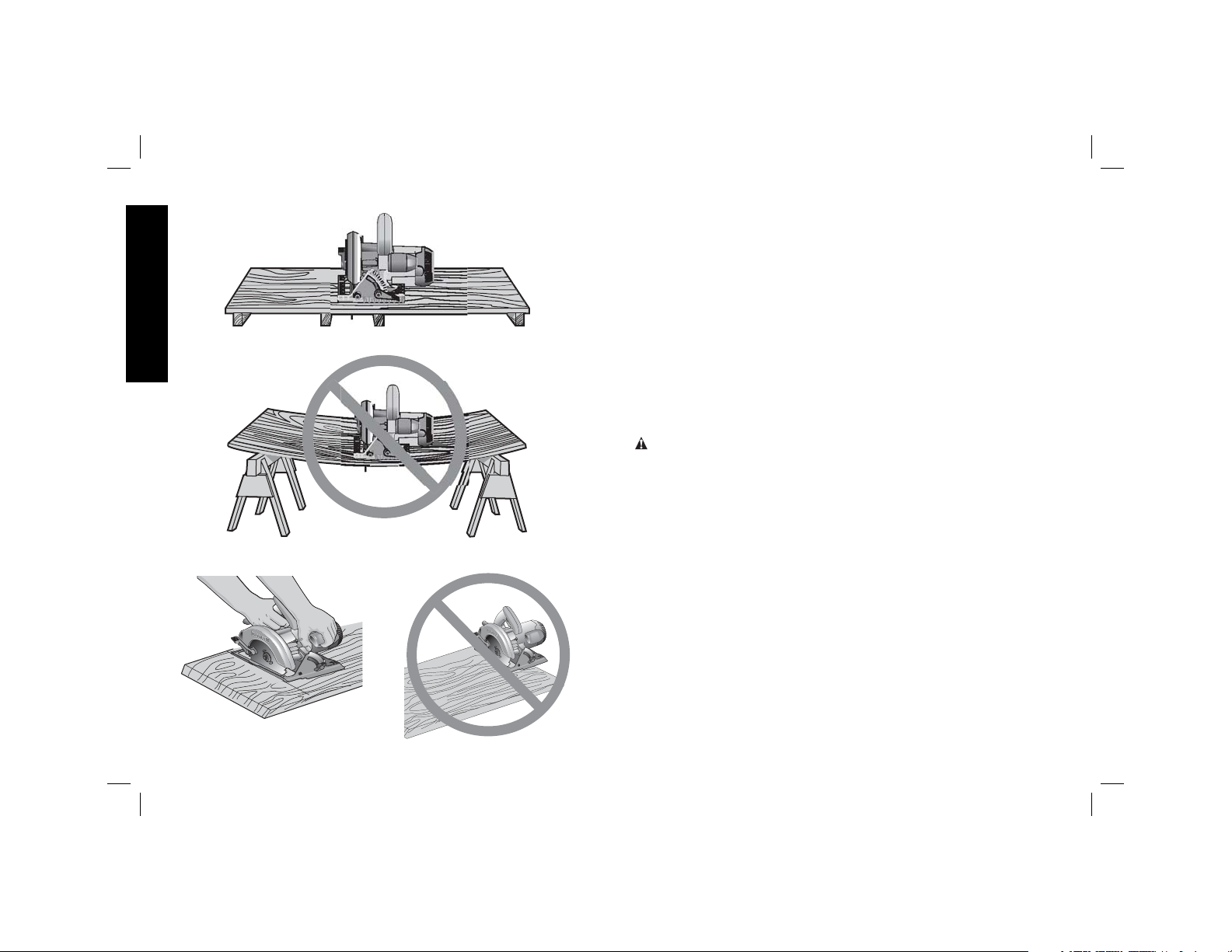

FIG. 9

English

FIG. 10

FIG. 11

FIG. 12

Switch

Pull the trigger switch to turn the motor ON. Releasing the trigger

turns the motor OFF. This tool has no provision to lock the switch in

the ON position, and should never be locked ON in any way.

Workpiece Support

Figures 9 and 11 show proper sawing position. Figures 10 and 12

show an unsafe condition. Hands should be kept away from cutting

area, and power cord is positioned clear of the cutting area so that it

will not get caught or hung up on the work.

To avoid kickback, DO support board or panel NEAR the cut,

(Figures 9, 11). DON’T support board or panel away from the cut

(Figures 10, 12). When operating the saw, keep the cord away from

the cutting area and prevent it from becoming hung up on the work

piece.

WARNING: It is important to support the work properly and to hold

the saw firmly to prevent loss of control which could cause personal

injury; Figure 11 illustrates typical hand support of the saw.

ALWAYS DISCONNECT SAW BEFORE MAKING ANY

ADJUST MENTS! Place the work with its “good” side - the one on

which appearance is most important - down. The saw cuts upward, so

any splintering will be on the work face that is up when you saw it.

Cutting

Support the work so that the waste will be on your right. Place the

wider portion of the saw shoe on that part of the work piece which is

solidly supported, not on the section that will fall off when the cut is

made. As examples, Figure 11 illustrates the RIGHT way to cut off

the end of a board, and Figure 12 the WRONG way. Always clamp

work. Don’t try to hold short pieces by hand! Remember to support

cantilevered and overhanging material. Use caution when sawing

material from below.

Be sure saw is up to full speed before blade contacts material to

be cut. Starting saw with blade against material to be cut or pushed

forward into kerf can result in kickback.

8

Page 11

Push the saw forward at a speed which allows the blade to cut without

laboring. Hardness and toughness can vary even in the same piece

of material, and knotty or damp sections can put a heavy load on the

saw. When this happens, push the saw more slowly, but hard enough

to keep it working without much decrease in speed.

Kickback

When the saw blade becomes pinched or twisted in the cut, kickback

can occur. The saw is thrust rapidly back toward the operator. When

the blade is pinched or bound tightly by the kerf closing down, the

blade stalls and the motor reaction drives the unit backward. When

the blade becomes twisted or misaligned in the cut, the teeth at the

back edge of the blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and jump back toward the

operator.

Kickback is more likely to occur when any of the following conditions

exist.

1. IMPROPER WORKPIECE SUPPORT

A. Sagging or improper lifting of the cut off piece causing pinching

of the blade (Figure 10).

B. Cutting through material supported at the outer ends only. As

the material weakens it sags, closing down the kerf and pinching the blade.

C. Cutting off a cantilevered or overhanging piece of material from

the bottom up in a vertical direction. The falling cut off piece can

pinch the blade.

D. Cutting off long narrow strips (as in ripping). The cut off strip

can sag or twist closing the kerf and pinching the blade.

E. Snagging the lower guard on a surface below the material

being cut momentarily reducing operator control. The saw can

lift partially out of the cut increasing the chance of blade twist.

2. IMPROPER DEPTH OF CUT SETTING ON SAW

Using the saw with an excessive depth of cut setting increases

loading on the unit and susceptibility to twisting of the blade in the

kerf. It also increases the surface area of the blade available for

pinching under conditions of kerf close down. See page 4 Cutting

Depth Adjustment.

3. BLADE TWISTING (MISALIGNMENT IN CUT)

A. Pushing harder to cut through a knot, a nail, or a hard grain

area can cause the blade to twist.

B. Trying to turn the saw in the cut (trying to get back on the

marked line) can cause blade twist

C. Extended reach or operating saw with poor body control (out of

balance), can result in twisting the blade.

D. Changing hand grip or body position while cutting can result in

blade twist.

E. Backing unit up to clear blade can lead to twist if not done care-

fully.

4. MATERIALS THAT REQUIRE EXTRA ATTENTION

A. Wet lumber

B. Green lumber (material freshly cut or not kiln dried)

C. Pressure treated lumber (material treated with preservatives or

anti-rot chemicals)

5. USE OF DULL OR DIRTY BLADES

Dull blades cause increased loading of the saw. To compensate,

an operator will usually push harder which further loads the unit

and promotes twisting of the blade in the kerf. Worn blades may

also have insufficient body clearance which increases the chance

of binding and increased loading.

6. LIFTING THE SAW WHEN MAKING BEVEL CUTS

Bevel cuts require special operator attention to proper cutting

techniques - especially guidance of the saw. Both blade angle to

the shoe and greater blade surface in the material increase the

chance for binding and misalignment (twist) to occur.

English

9

Page 12

7. RESTARTING A CUT WITH THE BLADE TEETH JAMMED

AGAINST THE MATERIAL

The saw should be brought up to full operating speed before

starting a cut or restarting a cut after the unit has been stopped

with the blade in the kerf. Failure to do so can cause stalling and

kickback.

Any other conditions which could result in pinching, binding, twisting,

or misalignment of the blade could cause kickback. Refer to the

English

sections on Adjustments And Set-Up and Operation for procedures

and techniques that will minimize the occurrence of kickback.

MAINTENANCE

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

making any adjustments or removing/installing attachments or

accessories.

Cleaning

WARNING: Blow dirt and dust out of the main housing with dry air

as often as dirt is seen collecting in and around the air vents. Wear

approved eye protection and approved dust mask when performing

this procedure.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the materials used in these parts. Use a cloth dampened only

with water and mild soap. Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid.

Lubrication

Self lubricating ball and roller bearings are used in the tool and

relubrication is not required. However, it is recommended that, once

a year, you take or send the tool to a service center for a thorough

cleaning, inspection and lubrication of the gear case.

Brushes

Inspect carbon brushes regularly by unplugging tool, removing the

End Cap (Detail Page 5) and withdrawing the brush assembly. Keep

brushes clean and sliding freely in their guides. Always replace a used

brush in the same orientation in the holder as it was prior to removal.

Carbon brushes have varying symbols stamped into their sides, and

if either brush is worn down to the line closest to the spring, they

must be replaced. Use only identical D

assemblies are available at your local service center. The tool should

be allowed to “run in” (run at no load without a blade) for 5 minutes

before use to seat new brushes.

While “running in” DO NOT TIE, TAPE, OR OTHERWISE LOCK THE

TRIGGER SWITCH ON. HOLD BY HAND ONLY.

EWALT brushes. New brush

Shoe Adjustment

Your shoe has been factory set to assure that the blade is perpendicular to the shoe. If after extended use, you need to re-align the

blade as follows:

ADJUSTING FOR 90º CUTS (FIG. 8, 13, 14)

1. Return the saw to 0º bevel.

2. Loosen the bevel adjustment knob (C, Fig. 8). Place a square (M)

against the blade and the shoe.

3. Adjust screw (O) until pointer (L) aligns with 0°, then tighten nut

(P).

4. Retighten the bevel adjust knob (C).

FIG. 13

M

FIG. 14

O

LOOSEN

L

P

TIGHTEN

10

Page 13

Blades

A dull blade will cause slow, inefficient cutting, overload on the saw

motor, excessive splintering and increase the possibility of kickback.

Change blades when it is no longer easy to push the saw through

the cut, when the motor is straining, or when excessive heat is built

up in the blade. It is a good practice to keep extra blades on hand so

that sharp blades are available for immediate use. Dull blades can be

sharpened in most areas; see SAWS-SHARPENING in the yellow

pages.

Hardened gum on the blade can be removed with kerosene,

turpentine, or oven cleaner. Anti-stick coated blades can be used

in applications where excessive build-up is encountered, such as

pressure treated and green lumber.

VISUALLY EXAMINE CARBIDE BLADES BEFORE USE.

REPLACE IF DAMAGED.

COMBINATION FRAMING - 5/8" Round arbor, 24 teeth

All purpose fast rip and cross cuts.

PRESSURE TREATED/WET LUMBER - 5/8" Round arbor, 20 teeth

Coated - Resistant to gum build-up

EXTREME DURABILITY - 5/8" Round arbor, 18 teeth

Cooled, rock carbide

FINISHING - 5/8" Round arbor, 36 teeth

More teeth for finer finish cuts.

FAST CUT FRAMING - 5/8" Round arbor, 16 teeth

Fastest blade for rips and cross cuts

Accessories

WARNING: Since accessories, other than those offered by

EWALT, have not been tested with this product, use of such

D

accessories with this tool could be hazardous. To reduce the risk of

injury, only D

this product.

Recommended accessories for use with your tool are available at extra

cost from your local dealer or authorized service center.

WATER FEED ATTACHMENTS ARE NOT RECOMMENDED FOR

THIS SAW.

EWALT, recommended accessories should be used with

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

SPECIFICATIONS

DW366-B3

Voltage 120 V

Frequency 50–60 Hz

Power–Watts 1 800 W

RPM 5 800/min

English

11

Page 14

Definiciones: Normas

de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada advertencia. Lea el manual y preste atención a estos

símbolos.

PELIGRO:

no se evita,

ADVERTENCIA:

que, si no se evita,

graves

ATENCIÓN:

no se evita,

AVISO: Se refiere a una práctica

corporales

propiedad.

Español

ADVERTENCIA: para reducir el riesgo de lesiones, lea el

manual de instrucciones.

indica una situación de peligro inminente que, si

provocará

puede

que de no evitarse

la

muerte o lesiones graves.

Indica una situación de peligro potencial

podría

Indica una situación de peligro potencial que, si

provocar

provocar la

lesiones leves o moderadas.

puede resultar

muerte o lesiones

no relacionada a lesiones

en

daños a la

Advertencias generales de seguridad

para las herramientas eléctricas

ADVERTENCIA: Lea todas las advertencias de seguridad e

instrucciones. El incumplimiento de las advertencias o instrucciones

puede provocar descargas eléctricas, incendios o lesiones graves.

GUARDE LAS ADVERTENCIAS E

INSTRUCCIONES PARA PODER

CONSULTARLAS EN EL FUTURO

El término “herramienta eléctrica” incluido en todas las advertencias se

refiere a su herramienta eléctrica conectada a la red (cable eléctrico)

o a su herramienta eléctrica accionada con baterías (inalámbrica).

1) SEGURIDAD DEL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las

áreas abarrotadas u oscuras propician accidentes.

b) No haga funcionar las herramientas eléctricas en atmósferas

explosivas, como ambientes donde haya polvo, gases o

líquidos inflamables. Las herramientas eléctricas originan

chispas que pueden encender el polvo o producir humo.

c) Mantenga alejados a los niños y a los espectadores de la

herramienta eléctrica en funcionamiento. Las distracciones

pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse

a la toma de corriente. Nunca modifique el enchufe de

ninguna manera. No utilice ningún enchufe adaptador con

herramientas eléctricas con conexión a tierra. Los enchufes

no modificados y que se adaptan a las tomas de corrientes

reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies con toma de

tierra como, por ejemplo, tuberías, radiadores, cocinas y

refrigeradores. Existe mayor riesgo de descarga eléctrica si su

cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia ni a

condiciones de humedad. Si entra agua en una herramienta

eléctrica, aumentará el riesgo de descarga eléctrica.

d) No use el cable indebidamente. Nunca utilice el cable para

transportar, tirar o desenchufar la herramienta eléctrica.

Mantenga el cable alejado del calor, el aceite, los bordes

afilados o las piezas móviles. Los cables dañados o enredados

aumentan el riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un

cable prolongador adecuado para tal uso. Utilice un cable

adecuado para uso en exteriores a fin de reducir el riesgo de

descarga eléctrica.

12

Page 15

f) Si no se puede evitar el uso de una herramienta eléctrica

en una zona húmeda, utilice un dispositivo de corriente

residual (residual current device, GFCI) de seguridad. El uso

de un GFCI reduce el riesgo de sufrir una descarga eléctrica.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice

el sentido común cuando emplee una herramienta eléctrica.

No utilice una herramienta eléctrica si está cansado o bajo

el efecto de drogas, alcohol o medicamentos. Un momento

de descuido mientras se opera una herramienta eléctrica puede

provocar lesiones personales graves.

b) Utilice equipo de seguridad personal. Utilice siempre

protección ocular. El uso de equipo de seguridad, como

mascarillas para polvo, calzado de seguridad antideslizante,

cascos o protección auditiva en las condiciones adecuadas

reducirá las lesiones personales.

c) Evite poner en marcha la herramienta involuntariamente.

Asegúrese de que el interruptor está apagado antes de

conectar la fuente de alimentación y/o la batería, coger

o transportar la herramienta. Transportar herramientas

eléctricas con su dedo apoyado sobre el interruptor o enchufar

herramientas eléctricas con el interruptor en la posición de

encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de

encender la herramienta eléctrica. Una llave de tuercas o una

clavija de ajuste que quede conectada a una pieza giratoria de

la herramienta eléctrica puede provocar lesiones personales.

e) No se estire demasiado. Conserve el equilibrio y posiciónese

adecuadamente en todo momento. Esto permite un mejor

control de la herramienta eléctrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni

joyas. Mantenga el cabello, la ropa y los guantes alejados

de las piezas en movimiento. Las ropas holgadas, las joyas

o el cabello largo pueden quedar atrapados en las piezas

en movimiento.

g) Si se suministran dispositivos para la conexión de

accesorios con fines de recolección y extracción de polvo,

asegúrese de que estén conectados y que se utilicen

correctamente. El uso del extractor de polvo puede reducir los

riesgos relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta

eléctrica correcta para el trabajo que realizará. La herramienta

eléctrica correcta hará el trabajo mejor, y de un modo más

seguro, a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla o

apagarla con el interruptor. Las herramientas que no puedan

ser controladas con el interruptor constituyen un peligro y deben

repararse.

c) Desconecte el enchufe de la fuente de alimentación o la

batería de la herramienta eléctrica antes de realizar cualquier

ajuste, cambio de accesorios o almacenar las herramientas

eléctricas. Estas medidas de seguridad preventivas reducen

el riesgo de encender la herramienta eléctrica de forma

accidental.

d) Guarde la herramienta eléctrica que no esté en uso fuera

del alcance de los niños y no permita que otras personas

no familiarizadas con ella o con estas instrucciones operen

la herramienta. Las herramientas eléctricas son peligrosas si

son operadas por usuarios que no tienen formación.

e) Mantenimiento de las herramientas eléctricas. Revise que

no haya piezas en movimiento mal alineadas o trabadas,

piezas rotas o cualquier otra situación que pueda afectar

el funcionamiento de las herramientas eléctricas. Si

encuentra daños, haga reparar la herramienta eléctrica

antes de utilizarla. Se producen muchos accidentes a causa

Español

13

Page 16

de las herramientas eléctricas que carecen de un mantenimiento

adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las

herramientas de corte con mantenimiento adecuado y con los

bordes de corte afilados son menos propensas a trabarse y son

más fáciles de controlar.

g) Utilice las herramientas eléctricas, sus accesorios y piezas,

etc. de acuerdo con las presentes instrucciones, teniendo

siempre en cuenta las condiciones de trabajo y el trabajo

que deba llevar a cabo. El uso de la herramienta eléctrica para

operaciones diferentes de aquellas para las que fue diseñada

podría originar una situación peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona cualificada en reparaciones que

realice el mantenimiento de su herramienta eléctrica y que

solo utilice piezas de repuesto idénticas. Esto garantizará la

seguridad de la herramienta eléctrica.

Medidas adicionales de seguridad para

sierras circulares

Español

¡PELIGRO! Mantenga las manos alejadas del área de corte y del

disco de la sierra. Mantenga la otra mano sobre la manija auxiliar o en

la caja del motor. Si usted está sosteniendo la sierra con sus manos,

éstas no pueden ser cortadas por el disco de la sierra.

• Mantenga su cuerpo ubicado a ambos lados del disco de la

sierra, pero NO alineado con ésta. Un REBOTE podría hacer

que la sierra salte hacia atrás (Lea la sección “Causas del rebote

y su prevención por parte del operario” página 15 y “REBOTE”,

página 21).

• No meta sus manos por debajo de la pieza de trabajo. Allí el

protector no puede protegerlo.

• Verifique la parte inferior del protector para constatar su

cierre adecuado antes de cada utilización. No utilice la sierra

si el protector inferior no se mueve libremente y si no cierra

instantáneamente. Nunca sujete o amarre el protector inferior

con el fin de mantenerlo abierto. Si la sierra cae accidentalmente,

el protector inferior puede doblarse. Levante el protector utilizando

el mango de retracción y asegúrese que éste se mueve libremente

y que no toca el disco de corte o cualquier otra parte en cualquier

ángulo y a cualquier profundidad de corte.

• Verifique el funcionamiento y el estado del resorte del protector

inferior. Si el protector y el resorte no están funcionando

adecuadamente, éstos deben ser reparados antes de ser

utilizados. El protector inferior puede funcionar lentamente debido

al funcionamiento inadecuado de un componente, a la presencia

de depósitos pegajosos o a una acumulación de desechos.

• El protector inferior debe plegarse manualmente tan sólo

para realizar cortes especiales tales como “cortes internos”

y “cortes compuestos”. Baje el protector inferior utilizando el

mango de retracción. Tan pronto como el disco de corte entre

en el material, suelte el protector inferior. Para cualquier otro

corte, el protector inferior deberá funcionar automáticamente.

• Asegúrese siempre que el protector inferior esté cubriendo la

cuchilla antes de colocar la sierra en un banco o en el piso.

Un disco no protegido y libre podría hacer que la sierra dé marcha

atrás cortando lo que encuentre a su paso. Tenga en cuenta el

tiempo que le toma al disco detenerse después de haber activado

el interruptor.

• NUNCA sostenga la pieza que está cortando con sus manos o

entre sus piernas. Es importante sujetar la pieza adecuadamente

para minimizar la exposición del cuerpo al peligro, el atascamiento

del disco o la pérdida de control.

• Cuando realice un trabajo en el cual la herramienta de corte

pueda tener contacto con cables ocultos o con su propio

cable, tome la herramienta por las superficies aislantes de

sujeción. El contacto con un cable “vivo” hará que las partes

metálicas de la herramienta puedan transmitir una descarga

eléctrica al operario.

14

Page 17

• Cuando realice un corte recto, utilice siempre un protector

recto o una guía de borde recto. Esto aumenta la precisión del

corte y reduce las posibilidades de atascamiento del disco.

• Utilice siempre discos de corte cuyo tamaño y forma de

la perforación del árbol sea la especificada (diamante vs.

redonda). Los discos inadecuados para la sierra funcionarán de

manera excéntrica, produciendo la pérdida de control.

• Nunca utilice arandelas o tornillos inadecuados para el disco de

corte. Las arandelas y tornillos han sido diseñados específicamente

para su sierra, con el fin de lograr un funcionamiento óptimo y

seguro.

CAUSAS DEL REBOTE Y SU PREVECIÓN POR PARTE DEL

OPERARIO

• El rebote es una reacción inesperada debida al atascamiento, la

sujeción o la desalineación del disco de la sierra, causando el salto

de la misma hacia arriba o fuera de la pieza de trabajo, hacia el

operario.

• Cuando el disco queda firmemente sujeto al material mientras se

realiza un corte, se atasca y la reacción del motor hace que la

unidad rebote rápidamente hacia atrás contra el operario.

• Si el disco de la sierra se tuerce o realiza cortes desalineados, los

dientes de la parte posterior del disco pueden penetrar en la parte

superior de la superficie de la madera, haciendo que el disco suba

y se mueva bruscamente hacia atrás, en dirección al usuario.

• El rebote es el resultado de un uso inadecuado de la herramienta y/o

de procedimientos o condiciones de funcionamiento inadecuados.

El rebote puede ser evitado tomando las precauciones que se

describen a continuación:

a. Mantenga firmemente agarrada la sierra con sus dos manos

y coloque su cuerpo y brazo de manera que le permita

resistir la fuerza del REBOTE. La fuerza del rebote puede ser

controlada por el operario si toma las medidas adecuadas.

b. Cuando el disco se atasque o cuando se interrumpa un

corte por cualquier razón, suelte el gatillo y sostenga la

sierra inmóvil en el material hasta que el disco se halla

detenido completamente. Nunca intente retirar la sierra de

la pieza de trabajo o halar la sierra hacia afuera mientras que

el disco se encuentre girando, ya que esto puede provocar

el REBOTE. Investigue y tome las medidas correctivas para

eliminar la causa del atascamiento del disco de la sierra.

c. Cuando inicie un corte en el material, centre el disco de

la sierra en la línea de corte y verifique que el disco de la

sierra no se encuentra atascado en el material. Si el disco

de corte se encuentra atascado, éste puede subir bruscamente

o REBOTAR en el momento que la sierra sea encendida.

d. Apoye los materiales largos para minimizar el riesgo de

atascamiento del disco y el REBOTE. Los paneles largos

tienden a pandearse bajo su propio peso. El apoyo debe

colocarse a ambos lados bajo el panel, cerca de la línea de

corte y del borde del panel.

e. No utilice un disco desafilado o en mal estado. Los discos

sin filo o mal instalados producen cortes angostos que causan

una excesiva fricción, el atascamiento del disco y el REBOTE.

f. La profundidad del disco y las palancas de aseguramiento del

ajuste del bisel deben encontrarse apretadas y aseguradas

antes de iniciar un corte. Si los ajustes del disco cambian

mientras se realiza el corte, esto puede causar el atascamiento

y el REBOTE.

g. Tenga mucho cuidado cuando se trate de realizar un

“corte interno” en paredes existentes u otras áreas que no

ofrezcan visibilidad. La parte sobresaliente del disco puede

cortar objetos que provoquen el REBOTE.

Instrucciones especificas adicionales

ATENCIÓN: Cuando corte en paredes, pisos o dondequiera que

pueda encontrar cables eléctricos “vivos”, ¡NO TOQUE NINGUNA

PARTE METÁLICA DE SU HERRAMIENTA! Sostenga la sierra

solamente por medio de sus mangos plásticos, con el fin de prevenir

el choque eléctrico en caso de cortar accidentalmente un cable vivo.

Español

15

Page 18

• MANTENGA LOS DICOS LIMPIOS Y BIEN AFILADOS. Los

discos bien afilados minimizan el atascamiento y el REBOTE.

PELIGRO: MANTENGA LAS MANOS ALEJADAS DEL ÁREA DE

CORTE. Mantenga las manos alejadas del disco. No meta sus manos

por debajo del material mientras que el disco esté girando. No intente

retirar el material cortado cuando la cuchilla esté en movimiento.

ATENCIÓN: El disco continúa girando aún después de haber

apagado la herramienta.

• APOYE LOS PANELES DE GRAN TAMAÑO. Los paneles de

gran tamaño deben ser apoyados tal como se muestra en la Figura

10, con el fin de minimizar el riesgo de atascamiento y el rebote

del disco. Cuando un corte requiera que el disco se detenga en la

pieza de trabajo, el disco debe quedar en la porción más grande y

se debe cortar la porción más pequeña de la pieza.

• PROTÉJASE DE LOS REBOTES. El rebote ocurre cuando el

disco se atasca rápidamente y se dirige hacia el operario. Si el

disco se atasca, suelte el interruptor inmediatamente. Mantenga

los discos bien afilados. Apoye los paneles de gran tamaño

como se muestra en la Figura 10. Utilice una guía recta cuando

esté haciendo cortes longitudinales. No fuerce la herramienta.

Español

Esté alerta controlando la situación. Cuando realice un corte, no

retire la sierra del material mientras que el disco se encuentre en

movimiento.

• AJUSTES. Antes de cortar, asegúrese que el ajuste de la

profundidad y del ángulo de corte se encuentren apretados.

• EVITE EL CORTE DE CLAVOS. Antes de realizar un corte,

inspeccione la pieza de madera y retire todo clavo que se encuentre

en ella.

• NUNCA use discos abrasivos de corte.

• Los hilos del alargador deben ser de un calibre apropiado

(AWG o calibre americano de hilos) para su seguridad.

Mientras menor sea el calibre del hilo, mayor la capacidad del

cable. Es decir, un hilo calibre 16 tiene mayor capacidad que uno

de 18. Un cable de un calibre insuficiente causará una caída en

la tensión de la línea dando por resultado una pérdida de energía

y sobrecalentamiento. Cuando se utilice más de un alargador

para completar el largo total, asegúrese que los hilos de cada

alargador tengan el calibre mínimo. La tabla siguiente muestra el

tamaño correcto a utilizar, dependiendo de la longitud del cable

y del amperaje nominal de la placa de identificación. Si tiene

dudas sobre cuál calibre usar, use un calibre mayor. Cuanto más

pequeño sea el número del calibre, más resistente será el cable.

Ténsion (Volts)

120–127V 0–7 7–15 15–30 3–50

220–240V 0–15 15–30 30–60 60–100

Corriente nominal

(Ampéres)

0–6A 1,0 1,5 1,5 2,5

6–10A 1,0 1,5 2,5 4,0

10–12A 1,5 1,5 2,5 4,0

12–16A 2,5 4,0 No recomendado

Longitud del cable in metros (m)

Sección nominal mínima del cable in

milímetros quadrados (mm

2

)

ADVERTENCIA: Si el enchufe o el cable de alimentación están

dañados lo debe reemplazar el fabricante o su representante o por

una persona igualmente calificada para evitar peligro.

ADVERTENCIA: Siempre use protección ocular. Todos los

usuarios y transeúntes deben de usar la protección ocular para

cumplir con ANSI Z87.1.

ADVERTENCIA: Ciertos polvos creados por el lijado, aserrado,

trituración, taladrado y otras actividades de construcción contienen

químicos causantes de cáncer, defectos de nacimiento u otros daños

en la reproducción. Algunos ejemplos de estos químicos son:

• el plomo de las pinturas a base de plomo,

• la sílice cristalina de los ladrillos y cemento y otros productos de

albañilería, y

• el arsénico y el cromo de las maderas tratadas con químicos

(CCA).

16

Page 19

El riesgo a la exposición varía, dependiendo de cuán a menudo

usted ejecuta este tipo de trabajo. Para reducir la exposición a estos

químicos: trabaje en un área bien ventilada y hágalo con equipos de

seguridad aprobados, tales como las máscaras de polvo que están

especialmente diseñadas para filtrar las partículas microscópicas.

• La etiqueta de su herramienta puede incluir los siguientes

símbolos.

V ........ voltios A ...........amperios

Hz ...... hertz W ..........vatios

min ..... minutos

...... corriente alterna o ..... corriente directa

........... directa

......... corriente alterna

n

o ..........velocidad sin carga

....... Construcción Clase II …/min ... por minuto

....... terminal a tierra

........... (con aislamiento doble)

Características (Fig. 1)

A. Tapa posterior

FIG. 1

B

A

B. Interruptor del gatillo

C. Ajuste del ángulo de corte

D. Zapata

E. Perno del disco

F. Protector inferior

Motor

Su herramienta DEWALT está accionada

por un motor D

EWALT. Asegúrese que

D

E

F

C

el suministro de corriente corresponde a las especificaciones de

la placa. Una pequeña disminución de un 10% en el voltaje puede

causar una pérdida de potencia y producir el recalentamiento.

Todas las herramientas D

EWALT son verificadas en fábrica. Si esta

herramienta no funciona, verifique el suministro de energía.

AJUSTES Y MONTAJE

ADVERTENCIA: Para reducir el riesgo de lesiones corporales

graves, apague la herramienta y desconéctela de la fuente

de alimentación antes de realizar ajustes o de quitar o poner

accesorios.

FIG. 2

H

E

E

H

G

EJE

G

Español

17

HOJA

Page 20

Instalación y Remoción De Discos

(Fig. 1–4)

Para instalar un disco, retracte el protector inferior (F) y coloque

la arandela de la abrazadera interior (G) y el disco en el eje de la

sierra, con el lado impreso de la sierra hacia afuera [con los dientes

inferiores apuntando hacia adelante (Fig. 2)]. Coloque la arandela de

la abrazadera externa en el eje de la sierra. Las mayores superficies

de las dos arandelas deben quedar de frente al disco. Apriete con

sus manos firmemente los pernos (E) de las abrazaderas del disco

para sostener las dos arandelas en su posición. Suelte el pasador del

seguro, (I, Fig. 3), y gire el eje de la sierra hasta que el pasador del

seguro engrane en el eje. Con la llave del disco, apriete los pernos de

éste en el sentido de las manecillas del reloj.

FIG. 4FIG. 3

1. Presione el PASADOR del SEGURO (I, Fig. 3), y gire la cuchilla

hasta que el PASADOR DEL SEGURO engrane firmemente en

el eje de la sierra.

2. Afloje y retire el perno (E) de la sierra por medio de la llave del

disco, girándolo en el sentido opuesto al de las manecillas del

reloj (haciendo frente al disco). Retracte el protector inferior (F)

del disco y retire el disco.

3. Cuando instale un nuevo disco, los dientes deben apuntar en la

dirección de rotación del disco. Coloque nuevamente la arandela

de la abrazadera externa (H). Coloque de nuevo el disco y apriete

el perno del mismo con sus dedos tanto como pueda, y luego

apriete firmemente con la llave del disco.

FIG. 5

AFLOJAR

K

Español

I

Cambio De Discos (Fig. 1–4)

ADVERTENCIA: Para reducir el riesgo de lesiones corporales

graves, apague la herramienta y desconéctela de la fuente

de alimentación antes de realizar ajustes o de quitar o poner

accesorios.

Su sierra D

árbol de 16 mm (5/8").

EWALT acepta cuchillas con perforaciones circulares del

J

AJUSTAR

Ajuste De La Profundidad De Corte

(Figs. 5–7)

Sostenga firmemente la sierra. Levante la palanca de ajuste de

profundidad para aflojarla (J, Fig. 5), y mueva la zapata hasta obtener

la profundidad de corte deseada, tal como se ilustra. Asegúrese de

18

Page 21

apretar nuevamente la palanca de ajuste de profundidad (bajándola)

antes de utilizar la sierra.

Su sierra está equipada con discos de corte en carburo para una

larga vida y un corte eficiente.

Al ajustar la sierra a una profundidad de corte adecuada se logra

una mínima fricción del disco, se retira el polvo acumulado entre

los dientes del disco, se produce un corte más frío y más rápido y

se reducen las posibilidades de rebote de la herramienta. Alinee la

marca de la profundidad adecuada que se encuentra sobre la banda

de ajuste de profundidad, con el triángulo que se encuentra sobre

el protector superior del disco (K, Fig. 5). La profundidad queda

ajustada.

Para un corte más eficiente al utilizar un disco de carburo, coloque

el ajuste de profundidad de manera que la mitad de la altura de los

dientes se proyecte por debajo de la superficie de la madera que va

a ser cortada (Fig. 6).

FIG. 6

En la Figura 7 se presenta un método para verificar la profundidad

adecuada del corte. Coloque una pieza del material que usted planea

cortar al lado del disco, tal como se muestra en la figura, y observe

qué tanto se proyectan los dientes del disco más allá del material.

FIG. 7

Ajuste Del Ángulo De Corte (Fig. 8)

El rango total de ajuste del ángulo de corte va de 0 a 50º. El soporte

del pivote está graduado cada grado.

Al frente de la sierra se encuentra un mecanismo de ajuste del ángulo

de corte consistente en un cuadrante con un indicador (L) y una

palanca (C).

FIG. 8

1. Para ajustar la sierra para un corte a ángulo, levante la palanca

(C) de ajuste del ángulo de corte para aflojarla.

2. Incline la zapata en el ángulo deseado, alineando el indicador (L)

con la marca del ángulo deseado en el soporte del pivote.

3. Apriete firmemente de nuevo, descendiendo para ello la palanca

(C).

L

AFLOJAR

C

AJUSTAR

Dispositivo De Parada Del Corte A

Ángulo (Fig. 8)

La sierra tiene una parada de corte a angulo de 45 grados. Para

colocar esta parada a un ángulo mayor de 45 grados, deslice la perilla

(C) hacia la ranura en la parte superior. Cuando logre el ángulo

deseado, ajuste la perilla.

Español

19

Page 22

Indicador Del Corte

El frente de la zapata de la sierra tiene un indicador de corte para

cortes rectos y a ángulo (bisel). El indicador le permite guiar la sierra a

lo largo de la línea de corte trazada en el material que será cortado.

FUNCIONAMIENTO

ADVERTENCIA: Para reducir el riesgo de lesiones corporales

graves, apague la herramienta y desconéctela de la fuente

de alimentación antes de realizar ajustes o de quitar o poner

accesorios.

Interruptor

Hale el interruptor del gatillo para ENCENDER el motor (“ON”). Al

soltar el gatillo el motor se APAGA (“OFF”). Esta herramienta no ha

sido concebida para que el interruptor sea asegurado en la posición

de encendido (“ON”), lo cual nunca debe hacerse de ninguna

manera.

Apoyo de La Pieza de Trabajo

Las Figuras 9 y 11 presentan la posición correcta para realizar un

Español

corte. Las Figuras 10 y 12 muestran una situación peligrosa. Las

manos deben ser mantenidas alejadas del área de corte, así como

el cable de alimentación, de manera que éste no quede atrapado o

enredado por la pieza de trabajo.

Para evitar el rebote, APOYE la lámina o el panel CERCA del corte

(Figuras 9 y 11). NO APOYE la lámina o el panel lejos del corte

(Figuras 10 y 12). Cuando utilice la herramienta, mantenga el cable

alejado del área de corte y evite que éste quede enredado en el

material.

ADVERTENCIA: Es importante apoyar adecuadamente el material

y sostener la sierra firmemente para evitar la pérdida de control, lo

cual podría provocar lesiones personales. La Figura 11 ilustra una

manera típica de sostener la sierra.

FIG. 9

FIG. 10

FIG. 11

FIG. 12

20

Page 23

¡DESCONECTE SIEMPRE LA SIERRA ANTES DE REALIZAR

CUALQUIER AJUSTE! Coloque la pieza de trabajo por su lado

“correcto” -aquél cuya apariencia es la más importante- hacia abajo.

La sierra corta de manera ascendente, de modo que las astillas se

producen en la superficie que se encuentra hacia arriba.

Corte

Apoye la pieza de trabajo de manera que el pedazo restante quede a

su derecha. Coloque la porción más ancha de la zapata de su sierra

en aquella parte de la pieza de trabajo que se encuentra sólidamente

apoyada, y no en la sección que caerá una vez realizado el corte.

Como ejemplo, la Figura 11 ilustra la manera CORRECTA de cortar

el final de la lámina y la Figura 12 ilustra la manera INCORRECTA.

Sujete siempre el material. ¡No trate de sostener las piezas cortas con

la mano! Recuerde apoyar el material saliente o en voladizo. Tenga

cuidado cuando esté cortando material desde abajo. Asegúrese que

la sierra haya alcanzado su máxima velocidad antes de que el disco

tenga contacto con el material que va a ser cortado. Encender la

sierra cuando el disco se encuentre en contacto con el material que

va a ser cortado o en la ranura de corte, puede provocar el rebote.

Empuje la sierra hacia adelante a una velocidad que le permita

realizar el corte sin esfuerzo. La dureza y la resistencia del material

pueden variar inclusive en la misma pieza, y las secciones húmedas

o con vetas pueden ofrecer una gran resistencia a la sierra. Cuando

esto suceda, empuje más lentamente la sierra, pero con suficiente

fuerza para mantenerla trabajando sin que su velocidad disminuya

significativamente.

Rebote

El atascamiento o la torcedura del disco de la sierra en el corte

pueden provocar el rebote. La sierra es propulsada rápidamente

hacia atrás, contra el operario. Cuando el disco es pellizcado o se

pega fuertemente a causa de un corte que se cierra, el disco se

atasca y la reacción del motor hace rebotar la unidad hacia atrás.

Cuando el disco se tuerce o se desalinea en el corte, los dientes de

la parte posterior del disco pueden cavar en la superficie superior de

la madera, haciendo que el disco salga fuera del corte y salte hacia

atrás contra el operario.

El rebote es más probable cuando cualquiera de las siguientes

condiciones tiene lugar:

1. APOYO INADECUADO DE LA PIEZA DE TRABAJO

A. El pandeo de la pieza de trabajo o el levantamiento inadecuado

del corte provocan el pellizco de la cuchilla (Figura 10).

B. El corte del material apoyado tan sólo en sus extremos. En la

medida que el material se debilita éste se flexiona, cerrando

así el corte y pellizcando el disco.

C. El corte de una pieza de trabajo que se encuentre suspendida

o en voladizo, desde su parte inferior y en dirección vertical. La

pieza que cae puede pellizcar el disco.

D. El corte de tiras largas y estrechas (corte longitudinal). La

tira cortada puede flexionarse o torcerse cerrando el corte y

pellizcando el disco.

E. El Enganche del protector inferior con la superficie bajo el

material que está siendo cortado, reduce momentáneamente

el control del operario. La sierra puede salirse parcialmente

del corte, incrementando así las posibilidades de que ésta se

tuerza.

2. AJUSTE INADECUADO DE LA PROFUNDIDAD DEL CORTE

DE LA SIERRA

La utilización de la sierra con una profundidad de corte excesiva

aumenta el esfuerzo de la unidad y la posibilidad de torcedura

del disco dentro del corte. Igualmente, aumenta la superficie del

disco expuesta al pellizco producido por el corte. Ver página 18,

Ajuste De La Profundidad De Corte.

3. TORCEDURA DEL DISCO (DESALINEACIÓN EN EL CORTE)

A. Empujar con fuerza para cortar un nudo, un clavo o un área de

vetas duras, puede provocar la torcedura del disco.

Español

21

Page 24

B. Tratar de girar la sierra dentro del corte (para regresar a la línea

trazada del corte) puede provocar la torcedura del disco.

C. La inclinación excesiva del cuerpo o un bajo control del mismo

(desequilibrio), mientras se utiliza la sierra, puede provocar la

torcedura del disco.

D. El cambio de asidero o de la posición del cuerpo mientras se

lleva a cabo un corte, puede provocar la torcedura del disco.

E. Dar marcha atrás a la unidad para desatascar el disco, puede

provocar su torcedura si no se procede cuidadosamente.

4. MATERIALES QUE REQUIEREN UN MAYOR CUIDADO

A. Madera húmeda

B. Madera verde (material fresco cortado o no secado al horno)

C. Madera tratada a presión (material tratado con preservativos o

químicos antiputrefacción)

5. UTILIZACIÓN DE DISCOS DESAFILADOS O SUCIOS

Los discos desafilados provocan el aumento de la carga del

disco. Para compensar, el operario normalmente empuja con más

fuerza, lo que recarga aún más el trabajo de la unidad y provoca

la torcedura del disco en el corte. Los discos desgastados

Español

también pueden presentar un ancho insuficiente en el corte, lo

que aumenta la carga y las posi bilidades de atascamiento.

6. LEVANTAMIENTO DE LA SIERRA CUANDO SE REAL IZAN

CORTES A ÁNGULO

Los cortes a ángulo requieren una atención especial por parte del

operario para la utilización de las técnicas adecuadas –particularmente para guiar la sierra. Tanto el ángulo del disco con

relación a la zapata como el mayor contacto del disco con el

material, aumentan las posibilidades de atascamiento, pudiendo

ocasionar la desalineación (torcedura).

7. REINICIAR UN CORTE CON LOS DIENTES DEL DISCO

ATASCADOS EN EL MATERIAL

La sierra debe alcanzar su máxima velocidad de funcionamiento

antes de empezar o reiniciar un corte, después de que la unidad

haya sido detenida con el disco dentro del corte; de lo contrario,

es posible provocar su atascamiento y rebote.

Cualquier otra condición que provoque el pellizco, el atascamiento,

la torcedura o la desalineación del disco, puede provocar el rebote.

Refiérase a las secciones Ajuste y montaje y Funcionamiento

para informarse acerca de los procedimientos y técnicas que

pueden minimizar la ocurrencia del rebote.

MANTENIMIENTO

ADVERTENCIA: Para reducir el riesgo de lesiones corporales

graves, apague la herramienta y desconéctela de la fuente

de alimentación antes de realizar ajustes o de quitar o poner

accesorios.

Limpieza

ADVERTENCIA: Sople la suciedad y el polvo de la carcasa

principal con aire seco siempre que vea acumularse el polvo

alrededor de los respiraderos. Utilice protección ocular y mascarillas

antipolvo aprobadas cuando realice este procedimiento.

ADVERTENCIA: no use nunca disolventes ni otros agentes

químicos agresivos para limpiar las piezas no metálicas de la

herramienta. Estos agentes químicos pueden debilitar los materiales

de dichas piezas. Use un trapo humedecido sólo con agua y jabón

suave. No deje que penetre ningún líquido dentro de la herramienta y

no sumerja ninguna pieza de la herramienta en líquidos.

Lubricación

La herramienta cuenta con rodamientos autolubricantes que no

requieren una lubricación periódica. No obstante, se recomienda que

envíe su herramienta una vez por año a un centro de servicio, para la

limpieza, inspección y lubricación de la caja de engranajes.

Escobillas

Verifique las escobillas de carbón regularmente. Para ello, desconecte

primero la herramienta, retire la tapa posterior (detalles en la

página 17) y retire el conjunto de escobillas. Mantenga las escobillas

22

Page 25

limpias de manera que puedan moverse libremente dentro de sus

guías. Reemplace siempre las escobillas desgastadas conservando

la misma orientación en la que se encontraban antes de ser

retiradas. Las escobillas de carbón traen varios símbolos estampados

en sus lados; si se encuentran desgastadas hasta la línea más

cercana al resorte, deben ser reemplazadas. Utilice solamente

escobillas originales D

EWALT. Los conjuntos de escobillas nuevas

se encuentran disponibles en su centro de servicio local. La

herramienta debe hacerse funcionar (sin carga de trabajo ni disco)

durante 5 minutos antes de ser utilizada, con el fin de que las nuevas

escobillas se asienten. Mientras la herramienta funciona libremente,

NO ATE, PEGUE O ASEGURE DE CUALQUEIR MANERA EL

INTERRUPTOR DEL GATILLO EN LA POSICIÓN DE ENCENDIDO

(“ON”). SOSTÉNGALA CON SUS MANOS SOLAMENTE.

Ajuste de la Zapata

La zapata de su herramienta ha sido ajustada en fábrica con el

fin de asegurar que el disco se encuentre perpendicular a ésta. Si

después de un uso prolongado se requiere realinear el disco, siga las

siguientes instrucciones:

AJUSTE PARA CORTES

A 90 GRADOS (FIG. 8, 13, 14)

1. Coloque nuevamente el disco en la posición “0” grados.

2. Afloje la botón de ajuste del ángulo de corte (C, Fig. 8). Coloque

una escuadra (M) entre el disco y la zapata.

3. Ajuste el tornillo (O) hasta que el indicador (L) se alinea a 0°,

luego ajuste la tuerca (P).

FIG. 13

M

FIG. 14

O

APRETAR

L

P

AFLOJAR

4. Reajuste la perilla de ajuste de ángulo.

Discos

Un disco desafilado producirá un corte lento e ineficiente, una

sobrecarga en el motor de la sierra, una excesiva cantidad de astillas

y aumentará la posibilidad de rebote de la herramienta. Cambie los

discos cuando no resulte fácil empujar la sierra a lo largo del corte,

cuando el motor se encuentre forzado o cuando el disco se caliente

excesivamente. Se recomienda tener a disposición algunos discos

de manera que estén disponibles para su utilización inmediata. Los

discos desafilados pueden afilarse en la mayor parte de los centros

de servicio. Vea la sección Sierras-afilado (SAWS-SHARPENING) en

las páginas amarillas.

La goma endurecida acumulada en el disco puede ser retirada con

queroseno, trementina o limpiahornos. Los discos recubiertos con

substancias antipegajosas pueden ser utilizados cuando se presente

una excesiva concentración de dicha goma, como es el caso de la

madera tratada a presión y la madera verde.

INSPECCIONE VISUALMENTE LOS DISCOS DE CARBURO

ANTES DE SU UTILIZACIÓN REEMPLÁCELOS SI SE

ENCUENTRAN DAÑADOS

CORTE MIXTO - Árbol circular de 5/8", 24 dientes Para uso general,

cortes rápidos y cortes transversales.

MADERA TRATADA A PRESIÓN y MADERA HÚMEDA

Árbol circular de 5/8", 20 dientes revestido – resistente a la

acumulación de goma

EXTREMA DURABILIDAD - Árbol circular de 5/8", 18 dientes, de

carburo de tungsteno enfriado

ACABADOS -Árbol circular de 5/8", 36 dientes Con más dientes para

cortes de un acabado más fino

CORTE RÁPIDO - Árbol circular de 5/8", 16 dientes Discos rápidos

para cortes longitudinales y transversales

23

Español

Page 26

Para cualquier información relacionada con discos o accesorios,

consulte a su distribuidor.

Accesorios

ADVERTENCIA: Dado que algunos accesorios, diferentes de los

ofrecidos por D

EWALT, no se han probado con este producto, el

empleo de tales accesorios podría constituir un riesgo. Para reducir el

riesgo de lesiones, sólo deben usarse con el producto los accesorios

recomendados D

EWALT.

Si desea más información sobre los accesorios adecuados, consulte

a su distribuidor

LA UTILIZACIÓN DE ACOPLES PARA ENFRIAMIENTO CON AGUA

NO SE RECOMIENDA CON ESTA HERRAMIENTA.

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros autorizados de servicio D

autorizadas. Estas organizaciones prestan servicio a las herramientas

D

EWALT y emplean siempre refacciones legitimas DEWALT.

Español

ESPECIFICACIONES

DW366-B3 DW366-AR DW366-B2

Voltaje 120 V 220 V 220 V

Frecuencia de Alimentación 50–60 Hz 50Hz 50–60Hz

Potencia nominal 1 800 W 1 800 W 1 800 W

Rotación sin carga 5 800/min 5 800/min 5 800/min

EWALT u otras organizaciones

24

Page 27

Definições: Diretrizes de

Segurança

As definições abaixo apresentadas descrevem o grau de

gravidade correspondente a cada palavra de advertência.

Leia cuidadosamente o manual e preste atenção a estes

símbolos.

PERIGO: Indica uma situação de risco iminente que, se

não for evitada, resultará em morte ou ferimentos graves.

ATENÇÃO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em morte ou ferimentos

graves.

CUIDADO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em ferimentos leves ou

moderados.

AVISO: Se refere a uma prática não relacionada a lesões

corporais que se não evitadas podem resultar em danos

materiais.

ATENÇÃO: para reduzir o risco de ferimentos, leia o manual

de instruções.

Regras Gerais de Segurança

ATENÇÃO! Leia todas as instruções. Falha no seguir de todas

as instruções listadas abaixo pode resultar em choque elétrico,

fogo e/ou em ferimento sério. O termo “ferramenta” em todos os

avisos listados abaixo referem-se a ferramenta alimentada através de

seu fio ou a ferramenta operada a bateria (sem cordão).

GUARDE ESTAS INSTRUÇÕES

1) ÁREA DE TRABALHO

a) Mantenha a área de trabalho limpa e iluminada. As áreas

desorganizadas e escuras são um convite aos acidentes.

b) Não opere ferramentas em atmosferas explosivas, como

na presença de líquidos inflamáveis, gases ou poeira. As

ferramentas criam faíscas que podem inflamar a poeira ou os

vapores.

c) Mantenha crianças e visitantes afastados ao operar

uma ferramenta. As distrações podem fazer você perder o

controle.

2) SEGURANÇA ELÉTRICA

a) Os plugues da ferramenta devem ser compatíveis com

as tomadas. Nunca modifique o plugue. Não use nenhum

plugue adaptador com as ferramentas aterradas. Os plugues

sem modificações aliados a utilização de tomadas compatíveis

reduzirão o risco de choque elétrico

b) Evite o contato do corpo com superfícies ligadas ao terra

ou aterradas tais como as tubulações, radiadores, escalas

e refrigeradores. Há um aumento no risco de choque elétrico

se seu corpo for ligado ao terra ou aterramento.

c) Não exponha a ferramentas à chuva ou às condições

úmidas. A água entrando na ferramenta aumentará o risco de

choque elétrico.

d) Não force o cabo elétrico. Nunca use o cabo elétrico para

carregar, puxar ou o para desconectar a ferramenta da

tomada. Mantenha o cabo elétrico longe do calor, óleo,

bordas afiadas ou das partes em movimentos. Os cabos

danificados ou emaranhados aumentam o risco de choque

elétrico.

e) Ao operar uma ferramenta ao ar livre, use um cabo de

extensão apropriado para o uso ao ar livre. O uso de um

cabo apropriado ao ar livre reduz o risco de choque elétrico.

3) SEGURANÇA PESSOAL

a) Fique atento, olhe o que você está fazendo e use o bom

senso ao operar uma ferramenta. Não use a ferramenta

quando você estiver cansado ou sob a influência de

Português

25

Page 28

drogas, álcool ou de medicamentos. Um momento de

desatenção enquanto opera uma ferramenta pode resultar em

grave ferimento pessoal.

b) Use equipamento de segurança. Sempre use óculos de

segurança. O equipamento de segurança tais como a máscara

contra a poeira, sapatos de segurança antiderrapantes, capacete

de segurança, ou protetor auricular usados em condições

apropriadas reduzirão os ferimentos pessoais.

c) Evite acidente inicial. Assegure que o interruptor está na

posição desligada antes de conectar o plugue na tomada.

Carregar a ferramentas com seu dedo no interruptor ou

conectar a ferramenta que apresenta o interruptor na posição “

ligado” são um convite à acidentes.

d) Remova qualquer chave de ajuste antes de ligar a ferramenta.

Uma chave de mandril ou de ajuste unida a uma parte rotativa

da ferramenta pode resultar em ferimento pessoal.

e) Não force além do limite. Mantenha o apoio e o equilíbrio

adequado todas as vezes que utilizar a ferramenta.

Isto permite melhor controle da ferramenta em situações

inesperadas.

f) Vista-se apropriadamente. Não use roupas demasiadamente

largas ou jóias. Mantenha seus cabelos, roupas e luvas longe

das peças móveis. A roupa folgada, jóias ou cabelos longos

podem ser presos pelas partes em movimento.

g) Se os dispositivos são fornecidos com conexão para