Page 1

(APR10) Part No. N079133 DW317 Copyright © 2004, 2010 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the "D" shaped

air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps

on the surface of the tool.

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal

word. Please read the manual and pay attention to these symbols.

ADANGER: Indicates an imminently hazardous sfuation which, if

not avoided, will result in death or serious injury.

,&WARNING: Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

ACAUTION: Indicates apotentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which,

ff not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

General Safety Instructions

_ WARNING! Read and understand all instructions. Failure to follow all

instructions listed below, may result in electric shock, fire and/or serious personal

injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

• Keep bystanders, children, and visitors away while operating a power tooL

Distractions can cause you to lose control

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adaptor plugs. Check with a qualified

electrician ff you are in doubt as to whether the outlet is properly grounded, ff the

tools should electrically malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user. Applicable only to Class I (grounded)

tools.

• Double insulated tools are equipped with a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug. flit still does not fit, contact a qualified electrician

to install a polarized outlet. Do not change the plug in any way. Double insulation []

eliminates the need for the three wire grounded power cord and grounded power

supply system. Applicable only to Class II (double insulated) tools.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don't expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from

an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use and reduce the risk of electric shock. When

using an extension cord, be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length

and nameplate ampere rating, ff in doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0 6 18 16 16 14

6 10 18 16 14 12

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in serious

personal injury.

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving parts. Loose clothing, jewelry, or long

hair can be caught in moving parts. Air vents often cover moving parts and should also

be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss

of control

• Do not force tool Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tooL Such preventative safety measures reduce

the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control

• Check for misallgnment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool's operation, ff damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair personneL Service or

maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or injury.

Minimum Gauge for Cord Sets

Additional Specific Safety Instructions for Jig Saws

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

• Allow the motor to come to a complete stop before withdrawing the blade from the

kerf (the slot created by cutting). A moving blade may impact the workpiece causing a

broken blade, workpiece damage or loss of control and possible personal injury.

• Keep handles dry, clean, free from oil and grease. This will enable better control of the

tooL

• Keep blades sharp. Dull blades may cause the saw to swerve or stall under pressure.

• Clean out your tool often, especially after heavy use. Dust and grit containing metal

particles often accumulate on interior surfaces and could create an electric shock hazard.

• Do not operate this tool for long periods of time. Vibration caused by the operating

action of this tool may cause permanent injury to fingers, hands, and arms. Use gloves to

provide extra cushion, take frequent rest periods, and limit daily time of use.

A WARNING: Always wear eye protection while operating this power tool.

_)_WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

,&WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

AWARNING: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V.................. volts

Hz................ hertz

min .............. minutes

................ direct current

[] ............... Class II Construction

................ earthing terminal

A ................ safety alert symbol

A ................... amperes

W.................. watts

................ alternating current

no ................. no load speed

.../min ........... revolutions per minute

sfpm.............. surface feet per minute

SAVE THESE INSTRUCTIONS

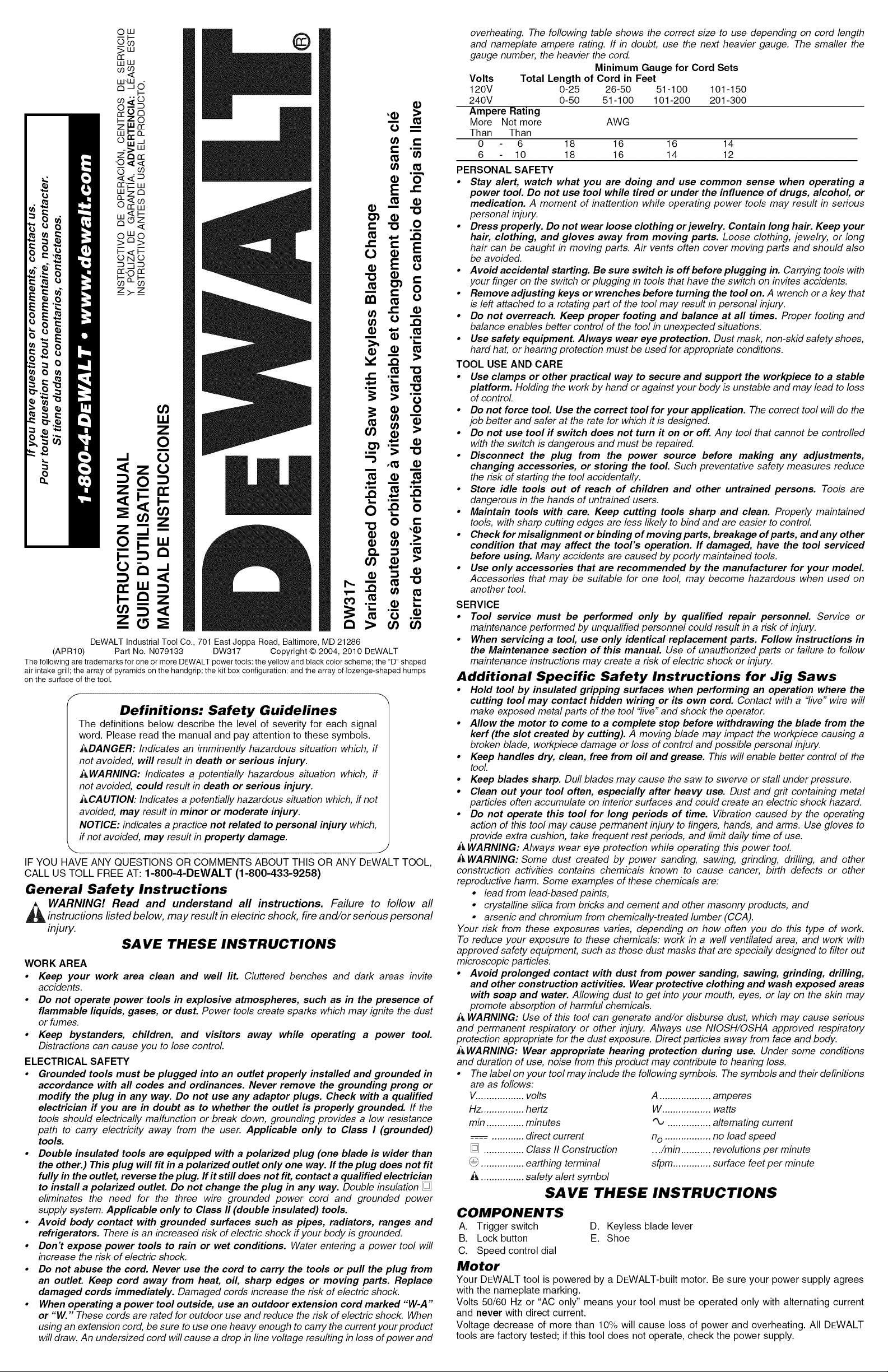

COMPONENTS

A. Trigger switch D. Keyless blade lever

B. Lock button E. Shoe

C. Speed control dial

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your power supply agrees

with the nameplate marking.

Volts 50/60 Hz or "AC only" means your tool must be operated only with alternating current

and never with direct current.

Voltage decrease of more than 10% will cause loss of power and overheating. All DEWALT

tools are factory tested; if this tool does not operate, check the power supply.

Page 2

OPERA TION

_ WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

too! from power source before making any adjustments or removing!installing

attachments or accessories.

Trigger Switch (Fig, 1)

To start the jig saw, squeeze the trigger switch (A).

To slow and stop _ jig saw, release the trigger switch.

For co_nuous operation squeeze the trigger switch then depress the lock button (B), Once

lock button is depressed, release the trigger switch.

To release from continuous operation, squeeze the trigger and the lock wiil disengage.

Variable Speed Switch (Fig. 1, 2)

The variable speed is controited in two ways: speed control dia_ (C) and the trigger switch

(A),

SPEED CONTROL DIAL

By rotating the speed control dial (C) in either direction, the maximum speed or strokes-per-

minute at which the blade will cut is adjusted, The speed control dial adjusts the speed that

the b_ade wiil cut from approximately 5_ SPM to approximately 3,100 SPM

TRIGGER SWITCH

As the trigger switch is pres_ in, the strokes-per-minute continue to increase, but not to

exceed the maximum setting on the speed control dial As the trigger is released, the blade

strokes-per-minute reduce.

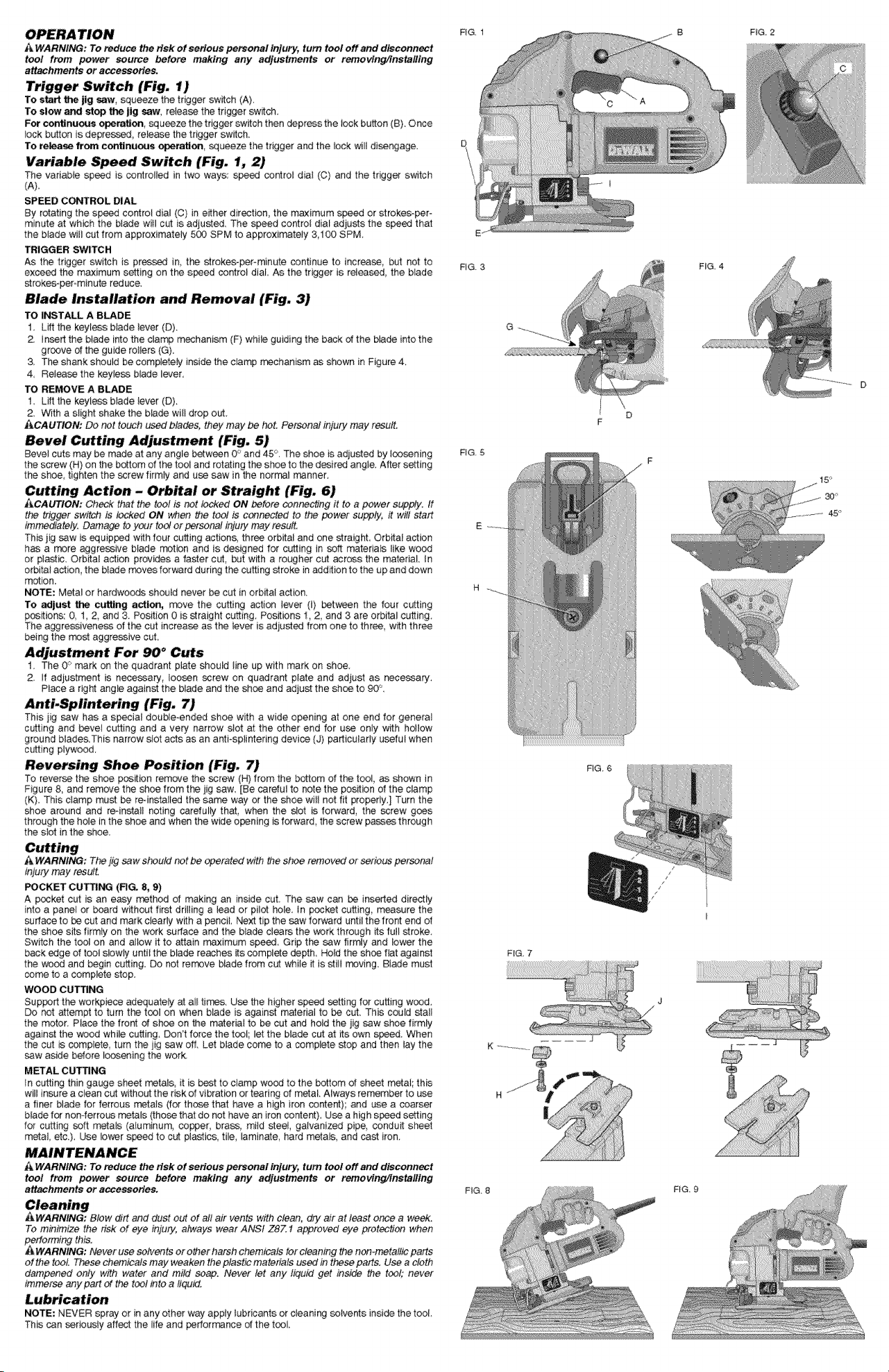

Blade Installation and Removal (Fig. 3)

TO INSTALL A BLADE

1, Lift the keyless blade iever (D).

2. Insert the blade into the clamp mechanism (F) while guiding the back of the blade into the

groove d the guide ro_ers (G),

3, The shank should be completely inside the clamp rsechanism as shown in Figure 4,

4, Release the keyless b_ade lever,

TO REMOVE A BLADE

1, Lift the keyless blade _ever (D).

2, With a slight shake the blade witl drop out.

_CAUTION: Do not touch used blades; they may be hot: Pemonat injury may resutt,

Bevel Cutting Adjustment (Fig.

Beve_ cuts may be made at any angle between 0_ and 45 _',The shoe is adjusted by loosening

the screw (H) on the bottom of the tool and rotating the shoe to the d_ired angle. After setting

the shoe, tighten the screw firmly and use saw in the norrsai manner.

Cutting Action - Orbital or Straight (Fig. 6)

_,CAUTION: Check that the tool is not locked ON before connecting it to a power supply, tt

the trigger switch is locked ON when _e tool is connected to the power supply, it _zill start

immediately, Damage to your toot or personal injury may result.

This jig saw is equipped with four cutting actions, three orbital and one straight, Orbital action

has a rrere aggre_ive blade motion and is designed for c_ing in soft materials like wood

or pla_ic. Orbital action provides a faster cut, but w_h a rougher cut across the material In

orbitai action the blade moves forward during the cutting stroke in addition to the up and down

motion,

NOTE; Metal or hardwoods should never be cut in orbita_ action,

To adjust t_ c_ing action, move the cutting action lever (I) between the four cutting

p_itions: 0, 1, 2, and 3. Position 0 is straight cutting, Positions 1, 2, and 3 are orbital cutting,

The aggressivene_ of the cut increase as the lever is adjusted from one to three, with three

being the most aggressive cut.

Adjustment For 90 ° Cuts

1 The 0 ° mark on the quadrant plate should Hne up with mark on shoe

2. If adjustment is necessary, loosen _rew on quadrant plate and adjust as necessary.

Place a right angle against the blade and the sh_ and adjust the shoe to 90'.

Anti.Splintering (Fig, 7)

This jig saw has a special double-ended shoe with a wide opening at one end for general

cutting and bevel cutting and a very narrow slot at the other end for use only with hollow'

ground blades, This narrow slot acts as an anti*splintering device (J) particularly useful when

cutting plywood,

Reversing Shoe Position (Fig. 7)

To reverse the shoe position remc_,!e the screw (H) from the bottom of the tool, as shown in

Figure 8, and remove the shoe from the jig saw, [Be careful to note the position of the clamp

(K). This clamp must be re-instalLed the same way or the shoe will not fit properly,] Turn the

shoe around and reqnstai} noting carefully that, when the slot is forward, the screw goes

through the hole in the shoe and when the wide opening is forward, the screw passes through

the slot in the shoe,

FIG, 5

FIG, 2

FIG_ 4

G

D

F

30 _

45°

FIG 6

A WARNING: The jig saw should not be operated with the shoe removed or serious persona!

injury may result.

POCKET CUTTING (FIG, & 9)

A pocket cut is an easy _thod of making an inside cut The saw can be inserted directly

into a panel or board without first drilling a lead or pilct hole. tn pocket cutting, measure the

surface to be cut and mark clearly with a pencil Next tip the _w forward until the front end o1

the shoe sits firmly on the work surface and the b_ade clears the work through its full stroke

Switch the tect on and allow it to attain maximum speed, Grip the saw firmly and lower the

back edge of tool slowly until the biade reaches its complete depth, Hoid the shoe flat against

the wood and begin cutting, Do net remove blade from cut white it is stitl moving, Blade must

come to a complete stop,

WOOD CUTTING

Support the work, piece adequately at al_ times. Use the higher speed setting for cutting wood,

Do not attempt to turn the teel on when blade is against material to be cuL This could stall

the motor, Place the front of shoe on the material to be cut and hold the jig saw shoe firmly

against the wood while cutting, Don't force the tool; let the blade cut at _s own speed When

the cut is complete, turn the jig saw off, Let blade come to a complete stop and then lay the

saw aside before loosening the work.

METAL CUTTING

fn cutting thin gauge sheet metals it is best to clamp wood to the bottom of sheet metal; this

will insure a clean cut without the risk of vibration or tearing of metal Always remember to use

a finer blade for ferrous metals (for those that have a high iron content); and use a coarser

blade for non4errous metals (those that do not have an iron content). U_ a high speed setting

for cutting soft metals (aluminum, copper, brass, mild steel, galvanized pipe conduit sheet

metal etc.). Use lower speed to cut plastics, tile, laminate, hard metals, and cast iron.

MAINTENANCE

A WARNING: To reduce the risk of serous personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing

attachments or accessories.

Cleaning

_JLWARNING: Blew dirt and dust out of all air vents with clean, dry air at least once a week:

To minimize the risk of eye injury, always wear ANSI ZSZ f approved eye protection when

performing this,

_ WARNING: Never use solvents or o_er harsh chemicals for cleaning the non*metallic parts

of the toot. These chemicals may weaken the plastic materials used in these parts. Use a cloth

damp-ened only with water and mild soap. Never let any liquid get inside the tool: never

immerse any part of the toot into a liquid.

Lubrication

NOTE: NEVER spray or in any other way apply lubricants or cleaning solvents inside the tool

This can seriously dfect the iife and performance of the tool.

FIG, 7

FtG, 9

Page 3

DEWALT tools are properly lubricated at the factory and are ready for use. However, it is

recommended that, once a year, you take or send the tool to a certified service center for

a thorough cleaning and inspection.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment

(including brush inspection and replacement) should be performed by authorized service

centers or other qualified service personnel, always using identical replacement parts.

Accessories

_, WARNING: Since accessories, other than those offered by DEWAL T, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only DEWAL T, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local

service center. If you need any assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT

(1-800-433-9258) or visit our website www.dewalt.com.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not

apply to accessories or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have other rights which vary

in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser,

or Nailer for any reason, you can return it within 90 days from the date of purchase with a

receipt for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained either in

the packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

_ , z , , PARk_ISMINUIr_tRBESGO

0_ LEE_YcomP_eN,e__ Ma_U_OEINstrucclo_es.

LAWS_ yP_A L_S_S _ES_tO_S.

_UtlLIS_EU_OOItTOUJOU_SUrE_T COmP_NO_E_e_uIoe

_ro_LIS_tlON.ILFA__OUJO_S_e_T_ _E_'tOUIpEmE_Toe

oeL_SIONES,_LUSOArIO

_Fl__ ml_lmlsErLE_

_SOUESDEBL_SSUrES

Ddfinitions : lignes directrices en matidre de

sdcuritd

Les d_finitions ci-dessous d_crivent le niveau de danger pour chaque mot-

indicateur employ& Lire le mode d'emploi et porter une attention particuli_re

ces symboles.

,&DANGER : indique une situation dangereuse imminente qui, si e//e n'est pas

evitee, entrainera la mort ou des blessures graves

_\A VERTISSEMENT : indique une situation potentiellement dangereuse qui, si

elle n'est pas evitee, pourrait entrafner la mort ou des blessures graves

,&ATTENTION : indique une situation potentiellement dangereuse qui, si elle

n'est pas evitee, pourrait entrafner des blessures legeres ou moderees.

AVlS : indique une pratique ne posant aucun risque de dommages corporels

mais qui par contre, si rien n'est fait pour I'eviter, pourrait poser des risques de

dommages materiels.

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FAIRE PART DE VOS

COMMENTAIRES CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL DEWALT,

COMPOSEZ SANS FRAIS LE • 1 800 433-9258. (1-800-4-DEWALT).

Rdgles de sdcuritd - Gdndralitds

A A VERTISSEMENT : Lire, comprendre et suivre toutes les directives pr#cis#es

ci-dessous, y compris les consignes de s#curit#, afin d'#viter les risques de

choc #lectrique, d'incendie ou de blessure grave.

CONSERVER CES DIRECTIVES

AIRE DE TRAVAIL

• L'aire de travail doff #tre propre et bien eclairee. Les etablis encombres et les endroits

sombres peuvent entrafner des accidents.

• Ne pas faire fonctionner des outils electriques clans des atmospheres explosives,

comme en presence de liquides, de gaz et de poussieres inflammables. Les outils

electriques produisent des etincelles qui peuvent enflammer la poussiere ou les vapeurs

• Tenir les enfants, les visiteurs ou toute autre personne a I'ecart Iorsqu'on utilise un

outil electrique; les distractions peuvent faire perdre la maftrise de ce demier.

MESURES DE SE_CURITE_- E_LECTRICITE_

• Les outils mis a la terre doivent #tre branches clans une prise correctement installee

et mise a la terre tel que I'indiquent les codes et reglements en vigueur. Ne jamais

retirer la broche de mise a la terre ou modifier la prise en aucune fagon. Ne pas

utiliser de fiche d'adaptation. Consulter un electricien qualifie s'il y a un doute en ce

qui concerne la mise a la terre de la prise. En cas de defaillance electrique ou de bris de

I'outil, la mise a la terre procure un chemin de faible resistance au courant afin de reduire

les risques de choc electrique. Cette protection ne s'applique qu'aux outils de classe I

(mis a la terre).

• Les outils a double isolation sont munis d'une fiche polarisee (c'est-a-dire que I'une

des lames est plus large que I'autre), laquelle ne peut #tre raccordee qu'a une prise

polarisee et ce, clansun seul sens; on dolt I'inverser si on est incapable de I'enfoncer

completement. Si la fiche ne s'adapte toujours pas, on dolt faire appel a un electricien

qualifie pour qu'il installe la prise appropriee. On ne dolt jamais modifier la fiche. La

double isolation [] elimine le besoin d'installer un cordon d'alimentation trifilaire et un

systeme d'alimentation electrique pourvus d'une mise a la terre; seuls les outils de classe

II (a double isolation) sont munis d'une telle protection.

• _:viter tout contact entre le corps et les elements mis a la terre, comme les tuyaux,

les radiateurs, les cuisinieres et les refrigerateurs, afin de reduire les risques de choc

electrique.

• Ne pas utiliser I'outil electrique clans des endroits mouilles, ni I'exposer a la pluie;

I'infiltration d'eau a I'interieur de I'outil augmente les risques de choc electrique.

• Ne pas utiliser le cordon de maniere abusive; on ne dolt pas transporter I'outil en

le tenant par le cordon, ou utiliser ce dernier pour le debrancher. On doit tenir le

cordon a I'ecart des sources de chaleur, de I'huile, des bords tranchants ou des

pieces mobiles. Remplacer immediatement les cordons endommages, car ces

derniers augmentent les risques de choc electrique.

• Lorsqu'on utilise un outil electrique a I'exterieur, on ne dolt utiliser que des rallonges

con_ues pour cet usage, comme celles de type _ W-A _ ou _ W _, afin de reduire /es

risques de choc electrique. S'assurer que la rallonge est en mesure de porter le courant

necessaire a I'outil. Une rallonge de calibre inferieur entrafnera une chute de tension se

traduisant par une perte de puissance et une surchauffe. Le tableau ci-dessous illustre les

calibres que I'on doit utiliser selon la Iongueur de la rallonge et I'intensite nominale indiquee

sur la plaque signaletique. En cas de doute, utiliser le calibre suivant. Plus le calibre est

petit, plus la rallonge peut porter de courant.

Calibre minimal des cordons de rallonge

TensionLongueur totale du cordon en meters

120V De0&7 De7&15 De15&30 De 30&45

240V De0&7 De7&15 De15&39 De 30&45

Intensit_ (A)

Au Au Calibre moyen de fil

moins plus

0 6 18 16 16 14

6 10 18 16 14 12

SE_CURITE_PERSONNELLE

• Rester vigilant en tout temps et faire preuve de jugement Iorsqu'on utilise un

outil electrique. Ne pas utiliser I'outil Iorsqu'on est fatigue ou sous I'influence de

drogues, d'alcool ou de medicaments, car un moment d'inattention pourrait entrafner

des blessures graves.

• Porter des v_tements appropries. Ne pas porter des v_tements amples ou des

bijoux. Couvrir ou attacher les cheveux longs. Carder les cheveux, les v_tements,

les bijoux et les gants eloignes des pieces mobiles, car ceux-ci peuvent s'y coincer. Se

tenir eloigne des events puisque ces derniers pourraient camoufler des pieces mobiles.

• Eviter les demarrages accidentels; s'assurer que I'interrupteur est en position d'arr#t

avant de brancher I'outil. Ne pas transporter Ibutil en laissant le doigt sur I'interrupteur

nile brancher Iorsque I'interrupteur est en position de marche, car cela pourra# causer un

accident.

• Retirer les cles de reglage avant de demarrer I'outil. Une cle laissee sur une piece

rotative pourrait entrafner des blessures.

• Ne pas trop etendre les bras. Les pieds doivent rester ancres fermement au sol afin

de maintenir son equilibre en tout temps et de mieux maftriser I'outil dans des situations

imprevues.

• Utiliser le materiel de securite approprie; toujours porter des lunettes de protection.

Porter un masque anti-poussieres, des chaussures antiderapantes, un casque de securite

ou des protecteurs auditifs Iorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L'OUTIL

• Fixer et soutenir la piece sur une plate-forme stable au moyen d'une bride de

serrage ou de tout autre dispositif semblable. La piece est instable Iorsqu'on la retient

manuellement ou qu'on I'appuie contre le corps, ce qui pourrait faire perdre la maftrise de

I'outil.

• Ne pas forcer I'outil ni I'utiliser pour des travaux autres que ceux pour lesquels il a

ete congu. Pour obtenir de meilleurs resultats et prevenir les risques de blessure, laisser

I'outil couper a la vitesse pour laquelle il a ete congu.

• Ne pas utiliser I'outil Iorsque I'interrupteur marche-arr#t ne fonctionne pas. Tout outil

qui ne peut #tre commande au moyen de I'interrupteur est dangereux et doit #tre repare.

• Debrancher I'outil de la source d'alimentation electrique avant d'effectuer un

reglage, de changer les accessoires ou de ranger I'outil; ces mesures de securite

preventives reduisent les risques de demarrage accidenteL

• Lorsqu'on n'utilise pas I'outil, le ranger hors de la portee des enfants ou des

personnes non quafifiees. Les outils sont dangereux entre les mains de personnes

inexperimentees.

• Bien entretenir I'outil; s'assurer qu'il est toujours bien propre et aiguise. Les outils

bien entretenus et dont les bords sont bien tranchants sont moins susceptibles de rester

coinces et sont plus faciles a maftriser.

• Verifier les pieces mobiles afin de s'assurer qu'elles sont bien alignees et qu'elles

ne restent pas coincees. Verifier egalement les pieces afin de s'assurer qu'il n'y a

aucun bris ni aucune autre condition susceptible de nuire au bon fonctionnement

de I'outil. Faire reparer I'outil sice dernier est endommage avant de s'en servir

nouveau, car les accidents sont souvent causes par des outils mal entretenus.

• N'utiliser que les accessoires recommandes par le fabricant pour le modele

concerne. Un accessoire destine a un outil particulier peut devenir dangereux Iorsqu'il

est utilise avec un autre.

ENTRETIEN

• L'outil dolt #tre entretenu par le personnel qualifie seulement; toute maintenance

effectuee par une personne non qualifiee pourrait entrafner des risques de blessure.

• Lors de I'entretien, n'utiliser que des pieces de rechange identiques et suivre les

directives precisees a la section _ Entretien _ du present guide afin de prevenir les

risques de choc #lectrique ou de blessure.

R_gles de s_curit_ additionnelles particuli_res

concernant les scies sauteuses

• Tenir I'outil par les surfaces isolees prevues a cette fin Iorsqu'il risque d'entrer en

contact avec des ills caches, car de tels contacts peuvent mettre les pieces metalliques

de I'outil sous tension, engendrant des risques de choc electrique.

• Attendre que le moteur s'arr#te completement avant de retirer la lame de I'entaille (la

fente creee par la coupe). Une lame qui bouge peut rebondir contre la piece et se briser

ou endommager la piece ou encore, faire perdre la maftrise de I'outil et causer des risques

de blessure.

• Garder les poignees propres, seches et exemptes de toute trace d'huile et de graisse

afin d'eviter de perdre la maftrise de I'outil.

• Maintenir les lames bien aiguisees, car les lames usees peuvent faire devier la scie ou

faire caler le moteur Iorsqu'on exerce trop de pression sur I'outil.

• Bien nettoyer I'outil periodiquement, surtout apres I'avoir utilise Ionguement, car la

poussiere et les particules metalliques tendent a s'accumuler sur les surfaces internes et

peuvent entrafner des risques de choc electrique.

• Ne pas utiliser cet outil pendant des periodes prolongees. Les vibrations causees par

I'action de fonctionnement de I'outil peuvent blesser en permanence les doigts, les mains

et les bras. Porter des gants pour amortir les vibrations, faire des pauses frequentes et

limiter le temps d'utilisation quotidien de I'outil.

_A VERTISSEMENT : Toujours porter des lunettes de protection Iorsqu'on utilise un outil

electrique.

_AVERTI$$EMENT : Certains outils electriques, tels que les sableuses, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent produire de la

poussiere contenant des produits chimiques susceptibles d'entrafner le cancer, des

malformations congenitales ou pouvant _tre nocifs pour le systeme reproductif. Parmi ces

produits chimiques, on retrouve :

• le plomb dans les peintures a base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de ma_onnerie,

• I'arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (comme

I'arseniate de cuivre et de chrome).

Le risque associe a de telles expositions varie selon la frequence avec laquelle on effectue

ces travaux. Pour reduire I'exposition a de tels produits, il faut travailler dans un endro# bien

aere et utiliser le materiel de securite approprie, tel un masque anti-poussieres specialement

con_u pour filtrer les particules microscopiques.

• Eviter tout contactprolonge avec la poussiere soulevee par cet outil ou autres outils

electriques. Porter des v_tements de protection et nettoyer les parties exposees du

corps a I'eau savonneuse. S'assurer de bien se proteger afin d'eviter d'absorber par la

bouche, les yeux ou la peau des produits chimiques nocifs.

J_AVERTISSEMENT : Cet outil peut produire et repandre de la poussiere susceptible de

causer des dommages serieux et permanents au systeme respiratoire. Toujours utiliser un

appareil respiratoire anti-poussieres approprie approuve par le NIOSH ou I'OSHA. Diriger les

particules dans le sens oppose du visage et du corps.

/&AVERTISSEMENT : Porter un appareil de protection personnel anti-bruit approprie

durant I'utilisation. Sous certaines conditions et pendant toute la duree de I'utilisation, le bruit

Page 4

emanantdeceproduitpourra#contribueralaperted'audition.

• L'etiquette apposee sur Ibutil peut afficher les symboles suivants. Ces symboles et leurs

definitions sont les suivants :

V.................. volts

Hz................ hertz

min .............. minutes

................ courant continu

[] ............... construction de classe II

0 ................ borne de terre

symbole d'avertissement

CONSERVER CES DIRECTIVES

COMPOSANTS

A. Interrupteur & g&chette

B. Bouton de verrouillage

C. Bouton de r6glage de la vitesse

D. Levier de la lame sans cl_

E. Patin

Moteur

Cet outil DEWALT est entrain6 par un moteur fabriqu6 par DEWALT. On doit s'assurer que

I'intensit6 nominale du cordon d'alimentation corresponde & celle indiqu6e sur la plaque

signal_tique.

La mention <<c.a., 50 & 60 Hz >>,signifie que I'outil ne doit 6tre branch6 que dans une prise

de courant alternatif et qu'il ne doit jamais 6tre raccord_ & une prise de courant continu, alors

que la mention <<c.c. 60 Hz >>ou <<c.c. / c.a. >>signifie qu'il peut 6tre branch6 dans une prise

&courant continu ou & courant alternatif.

Une chute de tension de plus de 10 % se traduira par une perte de puissance et une surchauffe.

Tous les outils DEWALT sont soumis & des essais en usine; si cet outil ne fonctionne pas, on

doit d'abord v_rifier le cordon d'alimentation.

FONCTIONNEMENT

_A VERTISSEMENT : pour reduire tout risque de dommages corporels graves, arr_ter

et debrancher I'outil avant tout reglage ou avant de retirer ou installer toute piece ou

tout accessoire.

Interrupteur a gachette (fig. 1)

Pour d_marrer la scie, enfoncer I'interrupteur & g&chette (A).

Pour ralentir et arr6ter la scie, rel&cher I'interrupteur.

Pour un fonctionnement continu, enfoncer I'interrupteur, puis le bouton de verrouillage (B).

Une fois le bouton enfonc_, rel&cher I'interrupteur & g&chette.

Pour arr6ter I'outil en mode de fonctionnement continu, appuyer sur I'interrupteur afin de

d_gager le bouton de verrouillage.

Interrupteur a vitesse variable (fig. 1 et 2)

La vitesse variable de I'outil est command_e de deux fa£ons, soit en utilisant le bouton de

r6glage de la vitesse (C) ou I'interrupteur & g&chette (A).

BOUTON DE RI_GLAGE DE LA VlTESSE

Tourner le bouton de r_glage de la vitesse (C) dans un sens ou dans I'autre afin de r6gler

la vitesse maximale ou la course/minute de la lame Iors de la coupe. Le bouton de r6glage

de la vitesse sert & r_gler la vitesse de coupe de la lame selon une plage qui varie entre

500 courses/minute et 3 100 courses/minute.

INTERRUPTEUR .&,G.A,CHETTE

Plus on enfonce I'interrupteur & g&chette, plus la course/minute augmente, sans toutefois

d_passer la vitesse maximale indiqu_e sur le bouton de r6glage de la vitesse; rel&cher la

g&chette afin de r6duire la course/minute de la lame.

Installation et retrait de la lame (fig. 3)

INSTALLATION DE LA LAME

1. Soulever le levier de la lame sans cl_ (D).

2. InsUrer la lame dans le m_canisme de serrage (F) en guidant la partie arri_re de la lame

dans la rainure des rouleaux de guidage (G).

3. La tige doit 6tre compl_tement ins6r6e dans le m_canisme de serrage, tel qu'illustr6 &

la figure 4.

4. Rel&cher le levier de la lame sans cl&

RETRAIT DE LA LAME

1. Soulever le levier de la lame sans cl_ (D).

2. Osciller I_g_rement la lame afin de la faire sortir.

_,MISE EN GARDE : Ne pas toucher les lames usees, car ces demieres peuvent #tre

chaudes et causer des blessures.

Rdglage de coupe en biseau (fig. 5)

Les coupes en biseau peuvent 6tre faites & n'importe quel angle entre 0 ° et 45 °. Pour r_gler

le patin, d_visser la vis (H) sur la partie inf_rieure de I'outil puis le disposer & I'angle d_sir& Une

fois le patin & I'angle d_sir6, serrer la vis fermement puis utiliser la scie comme & I'habitude.

Coupe en mode orbital ou coupe droite (fig. 6)

AMISE EN GARDE : S'assurer que I'outil n'est PAS verrouille en position de marche (_ ON

>_)avant de le brancher a une source d'alimentation electrique afin d'eviter de demarrer

accidentellement I'outil et de causer des dommages ou des blessures.

La scie sauteuse est munie d'un levier qui permet d'effectuer quatre types de coupes, dont

trois en mode orbital et un en mode de coupe droite. Lors de la coupe en mode orbital, qui est

con£u pour la coupe de mat_riaux mous tels que lebois et le plastique, la lame se d_place de

fa£on plus prononc_e. Le mouvement orbital acc_l_re la coupe, mais celle-ci sera grossi_re.

En utilisation orbitale, la lame avance tout en effectuant un mouvement de haut en bas.

REMARQUE : On ne doit jamais utiliser la scie en mode orbital pour couper le m_tal ou le

bois dur.

Pour r_gler le levier de coupe, d_placer ce dernier (I) entre les quatre positions, soit 0, 1,

2 et 3. La position <<0 >>correspond & la coupe droite et les positions 1, 2 et 3, & la coupe en

mode orbital. Plus la position est _lev_e, plus la coupe est prononc_e.

R_glage de coupe a 90 o

1. La marque 0° sur le cadran doit _tre align_e avec la marque sur le patin.

2. Si un r6glage est n_cessaire, d_visser la vis sur le cadran et r6gler & la position d_sir6e.

Mettre une _querre & I'angle droit contre la lame et le patin puis r6gler ce dernier &90 °.

Action anti-_clat (fig. 7)

Cette scie sauteuse est _quip_e d'un patin special & bouts doubles avec une large ouverture

d'un c6t6 pour les coupes g_n_rales et les coupes en biseau, et une ouverture tr_s _troite de

I'autre c6t6 pour _tre utilis_e avec des lames _vid_es en creux. Cette ouverture _troite a une

action anti-_clat (J), ce qui est particuli_rement utile pour couper le contreplaqu&

Inverser la position du patin (fig. 7)

Pour inverser la position du patin retirer la vis (H)sur la partie inf_rieure de I'outil, comme illustr_

en Figure 8 puis retirer le patin de la scie sauteuse. [Faire attention & bien noter la position du

bouton de serrage (K). Ce bouton de serrage doit _tre r_install_ exactement de la m_me fa£on

pour que le patin s'adapte correctement. Faire tourner le patin puis le r_installer en remarquant

que, Iorsque I'ouverture _troite est vers I'avant, la vis passe par le trou dans le patin et Iorsque

I'ouverture large est en avant, la vis passe par I'ouverture _troite dans le patin.

Coupe

_AVERTISSEMENT : Ne pas utiliser la scie sauteuse sans y avoir d'abord installe le patin

afin d'eviter les risques de blessure grave.

COUPE INTERNE (FIG. 8, 9)

II s'agit d'une m_thode facile d'effectuer une coupe & I'int6rieur d'un mat6riau. On peut

introduire la scie directement dans un panneau ou une planche sans qu'il ne soit n_cessaire de

percer d'abord un trou de guidage. Pour r_aliser une coupe & I'int6rieur d'une piece, mesurer la

surface & couper et inscrire clairement une marque au crayon & I'endroit voulu. Incliner la scie

A ................... amperes

W.................. watts

"%, ................ courant altematif

no ................. aucune option a vide

.../min ........... tours par minute

sfpm.............. surface de sciage en pieds

par minute

vers I'avant de mani_re & ce que le devant du patin repose fermement sur la surface de travail

et que la lame soit compl_tement d_gag_e de la piece Iors de sa course maximale. Mettre

I'outil sous tension et attendre qu'il atteigne sa vitesse maximale. Le saisir fermement I'outil et

abaisser lentement son bord arri_re jusqu'& ce que la lame atteigne toute sa profondeur. Tenir

le patin & plat contre le mat6riau et amorcer la coupe. Ne pas retirer la lame de la ligne de

coupe Iorsqu'elle bouge encore; on doit attendre qu'elle s'immobilise compl_tement.

COUPE DU BOIS

Soutenir ad_quatement la piece en tout temps. Toujours s_lectionner la vitesse maximale

pour couper le bois. Ne pas tenter de mettre I'outil sous tension Iorsque la lame est appuy_e

contre le mat6riau & couper afin d'_viter de caler le moteur. Placer le devant du patin sur le

mat6riau & couper et tenir fermement le patin contre le mat6riau Iors de la coupe. Ne pas

forcer I'outil; laisser la lame couper & la vitesse normale. Une fois la coupe termin_e, mettre

I'outil hors tension et attendre que la lame s'immobilise compl_tement. D_poser ensuite la scie

de c6t6 avant de desserrer la piece.

COUPE DU MI_TAL

Lorsqu'on coupe une feuille de t61emince, il est preferable de fixer un morceau de bois sous

la t61eafin d'assurer une coupe precise sans risquer de causer des vibrations ou de d_chirer

la t61e. Utiliser une lame & dents fines pour couper les m_taux ferreux (c'est-&-dire, ceux

contenant du fer) et une lame & grosses dents pour les m_taux non ferreux (ceux ne contenant

aucun fer).

Utiliser une haute vitesse pour couper les alliages doux (l'aluminium, le cuivre, le laiton, I'acier

doux, les tuyaux en acier galvanis6, conduits de t61e,etc.), et une basse vitesse pour couper

les plastiques, les tuiles, les stratifies, les m_taux durs et la fonte.

ENTRETIEN

_AVERTISSEMENT : pour reduire le risque de blessures graves, eteindre I'outil et le

debrancher avant d'effectuer tout reglage et d'enlever ou d'installer tout accessoire.

Nettoyage

_,A VERTISSEMENT : enlever les saletes et la poussiere hors des events au moyen d'air

comprime propre et sec, au moins une fois par semaine. Pour minimiser le risque de blessure

aux yeux, toujours porter une protection oculaire conforme a la norme ANSI Z87.1 Iors du

nettoyage.

AA VERTISSEMENT : ne jamais utiliser de solvants ni d'autres produits chimiques puissants

pour nettoyer les pieces non metalliques de I'outil. Ces produits chimiques peuvent affaiblir les

materiaux de plastique utilises dans ces pieces. Utiliser un chiffon humecte uniquement d'eau

et de savon doux. Ne jamais laisser de liquide penetrer dans I'outil et n'immerger aucune

partie de I'outil dans un liquide.

Lubrification

REMARQUE : NE JAMAIS pulv_riser, ni appliquer de quelque mani_re que ce soit, un

lubrifiant ou un solvant de nettoyage & I'int_rieur de I'outil, car cela pourrait nuire s6rieusement

& la dur6e de vie et au rendement de I'outil.

Les outils DEWALT sont lubrifi_s en usine et sont donc pr_ts & utiliser. Cependant, on

recommande d"apporter ou d'envoyer I'outil une fois par annie dans un centre de service

qualifi_ afin qu'il puisse _tre compl_tement nettoy_ et inspect&

R_parations

Pour assurer la S¢:CURIT¢: et la FIABILIT¢: de ce produit, toutes les operations de r_paration,

d'entretien et de r6glage doivent _tre effectu6es dans un centre de service autoris_ ou par du

personnel qualifi_ (cela comprend I'inspection et le remplacement du balai); on ne doit utiliser

que des pi_ces de rechange identiques.

Accessoires

_A VERTISSEMENT : puisque les accessoires autres que ceux offerts par DEWALT n'ont

pas ete testes avec ce produit, leur utilisation pourrait s'averer dangereuse. Pour reduire le

risque de blessures, utiliser exclusivement les accessoires DEWAL T recommandes avec le

present produit.

Les accessoires recommand_s pour cet outil sont vendus s_par6ment au centre de service

de votre r6gion. Pour obtenir de I'aide concernant I'achat d'un accessoire, commun!quer avec

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 aux Etats-Unis;

composer le 1 (800) 4-DEWALT (1-800-433-9258) ou visiter notre site Web www.dewalt.

com.

Garantie limitde trois ans

DEWALT r_parera gratuitement tous les probl_mes dus & des d_fauts de mat_riau ou de

fabrication pendant trois ans & compter de la date d'achat. Cette garantie ne couvre pas des

d_faillances de piece dues &une usure normale ou & une mauvaise utilisation de I'outil. Pour

plus de d_tails relatifs & la couverture de la garantie et aux r6parations sous garantie, visiter

le site Web www.dewalt.com ou composer le 1 (800) 4-DEWALT (1 (800) 433-9258). Cette

garantie ne s'applique pas aux accessoires ni aux dommages caus6s par des r6parations

r6alis6es ou tent6es par des tiers. Cette garantie vous accorde des droits I_gaux sp_cifiques

et il est possible que vous ayez d'autres droits qui varient d'un €:tat ou d'une province &

I'autre.

En plus de la garantie, les outils DEWALT sont couverts par notre :

SERVICE D'ENTRETIEN GRATUlT DE 1 AN

DEWALT entretiendra I'outil et remplacera les pi_ces us_es par une utilisation normale et ce,

gratuitement, & tout instant pendant la premiere ann6e & compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n'_tes pas enti_rement satisfait des performances de votre outil _lectrique, laser

ou de votre cloueuse DEWALT pour quelque raison que ce soit, vous pouvez le retourner

accompagn_ d'un re£u dans les 90 jours suivant la date d'achat et nous vous rembourserons

enti_rement - sans poser de questions.

AM#RIQUE LATINE : cette garantie ne s'applique pas aux produits vendus en Am_rique

latine. Pour ceux-ci, veuillez consulter les informations relatives & la garantie sp_cifique

pr6sente dans I'emballage, appeler I'entreprise locale ou consulter le site Web pour les

informations relatives & cette garantie.

_DW317............... ]

_ , e , , PABADISMINUI_ELBIESG0

_EB_A_E_YCOr_p_ND_E_MAN_L_EINST_UCCl0N_S.

LAVISTAVPAPA_ASVlAS_S_IBATOBIAS.

_AFIN _EMINIMISEBL_S

D'UTILISA_ON.IL_AUTT_U_0_SPORT__E_QU!P_MENTD_

OEL_Sl0NES,_ USUA_IO

_ISQ_ES_ BL_SSU_ES.

I" STROKE (25ram)

_o_ED_CE_-m:msg oF_NJU_V._SE_MUS_BEAaA_

UN_STA_. _NST_UC_I_NMA_AL _LWAYSUS_e_Oe_

_YEAN_ RESPIRATORYPROTECTION.A TI/RE pB_V£NTIFr

D_BE_ALE_YC0MP_EN,E__ MANUA_DEINS_UC_I0_ES.

SlEMP_ES__EBE_A_EVA_[AP_O_CCl0NAp_0pI_D_pApA

[AVISTAy PAPA[ASVlAS_SpIB_TOBIAS.

_U_ILISATEU__01_T0_JOU_SU_E_TCOMP_ND_ELEGUIOE

D'U_LISATION.IL_AL_TOUJOU_S_O_E__ _E_UJPEMENT_E

P_0TECTION0CUL_ _T_ES_I_DI_ App_OPB_E.

_ _ | , , PARABISMINUIRF_I_ES60

O__Sl0NES,_LUSUA_IO

AFINDEMINIMIS_BLE_

BISOUESDEBLESSU_ES,

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada

palabra de sepal. Lea el manual y preste atenci6n a estos simbolos.

_PELIGRO: indica una situacidn de peligro inminente que, si no se

evita, provocara la muerte o lesiones graves.

_,ADVERTENClA: indica una situacidn de peligro potencial que, si no se

evita, podrfa provocar la muerte o lesiones graves.

_,A TENClON: indica una situacidn de peligro potencial que, si no se

evita, posiblemente provocarfa lesiones leves o moderadas.

A VI$O: se refiere a una practica no relacionada a lesiones corporales

que de no evitarse puede resultar en dafios a la propiedad.

SITIENE ALGUNA DUDA O ALGON COMENTARIO SOBRE 12STAU OTRA HERRAMIENTA

DEWALT, LL,&MENOS AL NOMERO GRATUITO: 1-800-4-DEWALT (1-800-433-9258).

Page 5

Instrucciones de seguridad generales

_ iADVERTENCIA! Lea todas las instrucciones hasta comprenderlas. No

ajustarse a las instrucciones siguientes puede ser causa de cheque el_ctrico,

incendio o lesiones graves.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Mantenga el #rea de trabajo limpia y bien iluminada. Las bancadas desordenadas y

las zonas oscuras propician los accidentes.

• No opere herramientas electricas en atmosferas explosivas, come en presencia de

liquidos, gases o pelves inflamables. Las herramientas electricas producen chispas que

pueden eriginar la ignici6n del pelve e los vapores.

• Mientras opere una herramienta electrica, mantenga lejos a los observadores, ni#os

y visitantes. Las distraccienes pueden ecasionar que pierda el control

SEGURIDAD EL#CTRICA

• Las herramientas con conexion a tierra deben conectarse a una toma de corriente

debidamente instalada y con conexion a tierra, de acuerdo con todos los codigos

y ordenanzas aplicables. Nunca quite la pata de conexion a tierra ni modifique el

enchufe en ninguna manera. No emplee ningOn adaptador para enchufes. Si tiene

alguna duda acerca de si la toma de corriente esta debidamente conectada a tierra,

consulte a un electricista calificado. Si las herramientas presentasen fallas electricas

o averfas, la conexi6n a tierra ofrece una vfa de baja resistencia para alejar la corriente

electrica del usuario. Solo es aplicable alas herramientas de Clase I (con conexion a

tierra).

• Las herramientas con doble aislamiento estan equipadas con una clavija polarizada

(una pata es mas ancha que la otra). Esta clavija se acoplara a un enchufe polarizado

de una sola manera. Si la clavija no se acopla al contacto, inviertala. Si aOn as( no

se ajusta, comuniquese con un electricista cualificado para que instale un enchufe

polarizado apropiado. Nunca cambie la clavija. El doble aislamiento [] elimina la

necesidad de cables con tres hiles y sistemas de suministre electrico con

conexi6n a tierra. Solo es aplicable a las herramientas de Clase IL

• Evite el contacto del cuerpo con superficies conectadas a tierra, tales come

tuberias, radiadores, registros y refrigeradores. El riesgo de cheque electrico aumenta

si su cuerpo hace tierra.

• No exponga las herramientas electricas a la Iluvia o a condiciones de mucha

humedad. Si entra agua en una herramienta electrica, aumenta el riesgo de cheque

electrico.

• No maltrate el cable. Nunca tome el cable para transportar la herramienta ni para

desconectarla del enchufe. Mantenga el cable alejado de las fuentes de calor, el

ace#e, las orillas afiladas o las piezas en movimiento. Cambie inmediatamente los

cables da#ados. Los cables dahades aumentan el peligre de cheque electrico.

• Cuando opere una maquina herramienta a la intemperie, utilice un alargador marcado

"W-A" o "W': Estes alargadores estan clasificades para ser usades a la intemperie y

reducen el riesgo de descarga electrica. AI usar un alargador, aseg#rese de que tenga el

calibre necesario para Ilevar la corriente que su preducto requerira. Un alargador de un

calibre insuficiente causara una cafda en la tensi6n de la ffnea dande per resultado la

perdida de energfa y sobrecalentamiento. La tabla siguiente muestra el tamaho correcte

para utilizar dependiendo de la Iongitud del alargador y del amperaje nominal de la placa

de identificaci6n. En case de duda, utilice el de mayor calibre. Cuante mas pequehe es el

n#mere del calibre, mas resistente es el alargader.

Calibre minimo para cordones de extension

Volts Longitud total del cordon en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

Amperaje

MAs No mAs Calibre del cord6n AWG

de de

0 - 6 18 16 16 14

6 10 18 16 14 12

SEGURIDAD PERSONAL

• AI utilizar una herramienta electrica, este atento, concentrese en Io que hace y

aplique el sentido comOn. No utilice la herramienta si se encuentra fatigado o bajo la

influencia de drogas, alcohol o f#rmacos. Mientras se utilizan herramientas electricas,

basta un instante de distracci6n para sufrir lesienes graves.

• Lleve ropa adecuada. No utilice ropa suelta ni joyas. Recojase el cabello largo.

Mantenga el cabello, la ropay los guantes apartados de las piezas en movimiento.

Las partes m6viles pueden atrapar las prendas de vestir sueltas, las joyas y el cabelle.

Los orificios de ventilaci6n suelen cubrir piezas en mevimiente, per le que tambien se

deben evitar.

• Evite puestas en marcha accidentales. Aseg#rese de que el interrupter este apagado

antes de enchufar la maquina. Transportar las herramientas con el dedo sebre el interrupter

e enchufarlas con el interrupter encendide faverece los accidentes.

• Antes de poner en marcha la herramienta, retire las Ilaves de ajuste. Una Ilave que se

deje en una pieza giratoria de la herramienta puede provocar lesiones.

• No ponga en peligro su estabilidad. Mantengase siempre bien apoyado y equilibrado.

Un buen apoyo y equilibrio permiten controlar mejor la herramienta si se produce alg_n

impreviste.

• Utilice el equipo de seguridad. Lleve siempre lentes protectores. Cuando sea

adecuado, tambien se debe usar mascarilla antipolvo, zapatos de suela antideslizante,

casco oprotecteres auditivos.

use Y CUlDADOS DE LA HERRAMIENTA

• Utilice abrazaderas u otro elemento adecuado para sujetar y apoyar la pieza de

trabajo en una plataforma estable. Sujetar la pieza con la mane o contra el cuerpo es

inestable y facilita la perdida de control

• No fuerce la herramienta. Emplee la herramienta correcta para cada aplicaci6n. La

herramienta correcta hace el trabajo mejor y mas segure dentre del range para el que ha

side disehada.

• No utilice la herramienta si elinterruptor no la enciende yapaga. Cualquier herramienta

que no pueda contrelarse con el interrupter es peligrosa y se debe reparar.

• Desconecte la clavija del enchufe antes de preceder a cualquier ajuste, cambiar un

accesorio o guardar la herramienta. Estas medidas de seguridad preventiva reducen el

riesgo de pener en marcha la herramienta accidentalmente.

• Cuande no las utilice, guarde las herramientas fuera del alcance de los hides e de

cualquier persona no capacitada. Las herramientas son peligrosas en manes de

usuaries no capacitados.

• Cuide las herramientas. Conserve las herramientas de corte afiladas y limpias. Unas

herramientas adecuadamente cuidadas y con los berdes de corte afilados se atascan

menes y son mas faciles de contrelar.

• Compruebe si las piezas moviles se desalinean o atascan, si hay alguna pieza rota

o cualquier otra circunstancia que pueda afectar la operaci6n de la herramienta. Si

la herramienta esta da_ada, hagala reparar antes de usarla. Muches accidentes los

prevecan unas herramientas mal cuidadas.

• Utilice Onicamente los accesorios recomendados per el fabricante para su modelo.

Un misme accesorie puede ser adecuado para una herramienta, pere peligreso si se usa

en otra.

SERVICIO

• El servicio a la herramienta solo debe realizarlo personal cualificado. El servicio o

mantenimiente realizades per personal no calificade puede dar come resultado un riesgo

de lesiones.

• AI preceder al mantenimiento de una herramienta, utilice Onicamente refacciones

identicas. Siga las instrucciones de la seccion "Mantenimiento" de este manual La

utilizaci6n de piezas no autorizadas, e no respetar las instruccienes de mantenimiente,

puede suponer un peligre de cheque electrico e de lesienes.

Normas especificas de seguridad adicionales para

sierras de vaivdn

• Sujete la herramienta per las superficies aislantes si Ileva a cabo una operaci6n en

que la herramienta pueda tocar un conductor oculto. El contacto con un conductor

active provocara que las piezas metalicas de la herramienta conduzcan electricidad y que

el operador reciba una descarga electrica.

• Permita que el motor se detenga per complete antes de retirar la hoja de la linea de

corte. Las hojas en movimiento pueden impactar la pieza de trabajo y romperse, dahar

la pieza de trabajo e causar la perdida de control de la herramienta y posibles lesienes

corporales.

• Mantenga las empu#aduras secas, limpias, libres de aceite y grasa. Esto permitira un

mejor control de la herramienta.

• Mantenga las hojas afiladas. Las hejas remas pueden hacer que la sierra se desvfe e

estanque bajo presidn.

• Limpie su herramienta con frecuencia, especialmente despues de uses prolongados.

El polve y la arenilla que contienen partfculas metalicas se acumulan con frecuencia en las

superficies interieres y podrfan ecasionar peligre de descarga electrica.

• No opere esta herramienta durante periodos largos de tiempo. La vibracidn causada

per la accidn de operacidn de esta herramienta puede causar lesiones permanentes a

los dedos, las manes y los brazes. Utilice guantes para una mayor amertiguacidn, tome

descansos frecuentes y limite el tiempo de use diario.

i_ADVERTENClA: Siempre utilice preteccidn ocular cuando opere esta maquina

herramienta.

AADVERTENClA: Parte del pelve generado al lijar, serrar, esmerilar y taladrar con maquinas

herramienta, asf come al realizar otras actividades del sector de la construccidn, contienen

productos qufmicos que pueden preducir cancer, defectos congenites u etras afeccienes

reproductivas. Ejemplos de esas substancias qufmicas son:

• plomo procedente de pinturas a base de plomo,

• dxido de silicie cristalino precedente de ladrilles, cemente y etres preductes de

mampesterfa y

• arsenico y creme procedentes de madera tratada qufmicamente (CCA).

El peligro derivade de estas expesiciones que usted enfrente varfa en funcidn de la frecuencia

con que se realice este tipo de trabajo. Para reducir la exposicidn a esas sustancias qufmicas:

trabaje en una zena bien ventilada y Ilevando equipos de seguridad aprebades, come

mascarillas antipolvo especialmente disehadas para filtrar partfculas micrescdpicas.

• Evite el contacto prolongado con el polvo procedente del lijado, serrado, esmerilado

y taladrado electricos, as( come de otras actividades del sector de la construccion.

Lleve ropa protectora y lave con agua y jabon las zonas expuestas. Si permite que

el polve se intreduzca en la boca o los ojos e quede sebre la piel, puede faverecer la

absorcidn de preductes qufmicos peligresos.

i_ADVERTENClA: El use de esta herramienta puede generar o dispersar polvo le cual puede

causar lesiones respiraterias serias y permanentes y etres tipos de lesidn. Siempre use

proteccidn respirateria aprobada per NIOSH/OSHA para la exposicidn al pelve. Dirija las

partfculas en direccidn opuesta a su cara y cuerpo.

•&ADVERTENClA: Utilice una proteccion auditiva apropiada durante el use. En

determinadas condiciones y con utilizaciones prolongadas, el ruide generade per este

preducte puede faverecer la perdida de audicidn.

• La etiqueta de su herramienta puede incluir los siguientes sfmboles. Los sfmbeles y sus

definiciones son los siguientes:

V............... voltios

Hz............. hertzios

min ........... minutes

............. corriente directa

[] ............ construccidn de Clase II

............. terminal con conexidn a tierra

•& ............. sfmbolo de alerta de seguridad

A................ amperies

W............... vaties

'_ ............. corriente alterna

no .............. velocidad sin carga

.../min ....... reveluciones per minute

sfpm .......... pies de superficie per minute

CONSERVE ESTAS INSTRUCCIONES

COMPONENTES

A. Conmutador tipo gatillo

B. Bot6n de bloqueo

C. Cuadrante de control de velocidad

D. Palanca sin Ilave de la hoja

E. Base

Motor

Su herramienta DEWALT viene con un motor fabricado per DEWALT. Compruebe que su

suministro el6ctrico concuerde con el indicado en la placa nominal.

Voltios 50/60 Hz o '%61oAC" significa que su herramienta debe operarse con corriente alterna

y nunca con corriente continua. Voltios DC-60 Hz 6 AC/DC significa que su herramienta

puede ser operada con corriente alterna o continua.

Una reducci6n de voltaje superior a110% provocara p6rdida de potenciay sobrecalentamiento.

Todas las herramientas DEWALT vienen probadas de fabrica; siesta herramienta no

funciona, revise el abastecimiento el6ctrico.

FUNCIONAMIENTO

JkADVERTENCIA : Para reducir el riesgo de lesiones corporales graves, apague la

herramienta y desconectela de la fuente de alimentaci6n antes de realizar ajustes o de

quitar o poner accesorios.

Conmutador tipo gatillo (Fig. 1)

Para arrancar la sierra de vaiv6n, apriete el conmutador tipo gatillo (A).

Para hacer que la sierra opere a una velocidad menor y detenerla completamente,

suelte el conmutador tipo gatillo.

Para una operacion continua, apriete el conmutador tipo gatillo y luego presione el bot6n del

seguro (B). Una vez presionado el bot6n del seguro, suelte el conmutador tipo gatillo.

Para dejar de operar continuamente la sierra, apriete el gatillo y el seguro se desactivar&

Conmutador de velocidad variable (Fig. 1, 2)

La velocidad variable se controla en una de dos formas: con el cuadrante de control de

velocidad (C) o con el conmutador tipo gatillo (A).

CUADRANTE DE CONTROL DE VELOCIDAD

AI girar el cuadrante de control de velocidad (C) en cualquiera de las dos direcciones, ajustara

la velocidad maxima u oscilaciones per minute a la cual corta la hoja. El cuadrante de control

de velocidad ajusta la velocidad a la cual corta la hoja, de aproximadamente 500 SPM a

aproximadamente 3100 SPM.

CONMUTADOR TIPO GATILLO

AI presionar el conmutador tipo gatillo, las oscilaciones per minute seguiran aumentando pero

no sobrepasaran la configuraci6n maxima del cuadrante de control de velocidad. AI soltar el

gatillo, las oscilaciones per minute de la hoja disminuiran.

Instalacidn y desinstalacidn de la hoja (Fig. 3)

J_PRECAUCI6N: Apague y desenchufe la herramienta antes de realizar cualquier

ajuste o de instalar/desinstalar accesorios.

PARA INSTALAR UNA HOJA

1. Levante la palanca sin Ilave de la hoja (D).

2. Inserte la hoja en el mecanismo de sujeci6n (F) al tiempo que guia la parte posterior de

la hoja en la ranura de los rodillos de guia (G).

3. El vastago deberia encontrarse completamente dentro del mecanismo de sujeci6n come

Io muestra la Figura 4.

4. Suelte la palanca sin Ilave de la hoja.

PARA RETIRAR UNA HOJA

1. Levante la palanca sin Ilave de la hoja (D).

2. Sacuda ligeramente para hacer que la hoja se salga.

_PRECAUCI6N: No toque las hojas usadas, puede que esten calientes. Podrfa resultar en

lesiones corporales.

Page 6

Ajuste para cortes biselados (Fig. 5)

Se pueden realizar cortes biselados de cualquier angulo, entre 0 y 45 grados. Para ajustar la

base de la sierra, afloje el tornillo (H) que se encuentra en la parte inferior de la herramienta y

gire la base hasta colocarla en el angulo deseado. Una vez fijada la base, ajuste bien el tornillo

y utilice la sierra como de costumbre.

Accidn de corte - Orbital o recto (Fig. 6)

,&PRECAUCl6N: Verifique que la herramienta no este bloqueada en operaci6n continua

antes de enchufarla a la toma de corriente. Si el conmutador tipo gatillo est# bloqueado en

operaci6n continua, la herramienta arrancar# apenas sea enchufada. Esto podrfa dahar la

herramienta o resultar en lesiones corporales..

Esta sierra de vaiv_n viene equipada para cortar de cuatro formas, tres tipos de corte orbital y

uno recto. La acci6n orbital tiene un movimiento mas agresivo de hoja y esta diseSado para

cortar materiales blandos como madera o plastico. La acci6n orbital permite un corte mas

rapido pero mas tosco del material. En una acci6n orbital, la hoja se mueve hacia adelante

durante la oscilaci6n del corte ademas del movimiento vertical.

NOTA: Jamas se deberian cortar metales o maderas duras con acci6n orbital.

Para ajustar la accion de corte, mueva la palanca de acci6n de corte (I) entre las cuatro

posiciones de corte: 0, 1, 2 y 3. La posici6n 0 es un corte recto. Las posiciones 1, 2 y 3 son

de corte orbital. La agresividad del corte aumenta en la medida que la palanca se ajuste de

uno a tres, siendo tres el corte mas agresivo.

Ajuste para cortes de 90 °

_PRECAUCI6N: Apague y desenchufe la herramienta antes de realizar cualquier

ajuste o de instalar/desinstalar accesorios.

1. La marca de 0° de la placa del cuadrante deberia quedar alineada con la marca en la

base.

2. Si es necesario ajustar la sierra, afloje el tornillo en la placa del cuadrante y ajt]stela

segt]n necesite. Coloque una escuadra contra la hoja y la base y ajuste la base para que

quede a 90°.

Contra astillado (Fig. 7)

Esta sierra de vaiv_n tiene una base especial doble que posee una apertura amplia en un

extremo, para cortes generales y biselados, y una ranura bastante angosta en el otro extremo

para ser utilizado exclusivamente con hojas c6ncavas. Esta ranura estrecha hace las veces de

un dispositivo contra astillado (J) yes particularmente Qtil cuando se corta contrachapado.

Para invertir la posicidn de la base (Fig. 7)

APRECAUCI6N: Apague y desenchufe la herramienta antes de realizar cualquier

ajuste o de instalar/desinstalar accesorios.

Para invertir la posici6n de la base, retire el tornillo (H) que se encuentra en la parte inferior de

la herramienta, como Io muestra la Figura 8 y separe la base de la sierra de vaiv_n. [Tenga

cuidado de fijarse en la posici6n de la abrazadera (K). Esta abrazadera debera volverse a

instalar en la misma posici6n. De Io contrario, la base no entrara bien.] Voltee la base y vuelva

a instalarla teniendo cuidado que cuando la ranura est6 hacia adelante, el tornillo entre por

el orificio de la base pero que cuando la apertura amplia est6 hacia adelante, el tornillo pase

por la ranura de la base.

Corte

i_,ADVERTENCIA: La sierra vaiven no deberfa operarse si no tiene puesta la base. De Io

contrario, podrfa resultar en lesiones corporales serias.

CORTES DE ORIFIClOS (FIG. 8, 9)

Un corte de orificio es un m_todo sencillo para hacer un corte interior. La sierra se puede

insertar directamente en el panel o tabla sin antes perforarlo para guiar el corte. En los

cortes de orificio, mida la superficie a cortar y marquela claramente con un lapiz. Luego

incline la sierra hacia adelante hasta que el extremo delantero de la base quede firmemente

sentada sobre la superficie de trabajo y la hoja sea capaz de cortar el grosor completo con

una oscilaci6n completa. Encienda la herramienta y deje que alcance su velocidad maxima.

Sostenga firmemente la sierra y baje el borde posterior de la herramienta lentamente,

hasta que la hoja alcance el mAximo de profundidad. Sostenga la base al ras de la madera

y comience a cortar. No retire la hoja del corte mientras se siga moviendo. La hoja debe

detenerse por completo.

CORTE DE MADERA

En todo momento, sostenga correctamente la pieza de trabajo. Use la velocidad mayor para

cortar madera. No intente girar la herramienta cuando la hoja est6 contra el material a cortar.

Esto podria estancar el motor. Coloque la parte delantera de la base en el material al cortar

y sostenga la base de la sierra de vaiv_n firmemente contra la madera mientras la corte. No

fuerce la herramienta; deje que la hoja corte a su propia velocidad. Cuando el corte est6

completo, apague la sierra de vaiv_n. Deje que la hoja se detenga completamente y luego

ponga la sierra a un lado antes de liberar la pieza.

CORTE DE METALES

Cuando corte laminas de metal, es mejor si sujeta una pieza de madera a la parte de abajo

de la lamina; esto asegurara que se haga un corte limpio sin riesgo de vibraci6n o rasgadura

del metal. Siempre recuerde usar una hoja mas fina para metales ferrosos (para aquellos

que contengan mucho hierro); y use una hoja mas gruesa para metales no ferrosos (que no

contienen hierro). Use la velocidad mayor para cortar metales blandos (aluminio, cobre, lat6n,

acero suave, caSeria galvanizada, ductos de laminas de metal, etc.). Use la velocidad menor

para cortar plasticos, azulejos, superficies laminadas, metales duros y hierro fundido.

MANTENIMIENTO

_ADVERTENCIA: Para reducir el riesgo de lesiones personales graves, apague la

herramienta y desconectela de la fuente de energ(a antes de realizar ajustes o de retirar

o instalar cualquier dispositivo o accesorio.

Limpieza

Z&ADVERTENCIA: Sople la suciedad y el polvo de todos los conductos de ventilacidn con

aire seco, al menos una vez por semana. Para reducir el riesgo de lesiones, utilice siempre

proteccidn para los ojos aprobada ANSI Z87.1 al realizar esta tarea.

i},ADVERTENClA: Nunca utilice solventes ni otros qufmicos abrasivos para limpiar las piezas

no metalicas de la herramienta. Estos productos qufmicos pueden debilitar los materiales

plasticos utilizados en estas piezas. Utilice un paho humedecido sdlo con agua y jabdn neutro.

Nunca permita que penetre Ifquido dentro de la herramienta ni sumerja ninguna de las piezas

en un Ifquido.

Lubricacidn

NOTA: NUNCA rocie o aplique en ninguna otra forma lubricantes o solventes de limpieza

dentro de la herramienta. Esto puede afectar seriamente la duraci6n y el desempeSo de la

herramienta.

Las herramientas DEWALT vienen debidamente lubricadas de la fabrica y estan listas para

usarse. Sin embargo, se recomienda que una vez al aSo un Ileve o envie la herramienta a un

centro de servicio certificado para una inspecci6n y limpieza a fondo.

Accesorios

_ADVERTENCIA: Debido a que no se han probado con este producto otros accesorios que

no sean los que ofrece DEWAL T, el uso de dichos accesorios con esta herramienta podrfa

ser peligroso. Para reducir el riesgo de lesiones, con este producto deben usarse sdlo los

accesorios recomendados por DEWAL T.

Los accesorios que se recomiendan para utilizar con la herramienta estan disponibles a un

costo adicional en su distribuidor local o en un centro de mantenimiento autorizado. Si necesita

ayuda para Iocalizar algQn accesorio, p6ngase en contacto con DEWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286, Ilame al 1-800-4-DEWALT (1-800-433-9258) o

visite nuestro sitio web www.dewalt.com..

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberan hacerse reparaciones,

mantenimiento y ajustes de esta herramienta en los centros autorizados de servicio DEWALT

u otras organizaciones autorizadas. Estas organizaciones prestan servicio a las herramientas

DEWALT y emplean siempre refacciones legitimas DEWALT.

Pdliza de Garantia

IDENTIFICACION DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: Mod./Cat.:

Marca: NQm. de serie:

(Datos para ser Ilenados por el distribuidor)

Fecha de compra y/o entrega del producto:

Nombre y domicilio del distribuidor donde se adquiri6 el producto:

Este producto esta garantizado por un aSo a partir de la fecha de entrega, contra cualquier

defecto en su funcionamiento, asi como en materiales y mano de obra empleados para su

fabricaci6n. Nuestra garantia incluye la reparaci6n o reposici6n del producto y/o componentes

sin cargo alguno para el cliente, incluyendo mano de obra, asi como los gastos de

transportaci6n razonablemente erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garanfia debera presentar su herramienta y esta p61iza sellada por

el establecimiento comercial donde se adquiri6 el producto, de no contar con _sta, bastara la

factura de compra.

EXCEPCIONES.

Esta garanfia no sera valida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el instructivo de uso que

se acompaSa;

• Cuando el producto hubiese sido alterado o reparado por personas distintas a las

enlistadas al final de este certificado.

Anexo encontrara una relaci6n de sucursales de servicio de fabrica, centros de servicio

autorizados y franquiciados en la RepQblica Mexicana, donde podra hacer efectiva su

garanfia y adquirir partes, refacciones y accesorios originales.

Garantia limitada por tres a_os

DEWALT reparar& sin cargo, cualquier falla que surja de defectos en el material o la

fabricaci6n del producto, por hasta tres aSos a contar de la fecha de compra. Esta garantia

no cubre fallas de las piezas causadas por su desgaste normal o abuso a la herramienta.

Para mayores detalles sobre lacobertura de la garantia e informaci6n acerca de reparaciones

realizadas bajo garantia, visitenos en www.dewalt.com o dirigase al centro de servicio mas

cercano. Esta garantia no aplica a accesorios o a daSos causados por reparaciones realizadas

o intentadas por terceros. Esta garantia le otorga derechos legales especificos, ademas de

los cuales puede tener otros dependiendo del estado o la provincia en que se encuentre.

Ademas de la garantia, las herramientas DEWALT estan cubiertas por:

1 ANO DE SERVICIO GRATUITO

DEWALT mantendra la herramienta y reemplazara las piezas gastadas por su uso normal, sin

cobro, en cualquier momento durante un aSo a contar de la fecha de compra. Los articulos

gastados por la clavadora, tales como la unidad de hoja y retorno del impulsador, no estan

cubiertas.

GARANT|A DE REEMBOLSO DE SU DINERO POR 90 D|AS

Si no esta completamente satisfecho con el desempe_o de su maquina herramienta, laser

o clavadora DEWALT, cualquiera sea el motivo, podra devolverlo hasta 90 dias de la fecha

de compra con su recibo y obtener el reembolso completo de su dinero - sin necesidad de

responder a ninguna pregunta.

AMI_RICA LATINA: Esta garanfia no se aplica a los productos que se venden en America

Latina. Para los productos que se venden en America Latina, debe consultar la informaci6n de

la garantia especifica del pais que viene en el empaque, Ilamar a la compaSia local o visitar

el sitio Web a fin de obtener esa informaci6n.

_BW317...............

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS ELI-CTRICAS, FAVOR DE

DIRIGIRSE AL CENTRO DE SERVICIO MAS CERCANO

CULIACAN, SIN

Blvd.Emiliano Zapata 5400-1 Poniente

Col. San Rafael (667) 717 89 99

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juarez (33) 3825 6978

MEXICO, D.F.

Eje Central Lazaro Cardenas No. 18

Local D, Col. Obrera (55) 5588 9377

MERIDA, YUC

Calle 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L

Av. Francisco I. Madero 831 Poniente - Col. Centro (818) 375 23 13