Page 1

003

_w

CC

UJLU

0303

<

IjJ "LLI

rmJ

..O

o

Z_

wO

I,-pr

Wj

_w

ace

<<

.03

,_ D

i-- w

zc3

rr03

5<V--

NO

D--SD

rr'O N

_z>__z

@

NOTE: Air tanks, compressors and similar

equipment used to inflate tires can fill small

tires very rapidly. Adjust pressure regulator on

air supply to no more than the rating of the

tire pressure. Add air in small increments and

frequently use the tire gauge to prevent over

inflation.

_WARNING: RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN HOW TO PREVENT iT

" Your air compress0r is powered by . Never operate the compressor outdoors when

electricity. Like any other e!ectdca!ly it iSraining orin wet condition&

Powered device, If it !shot used proPerlY • Never operate compressor with protective

it may cause electric shock: Covers rem0ved or damaged.

• Repairs attempted by unqualified • Any electrical wiring or repairs required on this

personnel can result in serious injury or product should be performed by a DEWALT

death by electrocution, factory service center or a DEWALTauthorized

service center in accordance with national

and local electrical codes.

,, Electrical Grounding: Failureto provide Make certain that the electrical circuit to

adequate grounding to this product which the compressor iS connected provides

could result in serious injury O_death proper electrical grounding, correct voltage

from electrocution. See Grounding and adequate fuse protection,

Instructions under Installation. ......................................................................................

_AWARNING: RISK FROM FLYING OBJECTS

L ,.c ._

O O

Z

O

-J O

m

O

o .c

///

Bm

<.,-

Z

z --'i -

F-. a

O

N EE

000

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

(DEC10) Part No. N100202 D55146 Copyright © 2007, 2008, 2009, 2010 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the "D"

shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-

shaped humps on the surface of the tool.

/t

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read

the manual and pay attention to these symbols.

_J_ANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

_,WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

,&CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided,

may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258}

Important Safety Instructions

WARNING: Do not operate this unit until you read this instruction manual for safety,

operation and maintenance instructions.

_WARNING: This product contains chemicals known to the State of Cafifornia to cause

cancer, and birth defects or other reproductive harm. Wash hands after handling.

AWARNING: Some dust contains chemicals known to the State of Cafifornia to cause

cancer, birth defects or other reproductive harm such as asbestos and lead in lead based

paint.

SAVE THESE INSTRUCTION

.&DANGER." RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

_ It iS normal for e!ectdca! contacts with- _ Always operate the c0mpressor in a well

in the motor and pressure switch to ventilated area free of combustible materi_

spark, als, gas01ine or solvent vaporsl

• If electrical sparks from compressor • If spraying flammable materials, locate com-

come into contact with flammable pressor at least 20' (6.1 m) away from spray

vapors, they may ignite, causing fire or area. An additional length of hose may be

explosion, require&

Store flammable materials in a secure loca-

Restricting any ofthe compressor Veto- Never p!ace objects against or on top of

ti!at!on openings will caus e serious compressor pump,

overheating and could cause fire: • Operate c0mpressor in an open area at least

• Unattended operation of this product • Always remain in attendance with the prod-

could result in personal injury or prop- uct when it is operating.

erty damage. To reduce the risk of fire, • Always turn off and unplug unit when not in

do not allow the compressor to operate use.

unattended.

_ _DANGER: RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air directly from your ,, Never use air obtained directly from the com-

compressor is safe for breathing, press0r to supply air for human consumption.

The air stream may contain carbon mon- The c0mpressor isnot equipped with suitable

oxide, tox!c vap0rs, or solid particles filters and inqine safety equipment f0r human

from the air tank. Breathing these con-consumption.

taminants can caus e seri0us injury or

death:

• Exposure to chemicals in dust created

by power sanding, sawing, grinding,

drilling, and other construction activi-

ties may be harmful.

• Sprayed materials such as paint, paint

solvents, paint remover, insecticides,

weed killers, may contain harmful

vapors and poisons.

_WARNING: RISK OF BURSTING

Air Tank: On February 26, 2002, the U;S. Consumer Product Safety Commission published

Release # 02-108 concerning air c0mpressor tank safety:

Air compressor receiver tanks do not have an infinite !ife; Tank life is dependent uPOnseveral

factors, some of which include operating conditions, ambient conditions, proper instal!a-

tons field modifications; and the level of maintenancel The exact effect of these factors on

air receiver life is difficult to Predict.

Ifproper maintenance procedures are not followed, interna! corrosion t ° the inner wa!! of the

air receiver tank can cause the air tank to unexpectedly rupture allowing pressurized air to

sudden!y and forcefully escape;p0sing risk of injury to

Your compressor air tank must be removed from service by the end of the year shown on

your tank warning label.

The fo!!owing conditions could !ead to a weakening of the air tank, and result in a vio!ent air

tank explosion:

• Failure to properly drain condensed • Drain air tank daily or after each use. If air tank

• Unauthorized modifications to the safety • The air tank is designed to withstand specific

Attachments&accessories:

_' ExCeeding the preSsure rating of Follow the equipment manufacturers

Sories, tires, and other inflatables can maximum a!!owab!e pressure rating of

Tires:

WHAT CAN HAPPEN HOW TO PREVENT IT

water from air tank, causing rust and develops a leak, replace it immediately with a

thinning of the steel air tank. new air tank or replace the entire compressor.

Modifications or attempted repairs to the _ Neverdri!linto_weld,ormakeanymodifications

airtank, to the ai_ tank or ts attachments. Never

valve or any other components which operating pressures. Never make adjustments

control air tank pressure, or parts substitutions to alter the factory set

tools, spray guns, air operated acces_ recommendation and never exceed the

causethem to exp!ode or fly apart, and attachmentsl Never use compressor to

could result in serious injury, inflate small :!ow pressure objects such as

Over inflation of tires could result in • Use a tire pressure gauge to check the tires

serious injury and property damage, pressure before each use and while inflating

tion away from compressor.

12 (3015cm) away from any wa!l or 0bstruc-

tion that would restrict the flow of fresh air to

the venti!ati0n 0peningSl

, operatec0mpress0r naclean dry well ven_

t!lated areal D0 not operate Unit indo0rs or in

any confined areal

Work in an area with good cross ventilation.

Read and follow the safety instructions pro-

vided on the label or safety data sheets for

the materials you are spraying. Always use

certified safety equipment: NIOSH/OSHA

respiratory protection or properly fitting face

mask designed for use with your specific

application.

attempt to rePair a damaged or leaking air

tank: Rep!ace with a new air tank:

operating pressures.

chi!dren,s toys, footba!!s, basketba!!s, etc,

tires; see the tire sidewall for the correct tire

pressure.

WHAT CAN HAPPEN

• The compressed air stream can cause

soft tissue damage to exposed skin

and can propel dirt, chips, loose par-

ticles, and small objects at high speed,

resulting inproperty damage or personal

injury.

_ _WARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

Touching exposed metal such asthe Never touch any exposed metal parts on

compressor head, engine head, engine compressor during or immediately after

exhaust or outlet tubes, can result in operation. Compressor will remain hot for

serious burns: several minutes after operation.

__ _WARNING: RISK FROM MOViNG PARTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Moving parts such as the pulley, fly- • Never operate the compressor with guards or

wheel, and belt can cause serious injury covers which are damaged or removed.

if they come into contact with you or • Keep your hair, clothing, and gloves away

your clothing, from moving parts. Loose clothes, jewelry, or

. Attempting to operate compressor with • Any repairs required on this product should

damaged or missing parts or attempt, be performed bya DEWALT factory service

ing to repair compressor with protective center or a DEWALTauthorized service center.

shrouds removed can exPose you to

moving parts and can result in serious

injury.

_ AWARNING: RiSK OF UNSAFE OPERATION

WHAT CAN HAPPEN

Unsafe operation of your air compres-

sor could lead to serious injury or death

to you or others.

_j_WARNING:

WHAT CAN HAPPEN

A portab!e €ompreSsor can fa!! from • AlwaYs operate compressor in a stable

a tab!e, workbench, or r0of causing secure position to prevent accidental move,

damage to the compressor and could ment of the unit. Never operate compressor

result in seri0us injury or death tothe on a roof 0r other elevated position. Use

operator, additional air hose to reach high locations.

_ J_WARNING: RISK OF INJURY FROM LIFTING

WHAT CAN HAPPEN

• Serious injury can result from attempting

to lift too heavy an object.

_WARNING: RISK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT iT

Under some conditions and duration of _ Always wear proper hearing protection during

use, n0ise from th!s product may con- usei

tribute to hearing loss: ........

• Always wear certified safety equipment: ANSi

Z87.1 eye protection (CAN/CSA Z94.3) with

side shields when using the compressor.

• Never point any nozzle or sprayer toward any

part of the body or at other people or animals.

• Always turn the compressor off and bleed

pressure from the air hose and air tank before

attempting maintenance, attaching tools or

accessories.

Do not reach around protective shrouds Or

attempt maintenance until unit has been

allowed to cool.

long hair can be caught in moving parts.

Air vents may cover moving parts and should

be avoided as well.

• Review and understand all instructions and

warnings in this manual.

• Become familiar with the operation and con-

trols of the air compressor.

• Keep operating area clear of all persons,

pets, and obstacles.

• Keep children away from the air compressor

at all times.

• Do not operate the product when fatigued or

under the influence of alcohol or drugs. Stay

alert at all times.

• Never defeat the safety features of this prod-

uct.

• Equip area of operation with a fire extin-

guisher.

o

Do not operate machine with missing, bro-

ken, or unauthorized parts.

o

Never stand on the compressor.

RISK OF FALLING

• The compressor is too heavy to be lifted by

one person. Obtain assistance from others

before lifting.

HOW TO PREVENT IT

HOW TO PREVENT IT

HOW TO PREVENT iT

HOW TO PREVENT IT

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

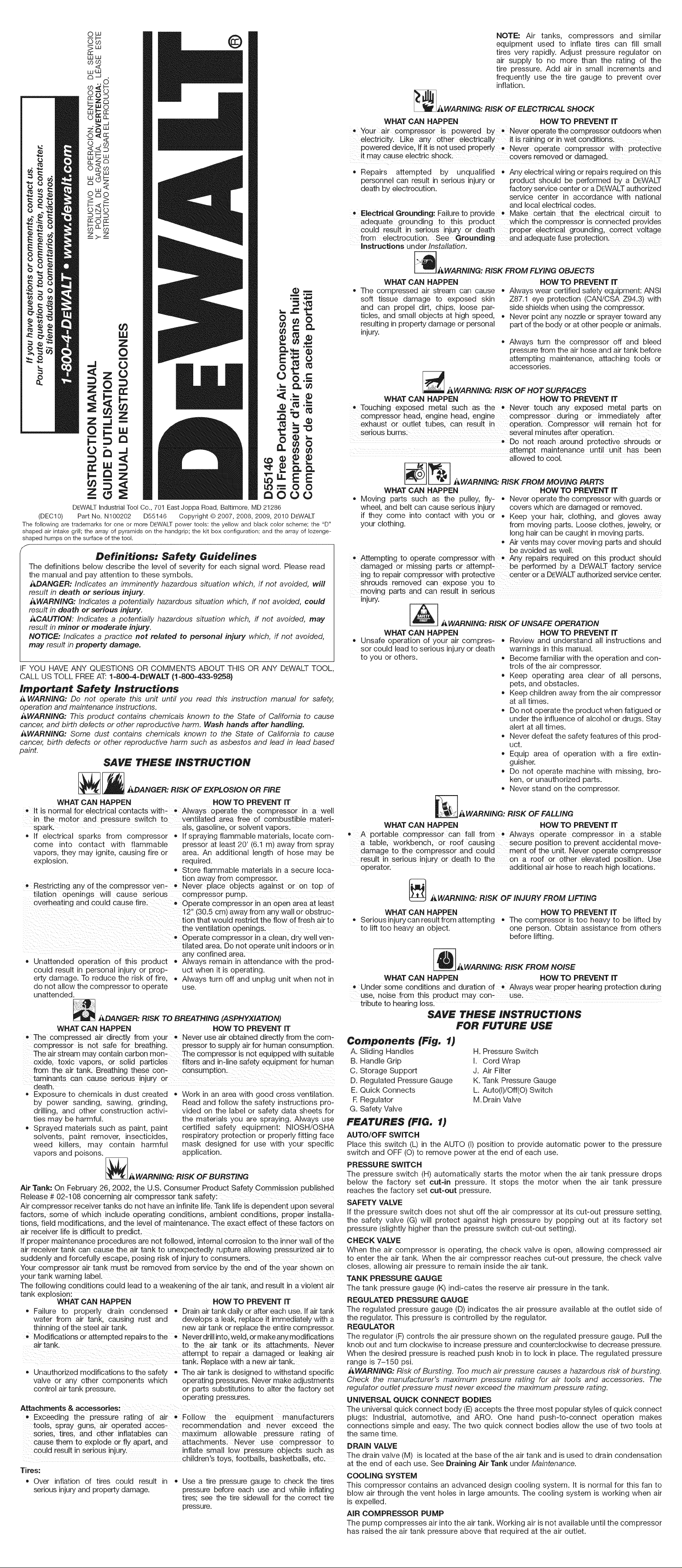

Components (Fig. 1)

A Sliding Handles

B. Handle Grip

C. Storage Support

D. Regulated Pressure Gauge

E. Quick Connects

F. Regulator

G. Safety Valve

H. Pressure Switch

I. Cord Wrap

J. Air Filter

K. Tank Pressure Gauge

L. Auto(I)/Off(O) Switch

M. Drain Valve

FEATURES (FIG. 1)

AUTO/OFF SWITCH

Place this switch (L) in the AUTO (I) position to provide automatic power to the pressure

switch and OFF (O) to remove power at the end of each use.

PRESSURE SWITCH

The pressure switch (H) automatically starts the motor when the air tank pressure drops

below the factory set cut-in pressure. It stops the motor when the air tank pressure

reaches the factory set cut-out pressure.

SAFETY VALVE

If the pressure switch does not shut off the air compressor at its cut-out pressure setting,

the safety valve (G) will protect against high pressure by popping out at its factory set

pressure (slightly higher than the pressure switch cut-out setting).

CHECK VALVE

When the air compressor is operating, the check valve is open, allowing compressed air

to enter the air tank. When the air compressor reaches cut-out pressure, the check valve

closes, allowing air pressure to remain inside the air tank.

TANK PRESSURE GAUGE

The tank pressure gauge (K) indi-cates the reserve air pressure in the tank.

REGULATED PRESSURE GAUGE

The regulated pressure gauge (D) indicates the air pressure available at the outlet side of

the regulator. This pressure is controlled by the regulator.

REGULATOR

The regulator (F) controls the air pressure shown on the regulated pressure gauge. Pull the

knob out and turn clockwise to increase pressure and counterclockwise to decrease pressure.

When the desired pressure is reached push knob in to lock in place. The regulated pressure

range is 7-150 psi.

AWARNING: Risk of Bursting. Too much air pressure causes a hazardous risk of bursting.

Check the manufacturer's maximum pressure rating for air tools and accessories. The

regulator outlet pressure must never exceed the maximum pressure rating.

UNIVERSAL QUICK CONNECT BODIES

The universal quick connect body (E) accepts the three most popular styles of quick connect

plugs: industrial, automotive, and ARC. One hand push-to-connect operation makes

connections simple and easy. The two quick connect bodies allow the use of two tools at

the same time.

DRAIN VALVE

The drain valve (M) is located at the base of the air tank and is used to drain condensation

at the end of each use. See Draining Air Tank under Maintenance.

COOLING SYSTEM

This compressor contains an advanced design cooling system. It is normal for this fan to

blow air through the vent holes in large amounts. The cooling system is working when air

is expelled.

AIR COMPRESSOR PUMP

The pump compresses air into the air tank. Working air is not available until the compressor

has raised the air tank pressure above that required at the air outlet.

Page 2

AIRINTAKEFILTER

Thefilter(J)isdesignedtocleanairenteringthepump.Toensurethepumpcontinuallyreceives

aclean,cool,anddryairsupplythefiltermustalwaysbecleanandthefilterintakemustbefree

fromobstructions.

MOTOROVERLOADPROTECTOR

Themotorhasa thermaloverloadprotector.If themotoroverheatsforanyreason,the

overloadprotectorwillshutoffthemotor.Themotormustbeallowedtocooldownbefore

restarting.Torestart:

1.SettheAuto/Offlever(L)toOFF and unplug unit.

2. Allow the motor to cool.

3. Plug the power cord into the correct branch circuit receptacle.

4. Set the Auto/Off lever to AUTO position.

INSTALLATION

Assembly (Fig. 1)

iNSTALLING HOSES

_WARNING: Risk of unsafe operation. Firmly grasp hose in hand when installing or

disconnecting to prevent hose whip.

1. Ensure regulated pressure gauge reads 0 psi.

2. Grasp the hose at the quick connect plug and push the plug into the quick connect

body (E). Coupler will snap into place.

3. Grasp the hose and pull to ensure coupler is seated.

DISCONNECTING HOSES

,&WARNING: Risk of unsafe operation. Firmly grasp hose in hand when installing or

disconnecting to prevent hose whip.

1. Ensure regulated pressure gauge reads 0 psi.

2. Push coupler on quick connect body back to release quick connect plug on hose.

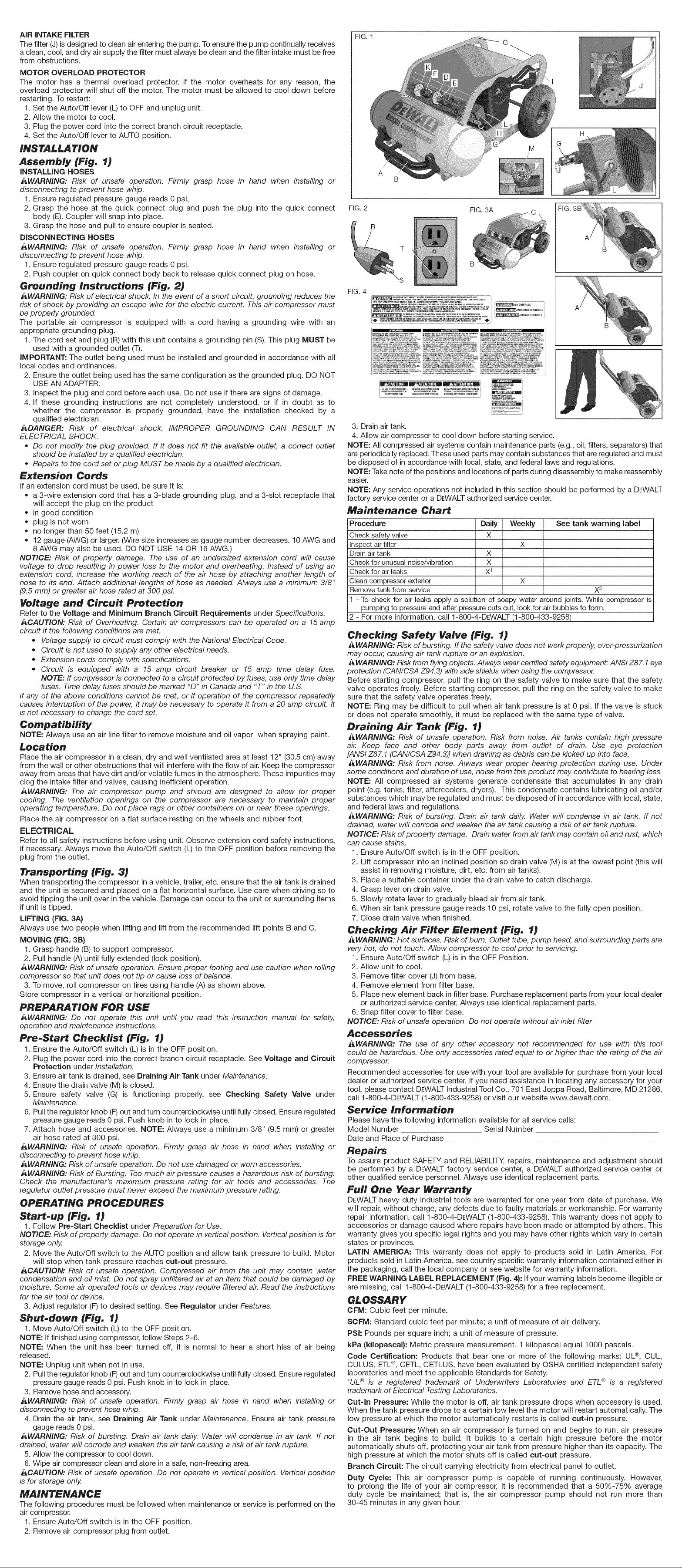

Grounding Instructions (Fig. 2)

`&WARNING: Risk of electrical shock. In the event of a short circuit, grounding reduces the

risk of shock by providing an escape wire for the electric current. This air compressor must

be properly grounded.

The portable air compressor is equipped with a cord having a grounding wire with an

appropriate grounding plug.

1. The cord set and plug (R) with this unit contains a grounding pin (S).This plug MUST be

used with a grounded outlet ([).

IMPORTANT: The outlet being used must be installed and grounded in accordance with all

local codes and ordinances.

2. Ensure the outlet being used has the same configuration as the grounded plug. DO NOT

USE AN ADAPTER.

3. Inspect the plug and cord before each use. Do not use if there are signs of damage.

4. If these grounding instructions are not completely understood, or if in doubt as to

whether the compressor is properly grounded, have the installation checked by a

qualified electrician.

ADANGER: Risk of electrical shock. IMPROPER GROUNDING CAN RESULT IN

ELECTRICAL SHOCK.

• Do not modify the plug provided. If it does not fit the available outlet, a correct outlet

should be installed by a qualified electrician.

Repairs to the cord set or plug MUST be made by a qualified electrician.

Extension Cords

If an extension cord must be used, be sure it is:

• a 3-wire extension cord that has a 3-blade grounding plug, and a 3-slot receptacle that

will accept the plug on the product

• in good condition

• plug is not worn

• no longer than 50 feet (15.2 m)

12 gauge (AWG) or larger. (Wire size increases as gauge number decreases. 10 AWG and

8 AWG may also be used. DO NOT USE 14 OR 16 AWG.)

NOTICE: Risk of property damage. The use of an undersized extension cord will cause

voltage to drop resulting in power loss to the motor and overheating. Instead of using an

extension cord, increase the working reach of the air hose by attaching another length of

hose to its end. Attach additional lengths of hose as needed. Always use a minimum 3/8"

(9.5 ram) or greater air hose rated at 300 psi.

Voltage and Circuit Protection

Refer to the Voltage and Minimum Branch Circuit Requirements under Specifications.

ACAUTION: Risk of Overheating. Certain air compressors can be operated on a 15 amp

circuit if the following conditions are met.

= Voltage supply to circuit must comply with the National Electrical Code.

= Circuit is not used to supply any other electrical needs.

= Extension cords comply with specifications.

= Circuit is equipped with a 15 amp circuit breaker or 15 amp time delay fuse.

NOTE: If compressor is connected to a circuit protected by fuses, use only time delay

fuses. Time delay fuses should be marked "D" in Canada and "T" in the U.S.

If any of the above conditions cannot be met, or if operation of the compressor repeatedly

causes interruption of the power, it may be necessary to operate it from a 20 amp circuit. It

is not necessary to change the cord set.

Compatibility

NOTE: Always use an air line filter to remove moisture and oil vapor when spraying paint.

Location

Place the air compressor in a clean, dry and well ventilated area at least 12" (30.5 cm) away

from the wall or other obstructions that will interfere with the flow of air. Keep the compressor

away from areas that have dirt and/or volatile fumes in the atmosphere. These impurities may

clog the intake filter and valves, causing inefficient operation.

`&WARNING: The air compressor pump and shroud are designed to allow for proper

cooling. The ventilation openings on the compressor are necessary to maintain proper

operating temperature. Do not place rags or other containers on or near these openings.

Place the air compressor on a flat surface resting on the wheels and rubber foot.

ELECTRICAL

Refer to all safety instructions before using unit. Observe extension cord safety instructions,

if necessary. Always move the Auto/Off switch (L) to the OFF position before removing the

plug from the outlet.

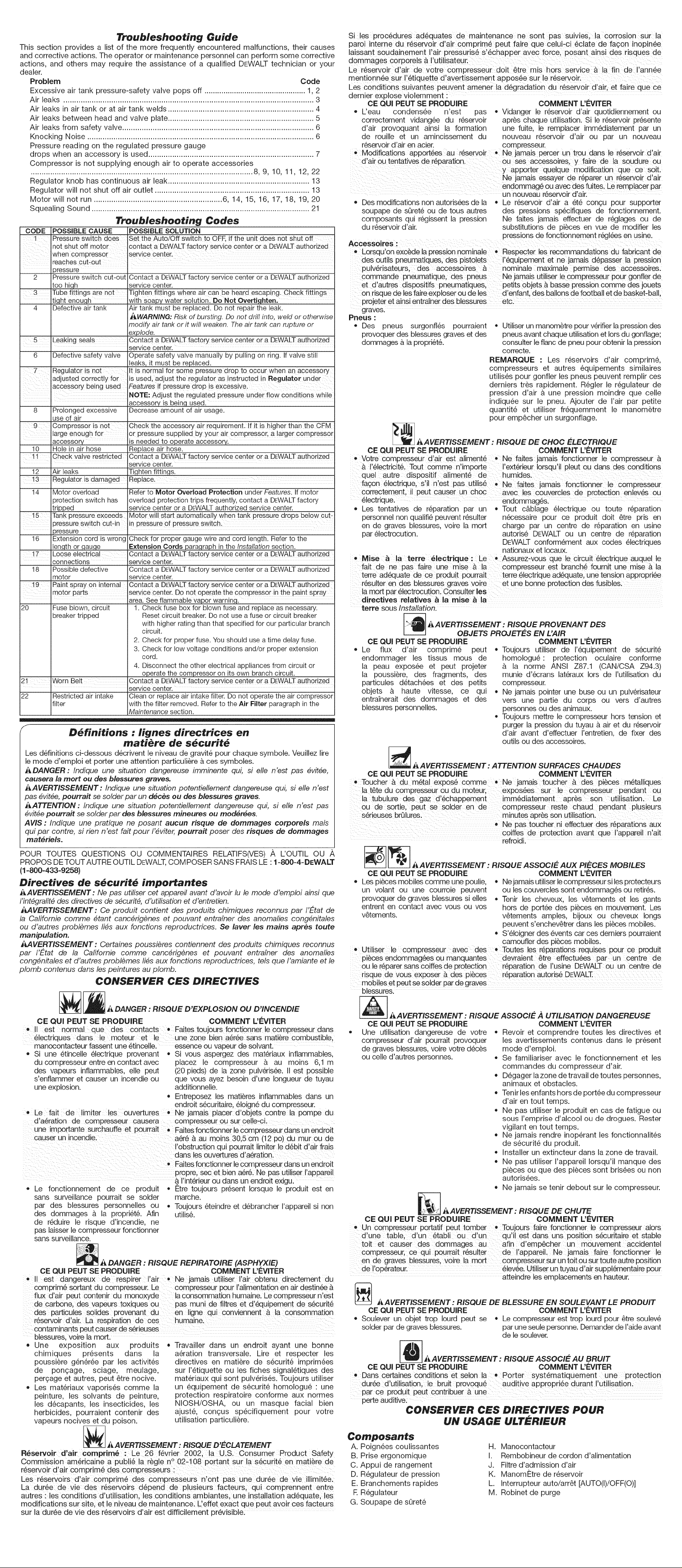

Transporting (Fig. 3)

When transporting the compressor in a vehicle, trailer, etc. ensure that the air tank is drained

and the unit is secured and placed on a flat horizontal surface. Use care when driving so to

avoid tipping the unit over in the vehicle. Damage can occur to the unit or surrounding items

if unit is tipped.

LIFTING (FIG. 3A)

Always use two people when lifting and lift from the recommended lift points B and C.

MOVING (FIG. 3B}

1. Grasp handle (B) to support compressor.

2. Pull handle (A) until fully extended (lock position).

`&WARNING: Risk of unsafe operation. Ensure proper footing and use caution when rolling

compressor so that unit does not tip or cause loss of balance.

3. To move, roll compressor on tires using handle (A) as shown above.

Store compressor in a vertical or horzitional position.

PREPARATION FOR USE

`&WARNING: Do not operate this unit until you read this instruction manual for safety,

operation and maintenance instructions.

Pro-Start Checklist (Fig. 1)

1. Ensure the Auto/Off switch (L) is in the OFF position.

2. Plug the power cord into the correct branch circuit receptacle. See Voltage and Circuit

Protection under Installation.

3. Ensure air tank is drained, see Draining Air Tank under Maintenance.

4. Ensure the drain valve (M) is closed.

5. Ensure safety valve (G) is functioning properly, see Checking Safety Valve under

Maintenance.

6. Pull the regulator knob (F)out and turn counterclockwise until fully closed. Ensure regulated

pressure gauge reads 0 psi. Push knob in to lock in place.

7. Attach hose and accessories. NOTE: Always use a minimum 3/8" (9.5 ram) or greater

air hose rated at 300 psi.

_,WARNING: Risk of unsafe operation. Firmly grasp air hose in hand when installing or

disconnecting to prevent hose whip.

`&WARNING: Risk of unsafe operation. Do not use damaged or worn accessories.

`&WARNING: Risk of Bursting. Too much air pressure causes a hazardous risk of bursting.

Check the manufacturer's maximum pressure rating for air tools and accessories. The

regulator outlet pressure must never exceed the maximum pressure rating.

OPERATING PROCEDURES

Start-up (Fig. f)

1. Follow Pre-Start Checklist under Preparation for Use.

NOTICE: Risk of property damage. Do not operate in vertical position. Vertical position is for

storage only.

2. Move the Auto/Off switch to the AUTO position and allow tank pressure to build. Motor

will stop when tank pressure reaches cut-out pressure.

,&CAUTION: Risk of unsafe operation. Compressed air from the unit may contain water

condensation and oil mist. Do not spray unfiltered air at an item that could be damaged by

moisture. Some air operated tools or devices may require filtered air. Read the instructions

for the air tool or device.

3. Adjust regulator (F) to desired setting. See Regulator under Features.

Shut-down (Fig. f)

1. Move Auto/Off switch (L) to the OFF position.

NOTE: If finished using compressor, follow Steps 2-6.

NOTE: When the unit has been turned off, it is normal to hear a short hiss of air being

released.

NOTE: Unplug unit when not in use.

2. Pull the regulator knob (F)out and turn counterclockwise until fully closed. Ensure regulated

pressure gauge reads 0 psi. Push knob in to lock in place.

3. Remove hose and accessory.

,&WARNING: Risk of unsafe operation. Firmly grasp air hose in hand when installing or

disconnecting to prevent hose whip.

4. Drain the air tank, see Draining Air Tank under Maintenance. Ensure air tank pressure

gauge reads 0 psi.

,_WARNING: Risk of bursting. Drain air tank daily. Water will condense in air tank. If not

drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

5. Allow the compressor to cool down.

6. Wipe air compressor clean and store in a safe, non-freezing area.

_CAUTION: Risk of unsafe operation. Do not operate in vertical position. Vertical position

is for storage only.

MAINTENANCE

The following procedures must be followed when maintenance or service is performed on the

air compressor.

1. Ensure Auto/Off switch is in the OFF position.

2. Remove air compressor plug from outlet.

FIG. 1

M

/

A

B

FIG. 2

R

FIG. 4

3. Drain air tank.

4. Allow air compressor to cool down before starting service.

NOTE: All compressed air systems contain maintenance parts (e.g., oil, filters, separators) that

are periodically replaced. These used parts may contain substances that are regulated and must

be disposed of in accordance with local, state, and federal laws and regulations.

NOTE: Take note of the positions and locations of parts during disassembly to make reassembly

easier.

NOTE: Any service operations not included in this section should be performed by a DEWALT

factory service center or a DEWALTauthorized service center.

FIG. 3A

Maintenance Chart

Procedure Daily Weekly

Check safety valve X

Inspect air filter X

Drain airtank X

Check for unusual noise/vibration X

Check for air leaks X_

Clean compressor exterior X

Removetank from service

1 - To check for air leaks apply a solution of soapy water around joints. While compressor is

pumping to pressure and after pressure cuts out, look for air bubbles to form.

2 - For more information, call 1-800-4-DEWALT (1-800-433-9258)

See tank warning label

X 2

Checking Safety Valve (Fig. 1)

`&WARNING: Risk of bursting. If the safety valve does not work properly, over-pressurization

may occur, causing air tank rupture or an explosion.

`&WARNING: Risk from flying objects. Always wear certified safety equipment: ANSI Z87.1 eye

protection (CAN/CSA Z94.3) with side shields when using the compressor.

Before starting compressor, pull the ring on the safety valve to make sure that the safety

valve operates freely. Before starting compressor, pull the ring on the safety valve to make

sure that the safety valve operates freely.

NOTE: Ring may be difficult to pull when air tank pressure is at 0 psi. If the valve is stuck

or does not operate smoothly, it must be replaced with the same type of valve.

Draining Air Tank (Fig. 1)

_WARNING: Risk of unsafe operation. Risk from noise. Air tanks contain high pressure

air. Keep face and other body parts away from outlet of drain. Use eye protection

[ANSI Z87.1 (CAN/CSA Z94.3)] when draining as debris can be kicked up into face.

AWARNING: Risk from noise. Always wear proper hearing protection during use. Under

some conditions and duration of use, noise from this product may contribute to hearing loss.

NOTE: All compressed air systems generate condensate that accumulates in any drain

point (e.g. tanks, filter, aftercoolers, dryers). This condensate contains lubricating oil and/or

substances which may be regulated and must be disposed of in accordance with local, state,

and federal laws and regulations.

`&WARNING: Risk of bursting. Drain air tank daily. Water will condense in air tank. If not

drained, water will corrode and weaken the air tank causing a risk of air tank rupture.

NOTICE: Risk of property damage. Drain water from air tank may contain oil and rust, which

can cause stains.

1. Ensure Auto/Off switch is in the OFF position.

2. Lift compressor into an inclined position so drain valve (M) is at the lowest point (this will

assist in removing moisture, dirt, etc. from air tanks).

3. Place a suitable container under the drain valve to catch discharge.

4. Grasp lever on drain valve.

5. Slowly rotate lever to gradually bleed air from air tank.

6. When air tank pressure gauge reads 10 psi, rotate valve to the fully open position.

7. Close drain valve when finished.

Checking Air Filter Element (Fig. 1)

AWARNING: Hot surfaces. Risk of burn. Outlet tube, pump head, and surrounding parts are

very hot, do not touch. Allow compressor to cool prior to servicing.

1. Ensure Auto/Off switch (L) is in the OFF Position.

2. Allow unit to cool.

3. Remove filter cover (J) from base.

4. Remove element from filter base.

5. Place new element back in filter base. Purchase replacement parts from your local dealer

or authorized service center. Always use identical replacement parts.

6. Snap filter cover to filter base.

NOTICE: Risk of unsafe operation. Do not operate without air inlet filter

Accessories

_&WARNING: The use of any other accessory not recommended for use with this tool

could be hazardous. Use only accessories rated equal to or higher than the rating of the air

compressor.

Recommended accessories for use with your tool are available for purchase from your local

dealer or authorized service center. If you need assistance in locating any accessory for your

tool, please contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

call 1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

Service Information

Please have the following information available for all service calls:

Model Number Serial Number

Date and Place of Purchase

Repairs

To assure product SAFETY and RELiABiLiTY, repairs, maintenance and adjustment should

be performed by a DEWALT factory service center, a DEWALTauthorized service center or

other qualified service personnel. Always use identical replacement parts.

Full One Year Warranty

DEWALT heavy duty industrial tools are warranted for one year from date of purchase. We

will repair, without charge, any defects due to faulty materials or workmanship. For warranty

repair information, call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained either in

the packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT (Fig. 4): Ifyour warning labels become illegible or

are missing, call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

GLOSSARY

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of air delivery.

PSI: Pounds per square inch; a unit of measure of pressure.

kPa (kilopascal): Metric pressure measurement. 1 kilopascal equal 1000 pascals.

Code Certification: Products that bear one or more of the following marks: UL®, CUL,

CULUS, ETL®, CETL, CETLUS, have been evaluated by OSHA certified independent safety

laboratories and meet the applicable Standards for Safety.

*UL® is a registered trademark of Underwriters Laboratories and ETL® is a registered

trademark of Electrical Testing Laboratories.

Cut-In Pressure: While the motor is off, air tank pressure drops when accessory is used.

When the tank pressure drops to a certain low level the motor will restart automatically. The

low pressure at which the motor automatically restarts is called cut-in pressure.

Cut-Out Pressure: When an air compressor is turned on and begins to run, air pressure

in the air tank begins to build. It builds to a certain high pressure before the motor

automatically shuts off, protecting your air tank from pressure higher than its capacity. The

high pressure at which the motor shuts off is called cut-out pressure.

Branch Circuit: The circuit carrying electricity from electrical panel to outlet.

Duty Cycle: This air compressor pump is capable of running continuously. However,

to prolong the life of your air compressor, it is recommended that a 50%-75% average

duty cycle be maintained; that is, the air compressor pump should not run more than

30-45 minutes in any given hour.

Page 3

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes

and corrective actions. The operator or maintenance personnel can perform some corrective

actions, and others may require the assistance of a qualified DEWALT technician or your

dealer.

Problem Code

Excessive air tank pressure-safety valve pops off ................................................ 1, 2

Air leaks ................................................................................................................... 3

Air leaks in air tank or at air tank welds ................................................................... 4

Air leaks between head and valve plate ................................................................... 5

Air leaks from safety valve ........................................................................................ 6

Knocking Noise ........................................................................................................ 6

Pressure reading on the regulated pressure gauge

drops when an accessory is used ............................................................................ 7

Compressor is not supplying enough air to operate accessories

...................................................................................................... 8, 9, 10, 11, 12, 22

Regulator knob has continuous air leak ................................................................. 13

Regulator will not shut off air outlet ....................................................................... 13

Motor will not run ........................................................... 6, 14, 15, 16, 17, 18, 19, 20

Squealing Sound .................................................................................................... 21

Troubleshooting Codes

CODE POSSIBLECAUSE POSSIBLESOLUTION

1 Pressureswitch does Set the Auto/Off switch to OEF,if the unit does not shut off

not shut off motor ,contact a DEWALTfactory service center or a DEWALTauthorized

3ressure

2 Pressureswitch cut-out Contact a DEWALTfactory service center or a DEWALTauthorized

too high servicecenter.

3 Tubefittings are not Tighten fittings where air can be heard escaping. Check fittings

tight enough with soapy water solution. Do Not Overtiqhten.

4 Defective air tank Air tank must be replaced. Do not repairthe leak.

5 Leakingseals contact a DEWALTfactory service center ora DEWALTauthorized

' service center.

6 Defective safety valve Operate safety valve manually by pullingon ring. If valve still

Regulator is not It is normal for some pressure drop to occur when an accessory

adjusted correctly for is used, adjust the regulator as instructed in Regulator under

accessorYbeing used Featuresif pressure drop is excessive.

, NOTE:Adjust the regulated pressure underflow conditions while

• accessory is being used.

8 Prolonged excessive Decrease amount of air usage.

use of air

9 Compressor is not Check the accessory air requirement. If it is higher than the CFM

largeenough for or pressuresupplied byYOurair compressor, a largercompressor

accessory is needed to operate accessory.

10 Hole in air hose Replace air hose.

11 Check valve restricted Contacta DEWALTfactory seryice center ora DEWALTauthorized

• servicecenter.

12 Air leaks Tighten fittings.

13 .Regulatoris damaged Replace.

14 Motor overload Referto Motor Overload Protection underFeatures. If motor

3rotection switch has overloadprotection trips frequently,contact a DEWALTfactory

tripped servicecenter or a DEWALTauthorized servicecenter.

t5 TankPressureexceeds Motor will start automatically when tank pressuredrops below cut:

pressureswitch cutqn mpressure 0f Pressuresw!tch.

3ressure

16 Extensioncord is wrong Checkfor proper gaugewire andcord length. Referto the

length or gauge Extension Cords paragraph inthe Installation section.

17 Loose electrical Contact a DEWALTfact0ry seryicecenter or a DEWALTauthorized

connections servicecenter.

18 Possibledefective Contact a DEWALTfactory service center ora DEWALTauthorized

motor service center.

19 Paint spray on interna! Contact a DEWALTfactory service center or a DEWALTauthorized

,motor parts servicecenter. DOnot operate thecompressor inthe paint sPraY

20 Fuseblown, circuit 1. Check fuse box for blown fuseand replace asnecessary.

21 Worn Belt ContactaDEWALTfactoryseryicecenteroraDEWALTauther!zed

22 Restricted air intake Cleanor replace air intakefilter. Do not operate the air compressor

f

' area:See flammable vapor warning.

breakertripped Resetcircuit breaker. Donot use afuse or circuit breaker

' service center.

filter with the filter removed. Referto the Air Filter paragraph in the

_,WARNING: Riskof bursting. Do not drill into, weld or otherwise

modify air tank or it will weaken. The air tank can rupture or

explode.

leaks, it must be replaced.

with higher rating thanthat specified for our particular branch

circuit.

2. Checkfor proper fuse.You should usea time delayfuse.

3. Checkfor low voltage conditions and/or proper extension

cord.

4. Disconnect the other electricalappliances from circuit or

operate thecompressor on its own branchcircuit.

Maintenancesection.

D_finitions : lignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de gravite pour chaque symbole. Veuillez lire

le mode d'emploi et porter une attention particuliere _.ces symboles.

.&DANGER: Indique une situation dangereuse imminente qui, si elle n'est pas 6vitae,

causera la mort ou des blessures graves.

AAVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle n'est

pas 6vitae, pourra# se solder par un d_c&s ou des blessures graves.

_ATTENTION : Indique une situation potentie/lement dangereuse qui, si e/le n'est pas

6vit6e pourra# se solder par des blessures mineures ou modifies.

AVIS : Indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n'est fait pour 1'6viter, pourrait poser des risques de dommages

mat6riels.

POUR TOUTES QUESTIONS OU COMMENTAIRES RELATIFS(VES) _, UOUTIL OU A

PROPOS DETOUTAUTRE OUTIL DEWALT,COMPOSER SANS FRAIS LE : 1-800-4-DEWALT

(1-800-433-9258)

Directives de s_curit_ importantes

AAVERTISSEMENT : Ne pas utiliser cet appareil avant d'avoir lu le mode d'emploi ainsi que

/'int6gralite des directives de s6curit6, d'utilisation et d'entretien.

_JWERTISSEMENT : Ce produit contient des produits chimiques reconnus par I'E-tat de

/a Cafifornie comme 6tant canc6rigenes et pouvant entrafner des anomalies cong6nitales

ou d'autres prob/emes li6s aux fonctions reproductrices. Se laver los mains apr_s toute

manipulation.

AAVERTISSEMENT : Certaines poussieres contiennent des produits chimiques reconnus

par I'E-tat de /a Ca/ifomie comme canc6rigenes et pouvant entrafner des anomalies

cong6nita/es et d'autres problemes li6s aux fonctions reproductrices, te/s que /'amiante et le

o/omb contenus dans les peintures au p/omb.

CONSERVER CES DIRECTIVES

Si !es procedureS ad_quates de maintenance ne sont pas suivieS, !a corrosi0n sur la

paro! interne du r_servoir d'air c0m pr!m6 pout faire que ce!uFci _clate de fagon inopin_e

laissant soudainement I'air pressuris_ s'_chapper avec force, posant ainsi des risques de

dommages corporels & I utilisateur.

Le r_servoir d'air de votre €ompresseur doit _tre mis hors service Ala fin de I'ann6e

mentionn6e SurI'_tiquette d'avertissement appos_e sur le r_serv0ir.

Les conditions suivantes peuvent amener !a d_gradation du r_servoir d!air, et fa!re que ce

dernier explose violemment :

CE QUI PEUT SE PRODUIRE COMMENT L'EVITER

* L'eau condens_e n'est pas * Vidanger le r_servoir d'air quotidiennement ou

correctement vidang_e du reservoir apr_s chaque utilisation. Sile r_servoir pr_sente

d'air provoquant ainsi la formation une fuite, le remplacer imm_diatement par un

de rouille et un amincissement du nouveau r_servoir d'air ou par un nouveau

reservoir d'air en acier, compresseur.

* M0difications apport_es au r_servoir _Ne]ama!s percer un trou dans !e r_servoir d,air

d,a!rou tentatives de r_paration, 0U ses accessoires, y faire de !a soudure ou

y apporter quelque modification quece soit.

Ne jamais essayer de r_parer un r6servoir d air

endommag6 ou avec des fuite& Le remplacer par

un nouveau r_servoir d air.

* Des modifications non autoris_es de la * Le r_servoir d'air a _t_ congu pour supporter

soupape de sOret_ ou de tous autres des pressions sp_cifiques de fonctionnement.

composants qui r_gissent la pression Ne faites jamais effectuer de rg_jlages ou de

du reservoir d'air, substitutions de pi_ces en vue de modifier les

Accessoires :

Lorsqu,on exc_de la pression nominale _ Respecter les recommandations du fabricant de

des outi!s pneumatiques, des pisto!ets : !,_uipement et ne jamais d#passer la pression

pu!v6dsateurs, des accessoires & nominale maximale permise des accessoires:

commande pneumatique, des pneus Ne jamais utiliser le c0mpresseur pour gonfler de

et d'autres dispositifs pneumatiques, petits 0bjets b.basse pression comme des jouets

on risque de lesfaire exp!oser ou de les d enfant, des ballons de football et de basket-ball,

projeter et ains! entrafne_des b!essures etc:

graves.

Pneus :

Des pneus surgonfl_s pourraient

provoquer des blessures graves et des

dommages b. la propri_t&

_ _AVERTISSEMENT : RISQUE DE CHOC ELECTRIQUE

CE QUI PEUT SE PRODUIRE COMMENT L'#VITER

• Votre compresseur d,air est aliment_ -Ne faites jamais fonctionner lecompresseur b.

b.!,61ectricit& Tout comme n'importe I'ext_rieur Iorsqu'i pleut ou dans des conditions

quel autre dispositif aliment_ de humides.

fagon #!ectrique, silnest pas utilis_ • ae faites jamais fonCtionner le Compresseur

correctement, il peut causer un choc avec !esCouvercles de protection enlev_s ou

61ectrique. endommag_s.

• Les tentatives de reparation par un * Tout c&blage _lectrique ou toute r_paration

personnel non qualifie peuventr6sulter n_essaire pour ce produit dolt _tre pris en

en de graves blessures, voire la mort charge par un centre de r_paration en usine

par _lectrocution. autoris_ DEWALT ou un centre de r_paration

fait de ne pas faire une mise & !a compresseur est branch_ fournit une mise & la

!a mort pa__!ectrocuti0n. Consu!ter les

* Le flux d'air comprim_ peut * Toujours utiliser de I'_luipement de s_curit6

• Toucher A du m_tal expos6 comme Ne ]amais toucher A des pi_ces m_talliques

la tubulure des gaz d'_chappement imm_diatement apr_s son utilisation. Le

_ la terre _lectrique : Le Assurez-vous que le circuit _lectrique auquel le

terre ad_uate de ce produit Pourrait terre #!ectrique ad#quate, une tension appropri6e

r_sulter en des blessures graves voire et une bonne protection des fusible&

directives re!atives _ la raise _ la

torte sous Installation.

CE QUI PEUT SE PRODUIRE COMMENT UEVlTER

endommager les tissus mous de homologue: protection oculaire conforme

la peau expos_e et peut projeter & la norme ANSI Z87.1 (CAN/CSA Z94.3)

la poussi_re, des fragments, des munie d'ecrans lat6raux Iors de I'utilisationdu

particules detach_es et des petits compresseur.

objets & haute vitesse, ce qui * Ne jamais pointer une buse ou un pulv_risateur

entrafnerait des dommages et des vers une partie du corps ou vers d'autres

blessures personnelles, personnes ou des animaux.

_ AAVERTISSEMENT : ATTENTION SURFACES CHAUDES

CE QUi PEUT SE PRODUIRE COMMENT L'EVITER

la t_te du compresseur ou du moteur, exposees sur le compresseur pendant oU

OU de sortie, peut se solder en de compresseur reste chaud pendant plusieurs

S_rieuses brOlures, minutes apr_s s0n utilisati0n.

__AVERTISSEMENT:RISQUEASSOCIEAUXPIECESMOBILES

CE QUI PEUT SE PRODUIRE COMMENT L'#VITER

Les pi_ces mobiles comme une poulie, • Nejamais utiliser lecompresseur siles protecteurs

un volant ou une courroie peuvent ou les couvercles sont endommag6s ou retires.

provoquer de graves blessures si elles • Tenir les cheveux, les v_tements et les gants

entrent en contact avec vous ou vos hors de port_:e des pi_ces en mouvement. Les

v_tements, v_tements amples, bijoux ou cheveux longs

Utiliser le compresseur avec des * Toutes !es r_parations requises pour ce produit

pi#ces endommag_s ou manquantes devraient _tre effectu6es par un centre de

ou le r_parer sans coiffes de protect on r_paration de I'usine DEWALT ou un centre de

risque de vous exposer b,des pi6ces reparation autoris_ DEWALT.

mobi!es et peut se solder parde graves

blessures.

pressions de fonctionnement r_:jl_es en usine.

Utiliser un manom_tre pour v6rifier la pression des

pneus avant chaque utilisation et Iorsdu gonfiage;

consulter le fianc de pneu pour obtenir lapression

correcte.

REMARQUE : Les r6servoirs d'air comprim_,

compresseurs et autres _quipements similaires

utilis_s pour gonfler les pneus peuvent remplir ces

derniers tres rapidement. R6gler le r_gulateur de

pression d'air & une pression moindre que celle

indiqu_e sur le pneu. Ajouter de I'air par petite

quantit_ et utiliser fr_quemment le manometre

pour emp_cher un surgonflage.

DEWALT conform6ment aux codes electriques

nationaux et Iocaux.

* Toujours mettre le compresseur hors tension et

purger la pression du tuyau b,air et du r_servoir

d'air avant d'effectuer I'entretien, de fixer des

outils ou des accessoires.

Ne pas toucher ni effectuer des r_parations aux

coiffes de protection avant que lappareil n ait

refroidi.

peuvent s'enchev_trer dans les pi_ces mobiles.

S'_loigner des _vents car ces demiers pourraient

camoufler des pi_ces mobiles.

ADANGER : RISQUE D EXPLOSION OU D INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT L'i_VlTER

• II est normal que des contacts • Faites toujours fonctionner le compresseurdans

61ectriques dans !e moteur et le une zone bien a6r6e sans mati_re combustible,

manocontacteur fassent une 6tincelle. essence ou vapeur de s01vant.

Si une 6tincelle 61ectrique provenant

du compresseur entre en contact avec

des vapeurs inflammables, elle peut

s'enfiammer et causer un incendie ou

une explosion.

• Le fait de limiter les ouvertures. Nejamais placerd'objets contrela pompedu

d,aeration de compresseur causera compresseurou surce!!e:cL

uneimportante surchauffe et pourrait _ Faites fonctionner le compresseur dans unendroit

causer un incendie: a6r_ & au moins 30 5 cm (12 pc) du mur ou de

• Le fonctionnement de ce produit * #tre toujours present Iorsque le produit est en

sans surveillance pourrait se solder marche.

par des blessures personnelles ou * Toujours 6teindre et debrancher I'appareil si non

des dommages & la propri_t& Afin utilis&

de r_duire le risque d'incendie, ne

pas laisser le compresseur fonctionner

sans surveillance.

_ _ DANGER : RISQUE REPIRATOIRE (ASPHYXIE)

CE QUI PEUT SE PRODUIRE COMMENT L'EVITER

_ II est dangereux de respirer I,air _ Ne jamais uti!iser Iiair obtenu directement du

comprim_ sortant du compresseur. Le compresseur POUrI,alimentati0n en air destin_e &

flux d,air peut contenir du monoxyde la consommation humaine. Lecompresseur n,est

de carbone, des vapeurs toxiques ou pas muni de fi!tres et d,C-=quipementde S_curit6

des particules s01ides provenant du en ligne qui conviennent b. la c0nsommati0n

r_servoir dair. La respiration de ces humaine:

contaminants peut causer de s_rieuses

blessures, voire la mort.

* Une exposition aux produits

chimiques presents dans la

poussiere g_n_r_e par les activit_s

de pongage, sciage, meulage,

pergage et autres, peut _tre nocive.

Les mat6riaux vaporis_s comme la

peinture, les solvants de peinture,

les d_capants, les insecticides, les

herbicides, pourraient contenir des

vapeurs nocives et du poison.

* Si vous aspergez des mat6riaux inflammables,

placez le compresseur b, au moins 6,1 m

(20 pieds) de la zone pulv6ris_e, il est possible

que vous ayez besoin d'une Iongueur de tuyau

additionnelle.

. Entreposez les mati6res inflammables dans un

endroit securitaire, eloigne du compresseur.

IobStructi0n qui pourrait limiter !ed_bit d air frais

dans les ouvertures d a_ration;

Faitesfonctionner le cempresseur darts Unend[oit

b, I'int6rieur ou darts un endroit exigu.

propre, sec et bien a_r_ Ne pas utiliser Iappareil

* Travailler dans un endroit ayant une bonne

a_ration transversale. Lire et respecter les

directives en matiere de s6curit_ imprim_es

sur I'_tiquette ou les fiches signal_tiques des

mat6riaux qui sont pulv_ris_s. Toujours utiliser

un _quipement de s_curit6 homologu_ : une

protection respiratoire conforme aux normes

NIOSH/OSHA, ou un masque facial bien

ajust_, congus sp_cifiquement pour votre

utilisation particuliere.

_ /_AVERTISSEMENT : RISQUE ASSOCIE A UTILISATION DANGEREUSE

CE QUI PEUT SE PRODUIRE COMMENT L'EVITER

Une utilisation dangereuse de votre • Revolt et comprendre toutes les directives et

compresseur d'air pourrait provoquer les avertissements contenus dans le present

de graves blessures, voire votre decks mode d'emploi.

ou celle d'autres personnes. • Se familiariser avec le fonctionnement et les

commandes du compresseur d'air.

D_gager la zone de travail de toutes personnes,

animaux et obstacles.

Tenir les enfants hors de pottle du compresseur

d'air en tout temps.

Ne pas utiliser le produit en cas de fatigue ou

sous I'emprise d'alcool ou de drogues. Rester

vigilant en tout temps.

Ne jamais rendre inop6rant les fonctionnalit_s

de s_curit_ du produit.

Installer un extincteur darts la zone de travail.

Ne pas utiliser I'appareil Iorsqu'il manque des

pieces ou que des pieces sont bris_es ou non

autoris_es.

Ne jamais se tenir debout sur le compresseur.

_ _AVERTISSEMENT : RISQUE DE CHUTE

CE QUI PEUT SE PRODUIRE COMMENT L'EVITER

Un compresseur portatif peut tomber , Toujours faire f0nctionner le compresseur alors

d'une table, d'un _tabli ou d'un qu'il est dans uns position s_curitaire et stable

toit et causer des dommages au afin d'emp#cher un mouvement accidentel

compresseur, ce qui pourrait resulter de I'appareil. Ne jamais faire fonctionner le

en de graves blessures, voire la mort compresseur sur un toit ou sur route autre Position

de ! op_rateur. _lev6e. Utiliser untuyau d air Suppl_mentaire pour

atteindre les emplacements en hauteur.

_ ,_AVERTISSEMENT : RISQUE DE BLESSURE EN SOULEvANT LE PRODUIT

CE QUI PEUT SE PRODUIRE COMMENT L'I_VITER

Soulever un objet trop Iourd peut se = Le compresseur est trop Iourd pour _tre soulev_

solder par de graves blessures, par une seulepersonne. Demander de I'aideavant

de le soulever.

J_AVERTISSEMENT : RISQUE ASSOCIE AU BRUIT

CE QUI PEUT SE PRODUIRE COMMENT L'E'VITER

_Dans certaines conditions et selon la _ Porter syst6matiquement protection

dur_e d'utilisation le bruit provoqu# audit!ve appropri6e durant I'utilisation,

Parce produit peut contribuer & une

perte auditive:

CONSERVER CES DIRECTIVES POUR

UN USAGE ULTERIEUR

_ AAVERTISsEMENT : RISQUE D'F=CLATEMENT

R_servoir d'air cornprim_ : Le 26 f6vrier 2002; laU.S. Consumer Product Safety

Commission am_ricaine a publi_ !a regle n° 02:108 pertant sur la s_curit_ en mati_re de

r#servoir d air comprim# des €omPresseurs ;

Les r6servoirs d,air comprim6 des compresseurs n'ont pas une dur_e de vie illimit_e.

/a dur_e de vie des r_servoirs d_pend de plusieurs facteurs, qui comprennent entre

autres :les conditions d'utilisation, les conditions ambiantes, une installation ad6quate, les

modifications sur site, et le niveau de maintenance:/'effet exact que peut avoir ces facteuEs

sur la dur_e de vie des r_servoirs d'air est difficilement pr_visible:

Cornposants

A. Poign_es coulissantes

B. Prise ergonomique

C. Appui de rangement

D. R_gulateur de pression

E. Branchements rapides

E R_gulateur

G. Soupape de sQret6

H. Manocontacteur

I. Rembobineur de cordon d'alimentation

J. Filtre d'admission d'air

K. ManomEtre de r_servoir

L. Interrupteur auto/arr_t [AUTO(I)/OFF(O)]

M. Robinet de purge

Page 4

CARACTERISTIQUF.S (FIG. 1)

INTERRUPTEUR AUTO/ARRET

Mettre cet interrupteur (L) sur la position AUTO(I) pour avoir une alimentation automatique

au manocontacteur et sur la position OFF(O) pour la mise hors tension & la fin de chaque

utilisation.

MANOCONTACTEU R

Le manocontacteur (H) d6marre automatiquement le moteur Iorsque la pression du

r6servoir d'air chute sous la pression d'enclenchement r6gl6e en usine. II arr_te le moteur

Iorsque la pression du r6servoir d'air atteint la pression de d_clenchement r6gl6e en usine.

SOUPAPE DE SORETE

Si le manocontacteur ne met pas hors tension le compresseur d'air & sa pression de

d6clenchement r6gl6e, la soupape de sQret6 (G) sert de protection contre une pression

61ev6e en allant & la pression r6gl6e en usine (pression 16gerement plus 61ev6e que le

r6glage de d6clenchement du manocontacteur).

CLAPET

Lorsque le compresseur d'air fonctionne, le clapet est ouvert, ce qui permet & I'air

comprim6 d'entrer darts le r6servoir d'air. Lorsque le compresseur d'air atteint la pression

de d6clenchement, le clapet se ferme, ce qui permet & la pression d'air de rester dans le

r6servoir d'air.

MANOM#TRE DE R(-=SERVOIR

Le manometre de r6servoir (K) indique la pression d'air de r6serve dans le r6servoir.

MANOMETRE R(GUL#

Le manometre de prise (D) indique la pression d'air disponible du c6t6 de la prise du

r6gulateur. Cette pression est contr616e par le r6gulateur.

REGULATEUR

Le r6gulateur (F) contr61e la pression d'air montr6e sur le manometre de prise. Tirez le

bouton et tournez-le darts le sens des aiguilles d'une montre pour augmenter la pression et

darts le sens contraire pour r6duire la pression. Une fois que la pression d6sir6e est atteinte,

poussez le bouton pour le verrouiller. La gamme de pression r6gl6e est de 7-150 psi.

AAVERTISSEMENT : Risque d'6clatement. Purger le r6servoir d'air quotidiennement. L'eau

se condensera dans /e r6servoir d'air. Si /'eau n'est pas vidang6e, elle corrodera et affaib/ira

/e r6servoir d'air, provoquant ainsi un risque de rupture du reservoir d'air.

CORPS DE BRANCHEMENT RAPIDE UNIVERSELS

Le corps de branchement rapide universel (E) accepte les trois styles de prises de

branchement rapide les plus populaires: industrielle, automobile, et ARC. II suffit tout

simplement d'appuyer une seule fois pour connecter le corps de branchement rapide & la

prise. Les deux corps de branchement rapide permettent d'utiliser deux outils en m6me

temps.

ROBINET DE PURGE

Le robinet de purge (M) se trouve & la base du r6servoir d'air et est utilis6 pour vidanger

la condensation & la fin de chaque utilisation. Consulter le chapitre Vidange du r_servoir

sous Entretien.

SYSTi_ME DE REFROIDISSEMENT

Ce compresseur contient un systeme de refroidissement de conception 6volu6e. II est tout

&fait normal pour ce ventilateur de scuffler de I'air par les orifices d'a6ration en grandes

quantit6s. Le systeme de refroidissement fonctionne Iorsque I'air est expuls&

POMPE DE COMPRESSEUR D'AIR

La pompe compresse I'air darts le r6servoir d'air. Uair de travail n'est pas disponible avant

que le compresseur ait augment6 la pression du r6servoir d'air au-dessus de ce qui est

requis & la sortie d'air.

FILTRE D'ADMISSION D'AIR

Le filtre (J) sert b.purifier I'air qui ente dans la pompe. Pour que la pompe re£;oive un flux d'air

constant propre, froid et sec, lefiltre dolt toujours 6tre propre et I'entr6e d'air dolt 6tre exempte

d'obstructions.

PROTECTEUR DE SURCHARGE DU MOTEUR

Le moteur dispose d'un protecteur de surcharge thermique. Sile moteur surchauffe, peu

importe la raison, le protecteur de surcharge met le moteur hors tension. II faut donner au

moteur le temps de refroidir avant de le red6marrer. Red6marrage :

1. Mettre le levier Auto/Arr6t (L) en position OFF, puis d6brancher I'appareil.

2. Laisser le moteur refroidir.

3. Brancher le cordon d'alimentation dans le bon r6ceptacle de circuit de d6rivation.

4. Mettre le levier Auto/Arr_t en position de AUTO.

iNSTALLATiON

Assemblage (Fig. 1)

RACCORDEMENT DES TUYAUX

,&AVERTISSEMENT : Risque d'utilisation dangereuse. Saisir fermement le tuyau en main

Iors du raccordement ou de la d6connexion pour emp6cher un a-coup du tuyau.

1. S'assurer que le manometre r6gul6 indique 0 psi.

2. Saisir le tuyau au niveau de la prise de branchement rapide et enfoncer la prise dans

le corps de branchement rapide (E). Le coupleur se mettra en place.

3. Saisir le tuyau et tirer pour s'assurer que le coupleur est bien en place.

D#CONNEXION DES TUYAUX

AAVERTISSEMENT : Risque d'utilisation dangereuse. Saisir fermement le tuyau en main

Iors du raccordement ou de/a d6connexion pour emp6cher un a-coup du tuyau.

1. S'assurer que le manometre r6gul6 indique 0 psi.

2. Pousser le coupleur du corps de branchement rapide vers I'arriere pour d6gager la prise

de branchement rapide du tuyau.

Directives relatives _ la raise _ la terre (Fig. 2)

AAVERTISSEMENT : Risque de choc 61ectrique. Au cas ob un court-circuit se produirait, la

mise b/a terre reduit /e risque de choc 6/ectrique en fournissant un fil d'6chappement pour/e

courant 6/ectrique. Le compresseur d'air dolt #tre correctement mis b/a terre.

Le compresseur d'air portatif est muni d'un cordon ayant un fil de raise & terre avec une prise

de raise a la terre.

1. Le cordon qui se fixe et se branche (R) avec cet appareil contient une goupille de raise &

la terre (S). Cette prise DOlT _tre utilis_e avec une prise correctement raise & la terre (T).

iMPORTANT : La prise utilis_e dolt _tre install_e et raise & la terre en fonction de tousles

codes et de toutes les ordonnances a I'_chelle locale.

2. Assurez-vous que la prise utilis_e a la m_me configuration que la fiche raise & la terre.

N'UTILISEZ PAS UN ADAPTATEUR

3. Inspectez la fiche et le cordon avant chaque utilisation. Ne les utilisez pas s'ils pr_sentent

des signes de dommages.

4. Si ces directives sur la raise & la terre ne sont pas entierement comprises, ou si vous

n'_tes pas certain que le compresseur a correctement _t_ mis & la terre, faites v_rifier

I'installation par un _lectricien qualifi&

_,DANGER : Risque de choc #lectrique. UNE MISE A LA TERRE INADE-QUATE PEUT

PROVOQUER UN CHOC E-LECTRIQUE.

• Ne modifiez pas/a fiche fournie. Si e/le ne s'incere pas dans la prise disponib/e, une prise

adequate dolt #tre instal/#e par un #lectricien qualifi#.

Les r#parations au cordon ou b la fiche DOIVENT #tre faites par un #/ectricien qualifi&

Rallonges

Si une rallonge dolt _tre utilis_e, s'assurer :

d'utiliser une rallonge a trois ills, munie d'une fiche a trois lames avec mise a la terre et

une prise de courant a trois fentes qui accepte la fiche de la rallonge;

qu'elle est en bon _tat;

• prise n'est pas us_e;

qu'elle n'excede pas 15,2 m (50 pi);

que les fils sont d'un calibre minimum de 12 AWG. (La grosseur du fil augmente comme

le num_ro de calibre diminue. Les fils de calibre 10 AWG et 8 AWG peuvent _galement

_tre utilis_s. NE PAS UTILISER UN FIL DE CALIBRE 14 OU 16 AWG.)

AViS : Risque de dommages b la proprietY. L'utilisation d'une rallonge produira une chute

de tension qui entrafnera une perte de puissance au moteur ainsi qu'une surchauffe. Au

lieu d'utiliser une rallonge #lectrique, augmentez plutSt la Iongueur du boyau d'air en

connectant un autre boyau b I'extr#mite. Connectez des boyaux suppl#mentaires au

besoin. Toujours utiliser un tuyau d'air de 9,5 mm (,3/8pc) ou plus pr#vu pour une pression

de 300 psi.

Protection de la tension et du circu#

Consulter les Exigences en rnati_re de tension et de circuit de d_rivation minimales sous

Fiche technique de la pompe/du moteur.

_, ATTENTION : Risques de surchauffe. Certains compresseurs d'air peuvent fonctionner sur

un circuit de 15 A si les conditions suivantes sont r#unies.

L'alimentation en tension dolt se conformer au Code #lectrique national.

Le circuit n'est pas utilis# pour alimenter d'autres besoins en #lectricit&

Les raflonges doivent se conformer aux specifications.

Le circuit est #quip# d'un disjoncteur de 15A au minimum ou d'un fusible b

temporisation de 15 A. REMARQUE : Sile compresseur est branch# bun circuit

prot#g# par des fusibles, utiliser seulement des circuits b temporisation. Les fusibles

de temporisation devraient avoir I'inscription _ D _ au Canada et _ T _ aux E.-U.

Si une des conditions ci-dessus n'est pas satisfaite, ou si le fonctionnement du

compresseur cause des interruptions du courant #lectrique, il peut s'av#rer n#cessaire de

faire fonctionner I'appareil b partir d'un circuit b 20 A. II n'est pas n#cessaire de changer

les cordons.

Compatibilit_

REMARQUE : Toujours utiliser un filtre de canalisation d'air pour retirer I'humidit_ et les

vapeurs d'huile lots de la pulv_risation de peinture.

F.mplacement

Placer le compresseur d'air dans un endroit propre, sec et bien a_r_ Aau moins 30,5 cm (12 pc)

du mur ou d'autres obstructions qui pourraient interf_rer avec led_bit d'air. Tenir lecorn presseur

&I'_cart des endroits poussi_reux et charges d'_manations. Ces impuret_s pourraient boucher

le filtre et les soupapes d'admission et s'y agglutiner, nuisant ainsi au bon fonctionnement du

compresseur d'air.

_AVERTISsEMENT : La pompe de compresseur d'air et le d_fiecteur ont _te conqus pour

assurer un refroidissement adequat. Les ouvertures d'aeration sur /e compresseur sont

n#cessaires pour garder une temperature de fonctionnement appropri#e. Ne p/acez pas de

chiffons ou d'autres contenants sur /es ouvertures oub proximit# de ce/les-ci.

Placer le compresseur d'air sur ses pieds de caoutchouc et roues sur une surface plane.

#LECTRICIT#

Consulter toutes les directives de s_curit_ avant d'utiliser I'appareil. Respecter les directives

de s_curit_ du cordon d'alimentation le cas _ch_ant. Toujours mettre I'interrupteur Auto/

Arr_t (L) en position OFF avant de retirer la fiche de la prise.

Transport (Fig. 3)

Lors du transport du compresseur d'air dans un v_hicule, une remorque, etc. s'assurer

que le r_servoir d'air soit bien purg_ et que I'appareil soit bien ancr_ sur une surface plane

horizontale. Conduire prudemment pour _viter de basculer I'appareil dans le v_hicule. Un

basculement risque d'endommager I'appareil ou les pieces contigu_s.

LEVAGE (FIG. 3A)

Toujours transporter I'appareil & deux personnes et utiliser les points de transport (Bet C)

recommand_s.

D#PLAcEMENT (FIG. 3B)

1. Saisir la poign_e (B) pour soutenir le compresseur.

2. Tirer sur la poign_e (A) pour la d_ployer completement (position de verrouillage).

,_,AVERT/SSEMENT : Risque d'utilisation dangereuse. Garder les pieds bien ancr#s et faire

preuve d'une grande prudence en roulant le compresseur afin d'#viter de le faire basculer ou

de perdre I'#quilibre.

3. Pour le d_placer, faire rouler le compresseur sur ses pneus a I'aide de la poign_e (A)

comme indiqu_ ci-dessus.

Ranger le compresseur en position verticale ou horizontale.

MODF" D_F'MPLOi

_AVERTISSEMENT :Ne pas utiliser cet apparefl avant d'avoir lu le mode d'emploi ainsi que

/'int#grafit# des directives de s#curit#, d'uti/isation et d'entretien.

Liste de v_rification de pr_-d_marrage (Fig. 1)

1. S'assurer que le commutateur Auto/Arr_t (L) est en position OFF.

2. Branchez le cordon d'alimentation dans le bon r_ceptacle de circuit de derivation.

Consulter la rubrique Protection de la tension et du circuit sous Installation.

3. S'assurer que le r_servoir d'air soit bien purge, consulter la rubrique Vidange du

r_servoir d'air sous Entretien.

4. S'assurer que la soupape de purge (M) soit ferm_e.

5. S'assurer que la soupape de sQret_ (G) fonctionne correctement, consulter la rubrique

V_rification de la soupape de s_ret_ sous Entretien.

6. Tirez le bouton du r_gulateur et tourner le bouton du r_gulateur (F) en sens antihoraire

jusqu'& fermeture complete. S'assurer que le manometre r_gul_ indique 0 psi. Poussez le

bouton pour le verrouiller.

7. Fixez le tuyau et les accessoires. NOTE: Toujours utiliser un tuyau d'air de 9,5 mm (3/8

pc) ou plus pr_vu pour une pression de 300 psi.

_AVERTISSEMENT : Risque d'utilisation dangereuse. Saisir fermement le tuyau en main Iors

du raccordement ou de/a d#connexion pour emp#cher un a-coup du tuyau.

_AVERTISSEMENT: Risque d'utilisation dangereuse. N'uti/isez pas les accessoires

endommag#s ou portes.

_AVERTISSEMENT: Risque d'#clatement. Trop de pression d'air cause un risque

s#rieux d'#clatement. V#rifiez /a pression maximum sugg#ree par le fabricant pour/es

outils pneumatiques et les accessoires. La pression de sortie du r#gu/ateur ne dolt jamais

d#passer une pression nominale maximale.

PROCEDURF.S DF. FONCTIONNF.MF.NT

D_marrage (Fig. 1)

1. Utiliser la Liste de v_rification de pr_-d_marrage sous Mode d'emploi.

AViS : Risque d'utilisation dangereuse. Ne pas faire fonctionner en position verticale. La

position verticale est r#serv#e au stockage uniquement.

2. Mettre I'interrupteur Auto/Arr_t en position AUTO et laisser du temps pour I'accumulation

de pression du r_servoir. Le moteur s'arr_te Iorsque la pression du r_servoir atteint la

pression de d_clenchement.

AATTENTION : Risque de dommages b la propri#t& L'air comprim# de I'appareil pourrait

contenir de I'eau condens#e et des brumes d'huile. Ne pas vaporiser de I'air non filtr# sur

un article que I'humidit# pourrait endommager. Certains outils ou dispositifs pneumatiques

pourraient requ#rir de I'air filtr& Lire les directives pour I'outil ou le dispositif pneumatique.

3. R_gler le r_gulateur (F) & la valeur souhait_e. Consulter la rubrique R_gulateur sous

Caract#ristiques.

_rr_t (Fig. 1)

1. Mettre I'interrupteur Auto/Arr_t (L) en position OFF.

REMARQUE : Si I'utilisation du compresseur est termin_e, suivre les _tapes 2 &6.

REMARQUE: Lorsque I'appareil est _teint, il est normal d'entendre un court sifflement

quand I'air s'_chappe.

REMARQUE : D_branchez I'appareil apres utilisation.

2. Tirez le bouton du r_gulateur et tourner le bouton du r_gulateur (F) en sens antihoraire

jusqu'& fermeture complete. S'assurer que le manometre r_gul_ indique 0 psi. Poussez le

bouton pour le verrouiller.

3. Retirer le tuyau et I'accessoire.

AAVERTISSEMENT : Risque d'utilisation dangereuse. Saisir fermement le tuyau en main Iors

du raccordement ou de la d#connexion pour emp_cher un a-coup du tuyau.

4. Purger le r_servoir d'air, consulter la rubrique Purger le r_servoir d'air sous Entretien.

S'assurer que le manometre du r_servoir d'air affiche 0 psi.

_AVERTISSEMENT : Risque d'#clatement. Purger le r#servoir d'air quotidiennement. L'eau

se condensera darts le r#servoir d'air. Si I'eau n'est pas vidang#e, elle corrodera et affaiblira

le reservoir d'air, provoquant ainsi un risque de rupture du r#servoir d'air.

5. Laisser refroidir le compresseur.

6. Nettoyer le compresseur d'air avec un chiffon et le ranger dans un endroit sQr sans risque

de gel.

AATTENTION : Risque d'utilisation dangereuse. Ne pas faire fonctionner en position

verticale. La position verticale est r#serv#e au stockage uniquement.

F-NTRF.TIF.N

Suivre les procedures suivantes lots de I'entretien ou des r_parations du compresseur d'air.

1. S'assurer que le commutateur Auto/Arr_t est en position OFE

2. D_brancher le compresseur d'air.

3. Purger le r_servoir d'air.

4. Laisser refroidir le compresseur d'air avant de d_buter une r_paration.

REMARQUE : Tousles systemes de compression d'air comprennent des pieces (par ex., huile,

filtres, s_parateurs) qui sont r_gulierement remplac_es. Ces pieces us_es pourraient contenir

des substances contr61_es et doivent _tre mises au rebut conform_ment aux lois et reglements

municipaux, provinciaux, territoriaux et f_d_raux.

REMARQUE : Noter la position et I'emplacement des pieces au d_montage pour faciliter le

remontage subsequent.

REMARQUE : Toute r_paration non d_crite dans cette rubrique devrait _tre ex_cut_e & un

centre de r_paration de I'usine DEWALT ou un centre de r_paration agr_ DEWALT.

Programme d_entretien

Se reporter

Procedure Quoti- Hebdo- _ I'_tiquette

V@ification de la soupape de sQret_ X

Inspecter le filtre &air X

Vidange du r_servoir d'air X

Recherche de bruits ou de vibrations inhabituels X

V@ification des fuites d'air X_

Nettoyage de la partie externe du compresseur X

Mettre le r_servoir hors service X2

1 - Pour trouver des fuites d'air, appliquer une solution d'eau savonneuse autour des joints. Alors

que le compresseur d6veloppe la pression et que I'accumulation de pression cesse, rechercher

toute trace de bulles d'air.

2 - Pour plus d'informations, composer le 1-800-4-DEWALT (1-800-433-9258).

dienne rnadaire d'avertissement sur

le r_servoir

V_rification de la soupape de sBretd (Fig. 1)

J_,AVERTISSEMENT: Risque d_clatement. Si la soupape de sOret# ne fonctionne pas

correctement, i/ peut se produire une surpressurisation, causant ainsi /a rupture du r#servoir

d'air ou une explosion.

z&AVERTISSEMENT: Risque provenant des objets projet. E-s Toujours utiliser de

I'_quipement de s_curit_ homologu_ :protection oculaire oonforme b la norme ANSI Z87, I

(CAN/CSA Z94.3) munie d'_crans lat_raux lots de I'utilisation du compresseur.

Avant de mettre en marche le compresseur, tirez sur la bague de la soupape de sQret_ pour

vous assurer que la soupape fonctionne librement.

REMARQUE : II peut _tre difficile de tirer sur I'anneau si la pression du r_servoir d'air est

0 psi. Si la soupape est coinc_e oune fonctionne pas bien, il faut la remplacer par une

soupape du m_me type.

Vidange du r_servoir d_air (Fig. 1)

_AVERTISSEMENT: Risque d'utilisation dangereuse. Risque associ_ au bruit. Les

r#servoirs d'air contiennent de I'air sous haute pression. E-/oignerle protection oculaire [ANSI

Z87.1 (CAN/CSA Z94.3)] et toutes autres parties du corps de/'orifice de vidange. Porter des

lunettes de s#curit# Iors de la vidange car i/ y a risque de projection de d#bris au visage.

_AVERTISSEMENT : Risques auditifs. Porter syst#matiquement une protection auditive

appropri_e durant /'utilisation. Sous certaines conditions et suivant /a duree d'uti/isation, le

bruit #manant de ce produit pourrait contribuer b une perte de/'acuit# auditive.

REMARQUE: Tousles systemes de compression d'air g_nerent des condensats qui

s'accumulent & un point de vidange (par ex., r_servoir, filtre, dispositifs de postrefroidissement

ou s_cheur). Le condensat contient de I'huile lubrifiante ou des substances contr61_es, ou les

deux, et doivent _tre _limin_s conform_ment aux lois et reglements municipaux, provinciaux,

territoriaux et f_d_raux.

_AVERTISSEMENT : Risque d'#clatement. Purger le r#servoir d'air quotidiennement. L'eau

se condensera darts le r#servoir d'air. Si I'eau n'est pas vidang#e, elle corrodera et affaiblira

le reservoir d'air, provoquant ainsi un risque de rupture du r#servoir d'air.

AViS : Risque de dommages b la proprietY. L'eau qui est purg#e du reservoir d'air pourrait

contenir de I'huile et de la rouille. Ces demiers risquent de tacher.

1. S'assurer que le commutateur Auto/Arr_t est en position OFE

2. Soulever du compresseur pour I'incliner et de maniere & ce que la soupape de purge (M)

soit au point le plus bas (cette position aidera & _liminer I'humidit_, les salet_s, etc. des

r_servoirs d'air).

3. D_poser un r_cipient convenable sous lasoupape de purge pour recueillir les r_sidus.

4. Saisir le levier molet_ sur la soupape de purge.

5. Tourner lentement le levier pour purger graduellement I'air du r_servoir.

6. Une fois que le manometre du r_servoir affiche 10 psi, tourner completement le levier

en position ouverte.

7. Fermer la soupape de purge des la fin de I'op_ration.

V_rification des _l_ments du filtre d_air (Fig. 1)

_AVERTISsEMENT : Surfaces chaudes. Risque de brOlure. Le postrefroidisseur, /a t_te

de pompe et /es pieces contigu#s sont tres chaudes - ne pas les toucher. Laisser refroidir /e

compresseur avant d'effectuer des r#parations sur I'appareiL

1. S'assurer que le commutateur Auto/Arr_t (L) en position OFR

2. Permettez & I'unit_ de se refroidir.

3. Enlevez la couverture de filtre (J) de la base.

4. Enlevez I'_l_ment de la base de filtre.

5. Placez le nouvel _l_ment en arriere dans la base de filtre. Achetez les pieces de rechange

de votre revendeur local ou centre commercial autoris& Employez toujours les pieces de

rechange identiques.

6. Couverture instantan_e de filtre pour filtrer la base.

AVIS: Risque d'uti/isation dangereuse. Ne pas uti/iser sans le fi/tre d'admission d'air.

_ccessoires

_,AVERTISsEMENT : L'utilisation de tout autre accessoire non recommand_ avec cet outil

pourrait s'av#rer dangereuse. Utiliser uniquement des accessoires de classement #gal ou

sup#rieur b celui de/a compresseur d'air.

Les accessoires recommand_s pour votre outil peuvent _tre achet_s aupres du distributeur

local ou d'un centre de r_paration agr_& Si vous avez besoin d'assistance pour trouver un

accessoire pour votre outil, veuillez contacter DEWALTIndustrial Tool Co., 701 East Joppa Road,

Baltimore, MD 21286, Etats-Unis, composer le 1-800-4-DEwALT (1-800-433-9258) ou visiter

notre site Web a www.dewalt.com.

information sur ies r_parations

Veuillez recueillir les informations suivantes pour tousles appels au Service & la clientele "

Num_ro du modele Num_ro de s_rie

Date et lieu de I'achat