Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (FEB03) Form No. 5134370-00 Various Air Compressors Copyright © 2001

DEWA LT The following are trademarks for one or more DEWA LT power tools: the yellow and black color scheme; the “D” shaped air intake grill;

the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Gas Manual 10-5-01 2/10/03 2:31 PM Page 2

Page 2

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

D55270, D55270T, D55271, D55271T, D55275, D55276

Contractor’s Gas Wheeled Portable Air Compressor

Compresseurs d’air portatif à moteur à essence sur roues de classe entrepreneur

Compresor de aire portátil a gasolina con ruedas para contratistas

Questions? See us on the World Wide Web at www.dewalt.com

Gas Manual 10-5-01 2/10/03 2:31 PM Page 3

Page 3

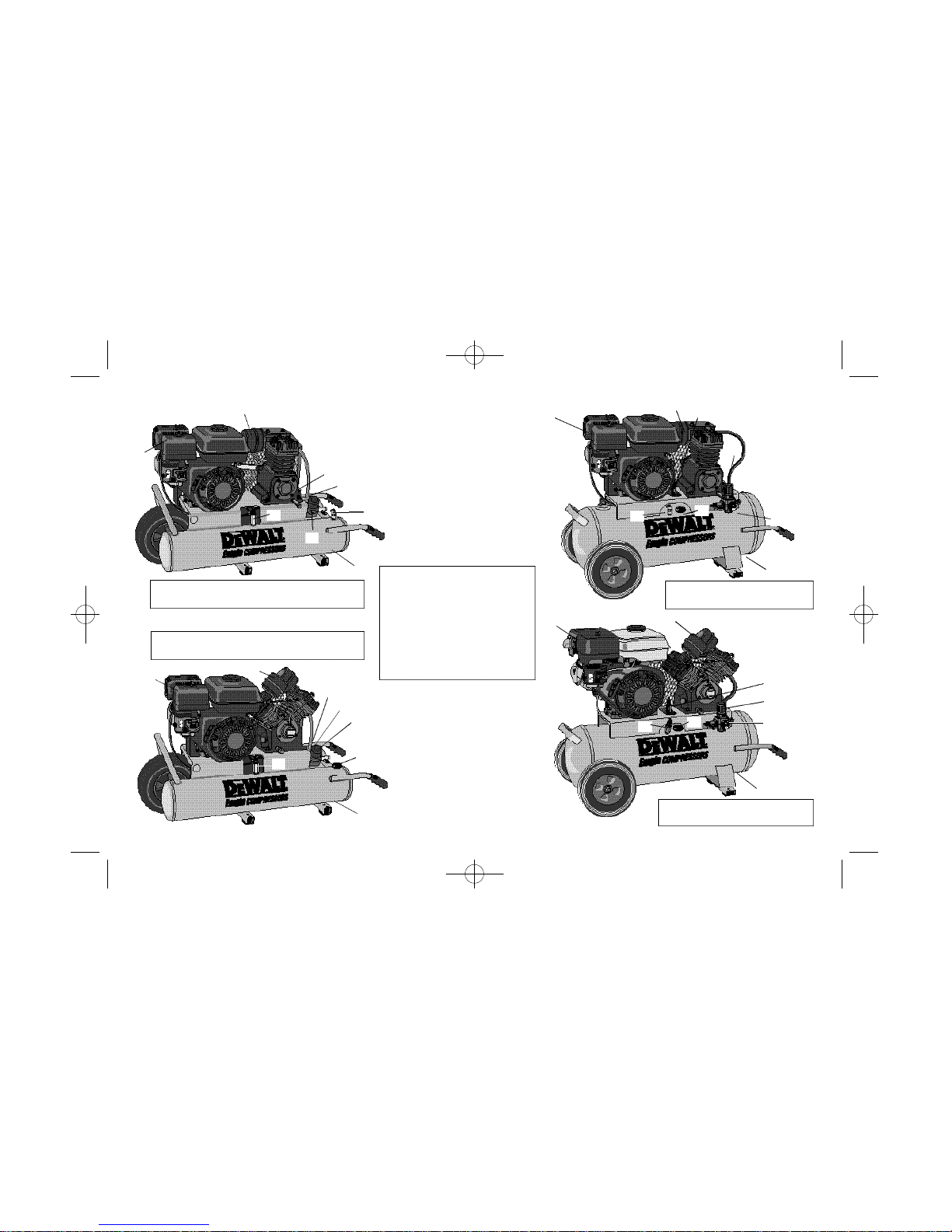

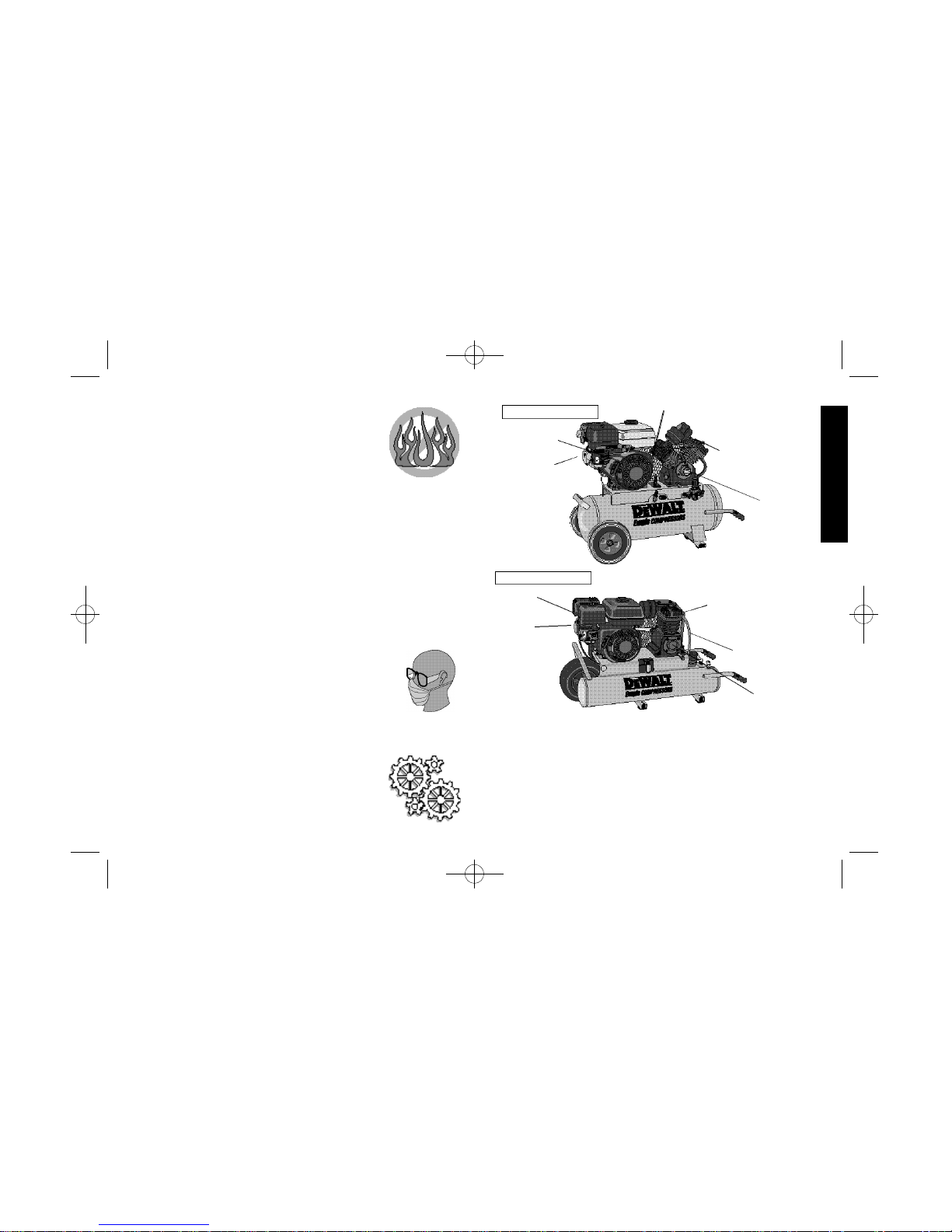

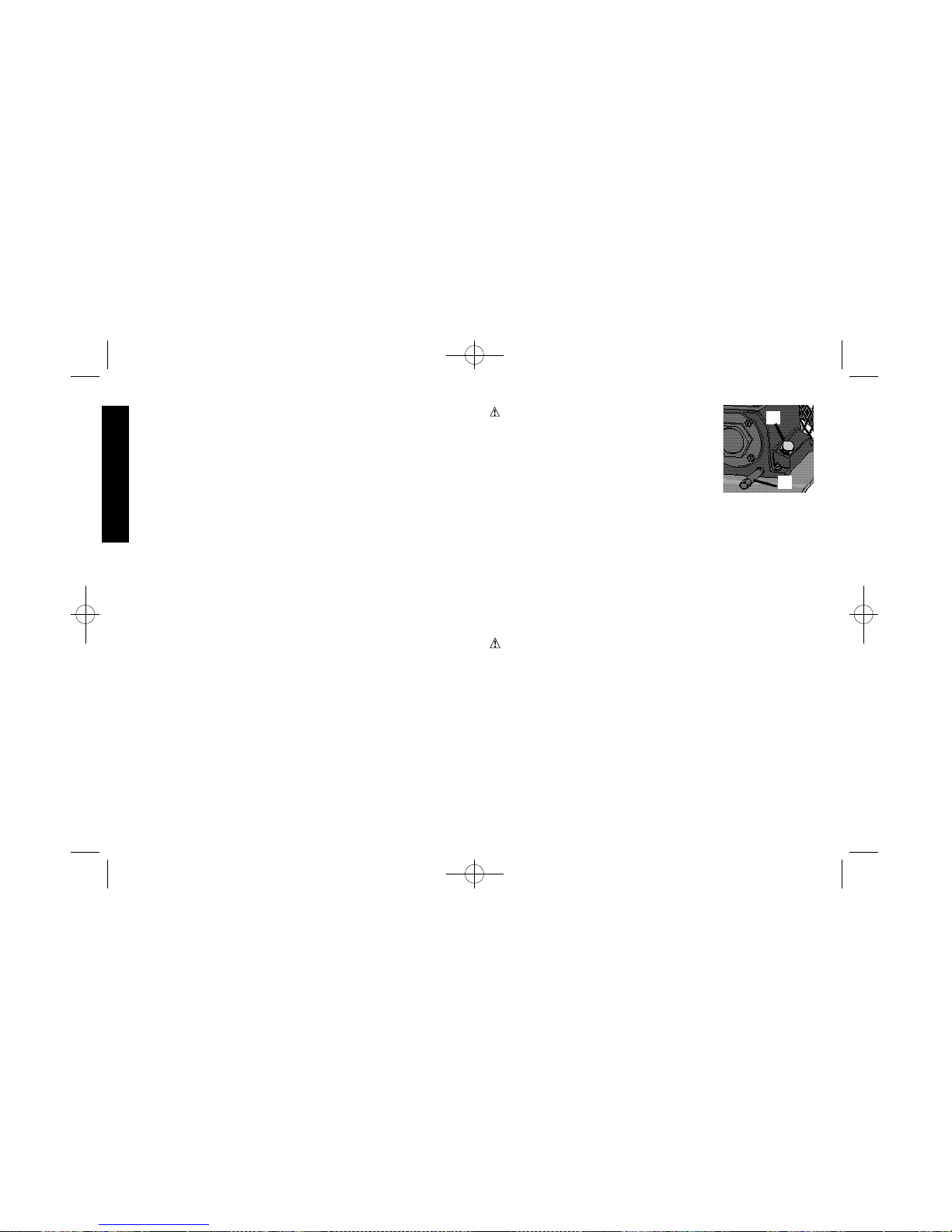

1 .Pump Air Filter

2 .Engine Air Filter

3 .Tank Pressure Gauge

4 .Regulated Pressure Gauge

5 .Pressure Regulator

6 .Pilot valve

7 .Safety Va l v e

8 .Tank Drain(s)

1

1

1

1

2

2

2

2

3

3

4

5

6

7

8

3

4

5

6

7

3 4

5

6

7

8

4

5

6

7

8

8

8 GALLON PORTABLE

D55271, D55271T* - 8 HP Honda Engine

17 GALLON PORTABLE

D55276 - 5.5 HP Honda Engine

17 GALLON PORTABLE

D55275 - 8 HP Honda Engine

8 GALLON PORTABLE

D55270, D55270T* - 5.5 HP Honda Engine

*Denotes 2-wheeled version.

Gas Manual 10-5-01 2/10/03 2:31 PM Page 4

Page 4

Engine Specifications

5.5 Hp Honda GX-160 8 Hp Honda GX-240

Internal Combustion Internal Combustion

4-stroke 4-stroke

3450 RPM 3450 RPM

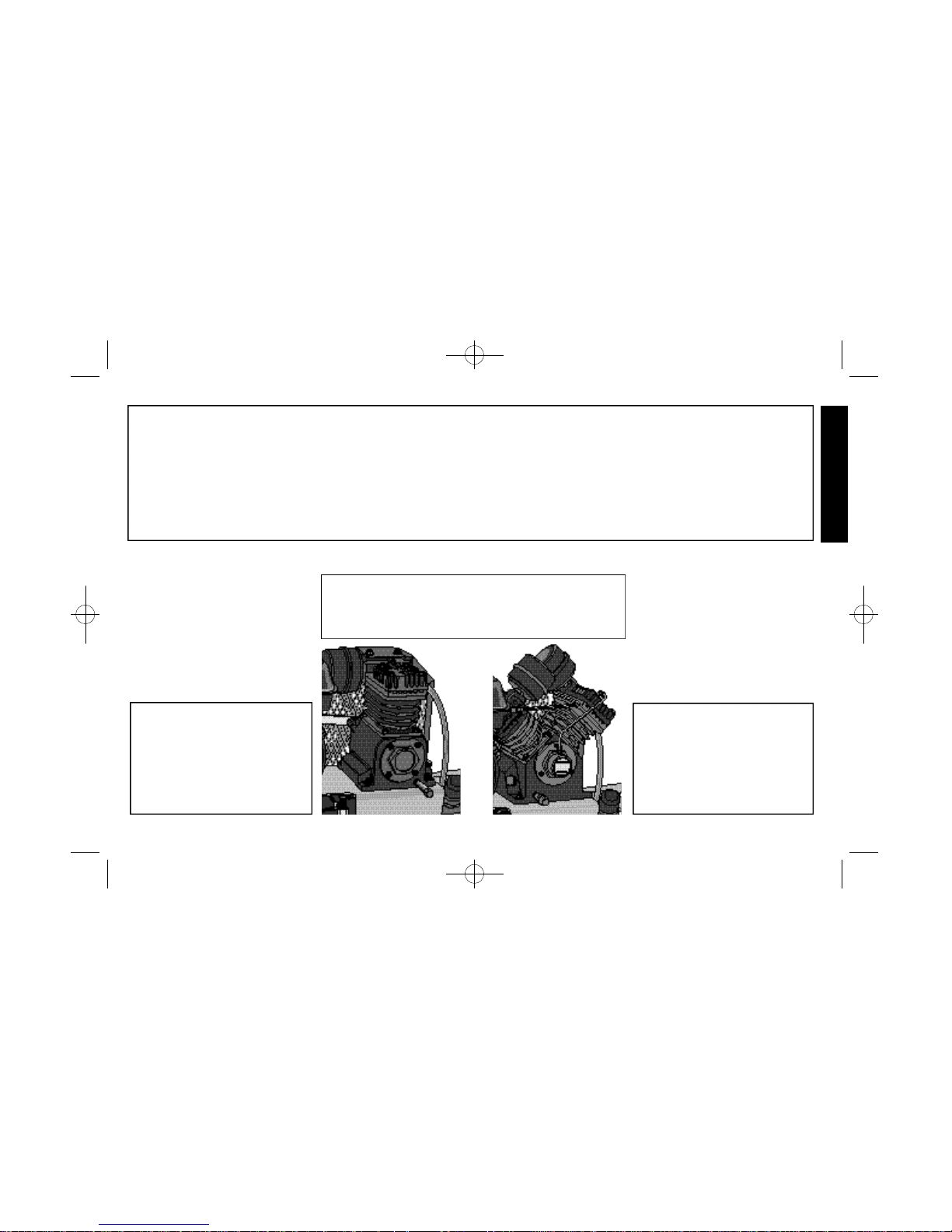

G Pump Specifications

V - twin 4 cylinder

Single Stage

Oil Lubricated

Cast Iron crankcase, cylinder, and head

Bore: 2-1/2 “ (63.5 mm)

Stroke: 2-3/8” (60.33 mm)

Weight: 69 lbs. (31.3 kg.)

Oil Capacity: 30 oz.

K Pump Specifications

Inline, vertical twin cylinder

Single Stage

Oil Lubricated

Cast Iron crankcase, cylinder, and head

Bore: 2-1/2“ (63.5 mm)

Stroke: 2” (50.8 mm)

Weight: 47 lbs. ( 21.32 kg.)

Oil Capacity: 14 oz.

SPECIFICATIONS

MODEL WEIGHT HEIGHT WIDTH LENGTH Typical values @ 100 psi

CFM

D55270 160 lbs. (72.57 Kg.) 25 in. (635 mm.) 18.25 in. (463.55 mm.) 43 in. (1092.2 mm.) 8.9

D55271 213 lbs. (96.62 Kg.) 27.75 in. (704.85 mm.) 18.25 in. (463.55 mm.) 43 in. (1092.2 mm.) 16.2

D55275 238 lbs. (107.96 Kg.) 33.75 in. (857.25 mm.) 20.25 in. (514.35 mm.) 43 in. (1092.2 mm.) 16.2

D55276 185 lbs. (83.91 Kg.) 31 in. (787.4 mm.) 20.25 in. (514.35 mm.) 43 in. (1092.2 mm.) 8.9

1

Gas Manual 10-5-01 2/10/03 2:31 PM Page 1

Page 5

(for units with tanks greater than 6 inch diameter)

according to ASME Section VIII, Div. 1 rules. All pressure

vessels should be inspected once every two years. To

find your state pressure vessels inspector, look under

the Division of Labor and Industries in the government

section of a phone book or call 1-800-4DEWA LT for

a s s i s t a n c e .

The following conditions could lead to a weakening of the tank, and

result in a violent tank explosion:

1. Failure to properly drain condensed water from the tank can

causing rust and thinning of the steel tank. Drain tank daily or

after each use. If tank develops a leak, replace it immediately with

a new tank or new compressor outfit.

2. Modifications or attempted repairs to the compressor tank.

Never drill into, weld, or make any modifications to the tank or its

a t t a c h m e n t s .

3. Do not modify the safety valve, or any other components that

control tank pressure. The tank is designed to withstand specific

operating pressures. Never make adjustments or parts substi tutions to alter the factory set operating pressures.

ATTACHMENTS & ACCESSORIES

Exceeding the pressure rating of air tools, spray guns, air operated

accessories, tires and other inflatables can cause them to explode or

fly apart, and could result in serious injury. Follow the

equipment manufacturers recommendation and

never exceed the maximum allowable pressure

rating of attachments. Never use the compressor

to inflate small low-pressure objects such as

c h i l d r e n ’s toys, footballs, basketballs, etc.

RISK OF EXPLOSION OR FIRE

Always operate the compressor in a well-ventilated area free of

combustible materials, gasoline or solvent vapors. If sparks from

compressor come into contact with flammable vapors, they may ignite,

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY DEWA LT TOOL, CALL US TOLL FREE AT 1-800-4D E WA LT (1-800-433-9258).

WARNING! READ AND UNDERSTAND ALL INSTRUCTIONS

BEFORE OPERATING THIS COMPRESSOR. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

Safety Instructions

WARNING: Some dust created by this product contains chemicals

known to State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• compounds in fertilizers

• compounds in insecticides, herbicides and pesticides

• arsenic and chromium from chemically treated lumber

To reduce your exposure to these chemicals, wear approved safety

equipment such as dust masks that are specially designed to filter out

microscopic particles.

WARNING: Use of this product will expose you to chemicals known

to the State of California to cause cancer, birth defects and other

reproductive harm. Avoid inhaling vapors and dust, and wash

hands after using.

WARNING: This product contains chemicals, including lead, known

to the State of California to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

The user of the air compressor must understand these instructions.

Each person operating the air compressor must be of sound mind and

body and must not be under the influence of any substance, which

might impair vision, dexterity, or judgement.

AIR TANK

The tank on your Air Compressor is designed and may be UM coded

2

Gas Manual 10-5-01 2/10/03 2:31 PM Page 2

Page 6

3

causing fire or explosion. If spraying flammable

materials, locate compressor at least 20 feet up wind

from spray area. An additional length of hose may be

r e q u i r e d .

Store flammable materials in a secure location away

from compressor.

Restricting any of the compressor ventilation openings will cause

serious overheating and could cause fire. Never place objects against

or on top of compressor. Operate compressor in an open area at

least 3 feet away from any wall or obstruction that would restrict the

flow of fresh air to the ventilation openings.

RISK FROM FLYING OBJECTS

The compressed air stream can cause soft tissue damage to exposed

skin and can propel dirt, chips, loose particles and small objects at high

speed, resulting in serious injury. Always wear ANSI Z28.1 approved

safety glasses with side shields when using the compressor. Never

direct air stream at people or animals. Use only OSHA approved air

blow guns.

RISK TO BREATHING

The compressed air from your compressor is not safe for

breathing! The air stream may contain carbon monoxide,

toxic vapors or solid particles. Never inhale air from the

compressor either directly or from a breathing device

connected to the compressor.

Sprayed materials such as paint, paint solvents, paint

r e m o v e r, insecticides, weed killers, etc. contain harmful vapors and

p o i s o n s. NOTE: Operate air compressor only in a well ventilated area.

Read and follow the safety instructions provided on

the label or safety data sheets for the material you are

spraying. Use a NIOSH/MSHA approved respirator

designed for use with the specific application.

RISK FROM MOVING PARTS

The compressor is designed to run continuously.

Always turn off the compressor, bleed pressure from the air hose and

tank, and disconnect from power source before performing

maintenance or attaching tools and accessories.

Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts. Air vents

may cover moving parts and should be avoided as well. Do not

remove the protective covers from this product. Never operate

compressor with guards or protective covers that are damaged or

COMPRESSOR

CYLINDER & HEAD

PUMP

CRANKCASE

GASOLINE

ENGINE

HOT SURFACES

COMPRESSOR

CYLINDER & HEAD

AFTERCOOLER

PUMP

CRANKCASE

ENGINE

MUFFLER

ENGINE

HEAD

HOT SURFACES

ENGINE

MUFFLER

AFTERCOOLER

Gas Manual 10-5-01 2/10/03 2:31 PM Page 3

Page 7

4

removed. Never stand on the compressor.

HOT SURFACES

Touching exposed metal such as the compressor head or aftercooler

can result in serious burns. Never touch any exposed metal parts on

compressor during or immediately after operation. Compressor will

remain hot for several minutes after operation. Do not move the

compressor while it is running. Hot motor parts could cause burns

contributing to the dropping of the compressor, damaging the

compressor and/or injuring the operator.

RISK FROM NOISE

C A U T I O N : Wear appropriate personal hearing protection

during use. Under some conditions and duration of use,

noise from this product may contribute to hearing loss.

ENGINE

Your air compressor is powered by a Honda®g a s o l i n e

engine. Most accidents with engines can be prevented if

you follow all instructions in this manual, the engine owner’s manual

and on the engine. Some of the most common hazards are discussed

herein, along with the best way to protect yourself and others:

• Know how to stop the engine quickly, and understand

the operation of all controls.

• Never permit anyone to operate the engine without proper

i n s t r u c t i o n s .

• Do not allow children to operate the engine.

• Keep children and pets away from the area of operation.

Refuel with care: ALLOW ENGINE TO COOL. Gasoline is extremely

flammable, and gasoline vapor can explode. Refuel outdoors, in a wellventilated area, with the engine off. Never smoke near gasoline, and

keep other flames and sparks away. Always store gasoline in an

approved container. If any fuel is spilled, move compressor to another

location before starting the engine.

Carbon Monoxide Hazards:Exhaust gas contains poisonous carbon

monoxide. Avoid inhalation of exhaust gas. Never run the engine in a

closed garage or confined area.

A LWAYS STORE COMPRESSOR IN A HORIZONTAL POSITION,

ON ALL FOUR RUBBER MOUNTS.

Introduction

Congratulations on the purchase of your new DEWA LT Air Compressor! You can be assured that this tool has been constructed with

the highest level of precision and accuracy. Each component has been

rigorously tested to ensure the quality, endurance and performance of

this air compressor.

By reading and following the safety, operation, maintenance and

troubleshooting steps described in this manual, you will receive years

of trouble free operation.

The manufacturer reserves the right to make changes in price, color,

materials, equipment specifications or models at any time without

n o t i c e .

Inspection of Compressor

Inspect for signs of obvious or concealed freight damage. Report any

damage to the delivering freight carrier immediately. Be sure that all

damaged parts are replaced and any mechanical problems are

corrected prior to the operation of the air compressor. The air

compressor serial number is located on the deck of the air compressor

and pump bearing cap. Please write the serial number in the space

provided in the service section for future reference.

Features

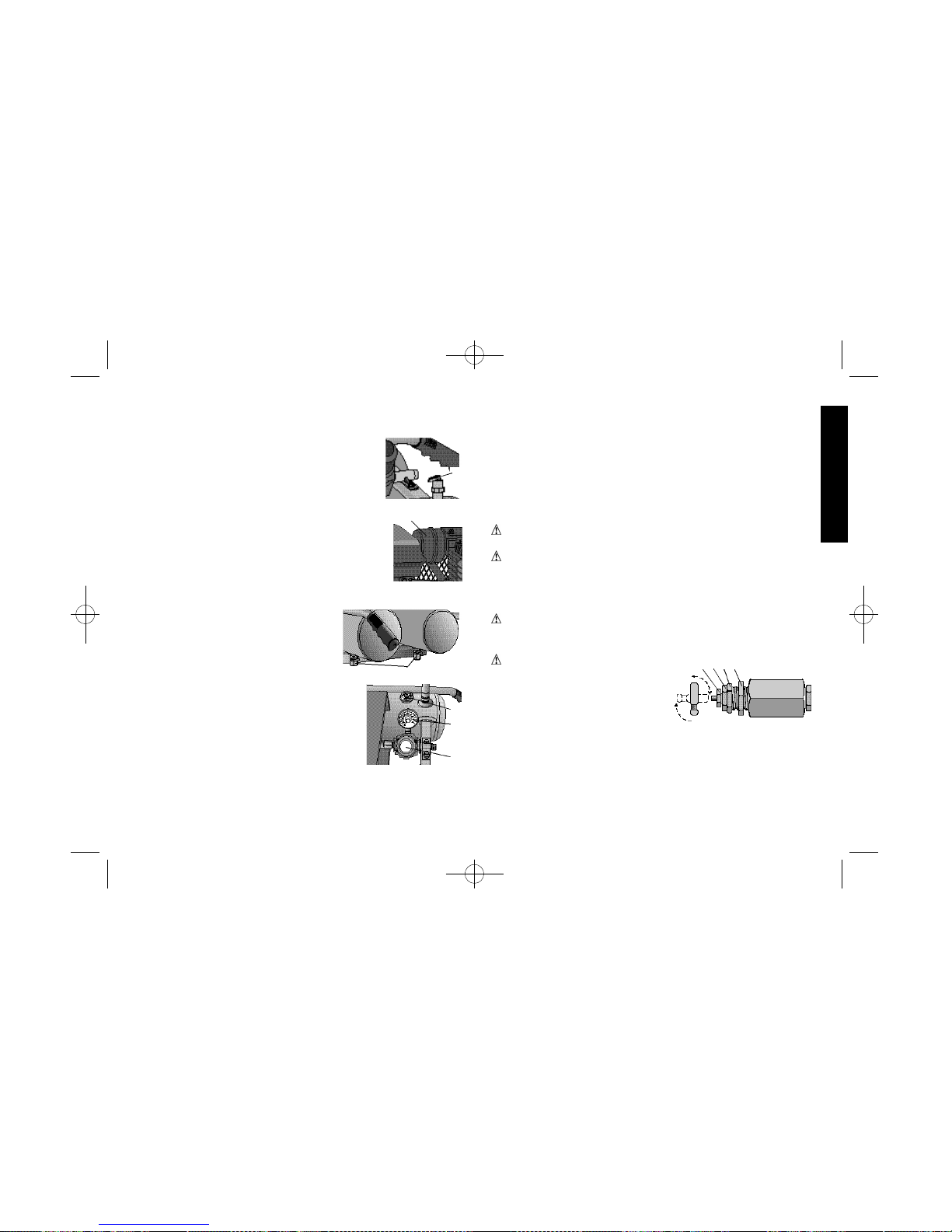

PILOT VALVE:

Pilot valves are used to maintain a

constant pressure range while running

c o n t i n u o u s l y. The pilot valve may be

used to operate a discharge line

unloader or an unloading device in the

compressor head. The DEWA LT compressor unloads through the compressor head. Unloading occurs when the receivers (tanks) reach a

Gas Manual 10-5-01 2/10/03 2:31 PM Page 4

Page 8

5

preset cut-out pressure. The pilot valve opens, actuating the unloading

device that allows the compressor to run in an unloaded mode. When

the tank pressure drops to the preset cut-in pressure,

the pilot valve closes allowing the unloading device to

close and the compressor once again pumps into the

t a n k s .

Manual Lock:

The manual lock allows you to manually unload the

compressor with air pressure in the tank. To operate the

unloading device in the head, rotate the flip lever to an

in-line position (dashed lines). Be sure to return lever to

the loaded position after starting the engine or the pump

will not operate at preset pressures.

SAFETY RELIEF VALVE:

This valve (A) is designed to prevent system failures by relieving

pressure from the system when the

compressed air reaches a predetermined

level. The valve is preset by the manufacturer and must not be removed or

modified in any way.

AIR INTAKE FILTER(S):

The filter(s) (B) are designed to clean air entering

the pump. To ensure the pump continually

receives a clean, cool, and dry air supply the

filter(s) must always be clean and the filter intake

must be free from obstructions.

AIR TANK DRAIN VALVE(S):

The drain valve(s) (C) are used to remove

moisture from the air tank after the air compressor

is shutoff .

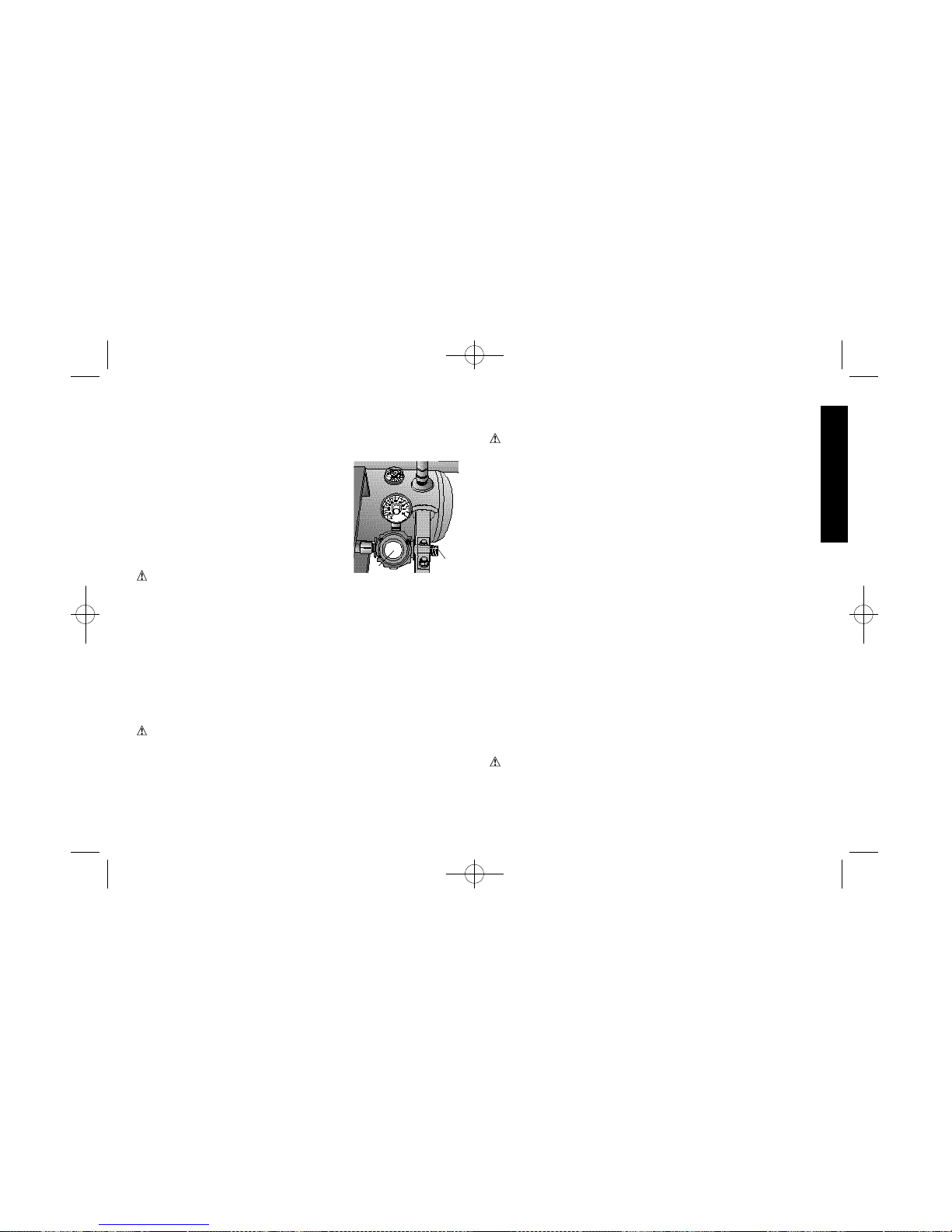

TANK PRESSURE GAUGE:

The tank pressure gauge (D) indicates air pressure in the air tank.

REGULATED PRESSURE GAUGE:

The regulated pressure gauge (E) indicates the air pressure available

at the outlet side of the regulator. This pressure is controlled by the

regulator and is always less or equal to the air tank pressure.

PRESSURE REGULATOR:

The regulator knob (F) controls the air pressure coming from the air

t a n k .

PILOT VALVE CUT-OUT PRESSURE ADJUSTMENT

N O T E : Unit can remain running while performing this adjustment

WARNING : A f t e r c o o l e r, pump head, and surrounding parts are

very hot; do not touch. (see the Hot Surfaces identified on page 2)

WARNING - Moving Parts: Keep your hair, clothing and gloves

away from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts. Air vents may cover moving parts and should

be avoided as well. Do not remove the protective covers from this

p r o d u c t .

WARNING : The pilot valve is brass which is a soft metal. Do not

overtighten screw as threads can strip out.

1. Hold “I” firmly and loosen nut “H”.

WARNING : Do not loosen screw

“G” more than 1 revolution as screw

is subjected to tank pressure and can

burst out which can harm the user or

surrounding personnel.

2 . Turn screw “G” clockwise to

increase cut-out pressure limit or counter clockwise to decrease cutout pressure. (example: if the cut-out pressure on the tank gauge

reads 120 psi. and desired cut out is 130 psi, turn screw “G”

c l o c k w i s e )

3 . Drain air from tanks through drain valves until pump begins to

charge tanks.

4 . Close drain valves.

5 . Monitor cut-out pressure to verify the new setting

C

D

E

F

G

H I J

A

B

Gas Manual 10-5-01 2/10/03 2:31 PM Page 5

Page 9

6

6 . Once setting is complete hold screw “G” firmly

7 . Hold “G” firmly and tighten nut “H”

PILOT VALVE PRESSURE DIFFERENTIAL ADJUSTMENT

N O T E : Unit can remain running while performing this adjustment

WARNING : A f t e r c o o l e r, pump head, and surrounding parts are

very hot; do not touch. (see the Hot Surfaces identified on page 2)

WARNING - Moving Parts: Keep your hair, clothing and gloves

away from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts. Air vents may cover moving parts and should

be avoided as well. Do not remove the protective covers from this

p r o d u c t .

1 . Hold “I” firmly and loosen nut “J”

WARNING : Do not loosen barrel “I” more than 1 revolution as barrel

is subjected to tank pressure and can burst out which can harm the

user or surrounding personnel.

2. Turn barrel “I” clockwise to increase differential or counter clockwise

to decrease differential. (for example: if pressure differential is 100 130 psi and 100 - 120 psi is desired, turn “I”

counter clockwise)

NOTE : Too narrow of a differential can cause

chatter of the pilot valve. Increase differential to

eliminate chatter.

3 . Hold barrel “I”

4 . Hold “I” firmly and tighten nut “J”

CHECKING COMPRESSOR PUMP OIL LEVEL

WA R N I N G :A f t e r c o o l e r, pump head, and surrounding parts are very

hot, do not touch. (see the Hot Surfaces identified on page 2)

1 . Ensure Unit is off .

2. Locate unit onto a flat horizontal surface.

3 . Remove knurled filler knob (K) from crankcase.

4 . Insert a clean screwdriver into the crankcase and remove it.

5 . Look for visual signs of contaminants (water, dirt, etc.) Change

pump oil if contaminants are present.

6 . Oil should not exceed top raised line on side of crankcase (oil will be

even with bottom of threads in crankcase fill port). If necessary fill

with DEWA L T synthetic oil.

CHECKING SAFETY RELIEF VALVE OPERATION

WA R N I N G :A f t e r c o o l e r, pump head, and surrounding parts are very

hot, do not touch. (see the Hot Surfaces identified on page 2)

1 . Ensure unit is off.

2 . Ensure tanks are empty by looking at tank pressure gage. Drain

tanks if necessary.

3 . Grasp wire ring on safety valve.

4 . Pull and release ring a few times to ensure plunger moves in and

o u t .

CHECKING AIR FILTER ELEMENT

WA R N I N G :A f t e r c o o l e r, pump head, and surrounding parts are very

hot, do not touch. (see the Hot Surfaces identified on page 2)

1 . Ensure unit is off .

2 . Allow unit to cool.

3 . Unscrew filter top from filter base by turning counter clockwise

about 5 degrees.

4 . Separate filter top from base.

5 . Remove element from filter base.

6 . If element needs cleaning, blow out with air. Replace element if

u n s u r e .

7 . Place element back in filter base.

8 . Reconnect filter top to filter base and while pushing in, rotate top

clockwise 5 degrees.

STARTING UNIT

Follow the pre-start and start-up procedures in the operating procedure

K

Gas Manual 10-5-01 2/10/03 2:31 PM Page 6

Page 10

7

s e c t i o n .

TURNING UNIT OFF

Follow the shut-down procedure in the operating procedures section.

ADJUSTING REGULATOR

1 . Pull regulator knob (L) out

2 . Turn knob clockwise to increase regulated

pressure and counter clockwise to

decrease regulated pressure.

3 . When desired pressure is shown on the

regulated pressure gage push knob in to

l o c k .

INSTALLING HOSES

WARNING: Firmly grasp hose in hand

when installing or disconnecting to prevent hose whip.

1 . Ensure regulated pressure gage reads 0 PSI.

2 . Grasp hose in hand at coupler location.

3 . Pull back collar on female quick connect coupler (M) located on

c o m p r e s s o r.

4 . Push male connector into female connector.

5 . Release female connector

6 . Grasp hose and pull to ensure couplers are seated

7 . Adjust regulator to desired pressure.

DISCONNECTING HOSES

WARNING: Firmly grasp hose in hand when installing or

disconnecting to prevent hose whip.

1 . Ensure regulated pressure gage reads 0 PSI.

2 . Grasp hose in hand at coupler location

3 . Pull back collar on female quick connect coupler located on

c o m p r e s s o r.

4 . Pull male connector out of female connector.

5 . Release female connector

DRAINING TANKS

WA R N I N G : Tanks contain high pressure air. Keep face and other

body parts away from outlet of drain. Use safety glasses when

draining as debris can be kicked up into face. Use ear protection as air

flow noise is loud when draining.

N O T E : All compressed air systems generate condensate that

accumulates in any drain point (e.g. tanks, filter, aftercoolers, dryers).

This condensate contains lubricating oil and/or substances which may

be regulated and must be disposed of in accordance with local, state,

and federal laws and regulations.

1 . Ensure ON/OFF switch is in the OFF position.

2 . Move compressor into an inclined position so drain valve(s) are at

the lowest point (this will assist in removing moisture, dirt, etc. from

t a n k s )

3 . Place a suitable container under the drains to catch discharge.

4 . Grasp black lever on one drain valve.

5 . Slowly rotate lever so as to gradually bleed air from tank.

6 . Grasp black lever on other drain valve and rotate to approximately

the same position as the first. (For twin tank units)

7 . When tank pressure gauge reads 10 psi, rotate valve(s) to the fully

open position.

8 . Close drain valve(s) when finished.

Preparation For Use

INITIAL SET-UP:

Read safety instructions before setting-up air compressor.

C A U T I O N : Do not operate without lubricant or with inadequate

lubricant. DEWA LT is not responsible for compressor failure caused by

inadequate lubrication.

Compatibility

Air tools and accessories that are run off the compressor must be

L

M

Gas Manual 10-5-01 2/10/03 2:31 PM Page 7

Page 11

8

compatible with petroleum based products. If you suspect that a

material is not compatible with petroleum products, an air line filter for

removal of moisture and oil vapor in compressed air is required.

N O T E : Always use an air line filter to remove moisture and oil vapor

when spraying paint.

Location

C A U T I O N : In order to avoid damaging the air compressor, do not

allow the unit to be tilted more than 10˚ when operating.

Place air compressor at least 3 feet away from obstacles that may

prevent proper ventilation. Keep unit away from areas that have dirt,

vapor and volatile fumes in the atmosphere which may clog and gum

up the intake filter and valves, causing inefficient operation.

HUMID AREAS

In frequently humid areas, moisture may form in the bare pump and

produce sludge in the lubricant, causing running parts to wear out

p r e m a t u r e l y. Excessive moisture is especially likely to occur if the unit

is located in an unheated area that is subject to large temperature

changes. Two signs of excessive humidity are external condensation

on the bare pump when it cools down and a “milky” appearance in

compressor lubricant. You may be able to prevent moisture from

forming in the bare pump by increasing ventilation or operating for

longer intervals.

NOISE CONSIDERATIONS

Consult local officials for information regarding acceptable noise levels

in your area. To reduce excessive noise, use vibration mounts or

silencers, relocate the unit or construct total enclosures or baffle walls.

Contact a DEWA LT service center or call 1-800-4DEWA LT for

a s s i s t a n c e .

TRANSPORTING:

WARNING: Unit weighs more than 160 lbs. Do not move or lift

without assistance.

When transporting the compressor in a vehicle, trailer, etc. ensure that

the tanks are drained and the unit is secured and placed on a flat

horizontal surface. Use care when driving so to avoid tipping the unit

over in the vehicle. Damage can occur to the unit or surrounding items

if unit is tipped. Use a ramp if loading or unloading the unit from a

height of more than 12”.

MOVING:

When moving the unit into a position for use, grasp handle grips at rear

of compressor, and lift compressor high enough so unit can be rolled

on the front tire.

WARNING: Ensure proper footing and use caution when rolling

compressor so that unit does not tip or cause loss of balance.

When location is reached slowly lower rear of compressor to ground.

A LWAYS STORE COMPRESSOR IN A HORIZONTAL POSITION,

ON ALL FOUR RUBBER MOUNTS.

NOTE: Should the unit tip over, hard starting and smoking will occur

due to oil spillage.

Air Inlet Filter

C A U T I O N : Do not operate without air inlet filter

General Requirements

The piping, fittings, receiver tank, etc. must be certified safe for at

least the maximum working pressure of the unit. Use hard welded or

threaded steel or copper pipes, cast iron fittings and hoses that are

certified safe for the units discharge pressure and temperature. Use

pipe thread sealant on all threads, and tighten joints thoroughly to

prevent air leaks. DO NOT USE PVC PLASTIC.

CONDENSATE DISCHARGE PIPING

If installing a condensate discharge line, the piping must be at least one

size larger than the connection, as short and direct as possible,

secured tightly and routed to a suitable drain point. Condensate must

be disposed of in accordance with local, state and federal laws and

r e g u l a t i o n s .

N O T E : All compressed air systems generate condensate that

Gas Manual 10-5-01 2/10/03 2:31 PM Page 8

Page 12

9

accumulates in any drain point (e.g. tanks, filter, aftercoolers, dryers).

This condensate contains lubricating oil and/or substances which may

be regulated and must be disposed of in accordance with local, state,

and federal laws and regulations.

Operating Procedures

Pre-Start Checklist

1 . Ensure the ON/OFF lever on the engine is in the OFF position.

2 . Ensure tank(s) is/are drained so that moisture, dirt, etc. can be

e l i m i n a t e d .

3 . Ensure tank pressure gauge reads 0 psi.

4 . Ensure safety and drain valve(s) is /are functioning properly.

5. Ensure the drain valve(s) is / are closed.

6 . Check oil level in pump.

7 . Check oil level in engine crankcase.

8 . Visually inspect drive belt. Replace belt if frayed, cracked, or worn.

9. Ensure all guards, covers, and labels are in place, legible (for labels)

and securely mounted. Do not use compressor until all items have

been verified.

START-UP

1 . Ensure the ON/OFF lever on the engine is in the OFF position.

2 . Pull out and turn regulator knob counterclockwise until fully closed.

Push in to lock. Regulated pressure gage should read 0 psi.

3. Ensure fuel is in fuel tank.

4. Turn the ON/OFF lever on the engine to the ON position.

5. Rotate the manual lock on the pilot valve into the in line position to

assist with start up.

6 . Follow the “Starting the Engine” procedures in the engine’s owner

m a n u a l .

7 . Rotate the manual lock on the pilot valve into a perpendicular

position so the pump can charge the tanks.

8 . Allow compressor to pump up to “cut out” pressure.

N O T E : If any unusual noise or vibration is noticed, stop the

compressor and refer to the troubleshooting section.

9 . Attach hose and accessory.

10. Adjust regulator to desired setting.

SHUT-DOWN

1 . Follow the “Stopping the Engine” procedures in engine owner’s

m a n u a l .

N O T E : If finished using compressor, follow steps 2 - 6 below.

2. Turn regulator knob counterclockwise until fully closed. Ensure

regulated pressure gage reads 0 PSI.

3 . Remove hose and accessory.

4 . Drain the air tank(s). Ensure tank pressure gage reads 0 PSI

5 . Allow the compressor to cool down.

6 . Wipe air compressor clean and store in a safe, non freezing area.

Maintenance

The following procedures must be followed when maintenance or

service is performed on the air compressor.

1 . Turn off air compressor

2 . Disconnect spark plug wire

3 . Drain tank(s)

4 . Allow air compressor to cool down before starting service

N O T E : All compressed air systems contain maintenance parts (e.g.

lubricating oil, filters, separators) that are periodically replaced. These

used parts may contain, substances that are regulated and must be

disposed of in accordance with local, state, and federal laws and

r e g u l a t i o n s .

N O T E : Take note of the positions and locations of parts during

Gas Manual 10-5-01 2/10/03 2:31 PM Page 9

Page 13

10

disassembly to make reassembly easier.

N O T E : Any service operations not included in this section should be

performed by authorized service personnel.

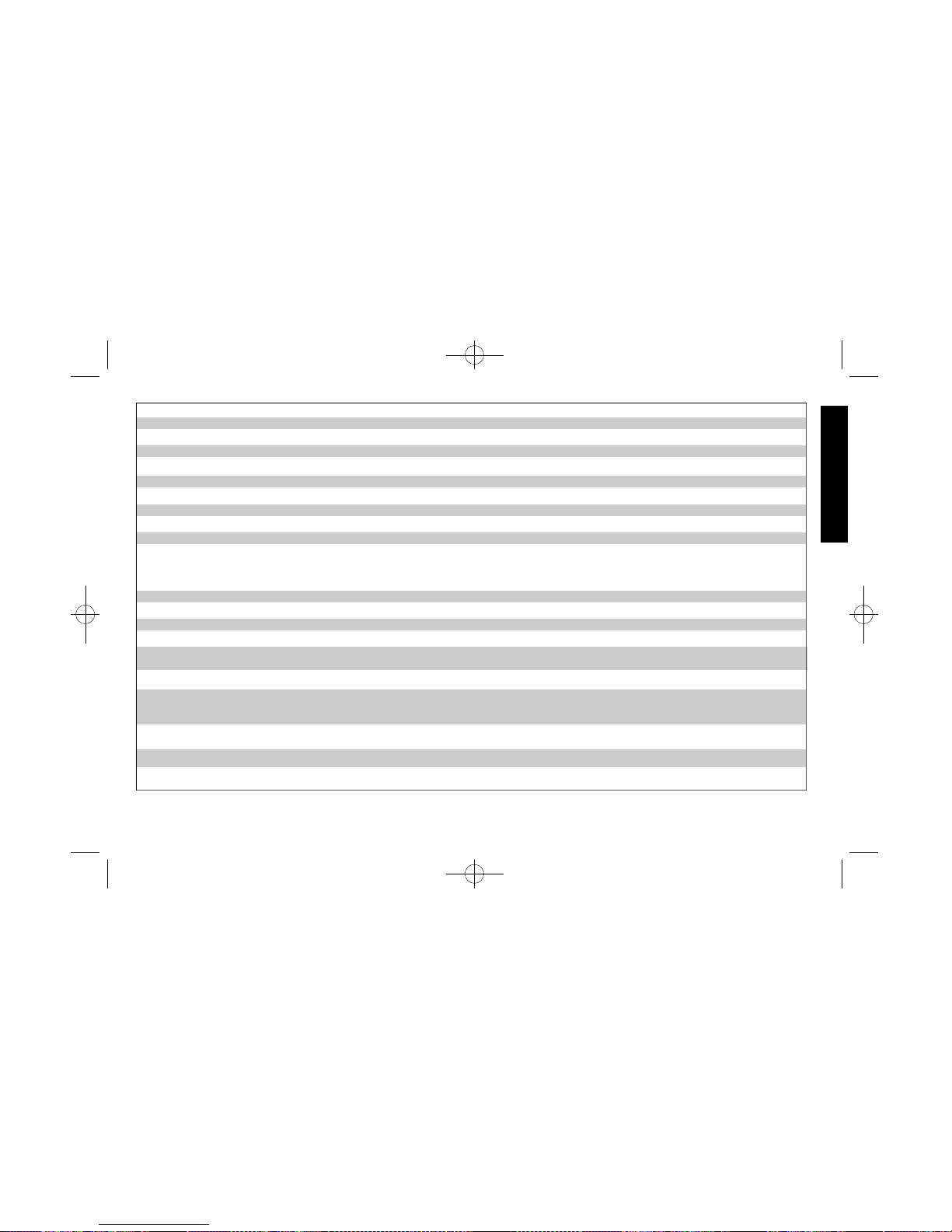

MAINTENANCE CHART

P r o c e d u r e I Year or

D a y We e k M o n t h 200 Hrs.

Check pump oil level X

Oil leak inspection X

Drain condensation in air tank(s) X

Check for unusual noise/vibration X

Check for air leaks* X

Inspect belt X

Inspect air filter X

P r o c e d u r e I Year or

D a y We e k M o n t h 200 Hrs.

Clean exterior of compressor X

Check safety relief valve X

Check belt adjustment X

Change pump oil ** X

E n g i n e See engine owner’s manual.

* To check for air leaks apply a solution of soapy water around joints.

While compressor is pumping to pressure and after pressure cuts out,

look for air bubbles to form.

** The pump oil must be changed after the first 20 hours or operation.

T h e r e a f t e r, when using DEWA LT synthetic oil, change oil every 200

hours of operation or once a year, whichever comes first. In harsh

environments, maintenance must be performed on a more accelerated

s c h e d u l e .

COMPRESSOR PUMP OIL CHANGE

NOTE: Pump oil contains substances that are regulated and must be

disposed of in accordance with local, state and federal laws and

r e g u l a t i o n s .

WARNING : A f t e r c o o l e r, pump head, and

surrounding parts are very hot; do not touch. (see

the Hot Surfaces identified on page 2)

1 . Ensure unit is off .

2 . Allow the unit to cool.

3 . Locate a suitable container under drain plug

( O ) .

4 . Remove the knurled filler knob (N) from crankcase.

5 . Remove the oil drain plug.

6 . Allow ample time for all oil to drain out. (Tilting the compressor

towards the drain plug will assist in draining.)

7 . Install the oil drain plug.

8 . Fill pump with DEWA LT synthetic compressor oil. Oil should not

exceed top raised line on side of crackcase. (Oil will be even with

bottom of threads in crankcase fill port.)

9 . Install knurled filler knob.

CHECKING BELT TENSION

WARNING : A f t e r c o o l e r, pump head, and surrounding parts are

very hot; do not touch. (see the Hot Surfaces identified on page 2)

1 . Ensure unit is off and unplugged from wall.

2. Allow unit to cool down so pump can be touched.

3 . F O R K P U M P U N I T S

Remove six belt guard mounting fasteners (2 on the pump head

and 4 on the deck)

F O R G P U M P U N I T S

Remove seven belt guard mounting fasteners (2 on the pump head,

1 J-hook, and 4 on the deck)

4 . Remove guard.

5 . Place a 12" ruler perpendicular to belt and at the middle of the

longest span.

N

O

Gas Manual 10-5-01 2/10/03 2:31 PM Page 10

Page 14

11

6 . Push up and down on the belt in the middle of the span with

approximately 8 lbs. of force and notice the amount of deflection

using the ruler. Belt should not move more than 1/2"; if so, see

ADJUSTING BELT TENSION section.

7 . Replace belt guard

ADJUSTING BELT TENSION

WA R N I N G :Pump and surrounding components are hot.

1 . Follow procedures 1 - 4 in checking belt tension section.

2 . Scribe a mark at the base of the pump on the deck to be used

as a reference.

3. Loosen four pump mounting bolts.

4. Remove the belt.

5. Scribe a mark approximately 1/8" from the original mark.

6. Slide the pump to the new mark and retighten the pump

mounting bolts.

WARNING : Use caution when rolling belt onto flywheel as fingers

can get caught between the belt and flywheel.

7. With the pump secure, roll the belt over the flywheel and the

pulley.

8. Check the belt tension again.

9. If tension is good, retighten the engine brace and replace belt

guard.

Accessories

Recommended accessories for use with your tool are available for

purchase from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, contact:

DEWA LT Industrial Tool Co., 701 East Joppa Road, Baltimore,MD

21286 or call 1-800-4-DEWALT.

C A U T I O N : The use of any other accessory not recommended for

use with this tool could be hazardous.

Service Information

Please have the following information available for all service calls:

Model Number _____________Serial Number _______________

Date and Place of Purchase _____________________________

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by authorized service centers or

other qualified service organizations, always using identical replacement parts.

Full One Year Warranty

DEWA LT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1 - 8 0 0 - 4 - DEWA LT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWA LT for a free

r e p l a c e m e n t .

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Gas Manual 10-5-01 2/10/03 2:31 PM Page 11

Page 15

12

TROUBLESHOOTING GUIDE

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or

maintenance personnel can perform some corrective actions, and others may require the assistance of a qualified DeWalt technician or

your dealer.

P r o b l e m C o d e

Compressor does not start or restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 6 , 3 2 , 3 3 , 3 4 , 3 6

Compressor Stalls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 6 , 3 4 , 3 6

Unit does not or is slow to come up to speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 , 9 , 1 0 , 1 2 , 1 3 , 1 5 , 1 6 , 2 6 , 2 7 , 3 3 , 3 4 , 3 6

Air compressor not making enough air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 , 3 , 8 , 9 , 1 0 , 11 , 1 4 , 1 6 , 1 7 , 2 0 , 2 1 , 2 4 , 2 5

I n s u fficient pressure at air tool or accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 , 3 , 8 , 9 , 1 0 , 11 , 1 4 , 1 6 , 1 7 , 2 0 , 2 1 , 2 3 , 2 4 , 2 5

High oil consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 , 7 , 1 0 , 1 2 , 1 3 , 1 6 , 2 6 , 2 8

Unit runs excessively hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 , 2 , 5 , 11 , 1 2 , 1 3 , 1 6 , 2 6

Excessive starting and stopping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 , 8 , 1 7 , 2 0 , 2 1 , 2 5 , 3 0

Excessive noise during operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 , 4 , 5 , 6 , 8 , 9 , 1 0 , 11 , 1 2 , 1 3 , 1 6 , 2 1 , 2 5 , 2 6 , 2 7

Moisture in discharge air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 0 , 3 1

Moisture in crankcase or "milky" appearance

in petroleum lubricant or rusting in cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 , 1 0 , 11 , 1 6 , 2 2 , 2 9 , 3 1

Oil in discharge air (oil pumping) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 , 7 , 9 , 1 0 , 11 , 1 6 , 2 7 , 2 8

Oil leaking from shaft seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 3

Safety relief valve "pops" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 8 , 1 9

Air leaks at pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 0 , 2 1

Air leaks at fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 1

Air leaks from tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 2

Abnormal piston ring or cylinder wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 , 5 , 6 , 11 , 1 2 , 1 4

Gas Manual 10-5-01 2/10/03 2:31 PM Page 12

Page 16

13

C o d e Possible Cause Possible Solution

1 Clogged or dirty inlet and/or discharge line filter. Clean or replace

2 Lubricant Viscosity too low Drain existing lubricant and refill with DEWA LTSynthetic lubricant

3 Air leaks in air discharge piping Check tubing and connections

4 Lubricant viscosity too high Drain existing lubricant and refill with DEWA LTSynthetic lubricant

5 Lubricant level too low Add lubricant to crankcase to proper level. Check for bearing damage.

6 Detergent type lubricant being used Drain existing lubricant and refill with DEWA LTSynthetic lubricant

7 Extremely light duty cycles. Run unit for longer duty cycles

8 Compressor check valve leaky, broken, carbonized or loose Inspect valves.Clean or replace as required.

9 Carbon build up on top of compressor pump piston Clean piston. Repair or replace as required.

1 0 Compressor pump piston rings damaged or worn (broken, rough, Install new rings

or scratched). Excessive end gap or side clearance. Piston rings

not seated, are stuck in grooves or end gaps not staggered.

11 Compressor pump cylinder or piston scratched, worn, or scored. Repair or replace as required

1 2 Compressor pump connecting rod, piston pin, or crankpin bearings worn or scored Inspect all. Repair or replace as required.

1 3 Compressor pump crankshaft seal worn or crankshaft scored Replace seal or crankshaft assembly

1 4 Extremely dusty atmosphere Install more effective filtration or relocate unit

1 5 Ambient temperature too low Relocate unit to warmer environment. Ensure DEWA LT synthetic oil

is in crankcase.

1 6 Compressor pump worn cylinder finish Degalze cylinder with 180 grit flex-hone

1 7 Air compressor is not large enough for air required Check the accessory air requirement. If it is higher than the CFM or

pressure supply of the air compressor, you need a larger air

c o m p r e s s o r.

1 8 Possible defective safety/relief valve Operate safety relief valve manually by pulling on test ring. If it still

leaks, replace.

1 9 Excessive air tank pressure Adjust pilot valve. If problem still exists replace pilot valve.

Gas Manual 10-5-01 2/10/03 2:31 PM Page 13

Page 17

14

C o d e Probable Cause Probable Solution

2 0 Defective gaskets Replace and torque head bolts to 6 - 7 ft lb

2 1 Fittings not tight enough Warning : drain air before tightening; tighten fittings where air can

not be heard escaping.Check joint with soap solution.Do not

o v e r t i g h t e n

2 2 Defective or rusted air tank Air tank must be replaced. Do not attempt to repair air tank

2 3 Pressure regulator knob not turned to high enough pressure Adjust pressure regulator knob to proper setting or replace.

or defective pressure regulator.

2 4 Hose or hose connections are to small or long. Replace with larger hose or connectors.

2 5 Possible defective (reed) valve. Remove pump head and inspect valve plate and (reed) valve. Clear or

replace valves as required.

2 6 Air compressor on unlevel surface. Do not incline the air compressor more than 10˚ in any direction while

r u n n i n g .

2 7 Crankcase overfilled with oil. Drain oil. Refill to proper level with DEWA LT synthetic oil.

2 8 Plugged crankcase vent. C l e a n .

2 9 Water in oil due to condensation. Drain oil. Refill to proper level with DEWA LT synthetic oil.

3 0 Condensation in air tank caused by high level of Drain air tank after every use.

atmospheric humidity. Drain air tank more often in humid weather and use an air line filter.

3 1 Unit located in damp or humid location. Relocate unit

3 2 Engine oil too low. Low oil shut off is on. Add engine oil.

3 3 Manual lock on pilot valve is in the loaded position. Move manual lock into an in-line position.

3 4 Engine idle speed too low Increase idle speed

3 5 Vee belt loose Adjust vee belt

3 6 Engine problem See “Taking care of unexpected problems” in engine owners manual.

Gas Manual 10-5-01 2/10/03 2:31 PM Page 14

Page 18

15

1. Filtres d’admission d’air

de Pompe

2. Filtres d’admission d’air

de Moteur

3. Manométre de Réservoir

4. Manométre Régulé

5. Régulateur

6. Vanne pilote

7. Soupape de sûreté

8. Robinets de purge

1

1

1

1

2

2

2

2

3

3

4

5

6

7

8

3

4

5

6

7

3 4

5

6

7

8

4

5

6

7

8

8

COMPRESSEUR PORTATIF DE 8 GALLONS

D55271, D55271T* – Moteur Honda de 8 HP

COMPRESSEUR PORTATIF

DE 17 GALLONS

D55276 – Moteur Honda de

5,5 HP

COMPRESSEUR PORTATIF

DE 17 GALLONS

D55275 – Moteur Honda de

8 HP

COMPRESSEUR PORTATIF DE 8 GALLONS

D55270, D55270T* – Moteur Honda de 5,5 HP

* ”T” dénote la version 2-wheel

Gas Manual 10-5-01 2/10/03 2:31 PM Page 15

Page 19

16

Caractéristiques de la Moteur

5,5 Hp Honda GX-160 8 Hp Honda GX-240

Combustion interne Combustion interne

4 courses 4 courses

3 450 tr / min 3 450 tr / min

CARACTÉRISTIQUES TECHNIQUES

MODÉLE POIDS HEUTEUR LARGEUR LONGUEUR Valeurs types

à 100 lb/po

2

pi3/min

D55270 72,57 Kg. (160 lb) 635 mm. (25 in.) 463,55 mm. (18,25 in.) 1092,2 mm. (43 in.) 8,9

D55271 72,57 Kg. (213 lbs.) 704,85 mm. (27,75 in.) 463,55 mm. (18,25 in.) 1092,2 mm. (43 in.) 16,2

D55275 213 lbs. (238 lbs.) 857,25 mm. (33,75 in.) 514,35 mm. (20,25 in.) 1092,2 mm. (43 in.) 16,2

D55276 83,91 Kg. (185 lbs.) 787,4 mm. (31 in.) 514,35 mm. (20,25 in.) 1092,2 mm. (43 in.) 8,9

Caractéristiques de la pompe G

Quatre cylindres verticaux, jumelés

Mono-étagée

Lubrifiée à l’huile

Carter, cylindre et tête en fonte

Âme : 63,5 mm (2 1/2 po)

Course : 60,33 m (2 3/8 po)

Poids : 31,29 kg (69 lb)

Capacité en huile : 30 oz.

Caractéristiques de la pompe K

Deux cylindres verticaux, en ligne

Mono-étagée

Lubrifiée à l’huile

Carter, cylindre et tête en fonte

Âme : 63,5 mm (21/2 po)

Course : 50,8 m (2 po)

Poids : 21,31 kg (47 lb)

Capacité en huile : 14 oz.

Gas Manual 10-5-01 2/10/03 2:31 PM Page 16

Page 20

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FA I R E

PA RT DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU

TOUT AUTRE OUTIL DEWA LT, COMPOSEZ SANS FRAIS LE :1 800

4 3 3 - 9 2 5 8 .

AV E RT I S S E M E N T !Lire et comprendre toutes les directives avant

d’utiliser le compresseur d’air, car le non-respect des directives

suivantes peut entraîner un choc électrique, un incendie ou des

blessures graves.

CONSERVER CES INSTRUCTIONS

Consignes de sécurité

AV E RT I S S E M E N T: Une partie de la poussière créée par ce produit

contient des produits chimiques qui, dans l’État de la Californie, sont

reconnus comme étant susceptibles de causer le cancer, d’entraîner

des malformations congénitales ou d’être nocifs pour le système

r e p r o d u c t e u r. Parmi ces produits chimiques, mentionnons notamment:

• les composés dans les engrais;

• les composés dans les insecticides, les herbicides et les pesticides;

• l’arsenic et le chrome dans le bois d’œuvre traité chimiquement.

Pour réduire le risque d’exposition à ces produits chimiques, porter un

équipement de sécurité approuvé, comme des masques

antipoussières, qui sont spécialement conçus pour filtrer les particules

m i c r o s c o p i q u e s .

AV E RTISSEMENT : l’utilisation de ce produit augmente les risques

d’exposition à des produits chimiques qui, dans l’État de la Californie,

sont reconnus comme étant susceptibles de causer le cancer,

d’entraîner des malformations congénitales ou d’être nocifs pour le

système reproductif. Éviter d’inhaler les vapeurs environnantes. Se

laver les mains après chaque utilisation.

AV E RT I S S E M E N T: Ce produit contient des produits chimiques, y

compris du plomb, qui, dans l’État de la Californie, sont reconnus

comme étant susceptibles de causer le cancer, d’entraîner des

malformations congénitales ou d’être nocifs pour le système

r e p r o d u c t e u r. Se laver les mains après la manipulation.

L'utilisation ou l'entretien inapproprié de ce produit peut entraîner des

blessures graves et des dommages matériels.

Le propriétaire de cet outil doit comprendre toutes ces directives et

n’autoriser que les personnes qui comprennent bien le guide

d’utilisation du compresseur à l’utiliser. Toute personne qui utilise cet

outil doit être sain d’esprit et faire preuve d’intégrité physique totale et

ne pas être sous l’influence d’une substance susceptible de réduire

son acuité visuelle ou sa dextérité ou nuire à son jugement.

RÉSERVOIR D'AIR

Le réservoir dont est doté le compresseur d'air porte le code UM (dans

le cas d’appareils munis de réservoirs supérieurs à 6

pouces de diamètre) et il est conçu conformément à la

Section VIII, Div. 1 de l'ASME. Tous les appareils sous

pression doivent être inspectés tous les deux ans. Pour

trouver l'inspecteur des appareils sous pression de votre

région, consulter la section appropriée des organismes

gouvernementaux de l’annuaire téléphonique ou composer le 1 800

433-9258 pour obtenir de l’aide.

Les conditions indiquées ci-après peuvent affaiblir le réservoir et

entraîner une violente explosion du réservoir :

1. Le fait de ne pas drainer convenablement l'eau condensée du

r é s e r v o i r, entraînant la corrosion et l'amincissement des

parois en acier du réservoir. Drainer le réservoir

quotidiennement ou après chaque utilisation. Si le réservoir

présente une fuite, le remplacer immédiatement par un nouveau

réservoir ou un nouvel équipement de compresseur.

2. Modifications apportées au réservoir du compresseur ou

tentatives de réparation. Ne jamais percer un trou dans le

réservoir ou ses accessoires, y faire de la soudure ou y apporter

quelque modification que ce soit.

3. Ne pas modifier la soupape de sûreté ou tout autre composant

régissant la pression du réservoir. Le réservoir est conçu pour

résister à des pressions de fonctionnement précises. Ne jamais

17

Gas Manual 10-5-01 2/10/03 2:31 PM Page 17

Page 21

18

effectuer des réglages ou de remplacer des pièces en vue de

modifier les pressions de fonctionnement réglées en usine.

ACCESSOIRES

Lorsqu’on excède la pression nominale des outils pneumatiques, des

pistolets pulvérisateurs, des accessoires à

commande pneumatique, des pneus et autres

produits gonflables, on risque de les faire exploser

ou de les faire projeter et entraîner des blessures

graves. Il faut installer, comme dispositif

indispensable de contrôle de la pression d'air, un

régulateur et un manomètre à la sortie d'air du

c o m p r e s s e u r. Respecter les recommandations des fabricants

d'équipement et ne jamais excéder les pressions nominales

maximales permises des accessoires. Ne jamais utiliser le

compresseur pour gonfler de petits objets nécessitant une basse

pression comme des jouets d'enfant, des ballons de football et de

basket-ball, etc.

RISQUE D'EXPLOSION OU D'INCENDIE

Toujours faire fonctionner le compresseur dans un

endroit bien aéré, exempt de matériaux combustibles,

d'essence ou de vapeurs de solvants. L'entrée en

contact d'étincelles électriques provenant du moteur

avec des vapeurs inflammables peut enflammer celles-ci

et entraîner un incendie ou une explosion . Si des

matériaux inflammables sont pulvérisés, installer le compresseur à au

moins vingt pieds en amont de la zone de pulvérisation. Une section

supplémentaire de tuyau peut être nécessaire.

Entreposer les matériaux inflammables en lieu sûr, loin du

c o m p r e s s e u r.

Toute obstruction des ouvertures de ventilation du compresseur peut

provoquer une surchauffe importante et entraîner un incendie. Ne

jamais placer d'objets sur le dessus du compresseur ou contre celui-ci.

Faire fonctionner le compresseur dans une zone dégagée, située à

au moins 12 pouces d'un mur ou de tout obstacle pouvant restreindre

l'apport d'air frais aux ouvertures de ventilation.

RISQUE DE BRUIT

AV E RTISSEMENT! Porter des lunettes de sécurité ou

autre dispositif de protection oculaire car le martelage peut

faire projeter des particules et entraîner des dommages

irréversibles aux yeux.

RISQUES ASSOCIÉS AUX OBJETS PROJETÉS EN L'AIR

Le flux de l'air comprimé peut endommager les tissus mous de la peau

exposée et peut projeter à haute vitesse des impuretés, des fragments,

des particules détachées et de petits objets pouvant causer des

blessures graves. Toujours porter les lunettes de sécurité approuvées,

conformes à la norme ANSI Z28.1, et dotées d'écrans latéraux lors de

l'utilisation du compresseur. Ne jamais diriger le flux d'air vers des

personnes ou vers des animaux. N'utiliser que les souff l e t t e s

approuvées par la OSHA.

CYLINDRE DU

COMPRESSEUR

TUBE DE

TRANSFERT

SILENCIEUX

TETE DE

POMPE DU

COMPRESSEUR

SURFACES CHAUDES

CYLINDRE

DU

MOTEUR

Gas Manual 10-5-01 2/10/03 2:31 PM Page 18

Page 22

RISQUES ENTRAÎNÉS PAR LA RESPIRATION DE

L'AIR COMPRIMÉ

Il est dangereux de respirer l'air comprimé sortant du

compresseur! Le flux d'air peut contenir du monoxyde de

carbone, des vapeurs toxiques et des particules solides.

Ne jamais inhaler l'air comprimé sortant directement du

compresseur ou à partir d'un appareil respiratoire branché au

c o m p r e s s e u r.

Les matériaux pulvérisés comme la peinture, les solvants de peinture,

le décapant, les insecticides, les herbicides, etc. contiennent des

vapeurs nocives et des poisons. REMARQUE : ne faire fonctionner le

compresseur que dans une endroit bien aéré. Lire et respecter les

consignes de sécurité indiquées sur l'étiquette ou les fiches

signalétiques du produit qui est pulvérisé. Utiliser un appareil

respiratoire approuvé par NIOSH/MSHA et conçu

pour une application particulière.

RISQUES ASSOCIÉS AUX PIÈCES MOBILES

Le compresseur d’air est conçu pour être utilisé en

mode de fonctionnement continu. Toujours arrêter le

c o m p r e s s e u r, purger la pression du tuyau à air et

du réservoir et le débrancher de la source d'alimentation avant d'en

e ffectuer l'entretien ou d'y fixer des outils ou des accessoires.

Couvrir ou attacher les cheveux longs. Garder les cheveux, les

vêtements, les bijoux et les gants éloignés des pièces mobiles, car

ceux-ci peuvent s’y coincer. Ne pas retirer les couvercles de protection

de cet appareil. Ne jamais faire fonctionner le compresseur si les

protecteurs ou les couvercles de protection sont endommagés ou

retirés. Ne jamais se tenir debout sur le compresseur.

SURFACES CHAUDES

Le silencieux devient très chaud pendant le fonctionnement de l’outil et

il demeure chaud pendant un certain temps après l’arrêt du moteur.

Prendre soin de ne pas toucher le silencieux lorsqu’il est chaud.

Attendre que le moteur se refroidisse avant de le ranger à l’intérieur.

Afin d’éviter les risques d’incendie et de fournir une ventilation

adéquate lorsqu’on utilise un compresseur fixe, garder le moteur à au

moins 1 mètre (3 pi) des murs du bâtiment et des autres équipements

durant le fonctionnement de l’outil. Ne pas mettre d’objet inflammable

près du moteur.

MOTEUR

Cet outil est entraîné par un moteur à essence Honda. On peut

prévenir la plupart des accidents causés par un moteur en suivant

toutes les directives du présent manuel, du guide d’utilisation du

moteur ainsi que celles inscrites sur le moteur. Ces directives

expliquent quelques-uns des risques les plus courants et décrivent les

meilleures façons de se protéger et de protéger les autres.

S’assurer de savoir comment arrêter le moteur rapidement et bien

comprendre le fonctionnement des commandes. Ne jamais permettre

à qui que ce soit de mettre le moteur en marche avant d’avoir compris

toutes les directives. Ne jamais permettre à un enfant de démarrer le

m o t e u r. Tenir les enfants et les animaux domestiques éloignés de la

zone de travail.

Précautions à prendre lorsqu’on fait le plein : l’essence est une

substance extrêmement inflammable qui peut faire exploser les

19

CYLINDRE DU

COMPRESSEUR

TUBE DE

TRANSFERT

SILENCIEUX

TETE DE

POMPE DU

COMPRESSEUR

SURFACES CHAUDES

CYLINDRE

DU

MOTEUR

Gas Manual 10-5-01 2/10/03 2:31 PM Page 19

Page 23

20

vapeurs environnantes. Faire le plein à l’extérieur, dans un endroit bien

aéré, une fois le moteur arrêté. Ne jamais fumer à proximité de

l’essence. Éviter de créer des étincelles et des flammes. To u j o u r s

entreposer l’essence dans un contenant approuvé. En cas de

déversement, s’assurer que l’endroit touché est bien sec avant de

démarrer le moteur. Ne pas fumer. En cas de déversement, déplacer

le compresseur dans un autre endroit avant de démarrer le moteur.

Gaz chaud : le silencieux devient très chaud pendant le

fonctionnement de l’outil et il demeure chaud pendant un certain temps

après l’arrêt du moteur. Prendre soin de ne pas toucher le silencieux

lorsqu’il est chaud. Attendre que le moteur se refroidisse avant de le

ranger à l’intérieur. Afin d’éviter les risques d’incendie et de fournir

une ventilation adéquate lorsqu’on utilise un compresseur fixe, garder

le moteur à au moins 1 mètre (3 pi) des murs du bâtiment et des autres

équipements durant le fonctionnement de l’outil. Ne pas mettre d’objet

inflammable près du moteur.

Risques associés au monoxyde de carbone : les gaz

d’échappement contiennent du monoxyde de carbone toxique. Éviter

d’inhaler ces gaz. Ne jamais faire fonctionner le moteur dans un

garage fermé ou un espace clos.

TOUJOURS RANGER LE COMPRESSEUR EN POSITION

H O R I Z O N TALE, EN LE POSANT SUR LES QUATRE SUPPORTS

EN CAOUTCHOUC.

Introduction

Nous vous félicitons d'avoir fait l'acquisition d'un compresseur d'air

DEWA LT! Nous tenons à vous assurer que cet appareil a été construit

en respectant le plus haut niveau d'exactitude et de précision. Chaque

composant a été rigoureusement testé par des techniciens pour

garantir la qualité, l'endurance et le rendement de ce compresseur

d ' a i r.

La lecture des étapes décrites dans le présent guide et qui traitent des

consignes de sécurité, de l'installation et du fonctionnement, de

l'entretien et du dépannage de cet appareil, garantit à son nouveau

propriétaire de nombreuses années de fonctionnement sans

problème. Le fabricant se réserve le droit d'apporter en tout temps,

sans avis préalable, des changements au prix, à la couleur, aux

matériaux, aux caractéristiques de l'équipement ou aux modèles.

Inspection du compresseur

Inspecter le compresseur pour y déceler des signes évidents ou

dissimulés de dommages causés durant le transport. Signaler

immédiatement tout dommage au transporteur. S'assurer que toutes

les pièces endommagées sont remplacées et que tous les problèmes

mécaniques sont corrigés avant de faire fonctionner le compresseur.

Le numéro de série du compresseur d'air se situe sur le couvercle de

protection du compresseur. Écrire le numéro de série dans l'espace

réservé à cette fin dans la section traitant du service, pour toute

consultation ultérieure.

Composants

Vanne pilote :

Les vannes pilotes servent à maintenir une

plage de pressions constante lorsque

l’outil est en mode de fonctionnement

continu. On peut utiliser ce dispositif pour commander le dispositif de

décompression de la conduite de décharge ou celui situé sur la tête de

c o m p r e s s e u r. Le compresseur d’air DEWA LT se

décharge par la tête de compresseur lorsque les

bâches de récupération (réservoirs) atteignent la

pression de déclenchement réglée en usine. La

vanne pilote s’ouvre et actionne le dispositif de

décompression, ce qui permet au compresseur de

fonctionner en mode de décompression. Lorsque

la pression des réservoirs descend jusqu’à la

pression de déclenchement réglée en usine, la

vanne pilote se ferme, ce qui permet au dispositif

de décompression de se fermer et au

compresseur de repomper l’air dans les

réservoirs.

B

A

Gas Manual 10-5-01 2/10/03 2:31 PM Page 20

Page 24

Dispositif de blocage manuel :

Le dispositif de blocage manuel permet de

décharger le compresseur manuellement

lorsqu’il y a une pression d’air dans le

r é s e r v o i r. Pour commander le dispositif de

décharge situé sur la tête, tourner le levier à

bascule jusqu’à une position en ligne (lignes

pointillées), en s’assurant de remettre le levier

en position de déclenchement après avoir mis

le moteur en marche. Sinon, la pompe ne

fonctionnera pas aux pressions préétablies.

SOUPAPE DE SÛRETÉ :

Cette soupape (A) sert à empêcher les pannes en libérant de la

pression lorsque le compresseur atteint un niveau de pression

préétabli. Elle est préréglée en usine et ne doit pas être modifiée de

quelque manière que ce soit.

FILTRES D’ADMISSION D’AIR :

Ces filtres (B) servent à purifier l’air qui entre dans la pompe. Pour

que la pompe reçoive un flux constant d’air pur, frais et sec, ces filtres

doivent toujours être propres et l’entrée d’air doit être exempte de toute

o b s t r u c t i o n .

ROBINET DE PURGE DU RÉSERVOIR D’AIR :

Le robinet de purge (C) sert à déshumidifier le réservoir d’air après

l’arrêt du compresseur. Voir la section « Purge du réservoir » sous la

rubrique « Procédures courantes » pour obtenir les directives

a p p r o p r i é e s .

MANOMÈTRE DU RÉSERVOIR :

Le manomètre (D) indique la pression dans le réservoir d’air.

MANOMÈTRE RÉGULÉ :

Le manomètre régulé (E) indique la pression d’air à la sortie du

r é g u l a t e u r. Cette pression est contrôlée par le régulateur et est toujours

inférieure ou égale à celle du réservoir d’air.

RÉGULATEUR :

Le bouton du régulateur (F) contrôle la pression provenant du réservoir

d ’ a i r. Voir la section « Réglage du

régulateur ».

RÉGLAGE DE LA PRESSION DE

DÉCLENCHEMENT RÉGLÉE EN USINE

DE LA VANNE PILOTE

Remarque : l’appareil peut demeurer en

marche lorsqu’on effectue ces réglages.

AV E RTISSEMENT : le robinet pilote est constitué de laiton, qui est

un alliage doux. Ne pas trop serrer la vis afin d’éviter de fausser le pas

de vis. (Consulter les surfaces chaudes identifiées à la page 17).

1 . Tenir fermement l’élément « I » et desserrer l’écrou « H ».

AV E RTISSEMENT : ne pas desserrer la vis « G » plus d’un tour

puisqu’elle est soumise à la pression du réservoir et pourrait éclater,

causant des blessures à l’utilisateur ou aux personnes qui se trouvent

à proximité du compresseur.

2 . Tourner la vis « G » vers la droite pour augmenter la pression de

coupure, ou vers la gauche pour la réduire (p. ex., si la pression de

coupure affichée sur le manomètre du réservoir indique 120 lb/po2

et la pression de coupure désirée est 130 lb/po2, tourner la vis « G

» vers la droite).

3 . Purger l’air des réservoirs par les robinets de purge jusqu’à ce que

la pompe commence à alimenter les réservoirs d’air.

4 . Fermer les robinets de purge.

5 . Surveiller la pression de déclenchement afin de vérifier le nouveau

r é g l a g e .

6 . Une fois le réglage établi, tenir fermement la vis « G ».

7. Tenir fermement l’élément « G » et serrer l’écrou «H ».

RÉGLAGE DE LA PRESSION DIFFÉRENTIELLE

REMARQUE :l’appareil peut demeurer en marche lorsqu’on eff e c t u e

ces réglages.

21

GHIJ

C

D

E

F

Gas Manual 10-5-01 2/10/03 2:31 PM Page 21

Page 25

22

AV E RTISSEMENT : le refroidisseur complémentaire, la tête de

pompe et les pièces contiguës sont très chauds. Ne pas y toucher.

AV E RT I S S E M E N TConcernant les pièces mobiles : couvrir ou

attacher les cheveux longs. Garder les cheveux, les vêtements, les

bijoux et les gants éloignés des pièces mobiles, car ceux-ci peuvent s’y

c o i n c e r.

1. Tenir fermement l’élément « I » et desserrer l’écrou « J ».

AV E RT I S S E M E N T : ne pas desserrer le tube allongé « I » plus

d’un tour puisqu’il est soumis à la pression du réservoir et pourrait

é c l a t e r, causant des blessures à l’utilisateur ou aux personnes qui se

trouvent à proximité du compresseur.

2. Tourner le tube allongé « I » vers la droite pour augmenter la

pression différentielle, ou vers la gauche pour la réduire (p. ex., si la

d i fférence de pression se situe entre 100 et 130 lb/po2 et la

pression désirée varie entre 100 et 120 lb/po2, tourner l’élément «

I » vers la droite).

REMARQUE : un écart trop minime pourrait faire vibrer le robinet

pilote. Si tel est le cas, augmenter la pression différentielle pour

éliminer les vibrations.

3. Tenir fermement l’élément « I ».

4. Tenir fermement l’élément « I » et serrer l’écrou « J ».

RÉGLAGE DE LA PRESSION DIFFÉRENTIELLE

REMARQUE : l’appareil peut demeurer en marche lorsqu’on eff e c t u e

ces réglages.

AV E RTISSEMENT : le refroidisseur complémentaire, la tête de

pompe et les pièces contiguës sont très chauds. Ne pas y toucher.

(Consulter les surfaces chaudes identifiées à la page 17).

AV E RT I S S E M E N Tconcernant les pièces mobiles : couvrir ou

attacher les cheveux longs. Garder les cheveux, les vêtements, les

bijoux et les gants éloignés des pièces mobiles, car ceux-ci peuvent s’y

c o i n c e r.

1 . Desserrer l’écrou « D ».

2 . Tourner le tube allongé « C » vers la gauche pour réduire la

pression différentielle, ou vers la droite pour l’augmenter (p.ex., si la

pression différentielle est réglée entre 100 et 130 lb/po2 et qu’on

veut obtenir une pression qui varie entre 100 et 120 lb/po2, on doit

tourner le tube allongé « C » vers la gauche).

REMARQUE : si la soupape vibre, augmenter la

pression diff é r e n t i e l l e .

3 . Tenir fermement le tube allongé « C ».

4 . Serrer l’écrou « D ».

VÉRIFICATION DU NIVEAU D'HUILE DE LA

POMPE À COMPRESSION

AV E RTISSEMENT : le refroidisseur complé mentaire, la tête de pompe et les pièces contiguës sont très chauds.

Ne pas y toucher. (Consulter les surfaces chaudes identifiées à la page

1 7 ) .

1 . S’assurer que l’appareil est arrêté et que le moteur est fermé (voir

la section « Arrêt de l’appareil »).

2 . Retirer le bouton de remplissage moleté du carter (K).

3 . Vérifier la présence d’impuretés (eau, saletés, etc.) dans l’huile.

4 . Le niveau d’huile ne doit pas dépasser la marque supérieure

indiquée sur le côté du carter (le niveau doit être égal à celui de la

partie inférieure des filets). Au besoin, remplir la pompe d’huile

synthétique DEWA LT.

VÉRIFICATION DU FONCTIONNEMENT DE LA SOUPAPE DE

SÛRETÉ :

AV E RTISSEMENT : Le refroidisseur complémentaire, la tête de

pompe et les pièces contiguës sont très chauds. Ne pas y toucher.

(Consulter les surfaces chaudes identifiées à la page 17).

1 . S’assurer que l’appareil est arrêté et que le moteur est fermé (voir

la section « Arrêt de l’appareil »).

2 . S’assurer que les réservoirs sont vides en vérifiant sur le

manomètre du réservoir. Purger les réservoirs au besoin. (Voir la

section « Purge du réservoir »).

K

Gas Manual 10-5-01 2/10/03 2:31 PM Page 22

Page 26

3 . Saisir l’anneau métallique de la soupape de sûreté.

4 . Tirer sur l’anneau puis la relâcher pour s’assurer que le piston se

déplace librement.

VÉRIFICATION DE L’ÉLÉMENT DU FILTRE À AIR

AV E RTISSEMENT : le refroidisseur complémentaire, la tête de

pompe et les pièces contiguës sont très chauds. Ne pas y toucher.

(Consulter les surfaces chaudes identifiées à la page 17).

1 . S'assurer que l'appareil est arrêté et que le moteur est fermé. (Vo i r

la section « Arrêt de l'appareil ».

2 . Détacher la partie supérieure du filtre de la base de ce dernier en

la dévissant d’environ 5 º vers la gauche.

3 . Séparer la partie supérieure du filtre de la base.

4 . Retirer l’élément de la base.

5 . Si l’élément doit être nettoyé, utiliser un jet d’air. En cas de doute,

remplacer l’élément.

6 . Remettre l’élément dans la base du filtre.

7 . Réinstaller la partie supérieure du filtre sur la base et, tout en

l’enfonçant, tourner la partie supérieure du filtre environ 5 º vers la

d r o i t e .

MISE EN MARCHE DE L’APPAREIL

AV E RTISSEMENT : le monoxyde de carbone est un gaz toxique.

La respiration de ce gaz pourrait provoquer l’inconscience ou même

la mort. Éviter tout endroit ou toute action qui pourrait vous exposer

au monoxyde de carbone.

1 . S'assurer que le levier de marche-arrêt (« ON/OFF ») du moteur est

à la position d’arrêt.

2 . S'assurer que le manomètre du réservoir indique 0 lb/po2. Sinon,

régler le régulateur.

3 . Vérifier le niveau d'huile dans la pompe. (Voir la section «

Vérification du niveau d'huile de la pompe à compression »).

4 . Vérifier le niveau d’huile du moteur. (Consulter le guide d’utilisation

du moteur).

REMARQUE :le moteur est muni d’un détecteur de bas niveau d’huile

qui empêchera le moteur de tourner lorsque le niveau d’huile est trop

b a s .

5 . S’assurer que le réservoir d’essence est plein. (Consulter le guide

d’utilisation du moteur afin d’obtenir les consignes de remplissage

a p p r o p r i é e s ) .

6 . S'assurer que la soupape de sûreté et le robinet de purge

fonctionnent correctement.

7 . S’assurer que les réservoirs sont vides et qu’il n’y a aucune

impureté (humidité, saletés, etc.).

8 . S'assurer que les robinets de purge sont fermés.

9 . Inspecter visuellement la courroie d’entraînement. La remplacer si

l’on détecte tout signe de fissure ou d’effilochage.

1 0 . S’assurer que les dispositifs de protection et les couvercles sont

bien installés et que les étiquettes sont lisibles. Ne pas utiliser le

compresseur tant que ces éléments ne sont pas corrects.

11 .Tourner le dispositif de blocage manuel situé sur la vanne pilote

jusqu’à la position en ligne.

1 2 . Suivre les directives indiquées à la section « Démarrage du

moteur » du guide d’utilisation du moteur.

1 3 . Laisser le compresseur atteindre la pression de déclenchement.

REMARQUE : lorsque le compresseur atteint la pression de

déclenchement, l’appareil continuera de fonctionner sans dégager

d ’ a i r. Le moteur ralentira graduellement. L’appareil peut émettre un

s i fflement léger lorsque l’air sort par le filtre.

RÉGLAGE DU RÉGULATEUR

LIRE LES CONSIGNES DE SÉCURITÉ CONCERNANT LES

ACCESSOIRES AVANT DE RÉGLER LE RÉGULAT E U R .

1 . S’assurer que la poignée de la vanne de réglage est en position de

marche (L).

2 . Tirer sur le bouton.

3 . Tourner le bouton vers la droite pour augmenter la pression régulée

ou vers la gauche pour la diminuer.

23

Gas Manual 10-5-01 2/10/03 2:31 PM Page 23

Page 27

24

4 . Lorsque la pression voulue est indiquée sur

le manomètre régulé, pousser sur le bouton

pour le verrouiller.

INSTALLATION DES BOYAUX

LIRE LES CONSIGNES DE SÉCURITÉ

CONCERNANT LES RISQUES ASSOCIÉS

AUX OBJETS PROJETÉS EN L'AIR AVA N T

D ’ I N S TALLER LES BOYAUX OU LES

A C C E S S O I R E S .

1 . S'assurer que le manomètre régulé indique 0 lb/po2. Régler le

r é g u l a t e u r, le cas échéant.

2 . Saisir le boyau au niveau du raccord.

3 . Tirer sur le collet du raccord rapide femelle du compresseur (M).

4 . Pousser le raccord mâle dans le raccord femelle.

5 . Libérer le connecteur femelle.

6 . Saisir le boyau et tirer sur ce dernier pour s’assurer que le raccord

est bien en place.

7 . Régler le régulateur à la pression voulue.

DÉSACCOUPLEMENT DES BOYAUX

LIRE LES CONSIGNES DE SÉCURITÉ CONCERNANT LES

RISQUES ASSOCIÉS AUX OBJETS PROJETÉS EN L'AIR AVA N T

DE RETIRER LES BOYAUX OU LES ACCESSOIRES.

1 . S'assurer que le manomètre régulé indique 0 lb/po2. Régler le

r é g u l a t e u r, le cas échéant.

2 . Saisir le boyau au niveau du raccord.

3 . Tirer sur le collet du raccord rapide femelle du compresseur.

4 . Tirer sur le raccord mâle pour le désaccoupler du raccord femelle.

5 . Libérer le connecteur femelle.

PURGE DES RÉSERVOIRS

AV E RTISSEMENT : les réservoirs contiennent de l’air à haute

pression. Garder l’orifice de purge éloigné du visage et du reste du

corps. Porter des lunettes de protection pendant la purge étant donné

que des débris risquent d’atteindre le visage. Porter un protège-oreilles

car le flux d’air émet un sifflement strident pendant la purge.

REMARQUE : tous les systèmes à air comprimé génèrent un

condensat qui s’accumule à un point de vidange (par exemple, un

r é s e r v o i r, un filtre, un refroidisseur complémentaire ou un sécheur). Ce

condensat peut contenir du lubrifiant ou des substances contrôlées, ou

encore les deux, et doit être éliminé conformément aux lois et aux

règlements municipaux, provinciaux et fédéraux.

1 . S’assurer que l’interrupteur de marche-arrêt est à la position d’arrêt.

( Voir la section « ARRÊT DE L’ A P PAREIL »).

2 . Mettre un contenant approprié sous l’orifice de purge pour y laisser

s’écouler les débris.

3 . Saisir le levier noir sur l’un des robinets de purge.

4 . Tourner lentement le levier pour purger graduellement l’air du

r é s e r v o i r.

5 . Lorsque la pression du réservoir atteint 10 lb/po2, ouvrir

complètement les deux robinets.

6 . Incliner le compresseur afin de positionner les robinets de purge

aussi bas que possible pour vider plus facilement le réservoir de

toute trace d’humidité, de saletés, etc.

7 . Fermer les robinets de purge une fois terminé.

ARRÊT DE L’APPAREIL

1 . Suivre les directives indiquées à la section « Arrêt du moteur » du

guide d’utilisation du moteur.

2 . Purger le réservoir. (Voir la section « Purge des réservoirs »).

3 . Laisser refroidir le compresseur.

4 . Nettoyer le compresseur d’air au moyen d’un chiffon et l’entreposer

dans une zone sécuritaire, à l’abri du gel.

Préparations avant utilisation

RÉGLAGE INITIAL :

Lire et comprendre toutes les instructions avant d'utiliser ce

c o m p r e s s e u r.

M

L

Gas Manual 10-5-01 2/10/03 2:31 PM Page 24

Page 28

MISE EN GARDE : ne pas faire fonctionner le compresseur sans

lubrifiant ou avec un lubrifiant inadéquat. DEWA LT ne peut pas être

tenue responsable des défaillances de compresseur causées par une

lubrification inadéquate.

Emplacement

MISE EN GARDE :pour éviter d’endommager le compresseur d’air,

ne pas l’incliner à plus de 10° lorsqu’il fonctionne.

Laisser un espace d’au moins 12 pouces autour du compresseur pour

assurer une ventilation appropriée. Éloigner l’appareil des zones à

atmosphère chargée de saletés, de vapeur ou d’émanations qui

risquent d’obstruer le filtre et les soupapes d’admission d’air, ou de s’y

a g g l u t i n e r, ce qui réduirait l’efficacité de fonctionnement.

ENVIRONNEMENTS HUMIDES

Dans les environnements souvent humides, il est possible que

l’humidité s’accumule dans la pompe à vide et se condense dans le

lubrifiant, entraînant ainsi l’usure prématurée des pièces mobiles. Un

excès d’humidité risque de se produire dans l’appareil si elle est située

dans un environnement non chauffé soumis à des variations

thermiques importantes. Il existe deux signes d’humidité excessive :