Page 1

D28111

D28113(K)

D28130

D28132C

D28134

D28135(K)

D28139

www .

.eu

D28141

1

Page 2

2

Copyright DEWALT

Page 3

A

1

3 4

2

1

Page 4

85

3

5

6

6

3

7

6

9

6

B1

C1

14

13

12

10

11

B2

14

12

10

11

A

14

12

2

10

11

B

C2

2

Page 5

D

15

15

4

3

Page 6

ENGLISH

ANGLE GRINDER D28111/D28113(K)/D28130/

D28132C/D28134/D28135(K)/D28139/D28141

Congratulations!

You have chosen a DEWALT tool. Years of experience, thorough product development and innovation make

EWALT one of the most reliable partners for professional power tool users.

D

Technical data

D28111 D28113(K) D28130 D28132C D28134 D28135(K) D28139 D28141

Voltage V 230 230 230 230 230 230 230 230

U.K. & Ireland only V 230/115 230/115 – – – 230/115 – –

Power input W 850 900 900 1,200 1,100 1,400 850 1,400

No-load speed min

Wheel diameter mm 115 115 125 125 125 125 125 150

Spindle diameter M14 M14 M14 M14 M14 M14 M14 M14

Weight kg 2,1 2,1 2,2 2,5 2,2 2,5 2,1 2,6

L

(sound pressure) dB(A) 90 89 90 89 89 91 89 91

pA

K

(sound pressure

PA

uncertainty) dB(A) 5 3 3 3 3 3 3 3

L

(acoustic power) dB(A) 101 100 101 100 100 102 100 102

WA

K

(acoustic power

WA

uncertainty) dB(A) 5 3 3 3 3 3 3 3

-1

10,000 10,000 10,000 10,000 10,000 10,000 10,000 9,000

Vibration total values (triax vector sum) determined according to EN 60745:

Vibration emission value for surface grinding

ahAG

=

Uncertainty K = m/s²

m/s² 7.9 7.8 7.3 8.1 8.7 8.2 8.2 7.1

1.6 1.5 1.5 1.5 1.5 1.5 1.5 1.5

The vibration emission level given in this information

sheet has been measured in accordance with a

standardised test given in EN 60745 and may be

used to compare one tool with another. It may be

used for a preliminary assessment of exposure.

WARNING: The declared vibration

Identify additional safety measures to

emission level represents the main

applications of the tool. However if the

tool is used for different applications,

with different accessories or poorly

maintained, the vibration emission may

differ. This may significantly increase the

exposure level over the total working

period.

An estimation of the level of exposure to

Fuses:

Europe 230 V tools 10 Amperes, mains

U.K. & Ireland 230 V tools 13 Amperes, in plugs

U.K. & Ireland 115 V tools 16 Amperes, mains

vibration should also take into account

the times when the tool is switched off or

4

when it is running but not actually doing

the job. This may significantly reduce

the exposure level over the total working

period.

protect the operator from the effects of

vibration such as: maintain the tool and

the accessories, keep the hands warm,

organisation of work patterns.

Page 7

ENGLISH

Defi nitions: Safety Guidelines

The definitions below describe the level of severity for

each signal word. Please read the manual and pay

attention to these symbols.

CAUTION: Indicates a potentially

CAUTION: Used without the safety alert

Denotes risk of electric shock.

DANGER: Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

hazardous situation which, if not avoided,

may result in minor or moderate

injury.

symbol indicates a potentially hazardous

situation which, if not avoided, may result

in property damage.

Denotes risk of risk of fire.

EC-Declaration of conformity

D28111/D28113(K)/D28130/D28132C/D28134/D28135(K)/

D28139/D28141

DEWALT declares that these products described

under “technical data” have been designed in

compliance with:

98/37/EC (until 28.December 2009); 2006/42/EC

(from 29.December 2009); 2004/108/EC;

2006/95/EC; EN 60745-1; EN60745-2-3;

EN 55014-1; EN 55014-2; EN 61000-3-2; EN

61000-3-3.

For more information, please contact DEWALT at the

following address or refer to the back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

DEWALT.

Horst Grossmann

Vice President Engineering and Product Development

DEWALT, Richard-Klinger-Straße 11,

D-65510, Idstein, Germany

14.04.08

WARNING: To reduce the risk of injury,

read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings

and instructions Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body

is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply. Use

of an RCD reduces the risk of electric shock.

5

Page 8

ENGLISH

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your finger on the

switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power

tool before making any adjustments,

changing accessories, or storing power

tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions taking into account the working

conditions and the work to be performed.

Use of the power tool for operations different

from those intended could result in a

hazardous situation.

5) SERVICE

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

ADDITIONAL SPECIFIC SAFETY RULES

Safety instructions for all operations

a) This power tool is intended to function

as a grinder. Read all safety warnings,

instructions, illustrations and specifications

provided with this power tool. Failure to follow

all instructions listed below may result in electric

shock, fire and/or serious injury.

b) Operations such as polishing or cutting-off

are not recommended to be performed with

this power tool. Operations for which the power

tool was not designed may create a hazard and

cause personal injury.

c) Do not use accessories which are not

specifically designed and recommended

by the tool manufacturer. Just because the

accessory can be attached to your power tool, it

does not assure safe operation.

d) The rated speed of the accessory must

be at least equal to the maximum speed

marked on the power tool. Accessories

running faster than their rated speed can break

and fly apart.

6

Page 9

ENGLISH

e) The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannon be adequately guarded or

controlled.

f) The arbour size of wheels, flanges, backing

pads or any other accessory must properly

fit the spindle of the power tool. Accessories

with arbour holes that do not match the

mounting hardware of the power tool will run out

of balance, vibrate excessively and may cause

loss of control.

g) Do not use a damaged accessory. Before

each use inspect the accessory such

as abrasive wheel for chips and cracks,

backing pad for cracks, tear or excess

wear, wire brush for loose or cracked

wires. If power tool or accessory is

dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory, position yourself

and bystanders away from the plane of the

rotating accessory and run the power tool

at maximum no-load speed for one minute.

Damaged accessories will normally break apart

during this test time.

h) Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing

protectors, gloves and shop apron capable

of stopping small abrasive or workpiece

fragments. The eye protection must be capable

of stopping flying debris generated by various

operations. The dust mask or respirator must be

capable of filtrating particles generated by your

operation. Prolonged exposure to high intensity

noise may cause hearing loss.

i) Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken accessory

may fly away and cause injury beyond immediate

area of operation.

j) Hold power tool by insulated gripping

surfaces only, when performing an

operation where the cutting accessory

may contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool

“live” and shock the operator.

k) Position the cord clear of the spinning

accessory. If you lose control, the cord may be

cut or snagged and your hand or arm may be

pulled into the spinning accessory.

l) Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and

pull the power tool out of your control.

m) Do not run the power tool while carrying

it at your side. Accidental contact with the

spinning accessory could snag your clothing,

pulling the accessory into your body.

n) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside

the housing and excessive accumulation of

powdered metal may cause electrical hazards.

o) Do not operate the power tool near

flammable materials. Sparks could ignite these

materials.

p) Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Causes and Operator Prevention

of Kickback

• Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush

or any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power

tool to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

• For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under

these conditions.

• Kickback is the result of tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below:

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control

over kickback or torque reaction during

start up. The operator can control torque

reaction or kickback forces, if proper precautions

are taken.

b) Never place your hand near the rotating

accessory. Accessory may kickback over your

hand.

7

Page 10

ENGLISH

c) Do not position your body in the area

where power tool will move if kickback

occurs. Kickback will propel the tool in direction

opposite to the wheel’s movement at the point of

snagging.

d) Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp edges

or bouncing have a tendency to snag the rotating

accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of control.

Safety Warnings Specifi c for Grinding

Operations

a) Use only wheel types that are recommended

for your power tool and the specific guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot

be adequately guarded and are unsafe.

b) The guard must be securely attached to

the power tool and positioned for maximum

safety, so the least amount of wheel is

exposed towards the operator. The guard

helps to protect operator from broken wheel

fragments and accidental contact with wheel.

c) Wheels must be used only for recommended

applications. For example: do not grind with

the side of cut-off wheel. Abrasive cut-off

wheels are intended for peripheral grinding, side

forces applied to these wheels may cause them

to shatter.

d) Always use undamaged wheel flanges

that are of correct size and shape for your

selected wheel. Proper wheel flanges support

the wheel thus reducing the possibility of wheel

breakage. Flanges for cut-off wheels may be

different from grinding wheel flanges.

e) Do not use worn down wheels from larger

power tools. Wheel intended for larger power

tool is not suitable for the higher speed of a

smaller tool and may burst.

LABELS ON TOOL

The following pictographs are shown on the tool:

Read the instruction manual before use.

Wear ear protection.

Package contents

The package contains:

1 Angle grinder

1 Guard

1 Side handle

1 Flange set

1 Two-pin spanner

1 Kitbox (K-models only)

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and understand

this manual prior to operation.

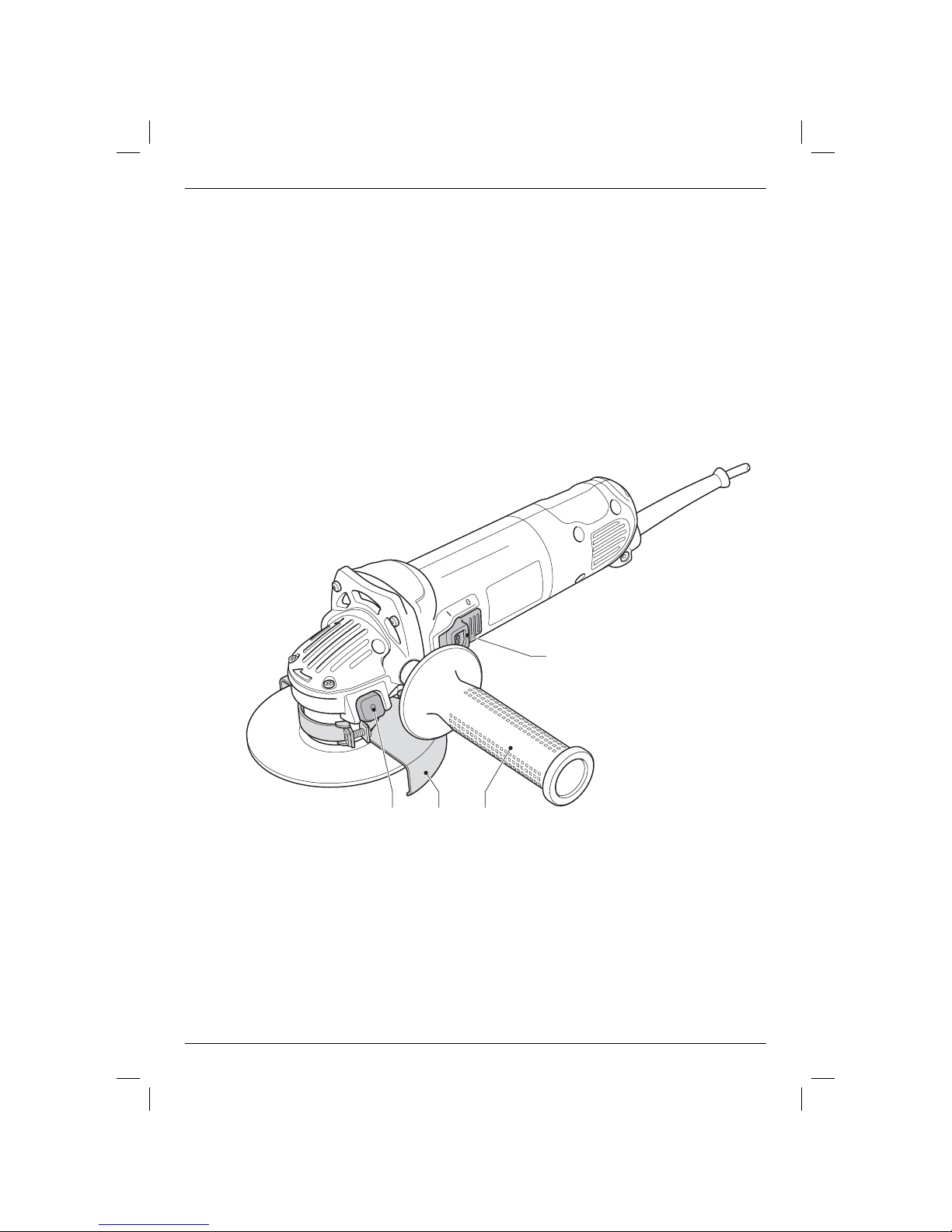

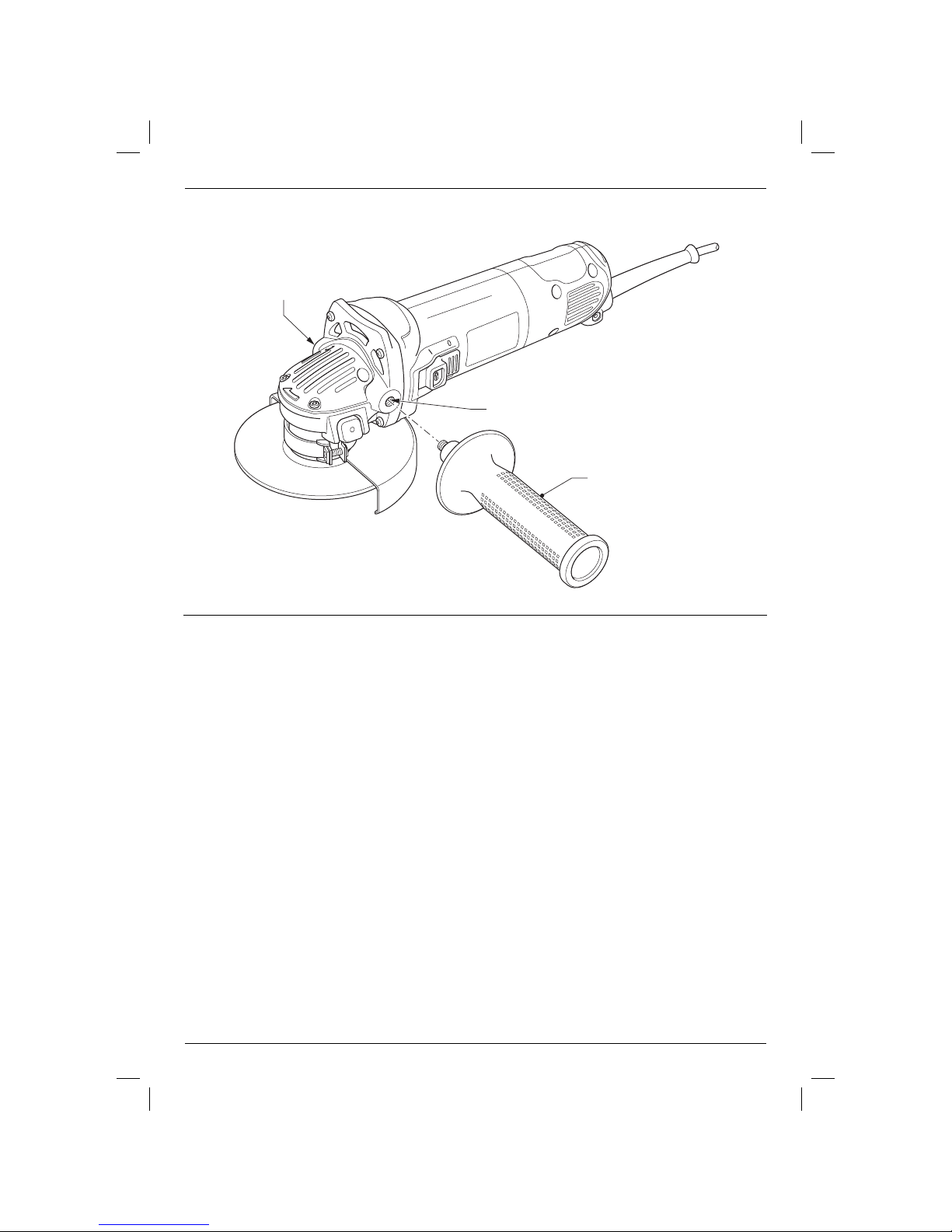

Description (fi g. A)

WARNING: Never modify the power tool

INTENDED USE

Your angle grinder D28111/D28113(K)/D28130/

D28132C/D28134/D28135(K)/D28139/D28141 has

been designed for professional grinding and cutting

applications .

DO NOT use under wet conditions or in presence of

flammable liquids or gases.

DO NOT use grinding wheels other than center

depressed wheels and flap-disk.

These heavy-duty angle grinders are professional

power tools. DO NOT let children come into

contact with the tool. Supervision is required when

inexperienced operators use this tool.

1 On/off switch

2 Spindle lock

3 Guard

4 Side handle

or any part of it. Damage or personal

injury could result.

Wear safety glasses.

8

D28113(K)/D28130/D28132C/D28135(K)/D28141 ANTI-VIBRATION SIDE HANDLE

The anti-vibration side handle offers added comfort

by absorbing the vibrations caused by the tool.

Page 11

D28113(K)/D28130/D28132C/D28134/D28135(K)/D28141 KEYLESS GUARD

The keyless guard allows for quick adjustment during

the application to enhance application versatility.

ENGLISH

1

D28113(K)/D28130/D28132C/D28134/D28135(K)/D28141 DUST EJECTION SYSTEM

The dust ejection system prevents dust pile-up

around the guard and motor inlet, and minimises the

amount of dust entering the motor housing.

Electrical safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Your DEWALT tool is double insulated in

accordance with EN 60745; therefore no

earth wire is required.

WARNING: 115 V units have to

be operated via a fail-safe isolating

transformer with an earth screen between

the primary and secondary winding.

If the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

DEWALT service organization.

Mains plug replacement

(U.K. & Ireland only)

• Should your mains plug need replacing and you

are competent to do this, proceed as instructed

below. If you are in doubt, contact an authorized

DEWALT repair agent or a qualifi ed electrician.

• Disconnect the plug from the supply.

• Cut off the plug and dispose of it safely; a plug

with bared copper conductors is dangerous if

engaged in a live socket outlet.

• Only fi t 13 Amperes BS1363A approved plugs

fi tted with the correctly rated fuse (1).

• The cable wire colours, or a letter, will be marked

at the connection points of most good quality

plugs. Attach the wires to their respective points

in the plug (see below). Brown is for Live (L) (2)

and Blue is for Neutral (N) (4).

• Before replacing the top cover of the mains plug

ensure that the cable restraint (3) is holding the

outer sheath of the cable fi rmly and that the two

leads are correctly fi xed at the terminal screws.

4

3

WARNING: Never use a light socket.

Never connect the live (L) or neutral (N)

wires to the earth pin marked E or .

For 115 V units with a power rating exceeding 1500 W,

we recommend to fi t a plug to BS4343 standard.

2

Using an extension cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see technical data). The minimum conductor

size is 1.5 mm

When using a cable reel, always unwind the cable

completely.

Also refer to the table below.

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - 230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

2

.

9

Page 12

ENGLISH

Assembly and adjustment

WARNING: Prior to assembly and

adjustment always unplug the tool.

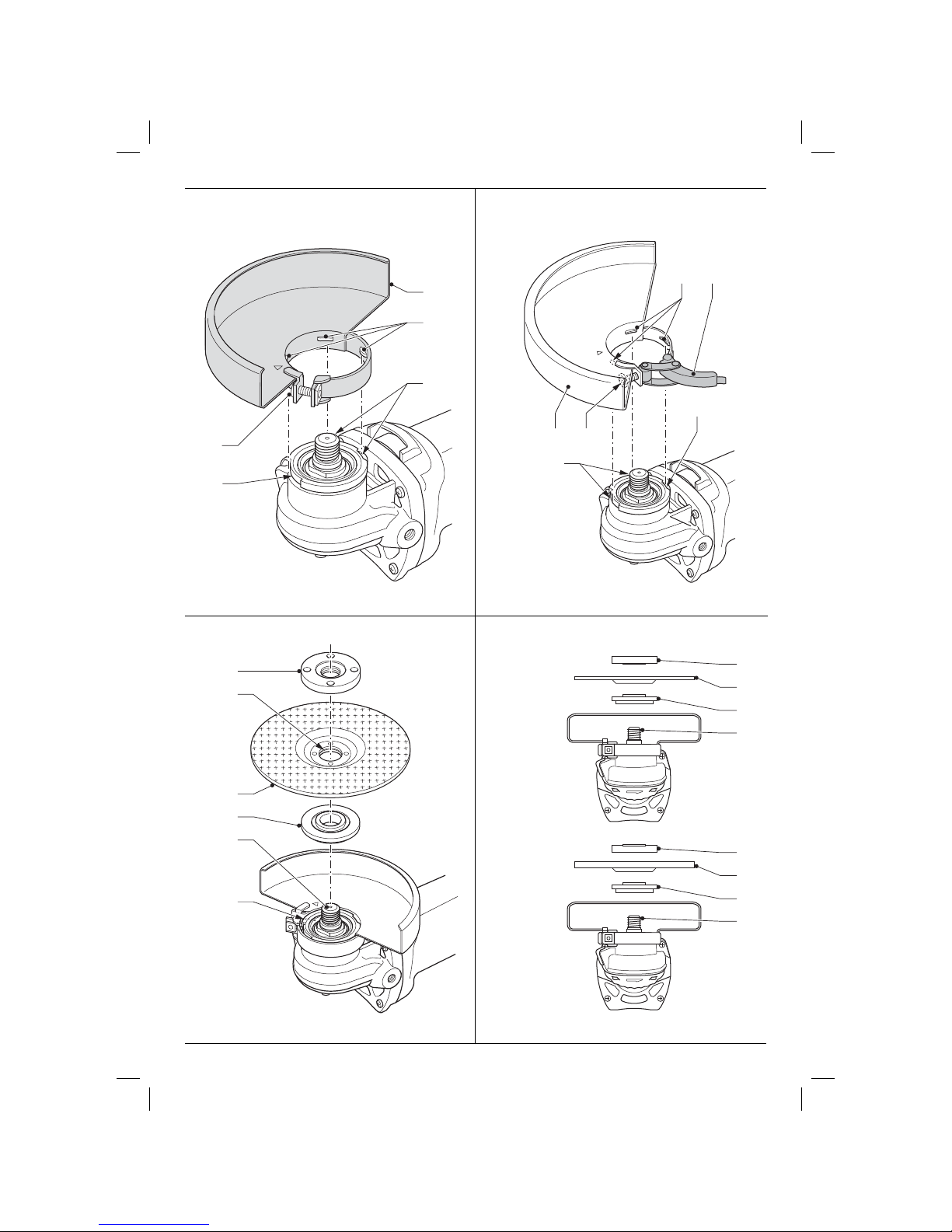

MOUNTING AND REMOVING THE GUARD (FIG. B1 & B2)

D28111/D28139 - GUARD WITH FIXING SCREW (FIG. B1)

• Place the angle grinder on a table, spindle up.

• Align the lugs (5) with the notches (6).

• Press the guard down and rotate it to the

required position.

• Securely tighten the screw (7).

• To remove the guard, slacken the screw.

WARNING: Never use the tool without

the guard in place.

D28113(K)/D28130/D28132C/D28134/D28135(K)/D28141 KEYLESS GUARD (FIG. B2)

• Place the angle grinder on a table, spindle up.

• Release the clamping lock (8) and hold the guard

(3) over the tool as shown.

• Align the lugs (5) with the notches (6).

• Press the guard down and rotate it to the

required position.

• If required, increase the clamping force by

tightening the screw (9).

• Tighten the clamping lock.

• To remove the guard, release the clamping lock.

WARNING: Never use the tool without

the guard in place.

FITTING AND REMOVING A GRINDING OR CUTTING DISC

(FIG. C1 & C2)

• Place the tool on a table, guard up.

• Fit the inner fl ange (10) correctly onto the spindle

(11) (fi g. C1).

• Place the disc (12) on the fl ange (10). When

fi tting a disc with a raised center, make sure that

the raised centre (13) is facing the fl ange (10).

• Screw the outer fl ange (14) onto the spindle (11)

(fi g. C2):

– the ring on the fl ange (14) must face towards

the disc when fi tting a grinding disc (A);

– the ring on the fl ange (14) must face away from

the disc when fi tting a cutting disc (B).

• Press the spindle lock (2) and rotate the spindle

(11) until it locks in position.

• Tighten the fl ange (14) with the two-pin spanner

supplied.

• Release the spindle lock.

• To remove the disc, loosen the fl ange (14) with

the two-pin spanner.

WARNING: Do not use a damaged disc.

MOUNTING THE SIDE HANDLE (FIG. D)

• Screw the side handle (4) tightly into one of the

holes (14) on either side of the gear case.

Instructions for use

WARNING:

• Always observe the safety instructions

and applicable regulations.

• Ensure all materials to be ground or cut

are secured in place.

• Apply only a gentle pressure to the tool.

Do not exert side pressure on the disc.

• Avoid overloading. Should the tool

become hot, let it run a few minutes

under no load condition.

• Wear hearing protection and safety

glasses.

PRIOR TO OPERATION:

• Install the guard and appropriate disc or wheel.

Do not use excessively worn discs or wheels.

• Be sure the inner and outer fl ange are mounted

correctly.

• Make sure the disc or wheel rotates in the direction

of the arrows on the accessory and the tool.

SWITCHING ON AND OFF (FIG. A)

• To run the tool, press the on/off switch (1).

• For continuous operation, press the switch

completely forward.

• To stop the tool, release the switch. To stop the

tool in continuous operation, press on the back

part of the switch.

WARNING: Do not switch the tool on or

off when under load.

10

Page 13

METAL APPLICATIONS

• When using the tool in metal applications, make

sure that a residual current device (RCD) has

been inserted to avoid residual risks caused by

metal swarf.

• If the power supply is shut off by the RCD, take

the tool to authorised D

WARNING: In extreme working

conditions, conductive dust can

accumulate inside the machine housing

when working with metal. This can result

in the protective insulation in the machine

becoming degraded with a potential risk

of an electrical shock.

To avoid build-up of metal swarf inside the machine,

we recommend to clear the ventilation slots on a

daily basis. See “Maintenance”.

EWALT repair agent.

ENGLISH

Your D

EWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

POP-OFF BRUSHES

The motor will be automatically shut off indicating

that the carbon brushes are nearly worn out and that

the tool needs servicing. The carbon brushes are

not user-serviceable. Take the tool to an authorised

D

EWALT repair agent.

LUBRICATION

Your power tool requires no additional lubrication.

USING FLAP DISCS

WARNING: Metal dust build-up.

• Extensive use of fl ap discs in metal applications

can result in the increased potential for electric

shock. To reduce this risk, insert an RCD before

use and clean the ventilation slots daily by

blowing dry compressed air into the ventilation

slots in accordance with the below maintenance

instructions.

Optional accessories

WARNING: Since accessories, other

than those offered by DEWALT, have

not been tested with this product, use

of such accessories with this tool could

be hazardous. To reduce the risk of

injury, only DEWALT, recommended

accessories should be used with this

product.

Consult your dealer for further information on the

appropriate accessories.

MAINTENANCE

WARNING: Prior to assembly and

adjustment always unplug the tool.

CLEANING

WARNING: Blow dirt and dust out of the

main housing with dry air as often as dirt

is seen collecting in and around the air

vents. Wear approved eye protection and

approved dust mask when performing

this procedure.

WARNING: Never use solvents or other

harsh chemicals for cleaning the nonmetallic parts of the tool. These chemicals

may weaken the materials used in these

parts. Use a cloth dampened only with

water and mild soap. Never let any liquid

get inside the tool; never immerse any

part of the tool into a liquid.

Protecting the environment

Separate collection. This product must

not be disposed of with normal household

waste.

Should you fi nd one day that your D

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products

and packaging allows materials to

EWALT product

11

Page 14

ENGLISH

be recycled and used again. Re-use

of recycled materials helps prevent

environmental pollution and reduces the

demand for raw materials.

Local regulations may provide for separate collection

of electrical products from the household, at municipal

waste sites or by the retailer when you purchase

a new product.

D

EWALT provides a facility for the collection and

recycling of DEWALT products once they have

reached the end of their working life. To take

advantage of this service please return your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest authorised

repair agent by contacting your local DEWALT offi ce

at the address indicated in this manual. Alternatively,

a list of authorised DEWALT repair agents and full

details of our after-sales service and contacts are

available on the Internet at: www.2helpU.com

GUARANTEE

• 30 DAY NO RISK

SATISFACTION GUARANTEE •

If you are not completely satisfied with

the performance of your D

simply return it within 30 days, complete as

purchased, to the point of purchase, for a full

refund or exchange. Proof of purchase must

be produced.

• ONE YEAR FREE SERVICE CONTRACT •

If you need maintenance or service for your

DEWALT tool, in the 12 months following

purchase, it will be undertaken free of charge

at an authorized DEWALT repair agent. Proof

of purchase must be produced. Includes

labour and spare parts for Power Tools.

Excludes accessories.

• ONE YEAR FULL WARRANTY •

If your DEWALT product becomes defective

due to faulty materials or workmanship within

12 months from the date of purchase, we

guarantee to replace all defective parts free of

charge or, at our discretion, replace the unit

free of charge provided that:

• The product has not been misused.

• Repairs have not been attempted by

unauthorized persons.

• Proof of purchase date is produced. This

guarantee is offered as an extra benefit

and is additional to consumers statutory

rights.

For the location of your nearest authorized

EWALT repair agent, please use the

D

appropriate telephone number on the back of

this manual. Alternatively, a list of authorized

DEWALT repair agents and full details on our

after-sales service are available on the Internet

at www.2helpU.com.

EWALT tool,

12

Page 15

13

Page 16

Belgique et Luxembourg Black & Decker - DEWALT Tel: +32 (0)015 - 15 47 9211

België en Luxemburg Nieuwlandlaan 7, IZ Aarschot B156 Fax: +32 (0)015 - 15 47 9210

B-3200 Aarschot www.dewalt.be

Danmark D

EWALT Tlf: 70201511

Sluseholmen 2-4 Fax: 70224910

2450 København SV www.dewalt.dk

Deutschland D

EWALT Tel: 06126-21-1

Richard-Klinger-Straße Fax: 06126-21-2770

65510 Idstein www.dewalt.de

Ελλάς Black & Decker (Hellas) S.A. Τηλ: (01) 8981-616

Στράβωνος 7 & Βουλιαγμένης 159 Φαξ: (01) 8983-570

Γλυφάδα 16674, Αθήνα Service: (01) 8982-630

España D

EWALT Tel: 934 797 400

Parque de Negocios “Mas Blau” Fax: 934 797 439

Edificio Muntadas, c/Bergadá, 1, Of. A6 www.dewalt.es

08820 El Prat de Llobregat (Barcelona)

France D

EWALT Tel: 472 20 39 72

Le Paisy Fax: 472 20 39 02

BP 21, 69571 Dardilly Cedex www.dewalt.fr

Schweiz D

EWALT Tel: 01 - 730 67 47

Suisse In der Luberzen 40 Fax: 01 - 730 70 67

Svizzera 8902 Urdorf www.dewalt.ch

Ireland D

EWALT Tel: 00353-2781800

Calpe House Rock Hill Fax: 00353-2781811

Black Rock, Co. Dublin www.dewalt.ie

Italia D

EWALT Tel: 800-014353

Viale Elvezia 2 Fax: 039-2387592

20052 Monza (Mi) www.dewalt.it

Nederlands Black & Decker - D

EWALT Tel: 0164 283000

Joulehof 12 Fax: 0164 283100

4600 AB Bergen Op Zoom www.dewalt.nl

Norge D

EWALT Tel: 22 90 99 00

Postboks 4814, Nydalen Fax: 22 90 99 01

0422 Oslo www.dewalt.no

Österreich D

EWALT Tel: 01 - 66116 - 0

Werkzeugevertriebs GmbH Fax: 01 - 66116 - 14

Erlaaerstraße 165, Postfach 320,1231 Wien www.dewalt.at

Portugal D

EWALT Tel: 214 66 75 00

Rua Egas Moniz 173 Fax: 214 66 75 75

João do Estoril, 2766-651 Estoril www.dewalt.pt

Suomi D

EWALT Oy Puh: 010 400 430

Tekniikantie 12 Faksi: 0800 411 340

02150 Espoo, Finland www.dewalt.fi

D

EWALT Oy Tel: 010 400 430

Teknikvägen 12 Fax: 0800 411 340

02150 Esbo, Finland www.dewalt.fi

Sverige D

EWALT Tel: 031 68 61 00

Box 94 Fax: 031 68 60 08

431 22 Mölndal www.dewalt.se

Türkiye

Merkez Servis Tel: 0212 533 52 55

Defterdar Mah.Savaklar Cad.No:15 34050 Faks: 0212 533 10 05

Edirnekapı, Eyüp - İstanbul www.dewalt.com.tr

United Kingdom D

EWALT Tel: 01753-56 70 55

210 Bath Road Fax: 01753-57 21 12

Slough, Berks SL1 3YD www.dewalt.co.uk

660824-00

14

06/08

Loading...

Loading...