Page 1

ff you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contactenos.

iNSTRUCTiON MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA DE GARANTfA.

ADVERTENClA: LEASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Generator DG3000

Generator with Electric Start DG4400B, DG6300B, DG7000B

G_n_ratrice DG3000

G_n_ratrice avec d_marrage _lectrique DG4400B, DG6300B, DG7000B

Generador DG3000

Generador de encendid el_ctrico DG4400B, DG6300B, DG7000B

Page 2

Components

A. Wheel and handle kit (DG44OOB,

DG6300B and DGTOOOB)

B. DEWALT engine

C. Lifting hook (included in A)

(DG4400B, DG6300B and

DGTOOOB)

D. Control panel, see Fig. 2 for

individual model's control panel

E. Air filter

R 18V DEWALT battery pack F

and charger (DG4400B,

DG6300B and DGTOOOB)

G. Fuel cap

H. Fuel tank

I. Fuel gauge

J. Choke control

K. Fuel shut-off valve

L. Recoil pull starter

M. Oil fill/dipstick

N. Oil drain plug

O. Carbon canister (if equipped)

R Roll over valve (if equipped)

Control Panel Layouts

Q. Battery pack receptacle

(shown with battery pack)

R. Voltage selector switch

S. Engine switch

T. Main breaker

FIG. 2

T W

S U X T Q

FIG. 1

A

J

E

C

A

U. Receptacle thermal circuit breakers

V. GFCI duplex receptacles (120V)

W. Twistlock receptacles (120V)

X. Twistlock receptacles (120V/240V

Y. Battery lock

Z. Idle control switch

S

v iw

u

z

Product Specifications

Model

Alternator

Type

Excitation

Max ACOutput (Watts)

Rated AC Output(Watts)

Rated Current (A)

Phase

Frequency

Engine

Model

Horse Power(*Gross HP)

M

Displacement(CC)

FuelTank Capacity (gal)

Recommended Fuel

Oil Capacity See engine See engine

Recommended Oil See engine See engine instruction

Low Oil Shutdown Yes Yes

Starting system Recoil Recoil/Elec. Start

Receptacles

12ov 20 Amp GFCI Duplex Yes (1) Yes (2)

120V 20 A Twist-Locking (NEMA L5-20R) + Yes (1) Yes (1)

120V 30 A Twist-Locking (NEMA L5-30R) + No No

Q

T Q

X

120/240V 20 A Twist-Locking No Yes (1)

(NEMA L14-20R)+

120/240V 30 A Twist-Locking No No

(NEMA L14-30R)+

General

Dimensions • (in./cm) (L x W x H) (23.6 x 19.3 x 20.5/ (28.0 x 21.7 x 21.5/

Dry Weight" 118 Ibs. (53.5 kg) 234 Ibs. (106 kg)

i" Dimensions do not include wheel kit.

i* Gross horsepower (HP). This horsepower rating represents the maximum output under

laboratory conditions at 3600 RPM in accordance with SAE (Society of Automotive

Engineers) J1995 and should be used for comparison purposes only. Actual engine output

will be lower and will vary depending on the application, speed and other variables includ-

ing altitude and temperature.

i+ When using the 20A or 30A twist-locking receptacle, you must connect through a GFCI

protected spider box or use an in-line GFCI adapter.

DG3000 DG4400B

Brushless, 2-Pole Brushless, 2-Pole

Condenser Condenser

3000 4400

2920 4180

20 A 31.7/15.9 A

Single Single

60 60

DW168F-2F DW177F-F

"6.5 *9

196 270

3.3 (12,5 liters) 4.6 (17,4 liters)

See engine See engine

instruction manual instruction manual

instruction manual instruction manual

instruction manual manual

59,9 x 49,0 x 52,1 cm) 71,1 x 55,1 x 54,6 cm)

W U U

R

Y

Z

W U

Page 3

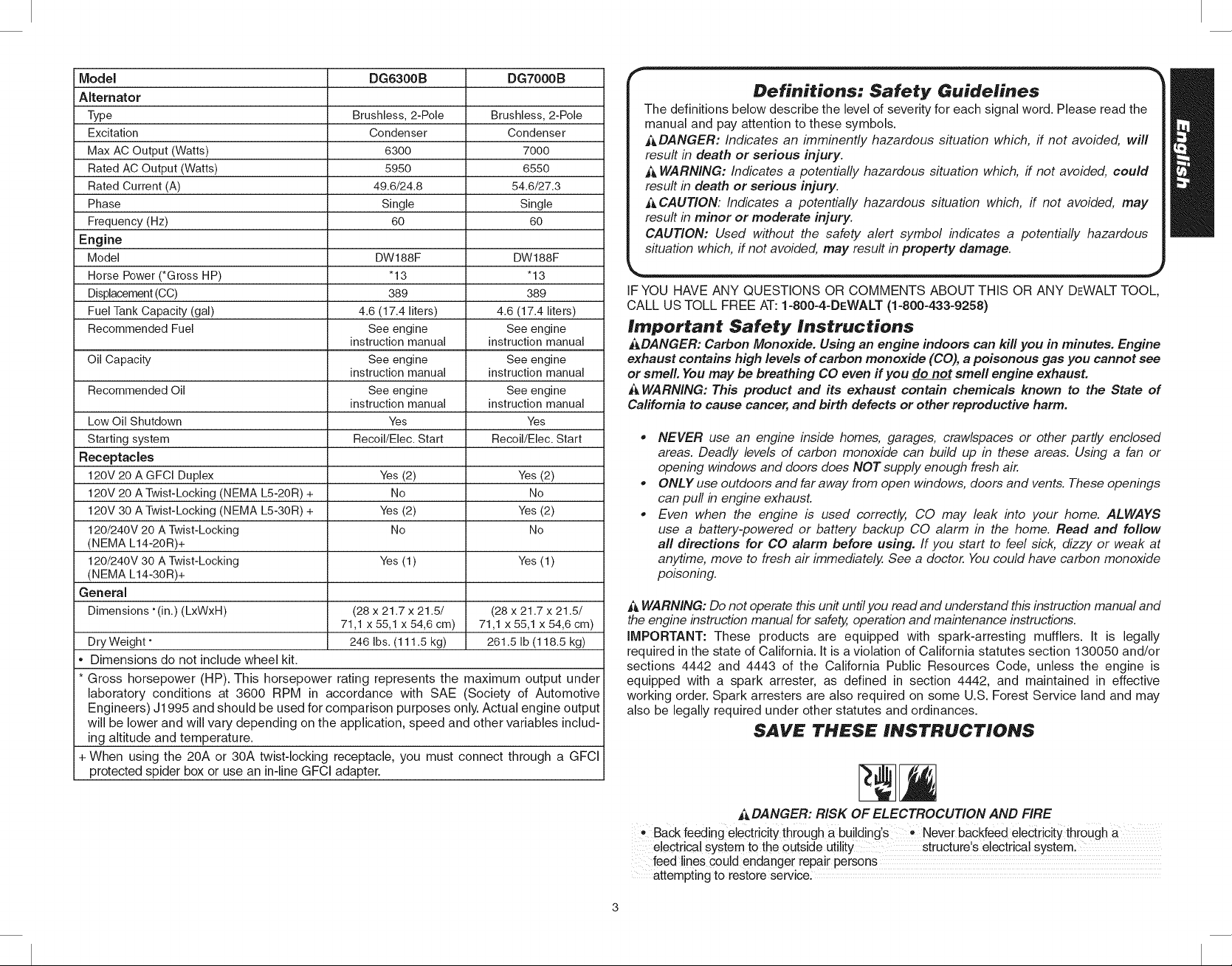

Model DG6300B DG7000 B

Alternator

Type Brushless, 2-Pole Brushless, 2-Pole

Excitation Condenser Condenser

Max AC Output (Watts) 6300 7000

Rated AC Output (Watts) 5950 6550

Rated Current (A) 49.6/24.8 54.6/27.3

Phase Single Single

Frequency (Hz) 60 60

Engine

Model DW188F DW188F

Horse Power (*Gross HP) "13 "13

Displacement (CC) 389 389

Fuel Tank Capacity (gal) 4.6 (17.4 liters) 4.6 (17.4 liters)

Recommended Fuel See engine See engine

instruction manual instruction manual

Oil Capacity See engine See engine

instruction manual instruction manual

Recommended Oil See engine See engine

instruction manual instruction manual

Low Oil Shutdown Yes Yes

Starting system Recoil/Elec. Start Recoil/Elec. Start

Receptacles

120V 20 A GFCI Duplex Yes (2) Yes (2)

120V 20 A Twist-Locking (NEMA L5-20R) + No No

120V 30 A Twist-Locking (NEMA LS-30R) + Yes (2) Yes (2)

120/240V 20 A Twist-Locking No No

(NEMA L14-20R)+

120/240V 30 A Twist-Locking Yes (1) Yes (1)

(NEMA L14-30R)+

General

Dimensions "(in.) (LxWxH) (28 x 21.7 x 21.5/ (28 x 21.7 x 21.5/

71,1 x 55,1 x 54,6 cm) 71,1 x 55,1 x 54,6 cm)

Dry Weight" 246 Ibs. (111.5 kg) 261.5 Ib (118.5 kg)

, Dimensions do not include wheel kit.

* Gross horsepower (HP). This horsepower rating represents the maximum output under

laboratory conditions at 3600 RPM in accordance with SAE (Society of Automotive

Engineers) J1995 and should be used for comparison purposes only. Actual engine output

will be lower and will vary depending on the application, speed and other variables includ-

ing altitude and temperature.

+ When using the 20A or 30A twist-locking receptacle, you must connect through a GFCI

protected spider box or use an in-line GFCI adapter.

Definitions: Safety Guidelines

|The definitions below describe the level of severity for each signal word. Please read the

|manual and pay attention to these symbols.

|ADANGER: Indicates an imminently hazardous situation which, if not avoided, will

|result in death or serious injury.

|_ WARNING: Indicates a potentially hazardous situation which, if not avoided, could

|result in death or serious injury.

| A CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

|result in minor or moderate injury.

|CAUTION: Used without the safety alert symbol indicates a potentially hazardous

_uation which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALTTOOL,

CALL US TOLL FREE AT: I=800=4=DEWALT (1=800=433-9258)

Irnportant Safety Instructions

t&DANGER: Carbon Monoxide. Using an engine indoors can kill you in minutes. Engine

exhaust contains high levels of carbon monoxide (CO), a poisonous gas you cannot see

or smell. You may be breathing CO even if you do not smell engine exhausL

i_ WARNING: This product and its exhaust contain chemicals known to the State of

California to cause cancer, and birth defects or other reproductive harm.

NEVER use an engine inside homes, garages, crawlspaces or other partly enclosed

areas. Deadly levels of carbon monoxide can build up in these areas. Using a fan or

opening windows and doors does NOT supply enough fresh air.

, ONLY use outdoors and far away from open windows, doors and vents. These openings

can pull in engine exhaust.

, Even when the engine is used correctly, CO may leak into your home. ALWAYS

use a battery-powered or battery backup CO alarm in the home. Read and follow

aft directions for CO alarm before using. If you start to feel sick, dizzy or weak at

anytime, move to fresh air immediately, See a doctor. Youcould have carbon monoxide

poisoning.

WARNING: Do not operate this unit until you read and understand thb instruction manual and

the engine instruction manual for safety, operation and maintenance instructions.

IMPORTANT: These products are equipped with spark-arresting mufflers. It is legally

required in the state of California. It is a violation of California statutes section 130050 and/or

sections 4442 and 4443 of the California Public Resources Code, unless the engine is

equipped with a spark arrester, as defined in section 4442, and maintained in effective

working order. Spark arresters are also required on some U.S. Forest Service land and may

also be legally required under other statutes and ordinances.

SAVE THESE INSTRUCTIONS

DANGER: RISK OF ELECTROCUTION AND FIRE

Back feeding electricity thi0ugh a building's * Never backfeed electricity through a

electrical system to the 0utside structure's electrical systeml

!jnes could endanger repa!r persons

attempting to restore service.

Page 4

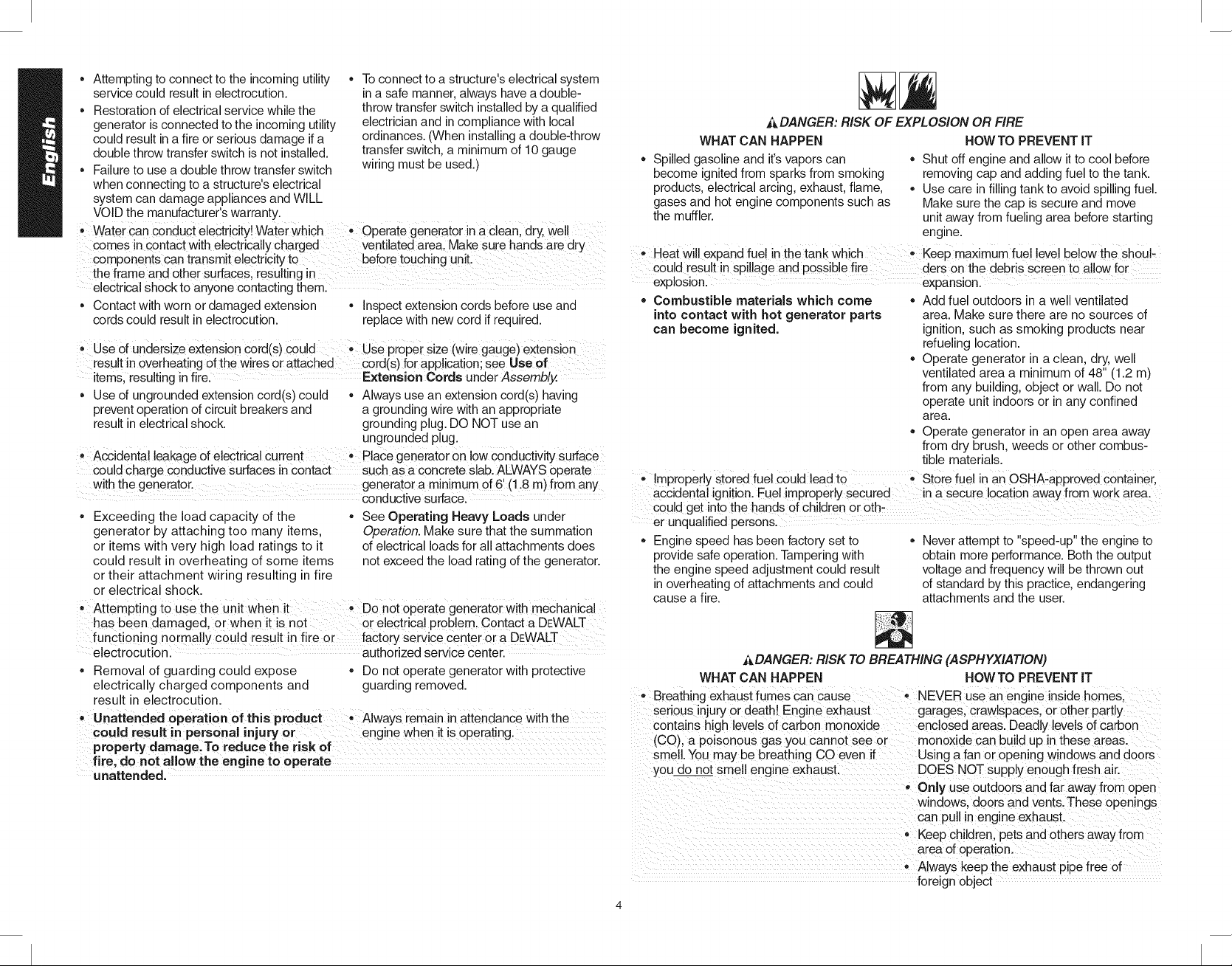

• Attempting to connect to the incoming utility

service could result in electrocution.

• Restoration of electrical service while the

generator is connected to the incoming utility

could result in a fire or serious damage ifa

double throw transfer switch is not installed.

• Failure to use a double throw transfer switch

when connecting to a structure's electrical

system can damage appliances and WILL

VOID the manufacturer's warranty.

" Water CanConductelectricity! Water Which ,Operate generator in a clean, dry, Well

comes in contact with electrically charged ventilated area. Make sure,hands are dry

components can transmit electricity to before touching unitl

the frame and other surfaces; resulting in

electrical shock to anyone contacting them.

• Contact with worn or damaged extension . Inspect extension cords before use and

cords could result in electrocution, replace with new cord if required.

useof undersize e_ension c0rd(s)Could ,, use proper Size (wiregauge) extension

result in Overheating Ofthe wires 0r attached cord(s) forapplication; see Useof

items, resulting in fire. Extension Cords under Assembly

• Use of ungrounded extension cord(s) could , Always use an extension cord(s) having

prevent operation of circuit breakers and a grounding wire with an appropriate

result in electrical shock, grounding plug. DO NOT use an

Accidenta! leakage 0f electrical Current Place generator Onlow Conductivity Surface

could charge conductive surfaces in contact such as a concrete slab. ALWAYS Operate

with the generat0 r generator a minimum of 6 (1.8 m) from any

• Exceeding the load capacity of the

generator by attaching too many items,

or items with very high load ratings to it

could result in overheating of some items

or their attachment wiring resulting in fire

or electrical shock.

o Attempting tOuse the Unit When it Do not operate generat0r with mechanical

has been damaged or when it is not or electrical problem, Contact a DEWALT

functioning normally c0uld iesu!t in fireor fact0ry Service Center oi a DEWALT

electrocution, authorized service center.

• Removal of guarding could expose ,, Do not operate generator with protective

electrically charged components and guarding removed.

result in electrocution.

'Unattended 0potation of this product. Always remain in attendance With the

could result in personal injury or engine when it is operating.

property damage_To reduce the risk of

fire, do not allow the engine to operate

unattended.

,, To connect to a structure's electrical system

in a safe manner, always have a double-

throw transfer switch installed by a qualified

electrician and incompliance with local

ordinances. (When installing a double-throw

transfer switch, a minimum of 10 gauge

wiring must be used.)

ungrounded plug.

conductive surface.

• See Operating Heavy Loads under

Operation. Make sure that the summation

of electrical loads for all attachments does

not exceed the load rating of the generator.

_DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOWTO PREVENT IT

Spilled gasoline and it's vapors can • Shut off engine and allow itto cool before

become ignited from sparks from smoking removing cap and adding fuel to the tank.

products, electrical arcing, exhaust, flame, • Use care in filling tank to avoid spilling fuel.

gases and hot engine components such as Make sure the cap is secure and move

the muffler, unit away from fueling area before starting

engine.

, Heat will expand fue! in the tank Which ,, Keep maximum fue! !eve!be!ow the Sh0ul-

could result in spillage and possible fire ders on the debris screen to al ow for

explosionl expansionl

• Combustible materials which come • Add fuel outdoors in a well ventilated

into contact with hot generator parts area. Make sure there are no sources of

can become ignited, ignition, such as smoking products near

refueling location.

• Operate generator in a clean, dry, well

ventilated area a minimum of 48" (1.2 m)

from any building, object or wall. Do not

operate unit indoors or inany confined

area.

,, Operate generator in an open area away

from dry brush, weeds or other combus-

tible materials.

,, improperlY stored fuel Could lead to ,, Store fuel in an OSHA-approved Container,

accidental ignition. Fuel improperly secured in a Secure location away from work area.

cou!d get into the hands ofchildren or oth-

er unqualified persons.

Engine speed has been factory set to • Never attempt to "speed-up" the engine to

provide safe operation. Tampering with obtain more performance. Both the output

the engine speed adjustment could result voltage and frequency will be thrown out

in overheating of attachments and could of standard by this practice, endangering

cause a fire. attachments and the user.

ADANGER: RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOWTO PREVENT iT

• Breathing exhaust fumes can cause • NEVER use an engine inside homes.

serious injury or death! Engine exhaust garages, crawlspaces, or other partly

contains high levels of carbon monoxide enclosed areas. Deadly levels of carbon

(CO), a poisonous gas you cannot see or monoxide can build up in these areas.

smell. You may be breathing CO even if Using a fan or opening windows and doors

you do not smell engine exhaust. DOES NOT supply enough fresh air.

- Only use outdoors and far away from open

windows, doors and vents. These openings

can pull inengine exhaust.

= Keepchildren, pets and others away from

area of operation.

- Always keep the exhaust pipe free of

foreign object

Page 5

ADANGER:RISK OF INJURY OR PROPERTY DAMAGE

WHEN TRANSPORTING OR STORING

WHATCAN HAPPEN

• Oil and fuel can leak or spill and could result

in fire or breathing hazard; serious injury

or death can result.Oil leaks will damage

carpet, paint or other surfaces in vehicles or

trailers.

AWARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOWTO PREVENT IT

Touching exposed metal (muffler and 0ther Never touch any exposed meta! paits

engine parts) can result in serious burns: on generator during orimmediately after

................................................ attempt maintenance until generator has

_'kWARNING: RISK FROM MOVING PARTS

WHAT CAN HAPPEN HOWTO PREVENT IT

• The engine can start accidentally ifthe • Always disconnect the spark plug before

flywheel is turned by hand or moved by performing maintenance.

pulling on the pull starter•

,, Moving paits Such as the pulley, flywheel Never operate the generator Withguards or

andbelt CanCause serious njury ifthey covers Which are damaged or removed:

COme nto contact wth you or your cloth ng , Kee ourhair, clothin and Iovesawa

• Attempting to operate generator with

damaged or missing parts or attempting to

repair generator with protective shrouds

removed can expose you to moving parts

and can result inserious injury.

• Never transport generator with fuel in

the fuel system, fuel valve open or while

generator is in operation.

• Always place generator on a protective

mat when transporting to protect against

damage to vehicle from leaks. Remove

generator from vehicle immediately upon

arrival at your destination. Always keep

generator level and never lie on its side.

• Transport fuel only inan OSHA approved

container.

* Do n0t reach around protective Shrouds 0r

• py g g Y

from moving Part& Loose clothes, jewe!ry

or !ong hair Can be caught in moving parts.

Air vents may Covermoving partSand

should be avoided as well.

• Any repairs required on this product should

be performed by a DEWALTfactory service

center or a DEWALT authorized service

center.

HOWTO PREVENT IT

0perati0n, The generatorwi!! remain hot

for several minutes after operation.

been allowed to cool.

A WARNING: RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOWTOPREVENTIT

- Unsafe operation of your generator could

lead to serious injury or death to you or

others.

• Any gasoline operated household • Always use a U.L listed voltage sensitive

generator can produce voltage variations surge protector to connect voltage

causing damage to voltage sensitive sensitive appliances (TV, computer, stereo.

appliances or could result in fire. etc.). Failure to use a U.L listed voltage

DG4400B, DG6300B and DGT000B

Raising or suspending generators ,, Always use proper connecting procedures

equipped with lifting hooks improperly could as described in this manual when

cause generator to fall causing serious connecting cables, chains or straps for

injury or death to you or others, raising or suspending generators equipped

• Improper raising or suspending of ,, Always use cables, chains or straps rated

generator can cause damage to the at 2000 Ibs working load or more to raise

generator, or suspend generator.

,, Generator wi!lnot operate proPerly while ,, Never oPerate generat0i while suspended

suspended and will cause damage to the or in an unlevel position. Always operate

generator and could cause serious injury generate on a flat, level surfacel

death to you or others.

• Review and understand all instructions and

warnings in this manual.

- Become familiar with the operation and

controls of the generator. Know how to

shut it off quickly.

• Keep ope rating area clear of all persons.

pets and obstacles.

- Keep children away from the generator at

all times.

,, Do not operate the generator when

fatigued or under the influence of alcohol

or drugs. Stay alert at all times.

• Never defeat the safety features of this

product.

,, Equip area of operation with a fire

extinguisher.

- Do not operate generator with missing,

broken or unauthorized parts.

,, Never stand on the generator.

surge protector will void the warranty

on your generator. NOTICE: A multiple

outlet strip is not a surge protector. Make

sure you use an U.L. listed voltage surge

protector

with lifting hook.

Page 6

WARNING: RISK FROM NOISE

WHAT CAN HAPPEN HOWTO PREVENT IT

• Under some conditions, applications and • Always wear certified safety equipment:

duration of use, noise from this product ANSI S12.6 (S3.19) hearing protection.

may contribute to hearing loss.

_ CAUTION: RISK FROM LIFTING

WHAT CAN HAPPEN HOWTO PREVENT iT

• Serious injury can resu!t from attempting tO • The generator is tOOheavy t0be lifted by

lift too heavy an object, one person. Obtain assistance fr0m 0thers

before you try to move it:

SAVE THESE INSTRUCTIONS

Important Safety Instructions for Battery Packs

DG4400B, DG6300B AND DGT000B

An 18V DEWALT battery pack is used to start these units using the electric start feature. When

ordering replacement battery packs be sure to include catalog number and voltage: Extended

Run Time battery packs deliver 25% more run-time than standard battery packs. Consult the

chart at the end of this manual for compatibility of chargers and battery packs.

NOTE: Your tool will accept either standard or Extended Run Time battery packs. However, be

sure to select proper voltage.

The battery pack is not fully charged out of the carton. Before using the battery pack and

charger, read the safety instructions below. Then follow charging procedures outlined.

READ A££ INSTRUCTIONS

* Do not incinerate the battery pack even if it is severely damaged or is completely

worn out. The battery pack can explode in a fire.

* A smafl leakage of liquid from the battery pack cells may occur under extreme usage

or temperature conditions. This does not indicate a failure. However, ff the outer seal is

broken and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water for a minimum of 10

minutes and seek immediate medical attention. (Medical note: The liquid is 25-35%

solution of potassium hydroxide.)

* Charge the battery packs only in DEWALT chargers.

* DO NOT splash or immerse in water or other liquids.

* Do not store or use the batterypack in locations where the temperature

may reach or exceed I05°F (such as outside sheds or metal buildings

in summer).

ADANGER: Electrocution hazard. Never attempt to open the battery pack for

any reason. If battery pack case is cracked or damaged, do not insert into

charger. Electric shock or electrocution may result. Damaged battery packs

should be returned to service center for recycling.

NOTE: Battery storage and carrying caps are provided for use whenever the battery is out

of the generator or charger. Remove cap before placing battery in charger or generator.

_, WARNING: Fire hazard. Do not store or carry battery so that metal objects can contact

exposed battery terminals. For example, do not place battery in aprons, pockets, tool boxes,

product kit boxes, drawers, etc., with loose nails, screws, keys, etc. without battery cap.

Transporting batteries can possibly cause fires if the battery terminals inadvertently

come in contact with conductive materials such as keys, coins, hand tools and the like.

The US Department of Transportation Hazardous Material Regulations (HMR) actually pro-

hibit transporting batteries in commerce or on airplanes (i.e., packed in suitcases and carry-on

luggage) UNLESS they are properly protected from short circuits. So when transporting indi-

vidual batteries, make sure that the battery terminals are protected and weft insulated from

materials that could contact them and cause a short circuit.

The RBRC TM Seal

The RBRC TM (Rechargeable Battery Recycling Corporation) Seal on the nickel

cadmium and nickel metal hydride batteries (or battery packs) indicate that the

costs to recycle these batteries (or battery packs) at the end of their useful life

have already been paid by DEWALT. In some areas, it is illegal to place spent

nickel cadmium and nickel metal hydride batteries in the trash or municipal solid

waste stream and the RBRC program provides an environmentally conscious

alternative.

RBRC TM in cooperation with DEWALT and other battery users, has established programs in the

United States and Canada to facilitate the collection of spent nickel cadmium and nickel metal

hydride batteries. Help protect our environment and conserve natural resources by returning

the spent nickel cadmium and nickel metal hydride batteries to an authorized DEWALT service

center or to your local retailer for recycling. You may also contact your local recycling center

for information on where to drop off the spent battery.

RBRCTM isa registeredtrademark of the RechargeableBatteryRecyclingCorporation.

Irnportant Safety Instructions for Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important safety instructions for battery

chargers.

* Before using charger, read aft instructions and cautionary markings on charger, battery

pack, and product using battery pack.

ADANGER: Electrocution hazard. 120 volts are present at charging terminals. Do not probe

with conductive objects.

_, WARNING: Shock hazard. Do not allow any fiquid to get inside charger.

_CAUTION: Burn hazard. To reduce the risk of injury, charge only DEWALT nickel cadmium

rechargeable batteries. Other types of batteries may burst causing personal injury and dam-

age.

_,CAUTION: Under certain conditions, with the charger plugged in to the power supply, the

exposed charging contacts inside the charger can be shorted by foreign material Foreign mate-

rials of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup

of metallic particles should be kept away from charger cavities. Always unplug the charger from

the power supply when there b no battery pack in the cavity. Unplug charger before attempting

to clean.

* DO NOTattempt to charge the battery pack with any chargers other than the ones in

this manual. The charger and battery pack are specifically designed to work together.

* These chargers are not intended for any uses other than charging DEWALT recharge-

able batteries. Any other uses may result in risk of fire, electric shock or electrocution.

* Do not allow charger to get wet.

* DO NOT ABUSE CORD. Never carry charger by cord or yank to disconnect from

receptacle. Puff by plug rather than cord when disconnecting charger. This will reduce risk

of damage to electric plug and cord. Have damaged or worn power cord and strain relief

replaced immediately,

* Make sure that cord is located so that it will not be stepped on, tripped over, or oth-

erwise subjected to damage or stress.

Page 7

• Do not use an extension cord unless it is absolutely necessary. Use of improper

extension cord could result in risk of fire, electric shock, or electrocution.

• An extension cord must have adequate wire size (AWG orAmerican Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable,

that is 16 gauge has more capacity than 18 gauge. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size. If an extension cord is to be used outdoors it must be marked with the suffix

W-A or W following the cord type designation. For example - SJTW-A to indicate it is

acceptable for outdoor use.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

• Do not place any object on top of charger or place the charger on a soft surface

that might block the ventilation slots and result in excessive internal heat. Place the

charger in a position away from any heat source. The charger is ventilated through slots in

the top and the bottom of the housing.

• Do not operate charger with damaged cord or plug -- have them replaced immedi-

ately.

• Do not operate charger if it has received a sharp blow, been dropped, or otherwise

damaged in any way. Take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service center when service or

repair is required. Incorrect reassembly may result in a risk of electric shock, electrocu-

tion or fire.

• Disconnect the charger from the outlet before attempting any cleaning. This will

reduce the risk of electric shock. Removing the battery pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household electrical power (120

Volts). Do not attempt to use it on any other voltage. This does not apply to the

vehicular charger.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Charging Procedure

DG4400B, DG6300B AND DGT000B

A DANGER: Electrocution hazard. 120 volts are present at charging terminals. Do not probe

withconductive objects.

1. Plug the charger into an appropriate outlet before inserting battery

pack.

2. Remove the caps from the battery pack and insert battery pack

into the charger. The red (charging) light will blink continuously

indicating that the charging process has started.

3. The completion of charge will be indicated by the red light

remaining ON continuously. The pack is fully charged and may

be used at this time or left in the charger.

Using Automatic Tune-Up TM Mode

DG4400B, DG6300B AND DGT000B

The automaticTune-Up TM Mode equalizes or balances the individual cells in the battery pack

allowing it to function at peak capacity. Battery packs should be tuned up weekly or after

10 charge/discharge cycles or whenever the pack no longer delivers the same amount of

work. To use the Automatic Tune-Up TM, place the battery pack in the charger and leave it

for at least 8 hours.

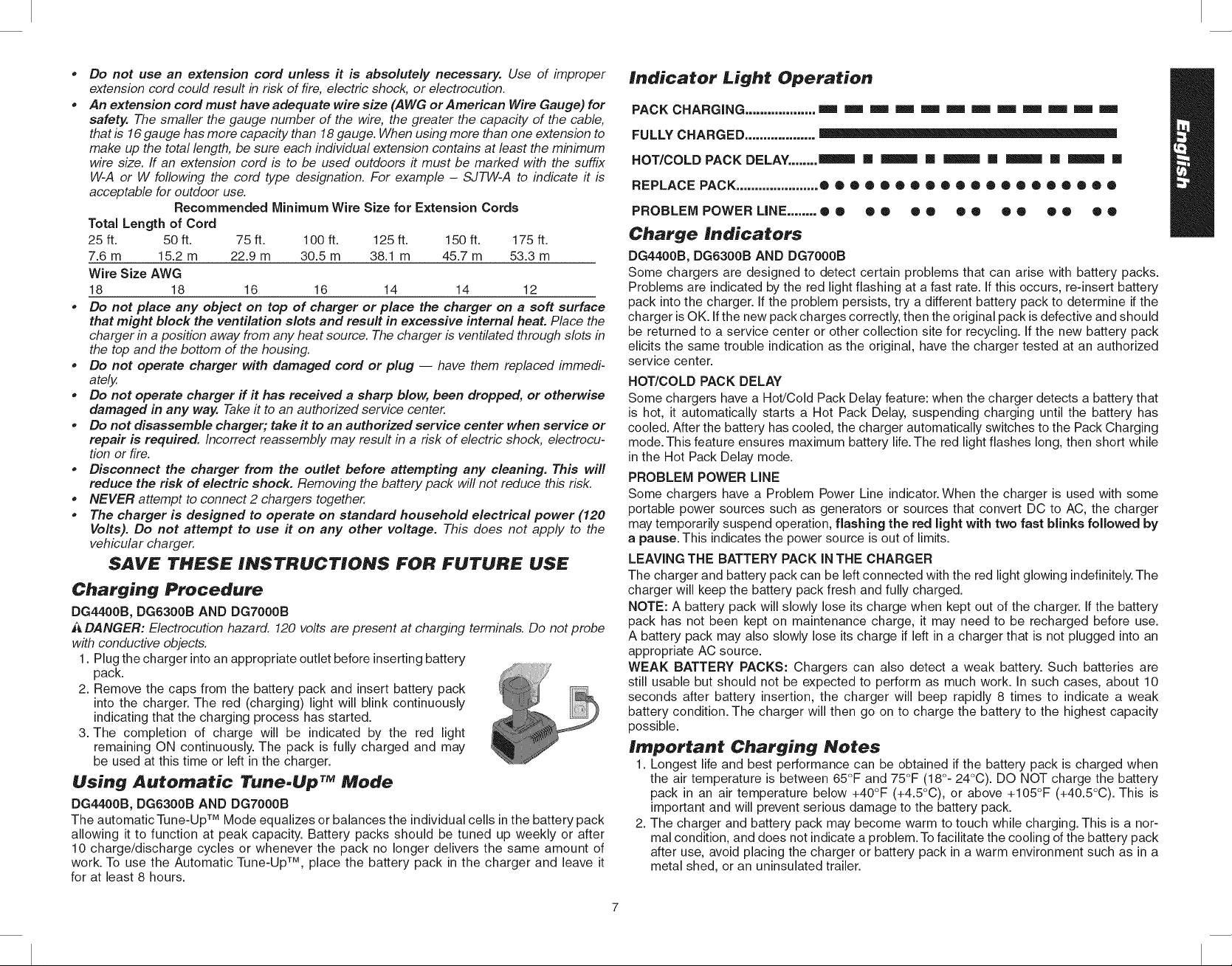

Indicator Light Operation

PACK CHARGING ................... === === === === === === =m =m =m =m =m ===

FULLY CHARGED ...................

HOT/COLD PACK DELAY........ _ [] _ [] _ [] _ [] _ []

REPLACE PACK ...................... ®e®®®o®o®®o®®o®®®e®®

PROBLEM POWER LiNE ........ ® ® ® • ® ® ® ® O ® O ® ® ®

Charge Indicators

DG4400B, DG6300B AND DG7000B

Some chargers are designed to detect certain problems that can arise with battery packs.

Problems are indicated by the red light flashing at a fast rate. if this occurs, re-insert battery

pack into the charger, if the problem persists, try a different battery pack to determine if the

charger is OK. if the new pack charges correctly, then the original pack is defective and should

be returned to a service center or other collection site for recycling, if the new battery pack

elicits the same trouble indication as the original, have the charger tested at an authorized

service center.

HOT/COLD PACK DELAY

Some chargers have a Hot/Cold Pack Delay feature: when the charger detects a battery that

is hot, it automatically starts a Hot Pack Delay, suspending charging until the battery has

cooled. After the battery has cooled, the charger automatically switches to the Pack Charging

mode. This feature ensures maximum battery life.The red light flashes long, then short while

in the Hot Pack Delay mode.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When the charger is used with some

portable power sources such as generators or sources that convert DC to AC, the charger

may temporarily suspend operation, flashing the red light with two fast blinks followed by

a pause. This indicates the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light glowing indefinitely. The

charger will keep the battery pack fresh and fully charged.

NOTE: A battery pack will slowly lose its charge when kept out of the charger, if the battery

pack has not been kept on maintenance charge, it may need to be recharged before use.

A battery pack may also slowly lose its charge if left in a charger that is not plugged into an

appropriate AC source.

WEAK BATTERY PACKS: Chargers can also detect a weak battery. Such batteries are

still usable but should not be expected to perform as much work. In such cases, about 10

seconds after battery insertion, the charger will beep rapidly 8 times to indicate a weak

battery condition. The charger will then go on to charge the battery to the highest capacity

possible.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery pack is charged when

the air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the battery

pack in an air temperature below +40°F (+4.5°C), or above +105°F (+40.5°C). This is

important and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while charging. This is a nor-

mal condition, and does not indicate a problem. To facilitate the cooling of the battery pack

after use, avoid placing the charger or battery pack in a warm environment such as in a

metal shed, or an uninsulated trailer.

Page 8

3.Ifthebatterypackdoesnotchargeproperly:

a.Checkcurrentatreceptaclebyplugginginalamporotherappliance

b.Checktoseeifreceptacleisconnectedtoa lightswitchwhichturnspoweroffwhen

youturnoutthelights.

c.Movechargerandbatterypacktoalocationwherethesurroundingairtemperatureis

approximately65°F-75°F(18°-24°C).

d.Ifchargingproblemspersist,takethetool,batterypackandchargertoyourlocal

servicecenter.

4.Thebatterypackshouldberechargedwhenitfailstoproducesufficientpoweronjobs

whichwereeasilydonepreviously.DONOTCONTINUEtouseundertheseconditions.

Followthechargingprocedure.Youmayalsochargeapartiallyusedpackwheneveryou

desirewithnoadverseaffectonthebatterypack.

5.Undercertainconditions,withthechargerpluggedintothepowersupply,theexposed

chargingcontactsinsidethechargercanbeshortedbyforeignmaterial.Foreignmaterials

ofaconductivenaturesuchas,butnotlimitedto,steelwool,aluminumfoil,oranybuildup

ofmetallicparticlesshouldbekeptawayfromchargercavities.Alwaysunplugthecharger

fromthepowersupplywhenthereisnobatterypackinthecavity.Unplugchargerbefore

attemptingtoclean.

6.Donotfreezeorimmersechargerinwateroranyotherliquid.

i_,WARNING: Shock hazard. Do not allow any liquid to get inside charger.

A CAUTION: Never attempt to open the battery pack for any reason, ff the plastic housing of

the battery pack breaks or cracks, return to a service center for recycling.

Charging Portable Power Tool Batteries

_ WARNING: Condenser type chargers should not be used with portable generators. Irregular

generator power could cause a condenser type charger to fail. DEWALT has produced con-

denser type chargers in the past. (DW9104 and DW9106). ff you have any questions regard-

ing the use of a DEWALT Charger with a generator, please call 1-800-4-DEWALT.

NOTE: Other battery charger manufacturers have and still produce condenser type chargers.

Please contact manufacturer to see if it is safe to use chargers with portable generators.

ASSEMBLY

Grounding the Generator

Agrounding lug (VV)is supplied withthe generator for use when

required by local electrical ordinances. Refer to article 250 of

the National Electrical Code to clarify any needed grounding

information. Your local electric company or a certified electri-

cian should be able to help you with this information.

NOTE: Your engine is already grounded to the frame by a

grounding strap.

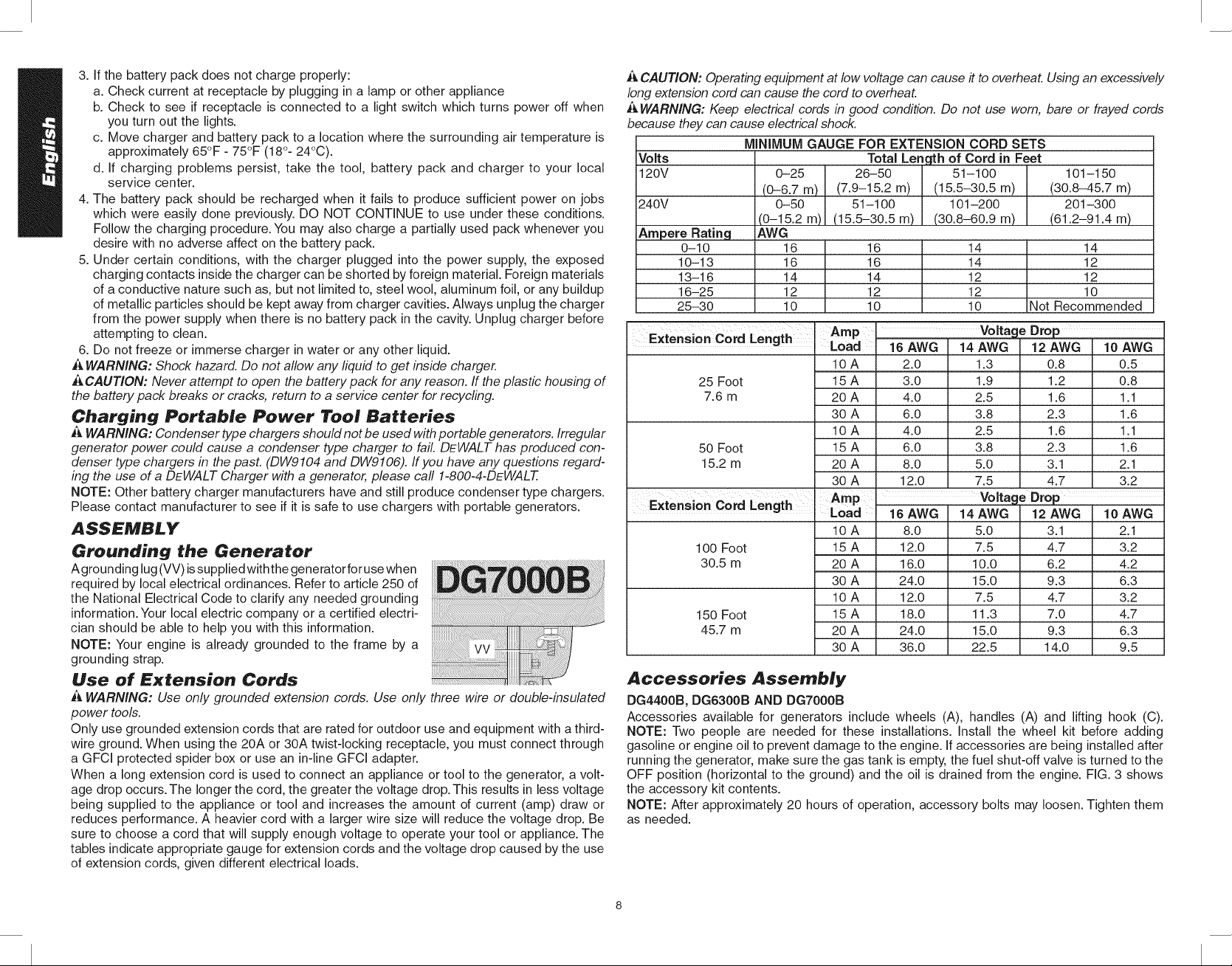

Use of Extension Cords

_, WARNING: Use only grounded extension cords. Use only three wire or double-insulated

power tools.

Only use grounded extension cords that are rated for outdoor use and equipment with a third-

wire ground. When using the 20A or 30A twist-locking receptacle, you must connect through

a GFCI protected spider box or use an in-line GFCI adapter.

When a long extension cord is used to connect an appliance or tool to the generator, a volt-

age drop occurs. The longer the cord, the greater the voltage drop. This results in less voltage

being supplied to the appliance or tool and increases the amount of current (amp) draw or

reduces performance. A heavier cord with a larger wire size will reduce the voltage drop. Be

sure to choose a cord that will supply enough voltage to operate your tool or appliance. The

tables indicate appropriate gauge for extension cords and the voltage drop caused by the use

of extension cords, given different electrical loads.

_J,CAUTION: Operating equipment at low voltage can cause # to overheat. Using an excessively

long extension cord can cause the cord to overheat.

WARNING: Keep electrical cords in good condition. Do not use worn, bare or frayed cords

because they can cause electrical shock.

MINIMUM GAUGE FOR EXTENSION CORD SETS

Volts

120V

240V

Ampere Rating

0-10

10-13

13-16

16-25

25-30

Extension Cord Length I LAo_p ' Voltage Drop

25 Foot 15 A 3.0

7.6 m 20 A 4.0

50 Foot 15 A 6.0

15.2 m 20 A 8.0

Extension Cord Length Amp Voltage Drop

100 Foot 15 A 12.0

30.5 m 20 A 16.0

150 Foot 15 A 18.0

45.7 m 20 A 24.0

0-25

(0-6.7 m)

0-50

(0-15.2 m)

AWG

16

16

14

12

10

Total Length of Cord in Feet

26-50 51-100 101-150

(7.9-15.2 m) (15.5-30.5 m) (30.8-45.7 m)

51-100 101-200 201-300

(15.5-30.5 m) (30.8-60.9 m) (61.2-91.4 m)

16 14

16 14

14 12

12 12

10 10

Not Recommended

14

12

12

10

16AWG14AWG 2AWG 0AWG

10A 2.0

30 A 6.0

10 A 4.0

30 A 12.0

Load 16 AWG 14 AWG 12 AWG 10 AWG

10 A 8.0

30 A 24.0

10 A 12.0

30 A 36.0

1.3

1.9

2.5

3.8

2.5

3.8

5.0

7.5

5.0

7.5

10.0

15.0

7.5

11.3

15.0

22.5

0.8

1.2

1.6

2.3

1.6

2.3

3.1

4.7

3.1

4.7

6.2

9.3

4.7

7.0

9.3

14.0

0.5

0.8

1.1

1.6

1.1

1.6

2.1

3.2

2.1

3.2

4.2

6.3

3.2

4.7

6.3

9.5

Accessories Assembly

DG4400B, DG6300B AND DGT000B

Accessories available for generators include wheels (A), handles (A) and lifting hook (C).

NOTE: Two people are needed for these installations. Install the wheel kit before adding

gasoline or engine oil to prevent damage to the engine. If accessories are being installed after

running the generator, make sure the gas tank is empty, the fuel shut-off valve is turned to the

OFF position (horizontal to the ground) and the oil is drained from the engine. FIG. 3 shows

the accessory kit contents.

NOTE: After approximately 20 hours of operation, accessory bolts may loosen. Tighten them

as needed.

Page 9

LL

JJ

cc

_ KK

GG

FF

AA

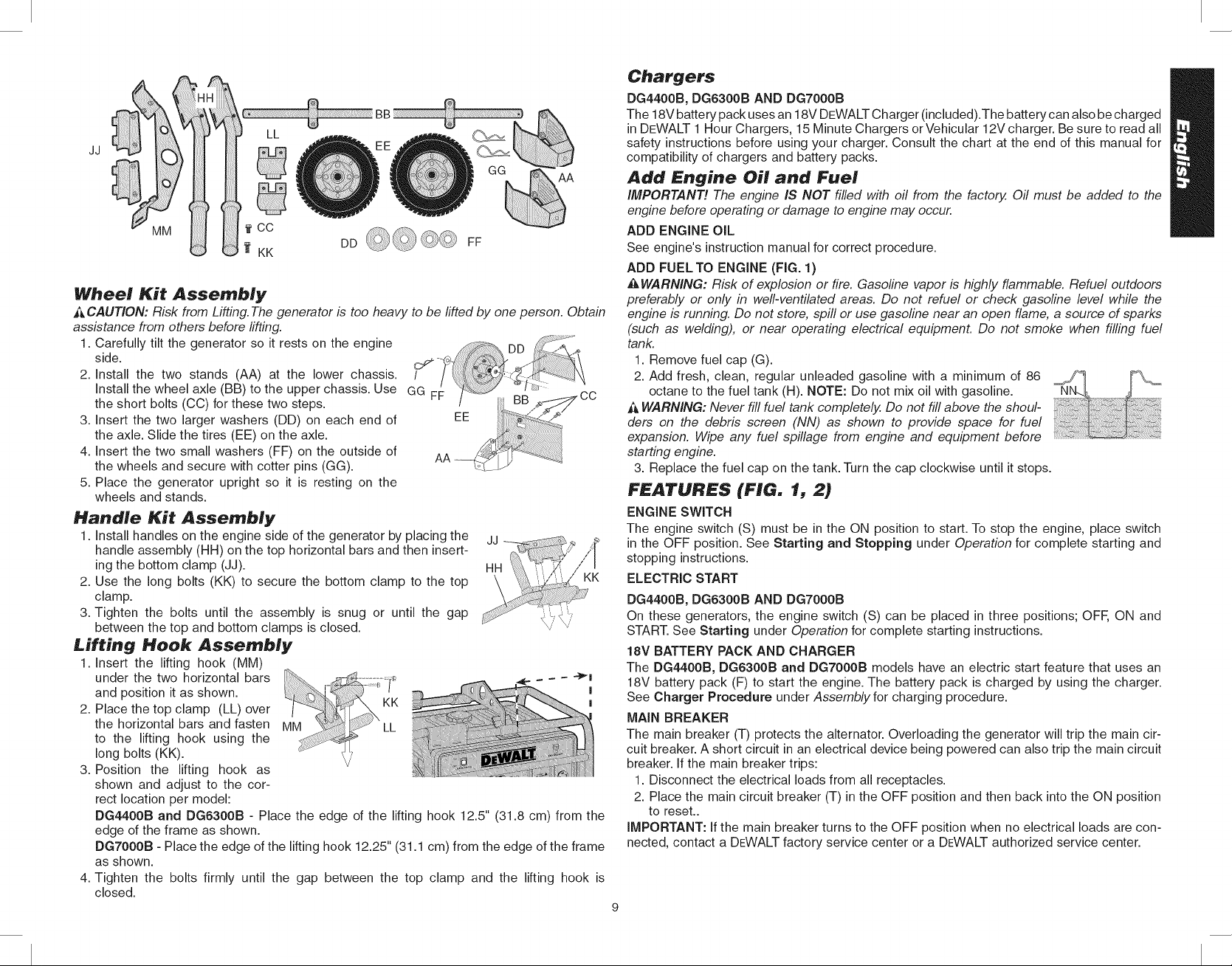

Wheel Kit Assembly

_ CAUTION: Risk from Lifting.The generator is too heavy to be lifted by one person. Obtain

assistance from others before lifting.

1. Carefully tilt the generator so it rests on the engine DD

side. )_ _I_

2. Install the two stands (AA) at the lower chassis. / :_'. --

Install the wheel axle (BB) to the upper chassis. Use GG FF / LI::: ....,-,,-,

the short bolts (CC) for these two steps. / BB._ ....

3. Insert the two larger washers (DD) on each end of EE _<_

the axle. Slide the tires (EE) on the axle.

4. Insert the two small washers (FF)on the outside of

the wheels and secure with cotter pins (GG). AA _ _

5. Place the generator upright so it is resting on the

wheels and stands.

Handle Kit Assembly

1. Install handles on the engine side of the generator by placing the

handle assembly (HH) on the top horizontal bars and then insert-

ing the bottom clamp (JJ).

2. Use the long bolts (KK) to secure the bottom clamp to the top

clamp.

3. Tighten the bolts until the assembly is snug or until the gap

between the top and bottom clamps is closed.

£iff:ing Hook Assembly

1. Insert the lifting hook (MM)

under the two horizontal bars "_

and position it as shown. I

2. Place the top clamp (LL) over I

the horizontal bars and fasten

to the lifting hook using the

long bolts (KK).

3. Position the lifting hook as

shown and adjust to the cor-

rect location per model:

DG4400B and DG6300B - Place the edge of the lifting hook 12.5" (31.8 cm) from the

edge of the frame as shown.

DG7000B - Place the edge of the lifting hook 12.25" (31.1 cm) from the edge of the frame

as shown.

4. Tighten the bolts firmly until the gap between the top clamp and the lifting hook is

closed.

Chargers

DG4400B, DG6300B AND DG7000B

The 18V battery pack uses an 18V DEWALT Charger (included).The battery can also be charged

in DEWALT 1 Hour Chargers, 15 Minute Chargers or Vehicular 12V charger. Be sure to read all

safety instructions before using your charger. Consult the chart at the end of this manual for

compatibility of chargers and battery packs.

Add Engine Oil and Fuel

IMPORTANT! The engine IS NOT filled with oil from the factory. Oil must be added to the

engine before operating or damage to engine may occur.

ADD ENGINE OIL

See engine's instruction manual for correct procedure.

ADD FUELTO ENGINE (FIG. 1)

,&WARNING: Risk of explosion or fire. Gasoline vapor is highly flammable. Refuel outdoors

preferably or only in well-ventilated areas. Do not refuel or check gasoline level while the

engine is running. Do not store, spill or use gasoline near an open flame, a source of sparks

(such as welding), or near operating electrical equipment. Do not smoke when filling fuel

tank.

1. Remove fuel cap (G).

2. Add fresh, clean, regular unleaded gasoline with a minimum of 86

octane to the fuel tank (H). NOTE: Do not mix oil with gasoline.

WARNING: Never fill fuel tank completely. Do not fill above the shoul-

ders on the debris screen (NN) as shown to provide space for fuel

expansion. Wipe any fuel spillage from engine and equipment before

starting engine.

3. Replace the fuel cap on the tank. Turn the cap clockwise until it stops.

FEATURES (FIG. 1{, 2)

ENGINE SWITCH

The engine switch (S) must be in the ON position to start. To stop the engine, place switch

in the OFF position. See Starting and Stopping under Operation for complete starting and

stopping instructions.

ELECTRIC START

DG4400B, DG6300B AND DG7000B

On these generators, the engine switch (S) can be placed in three positions; OFF, ON and

START. See Starting under Operation for complete starting instructions.

18V BATTERY PACK AND CHARGER

The DG4400B, DG6300B and DG7000B models have an electric start feature that uses an

18V battery pack (F) to start the engine. The battery pack is charged by using the charger.

See Charger Procedure under Assembly for charging procedure.

MAIN BREAKER

The main breaker (T) protects the alternator. Overloading the generator will trip the main cir-

cuit breaker. A short circuit in an electrical device being powered can also trip the main circuit

breaker. If the main breaker trips:

1. Disconnect the electrical loads from all receptacles.

2. Place the main circuit breaker (T) in the OFF position and then back into the ON position

to reset..

iMPORTANT: Ifthe main breaker turns to the OFF position when no electrical loads are con-

nected, contact a DEWALT factory service center or a DEWALT authorized service center.

Page 10

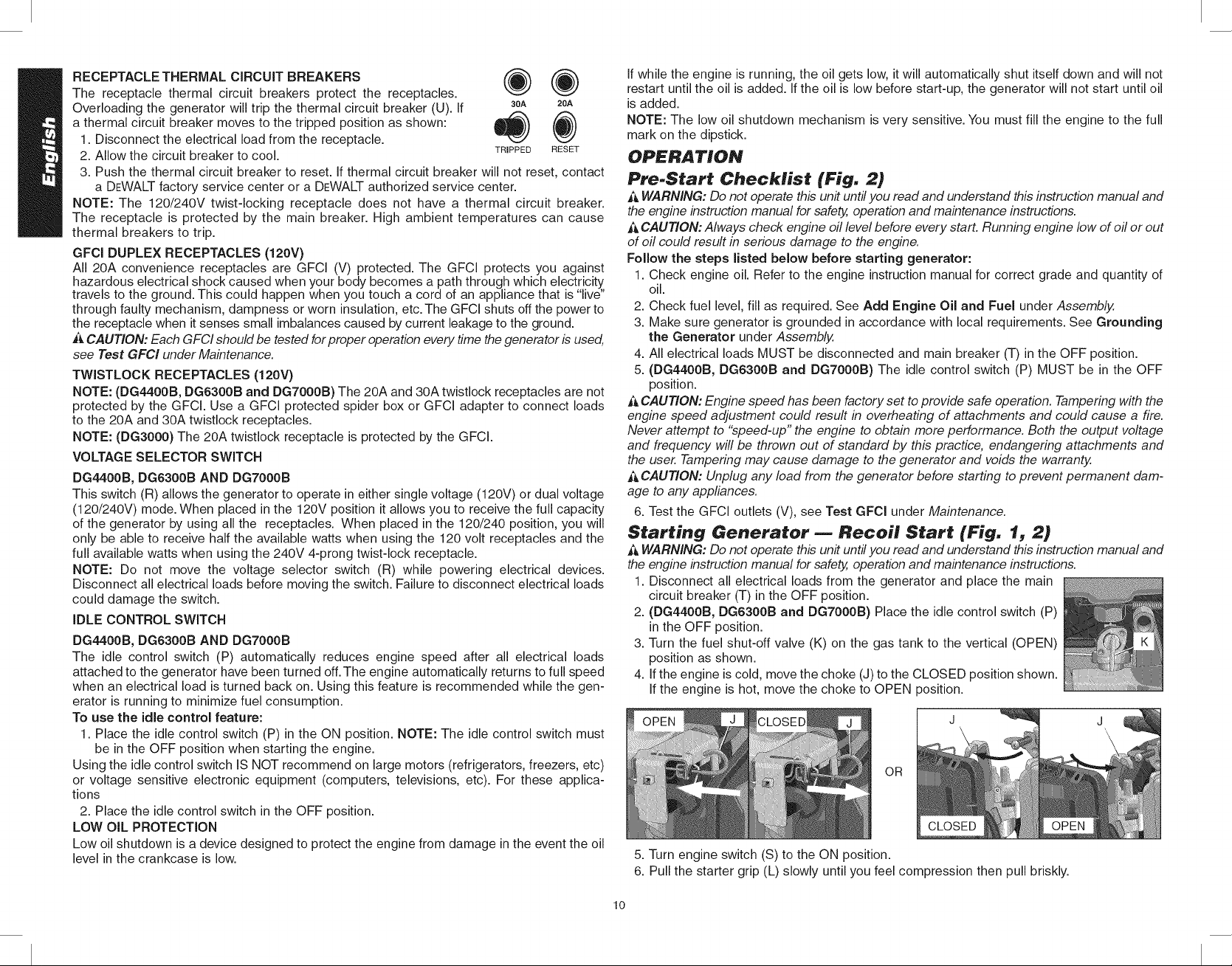

RECEPTACLE THERMAL CIRCUIT BREAKERS @ @

The receptacle thermal circuit breakers protect the receptacles.

Overloading the generator will trip the thermal circuit breaker (U). If 1_,,3°A 2oA

a thermal circuit breaker moves to the tripped position as shown: _ (i'_)'J

1. Disconnect the electrical load from the receptacle.

2. Allow the circuit breaker to cool. TRIPPED RESET

3. Push the thermal circuit breaker to reset. If thermal circuit breaker will not reset, contact

a DEWALT factory service center or a DEWALT authorized service center.

NOTE: The 120/240V twist-locking receptacle does not have a thermal circuit breaker.

The receptacle is protected by the main breaker. High ambient temperatures can cause

thermal breakers to trip.

GFCl DUPLEX RECEPTACLES (120V)

All 20A convenience receptacles are GFCI (V) protected. The GFCI protects you against

hazardous electrical shock caused when your body becomes a path through which electricity

travels to the ground. This could happen when you touch a cord of an appliance that is "live"

through faulty mechanism, dampness or worn insulation, etc. The GFCI shuts off the power to

the receptacle when it senses small imbalances caused by current leakage to the ground.

t&CAUTION: Each GFCI should be tested for proper operation every time the generator is used,

see Test GFCI under Maintenance.

TWISTLOCK RECEPTACLES (120V)

NOTE: (DG4400B, DG6300B and DG7000B) The 20A and 30A twistlock receptacles are not

protected by the GFCI. Use a GFCI protected spider box or GFCI adapter to connect loads

to the 20A and 30A twistlock receptacles.

NOTE: (DG3000) The 20A twistlock receptacle is protected by the GFCI.

VOLTAGE SELECTOR SWITCH

DG4400B, DG6300B AND DG7000B

This switch (R) allows the generator to operate in either single voltage (120V) or dual voltage

(120/240V) mode. When placed in the 120V position it allows you to receive the full capacity

of the generator by using all the receptacles. When placed in the 120/240 position, you will

only be able to receive half the available watts when using the 120 volt receptacles and the

full available watts when using the 240V 4-prong twist-lock receptacle.

NOTE: Do not move the voltage selector switch (R) while powering electrical devices.

Disconnect all electrical loads before moving the switch. Failure to disconnect electrical loads

could damage the switch.

IDLE CONTROL SWITCH

DG4400B, DG6300B AND DG7000B

The idle control switch (P) automatically reduces engine speed after all electrical loads

attached to the generator have been turned off. The engine automatically returns to full speed

when an electrical load is turned back on. Using this feature is recommended while the gen-

erator is running to minimize fuel consumption.

To use the idle control feature:

1. Place the idle control switch (P) in the ON position. NOTE: The idle control switch must

be in the OFF position when starting the engine.

Using the idle control switch IS NOT recommend on large motors (refrigerators, freezers, etc)

or voltage sensitive electronic equipment (computers, televisions, etc). For these applica-

tions

2. Place the idle control switch in the OFF position.

LOW OIL PROTECTION

Low oil shutdown is a device designed to protect the engine from damage in the event the oil

level in the crankcase is low.

If while the engine is running, the oil gets low, it will automatically shut itself down and will not

restart until the oil is added. If the oil is low before start-up, the generator will not start until oil

is added.

NOTE: The low oil shutdown mechanism is very sensitive. You must fill the engine to the full

mark on the dipstick.

OPERATION

PreoStart Checklist (Fig. 2)

_, WARNING: Do not operate this unit until you read and understand this instruction manual and

the engine instruction manual for safe_ operation and maintenance instructions.

A CAUTION: Always check engine oil level before every start. Running engine low of oil or out

of oil could result in serious damage to the engine.

Follow the steps listed below before starting generator:

1. Check engine oil. Refer to the engine instruction manual for correct grade and quantity of

oil.

2. Check fuel level, fill as required. See Add Engine Oil and Fuel under Assembly.

3. Make sure generator is grounded in accordance with local requirements. See Grounding

the Generator under Assembly.

4. All electrical loads MUST be disconnected and main breaker (T) in the OFF position.

5. (DG4400B, DG6300B and DG7000B) The idle control switch (P) MUST be in the OFF

position.

CAUTION: Engine speed has been factory set to provide safe operation. Tampering with the

engine speed adjustment could result in overheating of attachments and could cause a fire.

Never attempt to "speed-up" the engine to obtain more performance. Both the output voltage

and frequency will be thrown out of standard by this practice, endangering attachments and

the user. Tampering may cause damage to the generator and voids the warranty.

ik CAUTION: Unplug any load from the generator before starting to prevent permanent dam-

age to any appliances.

6. Test the GFCI outlets (V), see Test GFCl under Maintenance.

Starting Generator _ Recoil Start (Fig. 1, 2)

WARNING: Do not operate this unit until you read and understand this instruction manual and

the engine instruction manual for safety, operation and maintenance instructions.

1. Disconnect all electrical loads from the generator and place the main

circuit breaker (T) in the OFF position.

2. (DG4400B, DG6300B and DG7000B) Place the idle control switch (P)

in the OFF position.

3. Turn the fuel shut-off valve (K) on the gas tank to the vertical (OPEN)

position as shown.

4. If the engine is cold, move the choke (J) to the CLOSED position shown.

If the engine is hot, move the choke to OPEN position.

OR

5. Turn engine switch (S) to the ON position.

6. Pull the starter grip (L) slowly until you feel compression then pull briskly.

lO

Page 11

NOTE: Do not allow the starter grip to snap back. Return it slowly by hand.

NOTE: If the oil level in the engine is low, the engine will not start. Ifthe engine does not start,

check the oil level and add oil as needed.

NOTE: To ensure maximum oil lubrication, place the generator on a level surface.

7. As the engine warms up, move the choke to the OPEN position.

8. Allow the engine to warm up for five minutes. Then place the main breaker (T) in the ON

position. Connect electrical loads, see Connecting Electrical Loads under Operation.

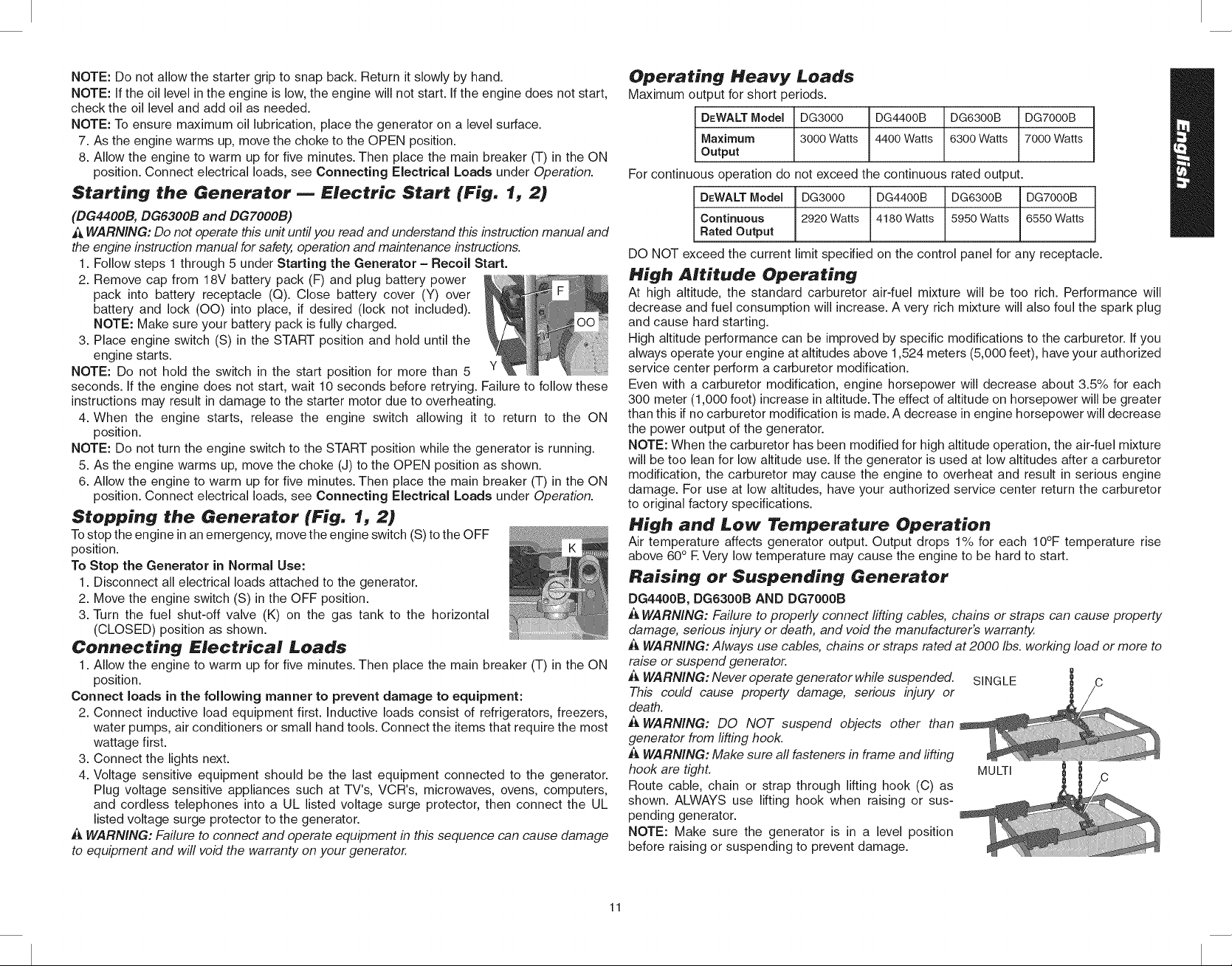

Starting the Generator _ Electric Start (Fig. 1, 2)

(DG4400B, DG6300B and DGTOOOB)

WARNING: Do not operate this unit until you read and understand this instruction manual and

the engine instruction manual for safety, operation and maintenance instructions.

1. Follow steps 1 through 5 under Starting the Generator - Recoil Start.

2. Remove cap from 18V battery pack (F) and plug battery power

pack into battery receptacle (Q). Close battery cover (Y) over

battery and lock (OO) into place, if desired (lock not included).

NOTE: Make sure your battery pack is fully charged.

3. Place engine switch (S) in the START position and hold until the

engine starts.

NOTE: Do not hold the switch in the start position for more than 5 Y

seconds. If the engine does not start, wait 10 seconds before retrying. Failure to follow these

instructions may result in damage to the starter motor due to overheating.

4. When the engine starts, release the engine switch allowing it to return to the ON

position.

NOTE: Do not turn the engine switch to the START position while the generator is running.

5. As the engine warms up, move the choke (J) to the OPEN position as shown.

6. Allow the engine to warm up for five minutes. Then place the main breaker (T) in the ON

position. Connect electrical loads, see Connecting Electrical Loads under Operation.

Stopping the Generator (Fig. 1, 2)

Tostop the engine inan emergency, move the engine switch (S) to the OFF

position.

To Stop the Generator in Normal Use:

1. Disconnect all electrical loads attached to the generator.

2. Move the engine switch (S) in the OFF position.

3. Turn the fuel shut-off valve (K) on the gas tank to the horizontal

(CLOSED) position as shown.

Connecting Electrical Loads

1. Allow the engine to warm up for five minutes. Then place the main breaker (T) in the ON

position.

Connect loads in the following manner to prevent damage to equipment:

2. Connect inductive load equipment first. Inductive loads consist of refrigerators, freezers,

water pumps, air conditioners or small hand tools. Connect the items that require the most

wattage first.

3. Connect the lights next.

4. Voltage sensitive equipment should be the last equipment connected to the generator.

Plug voltage sensitive appliances such at TV's, VCR's, microwaves, ovens, computers,

and cordless telephones into a UL listed voltage surge protector, then connect the UL

listed voltage surge protector to the generator.

A WARNING: Failure to connect and operate equipment in this sequence can cause damage

to equipment and will void the warranty on your generator.

Operating Heavy Loads

Maximum output for short periods.

DEWALT Model DG3000 DG4400B DG6300B DG7000B

Maximum 3000 Watts 4400 Watts 6300 Watts 7000 Watts

Output

For continuous operation do not exceed the continuous rated output.

DEWALTModel DG3000 DG4400B DG6300B DG7000B

Continuous 2920 Watts 4180Watts 5950 Watts 6550 Watts

Rated Output

DO NOT exceed the current limit specified on the control panel for any receptacle.

High Altitude Operating

At high altitude, the standard carburetor air-fuel mixture will be too rich. Performance will

decrease and fuel consumption will increase. A very rich mixture will also foul the spark plug

and cause hard starting.

High altitude performance can be improved by specific modifications to the carburetor. Ifyou

always operate your engine at altitudes above 1,524 meters (5,000 feet), have your authorized

service center perform a carburetor modification.

Even with a carburetor modification, engine horsepower will decrease about 3.5% for each

300 meter (1,000 foot) increase in altitude. The effect of altitude on horsepower will be greater

than this if no carburetor modification is made. A decrease in engine horsepower will decrease

the power output of the generator.

NOTE: When the carburetor has been modified for high altitude operation, the air-fuel mixture

will be too lean for low altitude use. If the generator is used at low altitudes after a carburetor

modification, the carburetor may cause the engine to overheat and result in serious engine

damage. For use at low altitudes, have your authorized service center return the carburetor

to original factory specifications.

High and Low Temperature Operation

Air temperature affects generator output. Output drops 1% for each 10°F temperature rise

above 60° R Very low temperature may cause the engine to be hard to start.

Raising or Suspending Generator

DG4400B, DG6300B AND DG7000B

_&WARNING: Failure to properly connect lifting cables, chains or straps can cause property

damage, serious injury or death, and void the manufacturer's warranty.

WARNING: Always use cables, chains or straps rated at 2000 Ibs. working load or more to

raise or suspend generator.

,& WARNING: Never operate generator while suspended.

This could cause property damage, serious injury or

death.

A WARNING: DO NOT suspend objects other than

generator from lifting hook.

A WARNING: Make sure all fasteners in frame and firing

hook are tight.

Route cable, chain or strap through lifting hook (C) as

shown. ALWAYS use lifting hook when raising or sus-

pending generator.

NOTE: Make sure the generator is in a level position

before raising or suspending to prevent damage.

SINGLE C

MULTI

11

Page 12

MAINTENANCE

Importance of Maintenance

Good maintenance is essential for safe, economical and trouble-free operation. It will also

help reduce air pollution.

WARNING: Improper maintenance or failure to correct a problem before operation can

cause malfunction, serious injury or death. Always follow the inspection and maintenance

recommendation and schedules in this manual

The following pages include a maintenance schedule, routine inspection procedures and

simple maintenance procedures using basic hand tools to help you properly care for your

generator. If you are not comfortable with any maintenance procedure, contact a DEWALT

factory service center or a DEWALT authorized service center.

Maintenance, replacement or repair of the emission control devices and system may be per-

formed by any engine repair establishment or individual using parts that are certified to EPA

standards.

Maintenance Safety

_, WARNING: Do not operate this unit until you read and understand this instruction manual and

the engine instruction manual for safety, operation and maintenance instructions..

SAFETY PRECAUTIONS

_, WARNING: Make sure the engine is off before beginning any maintenance or repairs. This

will eliminate several potential hazards, including:

• carbon monoxide poisoning from engine exhaust. Be sure there is adequate ventilation

whenever you operate the engine.

• burns from hot parts. Let the engine and exhaust system cool before you touch it to

prevent burns.

• injury from moving parts. Wear appropriate clothing, tie back long hair, and stay alert

around the generator to prevent injury from moving parts.

A WARNING: To reduce the possibility of fire or explosion, be careful when working around

gasoline. Use only a nonflammable solvent, not gasoline, to clean parts. Keep smoking prod-

ucts, sparks and flames away from aft fuel related parts.

Read all instructions before beginning and make sure you have the tools and skills required.

A DEWALT factory service center or a DEWALT authorized service center knows your generator

best and is fully equipped to do maintenance and repair. To ensure the best quality and reli-

ability, use only new genuine parts or their equivalents for repair or replacement.

General Maintenance

,& WARNING: Contact with a hot engine or exhaust system can cause serious burns or fires.

Let the engine and muffler cool before storing the generator.

NOTE: All generators contain maintenance parts (e.g. oil, filters, etc.) that are periodically

replaced. These used parts may contain substances that are regulated and must be disposed of

in accordance with local, state, provincial and federal laws and regulations.

NOTE: Take note of the positions and locations of parts during disassembly to make reassembly

easier.

NOTE: Any service operations not included in this section should be performed by a DEWALT

factory service center or a DEWALT authorized service center.

The following procedures must be followed when maintenance or service is performed on the

generator.

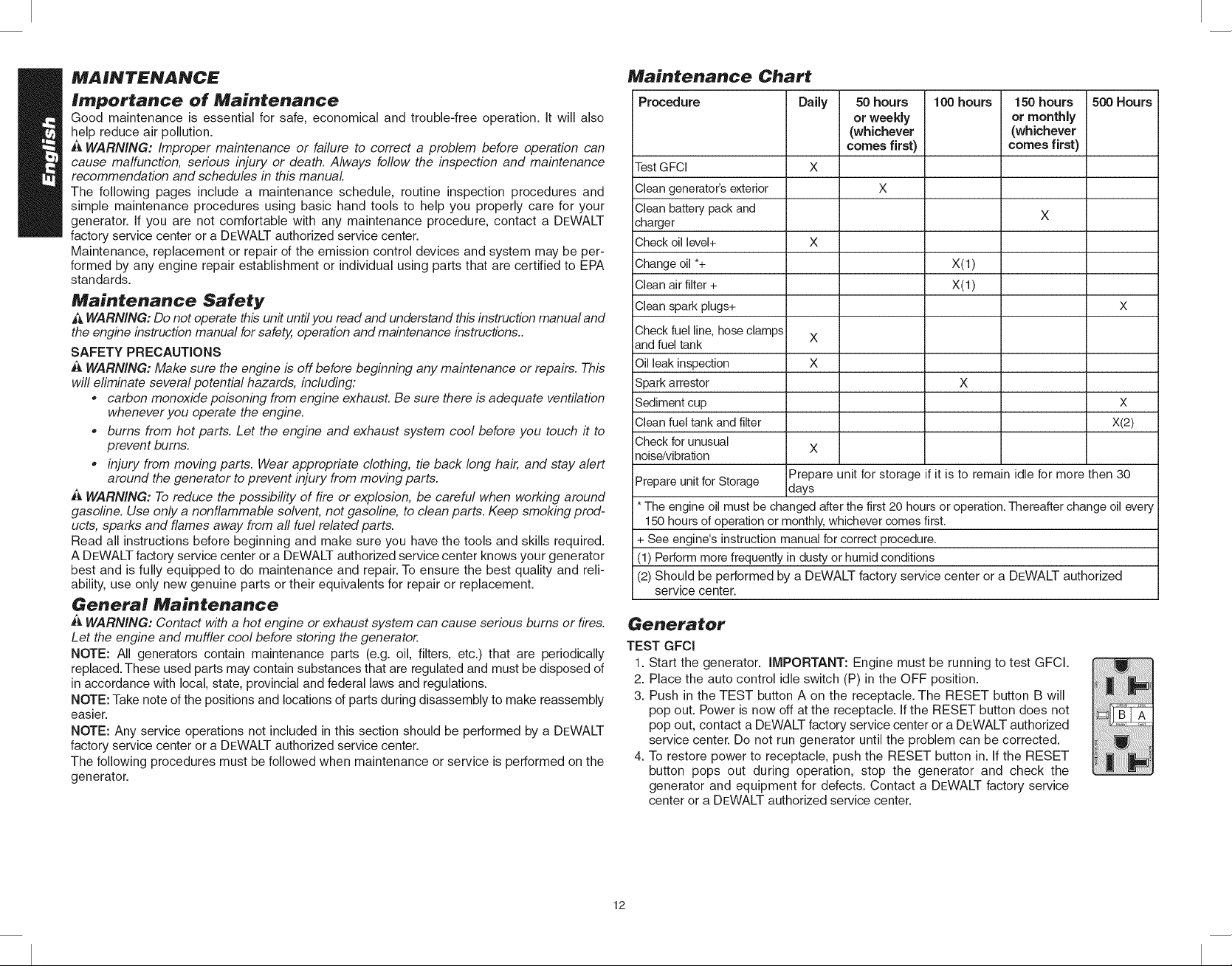

Maintenance Chart

Procedure

Test GFCI

Clean generator's exterior

Clean battery pack and

charger

Check oil level+

Change oil *+

Clean air filter +

Clean spark plugs+

Check fuel line, hose clamps

and fuel tank

iOil leak inspection

Spark arrestor

Sediment cup

Clean fuel tank and filter

Check for unusual

inoise/vibration

Prepare unit for Storage

i* The engine oil must be changed after the first 20 hours or operation. Thereafter change oil every

150 hours of operation or monthly, whichever comes first.

+ See engine's instruction manual for correct procedure.

(1) Perform more frequently in dusty or humid conditions

(2) Should be performed by a DEWALT factory service center or a DEWALT authorized

service center.

Daily

X

X

X

X

x

Prepare unit for storage if it is to remain idle for more then 30

days

50 hours

or weekly

(whichever

comes first)

X

100 hours

x(1)

x(1)

X

150 hours

or monthJy

(whichever

comesfirst)

500 Hours

X

X

X(2)

Generator

TEST GFCl

1. Start the generator.

2.

Place the auto control idle switch (P) in the OFF position.

3.

Push in the TEST button A on the receptacle. The RESET button B will

pop out. Power is now off at the receptacle. If the RESET button does not

pop out, contact a DEWALT factory service center or a DEWALT authorized

service center. Do not run generator until the problem can be corrected.

4.

To restore power to receptacle, push the RESET button in. If the RESET

button pops out during operation, stop the generator and check the

generator and equipment for defects. Contact a DEWALT factory service

center or a DEWALT authorized service center.

IMPORTANT: Engine must be running to test GFCI.

12

Page 13

CLEANING

WARNING: When cleaning, use only mild soap and a damp cloth on plastic parts. Many

household cleaners contain chemicals which could seriously damage plastic. Also, do not use

gasoline, turpentine, lacquer, paint thinner, dry cleaning fluids or similar products which may

seriously damage plastic parts. Never let any liquid get inside the tool; never immerse any

part of the tool into a liquid.

The generator should be kept clean and dry at all times. The generator should not be stored

or operated in environments that include excessive moisture, dust or any corrosive vapors.

If these substances are on the generator, clean with a cloth or soft bristle brush. Do not use

a garden hose or anything with water pressure to clean the generator. Water may enter the

cooling air slots and could possibly damage the rotor, stator and the internal windings of the

alternator.

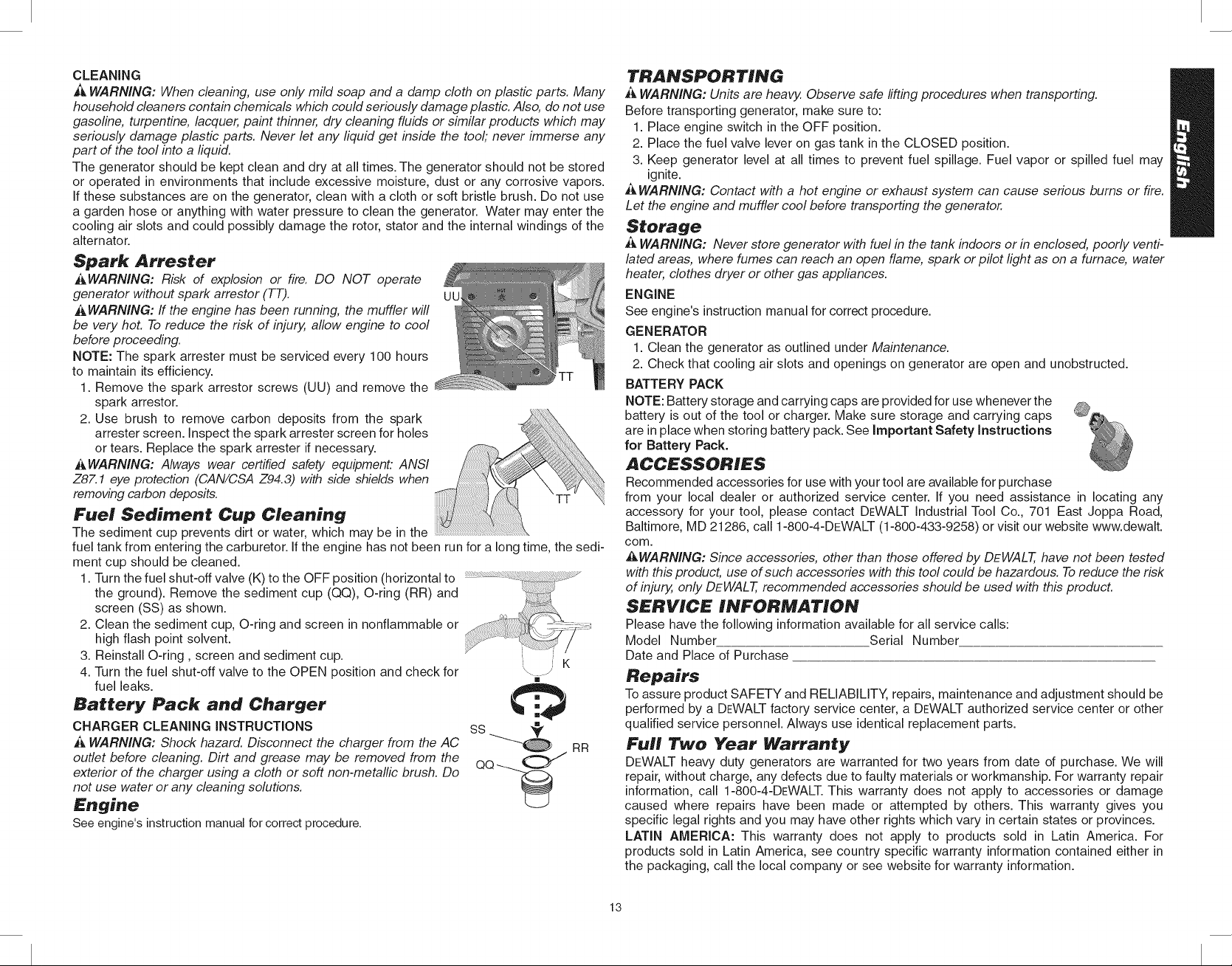

Spark Arrester

_WARNING: Risk of explosion or fire. DO NOT operate

generator without spark arrestor (TT). UU

_WARNING: ff the engine has been running, the muffler will

be very hot. To reduce the risk of injury, allow engine to cool

before proceeding.

NOTE: The spark arrester must be serviced every 100 hours

to maintain its efficiency.

1. Remove the spark arrestor screws (UU) and remove the

spark arrestor.

2. Use brush to remove carbon deposits from the spark

arrester screen. Inspect the spark arrester screen for holes

or tears. Replace the spark arrester if necessary.

_,WARNING: Always wear certified safety equipment." ANSI

Z87.1 eye protection (CAN/CSA Z94.3) with side shields when

removing carbon deposits.

Fuel Sediment Cup Cleaning

The sediment cup prevents dirt or water, which may be in the

fuel tank from entering the carburetor. If the engine has not been run for a long time, the sedi-

ment cup should be cleaned.

1. Turn the fuel shut-off valve (K) to the OFF position (horizontal to

the

ground). Remove the sediment cup (QQ), O-ring (RR) and

2. Clean the sediment cup, O-ring and screen in nonflammable or ,jj.s_

screen (SS) as shown.

high flash point solvent. _ ............... K3. Reinstall O-ring, screen and sediment cup.

4. Turn the fuel shut-off valve to the OPEN position and check for '_- -_

fuel leaks.

Battery Pack and Charger

CHARGER CLEANING INSTRUCTIONS

_ WARNING: Shock hazard. Disconnect the charger from the AC

outlet before cleaning. Dirt and grease may be removed from the

exterior of the charger using a cloth or soft non-metallic brush. Do

not use water or any cleaning solutions.

Engine

See engine's instruction manual forcorrect procedure.

,..'b

ss '_

Q_ RR

TRANSPORTING

_ WARNING: Units are heavy, Observe safe rifting procedures when transporting.

Before transporting generator, make sure to:

1. Place engine switch in the OFF position.

2. Place the fuel valve lever on gas tank in the CLOSED position.

3. Keep generator level at all times to prevent fuel spillage. Fuel vapor or spilled fuel may

ignite.

WARNING: Contact with a hot engine or exhaust system can cause serious burns or fire.

Let the engine and muffler cool before transporting the generator.

Storage

_J,WARNING: Never store generator with fuel in the tank indoors or in enclosed, poorly venti-

lated areas, where fumes can reach an open flame, spark or pilot light as on a furnace, water

heater, clothes dryer or other gas appliances.

ENGINE

See engine's instruction manual for correct procedure.

GENERATOR

1. Clean the generator as outlined under Maintenance.

2. Check that cooling air slots and openings on generator are open and unobstructed.

BATTERY PACK

NOTE: Battery storage and carrying caps are provided for use whenever the

battery is out of the tool or charger. Make sure storage and carrying caps

are in place when storing battery pack. See Important Safety Instructions

for Battery Pack.

ACCESSORIES

Recommended accessories for use with your tool are available for purchase

from your local dealer or authorized service center. If you need assistance in locating any

accessory for your tool, please contact DEWALT Industrial Tool Co., 701 East Joppa Road,

Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.

com.

_WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only DEWALT, recommended accessories should be used with this product.

SERVICE INFORMATION

Please have the following informationavailable for all service calls:

Model Number Serial Number

Date and Place of Purchase

Repairs

Toassure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be

performed by a DEWALT factory service center, a DEWALT authorized service center or other

qualified service personnel. Always use identical replacement parts.

FUll Two Year Warrant)/

DEWALT heavy duty generators are warranted for two years from date of purchase. We will

repair, without charge, any defects due to faulty materials or workmanship. For warranty repair

information, call 1-800-4-DEWALT. This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This warranty gives you

specific legal rights and you may have other rights which vary in certain states or provinces.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained either in

the packaging, call the local company or see website for warranty information.

13

Page 14

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT for a free replacement.

TROUB£ESHOOT_NG GUIDE

This section provides a list of the more frequently encountered malfunctions, their causes

and corrective actions. The operator or maintenance personnel can perform some corrective

actions, and others may require the assistance of a qualified DEWALT technician or your

dealer.

Problem Code

Engine will not start (See engine instruction manual for more information) ................ 1,2,3,4

No electrical output ................................................................................................. 5,6,7,8,9,18

NOTE: Ifthere is still no power atthe receptacles, takethe generator to an authorized DEWALT

service center. To locate a DEWALTservice center nearest to you, call 1-800-4-DEWALT

Repeated circuit breaker tripping ....................................................................................... 10,11

Generator overheating ....................................................................................................... 10,12

No auto idle ........................................................................................................ 13,14,15,16,17

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

1 Engine Switch in OFF p0Siti0n.' Turn toON

2 Choke in wrong position Adjust choke accordingly

j Fuel Shut'off valve in cl0sed open rue! Shut,off va!ve

!position i

4 Unit loaded during start-up Remove load from unit

I

5 Faulty receptac!e Contact a DEWALT factory service center or a

: DEWALTauthorized service center

6 Receptacle thermal circuit Depress and reset

breaker tripped

I

Defective CapaCit0r Contact a DEWALT iact0rY service Center or a

• DEWALTauthorized service center:

8 Faulty power cord Repair or replace cord

9 GFCI switch breaker tripped Depress and reset

10 Generator overloaded Reduce load

11 Faulty c0rds or equipment CheCk foi damaged, baie or fiayed wireS on

'. equipment: Replacel

12 Insufficient ventilation Move to adequate supply of fresh air

CODE POSSIBLE CAUSE

Fauity so!enoid

I

14 Faulty idle control switch

POSSIBLE SOLUTION

Contact a DEWALT faCtorY Service Center 0ra

DEWALT authorized service center:

Contact a DEWALT factory service center or a

DEWALT authorized service center.

FaUlty windingS in Stator

Contact a DEWALT factorY ServiCe Centei ora

DEWALT authorized service center:

16 Faulty circuit board

Contact a DEWALT factory service center or a

DEWALT authorized service center.

FaUlty wire harness

i

18 Voltage selector in the 120V

position

Contact a DEWALT factoiy service Center or a

DEWALTauthorized service center:

Place the voltage selector to the 240V position

when using a tool that requires 240V.

THE FOLLOWING WARRANTY APPLIES ONLY TO PRODUCTS

MANUFACTURED TO MEET CALiFORNiA AND UNITED STATES

ENViROMENTAL PROTECTION AGENCY SPECiFiCATiONS, WHICH ARE

DiSTRiBUTED AND SOLD iN THE UNITED STATES.

i. EMiSSiON CONTROLWARRANTY STATEMENT

Your warranty rights and obligations: The California Air Resources Board, the United

States Environmental Protection Agency and DEWALT, are pleased to explain the emission

control system warranty on your 2008 model year small off-road engine. In the United States

and California, new small off-road engines must be designed, built and equipped to meet the

State's stringent anti smog standards. DEWALT must warrant the emission control system on

your small off-road engine for the periods of time listed below provided there has been no

abuse, neglect or improper maintenance of your small off-road engine.

Your emission control system may include parts such as the carburetor or fuel injection sys-

tem, the ignition system, and catalytic converter. Also included may be hoses, belts, connec-

tors and other emission related assemblies.

Where a warrantable condition exists, DEWALT will repair your small off-road engine at no

cost to you including diagnosis, parts and labor.

Manufacturer's warranty coverage: The 1995 and later small off-road engines are

warranted for two years. If any emission related part on your engine is defective, the part will

be repaired or replaced by DEWALT.

Owner's warranty responsibilities: As the small off-road engine owner, you are responsible

for the performance of the required maintenance listed in your owner's manual. DEWALT

recommends that you retain all receipts covering maintenance on your small off-road engine,

but DEWALT cannot deny warranty solely for the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance.

As the small off-road engine owner, you should however be aware that DEWALT may deny

you warranty coverage if your small off-road engine or a part has failed due to abuse, neglect,

improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine to a DEWALT distribution center

as soon as a problem exists. The warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.If you have any questions regarding your warranty

rights and responsibilities, you should contact DEWALT Industrial Tool Co., Phone number

1-800-4-DEWALT (1-800-433-9258), or visit DEWALT website at www.dewalt.com for more

information and assistance.

14

Page 15

I1.EMISSION CONTROL SYSTEM WARRANTY

Emission Control System Warranty (ECS Warranty) for 1997 and later model engines

(a) Applicability: This warranty shall apply to 1997 and later model year engines. The ECS

Warranty Period shall begin on the date the new engine or equipment is purchased by/

delivered to its ultimate purchaser and shall continue for 24 consecutive months thereaf-

ter.

(b) General Emissions Warranty Coverage: DEWALT warrants to the ultimate purchaser of

the new engine or equipments and each subsequent purchaser for a two-year period.

(1) Designed, built and equipped so as to conform with all applicable regulations adopted

by the EPA and CARB pursuant to their respective authority, and

(2) Free from defects in materials and workmanship, which, at any time during the ECS

Warranty Period, may cause a warranted emissions-related part to fail to be identical in

all material respects to the part as described in the engine manufacturer's application

for certification.

The ECS Warranty only pertains to emissions-related parts on your engine, as fol-

lows:

(1) Any warranted, emissions-related parts that are not scheduled for replacement as required

maintenance in the Owner's Manual must be warranted for the ECS Warranty Period. If

any such part fails during the ECS Warranty Period, it shall be repaired or replaced by

DEWALT according to Subsection (4) below. Any such part repaired or replaced under the

ECS Warranty shall be warranted for the remainder of the ECS Warranty Period.

(2) Any warranted, emissions-related part that is scheduled only for regular inspection as

specified in the Owner's Manual must be warranted for the ECS Warranty Period. A state-

ment in such written instructions to the effect of "repair or replace as necessary" shall

not reduce the ECS Warranty Period. Any such part repaired or replaced under the ECS

Warranty shall be warranted for the remainder of the ECS Warranty Period.

(3) Any warranted, emissions-related part that is scheduled for replacement as required

maintenance in the Owner's Manual shall be warranted for the period of time prior to the

first scheduled replacement point for that part. If the part fails prior to the first scheduled

replacement, the part shall be repaired or replaced by DEWALT according to Subsection

(4) below. Any such emissions-related part repaired or replaced under the ECS Warranty

shall be warranted for the remainder of the ECS Warranty Period prior to the first sched-

uled replacement point for such emissions-related part.

(4) Repair or replacement of any warranted, emissions-related part under this ECS

Warranty shall be performed at no charge to the owner at a DEWALT Authorized

Warranty Service Facility. The warranty services or repairs must be provided at all

manufacturer distribution centers that are franchised to service the subject engines.

(5) When the engine is inspected by a DEWALT Authorized Warranty Service Facility, the

owner shall not be held responsible for diagnostic costs if the repair is deemed warrant-

able.

(6) DEWALT shall be liable for damages to other original engine components or approved

modifications proximately caused by a failure under warranty of any emission-related part

covered by the ECS Warranty.

(7) Throughout the ECS Warranty Period, DEWALT shall maintain a supply of warranted

emission-related parts sufficient to meet the expected demand for such emission-related

parts.

(8) Any replacement part may be used in the performance of any Warranty maintenance or

repairs and will be provided without charge to the ultimate purchaser. Such use shall not

reduce DEWALT's ECS warranty obligations.

(9) Add-on or modified parts that are not exempted by the Air Resources Board may not be

used. Such use will be grounds for disallowing a warranty claim made in accordance with

this article. DEWALT will not be liable under this article to warrant failures of warranted