Page 1

DEWALT Industrial Tool Company, P.O. Box 158, 626 Hanover Pike, Hampstead, MD 21074 Printed in U.S.A. (APR97-CD-1) Form No. 384102

DW359-220 Copyright © 1997

384102/DW359-220 5/2/02 3:14 PM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW359-220 7-1/4"(184 mm) Circular Saw

Scie circulaire de 184 mm (7 1/4 po)

Sierra circular de 184 mm (7-1/4")

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTIA. ADVERTENCIA: LEASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO. SI TIENE DUDAS, POR FAVOR LLAME.

384102/DW359-220 5/2/02 3:14 PM Page 3

Page 3

English

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

Grounding Instructions (DW359-220)

This tool should be grounded while in use

to protect the operator from electric shock.

The tool is equipped with a 3-conductor

cord to fit the proper grounding type

receptacle. The green (or green and

yellow) conductor in the cord is the

grounding wire. Never connect the green

(or green and yellow) wire to a live

terminal.

The two grounding contacts and the grounding receptacle in the

plug must be connected to a permanent ground, such as a properly

grounded outlet. No adapter is available for a plug as shown in

Figure A.

Safety Instructions For All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with

grounded surfaces. For example; pipes, radiators, ranges, and

refrigerator enclosures.

• KEEP CHILDREN AWAY. Do not let visitors contact tool or

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

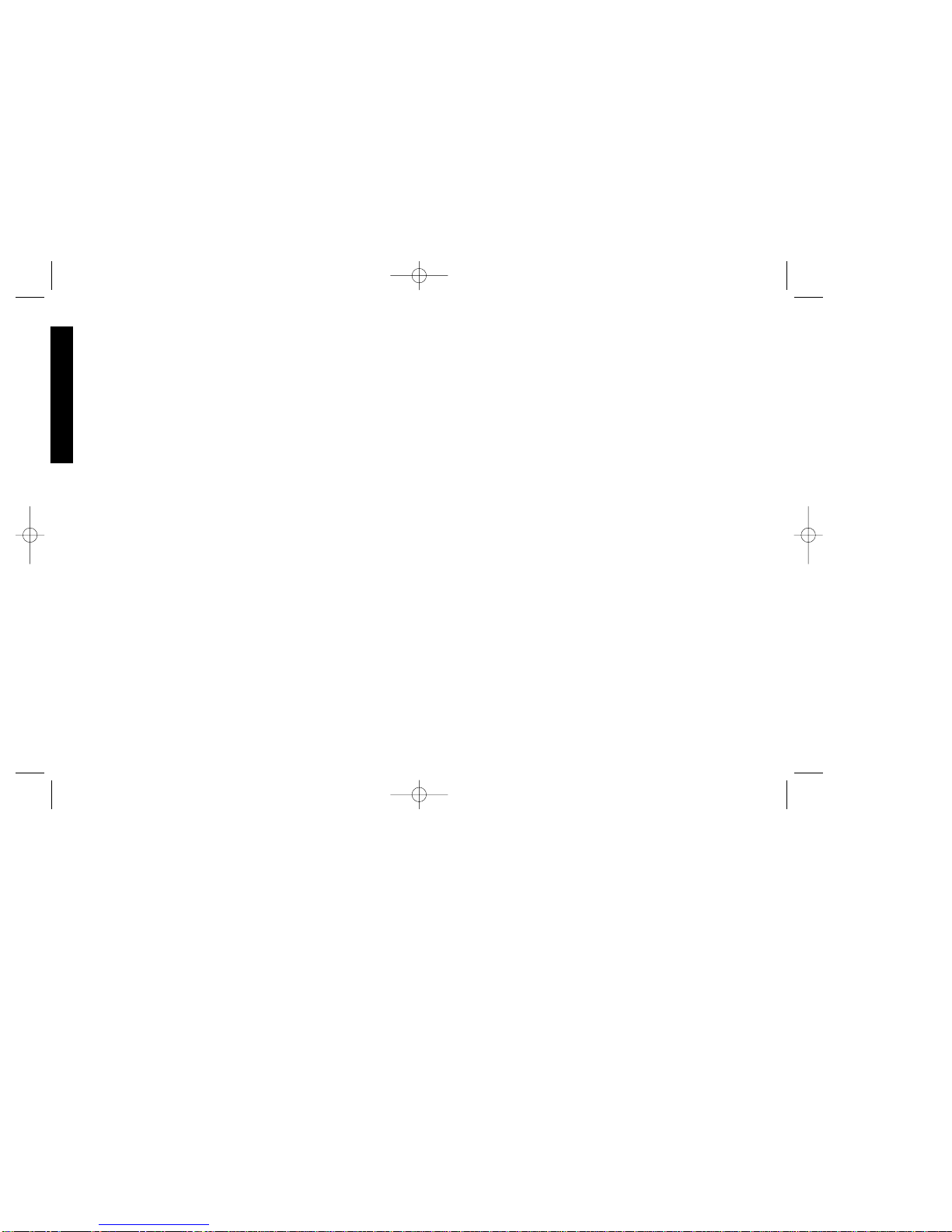

TRIGGER

SWITCH

RETRACTING

LEVER

LOWER GUARD

SHOE

QUADRANT KNOB

BEVEL

QUADRANT

A

384102/DW359-220 5/2/02 3:14 PM Page 4

Page 4

extension cord. All visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the rate

for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy-duty tool. Don’t use tool for purpose not intended- for

example- don’t use circular saw for cutting tree limbs or logs.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

• USE SAFETY GLASSES. Also use face or dust mask if cutting

operation is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep handles

dry, clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger

1

English

on switch. Be sure switch is off when plugging in.

• EXTENSION CORDS. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage number, the

heavier the cord.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

so marked.

• STAY ALERT. Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

• CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

384102/DW359-220 5/2/02 3:14 PM Page 1

Page 5

English

2

Additional Safety Instructions for Circular

Saws

• CAUTION: When cutting into walls, floors or wherever live electrical

wires may be encountered, DO NOT TOUCH ANY METAL PARTS

OF THE TOOL! Hold the tool only by insulated grasping surfaces to

prevent electric shock if you cut in the live wire.

• KEEP GUARDS IN PLACE AND IN WORKING ORDER. Never

wedge or tie lower guard open. Check operation of lower guard

before each use. Do not use if lower guard does not close briskly

over saw blade. CAUTION: If saw is dropped, lower guard may be

bent, restricting full return.

• KEEP BLADES CLEAN AND SHARP. Sharp blades minimize

stalling and kickback.

• DANGER: KEEP HANDS AWAY FROM CUTTING AREA. Keep

hands away from blades. Do not reach underneath work while

blade is rotating. Do not attempt to remove cut material when blade

is moving. CAUTION: Blades coast after turn off.

• SUPPORT LARGE PANELS. Large panels must be supported as

shown in Figure16 to minimize the risk of blade pinching and

kickback. When cutting operation requires the resting of the saw on

the work piece, the saw shall be rested on the larger portion and the

smaller piece cut off.

• USE RIP FENCE. Always use a rip fence or straight edge guide

when ripping.

• GUARD AGAINST KICKBACK. Kickback occurs when the saw

stalls rapidly and is driven back towards the operator. Release

switch immediately if blade binds or saw stalls. Keep blades sharp.

Support large panels as shown in Figure 16. Use fence or straight

edge guide when ripping. Don’f force tool. Stay alert-exercise

control. Don’t remove saw from work during a cut while the blade is

moving.

• LOWER GUARD. Raise lower guard with the retracting handle.

• ADJUSTMENTS. Before cutting be sure depth and bevel

adjustments are tight.

• USE ONLY CORRECT BLADES IN MOUNTING. Do not use

blades with incorrect size holes. Never use defective or incorrect

blade washers or bolts.

• AVOID CUTTING NAILS. Inspect for and remove all nails from

lumber before cutting.

• CAUTION: Some wood contains preservatives such as copper

chromium arsenate (CCA) which can be toxic. When cutting these

materials extra care should be taken to avoid inhalation and

minimize skin contact.

SAVE THESE INSTRUCTIONS

Motor

Your DeWalt tool is powered by a DeWalt motor. Be sure your power

supply agrees with nameplate marking. 220 Volts AC/DC means your

saw will operate on alternating or direct current. Lower voltage can

cause loss of power and can result in overheating. All DeWalt tools are

factory-tested; if this tool does not operate, check the power supply.

Brushes

DISCONNECT PLUG FROM POWER SUPPLY BEFORE

SERVICING

Inspect carbon brushes regularly by unplugging tool, removing the

Brush Inspection Cap (Fig. 2) and withdrawing the brush assembly.

Keep brushes clean and sliding freely in their guides. Always replace

a used brush in the same orientation in the holder as it was prior to

removal. Carbon brushes have varying symbols stamped into their

sides, and if the brush is worn down to the line closest to the spring,

they must be replaced. Use only identical DeWalt brushes. Always

replace both brushes. Use of the correct grade of brush is essential

for proper operation. New brush assemblies are available at your

authorized service center. The tool should be allowed to “run in” (run

at no load without a blade) for 10 minutes before use to seat new

brushes.

384102/DW359-220 5/2/02 3:14 PM Page 2

Page 6

While “running in” DO NOT TIE, TAPE, OR OTHERWISE LOCK THE

TRIGGER SWITCH ON. HOLD BY HAND ONLY.

Adjustments and Setup

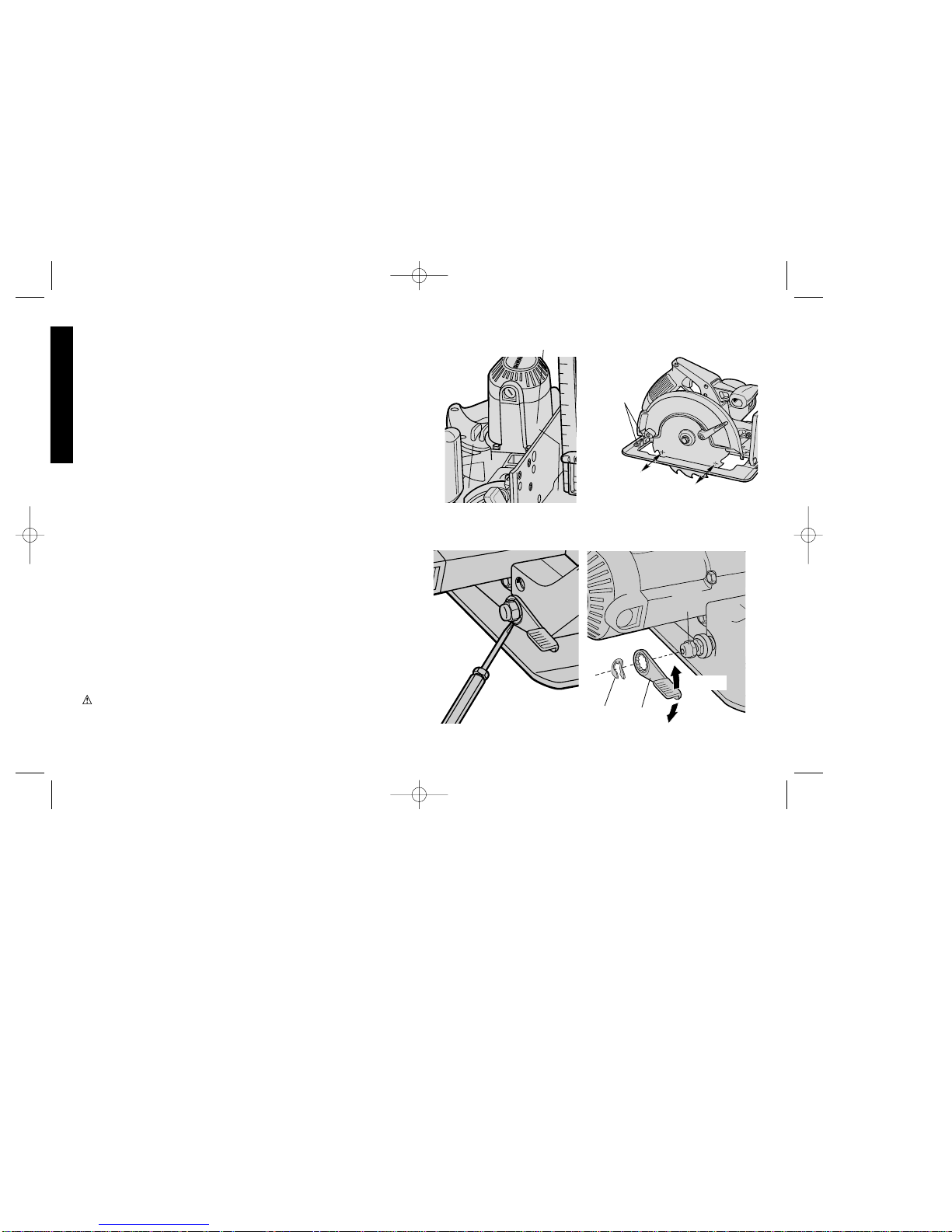

ATTACHING AND REMOVING BLADES

DISCONNECT PLUG FROM POWER SUPPLY.

To attach the blade, retract lower blade guard and place inner clamp

washer and blade on saw spindle with printed side of blade out (teeth

at bottom of blade pointing forward) (FIG. 1.) Place outer clamp

washer on saw spindle. The larger surfaces of both washers must

face the blade. Thread on blade clamping screw firmly by hand to

hold both blade washers in position.

Lightly depress the blade lock (FIG. 2) while turning the spindle until

the blade stops rotating. Tighten blade clamping screw (clockwise)

firmly with the blade wrench (FIG. 3).

NEVER ENGAGE BLADE LOCK WHILE SAW IS RUNNING, OR

ENGAGE IN AN EFFORT TO STOP THE TOOL. NEVER TURN

SWITCH ON WHEN BLADE LOCK IS ENGAGED. SERIOUS

DAMAGE TO YOUR SAW WILL RESULT.

When removing the blade, first unplug the saw. Engage the blade

lock and unscrew the blade clamping screw by turning it counterclockwise with the blade wrench.

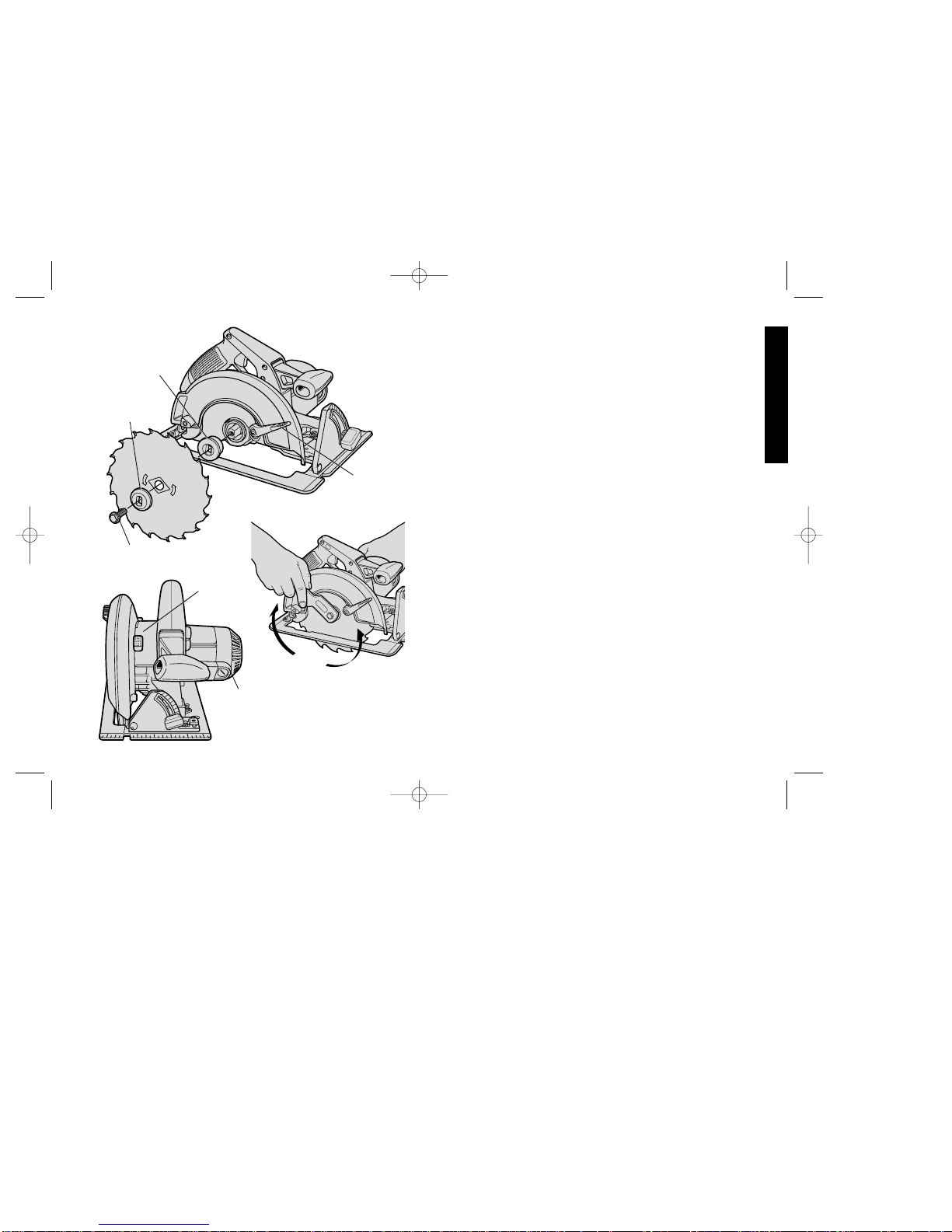

CUTTING DEPTH ADJUSTMENT

DISCONNECT PLUG FROM POWER SUPPLY.

Hold the saw firmly as shown in Figure 4. Loosen (counterclockwise)

the Depth Adjustment Lever and move shoe to obtain the desired

depth of cut, as shown in Figure 5. Make sure the Depth Adjustment

Lever has been retightened (clockwise) before operating saw.

Your saw is equipped with a carbide tipped saw blade for long life and

efficient cutting.

For the most efficient cutting action using a carbide tipped saw blade,

set the depth adjustment so that about one half of a tooth projects

below the surface of the wood to be cut. The height of a whole tooth

is the distance from the tip of the tooth to the bottom of the gullet in

3

English

FIG. 1

INNER

CLAMP

WASHER

OUTER

CLAMP

WASHER

BLADE CLAMPING SCREW

RETRACTING

LEVER

BLADE

LOCK

BRUSH

INSPECTION

CAP

FIG. 2

FIG. 3

TIGHTEN

LOOSEN

384102/DW359-220 5/2/02 3:15 PM Page 3

Page 7

4

front of it. Study Figures 5A and 5B to determine what one half tooth

means. (5A shows one half tooth projecting below the surface and

figure 5B shows a whole tooth projecting below the surface.)

Setting the saw at the proper cutting depth keeps blade friction to a

minimum, removes sawdust from between the blade teeth, results in

cooler, faster sawing and reduces the chance of kickback.

A method of checking for the correct cutting depth is shown in Figure

6. Lay a piece of the material you plan to cut along the side of the

blade, as shown in the figure, and observe how much tooth projects

beyond the material.

NOTE: When using a non carbide tipped blade, make an exception to

the above procedure and allow a full tooth to project below the

material, as shown in Figure 5B.

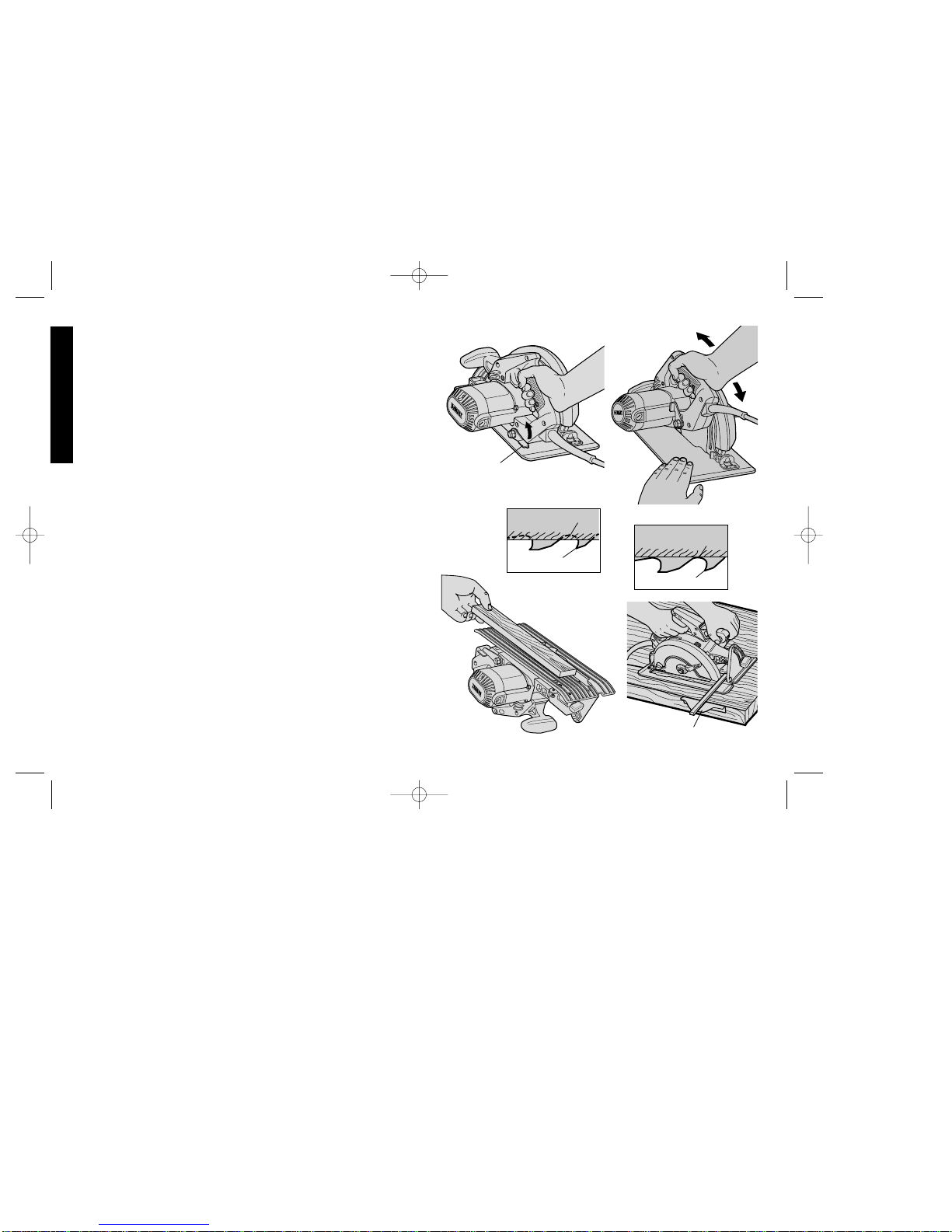

BEVEL ANGLE ADJUSTMENT

DISCONNECT THE SAW FROM THE POWER SUPPLY.

The full range of the Bevel Adjustment is from 0 TO 50 DEGREES.

The quadrant is graduated in increments of 5 degrees.

On the front of the saw is a bevel angle adjustment mechanism (Figure

8) consisting of a calibrated quadrant and a lever or knob. To set the

saw for a bevel cut, loosen (counterclockwise) the quadrant knob and

tilt shoe to the desired angle by aligning the pointer with the desired

angle mark. Retighten knob firmly (clockwise).

NOTE: The quadrant pointer , located between the quadrant knob and

the quadrant, can be adjusted after loosening its screw. Retighten

firmly after adjustment.

KERF INDICATOR

The front of the saw shoe has a kerf indicator (Figure 8) for vertical

and bevel cutting. This indicator enables you to guide the saw along

cutting lines penciled on the material being cut. The indicator lines up

with the left (inner) side of the saw blade, which makes the slot or

“kerf” cut by the moving blade fall to the right of the indicator. Guide

along the penciled cutting line so that the kerf falls into the waste or

surplus material – See Figure 9. Figure 9 shows the dimensions of the

shoe. The right dimension is 1-1/2” (standard 2x lumber).

English

FIG. 4

DEPTH

ADJUSTMENT

LEVER

FIG. 5

FIG. 6

GULLETSURFACE

OF WOOD

FIG. 7

RIP FENCE

TIP OF TOOTH

TIP OF TOOTH

FIG. 5A

FIG. 5B

GULLET

SURFACE

OF WOOD

384102/DW359-220 5/2/02 3:15 PM Page 4

Page 8

SHOE ALIGNMENT

Your saw has been set at the factory for accurate vertical cuts (a 90

degree angle between the bottom of the shoe and the blade). The

edge of the shoe has also been set parallel to the blade so that it will

not bind when using an edge guide. If the saw should ever need

adjustment, it may be done as follows:

ADJUSTING FOR 90° CUTS

1. DISCONNECT PLUG FROM POWER SUPPLY.

2. Adjust the saw to 0° bevel.

3. Place saw on blade side (Fig. 10). Retract blade guard.

4. Loosen quadrant lever or knob (Fig. 10). Place a square against

the blade and shoe to adjust the 90° setting.

5. Loosen the hex nut and move the adjustment screw so that the

shoe will stop at the proper angle as shown in Figure 11. Lock

the screw in place by tightening the hex nut.

6. It may be necessary to adjust the quadrant angle pointer to line

up on “O” after shoe has been adjusted.

ADJUSTING THE SHOE PARALLEL TO THE BLADE

(Your saw is adjusted at the factory so that the blade and shoe are

parallel. If these parts become misaligned, adjust as follows.)

1. Disconnect plug from power supply.

2. Loosen the (2) screws at the adjusting bracket at the rear of the

shoe, as shown in Figure 12.

3. Adjust the shoe until it is parallel to the blade by measuring from

the edge of the shoe to the blade, front & rear. You can measure

from the outside edge of the blade to the shoe as shown in

Figure 12 or from the inner edge of the blade to the wider part

of the shoe. (Do not measure from the tips of any saw blade

teeth.)

4. When shoe is parallel, tighten all screws.

5

English

FIG. 8

QUADRANT

KERF

INDICATOR

45 0

123451

FIG. 9

GUIDE ALONG PENCILED

CUTTING LINE SO KERF

FALLS IN WASTE STOCK

DIRECTION OF CUT

KERF

QUADRANT

KNOB

WASTE OR

SURPLUS STOCK

Align left side of

saw blade

with“45” mark, as

shown, for 45°

bevel cutting

5 "

1-1/2"

Align left side of

saw blade with

“0” mark for

straight cutting

QUADRANT KNOB

FIG. 10

DESIRED WIDTH

OF STOCK

CORD

KEEPER

384102/DW359-220 5/2/02 3:15 PM Page 5

Page 9

6

ADJUSTING DEPTH ADJUSTMENT LEVER

It may be desirable to adjust the Depth Adjustment. (It will sometimes

hit the shoe before tightening or loosening completely.)

To adjust lever, follow the steps below.

1. Disconnect plug from power supply.

2. Using a small screwdriver, pry the lock ring off, as shown in Figure

13.

3. Remove the lever and rotate it in the desired direction about 1/8

revolution. (More or less as necessary.)

4. Reinstall the lever and insert the lock ring with concave side

against lever to hold it in place. (Figure 14)

Operation

SWITCH

Pull the trigger switch to turn the motor “ON”. Releasing the trigger

turns the motor “OFF”. This tool has no provision to lock the switch

in the “ON” position, and should never be locked “ON” in any way.

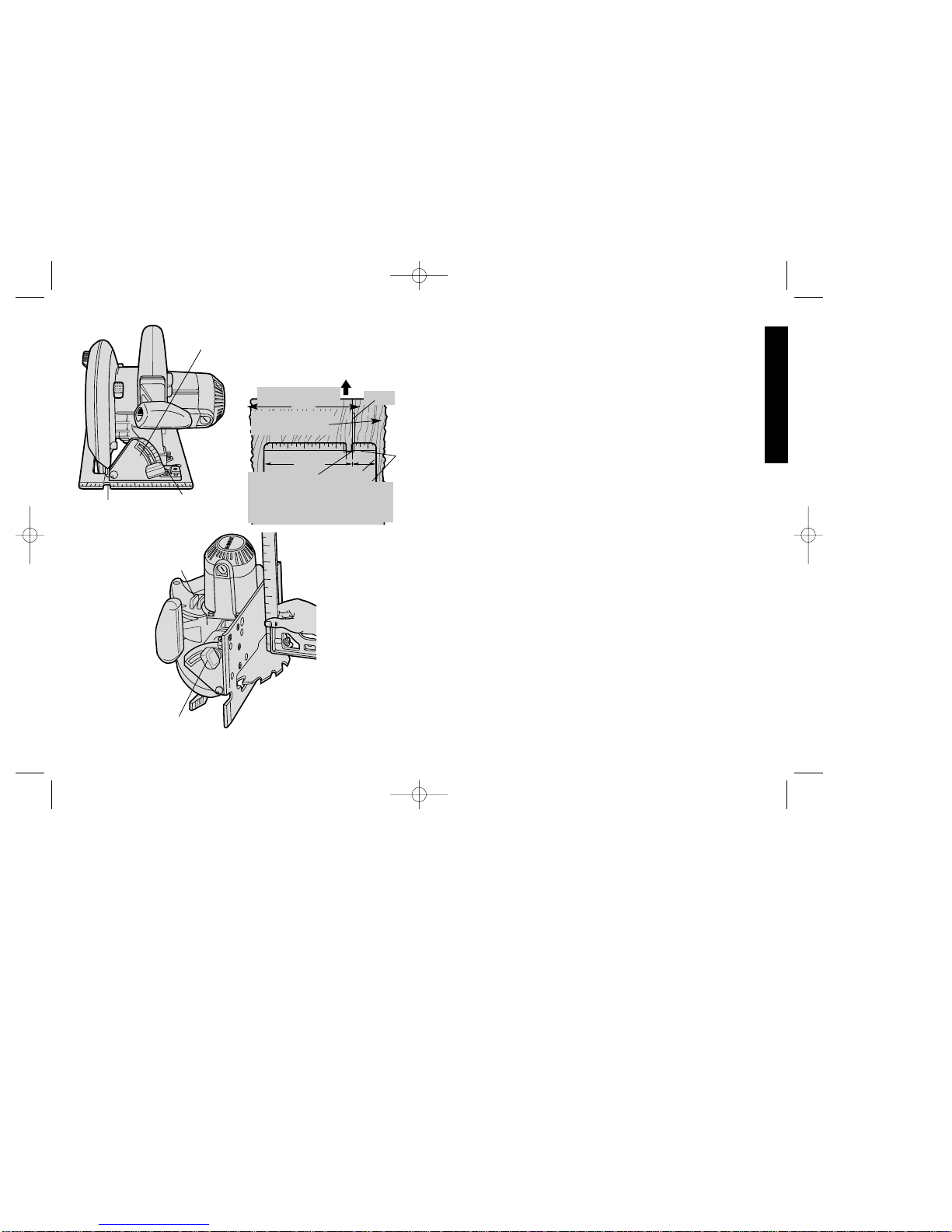

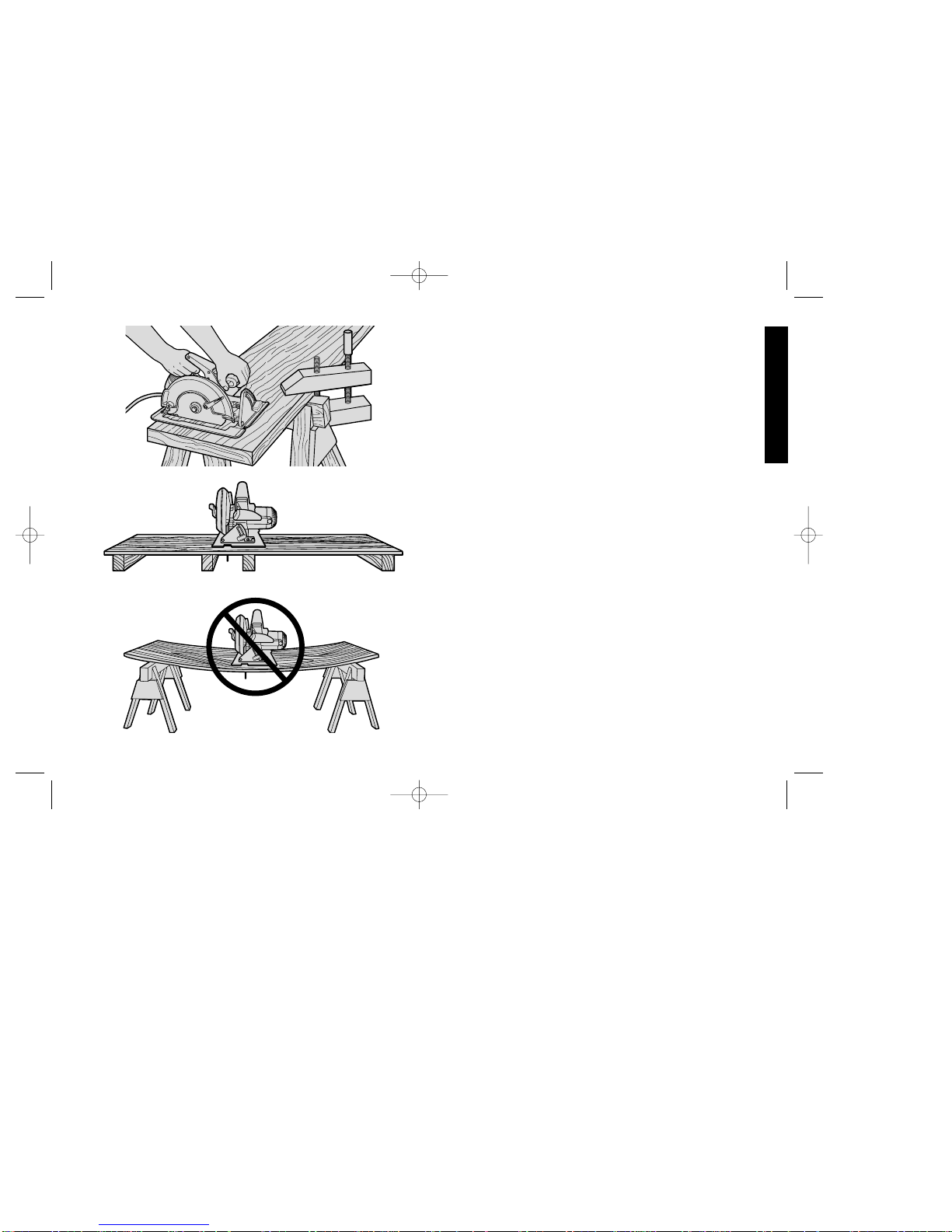

WORKPIECE SUPPORT

Figure 15 shows proper sawing position. Note that hands are kept

away from cutting area, and power cord is positioned clear of the

cutting area so that it will not get caught or hung up on the work.

T o avoid kickback, DO support board or panel NEAR the cut, (Figure

16). DON’T support board or panel away from the cut (Figure 17).

When operating the saw, keep the cord away from the cutting area

and prevent it from becoming hung up on the work piece. Note that

a special Cord Keeper has been provided on the tool’s handle. (See

Fig. 10 on page 6.) Press the cord firmly into the cord keeper to keep

it out of the way but in sight so you know where it is at all times.

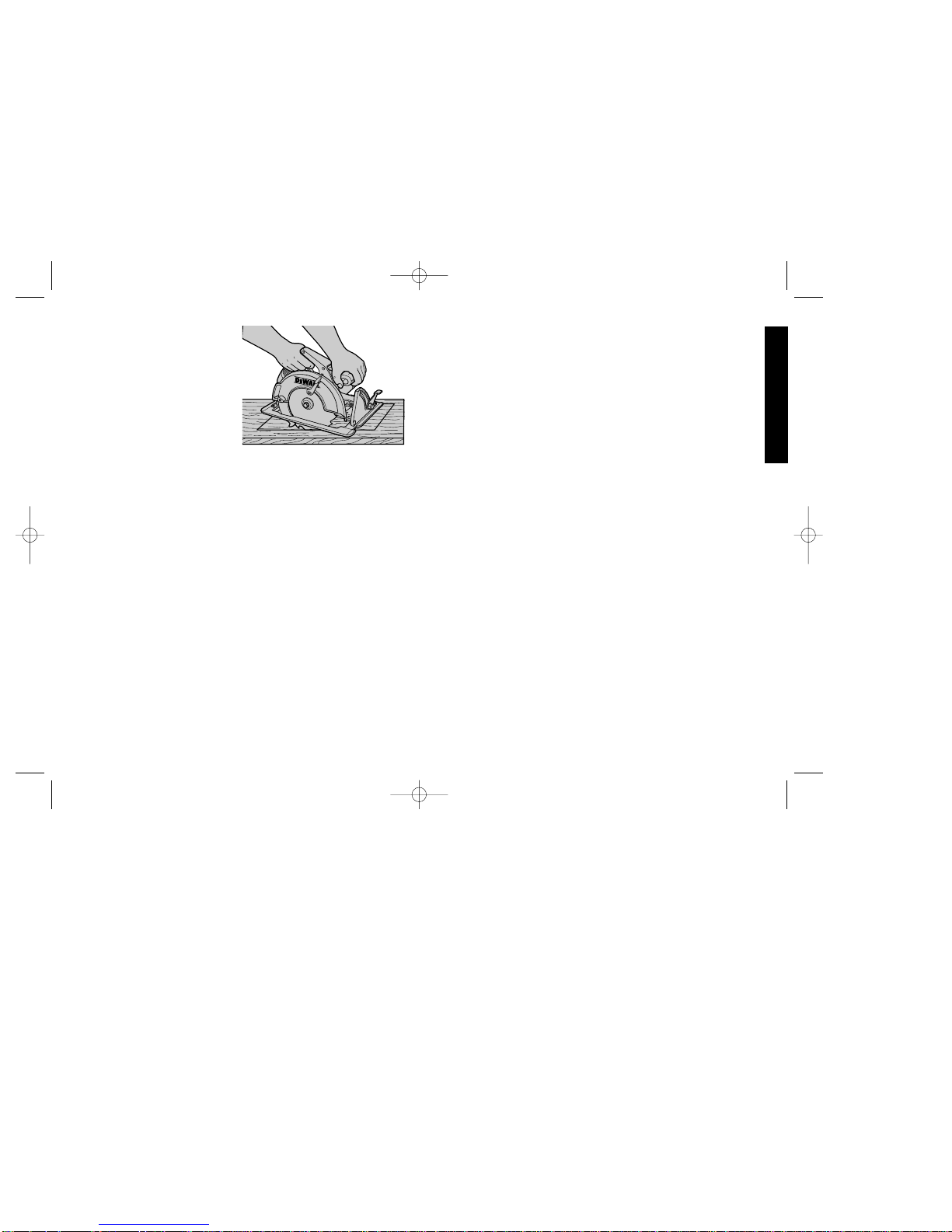

WARNING: It is important to support the work properly and to hold

the saw firmly to prevent loss of control which could cause personal

injury; Figure 18 illustrates typical hand support of the saw.

English

FIG. 12

SCREWS

FIG. 13

FIG. 14

LOCK

NUT

LOCK

RING

LEVER

TIGHTEN

LOOSEN

FIG. 11

SCREWS

QUADRANT

KNOB

ADJUSTMENT SCREW

384102/DW359-220 5/2/02 3:15 PM Page 6

Page 10

ALWAYS DISCONNECT SAW BEFORE MAKING ANY

ADJUSTMENTS! Place the work with its “good” side – the one on

which appearance is most important – down. The saw cuts upward,

so any splintering will be on the work face that is up when you saw it.

CUTTING

Support the work so that the cut will be on your right. Place the wider

portion of the saw shoe on that part of the work piece which is solidly

supported, not on the section that will fall off when the cut is made.

As examples, Figure 18 illustrates the RIGHT way to cut off the end

of a board, and Figure 19 the WRONG way. Always clamp work.

Don’t try to hold short pieces by hand! Remember to support

cantilevered and overhanging material. Use caution when sawing

material from below.

Be sure saw is up to full speed before blade contacts material to be

cut. Starting saw with blade against material to be cut or pushed

forward into kerf can result in kickback.

Push the saw forward at a speed which allows the blade to cut

without laboring. Hardness and toughness can vary even in the same

piece of material, and knotty or damp sections can put a heavy load

on the saw. When this happens, push the saw more slowly, but hard

enough to keep it working without much decrease in speed.

Forcing the saw can cause rough cuts, inaccuracy, kickback and

over-heating of the motor.

Should your cut begin to go off the line, don’t try to force it back on.

Release the switch and allow blade to come to a complete stop. Then

you can withdraw the saw, sight anew, and start a new cut slightly

inside the wrong one. In any event, withdraw the saw if you must shift

the cut. Forcing a correction inside the cut can stall the saw and lead

to kickback. IF SAW STALLS, RELEASE THE TRIGGER AND BACK

THE SAW UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN

THE CUT AND CLEAR OF THE EDGE BEFORE RESTARTING.

As you finish a cut, release the trigger and allow the blade to stop

before lifting the saw from the work. As you lift the saw, the spring-

7

English

FIG. 15

FIG. 16

SUPPORT WORK

NEAR CUT

FIG. 17

WRONG -

MATERIAL BENDS ON

BLADE CAUSING HEAVY

LOADS OR KICKBACK.

RIGHT

384102/DW359-220 5/2/02 3:15 PM Page 7

Page 11

8

exist.

1. IMPROPER WORKPIECE SUPPORT

A. Sagging or improper lifting of the cut off piece causing

pinching of the blade.

B. Cutting through material supported at the outer ends only

(see Figure 17). As the material weakens it sags, closing

down the kerf and pinching the blade.

C. Cutting off a cantilevered or overhanging piece of material

from the bottom up in a vertical direction. The falling cut off

piece can pinch the blade.

D. Cutting off long narrow strips (as in ripping). The cut off strip

can sag or twist closing the kerf and pinching the blade.

E. Snagging the lower guard on a surface below the material

being cut momentarily reducing operator control. The saw can

lift partially out of the cut increasing the chance of blade twist.

2. IMPROPER DEPTH OF CUT SETTING ON SAW

Using the saw with an excessive depth of cut setting increases

loading on the unit and susceptibility to twisting of the blade in

the kerf. It also increases the surface area of the blade avaliable

for pinching under conditions of kerf close down.

English

tensioned telescoping guard will automatically close under the blade.

Remember the blade is exposed until this occurs, never reach under

the work for any reason whatsoever. When you have to retract the

telescoping guard manually (as is necessary for starting pocket cuts)

always use the retracting lever.

NOTE: When cutting thin strips, be careful to ensure that small cutoff

pieces don’t hang up on inside of lower guard.

When ripping (cutting with the grain) the use of a rip fence is

recommended. (See Figure 7)

POCKET CUTTING

DISCONNECT PLUG FROM POWER SUPPLY WHEN MAKING

THIS OR ANY OTHER ADJUSTMENT. Adjust saw shoe so blade

cuts at desired depth. Tilt saw forward and rest front of the shoe on

material to be cut. Using the retracting lever, retract blade guard to an

upward position. Lower rear of shoe until blade teeth almost touch

cutting line. Now release the blade guard (its contact with the work

will keep it in position to open freely as you start the cut) (Figure 20).

Start the motor and gradually lower the saw until its shoe rests flat on

the material to be cut. Advance saw along the cutting line until cut is

completed. Release trigger and allow blade to stop completely before

withdrawing the blade from the material. When starting each new cut,

repeat as above. Never tie the blade guard in a raised position.

Kickback

When the saw blade becomes pinched or twisted in the cut, kickback

can occur. The saw is thrust rapidly back toward the operator. When

the blade is pinched or bound tightly by the kerf closing down, the

blade stalls and the motor reaction drives the unit backward. When

the blade becomes twisted or misaligned in the cut, the teeth at the

back edge of the blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and jump back toward the

operator.

Kickback is more likely to occur when any of the following conditions

FIG. 18 FIG. 19

WRONG

384102/DW359-220 5/2/02 3:15 PM Page 8

Page 12

3. BLADE TWISTING (MIS-

ALIGNMENT IN CUT)

A. Pushing harder to cut

through a knot, a nail, or

a hard grain area can

cause the blade to

twist.

B. Trying to turn the saw in

the cut (trying to get

back on the marked

line) can cause blade

twist.

C. Extended reach or operating saw with poor body control (out

of balance), can result in twisting the blade.

D. Changing hand grip or body position while cutting can result

in blade twist.

E. Backing unit up to clear blade can lead to twist if not done

carefully.

4. MATERIALS THAT REQUIRE EXTRA ATTENTION

A. Wet lumber

B. Green lumber (material freshly cut or not kiln dried)

C. Pressure treated lumber (material treated with preservatives

or anti-rot chemicals)

5. USE OF DULL OR DIRTY BLADES

Dull blades cause increased loading of the saw. To

compensate, an operator will usually push harder which further

loads the unit and promotes twisting of the blade in the kerf.

Worn blades may also have insufficient body clearance which

increases the chance of binding and increased loading.

6. LIFTING THE SAW WHEN MAKING BEVEL CUTS

Bevel cuts require special operator attention to proper cutting

techniques – especially guidance of the saw. Both blade angle

to the shoe and greater blade surface in the material increase

the chance for binding and misalignment (twist) to occur.

7. RESTARTING A CUT WITH THE BLADE TEETH JAMMED

AGAINST THE MATERIAL

The saw should be brought up to full operating speed before

starting a cut or restarting a cut after the unit has been stopped

with the blade in the kerf. Failure to do so can cause stalling

and kickback.

Any other conditions which could result in pinching, binding, twisting,

or misalignment of the blade could cause kickback. Refer to the

sections on “Adjustments And Set-Up” and “Operation” for

procedures and techniques that will minimize the occurrence of

kickback.

Blades

A dull blade will cause slow, inefficient cutting, overload on the saw

motor, excessive splintering and increase the possibility of kickback.

It is a good practice to keep extra blades on hand so that sharp

blades are available while the dull ones are being sharpened (See

“SAWS-SHARPENING” in the Yellow Pages). In fact, many lower

priced blades can be replaced with new ones at very little cost over

the sharpening price.

Hardened gum on the blade will slow down the cutting. This gum

can best be removed with trichlorethylene, kerosene, turpentine or

oven cleaner.

DeWalt manufactures a complete line of 7-1/4” (180mm) diameter

saw blades and they are available from your authorized service

center.

VISUALLY EXAMINE CARBIDE BLADES BEFORE USE.

REPLACE IF DAMAGED.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local service center. A complete listing of service

centers is included with your tool.

9

English

FIG. 20

384102/DW359-220 5/2/02 3:15 PM Page 9

Page 13

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

EWAL T. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

DEWALTheavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

10

If you need any assistance in locating any accessory, please contact

DeWalt Industrial Tool Company, P.O. Box 158, 626 Hanover Pike,

Hampstead MD 21074 or call 1-800-732-4441.

A. RIP FENCE: Attaches to top of saw shoe. Permits rip cuts without

penciled guide line.

B. SAW PROTRACTOR: Guides saw for accurate cut-off work.

Adjusts from 0 to 70 degrees.

C. CUT-OFF GUIDE: For 90 degree or 45 degree cuts.

CAUTION: Recommended accessories and saw blades for your

saw are listed in this manual. The use of any other accessory or

attachment may be hazardous.

Cleaning and Lubrication

Use only mild soap and a damp cloth to clean the tool. Never let any

liquid get inside the tool; never immerse any part of the tool into a

liquid.

Accesories

Recommended accessories for use with your tool are available at

estra cost from your distributor or authorized service center.

CAUTION: The use of any non-recommended accessory may be

hazardousl.

Important!

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts

English

384102/DW359-220 5/2/02 3:15 PM Page 10

Page 14

11

Français

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉR SUIVANT.

1 800 4-DEWALT (1 800 433-9258)

Importantes mesures de sécurité

AVERTISSEMENT : Afin de réduire les risques d’incendie, de

secousses électriques ou de blessures lorsqu’on utilise des outils

électriques, il faut toujours respecter les mesures de sécurité

suivantes.

LIRE TOUTES LES DIRECTIVES.

Mise à la terre

L’outil devrait être mis à la terre lorsqu’on

s’en sert afin de protéger l’utilisateur contre

les secousses électriques. Le conducteur

vert (ou vert et jaune) du cordon sert de

mise à la terre. Ne jamais relier le

conducteur vert (ou vert et jaune) à une

borne sous tension.

Il faut relier les deux contacts de mise à la

terre et la fiche de mise à la terre à une

mise à la terre permanente, comme une prise bien mise à la terreIl

n’existe aucun adaptateur pour une fiche semblable à celle illustrée

à la figure A.

Mesures de sécurité pour tous les outils

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail. Ne pas se

servir de l’outil en présence de liquides ou de vapeurs

inflammables.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES.

Éviter tout contact avec des objets mis à la terre, comme des

tuyaux, radiateurs, cuisinières, réfrigérateurs et autres objets du

genre.

INTERRUPTEUR

À DÉTENTE

RESSORT DE

RAPPEL

PROTÈGE-LAME INFÉRIEUR

PATIN

BOUTON OU LEVIER

DU SECTEUR

SECTEUR

A

384102/DW359-220 5/2/02 3:15 PM Page 11

Page 15

12

Français

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail et il faut les empêcher de toucher à

l’outil ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans

un endroit sec, situé en hauteur ou fermé à clé, hors de la portée

des enfants.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr

et efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil

ou d’un accessoire le rendement d’un outil de fabrication plus

robuste. Se servir de l’outil selon l’usage prévu.

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples et des bijoux qui peuvent être happés par les

pièces en mouvement. Porter des gants de caoutchouc et des

chaussures à semelle antidérapante pour travailler à l’extérieur.

Protéger la chevelure si elle est longue.

• PORTER DES LUNETTES DE SÉCURITÉ. Porter également un

masque respiratoire si le travail de coupe produit de la poussière.

• NE PAS MANIPULER LE CORDON DE FAÇON ABUSIVE. Ne

pas transporter l’outil par le cordon ni tirer sur ce dernier pour le

débrancher de la prise. Éloigner le cordon des sources de chaleur,

des flaques d’huile et des arêtes tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides

ou d’un étau. On peut alors se servir des deux mains pour faire

fonctionner l’outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres pour

qu’ils donnent un rendement supérieur et sûr. Suivre les directives

concernant la lubrification et le remplacement des accessoires.

Inspecter régulièrement le cordon de l’outil et le faire réparer au

besoin à un atelier d’entretien autorisé. Inspecter régulièrement les

cordons de rallonge et les remplacer lorsqu’ils sont endommagés.

S’assurer que les poignées sont toujours propres, sèches et libres

de toute tache d’huile ou de graisse.

• DÉBRANCHER OU VERROUILLER EN POSITION HORS

TENSION LES OUTILS NON UTILISÉS. Respecter cette mesure

lorsqu’on ne se sert pas de l’outil, ou qu’on doit le réparer ou en

changer un accessoire (comme une lame, un foret ou un couteau).

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de

vérifier si les clés de réglage ont été retirées avant de faire

démarrer l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur l’interrupteur lorsqu’on transporte l’outil. S’assurer que

l’interrupteur est à la position hors circuit lorsqu’on branche l’outil.

• CORDONS DE RALLONGE. S’assurer que le cordon de rallonge

est en bon état. Lorsqu’on se sert d’un cordon de rallonge,

s’assurer qu’il est de calibre approprié pour la tension nécessaire

au fonctionnement de l’outil. L’utilisation d’un cordon de calibre

inférieur occasionne une baisse de tension entraînant une perte de

puissance et la surchauffe. Le tableau suivant indique le calibre

approprié selon la longueur du cordon et les mentions de la plaque

signalétique de l’outil. En cas de doute, utiliser un cordon de calibre

supérieur. Le chiffre indiquant le calibre est inversement

proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Longueur totale du cordon

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Intensité

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR.

Lorsque l’outil est utilisé à l’extérieur, ne se servir que d’un cordon

de rallonge conçu pour l’extérieur et portant la mention appropriée.

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de l’outil lorsqu’on est fatigué.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à

384102/DW359-220 5/2/02 3:15 PM Page 12

Page 16

utiliser l’outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré

d’usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l’outil. Faire réparer

ou remplacer tout protecteur ou toute autre pièce endommagée

dans un centre de service autorisé, sauf si le présent guide fait

mention d’un avis contraire. Confier le remplacement de tout

interrupteur défectueux à un centre de service autorisé. Ne jamais

se servir d’un outil dont l’interrupteur est défectueux.

Mesures de sécurité additionnelles

relatives aux scies circulaires

• MISE EN GARDE : Lorsqu’on coupe dans les murs, les planchers

ou tout autre endroit où peuvent se trouver des fils sous tension,

NE PAS TOUCHER AUX COMPOSANTS MÉTALLIQUES DE

L’OUTIL. Ne le saisir que par ses surfaces en plastique afin de se

protéger des secousses électriques si on entre en contact avec

un fil sous tension.

• S’ASSURER QUE LES PROTECTEURS EN PLACE ET EN

ÉTAT DE FONCTIONNEMENT. Ne jamais bloquer ni attacher le

protecteur inférieur en position ouverte. Vérifier le fonctionnement

du protecteur inférieur avant chaque utilisation. Ne pas e servir de

l’outil lorsque le protecteur inférieur ne se ferme pas complètement

sur la lame. MISE EN GARDE : Si la scie tombe, le protecteur

inférieur peut se tordre et ne plus se refermer complètement.

• S’ASSURER QUE LES LAMES SONT PROPRES ET

AFFÛTÉES. Des lames affûtées minimisent les risques de calage

et de rebond.

• DANGER : ÉLOIGNER LES MAINS DE LA ZONE DE COUPE.

Éloigner les mains de la lame. Ne pas placer les mains sous la

pièce à découper pendant les travaux lorsque la lame tourne. Ne

pas tenter de retirer du matériau lorsque la lame est en

mouvement. MISE EN GARDE : La lame continue de tourner

après la mise hors tension.

• SOUTENIR LES GRANDS PANNEAUX. Il faut soutenir les

panneaux de grandes dimensions de la façon illustrée à la figure

16 afin de minimiser les risques de coincement de la lame et de

rebond. Lorsqu’il faut déposer la scie contre la pièce à découper

pendant les travaux, il faut la déposer sur la partie la plus large du

matériau et découper la plus petite partie.

• UTILISER UN GUIDE DE REFENTE. Toujours utiliser un guide

de refente ou un guide à rebord droit lors des coupes en refente.

• SE PROTÉGER CONTRE LES RISQUES DE REBOND. Le

rebond se produit lorsque la lame se bloque rapidement et qu’elle

ressort du matériau vers l’utilisateur. Il faut relâcher

immédiatement l’interrupteur en cas de blocage ou de calage.

Maintenir les lames bien affûtées. Soutenir les panneaux de

grandes dimensions de la façon illustrée à la figure 16. Utiliser un

guide de refente ou à rebord droit lors des coupes en refente. Ne

pas forcer l’outil. Rester vigilant; maîtriser la situation. Ne pas

retirer la scie du matériau lorsque la scie est en mouvement.

• PROTECTEUR INFÉRIEUR. Utiliser le ressort de rappel pour

soulever le protecteur inférieur.

• RÉGLAGES. S’assurer que les réglages de coupe en biseau et de

profondeur sont bien serrés avant la coupe.

• LORS DU MONTAGE, UTILISER SEULEMENT DES LAMES

APPROPRIÉES. Ne pas utiliser une lame dont le diamètre du trou

n’est pas approprié. Ne jamais utiliser des rondelles ou des

boulons de lames défectueux ou de dimensions inappropriées.

• ÉVITER DE COUPER DES CLOUS. Examiner la pièce à

découper pour s’assurer qu’elle ne renferme aucun clou avant les

travaux. Le cas échéant, les retirer.

• MISE EN GARDE : Certaines essences de bois renferment des

agents de conservation (comme de l’arséniate de cuivre et de

chrome) qui peuvent être toxiques. Lorsqu’on doit couper de tels

matériaux, prendre des mesures supplémentaires afin d’éviter

d’inhaler les vapeurs toxiques et de minimiser les contacts avec la

peau.

13

Français

384102/DW359-220 5/2/02 3:15 PM Page 13

Page 17

14

CONSERVER CES MESURES.

Moteur

Un moteur DeWalt entraîne l’outil DeWalt. Veiller à ce que la tension

d’alimentation soit conforme aux exigences de la plaque signalétique

de l’outil. La mention 220 volts c.a./c.c. signifie que l’outil fonctionne

également sur une alimentation en courant alternatif ou continu.

Une baisse de tension entraîne une perte de puissance et la

surchauffe. Tous les outils DeWalt sont essayés avant de quitter

l’usine. Lorsque celui-ci refuse de fonctionner, vérifier la source de

courant électrique.

Balais

DÉBRANCHER L’OUTIL AVANT D’EN FAIRE L’ENTRETIEN.

Inspecter régulièrement les balais en charbon en débranchant

d’abord la scie, en retirant le couvercle d’inspection des balais (fig. 2)

et en sortant l’assemblage-balais. S’assurer que les balais sont

propres et qu’ils glissent bien dans leurs guides. Toujours remplacer

les balais usés par des balais placés dans le même sens dans le

porte-balai. Différents symboles sont inscrits sur les côtés des balais

en charbon. Lorsque le balai est usé jusqu’à la ligne la plus près du

ressort, il faut le remplacer. N’utiliser que des balais de rechange

identiques DeWalt. Il faut toujours remplacer les deux balais. Il faut

utiliser des balais de même qualité pour s’assurer du bon

fonctionnement du frein électrique (dans le cas des modèles qui en

sont pourvus). Le centre de service de la région vend des balais de

rechange. Il faut laisser l’outil fonctionner à vide (sans charge et sans

lame) pendant dix minutes avant de l’utiliser afin de permettre aux

nouveaux balais de s’installer. Cette mesure est des plus importantes

car les scies dotées de freins électriques peuvent fonctionner de

façon irrégulière jusqu’à ce que les balais se placent.

Pendant le fonctionnement à vide de la scie, NE PAS ATTACHER,

COLLER NI BLOQUER DE TOUTE AUTRE FAÇON

L’INTERRUPTEUR À DÉTENTE. LE TENIR À LA MAIN

SEULEMENT.

Réglage et installation

INSTALLATION ET RETRAIT DE LA LAME

DÉBRANCHER LA SCIE.

Pour installer la lame, escamoter le protège-lame inférieur et placer

la rondelle de fixation interne et la lame sur l’arbre de la scie en

plaçant la face imprimée de la lame vers l’extérieur (les dents au

bas de la lame pointant vers l’avant) (fig. 1). Installer la rondelle de

fixation externe de la lame sur l’arbre de la scie. Les surfaces larges

des deux rondelles doivent se trouver sur la lame. Serrer fermement

à la main la vis de fixation de la lame de manière à retenir les deux

rondelles en place.

Enfoncer légèrement le dispositif de verrouillage de la lame (fig. 2) en

faisant tourner l’arbre jusqu’à ce que la lame s’immobilise. Serrer

fermement (dans le sens horaire) la vis de fixation de la lame avec

la clé de la scie (fig. 3).

NE JAMAIS ENGAGER LE DISPOSITIF DE VERROUILLAGE DE

LA LAME LORSQUE LA SCIE FONCTIONNE NI POUR

IMMOBILISER L’OUTIL. NE JAMAIS METTRE LA SCIE EN

MARCHE LORSQUE LE DISPOSITIF DE VERROUILLAGE DE LA

LAME EST EN PLACE, AU RISQUE DE GRAVEMENT

ENDOMMAGER LA SCIE.

Pour retirer la lame, débrancher tout d’abord la scie. Mettre le

dispositif de verrouillage de la lame en place et desserrer la vis de

fixation de la lame en la faisant tourner dans le sens antihoraire à

l’aide de la clé de la lame.

Français

384102/DW359-220 5/2/02 3:15 PM Page 14

Page 18

RÉGLAGE DE LA PROFONDEUR DE COUPE

DÉBRANCHER LA SCIE.

Saisir fermement la scie comme le montre la figure 4. Desserrer

(dans le sens antihoraire) le levier de réglage de la profondeur de

coupe et déplacer le patin de façon à obtenir la profondeur de coupe

voulue, illustré à la figure 5. Bien resserrer (dans le sens horaire) le

levier de réglage de la profondeur de coupe avant de se servir de la

scie.

La scie est munie d’une lame à dents au carbure qui en prolongent la

durée et en rend la coupe des plus efficaces.

Pour optimiser les résultats de coupe lorsqu’on utilise une lame à

dents au carbure, régler la profondeur de coupe de sorte qu’une

moitié de dent de la lame sorte du dessous du matériau à découper.

La hauteur de la dent correspond à la distance à partir du bout de la

dent jusqu’au fond du creux en forme d’hameçon situé devant la

dent. Bien examiner les figures 5A et 5B afin de déterminer à quoi

correspond une moitié de dent. (La figure 5A montre une moitié de

dent sortant du dessous du matériau et la figure 5B montre toute une

dent sortant du dessous du matériau.)

Cette mesure minimise la friction de la lame, permet l’évacuation de

la sciure, assure une coupe rapide et en douceur tout en réduisant

les risques de rebond.

La figure 6 illustre la marche à suivre pour vérifier le réglage de la

profondeur. Déposer un échantillon du matériau à découper le long

de la lame. Remarquer comment la dent de la lame sort de

l’échantillon.

NOTE : Lorsqu’on utilise une lame dont les dents ne sont pas au

carbure, ne pas se conformer aux directives précédentes et faire

sortir la dent au complet du matériau à découper (fig. 5B).

RÉGLAGE POUR COUPES EN BISEAU

DÉBRANCHER LA SCIE.

La gamme complète de réglage pour les coupes en biseau va de

0 À 50 DEGRÉS. Le secteur est calibré en multiples de 5 degrés.

15

Français

FIG. 1

RONDELLE

DE FIXATION

INTERNE

RONDELLE

DE FIXATION

EXTERNE

VIS DE FIXATION DE LA LAME

RESSORT DE

RAPPEL

DISPOSITIF DE

VERROUILLAGE

DE LA LAME

COUVERCLE

D’INSPECTION

DES BALAIS

FIG. 2

FIG. 3

SERRER

DESSERRER

384102/DW359-220 5/2/02 3:15 PM Page 15

Page 19

16

Français

FIG. 4

LEVIER DE

RÉGLAGE DE LA

PROFONDEUR

FIG. 5

FIG. 6

SURFACE

DU BOIS

FIG. 7

GUIDE DE REFENTE

BOUT DE LA DENT BOUT DE LA DENT

FIG. 5A

FIG. 5B

CREUX EN FORME

D’HAMEÇON

SURFACE

DU BOIS

Le mécanisme de réglage de l’angle de coupe se trouve à l’avant de la

scie (figure 8) et il consiste en un secteur calibré et en un levier ou un

bouton. Le réglage de la scie pour les coupes en biseau se fait en

desserrant (dans le sens antihoraire) le levier ou le bouton du secteur,

et en faisant basculer le patin jusqu’à ce qu’on obtienne l’angle voulu

en alignant l’indicateur sur l’angle indiqué. Resserrer fermement (dans

le sens horaire) le levier ou le bouton.

NOTE : L’indicateur qui se trouve entre le levier ou le bouton et le

secteur peut être réglé en desserrant sa vis. Bien la resserrer après le

réglage.

INDICATEUR DE VOIE

À l’avant du patin de la scie, il y a un indicateur de voie (fig. 8) servant

aux coupes à la verticale et en biseau. L’indicateur permet de guider la

scie le long de lignes de coupe tracées sur le matériau à découper.

L’indicateur s’aligne sur le côté gauche (interne) de la lame de la scie

permettant à la lame de couper la voie à droite de l’indicateur. Guider

la scie le long de la ligne de coupe tracée de sorte que la voie se trouve

du côté du surplus de matériau (voir la figure 9). La figure 9 montre les

dimensions du patin.Le côté droit mesure 38 mm (1 1/2 po) (mesure

standard d’une pièce de bois de 2 po sur x 2 po).

RÉGLAGE DU PATIN

La scie est réglée à l’usine pour assurer la précision des coupes

verticales (angle de 90° entre le dessous du patin et la lame). Le

rebord du patin est également réglé de façon à être parallèle à la lame

afin que celle-ci ne bloque pas lorsqu’on utilise un guide. Dans le cas

peu probable où il faudrait régler la scie, voici la marche à suivre.

RÉGLAGE POUR COUPES À 90°

1. Débrancher la scie.

2. Régler la scie à la mention 0°.

3. Placer la scie sur le côté (fig. 10). Escamoter le protège-lame.

4. Desserrer le levier ou le bouton du secteur (fig. 10). Placer une

équerre contre la lame et le patin afin de régler l’angle à 90°.

5. Desserrer l’écrou hexagonal et déplacer la vis de réglage de

384102/DW359-220 5/2/02 3:15 PM Page 16

Page 20

45 0

123451

manière à ce que le patin s’arrête à l’angle voulu, comme le montre

la figure 11. Bloquer la vis en place en resserrant l’écrou

hexagonal.

6. Il peut être nécessaire de régler l’indicateur du secteur de manière

à l’aligner sur la mention «0» après avoir réglé le patin.

RÉGLAGE DU PATIN PARALLÉLE À LA LAME

(La scie est réglée en usine de sorte que la lame soit parallèle au patin.

Si l’alignement de ces composantes se défait, le régler comme suit.)

1. Débrancher la scie.

2. Desserrer les deux vis de la bride de réglage à l’arrière du patin,

comme le montre la figure 12.

3. Régler le patin jusqu’à ce qu’il soit parallèle à la lame en mesurant

à partir du rebord du patin jusqu’à la lame (à l’avant et à l’arrière).

On peut mesurer à partir de la partie extérieure de la lame jusqu’au

patin (illustré à la figure 12) ou de la partie intérieure de la lame

jusqu’à la partie large du patin. (Ne jamais mesurer à partir du bout

d’une dent de la lame.)

4. Lorsque le patin est parallèle à la lame, resserrer toutes les vis.

RÉGLAGE DE BOUTONS DU RÉGLAGE DE LA PROFONDEUR

DE COUPE ET DU SECTEUR

On peut vouloir régler le boutons de réglage de la profondeur de coupe

ou du secteur. (Ceux-ci peuvent parfois frapper contre le patin

lorsqu’ils ne sont pas complètement serrés ou desserrés.) Pour régler

l’un ou l’autre, se conformer aux étapes suivantes.

1. Débrancher la scie.

2. Au moyen d’un petit tournevis, soulever la bague de blocage,

comme le montre la figure 13.

3. Retirer le levier et le faire tourner dans le sens voulu d’environ

1/8 de tour. (Plus ou moins, au besoin.)

4. Réinstaller le levier et insérer la bague de blocage en plaçant le

côté concave contre le levier pour le retenir en place (fig. 14).

17

Français

FIG. 8

SECTEUR

INDICATEUR

DE VOIE

FIG. 9

GUIDER LE LONG DE LA

LIGNE TRACÉE DE SORTE

QUE LA VOIE SE TROUVE

DANS LE SURPLUS DE

MATÉRIAU.

SENS DE COUPE

VOIE

BOUTON OU LEVIER

DU SECTEUR

SURPLUS DE

MATÉRIAU

Aligner le côté

gauche de la lame

sur la mention

«45», comme

illustré, pour couper

à un angle de 45°.

5 po

1 1/2 po

Aligner le côté

gauche de la lame

sur la mention «0»

pour couper en ligne

droite.

BOUTON OU

LEVIER DU

SECTEUR

FIG. 10

LARGEUR VOULUE

DE MATÉRIAU

SERRE-FIL

384102/DW359-220 5/2/02 3:15 PM Page 17

Page 21

Fonctionnement

INTERRUPTEUR

Enfoncer la détente pour mettre le moteur en marche et la relâcher

pour arrêter le moteur. L’outil ne peut pas être bloqué en marche

continue et il ne faudrait jamais essayer de le bloquer dans cette

position.

SOUTIEN DU MATÉRIAU À DÉCOUPER

La figure 15 illustre la meilleure position de coupe. Il faut toujours

éloigner les mains de la zone de coupe et le cordon électrique est

tenu à l’écart de la zone de coupe de sorte qu’il ne peut s’accrocher

sur la surface de travail.

Pour éviter les risques de rebond, SOUTENIR le matériau PRÈS de

la ligne de coupe (fig. 16). NE PAS soutenir le matériau loin de la

ligne de coupe (fig. 17).

Lorsqu’on se sert de la scie, éloigner le cordon de la zone de coupe

et l’empêcher de s’accrocher sur la surface de travail. Prendre note

que la poignée de la scie est dotée d’un serre-fil conçu spécialement

à cet effet (fig. 10 à la page 6). Enfoncer fermement le cordon dans

le serre-fil afin de l’éloigner de la lame tout en le gardant à l’œil en

tout temps.

AVERTISSEMENT : Il est essentiel de bien soutenir la pièce à

découper et de bien saisir la scie afin de prévenir les risques de

blessures. La figure 18 montre la bonne façon de tenir l’outil.

TOUJOURS DÉBRANCHER LA SCIE AVANT DE LA RÉGLER.

Placer le «bon» côté du matériau à découper (celui dont l’apparence

importe le plus) vers le bas. En effet, la scie coupe vers le haut de

sorte que les éclats se trouvent sur la face supérieure de la pièce.

COUPE

Soutenir la pièce à découper de sorte que la ligne de coupe se trouve

sur la droite. Placer la partie large du patin sur la partie soutenue du

matériau et non sur la partie du matériau qui tombera après la coupe.

La figure 18, par exemple, illustre la BONNE façon de découper

l’extrémité du matériau; tandis que le figure 19 montre la MAUVAISE

18

Français

45

30

2

2

.5

15

0

BOUTON OU

LEVIER DU

SECTEUR

FIG. 11

VIS DE

RÉGLAGE

ÉCROU

HEXAGONAL

FIG. 12

VIS

FIG. 13

FIG. 14

ÉCROU DE

BLOCAGE

BAGUE DE

BLOCAGE

LEVIER

SERRER

DESSERRER

384102/DW359-220 5/2/02 3:15 PM Page 18

Page 22

façon. Toujours placer le matériau dans un étau. Ne pas essayer de

retenir les petites pièces à la main. Soutenir également les pièces

en porte-à-faux ou en saillie. Prendre garde lorsqu’on scie des pièces

par le bas.

S’assurer que la scie tourne à plein régime avant d’insérer la lame

dans la pièce à découper. Il existe des risques de rebond lorsqu’on

démarre la scie et que la lame est contre la pièce à découper ou

que la lame se trouve dans la voie.

Faire avancer la scie à une vitesse qui ne force pas la lame. La

difficulté de la coupe peut varier dans une même pièce en raison de

la teneur en humidité et en noeuds du bois. Lorsque l’humidité et les

noeuds exercent une surcharge sur la scie, la faire avancer

lentement mais assez fermement pour que la scie maintienne son

régime.

Lorsqu’on force la scie, on obtient des coupes imprécises et rudes,

et il y a risque de rebonds ou de surchauffe du moteur.

Lorsque la scie s’éloigne de la ligne de coupe, ne pas la forcer dans

le sens voulu. Relâcher la détente de l’interrupteur et attendre que

la scie s’immobilise. Retirer alors la lame de la pièce et reprendre la

coupe dans la trajectoire voulue. Dans tous les cas, il faut retirer la

lame de la pièce pour modifier le sens de la coupe. Autrement, on

peut faire caler la scie et cela présente des risques de rebonds.

LORSQUE LA SCIE CALE, RELÂCHER L’INTERRUPTEUR À

DÉTENTE ET RETIRER LA SCIE DE LA PIÈCE. S’ASSURER QUE

LA LAME EST DROITE DANS LA LIGNE DE COUPE AVANT DE

REPRENDRE LES TRAVAUX.

Lorsque la coupe est terminée, relâcher l’interrupteur et attendre que

la lame s’immobilise avant de sortir la scie de la pièce. Lorsqu’on

soulève la scie, le protège-lame télescopique à ressort se referme

automatiquement sous la lame. Se rappeler que la lame est à

découvert jusqu’à ce qu’on la retire de la pièce. C’est pourquoi il ne

faut jamais mettre les mains sous la pièce. Lorsqu’il faut escamoter

le protège-lame télescopique à la main (comme il faut faire avant une

19

Français

FIG. 15

FIG. 16

SOUTENIR LA PIÈCE PRÈS

DE LA LIGNE DE COUPE.

FIG. 17

INCORRECT - LE

MATÉRIAU PLIE AU

CONTACT DE LA LAME

CAUSANT DE LOURDES

SURCHARGES OU DES

REBONDS.

CORRECT

384102/DW359-220 5/2/02 3:15 PM Page 19

Page 23

coupe en retrait, par exemple), toujours utiliser le ressort de rappel.

NOTE : Lorsqu’on découpe de minces sections de matériau,

s’assurer que les petites pièces détachées ne s’accrochent pas à

l’intérieur du protège-lame inférieur.

Il est conseillé d’utiliser un guide de refente pour les coupes dans le

sens du grain (coupes de refente) (voir la figure 7).

COUPE EN RETRAIT

DÉBRANCHER LA SCIE AVANT DE LA RÉGLER. Régler le patin de

sorte que la lame coupe à la profondeur voulue. Faire basculer la

scie vers l’avant et appuyer le devant du patin contre le matériau à

découper. À l’aide du ressort de rappel, escamoter le protège-lame

vers le haut. Abaisser l’arrière du patin jusqu’à ce que les dents de

la lame touchent presque à la ligne de coupe. À ce moment, relâcher

le protège-lame (son contact avec la pièce le met dans une position

lui permettant de s’ouvrir facilement au moment de la coupe) (fig. 20).

Mettre le moteur en marche et abaisser graduellement la scie jusqu’à

ce que le patin repose contre le matériau à découper. Faire avancer

la scie le long de la ligne de coupe jusqu’à la fin des travaux.

Relâcher la détente et attendre que la lame s’immobilise avant de

retirer la lame du matériau. Répéter les étapes précédentes à

chaque nouvelle coupe. Ne jamais bloquer le protège-lame en

position ouverte.

Rebond

Lorsque la lame se coince dans la pièce à découper, il y a un rebond.

La scie sort alors rapidement de la pièce à découper vers l’utilisateur.

Lorsque la lame est coincée en raison de le fermeture de la voie, la

lame se bloque et la réaction du moteur fait sortir la scie de la pièce à

découper vers l’arrière. Lorsque la lame est coincée ou n’est pas bien

alignée sur la ligne de coupe, les dents à l’arrière de la lame peuvent

creuser la surface supérieure de la pièce faisant sortir la lame de la

voie, vers l’utilisateur.

Les situations suivantes présentent des risques de rebonds.

1. MAUVAIS SOUTIEN DE LA PIÈCE À DÉCOUPER

A. L’affaissement ou le mauvais soutien de la pièce découpée

peut causer le blocage de la lame.

B. Le découpage d’un matériau seulement soutenu à l’extrémité

externe (voir la figure 17) fait affaisser le matériau à mesure

qu’il s’affaiblit, refermant ainsi la voie et bloquant la lame.

C. Le découpage d’une pièce en porte-à-faux ou en saillie à

partir du bas vers le haut, à la verticale, provoque le blocage

de la lame lorsque la pièce découpée tombe.

D. Le découpage de longues bandes étroites (coupes en

refente) peut causer l’affaissement ou la torsion de la bande

bloquant ainsi la voie et coinçant la lame.

E. L’accrochage du protège-lame inférieur sur la surface sous le

matériau peut réduire momentanément la maîtrise de

l’utilisateur sur l’outil. La scie peut alors sortir en partie de la

pièce augmentant le risque de torsion de la lame.

2. RÉGLAGE INCORRECT DE LA PROFONDEUR DE COUPE

Lorsque le réglage de la profondeur de coupe dépasse la

profondeur requise, la charge de l’outil ainsi que les risques de

torsion de la lame dans la voie augmentent. Le réglage incorrect

20

Français

FIG. 18 FIG. 19

INCORRECT

384102/DW359-220 5/2/02 3:15 PM Page 20

Page 24

21

Français

augmente également la surface de coinçage de la lame dans le

cas où la voie se referme.

3. TORSION DE LA LAME (COUPE MAL ALIGNÉE)

A. Le fait de pousser fort pour découper un noeud, un clou ou

une section à grain dur peut provoquer la torsion de la lame.

B. Lorsqu’on essaie de faire dévier la scie pendant le

découpage (pour revenir dans la ligne de coupe) peut

également provoquer la torsion de la lame.

C. Le fait de s’étirer hors de sa portée ou de ne pas garder son

équilibre peut causer la torsion de la lame.

D. Le changement de position des mains ou du corps pendant

la coupe peut provoquer la torsion de la lame.

E. Le retrait de la scie pour dégager les copeaux de la lame

peut faire tordre la lame si le retrait ne se fait pas

soigneusement.

4. MATÉRIAUX PRÉSENTANT DES RISQUES

A. Le bois qui est humide.

B. Le bois vert; qui est frais coupé ou qui n’a pas encore passé

au séchoir.

C. Le bois qui est traité à la pression (traité avec des agents de

conservation ou des produits chimiques contre la

moisissure).

5. UTILISATION DES LAMES ÉMOUSSÉES OU SALES

Les lames émoussées augmentent la charge de la scie. Pour

compenser, l’utilisateur pousse habituellement fort ce qui

charge un peu plus la scie et occasionne la torsion de la lame

dans la voie. Les lames usées n’ont pas suffisamment de jeu ce

qui augmente les risques de pliage et de surcharge.

6. RETRAIT DE LA SCIE PENDANT LES COUPES EN BISEAU

Les coupes en biseau doivent être faites en respectant un

certain nombre de techniques, particulièrement relatives au

guidage de la scie. En effet, l’angle de la lame au patin et la

grande surface de la lame sur le matériau augmentent les

risques de pliage et de torsion.

7. REDÉMARRAGE D’UNE COUPE AVEC LES DENTS DE LA

LAME COINCÉES DANS LE MATÉRIAU

Il faut attendre que la scie atteigne son plein régime avant de

commencer à découper ou avant de remettre la scie en

marche. Autrement, la scie peut caler ou rebondir.

Toute autre condition qui peut occasionner le coincement, le pliage,

la torsion ou l’alignement incorrect de la lame peut également

résulter en un rebond. Consulter les rubriques relatives aux réglages

et à l’installation ainsi qu’au fonctionnement de la scie afin de

minimiser les risques de rebond.

Lames

Une lame émoussée procure des coupes lentes et inefficaces qui

augmentent la surcharge du moteur, la production excessive d’éclats

et les risques de rebond. C’est pourquoi il est conseillé d’avoir à

portée de la main quelques lames de rechange qui sont utiles

lorsque les lames émoussées se font affûtées (voir la rubrique

«Scies - Aiguisage et réparation» des Pages Jaunes). En fait, dans

le cas de nombreux types de lames, l’achat de nouvelles lames est

plus économique que l’affûtage des lames.

La gomme durcie sur la lame ralentit la coupe. Utiliser du

trichloréthylène, du kérosène, de la térébenthine ou un produit

FIG. 20

384102/DW359-220 5/2/02 3:15 PM Page 21

Page 25

nettoyant pour le four pour enlever la gomme.

DeWalt fabrique une gamme complète de lames de scies de 180mm

(7 1/4 po) et les centres de service vendent les types de lames

suivants.

VÉRIFIER LES LAMES AU CARBURE AVANT DE S’EN SERVIR.

REMPLACER LES LAMES ENDOMMAGÉES.

Accessoires

Les détaillants ou le centre de service de la région vendent les

accessoires décrits dans le présent guide. La liste des centres de

service se trouve sur la carte d’enregistrement du propriétaire dans

l’emballage.

Pour trouver un accessoire, communiquer avec DeWalt Industrial

Tool Company, P.O. Box 158, 626 Hanover Pike, Hampstead MD

21074, É.-U. ou composer le 1 800 732-4441.

A. GUIDE DE REFENTE : Se fixe sur le dessus du patin. Permet des

coupes en refente sans avoir à tracer la ligne de coupe au

préalable.

B. RAPPORTEUR : Permet des coupes précises de 0° à 70°.

C. GUIDE DE TRONÇONNAGE : Pour effectuer des coupes de 45°

ou de 90°.

MISE EN GARDE : Les lames et les accessoires recommandés

pour la scie circulaire sont indiqués dans le présent guide.

L’utilisation de tout autre accessoire peut être dangereuse.

Nettoyage et lubrification

Nettoyer l’outil seulement à l’aide d’un savon doux et d’un linge

humide. De nombreux produits de nettoyage domestiques renferment

des produits chimiques qui peuvent causer d’importants dommages

au plastique. Ne pas utiliser non plus de l’essence, de la térébenthine,

de la laque, des solvants, des liquides pour le nettoyage à sec ni tout

autre produit semblable. Ne laisser aucun liquide s’infiltrer dans l’outil

et ne jamais immerger l’outil.

L’outil est monté sur des roulements autolubrifiants qui ne requièrent

pas de lubrification périodique. Il est toutefois conseillé de confier une

fois l’an la scie à un centre de service pour une inspection, une

lubrification et un nettoyage complets du boîtier d’engrenages. La

division des outils industriels de Black & Decker (U.S.) Inc. s’occupe

de l’entretien et des réparations des outils DeWalt.

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’au personnel d’un

centre de service D

EWALT ou d’un atelier d’entretien autorisé

n’utilisant que des pièces de rechange identiques.

Garantie complète

Les outils industriels de service intensif DEWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée ou remplacée sans frais. Pour obtenir de

plus amples renseignements sur les réparations couvertes par la

garantie, composer le 1 (800) 4-D

EWALT (! (800) 433-9258). La ga

rantie ne couvre pas les accessories ni les réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnent des droits légaux spécifiques. L’utilisateur peut également

se prévaloir d’autres droits selon l’état ou la province qu’il habite.

En outre, la garantie suivante couvre les outils D

EWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service intensif

D

EWALT ne donne pas entière satisfaction, il suffit de le retourner

chez le marchand participant dans les 30 jours suivant la date

d’achat afin d’obtenir un remboursement complet. Il faut retourner,

port payé, l’outil complet. On peut exiger une preuve d’achat.

22

Français

384102/DW359-220 5/2/02 3:15 PM Page 22

Page 26

23

Español

Instrucciones importantes de seguridad

ADVERTENCIA: Es indispensable sujetarse a las precauciones

básicas de seguridad, con la finalidad de reducir el peligro de

incendio, choque eléctrico y lesiones personales, en todas las

ocasiones en que se utilicen herramientas eléctricas. Entre estas

precauciones se incluyen las siguientes.

LEA TODAS LAS INSTRUCCIONES

Instrucciones de conexión a tierra

Esta herramienta debe conectarse a tierra

durante su operación para proteger al

operador de un posible choque eléctrico.

La herramienta está equipada con un

cable con 3 conductores para acoplarse a

la toma de corriente aterrizada apropiada.

El conductor verde (o verde con amarillo)

del cable es el de conexión a tierra. Nunca

conecte el cable verde (o verde con

amarillo) a una terminal viva.

Los dos contactos de conexión a tierra y la toma de aterrizaje en la

clavija deben conectarse a tierra permanente, tal como un contacto

aterrizado. No existen adaptadores para las clavijas como la que se

muestra en la figura A.

Instrucciones de seguridad para todas

las herramientas

• CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

• OTORGUE PRIORIDAD AL AMBIENTE DE TRABAJO. No deje

las herramientas eléctricas expuestas a la lluvia. No las utilice en

SI TIENE USTED PREGUNTAS O COMENTARIOS SOBRE ESTA

HERRAMIENTA, O CUALQUIER OTRA HERRAMIENTA DEWALT,

SIRVASE LLAMARNOS SIN CARGO AL NÚMERO:

1-800-4-DEWALT (1-800-433-9258)

GATILLO

INTERRUPTOR

PALANCA

RETRACTIL

GUARDA INFERIOR

ZAPATA

PERILLA O

PALANCA DEL

CUADRANTE

CUADRANTE

DE BISEL

ESPECIFICACIONES

Tensión de alimentación 220 V CA

Potencia nominal: 1700 W

Consumo de corriente: 13, 0 A

A

384102/DW359-220 5/2/02 3:15 PM Page 23

Page 27

24

Español

lugares inundados o mojados. Conserve bien iluminada la zona de

trabajo.

• PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el

contacto corporal con superficies aterrizadas, por ejemplo,

tuberías, radiadores, antenas y gabinetes de refrigeración.

• CONSERVE APARTADOS A LOS NIÑOS. No permita que los

visitantes toquen las herramientas o los cables de extensión. Los

visitantes deben estar alejados del área de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las

herramientas que no se están utilizando deben guardarse en un

lugar seco y elevado o bajo llave, fuera del alcance de los niños.

• NO FUERCE LA HERRAMIENTA.Esta cumplirá su función mejor

y con más seguridad a la velocidad y la presión para las que se

diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta pequeña o a sus dispositivos de montaje en un

trabajo de tipo pesado. No emplee la herramienta en una tarea

para la que no se diseñó; por ejemplo, no recurra a una sierra

circular para cortar ramas o troncos de árbol.

• VISTASE DE LA MANERA ADECUADA.No tenga puestas ropas

o artículos de joyería flojos, pues podrían quedar atrapados por las

partes móviles de las herramientas. Se recomienda el empleo de

guantes de caucho y calzado antiderrapante cuando se trabaja al

aire libre. Cúbrase bien la cabeza para sujetarse el pelo si lo tiene

largo.

• COLOQUESE ANTEOJOS DE SEGURIDAD. Póngase también

una mascarilla contra el polvo si lo produce la operación de corte

que va a efectuar.

• TENGA MUCHO CUIDADO CON EL CORDON ELECTRICO.

Nunca levante la herramienta por el cordón ni tire de éste para

desconectarlo del enchufe. Apártelo del calor y los objetos

calientes, las sustancias grasosas y los bordes cortantes.

• SUJETE FIRMEMENTE LOS OBJETOS SOBRE LOS QUE

TRABAJE. Utilice prensas o tornillos de banco para sujetar bien

los objetos sobre los que va a trabajar. Esto ofrece mayor

seguridad que sujetar los objetos con la mano, y además deja

libres ambas manos para operar la herramienta.

• NO SALGA DE EQUILIBRIO. Conserve en todo momento bien

apoyados los pies, lo mismo que el equilibrio.

• CUIDE BIEN SUS HERRAMIENTAS.Conserve sus herramientas

bien afiladas y limpias para que funcionen mejor y con mayor

seguridad. Obedezca las instrucciones de lubricación y cambio

de accesorios. Inspeccione los cordones eléctricos con frecuencia

y, si los encuentra dañados, hágalos cambiar o reparar en un

centro de servicio autorizado. Revise también con frecuencia las

extensiones eléctricas y reemplácelas si están dañadas. Conserve

los mangos secos, limpios y libres de aceites y grasas.

• DESCONECTE LAS HERRAMIENTAS. Hágalo cuando no las

emplee, antes de darles servicio y cuando vaya a cambiarles

accesorios como seguetas, discos, brocas y otros dispositivos de

corte.

• RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera

el hábito de asegurarse de que se han retirado las llaves de ajuste

de la herramienta antes de accionarla.

• EVITE QUE LA HERRAMIENTA SE ACCIONE ACCIDEN-

TALMENTE. Nunca sostenga una herramienta con el dedo en el

interruptor si se encuentra conectada a la corriente eléctrica.

Asegúrese que el interruptor está en la posición de “apagado”

antes de conectarla.

• CORDONES DE EXTENSION. Asegúrese que su extensión esté

en buenas condiciones. Cuando utilice un cordón de extensión,

asegúrese de emplear uno con el calibre suficiente para soportar

la corriente necesaria para su producto. Una extensión con calibre

menor al necesario causará una caída en el voltaje de la línea,

resultando en pérdida de potencia y sobrecalentamiento. El

cuadro siguiente muestra los calibres correctos para usarse de

acuerdo con la longitud de la extensión y el amperaje especificado.

Si tiene dudas, utilice el calibre siguiente, más pesado. Cuanto

384102/DW359-220 5/2/02 3:15 PM Page 24

Page 28

25

Español

más pequeño el número de calibre del alambre, mayor la

capacidad del cable.

Calibre mínimo requerido (AWG) para cables de extensión

Longitud total del cable de extensión

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Calibre promedio del alambre

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• CORDONES DE EXTENSION PARA INTEMPERIE. Cuando

trabaje a la intemperie, utilice siempre cordones de extensión

diseñados exclusivamente para esta finalidad.

• NO SE DISTRAIGA. Concéntrese en lo que está haciendo.

Recurra al sentido común. No opere ninguna herramienta si se

encuentra fatigado.

• VERIFIQUE LAS PARTES DAÑADAS. Antes de seguir

empleando cualquier herramienta, es indispensable verificar con

mucho cuidado que las guardas u otras partes dañadas puedan

operar de la manera adecuada para cumplir con su función.

Verifique la alineación de las partes móviles, la firmeza con que

deben encontrarse sujetas en sus montaduras, las partes rotas,

las propias montaduras y cualesquiera otros detalles que pudieran

afectar a la operación de la herramienta. Las guardas y las otras

partes que se encuentren dañadas deberán repararse bien o

cambiarse en un centro de servicio autorizado, a menos que se

diga otra cosa en el manual del usuario. Haga que se cambien los

interruptores dañados en un centro de servicio autorizado. No

emplee ninguna herramienta que tenga inutilizado o estropeado

el interruptor.

Reglas adicionales de seguridad para

sierras circulares

• PRECAUCION: Cuando emplee esta herramienta para el corte

sobre paredes, suelos u otras zonas en las que puedan

encontrarse cables eléctricos “vivos”, ¡NO TOQUE NINGUNA

PARTE METALICA FRONTAL DE LA MISMA! Sostenga la sierra

sólo por las superficies aislantes de plástico para evitar el choque

eléctrico si la sierra entrara en contacto con un cable “vivo”.

• Conserve las guardas en posición y funcionando correctamente.

Nunca ate o sostenga abierta la guarda inferior. Verifique el

funcionamiento de ésta antes de cualquier operación. No emplee

la herramienta si la guarda no cierra completamente sobre el

disco. PRECAUCION: Si se suelta la sierra, la guarda inferior

puede abollarse y restringir la carrera. No opere la herramienta

mientras no haya sido reparada.

• CONSERVE LOS DISCOS LIMPIOS Y CON FILO. Los discos

afilados minimizan atascos, sobrecarga y contragolpes.

• PELIGRO: CONSERVE LAS MANOS LEJOS DEL AREA DE

CORTE. Mantenga las manos alejadas del disco. No las coloque

por debajo de la pieza de trabajo mientras el disco gire. No intente

remover el material cortado cuando la sierra se encuentre en

movimiento. PRECAUCION:El disco continúa en movimiento aún

después que se ha soltado el gatillo.

• APOYE BIEN PANELES LARGOS. Los páneles grandes se

deben soportar como se ilustra en la figura 16 para minimizar el

riesgo de sobrecarga o de contragolpes al atorarse el disco.

Cuando la operación de corte requiera que la sierra descanse

sobre la pieza de trabajo, ésta debe descansar sobre la parte

mayor, y la parte menor debe ser la que se retire.

• UTILICE UNA GUIA. Emplee siempre una guía cuando vaya a

hacer cortes al hilo.

• PROTEJASE CONTRA LOS CONTRAGOLPES. Los

contragolpes ocurren cuando la sierra comienza a atascarse

rápidamente y salta hacia el operador. Libere el interruptor

384102/DW359-220 5/2/02 3:15 PM Page 25

Page 29

26

inmediatamente si el disco se traba o la sierra se atasca. Conserve

afilados los discos. Soporte los páneles grandes como se muestra

en la figura 16. Utilice una guía. No fuerce la herramienta, y

manténgase alerta y en control de la situación No retire la sierra de

un corte mientras el disco esté en movimiento.

• GUARDA INFERIOR. Levante la guarda inferior con el

mecanismo retráctil.

• AJUSTES. Antes de cortar, asegúrese que los ajustes de

profundidad y bisel estén apretados

• EMPLEE SOLAMENTE LOS DISCOS CORRECTOS EN EL

MONTAJE. No use discos con orificios de tamaño incorrecto.

Nunca emplee pernos o tuercas defectuosos o inapropiados.

• EVITE CORTAR CLAVOS. Busque y retire todos los clavos de la