Page 1

iNSTRUCTiON MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

D55168

Oil Free Portable Air Compressor

Compresseur d'air portatif sans huile

Compresor de aire sin aceite port_til

tNSTRUCTIVO DE OPERACtON, CENTROS DE SERVICIO Y POLtZA

DE GARANT{A. ADVERTENClA: LEASE ESTE INSTRUCTtVO ANTES

DE USAR EL PRODUCTO.

®

Page 2

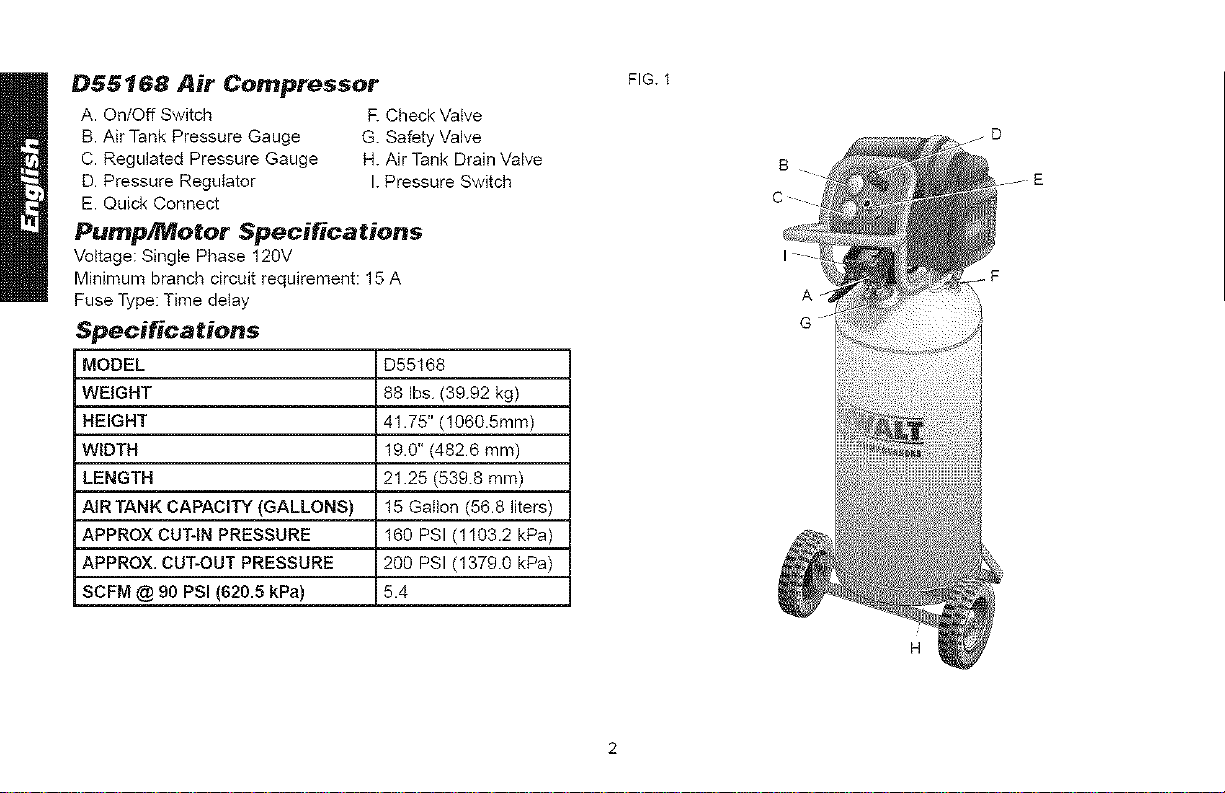

D55168 Air Compressor

A. On/Off Switch P Check Valve

B. Air Tank Pressure Gauge G. Safety Valve

C. Regulated Pressure Gauge H. Air Tank Drain VaLve

D. Pressure Regulator I. Pressure Switch

E. Quick Connect

Pu_p/Moter Specifications

Voltage: SingLe Phase 120V

Minimum branch circuit requirement: 15 A

Fuse Type: Time delay

Specifncations

MODEL D55168

WEIGHT 88 Ibs. (39.92 kg)

HEIGHT 41.75" (1060.5mm)

WIDTH 19.0" (4826 mm)

LENGTH 21.25 (539.8 ram)

AIRTANK CAPACITY (GALLONS) 15 Gallon (56.8 fiters)

APPROX CUT-_NPRESSURE 160 PSI (1103.2 kPa)

APPROX. CUT-OUT PRESSURE 200 PSI (1379.0 kPa)

SCFM @ 90 PSI (620.5 kPa_ 5._

FIG. 1

A

Page 3

Definitions: Safety Guidelines

Tile definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

_,DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

_,WARNING: Indicates a potentially" hazardous

situation which, finer avoided, could result in death

or serious injury.

_CAUTION: Indicates a potentially hazardous

situation which, if net avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol

indicates a potentially hazardous situation which, if

net avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT

THIS OR ANY DEWALT TOOL, CALL US TOLL FREE AT:

1-800-4-BEWALT (1-800-433-9258)

Important Safety instructions

_&WARNING: Do not operate this unit until you read and understand

this instruction manual for safety, operation and maintenance

instructions.

_,WARNING: Some dust created by power sanding sawing, grinding,

drilling, and other construction activities contains chemicals known

(to the State of California) to cause cancer, birth defects or other

reproductive harm. Some example of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks and cement and other masonry

products

• arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a weft ventilated area, and work with approved safety

equipment, always wear OSHA/MSHA/NIOSH approved, properly

fitting face mask or respirator when using such tools.

When using air tools, basic safety precautions should always be

followed to reduce the risk of of personal injury

_,WARNING: This product contains chemicals, including lead,

known to the State of California to cause cancer, and birth

defects or other reproductive harm. Wash hands after handling.

SAVE THESE INSTRUCTION

_DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOWTO PREVENT IT

Page 4

* Ifelectrical sparks from

compressor come into con-

tact with flammabte vapors,

they may ignite, causing fire

or explosion.

• If spraying flammable materi-

als, locate compressor at

least 20 feet (6.1 m) away

from spray area. An addi-

tional length of hose may be

required.

• Store flammable materials in

a secure location away from

compressor.

,&DANGER: RISK TO BREATHING (ASPHYXIATIOI,,

WHAT CAN HAPPEN HOWTO PREVENT I"

n_ve

_ _ _: _fe__

_nj_i i_

• Unattended operation of

this product could result in

personal injury or property

damage. Toreduce the risk

of fire, do not allow the

compressor to operate unat-

tended

" Always remain in attendance

with the product when it is

operating.

• Always turn off and unplug

unit when not in use.

• Sprayed materials such as

paint, paint solvents, paint

remover, insecticides, 'weed

killers, may contain harmful

vapors and poisons.

• Work Jnan area with good

cross ventilation. Read and

follow the safety instructions

provided on the label or safety

data sheets for the materials

you are spraying. Always use

certified safety equipment:

OSHA/MSHAZNIOSH

respiratory protection designed

for use with your specific

application.

Page 5

WARNING: RISK OF BURSTING

WHATCANHAPPEN

• Failure to properly drain

condensed water from

air tank, causing rust and

thinning of the steel air tank.

• Unauthorized modifications to

the safety valve or any other

components which control air

tank pressure.

HOWTO PREVENT IT

* Drain air tank daily or after

each use. tf air tank develops

a leak, replace it immediate{y

with a new air tank or replace

the entire compressor.

° The air tank is designed

to withstand specific

operating pressures. Never

make adjustments or parts

substitutions to alter the factory

set operating pressures.

,_WARNING: RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN

• Your air compressor is

powered by electricity.

Like any other electrically

powered device, tf it is not

used properly it may cause

electric shock.

HOWTO PREVENTIT

• Never operate the compressor

outdoors when it is raining or

in wet conditions.

, Never operate compressor

with protective covers

removed or damaged.

Page 6

• ElectricalGrounding:

Failuretoprovideadequate

groundingtothisproduct

couldresultinseriousinjury

or death from electrocution.

See Grounding

instructions under

Installation.

,&WARNING: RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN H_WTO PREVENTIT

• Make certain that the

electrical circuit to which the

compressor isconnected

provides proper electrical

grounding, correct voltage and

adequate fuse protection.

_&WARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOWTO PREVENT IT

* Touching exposed metal such

as the compressor head,

engine head, engine exhaust

or outlet tubes, can result in

serious burns.

._WARNING: RISK FROM MOVING PARTS

WHAT CAN HAPPEN HOWTO PREVENT IT

. Never touch any exposed

metal parts on compressor

during or immediately after

operation. Compressor will

remain hot for several minutes

after operation.

• Do not reach around

protective shrouds or attempt

maintenance until unit has

been allowed to coot

Page 7

• Attempting to operate

compressor with damaged or

missing parts or attempting

to repair compressor with

protective shrouds removed

can expose you to moving

parts and can result in

serious injury.

,&WARNING: RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOWTO PREVENTIT

• Any repairs required on this

product should be performed

by a DEWALT factory service

center or a DEWALT authorized

service center.

%

,&WARNING: RISK OF FALLING

WHAT CAN HAPPEN HOWTO PREVENTIT

• A portable compressor

can fall from a table,

workbench, or roof causing

damage to the compressor

and could result in serious

injury or death to the

operator.

,& CAUTION: RISK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Always operate compressor

in a stable secure position to

prevent accidental movement

of the unit. Never operate

compressor on a roof or

other elevated position. Use

additional air hose to reach

high locations

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Page 8

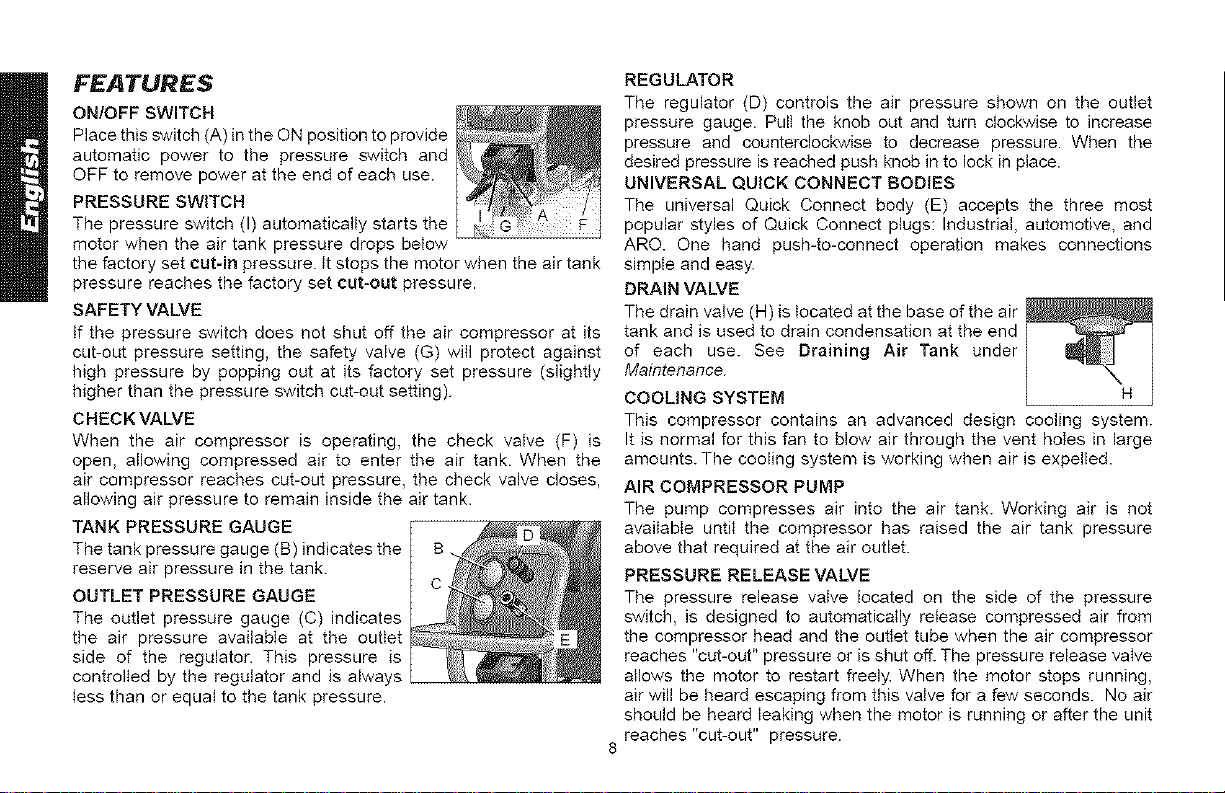

FEATURES

ON!OFF SWITCH

Place this switch (A) in the ON position to provide

automatic power to the pressure switch and

OFF to remove power at the end of each use.

PRESSURE SWITCH

The pressure switch (I) automatically starts the

motor when the air tank pressure drops below

the factory set cut-in pressure. It stops the motor when the air tank

pressure reaches the factory set cut-out pressure.

SAFETY VALVE

If the pressure switch does not shut off the air compressor at its

cut-out pressure setting, the safety valve (G) witl protect against

high pressure by popping out at its factory set pressure (slightly

higher than the pressure switch cut-out setting).

CHECK VALVE

When the air compressor is operating, the check valve (F) is

open, allowing compressed air to enter the air tank. When the

air compressor reaches cut-out pressure, the check valve closes,

allowing air pressure to remain inside the air tank.

TANK PRESSURE GAUGE

The tank pressure gauge (B) indicates the

reserve air pressure in the tank.

OUTLET PRESSURE GAUGE

The outlet pressure gauge (C) indicates

the air pressure available at the outtet

side of the regulator. This pressure is

controlled by the regulator and is always

tess than or equat to the tank pressure.

REGULATOR

The regulator (D) controls the air pressure shown on the outlet

pressure gauge. Putt the knob out and turn clockwise to increase

pressure and counterclockwise to decrease pressure. When the

desired pressure is reached push knob in to lock in place.

UNIVERSAL QUICK CONNECT BODIES

The universal Quick Connect body (E) accepts the three most

popular styles of Quick Connect plugs: Industrial, automotive, and

ARC. One hand push-to-connect operation makes connections

simpte and easy.

DRAIN VALVE

The drain valve (H) is tocated at the base of the air

tank and is used to drain condensation at the end

of each use. See Draining Air Tank under

Maintenance.

COOLING SYSTEM H

This compressor contains an advanced design cooling system.

It is normal for this fan to blow air through the vent holes in large

amounts. The cooling system is working when air is expelled.

AIR COMPRESSOR PUMP

The pump compresses air into the air tank. Working air is not

availaMe until the compressor has raised the air tank pressure

above that required at the air outlet.

PRESSURE RELEASE VALVE

The pressure release valve iocated on the side of the pressure

switch, is designed to automatically release compressed air from

the compressor head and the outtet tube when the air compressor

reaches "cut-out" pressure or is shut off.The pressure release valve

atlows the motor to restart freely. When the motor stops running,

air will be heard escaping from this valve for a few seconds. No air

should be heard leaking when the motor is running or after the unit

reaches "cut-out" pressure.

Page 9

MOTOROVERLOADPROTECTOR

Themotorhasamanualthermaloverloadprotector.Ifthemotor

overheatsforanyreason,theoverloadprotectorwillshutoffthe

motor.Themotormustbeailowedtocooldownbeforerestarting.

Torestart:

1.SettheOn/Auto/OfflevertoOFFandunplugunit.

2.Allowthemotortocoot.

3.Plugthepowercordintothecorrectbranchcircuitreceptacle.

4.SettheOn/Auto/OfflevertoON/AUTOposition.

INSTALLATION

Assembly

INSTALLING HOSES

_WARNING: Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose whip.

1. Ensure regulated pressure gauge reads O PSI (OkPa).

2. Grasp the hose at the Quick Connect plug and push the plug

into the Quick Connect body (E). Coupler will snap intoplace.

3 Grasp the hose and pull to ensure coupier is seated

DISCONNECTING HOSES

_.WARNING: Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose whip.

1. Ensure regulated pressure gauge reads O PSI (OkPa).

2. Pull coupler on Quick Connect body back to reIease Quick

Connect plug on hose.

Grounding Instructions

_,WARNING: Risk of Electrical Shock. In the event of a short

circuit, grounding reduces the risk of shock by providing an escape

wire for the electric current. This air compressor must be properly

grounded.

9

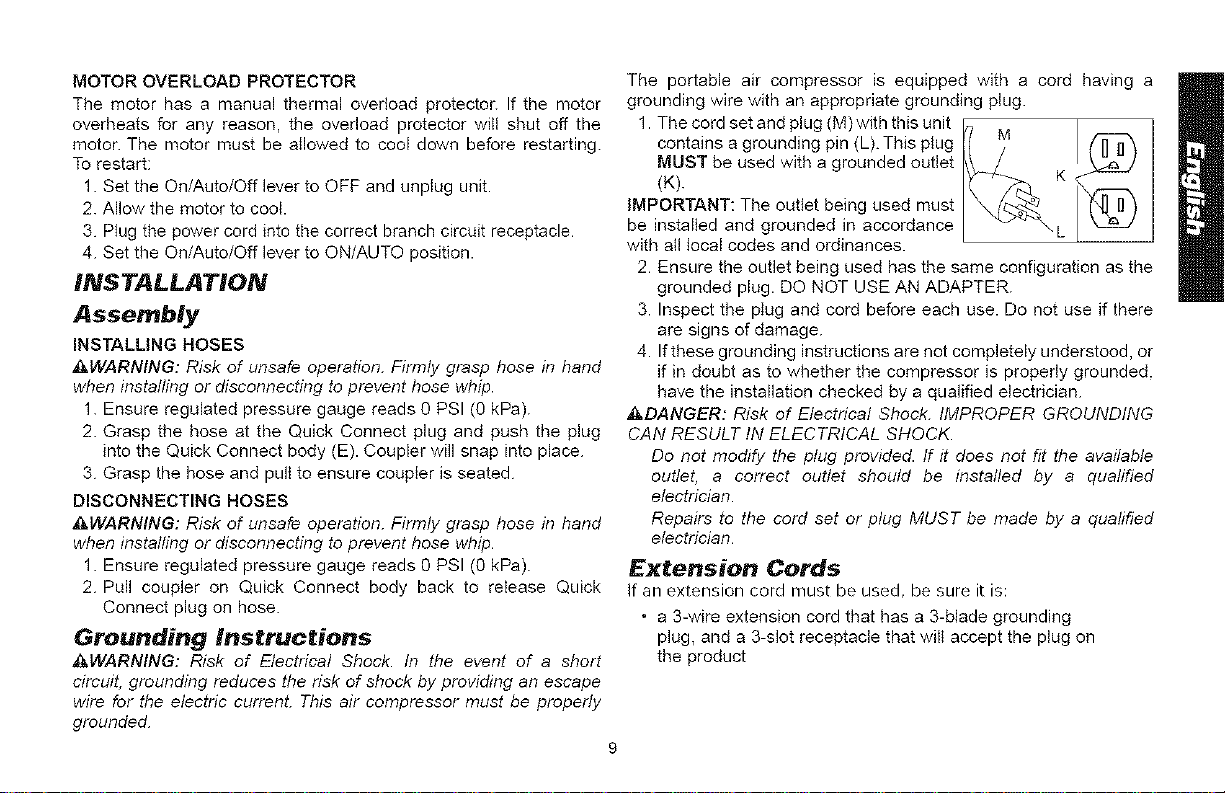

The portable air compressor is equipped with a cord having a

grounding wire with an appropriate grounding plug.

1. The cord set and plug (M)with this unit i-#T',

contains a grounding pin (L). This plug M

MUST be used with a grounded outlet

(K).

IMPORTANT: The outlet being used must

be installed and grounded in accordance

with all local codes and ordinances.

2. Ensure the outlet being used has the same configuration as the

grounded plug. DO NOT USE AN ADAPTER.

3. Inspect the plug and cord before each use. Do not use if there

are signs of damage.

4. If these grounding instructions are not completely understood, or

if in doubt as to whether the compressor is properly grounded,

have the installation checked by a qualified electrician.

_,DANGER: Risk of Electrical Shock. IMPROPER GROUNDING

CAN RESULT tN ELECTRICAL SHOCK.

Do not modify the plug provided, ff it does not fit the available

outlet, a correct outlet should be instafled by a qualified

electrician.

Repairs to the cord set or plug MUST be made by a quafified

electrician.

Extension Cords

If an extension cord must be used, be sure it is:

• a 3-wire extension cord that has a 3-blade grounding

plug, and a 3-slot receptacle that wilt accept the plug on

the product

Page 10

* ingoodcondition

* nolongerthan50feet

. 12gauge(AWG)orlarger.(Wiresizeincreasesasgaugenum-

berdecreases.10AWGand8AWGmayalsobeused.DONOT

USE14OR16AWG.)

CAUTION: The use of an undersized extension cord will cause volt-

age to drop resulting in power loss to the motor and overheating.

Instead of using an extension cord, increase the working reach of

the air hose by attaching another length of hose to its end. Attach

additional lengths of hose as needed.

Voltage and Circuit Protection

Refer to the Voltage and Minimum Branch Circuit Requirements

under Pump/Motor Specifications.

_.CAUTION: Certain air compressors can be operated on a

15 amp circuit if the following conditions are met.

. Voltage supply to circuit must compty with the National Electrical

Code.

* Circuit is not used to supply any other electrical needs.

. Extension cords comply with specifications.

. Circuit is equipped with a 15 amp circuit breaker or 15 amp

time delay fuse. NOTE: If compressor is connected to a circuit

protected by fuses, use only time delay fuses. Time delay fuses

should be marked "D" in Canada and "T" in the US.

If any of the above conditions cannot be met, or ff operation of the

compressor repeatedly causes interruption of the power, it may be

necessary to operate it from a 20 amp circuit tt is not necessary

to change the cord set.

Compatibility

NOTE: Always use an air _ine filter to remove moisture when

spraying paint.

Location

Ptace the air compressor in a clean, dry and v!eli ventilated area

at least 12" (30 mm) away from the wail or other obstructions that

will interfere with the flow of air. Keep the compressor away from

areas that have dirt and/or volatile fumes in the atmosphere. These

impurities may clog the intake filter and valves, causing inefficient

operation.

_i_WARNING: The air compressor pump and shroud are designed to

allow for proper cooling. The ventilation openings on the compressor

are necessary to maintain proper operating temperature. Do not

place rags or other containers on or near these openings.

Place the air compressor on a fiat surface resting on the rubber

feet.

ELECTRICAL

Refer to all safety instructions before using unit. Observe extension

cord safety instructions if necessary. Always move the On/Off

switch (A) to the OFF position before removing the plug from the

outlet.

TRANSPORTING

When transporting the compressor in a vehicle, trailer, etc., make

sure the tank is drained and the unit is secured with straps to prevent

tipping. Use care when driving to prevent tipping the unit over in the

vehicle. Damage can occur to the compressor or surrounding items

if the compressor is tipped.

10

Page 11

LIFTING

Always use two people when lifting and liftfrom

the recommended lift points (O). DO NOT lift

by wheels or shroud.

Moving

_CAUTION: The wheels and handle do

not provide adequate clearance, stabitity, or

support for pulling the unit up and down stairs

or steps. The unit must be lifted or pushed up

a ramp.

1. Grasp handle of compressor and tilt compressor back to rest on

wheels.

_2_WARNING: Risk of Unsafe Operation. Ensure proper footing and

use caution when roiling compressor so that unit does net tip or

cause loss of balance.

2 When location is reached slowly lower compressor to ground.

Always store compressor in a vertical position resting on the

rubber bumpers and wheels.

PREPARATION FOR USE

Pre=Start Checklist (Fig. I)

1 Ensure the On/Off switch (A) is in the OFF position.

2. Plug the power cord into the correct branch circuit receptacle See

Voltage and Circuit Protection under Installation.

3 Ensure air tank is drained, see Draining Air Tank under

Maintenance.

4 Ensure the drain valve (H) is closed.

5 Ensure safety valve (G) is functioning properly, see Checking

Safety Valve under Maintenance.

6. Pull the knob (D) out and turn clockwise to increase pressure

and counterclockwise to decrease pressure. When the desired

pressure is reached push knob in to lock in place.

7. Attach hose and accessories

CAUTION: Risk of unsafe operation. Compressed air from the unit

may contain water condensation and oil mist. Do not spray unfiltered

air at an item that could be damaged by moisture. Some air tools and

accessories may require filtered ai_ Read the instructions for the air

tools and accessories.

_WARNING: Risk of Bursting. Too much air pressure causes a

hazardous risk of bursting Check the manufacturer's maximum

pressure rating for air tools and accessories. The regulator outlet

pressure must never exceed the maximum pressure rating.

Initial Set.up (Fig. 1)

WARNING: Do not operate this unit until you read and understand

this instruction manual for safety, operation and maintenance

instructions.

BREAK-IN PROCEDURE

_WARNING: Risk of property damage. Serious damage may result ff

the following break-in instructions are not closely fellowed.

This procedure is required before the air compressor is put into

service for the first time and when the check valve or a compressor

pump/motor has been replaced.

1. Ensure the On/Off switch (A) is in the OFF position.

NOTE: If hose is not connected to Quick Connect body, pulI coupler

back until it clicks to prevent air from escaping through the quick

connect.

2. Plug the power cord into the correct branch circuit receptacle. See

Voltage and Circuit Protection under Installation.

11

Page 12

3. Open the drain valve (turn lever counter-clockwise) fuIly to

permit air to escape and prevent air pressure build up in the air

tank during the break-in period.

4. Move the On/Off switch to the ON position. The compressor will

start.

5. Run the compressor for 15 minutes.

6. After 15 minutes, close the drain valve by turning lever

clockwise. The tank will fill to cut-out pressure and the motor

will stop.

7. Compressed air will be available until it is used or bled off

OPERATING PROCEDURES

Start-up (Fig. I)

1. Follow Pre-Start Checklist under Preparation for Use.

2. Move the On/Off switch to the ON position and allow tank

pressure to build. Motor will stop when tank pressure reaches

cut-out pressure

&CAUTION: Risk of unsafe operation. Compressed air from the

unit may contain water condensation and eft mist. Do not spray until-

tered air at an item that could be damaged by moisture. Some air

operated tools or devices may require filtered air. Read the instruc-

tions for the air tool or device.

3. Adjust regulator (D) to desired setting. See Regulator under

Features.

Shut-down (Fig. I)

1. Move On/Off switch (A) to the OFF position. NOTE: If finished

using compressor, follow Steps 2 - 6.

NOTE: When the unit has been turned off, it is normal to hear a

short hiss of air being released.

2. Turn regulator knob (D) counterclockwise until fully closed. Ensure

regulated pressure gauge reads 0 PSI (0 kPa).

3. Remove hose and accessory.

_, WARNING: Risk of unsafe operation. Firmly grasp air hose in hand

when installing or disconnecting to prevent hose whip.

4. Drain the air tank, see Draining Air Tank under Maintenance.

Ensure airtank pressure gauge reads OPSi (0 kPa).

_t,WARNING: Risk of bursting. Drain air tank daily. Water will

condense in air tank. If net drained, water will corrode and weaken

the air tank causing a risk of air tank rupture.

5. Allow the compressor to coot down.

6. Wipe air compressor clean and store in a safe, non-freezing area.

MAINTENANCE

The following procedures must be followed 'when maintenance or

service is performed on the air compressor.

1. Ensure On/Off switch is in the OFF position.

2. Remove air compressor plug from outlet.

3. Drain air tank.

4. Allow air compressor to coot down before starting service.

NOTE: All compressed air systems contain maintenance parts (e.g.,

oil, filters, separators) that are periodically replaced. These used parts

may contain substances that are regulated and must be disposed of in

accordance with local, state, and federat taws and regulations.

NOTE: Take note of the positions and locations of parts during

disassembly to make reassembly easier.

NOTE: Any service operations not included in this section shoutd

be performed by a DEWALT factory service center or a DEWALT

authorized service center

12

Page 13

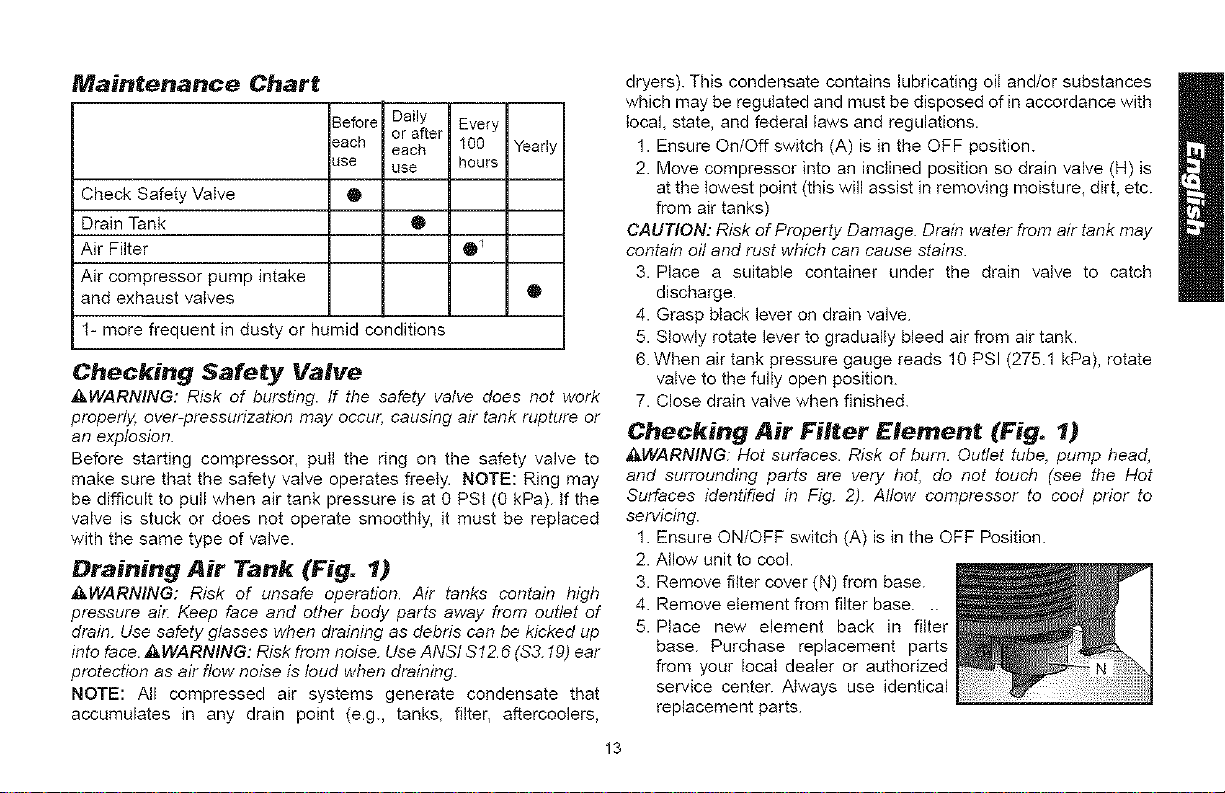

Maintenance Chart

3efore Daily Every

or after

_ach each 100 Yearly

_se use hours

Check Safety Valve •

Drain Tank O

Air Filter O _

Air compressor pump intake

and exhaust valves O

1- more frequent in dusty or humid conditions

Checking Safety Valve

_&WARNING: Risk of bursting. If the safety valve does not work

propedy_ over-pressurization may occu_ causing air tank rupture or

an explosion.

Before starting compressor, pull the ring on the safety valve to

make sure that the safety valve operates freely. NOTE: Ring may

be difficult to pull when air tank pressure is at 0 PSI (0 kPa). tf the

valve is stuck or does not operate smoothly, it must be replaced

with the same type of valve.

Draining Air Tank (Fig. 1)

_&WARNING: Risk of unsafe operation. Air tanks contain high

pressure air. Keep face and other body parts away from outlet of

drain. Use safety glasses when draining as debris can be kicked up

into face. _,WARNING: Risk from noise. Use ANSI S 12.6 ($3. fg) ear

protection as air flow noise is loud when draining.

NOTE: All compressed air systems generate condensate that

accumulates in any drain point (e.g. tanks, filter, aftercoolers,

dryers). This condensate contains lubricating oit and/or substances

which may be regulated and must be disposed of in accordance with

local, state, and federal laws and regulations.

1. Ensure On/Off switch (A) is in the OFF position.

2. Move compressor into an inclined position so drain valve (H) is

at the lowest point (this will assist in removing moisture_ dirt_ etc.

from air tanks)

CAUTION: Risk of Property Damage. Drain water from air tank may

contain off and rust which can cause stains.

3. Place a suitable container under the drain valve to catch

discharge.

4. Grasp black lever on drain valve

5. Slowly rotate lever to gradually bleed air from air tank.

6. When air tank pressure gauge reads 10 PSI (275.1 kPa), rotate

valve to the fully open position.

7. Close drain valve when finished.

Checking Air Filter Element (Fig. 1)

_WARNINO: Hot surfaces. Risk of burn. Outlet tube pump head_

and surrounding parts are very hot, do not touch (see the Hot

Surfaces identified in Fig. 2). Allow compressor to cool prior to

servicing.

1. Ensure ON/OFF switch (A) is in the OFF Position.

2. Allow unit to cool.

3. Remove filter cover (N) from base.

4. Remove etement from filter base...

5. Place new element back in filter

base. Purchase replacement parts

from your Iocai dealer or authorized

service center. Always use identical

replacement parts

13

Page 14

6.Snapfiltercovertofilterbase.

_,CAUTION:Risk of unsafe operation. Do not operate without air

inlet filter

AIR COMPRESSOR PUMP INTAKE AND

EXHAUST VALVES

Once a year have a Trained Service Technician check the air

compressor pump intake and exhaust valves.

ACCESSORIES

Recommended accessories for use with your toot are available

for purchase from your local dealer or authorized service center.

if you need assistance in locating any accessory for your tool,

please contact DEWALT Industrial Toot Co., 701 East Joppa Road,

BaItimore_ MD 21286_ call 1-800-4-DEWALT (1-800-433-9258) or visit

our website wvTw.dewaIt.com.

_&CAUTION: The use of any other accessory" not recommended for

use with this tool could be hazardous. Use only accessories rated

equal to or higher than the rating of the air compressor.

SERVICE INFORMATION

Please have the following information available for all service catls:

Model Number Serial Number

Date and Place of Purchase

Repairs

To assure product SAFETY and RELIABILITY_ repairs, maintenance

and adjustment should be performed by a DEWALT factory service

center, a DEWALT authorized service center or other qualified

service personnel. Always use identical replacement parts.

Full One Year Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due

to faulty materials or workmanship. For warranty repair information,

calt 1-80O-4-DEWALT. This warranty does not apply to accessories

or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained either in the packaging, call

the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, calt 1-8O0-4-DEWALT for a free

replacement.

14

Page 15

GLOSSARY

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of air delivery.

PSI: Pounds per square inch; a unit of measure of pressure.

kPa (kilopaseal): Metric pressure measurement. 1 kilepascaI equal 1000 pascaIs.

Code Certification: Products that bear one or more of the following marks: UL, CUL, ETL, CETL, have been evaluated by OSHA certified

independent safety laboratories and meet the applicable Undepwriters Laboratories Standards for Safety.

Cut-In Pressure: While the motor is off, air tank pressure drops when accessory is used. When the tank pressure drops to a certain tow

level the motor will restart automatically The low pressure at which the motor automatically restarts is called cut-in pressure

Cut-Out Pressure: When an air compressor is turned on and begins to run, air pressure in the air tank begins to build, tt builds to a

certain high pressure before the motor automatically shuts off, protecting your air tank from pressure higher than its capacity. The high

pressure at which the motor shuts off is called cut-out pressure.

Branch Circuit: The circuit carrying electricity from electrical panet to outlet.

Duty Cycle: This air compressor pump is capable of running continuously. However, to prolong the life of your air compressor, it is

recommended that a 50%-75% average duty cycle be maintained; that is, the air compressor pump should not run more than 30-

45 minutes in any given hour.

15

Page 16

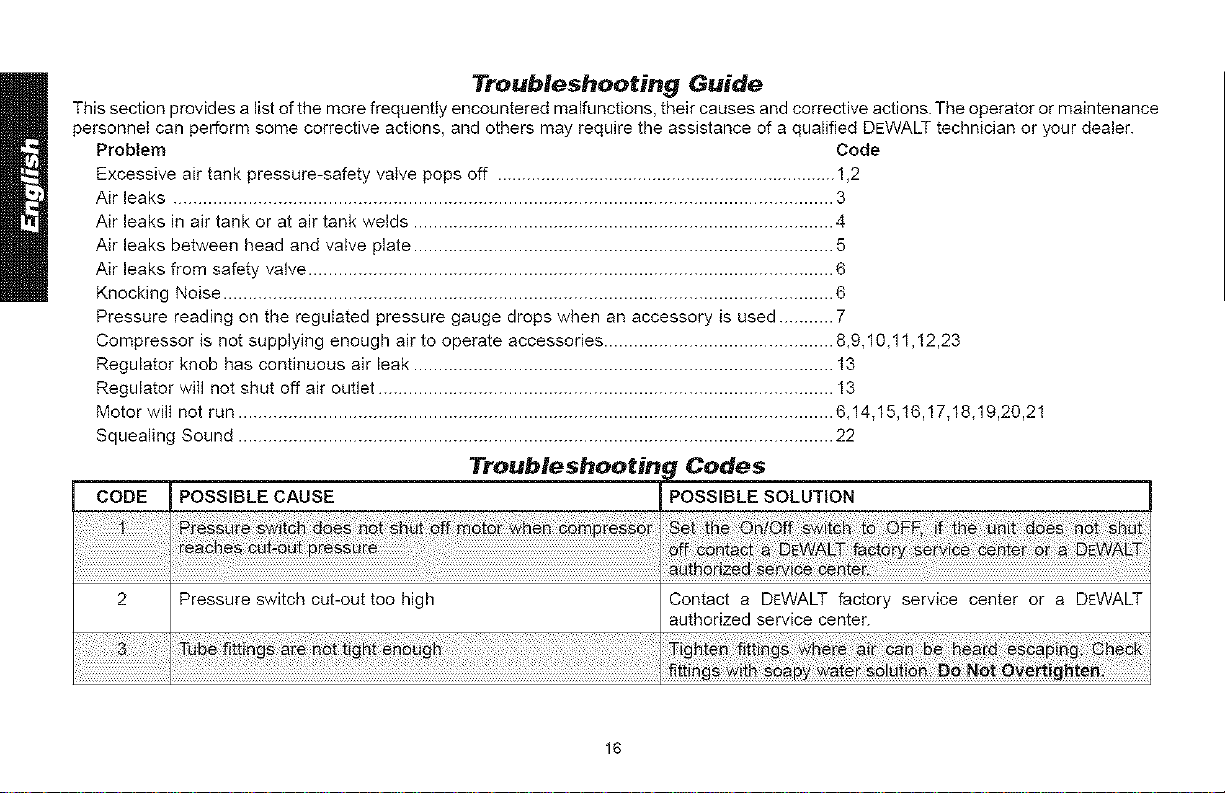

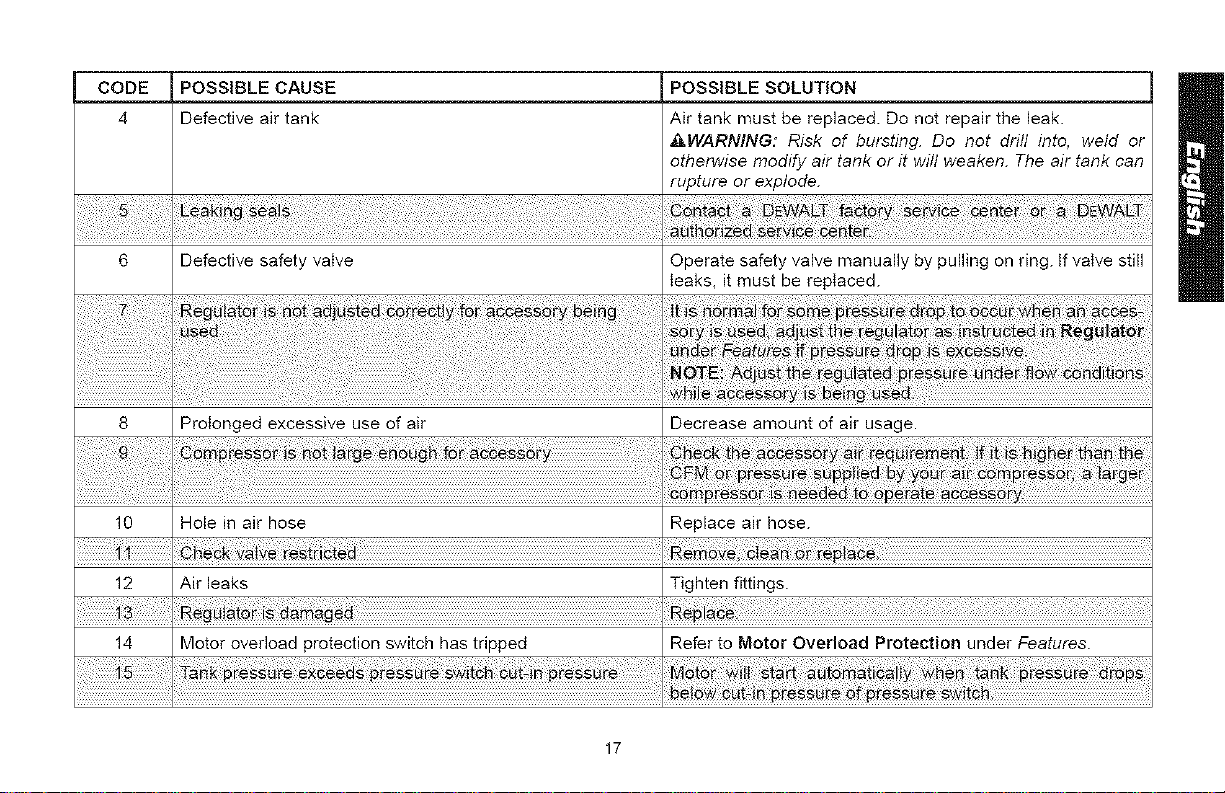

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or maintenance

personnel can perform some corrective actions and others may require the assistance of a qualified DEWALT technician or your dealer.

Problem Code

Excessive air tank pressure-safety valve pops off ...................................................................... 1,2

Air leaks .................................................................................................................................... 3

Air leaks in air tank or at air tank welds .................................................................................... 4

Air leaks between head and valve plate .................................................................................... 5

Air leaks from safety valve ......................................................................................................... 6

Knocking Noise .......................................................................................................................... 6

Pressure reading on the regulated pressure gauge drops when an accessory is used ........... 7

Compressor is not supplying enough air to operate accessories .............................................. 8,9,10,11,12,23

Regulator knob has continuous air leak .................................................................................... 13

Regulator will not shut off air outlet ........................................................................................... 13

Motor will not run ....................................................................................................................... 6,14,15,16,17,18,19,26,21

Squealing Sound ....................................................................................................................... 22

Troubleshootin( Codes

CODE POSSIBLE CAUSE

POSSIBLE SOLUTION

Pressure switch cut-out too high

Contact a DEWALT factory service center or a DEWALT

authorized service center.

16

Page 17

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

4 Defective air tank

6 Defective safety valve Operate safety valve manually by pulling on ring. tf vatve still

Air tank must be replaced. Do not repair the leak.

&WARNING: Risk of bursting. Do not drill into, weld or

otherwise modify air tank or it will weaken. The air tank can

rupture or explode.

leaks, it must be replaced.

8

12 Air leaks Tighten fittings.

14 Motor overload protection switch has tripped Refer to Motor Overload Protection under Features.

Prolonged excessive use of air

Hole in air hose10

Decrease amount of air usage•

Replace air hose.

17

Page 18

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

16 Extension cord iswrong tength or gauge Checkforpropergaugewireandcordlength under Extension

i

18

ii_iiiiiiiiiiiiiiiiiiiii _i_iii

Possible defective motor

Cords

Contact a DEWALT factory service center or a DEWALT

authorized service center.

2O

Pressure release valve on pressure switch has not

unloaded head pressure

iiiiiii

22

_iiiiiiiiiiiiiiiiiiiiiiiii_i_

Worn Belt

Bleed the line by pushing the lever on the pressure switch to

the "0" position; if the valve does not open, replace switch,

Contact a DEWALT factory service center or a DEWALT

authorized service center.

18

Page 19

Compresseur d'aJr, modelo D55168

A. Interrupteur Marche/ArrGt

B. Manometre du reservoir d'air

C Manometre regul6

D. Regutateur de pression

E. Branchements rapides

E Ctapet

G. Soupape de sQrete

H. Soupape de purge du

reservoir d'air

I. Rembobineur de cordon

d'alimentation

Fiche technique de la pompe/du moteur

Tension : monophasG, 120V

Exigence minimaLe du circuit de derivation : 15 A

Type de fusible : tempodsation

Fiche technique

MOD#LE D55168

POIDS 39,92 kg (88 Iivres)

HAUTEUR 1080.5, ram(41,75 po)

LARGEUR

LONGUEUR

CAPACITE DU RESERVOIR D'AIR

(GALLONS)

PRESSION D'ENCLENCHEMENT

APPROX.

ENV. PRESSION DE DECLENCHEMENT

PCMS (SCFM) 100 PSI (689,5 kPa)

482,6 mm (19,0 po)

21,25 mm (536_8 po)

15 (56,8 iiters)

11032 kPa (160 PSI)

t379_0 kPa (200 PSi)

5,_

FIG. 1

A

G

19

Page 20

DermitNons : lignes directrNces en

rnat_ere de securite

Les definitions ci-dessous decdvent le niveau de gravite pour

chaque symbole. Veuillez lire le mode d'empIoi et porter une atten-

tion particuticre aces symbotes.

&DANGER : Indique une situation dangereuse imminente quL si

elle n'est pas _vit_e, caueera la mort ou des bleasures graves.

_,AVERTISSEMENT : lndique une situation potentie/lement dan-

gereuse quL si die n'est pas _vitee, pourrsit se solder par un

deeea ou dee blesaurea graves.

_,MISE EN GARDE : Indique une situation potentie/lement dan-

gereuse qua.si elle n'est pas _vit_e pourrait se solder par des

bleeeurea mineurea ou moderees.

MISE EN GARDE : Utilis_ sans le symbole d'alerte _ la s_eurit_,

indique une situation potentiellement dangereuse qua.si e/le n'eat

pas _vit_e pourrait se solder par des dommagea b la propriete.

POURTOUTES QUESTIONS OU COMMENTAIRES RELATtFS(MES)

_OUTtL OU Jk PROPOS DE TOUT AUTRE OUTIL DEWALT_

COMPOSER SANS FRAIS LE : 1-800..4-DEWALT (1=800-433-9258)

Directives de securite irnportantes

_,AVERT/SSEMENT : Ne pas utiliser cet appareil avant d'avoir lu

et oompris le mode d'emploi ainsi que I'int_gra/it& des directives de

s#curit_, d'utilisation et d'entretien.

,_,AVERTISSEMENT : Nertaines poussi&res produites par les travaux

de pon_age, soiage, meu/age, per9age et autres peuvent eontenir des

produits ohimiques pouvant (selon /'_tat de Californie) causer/e cancer,

des anomalies eong_nita/es ou d'autres probl&mes /i_s aux fonctions

reproductrioes. Voicique/ques exemp/es de ees produits ohimiques :

• le plomb contenu dane les peintures _ base de plomb;

• la silice cristalline provenant de la brique, du ciment et d'autres

produits de ma_onnerie;

• /'arsenic et chrome provenant de bois trait# chimiquement.

Les risques reli#s _ /'exposition _ ces poussi&res varient selon la

fr&quenee _ laquelle I'utilisateur travaille avec ee type de mat&riaux.

Pour r&duire votre exposition _ ces produits chimiques : travailler darts

un endroit bien ventil& et porter un &quipement de s&curit& approuv&

par IOSHA/MSHA/NIOSH eomme un masque anti-poussi&res

sp_cialement adapt& ou unrespirateur /ors de I'utilisation de ces outils.

Lots de l'utilisation d'outils pneumatiques, des precautions de base

en mati&re de s&curit# doivent _tre suivies afin de r&duire le risque de

blessure personnelle.

_t,AVERTISSEMENT : Ce produit contient des produita chimiques,

notamment le plomb, reconnus par t'Etat de Califomie comme

etant caneerigenes et pouvant entrainer des anomalies conge-

nitales et d'autres dangers relatifs a ta reproduction. Se laver lee

mains apres toute manipulation.

CONSERVER CES DIRECTIVES

_DANGER : RISOUE D'EXPLOSION OU D'INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT L'EVITER

2O

Page 21

• Si une etincelle 61ectdque

provenant du compresseur

entre en contact avec des

vapeurs inflammables,

eile peat denflammer et

causer an incendie ou une

explosion.

• Si vous aspergez des

materiaux inflammables,

placez le compresseur

au moins 6,1 m (20 pieds)

de la zone palveris6e 11est

possible qae vous ayez besoin

d'une Iongueur de tuyau

additionnelle.

• Entreposez les matieres

inflammables dans un

endroit s6curitaire, 61oign6du

compressear

• Le fonctionnement de ce

produit sans surveillance

pourrait se solder par des

blessures personnelles

ou des dommages a la

• Etre toujours present Iorsque

le produit est en marche.

• Toujours 6teindre et

debrancher I'appareil si non

utilis6

propri6t6. Afin de r6duire

le risque d'incendie, ne

pas laisser le compresseur

fonctionner sans surveillance.

,&DANGER : RISQUE REPIRATOIRE (ASPHYXIE)

CE QUI PEUT SE PRODUIRE COMMENT L'EVtTER

#Ei_6_

21

Page 22

• Les matcriaux vaporises • Travaillerdans un endroit

comme lapeinture, les ayant une bonne ventilation

solvants de peinture, les transversale Lire et respecter

decapants, les insecticides, les directives en matiere

les herbicides, pourraient de securit6 imprimees sur

contenir des vapeurs nocives I'etiquette ou les fiches

et du poison signalctiques des matedaux qui

sont pulveriscs. Toujours utiliser

an equipement de securite

homologue :une protection

respiratoire conforme aux

normes OSHA/MSHA/NIOSH,

con#ue specifiquement pour

une utilisation particuliere.

_,,AVERTISSEMENT : RISQUE D'ECLATEMENT

R&servoir d'air :le reservoir dont est dote le compresseur d'air porte le

code <<UM >>(dans le cas d'appareils munis de reservoirs superieurs &

152 mm (6 po) de diametre) et ilest cengu cenfermement a la section

VII Div. 1 de IASME Teas les recipients sous pression devraient _tre

inspectee une fois teus les deux arts Pour lecaliser linspecteur des

recipients seus pression de vetre region, consulter la section appropriee

des erganismes geuvernementaux de lannuaire t61ephonique eu

composer le 1-8004-DEWALT pour obtenir de I'aide

Les conditions indiquees ci-apres pourraient affaiblir le reservoir d'air et

se solder par une viotente explosion de celui-ci :

CE QUt PEUT SE PRODUIRE

* Modifications apportees au

reservoir d'air ou tentatives de

reparation

COMMENT UI_VITER

• Ne jamais percer un trou

dans ie reservoir d'air ouses

accessoires, y faire de la

soudure ou y apporter quelque

modification que ce soit Ne

jamaJsessayer de reparer an

reservoir d'air endommage ou

avec des fuites. Le remptacer

par un nouveau reservoir d'air

22

Page 23

Accessoires :

• Lorsqu'on excede la

pression nominale des

oatils pneumatJques, des

pistolets pulv6risateurs, des

accessoires a commande

pneumatique, des pneus

et d'autres dispositifs

pneumatiques, on risque de

les faire exploser ou de les

projeter et ainsi entrafner des

• Respecter les recommanda-

tions du fabricant de I'eqaipe-

ment et ne jamais depasser la

pression nominale maximale

permise des accessoires. Ne

jamais utiliser le compresseur

pour gonfler de petits objets

basse pression comme des

jouets d'enfant, des ballons de

football et de basket-ball, etc.

blessures graves.

_AVERTISSEMENT : RISQUE DE CHOC L=LECTRIQUE

CE QUI PEUT SE PRODUIRE COMMENT L'EVITER

• Les tentatives de reparation

par un personnel non qualifie

peuvent resulter en de

graves blessures, voire la

mort par electrocution.

• Tout c_blage electrique ou

toute reparation n¢cessaire

pour ce produit doit 6tre pris

en charge par un centre de

reparation ee usine autorise

DEWALTou un centre

de reparation DEWALT

cooformement aux codes

electriques nationaux et

Iocaux

23

Page 24

&AVERTISSEMENT : RISQUE PROVENANT DES

OBJETS PROJETE:S EN L'AIR

CE QUI PEUT SE PRODUIRE COMMENT L'E_VlTER

• Le flux d'air comprime peut

endommager lestissus mous

de la peau exposee et peut

projeter la poussiere, des

fragments, des particules

d6tachees et des petits

objets a haute vitesse, ce qui

entrafnerait des dommages et

des blessures personnelles.

• Toujours utiliser de I'equipement

de securit6 homologue :

protection oculaire conforme

la norme ANSI Z87.1 (CAN/

CSA Z94.3) munie d'ecrans

lateraux lots de I'utilisation du

compresseur.

• Nejamais pointer une buse

ou un pulverisateur vers une

pattie du corps ou vers d'autres

personnes ou des animaux.

* Toujours mettre le compresseur

hors tension et purger la

pression du tuyau a air et du

reservoir dair avant d'effectuer

I'entretien, de fixer des outils ou

des accessoires.

,_AVERTISSEMENT : ATTENTION SURFACES CHAUDES

CE QUI PEUT SE PRODUtRE COMMENT L'_:VITER

24

Page 25

&AVERTISSEMENT : RISQUE A SSOCI_-

AUX PIf CES MOBILES

CE QUI PEUT SE PRODUJRE COMMENT L'EVtTER

• Les pieces mobiles comme

une poulie, un volant ou une

courroie peuvent provoquer

de graves Nessures si elles

entrent en contact avec vous

oa vos v_tements

• Ne jamais utiliser le

compresseur si les protecteurs

ou les coavercles sont

endommages ou retires

Tenir les cheveux, les

vCtements et les gants hors

de portee des pieces en

mouvement, hes vCtements

amples, bijoux ou cheveux

longs peuvent s'enchev_trer

dans les pieces mobiles.

• S'6ioigner des events car ces

derniers pourraient camoufler

des pieces mobiles.

_AVERTISSEMENT : RISQUE ASSOCIeL

UTILISATION DANGEREUSE

CE QUI PEUT SE PRODUIRE COMMENT L'EVITER

• Une utilisationdangereuse

de votre compresseur d'air

pourrait provoquer de graves

blessures, voire votre deces

ou celle d'aatres personnes

•Revoir et comprendre toutes les

directives et les avertissements

contenas dans le present mode

demploi.

• Se familiariser avec le

fonctionnement et les

commandes da compresseur

d'air.

• Degager lazone de travail de

toutes personnes, animaux et

obstacles.

• Tenir les enfants hers de portee

du compresseur d'air en tout

temps

• Ne pas utiliser le produit en cas

de fatigue ou sous I'emprise

d'alcool ou de drogues Rester

vigilant en tout temps

• Ne jamais rendre inoperant les

fonctionnalites de securite du

produit

25

Page 26

• Installer an extincteur darts la

zone de travail.

• Ne pas utiliser I'appareil Iorsqu'il

manque des pieces ou que

des pieces sont brisees ou non

autorisees.

• Ne jamais se tenir debout sur le

compresseur

&MISE EN GARDE : RISQUE ASSOCIE AU BRUIT

CE QUI PEUT SE PRODUIRE COMMENT UI_VITER

° Dans certaines conditions et

selon la daree d'atilisation le

bruit provoqae par ce produit

peut contribuer a ane perte

auditive

° Toajours utiliser an Cqaipement

de securit¢ homologue :

protection auditive conforme

la norme ANSI $12.6 ($3.19).

&AVERTISSEMENT : RISQUE DE CHUTE

CONSERVER CES DIRECTIVES

POUR UN USAGE ULTERIEURC

CARACTERISTIQUES

INTERRUPTEUR MARCHE/ARRI_T

Mettre cet interrupteur (A) sur la position

MARCHE pour avoir une alimentation

automatique au manocontacteur et sur la

position ARRET pour la raise hors tension

& la fin de chaque utilisation.

MANOCONTACTEUR

Le manocontacteur demarre automatiquement ie moteur Iorsque la

pression du reservoir d'air chute sous ta pression d'enclenchement

reglee en usine, tl arr_te le moteur iorsqae la pression da reservoir

d'air atteint la pression de d_¢lenchement regt6e en usine.

26

Page 27

SOUPAPE DE SURETE

Si le manocontacteur ne met pas hers tension le compresseur

d'air a sa pression de declenchement r6glee, la soupape de sOrete

(G) serf de protection contre une pression etevee en altant a la

pression r6glee en usine (pression legerement plus elev6e que te

regIage de declenchement du manocentacteur).

CLAPET

Lorsque le compresseur d'air fonctionne, le clapet (F) est ouvert,

ce qui permet & Fair comprime d'entrer dans le reservoir d'air.

Lorsqae le compresseur d'air atteint ta pression de declenchement,

te clapet se ferme, ce qui permet & la pression d'air de rester dans

Ie reservoir d'air.

MANOMETRE DE RI_SERVOIR

Le manometre de reservoir (B) indique ia

pression d'air de reserve dans le

reservoir.

MANOMETRE DE PRISE DE COURANT

Le manometre de prise (C} indique la

pressien d'air disponible du c6te de ta

prise du regulateur. Cette pression est

contr61ee par le regulateur et est toujours inferieure oa egale a la

pression du reservoir.

REGULATEUR

Le regutatear (D) contr61e Ia pression d'air montree sur le

manemetre de prise. Tournez la poignee du regulateur en sens

horaire pour augmenter la pressien et en sens antihoraire pour ta

diminuer.

CORPS DE BRANCHEMENT RAPIDE UNIVERSELS

Le corps de branchement rapide universel (E) accepte les trois

styIes de prises de branchement rapide tes plus populaires:

industrietle, automobile, et ARO. It suffit tout simplement d'appuyer

une seule feis pour connecter le corps de branchement rapide a la

prise. Les deux corps de branchement rapide permettent d'utiliser

deux outils en m_.me temps.

ROBINET DE PURGE

Le rebinet de purge (H) se treuve & ta base du

reservoir d'air et est utilise pour vidanger la

condensation a la fin de chaque atilisation.

Consulter _echapitre Vidange du r&servoir sous

Entretien

SYSTEME DE REFROIDISSEMENT

Ce compresseur contient un systeme de refroidissement de

conception evoluee. II est tout a fait normal pour ce ventilateur de

souffler de Fair par les orifices d'aeration en grandes quantites. Le

systeme de reffoidissement fenctionne Iorsque Fair est expuis&

POMPE DE COMPRESSEUR D'AIR

La pompe compresse Fair dans ie reservoir d'air. I'air de travail

n'est pas disponible avant que ie compresseur ait augmente la

pression du reservoir d'air au-dessas de ce qui est requis a la

sortie d'air.

PROTECTEUR DE SURCHARGE DU MOTEUR

Le moteur est muni d'un protecteur de surcharge thermique de

remise a zero automatique. Si le moteur surchauffe, peu importe Ia

raison, le protecteur de surcharge met te moteur hers tension, tl faut

donner au moteur le temps de refroidir avant de le redemarrer. Le

compresseur se remet automatiquement sous tension apres que le

moteur se soit refroidi.

27

Page 28

INSTALLATION

Assemblage

RACCORDEMENT DES TUYAUX

_.AVERTISSEMENT: Risque d'utilisatien dangereuse. Saisir

refinement /e tuyau en main /ors du raecerdement eu de la

d&connexien pour emp@eher un a-coup du tuyau.

1. S'assurer que le manometre regute indique 0 PSI (0 kPa).

2. Saisir le tuyau au niveau de ta prise de branchement rapide

et enfoncer la prise darts le corps de branchement rapide (E). Le

coupteur se mettra en place.

3. Saisir le tuyau et tirer pour s'assurer que te coupleur est bien en

place.

DECONNEXION DES TUYAUX

_,AVERTISSEMENT: Risque d'utiliaatien dangereuee. Saiair

refinement le tuyau en main tore du raccordement eu de la

d&cennexion pour emp6eher un a-coup du tuyau.

1 S'assurer que le manometre regut6 indique 0 PSI (0 kPa).

2. Retirer le coupteur du corps de branchement rapide pour

degager Ia prise de branchement rapide du tuyau.

Directives relatives #1la rnise a la terre

_,AVERTISSEMENT : Risque de choc &lectrique. Au cas ob un

court-circuit ee produirait, la raise b la terre r&duit le risque de chec

&lectrique en foumiseant un fil d'&chappement pour le courant

&lectrique. Le cempresseur d'air dolt 6tre eorrectement mie b la

terre.

Le compresseur d'air portatif est muni d'un cordon ayant un fil de

mise a terre avec une prise de mise a la terre.

1. Le cordon qui se fixe et se branche (J)

avec cet appareil contient une goupille

de mise a la terre (L). Cette prise DOlT

&tre utilis6eavec une prise correctement

raise &ta terre (K).

IMPORTANT: la prise utilis&e dolt 6tre

installee et mise & la terre en fonction de

tousles codes et de toutes les ordonnances a t'echelle locale.

2. Assurez-vous que la prise utilisee a la m_me configuration que

ia fiche raise a la terre. N'UTILISEZ PAS UN ADAPTATEUR

3. tnspectez la fiche et le cordon avant chaque utilisation. Ne les

utilisez pas s'ils presentent des signes de dommages.

4. Si ces directives sur ta mise & la terre ne sont pas entierement

comprises, ou si vous n'&tes pas certain que le compresseur a

correctement et6 mis & la terre, faites verifier t'installation par un

&lectricien qualifi&

&DANGER: Risque de choc &lectrique. UNE MtSE A LA TERRE

INADEQUATE PEUT PROVOQUER UN CHOC ELECTRIQUE.

Ne modifiez pas la fiche fournie. Si elle ne s'inc&re pas dans la

prise dieponible, une prise ad&quate dolt _tre install&e par un

&lectricien qualifi&

Les r¶tions au cordon eu b ta fiche DOtVENT &tre faites par

un &lectricien qualifi&

Rallonges

Si une rallonge doit _tre utilisee, s'assurer :

• d'utiliser une rallonge a trois ills, munie d'une fiche a trois lames

avec raise a la terre et une prise de courant a trois fentes qui

accepte Ia fiche de Ia railonge;

• qu'elle est en bon &tat;

• qu'elle n'excede pas 50 pi (15,2 m);

• que les ills sont d'un calibre minimum de 12 AWG. (La grosseur

28

Page 29

du fil augmente comme le numero de calibre diminue. Les fils de

calibre 10 AWG et 8 AWG peuvent egalement 6tre utilises. NE

PAS UTILISER UN FIL DE CALIBRE 14 OU 16 AWG.)

MISE EN GARDE : L'utilisation d'une rallonge produira une chute

de tension qui entreinera une perte de puissance au moteur ainsi

qu'une surchauffe. Au lieu d'uti/iser une ra/lenge &leetdque, aug-

mentez p/ut6t /a Iongueur du boyau d'ah" en cennectant un autre

beyau _ I'extr&mit&. Cennectez des boyaux supp/#mentaires au

besoin.

Protection de la tension et du circuBt

Consulter tes Exigences en matiere de tension et de circuit

de derivation minimales sous Fiche technique de la pompe/du

moteu_

_.MISE EN GARDE: Certains compresseurs d'air peuvent

fonctionner sur un circuit de 15 A si les conditions suivantes sent

r&unies.

• IZalimentation en tension doit se conformer au Code electrique

national.

• Le circuit n'est pas ufilise pour aIimenter d'autres besoins en

electricit6.

• Les rallonges doivent se conformer aux specifications.

• Le circuit est equip6 d'un disjoncteur de 15A au minimum

ou d'un fusible a temporisation de 15A. REMARQUE : si te

compresseur est branche a un circuit proteg6 par des fusibles,

utiliser seulement des circuits a temporisation. Les fusibles de

temporisat!on devraient avoir I'inscription <_D >>au Canada et

<<T >>aux E.-U.

Si une des conditions ci-dessus n'est pas satisfaite, ou si le

fonctionnement du compresseur cause des interruptions du

ceurant &lectrique, il peut s'av&rer n&cessaire de faire fonctienner

I'appareil _ partir d'un circuit _, 20 A. II n'est pas n#cessaire de

changer les cordons.

Correpatibilite

REMARQUE : toujeurs utiliser un filtre de cana_isation d'air pour

retirer I'humidite et les vapeurs d'huile Iors de la putvbrisation de

peinture.

Emplacement

Placer le compresseur d'air dans un endroit propre, sec et bien

aer6 a au moins 304,8 mm (12 po) du mur ou d'autres obstructions

qui pourraient intefferer avec le debit d'air. Tenir le compresseur

I'ecart des endroits poussiereux et charges d'emanations. Ces

impuretes pourraient boucher le filtre et tes soupapes d'admission et

s'y agglutiner, nuisant ainsi au ben fonctionnement du compresseur

d'air.

AAVERT/SSEMENT: La pompe de compreseeur d'air et le

d_flecteur ont &t& cengus pour assurer un refroidissement ad&quat.

Les ouvertures d'a_ration sur le compresseur sent n&cessaires

pour garder une temperature de foncfiennement apprepri_e. Ne

placez pas de chiffons ou d'autres contenants sur les ouvertures

ou b proximit_ de eefles-ci.

Placer le compresseur d'air sur ses pieds de caoutchouc sur une

surface plane.

ELECTRIClTI_

Consulter toutes les directives de securit6 avant d'utitiser I'appareiL

Respecter les directives de s6curite du cordon d'atimentation le cas

echeant. Toujours mettre I'interrupteur Marche/Arr_t (A) en position

d'ARRET avant de retirer ta fiche de la prise.

29

Page 30

TRANSPORT

Lors du transport du compresseur d'air dans

un vehicute, une remorque, etc. s'assurer que

te reservoir d'air soit bien purge et que

i'appareit soit bien ancre. Conduire

prudemment pour eviter de basculer I'appareil

dans le vehicule. Un basculement risque

d'endommager te compresseur ou tes pieces

contigues.

LEVAGE

Toujours soulever I'appareit & deux personnes

et utiliser les points de transport (O) recommandes. NE PAS le lever

par la roues ou te deflecteur.

DEPLACEMENT

AMISE EN GARDE: Les roues et la poignee n'offrent pas le

degagement, la stabilite ou I'appui necessaire pour descendre

ou monter des escaiiers ou des marches avec I'appareil. On dolt

soulever I'appareil ou le pousser le long d'une rampe.

1. Pour ce faire, saisir la poignee du compresseur et l'incIiner vers

l'arriere sur ses roues.

_AVERT!SSEMENT : Garder les pieds bien ancres et faire preuve

d'une grande prudence en transportant le compresseur afin d'eviter

de perdre I'equilibre.

2. Une lois le compresseur a I'endroit voulu, I'abaisser ientement

sur le sol. Toujours ranger le compresseur en position verticate

en {'appuyant sur les amortisseurs et les roues.

MODE D'EMPLOI

Liste de vorification de pro.domarrage

(Fig. 1)

1 S'assurer que le commutateur MARCHE/ARRET (A) est en

position d'ARRET.

2. Branchez le cordon d'alimentation dans le bon receptacle de

circuit de derivation Consulter la rubrique Protection de la

tension et du circuit sous Installation

3. S'assurer que le reservoir d'air soit bien purge, consulter la

rubrique Vidange du r_servoir d'air sous Entretien.

4 S'assurer que la soupape de purge (H) soit fermee

5 S'assurer que la soupape de sQrete (G) fonctionne correctement,

consulter la rubrique V_rification de la soupape de sQret_ sous

Entretien.

6. Tourner le bouton du regulateur (D) en sens antihoraire jusqu'a

fermeture complete. S'assurer que le manometre regule indique

OPSt (OkPa).

7. Fixez le tuyau et les accessoires.

_&AVERTISSEMENT: Risque d'eclatement. Trop de pression

d'air cause un risque serieux d'&clatement. V&rifiez la pression

maximum sugg&ree par le fabricant pour les outils pneumatiques

et les accessoires. La preseion de sortie du regulateur ne dolt

jamais depaeser une pression nomina/e maximale.

Regiage inJtiM (Fig. 1)

_,AVERWSSEMENT : Ne pas utiliser cet appareil avant d'avoir lu

et compris le mode d'emploi ainsi que Fintegralit& des directives de

s&curite d'utilisation et d'entretien.

30

Page 31

PROCI_DURE DE RODAGE

&A VERTISSEMENT : Risque de dommages _la propri#t& Respecter

la lettre les directives de rodage ci-dessous pour emp6cher de

graves dommages.

Cette procedure est requise avant que le compresseur d'air soit

mis en service et Iorsque le ctapet ou une pompe de compresseur

complete a et6 remplac&

1. S'assurer que le commutateur MARCHE/ARRET (A) est en

position d'ARRET.

REMARQUE :siIetuyau n'est pas raccorde au corps de branchement

rapide, retirer le coupleur jusqu'a entendre un clic pour emp6cher

I'air de s'echapper par le branchement rapide.

2. Branchez le cordon d'alimentation dans le bon r6ceptacle de

circuit de derivation Consulter la rubrique Protection de la

tension et du circuit sous Installation.

3. Ouvrez le robinet de purge en entier (levier en sens antihoraire)

pour iaisser echapper Fair et empecher une accumulation

de pression d'air dans le reservoir d'air pendant la periode

d'adaptation.

4. Mettre I'interrupteur Marche/Arret en position MARCHE. Le

compresseur demarre.

5. Faites fonctionner le compresseur pendant 15 minutes.

6. Apres 15 minutes, fermez le robinet de purge en Ie faisant

tevier tourner en sens horaire. Le reservoir se remplira pour

d_clencher Ia pression et le moteur s'arr_tera.

7 L'air comprime sera disponib_ejusqu'& utilisation complete de I'air

ou sa purge

PROCEDURES DE FONCTIONNEMENT

Demarrage (Fig. _)

1. Utiliser la Liste de v_rifieatJon de pr_-d_marrage sous Mode

d'emploi.

2. Mettre I'interrupteur Marche/Arret en position MARCHE et hisser

du temps pour I'accumulation de pression du reservoir. Le

moteur s'arrete Iorsque la pression du reservoir atteint la

pression de declenchement.

_kMISE EN GARDE : Risque d'utilisation dangereuse. L'air comprim#

de I'appareil pourrait contenir de Peau condens_e et des brumes

d'huile. Ne pas vaporiser de Fair non filtr_ sur un article que

Phumidite pourrait endommager. Certains outils ou dispositifs

pneumatiques pourraient requ#rir de Pair filtr& Life les directives

pour Ioutil ou le dispositif pneumatique.

3 Regier le regulateur (D) a ia vateur souhaitee. Consulter la

rubrique R_gulateur sous Caract#ristiques

Arr_t (Fig. 1)

1. Mettre I'interrupteur Marche/Arr_t (A) en position d'ARRET.

REMARQUE : si I'utilisation du compresseur est terminee, suivre

tes etapes 2 & 6.

REMARQUE : Iorsque l'appareit est eteint, it est normal d'entendre

un court sifftement quand Fair s'eehappe,

2. Toumer le bouton du regutateur (D) en sens antihoraire jusqu'&

fermeture complete. S'assurer que le manometre regul6 indique 0

PSI (0 kPa).

3. Retirer [e tuyau et I'accessoire.

_,AVERTISSEMENT : Risque d'utilisation dangereuse. Saisir

fermement letuyau en main Iota du raccordement ou de la d_connexion

pour emp_cher un a-coup du tuyau.

31

Page 32

4. Purger le reservoir d'air, consulter la rubrique Purger le r_servoir

d'air sous Entretien. S'assurer que le manometre du reservoir

d'air afflche OPSi (0 kPa).

_.AVERTISSEMENT : Risque d'#clatement. Purger le r_serveir d'air

quotidiennement. L'eau se condensera dans le r_serveir d'air Si

I'eau n'est pes vidang_e, el/e corrodera et affaibfire le r#serveir d'air,

provoquant ainsi un risque de rupture du r_serveir d'ai_

5. Laisser refroidir le compresseur.

6. Nettoyer le compresseur d'air avec un chiffon et te ranger dans un

endroit sQr sans risque de gel.

ENTRETIEN

Suivre les procedures suivantes iors de I'entretien ou des reparations

du compresseur d'air.

1. S'assurer que le cemmutateur Marche/Arr_t est en position

d'ARRET.

2. Debrancher te compresseur d'air.

3. Purger le reservoir d'ain

4 Laisser refroidir le compresseur d'air avant de debuter une

reparation.

REMARGUE : tousles systemes de compression d'air comprennent

des pieces (par ex., huiIe, filtres, separateurs) qui sont regulierement

remplacees. Ces pieces usees pourraient contenir des substances

contrelees et doivent etre mises au rebut conformement aux lois et

reglements municipaux, provinciaux, territoriaux et federaux.

REMARGUE: rioter la position et l'emplacement des pieces au

demontage pour faciliter le remontage subsequent.

REMARGUE : toute reparation non decrite darts cette rubdque devrait

etre executee e un centre de reparation de I'usine DEWALT ou un

centre de reparation agree DEWALT.

Programme d'eretretien

Avant jour ou d_que g

chaque c_aque de 100 annee

utilisation utJlisatio_J heu_es

Verifier ta soupape de sOrete @

Vidanger le reservoir O

Filtre a air O _

Soupapes d'admission et

d'¢chappementde ta pompe du O

compresseur d'ait

1- plus frequemment dans des conditions poussiereuses ou humides

A chaque A

ares t[ailc[_ chaque

Verification de la soupape de s_rete

_AVERTISSEMENT : Risque d'_clatement. Si la soupape de

setter& ne fonctionne pas correctement, fl peut se produire une

surpressurisation, causant ainai la rupture du r&servoir d'air ou une

explosion.

Avant de mettre en marche le compresseur, tirez sur la bague de

la soupape de st_rete pour veus assurer que la soupape fonctionne

tibrement. REMARQUE : il peut etre difficile de tirer sur I'anneau

si la pression du reservoir d'air est a 0 kPa (0 PSi). Si ta soupape

est coincee ou ne fonctionne pas bien, il faut ta remplacer par une

soupape du meme type.

32

Page 33

Vidange du reservoir d'air (Fig. I)

_,AVERTISSEMENT: Risque d'uti/isation dangereuse. Risque

essoci_ au bruit. Les r#servoirs d'air contiennent de Fair sous

haute pression. E-leigner le visage et toutes autres parties du corps

de /'entice de vidange. Porter des lunettes de s&curit# Iors de la

vidange car il y a risque de projection de d_bris au visage. Utiliser

une protection auditive ANSI S'i2.6 ($3.19), car le flux d'air sertant

preduit un sen strident en cours de vidange.

REMARQUE : tousles systemes de compression d'air generent

des condensats qui s'accumulent & an point de vidange (par ex.,

reservoir, fittre, dispositifs de postrefroidissement ou secheur).

Le condensat contient de t'huite labrifiante ou des substances

contrbl6es_ ou les deux et doivent etre elimin6s conformement aux

lois et reglements municipaux, provinciaux, territorisux et fed6raux

1 S'assarer que te commutateur Marche/Arret (A) en position

d'ARRET

2. incliner le cempresseur de sorte que Is soupape de purge

(H) est au point le plus bss (cette position aiders & eliminer

l'humidit6, les salet6s_ etc. des reservoirs d'air).

MISE EN GARDE : Risque de d&gats materiels. _-vacuez I'eau le

r_servoir d'air peut eentenir /'huile et se rouiller qui peut causer des

taches.

3. Deposer an recipient convenable soas la soupape de purge pour

recueillir les residus.

4 Saisir le levier noir de la soupape de purge.

5. Toarner lentement le levier pour purger graduellement I'air da

reservoir.

6 Une fois que le manometre du reservoir affiche 10 PSI

(2751 kPa), tourner completement le tevier en position ouverte.

7. Fermer Is soapape de purge des ta fin de Foperation.

Verification des clients du Edtre d'air

(Fig. 1)

_,AVERTISSEMENT : Surfaces chaudes. Risque de brOlure. Le

postrefroidisseur, la t_te de pompe et les pi#ces contigu_s sent tr#s

chaudes - ne pss les toucher (consulter la rubfique Surfaces chaudes

de la Figure 2). Laisser refroidir te compresseur avant d'effectuer des

r_parations sur I'appareiL

1. S'assurer que ie commutateur Marche/Arr_t (A) en position

d'ARRET.

2. Permettez & t'anite de se refroidir.

3. Enlevez Is couverture de fittre (N) de

la base.

4. Enlevez I'et6ment de la base de filtre.

5. Placez le nouvel el6ment en arriere

dans la base de fiItre. Achetez les

pieces de rechange de votre revendeur

local ou centre commercial autoris&

EmpIoyez tou]ours les pieces de rechange identiques.

6. Couverture instantanee de fiItre pour filtrer la base.

&MISE EN GARDE : Risque d'utilisation dangereuse. Ne pas utiliser

sans te filtre d'admission d'ai_

ACCESSOIRES

Les accessoires recommandes pour votre oatil peuvent 6tre achetes

aupres du distributeur local ou d'un centre de reparation agre& Si vous

avez besoin d'assistance pour troaver an accessoire pour votre outil,

veuitlez contacter DEWALT Industrial Toot Co., 701 East Joppa Road,

Baltimore_ MD 21286, Etats-Unis, composer le 1(800) 4-DEWALT

(1-800-433-9258) ou visiter notre site Web a www.dewalt.com

33

Page 34

&MISE EN GARDE : Eutilisation de tout autre acceseoire non

recommend# avec eet outil pourrait s'av_rer dangereuse. Udliser

uniquement des accessoires de claseement _ga! ou sup_rieur &celui

de la compreseeur d'air.

Information sur les reparations

_uiliez _cueilHr les informations suivan_s pour _us les appe_s au

Service ala c_ien_Ie :

Num6_ du modele Numero de serie

Date et lieu de I'achat

R_,parations

Pour assurer la SECURITE et la FIABILITE du produit, les reparations,

I'entretien et les reglages doivent _tre realises par un centre de

reparation en usine DEWALT, un centre de reparation agr&e DEWALT

ou par d'autres techniciens qualifies. Toujours utiliser des pieces de

rechange identiques.

Garantie complete d'un (1) an

Les outHs indu_riels de service intens_ de DEWALT sont ga_ntis

pour une periode de un (1) an a partir de la date d'achat. DeWALT

reparera gratuitement toutes defectuosit6s provoquees par un defaut

de materiel ou de fabrication. Pour des renseignements relatifs aux

reparations sous garantie, composer le 1-8004-DEWALT. Cette

garantie ne s'applique pas aux accessoires ni aux dommages causes

par des reparations reaIisees ou tentees par des tiers. Cette garantie

vous accorde des droits legaux specifiques et ilest possible que vous

ayez d'autres droits qui varient d'un Etat ou d'une province a i'autre.

AMERIQUE LATINE : cette garantie ne s'apptique pas aux produits

vendus en Amedque latine. Pour ceux-ci veuillez consulter les

informations relatives ala garantie specifique presente dans

i'emballage appeler I'entreprise locale ou consulter le site Web pour

ies informations relatives a cette garantie.

REMPLACEMENT GRATUIT DES I_TIQUETTES

D'AVERTISSEMENT : si les etiquettes d'avertissement deviennent

illisibles ou sont manquantes, composer le 1-800-4-DEWALT pour en

obtenir {e remplacement gratuit.

--T--

34

Page 35

GLOSSAIRE

CFM : pied cube par minute.

SCFM : pied cube par minute (standard), une unite de mesure du souMage.

PSI : tivres par pouce carre, une unite de mesure de pressien.

kPa (kilopaseal) : unite de mesure de pressien. 1 kiiopascal est egal a 1000 pascals.

Code de certifications :tes produits qui affichent un ou ptusieurs des etampes suivantes : UL, CUL ETL, CETL ont et6 evalu6s pas

un laboratoire de securit6 independant sanctionne par I'OSHA et qui repond aux normes en vigueur des Underwriters Laboratories en

ce qui a trait a ia securit&

Pression d'enclenchement : iorsque ie moteur est eteint, la pression du reservoir d'air chute quand vous continuez a utiliser votre

accessoire. Lorsque la pression du reservoir chute pour atteindre un niveau bas, le moteur se remet en marche automatiquement. La

basse pression a iaquelle ie moteur se remet en marche automatiquement est appeIee presaion d'enctenchement.

Pression de d6clenehement : Iorsqu'un compresseur d'air est mis sous tension et se met & fonctionner, la pression d'air dans le

reservoir d'air commence a s'accumuIer. Une haute pression s'accumuIe avant que le moteur se mette automatiquement hors tension

en protegeant votre reservoir d'air d'une pression superieure a sa capacit& La haute pression & laquelle {e moteur se met hors tension

est appelee pression de declenchement.

Circuit de d_rivation : Ie circuit qui transporte de 1'61ectricite du panneau electrique a la prise.

Cycle de travail : cette pompe du compresseur d'air peut fonctionner en continu. Cependant, pour prolonger la duree de vie de votre

compresseur: il est recommande de maintenir un cycle de travail de 50 % a 75 % en moyenne, donc que la pomp du compresseur ne

doit pas fonctionner plus de 30 a 45 minutes par heure.

35

Page 36

Guide de depannage

Cette section enumere les defaillances les plus communes, leurs causes et tes mesures correctives. Eoperateur ou te personneI d'entretien

peut executer certaines mesures correctives_ d'autres exigent I'assistance d'un technicien DEWALT quatifie ou du distributeur.

Probleme Code

Pression excessive dans le reservoir d'air - lasoupape de sQrete claque ......................................... 1_2

Fuites d'air .............................................................................................................................................. 3

Fuites d'air dans le reservoir d'air ou dans ies soudures du reservoir d'air ........................................ 4

Fuites d'air entre la tete et la plaque porte-soupapes .......................................................................... 5

Fuites d'air a la soupape de sQrete........................................................................................................ 6

Ciiquetis ................................................................................................................................................... 6

Le reieve de pression sur le manometre reglemente chute Iorsque I'accesseire est utilise ..............7

Le compresseur ne fournit pas la quantite d'air requise pour le fonctionnement d'accessoires ........ 8,9,10,11,12

Fuite d'air continuelle au bouton du regulateur ..................................................................................... 13

Le regulateur ne parvient pas &fermer la sortie d'air ........................................................................... 13

Codes de depannage

CODE CAUSE POSSIBLE SOLUTION POSSIBLE

2 La pression de I'interrupLeur de declenchement est trop Communiqueravecuncentredereparationenusinede

e.levee

36

Page 37

CODE CAUSE POSSIBLE SOLUTION POSSIBLE

5 Joints d'etanch6it6 fuyants Commaniqaer avec un centre de reparation en asine de

DEWALT ou un centre de reparation agr6e DEWALT.

Le regulateur n'est pas regl6 correctement pour I'accessoire

utilise

II est normal que la pression chute Iorsqu'un accessoi-

re est utilise, ajuster le r_gulateur comme indique sous

Caract#ristiques si ta pression chute trop.

REMARQUE : Regter la pression regulee sous des conditions

de travail avec {'utilisation de I'accessoire.

9 Le compresseur ne dispose pas de la capacite adequate Verifier tes exigences d'air de I'accessoire. Si eiles sent supe-

pour I'utilisation d'accessoires rieares au CFM ou & la pression fournie par le compressear

d'air, un compresseur de plus grande capacite est requis pour

I'utilisation de I'accessoire.

11 Clapet obstrae Retirer, nettoyer ou remplacer.

_ rrezi_ ra

13 Le regatateur est endommage Le remplacer.

37

Page 38

Cornpresor de aire D55168

A. tnterruptor de encendido/

apagado

B. Man6metro del tanque de aire

C. Man6metro regulado

D. Regulador de presi6n

E. Conectores rapidos

E Vg_lvulade control

G. Valvula de seguridad

H. Wlvula de drenaje del tanque

de aire

I. Enroilacabte electrico

Especificaciones de la Bomba y el Motor

Vottaje:12OV_una sola fase

Requisito minimo para el circuito de derivaci6n: 15 A

Fusible de tipo acci6n retardada

Especificaciones

MODELO D55168

PESO 39,92 kg (88 libras)

ALTURA 1060.5 mm (4175")

ANCHO 482,6 mm (19,0")

LONGITUD 539,8 mm (21,25")

CAPAClDAD DEL TANQUE DE AIRE 56,8 (15 gal6n)

(LITROS)

PRESI6N DE ARRANQUE APROXIMADA 1103,2 kPa (160 PSI)

PRESI6N DE CORTE APROX. 1379,0 kPa (200 PSI)

SCFM A 100 PSI (689,5 kPa_ 5,_

FIG. 1

B

C

H

38

Page 39

" Def'mitions : Iignes directrices en

rnatiere de securite

Las siguientes definiciones describen el nivel de gravedad de cada

advertencia. Lea el manual y preste atenci6n a estos s/mbofos.

_PELIGRO: indiea una situaciSn de peligro inminente que, si no

se evita, provocar#_ la muerte o lesiones graves.

_ADVERTENCIA: lndica una situaci6n de petigro potencial que,

si no se evita, podria provocar la muerte o lesiones graves

IJ_PRECAUCI(_N: tndica una situaci6n de peligro potential que, si

no se evita, puede provocar lesiones leves o moderadas.

PRECAUCION: Util/zado sin el sfmbolo de alerta de seguridad

indfoa una situaciSn de peligro potencial que, ai no se evita, puede

provocar danes en lapropiedad.

Instrucciones de seguridad importantes

ADVERTENCIA: No opere esta unidad hasta que haya /e/do y com-

prendido este manual de fostrucciones de seguridad, operaeiSn y

mantenimiento.

_,ADVERTENCIA: Algunas particulas originadas a! /ijar, aserrar,

amolar, taladrar y realizar otras actividades de construcoi6n eontienen

produetos qu/mieos reconocidos per el Estado de California come

causantes de c#ncet; defectos de nacimiento u otros problemas repro-

ductivos. Algunos ejemp/os de estos preductos quimicos son:

• el plomo de las pinturas de base pfomo

• la silice cristalfoa de ladrillos, eemento y otros produetos de mam-

posteria,

• el ars#nico y creme de madera con tratamiento quimico.

El riesgo derivado de estas exposiciones varia segbn la frecuencia

con la que se realfoe este tipo de trabajo. Para reducir la exposici6n

a estos productos qu/micos: trabaje en _reas bien ventiladas y con

equipos de seguridad aprobados, use siempre mascarilla facial o de

respiraciSn adecuada y aprobada par OSHA/MSHA/NtOSH cuando

use este dpo de herramientas.

Cuando se utifizan herramientas neumaticas, siempre se deben res-

petar lasprecauciones de aeguridad para reducir el riesgo delesionea

peraona/e&

i_4DVERTENCIA: Este producto contiene sustancias quimicas,

incluido el pfomo, reconocidas loot el Estado de California come

eausantes de cancer, defectos de nacimien[o u otros problemas

reproductivos. Lavese las manes despues de udlizarfo.

GUARDE ESTAS INSTRUCCIONES

_,PELIGRO: Riesgo de explosion o incendio

i.,QUE PUEDE SUCEDER? come EVITARLO

• Si las chispas electricas

del compresor entran en

contacto con vapores

inflamabtes, pueden

encenderse, provocando un

incendio o unaexplosi6n

• Si se pulvedzan materiales

inflamables, ubique el

compresor al menos a

6,1 m (20 pies) del &rea de

pulverizaci6n Se puede

necesitar manguera adicional

• Guarde los materiales

inflamables en lugar seguro

lejos del compresor.

39

Page 40

,_,PELIGRO: RIESGO RESPtRATORIO (ASFIXIA)

_.QUt5PUEDE SUCEDER? come EVITARLO

• El funcionamiento sin

atencJ6nde es_epreducto

podr[a provocar lesiones

personales o da_os a la

prepiedad. Para disminuir

el riesgo de incendio, no

permita que el compresor

funcione sin que alguien to

controle

Permanezca siempre

contrelando el producto

cuando esta en

funcionamiento