Page 1

DC800 Heavy-Duty 36V 1/2" (13 mm) Cordless Impact Wrench / Clé à chocs industriel de 1/2 po (13 mm) sans fil

de 36 volts / Llaves de impacto inalámbricas de 36 V de 13 mm (1/2") para trabajo pesado

DC810 Heavy-Duty 28V 1/2" (13 mm) Cordless Impact Wrench / Clé à chocs industriel de 1/2 po (13 mm) sans fil

de 28 volts / Llaves de impacto inalámbricas de 28 V de 13 mm (1/2") para trabajo pesado

DC815 Heavy-Duty 28V 1/4" (6.35 mm) Cordless Impact Driver / Mandrin à chocs industriel de 1/4 po (6,35mm)

sans fil de 28 volts / Destornillador de impacto inalámbricas de 28 V de 6,35 mm (1/4") para trabajo pesado

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

Page 2

Page 3

Defi nitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

EWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258).

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable,

use a ground fault circuit interrupter (GFCI) protected

supply. Use of a GFCI reduces the risk of electric shock.

English

1

Page 4

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power tools

are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind and

are easier to control.

g) Use the power tool, accessories and tool bits, etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of fire when used with another

battery pack.

English

2

Page 5

b) Use power tools only with specifically designated battery

packs. Use of any other battery packs may create a risk of

injury and fire.

c) When battery pack is not in use, keep it away from other

metal objects, like paper clips, coins, keys, nails, screws,

or other small metal objects, that can make a connection

from one terminal to another. Shorting the battery terminals

together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally occurs,

flush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause

irritation or burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Additional Specifi c Safety Rules for

Impact Wrenches

• Hold power tool by insulated gripping surfaces, when

performing an operation where the fastener may contact

hidden wiring. Fasteners contacting a “live” wire may make

exposed metal parts of the power tool “live” and could give the

operator an electric shock.

• Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

• Wear safety goggles or other eye protection. Hammering and

drilling operations cause chips to fly. Flying particles can cause

permanent eye damage.

• Accessories and tools get hot during operation. Wear gloves

when touching them.

• Do not operate this tool for long periods of time. Vibration

caused by tool action may be harmful to your hands and

arms. Use gloves to provide extra cushion and limit

exposure by taking frequent rest periods.

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewelry or long hair can be caught in moving parts.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are

NOT safety glasses. Also use face or dust mask if cutting operation is

dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

English

3

Page 6

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust,

which may cause serious and permanent respiratory or other

injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

WARNING: Always wear proper personal hearing protection

that conforms to ANSI S12.6 (S3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

CAUTION: When not in use, place tool on its side on a stable

surface where it will not cause a tripping or falling hazard.

Some tools with large battery packs will stand upright on the battery

pack but may be easily knocked over.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ................... volts A ......................amperes

Hz ................. hertz W .....................watts

min ............... minutes

or AC ..........alternating

or DC ... direct current current

.................Class I Construction or AC/DC ...alternating or

.....................

(grounded) direct current

................. Class II Construction no ....................no load

(double insulated) speed

…/min .......... per minute

n ......................rated speed

BPM .............beats per minute

.....................earthing

IPM ............... impacts per minute terminal

RPM .............revolutions per

.....................safety alert

minute symbol

sfpm .............surface feet per minute

Important Safety Instructions for All

Battery Packs

When ordering replacement battery packs, be sure to include catalog

number and voltage. Consult the chart at the end of this manual for

compatibility of chargers and battery packs.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below. Then

follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not charge or use battery in explosive atmospheres,

such as in the presence of flammable liquids, gases or dust.

Inserting or removing the battery from the charger may ignite the

dust or fumes.

• NEVER force battery pack into charger. DO NOT modify

battery pack in any way to fit into a non-compatible charger

as battery pack may rupture causing serious personal

injury. Consult the chart at the end of this manual for compatibility

of batteries and chargers.

• Charge the battery packs only in D

EWALT chargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations

where the temperature may reach or exceed 105 °F (40 °C)

(such as outside sheds or metal buildings in summer).

DANGER: Electrocution hazard. Never attempt to open the battery

pack for any reason. If battery pack case is cracked or damaged, do

not insert into charger. Do not crush, drop or damage battery pack.

English

4

Page 7

Do not use a battery pack or charger that has received a sharp blow,

been dropped, run over or damaged in any way (i.e., pierced with a

nail, hit with a hammer, stepped on). Electric shock or electrocution

may result. Damaged battery packs should be returned to service

center for recycling.

WARNING: Fire hazard. Do not store or carry battery so

that metal objects can contact exposed battery terminals.

For example, do not place battery in aprons, pockets, tool boxes,

product kit boxes, drawers, etc., with loose nails, screws, keys, etc.

without battery cap. Transporting batteries can possibly cause

fires if the battery terminals inadvertently come in contact

with conductive materials such as keys, coins, hand tools

and the like. The U.S. Department of Transportation Hazardous

Material Regulations (HMR) actually prohibit transporting batteries

in commerce or on airplanes (i.e., packed in suitcases and carry-on

luggage) UNLESS they are properly protected from short circuits.

So when transporting individual batteries, make sure that the battery

terminals are protected and well insulated from materials that could

contact them and cause a short circuit.

SPECIFIC SAFETY INSTRUCTIONS FOR LITHIUM ION (Li-Ion)

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire. Toxic fumes and materials are created when

lithium ion battery packs are burned.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water. If battery

liquid gets into the eye, rinse water over the open eye for 15

minutes or until irritation ceases. If medical attention is needed,

the battery electrolyte is composed of a mixture of liquid organic

carbonates and lithium salts.

• Contents of opened battery cells may cause respiratory

irritation. Provide fresh air. If symptoms persist, seek medical

attention.

WARNING: Burn hazard. Battery liquid may be flammable if

exposed to spark or flame.

The RBRCTM Seal

The RBRC™ (Rechargeable Battery Recycling Corp oration) Seal on

the nickel cadmium, nickel metal hydride or lithiumion

batteries (or battery packs) indicate that the costs to

recycle these batteries (or battery packs) at the end of

their useful life have already been paid by D

EWALT. In

some areas, it is illegal to place spent nickel cadmium,

nickel metal hydride or lithium ion batteries in the trash

or municipal solid waste stream and the RBRC program

provides an environmentally conscious alternative.

RBRC™ in cooperation with D

EWALT and other battery users, has

established programs in the United States and Canada to facilitate

the collection of spent nickel cadmium, nickel metal hydride or lithium

ion batteries. Help protect our environment and conserve natural

resources by returning the spent nickel cadmium, nickel metal hydride

or lithium ion batteries to an authorized D

EWALT service center or

to your local retailer for recycling. You may also contact your local

recycling center for information on where to drop off the spent

battery.

RBRC™ is a registered trademark of the Rechargeable Battery

Recycling Corporation.

Important Safety Instructions for All

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important

safety and operating instructions for battery chargers.

• Before using charger, read all instructions and cautionary markings

on charger, battery pack, and product using battery pack.

English

5

Page 8

DANGER: Electrocution hazard. 120 volts are present at charging

terminals. Do not probe with conductive objects. Electric shock or

electrocution may result.

WARNING: Shock hazard. Do not allow any liquid to get inside

charger. Electric shock may result.

CAUTION: Burn hazard. To reduce the risk of injury, charge only

D

EWALT rechargeable batteries. Other types of batteries may burst

causing personal injury and damage.

NOTICE: Under certain conditions, with the charger plugged in to

the power supply, the exposed charging contacts inside the charger

can be shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, grinding dust, metal chips, steel

wool, aluminum foil, or any buildup of metallic particles should be

kept away from charger cavities. Always unplug the charger from

the power supply when there is no battery pack in the cavity. Unplug

charger before attempting to clean.

• DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual. The charger and

battery pack are specifically designed to work together.

• These chargers are not intended for any uses other than

charging D

EWALT rechargeable batteries. Any other uses

may result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting charger.

This will reduce risk of damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped

on, tripped over, or otherwise subjected to damage or

stress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in risk of

fire, electric shock, or electrocution.

• When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. When using more than one extension to make up the

total length, be sure each individual extension contains at least the

minimum wire size. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

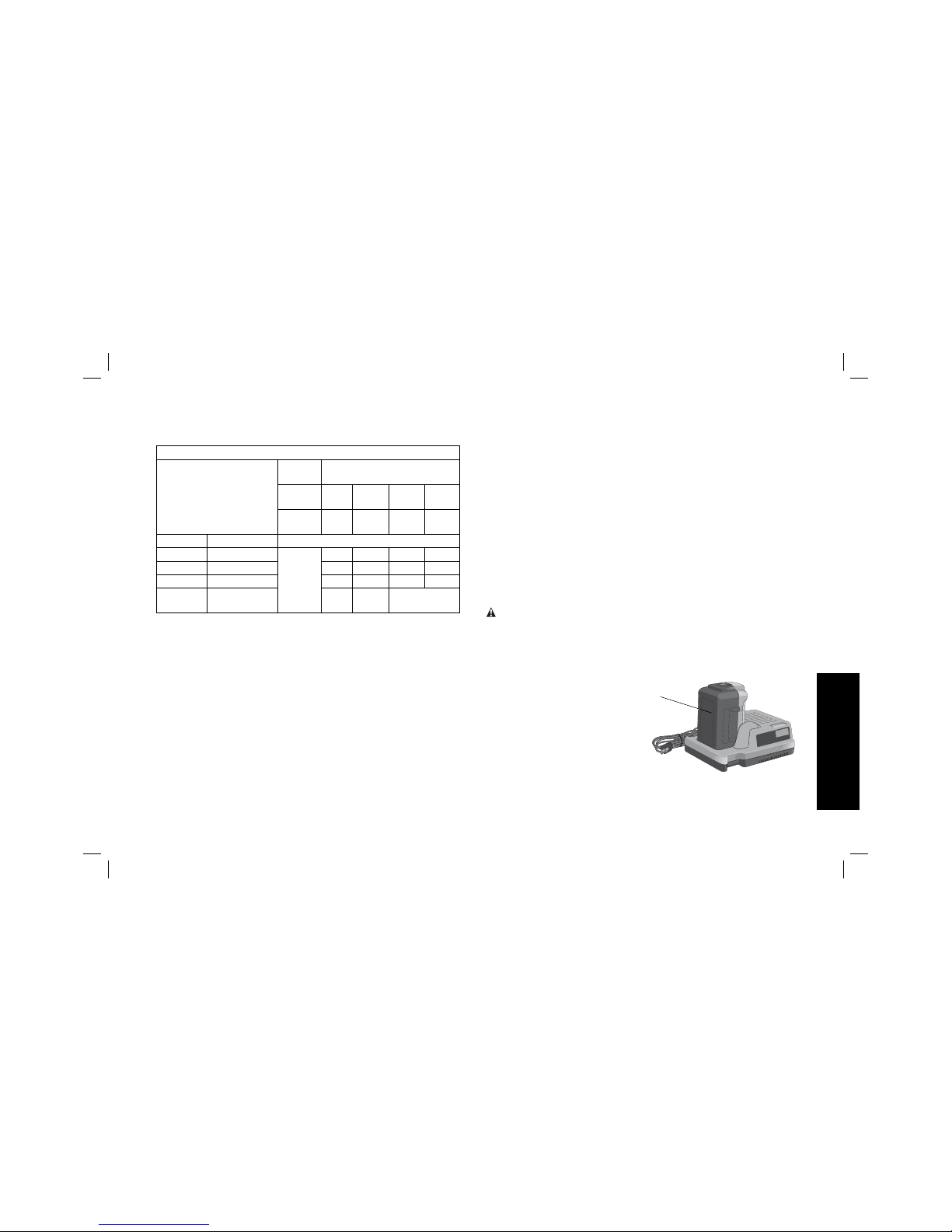

Minimum Gauge for Cord Sets

Ampere

Rating

Volts Total Length of Cord in Feet (meters)

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

More

Than

Not

More

Than

AWG

0 6 18 16 16 14

610 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

• Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation

slots and result in excessive internal heat. Place the charger

in a position away from any heat source. The charger is ventilated

through slots in the top and the bottom of the housing.

English

6

Page 9

• Do not operate charger with damaged cord or plug.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. Take it to an

authorized service center.

• Do not disassemble charger; take it to an authorized service

center when service or repair is required. Incorrect reassembly

may result in a risk of electric shock, electrocution or fire.

• Disconnect the charger from the outlet before attempting

any cleaning. This will reduce the risk of electric shock.

Removing the battery pack will not reduce this risk.

• NEVER attempt to connect two chargers together.

• The charger is designed to operate on standard 120 volt

household electrical power. Do not attempt to use it on any

other voltage. This does not apply to the vehicular charger.

Chargers

Your tool uses a DEWALT charger. Be sure to read all safety

instructions before using your charger. Consult the chart at the end of

this manual for compatibility of chargers and battery packs.

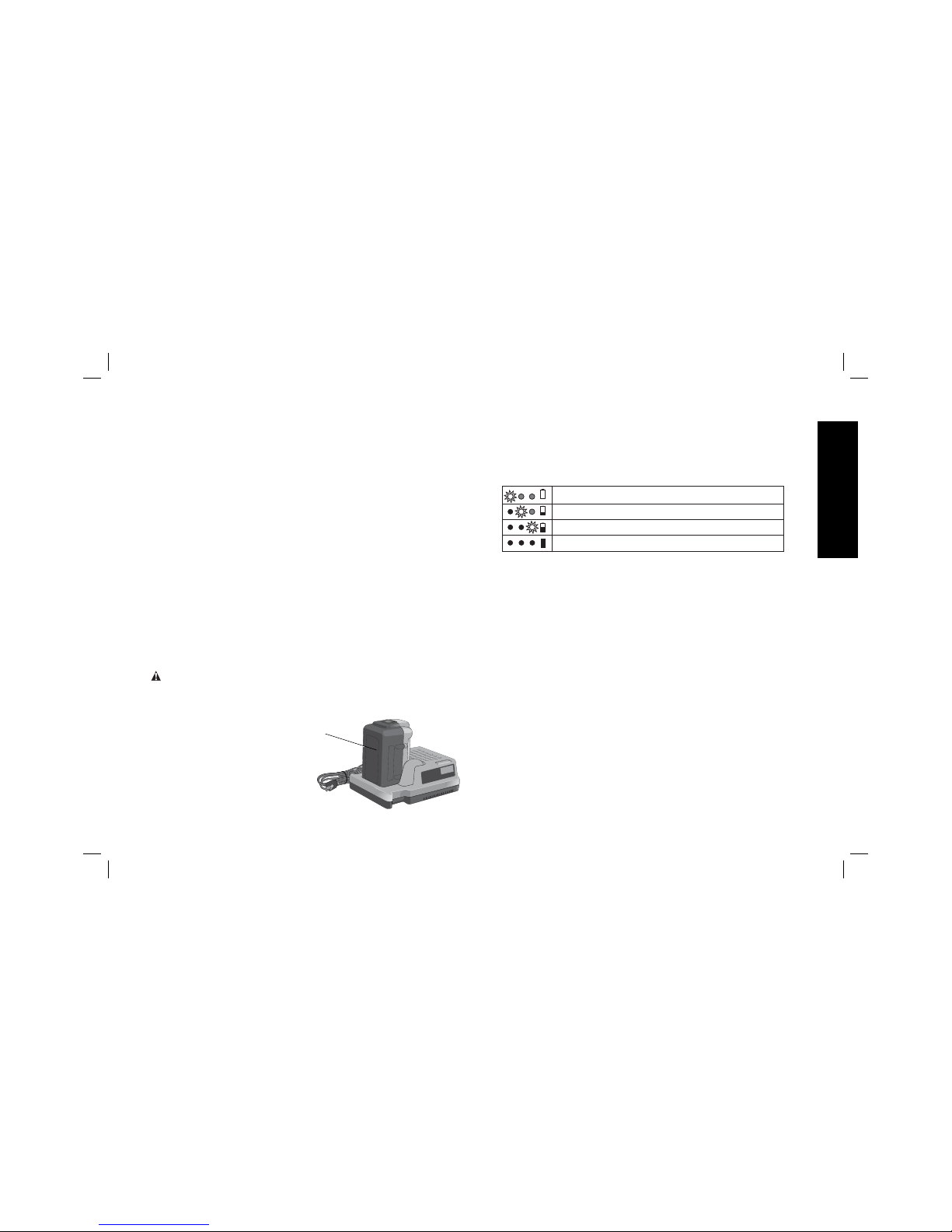

Charging Procedure (Fig. 1)

DANGER: Electrocution hazard. 120 volts are present at charging

terminals. Do not probe with conductive objects. Electric shock or

electrocution may result.

1. Plug the charger into an

G

FIG. 1

appropriate outlet before

inserting battery pack.

2. Insert the battery pack (G)

into the charger, as shown

in Figure 1, making sure

the pack is fully seated

in charger. The charger is

equipped with a three-light

fuel gauge that will blink according to the state of charge of the

battery pack.

3. The completion of charge is indicated by the three red lights

remaining ON continuously. The pack is fully charged and may be

used at this time or left on the charger.

0% - 33% 1st light blinks

33% - 66% 1

st

light on, 2nd light blinks

66% - 99% 1

st

, 2nd lights on, 3rd light blinks

100% 1

st

, 2nd, 3rd lights on

Charger Diagnostics

This charger is designed to detect certain problems that can arise

with the battery packs or the charger. Problems are indicated by the

three red lights flashing together in different patterns.

PROBLEM POWERLINE

When the charger is used with some portable power sources such

as generators or sources that convert DC to AC, the charger may

temporarily suspend operation. The three red lights will flash together

with two fast blinks followed by a pause. This indicates that the

power souce is out of limits.

BAD BATTERY

The charger can detect a weak or damaged battery. The three red

lights will flash together with rapid blinking. The battery will no longer

charge and should be returned to a service center or a collection site

for recycling.

BAD CHARGER

The charger will detect if it is not functioning properly. The three red

lights will flash together with one fast blink followed by a long

blink. The charger will no longer work and should be returned to an

authorized service center or replaced.

English

7

Page 10

LEAVING THE BATTERY IN THE CHARGER

The charger and battery pack can be left connected with the red

lights glowing indefinitely. The charger will keep the battery pack

fresh and fully charged. This charger features an automatic tune-up

mode which equals or balances the individual cells in the battery

pack to allow it to function at peak capacity. Battery packs should

be tuned up weekly or whenever the battery no longer delivers the

same amount of work. To use the automatic tune-up mode, place the

battery pack in the charger and leave it for at least 8 hours.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65 °F

and 75 °F (18 °–24 °C). DO NOT charge the battery pack in

an air temperature below +40 °F (+4.5 °C), or above +105 °F

(+40.5°C). This is important and will prevent serious damage to

the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem. To facilitate the cooling of the battery pack after use,

avoid placing the charger or battery pack in a warm environment

such as in a metal shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check operation of receptacle by plugging in a lamp or other

appliance;

b. Check to see if receptacle is connected to a light switch which

turns power off when you turn out the lights;

c. Move charger and battery pack to a location where the

surrounding air temperature is approximately 65 °F–75 °F

(18°– 24 °C);

d. If charging problems persist, take the tool, battery pack and

charger to your local service center.

4. The battery pack should be recharged when it fails to produce

sufficient power on jobs which were easily done previously. DO

NOT CONTINUE to use under these conditions. Follow the

charging procedure. You may also charge a partially used pack

whenever you desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can

be shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, grinding dust, metal chips, steel

wool, aluminum foil, or any buildup of metallic particles should be

kept away from charger cavities. Always unplug the charger from

the power supply when there is no battery pack in the cavity.

Unplug charger before attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING: Shock hazard. Don’t allow any liquid to get inside

charger. Electric shock may result.

WARNING: Burn hazard. Never attempt to open the battery pack

for any reason. If the plastic housing of the battery pack breaks or

cracks, return to a service center for recycling.

Storage Recommendations

1. The best storage place is one that is cool and dry away from

direct sunlight and excess heat or cold.

2. For long storage, it is recommended to store a fully charged

battery pack in a cool dry place out of the charger for optimal

results.

NOTE: Battery packs should not be stored completely depleted of

charge. The battery pack will need to be recharged before use.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

English

8

Page 11

COMPONENTS (Fig. 2)

WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Battery release buttons

B. Rocker switch (DC800)

C. Trigger switch

(DC810, DC815)

D. Forward/reverse button

(DC810, DC815)

E. Detent pin (DC800, DC810)

F. Anvil (DC800, DC810)

G. Battery pack

INTENDED USE

These heavy-duty impact wrenches are designed for professional

impact screwdriving applications. The impact function makes this

tool particularly useful for driving fasteners in wood, metal and

concrete.

DO NOT use under wet conditions or in presence of flammable

liquids or gases.

These heavy-duty impact wrenches are professional power tools.

DO NOT let children come into contact with the tool. Supervision is

required when inexperienced operators use this tool.

OPERATION

WARNING: To reduce the risk of injury, turn unit off

and disconnect it from power source before installing and

removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

FIG. 2

B

DC800 DC810

D

C

DC815

D

C

F

E

F

E

A A

A

G

G

G

English

9

Page 12

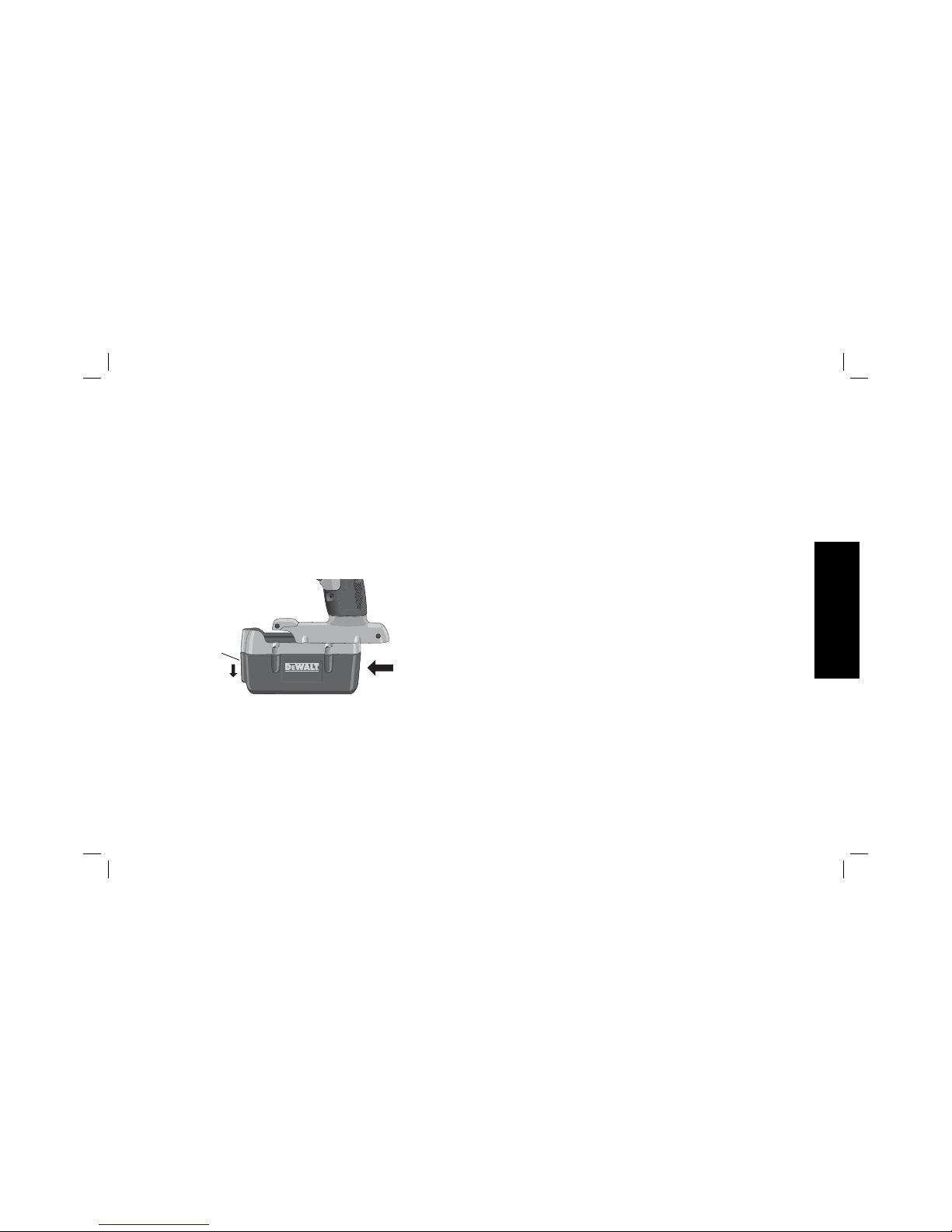

Installing and Removing the Battery Pack

(Fig. 3)

NOTE: For best results, make sure your battery pack is fully charged.

To install the battery pack into the tool handle, align the rails inside the

tool’s handle with the battery pack and slide the battery pack firmly

into the handle until you hear the lock snap into place.

To remove the battery pack from the tool, press the release buttons

(A) and firmly pull the battery pack out of the tool handle. Insert it into

the charger as described in the charger section of this manual.

A

FIG. 3

Switch (Fig. 2)

DC800

Pressing the BOTTOM part of the rocker switch (B) runs the

tool in forward (right-hand thread) direction. Pressing the TOP

of the switch reverses motor direction. This allows “rocking”

fasteners to break them loose.

Variable Speed Trigger Switch (Fig. 2)

DC810, DC815

To turn the tool on, squeeze the trigger switch (C). To turn the tool

off, release the trigger switch. Your tool is equipped with a brake.

The anvil will stop as soon as the trigger switch is fully released. The

variable speed switch enables you to select the best speed for a

particular application. The more you squeeze the trigger, the faster the

tool will operate. Use lower speeds for starting screws or fasteners.

For maximum tool life, use variable speed only for starting fasteners.

NOTE: Continuous use in variable speed range is not recommended.

It may damage the switch and should be avoided.

Forward/Reverse Control Button (Fig. 2)

DC810, DC815

A forward/reverse control button (D) determines the direction of the

tool and also serves as a lock off button.

To select forward rotation, release the trigger switch and depress

the forward/reverse control button on the right side of the tool.

To select reverse, depress the forward/reverse control button on

the left side of the tool. The center position of the control button locks

the tool in the off position. When changing the position of the control

button, be sure the trigger is released.

NOTE: The first time the tool is run after changing the direction of

rotation, you may hear a click on start up. This is normal and does

not indicate a problem.

English

10

Page 13

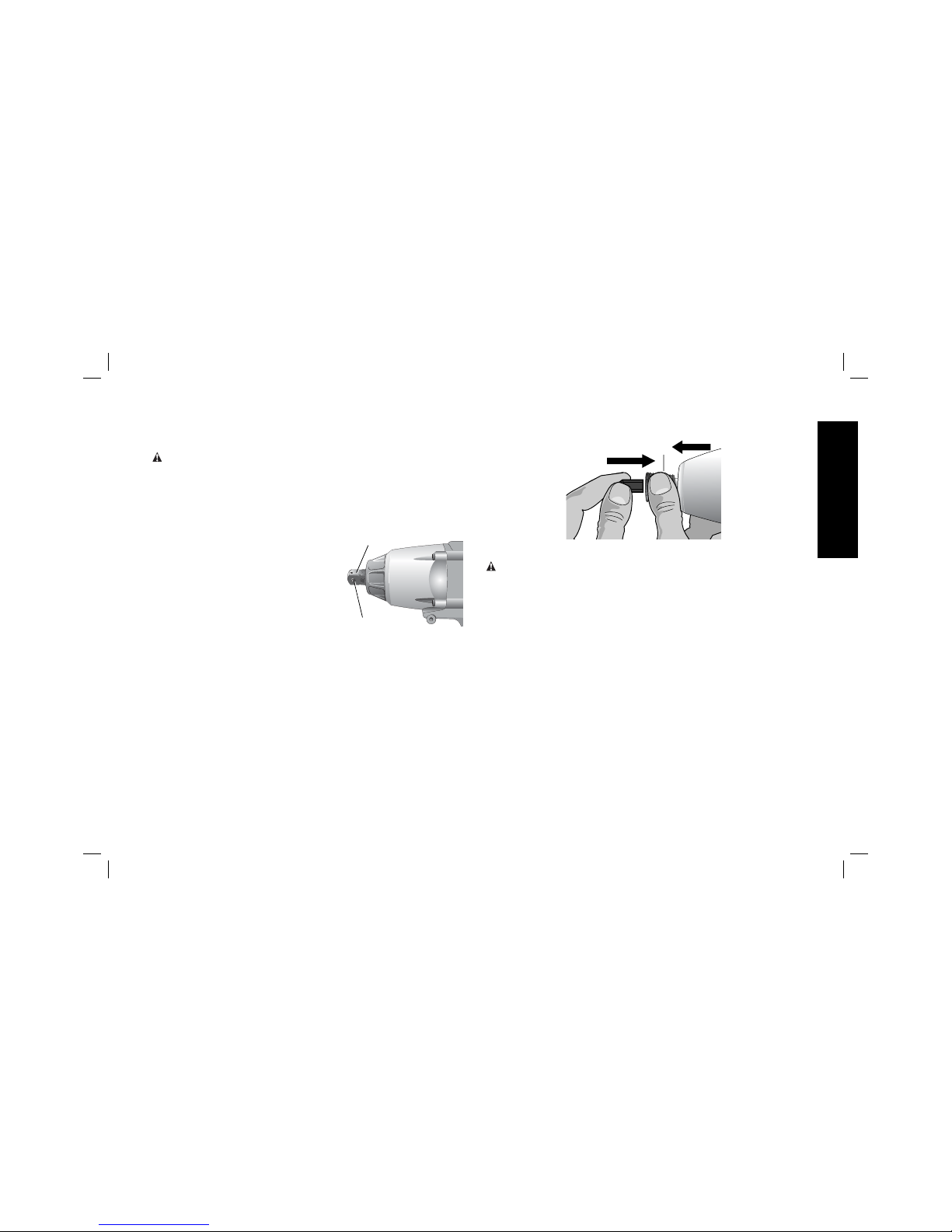

Anvil With Detent Pin (Fig. 4)

DC800, DC810

CAUTION: Use only impact accessorires. Non-impact accessories

may break and cause a hazardous condition. Inspect accessory prior

to use to ensure that it con tains no cracks.

Place the switch in the locked off (center) position or remove battery

pack before changing accessories.

To install an accessory on the anvil,

FIG. 4

E

F

align the hole in the side of the accessory

with the detent pin (E) on the anvil (F).

Press the accessory on until the detent

pin engages in the hole. Depression of

detent pin may be necessary to aid

installation of accessory.

To remove an accessory, depress the

detent pin through the hole and pull the

accessory off.

Quick-Release Chuck

(Fig. 5)

DC815

NOTE: The chuck accepts 1/4" (6.35 mm) hex accessories only.

Place the switch in the locked off (center) position or remove battery

pack before changing accessories.

To install an accessory, pull the chuck collar (H) away from the front

of the tool, insert the accessory and release the collar. The accessory

is locked in place.

To remove an accessory, pull the chuck collar away from the front

of the tool. Remove the accessory and release the collar.

FIG. 5

H

Usage

CAUTION: Ensure fastener and/or system will withstand the

level of torque generated by the tool. Excessive torque may cause

breakage and possible personal injury.

1. Place the accessory on the fastener head. Keep the tool pointed

straight at the fastener.

2. Press switch to start operation. Always check torque with a

torque wrench, as the fastening torque is affected by many

factors including the following:

• Voltage: Low voltage, due to a nearly discharged battery, will

reduce fastening torque.

• Accessory size: Failure to use the correct accessory size will

cause a reduction in fastening torque.

• Bolt Size: Larger bolt diameters generally require higher

fastening torque. Fastening torque will also vary according to

length, grade, and torque coefficient.

• Bolt: Ensure that all threads are free of rust and other debris to

allow proper fastening torque

English

11

Page 14

• Material: The type of material and surface finish of the material

will affect fastening torque.

• Fastening Time: Longer fasten ing time results in increased

fastening torque. Using a longer fastening time than recommended could cause the fasteners to be overstressed,

stripped or damaged.

Your impact tool generates the following output torque:

Cat # Ft.-Lbs. In.-Lbs. Nm

DC800 325 3900 440

DC810 160 1920 215

DC815 117 1400 160

MAINTENANCE

WARNING: To reduce the risk of injury, turn unit off

and disconnect it from power source before installing and

removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

Cleaning

WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

WARNING: Shock hazard. Disconnect the charger from the AC

outlet before cleaning. Dirt and grease may be removed from the

exterior of the charger using a cloth or soft non-metallic brush. Do not

use water or any cleaning solutions.

Accessories

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only D

EWALT recommended accessories should be used with

this product.

Recommended accessories for use with your tool are available at

extra cost from your local service center. If you need any assistance

in locating any accessory, please contact D

EWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-D

EWALT

(1-800-433-9258) or visit our website: www.dewalt.com.

WARNING: Use only impact accessories. Non-impact accessories

may break and cause a hazardous condition. Inspect accessories

prior to use to ensure that they con tain no cracks.

Repairs

The charger and battery pack are not serviceable.

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by a D

EWALT factory service center, a DEWALT

authorized service center or other qualified service personnel. Always

use identical replacement parts.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you

obtain more efficient warranty service in case there is a problem

with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance

loss, such as fire, flood or theft, your registration of ownership will

serve as your proof of purchase.

English

12

Page 15

• FOR YOUR SAFETY: Registering your product will allow us to

contact you in the unlikely event a safety notification is required

under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-D

EWALT (1-800-

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights

which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

2 YEARS FREE SERVICE ON D

EWALT BATTERY PACKS

DC9071, DC9091, DC9096, DC9280, DC9360, DC9180, DCB120

and DCB201

3 YEARS FREE SERVICE ON D

EWALT BATTERY PACKS

DCB200

D

EWALT BATTERY PACKS

Product warranty voided if the battery pack is tampered with in any

way. D

EWALT is not responsible for any injury caused by tampering

and may prosecute warranty fraud to the fullest extent permitted by

law.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT Power Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

EWALT (1-800-433-

9258) for a free replacement.

English

13

Page 16

Défi nitions: lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour

chaque mot-indicateur employé. Lire le mode d’emploi et porter

une attention particulière à ces symboles.

DANGER: indique une situation dangereuse imminente qui,

si elle n’est pas évitée, entraînera la mort ou des blessures

graves.

AVERTISSEMENT : indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner la

mort ou des blessures graves.

ATTENTION : indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner des

blessures légères ou modérées.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n’est fait

pour l’éviter, pourrait poser des risques de dommages

matériels.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET

OUTIL OU DE TOUT AUTRE OUTIL D

EWALT, COMPOSEZ LE

NUMÉRO SANS FRAIS : 1-800-4-D

EWALT (1-800-433-9258).

AVERTISSEMENT : afin de réduire le risque de blessures, lire

le mode d’emploi de l’outil.

Avertissements de sécurité généraux

pour les outils électriques

AVERTISSEMENT! lire tous les avertissements de

sécurité et toutes les directives. Le non-respect des

avertissements et des directives pourrait se solder par un

choc électrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTÉRIEUR

Le terme « outil électrique » cité dans les avertissements se rapporte

à votre outil électrique à alimentation sur secteur (avec fil) ou par piles

(sans fil).

1) SÉCURITÉ DU LIEU DE TRAVAIL

a) Tenir l’aire de travail propre et bien éclairée. Les lieux

encombrés ou sombres sont propices aux accidents.

b) Ne pas faire fonctionner d’outils électriques dans un

milieu déflagrant, tel qu’en présence de liquides, de

gaz ou de poussières inflammables. Les outils électriques

produisent des étincelles qui pourraient enflammer la poussière

ou les vapeurs.

c) Éloigner les enfants et les personnes à proximité pendant

l’utilisation d’un outil électrique. Une distraction pourrait en

faire perdre la maîtrise à l’utilisateur.

2) SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a) Les fiches des outils électriques doivent correspondre

à la prise. Ne jamais modifier la fiche d’aucune façon.

Ne jamais utiliser de fiche d’adaptation avec un outil

électrique mis à la terre. Le risque de choc électrique sera

Français

14

Page 17

réduit par l’utilisation de fiches non modifiées correspondant à

la prise.

b) Éviter tout contact physique avec des surfaces mises à la

terre comme des tuyaux, des radiateurs, des cuisinières

et des réfrigérateurs. Le risque de choc électrique est plus

élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à

l’humidité. La pénétration de l’eau dans un outil électrique

augmente le risque de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais

utiliser le cordon pour transporter, tirer ou débrancher

un outil électrique. Tenir le cordon éloigné de la chaleur,

de l’huile, des bords tranchants et des pièces mobiles.

Les cordons endommagés ou enchevêtrés augmentent les

risques de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se

servir d’une rallonge convenant à cette application.

L’utilisation d’une rallonge conçue pour l’extérieur réduira les

risques de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil

électrique dans un endroit humide, brancher l’outil dans

une prise ou sur un circuit d’alimentation dotés d’un

disjoncteur de fuite à la terre (GFCI). L’utilisation de ce type

de disjoncteur réduit les risques de choc électrique.

3) SÉCURITÉ PERSONNELLE

a) Être vigilant, surveiller le travail effectué et faire preuve

de jugement lorsqu’un outil électrique est utilisé. Ne

pas utiliser d’outil électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Un

simple moment d’inattention en utilisant un outil électrique peut

entraîner des blessures corporelles graves.

b) Utiliser des équipements de protection individuelle.

Toujours porter une protection oculaire. L’utilisation

d’équipements de protection comme un masque antipoussière,

des chaussures antidérapantes, un casque de sécurité ou des

protecteurs auditifs lorsque la situation le requiert réduira les

risques de blessures corporelles.

c) Empêcher les démarrages intempestifs. S’assurer que

l’interrupteur se trouve à la position d’arrêt avant de

relier l’outil à une source d’alimentation et/ou d’insérer

un bloc-piles, de ramasser ou de transporter l’outil.

Transporter un outil électrique alors que le doigt repose sur

l’interrupteur ou brancher un outil électrique dont l’interrupteur

est à la position de marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé avant de démarrer

l’outil. Une clé ou une clé de réglage attachée à une partie

pivotante de l’outil électrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son équilibre en

tout temps. Cela permet de mieux maîtriser l’outil électrique

dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de

vêtements amples ni de bijoux. Garder les cheveux, les

vêtements et les gants à l’écart des pièces mobiles. Les

vêtements amples, les bijoux ou les cheveux longs risquent de

rester coincés dans les pièces mobiles.

g) Si des composants sont fournis pour le raccordement de

dispositifs de dépoussiérage et de ramassage, s’assurer

que ceux-ci sont bien raccordés et utilisés. L’utilisation

d’un dispositif de dépoussiérage peut réduire les dangers

engendrés par les poussières.

Français

15

Page 18

4) UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique

approprié à l’application. L’outil électrique approprié

effectuera un meilleur travail, de façon plus sûre et à la vitesse

pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur

est défectueux. Tout outil électrique dont l’interrupteur est

défectueux est dangereux et doit être réparé.

c) Débrancher la fiche de la source d’alimentation et/ou du

bloc-piles de l’outil électrique avant de faire tout réglage

ou changement d’accessoire ou avant de ranger l’outil.

Ces mesures préventives réduisent les risques de démarrage

accidentel de l’outil électrique.

d) Ranger les outils électriques hors de la portée des

enfants et ne permettre à aucune personne n’étant

pas familière avec un outil électrique ou son mode

d’emploi d’utiliser cet outil. Les outils électriques deviennent

dangereux entre les mains d’utilisateurs inexpérimentés.

e) Entretien des outils électriques. Vérifier si les pièces

mobiles sont mal alignées ou coincées, si des pièces sont

brisées ou présentent toute autre condition susceptible

de nuire au bon fonctionnement de l’outil électrique.

En cas de dommage, faire réparer l’outil électrique

avant toute nouvelle utilisation. Beaucoup d’accidents sont

causés par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et

propres. Les outils de coupe bien entretenus et affûtés sont

moins susceptibles de se coincer et sont plus faciles à maîtriser.

g) Utiliser l’outil électrique, les accessoires, les forets,

etc. conformément aux présentes directives en tenant

compte des conditions de travail et du travail à effectuer.

L’utilisation d’un outil électrique pour toute opération autre que

celle pour laquelle il a été conçu est dangereuse.

5) UTILISATION ET ENTRETIEN DU BLOC-PILES

a) Ne recharger l’outil qu’au moyen du chargeur précisé

par le fabricant. L’utilisation d’un chargeur qui convient à

un type de bloc-piles risque de provoquer un incendie s’il est

utilisé avec un autre type de b loc-piles.

b) Utiliser les outils électriques uniquement avec les blocs-

piles conçus à cet effet. L’utilisation de tout autre bloc-piles

risque de causer des blessures ou un incendie.

c) Lorsque le bloc-piles n’est pas utilisé, le tenir éloigné

des objets métalliques, notamment des trombones, de

la monnaie, des clés, des clous, des vis ou autres petits

objets métalliques qui peuvent établir une connexion

entre les deux bornes. Le court-circuit des bornes du bloc-

piles risque de provoquer des brûlures ou un incendie.

d) En cas d’utilisation abusive, le liquide peut gicler hors

du bloc-piles; éviter tout contact avec ce liquide. Si

un contact accidentel se produit, laver à grande eau.

Si le liquide entre en contact avec les yeux, obtenir

également des soins médicaux. Le liquide qui gicle hors du

bloc-piles peut provoquer des irritations ou des brûlures.

6) RÉPARATION

a) Faire réparer l’outil électrique par un réparateur

professionnel en n’utilisant que des pièces de rechange

identiques. Cela permettra de maintenir une utilisation

sécuritaire de l’outil électrique.

Français

16

Page 19

Règles de sécurité spécifi ques

supplémentaires pour les clés à choc

• Tenir l’outil par les surfaces isolées prévues à cet effet

pendant toute utilisation où l’attache pourrait entrer en

contact avec des fils électriques cachés. Tout contact par

ces attaches avec un fil sous tension mettra les parties métalliques

exposées de l’outil sous tension et électrocutera l’utilisateur.

• Utiliser des brides de fixation ou tout autre dispositif de

fixation pratique permettant de soutenir et de retenir la

pièce sur une plate-forme stable. Tenir la pièce avec la main

ou contre le corps la rend instable et risque de provoquer une

perte de maîtrise de l’outil.

• Porter des lunettes de sécurité ou une autre protection

oculaire. Le martelage et la perforation peuvent projeter des

fragments. Les particules projetées peuvent endommager les

yeux irréversiblement.

• Les accessoires et outils peuvent devenir brûlants au

toucher pendant l’utilisation. Porter des gants avant tout

contact.

• Ne pas faire fonctionner cet outil durant de longues

périodes. Les vibrations provoquées par la percussion de l'outil

peuvent nuire à vos bras et mains. Utiliser des gants pour amortir

davantage les vibrations et limiter l'exposition à l'outil par de

fréquentes périodes de repos.

• Prendre des précautions à proximité des évents, car ils

cachent des pièces mobiles. Vêtements amples, bijoux ou

cheveux longs risquent de rester coincés dans ces pièces mobiles.

AVERTISSEMENT: porter SYSTEMATIQUEMENT des lunettes

de protection. Les lunettes courantes NE sont PAS des lunettes de

protection. Utiliser aussi un masque antipoussières si la découpe

doit en produire beaucoup. PORTER SYSTÉMATIQUEMENT UN

ÉQUIPEMENT DE SÉCURITÉ HOMOLOGUÉ:

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3);

• Protection auditive ANSI S12.6 (S3.19);

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

AVERTISSEMENT : les scies, meules, ponceuses, perceuses

ou autres outils de construction peuvent produire des poussières

contenant des produits chimiques reconnus par l’État californien

pour causer cancers, malformations congénitales ou être nocifs au

système reproducteur. Parmi ces produits chimiques, on retrouve:

• Le plomb dans les peintures à base de plomb;

• La silice cristallisée dans les briques et le ciment, ou autres

produits de maçonnerie; et

• L’arsenic et le chrome dans le bois ayant subi un traitement

chimique.

Le risque associé à de telles expositions varie selon la fréquence à

laquelle on effectue ces travaux. Pour réduire toute exposition à ces

produits: travailler dans un endroit bien aéré, en utilisant du matériel

de sécurité homologué, tel un masque antipoussières spécialement

conçu pour filtrer les particules microscopiques.

• Limiter toute exposition prolongée avec les poussières

provenant du ponçage, sciage, meulage, perçage ou toute

autre activité de construction. Porter des vêtements de

protection et nettoyer à l’eau savonneuse les parties du

corps exposées. Le fait de laisser la poussière pénétrer dans la

bouche, les yeux ou la peau peut favoriser l’absorption de produits

chimiques dangereux.

AVERTISSEMENT : cet outil peut produire et/ou répandre

de la poussière susceptible de causer des dommages sérieux et

permanents au système respiratoire. Utiliser systématiquement un

appareil de protection des voies respiratoires homologué par le

NIOSH ou l’OSHA. Diriger les particules dans le sens opposé au

visage et au corps.

Français

17

Page 20

AVERTISSEMENT : pendant l’utilisation, porter

systématiquement une protection auditive individuelle

adéquate homologuée ANSI S12.6 (S3.19). Sous certaines

conditions et suivant la durée d’utilisation, le bruit émanant de ce

produit pourrait contribuer à une perte de l’acuité auditive.

ATTENTION : après utilisation, ranger l’outil sur son côté,

sur une surface stable, là où il ne pourra ni faire trébucher

ni faire chuter quelqu’un. Certains outils équipés d’un large bloc-

piles peuvent tenir à la verticale sur celui-ci, mais manquent alors de

stabilité.

• L’étiquette apposée sur votre outil peut inclure les symboles

suivants. Les symboles et leur définition sont indiqués ci-après:

V ................... volts A ....................... ampères

Hz ................. hertz W ......................watts

min ............... minutes

ou AC .......... courant alternatif

ou DC ... courant continu ou AC/DC ... courant alternatif

................. classe I fabrication ou continu

(mis à la terre) no .....................vitesse à vide

................. fabrication n ....................... vitesse nominale

classe II (double

......................borne de terre

isolation)

...................... symbole

…/min ........... par minute d’avertissement

IPM ............... impacts par SPM (FPM) .......fréquence par

minute minute

BPM ............. battements par r/min .................tours par

minute minute

sfpm ............. pieds linéaires

par minute (plpm)

Consignes de sécurité importantes

propres à tous les blocs-piles

Pour commander un bloc-piles de rechange, s’assurer d’inclure son

numéro de catalogue et sa tension. Consulter le tableau figurant à

la fin du présent mode d’emploi pour connaître la compatibilité des

chargeurs et des blocs-piles.

Le bloc-piles n’est pas totalement chargé d’usine. Avant d’utiliser le

bloc-piles et le chargeur, lire les consignes de sécurité ci-dessous.

Puis suivre la procédure de charge indiquée.

LIRE TOUTES LES CONSIGNES

• Ne pas recharger ou utiliser un bloc-piles en milieu

déflagrant, en présence, par exemple, de poussières, gaz

ou liquides inflammables. Le fait d’insérer ou retirer un bloc-

piles de son chargeur pourrait causer l’inflammation de poussières

ou d’émanations.

• NE JAMAIS forcer l’insertion d’un bloc-piles dans un

chargeur. NE modifier un bloc-piles d’AUCUNE façon

pour le faire rentrer dans un chargeur incompatible, car

il pourrait se briser et causer des dommages corporels

graves. Consulter le tableau en dernière page de ce manuel pour

connaître les compatibilités entre chargeurs et blocs-piles.

• Recharger les blocs-piles exclusivement dans des chargeurs

D

EWALT.

• NE PAS éclabousser le bloc-piles ou l’immerger dans l’eau ou

dans tout autre liquide.

• Ne pas entreposer ou utiliser l’appareil et le bloc-piles en

présence de températures ambiantes pouvant excéder

40°C (105°F) (comme dans des hangars ou des bâtiments

métalliques l’été).

Français

18

Page 21

DANGER : risque d’électrocution. Ne jamais ouvrir le bloc-piles

pour quelque raison que ce soit. Si le boîtier du bloc-piles est fissuré

ou endommagé, ne pas l’insérer dans un chargeur. Ne pas écraser,

faire tomber ou endommager le bloc-piles. Ne pas utiliser un blocpiles ou un chargeur qui a reçu un choc violent, qui est tombé, a été

écrasé ou est endommagé de quelque manière que ce soit (p. ex.

percé par un clou, frappé d’un coup de marteau, piétiné). En effet,

il y a risque de choc électrique ou d’électrocution. Les blocs-piles

endommagés doivent être envoyés au centre de réparation pour

être recyclés.

AVERTISSEMENT : risque d’incendie. Ne pas ranger ni

ne transporter les piles de manière à ce que des objets

métalliques puissent entrer en contact avec les bornes

exposées des piles. On ne doit pas mettre, par exemple, le bloc-

piles sans capuchon dans un tablier, une poche, une boîte à outils,

une boîte de nécessaire de produit, un tiroir, etc. avec des clous, des

vis, des clés, etc. Le transport des piles peut causer un incendie

si les bornes des piles entrent en contact involontairement

avec des matières conductrices comme des clés, de la

monnaie, des outils manuels et d’autres éléments semblables.

La Hazardous Material Regulations (réglementation sur les produits

dangereux) du département américain des transports interdit en fait le

transport des blocs-piles pour le commerce et dans les avions (c.-à-d.

dans des valises et les bagages à main) À MOINS qu’ils ne soient

bien protégés contre les courts-circuits. Pour le transport de piles

individuelles, on doit donc s’assurer que les bornes sont protégées

et bien isolées contre toute matière pouvant entrer en contact avec

elles et provoquer un court-circuit.

DIRECTIVES DE SÉCURITÉ SPÉCIFIQUES POUR LES PILES

AU LITHIUM-ION (Li-Ion)

• Ne pas incinérer le bloc-piles même s’il est sévèrement

endommagé ou complètement usagé, car il pourrait exploser

et causer un incendie. Pendant l’incinération des blocs-piles au

lithium-ion, des vapeurs et matières toxiques sont dégagées.

• En cas de contact du liquide de la pile avec la peau, rincer

immédiatement au savon doux et à l’eau. En cas de contact

oculaire, rincer l’œil ouvert à l’eau claire une quinzaine de minutes

ou jusqu’à ce que l’irritation cesse. Si des soins médicaux

s’avéraient nécessaires, noter que l’électrolyte de la pile est

composé d’un mélange de carbonates organiques liquides et de

sels de lithium.

• Le contenu des cellules d’une pile ouverte peut causer une

irritation respiratoire. En cas d’inhalation, exposer l’individu à

l’air libre. Si les symptômes persistent, consulter un médecin.

AVERTISSEMENT: risques de brûlure. Le liquide de la pile peut

s’enflammer s’il est exposé à des étincelles ou à une flamme.

Le sceau SRPRC

MC

Le sceau SRPRCMC (Société de recyclage des piles

rechargeables au Canada) apposé sur une pile au

nickel-cadmium, à hydrure métallique de nickel ou au

lithium-ion (ou un bloc-piles) indique que les coûts de

recyclage de ces derniers en fin d’utilisation ont déjà

été réglés par D

EWALT. Dans certaines régions, la mise

au rebut ou aux ordures municipales des piles au nickel-cadmium, à

l’hydrure métallique de nickel ou au lithium-ion, est illégale ; le

programme de SRPRC constitue donc une solution pratique et

écologique.

Français

19

Page 22

La SRPRCMC, en collaboration avec DEWALT et d’autres utilisateurs

de piles, a mis sur pied des programmes aux États-Unis et au

Canada pour faciliter la collecte des piles au nickel-cadmium, à

l’hydrure métallique de nickel ou au lithium-ion usagées. Aidez-nous

à protéger l’environnement et à conserver nos ressources naturelles

en renvoyant les piles au nickel-cadmium, à l’hydrure métallique de

nickel ou au lithium-ion usagées à un centre de réparation autorisé

D

EWALT ou chez votre détaillant afin qu’elles y soient recyclées. On

peut en outre se renseigner auprès d’un centre de recyclage local

pour connaître d’autres sites les acceptant.

SRPRC

MC

est une marque déposée de la Société de recyclage des

piles rechargeables au Canada.

Directives de sécurité importantes

propres à tous les chargeurs de piles

CONSERVER CES INSTRUCTIONS : ce manuel contient des

directives de sécurité et d’utilisation importantes propres aux

chargeurs de piles.

• Avant d’utiliser le chargeur, lire toute consigne et tout avertissement

apposés sur le chargeur, le bloc-piles et le produit utilisant le blocpiles.

DANGER : risque d’électrocution. Les bornes de charge

présentent une tension de 120 volts. Ne pas sonder les bornes avec

des objets conducteurs. En effet, il y a risque de choc électrique ou

d’électrocution.

AVERTISSEMENT : risques de chocs électriques. Ne laisser

aucun liquide pénétrer dans le chargeur, des chocs électriques

pourraient en résulter.

ATTENTION : risques de brûlure. Pour réduire tout risque de

dommages corporels, ne recharger que des piles rechargeables

D

EWALT. Tout autre type de piles pourrait exploser et causer des

dommages corporels et matériels.

AVIS : sous certaines conditions, lorsque les contacts de

chargement exposés à l’intérieur du le chargeur est connecté au bloc

d’alimentation, des matériaux étrangers pourraient court-circuiter le

chargeur. Les corps étrangers conducteurs tels que (mais pas limité

à) poussières de rectification, débris métalliques, laine d’acier, feuilles

d’aluminium, ou toute accumulation de particules métalliques doivent

être maintenus à distance des orifices du chargeur. Débrancher

systématiquement le chargeur lorsque le bloc-piles n’y est pas inséré.

Débrancher systématiquement le chargeur avant tout entretien.

• NE PAS tenter de charger de bloc-piles avec des chargeurs

autres que ceux décrits dans ce manuel. Le chargeur et son

bloc-piles ont été conçus tout spécialement pour fonctionner

ensemble.

• Ces chargeurs n’ont pas été conçus pour une utilisation

autre que recharger les blocs-piles rechargeables D

EWA LT.

Toute autre utilisation comporte des risques d’incendie, de chocs

électriques ou d’électrocution.

• Protéger le chargeur de la pluie ou de la neige.

• Tirer sur la fiche plutôt que sur le cordon pour débrancher

le chargeur. Cela permet de réduire les risques d’endommager

la fiche ou le cordon d’alimentation.

• S’assurer que le cordon est protégé de manière à ce que

personne ne marche ni ne trébuche dessus, ou à ce qu’il

ne soit ni endommagé ni soumis à aucune tension.

• N’utiliser une rallonge qu’en cas de nécessité absolue.

L’utilisation d’une rallonge inadéquate comporte des risques

d’incendie, de chocs électriques ou d’électrocution.

• Lors de l’utilisation d’un outil électrique à l’extérieur, utiliser

une rallonge conçue à cet effet. L’utilisation d’une rallonge

conçue pour l’extérieur réduit les risques de chocs électriques.

Français

20

Page 23

• Pour la sécurité de l’utilisateur, utiliser une rallonge de

calibre adéquat (AWG, American Wire Gauge [calibrage

américain normalisé des fils électriques]). Plus le calibre est

petit, et plus sa capacité est grande. Un calibre16, par exemple,

a une capacité supérieure à un calibre18. L’usage d’une rallonge

de calibre insuffisant causera une chute de tension qui entraînera

perte de puissance et surchauffe. Si plus d’une rallonge est utilisée

pour obtenir une certaine longueur, s’assurer que chaque rallonge

présente au moins le calibre de fil minimum. Le tableau ci-dessous

illustre les calibres à utiliser selon la longueur de rallonge et

l’intensité nominale indiquée sur la plaque signalétique. En cas

de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la

rallonge peut supporter de courant.

Calibres minimaux des rallonges

Intensité (en ampères)

volts Longueur totale de

cordon en mètres (pieds)

120 V 7,6

(25)

15,2

(50)

30,5

(100)

45,7

(150)

240 V 15,2

(50)

30,5

(100)

61,0

(200)

91,4

(300)

Supérieur à Inférieur à AWG

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12

Non

recommandé

• Ne poser aucun objet sur le chargeur. Ne pas mettre le

chargeur sur une surface molle qui pourrait en bloquer la

ventilation et provoquer une surchauffe interne. Éloigner

le chargeur de toute source de chaleur. Le chargeur dispose

d’orifices d’aération sur le dessus et le dessous du boîtier.

• Ne pas le faire fonctionner avec un cordon d’alimentation

ou une fiche endommagée.

• Ne pas utiliser le chargeur s’il a reçu un coup, fait une chute

ou a été endommagé de quelque façon que ce soit. Le

ramener dans un centre de réparation agréé.

• Ne pas démonter le chargeur. Pour tout service ou réparation,

le rapporter dans un centre de réparation agréé. Le fait de le

réassembler de façon incorrecte comporte des risques de chocs

électriques, d’électrocution et d’incendie.

• Débrancher le chargeur du secteur avant tout entretien.

Cela réduira tout risque de chocs électriques. Le fait de retirer

le bloc-piles ne réduira pas ces risques.

• NE JAMAIS tenter de connecter deux chargeurs ensemble.

• Le chargeur a été conçu pour être alimenté en courant

électrique domestique standard de 120 volts. Ne pas tenter

de l’utiliser avec toute autre tension. Cela ne s’applique pas

aux chargeurs de postes mobiles.

Chargeurs

Votre outil fonctionne avec un chargeur DEWALT. S’assurer de bien

lire toutes les directives de sécurité avant toute utilisation du chargeur.

Consulter le tableau à l’arrière de ce manuel pour vous informer de la

compatibilité entre chargeurs et blocs-piles.

Procédure de charge (Fig.1)

DANGER : risque d’électrocution. Les bornes de charge

présentent une tension de 120 volts. Ne pas sonder les bornes avec

des objets conducteurs. En effet, il y a risque de choc électrique ou

d’électrocution.

1. Branchez le chargeur dans la prise appropriée avant d’y insérer le

bloc-piles.

Français

21

Page 24

2. Insérez le bloc-piles (G)

G

FIG. 1

le

dans chargeur, comme

illustré en figure 1. Le

chargeur est doté

d’une jauge de

carburant à trois

lumières qui clignotera

selon l’état de charge

du bloc-piles.

3. La fin de la charge sera indiquée par les trois voyants rouges qui

demeureront continuellement allumés. Le bloc-piles est chargé à

plein et peut être utilisé ou laissé dans le chargeur à ce moment.

0 % - 33 %

33 % - 66 %

66 % - 99 %

100 %

1er voyant allumé, 2e voyant clignote

1

er

, 2e voyants allumés, 3e voyant clignote

1

er

, 2e, 3e, voyants allumés

1

er

voyant clignote

Diagnostique de chargeur

Ce chargeur est conçu pour détecter certains problèmes pouvant

survenir avec les blocs-piles ou le chargeur. Les problèmes sont

indiqués par trois voyants clignotant ensemble dans des motifs

différents.

PROBLÈME AVEC LE SECTEUR

Lorsque le chargeur est utilisé avec certaines sources d’alimentation

portatifs comme des génératrices ou des sources qui font la

conversion de c.c. à c.a., le chargeur peut suspendre temporairement

son fonctionnement. Les trois voyants rouges clignoteront ensemble

avec deux clignotements rapides suivis par une pause. Cela

indique que la source d’alimentation est hors tolérance.

PILE EN MAUVAIS ÉTAT

Le chargeur peut aussi détecter les piles faibles ou endommagées. Les

trois voyants rouges clignoteront ensemble avec un clignotement

rapide. La pile ne se chargera plus et doit être retournée à un centre

de réparation ou à un site de collecte pour le recyclage.

CHARGEUR EN MAUVAIS ÉTAT

Le chargeur détectera s’il ne fonctionne pas correctement. Les trois

voyants rouges clignoteront ensemble avec un clignotement rapide

suivi d’un long clignotement. Le chargeur ne fonctionnera plus et

doit être retourné à un centre de réparation autorisé ou remplacé.

PILE LAISSÉ DANS LE CHARGEUR

Le chargeur et le bloc-piles peuvent être laissés branchés avec les

voyants rouges allumés indéfiniment. Le chargeur maintiendra le blocpiles chargé à plein et en bon état. Ce chargeur comprend un mode de

mise au point automatique qui égalise ou équilibre chaque cellule du

bloc-piles pour lui permettre de fonctionner à son rendement optimum.

Les blocs-piles doivent être réglés chaque semaine ou lorsque la pile

ne fonctionne plus de manière optimale. Pour utiliser le mode de

mise au point automatique, mettre le bloc-piles dans le chargeur et ’y

laisser pendant au moins 8 heures.

Remarques importantes concernant le

chargement

1. Pour augmenter la durée de vie du bloc-piles et optimiser son

rendement, le recharger à une température ambiante de 18°C

à 24 °C (65 °F à 75 °F). NE PAS recharger le bloc-piles à

une température inférieure à +4,5°C (+ 40 °F) ou supérieure

à + 40,5 °C (+ 105 °F). C’est important pour prévenir tout

dommage sérieux au bloc-piles.

Français

22

Page 25

2. Le chargeur et son bloc-piles peuvent devenir chauds au toucher

pendant la charge. C’est normal et ne représente en aucun cas

une défaillance du produit. Pour faciliter le refroidissement du

bloc-piles après utilisation, éviter de laisser le chargeur ou le blocpiles dans un local où la température ambiante est élevée comme

dans un hangar métallique ou une remorque non isolée.

3. Si le bloc-piles ne se recharge pas correctement:

a. Vérifier le bon fonctionnement de la prise en y branchant une

lampe ou tout autre appareil électrique.

b. Vérifier que la prise n’est pas contrôlée par un interrupteur qui

coupe le courant lorsqu’on éteint les lumières.

c. Déplacer le chargeur et le bloc-piles dans un local où la

température ambiante se trouve entre environ 18°C et 24°C

(65°F et 75°F).

d. Si le problème persiste, amener l’outil, le bloc-piles et son

chargeur dans un centre de réparation local.

4. Recharger le bloc-piles lorsqu’il ne produit plus assez de

puissance pour effectuer un travail qu’il faisait facilement

auparavant. NE PAS CONTINUER à l’utiliser dans ces conditions.

Suivre la procédure de charge. Si nécessaire, il est aussi possible

de recharger un bloc-piles partiellement déchargé sans effet

nuisible sur le bloc-piles.

5. Dans certaines circonstances, lorsque le chargeur est branché

au bloc d’alimentation, les contacts de chargement exposés

à l’intérieur du chargeur peuvent être court-circuités par des

corps étrangers conducteurs tels que, mais sans s’y limiter,

poussières de rectification, débris métalliques, laine d’acier, feuilles

d’aluminium, ou toute accumulation de particules métalliques. Ils

doivent être maintenus à distance des ouvertures du chargeur.

Débrancher systématiquement le chargeur lorsque le bloc-piles

n’y est pas inséré. Débrancher systématiquement le chargeur

avant tout entretien.

6. Ne pas congeler ou immerger le chargeur dans l’eau ou tout

autre liquide.

AVERTISSEMENT : risques de chocs électriques. Ne laisser

aucun liquide pénétrer dans le chargeur, des chocs électriques

pourraient en résulter.

AVERTISSEMENT: risques de brûlure. Ne jamais tenter d’ouvrir

le bloc-piles pour quelque raison que ce soit. Si le boîtier plastique

du bloc-piles est brisé ou fissuré, le retourner dans un centre de

réparation pour y être recyclé.

Recommandations de stockage

1. Le lieu idéal de rangement est un lieu frais et sec, à l’abri de toute

lumière solaire directe et de toute température excessive.

2. Pour un stockage prolongé, il est recommandé d’entreposer le

bloc-piles pleinement chargé dans un lieu frais et sec, hors du

chargeur pour optimiser les résultats.

REMARQUE : les blocs-piles ne devraient pas être entreposés

complètement déchargés. Il sera nécessaire de recharger le blocpiles avant réutilisation.

CONSERVER CES CONSIGNES POUR

UTILISATION ULTÉRIEURE

Français

23

Page 26

DESCRIPTION (Fig. 2)

AVERTISSEMENT: ne jamais modifier l’outil électrique ni aucun

de ses composants, car il y a risques de dommages corporels ou

matériels.

A. Boutons de dégagement du

bloc-piles

B. Commutateur à bascule

(DC800)

C. Détente (DC810, DC815)

D. Bouton marche avant/

marche arrière

(DC810, DC815)

E. Goupille d'arrêt (DC800,

DC810)

F. Enclume (DC800, DC810)

G. Bloc-piles

USAGE PRÉVU

Ces clés à chocs pour service intensif sont conçus pour des

applications de vissage professionnelles. La fonction de choc rend

cet outil tout particulièrement utile pour faire pénétrer les fixations

dans le bois, le métal et le béton.

NE PAS les utiliser en milieu ambiant humide ou en présence de

liquides ou de gaz inflammables.

Ces clés à chocs pour service intensif sont des outils électriques

pour professionnels. NE PAS le laisser à la portée des enfants. Une

supervision est nécessaire auprès de tout utilisateur non expérimenté.

UTILISATION

AVERTISSEMENT : pour réduire le risque de blessures,

éteindre l’appareil et le débrancher avant d’installer ou de

retirer tout accessoire et avant d’effectuer des réglages ou des

réparations. Un démarrage accidentel peut provoquer des blessures.

FIG. 2

B

DC800 DC810

D

C

DC815

D

C

F

E

F

E

A A

A

G

G

G

Français

24

Page 27

Installation et retrait du bloc-piles (Fig.3)

REMARQUE: pour des résultats optimums, s’assurer que le blocpiles est complètement chargé.

Pour installer le bloc-piles dans la poignée de l’outil, aligner la base

de l’outil avec les rainures situées à l’intérieur de la poignée et glisser

le bloc-piles fermement dans la poignée jusqu’à ce qu’on entende un

déclic indiquant qu’il est bien enclenché.

Pour retirer le bloc-piles de l’outil, poussez sur le bouton de

dégagement (A) et tirez fermement le bloc-piles hors de la poignée

de l’outil. Insérez-le dans son chargeur comme décrit dans la section

appropriée de ce manuel.

A

FIG. 3

Interrupteur (Fig. 2)

DC800

Pour la marche avant (filetage du côté droit), enfoncer la partie

inférieure de l'interrupteur à bascule (B). Inverser la direction de

rotation moteur en appuyant sur la partie supérieure de l'interrupteur.

Ce « va-et-vient » permet de dégager les dispositifs de fixation.

Détente à vitesse variable (Fig. 2)

DC810, DC815

Pour démarrer l’outil, presser sur la détente (C). Pour l’éteindre,

simplement la relâcher. L’outil est doté d’un frein. L’enclume s’arrêtera

dès le relâchement complet de la détente. L’interrupteur de vitesse

variable vous permet de choisir la vitesse convenant le mieux à une

application particulière. Plus la détente est enfoncée, plus la vitesse

de l’outil sera élevée. Utiliser des vitesses basses pour les vis ou les

fixations de départ. Pour une durée de vie accrue de l’outil, utiliser la

fonction de vitesse variable uniquement pour commencer le vissage

des fixations.

REMARQUE : l’utilisation prolongée à des vitesses variables n’est

pas recommandée. Cette pratique pourrait endommager la détente

et devrait être évitée.

Bouton de commande avant-arrière

(Fig. 2)

DC810, DC815

Le bouton de commande avant-arrière (D) détermine le sens de

rotation de l’outil et sert également de bouton de verrouillage.

Pour sélectionner la rotation avant, relâcher l’interrupteur et

enfoncer le bouton de commande avant-arrière sur le côté droit de

l’outil.