Page 1

®

D21101

Page 2

Page 3

8

9

Page 4

4

E N G L I S H

ROTARY DRILL

D21101

Congratulations!

You have chosen a DEWALT Power Tool. Years of

experience, thorough product development and

innovation make DEWALT one of the most reliable

partners for professional Power Tool users.

Technical data

D21101

022VegatloV

Power input W 650

No-load speed min

-1

0 - 850

Maximum drilling range in

steel/wood mm 13/38

Chuck spindle thread size UNF 1/2" x 20

Collar diameter mm 43

Maximum chuck capacity mm 13

8.1gkthgieW

Fuses:

220-240 V tools 10 Amperes, mains

The following symbols are used throughout this

manual:

Denotes risk of personal injury, loss of life

or damage to the tool in case of nonobservance of the instructions in this

manual.

Denotes risk of electric shock.

Page 5

Check for misalignment and seizure of moving

parts, breakage of parts and any other conditions

that may affect its operation.

Have damaged guards or other defective parts

repaired or replaced as instructed. Do not use

the tool if the switch is defective. Have the switch

replaced by an authorized D

Package contents

The package contains:

Rotary drill

Chuck key

Instruction manual

Auxiliary handle

Auxiliary handle

Warranty card

Service address card

• Check for damage to the tool, parts or accessories

which may have occurred during transport.

• Take the time to thoroughly read and understand

this manual prior to operation.

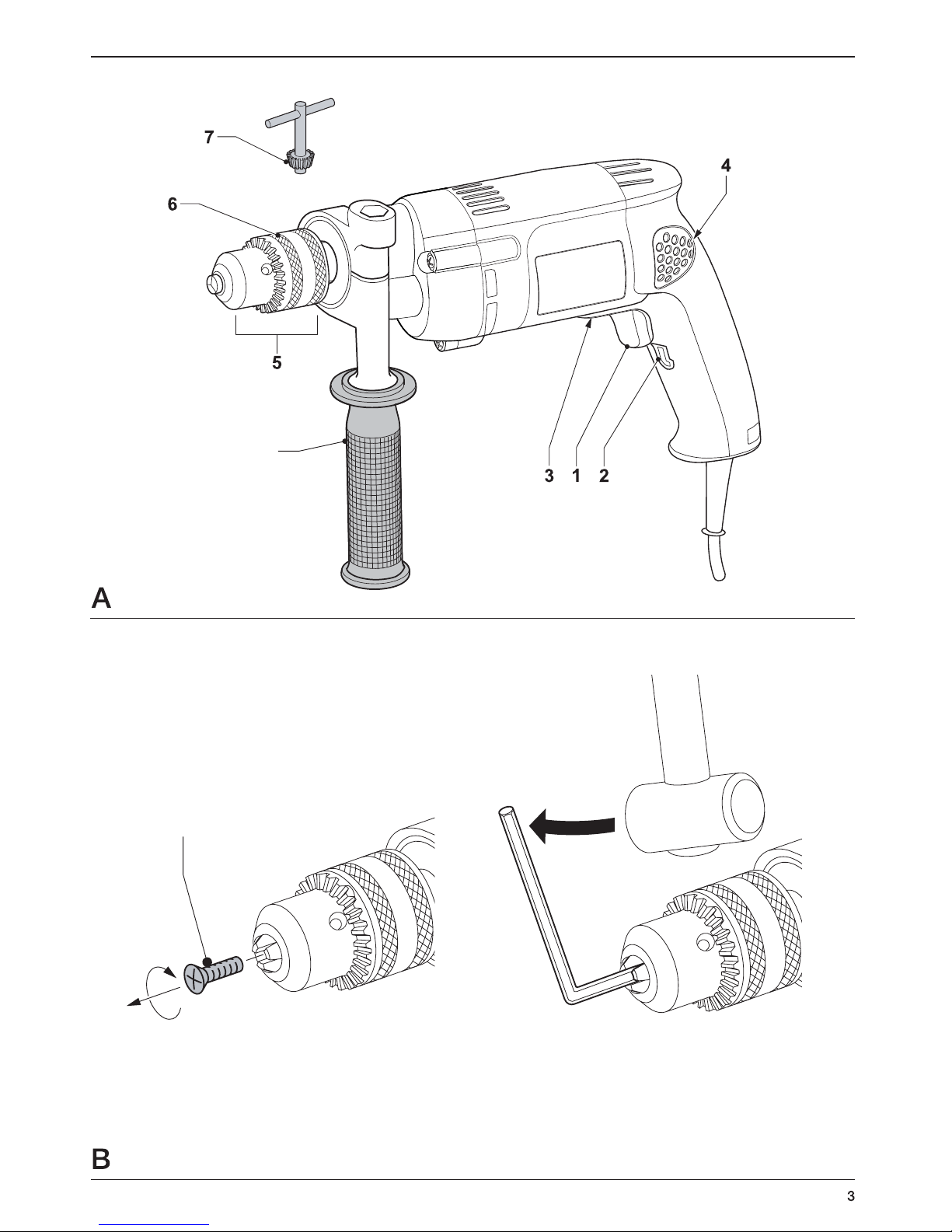

Description (fig. A)

1

1

1

1

1

1

1

Variable speed switch

2 Lock-on button

3 Forward/reverse slider

45Ventilation slots

6

7

8

Keyed chuck

Sleeve

Chuck key

5 Have your tool repaired by an authorized

D

E

WALT repair agent

This Power Tool is in accordance with the

relevant safety regulations. To avoid danger,

electric appliances must only be repaired by

qualified technicians.

Page 6

6

E N G L I S H

Electrical safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Your DEWALT tool is double insulated in

accordance with IEC 60745; therefore no

earth wire is required.

Using an extension cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see technical data). The minimum conductor

size is 1.5 mm2. When using a cable reel, always

unwind the cable completely.

Also refer to the table below.

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

220-240 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

Assembly and adjustment

Prior to assembly and adjustment always

unplug the tool.

The tool can be used in rotary drilling for steel,

wood and plastics.

Instructions for use

• Always observe the safety instructions

and applicable regulations.

• Be aware of the location of pipework

and wiring.

• Apply only a gentle pressure to the tool.

Excessive force does not speed up

drilling but decreases tool performance

and may shorten tool life.

• Use auxiliary handles supplied with the

tool. Loss of control can cause personal

injury.

Prior to operation:

• Insert the appropriate bit.

• Mark the spot where the hole is to be drilled.

Chuck removal (fig. B)

• Open the chuck jaws as far as possible.

Always wait until the motor has come to

a complete standstill before changing the

direction of rotation.

• Insert a screwdriver into the chuck and remove

the chuck retaining screw (9) by turning

clockwise.

• Tighten an Allen key into the chuck and strike it

with a hammer as shown.

Forward/reverse slider (fig. A)

• To select forward or reverse rotation, use the

forward/reverse-switch (3) (see arrow on tool).

Inserting and removing a bit (fig. A)

Keyed chuck

• Open the chuck by turning the sleeve (6)

counterclockwise and insert the bit shank.

• Put the chuck key (7) into each hole in the side

of the chuck and turn clockwise until tight.

• To remove the bit, proceed in reverse order.

Page 7

7

E N G L I S H

Switching on and off (fig. A)

• To run the tool, press the variable speed switch (1).

The pressure exerted on the variable speed switch

determines the tool speed.

• If necessary, press the lock-on button (2) for

continuous operation and release the switch.

The lock-on button works only in full speed,

forward rotation.

Maintenance

Your DEWALT Power Tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

Keep the ventilation slots clear and regularly clean

the housing with a soft cloth.

Unwanted tools and the environment

Take your tool to an authorized DEWALT repair

agent where it will be disposed of in an

environmentally safe way.

• To stop the tool, release the switch.

• To stop the tool in continuous operation, press

the switch briefly and release it. Always switch off

the tool when work is finished and before

unplugging.

Screwdriving

• Select forward or reverse rotation.

Consult your dealer for further information on the

appropriate accessories.

Page 8

8

简 体 中 文 版

D21101电钻

祝贺您!

技术数据

D21101

电压

V 220

输入功率

-A9 W 650

空载转速

min

-1

0 - 850

钢材/木材

最大钻孔直径

mm 13/38

夹头螺纹口尺寸

UNF 1/2" x 20

轴环直径

r mm 43

夹头最大尺寸(直径)

mm 13

重量

kg 1.8

保险丝:

220-240

伏特 10安培

本手册中普遍使用下列符号:

您已选择了得伟电动工具。多年的行业经验、全面

的产品开发和创新能力,使得伟成为了电动工具使

用者最可信赖的伙伴之一。

表示如违反本手册中的有关指示,将有

造成人身伤害、死亡或者工具损坏的危

险。

表示电击危险。

Page 9

8

Page 10

Page 11

Page 12

654608-00

Loading...

Loading...