Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contactenos.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA DE

GARANT[A. ADVERTENOIA: LEASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

DCH363

Heavy-Duty 36V Cordless Rotary Hammer

Perceuse & percussion haute r_sistance sans fil 36 V

Rotomartillo inal&mbrico de 36 V para trabajo pesado

®

Page 2

Definitions: Safety Guidelines

The definitions below describe the level of severity br each

signal word. Please read the manual and pay attention to these

symbols.

i_,DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

_ WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

i_,CAUTION: Indicates apotentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258}.

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

_ WARNING! Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tooL Distractions can cause you to lose control.

2} ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

If operating a powertool in a damp location is unavoidable,

use a ground fault circu# interrupter (GFCI) protected

supply. Use of a GFC/ reduces the risk of electric shock.

Page 3

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool Power tools

are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other

condition that may affect the power toors operation. If

damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind and

are easier to control

g) Use the power tool, accessories and tool bits, etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of fire when used with another

battery pack.

b) Use power tools only with specifically designated battery

packs. Use of any other battery packs may create a risk of

injury and fire.

Page 4

c) When battery pack is not in use, keep H away from other

metal objects, like paper clips, coins, keys, nails, screws,

or other small metal objects, that can make a connection

from one terminal to another. Shorting the battery terminals

together may cause bums or a fire.

d) Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally occurs,

flush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause

irritation or burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Additional Safety Rules for Rotary

Hammers

• Wear ear protectors. Exposure to noise can cause hearing loss.

• Use auxiliary handle(s) if supplied with the tool. Loss of

control can cause personal injury.

• Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory may

contact hidden wiring. Cutting accessory contacting a "live"

wire may make exposed metal parts of the power tool "live" and

could give the operator an electric shock.

• Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

• Wear safety goggles or other eye protection. Hammering

operations cause chips to fly.Flyingparticles can cause permanent

eye damage. Wear a dust mask or respirator for applications

that generate dust. Ear protection may be required for most

applications.

• Keep a firm grip on the tool at all times. Do not attempt

to operate this tool without holding # with both hands.

Operating this tool with one hand will result in loss of control.

Breaking through or encountering hard materials such as re-bar

may be hazardous as well.

• Do not operate this tool for long periods of time. Vibration

caused by hammer action may be harmful to your hands and

arms. Use gloves to provide extra cushion and limit exposure by

taking frequent rest periods.

• Do not recondition bits yourself. Chisel reconditioning should

be done by an authorized specialist. Improperly reconditioned

chisels could cause injury.

• Wear gloves when operating tool or changing bits. Accessible

metal parts on the tool and bits may get extremely hot during

operation. Small bits of broken material may damage bare hands.

• Never lay the tool down until the bit has come to a complete

stop. Moving bits could cause injury.

• Do not strike jammed bits with a hammer to dislodge them.

Fragments of metal or material chips could dislodge and cause

injury.

• Do not overheat the bit (discoloration) while grinding a new

edge. Badly worn chisels require reforging. Do not reharden and

temper the chisel

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewelry or long hair can be caught in moving parts.

i_,WARNING: ALWAYS use safety glasses. Everyday eyeglasses are

NOTsafety glasses. Also use face or dust mask if cutting operation is

dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

Page 5

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

A WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromMm from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

i_,WARNING: Use of this tool can generate and/or disperse dust,

which may cause serious and permanent respiratory or other

injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

,_ WARNING: Always wear proper personal hearing protection

that conforms to ANSI $12.6 ($3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

_ CAUTION: When not in use, place tool on its side on a stable

surface where it will not cause a tripping or falling hazard.

Some tools with large battery packs will stand upright on the battery

pack but may be easily knocked over.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ................... volts

Hz................. hertz

min ............... minutes

- -- or DC... direct current

_) ................. Class I Construction

(grounded)

[] ................. Class II Construction

(double insulated)

.../min .......... per minute

BPM ............. beats per minute

IPM ............... impacts per minute

RPM ............. revolutions per

minute

sfpm ............. surface feet

per minute

SPM ............. strokes per minute

A...................... amperes

W..................... watts

_, or AC ..........alternating

current

_-_or AC/DC... alternating

or direct

current

no .................... no load

speed

n ...................... rated

speed

..................... earthing

terminal

_t,..................... safety alert

symbol

Important Safety Instructions for All

Battery Packs

When ordering replacement battery packs, be sure to include catalog

number and voltage. Consult the chart at the end of this manual for

compatibility of chargers and battery packs.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below. Then

follow charging procedures outlined.

Page 6

READ ALL INSTRUCTIONS

• Do not charge or use battery in explosive atmospheres,

such as in the presence of flammable liquids, gases or dusL

Inserting or removing the battery from the charger may ignite the

dust or fumes.

• NEVER force battery pack into charger. DO NOT modify

battery pack in any way to fit into a non-compatible charger

as battery pack may rupture causing serious personal

injury. Consult the chart at the end of this manual for compatibility

of batteries and chargers.

• Charge the battery packs only in DEWALTchargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations

where the temperature may reach or exceed 105 °F (40 °C)

(such as outside sheds or metal buildings in summer).

_ WARNING: Never attempt to open the battery pack for any

reason. If battery pack case is cracked or damaged, do not insert

into charger, Do not crush, drop or damage battery pack. Do not

use a battery pack or charger that has received a sharp blow, been

dropped, run over or damaged in any way (Le., pierced with a nail,

hit with a hammer, stepped on). Damaged battery packs should be

returned to service center for recycling.

_ WARNING: Fire hazard. Do not store or carry battery so

that metal objects can contact exposed battery terminals.

For example, do not p/ace battery in aprons, pockets, too/boxes,

product kit boxes, drawers, etc., with loose nails, screws, keys, etc.

without battery cap. Transporting batteries can possibly cause

fires if the battery terminals inadvertently come in contact

with conductive materials such as keys, coins, hand tools

and the like. The U.S. Department of Transportation Hazardous

Material Regulations (HMR) actually prohibit transporting batteries

in commerce or on airplanes (i.e., packed in suitcases and carry-on

luggage) UNLESS they are properly protected from short circuits.

So when transporting individual batteries, make sure that the battery

terminals are protected and well insulated from materials that could

contact them and cause a short circuit.

SPECIFIC SAFETY INSTRUCTIONS FOR LITHIUM ION (Li-lon)

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire. Toxic fumes and materials are created when

lithium ion battery packs are burned.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water. If battery

liquid gets into the eye, rinse water over the open eye for 15

minutes or until irritation ceases. If medical attention is needed,

the battery electrolyte is composed of a mixture of liquid organic

carbonates and lithium salts.

• Contents of opened battery cells may cause respiratory

irritation. Provide fresh air, If symptoms persist, seek medical

attention.

_&WARNING: Bum hazard. Battery liquid may be flammable if

exposed to spark or flame.

The RBRC TM Seal

The RBRC TM (Rechargeable Batted/ Recycling Corporation) Seal on

the nickel cadmium, nickel metal hydride or lithiumion

batteries (or battery packs) indicate that the costs to

recycle these batteries (or battery packs) at the end of

their useful life have already been paid by DEWALT. In

some areas, it is illegal to place spent nickel cadmium,

nickel metal hydride or lithium ion batteries in the trash

or municipal solid waste stream and the RBRC program

provides an environmentally conscious alternative.

Page 7

RBRCTM in cooperation with DEWALT and other battery users, has

established programs in the United States and Canada to facilitate

the collection of spent nickel cadmium, nickel metal hydride or lithium

ion batteries. Help protect our environment and conserve natural

resources by returning the spent nickel cadmium, nickel metal hydride

or lithium ion batteries to an authorized DEWALT service center or

to your local retailer for recycling. You may also contact your local

recycling center for information on where to drop off the spent

battery.

RBRC TM is a registered trademark of the Rechargeable Battery

Recycling Corporation.

Important Safety Instructions for All

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important

safety and operating instructions for battery chargers.

• Before using charger, read a!!instructions and cautionary markings

on charger, battery pack, and product using battery pack.

WARNING: Shock hazard. Do not allow any liquid to get inside the

charger. Electric shock may result.

i_,CAUTION: Bum hazard. To reduce the risk of injury, charge only

DEWALT rechargeable battery packs. Other types of batteries may

overheat and burst resulting in personal injury and property damage.

NOTICE: Under certain conditions, with the charger plugged in to

the power supply, the exposed charging contacts inside the charger

can be shorted by foreign material Foreign materials of a conductive

nature such as, but not limited to, grinding dust, metal chips, steel

wool, aluminum foil, or any buildup of metallic particles should be

kept away from charger cavities. Always unplug the charger from

the power supply when there is no battery pack in the cavity, Unplug

charger before attempting to clean.

• DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual The charger and

battery pack are specifically designed to work together.

• These chargers are not intended for any uses other than

charging DEWALT rechargeable batteries. Any other uses

may result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting charger.

This will reduce risk of damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped

on, tripped over, or otherwise subjected to damage or

stress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in risk of

fire, electric shock, or electrocution.

• When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

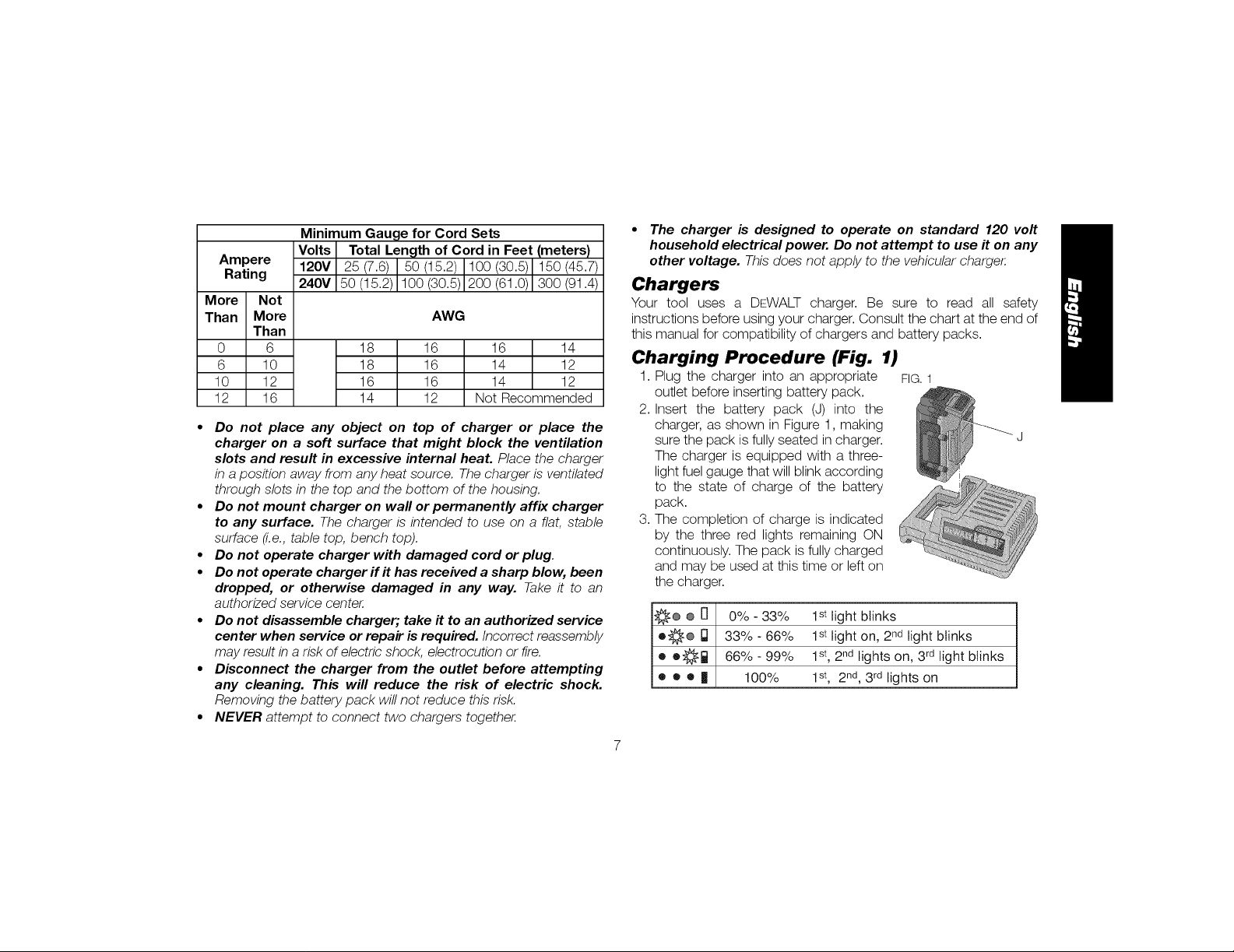

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. When using more than one extension to make up the

total length, be sure each individual extension contains at least the

minimum wire size. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in

doubt, use the next heaviergauge. The smaller the gauge number,

the heavier the cord.

Page 8

Minimum Gauge for Cord Sets

Ampere

Rating

More

Than

0 18 16 16 14

6 18 16 14 12

10 16 16 14 12

12 14 12 Not Recommended

• Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation

slots and result in excessive internal heat. Place the charger

in a position away from any heat source. The charger is ventilated

through slots in the top and the bottom of the housing.

• Do not mount charger on wall orpermanently affix charger

to any surface. The charger is intended to use on a flat, stable

surface (i.e., table top, bench top).

• Do not operate charger with damaged cord or plug.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. Take it to an

authorized service center.

• Do not disassemble charger; take it to an authorized service

center when service or repair is required. Incorrect reassemb/y

may result in a risk of electric shock, electrocution or fire.

• Disconnect the charger from the outlet before attempting

any cleaning. This will reduce the risk of electric shock.

Removing the battery pack will not reduce this risk.

• NEVER attempt to connect two chargers together.

Volts Total Length of Cord in Feet (meters)

120V 25 (7.6) 50 (15.2) 100 (30.5)

240V 50 (15.2) 100 (30.5) 200 (61.0)

Not

More

Than

6

10

12

16

AWG

150 (45.7)

300 (91.4)

• The charger is designed to operate on standard 120 volt

household electrical power. Do not attempt to use it on any

other voltage. This does not apply to the vehicular charger.

Chargers

Your tool uses a DEWALT charger. Be sure to read all safety

instructions before using your charger. Consult the chart at the end of

this manual for compatibility of chargers and battery packs.

Charging Procedure (Fig. 1)

1. Plug the charger into an appropriate FIG. 1

outlet before inserting battery pack.

2. Insert the battery pack (J) into the

charger, as shown in Figure 1, making

sure the pack is fully seated in charger. J

The charger is equipped with a three-

light fuel gauge that will blink according

to the state of charge of the battery

pack.

3. The completion of charge is indicated

by the three red lights remaining ON

continuously. The pack is fully charged

and may be used at this time or left on

the charger.

_e e [] 0% - 33% 1stlight blinks

e_® _ 33% - 66% 1stlight on, 2ndlight blinks

o e_ 66% - 99% 1 st, 2 nd lights on, 3 rd light blinks

• ® ® _ 100% 1st, 2 nd, 3 rd lights on

Page 9

Charger Diagnostics

This charger is designed to detect certain problems that can arise

with the battery packs or the charger. Problems are indicated by the

three red lights flashing together in different patterns.

PROBLEM POWERLINE

When the charger is used with some portable power sources such

as generators or sources that convert DC to AC, the charger may

temporarily suspend operation. The three red lights will flash together

with two fast blinks followed by a pause. This indicates that the

power souce is out of limits.

BAD BATTERY

The charger can detect a weak or damaged battery. The three red

lights will flash together with rapid blinking. The battery will no longer

charge and should be returned to a service center or a collection site

for recycling.

BAD CHARGER

The charger will detect if it is not functioning properly. The three red

lights will flash together with one fast blink followed by a long

blink. The charger will no longer work and should be returned to an

authorized service center or replaced.

LEAVING THE BATTERY IN THE CHARGER

The charger and battery pack can be left connected with the red

lights glowing indefinitely. The charger will keep the battery pack

fresh and fully charged. This charger features an automatic tune-up

mode which equals or balances the individual cells in the battery

pack to allow it to function at peak capacity. Battery packs should

be tuned up weekly or whenever the battery no longer delivers the

same amount of work. To use the automatic tune-up mode, place the

battery pack in the charger and leave it for at least 8 hours.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65 °F

and 75 °F (18 °-24 °C). DO NOT charge the battery pack in

an air temperature below +40 °F (+4.5 °C), or above +105 °F

(+40.5 °C). This is important and will prevent serious damage to

the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem. To facilitate the cooling of the battery pack after use,

avoid placing the charger or battery pack in a warm environment

such as in a metal shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check operation of receptacle by plugging in a lamp or other

appliance;

b. Check to see if receptacle is connected to a light switch which

turns power off when you turn out the lights;

c. Move charger and battery pack to a location where the

surrounding air temperature is approximately 65 °F-75 °F

(18 o_ 24 °C);

d. If charging problems persist, take the tool, battery pack and

charger to your local service center.

4. The battery pack should be recharged when it fails to produce

sufficient power on jobs which were easily done previously. DO

NOT CONTINUE to use under these conditions. Follow the

charging procedure. You may also charge a partially used pack

whenever you desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can

be shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, grinding dust, metal chips, steel

Page 10

wool,aluminumfoil,oranybuildupofmetallicparticlesshouldbe

keptawayfromchargercavities.Alwaysunplugthechargerfrom

thepowersupplywhenthereisnobatterypackinthecavity.

Unplugchargerbeforeattemptingtoclean.

6.Donotfreezeorimmersechargerinwateroranyotherliquid.

AWARNING: Shock hazard. Don't allow any liquid to get inside

charger. Electric shock may result.

i_ WARNING: Bum hazard. Never attempt to open the battery pack

for any reason. If the plastic housing of the battery pack breaks or

cracks, return to a service center for recycling.

Storage Recommendations

1. The best storage place is one that is cool and dry away from

direct sunlight and excess heat or cold.

2. For long storage, it is recommended to store a fully charged

battery pack in a cool dry place out of the charger for optimal

results.

NOTE" Battery packs should not be stored completely depleted of

charge. The battery pack will need to be recharged before use.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

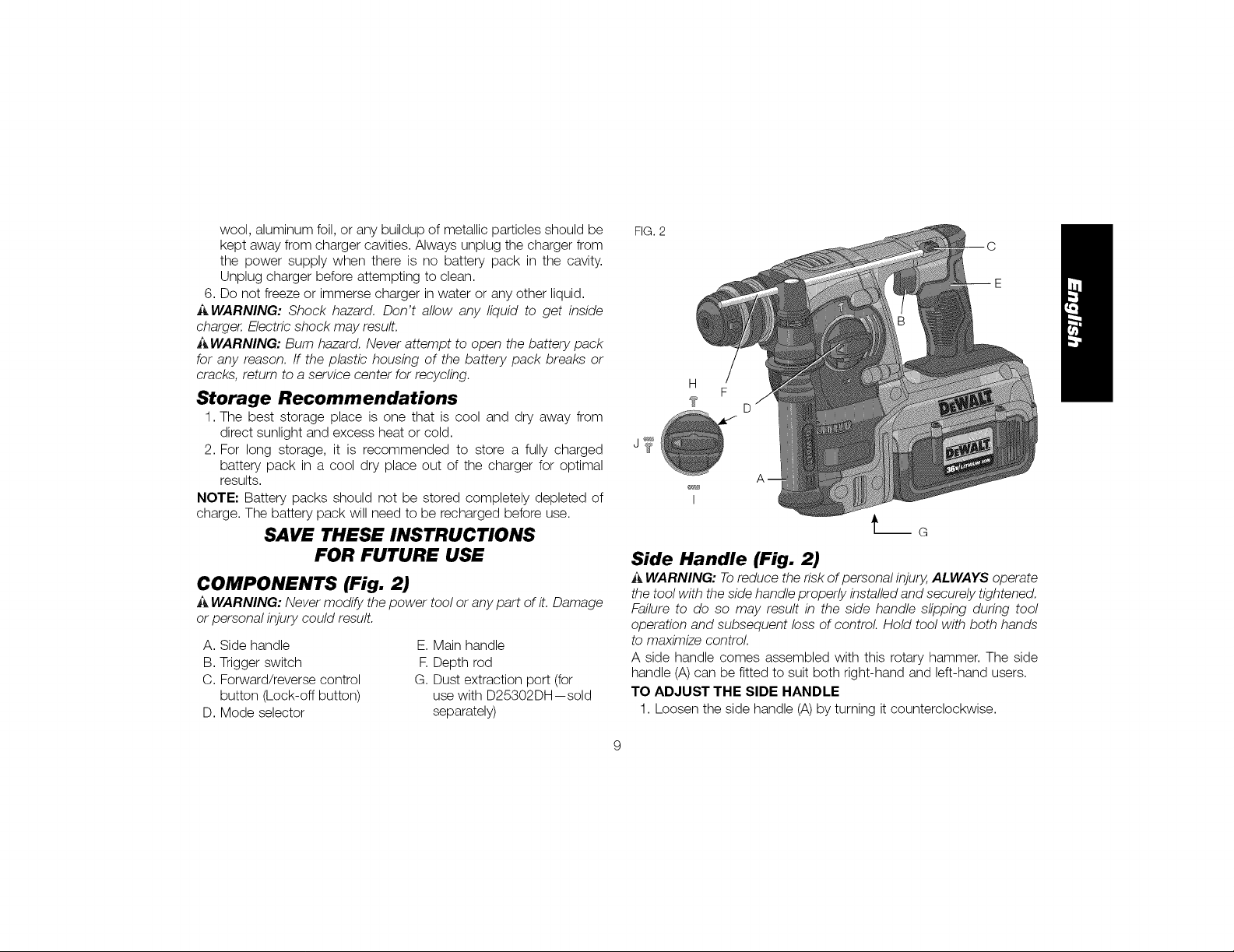

COMPONENTS (Fig. 2)

_ WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Side handle

B. Trigger switch

C. Forward/reverse control

button (Lock-off button)

D. Mode selector

E. Main handle

F. Depth rod

G. Dust extraction port (for

use with D25302DH--sold

separately)

FIG. 2

H

F

D

Side Handle (Fig. 2)

_ WARNING: To reduce the risk of personal injury,ALWAYS operate

the tool with the side handle properly installed and securely tightened.

Failure to do so may result in the side handle slipping during tool

operation and subsequent loss of control Hold tool with both hands

to maximize control

A side handle comes assembled with this rotary hammer. The side

handle (A)can be fitted to suit both right-hand and left-hand users.

TO ADJUST THE SIDE HANDLE

1. Loosen the side handle (A) by turning it counterclockwise.

Page 11

2.Rotatethesidehandletothedesiredposition.

3.Tightenthesidehandlebyturningitclockwiseuntilyouaresure

thesidehandlewon'tslip.

TO CHANGE SIDES

For right-hand users: slide the side handle clamp over the chuck,

handle at the left.

For left-hand users: slide the side handle clamp over the chuck,

handle at the right.

Depth Rod (Fig. 2)

Toadjust the depth rod (F),loosen the side handle (A) and move the

depth rod so that the distance between the end of the rod and the

end of the bit equals the desired drilling depth. When drilling with

depth rod, stop when end of rod reaches surface of material.

Switch (Fig. 2)

To turn the tool on, squeeze the trigger switch (B). To turn the tool

off, release the trigger switch. Your tool is equipped with a brake. The

chuck will stop as soon as the trigger switch is fully released.

VARIABLE SPEED SWITCH

The variable speed switch enables you to select the best speed for a

particular application. The farther you squeeze the trigger, the faster

the tool will operate. For maximum tool life, use variable speed only

for starting holes or fasteners.

NOTE" Continuous use in variable speed range is not recommended.

It may damage the switch and should be avoided.

Mode Selector (Fig. 2)

i_CAUTION: Never change the mode while the unit is running.

For straight drilling, rotate the mode selector (D) until the arrow points

to the drill bit symbol (H). For rotary hammer, align the arrow with the

hammer symbol (I). For chipping mode align arrow with the chipping

symbol (J).

NOTE" The mode selector (D) must be in drill, hammer or chipping

mode at all times. There are no operable positions in between.

Forward/Reverse Control Button

(Fig. 1, 3)

A forward/reverse control button (C)determines the direction and also

serves as a lock-off button.

To select forward rotation, release the trigger switch (B) and

depress the forward/reverse control button on the right side of thetool.

To select reverse, depress the forward/reverse control button on the

left side of the tool.

The center position of the control button locks the tool in the

off position. When changing the position of the control button, be

sure the trigger is released.

NOTE" The first time the tool is run after changing the direction of

rotation, you may hear a click on start up. This is normal and does

not indicate a problem.

FIG. 3

C

UNLOCKED, LOCKED UNLOCKED,

FORWARD REVERSE

10

Page 12

OPERATION

_ WARNING: To reduce the risk of serious personal injury,

depress the trigger lock button and disconnect battery

pack before making any adjustments or removing/installing

attachments or accessories. An accidental start-up can cause

injury.

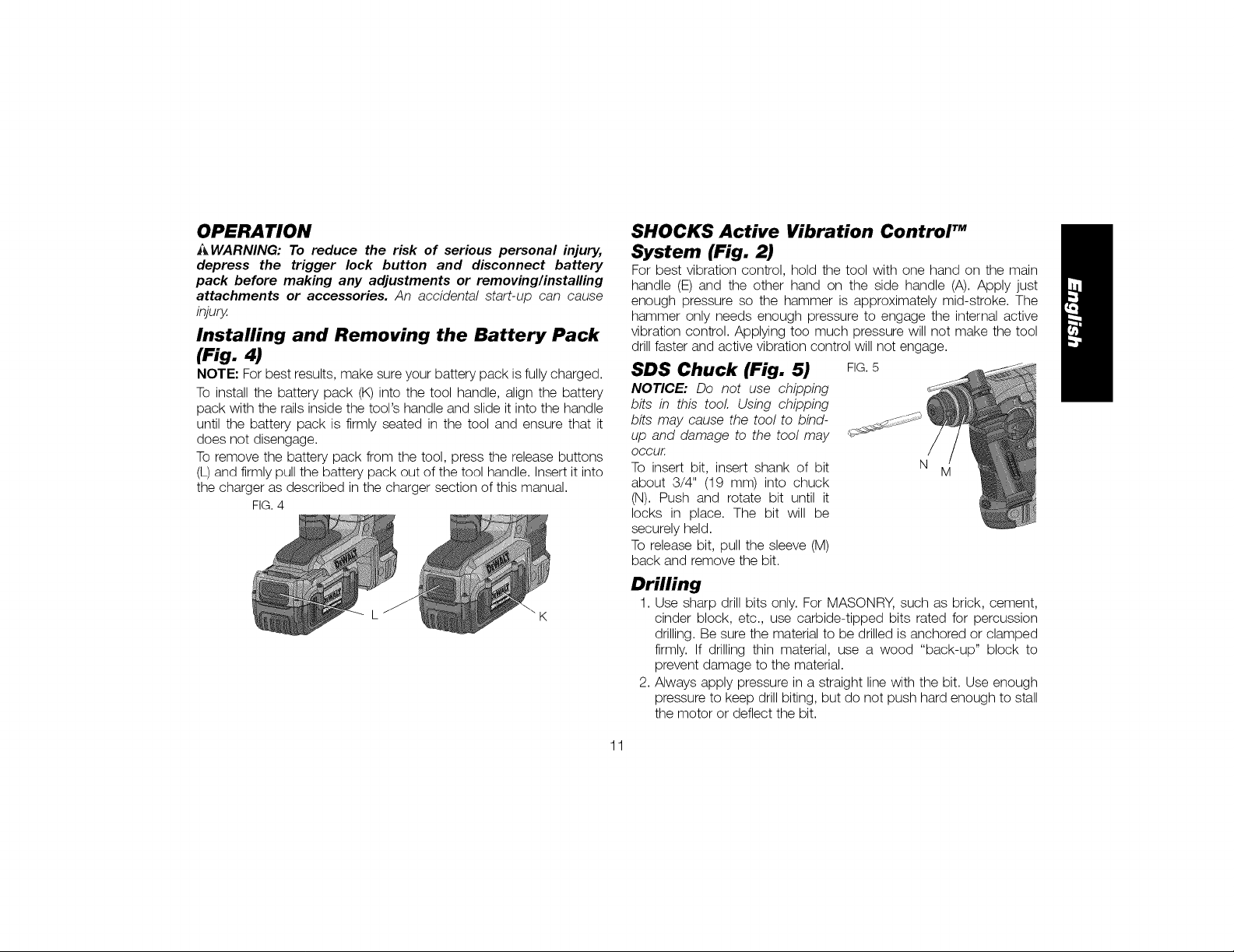

Installing and Removing the Battery Pack

(Fig. 4)

NOTE: For best results, make sure your battery pack is fully charged.

To install the battery pack (K) into the tool handle, align the battery

pack with the rails inside the tool's handle and slide it into the handle

until the battery pack is firmly seated in the tool and ensure that it

does not disengage.

To remove the battery pack from the tool, press the release buttons

(L)and firmly pull the battery pack out of the tool handle. Insert it into

the charger as described in the charger section of this manual.

FIG.4

SHOCKS Active Vibration ControF M

System (Fig. 2)

For best vibration control, hold the tool with one hand on the main

handle (E) and the other hand on the side handle (A). Apply just

enough pressure so the hammer is approximately mid-stroke. The

hammer only needs enough pressure to engage the internal active

vibration control. Applying too much pressure will not make the tool

drill faster and active vibration control will not engage.

SDS Chuck (Fig. 5) FIG.5

NOTICE: Do not use chipping

bits in this tool Using chipping

bits may cause the tool to bind-

up and damage to the tool may

OCCUil

To insert bit, insert shank of bit

about 3/4" (19 mm) into chuck

(N). Push and rotate bit until it

locks in place. The bit will be

securely held.

To release bit, pull the sleeve (M)

back and remove the bit.

Drilling

1. Use sharp drill bits only. For MASONRY, such as brick, cement,

cinder block, etc., use carbide-tipped bits rated for percussion

drilling. Be sure the material to be drilled is anchored or clamped

firmly. If drilling thin material, use a wood "back-up" block to

prevent damage to the material.

2. Always apply pressure in a straight line with the bit. Use enough

pressure to keep drill biting, but do not push hard enough to stall

the motor or deflect the bit.

11

Page 13

3.Holdtoolfirmlywithbothhandstocontrolthetwistingactionof

thedrill.

_,WARNING:Drill may staff if overloaded causing a sudden twist.

Always expect the stall. Grip the drill firmly with both hands to

control the twisting action and avoid injury.

4. IF DRILL STALLS, it is usually because it is being overloaded or

improperly used. RELEASE TRIGGER IMMEDIATELY, remove

drill bit from work, and determine cause of stalling. DO NOT

CLICK TRIGGER ON AND OFF IN AN A'n'EMPT TO START

A STALLED DRILL -- THIS CAN DAMAGE THE DRILL.

5. Keep the motor running when pulling the bit back out of a drilled

hole. This will help prevent jamming.

6. Use a slow speed to start the hole and accelerate by squeezing

the trigger harder when the hole is deep enough to drill without

the bit skipping out.

DRILLING IN MASONRY

When drilling in masonry, use carbide tipped bits rated for masonry

drilling. Be certain that the bit issharp. Ensure that the hammer mode

is selected. Use a constant and firm force on the tool to drill most

effectively. A smooth, even flow of dust indicates the proper drilling

rate.

MAINTENANCE

A WARNING: To reduce the risk of serious personal injury,

depress the trigger lock button and disconnect battery

pack before making any adjustments or removing/installing

attachments or accessories. An accidental start-up can cause

injury.

Cleaning

i_ WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

_WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool,"never immerse any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

_ WARNING: Shock hazard. Disconnect the charger from the AC

outlet before cleaning. Dirt and grease may be removed from the

exterior of the charger using a cloth or soft non-metallic brush. Do not

use water or any cleaning solutions.

Accessories

_WARNING: Since accessories, other than those offered by

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only DEWALTrecommended accessories should be used with

this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

call 1-800-4-DEWALT (1-800-433-9258) or visit our website: www.

dewalt.com.

12

Page 14

MAXIMUM RECOMMENDED CAPACITIES

DCH363

RPM 0-1150

BPM 0-4400

BITS, MASONRY DRILLING 1" (2.54 cm)

Repairs

The charger and battery pack are not serviceable.

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by a DEWALT factory service center, a DEWALT

authorized service center or other qualified service personnel. Always

use identical replacement parts.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you

obtain more efficient warranty service in case there is a problem

with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance

loss, such as fire, flood or theft, your registration of ownership will

serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to

contact you in the unlikely event a safety notification is required

under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DEiWALTwill repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800-

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights

which vary in certain states or provinces.

In addition to the warranty, DEiWALTtools are covered by our:

2 YEARS FREE SERVICE

DC212, DC233, DCH253, DCH363

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first two years after purchase.

2 YEARS FREE SERVICE ON DEWALT BATTERY PACKS

DC9071, DC9091, DC9096, DC9280, DC9360, DC9180, DCB120,

DCB201, DCB203 and DCB361

3 YEARS FREE SERVICE ON DEWALT BATTERY PACKS

DCB200, DCB204

DEWALT BATTERY PACKS

Product warranty voided if the battery pack is tampered with in any

way. DEiWALTis not responsible for any injury caused by tampering

and may prosecute warranty fraud to the fullest extent permitted by

law.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DEWALT Power Tool, Laser, or Nailer for any reason, you can return

13

Page 15

itwithin90daysfromthedateofpurchasewithareceiptbr a full

refund- noquestionsasked.

LATIN AMERICA" This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT (1-800-433-

9258) for a free replacement.

f- _.

DCHXXXsos..,,ME.

SER.

_USER MUST READ iNSTRUCTiON

MANUAL. ALWAYS USE PROPEREYEAND RESPIRATORY

PROTECTION.USEDEWALT BATTERIES.

DEWALT INDUSTRIAL TOOL CO., BALTIMORE, MD 21288 USA

FOR SERVICE JNFORMATJOM CALL 1-800-4-DEWALT www.DEWALT.com

MANEJO SEGIJROLEA EL A T]TRE PREVENTJE,EJRELE

MANUAL DE NSTRUCC ONES IJUIDE, IL FAUTTOUJOURS

SiEMPRE S.EDEBERA LLEVAR LA PORTER DE L'EQIJlPEMENT DE

PROTECCiON APROPiADA PARA PROTECTION OIJULAJREET

fA _VBR'IreMc!IIA:, PABA EL I ,_ AVZ=K'i!IlSsEuBM'tr: j

LAVISTA Y PARA LASVIAS RESPJRATOJREAPPROPRJE.

\.ESPIRATORIAS. I

TU REDUCE THE RiSK OF iNJURY,

J

14

Page 16

D_finitions : lignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de danger pour

chaque mot-indicateur employe. Lire le mode d'emploi et porter

une attention particuliere a.ces symboles.

_DANGER : indique une situation dangereuse imminente qui,

si elle n'est pas evitee, entraTnera la mort ou des blessures

graves.

i_AVERTISSEMENT : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourrait entra_ner /a

mort ou des blessures graves.

AATTENTION : indique une situation potentie//ement

dangereuse qui, si el/e n'est pas evitee, pourra_t entra_ner des

blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n'est fair

pour /'eviter, pourrait poser des risques de dommages

materiels.

J

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET

OUTIL OU DE TOUT AUTRE OUTIL DEWALT, COMPOSEZ LE

NUMFt:ROSANS FRAIS : 1-800-4-DEWALT (1-800-433-9258}.

_ VERTISSEMENT : afin de reduire le risque de blessures, life

le mode d'emploi de I'outil.

Avertissements de s_curit_ g_n_raux

pour les outils _lectriques

A AVERTISSEMENT! life tous les avertissements des_curit_ et toutes les directives. Le non-respect des

avertissements et des directives pourrait se solder par un

choc dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUSLES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTERIEUR

Le terme _ outil dectrique _ cite dans les avertissements se rapporte

votre outil dectrique a alimentation sur secteur (avec ill) ou par piles

(sans fil).

1) S#CURIT# DU LIEU DE TRAVAIL

a) Tenir I'aire de travail propre et bien _clair_e. Les /ieux

encombres ou sombres sont propices aux accidents.

b) Ne pas faire fonctionner d'outils _lectriques clans un

milieu d_flagrant, tel qu'en presence de liquides, de

gaz ou de poussi_res inflammables. Les outi/s dectriques

produisent des etincelles qui pourraient enflammer la poussiere

ou les vapeurs.

c) E-Ioigner les enfants et les personnes aproximit_ pendant

I'utilisation d'un outil _lectrique. Une distraction pourrait en

faire perdre la ma_trisea I'utilisateur.

2) SI_CURITI_ EN MATI#RE D'I_LECTRICITI_

a) Les fiches des outils _lectriques doivent correspondre

la prise. Ne jamais modifier la fiche d'aucune faqon.

Ne jamais utiliser de fiche d'adaptation avec un outil

_lectrique mis a la terre. Le risque de choc dectrique sera

reduit par I'utilisation de fiches non modifiees correspondant

la prise.

b) E-vitertout contact physique avec des surfaces mises a la

terre comme des tuyaux, des radiateurs, des cuisini_res

et des r_frig_rateurs. Le risque de choc electrique est plus

deve si votre corps est mis a la terre.

15

Page 17

c)Ne pas exposer les outils electriques a la pluie ou

I'humidite. La penetration de I'eau dans un outil dectrique

augmente le risque de choc dectrique.

d) Ne pas utiliser le cordon de fa_on abusive. Ne jamais

utiliser le cordon pour transporter, tirer ou debrancher

un outil electrique. Tenir le cordon eloigne de la chaleur,

de rhuile, des bords tranchants et des pieces mobiles.

Les cordons endommages ou enchev_tres augmentent les

risques de choc dectrique.

e) Pour I'utilisation d'un outil electrique a I'exterieur, se

servir d'une rallonge convenant a cette application.

L'utilisation d'une rallonge conque pour I'exterieur reduira les

risques de choc dectrique.

f) S'il est impossible d'eviter rutilisation d'un outil

electrique dans un endroff humide, brancher routil dans

une prise ou sur un circuit d'alimentation dotes d'un

disjoncteur de fuite a la terre (GFCI). L'util/sat/on de ce type

de disjoncteur reduit les risques de choc dectrique.

3) SI_CURITI_ PERSONNELLE

a) Etre vigilant, surveiller le travail effectue et faire preuve

de jugement Iorsqu'un outil electrique est utilise. Ne

pas utiliser d'outil electrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de medicaments. Un

simple moment d'inattention en utilisant un outil dectrique peut

entra_ner des blessures corporelles graves.

b) Utiliser des equipements de protection individuelle.

Toujours porter une protection oculaire. L'uti/isation

d' equipements de protection comme un masque antipoussiere,

des chaussures antiderapantes, un casque de securite ou des

protecteurs auditifs Iorsque la situation le requiert reduira les

risques de blessures corporelles.

c) Empecher /es demarrages intempestifs. S'assurer que

I'interrupteur se trouve a la position d'arret avant de

relier I'outil a une source d'alimentation et/ou d'inserer

un bloc-piles, de ramasser ou de transporter I'outil.

Transporter un outil dectrique alors que le doigt repose sur

I'interrupteur ou brancher un outil dectrique dont I'interrupteur

est a la position de marche risque de provoquer un accident.

d) Retirer toute cle de reglage ou cle avant de demarrer

I'outil. Une cle ou une cle de reglage attachee a une pattie

pivotante de I'outil dectrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son equilibre en

tout temps. Cela permet de mieux ma_triser I'outil dectrique

dans les situations imprevues.

S'habiller de maniere appropriee. Ne pas porter de

vetements amples ni de bijoux. Garder /es cheveux, /es

vetements et les gants a I'ecart des pieces mobiles. Les

v_tements amples, les bijoux ou les cheveux longs risquent de

rester coinces dans les pieces mobiles.

g) Si des composants sont fournis pour le raccordement de

dispositifs de depoussierage et de ramassage, s'assurer

que ceux-ci sont bien raccordes et utilises. L'ut//isat/on

d'un dispositif de depoussierage peut reduire les dangers

engendres par les poussieres.

4) UTILISATION ET ENTRETIEN D'UN OUTIL leLECTRIQUE

a) Ne pas forcer un outil electrique. Utiliser I'outil electrique

approprie a I'application. L'outil dectrique approprie

effectuera un meilleur travail, de faqon plus sore et a la vitesse

pour laquelle il a ete conqu.

b) Ne pas utiliser un outil electrique dont I'interrupteur

est defectueux. Tout outil dectrique dont I'interrupteur est

defectueux est dangereux et doit _tre repare.

16

Page 18

c)D_brancher la fiche de la source d'alimentation et/ou du

bloc-piles de routil _lectrique avant de faire tout r_glage

ou changement d'accessoire ou avant de ranger routil.

Ces mesures preventives reduisent les risques de demarrage

accidentel de I'outil dectrique.

d) Ranger les outils _lectriques hors de la pottle des

enfants et ne permettre a aucune personne n'_tant

pas famili_re avec un outil _lectrique ou son mode

d'emploi d'utiliser cet outil. Les outi/s dectriques deviennent

dangereux entre les mains d'utilisateurs inexperimentes.

e) Entretien des outils _lectriques. V_rifier si les pi_ces

mobiles sont mal align_es ou coinc_es, si des pi_ces sont

bris_es ou pr_sentent toute autre condition susceptible

de nuire au bon fonctionnement de I'outil _lectrique.

En cas de dommage, faire r_parer I'outil _lectrique

avant toute nouvelle utilisation. Beaucoup d'accidents sont

causes par des outils dectriques mal entretenus.

f) S'assurer que les outils de coupe sont aiguis_s et

propres. Les outi/s de coupe bien entretenus et affOtes sont

moins susceptibles de se coincer et sont plus faciles a ma_triser.

g) Utiliser I'outil _lectrique, les accessoires, les forets,

etc. conform_ment aux pr_sentes directives en tenant

compte des conditions de travail et du travail _ effectuer.

L'utilisation d'un outil dectrique pour toute operation autre que

celle pour laquelle il a ete conquest dangereuse.

5) UTILISATION ET ENTRETIEN DU BLOC-PILES

a) Ne recharger I'outil qu'au moyen du chargeur pr_cis_

par le fabricant. L'utilisation d'un chargeur qui convient

un type de bloc-piles risque de provoquer un incendie s'il est

utilise avec un autre type de b Ioc-piles.

b) Utiliser les outils _lectriques uniquement avec les blocs-

piles con_us a cet effet. L'utilisation de tout autre bloc-piles

risque de causer des blessures ou un incendie.

c) Lorsque le bloc-piles n'est pas utilis_, le tenir _loign_

des objets m_talliques, notamment des trombones, de

la monnaie, des cl_s, des clous, des vis ou autres petits

objets m_talliques qui peuvent _tablir une connexion

entre les deux bornes. Le court-circuit des bomes du bloc-

piles risque de provoquer des brOlures ou un incendie.

d) En cas d'utilisation abusive, le liquide peut gicler hors

du bloc-piles; _viter tout contact avec ce liquide. Si

un contact accidentel se produit, laver a grande eau.

Si le liquide entre en contact avec les yeux, obtenir

_galement des soins m_dicaux. Le /iquide qui gic/e hors du

bloc-piles peut provoquer des irritations ou des brOlures.

6) RI_PARATION

a) Faire r_parer routil _lectrique par un r_parateur

professionnel en n'utilisant que des pi_ces de rechange

identiques. Cela permettra de maintenir une utilisation

securitaire de I'outil dectrique.

Directives de s_curit_ suppl_mentaires

pour les perceuses _ percussion

• Porter des protecteurs d'oreilles. Une exposition au bruit peut

entra_ner une perte auditive.

• Utiliser la/les poign_e(s) auxiliaire(s) si fournie(s) avec I'outil.

Une perte de ma_trise de I'outil peut entra_ner des blessures

corporelles.

• Tenir routil _lectrique par les surfaces isol_es pr_vues

cet effet pendant toute utilisation ob rorgane de coupe

pourrait entrer en contact avec des ills _lectriques caches.

Tout contact de I'organe de coupe avec un fil sous tension

17

Page 19

mettralespartiesmetalliquesexposees de I'outil sous tension et

dectrocutera I'utilisateur.

• Utiliser des brides de fixation ou tout autre dispositif de

fixation permettant de soutenir et de retenir la piece sur

une plate-forme stable. Tenir la piece avec la main ou contre

son corps est instable et risque de provoquer une perte de

ma_trisede I'outil.

• Porter des lunettes de s_curit_ ou une autre protection

oculaire. Les operations de percussion peuvent projeter les

copeaux. Les particules projetees peuvent endommager les yeux

irreversiblement. Porter un masque antipoussieres ou un appareil

respiratoire. La plupart des applications peuvent demander

I'utilisation d'un dispositif de protection des oreilles.

• Tenir fermement I'outil en tout temps. Ne pas utiliser I'outil

sans le tenir des deux mains. Faire fonctionner cet outil d'une

seule main risque de provoquer la perte de ma_trise de I'outil.

II peut aussi _tre dangereux de percer ou de tomber sur des

materiaux durs comme une barre d'armature.

• Ne pas faire fonctionner cet outil durant de Iongues

p_riodes. Les vibrations causees par la percussion du marteau

peuvent _tre nuisibles pour vos mains et vos bras. Utiliser des

gants pour amortir davantage les vibrations et limiter I'exposition

I'outil par de frequentes periodes de repos.

• Ne pas remettre b neuf les m_ches vous-m_me. La remise

neuf du burin doit _tre realisee par un specialiste autorise. Les

burins mal remis a neuf peuvent causer des blessures.

• Porter des gants pour utiliser I'outil ou pour changer

les m_ches. Les pieces metal/iques accessibles de I'outil et

les meches peuvent devenir extr_mement chaudes durant le

fonctionnement de I'outil. De petits morceaux de materiau qui se

detachent peuvent endommager les mains nues.

• Ne jamais d_poser I'outil tant que la m_che ne s'est pas

compl_tement arr_t_e. Les meches mobiles peuvent provoquer

des blessures.

• Ne pas frapper sur les m_ches coinc_es avec un marteau

pour les d_loger. Des fragments de metal ou des copeaux de

materiau peuvent se ddoger et causer des blessures.

• Ne pas surchauffer la m_che (d_coloration) durant le

meulage d'un nouveau tranchant. Les bur/ns mal uses

demandent a _tre de nouveau forges. Ne pas durcir nine faire

revenir les burins.

• Prendre des precautions a proximit_ des _vents, car ils

cachent des pi_ces mobiles. Wtements amp/es, bijoux ou

cheveux longs risquent de rester coinces dans ces pieces mobiles.

_AVERTISSEMENT : porter SYSTEMATIQUEMENT des lunettes

de protection. Les lunettes courantes NE sont PAS des lunettes de

protection. Utiliser aussi un masque antipoussieres si la decoupe

doit en produire beaucoup. PORTER SYSTEMATIQUEMENT UN

EQUIPEMENT DE SECURITE HOMOLOGUE :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) ;

• Protection auditive ANSI $12.6 ($3.19) ;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

_AVERTISSEMENT : les scies, meules, ponceuses, perceuses

ou autres outils de construction peuvent produire des poussieres

contenant des produits chimiques reconnus par I'Etat califomien

pour causer cancers, malformations congenitales ou _tre nocifs au

systeme reproducteur. Parmi ces produits chimiques, on retrouve :

• Le plomb clans les peintures a base de plomb ;

• La silice cristallisee dans les briques et le ciment, ou autres

produits de maqonnerie ; et

• L'arsenic et le chrome dans le bois ayant subi un traitement

chimique.

18

Page 20

Le risque associe a de telles expositions varie selon la frequence

laquelle on effectue ces travaux. Pour reduire toute exposition aces

produits "travailler dans un endroit bien aere, en utilisant du materiel

de securite homologue, tel un masque antipoussieres specialement

conqu pour filtrer les particules microscopiques.

• Limiter toute exposition prolong_e avec les poussi_res

provenant du pongage, sciage, meulage, pergage ou toute

autre activit_ de construction. Porter des v_tements de

protection et nettoyer a I'eau savonneuse les parties du

corps expos_es. Le fait de laisser la poussiere penetrer dans la

bouche, les yeux ou la peau peut favoriser I'absorption de produits

chimiques dangereux.

AAVERTISSEMENT : cet outil peut produire et/ou repandre

de la poussiere susceptible de causer des dommages serieux et

permanents au systeme respiratoire. Utiliser systematiquement un

appareil de protection des voies respiratoires homologue par le

NIOSH ou I'OSHA. Diriger les particules dans le sens oppose au

visage et au corps.

_AVERTISSEMENT : pendant I'utilisation, porter

syst_matiquement une protection auditive individuelle

adequate homologu_e ANSI $12.6 ($3.19). Sous certaines

conditions et suivant la duree d'utilisation, le bruit emanant de ce

produit pourrait contribuer a une perte de I'acuite auditive.

_ATTENTION : apr_s utilisation, ranger I'outil sur son c6t_,

sur une surface stable, I_ ob il ne pourra ni faire tr_bucher

ni faire chuter quelqu'un. Certains outils equipes d'un large bloc-

piles peuvent tenir a la verticale sur celui-ci, mais manquent alors de

stabilit&

• L'etiquette apposee sur votre outil peut inclure les symboles

suivants. Les symboles et leur definition sont indiques ci-apres "

V................... volts A....................... amperes

Hz................. hertz W...................... watts

min ............... minutes

=-- ou DC... courant continu

(_)................. classe I

fabrication

(mis a la terre)

[] ................. fabrication

classe II

(double isolation) nominale

.../min ........... par minute G ..................... borne de terre

IPM ............... impacts par A ...................... symbole

minute d'avertissement

BPM ............. battements par r/min ................. tours par

minute minute

sfpm ............. pieds lineaires SPM (FPM)....... frequence par

par minute (plpm) minute

'_ ou AC .......... courant

altematif

ou AC/DC... courant

altematif

ou continu

no ..................... vitesse a vide

n....................... vitesse

Consignes de s_curit_ importantes

propres _ tous les blocs-piles

Pour commander un bloc-piles de rechange, s'assurer d'inclure son

numero de catalogue et sa tension. Consulter le tableau figurant a.

la fin du present mode d'emploi pour connaTtre la compatibilite des

chargeurs et des blocs-piles.

Le bloc-piles n'est pas totalement charge d'usine. Avant d'utiliser le

bloc-piles et le chargeur, lire les consignes de securite ci-dessous.

Puis suivre la procedure de charge indiquee.

LIRE TOUTES LES CONSIGNES

• Ne pas recharger ou utiliser un bloc-piles en milieu

d_flagrant, en presence, par exemple, de poussi_res, gaz

ou liquides inflammables. Le fait d'inserer ou retirer un bloc-

19

Page 21

pilesdesonchargeurpourraitcauserI'inflammationdepoussieres

oud'emanations.

• NE JAMAIS forcer I'insertion d'un bloc-piles dans un

chargeur. NE modifier un bloc-piles d'AUCUNE fa_on

pour le faire rentrer dans un chargeur incompatible, car

il pourrait se briser et causer des dommages corporels

graves. Consulter le tableau en derniere page de ce manuel pour

conna_tre les compatibilites entre chargeurs et blocs-piles.

• Recharger les blocs-piles exclusivement dans des chargeurs

DEWALT.

• NE PAS eclabousser le bloc-piles ou I'immerger dans I'eau ou

dans tout autre liquide.

• Ne pas entreposer ou utiliser I'appareil et le bloc-piles en

presence de temperatures ambiantes pouvant exc_der

40 °C (105 °F) (comme clans des hangars ou des b&timents

m_talliques I'_t_).

AAVERTISSEMENT : ne jamais ouvrir le bloc-piles pour quelque

raison que ce soit. Si le boftier du bloc-piles est fissure ou

endommage, ne pas I'inserer clans un chargeur. Ne pas broyer,

echapper ou endommager le bloc-piles. Ne pas utiliser un bloc-piles

ou un chargeur qui a requ un choc violent, qui est tombe, ecrase

ou qui a ete endommage de quelque maniere que ce soit (p. ex.

perce par un clou, frappe d'un coup de marteau, marche dessus).

Les blocs-piles endommages doivent _tre envoyes au centre de

reparation pour _tre recycles.

_AVERTISSEMENT: risque d'incendie. Ne pas ranger ni

ne transporter /es piles de mani_re a ce que des objets

m_talliques puissent entrer en contact avec les bornes

expos_es des piles. On ne doit pas mettre, par exemple, le bloc-

piles sans capuchon dans un tablier, une poche, une bofte a outils,

une bofte de necessaire de produit, un tiroir, etc. avec des clous, des

vis, des cles, etc. Le transport des piles peut causer un incendie

si les bornes des piles entrent en contact involontairement

avec des mati_res conductrices comme des cl_s, de la

monnaie, des outils manuels et d'autres _l_ments semblables.

La Hazardous Material Regulations (reglementation sur les produits

dangereux) du departement americain des transports interdit en fait le

transport des blocs-piles pour le commerce et dans les avions (c.-a-d.

dans des valises et les bagages a main) A MOINS qu'ils ne soient

bien proteges contre les courts-circuits. Pour le transport de piles

individuelles, on doit donc s'assurer que les bomes sont protegees

et bien isolees contre toute matiere pouvant entrer en contact avec

elles et provoquer un court-circuit.

DIRECTIVES DE SleCURITle SPleCIFIQUES POUR LES PILES

AU LITHIUM-ION (Li-lon)

• Ne pas incin_rer le bloc-piles m_me s'il est s_v_rement

endommag_ ou compl_tement usage, car il pourrait exploser

et causer un incendie. Pendant I'incineration des blocs-piles au

lithium-ion, des vapeurs et matieres toxiques sont degagees.

• En cas de contact du liquide de la pile avec la peau, rincer

imm_diatement au savon doux et a I'eau. En cas de contact

oculaire, rincer I'ceil ouvert a I'eau claire une quinzaine de minutes

ou jusqu'a ce que I'irritation cesse. Si des soins medicaux

s'averaient necessaires, noter que I'dectrolyte de la pile est

compose d'un mdange de carbonates organiques liquides et de

sels de lithium.

• Le contenu des cellules d'une pile ouverte peut causer une

irritation respiratoire. En cas d'inhalation, exposer I'individu

I'air libre. Si les sympt6mes persistent, consulter un medecin.

•_AVERTISSEMENT: risques de brOlure. Le liquide de la pile peut

s'enflammer s'il est expose a des etincelles ou a une flamme.

2O

Page 22

Le sceau SRPRC Mc

Le sceau SRPRCMc(Societe de recyclage des piles

rechargeables au Canada) appose sur une pile au

nickel-cadmium, a.hydrure metallique de nickel ou au

lithium-ion (ou un bloc-piles) indique que les co0ts de

recyclage de ces derniers en fin d'utilisation ont dejb.

et6 regles par DEWALT.Dans certaines regions, la mise

au rebut ou aux ordures municipales des piles au nickel-cadmium, a.

I'hydrure metallique de nickel ou au lithium-ion, est illegale ; le

programme de SRPRC constitue donc une solution pratique et

ecologique.

La SRPRCMc,en collaboration avec DEWALTet d'autres utilisateurs

de piles, a mis sur pied des programmes aux Etats-Unis et au

Canada pour faciliter la collecte des piles au nickel-cadmium, a.

I'hydrure metallique de nickel ou au lithium-ion usagees. Aidez-nous

a.proteger I'enwonnement et a.conserver nos ressources naturelles

en renvoyant les piles au nickel-cadmium, a. I'hydrure metallique de

nickel ou au lithium-ion usagees a.un centre de reparation autorise

DEWALT ou chez votre detaillant afin qu'elles y soient recyclees. On

peut en outre se renseigner aupres d'un centre de recyclage local

pour connaTtre d'autres sites les acceptant.

SRPRCMcest une marque deposee de la Societe de recyclage des

piles rechargeables au Canada.

Directives de s_curit_ importantes

propres _ tous les chargeurs de piles

CONSERVER CES INSTRUCTIONS : ce manuel contient des

directives de securite et d'utilisation importantes propres aux

chargeurs de piles.

• Avant d'utiliser lechargeur, life toute consigne et tout avertissement

apposes sur le chargeur, le bloc-piles et le produit utilisant le bloc-

piles.

I_AVERTISSEMENT : risques de chocs dectriques. Ne laisser aucun

liquide penetrer dans le chargeur, des chocs dectriques pourraient en

resulter.

_ATTENTION : risques de brOlure. Pour reduire tout risque de

dommages corporels, ne recharger que des blocs-piles rechargeables

DEWALT. Tout autre type de piles pourrait exploser et causer des

dommages corporels et materiels.

AVIS : sous certaines conditions, Iorsque les contacts de

chargement exposes a I'interieur du le chargeur est connecte au bloc

d'alimentation, des materiaux etrangers pourraient court-circuiter le

chargeur. Les corps etrangers conducteurs tels que (mais pas limite

a) poussieres de rectification, debris metalliques, laine d'acier, feuilles

d'aluminium, ou toute accumulation de particules metalliques doivent

_tre maintenus a distance des orifices du chargeur. Debrancher

systematiquement le chargeur Iorsque le bloc-piles n'y est pas insere.

Debrancher systematiquement le chargeur avant tout entretien.

• NE PAS tenter de charger de bloc-piles avec des chargeurs

autres que ceux d_crits dans ce manuel. Le chargeur et son

bloc-piles ont ete conqus tout specialement pour fonctionner

ensemble.

• Ces chargeurs n'ont pas _t_ census pour une utilisation

autre que recharger les blocs-piles rechargeables DEWALT.

Toute autre utilisation comporte des risques d'incendie, de chocs

dectriques ou d'dectrocution.

• Prot_ger le chargeur de la pluie ou de la neige.

• Tirer sur la fiche plutSt que sur le cordon pour d_brancher

le chargeur. Cela permet de reduire les risques d'endommager

la fiche ou le cordon d'alimentation.

• S'assurer que le cordon est prot_g_ de mani_re a ce que

personne ne marche ni ne tr_buche dessus, ou a ce qu'il

ne soit ni endommag_ ni soumis a aucune tension.

21

Page 23

N'utiliserunerallongequ'encasden_cessit_absolue.

L'utilisation d'une ral/onge inadequate comporte des risques

d'incendie, de chocs dectriques ou d'dectrocution.

Lots de I'utilisation d'un outil _lectrique _ I'ext_rieur, utiliser

une rallonge congue a cet effet. L'utilisation d'une ral/onge

conque pour I'exterieur reduit les risques de chocs dectriques.

Pour la s_curit_ de I'utilisateur, utiliser une rallonge de

calibre ad_quat (AWG, American Wire Gauge [calibrage

am_ricain normalis_ des fils _lectriques]). Plus le calibre est

petit, et plus sa capacite est grande. Un calibre 16, par exemple,

a une capacite superieure a un calibre 18. L'usage d'une rallonge

de calibre insuffisant causera une chute de tension qui entra_nera

perte de puissance et surchauffe. Si plus d'une rallonge est utilisee

pour obtenir une certaine Iongueur, s'assurer que chaque rallonge

presente au moins le calibre de fil minimum. Le tableau ci-dessous

illustre les calibres a utiliser selon la Iongueur de rallonge et

I'intensite nominale indiquee sur la plaque signaletique. En cas

de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la

rallonge peut supporter de courant.

Intensit_ (en

amperes)

Sup_rieur

0

6

10

12

Calibres minimaux des rallonges

Inf_rieur

6

10

12

16

volts

120 V

240 V

Longueurtotale de cordon

en m_tres (pieds)

7,6 15,2 30,5 45,7

(25) (50) (100) (150)

15,2 30,5 61,0 91,4

(50) (100)(200) (300)

AWG

18

16 16 14

18

16 14 12

16

16 14 12

14

12 Nonrecommande

• Ne poser aucun objet sur le chargeur. Ne pas mettre le

chargeur sur une surface molle qui pourraff en bloquer la

ventilation et provoquer une surchauffe interne. E/oigner

le chargeur de toute source de chaleur. Le chargeur dispose

d'orifices d'aeration sur le dessus et le dessous du boftier.

• Ne pas monter le chargeur sur un mur ni le fixer de mani_re

permanente sur une surface quelconque. Le chargeur est

destine a une utilisation sur une surface plane et stable (c.-a-d. un

dessus de table).

• Ne pas le faire fonctionner avec un cordon d'alimentation

ou une fiche endommag_e.

• Ne pas utiliser le chargeur s'il a regu un coup, fait une chute

ou a _t_ endommag_ de quelque fagon que ce soit. Le

ramener dans un centre de reparation agree.

• Nepasd_monterlechargeur.Pourtoutserviceour_paration,

le rapporter dans un centre de r_paration agree. Le fait de/e

reassembler de faqon incorrecte comporte des risques de chocs

dectriques, d'dectrocution et d'incendie.

• D_brancher le chargeur du secteur avant tout entretien.

Cela r_duira tout risque de chocs _lectriques. Le fait de retirer

le bloc-piles ne reduira pas ces risques.

• NE JAMAIS tenter de connecter deux chargeurs ensemble.

• Le chargeur a _t_ congu pour _tre aliment_ en courant

_lectrique domestique standard de 120 volts. Ne pas tenter

de I'utiliser avec toute autre tension. Ce/a ne s'app/ique pas

aux chargeurs de postes mobiles.

Chargeurs

Votre outil fonctionne avec un chargeur DEWALT. S'assurer de bien

lire toutes les directives de securite avant toute utilisation du chargeur.

Consulter le tableau a. rarriere de ce manuel pour vous informer de la

compatibilite entre chargeurs et blocs-piles.

22

Page 24

Procedure de charge (Fig. 1)

1. Branchez le chargeur dans la prise

appropriee avant d'y inserer le bloc-

piles.

2. Inserez le bloc-piles (J)dans le chargeur,

comme illustre en figure 1. Le chargeur

est dote d'une jauge de carburant a,

trois lumieres qui clignotera selon I'etat

de charge du bloc-piles.

3. La fin de lacharge sera indiquee par les

trois voyants rouges qui demeureront

continuellement allumes. Le bloc-piles

est charge a,plein et peut _tre utilise ou

laisse dans le chargeur a,ce moment.

_:¢ ¢ [] 0 % - 33 % 1°rvoyant clignote

e_e [] 33 % - 66 % 1_rvoyant allum_, 2evoyant clignote

• o:_ 66 % - 99 % 1% 2° voyants allum_s, 3evoyant clignote

• e e | 100% 1% 2%3e,voyants allum_s

FIG. 1

Diagnostique de chargeur

Ce chargeur est congu pour detecter certains problemes pouvant

survenir avec les blocs-piles ou le chargeur. Les problemes sont

indiques par trois voyants clignotant ensemble dans des motifs

differents.

PROBL#ME AVEC LE SECTEUR

Lorsque le chargeur est utilise avec certaines sources d'alimentation

portatifs comme des generatrices ou des sources qui font la

conversion de c.c. a c.a., le chargeur peut suspendre temporairement

son fonctionnement. Les trois voyants rouges clignoteront ensemble

avec deux clignotements rapides suivis par une pause. Cela

indique que la source d'alimentation est hors tolerance.

PILE EN MAUVAIS #TAT

Lechargeur peut aussi detecter lespiles faibles ou endommagees. Les

trois voyants rouges clignoteront ensemble avec un clignoternent

rapide. La pile ne se chargera plus et doit _tre retournee a,un centre

de reparation ou a,un site de collecte pour le recyclage.

CHARGEUR EN MAUVAIS E'I'AT

Le chargeur detectera s'il ne fonctionne pas correctement. Les trois

voyants rouges clignoteront ensemble avec un clignotement rapide

suivi d'un long clignotement. Le chargeur ne fonctionnera plus et

doit _tre retourne a,un centre de reparation autorise ou remplace.

PILE LAISS# DANS LE CHARGEUR

Le chargeur et le bloc-piles peuvent _tre laisses branches avec les

voyants rouges allumes indefiniment. Le chargeur maintiendra le bloc-

piles charge a,pleinet en bon etat. Ce chargeur comprend un mode de

mise au point automatique qui egalise ou equilibre chaque cellule du

bloc-piles pour lui permettre de fonctionner a,son rendement optimum.

Les blocs-piles doivent _tre regles chaque semaine ou Iorsque la pile

ne fonctionne plus de maniere optimale. Pour utiliser le mode de

mise au point automatique, mettre le bloc-piles dans le chargeur et 'y

laisser pendant au moins 8 heures.

Remarques importantes concernant le

chargement

1. Pour augmenter la duree de vie du bloc-piles et optimiser son

rendement, le recharger a,une temperature ambiante de 18 °C

a, 24 °C (65 °F a, 75 °F). NE PAS recharger le bloc-piles a,

une temperature inferieure a, + 4,5 °C (+ 40 °F) ou superieure

23

Page 25

a.+ 40,5°C(+105°F).C'estimportantpourprevenirtout

dommageserieuxaubloc-piles.

2.Lechargeuretsonbloc-pilespeuventdevenirchaudsautoucher

pendantlacharge.C'estnormaletnerepresenteenaucuncas

unedefaillanceduproduit.Pourfaciliterlerefroidissementdu

bloc-pilesapresutilisation,eviterdelaisserlechargeuroulebloc-

pilesdansunlocalo0latemperatureambianteestelev6ecomme

dansunhangarmetalliqueouuneremorquenonisolee.

3.Silebloc-pilesneserechargepascorrectement:

a.Verifierlebonfonctionnementdelapriseenybranchantune

lampeoutoutautreappareilelectrique.

b.Verifierquelaprisen'estpascontr61eeparuninterrupteurqui

coupelecourantIorsqu'oneteintleslumieres.

c.Deplacerlechargeuretlebloc-pilesdansunlocalo0la

temperatureambiantesetrouveentreenviron18°Cet24°C

(65°Fet75°F).

d.Sileproblemepersiste,amenerI'outil,lebloc-pilesetson

chargeurdansuncentredereparationlocal.

4.Rechargerle bloc-pilesIorsqu'ilneproduitplusassezde

puissancepoureffectuerun travailqu'ilfaisaitfacilement

auparavant.NEPASCONTINUERa.I'utiliserdanscesconditions.

Suivrelaproceduredecharge.Sinecessaire,ilestaussipossible

derechargerunbloc-pilespartiellementdechargesanseffet

nuisiblesurlebloc-piles.

5.Danscertainescirconstances,Iorsquelechargeurestbranche

aublocd'alimentation,lescontactsdechargementexposes

a.I'interieurduchargeurpeuvent_trecourt-circuitespardes

corpsetrangersconducteurstelsque,maissanss'y limiter,

poussieresderectification,debrismetalliques,lained'acier,feuilles

d'aluminium,outouteaccumulationdeparticulesmetalliques.IIs

doivent_tremaintenusa.distancedesouverturesduchargeur.

DebranchersystematiquementlechargeurIorsquelebloc-piles

n'yestpasinsere.Debranchersystematiquementlechargeur

avanttoutentretien.

6.NepascongelerouimmergerlechargeurdansI'eauoutout

autreliquide.

AAVERTISSEMENT: risques de chocs dectriques. Ne laisser

aucun liquide penetrer dans le chargeur, des chocs dectriques

pourraient en resulter.

_AVERTISSEMENT : risques de brOlure. Ne jamais tenter d'ouvrir

le bloc-piles pour quelque raison que ce soit. Si le boftier plastique

du bloc-piles est brise ou fissure, le retoumer dans un centre de

reparation pour y _tre recycle.

Recommandations de stockage

1. Le lieu ideal de rangement est un lieufrais et sec, a.I'abri de toute

lumiere solaire directe et de toute temperature excessive.

2. Pour un stockage prolonge, il est recommande d'entreposer le

bloc-piles pleinement charge dans un lieu frais et sec, hors du

chargeur pour optimiser les resultats.

REMARQUE • les blocs-piles ne devraient pas _tre entreposes

completement decharges. II sera necessaire de recharger le bloc-

piles avant reutilisation.

CONSERVER CES CONSIGNES POUR

UTILISATION ULTERIEURE

DESCRIPTION (Fig. 2)

_AVERTISSEMENT : ne jamais modifier I'outil dectrique ni aucun

de ses composants, car il y a risques de dommages corporels ou

materiels.

24

Page 26

A.Poigneelaterale

B.Detente

C.Boutondecommande

marcheavant/marchearriere

(Boutondeverrouillage)

D.Selecteurdemode

E.Poigneeprincipale

FIG. 2

H

F

D

J?

A

I

F.Tige de reglage de

profondeur

G. Buse d'extraction des

poussieres (A utiliser avec le

modele D25302DH - Vendu

separement)

Poignde latdrale (Fig. 2)

i_AVERTISSEMENT : pour reduire tout risque de dommages

corporels, utiliser SYSTEMATIQUEMENT I'outil avec sa poignee

laterale installee correctement et solidement arrimee, Tout

manquement a cette directive pourrait faire que la poignee laterale

glisse pendant I'utilisation de I'outil et entra_ner la perte du contr61e

de celui-cL Maintenir I'outil fermement a deux mains pour un contrOle

maximum,

Ce marteau rotatif est equipe d'origine d'une poignee laterale. La

poignee laterale (A)peut _tre installee pour pouvoir servir a,un droitier

ou a,un gaucher.

INSTALLATION DE LA POIGN#E LATI'--RALE