Page 1

Questions? See us on the World Wide Web at www.dewalt.com

¿Dudas? Visítenos en Internet: www.dewalt.com

Dúvidas? Visite-nos na Internet em www.dewalt.com.br

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

MANUAL DE INSTRUÇÕES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR

EL PRODUCTO.

INSTRUÇÕES DE OPERAÇÃO, CENTRO DE SERVIÇOS E CERTIFICADO

DE GARANTIA. ADVERTÊNCIA: LEIA ESTAS INSTRUÇÕES ANTES DE

UTILIZAR O PRODUTO.

DW300

VS Orbital Jig Saw

Sierra Caladora Orbital con VV

Serra Tico-Tico com Ação Orbital e Velocidade Variável

Page 2

Page 3

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool”in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable,

use a residual current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

English

1

Page 4

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energising power

tools that have the switch on invites accidents.

English

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

Safety Warnings for Jig Saws

• Hold power tools by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with a

“live” wire will make exposed metal parts of the tool “live” and

shock the operator.

• Use clamps or another practical way to secure and

support the work piece to a stable platform. Holding the

work by hand or against your body leaves it unstable and

may lead to loss of control.

2

Page 5

• Keep hands away from cutting area. Never reach underneath

the material for any reason. Hold front of saw by grasping the

contoured gripping area. Do not insert fingers or thumb into

the vicinity of the reciprocating blade and blade clamp. Do not

stabilize the saw by gripping the shoe.

• Keep blades sharp. Dull blades may cause the saw to

swerve or stall under pressure.

• When cutting pipe or conduit ensure that they are free

from water, electrical wiring, etc.

• Allow the motor to come to a complete stop before

withdrawing the blade from the kerf (the slot created by

cutting). A moving blade may impact the workpiece causing

a broken blade, workpiece damage or loss of control and

possible personal injury.

• Never hold work in your hand, lap or against parts of

your body when sawing. The saw may slip and the blade

could contact the body causing injury.

• Keep handles dry, clean, free from oil and grease. This

will enable better control of the tool.

• Clean out your tool often, especially after heavy use.

Dust and grit containing metal particles often accumulate on

interior surfaces and could create an electric shock hazard.

• Do not operate this tool for long periods of time. Vibration

caused by the operating action of this tool may cause

permanent injury to fingers, hands, and arms. Use gloves to

provide extra cushion, take frequent rest periods, and limit

daily time of use.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction

activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your

mouth, eyes, or lay on the skin may promote absorption of

harmful chemicals.

WARNING: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

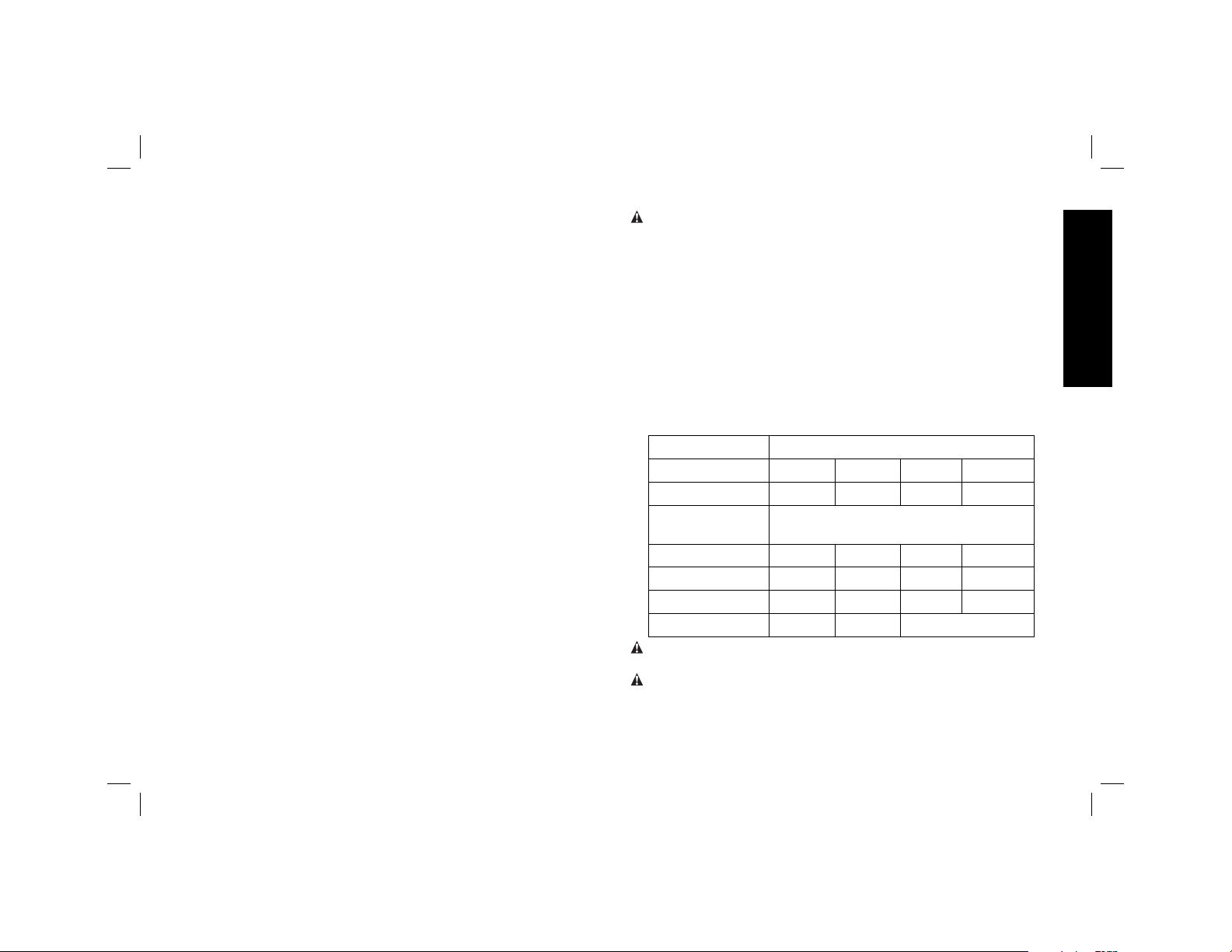

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized

cord will cause a drop in line voltage resulting in loss of power

and overheating. When using more than one extension to make

up the total length, be sure each individual extension contains

at least the minimum wire size. The following table shows the

correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Voltage (Volts)

Total length of cord in meters (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Rated Ampere

range

Minimal cross-sectional area of the

cord in meters (mm

2

)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Not Recommended

WARNING: Always use eye protection. All users and

bystanders must wear eye protection that conforms to ANSI Z87.1.

WARNING: Always wear proper personal hearing protection

that conforms to ANSI S12.6 (S3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

English

3

Page 6

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

English

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

WARNING: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ............ volts A ............ amperes

Hz .......... hertz W ........... watts

min ......... minutes

....... direct current

..........alternating current

n

o ........... no load speed

........... Class I Construction ........... earthing terminal

............... (grounded)

............ Class II Construction ...........safety alert symbol

............... (double insulated)

BPM....... beats per minute …/min .... revolutions or

sfpm ...... surface feet

............... reciprocation

.............. per minute (sfpm) ..............per minute

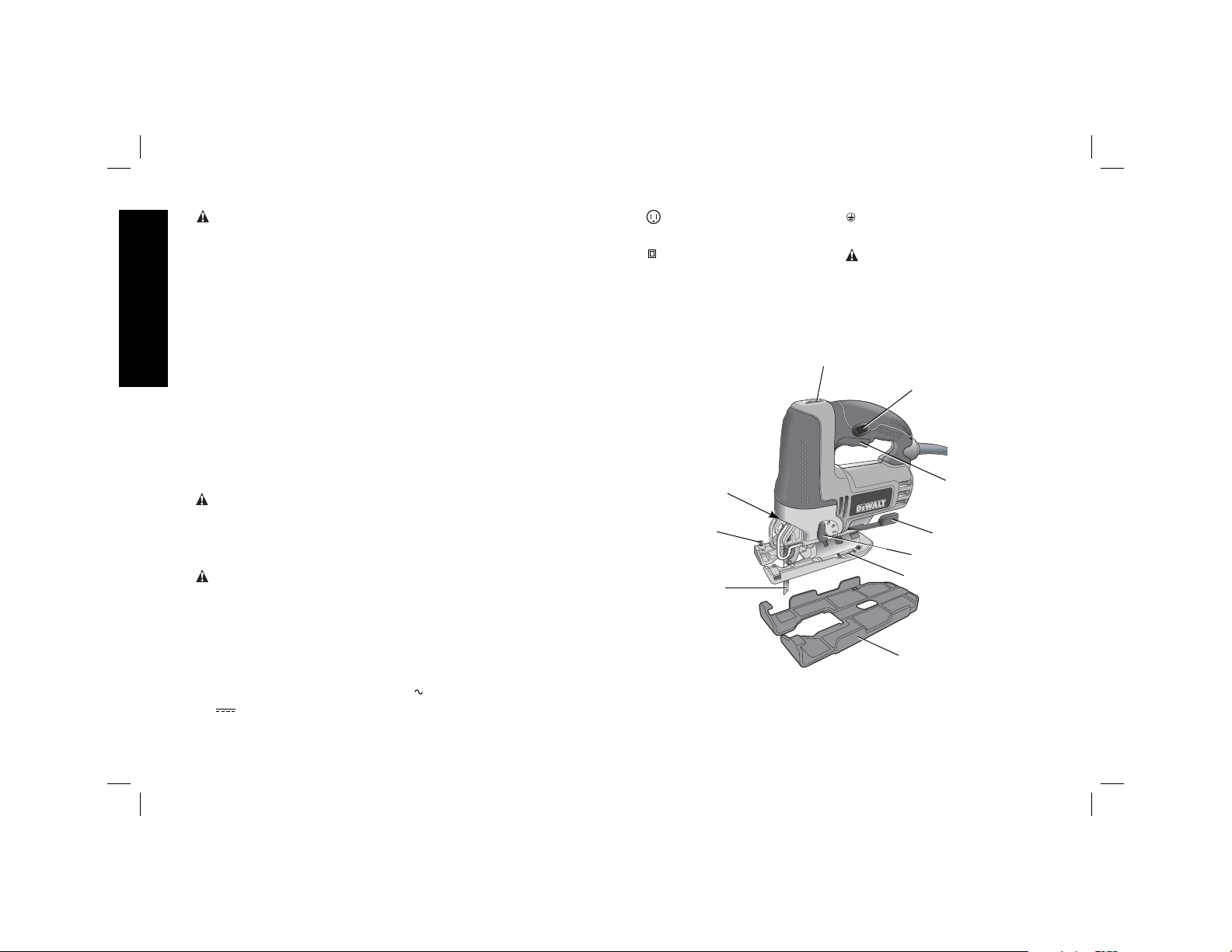

FIG. 1

J

C

D

H

B

A

G

I

F

E

4

Page 7

DESCRIPTION (FIG. 1)

WARNING: Never modify the power tool or any part of it.

Damage or personal injury could result.

A. Trigger switch G. Shoe beveling lever

B. Lock-on button H. Speed control wheel

C. Saw blade locking lever I. Cutting action lever

D. Saw blade J. LED Light

E. Shoe sleeve

F. Shoe

INTENDED USE

This jig saw is designed for professional sawing applications.

DO NOT use under wet conditions or in presence of flammable

liquids or gases.

This jig saw is a professional power tools. DO NOT let children

come into contact with the tool. Supervision is required when

inexperienced operators use this tool.

ASSEMBLY AND ADJUSTMENTS

WARNING: Prior to assembly and adjustment, ALWAYS unplug

tool.

OPERATION

WARNING: Always observe the safety instructions and applicable

regulations.

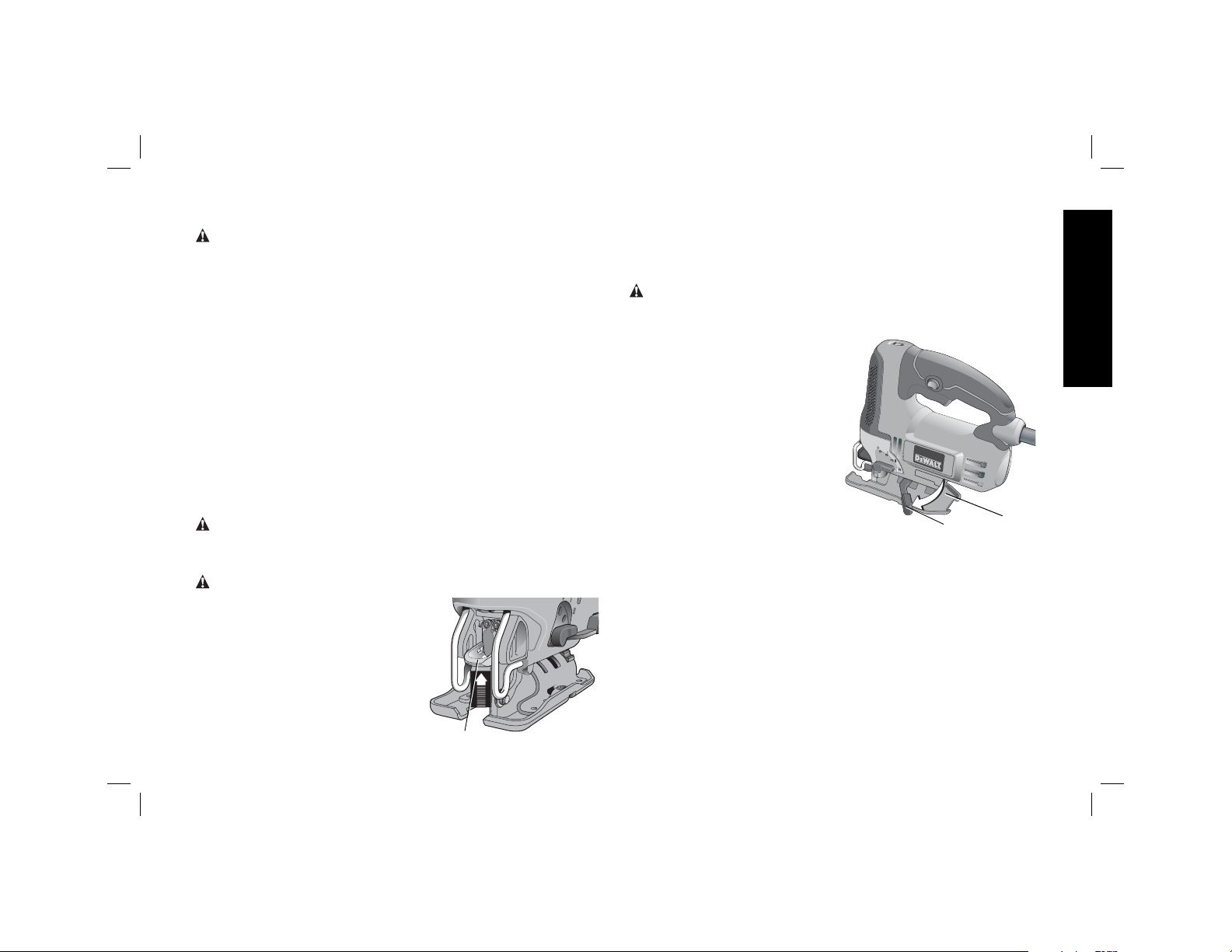

FIG. 2

Blade Installation

(Fig. 2)

1. Push the saw blade locking

lever (C) upward.

2. With teeth facing forward,

insert the shank of the saw

blade into the blade holder

as far as it will go.

C

3. Release the lever.

4. Check to ensure blade is secure before cutting.

Adjusting the Shoe for Bevel Cuts

(Fig. 3)

WARNING: Never use the tool when the shoe is loose or

removed. The shoe plate can be set to a left or right bevel angle of

up to 45°.

TO SET THE BEVEL ANGLE

1. Pull the shoe beveling

lever (G) out and away

from the saw to unlock

the shoe (F) as shown

in Figure 3.

2. Slide the shoe forward

to release it from the 0°

positive stop position.

3. The shoe can be

beveled to the left or

to the right and has

detents at 15°, 30° and

45°.

4. Set the shoe to the desired bevel angle. Use a protractor to

verify angle accuracy.

5. Push the shoe beveling lever back towards the saw to lock the

shoe.

TO RESET THE SHOE FOR STRAIGHT CUTS

1. Pull the shoe beveling lever (G) out and away from the saw to

unlock the shoe (F) as shown in Figure 3.

2. Rotate shoe to an angle of approximately 0° and then pull shoe

backwards to engage the 0° positive stop.

3. Push the shoe beveling lever back towards the saw to lock the

shoe.

5

FIG. 3

G

English

F

Page 8

Switching On and Off

To switch the tool on, squeeze the trigger switch (A).

For continuous operation, squeeze the trigger switch then depress

the lock-on button (B). Once lock-on button is depressed, release

the trigger switch.

To switch the tool off, release the trigger switch. To switch the tool

off, when in continuous operation, squeeze the trigger and the lock

English

will disengage.

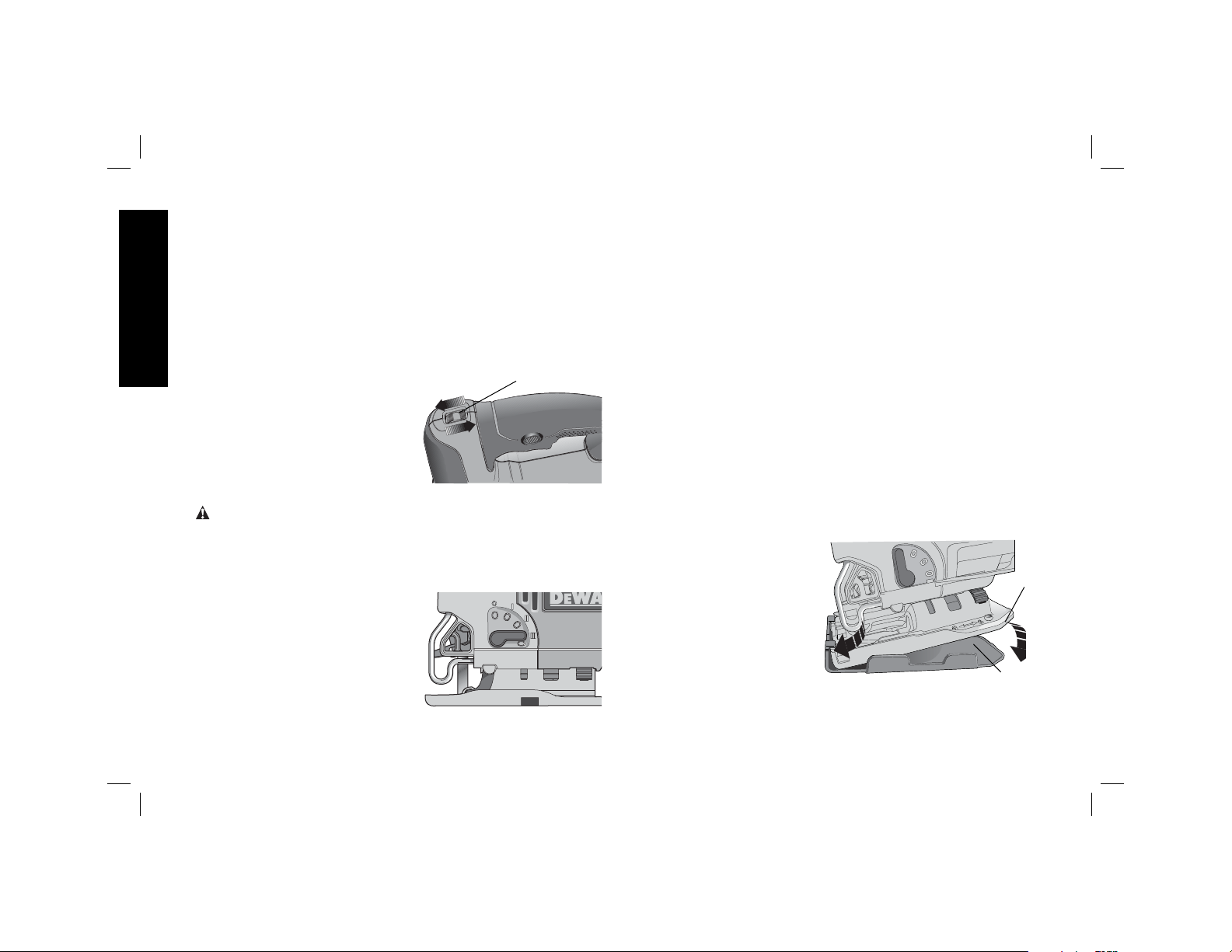

Variable Speed Control (Fig. 4)

A speed control wheel (H) is

located on the top of the saw. The

speed increases as the wheel is

turned from a low speed setting of

1 to a high speed setting of 7.

FIG. 4

H

Cutting Action –

Orbital or Straight

(Fig. 5)

WARNING: Check that the tool is not locked ON before

connecting it to a power supply. If the trigger switch is locked on

when the tool is connected to the power supply, it will start

immediately. Damage to your tool or personal injury may result.

This jig saw is equipped with

four cutting actions, three orbital

and one straight. Orbital action

has a more aggressive blade

motion and is designed for cutting

in soft materials like wood or

plastic. Orbital action provides a

faster cut, but with a less smooth

cut across the material. In orbital

action, the blade moves forward during the cutting stroke in addition

to the up and down motion.

FIG. 5

NOTE: Metal or hardwoods should never be cut in orbital action.

TO ADJUST THE CUTTING ACTION

1. Move the cutting action lever (I) between the four cutting

positions: 0, 1, 2, and 3.

2. Position 0 is straight cutting.

3. Positions 1, 2, and 3 are orbital cutting.

The aggressiveness of the cut increases as the lever is adjusted

from one to three, with three being the most aggressive cut.

LED Light

The jig saw is equipped with a light which projects on the cutting

path.

The light will come on when the trigger switch is depressed and will

go off when the trigger switch is released.

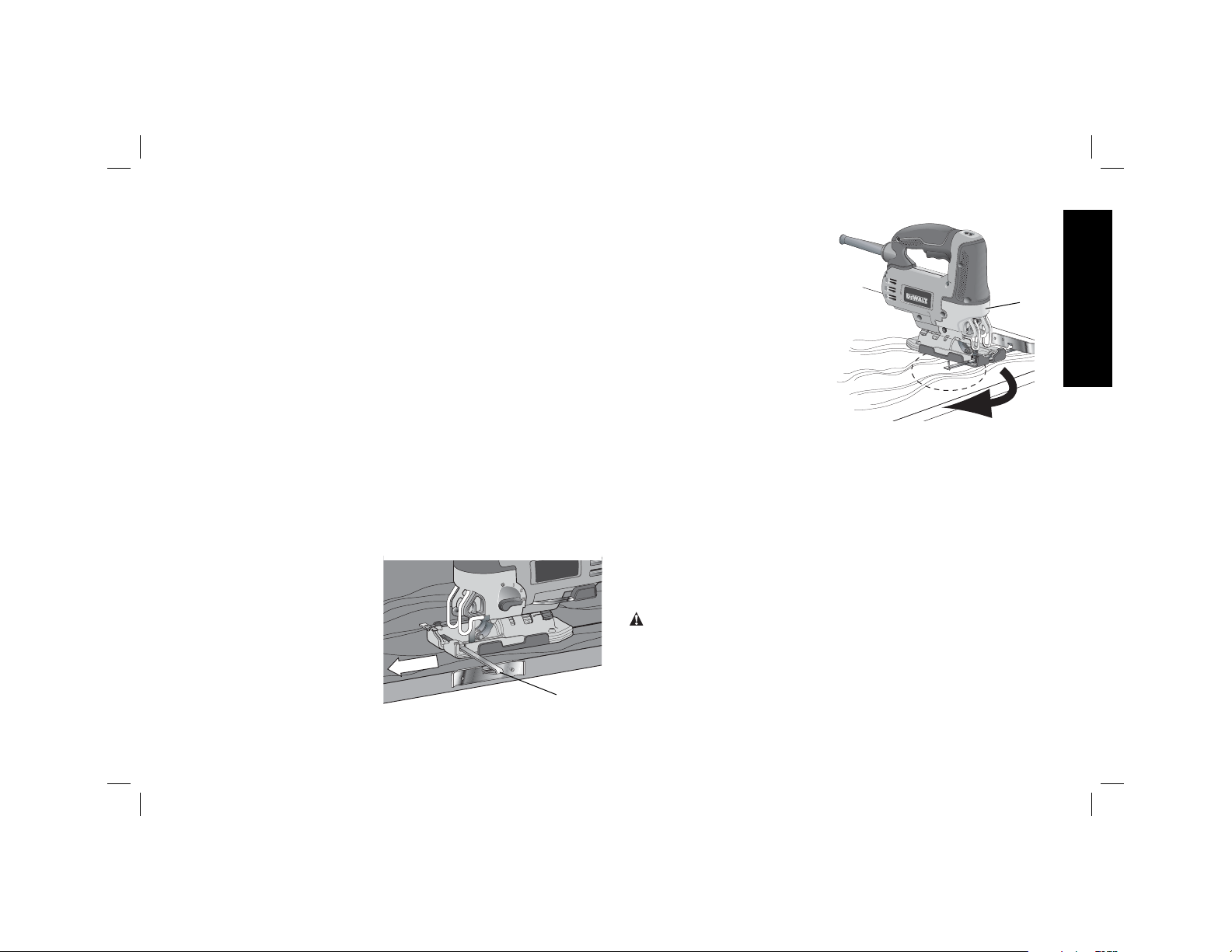

Removable Shoe Sleeve (Fig. 6)

The non-marring shoe sleeve (E) should be used when cutting

surfaces that scratch easily, such as laminate, veneer, or paint. It

can also be used to protect the shoe surface during transportation

and storage.

To attach shoe sleeve, place

the front of the shoe (F) into

the front of the shoe sleeve

(E) and lower the jig saw as

shown in Figure 6. The shoe

sleeve will click securely

onto the rear of the shoe.

To remove shoe sleeve,

grasp the sleeve from the

bottom at the two rear tabs

and pull down and away

from the shoe.

FIG. 6

F

E

6

Page 9

Hints for Optimum Use

SAWING LAMINATES

As the saw blade cuts on the upward stroke, splintering may occur

on the surface closest to the shoe plate.

– Use a fine-tooth saw blade.

– Saw from the back surface of the workpiece.

– To minimize splintering, clamp a piece of scrap wood or

hardboard to both sides of the workpiece and saw through this

sandwich.

SAWING METAL

– Be aware that sawing metal takes much more time than sawing

wood.

– Use a saw blade suitable for sawing metal.

– When cutting thin metal, clamp a piece of scrap wood to the

back surface of the workpiece and cut through this sandwich.

– Spread a film of oil along the intended line of cut for easier

operation and longer blade life. For cutting aluminum, kerosene

is preferred.

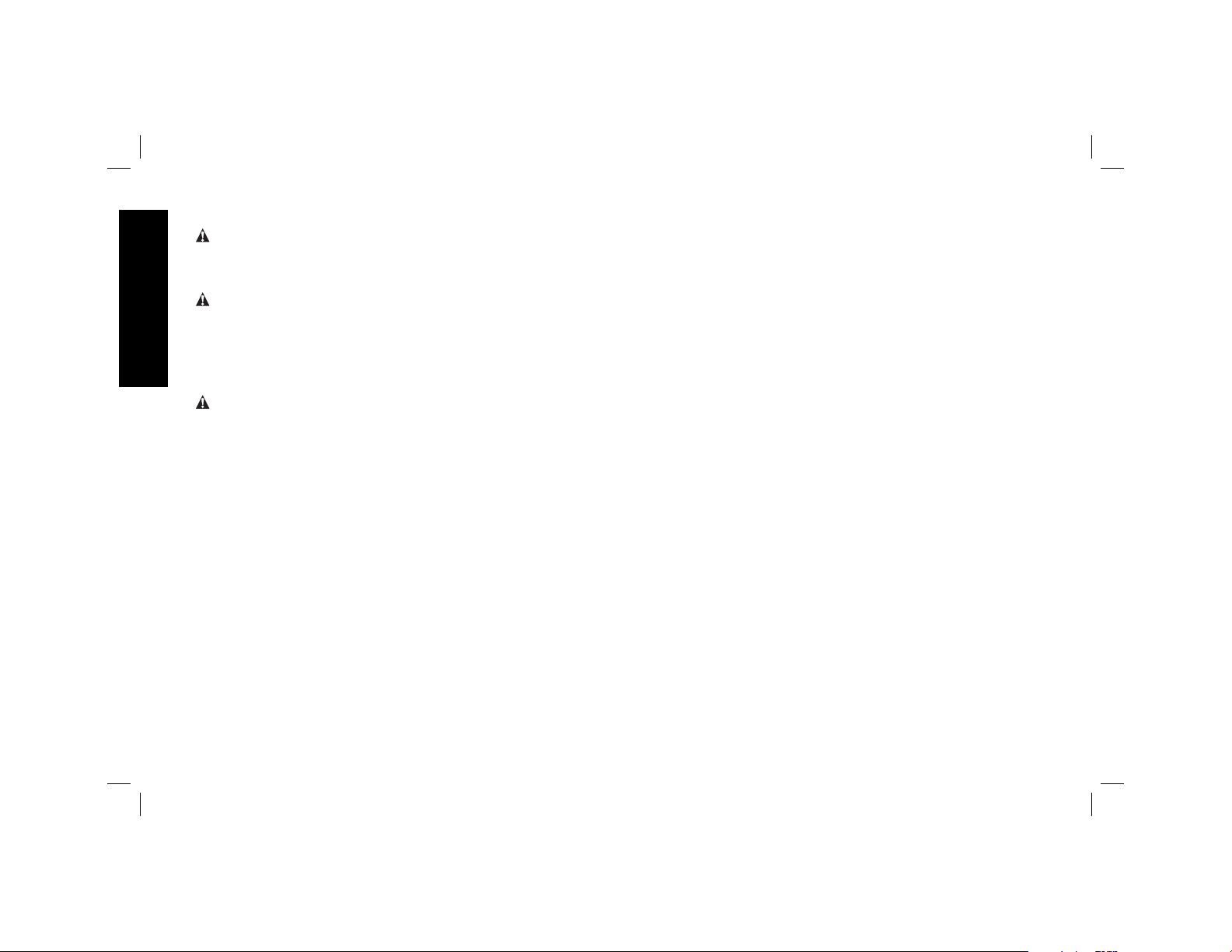

Rip/Circle Cutting (Fig. 7, 8)

Ripping and circle cutting

without a pencil line are

easily done with the rip

fence / circle guide (not

included; available at extra

cost).

Using the screw supplied

with the accessory guide,

position as shown in

Figure 7 and thread the

screw into the shoe to clamp

the fence securely.

FIG. 7

K

When ripping, position as

shown in Figure 7 and slide

the rip fence under the

screw from either side of the

saw. Set the cross bar (J) at

desired distance from blade

and tighten screw. For

ripping, the cross bar should

be down and against the

straight edge of the

workpiece as shown.

When circle cutting, adjust

rip fence so that distance

from blade to hole in fence

arm (K) is at the desired radius and tighten screw. Place saw so

that hole in fence arm is over center of circle to be cut (drill hole for

blade or cut inward from edge of material to get blade into position).

When saw is properly positioned, drive a small nail through hole in

fence arm. Using rip fence as a pivot arm, begin cutting circle. For

circle cutting, the cross bar should be up, as shown in Figure 8.

MAINTENANCE

Your DEWALT power tool has been designed to operate over a

long period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and regular

cleaning.

WARNING: To reduce the risk of injury, turn unit off and

disconnect tool from power source before installing and removing

accessories, before making any adjustments or removing/installing

attachments or accessories.

FIG. 8

Lubrication

Your power tool requires no additional lubrication.

English

J

7

Page 10

Cleaning

WARNING: Blow dirt and dust out of the main housing with dry

air as often as dirt is seen collecting in and around the air vents.

Wear approved eye protection and approved dust mask when

performing this procedure.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

English

weaken the materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

Accessories

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only D

with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center.

Volts 120V ~

Watts 500W

Hertz 50-60 Hz

RPM 0-3200/min

EWALT, recommended accessories should be used

SPECIFICATIONS

DW300-B3

8

Page 11

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unit will not start. • Cord not plugged in.

• Circuit fuse is blown.

• Circuit breaker is tripped. • Reset circuit breaker. (If the product

• Cord or switch is damaged. • Have cord or switch replaced at a

• Plug tool into a working outlet.

• Replace circuit fuse. (If the product

repeatedly causes the circuit fuse to

blow, discontinue use immediately and

have it serviced at a D

center or authorized servicer.)

repeatedly causes thecircuit breaker to

trip,discontinue use immediately and

have it serviced at a D

center or authorized servicer.)

DEWALT Center or authorized servicer.

English

EWALT service

EWALT service

9

Page 12

Definiciones: Normas

de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada

advertencia. Lea el manual y preste atención a estos símbolos.

PELIGRO:

se evita,

ADVERTENCIA:

si no se evita,

ATENCIÓN:

que, si no se evita,

moderadas.

AVISO: Se refi ere a una práctica no relacionada a lesiones

corporales que de no evitarse puede resultar en daños a la

propiedad.

ADVERTENCIA: para reducir el riesgo de lesiones, lea el

Español

manual de instrucciones.

Advertencias generales de seguridad

indica una situación de peligro inminente que, si no

provocará

la

muerte o lesiones graves.

Indica una situación de peligro potencial que,

podría

provocar la

indica una situación de peligro potencial

puede

muerte o lesiones graves.

provocar

lesiones leves o

para las herramientas eléctricas

ADVERTENCIA: Lea todas las advertencias de seguridad e

instrucciones.

instrucciones puede provocar descargas eléctricas, incendios o

lesiones graves.

El término “herramienta eléctrica” incluido en todas las advertencias

se refiere a su herramienta eléctrica conectada a la red (cable

eléctrico) o a su herramienta eléctrica accionada con baterías

(inalámbrica).

El incumplimiento de las advertencias o

GUARDE LAS ADVERTENCIAS E

INSTRUCCIONES PARA PODER

CONSULTARLAS EN EL FUTURO

1) SEGURIDAD DEL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las

áreas abarrotadas u oscuras propician accidentes.

b) No haga funcionar las herramientas eléctricas en

atmósferas explosivas, como ambientes donde haya

polvo, gases o líquidos inflamables. Las herramientas

eléctricas originan chispas que pueden encender el polvo o

producir humo.

c) Mantenga alejados a los niños y a los espectadores de la

herramienta eléctrica en funcionamiento. Las distracciones

pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse

a la toma de corriente. Nunca modifique el enchufe de

ninguna manera. No utilice ningún enchufe adaptador

con herramientas eléctricas con conexión a tierra. Los

enchufes no modificados y que se adaptan a las tomas de

corrientes reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies con toma de

tierra como, por ejemplo, tuberías, radiadores, cocinas y

refrigeradores. Existe mayor riesgo de descarga eléctrica si

su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia ni a

condiciones de humedad. Si entra agua en una herramienta

eléctrica, aumentará el riesgo de descarga eléctrica.

d) No use el cable indebidamente. Nunca utilice el cable para

transportar, tirar o desenchufar la herramienta eléctrica.

Mantenga el cable alejado del calor, el aceite, los bordes

afilados o las piezas móviles. Los cables dañados o

enredados aumentan el riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice

un cable prolongador adecuado para tal uso. Utilice un

cable adecuado para uso en exteriores a fin de reducir el

riesgo de descarga eléctrica.

10

10

Page 13

f) Si no se puede evitar el uso de una herramienta eléctrica

en una zona húmeda, utilice un dispositivo de corriente

residual (residual current device, RCD) de seguridad.

El uso de un RCD reduce el riesgo de sufrir una descarga

eléctrica.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el

sentido común cuando emplee una herramienta eléctrica.

No utilice una herramienta eléctrica si está cansado o

bajo el efecto de drogas, alcohol o medicamentos. Un

momento de descuido mientras se opera una herramienta

eléctrica puede provocar lesiones personales graves.

b) Utilice equipo de seguridad personal. Utilice siempre

protección ocular. El uso de equipo de seguridad, como

mascarillas para polvo, calzado de seguridad antideslizante,

cascos o protección auditiva en las condiciones adecuadas

reducirá las lesiones personales.

c) Evite poner en marcha la herramienta involuntariamente.

Asegúrese de que el interruptor está apagado antes de

conectar la fuente de alimentación y/o la batería, coger

o transportar la herramienta. Transportar herramientas

eléctricas con su dedo apoyado sobre el interruptor o

enchufar herramientas eléctricas con el interruptor en la

posición de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de

encender la herramienta eléctrica. Una llave de tuercas

o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta eléctrica puede provocar lesiones

personales.

e) No se estire demasiado. Conserve el equilibrio y

posiciónese adecuadamente en todo momento. Esto

permite un mejor control de la herramienta eléctrica en

situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni

joyas. Mantenga el cabello, la ropa y los guantes alejados

de las piezas en movimiento. Las ropas holgadas, las joyas

o el cabello largo pueden quedar atrapados en las piezas

en movimiento.

g) Si se suministran dispositivos para la conexión de

accesorios con fines de recolección y extracción de

polvo, asegúrese de que estén conectados y que se

utilicen correctamente. El uso del extractor de polvo puede

reducir los riesgos relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA

ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta

eléctrica correcta para el trabajo que realizará. La

herramienta eléctrica correcta hará el trabajo mejor, y de un

modo más seguro, a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla

o apagarla con el interruptor. Las herramientas que no

puedan ser controladas con el interruptor constituyen un

peligro y deben repararse.

c) Desconecte el enchufe de la fuente de alimentación o

la batería de la herramienta eléctrica antes de realizar

cualquier ajuste, cambio de accesorios o almacenar

las herramientas eléctricas. Estas medidas de seguridad

preventivas reducen el riesgo de encender la herramienta

eléctrica de forma accidental.

d) Guarde la herramienta eléctrica que no esté en uso fuera

del alcance de los niños y no permita que otras personas

no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas eléctricas son

peligrosas si son operadas por usuarios que no tienen

formación.

Español

11

11

Page 14

e) Mantenimiento de las herramientas eléctricas. Revise que

no haya piezas en movimiento mal alineadas o trabadas,

piezas rotas o cualquier otra situación que pueda afectar

el funcionamiento de las herramientas eléctricas. Si

encuentra daños, haga reparar la herramienta eléctrica

antes de utilizarla. Se producen muchos accidentes a

causa de las herramientas eléctricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias.

Las herramientas de corte con mantenimiento adecuado y

con los bordes de corte afilados son menos propensas a

trabarse y son más fáciles de controlar.

g) Utilice las herramientas eléctricas, sus accesorios y

piezas, etc. de acuerdo con las presentes instrucciones,

teniendo siempre en cuenta las condiciones de trabajo y

el trabajo que deba llevar a cabo. El uso de la herramienta

eléctrica para operaciones diferentes de aquellas para las

que fue diseñada podría originar una situación peligrosa.

5) MANTENIMIENTO

Español

a) Solicite a una persona cualificada en reparaciones que

realice el mantenimiento de su herramienta eléctrica

y que solo utilice piezas de repuesto idénticas. Esto

garantizará la seguridad de la herramienta eléctrica.

NORMAS ESPECÍFICAS DE SEGURIDAD

Advertencias de seguridad para sierras

caladoras

• Sostenga la herramienta por sus superficies de

empuñadura aisladas cuando realice una operación

en la cual la herramienta para cortar pudiera entrar en

contacto con instalaciones eléctricas ocultas o con su

propio cable. El contacto con un cable cargado, cargará a

su vez las partes metálicas expuestas de la herramienta y

dará un golpe de corriente al operador.

• Utilice abrazaderas u otra forma práctica para asegurar

y sostener la pieza de trabajo sobre una plataforma

estable. Sostener el trabajo con la mano o contra el cuerpo

no brinda la estabilidad requerida y puede llevar a la pérdida

del control.

• Mantenga las manos lejos de las zonas de corte.

Nunca se estire por debajo del material por ningún motivo.

Sostenga la parte frontal de la sierra desde el área de

sujeción contorneada. No inserte los dedos en la zona

cercana a la hoja alternativa y a la abrazadera de la hoja.

No estabilice la sierra sujetando la zapata.

• Mantenga las hojas afiladas. Las hojas sin filo pueden

hacer que la sierra se desvíe o atasque al recibir presión.

• Al cortar tuberías o conductos, asegúrese de que no

contengan agua, cableado eléctrico, etc.

• Espere a que el motor se detenga por completo antes de

retirar la hoja del indicador de corte (la ranura creada al

cortar). Una hoja en movimiento puede hacer impacto en la

pieza de trabajo provocando la rotura de una hoja, daños en

la pieza de trabajo o pérdida de control y posibles lesiones

personales.

• Al aserrar, nunca sostenga el trabajo en la mano, en

el regazo ni contra partes del cuerpo. La sierra puede

deslizarse y la hoja puede entrar en contacto con el cuerpo,

lo que ocasionaría lesiones personales.

• Mantenga los mangos secos, limpios y sin restos de

aceite ni grasa. Éstos permitirán controlar la herramienta de

mejor manera.

• Limpie su herramienta con frecuencia, especialmente

después de un uso intensivo. A menudo se acumulan

sobre las superficies interiores polvo y suciedad que

contienen partículas metálicas, que pueden provocar riesgo

de descarga eléctrica.

12

12

Page 15

• No haga funcionar esta herramienta durante períodos

prolongados. La vibración que produce el funcionamiento

de esta herramienta puede provocar lesiones permanentes

en dedos, manos y brazos. Use guantes para proveer

amortiguación adicional, tome descansos frecuentes y limite

el tiempo diario de uso.

• Evite el contacto prolongado con el polvo procedente

del lijado, serrado, esmerilado y taladrado eléctricos, así

como de otras actividades del sector de la construcción.

Lleve ropa protectora y lave con agua y jabón las zonas

expuestas. Si permite que el polvo se introduzca en la boca

u ojos o quede sobre la piel, puede favorecer la absorción de

productos químicos peligrosos.

ADVERTENCIA: Utilice protección para los oídos durante el

uso. Bajo ciertas condiciones y duración de uso, el ruido de este

producto puede contribuir a una pérdida del uso del oído.

• Los hilos del alargador deben ser de un calibre apropiado

(AWG o American Wire Gauge) para su seguridad. Mientras

menor sea el calibre del hilo, mayor la capacidad del cable.

Es decir, un hilo calibre 16 tiene mayor capacidad que uno

de 18. Un cable de un calibre insuficiente causará una caída

en la tensión de la línea dando por resultado una pérdida de

energía y sobrecalentamiento. Cuando se utilice más de un

alargador para completar el largo total, asegúrese que los

hilos de cada alargador tengan el calibre mínimo. La tabla

siguiente muestra el tamaño correcto a utilizar, dependiendo

de la longitud del cable y del amperaje nominal de la placa de

identificación. Si tiene dudas sobre cuál calibre usar, use un

calibre mayor. Cuanto más pequeño sea el número del calibre,

más resistente será el cable.

Ténsion (Volts) Longitud del cable en metros (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Corriente

nominal

(Ampéres)

0 - 6A 1,0 1,5 1,5 2,5

6 - 10A 1,0 1,5 2,5 4,0

10 - 12A 1,5 1,5 2,5 4,0

12 - 16A 2,5 4,0 No recomendado

ADVERTENCIA: Si el enchufe o el cable de alimentación están

dañados lo debe reemplazar el fabricante o su representante o por

una persona igualmente calificada para evitar peligro.

ADVERTENCIA: Siempre use protección ocular. Todos los

usuarios y personas circunstantes deben llevar protección ocular

en conformidad con ANSI Z87.1.

ADVERTENCIA: Siempre lleve la debida protección auditiva

personal en conformidad con ANSI S12.6 (S3.19) durante el

uso de esta herramienta. Bajo algunas condiciones y duraciones

de uso, el ruido producido por este producto puede contribuir a la

pérdida auditiva.

ADVERTENCIA: Parte del polvo creado al lijar, aserruchar,

moler o perforar con máquina, así como al realizar otras actividades

de la construcción, contiene substancias químicas que se sabe

producen cáncer, defectos congénitos u otras afecciones

reproductivas. Algunos ejemplos de esas substancias químicas

son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de

albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

Sección nominal mínima del cable en

milímetros cuadrados (mm2 )

Español

13

13

Page 16

El riesgo al contacto con estas substancias varía, según la

frecuencia en que se haga este tipo de trabajo. Para reducir la

exposición a esas substancias químicas: trabaje en un área bien

ventilada, y trabaje con equipos de seguridad aprobados, tales

como máscaras contra el polvo especialmente diseñadas para filtrar

las partículas microscópicas.

• Evite el contacto prolongado con polvos originados

por lijar, aserrar, esmerilar, taladrar y otras actividades

constructivas. Vista ropas protectoras y lave las áreas

expuestas con agua y jabón. Permitir que el polvo se

introduzca en su boca, ojos, o dejarlo sobre la piel promueve la

absorción de químicos dañinos.

ADVERTENCIA: La utilización de esta herramienta puede

originar polvo o dispersarlo, lo que podría causar daños graves y

permanentes al sistema respiratorio, así como otras lesiones.

Siempre use protección respiratoria aprobada por NIOSH/OSHA,

apropiada para su uso en condiciones de exposición al polvo.

Procure que las partículas no se proyecten directamente sobre su

rostro o su cuerpo.

• La etiqueta de la herramienta puede incluir los siguientes

Español

símbolos. A continuación se indican los símbolos y sus

definiciones:

V ...........voltios A ..............amperios

Hz .........hertz W .............vatios

min ........minutos

............corriente alterna

.....corriente directa ............corriente alterna o

..........Construcción Clase I .................directa

..............(con conexión a tierra) no .............velocidad sin carga

..........Construcción Clase II .............terminal a tierra

..............(con aislamiento doble) .............símbolo de alerta

RPM ......revoluciones o

.................de seguridad

..............reciprocidad …/min ......por minuto

..............por minuto gpm/ipm...golpes por minuto

DESCRIPCIÓN (FIG. 1)

ADVERTENCIA: Nunca modifique la herramienta eléctrica ni

ninguna pieza de esta. Puede producir daños o lesiones corporales.

USO PREVISTO

Esta sierra caladora está diseñada para aplicaciones de uso

profesional.

NO USE la herramienta bajo condiciones de humedad o en

presencia de gases o líquidos inflamables.

Esta sierra caladora es una herramienta profesional. NO permita

que los niños entren en contacto con la herramienta. Cuando la

hagan funcionar operarios sin experiencia, es necesaria supervisión.

FIG. 1

J

C

D

H

B

A

G

I

F

E

14

14

Page 17

A. Interruptor disparador

B. Botón de bloqueo

C. Palanca de bloqueo de la hoja de sierra

D. Hoja de sierra

E. Manga de la zapata

F. Zapata

G. Palanca para biselado de la zapata

H. Selector de control de velocidad

I. Palanca de acción de corte

J. Luz LED

MONTAJE Y AJUSTES

ADVERTENCIA: Asegúrese de quitar la batería antes de montar

el aparato y ajustarlo. Apague siempre el aparato antes de colocar

o quitar la batería.

FUNCIONAMIENTO

ADVERTENCIA: Respete siempre las instrucciones de seguridad

y la reglamentación aplicable.

Instalación de la hoja (Fig. 2)

1. Empuje la palanca de bloqueo

de la hoja de sierra (C) hacia

arriba.

2. Con los dientes orientados

hacia adelante, introduzca el

vástago de la hoja de sierra

en el portahojas tanto como

sea posible.

3. Suelte la palanca.

4. Verifique para asegurarse de

que la hoja esté firme antes

de cortar.

FIG. 2

C

Ajuste de la zapata para Cortes en

bisel (Fig. 3)

ADVERTENCIA: Nunca utilice la herramienta si la zapata está

suelta o no está colocada. La placa de la zapata puede fijarse para

un ángulo de biselado a la derecha o a la izquierda de hasta

45 grados.

PARA ESTABLECER EL ÁNGULO DE BISEL

1. Tire de la palanca de

biselado de la zapata

(G) hacia afuera de la

sierra para desbloquear

la zapata (F), como se

muestra en la Figura 3.

2. Deslice la zapata hacia

adelante para liberarla

de la posición de tope

positiva 0 grados.

3. La zapata puede ser

biselada hacia la

izquierda o la derecha y

tiene bloqueos a 15, 30

y 45 grados.

4. Coloque la zapata en el ángulo de bisel deseado. Use un

transportador para verificar la precisión del ángulo.

5. Tire de la palanca de biselado de la zapata hacia atrás en

dirección a la sierra para bloquear la zapata.

PARA FIJAR LA ZAPATA PARA CORTES RECTOS

1. Tire de la palanca de biselado de la zapata (G) hacia afuera de

la sierra para desbloquear la zapata (F), como se muestra en

la Figura 3.

FIG. 3

G

Español

F

15

15

Page 18

2. Rote la zapata a un ángulo de 0 grados aproximadamente y

luego tire la zapata hacia atrás para fijar el tope positivo de 0

grados.

3. Tire de la palanca de biselado de la zapata hacia atrás en

dirección a la sierra para bloquear la zapata.

Encendido y apagado

Para encender la herramienta, oprima el interruptor disparador (A).

Para obtener un funcionamiento continuo, oprima el interruptor

disparador y luego el botón de bloqueo (B). Una vez que haya

oprimido el botón de bloqueo, suelte el interruptor disparador.

Para apagar la herramienta, suelte el interruptor disparador. Para

apagar la herramienta cuando está en funcionamiento continuo,

oprima el disparador y se liberará el bloqueo.

Control de velocidad variable (Fig. 4)

En la parte superior de la sierra,

encontrará una rueda de control

de velocidad (H). La velocidad

aumenta a medida que se gira la

Español

rueda desde la configuración 1

de velocidad baja a la

configuración 7 de velocidad

alta.

FIG. 4

H

Acción de corte:

Orbital o en línea recta (Fig. 5)

ADVERTENCIA: Verifique que la herramienta no esté bloqueada

antes de conectarla al suministro de energía. Si el interruptor

disparador está bloqueado cuando conecta la herramienta al

suministro de energía, la herramienta arrancará inmediatamente.

Podría provocar lesiones o daños a su herramienta.

Esta sierra caladora está equipada

con cuatro acciones de corte, tres

orbitales y uno en línea recta. La

acción orbital tiene un movimiento

de hoja más agresivo y está

diseñada para cortar materiales

blandos como la madera o el

plástico. La acción orbital

proporciona un corte más rápido,

pero un corte menos uniforme del

material. En la acción orbital, la hoja se mueve hacia adelante

durante la carrera de corte además del movimiento hacia arriba y

hacia abajo.

NOTA: Nunca debe cortar metal o maderas duras con la acción

orbital.

PARA AJUSTAR LA ACCIÓN DE CORTE

1. Mueva la palanca de acción de corte (I) entre las cuatro

posiciones de corte: 0, 1, 2 y 3.

2. La posición 0 es para cortes rectos.

3. Las posiciones 1, 2 y 3 son para cortes orbitales.

La agresividad del corte aumenta a medida que ajusta la palanca

del 1 al 3, que es el corte más agresivo.

FIG. 5

Luz LED

La sierra caladora está equipada con una luz que se proyecta

sobre el trayecto de corte.

Se encenderá la luz cuando oprima el interruptor disparador y se

apagará cundo lo libere.

16

16

Page 19

Retire la manga de la zapata

(Fig. 6)

La manga de la zapata

antirrayaduras (E) se debe

utilizar cuando corta

superficies que se rayan

con facilidad, como

laminados, hojas de madera

o pintura. Además, se puede

utilizar para proteger la

superficie de la zapata

durante el transporte y el

almacenamiento.

Para acoplar la manga de la zapata, coloque el frente de la zapata

(F) en el frente de la manga de la zapata (E) y baje la sierra

caladora, como se muestra en la Figura 6. La manga de la zapata

hará un ruido seco que indicará que está asegurada en la parte

trasera de la zapata.

Para quitar la manga de la zapata, tome la manga de la base en

las dos lengüetas traseras y tire hacia abajo y en dirección contraria

a la zapata.

FIG. 6

F

E

Sugerencia para un uso óptimo

PARA ASERRAR LAMINADOS

Como la hoja de sierra hace el corte en su trayectoria hacia arriba,

puede que la superficie más cercana a la platina se astille.

– Use una hoja de dientes afinados.

– Haga el aserrado desde la superficie posterior de la pieza de

corte.

– A fin de minimizar el astillado, afiance un resto de madera o

madera prensada a ambos lado de la pieza de corte y proceda

a aserrar a través de esta especie de “sandwich”.

ASERRADO EN METAL

– Para empezar, recuerde que aserrar metales toma mucho más

tiempo que aserrar madera.

– Use una hoja apropiada para aserrar metales.

– En cortes de láminas delgadas, afiance un resto de madera a

la pare posterior de la pieza y corte a través de esta especie de

“sandwich”.

– Distribuya una capa de aceite a lo largo de la línea de corte

deseada para una mejor operación y una mayor duración de la

hoja. Para cortes en aluminio, coloque kerosén preferentemente.

Cortes longitudinales y cortes de

círculos (Fig. 7, 8)

Sin utilizar una línea de lápiz, el corte longitudinal y el corte de

círculos se realizan fácilmente con una guía de corte longitudinal y

una guía de círculo (no vienen incluidas; disponibles por un costo

adicional).

Utilizando el tornillo

provisto con la guía

accesoria, colóquelo como

se muestra en la Figura 7 y

enrosque el tornillo en la

zapata para ajustar bien la

guía.

Al hacer cortes

longitudinales, colóquelo

como se muestra en la

Figura 7 y deslice la guía

de corte longitudinal por debajo del tornillo desde ambos lados de

la sierra. Coloque la barra transversal (J) a la distancia deseada

con respecto a la hoja y ajuste el tornillo. Para realizar cortes

longitudinales, la barra transversal debe estar hacia abajo y contra

el borde recto de la pieza de trabajo, como se muestra.

FIG. 7

Español

K

17

17

Page 20

Al hacer cortes en círculo,

ajuste la guía de corte

longitudinal de modo que la

distancia desde la hoja hasta

el orificio del brazo de la guía

(K) sea del radio deseado, y

ajuste el tornillo. Coloque la

sierra de modo que el orificio

en el brazo de guía quede

sobre el centro del círculo que

se cortará (perfore un orificio

para la hoja o corte hacia

adentro desde el borde del

material para colocar la hoja

en posición). Cuando la sierra

esté colocada adecuadamente, deslice un clavo pequeño a través

del orificio del brazo de la guía. Con la guía de corte como brazo

giratorio, comience a cortar el círculo. Para realizar cortes de

círculos, la barra transversal debe estar levantada, como se

Español

muestra en la Figura 8.

FIG. 8

MANTENIMIENTO

Su herramienta DEWALT ha sido diseñada para funcionar

durante un largo período con un mínimo de mantenimiento.

Un funcionamiento continuo satisfactorio depende del cuidado

adecuado de la herramienta y de una limpieza periódica.

ADVERTENCIA: Para minimizar el riesgo de graves lesiones

personales, apague la herramienta y desconecte la batería

antes de realizar ajustes o quitar/instalar los acoples o accesorios.

Un encendido accidental puede causar lesiones.

Lubricación

La herramienta eléctrica no requiere lubricación adicional.

Limpieza

ADVERTENCIA: Sople la suciedad y el polvo de la carcasa

principal con aire seco siempre que vea acumularse el polvo

alrededor de los respiraderos. Utilice protección ocular y mascarillas

antipolvo aprobadas cuando realice este procedimiento.

J

ADVERTENCIA: no use nunca disolventes ni otros agentes

químicos agresivos para limpiar las piezas no metálicas de la

herramienta. Estos agentes químicos pueden debilitar los materiales

de dichas piezas. Use un trapo humedecido sólo con agua y jabón

suave. No deje que penetre ningún líquido dentro de la herramienta

y no sumerja ninguna pieza de la herramienta en líquidos.

Accesorios

ADVERTENCIA: Dado que algunos accesorios, diferentes de

los ofrecidos por D

el empleo de tales accesorios podría constituir un riesgo. Para

reducir el riesgo de lesiones, sólo deben usarse con el producto los

accesorios recomendados D

Si desea más información sobre los accesorios adecuados,

consulte a su distribuidor.

DW300-AR DW300-B2 DW300-B2C

Volts 220 V ~ 220 V ~ 220 V ~

Potencia 500 W 500 W 500 W

Frecuencia

de operación 50 Hz 60 Hz 50 Hz

Velocidad 0-3 200/min 0-3 200/min 0-3 200/min

DW300-B3

Volts 120 V ~

Potencia 500 W

Frecuencia

de operación 50–60 Hz

Velocidad 0-3 200/min

EWALT, no se han probado con este producto,

EWALT.

Especificaciones

18

Page 21

DETECCIÓN DE PROBLEMAS

Problema Causa posible Solución posible

• La unidad no enciende. • Cable desenchufado.

• Fusible quemado.

• El interruptor automático

está activado.

• Interruptor o cable

dañado

• Enchufe el cargador en un

tomacorriente que funcione.

• Reemplace el fusible quemado. (Si

repetidamente el producto hace que el

fusible del circuito se queme, deje de

utilizarlo inmediatamente y haga que le

realicen mantenimiento en un centro de

mantenimiento D

EWALT o en un centro

de servicio autorizado.)

• Reinicie el interruptor automático. (Si

repetidamente el producto hace que el

fusible del circuito se queme, deje de

utilizarlo inmediatamente y haga que le

realicen mantenimiento en un centro de

mantenimiento D

EWALT o en un centro

de servicio autorizado.)

• Haga reparar el cable o el interruptor en

un centro de mantenimiento D

EWALT

o en un centro de mantenimiento

autorizado.

Español

19

Page 22

Definições: Diretrizes

de Segurança

As definições abaixo apresentadas descrevem o grau de

gravidade correspondente a cada palavra de advertência.

Leia cuidadosamente o manual e preste atenção a estes

símbolos.

PERIGO: Indica uma situação de risco iminente que, se

não for evitada, resultará em morte ou ferimentos graves.

AVISO: Indica uma situação de risco potencial que, se não

evitada, poderá resultar em morte ou ferimentos graves.

CUIDADO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em ferimentos leves ou

moderados.

AVISO: Se refere a uma prática não relacionada a lesões

corporais que se não evitadas podem resultar em danos

materiais.

AVISO: para reduzir o risco de ferimentos, leia o manual de

instruções.

Regras Gerais de Segurança

AVISO! Leia todas as instruções. Falha no seguir de todas as

instruções listadas abaixo pode resultar em choque elétrico,

fogo e/ou em ferimento sério.

GUARDE ESTAS INSTRUÇÕES

O termo "ferramenta" em todos os avisos listados abaixo referemse a ferramenta alimentada através de seu cordão ou a ferramenta

operada a bateria (sem cordão).

1) ÁREA DE TRABALHO

Português

a) Mantenha a área de trabalho limpa e iluminada. As áreas

desorganizadas e escuras são um convite aos acidentes.

b) Não opere ferramentas em atmosferas explosivas, como

na presença de líquidos inflamáveis, gases ou poeira. As

ferramentas criam faíscas que podem inflamar a poeira ou os

vapores.

c) Mantenha crianças e visitantes afastados ao operar

uma ferramenta. As distrações podem fazer você perder o

controle.

2) SEGURANÇA ELÉTRICA

a) Os plugues da ferramenta devem ser compatíveis com

as tomadas. Nunca modifique o plugue. Não use nenhum

plugue adaptador com as ferramentas aterradas. Os

plugues sem modificações aliados a utilização de tomadas

compatíveis reduzirão o risco de choque elétrico

b) Evite o contato do corpo com superfícies ligadas ao terra

ou aterradas tais como as tubulações, radiadores, escalas

e refrigeradores. Há um aumento no risco de choque elétrico

se seu corpo for ligado ao terra ou aterramento.

c) Não exponha a ferramentas à chuva ou às condições

úmidas. A água entrando na ferramenta aumentará o risco

de choque elétrico.

d) Não force o cabo elétrico. Nunca use o cabo elétrico para

carregar, puxar ou o para desconectar a ferramenta da

tomada. Mantenha o cabo elétrico longe do calor, óleo,

bordas afiadas ou das partes em movimentos. Os cabos

danificados ou emaranhados aumentam o risco de choque

elétrico.

e) Ao operar uma ferramenta ao ar livre, use um cabo de

extensão apropriado para o uso ao ar livre. O uso de um

cabo apropriado ao ar livre reduz o risco de choque elétrico.

3) SEGURANÇA PESSOAL

a) Fique atento, olhe o que você está fazendo e use o bom

senso ao operar uma ferramenta. Não use a ferramenta

20

Page 23

quando você estiver cansado ou sob a influência de

drogas, álcool ou de medicamentos. Um momento de

desatenção enquanto opera uma ferramenta pode resultar

em grave ferimento pessoal.

b) Use equipamento de segurança. Sempre use óculos

de segurança. O equipamento de segurança tais como

a máscara contra a poeira, sapatos de segurança

antiderrapantes, capacete de segurança, ou protetor auricular

usados em condições apropriadas reduzirão os ferimentos

pessoais.

c) Evite acidente inicial. Assegure que o interruptor está na

posição desligada antes de conectar o plugue na tomada.

Carregar a ferramentas com seu dedo no interruptor ou

conectar a ferramenta que apresenta o interruptor na posição

“ ligado” são um convite à acidentes.

d) Remova qualquer chave de ajuste antes de ligar a

ferramenta. Uma chave de boca ou de ajuste unida a uma

parte rotativa da ferramenta pode resultar em ferimento

pessoal.

e) Não force além do limite. Mantenha o apoio e o equilíbrio

adequado todas as vezes que utilizar a ferramenta.

Isto permite melhor controle da ferramenta em situações

inesperadas.

f) Vista-se apropriadamente. Não use roupas

demasiadamente largas ou jóias. Mantenha seus cabelos,

roupas e luvas longe das peças móveis. A roupa folgada,

jóias ou cabelos longos podem ser presos pelas partes em

movimento.

g) Se os dispositivos são fornecidos com conexão para

extração e coleta de pó, assegure que estes estão

conectados e usados corretamente. O uso destes

dispositivos pode reduzir riscos relacionados a poeira.

4) USO E CUIDADOS DA FERRAMENTA

a) Não force a ferramenta. Use a ferramenta correta para

sua aplicação. A ferramenta correta fará o trabalho melhor

e mais seguro se utilizada dentro daquilo para a qual foi

projetada.

b) Não use a ferramenta se o interruptor não ligar e desligar.

Qualquer ferramenta que não pode ser controlada com o

interruptor é perigosa e deve ser reparada.

c) Desconecte o plugue da tomada antes de fazer qualquer

tipo de ajuste, mudança de acessórios ou armazenamento

de ferramentas. Tais medidas de segurança preventivas

reduzem o risco de se ligar a ferramenta acidentalmente.

d) Guarde as ferramentas fora do alcance das crianças e

não permitam que pessoas não familiarizadas com a

ferramenta ou com estas instruções operem a ferramenta.

As ferramentas são perigosas nas mãos de usuários não

treinados.

e) Manutenção das ferramentas. Cheque o desalinhamento

ou coesão das partes móveis, rachaduras e qualquer outra

condição que possa afetar a operação da ferramenta. Se

danificada, a ferramenta deve ser reparada antes do uso.

Muitos acidentes são causados pela pobre manutenção das

ferramentas.

f) Mantenha ferramentas de corte afiadas e limpas. A

manutenção apropriada das ferramentas de corte com lâminas

afiadas, tornam estas menos prováveis ao emperramento e

são mais fáceis de controlar.

g) Use a ferramenta, acessórios, suas partes etc., de acordo

com as instruções e na maneira designada para o tipo

particular da ferramenta, levando em consideração as

condições e o trabalho a ser desempenhado. O uso da

ferramenta em operações diferentes das designadas podem

resultar em situações de risco.

Português

21

Page 24

5) REPAROS

a) Tenha sua ferramenta reparada por um agente de reparos

qualificado e que somente use peças originais. Isto irá

assegurar que a segurança da ferramenta seja mantida.

REGRAS DE SEGURANÇA ESPECÍFICAS

Precauções de segurança para Serras

Tico-Tico

• Segure sempre uma ferramenta elétrica usando as

empunhaduras isoladas ao fazer um trabalho onde

a ferramenta de corte possa entrar em contato com

uma fiação oculta ou com o cabo elétrico da própria

ferramenta. O contato com um fi o “vivo” carregará as partes

metálicas expostas da ferramenta e causará um choque

elétrico no operador.

• Use morsas, braçadeiras ou qualquer maneira prática

para prender e apoiar a peça a ser trabalhada numa

bancada estável. Segurar a peça com as mãos ou contra

seu corpo faz com que a peça fi que instável e pode fazer

com que você perca o controle dela.

• Mantenha as mãos fora da área de corte. Nunca se incline

por debaixo do material por qualquer razão. Segure a a parte

frontal da serra ao agarrar a área contornada de agarre.

Não insira dedos ou polegar próximo da lâmina de vaivem

e prendedor da lâmina. Não estabilize a serra ao prender a

base.

• Mantenhas as lâminas afi adas. As lâminas sem fi o podem

fazer com que a serra se desvie ou gire se estiver sob

pressão.

• Ao cortar um tubo ou conduto verifi que se não contém

Português

água ou fi os elétricos, etc.

• Deixe que o motor pare completamente antes de retirar

a lâmina do corte (a fenda criada pelo corte). Uma lâmina

em movimento pode afetar a peça de trabalho e quebrar a

lâmina, danifi car a peça ou perder o controle e causar uma

possível lesão.

• Nunca segure o trabalho com suas mãos, colo ou contra

as peças de seu corpo ao serrar. A serra pode deslizar e

a lâmina pode entrar em contato com seu corpo e causar

lesão.

• Mantenha as empunhaduras secas, limpas e livres de

óleo, gordura ou graxa. Isto dá ao usuário um melhor

controle da ferramenta.

• Limpe sua ferramenta com frequência, especialmente

depois de uso intensivo. A poeira ou detritos com partículas

metálicas se acumulam com frequência nas superfícies

internas e podem causar risco de descarga elétrica.

• Não trabalhe com esta ferramenta durante períodos

muito longos. A vibração causada pelo funcionamento

desta ferramenta poderá causar lesões permanentes nos

dedos, mãos e braços. Use luvas para fornecer amortização

extra, faça pausas frequentes e limite o tempo diário de uso.

• Evite contato prolongado com poeira de lixagem, de

corte, de polimento, de perfuração e de outras atividades

de construção. Use roupa de proteção e lave as áreas

expostas com asbão e água. Se a poeira entrar em contato

com sua boca, olhos e pelo pode causar absorção de

produtos químicos danosos.

ATENÇÃO: Use proteção dos ouvidos apropriados durante

o trabalho. Em algumas condições e em função da duração da

utilização deste produto, o ruído do mesmo poderá contribuir para

a perda de audição.

• Para sua segurança, os cabos de extensão devem ter

um calibre adequado (AWG ou American Wire Gauge).

Quanto menor for o calibre do fio, maior será a capacidade

do cabo. Isto é, um fio de calibre 16 tem uma capacidade

22

Page 25

maior do que um fio de calibre 18. Uma extensão de menor

calibre causará uma queda de voltagem o que resultará em

perda de potência e superaquecimento da ferramenta. Ao

usar mais de uma extensão para completar o comprimento

total, tenha certeza de que os fios de cada extensão têm pelo

menos o calibre mínimo. A tabela a seguir indica o tamanho

que deve ser usado em função do comprimento do cabo e

da amperagem nominal. Em caso de dúvida, use um fio de

maior capacidade. Quanto menor o número do calibre, maior

será a capacidade do cabo.

Tensão

(Volts)

Comprimento do cabo de extensão

em Metros (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Faixa de Corrente

nominal (Ampéres)

Secção minima do cabo de exten-

são em milimetros quadrados (mm

2

)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Não Recomendado

ATENÇÃO: Use sempre uma proteção ocular. É necessário

que todos os utilizadores e pessoas presentes no local de trabalho

usem uma protecção ocular em conformidade com a norma ANSI

Z87.1.

ATENÇÃO: Use sempre proteção dos ouvidos adequadas

que seguem a norma ANSI S12.6 (S3.19)durante o uso do

equipamento. Em algumas condições e em função da duração

da utilização deste produto, o ruído do mesmo poderá contribuir

para a perda de audição.

ATENÇÃO: Alguma poeira gerada de lixagem, corte,

esmerilhamento, perfuração e outras atividades de construção

contém produtos químicos conhecidos como causadora de câncer,

anomalia de nascimento ou outra dano reprodutivo. Alguns

exemplos destes produtos químicos são:

• chumbo de tintas a base de chumbo

• sílica cristalina de tijolos e cimento e outros produtos de

construção e

• arsênico e crômio de madeira tratada quimicamente (CCA).

O risco a estas exposições variam dependendo da frequência que

executa este tipo de trabalho. Para reduzir sua exposição a estes

produtos químicos: Trabalhe em uma área bem ventilada e com

equipamento de segurança aprovado, tal como estas máscaras

de poeira que são especialmente criadas para filtrar partículas

microscópicas.

• Evite contato prolongado com poeira da lixadeira, de corte,

polimento, perfuração e outras atividades de construção.

Use roupa de proteção e lave as áreas expostas com asbão

e água. Se a poeira entrar em contato com sua boca, olhos e

pelo pode causar absorção de produtos químicos danosos.

ATENÇÃO: Usar esta ferramenta pode gerar e/ou espalhar

poeira, o que pode causar lesão respiratória permanente e séria

ou outro tipo de lesão. Use sempre proteção respiratória aprovada

pela NIOSH/OSHA para a exposição a poeira. Direcione as

partículas distante do rosto e corpo.

ATENÇÃO: Use proteção dos ouvidos apropriados durante

o trabalho. Em algumas condições e em função da duração da

utilização deste produto, o ruído do mesmo poderá contribuir para

a perda de audição.

• A etiqueta da ferramenta pode incluir os seguintes símbolos: Os

símbolos e suas definições são conforme a seguir:

V ............ volts A ............ ampéres

Hz .......... hertz W ........... watts

Português

23

Page 26

min ......... minutos ..........corrente alternada

....... corrente direta

........... construção de Classe I ........... terminal com conexão

............... (aterramento) ..............de aterramento

............ construção Classe II ........... símbolo de alerta de

............... (isolamento duplo) .......... segurança

BPM....... batimentos por minuto …/min .... revoluções ou

sfpm ......pés por minuto (sfpm)

.............. per minute (sfpm) ..............por minuto

n

o ........... velocidade sem carga

............... reciprocidade

Descrição (fig. 2)

AVISO: Nunca modifique a ferramenta eléctrica ou qualquer

uma das suas peças. Podem ocorrer danos ou lesões.

FIG. 1

J

C

D

H

Português

A. Gatilho G. Alavanca de inclinação

B. Botão de trava da base

C. Alavanca de bloqueio H. Botão de controle de velocidade

da lâmina de serra I. Alavanca de ação de corte

D. Lâmina de serra J. Luz de LED

E. Camisa da base

F. Base

FINALIDADE

Esta ferramenta foi fabricada para aplicações de corte profissionais.

NÃO utilize a ferramenta em condições de humidade, nem na

presença de líquidos ou gases inflamáveis.

Esta serra tico-tico é uma ferramenta elétrica profissional. NÃO

permita que crianças mexam na ferramenta. É necessária

B

supervisão quando operadores sem experiência utilizarem esta

ferramenta.

MONTAGEM E AJUSTES

AVISO: Antes de qualquer montagem e ajuste, desligue sempre

a ferramenta da alimentação.

A

G

I

F

FUNCIONAMENTO

AVISO: Respeite sempre as instruções de segurança e os

regulamentos aplicáveis.

AVISO: Risco de choque elétrico. Para reduzir o risco de

ferimentos graves, desligue a ferramenta e desconecte-a da

fonte de alimentação antes de fazer quaisquer ajustes ou de

remover/instalar dispositivos ou acessórios.

Instalação da Lâmina (Fig. 2)

1. Pressione a alavanca debloqueio da lâmina (C) para cima.

2. Com os dentes voltados para frente, insira a haste da serra no

prendedor da lâmina tanto quanto for possível.

E

24

Page 27

3. Libere a alavanca.

4. Verifique se a lâmina está

presa no lugar antes de cortar.

FIG. 2

Ajuste a Base para

Cortes Inclinados

(Fig. 3)

ATENÇÃO: Nunca use a

ferramenta quando a base estiver

solta ou removida. A placa da

base pode ser ajustada para um

ângulo de inclinação à direita ou

à esquerda de até 45°.

PARA DEFINIR O ÂNGULO DE INCLINAÇÃO

1. Puxe a alavanca de

inclinação da base

(G) para fora e distante

da serra para

desbloquear a base

(F), conforme mostrado

na Figura 3.

2. Deslize a base para

frente para liberar

de uma posição de

parada positiva de 0°.

3. A base pode ser

inclinada à esquerda

ou à direita e fica

bloqueada em 15°, 30°

e 45°.

4. Configure a base para o ângulo de inclinação desejado. Use

um transferidor para verificar a exatição do ângulo.

FIG. 3

C

G

F

5. Empurre a alavanca de inclinação da base em direção a serra

para bloquear a base.

PARA DEFINIR A BASE PARA CORTES RETOS

1. Puxe a alavanca de inclinação da base (G) para fora e distante

da serra para desbloquear a base (F), conforme mostrado na

Figura 3.

2. Gire a base em um ângulo de aproximadamente 0° e depois

puxe a base para trás para bloquear em uma parada positiva

de 0°.

3. Empurre a alavanca de inclinação da base em direção a serra

para bloquear a base.

Ligar e Desligar

Para ligar a ferramenta, pressione o gatilho (A).

Para a operação contínua, pressione o gatilho e depois o botão

de travamento (B). Ao pressionar o botão de travamento, libere o

gatilho.

Para desligar a ferramenta, libere o gatilho. Para desligar a

ferramenta, quando estiver em operação contínua, pressione o

gatilho e o travamento será desativado.

Gatilho de velocidade variável (Fig. 4)

Uma botão de controle de

velocidade (H) está localizado no

topo da serra. A velocidade

aumenta enquanto o botão varia

de uma configuração de

velocidade baixa de 1 a

configuração de velocidade alta

de 7.

FIG. 4

H

Português

25

Page 28

Ação de Corte – Orbital ou Reto

(Fig. 5)

ATENÇÃO: Verifique se a ferramenta não está bloqueada em ON

(LIG) antes de conectá-la na fonte de alimentação. Se o gatilho

estiver bloqueado em

fonte de alimentação, ela começará a funcionar imediatamente.

Isto poderá danificar a sua ferramenta e causar lesão pessoal.

Esta serra tico-tico está

equipada com quatro ações de

corte, três orbitais e uma reta. A

ação orbital tem um movimento de

lâmina mais agressivo e foi criada

para cortar materiais menos

resistentes, como madeira ou

plástico. A ação orbital fornece um

corte mais rápido, porém com um

corte menos preciso no material. Na ação orbital, a lâmina se move

para frente durante a batida de corte além do movimento para cima

e para baixo.

NOTA: Metal ou madeira dura nunca deve ser cortada na ação

orbital.

PARA AJUSTAR A AÇÃO DE CORTE

1. Mova a alavanca de ação de corte (I) entre as quatro posições

de corte: 0, 1, 2 e 3.

2. Posição 0 é o corte reto.

3. Posições 1, 2 e 3 são corte orbital.

A agressividade do corte aumenta enquanto a alavanca é ajustada

de um para três, com três sendo o corte mais agressivo.

ON (LIG) quando conectar a ferramenta na

FIG. 5

Luz de LED

Português

A serra tico-tico está equipada com uma luz que se projeta no

caminho do corte.

A luz será ativada quando o gatilho for pressionado e será

desativada quando o gatilho for liberado.

Camisa da Base Removível (Fig. 6)

A camisa da base de amortecimento (E) deve ser usada ao cortar

superfícies que são arranhadas facilmente, tal como laminado,

verniz ou tinta. Pode também ser usada para proteger uma

superfície de base durante o transporte e armazenagem.

Para anexar a camisa da

base, coloque a frente da

base (F) na frente da camisa

(E) e abaixe a serra,

conforme mostrado na

Figura 6. A camisa de base

ficará presa com segurança

na parte de trás da base.

Para remover a camisa de

base, segure a camisa do

fundo nas duas guias de

trás e puxe-a para distante

da base.

FIG. 6

Sugestões ideais de Uso

SERRAR LAMINADOS

Como a lâmina corta no sentido de baixo para cima, pode fazer

com que a superfície mais próxima da base rache.

– Use uma lâmina com dentes finos.

– Serre a partir da parte de trás da peça de trabalho.

– Para minimizar as rachaduras, encaixe uma peça de madeira

partida em ambos os lados da peça de trabalho.

SERRAR METAL

– Lembre-se de que serrar metal leva mais tempo do que serrar

madeira.

F

E

26

Page 29

– Use uma lâmina adequada para serrar metal.

– Ao cortar folhas metálicas finas, encaixe uma peça de madeira

partida em ambos os lados da peça de trabalho e serre entre

elas.

– Espalhe uma camada fina de óleo ao longo da linha de corte.

Recomenda-se usar querosene para cortar alumínio.

Corte Circular/Veio da madeira

(Fig. 7, 8)

Cortes transversais e

paralelos sem uma linha

riscada são facilmente feitos

com uma guia circular /

paralela (não incluído –

disponível com custo extra).

Usar um parafuso fornecido

com a guia de acessório,

posicione conforme

mostrado na Figura 7 e

enrosque o parafuso na

base para prender a topeguia com segurança.

Ao serrar, coloque conforme mostrado na Figura 7 e deslize a

tope-guia sob o parafuso de ambos os lados da serra. Defina a

barra de cruzamento (J) na distância desejada da lâmina e aperte

o parafuso. Para serrar, a barra de cruzamento deve ficar abaixo e

contra a borda reta da peça de trabalho, conforme mostrado.

Ao circundar o corte, ajuste o tope-guia para que a distância da

lâmina até o braço da guia (K) fique no raio desejado e aperte o

parafuso. Coloque a serra para que o orifício no braço da guia fique

acima do centro do círculo que será cortado (corte o orifício para a

lâmina ou corte dentro da borda do material para colocar a lâmina

na posição). Quando colocar a serra corretamente, insira um

FIG. 7

K

prego pequeno através do orifício no braço da guia. Use uma guia

como um braço de pivô e comece a cortar o círculo. Para cortar

um círculo, a barra de cruzamento deve ficar acima, conforme

mostrado na Figura 8.

MANUTENÇÃO

Esta ferramenta eléctrica DEWALT foi concebida para o servir

durante muito tempo com um mínimo de manutenção. Um

funcionamento satisfatório e longo depende de cuidados adequados

e de uma limpeza regular.

ATENÇÃO: Para reduzir o risco de lesões graves, desligue a

ferramenta e desligue a bateria antes de proceder a quaisquer

ajustes ou de remover/instalar instrumentos ou acessórios. Um

arranque acidental pode causar lesões.

Lubrificação

Esta ferramenta eléctrica não requer lubrificação adicional.

Limpeza

AVISO: Injecte ar seco para retirar a sujidade e o pó do

alojamento principal, sempre que notar uma acumulação de

sujidade nos respiradores ou em torno dos mesmos. Utilize uma

protecção adequada para os olhos e uma máscara para o pó

quando realizar esta operação.

AVISO: Nunca utilize solventes ou outros químicos agressivos

para limpar as partes não metálicas da ferramenta. Estes químicos

podem enfraquecer os materiais utilizados nestas partes. Utilize

um pano humedecido apenas com água e detergente suave.

Nunca permita que entre nenhum líquido na ferramenta; nunca

mergulhe qualquer parte da ferramenta em líquido.

Acessórios

AVISO: Uma vez que os acessórios que não sejam os

disponibilizados pela D

produto, a utilização de tais acessórios nesta ferramenta poderá

EWALT não foram testados com este

Português

27

Page 30

ser perigosa. Para reduzir o risco de lesão, deverão utilizar-se

apenas os acessórios recomendados pela D

produto.

Consulte o seu revendedor para mais informações acerca dos

acessórios adequados.

ESPECIFICAÇÕES

DW300-B2 DW300-BR

Volts 220 V ~ 127 V ~

Watts 500 W 500 W

Freqüência 60 Hz 60 Hz

GPM 0-3 200/min 0-3 200/min

EWALT com este

Português

28

Page 31

RESOLUÇÃO DE PROBLEMAS

Problema Causa possível Possível soluão

• O equipamento

não funciona.

• O cabo não foi ligado.

• O fusível está queimado.

• O disjuntor não foi desarmado. • Arme o disjuntor. (Se o fusível desarmar

• Cabo ou interruptor foi

danificado.

• Conecte a ferramenta em uma tomada

de parede.

• Substitua o fusível. (Se o fusível

queimar repetidamente, pare de usar o

equipamento imediatamente e envie-o

para reparo na assistência técnica ou

serviço autorizado D

repetidamente, pare de usar o

equipamento imediatamente e envie-o

para reparo na assistência técnica ou

serviço autorizado D

• Substitua o cabo ou interruptor na

assistência técnica ou serviço autorizado

DEWALT.

EWALT).

EWALT).