Page 1

Questions? See us on the World Wide Web at www.DEWALT.com

¿Dudas? Visítenos en Internet: www.D

EWALT.com

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR

EL PRODUCTO.

D28114

4-1/2"/5" (115 mm/125 mm) Small Angle Grinder

Mini Esmeriladora Angular de 4-1/2"/5" (115 mm/125 mm)

Esmerilhador de Ângulo Pequeno 115 mm/125 mm (4-1/2"/5")

Page 2

Page 3

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable,

use a residual current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

English

1

Page 4

non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energising power

tools that have the switch on invites accidents.

English

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

Additional Specific Safety Instructions

for Grinders

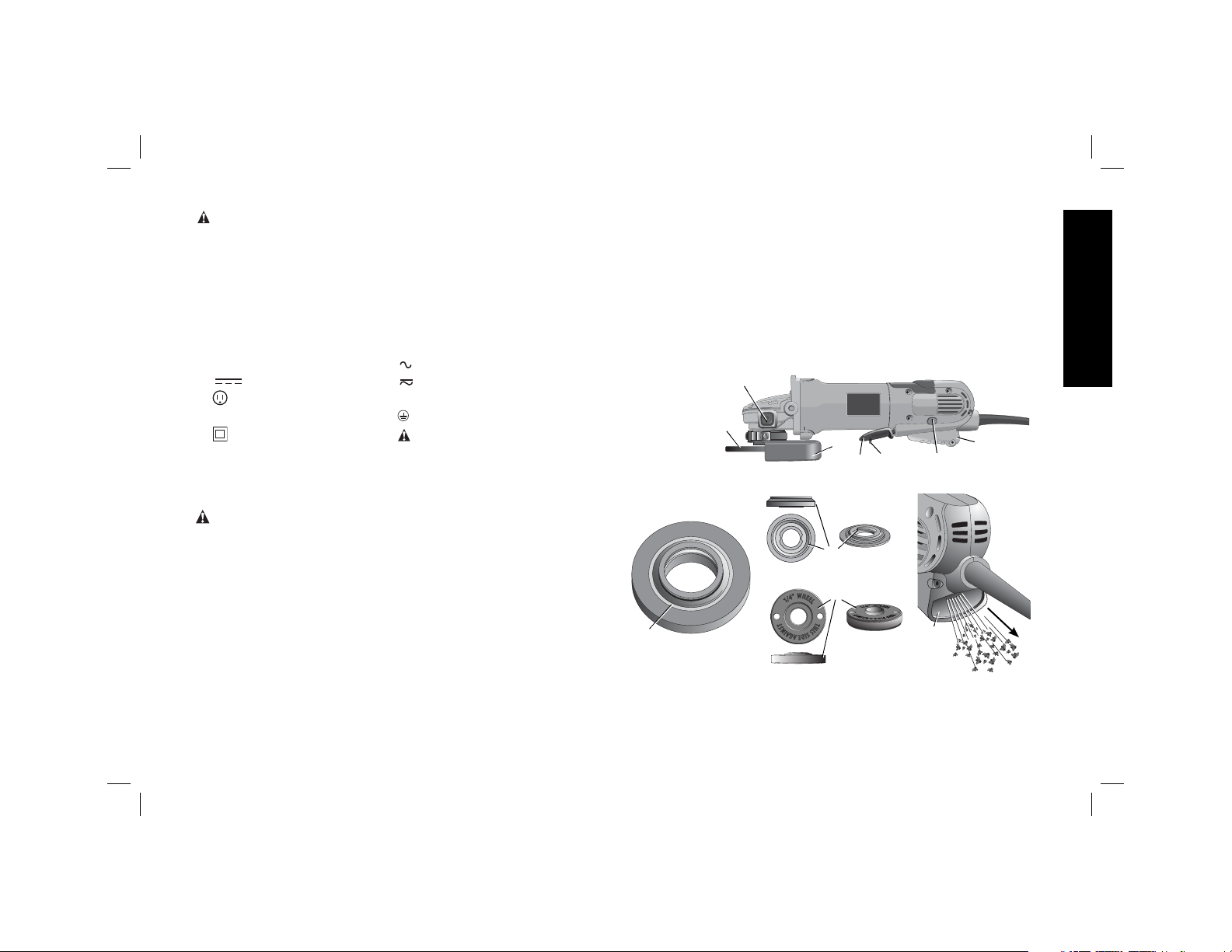

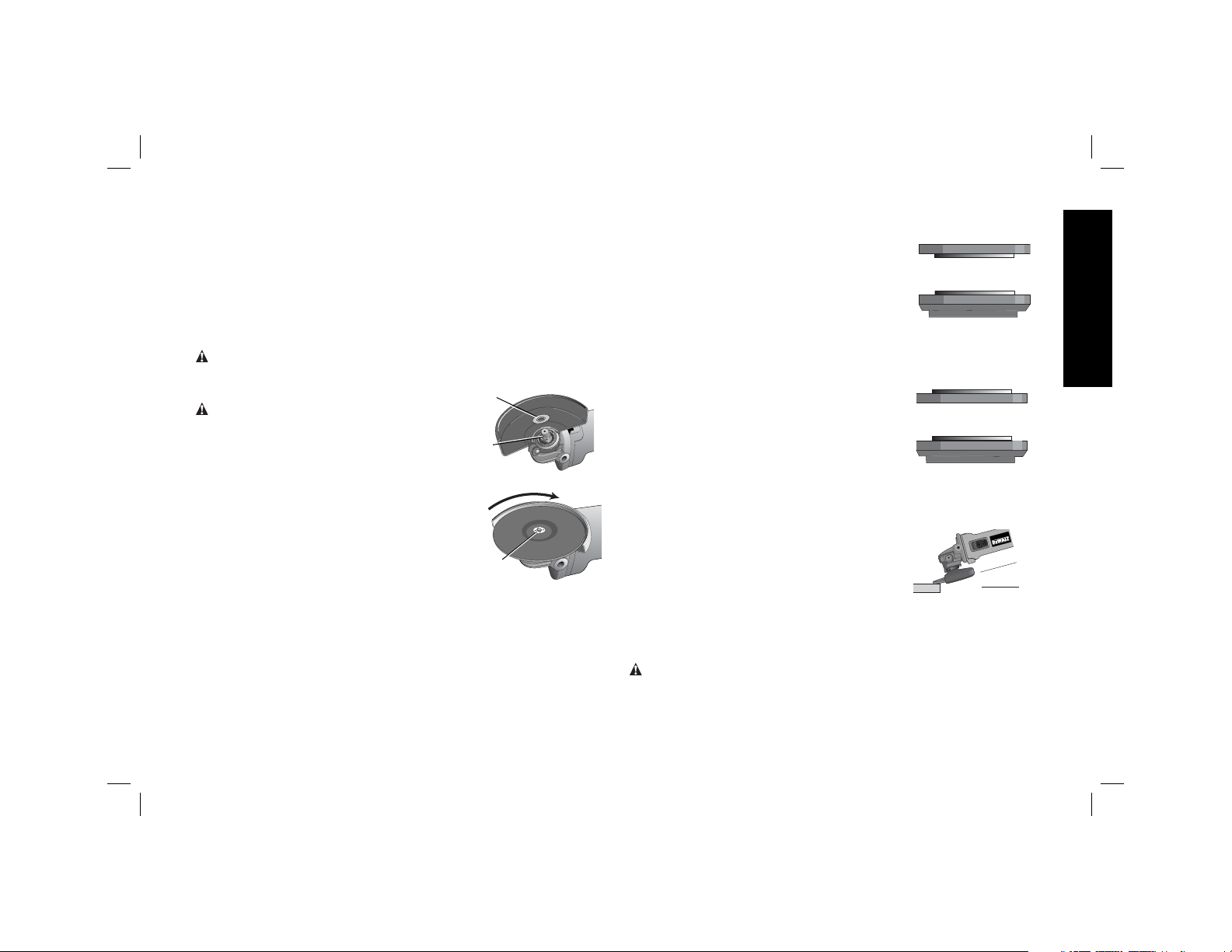

• Check that the grinding wheel backing flange has a yellow

rubber ring (D) installed, see Figure 1. Replace rubber ring if

missing, damaged or worn. See page 7 for details regarding

proper accessory installation.

WARNING: The grinding wheel or accessory may loosen

during coast-down of the tool when shut off if rubber ring is

missing or damaged. If grinding wheel or accessory loosens, it

may dismount from the machine and may cause serious personal

injury.

2

Page 5

• Always use proper guard with grinding wheel. A guard

protects operator from broken wheel fragments and wheel contact.

• Accessories must be rated for at least the speed recom mended

on the tool warning label. Wheels and other accessories running

over rated speed can fly apart and cause injury. Accessory ratings

must be above listed minimum wheel speed as shown on tool

nameplate.

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or its

own cord. Contact with a “live” wire will make exposed metal parts of

the tool “live” and shock the operator.

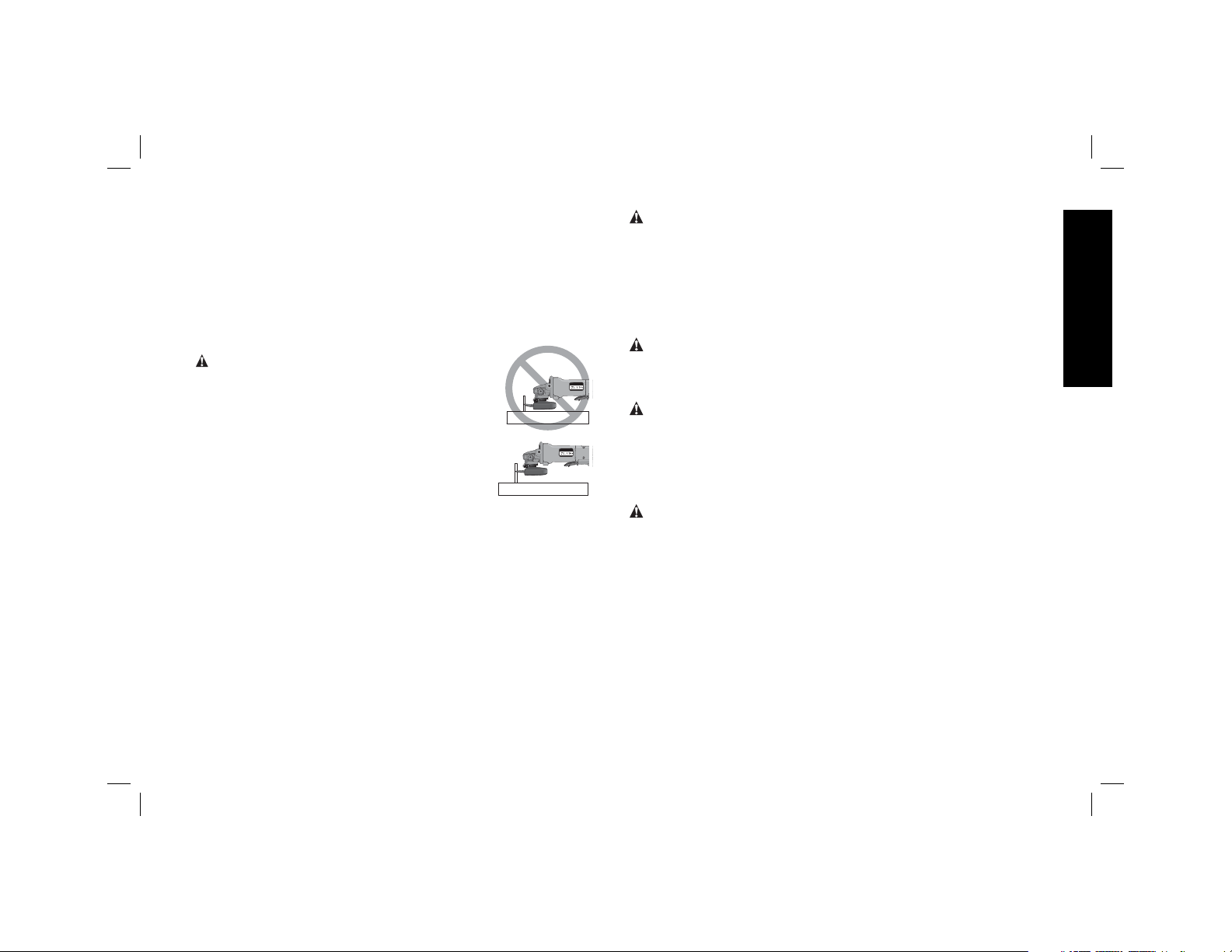

• Do not use Type 11 (flaring cup) wheels on this tool. Using

inappropriate accessories can result in injury.

• ALWAYS WEAR EYE PROTECTION WHEN USING THIS TOOL.

• Use of accessories not specified in this manual is not

recommended and may be hazardous. Use of power boosters

that would cause the tool to be driven at speeds greater than its rated

speed constitutes misuse.

• Do not use circular saw blades or any other toothed blades with

this tool. Serious injury may result.

• When starting the tool with a new or replacement wheel, or a

new or replacement wire brush installed, hold the tool in a well

protected area and let it run for one minute. If the wheel has an

undetected crack or flaw, it should burst in less than one minute. If the

wire brush has loose wires, they will be detected. Never start the tool

with a person in line with the wheel. This includes the operator.

• Avoid bouncing the wheel or giving it rough treatment. If this

occurs, stop the tool and inspect the wheel for cracks or flaws.

• Direct sparks away from operator, bystanders or flammable

materials. Sparks may be produced while cutting and/or grinding.

Sparks may cause burns or start fires.

• Always use side handle. Tighten the handle securely. The side

handle should always be used to maintain control of the tool at all

times.

• Never cut into area that may contain electrical wiring or

piping. Serious injury may result.

• Clean out your tool often, especially after heavy use. Dust

and grit containing metal particles often accumulate on interior

surfaces and could create an electric shock hazard.

• Do not operate this tool for long periods of time. Vibration

caused by the operating action of this tool may cause permanent

injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

• Direct the Dust Ejection System (DES) away from operator

and coworkers. Serious injury may result (Fig. 1, K).

Causes and Operator Prevention

of Kickback

• Kickback is a sudden reaction to a pinched, bound or misaligned

wheel, wire brush or flap disc causing an uncontrolled cut-off tool

to lift up and out of the workpiece toward the operator.

• When the wheel is pinched or bound tightly by the workpiece,

the wheel stalls and the motor reaction drives the unit rapidly

back toward or away from the operator.

• Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

• Maintain a firm grip with both hands on the unit and

position your body and arm to allow you to resist

kickback forces. Kickback forces can be controlled by the

operator, if proper precautions are taken.

• When wheel is binding, or when interrupting a cut for any

reason, release the trigger and hold the unit motionless

in the material until the wheel comes to a complete

stop. Never attempt to remove the unit from the work or

pull the unit backward while the wheel is in motion or

kickback may occur. Investigate and take corrective actions

to eliminate the cause of wheel binding.

English

3

Page 6

• When restarting a cut-off tool in the workpiece, check

that the wheel is not engaged into the material. If wheel is

binding, it may walk up or kickback from the workpiece as the

tool is restarted.

• Support large panels to minimize the risk of wheel

pinching and kickback. Large panels tend to sag under their

own weight. Support must be placed under the panel on both

English

sides, near the line of cut and near the edge of the panel.

CAUTION: Use extra care when working into a corner because

a sudden, sharp movement of the grinder may be experienced

when the wheel or other accessory contacts a secondary surface

or a surface edge.

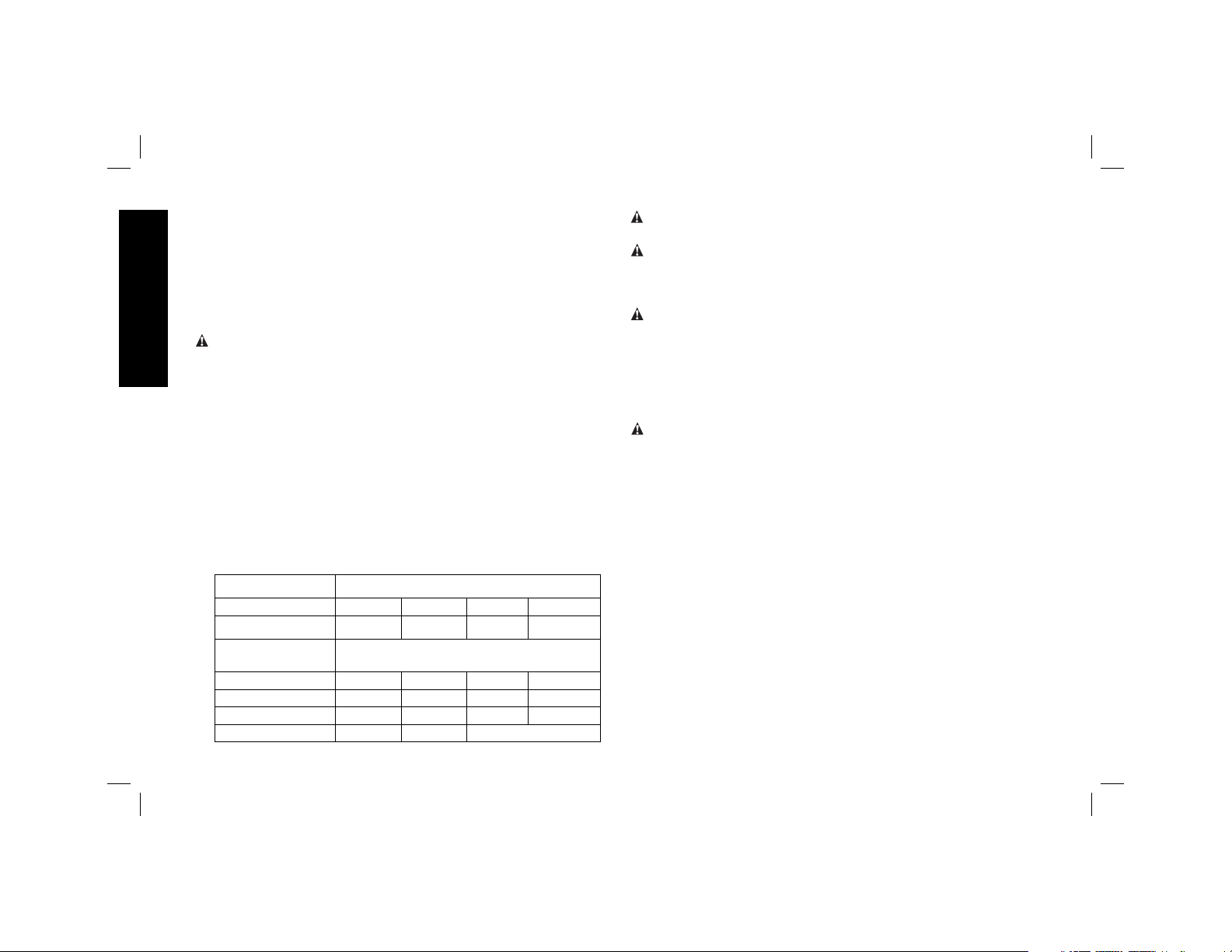

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized

cord will cause a drop in line voltage resulting in loss of power

and overheating. When using more than one extension to make

up the total length, be sure each individual extension contains

at least the minimum wire size. The following table shows the

correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Voltage (Volts)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Rated Ampere

range

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Not Recommended

Total length of cord in meters (m)

Minimal cross-sectional area of the

cord in meters (mm2 )

WARNING: Always use eye protection. All users and bystanders

must wear eye protection that conforms to ANSI Z87.1.

WARNING: Always wear proper personal hearing protection

that conforms to ANSI S12.6 (S3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses

are NOT safety glasses. Also use face or dust mask if cutting

operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

4

Page 7

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V .......... volts A ........ amperes

Hz ........ hertz W....... watts

min ....... minutes

..... alternating current

..... direct current ..... alternating or direct current

......... Class I Construction no ...... no load speed

............. (grounded) ...... earthing terminal

......... Class II Construction ...... safety alert symbol

............. (double insulated) …/min per minute

RPM ..... revolutions per minute

DESCRIPTION (FIG. 1)

WARNING: Never modify the power tool or any part of it.

Damage or personal injury could result.

INTENDED USE

This tool is designed for professional grinding applications.

DO NOT use under wet conditions or in presence of flammable

liquids or gases.

This small angle grinder is a professional power tool. DO NOT let

children come into contact with the tool. Supervision is required

when inexperienced operators use this tool.

A. Paddle Switch G. Quick-Change Backing Flange

B. Lock-Off Lever H. Threaded Clamp Nut

C. Spindle Lock Button I. Type 27 Guard

D. Yellow Rubber Ring J. Lock On Button

E. Anti-Vibration Side K. Dust Ejection System™ (DES)

Handle (not shown)

F. 5" Grinding Wheel

(Type 27)

FIG. 1

D

C

F

I

B

A

G

H

K

K

J

English

5

Page 8

FEATURES

E-SWITCH PROTECTION™

The ON/OFF switch has a no-volt release function. In the event of

a power outage or other unexpected shut down, the switch needs

to be cycled (turned off and on) to restart tool.

E-CLUTCH™

This unit is equipped with an E-Clutch™ (Electronic Clutch), which

English

in the event of a high-load or wheel pinch, the unit will shut off to

reduce the reaction torque to the user. The switch needs to be

cycled (turned off and on) to restart the tool.

POWER-OFF™ OVERLOAD PROTECTION

The power supply to the motor will be reduced in case of motor

overload. With continued motor overload, the tool will shut off. The

switch must be cycled (turned off and on) to restart tool. The power

will return to normal once the tool has cooled down to a suitable

operating temperature. NOTE: Run the tool at no load to reduce the

cool down time.

COMPLETE ELECTRONIC CONTROL™

The internal electronic speed control offers consistent wheel speed

while using the tool.

ASSEMBLY AND ADJUSTMENTS

WARNING: Turn off and unplug tool before

making any adjustments or removing or

installing accessories. Before reconnecting

the tool, depress and release the trigger

switch to ensure that the tool is off.

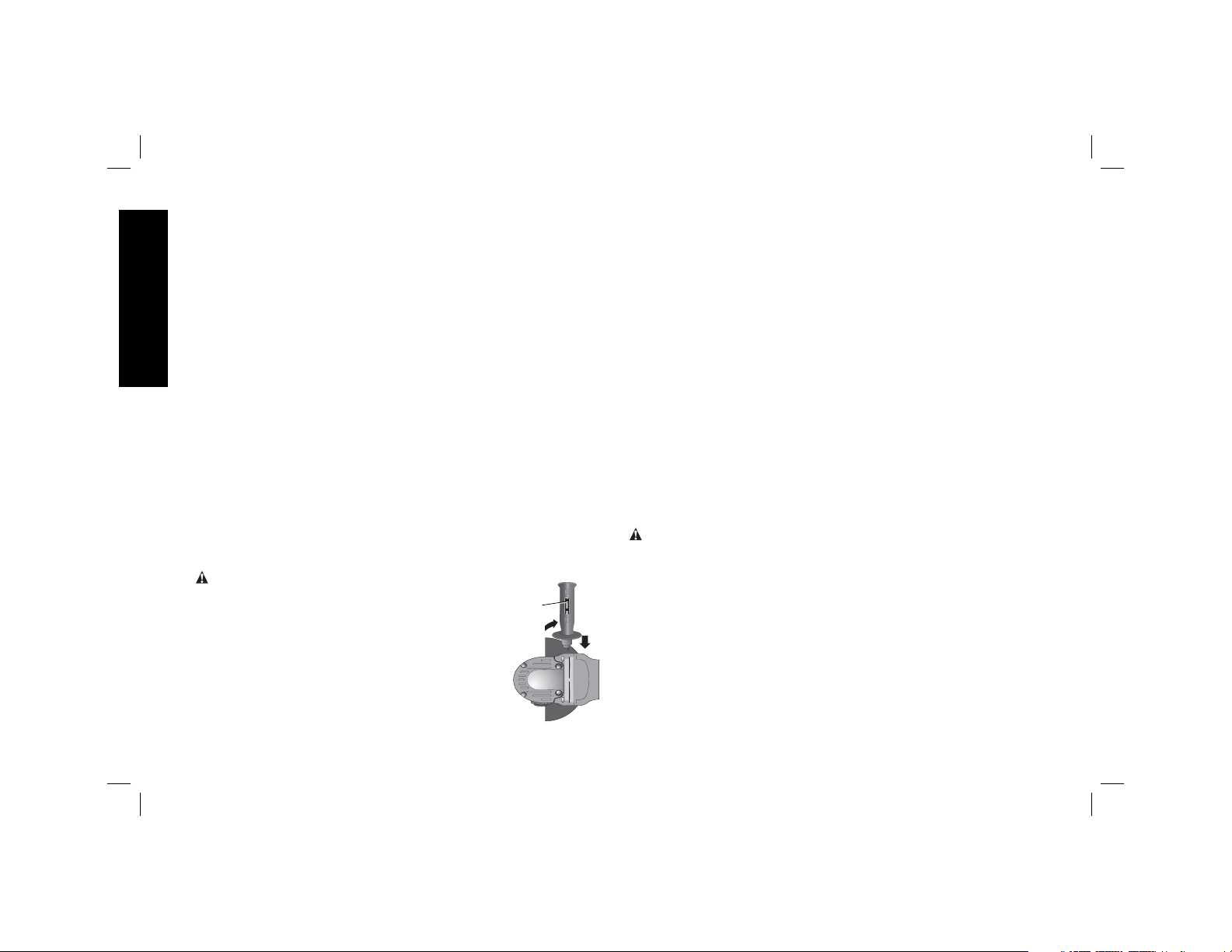

ATTACHING SIDE HANDLE

The side handle (E) can be fitted to either side

of the gear case in the threaded holes, as

shown. Before using the tool, check that the

handle is tightened se cure ly. Use a wrench to

firmly tighten the side handle.

Rotating the Gear Case

1. Remove guard and flanges from tool.

2. Remove the four corner screws attaching the gear case to

motor housing.

3. Separating the gear case from motor housing not more than

1/4", rotate the gear case head to desired position.

NOTE: If the gear case and motor housing become separated

by more than 1/4", the tool must be serviced and re-assembled

by a D

EWALT service center. Failure to have the tool serviced

may cause brush, motor and bearing failure.

4. Re-install screws to attach the gear case to the motor housing.

Tighten screws to 18 in./lbs. torque. Overtightening could cause

screws to strip.

5. Re-install guard and correct flanges for the appropriate

accessories.

Accessories

It is important to choose the correct guards, backing pads and

flanges to use with grinder accessories. See pages 7–9 for

information on choosing the correct accessories.

WARNING: Accessories must be rated for at least the speed

recom mended on the tool warning label. Wheels and other

accessories running over rated accessory speed may burst and

cause injury. Threaded accessories must have a 5/8-11 hub.

E

Every unthreaded accessory must have a 7/8" arbor hole. If it

does not, it may have been designed for a circular saw and should

not be used. Use only the accessories shown on pages 7–9 of this

manual. Accessory ratings must be above listed minimum wheel

speed as shown on tool nameplate.

6

Page 9

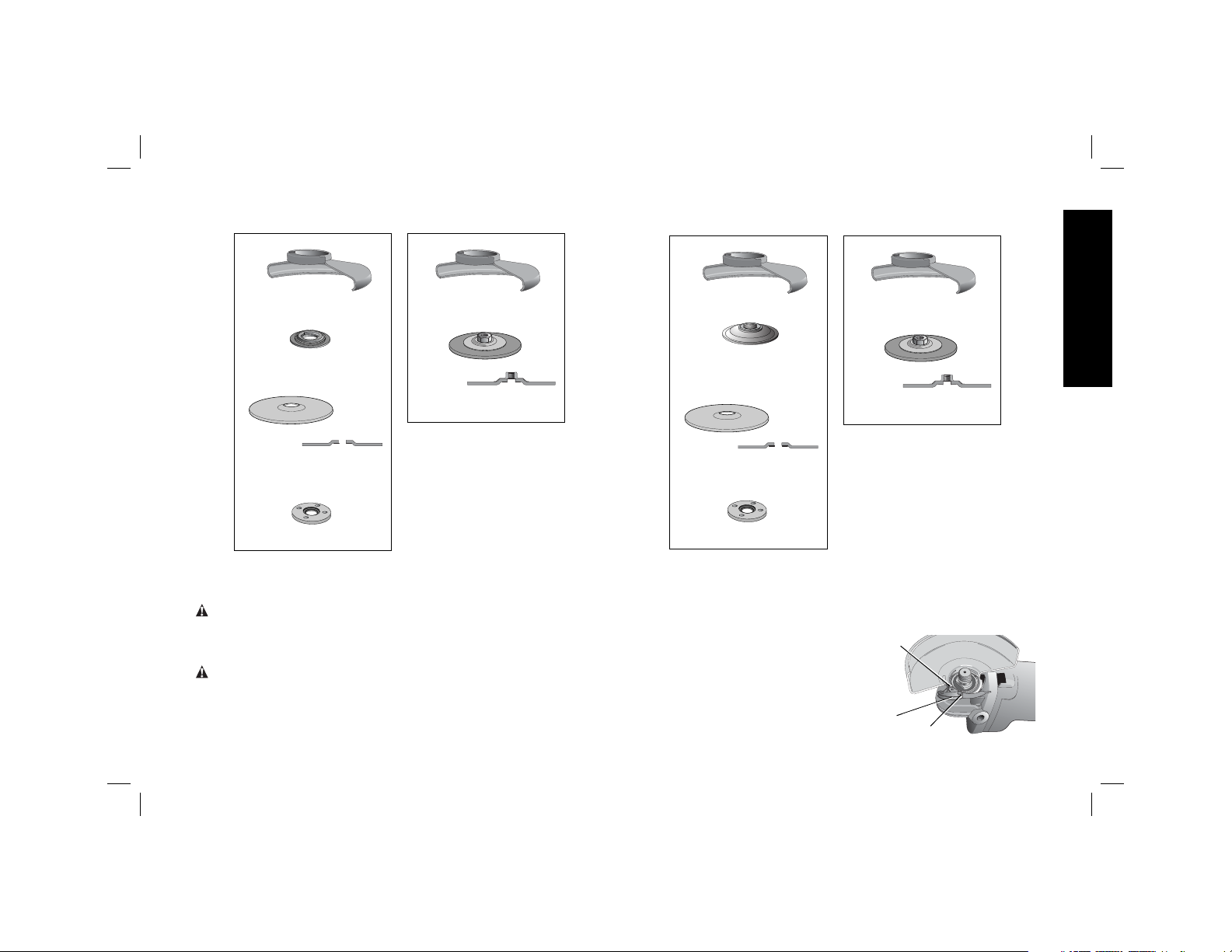

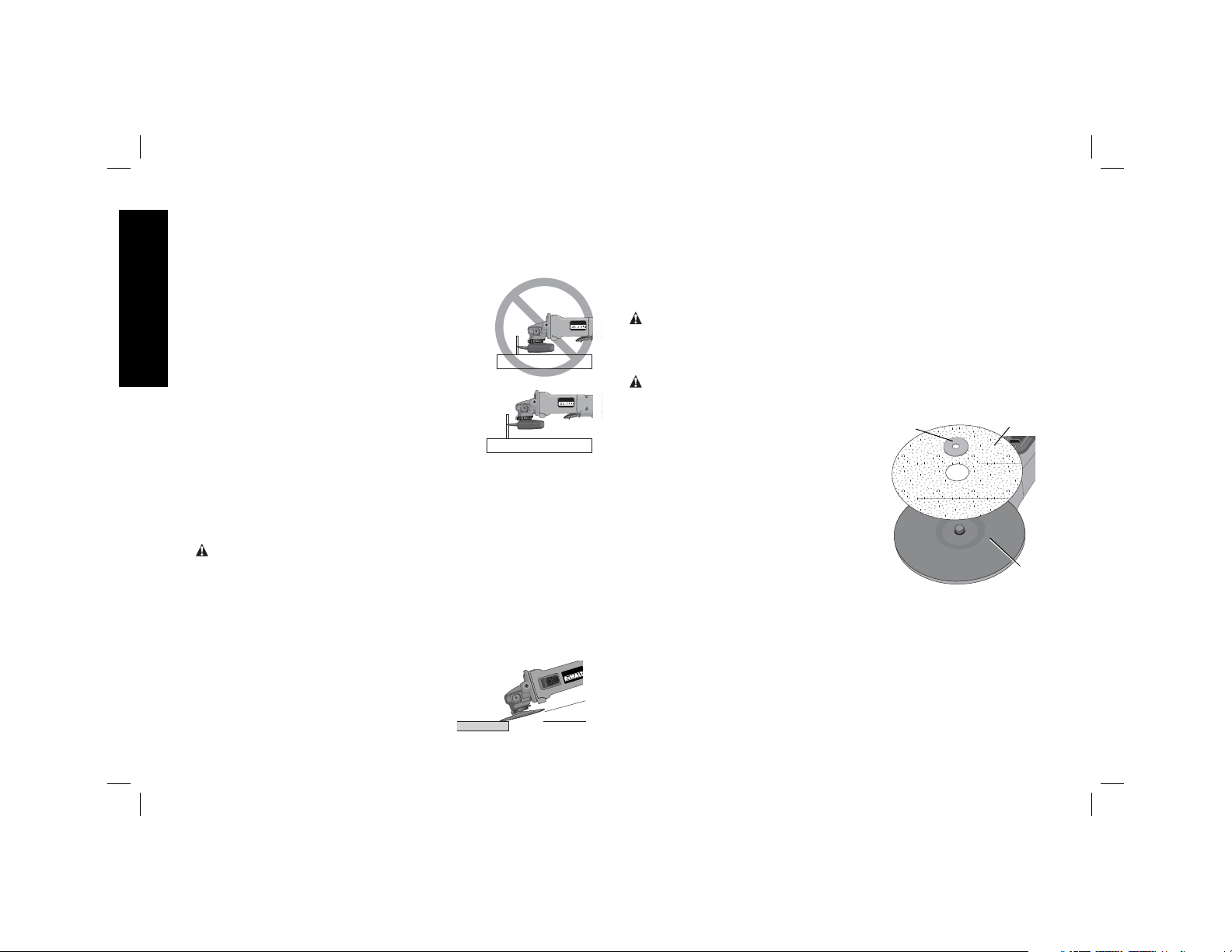

4-1/2" and 5" Grinding Wheels

6" Grinding Wheels

English

Type 27 guard

Quick-change

backing flange

Type 27 depressed

center wheel

threaded clamp nut

Type 27 guard

Type 27 hubbed wheel

Mounting Guard

MOUNTING AND REMOVING GUARD

WARNING: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or

accessories. Before reconnecting the tool, depress and release

the paddle switch to ensure that the tool is off.

CAUTION: Guards must be used with all grinding wheels,

sanding flap discs, wire brushes, and wire wheels. The tool may be

used without a guard only when sanding with conventional sanding

discs. Some D

for use with depressed center wheels (Type 27) and hubbed

EWALT models are provided with a guard intended

Type 27 guard

stamped steel

Quick-Change

backing flange

Type 27 depressed

center wheel

threaded clamp nut

grinding wheels (Type 27). The same guard is designed for use with

sanding flap discs (Type 27 and 29) and wire brushes. Grinding and

cutting with wheels other than Type 27 and 29 require different

accessory guards not included with tool. Mounting instructions for

these accessory guards are included in the accessory package.

1. Open the guard latch (M). Align the

lugs (N) on the guard with the slots

(O) on the gear case.

2. Push the guard down until the

guard lugs engage and rotate

freely in the groove on the gear

case hub.

Type 27 guard

Type 27 hubbed wheel

N

O

M

7

Page 10

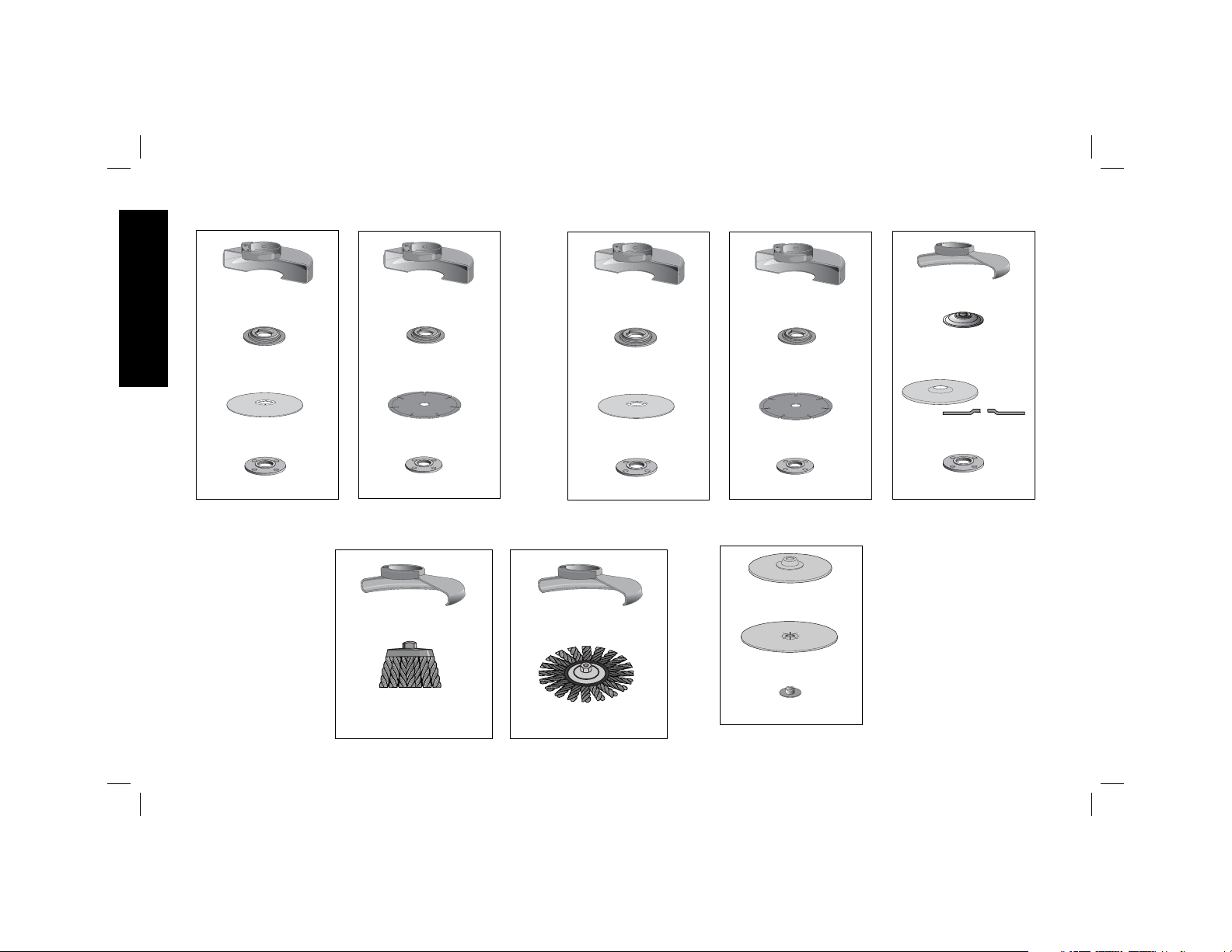

4-1/2" and 5" Cutting Wheels

6" Cutting Wheels

English

Type 1 abrasive

threaded clamp nut

Type 1 guard

Quick-Change

backing flange

cutting wheel

Type 1 guard

Quick-Change

backing flange

diamond cutting wheel

threaded clamp nut

Wire Wheels

Type 27 guard

3" wire cup

brush

Type 1 guard

Quick-Change

backing flange

Type 1 abrasive

cutting wheel

threaded clamp nut

Type 27 guard

4" wire wheel

Type 1 guard

Quick-Change

backing flange

diamond cutting wheel

threaded clamp nut

Sanding Discs

rubber backing pad

sanding disc

threaded clamp nut

Type 27 guard

stamped steel

Quick-Change

backing flange

Type 27 depressed

center wheel

threaded clamp nut

8

Page 11

4-1/2" and 5" Sanding Flap Discs

Type 27 guard

hubbed sanding

flap disc

3. With the guard latch open, rotate the guard (I) into the desired

working position. The guard body should be positioned

between the spindle and the operator to provide maximum

operator protection.

4. Close the guard latch to secure the guard

on the gear case. You should not be able

to rotate the guard by hand when the

latch is closed. Do not operate the grinder

with a loose guard or the clamp lever in

open position.

5. To remove the guard, open the guard latch, rotate the guard so

that the arrows are aligned and pull up on the guard.

Type 27 guard

Quick-Change

backing flange

non-hubbed sanding

flap disc

threaded clamp nut

I

NOTE: The guard is pre-adjusted to the

diameter of the gear case hub at the

factory. If, after a period of time, the guard

becomes loose, tighten the adjusting screw

(P) with clamp lever in the closed position.

CAUTION: Do not tighten the adjusting

screw with the clamp lever in open position. Undetectable damage

to the guard or the mounting hub may result.

CAUTION: If guard cannot be tightened by adjusting clamp, do

not use tool and take the tool and guard to a service center to repair

or replace the guard.

P

OPERATION

WARNING: Always observe the safety instructions and applicable

regulations.

WARNING: To reduce the risk of serious personal injury, turn

tool off and disconnect tool from power source before making

any adjustments or removing/installing attachments

or accessories.

Guards and Flanges

It is important to choose the correct guards and flanges to use

with the grinder accessories. See pages 7–9 for the correct

accessories.

NOTE: Edge grinding and cutting can be performed with Type 27

wheels designed and specified for this purpose.

WARNING: Accessories must be rated for at least the speed

recom mended on the tool warning label. Wheels and other

accessories running over rated accessory speed may burst and

cause injury. Every unthreaded accessory must have a 7/8" arbor

hole. If it does not, it may have been designed for a circular saw and

should not be used. Use only the accessories shown on

pages 7–9. Accessory ratings must be above listed minimum

wheel speed as shown on tool nameplate.

English

9

Page 12

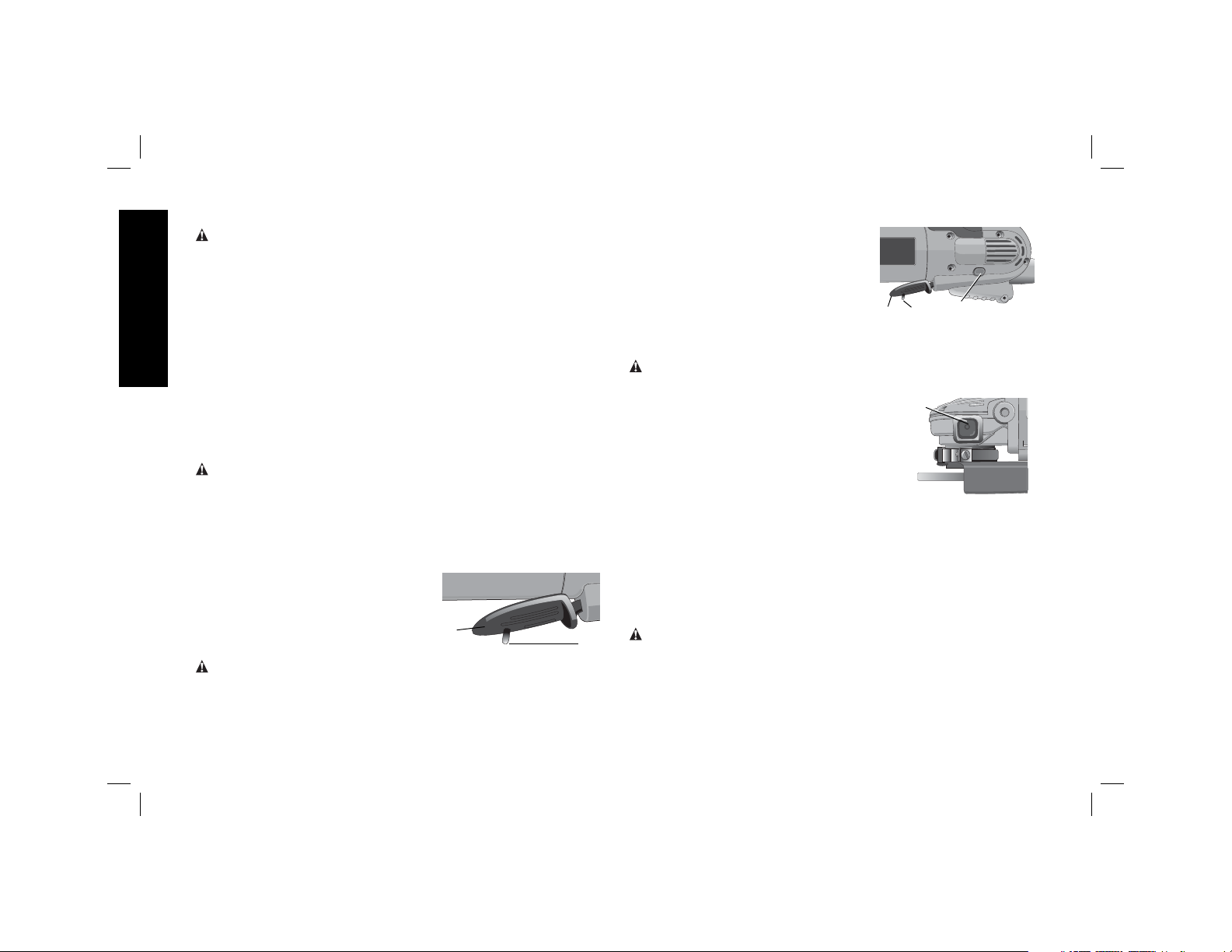

Switches

CAUTION: Hold the side handle and body of the tool firmly to

maintain control of the tool at start up and during use and until the

wheel or accessory stops rotating. Make sure the wheel has come

to a complete stop be fore laying the tool down.

NOTE: To reduce unexpected tool movement, do not switch the

tool on or off while under load conditions. Allow the grinder to run

up to full speed before touching the work surface. Lift the tool from

English

the surface before turning the tool off. Allow the tool to stop rotating

before putting it down.

SOFT START FEATURE

The soft start feature allows a slow speed build-up to avoid an initial

jerk when starting. This feature is particularly useful when working in

confined areas. Current surge will also be reduced.

PADDLE SWITCH

CAUTION: Before connecting the tool to a power source depress

and release the paddle switch (A) once without depressing the lockon button (Fig. 1, J) to ensure that the switch is off. Depress and

release the paddle switch as described above after any interruption

in power supply to the tool, such as the activation of a ground fault

interrupter, throwing of a circuit breaker, accidental unplugging, or

power failure.

To turn the tool on, push the

lock-off lever (B) toward the back of

the tool, then depress the paddle

switch (A). The tool will run while the

switch is depressed. Turn the tool off

by releasing the paddle switch.

WARNING: Do not disable the lock-off lever. If the lock-off lever

is disabled, the tool may start unexpectedly when it is laid down.

A

LOCK-ON BUTTON

The lock-on button (J) offers increased

comfort in extended use applications.

To lock the tool on, push the lock-off

lever (B) toward the back of the tool

then depress the paddle switch (A).

With the tool running, depress the lockon button (J). The tool will continue to

run after the paddle switch is released. To unlock the tool, depress

and release the paddle switch. This will cause the tool to stop.

CAUTION: Allow the tool to reach full speed before touching tool

to the work surface. Lift the tool from the work surface before

turning the tool off.

SPINDLE LOCK

The spindle lock (C) is provided to prevent

the spindle from rotating when installing or

removing wheels. Operate the spindle lock

only when the tool is turned off, unplugged

from the power supply, and has come to

a complete stop. Do not engage the spindle lock while the tool is

operating because damage to the tool will result. To engage the

lock, depress the spindle lock button and rotate the spindle until you

are unable to rotate the spindle further.

Mounting and Using Depressed Center

A

B

C

Grinding Wheels and Sanding Flap Discs

MOUNTING AND REMOVING HUBBED WHEELS

B

WARNING: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or

accessories. Before reconnecting the tool, depress and release

the paddle switch to ensure that the tool is off.

J

10

Page 13

Hubbed wheels install directly on the 5/8-11 threaded spindle.

Thread of accessory must match thread of spindle.

1. Backing flange is retained to the grinder by an O-ring on the

spindle. Remove backing flange by pulling and twisting flange

away form the machine.

2. Thread the wheel on the spindle by hand.

3. Depress the spindle lock button and use a wrench to tighten the

hub of the wheel.

4. Reverse the above procedure to remove the wheel.

CAUTION: Failure to properly seat the wheel before turning the

tool on may result in damage to the tool or the wheel.

MOUNTING NON-HUBBED WHEELS

G

WARNING: Turn off and unplug the

tool before making any adjustments or

removing or installing attachments or

D

accessories. Before reconnecting the

tool, turn the switch on and off as

previously described to ensure that the

tool is off.

Depressed center Type 27 grinding wheels

must be used with included flanges.

1. Be sure the backing flange recess is

seated onto the flats of the spindle by

H

pushing and twisting the flange before

placing wheel.

2. Place wheel against the backing flange, centering the wheel on

the raised section (pilot) of the backing flange.

3. While depressing the spindle lock button, thread the clamp nut

(H) on spindle. If the wheel you are installing is more than 1/8"

(3.17mm) thick, place the threaded clamp nut on the spindle so

that the raised section (pilot) fits into the center of the wheel.

If the wheel you are installing is 1/8" (3.17mm) thick or less,

place the threaded clamp nut on the spindle so that the raised

section (pilot) is not against the wheel.

4. While depressing the spindle lock button,

tighten the clamp nut with a wrench.

1/4" WHEELS

(6.35 mm)

5. To remove the wheel, depress the

spindle lock button and loosen the

threaded clamp nut with a wrench.

threaded clamp nut

NOTE: If the wheel spins after the clamp

nut is tightened, check the orientation of

the threaded clamp nut. If a thin wheel is

installed with the pilot on the clamp nut

against the wheel, it will spin because the

height of the pilot prevents the clamp nut

from holding the wheel.

SURFACE GRINDING WITH GRINDING

WHEELS

Quick-Change

backing flange

1/8" WHEELS

(3.17 mm)

threaded clamp nut

1. Allow the tool to reach full speed before

touching the tool to the work surface.

2. Apply minimum pressure to the work

surface, allowing the tool to operate at

Quick-Change

backing flange

high speed. Grinding rate is greatest

when the tool operates at high speed.

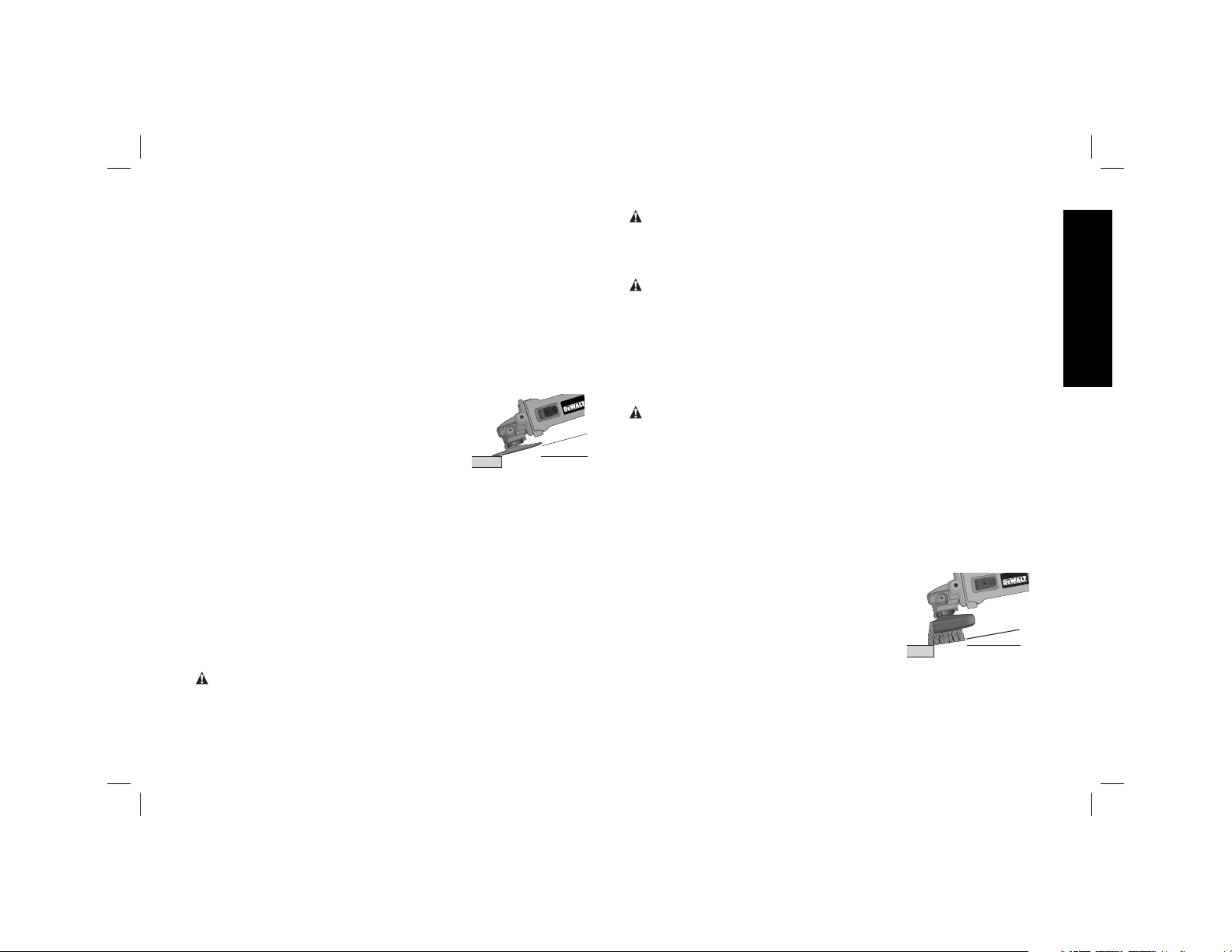

3. Maintain a 20˚ to 30˚ angle between the

tool and work surface.

4. Continuously move the tool in a forward

and back motion to avoid creating gouges

in the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

EDGE GRINDING WITH GRINDING WHEELS

CAUTION: Wheels used for cutting and edge grinding may break

if they bend or twist while the tool is being used to do cut-off work or

deep grinding. To reduce the risk of serious injury, limit the use of

these wheels with a standard Type 27 guard to shallow cutting and

notching (less than 1/2" in depth). The open side of the guard must

English

20˚-30˚

11

Page 14

be positioned away from the operator. For deeper cutting with a

Type 1 cut-off wheel, use a closed, Type 1 guard. See the chart on

page 8 for more information. Type 1 guards are available at extra

cost from your local dealer or authorized service center.

1. Allow the tool to reach full speed before

touching the tool to the work surface.

2. Apply minimum pressure to the work

English

surface, allowing the tool to operate at

high speed. Grinding rate is greatest

when the tool operates at high speed.

3. Position yourself so that the openunderside of the wheel is facing away

from you.

4. Once a cut is begun and a notch is

established in the workpiece, do not

change the angle of the cut. Changing

the angle will cause the wheel to bend and may cause wheel

breakage. Edge grinding wheels are not designed to withstand

side pressures caused by bending.

5. Remove the tool from the work surface before turning the tool

off. Allow the tool to stop rotating before laying it down.

WARNING: Do not use edge grinding/cutting wheels for surface

grinding applications because these wheels are not designed for

side pressures encountered with surface grinding. Wheel breakage

and injury may result.

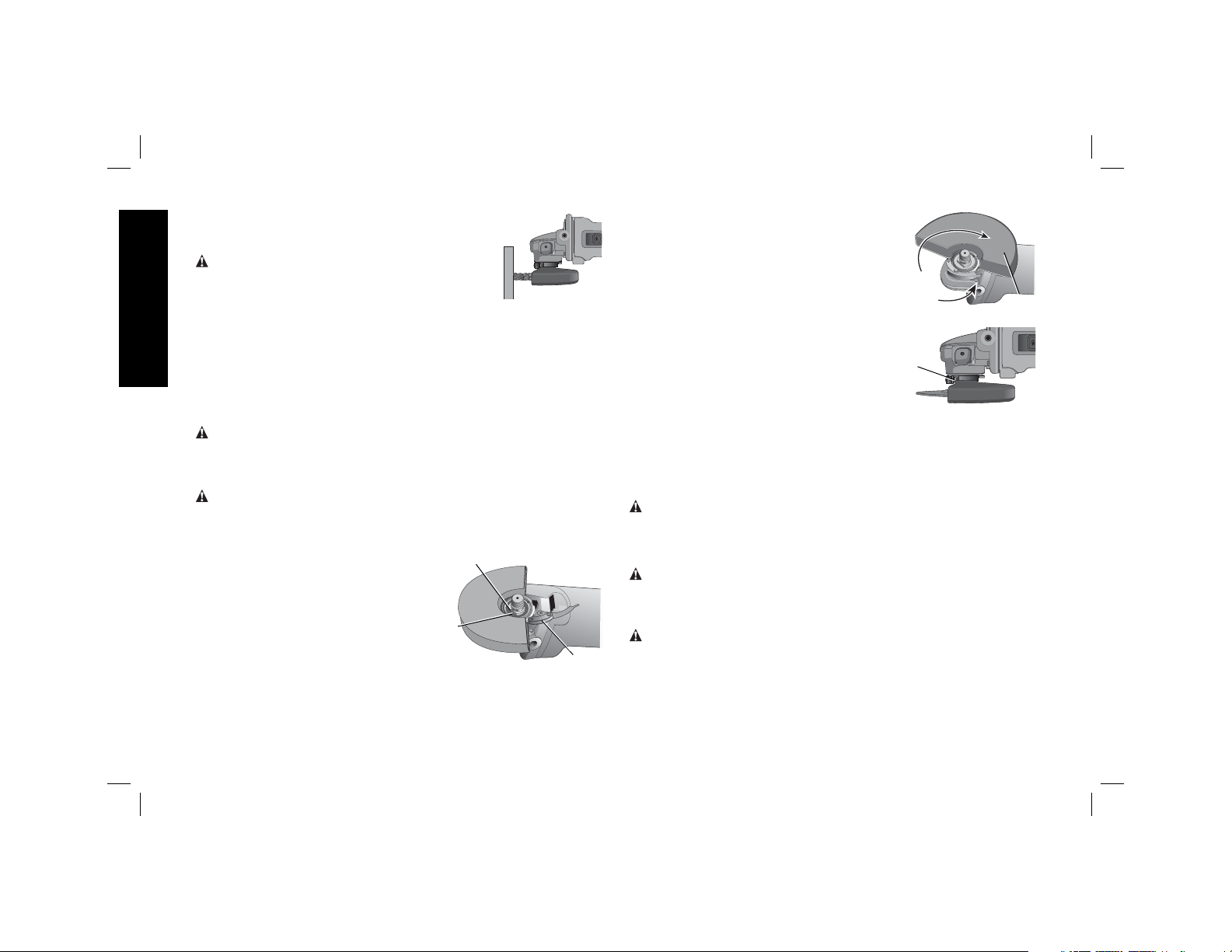

SURFACE FINISHING WITH SANDING FLAP DISCS

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to work

surface, allowing the tool to operate

at high speed. Sanding rate is

greatest when the tool operates at

high speed.

5˚-10˚

3. Maintain a 5˚ to 10˚ angle between the tool and work surface.

4. Continuously move the tool in a forward and backward motion to

avoid creating gouges in the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

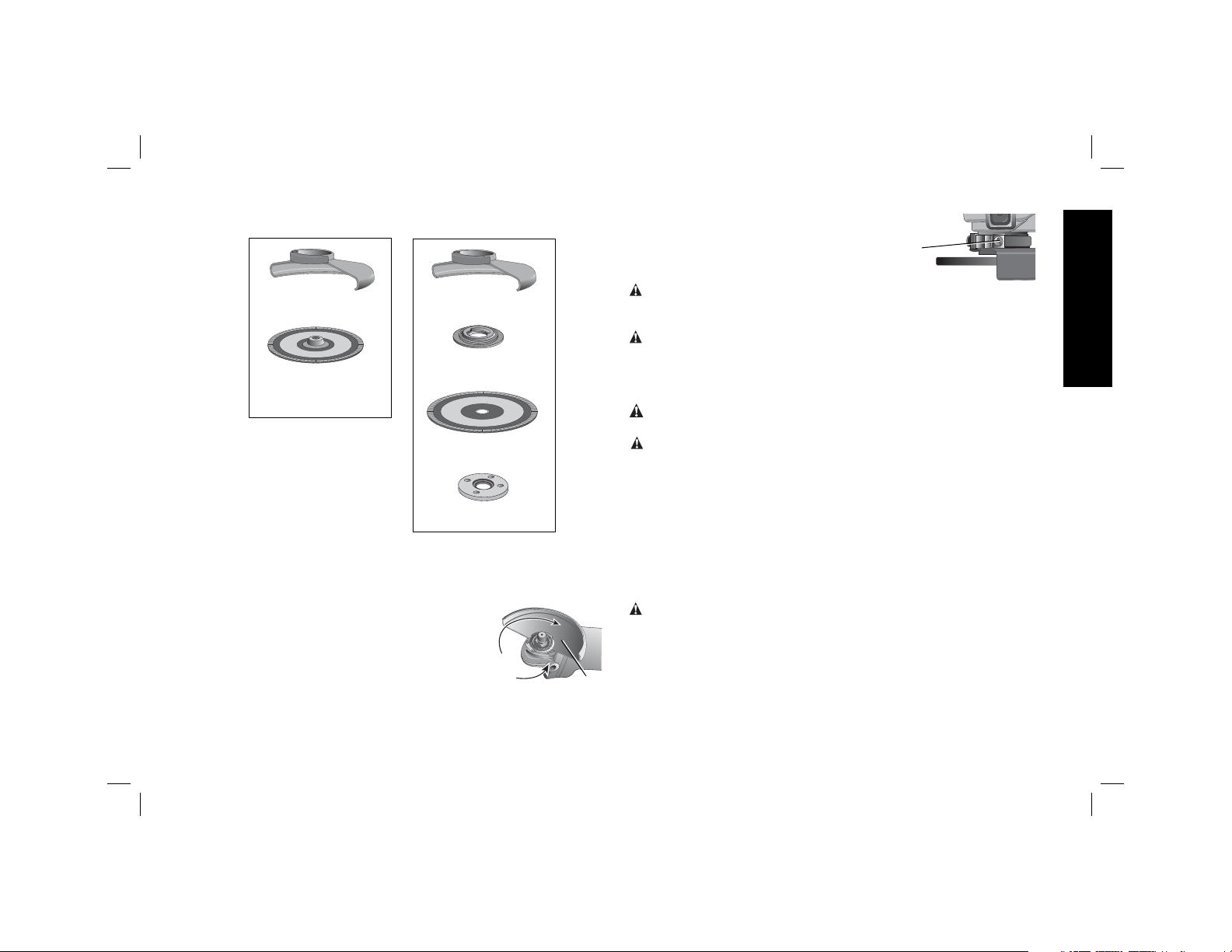

MOUNTING SANDING BACKING PADS

WARNING: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or

accessories. Before reconnecting the tool, turn the switch on

and off as previously described to ensure that the tool is off.

CAUTION: Proper guard must be reinstalled for grinding wheel,

sanding flap disc, wire brush or wire wheel applications after

sanding applications are complete.

1. Place or appropriately thread

H

pad backing (R) on the spindle.

2. Place the sanding disc (S) on the

backing pad.

3. While depressing spindle lock,

thread clamp nut (H) on spindle,

piloting the raised hub on the clamp

nut into the center of san ding disc

and backing pad.

4. Tighten the clamp nut by hand.

Then depress the spindle lock

button while turning the sanding disc until the sanding disc and

clamp nut are snug.

5. To remove the wheel, grasp and turn the backing pad and

sanding pad while depressing the spindle lock button.

USING SANDING BACKING PADS

Choose the proper grit sandpaper for your application. Sandpaper is

available in various grits. Coarse grits yield faster material removal

rates and a rougher finish. Finer grits yield slower material removal

and a smoother finish.

12

S

R

Page 15

Begin with coarse grit discs for fast, rough material removal. Move to a

medium grit paper and finish with a fine grit disc for optimal finish.

Coarse 16 - 30 grit

Medium 36 - 80 grit

Fine Finishing 100 - 120 grit

Very Fine Finishing 150 - 180 grit

1. Allow the tool to reach full speed before touching tool to the

work surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Sanding rate is greatest when the tool

operates at high speed.

3. Maintain a 5˚ to 15˚ angle between

the tool and work surface. The san ding

disc should contact approximately one

inch of work surface.

4. Move the tool constantly in a straight

line to prevent burning and swirling

of work surface. Allowing the tool to rest on the work surface

without moving, or moving the tool in a circular motion causes

burning and swirling marks on the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

5˚-15˚

Mounting and Using Wire Brushes

and Wire Wheels

Wire cup brushes or wire wheels screw directly on the grinder

spindle without the use of flanges. Use only wire brushes or

wheels provided with a 5/8-11 threaded hub. A Type 27 guard is

required when using wire brushes and wheels.

CAUTION: Wear work gloves when handling wire brushes

and wheels. They can become sharp.

CAUTION: Wheel or brush must not touch guard when mounted

or while in use. Undetectable damage could occur to the accessory,

causing wires to fragment from accessory wheel or cup.

MOUNTING WIRE BRUSHES AND WIRE WHEELS

WARNING: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or

accessories. Before reconnecting the tool, turn the switch on

and off as previously described to ensure that the tool is off.

1. Thread the wheel on the spindle by hand.

2. Depress spindle lock button and use a wrench on the hub of the

wire wheel or brush to tighten the wheel.

3. To remove the wheel, reverse the above procedure.

CAUTION: Failure to properly seat the wheel hub before turning

the tool on may result in damage to tool or wheel.

USING WIRE CUP BRUSHES AND WIRE WHEELS

Wire wheels and brushes can be used for removing rust, scale and

paint, and for smoothing irregular surfaces.

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Material removal rate is greatest when

the tool operates at high speed.

3. Maintain a 5˚ to 10˚ angle between the

tool and work surface for wire cup

brushes.

4. Maintain contact between the edge of

the wheel and the work surface with

wire wheels.

5. Continuously move the tool in a forward and backward motion

to avoid creating gouges in the work surface. Allowing the tool

to rest on the work surface without moving, or moving the tool

in a circular motion causes burning and swirling marks on the

work surface.

English

5˚-10˚

13

Page 16

6. Remove the tool from the work surface

before turning the tool off. Allow the tool to

stop rotating before setting it down.

CAUTION: Use extra care when working over

an edge, as a sudden sharp movement of

grinder may be experienced.

Mounting and Using Cutting

English

(Type 1) Wheels

Cutting wheels include diamond wheels and abrasive discs.

Abrasive cutting wheels for metal and concrete use are available.

Diamond blades for concrete cutting can also be used.

NOTE: All grinders that use Type 1 wheels use the quick-change

backing flange (G).

WARNING: Fail ure to use proper flange and guard can re sult in

injury resulting from wheel breakage and wheel contact. See page 7

for more information.

MOUNTING CLOSED (TYPE 1) GUARD

WARNING: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or

accessories. Before reconnecting the tool, turn the switch on

and off as previously described to ensure that the tool is off.

1. Open the guard latch (M). Align

the lugs (N) on the guard with the

slots (O) on the gear case.

2. Push the guard down until the

guard lug engages and rotates

freely in the groove on the gear

case hub.

O

N

3. Rotate guard (I) into desired working

position. The guard body should be

positioned between the spindle and

the operator to provide maximum

operator protection.

4. Close the guard latch to secure the

guard on the gear case cover. You

should be unable to rotate the guard by

hand when the latch is in closed position.

If rotation is possible, tighten the

adjusting screw (P) with clamp lever in

the closed position. Do not operate

grinder with a loose guard or clamp

lever in open position.

5. To remove the guard, open the guard

latch, rotate the guard so that the arrows are aligned and pull

up on the guard.

NOTE: If, after a period of time, the guard becomes loose, tighten

the adjusting screw (P) with the clamp lever in the closed position.

CAUTION: Do not tighten adjusting screw with clamp lever in

open position. Undetectable damage to guard or mounting hub

may result.

MOUNTING CUTTING WHEELS

WARNING: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or

accessories. Before reconnecting the tool, turn the switch on

and off as previously described to ensure that the tool is off.

CAUTION: Matching diameter backing flange and threaded

M

clamp nut (included with tool) must be used for cutting wheels.

1. Place the quick-change backing flange on spindle with the

raised section (pilot) facing up. The raised section (pilot) on

the backing flange will be against the wheel when the wheel is

installed.

P

I

14

Page 17

2. Place the wheel on the backing flange, centering the wheel on

the raised section (pilot).

3. Install the threaded clamp nut with the raised section (pilot)

facing away from the wheel.

4. Depress the spindle lock button and tighten clamp nut with

a wrench.

5. To remove the wheel, grasp and turn while depressing the

spindle lock button.

USING CUTTING WHEELS

WARNING: Do not use edge grinding/ cutting

wheels for surface grinding applications

because these wheels are not designed for side

pressures encountered with surface grinding.

Wheel breakage and injury may result.

1. Allow tool to reach full speed before

touching tool to work surface.

2. Apply minimum pressure to work surface,

allowing tool to operate at high speed.

Cutting rate is greatest when the tool

operates at high speed.

3. Once a cut is begun and a notch is established in the workpiece,

do not change the angle of the cut. Changing the angle will

cause the wheel to bend and may cause wheel breakage.

4. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before setting it down.

MAINTENANCE

Your DEWALT power tool has been designed to operate over a

long period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and regular

cleaning.

WARNING: To reduce the risk of injury, turn unit off and

disconnect tool from power source before installing and

removing accessories, before making any adjustments or

removing/installing attachments or accessories.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING: Blow dirt and dust out of the main housing with dry

air as often as dirt is seen collecting in and around the air vents.

Wear approved eye protection and approved dust mask when

performing this procedure.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

Accessories

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only D

with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center

EWALT, recommended accessories should be used

English

15

Page 18

Definiciones: Normas

de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada advertencia. Lea el manual y preste atención a estos

símbolos.

PELIGRO:

no se evita,

ADVERTENCIA:

que, si no se evita,

graves

ATENCIÓN:

no se evita,

ATENCIÓN:

indica una situación de peligro potencial que, si no se evita,

puede provocar

Español

ADVERTENCIA: para reducir el riesgo de lesiones, lea el

manual de instrucciones.

indica una situación de peligro inminente que, si

provocará

puede

Utilizado sin el símbolo de alerta de seguridad

la

muerte o lesiones graves.

Indica una situación de peligro potencial

podría

Indica una situación de peligro potencial que, si

provocar

daños en la

provocar la

lesiones leves o moderadas.

propiedad

muerte o lesiones

.

Advertencias generales de seguridad

para las herramientas eléctricas

ADVERTENCIA: Lea todas las advertencias de seguridad

e instrucciones. El incumplimiento de las advertencias o

instrucciones puede provocar descargas eléctricas, incendios o

lesiones graves.

GUARDE LAS ADVERTENCIAS E

INSTRUCCIONES PARA PODER

CONSULTARLAS EN EL FUTURO

El término “herramienta eléctrica” incluido en todas las advertencias

se refiere a su herramienta eléctrica conectada a la red (cable

eléctrico) o a su herramienta eléctrica accionada con baterías

(inalámbrica).

1) SEGURIDAD DEL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las

áreas abarrotadas u oscuras propician accidentes.

b) No haga funcionar las herramientas eléctricas en

atmósferas explosivas, como ambientes donde haya

polvo, gases o líquidos inflamables. Las herramientas

eléctricas originan chispas que pueden encender el polvo o

producir humo.

c) Mantenga alejados a los niños y a los espectadores

de la herramienta eléctrica en funcionamiento. Las

distracciones pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse

a la toma de corriente. Nunca modifique el enchufe de

ninguna manera. No utilice ningún enchufe adaptador

con herramientas eléctricas con conexión a tierra. Los

enchufes no modificados y que se adaptan a las tomas de

corrientes reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies con toma de

tierra como, por ejemplo, tuberías, radiadores, cocinas y

refrigeradores. Existe mayor riesgo de descarga eléctrica si

su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia ni a

condiciones de humedad. Si entra agua en una herramienta

eléctrica, aumentará el riesgo de descarga eléctrica.

d) No use el cable indebidamente. Nunca utilice el cable para

transportar, tirar o desenchufar la herramienta eléctrica.

Mantenga el cable alejado del calor, el aceite, los bordes

afilados o las piezas móviles. Los cables dañados o

enredados aumentan el riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice

un cable prolongador adecuado para tal uso. Utilice un

cable adecuado para uso en exteriores a fin de reducir el

riesgo de descarga eléctrica.

16

16

Page 19

f) Si no se puede evitar el uso de una herramienta eléctrica

en una zona húmeda, utilice un dispositivo de corriente

residual (residual current device, RCD) de seguridad.

El uso de un RCD reduce el riesgo de sufrir una descarga

eléctrica.

3) SEGURIDAD PERSONAL

NOTA: El término de "Dispositivo de Corriente Residual (RCD)"

puede ser sustituido por el término "Interruptor de Falla a Tierra

del Circuito (GFCI)" o "Disyuntor de Fugas a Tierra (ELCB)".

a) Permanezca alerta, controle lo que está haciendo y

utilice el sentido común cuando emplee una herramienta

eléctrica. No utilice una herramienta eléctrica si

está cansado o bajo el efecto de drogas, alcohol o

medicamentos. Un momento de descuido mientras se

opera una herramienta eléctrica puede provocar lesiones

personales graves.

b) Utilice equipo de seguridad personal. Utilice siempre

protección ocular. El uso de equipo de seguridad, como

mascarillas para polvo, calzado de seguridad antideslizante,

cascos o protección auditiva en las condiciones adecuadas

reducirá las lesiones personales.

c) Evite poner en marcha la herramienta involuntariamente.

Asegúrese de que el interruptor está apagado antes de

conectar la fuente de alimentación y/o la batería, coger

o transportar la herramienta. Transportar herramientas

eléctricas con su dedo apoyado sobre el interruptor o

enchufar herramientas eléctricas con el interruptor en la

posición de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de

encender la herramienta eléctrica. Una llave de tuercas

o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta eléctrica puede provocar lesiones

personales.

e) No se estire demasiado. Conserve el equilibrio y

posiciónese adecuadamente en todo momento. Esto

permite un mejor control de la herramienta eléctrica en

situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni

joyas. Mantenga el cabello, la ropa y los guantes alejados

de las piezas en movimiento. Las ropas holgadas, las joyas

o el cabello largo pueden quedar atrapados en las piezas

en movimiento.

g) Si se suministran dispositivos para la conexión de

accesorios con fines de recolección y extracción de

polvo, asegúrese de que estén conectados y que se

utilicen correctamente. El uso del extractor de polvo puede

reducir los riesgos relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA

ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta

eléctrica correcta para el trabajo que realizará. La

herramienta eléctrica correcta hará el trabajo mejor, y de un

modo más seguro, a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla

o apagarla con el interruptor. Las herramientas que no

puedan ser controladas con el interruptor constituyen un

peligro y deben repararse.

c) Desconecte el enchufe de la fuente de alimentación o

la batería de la herramienta eléctrica antes de realizar

cualquier ajuste, cambio de accesorios o almacenar

las herramientas eléctricas. Estas medidas de seguridad

preventivas reducen el riesgo de encender la herramienta

eléctrica de forma accidental.

d) Guarde la herramienta eléctrica que no esté en uso fuera

del alcance de los niños y no permita que otras personas

Español

17

17

Page 20

no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas eléctricas son

peligrosas si son operadas por usuarios que no tienen

formación.

e) Mantenimiento de las herramientas eléctricas. Revise que

no haya piezas en movimiento mal alineadas o trabadas,

piezas rotas o cualquier otra situación que pueda afectar

el funcionamiento de las herramientas eléctricas. Si

encuentra daños, haga reparar la herramienta eléctrica

antes de utilizarla. Se producen muchos accidentes a

causa de las herramientas eléctricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias.

Las herramientas de corte con mantenimiento adecuado y

con los bordes de corte afilados son menos propensas a

trabarse y son más fáciles de controlar.

g) Utilice las herramientas eléctricas, sus accesorios y

piezas, etc. de acuerdo con las presentes instrucciones,

Español

teniendo siempre en cuenta las condiciones de trabajo y

el trabajo que deba llevar a cabo. El uso de la herramienta

eléctrica para operaciones diferentes de aquellas para las

que fue diseñada podría originar una situación peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona cualificada en reparaciones que

realice el mantenimiento de su herramienta eléctrica

y que solo utilice piezas de repuesto idénticas. Esto

garantizará la seguridad de la herramienta eléctrica.

INSTRUCCIONES DE SEGURIDAD PARA

TODAS LAS OPERACIONES

Advertencias de seguridad comunes para todas las operaciones de

esmerilado, lijado, cepillado con cepillo de alambre y pulido, y para

operaciones de corte y desbaste abrasivo.

a) Esta herramienta eléctrica está diseñada para utilizarse

como esmeriladora, lijadora, cepillo de alambre, pulidora

o desbastadora. Lea todas las advertencias de seguridad,

instrucciones, ilustraciones y especificaciones provistas

con esta herramienta eléctrica. El incumplimiento de todas

las instrucciones enumeradas a continuación puede provocar

una descarga eléctrica, un incendio o lesiones graves.

b) No utilice accesorios que no estén diseñados y

recomendados específicamente por el fabricante de la

herramienta. El hecho que el accesorio pueda conectarse

a la herramienta eléctrica no garantiza un funcionamiento

seguro.

c) La velocidad nominal del accesorio debe ser equivalente a

la velocidad máxima indicada en la herramienta eléctrica,

como mínimo. Los accesorios que funcionen más rápido que

su velocidad nominal pueden romperse y desprenderse.

d) El diámetro externo y el grosor del accesorio deben

estar dentro del rango de capacidad de la herramienta

eléctrica. Los accesorios de tamaño incorrecto no pueden

protegerse ni controlarse adecuadamente.

e) El tamaño del eje de los discos, las bridas, las almohadillas

de respaldo y cualquier otro accesorio debe adaptarse

correctamente al eje de la herramienta eléctrica. Los

accesorios con orificios que no coincidan con el sistema

de montaje de la herramienta eléctrica se desequilibrarán,

vibrarán excesivamente y podrán producir la pérdida de

control de la herramienta.

f) No utilice un accesorio dañado. Inspeccione el accesorio

antes de cada uso; por ejemplo, el disco abrasivo para

verificar que no tenga astillas ni grietas; la almohadilla

de respaldo para ver si hay grietas, desprendimientos

o desgaste excesivo y el cepillo de alambre para ver si

tiene alambres sueltos o quebrados. Si la herramienta

18

18

Page 21

eléctrica o el accesorio sufre una caída, inspeccione

para ver si hay daños o instale un accesorio en buen

estado. Después de inspeccionar e instalar un accesorio,

ubíquese y ubique a los espectadores lejos del plano

del accesorio giratorio y haga funcionar la herramienta

a velocidad máxima sin carga durante un minuto. Los

accesorios dañados generalmente se romperán durante esta

prueba.

g) Utilice equipos de protección personal. Según la

aplicación, debe usar protector facial, anteojos de

seguridad o lentes de seguridad. Según corresponda,

utilice máscara para polvo, protectores auditivos,

guantes y delantal de taller para protegerse de los

pequeños fragmentos abrasivos y de los fragmentos de

la pieza de trabajo. La protección para los ojos debe ser

capaz de detener los residuos volátiles que se generan en las

diferentes operaciones. La máscara para polvo o respirador

debe ser capaz de filtrar las partículas generadas por el

funcionamiento de la herramienta. La exposición prolongada

al ruido intenso puede provocar pérdida de la audición.

h) Mantenga a los espectadores a una distancia segura

del área de trabajo. Toda persona que ingrese al área

de trabajo debe utilizar equipos de protección personal.

Los fragmentos de una pieza de trabajo o de un accesorio

roto pueden volar y provocar lesiones más allá del área de

operaciones cercana.

i) Cuando realice una operación en que el accesorio

de corte pueda tocar cables eléctricos ocultos o su

propio cable, sostenga la herramienta solamente por las

superficies de agarre aisladas. El contacto con un cable con

“corriente eléctrica” hará que las partes metálicas expuestas

de la herramienta también tengan “corriente eléctrica” y el

operador sufra una descarga.

j) Coloque el cable lejos del accesorio giratorio. Si pierde el

control de la herramienta, el cable puede cortarse o enredarse

y jalarle la mano o el brazo hacia el accesorio giratorio.

k) Nunca apoye la herramienta hasta que el accesorio se

haya detenido completamente. El accesorio giratorio puede

enganchar la superficie y producir la pérdida de control de la

herramienta.

l) No haga funcionar la herramienta eléctrica mientras la

carga a su lado. El contacto accidental con el accesorio

giratorio puede hacer que éste se le enganche en la ropa y

lance el accesorio hacia su cuerpo.

m) Limpie frecuentemente los orificios de ventilación de

la herramienta eléctrica. El ventilador del motor atraerá el

polvo dentro de la cubierta, y la acumulación excesiva de

polvo metálico puede producir riesgos eléctricos.

n) No use la herramienta eléctrica cerca de materiales

inflamables. Las chispas pueden encender estos materiales.

o) No utilice accesorios que requieran refrigerantes líquidos. El

uso de agua u otros refrigerantes líquidos puede producir una

electrocución o descarga eléctrica.

p) No utilice discos Tipo 11 (copas cónicas) en esta

herramienta. El uso de accesorios incorrectos puede producir

lesiones.

q) Siempre utilice el mango lateral. Ajuste el mango con

firmeza. Se debe utilizar siempre el mango lateral para

mantener el control de la herramienta en todo momento.

NORMAS ESPECÍFICAS DE SEGURIDAD

Instrucciones de seguridad adicionales

específicas para esmeriladoras

• Verifique que el flange de respaldo del disco para esmerilar

tenga un anillo de goma (D) amarillo instalado (Fig. 1).

Reemplace el anillo de goma en caso de que falte, esté

Español

19

19

Page 22

dañado o presente desgaste. Consulte la páginas 26–28 para

obtener información detallada en relación con la instalación

correcta de accesorios.

ADVERTENCIA: El disco para esmerilar o los accesorios

pueden aflojarse cuando la herramienta gire para apagarse si

el anillo de goma falta o está dañado. Si el disco para esmerilar

o los accesorios se aflojan, pueden salirse de la máquina y

ocasionar lesiones personales graves.

• Utilice siempre el protector apropiado con el disco de

esmerilar. Protegerá al operador de los fragmentos si se rompe

un disco, y del contacto con el disco.

• Los accesorios deben estar clasificados para la velocidad

recomendada en la etiqueta de advertencia de la herramienta,

como mínimo. Los discos y otros accesorios que funcionen por

encima de la velocidad nominal pueden quebrarse, despedir

fragmentos y provocar lesiones. La velocidad nominal de los

accesorios debe ser superior a la velocidad mínima aprobada

del disco, indicada en la placa de la herramienta.

• Sostenga la herramienta por las superficies de agarre

Español

aisladas cuando realiza una operación donde la herramienta de corte puede tocar cables eléctricos escondidos

o su propio cable. El contacto con un cable con “corriente

eléctrica” hará que las partes metálicas expuestas de la

herramienta tengan “corriente eléctrica” y el operador sufra

una descarga eléctrica.

• No utilice discos Tipo 11 (copas cónicas) en esta herra-

mienta. El uso de accesorios incorrectos puede producir

lesiones.

• UTILICE SIEMPRE PROTECCIÓN PARA LOS OJOS

CUANDO USE ESTA HERRAMIENTA.

• No se recomienda el uso de accesorios no especificados en

este manual, que constituyen un riesgo. El uso de elevadores

de tensión que pueden provocar que la herramienta opere a

velocidades mayores que su velocidad nominal constituye mal uso.

• No utilice hojas de sierra circular o cualquier otro tipo de

hojas dentadas en esta herramienta. Puede causar lesiones

graves.

• Al encender la herramienta con un disco o un cepillo nuevo

o de repuesto instalado, sostenga la herramienta en un

área protegida y hágala funcionar durante un minuto. Si el

disco o el cepillo tiene una grieta o un defecto que pasó

desapercibido, se desintegrará o separará en menos de un

minuto. Se detectará si el cepillo de alambre tiene alambres

sueltos. Nunca encienda la herramienta si una persona está

parada frente al disco. Esta instrucción incluye al operador.

• Evite darle botes al disco o maltratarlo. Si esto sucede,

detenga la herramienta e inspeccione el disco para detectar

grietas o defectos.

• Dirija las chispas lejos del operador, los espectadores

o los materiales inflamables. Se pueden producir chispas

mientras se corta o se esmerila. Las chispas pueden provocar

quemaduras o iniciar incendios.

• Siempre utilice la agarradera lateral. Ajuste la agarradera

con firmeza. Se debe utilizar siempre la agarradera lateral para

mantener el control de la herramienta en todo momento.

• Nunca corte en un área que pueda contener cables

eléctricos o cañerías. Puede causar lesiones graves.

• Limpie su herramienta con frecuencia, especialmente

después de un uso intensivo. A menudo se acumulan sobre

las superficies interiores polvo y suciedad que contienen

partículas metálicas, que pueden provocar riesgo de descarga

eléctrica.

• No haga funcionar esta herramienta durante períodos

prolongados. La vibración que produce el funcionamiento de

esta herramienta puede provocar lesiones permanentes en

dedos, manos y brazos. Use guantes para proveer amortiguación

extra, tome descansos frecuentes y limite el tiempo diario de uso.

20

20

Page 23

• Dirija el sistema de evacuación de polvo (DES, por su sigla

en inglés) de manera que no apunte hacia el operador o

sus compañeros de trabajo. Puede causar lesiones graves

(Fig. 1, K).

Causas del retroceso y su prevención

por parte del operador

• El retroceso es una reacción repentina al pellizco, el atascamiento

o la desalineación de un disco, un cepillo de alambre o un disco

de lija, que causa que la herramienta de corte salte del trabajo

en dirección al operador.

• Cuando el trabajo pellizca o atasca el disco, el disco se detiene

y la reacción del motor impulsa a la unidad hacia atrás con

rapidez, hacia el operador o en la dirección opuesta.

• El retroceso es el resultado de un mal uso de la herramienta

o de condiciones o procedimientos operativos incorrectos y

se puede evitar tomando las precauciones apropiadas que se

indican a continuación:

• Sujete la herramienta firmemente con ambas manos

y ubique su cuerpo y el brazo para poder resistir las

fuerzas de retroceso. El operador puede controlar las

fuerzas de retroceso, si se toman las precauciones correctas.

• Cuando se está atascando el disco, o cuando se

interrumpe un corte por alguna razón, suelte el disparador

y mantenga la unidad quieta en el material hasta que el

disco se detenga completamente. Nunca intente retirar

la unidad del trabajo o tirar de la unidad hacia atrás

mientras la rueda esté en movimiento, o se producirá un

retroceso. Investigue y tome las medidas correctivas para

eliminar la causa del atascamiento del disco.

• Cuando se vuelve a arrancar una herramienta de corte

en el trabajo, verifique que el disco no esté trabado en

el material. Si el disco está atascado, cuando se vuelve a

arrancar la herramienta, la misma puede saltarse del trabajo

o producir un retroceso.

• Sujete los paneles grandes para minimizar el riesgo de

que el disco se pellizque y se produzca el retroceso. Los

paneles grandes tienden a combarse por su propio peso. Se

deben colocar soportes bajo el panel, a ambos lados, cerca

de la línea de corte y cerca del borde del panel.

ANTES DE ATENCIÓN COLOCAR LO

SIGUIENTE

Advertencias de seguridad específicas

para operaciones de esmerilado y

cortes abrasivos

a) Utilice sólo los tipos de disco recomendados para

su herramienta eléctrica y el protector específico

para el disco seleccionado. Los discos para los que la

herramienta eléctrica no está diseñada no pueden protegerse

adecuadamente y son inseguros.

b) El protector debe fijarse en forma segura a la herramienta

eléctrica y ubicarse para brindar la máxima seguridad, de

manera que una mínima parte del disco quede expuesta

hacia el operador. El protector ayuda a resguardar al

operador de los fragmentos de discos rotos y el contacto

accidental con el disco.

c) Los discos sólo deben utilizarse para las aplicaciones

recomendadas. Por ejemplo: no esmerile con el costado

del disco de corte. Los discos para cortes abrasivos están

diseñados para esmerilados periféricos, si se aplican fuerzas

laterales a estos discos, pueden romperse.

d) Siempre utilice bridas de disco en buen estado, con la

forma y el tamaño apropiados para el disco seleccionado.

Las bridas de disco adecuadas brindan soporte al disco,

además de reducir la posibilidad de que el disco se rompa.

Las bridas de los discos de corte pueden ser diferentes a las

bridas de discos de esmerilado.

Español

21

21

Page 24

e) No utilice discos desgastados de herramientas eléctricas

más grandes. Los discos diseñados para herramientas

eléctricas más grandes no son apropiados para la mayor

velocidad de una herramienta más pequeña y pueden

estallar.

Advertencias de seguridad adicionales

específicas para operaciones de corte

abrasivo

a) No “atasque” el disco de corte ni aplique una presión

excesiva. No intente realizar una profundidad de corte

excesiva. La sobrecarga de tensión sobre el disco aumenta

la carga y la posibilidad de que el disco se tuerza o trabe

durante el corte y se produzca un retroceso o la rotura del

disco. Se puede evitar tomando las precauciones apropiadas

que se indican a continuación:

b) Sostenga la herramienta eléctrica con firmeza y ubique

el cuerpo y el brazo para poder resistir las fuerzas de

retroceso. Siempre utilice el mango lateral, en caso de

Español

tenerlo, para lograr el máximo control sobre el retroceso

o la reacción de torsión durante el encendido. El operador

puede controlar la reacción de torsión o las fuerzas de

retroceso si toma las precauciones adecuadas.

c) Nunca coloque la mano cerca del accesorio giratorio, ya

que éste puede hacer un retroceso sobre la mano.

d) No ubique el cuerpo en el área hacia donde la herramienta

eléctrica se desplazará si se produce un retroceso. El

retroceso impulsará la herramienta en la dirección opuesta al

movimiento del disco en el punto de atascamiento.

e) Tenga especial cuidado al trabajar en esquinas, bordes

filosos, etc. Evite hacer rebotar o enganchar el accesorio.

Las esquinas, los bordes filosos y el rebote tienden a

enganchar el accesorio giratorio y producir la pérdida de

control o el retroceso de la unidad.

f) No conecte una hoja para carpintería para sierra de

cadena ni una hoja de sierra dentada. Estas hojas puede

producir el retroceso y la pérdida de control frecuentes.

Advertencias de seguridad específicas

para operaciones de esmerilado y

cortes abrasivos

a) Utilice sólo los tipos de disco recomendados para

su herramienta eléctrica y el protector específico

para el disco seleccionado. Los discos para los que la

herramienta eléctrica no está diseñada no pueden protegerse

adecuadamente y son inseguros.

b) El protector debe fijarse en forma segura a la herramienta

eléctrica y ubicarse para brindar la máxima seguridad, de

manera que una mínima parte del disco quede expuesta

hacia el operador. El protector ayuda a resguardar al

operador de los fragmentos de discos rotos y el contacto

accidental con el disco.

c) Los discos sólo deben utilizarse para las aplicaciones

recomendadas. Por ejemplo: no esmerile con el costado

del disco de corte. Los discos para cortes abrasivos están

diseñados para esmerilados periféricos, si se aplican fuerzas

laterales a estos discos, pueden romperse.

d) Siempre utilice bridas de disco en buen estado, con la

forma y el tamaño apropiados para el disco seleccionado.

Las bridas de disco adecuadas brindan soporte al disco,

además de reducir la posibilidad de que el disco se rompa.

Las bridas de los discos de corte pueden ser diferentes a las

bridas de discos de esmerilado.

e) No utilice discos desgastados de herramientas eléctricas

más grandes. Los discos diseñados para herramientas

eléctricas más grandes no son apropiados para la mayor

velocidad de una herramienta más pequeña y pueden

estallar.

22

22

Page 25

Advertencias de seguridad adicionales

específicas para operaciones de corte

abrasivo

a) No “atasque” el disco de corte ni aplique una presión

excesiva. No intente realizar una profundidad de corte

excesiva. La sobrecarga de tensión sobre el disco aumenta

la carga y la posibilidad de que el disco se tuerza o trabe

durante el corte y se produzca un retroceso o la rotura del

disco.

ATENCIÓN: Tenga mucho cuidado al trabajar en una esquina

ya que puede producirse un movimiento repentino y violento de la

esmeriladora si el disco u otro accesorio entra en contacto con una

segunda superficie o el borde de la misma.

• Los hilos del alargador deben ser de un calibre apropiado

(AWG o American Wire Gauge) para su seguridad. Mientras

menor sea el calibre del hilo, mayor la capacidad del cable. Es

decir, un hilo calibre 16 tiene mayor capacidad que uno de 18.

Un cable de un calibre insuficiente causará una caída en la

tensión de la línea dando por resultado una pérdida de energía

y sobrecalentamiento. Cuando se utilice más de un alargador

para completar el largo total, asegúrese que los hilos de cada

alargador tengan el calibre mínimo. La tabla siguiente muestra

el tamaño correcto a utilizar, dependiendo de la longitud del

cable y del amperaje nominal de la placa de identificación. Si

tiene dudas sobre cuál calibre usar, use un calibre mayor.

Ténsion (Volts) Longitud del cable en metros (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Corriente

nominal

(Ampéres)

0 - 6A 1,0 1,5 1,5 2,5

6 - 10A 1,0 1,5 2,5 4,0

10 - 12A 1,5 1,5 2,5 4,0

12 - 16A 2,5 4,0 No recomendado

ADVERTENCIA: Siempre use protección ocular. Todos los

usuarios y las personas circunstantes deben llevar protección

ocular en conformidad con ANSI Z87.1.

ADVERTENCIA: Siempre lleve la debida protección auditiva

personal en conformidad con ANSI S12.6 (S3.19) durante el

uso de esta herramienta. Bajo algunas condiciones y duraciones

de uso, el ruido producido por este producto puede contribuir a la

pérdida auditiva.

ADVERTENCIA: Use SIEMPRE lentes de seguridad. Los

anteojos de diario NO SON lentes de seguridad. Utilice además

una máscara para la cara o guardapolvo si la operación de

corte genera demasiado polvo. SIEMPRE LLEVE EQUIPO DE

SEGURIDAD CERTIFICADO:

• Protección ocular ANSI Z87.1 (CAN/CSA Z94.3),

• Protección auditiva ANSI S12.6 (S3.19),

• Protección respiratoria NIOSH/OSHA/MSHA.

ADVERTENCIA: Parte del polvo generado al lijar, serrar,

esmerilar o taladrar, así como al realizar otras actividades del

sector de la construcción, contienen productos químicos que

pueden producir cáncer, defectos congénitos u otras afecciones

reproductivas. Algunos ejemplos de estos químicos son:

• plomo de algunas pinturas,

Sección nominal mínima del cable en

milímetros cuadrados (mm

2

)

Español

23

23

Page 26

• polvo de sílice proveniente de ladrillos y cemento y otros

productos de albañilería, y

• arsénico y cromo provenientes de maderas tratadas con

químicos (arseniato de cobre cromado).

Su riesgo de exposición a estos químicos varía, dependiendo de

la frecuencia con la cual realiza usted este tipo de trabajo. Para

reducir la exposición a esas sustancias químicas: trabaje en una

zona bien ventilada y llevando equipos de seguridad aprobados,

como mascarillas antipolvo especialmente diseñadas para filtrar

partículas microscópicas.

• Evite el contacto prolongado con polvo generado por

el lijado, serrado, pulido y taladrado eléctrico y otras

actividades de construcción. Vista ropa protectora y lave

las áreas de la piel expuestas con agua y jabón. Si permite

que el polvo se introduzca en la boca u ojos o quede sobre

la piel, puede favorecer la absorción de productos químicos

peligrosos.

ADVERTENCIA: La utilización de esta herramienta puede

generar polvo o dispersarlo, lo que podría causar daños graves

Español

y permanentes al sistema respiratorio, así como otras lesiones.

Siempre use protección respiratoria aprobada por NIOSH

(Instituto Nacional de Seguridad y Salud en el Trabajo) u OSHA

(Administración de Seguridad y Salud en el Trabajo) apropiada

para la exposición al polvo. Dirija las partículas en dirección

contraria a la cara y el cuerpo.

• La etiqueta de su herramienta puede incluir los siguientes

símbolos. Estos símbolos y sus definiciones son:

V ........voltios A ...........amperios

Hz ......hercios W ..........vatios

min ....minutos

...corriente directa ........ corriente alterna

......Construcción Clase I ............. o corriente directa

..........(conectada a tierra)

........ corriente alterna

n

o ......... velocidad sin carga

.......terminal de conexión ......... Construcción Clase II

.......a tierra ............. (doble aislamiento)

......símbolo de advertencia …/min ... por minuto

..........de seguridad RPM .....revoluciones por

.......... ............. minuto

DESCRIPCIÓN (FIG. 1)

ADVERTENCIA: Nunca modifique la herramienta eléctrica,

ni tampoco ninguna de sus piezas. Podría producir lesiones

corporales o daños.

USO PREVISTO

Esta herramienta es diseñados para aplicaciones profesionales de

perforación y atornillado.

NO USE la herramienta bajo condiciones de humedad o en

presencia de gases o líquidos inflamables.

La esmeriladora de ángulo pequeño esta herramienta profesional.

NO permita que los niños entren en contacto con la herramienta.

Cuando la hagan funcionar operarios sin experiencia, es necesaria

supervisión.

COMPONENTES (Fig. 1)

A. Interruptor de paleta

B. Palanca de bloqueo

C. Botón de bloqueo del eje

D. Anillo de goma amarillo

E. Mango lateral con sistema antivibración (no se muestra)

F. Disco de esmerilar de 127 mm (5") (Tipo 27)

G. Flange de respaldo de cambio rápido

H. Tuerca de fijación roscada

I. Protector Tipo 27

J. Botón de bloqueo

K. Dust Ejection System™ (DES)

24

Page 27

FIG. 1

D

C

F

I

B

A

G

H

K

K

J

CARACTERÍSTICAS

E-SWITCH PROTECTION™

El interruptor de encendido y apagado tiene una función de no

liberación de voltios. En el caso de un corte eléctrico u otro suceso

que produzca un apagón inesperado, el interruptor tiene que pasar

un ciclo (apagarse y encenderse) para reiniciar la herramienta.

E-CLUTCH™

Esta unidad está equipada con un embrague E-Clutch™

(embrague electrónico), que, en el caso de tener mucha carga

o de que se pellizque el disco, apagará la unidad para reducir la