Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DeWALT

Instruction Manual

Guide D’utilisation

Manual de instrucciones

DCCS670

60V Cordless Chainsaw

Scie à chaîne sans fil 60 V

Sierra de cadena inalámbrica de 60 V

Page 2

ENGLISH

English (original instructions) 1

Français (traduction de la notice d’instructions originale) 17

Español (traducido de las instrucciones originales) 34

Page 3

ENGLISH

1

Definitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations and your risk

of personal injury or property damage.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or seriousinjury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or seriousinjury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderateinjury.

(Used without word) Indicates a safety related message.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in propertydamage.

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

seriousinjury.

WARNING: To reduce the risk of injury, read the

instructionmanual.

If you have any questions or comments about this or

any

DeWALT tool, call us toll free at:

1-800-4-

DeWALT (1-800-433-9258).

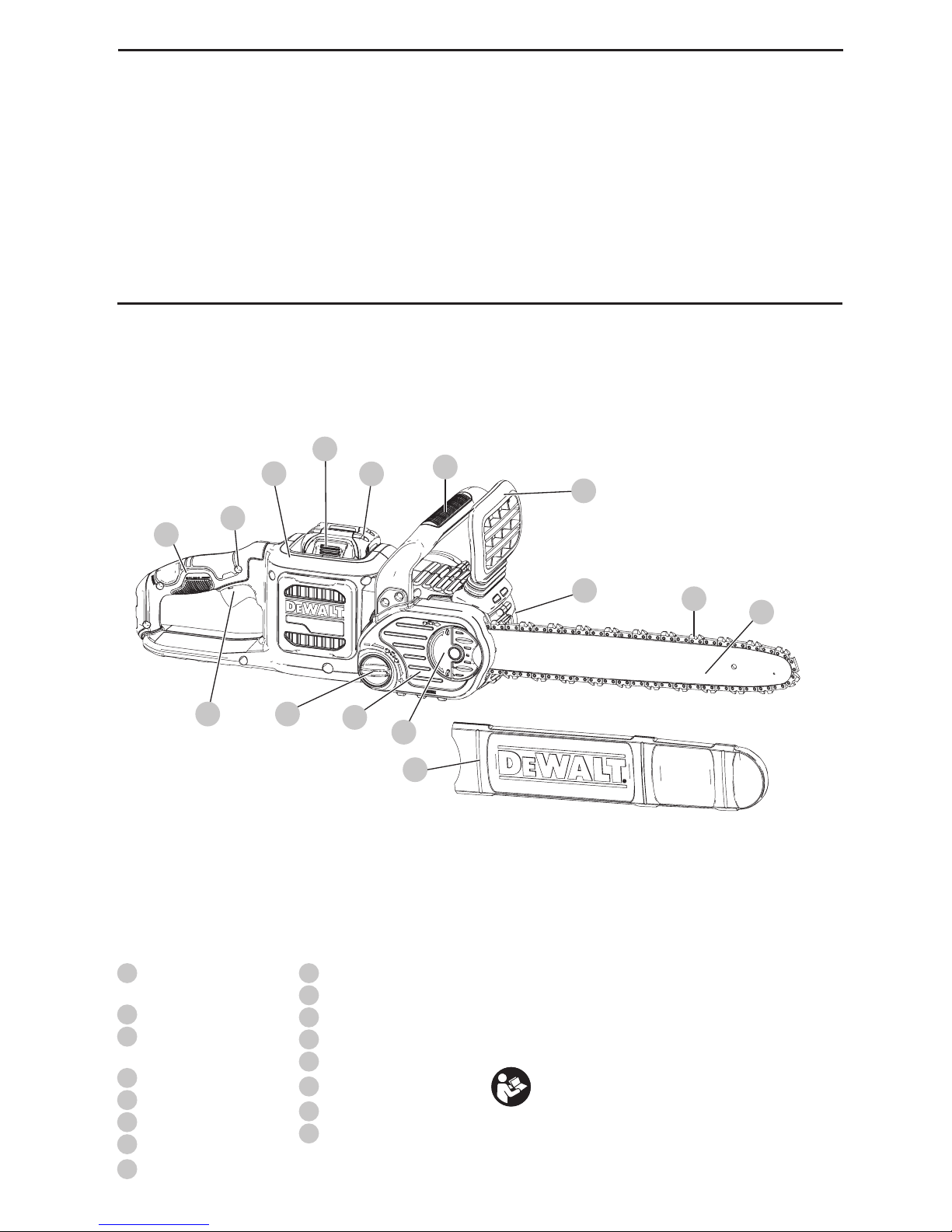

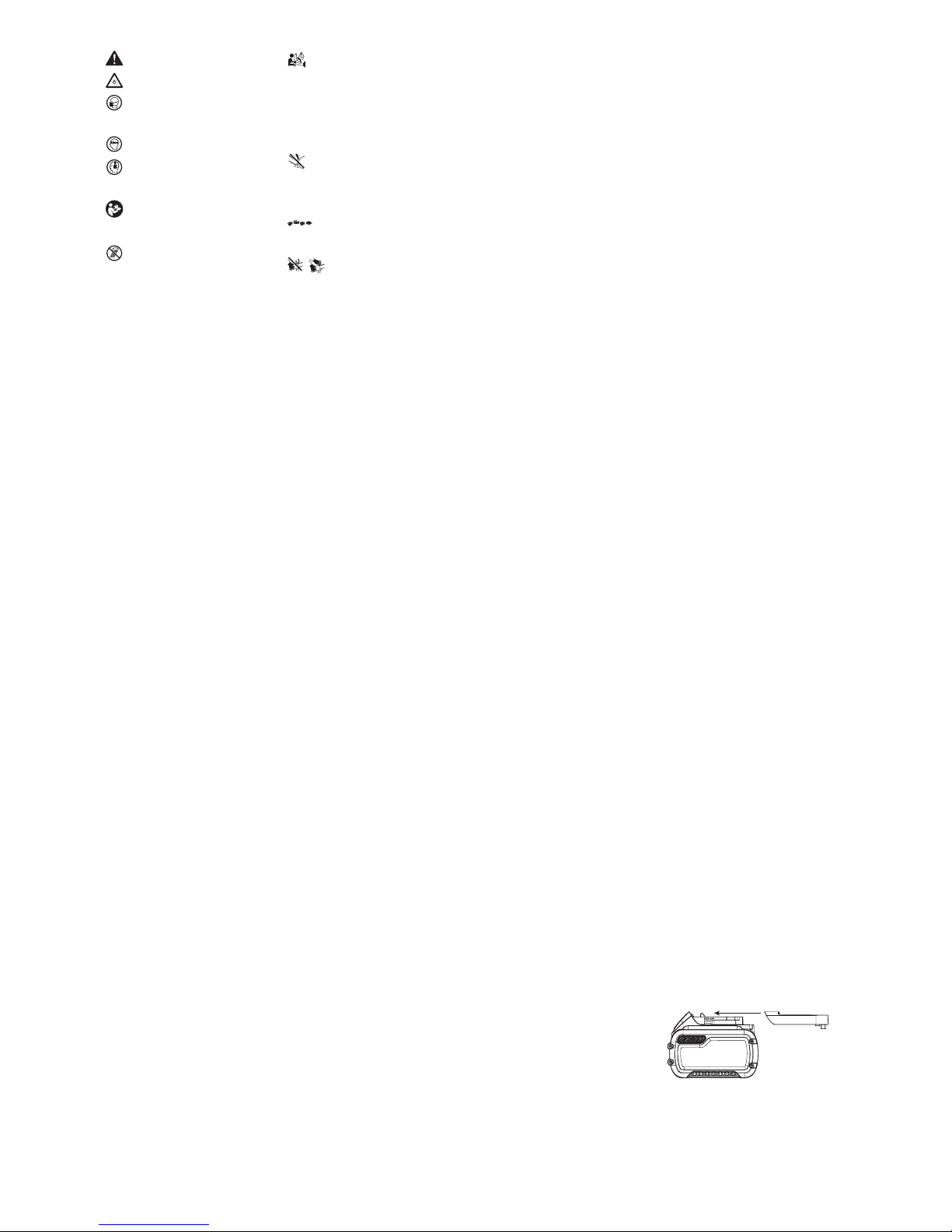

1

Variable speed trigger

switch

2

Lock-off lever

3

Chain brake / front hand

guard

4

Guide bar

5

Saw chain

6

Sprocket cover

7

Battery Pack

8

Bar adjust locking knob

9

Chain tensioning knob

10

Oil level indicator

11

Guide bar scabbard

12

Rear handle

13

Front handle

14

Battery housing

15

Battery release button

16

Oil cap (not shown)

Fig. A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Page 4

ENGLISH

2

GENERAL POWER TOOL SAFETY

WARNINGS

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

seriousinjury.

SAVE ALL WARNINGS AND

INSTRUCTIONS FOR FUTURE

REFERENCE

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

powertool.

1) Work Area Safety

a ) Keep work area clean and well lit. Cluttered or dark

areas inviteaccidents.

b ) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust orfumes.

c ) Keep children and bystanders away while

operating a power tool. Distractions can cause you

to losecontrol.

2) Electrical Safety

a ) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electricshock.

b ) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed orgrounded.

c ) Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electricshock.

d ) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electricshock.

e ) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electricshock.

f ) If operating a power tool in a damp location

is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of a GFCI

reduces the risk of electricshock.

3) Personal Safety

a ) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personalinjury.

b ) Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personalinjuries.

c ) Prevent unintentional starting. Ensure the

switch is in the off position before connecting to

power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

finger on the switch or energizing power tools that

have the switch on invitesaccidents.

d ) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personalinjury.

e ) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpectedsituations.

f ) Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry or

long hair can be caught in movingparts.

g ) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-relatedhazards.

4) Power Tool Use and Care

a ) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it wasdesigned.

b ) Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

berepaired.

c ) Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power

toolaccidentally.

d ) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrainedusers.

e ) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are

caused by poorly maintained powertools.

f ) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier tocontrol.

g ) Use the power tool, accessories and tool bits, etc.

in accordance with these instructions, taking

Page 5

ENGLISH

3

into account the working conditions and the

work to be performed. Use of the power tool for

operations different from those intended could result

in a hazardoussituation.

5) Battery Tool Use and Care

a ) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used

with another batterypack.

b ) Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury andfire.

c ) When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws, or other small metal objects,

that can make a connection from one terminal to

another. Shorting the battery terminals together may

cause burns or afire.

d ) Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally

occurs, flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from

the battery may cause irritation orburns.

6) Service

a ) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool ismaintained.

Chainsaw Safety Warnings

WARNING: Additional safety warnings for

chainsaws.

• Keep all parts of the body away from the saw chain

when the chain saw is operating. Before you start

the chain saw, make sure the saw chain is not

contacting anything. A moment of inattention while

operating chain saws may cause entanglement of your

clothing or body with the sawchain.

• Always hold the chain saw with your right hand

on the rear handle and your left hand on the front

handle. Holding the chain saw with a reversed hand

configuration increases the risk of personal injury and

should never bedone.

• Hold the power tool by insulated gripping surfaces

only, because the saw chain may contact hidden

wiring. Saw chains contacting a "live" wire may make

exposed metal parts of the power tool "live" and could give

the operator an electricshock.

• Wear safety glasses and hearing protection. Further

protective equipment for head, hands, legs and

feet is recommended. Adequate protective clothing

will reduce personal injury by flying debris or accidental

contact with the sawchain.

• Do not operate a chain saw in a tree. Operation of a

chain saw while up in a tree may result in personalinjury.

• Always keep proper footing and operate the chain

saw only when standing on fixed, secure and level

surface. Slippery or unstable surfaces such as ladders may

cause a loss of balance or control of the chainsaw.

• When cutting a limb that is under tension be alert

for spring back. When the tension in the wood fibers is

released the spring loaded limb may strike the operator

and/or throw the chain saw out ofcontrol.

• Use extreme caution when cutting brush and

saplings. The slender material may catch the saw chain

and be whipped toward you or pull you offbalance.

• Carry the chain saw by the front handle with the

chain saw switched off and away from your body.

When transporting or storing the chain saw always

fit the guide bar cover. Proper handling of the chain

saw will reduce the likelihood of accidental contact with

the moving sawchain.

• Follow instructions for lubricating, chain tensioning

and changing accessories. Improperly tensioned or

lubricated chain may either break or increase the chance

forkickback.

• Keep handles dry, clean, and free from oil and

grease. Greasy, oily handles are slippery causing loss

ofcontrol.

• Cut wood only. Do not use chain saw for purposes

not intended. For example: do not use chain saw

for cutting plastic, masonry or non-wood building

materials. Use of the chain saw for operations different

than intended could result in a hazardoussituation.

Causes and Operator Prevention of

Kickback:

Kickback may occur when the nose or tip of the guide bar

touches an object, or when the wood closes in and pinches

the saw chain in thecut.

Tip contact in some cases may cause a sudden reverse

reaction, kicking the guide bar up and back towards

theoperator.

Pinching the saw chain along the top of the guide bar may

push the guide bar rapidly back towards theoperator.

Either of these reactions may cause you to lose control of

the saw which could result in serious personal injury. Do not

rely exclusively upon the safety devices built into your saw.

As a chain saw user, you should take several steps to keep

your cutting jobs free from accident orinjury.

Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be avoided by

taking proper precautions as given below:

• Maintain a firm grip, with thumbs and fingers

encircling the chain saw handles, with both hands

on the saw and position your body and arm to allow

you to resist kickback forces. Kickback forces can be

controlled by the operator, if proper precautions are taken.

Do not let go of the chainsaw.

• Do not overreach and do not cut above shoulder

height. This helps prevent unintended tip contact

and enables better control of the chain saw in

unexpectedsituations.

Page 6

ENGLISH

4

• Only use replacement bars and chains specified

by the manufacturer. Incorrect replacement bars and

chains may cause chain breakage and/orkickback.

• Follow the manufacturer’s sharpening and

maintenance instructions for the saw chain.

Decreasing the depth gauge height can lead to

increasedkickback.

The Following Precautions Should Be

Followed to Minimize Kickback:

1 . Grip saw firmly. Hold the chain saw firmly with both

hands when the motor is running. Use a firm grip

with thumbs and fingers encircling the chain saw

handles. Chain saw will pull forward when cutting on the

bottom edge of the bar, and push backward when cutting

along the top edge of thebar.

2 . Do not overreach.

3 . Keep proper footing and balance at alltimes.

4 . Don’t let the nose of the guide bar contact a log,

branch, ground or otherobstruction.

5 . Don’t cut above shoulderheight.

6 . Use devices such as low kickback chain and reduced

kickback guide bars that reduce the risks associated

withkickback.

7 . Only use replacement bars and chains specified by

the manufacturer or theequivalent.

8 . Never let the moving chain contact any object at the

tip of the guidebar.

9 . Keep the working area free from obstructions such

as other trees, branches, rocks, fences, stumps, etc.

Eliminate or avoid any obstruction that your saw chain

could hit while you are cutting through a particular log

orbranch.

10 . Keep your saw chain sharp and properly tensioned.

A loose or dull chain can increase the chance of

kickback. Check tension at regular intervals with the

motor stopped and tool unplugged, never with the

motorrunning.

11 . Begin and continue cutting only with the chain

moving at full speed. If the chain is moving at a slower

speed, there is a greater chance for kickback tooccur.

12 . Cut one log at atime.

13 . Use extreme caution when re-entering a previous

cut. Engage ribbed bumpers into wood and allow chain

to reach full speed before proceeding withcut.

14 . Do not attempt plunge cuts or borecuts.

15 . Watch for shifting logs or other forces that could

close a cut and pinch or fall intochain.

Kickback Safety Features

WARNING: The following features are included

on your saw to help reduce the hazard of kickback;

however such features will not totally eliminate this

dangerous reaction. As a chain saw user do not rely

only on safety devices. You must follow all safety

precautions, instructions, and maintenance in this

manual to help avoid kickback and other forces which

can result in seriousinjury.

• Reduced-Kickback Guide Bar, designed with a small radius

tip which reduces the size of the kickback danger zone on

bar tip. A reduced - kickback guide bar is one which has

been demonstrated to significantly reduce the number

and seriousness of kickbacks when tested in accordance

with safety requirements for electric chainsaws.

• Low-Kickback Chain, designed with a contoured depth

gauge and guard link which deflect kickback force

and allow wood to gradually ride into the cutter. A

low-kickback chain is a chain which has met kickback

performance requirements of ANSI B175.1–2012.

• Do not operate chain saw while in a tree, on a ladder, on a

scaffold, or from any unstablesurface.

• Hold tool by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden

wiring. Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock theoperator.

• Do not attempt operations beyond your capacity or

experience. Read thoroughly and understand completely

all instructions in thismanual.

• Before you start chain saw, make sure saw chain is not

contacting anyobject.

• Do not operate a chain saw with one hand! Serious injury

to the operator, helpers, or bystanders may result from

one handed operation. A chain saw is intended for twohanded useonly.

• Keep the handles dry, clean, and free of oil orgrease.

• Do not allow dirt, debris, or sawdust to build up on the

motor or outside airvents.

• Stop the chain saw before setting itdown.

• Do not cut vines and/or small underbrush.

• Use extreme caution when cutting small size brush and

saplings because slender material may catch the saw

chain and be whipped toward you or pull you offbalance.

WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to the State

of California to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicalsare:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemicallytreatedlumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are

specially designed to filter out microscopicparticles.

• Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

Page 7

ENGLISH

5

wash exposed areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmfulchemicals.

WARNING: Use of this tool can generate and/

or disperse dust, which may cause serious and

permanent respiratory or other injury. Always use

NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles

away from face andbody.

Chainsaw Names and Terms

• Bucking - The process of cross cutting a felled tree or log

intolengths.

• Motor Brake - A device used to stop the saw chain when

the trigger isreleased.

• Chain Saw Powerhead - A chain saw without the saw

chain and guidebar.

• Drive Sprocket or Sprocket - The toothed part that drives

the sawchain.

• Felling - The process of cutting down atree.

• Felling Back Cut - The final cut in a tree felling operation

made on the opposite side of the tree from the

notchingcut.

• Front Handle - The support handle located at or toward

the front of the chainsaw.

• Front Hand Guard - A structural barrier between the front

handle of a chain saw and the guide bar, typically located

close to the hand position on the fronthandle.

• Guide Bar - A solid railed structure that supports and

guides the sawchain.

• Guide Bar Scabbard - Enclosure fitted over guide bar to

prevent tooth contact when saw is not inuse.

• Kickback - The backward or upward motion, or both of the

guide bar occurring when the saw chain near the nose of

the top area of the guide bar contacts any object such as a

log or branch, or when the wood closes in and pinches the

saw chain in thecut.

• Kickback, Pinch - The rapid pushback of the saw which

can occur when the wood closes in and pinches the

moving saw chain in the cut along the top of the

guidebar.

• Kickback, Rotational - The rapid upward and backward

motion of the saw which can occur when the moving saw

chain near the upper portion of the tip of the guide bar

contacts an object, such as a log orbranch.

• Limbing - Removing the branches from a fallen tree

• Low-Kickback Chain - A chain that complies with the

kickback performance requirements of ANSI B175.1–2012

(when tested on a representative sample of chain saws.)

• Normal Cutting Position - Those positions assumed in

performing the bucking and fellingcuts.

• Notching Undercut - A notch cut in a tree that directs the

tree’sfall.

• Rear Handle - The support handle located at or toward the

rear of thesaw.

• Reduced Kickback Guide Bar - A guide bar which has been

demonstrated to reduce kickbacksignificantly.

• Replacement Saw Chain - A chain that complies with

kickback performance requirements of ANSI B175.1–2000

when tested with specific chain saws. It may not meet

the ANSI performance requirements when used with

othersaws.

• Saw Chain - A loop of chain having cutting teeth, that cut

the wood,and that is driven by the motor and is supported

by the guidebar.

• Ribbed Bumper - The ribs used when felling or bucking to

pivot the saw and maintain position whilesawing.

• Switch - A device that when operated will complete or

interrupt an electrical power circuit to the motor of the

chainsaw.

• Switch Linkage - The mechanism that transmits motion

from a trigger to theswitch.

• Switch Lockout - A movable stop that prevents

the unintentional operation of the switch until

manuallyactuated.

Additional Safety Information

WARNING: ALWAYS use safety glasses. Everyday

eyeglasses are NOT safety glasses. Also use face or

dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETYEQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratoryprotection.

WARNING: Always wear proper personal hearing

protection that conforms to ANSI S12.6 (S3.19)

during use. Under some conditions and duration

of use, noise from this product may contribute to

hearingloss.

CAUTION: When not in use, place tool on its

base on a stable surface where it will not cause

a tripping or falling hazard. Some tools with large

battery packs will stand upright on the battery pack

but may be easily knockedover.

• Air vents often cover moving parts and should be

avoided. Loose clothes, jewelry or long hair can be

caught in movingparts.

The label on your tool may include the following symbols. The

symbols and their definitions are asfollows:

V ......................... volts

Hz ....................... hertz

min ..................... minutes

or DC ......direct current

...................... Class I

Construction

(grounded)

…/min ..............per minute

BPM .................... beats per minute

IPM ..................... impacts per

minute

RPM .................... revolutions per

minute

sfpm ................... surface feet per

minute

SPM .................... strokes per minute

A ......................... amperes

W ........................ watts

or AC ...........alternating current

or AC/DC .... alternating or

direct current

...................... Class II

Construction

(double insulated)

no ....................... no load speed

n ......................... rated speed

...................... earthing terminal

Page 8

ENGLISH

6

.............safety alert symbol

.............Visible radiation

............. Wear respiratory

protection

............. Wear eye protection

............. Wear hearing

protection

............. Read all documentation

CSPM .......... Cut strokes per minute

............. Do not leave in rain

............ Tip contact can cause

the guide bar to move

suddenly upward and

backward, which can

cause serious injury

............ Contact of the guide

bar tip with any object

should be avoided

........... Rotational direction of

the saw chain

...... Always use two hands

when operating the

chainsaw

BATTERIES AND CHARGERS

The battery pack is not fully charged out of the carton.

Before using the battery pack and charger, read the

safety instructions below and then follow charging

proceduresoutlined. When ordering replacement battery

packs, be sure to include the catalog number andvoltage.

Your tool uses a

DeWALT charger. Be sure to read all safety

instructions before using your charger. Consult the chart

at the end of this manual for compatibility of chargers and

batterypacks.

READ ALL INSTRUCTIONS

Important Safety Instructions for All

Battery Packs

WARNING: Read all safety warnings and all

instructions for the battery pack, charger and

power tool. Failure to follow the warnings and

instructions may result in electric shock, fire and/

or seriousinjury.

• Do not charge or use the battery pack in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Inserting or removing the battery

pack from the charger may ignite the dust orfumes.

• NEVER force the battery pack into the charger. DO

NOT modify the battery pack in any way to fit into

a non-compatible charger as battery pack may

rupture causing serious personal injury. Consult

the chart at the end of this manual for compatibility of

batteries andchargers.

• Charge the battery packs only in designated

DeWALTchargers.

• DO NOT splash or immerse in water or otherliquids.

• Do not store or use the tool and battery pack in

locations where the temperature may reach or

exceed 104°F (40°C) (such as outside sheds or metal

buildings in summer). For best life store battery packs in

a cool, drylocation.

NOTE: Do not store the battery packs in a tool with

the trigger switch locked on. Never tape the trigger

switch in the ONposition.

• Do not incinerate the battery pack even if it is

severely damaged or is completely worn out. The

battery pack can explode in a fire. Toxic fumes and

materials are created when lithium ion battery packs

areburned.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water. If

battery liquid gets into the eye, rinse water over the open

eye for 15 minutes or until irritation ceases. If medical

attention is needed, the battery electrolyte is composed of

a mixture of liquid organic carbonates and lithiumsalts.

• Contents of opened battery cells may cause

respiratory irritation. Provide fresh air. If symptoms

persist, seek medicalattention.

WARNING: Burn hazard. Battery liquid may be

flammable if exposed to spark orflame.

WARNING: Fire hazard. Never attempt to open the

battery pack for any reason. If the battery pack case

is cracked or damaged, do not insert into the charger.

Do not crush, drop or damage the battery pack. Do

not use a battery pack or charger that has received a

sharp blow, been dropped, run over or damaged in

any way (e.g., pierced with a nail, hit with a hammer,

stepped on). Damaged battery packs should be

returned to the service center forrecycling.

Transportation

WARNING: Fire hazard. Do not store or carry the

battery pack so that metal objects can contact

exposed battery terminals. For example, do

not place the battery pack in aprons, pockets, tool

boxes, product kit boxes, drawers, etc., with loose

nails, screws, keys, etc. Transporting batteries

can possibly cause fires if the battery terminals

inadvertently come in contact with conductive

materials such as keys, coins, hand tools and the

like. The US Department of Transportation Hazardous

Material Regulations (HMR) actually prohibit

transporting batteries in commerce or on airplanes in

carry-on baggage UNLESS they are properly protected

from short circuits. So when transporting individual

battery packs, make sure that the battery terminals

are protected and well insulated from materials that

could contact them and cause a shortcircuit.

Shipping the

DeWALT FLEXVOLT™ Battery

The D

eWALT FLEXVOLT™ battery has two modes: Use and

Shipping.

Use Mode: When the FLEXVOLT™ battery stands alone or is

in a D

eWALT 20V Max* product, it will operate as a 20V Max*

battery. When the FLEXVOLT™ battery is in a 60V Max* or a

120V Max* (two 60V Max* batteries) product, it will operate

as a 60V Max* battery.

Shipping Mode: When

the cap is attached to the

FLEXVOLT™ battery, the

battery is in Shipping Mode.

Strings of cells are electrically

disconnected within the pack resulting in three batteries

with a lower Watt hour (Wh) rating as compared to one

battery with a higher Watt hour rating. This increased

quantity of three batteries with the lower Watt hour rating

Page 9

ENGLISH

7

can exempt the pack from certain shipping regulations that

are imposed upon the higher Watt hourbatteries.

The battery label indicates two Watt hour ratings (see

example). Depending on how the battery is shipped, the

appropriate Watt hour rating must be used to determine

the applicable shipping requirements. If utilizing the

shipping cap, the pack will be considered 3 batteries at

the Watt hour rating indicated for “Shipping”. If shipping

without the cap or in a tool, the pack will be considered one

battery at the Watt hour rating indicated next to “Use”.

USE: 120 Wh Shipping: 3 x 40 Wh

Example of Use and Shipping Label Marking

For example, Shipping Wh rating might indicate 3 x 40 Wh,

meaning 3 batteries of 40 Watt hours each. The Use Wh

rating might indicate 120 Wh (1 battery implied).

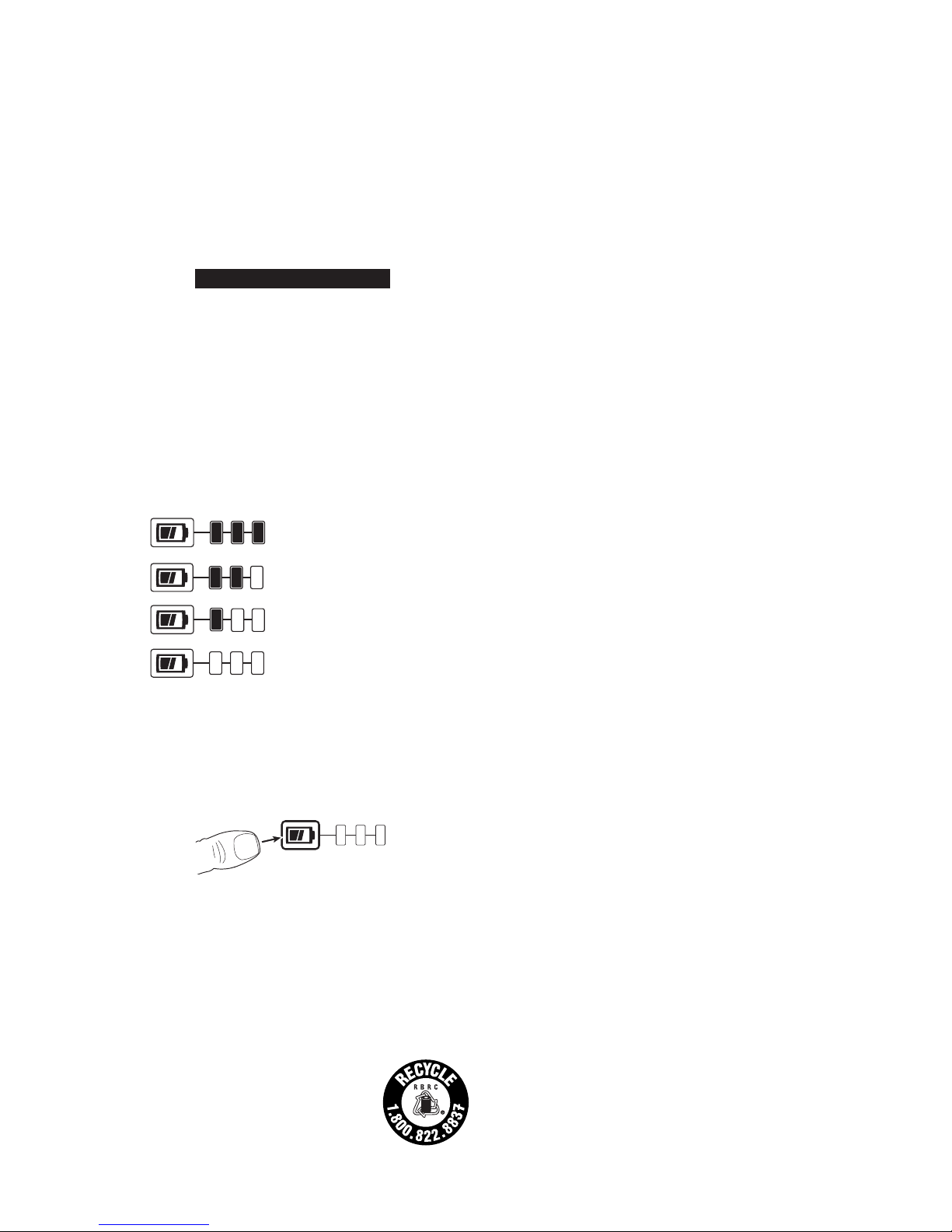

Fuel Gauge Battery Packs (Fig. B)

Some DeWALT battery packs include a fuel gauge which

consists of three green LED lights that indicate the level of

charge remaining in the batterypack.

The fuel gauge is an indication of approximate levels of

charge remaining in the battery pack according to the

followingindicators:

75–100% charged

51–74% charged

< 50% charged

Pack needs to be charged

To actuate the fuel gauge, press and hold the fuel gauge

button. A combination of the three green LED lights will

illuminate designating the level of charge left. When the

level of charge in the battery is below the usable limit, the

fuel gauge will not illuminate and the battery will need to

berecharged.

Fig. B

NOTE: The fuel gauge is only an indication of the charge left

on the battery pack. It does not indicate tool functionality

and is subject to variation based on product components,

temperature and end-userapplication.

For more information regarding fuel gauge battery packs,

please contact call 1-800-4-

DeWALT (1-800-433-9258) or

visit our website www.dewalt.com.

The RBRC® Seal

The RBRC® (Rechargeable Battery

Recycling Corporation) Seal on the nickel

cadmium, nickel metal hydride or lithiumion batteries (or battery packs) indicates

that the costs to recycle these batteries

(or battery packs) at the end of their useful life have already

been paid by

DeWALT. In some areas, it is illegal to place

spent nickel cadmium, nickel metal hydride or lithium-ion

batteries in the trash or municipal solid waste stream and

the Call2Recycle® program provides an environmentally

consciousalternative.

Call 2 Recycle, Inc., in cooperation with

DeWALT and other

battery users, has established the program in the United

States and Canada to facilitate the collection of spent nickel

cadmium, nickel metal hydride or lithium-ion batteries. Help

protect our environment and conserve natural resources by

returning the spent nickel cadmium, nickel metal hydride

or lithium-ion batteries to an authorized

DeWALT service

center or to your local retailer for recycling. You may also

contact your local recycling center for information on

where to drop off the spent battery. RBRC® is a registered

trademark of Call 2 Recycle,Inc.

Important Safety Instructions for All

Battery Chargers

WARNING: Read all safety warnings and all

instructions for the battery pack, charger and

power tool. Failure to follow the warnings and

instructions may result in electric shock, fire and/

or seriousinjury.

• DO NOT attempt to charge the battery pack with

any chargers other than the ones in this manual.

The charger and battery pack are specifically designed to

worktogether.

• These chargers are not intended for any uses other

than charging

DeWALT rechargeable batteries.

Any other uses may result in risk of fire, electric shock

orelectrocution.

• Do not expose the charger to rain orsnow.

• Pull by the plug rather than the cord when

disconnecting the charger. This will reduce the risk of

damage to the electric plug andcord.

• Make sure that the cord is located so that it will not

be stepped on, tripped over or otherwise subjected

to damage orstress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in

risk of fire, electric shock orelectrocution.

• When operating a charger outdoors, always provide

a dry location and use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electricshock.

• An extension cord must have adequate wire size

(AWG or American Wire Gauge) for safety. The smaller

the gauge number of the wire, the greater the capacity

of the cable, that is, 16 gauge has more capacity than 18

gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using

more than one extension to make up the total length,

be sure each individual extension contains at least the

minimum wire size. The following table shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The

lower the gauge number, the heavier thecord.

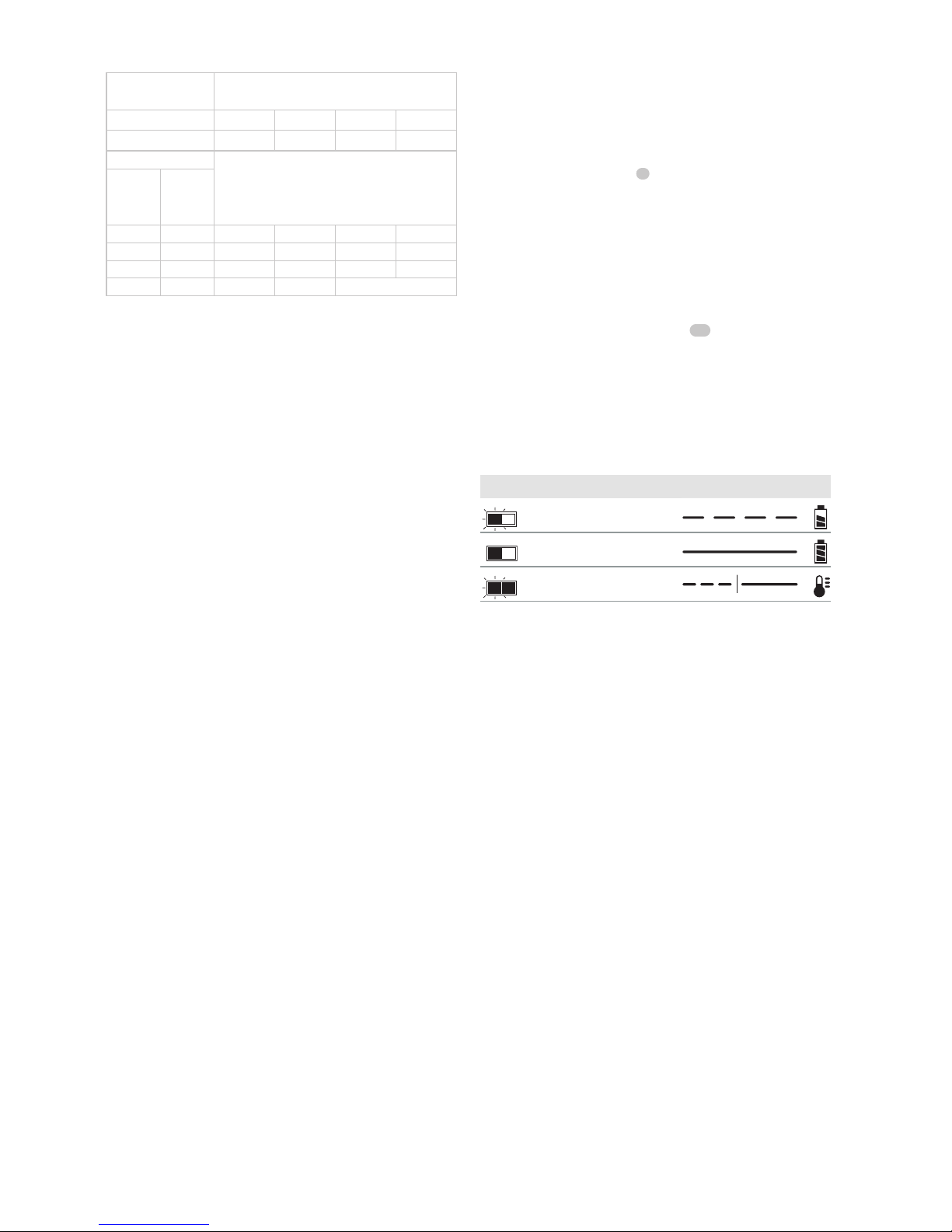

Page 10

ENGLISH

8

Minimum Gauge for Cord Sets

Volts

Total Length of Cord in Feet

(meters)

120 V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240 V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

Ampere Rating

American Wire Gauge

More

Than

Not

More

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

• Do not place any object on top of the charger or

place the charger on a soft surface that might block

the ventilation slots and result in excessive internal

heat. Place the charger in a position away from any heat

source. The charger is ventilated through slots in the top

and the bottom of thehousing.

• Do not operate the charger with a damaged cord

orplug.

• Do not operate the charger if it has received a sharp

blow, been dropped or otherwise damaged in any

way. Take it to an authorized servicecenter.

• Do not disassemble the charger; take it to an

authorized service center when service or repair

is required. Incorrect reassembly may result in a risk of

electric shock, electrocution orfire.

• Disconnect the charger from the outlet before

attempting any cleaning. This will reduce the risk of

electric shock. Removing the battery pack will not reduce

thisrisk.

• NEVER attempt to connect 2 chargerstogether.

• The charger is designed to operate on standard

120V household electrical power. Do not attempt to

use it on any other voltage. This does not apply to the

vehicularcharger.

WARNING: Shock hazard. Do not allow any liquid to

get inside the charger. Electric shock mayresult.

WARNING: Burn hazard. Do not submerge the

battery pack in any liquid or allow any liquid to

enter the battery pack. Never attempt to open the

battery pack for any reason. If the plastic housing of

the battery pack breaks or cracks, return to a service

center forrecycling.

CAUTION: Burn hazard. To reduce the risk of injury,

charge only

DeWALT rechargeable battery packs.

Other types of batteries may overheat and burst

resulting in personal injury and propertydamage.

NOTICE: Under certain conditions, with the charger

plugged into the power supply, the charger can

be shorted by foreign material. Foreign materials

of a conductive nature, such as, but not limited to,

grinding dust, metal chips, steel wool, aluminum

foil or any buildup of metallic particles should be

kept away from the charger cavities. Always unplug

the charger from the power supply when there is no

battery pack in the cavity. Unplug the charger before

attempting toclean.

Charging a Battery (Fig. A)

1. Plug the charger into an appropriate outlet before

inserting batterypack.

2. Insert the battery pack

7

into the charger, making sure

the battery pack is fully seated in the charger. The red

(charging) light will blink continuously indicating that

the charging process hasstarted.

3. The completion of charge will be indicated by the red

light remaining ON continuously. The battery pack is

fully charged and may be used at this time or left in the

charger. To remove the battery pack from the charger,

push the battery release button

15

on the batterypack.

NOTE: To ensure maximum performance and life of lithiumion battery packs, charge the battery pack fully before

firstuse.

Charger Operation

Refer to the indicators below for the charge status of the

batterypack.

DCB107, DCB112, DCB113, DCB115, DCB118, DCB132

Charging

Fully Charged

Hot/Cold Pack Delay*

* The red light will continue to blink, but a yellow indicator

light will be illuminated during this operation. Once the

battery pack has reached an appropriate temperature, the

yellow light will turn off and the charger will resume the

chargingprocedure.

The compatible charger(s) will not charge a faulty battery

pack. The charger will indicate faulty battery pack by

refusing to light or by displaying a problem pack or charger

blinkpattern.

NOTE: This could also mean a problem with acharger.

If the charger indicates a problem, take the charger and

battery pack to be tested at an authorized servicecenter.

Hot/Cold Pack Delay

When the charger detects a battery pack that is too hot

or too cold, it automatically starts a Hot/Cold Pack Delay,

suspending charging until the battery pack has reached an

appropriate temperature. The charger then automatically

switches to the pack charging mode. This feature ensures

maximum battery packlife.

A cold battery pack will charge at a slower rate than a warm

battery pack. The battery pack will charge at that slower rate

throughout the entire charging cycle and will not return to

maximum charge rate even if the battery packwarms.

The DCB118 charger is equipped with an internal fan

designed to cool the battery pack. The fan will turn on

automatically when the battery pack needs to becooled.

Never operate the charger if the fan does not operate

properly or if ventilation slots are blocked. Do not permit

foreign objects to enter the interior of thecharger.

Page 11

ENGLISH

9

Electronic Protection System

Li-Ion tools are designed with an Electronic Protection

System that will protect the battery pack against

overloading, overheating or deepdischarge.

The tool will automatically turn off if the Electronic

Protection System engages. If this occurs, place the lithiumion battery pack on the charger until it is fullycharged.

Wall Mounting

These chargers are designed to be wall mountable or to

sit upright on a table or work surface. If wall mounting,

locate the charger within reach of an electrical outlet,

and away from a corner or other obstructions which may

impede air flow. Use the back of the charger as a template

for the location of the mounting screws on the wall. Mount

the charger securely using drywall screws (purchased

separately) at least 1" (25.4 mm) long, with a screw head

diameter of 0.28–0.35" (7–9mm), screwed into wood to an

optimal depth leaving approximately 7/32" (5.5 mm) of the

screw exposed. Align the slots on the back of the charger

with the exposed screws and fully engage them in theslots.

Charger Cleaning Instructions

WARNING: Shock hazard. Disconnect the charger

from the AC outlet before cleaning. Dirt and grease

may be removed from the exterior of the charger using

a cloth or soft non-metallic brush. Do not use water or

any cleaningsolutions.

Important Charging Notes

1. Longest life and best performance can be obtained if

the battery pack is charged when the air temperature is

between 65°F and 75°F (18° – 24°C). DO NOT charge

the battery pack in an air temperature below +40°F

(+4.5°C), or above +104°F (+40°C). This is important

and will prevent serious damage to the batterypack.

2. The charger and battery pack may become warm to the

touch while charging. This is a normal condition, and

does not indicate a problem. To facilitate the cooling of

the battery pack after use, avoid placing the charger or

battery pack in a warm environment such as in a metal

shed or an uninsulatedtrailer.

3. If the battery pack does not charge properly:

a. Check operation of receptacle by plugging in a lamp

or other appliance;

b. Check to see if receptacle is connected to a light

switch which turns power off when you turn out the

lights;

c. Move the charger and battery pack to a location

where the surrounding air temperature is

approximately 65°F – 75°F (18° – 24°C);

d. If charging problems persist, take the tool, battery

pack and charger to your local servicecenter.

4. The battery pack should be recharged when it fails to

produce sufficient power on jobs which were easily

done previously. DO NOT CONTINUE to use under these

conditions. Follow the charging procedure. You may

also charge a partially used pack whenever you desire

with no adverse effect on the batterypack.

5. Foreign materials of a conductive nature such as, but

not limited to, grinding dust, metal chips, steel wool,

aluminum foil, or any buildup of metallic particles

should be kept away from charger cavities. Always

unplug the charger from the power supply when there

is no battery pack in the cavity. Unplug the charger

before attempting toclean.

6. Do not freeze or immerse the charger in water or any

otherliquid.

Storage Recommendations

1. The best storage place is one that is cool and dry, away

from direct sunlight and excess heat orcold.

2. For long storage, it is recommended to store a fully

charged battery pack in a cool dry place out of the

charger for optimalresults.

NOTE: Battery packs should not be stored completely

depleted of charge. The battery pack will need to be

recharged beforeuse.

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

COMPONENTS (FIG. A)

WARNING: Never modify the power tool or any part

of it. Damage or personal injury couldresult.

Refer to Figure A at the beginning of this manual for a

complete list ofcomponents.

INTENDED USE

Your DeWALT DCCS670 Chainsaw is ideal for pruning

applications and cutting logs up to 14" (355 mm)

indiameter.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

This chainsaw is a professional powertool. DO NOT let

children come into contact with the tool. Supervision is

required when inexperienced operators use thistool.

ASSEMBLY

Installing the Guide Bar and Saw Chain

(Fig. A, D–F, H)

CAUTION: Sharp chain. Always wear protective

gloves when handling the chain. The chain is sharp

and can cut you when it is notrunning.

WARNING: Sharp moving chain. To prevent

accidental operation, ensure that battery is removed

from the tool before performing the following

operations. Failure to do this could result in serious

personalinjury.

If the saw chain

5

and guide bar

4

are packed separately

in the carton, the chain has to be attached to the bar, and

both must be attached to the body of thetool.

• Place the saw on a flat, firmsurface.

Page 12

ENGLISH

10

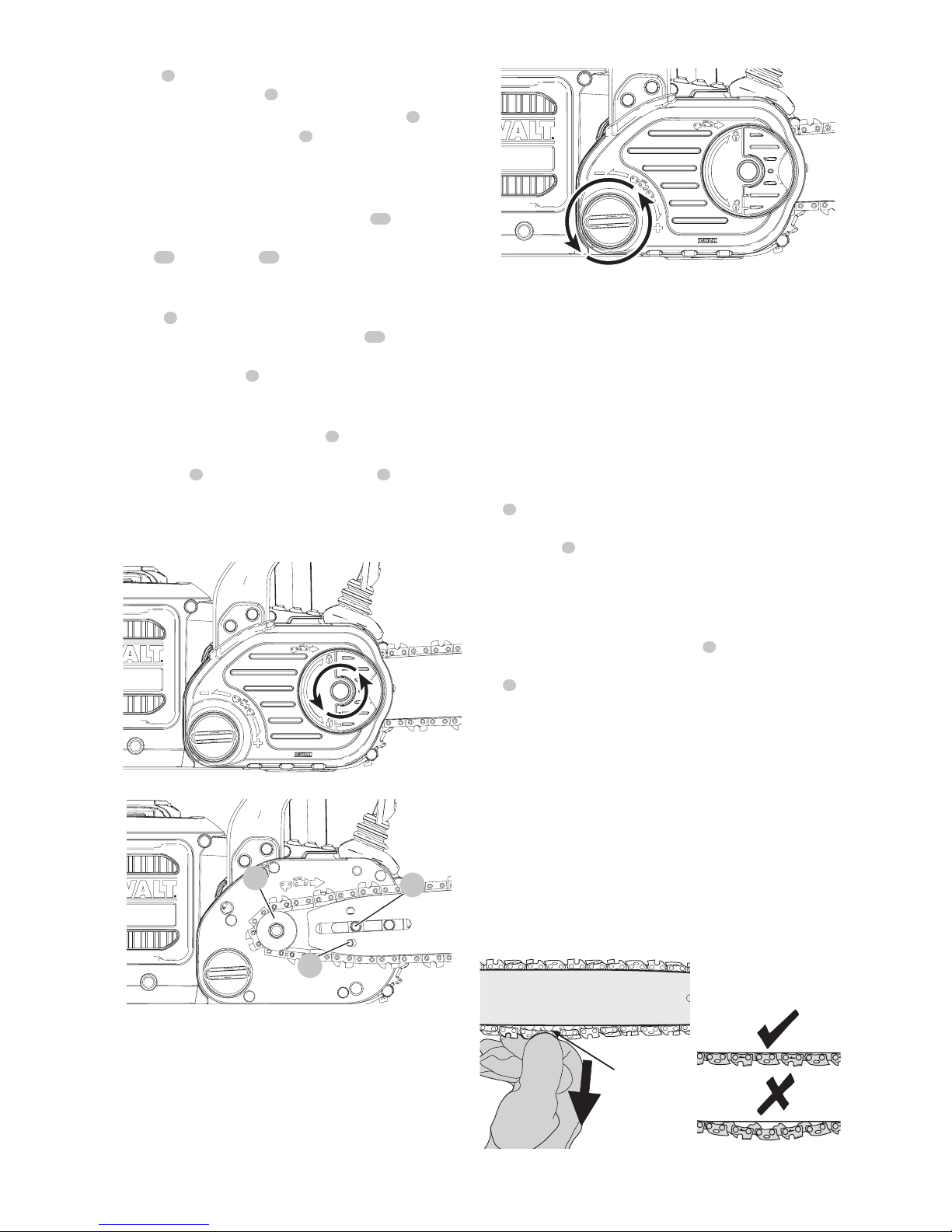

• Flip up locking lever and rotate the bar adjust locking

knob

8

counterclockwise as shown in FigureD to

remove sprocket cover

6

.

• Wearing protective gloves, grasp the saw chain

5

and

wrap it around the guide bar

4

, ensuring the teeth are

facing the correct direction (see FigureH).

• Ensure the chain is properly set in the slot around the

entire guidebar.

• Place the saw chain around the sprocket

18

. While

lining up the slot on the guide bar with chain tensioning

pin

20

, and the bolt

19

, on the base of the tool as

shown in FigureE.

• Once in place, hold the bar still, replace sprocket

cover

6

. Make sure tool-free tension assembly bolt

hole on the cover lines up with the bolt

19

, in the

main housing. Flip up locking lever and rotate the bar

adjust locking knob

8

clockwise until it clicks, then

loosen knob one full turn, so that the saw chain can be

properlytensioned.

• Rotate the chain tensioning knob

9

clockwise to

increase tension as shown in FigureF. Make sure the

saw chain

5

is snug around the guide bar

4

. Tighten

the bar adjust locking knob until it clicks. The bar is

secure after three audible clicks are heard. Further

tightening is notrequired.

Fig. D

Fig. E

18

19

20

Fig. F

Adjusting Chain Tension (Fig. A, G )

CAUTION: Sharp chain. Always wear protective

gloves when handling the chain. The chain is sharp

and can cut you when it is notrunning.

WARNING: Sharp moving chain. To prevent

accidental operation, ensure that battery is removed

from the tool before performing the following

operations. Failure to do this could result in serious

personalinjury.

• With the saw on a flat, firm surface, check the saw chain

5

tension. The tension is correct when the chain snaps

back after being pulled 1/8" (3mm) away from the

guide bar

4

with light force from the index finger and

thumb as shown in FigureI. There should be no “sag”

between the guide bar and the chain on the underside

as shown in FigureG.

• To adjust saw chain tension, flip up locking tab and

rotate the bar adjust locking knob

8

counterclockwise

one full turn. Rotate the chain tensioning knob

9

clockwise until the chain tension is correct as

instructedabove.

• Do not over-tension the chain as this will lead to

excessive wear and will reduce the life of the bar

andchain.

• Once chain tension is correct, securely tighten bar adjust

lockingknob.

NOTE: The bar adjust locking knob has a detent tightening

system. The sprocket cover is secure after three audible

clicks are heard. Further tigtening is notrequired.

• When the chain is new, check the tension frequently

(after removing battery) during the first 2 hours of use as

a new chain stretchesslightly.

Fig. G

1/8” (3mm)

Page 13

ENGLISH

11

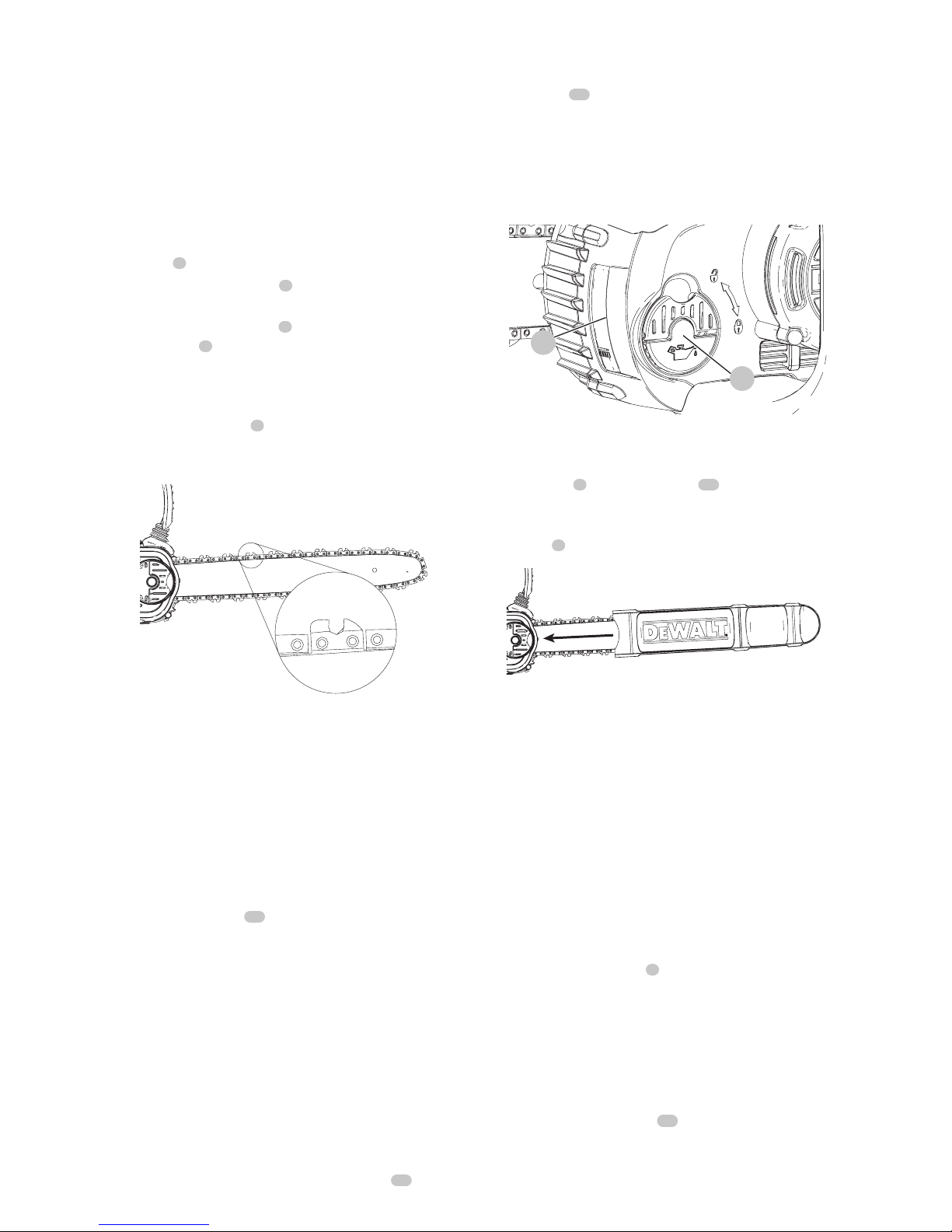

Replacing the Saw Chain (Fig. A, H)

CAUTION: Sharp chain. Always wear protective

gloves when handling the chain. The chain is sharp

and can cut you when it is notrunning.

WARNING: Sharp moving chain. To prevent

accidental operation, ensure that battery is removed

from the tool before performing the following

operations. Failure to do this could result in serious

personalinjury.

• Flip up locking tab and rotate the bar adjust locking

knob

8

counterclockwise to release chaintension.

• Remove sprocket cover

6

as described in Installing the

Guide Bar and Saw Chainsection.

• Lift the worn saw chain

5

out of the groove in the

guide bar

4

.

• Place the new chain in the slot of the guide bar, making

sure the saw teeth are facing the correct direction by

matching the arrow on the chain with the graphic on

the sprocket cover

6

shown in FigureH.

• Follow instructions for Installing the Guide Bar and

SawChain.

Fig. H

Replacement chain and bar are available from your

nearest

DeWALT servicecenter.

• DCCS670 requires replacement chain # DWRC1600,

service part number 90618541. Replacement 16” bar,

service part number90618542.

Saw Chain and Guide Bar Oiling (Fig. I)

Auto Oiling System

This chain saw is equipped with an auto oiling system that

keeps the saw chain and guide bar constantly lubricated.

The oil level indicator

10

shows the level of the oil in the

chain saw. If the oil level is less than a quarter full, remove

the battery from the chain saw and refill with the correct

type of oil. Always empty oil tank when finishedcutting.

NOTE: Use a high quality bar and chain oil for proper chain

and bar lubrication. As a temporary substitute, a nondetergent SAE30 weight motor oil can be used. The use of

a vegetable based bar and chain oil is recommended when

pruning trees. Mineral oil is not recommended because it

may harm trees. Never use waste oil or very thick oil. These

may damage yourchainsaw.

Filling the Oil Reservoir

• Flip down locking lever and unscrew counterclockwise

a quarter turn and then remove the oil cap

16

. Fill

the reservoir with the recommended bar and chain oil

until the oil level has reached the top of the oil level

indicator

10

.

• Refit the oil cap and tighten clockwise a quarter turn.

Flip up locking lever to its lockedposition.

• Periodically switch the chain saw off and check the oil

level indicator to ensure the bar and chain are being

properlyoiled.

Fig. L

16

10

Transporting Saw (Fig. A, J)

• Always remove the battery from the tool and cover the

guide bar

4

with the scabbard

11

(see FigureJ) when

transporting thesaw.

• Engage chain brake by pushing chain brake / front hand

guard

3

forward.

Fig. J

OPERATION

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

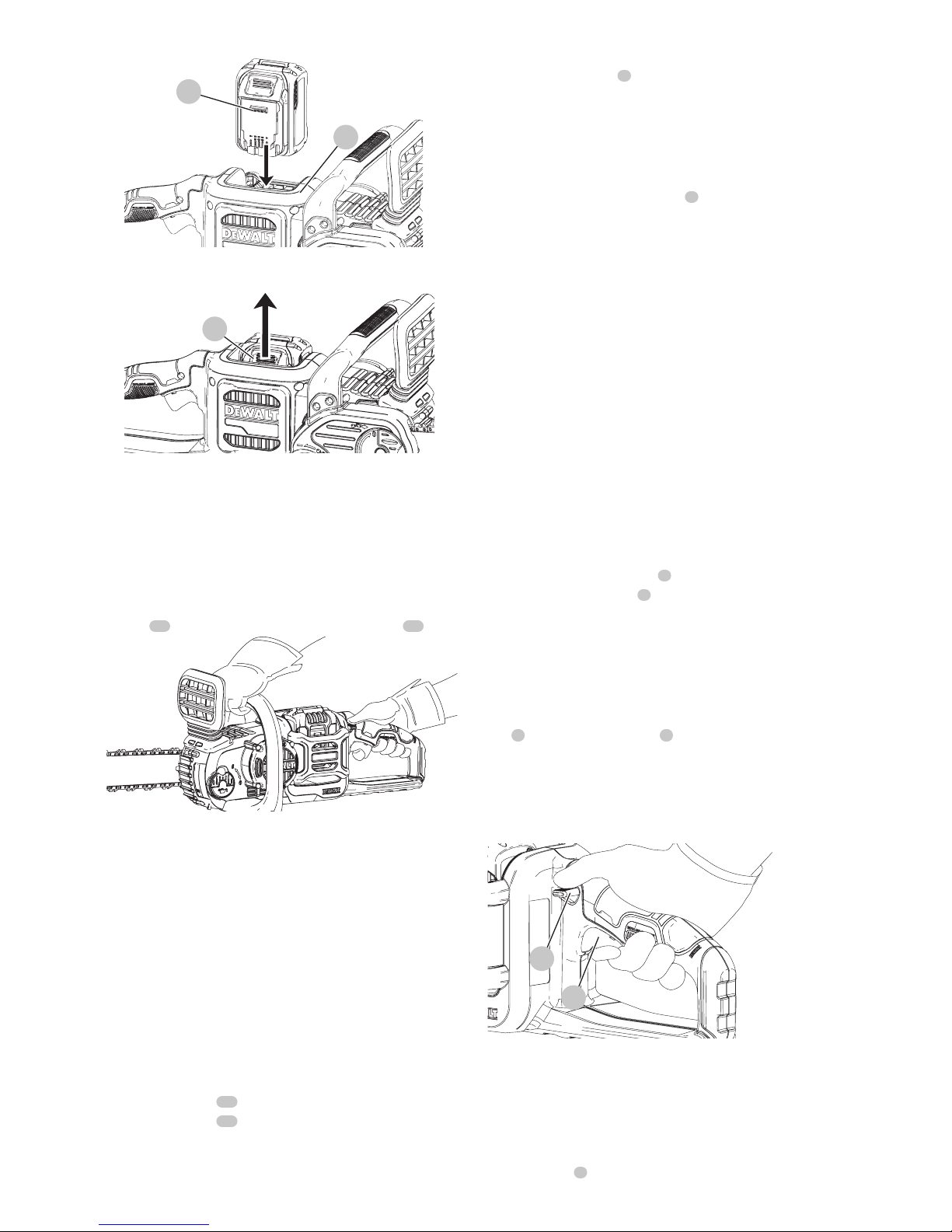

Installing and Removing the Battery Pack

(Fig. K, L)

NOTE: For best results, make sure your battery pack is

fullycharged.

To Install the Battery Pack into the Tool

1. Align the battery pack

7

with the rails inside the tool

(see FigureK).

2. Slide it into the tool until the battery pack is firmly

seated and ensure that you hear the lock snap

intoplace.

To Remove the Battery Pack from the

Tool

1. Press the release button

15

and firmly pull the battery

pack out of the toolhandle (see FigureL).

2. Insert battery pack into the charger as described in the

charger section of thismanual.

Page 14

ENGLISH

12

Fig. K

7

14

Fig. L

15

Proper Hand Position (Fig. A, M)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING:

To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires the left hand on the front

handle

13

, with the right hand on the rear handle

12

.

Fig. M

Operating the Chain Saw (Fig. A, N–O)

WARNING: Read and understand all instructions.

Failure to follow all instructions listed below

may result in electric shock, fire and/or serious

personalinjury.

• Guard Against Kickback which can result in severe

injury or death. See Important Safety Instructions

Guard Against Kickback, to avoid the risk

ofkickback.

• Do not overreach. Do not cut above chest height.

Make sure your footing is firm. Keep feet apart.

Divide your weight evenly on bothfeet.

• Use a firm grip with your left hand on the front

handle

13

and your right hand on the rear

handle

12

so that your body is to the left of the

guidebar.

• Do not hold chain saw by front hand guard/

chain brake

3

. Keep elbow of left arm locked so

that left arm is straight to withstand akickback.

WARNING: Never use a cross-handed grip (left

hand on the rear handle and right hand on the

fronthandle).

WARNING: Never allow any part of your body to

be in line with the guide bar

4

when operating the

chainsaw.

• Never operate while in a tree, in any awkward

position or on a ladder or other unstable surface.

You may lose control of saw causing severeinjury.

• Keep the chain saw running at full speed the entire

time you arecutting.

• Allow the chain to cut for you. Exert only light

pressure. Do not put pressure on chain saw at

end ofcut.

WARNING: When not in use always have the

chain brake engaged and batteryremoved.

On / Off Switch

Always be sure of your footing and grip the chain saw firmly

with both hands with the thumb and fingers encircling

bothhandles.

This tool is equipped with a variable speed trigger switch.

To turn the unit on, ensure chain brake is not engaged. Push

down on the the lock off lever

2

, shown in FigureN, and

squeeze the trigger switch

1

. Once the unit is running, you

may release the lock off lever. The farther you depress the

trigger, the faster it willoperate.

In order to keep the unit running you must continue to

squeeze the trigger. To turn the unit off, release thetrigger.

NOTE: If too much force is applied while making a cut the

saw will turn off. To restart saw, you must release the lock off

lever

2

and the trigger switch

1

before the saw will restart.

Begin your cut again this time with less force. Allow the saw

to cut at its ownpace.

WARNING: Never attempt to lock a switch in the

ONposition.

Fig. N

2

1

Setting The Chain Brake

Your chain saw is equipped with a motor chain braking

system which will stop the chain quickly in case ofkickback.

• Remove the battery from thetool.

• To engage the chain brake, push the chain brake / front

hand guard

3

forward until it clicks intoplace.

Page 15

ENGLISH

13

• Pull the chain brake / front hand guard

3

towards the

front handle

13

into the “set” position as shown in

FigureO.

• The tool is now ready touse.

NOTE: In the event of kickback, your left hand will come in

contact with the front guard, pushing it forward, toward the

workpiece. This will stop thetool.

Fig. O

3

13

Testing The Chain Brake

Test the chain brake before every use to make sure it

operatescorrectly.

• Place the tool on a flat, firm surface. Make sure the saw

chain

5

is clear of theground.

• Grip the tool firmly with both hands and turn the chain

sawon.

• Rotate your left hand forward around the front handle

13

so the back of your hand comes in contact with

the Chain brake / front hand guard

3

and push it

forward, toward the workpiece. The saw chain should

stopimmediately.

NOTE: If saw does not stop immediately, stop use of tool

and bring it to a

DeWALT service center nearestyou.

WARNING: Make sure to set chain brake

beforecutting.

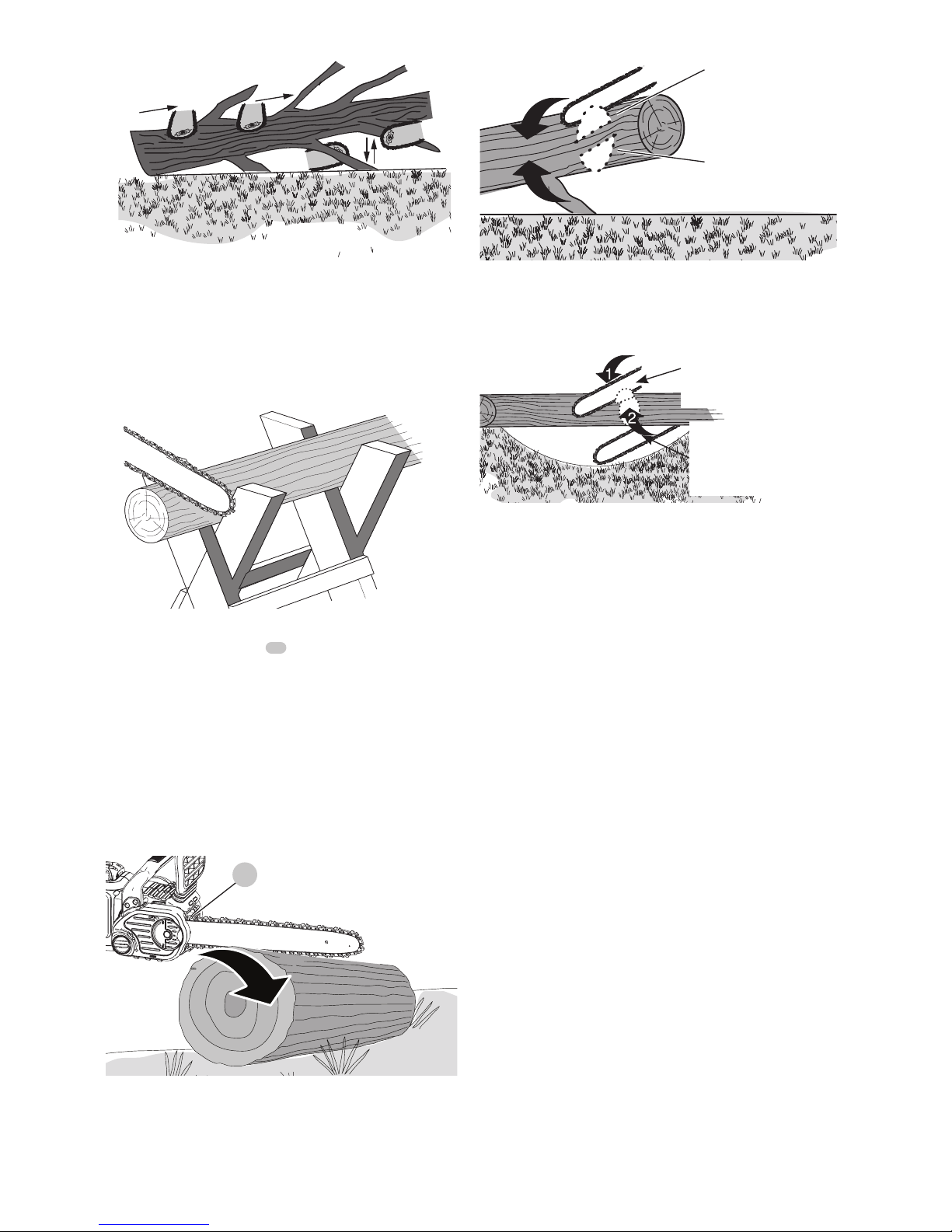

Common Cutting Techniques

(Fig. A, P, Q, R, S, T)

Felling

The process of cutting down a tree. Be sure battery is fully

charged before felling a tree so you can finish on a single

charge. Do not fell trees in high windconditions.

WARNING: Felling can result in injury. It should only

be performed by a trainedperson.

• A retreat path should be planned and cleared as

necessary before cuts are started. The retreat path

should extend back and diagonally to the rear of the

expected line of fall (see FigureP).

DIRECTION

OF

FALL

RETREAT

45°

TREE

Fig. P

• Before felling is started, consider the natural lean of

the tree, the location of larger branches and the wind

direction to judge which way the tree will fall. Have

wedges (wood, plastic or aluminum) and a heavy mallet

handy. Remove dirt, stones, loose bark, nails, staples,

and wire from the tree where the felling cuts are to

bemade.

• Notching Undercut - Make the notch 1/3 of the

diameter of the tree, perpendicular to the direction of

the fall. Make the lower horizontal notching cut first.

This will help to avoid pinching of either the saw chain

or the guide bar when the second notch cut is being

made (see FigureQ).

• Felling Back Cut - Make the felling back cut at least 2"

(51mm) higher than the horizontal notching cut. Keep

the felling back cut parallel to the horizontal notching

cut. Make the felling back cut so enough wood is left

to act as a hinge. The hinge wood keeps the tree from

twisting and falling in the wrong direction. Do not cut

through the hinge (see FigureQ).

• As the felling cut gets close to the hinge the tree should

begin to fall. If there is any chance that the tree may

not fall in the desired direction or it may rock back and

bind the saw chain, stop cutting before the felling cut

is complete and use wedges to open the cut and drop

the tree along the desired line of fall. When the tree

begins to fall remove the chain saw from the cut, stop

the motor, put the chain saw down, then use the retreat

path planned. Be alert for overhead limbs falling and

watch yourfooting.

2" (51 mm)

DIRECTION OF FALL

2" (51 mm)

HINGE

NOTCH

FELLING BACK CUT

Fig. Q

Limbing

Removing the branches from a fallen tree. When limbing,

leave larger lower limbs to support the log off the ground.

Remove the small limbs in one cut. Branches under tension

should be cut from the bottom of the branch towards the

top to avoid binding the chain saw as shown in FigureR.

Trim limbs from opposite side keeping tree stem between

you and saw. Never make cuts with saw between your legs

or straddle the limb to becut.

Page 16

ENGLISH

14

Fig. R

Bucking

WARNING: Recommend that first time users should

practice cutting on a sawhorse.

Cutting a felled tree or log into lengths. How you should cut

depends on how the log is supported. Use a saw horse (see

FigureS) wheneverpossible.

Fig. S

• Always start a cut with the chain running at fullspeed.

• Place the bottom spike

22

of the chain saw behind the

area of the initial cut as shown in FigureT.

• Turn the chain saw on then rotate the chain and bar

down into the tree, using the spike as ahinge.

• Once the chain saw gets to a 45 degree angle, level

the chain saw again and repeat steps until you cut

fullythrough.

• When the tree is supported along its entire length, make

a cut from the top (overbuck), but avoid cutting the

earth as this will dull your sawquickly.

CUT FROM TOP (OVERBUCK)

AVOID CUTTING EARTH

Fig. T

22

• FigureU- When supported at one end

First, cut 1/3 the diameter from the underside

(underbuck). Then make the finishing cut by

overbucking to meet the firstcut.

1

1

2

2nd CUT OVERBUCK

(2/3DIAMETER)

TO MEET 1st CUT

(TO AVOID PINCHING)

1st CUT UNDERBUCK

(1/3 DIAMETER)

AVOID SPLINTERING

Fig. U

• FigureV- When supported at bothends.

First, cut 1/3 down from the top overbuck. Then make

the finished cut by underbucking the lower 2/3 to meet

the firstcut.

2nd CUT UNDERBUCK

(2/3 DIAMETER)

TO MEET 1st CUT

(TO AVOID PINCHING)

1st CUT OVERBUCK

(1/3 DIAMETER)

TO AVOID SPLINTERING

Fig. V

• When on a slope always stand on the uphill side of the

log. When “cutting through”, to maintain complete

control reduce the cutting pressure near the end of the

cut without relaxing your grip on the chain saw handles.

Don’t let the chain contact the ground. After completing

the cut, wait for the saw chain to stop before you move

the chain saw. Always stop the motor before moving

from cut tocut.

CARE AND MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Do not

use solvents to clean the plastic housing of the saw. Never

let any liquid get inside the tool; never immerse any part of

the tool into aliquid.

IMPORTANT: To assure product SAFETY and RELIABILITY,

repairs, maintenance and adjustment should be performed

by a

DeWALT authorized service center, always using

identical replacementparts.

Regular maintenance ensures a long effective life for your

chainsaw.

Chain and Bar

After every few hours of use, remove the sprocket cover,

guide bar and chain and clean thoroughly using a soft

bristle brush. Ensure oiling hole on bar is clear of debris.

When replacing dull chains with sharp chains it is good

practice to flip the chain bar from bottom totop.

Saw Chain Sharpening

CAUTION: Sharp chain. Always wear protective

gloves when handling the chain. The chain is sharp

and can cut you when it is notrunning.

Page 17

ENGLISH

15

WARNING: Sharp moving chain. To prevent

accidental operation, ensure that battery is removed

from the tool before performing the following

operations. Failure to do this could result in serious

personalinjury.

NOTE: The cutters will dull immediately if they touch the

ground or a nail whilecutting.

To get the best possible performance from your chain saw

it is important to keep the teeth of the chain sharp. Follow

these helpful tips for proper saw chain sharpening:

1. For best results use a 4.5mm file and a file holder or

filing guide to sharpen your chain. This will ensure you

always get the correct sharpeningangles.

2. Place the file holder flat on the top plate and depth

gauge of thecutter.

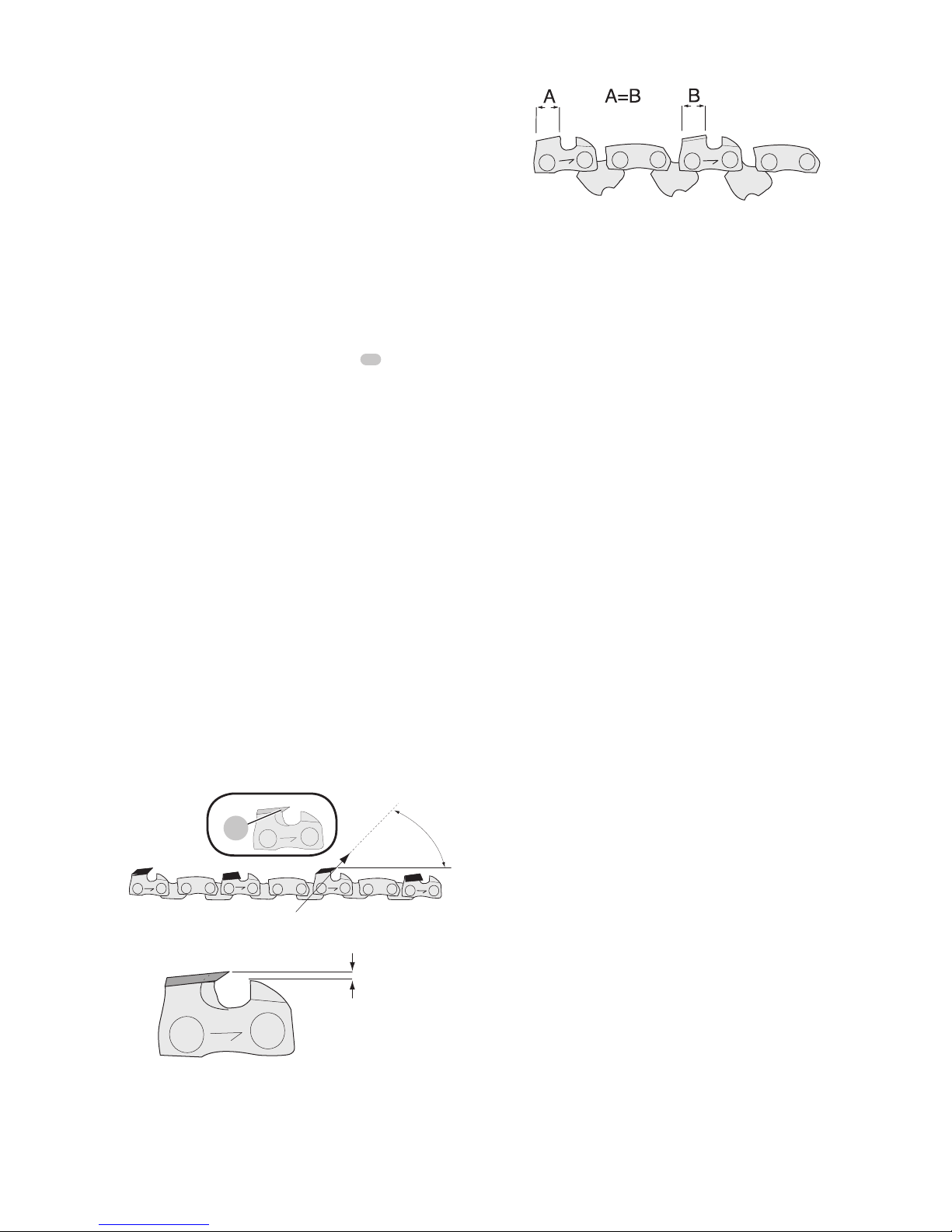

3. FigureW- Keep the correct top plate

19

filing angle

line of 30° on your file guide parallel with your chain (file

at 60° from chain viewed from the side).

4. Sharpen cutters on one side of the chain first. File from

the inside of each cutter to the outside. Then turn your

saw around and repeat the processes (2, 3, 4) for cutters

on the other side of thechain.

NOTE: Use a flat file to file the tops of the rakers (portion

of chain link in front of the cutter) so they are about

.025" (.635 mm) below the tips of the cutters as shown

in FigureX.

5. FigureY- Keep all cutter lengthsequal.

6. If damage is present on the chrome surface of the

top plates or side plates, file back until such damage

isremoved.

CAUTION: After filing, the cutter will be sharp, use

extra caution during thisprocess.

NOTE: Each time the chain is sharpened, it loses some of

the low kickback qualities and extra caution should be used.

It is recommended that a chain be sharpened no more than

fourtimes.

60°

Fig. W

19

.025"

(0.635mm)

Fig. X

Fig. Y

Accessories

WARNING: The use of accessories not recommended

in this manual may behazardous.

Replacement chain and bar are available from your nearest

DeWALT authorized service center. For use only with low

kick back bar andchain.

Available bars and chains for DCCS670:

Bar: 16” service part number 90641855

18” service part number N500117

Chain: 16” service part number 90618541

18” service part number N500152

MAINTENANCE

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

Cleaning

WARNING: Blow dirt and dust out of all air vents with

clean, dry air at least once a week. To minimize the risk

of eye injury, always wear ANSI Z87.1 approved eye

protection when performingthis.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic

materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool

into aliquid.

Accessories

WARNING: Since accessories, other than those

offered by DeWALT, have not been tested with this

product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only

DeWALT

recommended accessories should be used with

thisproduct.

Recommended accessories for use with your tool

are available at extra cost from your local dealer or

authorized service center. If you need assistance in

locating any accessory, please contact

DeWALT Industrial

Tool Co., 701East Joppa Road, Towson, MD 21286, call

1-800-4-DeWALT (1-800-433-9258) or visit our website:

www.dewalt.com.

Repairs

The charger and battery pack are notserviceable.

Page 18

ENGLISH

16

WARNING: To assure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(including brush inspection and replacement, when

applicable) should be performed by a

DeWALT factory

service center or a DeWALT authorized service center.

Always use identical replacementparts.

Register Online

Thank you for your purchase. Register your product nowfor:

• WARRANTY SERVICE: Registering your product will

help you obtain more efficient warranty service in case

there is a problem with yourproduct.

• CONFIRMATION OF OWNERSHIP: In case of

an insurance loss, such as fire, flood or theft, your

registration of ownership will serve as your proof

ofpurchase.

• FOR YOUR SAFETY: Registering your product will

allow us to contact you in the unlikely event a safety

notification is required under the Federal Consumer

SafetyAct.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DeWALT will repair, without charge, any defects due to

faulty materials or workmanship for three years from the

date of purchase. This warranty does not cover part failure

due to normal wear or tool abuse. For further detail of

warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-

DeWALT (1-800-433-9258).

This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and

you may have other rights which vary in certain states

orprovinces.

In addition to the warranty,

DeWALT tools are covered

byour:

1 YEAR FREE SERVICE

DeWALT will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year

afterpurchase.

DEWALT BATTERY PACKS

Product warranty voided if the battery pack is tampered

with in any way. DeWalt is not responsible for any injury

caused by tampering andmay prosecute warranty fraud to

the fullest extent permitted bylaw.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your

DeWALT Power Tool, Laser, or Nailer for any reason, you

can return it within 90 days from the date of purchase with

a receipt for a full refund – no questionsasked.

LATIN AMERICA: This warranty does not apply to products

sold in Latin America. For products sold in Latin America,

see country specific warranty information contained in

the packaging, call the local company or see website for

warrantyinformation.

FREE WARNING LABEL REPLACEMENT: If your warning

labels become illegible or are missing, call 1-800-4-

DeWALT

(1-800-433-9258) for a freereplacement.

Page 19

FRANÇAIS

17

Définitions : symboles et termes d'alarmes sécurité

Ces guides d'utilisation utilisent les symboles et termes d'alarmes sécurité suivants pour vous prévenir de situations

dangereuses et de risques de dommages corporels ou matériels.

DANGER: indique une situation dangereuse imminente qui, si elle n’est pas évitée, entraînera la mort ou des

blessuresgraves.

AVERTISSEMENT: indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner la

mort ou des blessuresgraves.

ATTENTION: indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner des

blessures légères oumodérées.

(Si utilisé sans aucun terme) Indique un message propre à la sécurité.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais qui par contre, si rien n’est fait

pour l’éviter, pourrait poser des risques de dommages matériels.

AVERTISSEMENT! lire tous les avertissements de

sécurité et toutes les directives. Le non-respect

des avertissements et des directives pourrait se

solder par un choc électrique, un incendie et/ou une

blessuregrave.

AVERTISSEMENT : afin de réduire le risque de

blessures, lire le mode d’emploi del’outil.

Pour toute question ou remarque au sujet de cet outil

ou de tout autre outil

DeWALT, composez le numéro

sans frais : 1-800-4-DeWALT (1-800-433-9258).

1

Gâchette à vitesse

variable

2

Levier de verrouillage

3

Frein de chaîne/Carter

de poignée avant

4

Guide-chaîne

5

Chaîne coupante

6

Cache de dent de

pignon

7

Bloc-piles

8

Bouton de verrouillage

du réglage de guidechaîne

9

Bouton de tension de

chaîne

10

Témoin de niveau d’huile

11

Fourreau du guidechaîne

12

Poignée arrière

13

Poignée avant

14

Logement du bloc-piles

15

Bouton de libération du

bloc-piles

16

Bouchon du réservoir

d’huile (non illustré)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Page 20

FRANÇAIS

18

AVERTISSEMENTS DE SÉCURITÉ

GÉNÉRAUX POUR LES OUTILS

ÉLECTRIQUES

AVERTISSEMENT! lire tous les avertissements de

sécurité et toutes les directives. Le non-respect

des avertissements et des directives pourrait se

solder par un choc électrique, un incendie et/ou une

blessuregrave.

CONSERVER TOUS LES

AVERTISSEMENTS ET TOUTES

LES DIRECTIVES POUR UN USAGE

ULTÉRIEUR

Le terme « outil électrique » cité dans les avertissements se

rapporte à votre outil électrique à alimentation sur secteur

(avec fil) ou par piles (sans fil).

1) Sécurité du lieu de travail

a ) Tenir l’aire de travail propre et bien éclairée.

Les lieux encombrés ou sombres sont propices

auxaccidents.

b ) Ne pas faire fonctionner d’outils électriques

dans un milieu déflagrant, tel qu’en présence de

liquides, de gaz ou de poussières inflammables.

Les outils électriques produisent des étincelles qui

pourraient enflammer la poussière ou lesvapeurs.

c ) Éloigner les enfants et les personnes à proximité

pendant l’utilisation d’un outil électrique. Une

distraction pourrait en faire perdre la maîtrise à

l’utilisateur.

2) Sécurité en matière d’électricité

a ) Les fiches des outils électriques doivent

correspondre à la prise. Ne jamais modifier la

fiche d’aucune façon. Ne jamais utiliser de fiche

d’adaptation avec un outil électrique mis à la

terre. Le risque de choc électrique sera réduit par

l’utilisation de fiches non modifiées correspondant à

laprise.

b ) Éviter tout contact physique avec des surfaces

mises à la terre comme des tuyaux, des

radiateurs, des cuisinières et des réfrigérateurs.

Le risque de choc électrique est plus élevé si votre corps

est mis à laterre.

c ) Ne pas exposer les outils électriques à la pluie ou

à l’humidité. La pénétration de l’eau dans un outil

électrique augmente le risque de chocélectrique.

d ) Ne pas utiliser le cordon de façon abusive.

Ne jamais utiliser le cordon pour transporter,

tirer ou débrancher un outil électrique. Tenir le

cordon éloigné de la chaleur, de l’huile, des bords

tranchants et des pièces mobiles. Les cordons

endommagés ou enchevêtrés augmentent les risques

de chocélectrique.

e ) Pour l’utilisation d’un outil électrique à

l’extérieur, se servir d’une rallonge convenant à

cette application. L’utilisation d’une rallonge conçue

pour l’extérieur réduira les risques de chocélectrique.

f ) S’il est impossible d’éviter l’utilisation d’un

outil électrique dans un endroit humide,

brancher l’outil dans une prise ou sur un circuit

d’alimentation dotés d’un disjoncteur de fuite à

la terre (GFCI). L’utilisation de ce type de disjoncteur

réduit les risques de chocélectrique.

3) Sécurité personnelle

a ) Être vigilant, surveiller le travail effectué et faire

preuve de jugement lorsqu’un outil électrique

est utilisé. Ne pas utiliser d’outil électrique en

cas de fatigue ou sous l’influence de drogues,