Page 1

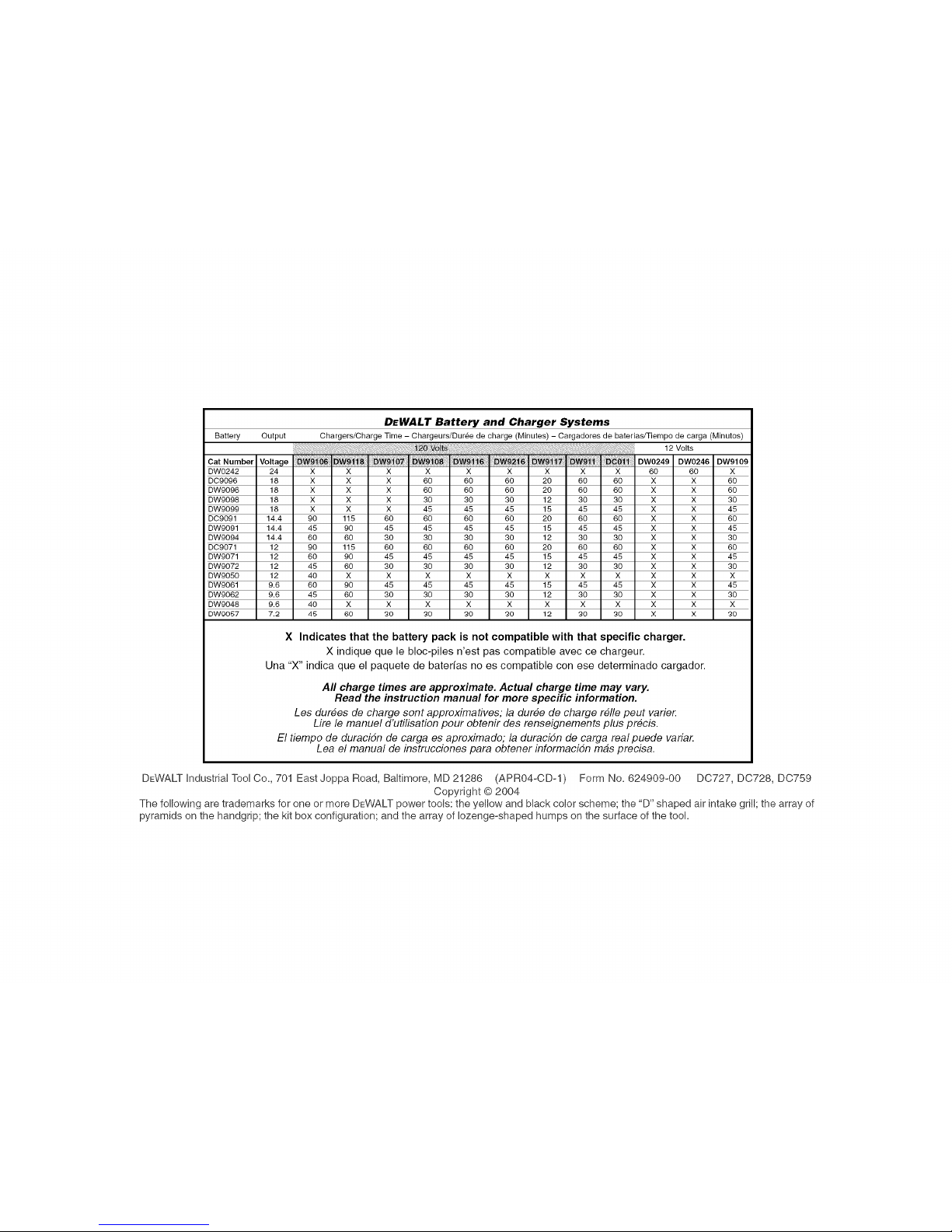

BatteryOutput

DEWALT Battery and Charger Systems

Chargers/Charge Time - Chargeurs/Duree de charge (Minutes) - Cargadores de baterias/Tiempo de carga (Minutos)

Cat Number Voltage DW0249 DW0246 DW9109

DW0242 24 X X X X X X X X X 60 60 X

DC9096 18 X X X 60 60 60 20 60 60 X X 60

DW9096 18 X X X 60 60 60 20 60 60 X X 60

DW9098 18 X X X 30 30 30 12 30 30 X X 30

DW9099 18 X X X 45 45 45 15 45 45 X X 45

DC9091 14.4 90 115 60 60 60 60 20 60 60 X X 60

DW9091 14.4 45 90 45 45 45 45 15 45 45 X X 45

DW9094 14.4 60 60 30 30 30 30 12 30 30 X X 30

D09071 12 90 115 60 60 60 60 20 60 60 X X 60

DW9071 12 60 90 45 45 45 45 15 45 45 X X 45

DW9072 12 45 60 30 30 30 30 12 30 30 X X 30

DW9050 12 40 X X X X X X X X X X X

DW9061 9.6 60 90 45 45 45 45 15 45 45 X X 45

DW9062 9.6 45 60 30 30 30 30 12 30 30 X X 30

DW9048 9.6 40 X X X X X X X X X X X

DWO057 7.2 45 60 90 90 90 90 12 90 90 X X 90

X Indicates that the battery pack is not compatible with that specific charger.

X indique que le bloc-piles n'est pas compatible avec ce chargeur.

Una "X" indica que el paquete de baterfas no es compatible con ese determinado cargador.

All charge times are approximate. Actual charge time may vary.

Read the instruction manual for more specific information.

Les durees de charge sont approximatives; la duree de charge relle peut varie_

Lire le manuel d'utilisation pour obtenir des renseignements plus precis.

El tiempo de duracion de carga es aproximado; la duracion de carga real puede varia_

Lea el manual de instrucciones para obtener informacion mas precisa.

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (APR04-CD-1) Form No. 624909-00 DC727, DC728, DC759

Copyright © 2004

The following are trademarks for one or more DEWALT power toois: the yellow and black color scheme; the "D" shaped air intake grill; the array of

pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Page 2

Questions? See us on the WoHd Wide Web at wwwodewaltocom

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACrON, CENTROS DE SERVrCIO Y POLIZA

DE GARANTiA. ADVERTENC_A: LEASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

®

D0727, D0728, D0759

Cordless Adjustable Clutch OrivedDrilt

Perceuse=toumevis sans fil a embrayage r6glable

Taladro/destornillador inalambrico con embrague a]ustable

Page 3

iF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THiS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258}

General Safety Rules - For All Battery

Operated Tools

A WARNtNG t.Read and understand all instructions. Failure

to foflow aft instructions listed below may result in electric

shock, tire and/or serious persona! injudz

SAVE THESE #NSTRUCT#OHS

WORK AREA

* Keep your work area clean and well lit. Cluttered benches and

dark areas invite accident&

* Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite t,_edust or fumes.

* Keep bystanders, ch#dren, and visitors away while operating

a power tool Distractions can cause you to lose control.

ELECTRICAL SAFETY

* Do not abuse the cord. Never use the cord to carry the tool.

Keep cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged cords may cre-

ate a tire.

* A battery operated tool with integral batteries or a separate

battery pack must be recharged only with the specified charg-

er for the battery. A cha_ger that may be suitable for one type of

battery may create a risk of tire when used with anot,_er battery:

* Use battery operated tool only with the specifically designated

battery pack. Use of any ot,_er batteries may create a risk of tire.

PERSONAL SAFETY

* Stay alert, watch what you are doing and use common sense

when operating a power tooL Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

moment of ,,hattention while operating power tools may result in

serious personal injury:

* Dress properly. Do not wearloose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clot,%_g,jewe/_ or tong hair can be caught

in moving parts. Air vents often cover moving parts and should also

be avoided.

* Avoidaccidentaistarting. Besureswitchisinthelockedoroff

position before inserting battery pack. Carrying tools wit,_your

finger on t,#eswitch or inserting the battery pack into a too! with the

sw,_'chor7invites accidents.

* Remove adjusting keys or wrenches before turning the tool

on. A wrench or a key t,_at is left attached to a rotating part of the

tool may result in personal injury:

* Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

* Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard ha_; or hearing protection must be

used for appropriate conditions.

TOOL USE AND CARE

* Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding t,_e work by hand or

against your body is unstable and may lead to a loss of control

* Do not force tool. Use the correct tool for your application. The

correct tool wfl/ do the job better and safer at the rate for which it is

designed.

* Do not use tool if switch does not turn it on or off. A tool that

cannot be controlled with t,_e swqtch is dangerous and must be

repaired.

* Disconnect battery pack from tool or place the switch in the

locked or off position before making any adjustments, chang-

ing accessories, or storing the tooL Such preventative safety

measures reduce the risk of starting the tool accidentally

Page 4

* Storeidle tools out of reach of chiMren and other untrained

persons. Tools are dangerous in the hands of untrained users,

* Whenbatterypaekisnotinuse, keepitawayfromothermetal

objects like: paper clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one ter-

minal to another Shorting t,_e battery terminals together may

cause sparks, bums, or a fire,

* Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less tikely

to bind and are easier to control

* Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tool's

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

* Use only accessories that are recommended by the manufac-

turer for your model Accessories that may be suitable for one

tool may create a risk of injury when used on anot,_er tool

SERWCE

* Tool service must be performed only by qualified repair per-

sonnel. Service or maim'enance performed by unquafified person-

ne/ may result in a risk of Zojurj4

* When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manu-

aL Use of unauthorized pails or failure to follow Maintenance

Instructions may create a risk of shock or inju_

Additional Specific Safety Rules

* Hold tool by insulated gripping surfaces when performing an

operation where the tool may contact hidden wiring. Contact

with a "live" wire will also make exposed metal parts of t,_e tool

"live" and shock the operator.

A WARNING: Some dust created by power sanding, sawing, grind-

ing, drN/ing, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of t,_ese chemicals are:

* lead from lead-based paints,

* crystalline silica from bricks and cement and other masonry

products, and

* arsenic and chromium from chemically-treated lumbe_

Your risk from these exposures varies, depending on how often you

do t,_b type of work, To reduce your exposure to these chemicals:

work in a weft ventilated area, and work with approved safety equip-

ment, such as those dust masks that are specially designed to filter

out microscopic particles,

* A void prolonged contact with dust from power sanding, saw-

ing, grinding, drilling, and other construction activities. Wear

protective clothing and wash exposed areas with soap and

water Allowing dust to get into your mouth, eyes, or lay on t,_eskin

may promote absorption of harmful chemicals,

_WARNING: L,tse of this toot can generate and/or disburse dust,

which may cause serious and permanent respiratory or other inju_

Always use N/OSH/OSHA approved respiratory protection appropri-

ate for the duat expoaure, Direct particlea away from face and body,

A CAUTION: When not in use, place tool on its side on a stable

surface where it will not cause a tripping or falling hazard. Some

tools with large battery packs wih'stand uprigM on the battery pack but

may be easily knocked over,

* The label on your tool may include t,_efollowing symbols, The sym-

bols and t,_eirdefinitions are as follows:

V .......... volts

Hz ........hertz

min ........minutes

.... ,,,,,,direct current

[] ..........Class II Construction

_'_,..........safety alert symbol

sfpm ......surface t_et per minute

A............ amperes

W .......... watts

'_ ........alternating current

no .......... no load speed

.......... eart,Sing tenninaf

,,,/min,,,, revolutions per minute

Page 5

#mportant Safety #.s*ruc*ions

for Batterv Packs

Your toot uses either a 12, 14.4 or 18 Volt DE'WALT battery pack_

When ordering replacement battery packs, be sure to include catalog

number and voltage: Extended Run-Time battery packs deliver 25%

more run-time than standard battery packs.

NOTE: Your tool will accept either standard or Extended Run Time

battery packs. However, be sure to select proper voitage. Batteries

slowly lose their charge when they are not on the charger, the best

place to keep your battery is on the charger at all times.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below. Then

follow charging procedures outlined.

READ ALL INSTRUCTIONS

* Do not incinerate the battery pack even if it is severely dam-

aged or is completely worn out. The battery pack can explode in

a fire.

* A small leakage of fiquid from the battery pack cells may

occur under extreme usage or temperature conditions. ThLs

does not indicate a failure. However, if the outer seal is broken and

this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize wh,#a mild acid such as lemon juice or vinega_

c. If battery liquid gets into your eyes, flush t,_em wh,_clean water

for a mit_imum of 10 minutes and seek immediate medical

attention. (Medical note: The liqdd /s 25-35% solution of potas-

sium ,_ydroxide.)

* Do not carry extra battery packs in aprons, pockets, or tool

boxes along with other metal objects. Battery pack could be

short cimuited causing damage to the battery pack and possibly

causing severe burns or fire.

* Charge the battery packs only in DEWALT chargers.

DO NOT splash or immerse in water or other liquids.

Do not store or use the tool and battery pack in locations

where the temperature may reach or exceed 105°F (40 °C)

(such as outside sheds or metal buildings in summer).

A DANGER: Never attempt to open t,_e battery pack for any reason.

If battery pack case is cracked or damaged, do not insert into charg-

er. Electric shock or electrocution may result. Damaged battery packs

should be returned to service center for recycling.

NOTE: Battery storage and carrying caps are provided

for use whenever the battery is out of the tool or charger. '_J#&_

Remove cap before placing battery in charger or tool.

A WARNtNG: Do not store or carry battery so that

metal objects can contact exposed battery terminals.

For example, do not place battery in aprons, pockets,

tool boxes, product kit boxes, drawers, etc. with loose nails,

screws, keys, etc. without battery cap. Wit,_out cap in place, battery

could short circuit causing fire or bums or damage to battery

CAUTION: Battery pack must be securely attached to tool If bat-

tory pack is detached, personal injury may result.

The _BF_C TM Seal

The RBRCTM (RechargeabIe Battery BecycI[ng Corpor-

ationt SeaI on the nickel-cadmium battery (or battery packt /_

indicates that the costs to recycle the battery (or battery __,_ ), )

pack) at the end of its useful life have already been paid by '_'

DEWALT. In some areas, it is illegai to place spent nicke!-

cadmium batteries in the trash or municipal solid waste stream and the

RBRC program provides an environmentally conscious alternative.

RBRC in cooperation with DEWALT and other battery users, has

established programs inthe United States to facilitate the collection of

spent nickel-cadmium batteries. Help protect our environment and

conserve natural resources by returning the spent nickel-cadmium

battery to an authorized DEWALT service center or to your !ocaI retail-

er for recycling. You may also contact your Ioca! recycling center for

information on where to drop off the spent battery.

Page 6

Important Safety lrestr.ctiores for Battery

C#argers

SAVE THESE INSTRUCTIONS: Th,;s manual contains important

safety ,_nstructiens for battery charger&

* Before using charger, read all instructionsand cautionary markings

on charger, battery pack, and product using battery pack.

A DANGER: 120 vo/_:sare present at charging termina,ts. Do not probe

with conductive objects. Flectric shock or electrocution may resdL

WARNING: Do not allow any liquid to get inside charge_ Electric

shock may result.

AOAUTION: To reduce the risk of #_jury,charge only DEWALTnickel

cadmium rechargeabte batteries. Ot,_er types of batteries may burst

causing persona/iX, jury and damage.

_ CAUTtON: Under certain conditions, wh.#the charger plugged in to

t,_epower suppt_ the exposed charging contacts inside t,_echarger

can be shorted by foreign material. Foreign materia,ts of a conductive

nature such as, but not limited to, steel wool, aluminum foil, or any

buildup of metah;icparticles should be kept away from chat:ger cavities.

Always unplug the charger from t,#epewer suppty when there,is no bah

tery pack ,_t_the cav/tj4 Unplug c,_arger before attempting to clean.

* DO NOT attempt to charge the battery pack with any chargers

other than the ones in this manual The charger and battery

pack are specifically designed to work toget,_er.

* These chargers are not intended for any uses other than

charging DEWALT rechargeable batteries. Any other uses may

result in risk of fire, electric shock or electrocution.

* Do not expose charger to rain or snow.

* Pull by plug rather than cord when disconnecting charger.

This wilt reduce risk of damage to electric plug and cord.

* Make sure that cord is located so that it will not be stepped on,

tripped over, or otherwise subjected to damage or stress.

* Do not use an extension cord unless it is absolutely neces-

sary. Use of improper extension cord could result in risk of fire,

electric shock, or electrocution.

* An extension cord must have adequate wire size (AWG or

American Wire Gauge) for safety. T,Sesmah'er the gauge number

of the wire, t,#e greater t,_ecapacity of t,#e cable, that is 16 gauge

has more capacity than 18 gauge. W,_en using more than one

extension to make _o the total length, be sure each individual

extension contains at least t,#e minimum wire size.

Recommended Minimum Wire Size for Extension Cords

TotamLength of Cord

25ft. 50ft. 75ft. 100ft. 125ft. 150ft. 175ft.

7.6m 15.2m 22.9m 30.5m 38.1 m 45.7m 53.3m

Wire Size AWG

18 18 16 16 14 14 12

. Do not place any object on top of charger or place the charg-

er on a soft surface that might block the ventilation slots and

result in excessive internal heat. Place the charger in a position

away from any heat soume. The charger is ventilated through slots

in the top and the bottom of the housing.

* Do not operate charger w#h damaged cord or plug- have

them replaced immediatetJ4

* Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. Take it to an autho-

rized service center.

* Do not disassemble charger; take it to an authorized service

center when service or repair is required. Incorrect reassembly

may result in a risk of electric shock, electrocution or fire.

* Disconnect the charger from the outlet before attempting any

cleaning. This will reduce the risk of electric shock. Removing

t,_ebattery pack will not reduce t,_isrisk.

* NEVER attempt to connect 2 chargers together.

* The charger is designed to operate on standard household

electrical power (t20 Volts). Do not attempt to use it on any

other voltage. This does net apply to the vehicular charge_

Page 7

Using Automatic TUEJe_Up TM MOde

The Automatic Tune-UpTM Mode equalizes or balances the individual

cells in the battery pack allowing it to function at peak capacity. Battery

packs shouid be tuned up weekly or after 10 charge/discharge cycles

or whenever the pack no longer delivers the same amount of work. To

use the Automatic Tune-Up TM, ptace the battery pack in the charger

and Ieave it for at Ieast 8 hours. The charger w[II cycle through the fol-

lowing modes.

1. The red I[ght will blink continuously indicating that the 1-hour

charge cycle has started.

2. When the 1-hour charge cycle is complete, the light w[lI stay on

continuously and will no longer bI[nk. This indicates that the pack

is fully charged and can be used at this time.

3. Whenever the pack is left in the charger after the initial 1-hour

charge, the charger will begin the Automatic Tune-Up TM Mode.

This mode continues up to 8 hours or until the individual cells in

the battery pack are equalized. The battery pack is ready for use

and can be removed at any time during the Tune-Up TM Mode.

4. Once the Automatic Tune-Up TM Mode is complete the charger w[l!

transition to a maintenance charge; the indicator light shuts off

when the Automatic Tune-Up TM Mode is complete.

SAVE THESE IHSTRUCTIOHS

FOR FUTURE USE

Chargers

Your tool uses a 12.0, 14.4, or 18.0 Volt DEWALT Charger. Your battery

can be charged in DEWALT 1 Hour Chargers, 15 Minute Chargers or

Vehicular 12 volt charger. Be sure to read all safety instructions before

using your charger. Consult the chart on the back cover of this manual

for compatibility of chargers and battery packs.

Charging Preced_re [Figo t)

1. Plug the charger into an appropriate outlet before inserting battery

pack.

FIG. 1

2. Insert the battery pack into the charger, as shown in Figure 1,

making sure the pack is fully seated in charger. The red (charging)

light will bt[nk continuously indicating that the charging process

has started.

3. The completion of charge will be indicated by the red light remain-

[ng ON continuously. The pack is fully charged and may be used

at this time or left in the charger.

A CAUTION: 120 volts present at chat:ging terminals. Do not probe

wit/7conductive objects. Danger of etectr/c shock or electrocution.

Indicator Light Operatien

PACK CHARGING ...................

FULLY CHANGED ...................

HOT/COLD PACK DELAY ........ _ [] _ [] _ [] _ [] _ []

nEPLACE PACK ...................... @@@@@@@@@@@@@@@@@@@@

PROBLEP,_ POWER LINE ........@ @ @ @ @ @ []@ @ [] @ @ @ @

Charge indicators

Some chargers are designed to detect certain problems that can

arise with battery packs. Problems are indicated by the red light flash-

ing at a fast rate. If this occurs, reqnsert battery pack into the charg-

er. If the problem persists, try a different battery pack to determine if

the charger is OK. If the new pack charges correctly, then the or[g[na!

pack is defective and should be returned to a service center or other

Page 8

collectionsiteforrecycling.Ifthenewbatterypackelicitsthesame

troubleindicationastheoriginal,havethechargertestedatanautho-

rizedservicecenter.

HOT/COLDPACKDELAY

SomechargershaveaHot/ColdPackDelayfeature:whenthecharg-

erdetectsabatterythatishot,itautomaticallystartsaRotPackDelay,

suspendingcharginguntilthebatteryhascooled.Afterthebatteryhas

cooled,thechargerautomaticallyswitchesto thePackCharging

mode.Thisfeatureensuresmaximumbatterylife.Theredlightflash-

eslong,thenshortwhileintheRotPackDelaymode.

PROBLEMPOWERUNE

SomechargershaveaProblemPowerLineindicator.Whenthecharg-

erisusedwithsomeportablepowersourcessuchasgeneratorsor

sourcesthatconvertDCtoAC,thechargermaytemporarilysuspend

operation,flasMngtheredmightwithtwofastMinksfollowedbya

pause.Thisindicatesthepowersourceisoutoflimits.

LEAVING THE BATTERY PACK _NTHE CHARGER

The charger and battery pack can be left connected with the red light

glowing indefinitely. The charger wilI keep the battery pack fresh and

fully charged.

NOTE: A battery pack will stowly lose its charge when kept out of the

charger. Ifthe battery pack has not been kept on maintenance charge,

it may need to be recharged before use. A battery pack may also slow-

ly Iose its charge if left in a charger that is not plugged into an appro-

priate AC source.

WEAK BATTERY PACKS: Chargers can also detect a weak battery.

Such batteries are still usable but should not be expected to perform

as much work. In such cases, about 10 seconds after battery inser-

tion, the charger wilI beep rapidly 8 times to indicate a weak battery

condition. The charger wiII then go on to charge the battery to the

highest capacity possible.

i_portant Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65°F and

75°F (18 °- 24°C). DO NOT charge the battery pack in an air tem-

perature below +40°F(+4.5°C), or above +105°F (+40.5°C). This

is important and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normaI condition, and does not indicate a

problem.

3. If the battery pack does not charge properly:

a. Check current at receptacle by pIugging in a lamp or other

appliance

b. Check to see if receptacle is connected to a light switch which

turns power off when you turn out the Iights.

c. Move charger and battery pack to a location where the

surrounding air temperature is approximately 65°F - 75°F (18°-

24°0).

d. If charging problems per_isL, Lake Lhe Loci, baLLery puck and

charger to your local service center.

4. The battery pack should be recharged when itfails to produce suf-

ficient power on jobs which were easily done previously. DO NOT

CONTINUE to use under these conditions. Follow the charging

procedure. You may aIso charge a partially used pack whenever

you desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can be

shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, steel woot, aluminum foil, or any

buildup of metallic particles should be kept away from charger

cavities. Always unplug the charger from the power supply when

there is no battery pack in the cavity. Unplug charger before

attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

A WARNING: Don't a!low any i/quid to get inside charger. Electric

shock may resu/L Tofacilitate t,_ecooiing of the battery pack after use,

Page 9

HG.2 HG.2A

avoid p/acit_g _,#echarger or battery pack in a warm environment such

as in a metal shed, or an uninsulated trailer.

A CAUTION: Never attempt to open _,_ebattery pack for any reason.

If the plastic housing of the battery pack breaks or cracks, return to a

service center for recycling.

installing and Removing the Battery Pack

NOTE: Make sure your battery pack is fully charged.

To install the battery pack into the toot handle, align the base of the

tool with the notch inside the tool's handle (Fig. 2) and slide the bat-

tery pack firmly into the handle until you hear the lock snap into place

as shown in Figure 2A.

To remove the battery pack from the tool, press the release buttons

and firmly pull the battery pack oat of the toot handle. Insert it into the

charger as described in the charger section of this manual.

Variable Speed Switch

To turn the tool on, squeeze the trigger switch. To turn the tool off,

release the trigger switch. Your tool is equipped with a brake. The

chuck will stop as soon as the trigger switch is fu!ly released.

The variable speed switch enables you to select the best speed for a

particular application. The farther you squeeze the trigger, the faster

the too! will operate. Use lower speeds for starting holes without a cen-

terpunch, drilling in metals or plastics, driving screws and drilling

ceramics, or in any application requiring high torque. Higher speeds

are better for dri!ling in wood, wood compositions and for using abra-

sive and polishing accessories. For maximum tool life, use variable

speed only for starting holes or fasteners.

NOTE: Continuous use in variable speed range is not recommended.

It may damage the switch and should be avoided.

Forward/Reverse Control Button (FJgo 3)

A forward/reverse control button FIG. 3

determines the direction of the Depressfor Reverse DepressforForward

tool and also serves as a lock off

button. To select forward rotation,

release the trigger switch and

depress the forward/reverse con-

trol button on the right side of the

tool. To select reverse, depress the forward/reverse control button on

the ieft side of the tool. The center position of the control button locks

the toot in the off position. When changing the position of the control

button, be sure the trigger is released.

NOTE: The first time the tool is run after changing the direction of rota-

tion, you may hear a click on start up. This is normal and does not indi-

cate a problem.

Terque Adjustment Cellar FIG.4

(Fig, 4)

The torque adjustment collar (A) is clearly

marked with numbers and a driI! bit

symbol.The collar should be rotated until the

desired setting is located at the top of the tool

(Fig. 4). Locators are provided in the collar to

eliminate the guess work when selecting fas-

tening torque. The higher the number on the

collar, the higher the torque and the larger the A

fastener which can be driven. To lock the

clutch for drilling operations, move to the drill

bit position.

Page 10

NOTE:WhenusingtheDrii!/Driverfordriftingholes,besurethatthe

TorqueAdjustingCollarissetsothefigureofthedrillisalignedwith

thecenterlineonthetopofthetoolFailuretodothiswillallowthe

clutchtoslipwhileattemptingtodrill

Dual Range Gearing (Fig. 5)

The dual range feature of your Driver/Drift allows you

to shift gears for greater versatility.

To select the low speed, high torque setting, turn the

too! off and permit to stop. Slide the gear shifter for-

ward (towards the chuck) as shown in Figure 5. To

select the high speed, low torque setting, turn the tool

off and permit to stop. Slide the gear shifter back

(away from chuck).

NOTE Do not change gears when the tool is running.

If you are having trouble changing gears, make sure

that the dual range gear shifter is either completeJy

pushed forward or completely pushed back.

Keyless Single Sleeve Chuck

FIG.B_

z

Your tool features a keyless chuck with one rotating sleeve for one-

handed operation of the chuck. To insert a drill bit or other accessory,

follow these steps.

1. Lock the trigger in the OFF position as previously described.

2. Grasp the black sleeve of the chuck with one hand and use the

other hand to secure the tool. Rotate the sleeve counterclock-

wise far enough to accept the desired accessory.

3. Insert the accessory about 3/4" (19 ram) into the chuck and tight-

en secureiy by rotating the chuck sleeve clockwise with one hand

while holding the tool with the other. Your tool is equipped with an

automatic spindle lock mechanism. This allows you to open and

close the chuck with one hand.

To release the accessory, repeat step 2 above.

L¢ WARNING: Do not attempt to tighten drill bits (orany other acces-

sory) by gripping the front part of the chuck and turning the tool on.

Damage to the chuck and personal Lr,,jurymay resdL Always lock off

Lngger switch when changing accessories.

Be sure to tighten chuck with one hand on the chuck sleeve and one

hand holding the tool for maximum tightness.

Operatien as a DHtl

Turn the collar to the drill bit symbol. Install and tighten the desired drill

bit in the chuck. Select the desired speed/torque range using the dual

range gear shifter to match the speed and torque to the planned oper-

ation. Followthese instructions for best results when drilling.

DRiLLiNG

1. Use sharp drill bits only. For WOOD, use twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use high speed steel

twist drill bits or hole saws. For MASONRY, such as brick, cement,

cinder b!ock, etc., use carbide-tipped bits.

2. Be sure the materia! to be drilled is anchored or clamped firmly. If

drilling thin material, use a "back-up" block to prevent damage to

the material

3. Always apply pressure in a straight line with the bit. Use enough

pressure to keep the drill bit biting, but do not push hard enough

to stall the motor or deflect the bit.

4. Hold the drill firmly with one hand on the grip and the other hand

on the bottom of the battery pack to control its twisting action.

5. IF DRILL STALLS, it is usually because it is being overloaded.

RELEASE TRIGGER IMMEDIATELY, remove drill bit from work,

and determine cause of stalling. DO NOT CLICK TRIGGER OFF

AND ON IN AN ATTEMPT TO START A STALLED DRILL - THIS

CAN DAMAGE THE DRILL.

6. To minimize stalling upon breaking through the material, reduce

pressure on drill and ease the bit through the last fractional part of

the hole.

7. Keep the motor running when pulling the bit back out of a drilled

hole. This will help prevent jamming.

Page 11

8.Withvariablespeeddrillsthereisnoneedtocenterpunchthepoint

tobedrilled.Useaslowspeedtostarttheholeandaccelerateby

squeezingthetriggerharderwhentheholeisdeepenoughtodrill

withoutthebitskippingout.Operateatfull-onafterstartingthebit.

Drilling in Weod

Holes in wood can be made with the same twist drills used for metal

These bits may overheat unless pulled out frequently to clear chips

from the flutes. For larger holes, use low speed wood bits. Work that

is likely to splinter should be backed up with a block of wood.

Drilling in Metals

Use a cutting lubricant when drilling metals_ The exceptions are cast

iron and brass which should be drilled dry. The cutting lubricants that

work best are sulphurized cutting oil or lard oil; bacon grease will also

serve the purpose.

Dritling Masonry

Use carbide tipped masonry bits at low speeds. Keep even force on

the dril! but not so much that you crack the brittle materials. A smooth,

even flow of dust indicates the proper drilling rate.

Operatien as a Screwdriver

Select the desired speed/torque range using the dual range gear

shifter on the top of tool to match the speed and torque to the planned

operation.

insert the desired fastener accessory into the chuck as you would any

drill bit. Make a few practice runs in scrap or unseen areas to deter-

mine the proper position of the clutch collar.

MA×IMUM RECOMMENDED CAPACiTiES

DC727, DC728 DC789

WOOD 1_1/2" 1_1/2"

STEEL 3/8" 1/2"

CONCRETE 3/16" 4/4"

Cleaning

A CAUTION: Wi_;hthe motor running, blow dirt and dust out of all air

vents wit,5 dry air at least once a week. Wear safety glasses when per-

forming t,_is.Exterior plastic parts may be cleaned t44it,5a damp cloth

and mild detergenL Ah,#ough these parts are highly solvent resistant,

NEVER use solvents.

CHARGER CLEANING INSTRUCTIONS

A WARNING: Disconnect the charger from t,_e AC outlet before

cleaning. Dirt and grease may be removed from the exterior of the

charger using a cloth or solI_non-meta_;qcbrush. Do not use water or

any cleaning solutions

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local service center.

If yol; need any assistance in locating any accessory, please contact

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

24286 or call 1-800-4-DEWALT (1-800-433-9258).

i& CAUTION: The use of any non-recommended accessory may be

hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adiustment (including brush inspection and replacement) should

be performed by certified service centers or other qualified service

organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALT wilI repair, without charge, any defects due to faulty materi-

als or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair informa-

tion, visit www.dewalt.com or call 1-800-4-DEWALT. This warranty

Page 12

doesnotapplytoaccessoriesordamagecausedwhererepairshave

beenmadeorattemptedbyothers.Thiswarrantygivesyouspecific

legalrightsandyoumayhaveotherrightswNchvaryincertainstates

orprovinces.

Inadditiontothewarranty,DEWALTtoolsarecoveredbyour:

1YEARFREESERVICE

DEWALTwillmaintainthetoolandreplacewornpartscausedbynor-

maluse,forfree,anytimeduringthefirstyearafterpurchase.

90DAYMONEYBACKGUARANTEE

Ifyouarenotcompletelysatisfiedwiththeperformanceofyour

DEWALTPowerTool,Laser,orNailerforanyreason,youcanreturnit

within 90 days from the date of purchase with a receipt for a fulI refund

- no questions asked.

FREE WARNING LABEL REPLACEMENT: if your warning labels

become Hlegible or are missing, call 1-800-4-DEWALT for a free

replacement.

/ 3/_" {18mm}V$O

D {_7_7 CORDLESS DR@Lt/BR@VER

_s_Eo_c_

TYPEI SE&

,$voo=

uto O=@o/min/o4 _/miu_(RpM ) -- ,.

AVERTISSENENT

TO REBU_E _HE RH,_KOF HNJURY, USeR MU$$ I_EAD A_D

UIIID_RTTA_ D HN_TRUC%lON MABUAL USE OI_LY W]Yff OEWALT

BATTEF$1ES ,e,NB CBA_GE_, ALWAYS USE PROPE_ EYE A,_)

R_SPHP,AT_R¥ P_ OTEC'_ll0N=A THT_E P_EVEN_E LURELE GUHDE,

$0_0LE85 B_@LLrZO_VE_{

TYPE1 $E& List__

no Lt_4_VminN=14OO/min{RPN}

AVERTiSSENENT

TO _E_UCE THE R_$_{ _F _N,_8}f% _SE_ _U_I REA_ ANB

U_DE_TA_D _NSTRU_T_O_ MANUAL _$E O[_L¥ W_H DEWALT

_AT_E_E$ AND _,¢BGER. A[WAV_ U_£ P_OPEB EVE AND

_E_P_RATO_Y PROSE£1_0N= A T]T_E PR_VENT_F, L_E L_ G_DE=

$ORDLE$S DRILL/DR_VE$

TYPEI SE& _tE__A

_o O=450/min/O=1_hni_H RP_ }

_;_][E_ AVERTiSSENENT

_O REDUCE THE R_$K OF _NJURY, U_;E_ _UST _EA° AND

UNdERSTaNDP_ST_UST_ON_Ar_UAL US_O_LYW_H OeWALT

BAT_R_$ AND _HAR_E_. ALWAYS USE _ ROmPE_ EyE AI_D

EESP_RATORY PRO_CT_O[_. A 7_T]{E p_EVE_F, L_BE LE _U_D_,

lO

Page 13

SIVOUSAVEZDESQUESTIONSOUVOULEZNOUSFAIREPART

DEVOSCOMMENTAIRESCONCERNANTCETQUTILOUTOUT

AUTREOUTILDEWALT,COMPOSEZSANSFRAISLE:

1800433-9258.

R#gles g_n#rales de s#c#Ht#

concernant #es ou*ils i, pi#es

AVERTISSEMENT _.Lire et comprendre toutes lee directives,

car le non-respect des directives suivantes pou_rait entra,;ner un

choc #iectrique, un incendie ou des btessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

* Garder ]a zone de trava# propre et bien #clair#e; les 6tab/is

encombr#s et los endroits sombres sent propicee aux accidents,

* Ne pae utiliser lee outils #lectriquee dane une atmosphere

explosive, comme # proximit# de liquides, de gaz ou de pous-

sieres inflammables; le moteur peut crier des #tinceiies et

enflammer les vapeurs ou les poussieres environnantes.

* Tenir ]es enfants, lee vie#ours ou route autre personne #

F#eart ]orsqu'on ut#ise un outil #lectrique; /es distractions peu-

vent faire perdre /a maftrise de ce demie_

MESURES DE SECUR_TE : ELECTRIO_TE

* Ne pae ut#iser le cordon de maniere abusive; on ne doit pas

transporter l'outil en ie tenant par ie cordon. On doit tenir le cordon

I'#cart des sources de chaleur, del'huile, des bords tranchants ou

des pibces mobiles. Remp/acer imm#diatement les cordons

endommag#s, car ces demiers augmentent tes risques d'incendie.

* Un outi] a piles int#gr#es ou a bloc-piles externe dolt _tre

recharge eeu]ement au moyen du chargeur approprie, car un

chargeur destin# a une pile particuilere pourrait entrMner un risque

d'incendie Iorsqu'il est utitis# avec une autre.

* N'utiliser Foutil # piles qu'avec le bloc-piles d#signe, car/'utiti-

sation d'un autre type de piles pourrait entrafner un risque

d'incendie.

11

SECUR_T¢: PERSONNELLE

* Rester vigilant en tout temps et fMre preuve de jugement

Iorsqu'on ut#ise un outil electrique; ne pas utiliser Fouti]

Iorsqu'on est fatigue ou sous Finfiuence de drogues, d'a]coo]

ou de m#dicaments, car un moment d'inattention pourrait entrafn-

er des btessures graves.

* Porter des v@tements appropH#s; ne pas porter de v#tements

amples ni de bijoux. Couvrir ou attacher lee cheveux longs.

Garder lee cheveux, ]es v#tements, lee bijoux et los gants

61oign6s des pieces mobiles, car ceuxoci peuvent s'y coincer.

Se tenir _toign_ des _vents puisque ces demiers pou_raient cam-

outer des pieces mobiles.

* Eviter lee d_marrages accidentele; e'assurer que Finterrup-

tour soit plac# en position de verrouil]age ou d'arr#t avant

d'ins#rer le bloc-piles. Ne pas transporter l'outii en /aissant le

doigt sur l'interm'pteur ni ins#rer te b/oc-piles /orsque t'outii est en

position de marche, car ceia pou_rait causer un accidenL

* Rotifer lee cles de tog]age avant de demarrer Foutil; une ci#

laiss6e sur une piece mtative pourrait entrafner des btessures.

* Ne pas trop etendre lee brae;/es pieds doivent rester ancr#s fer-

mement sur le so/af,,n de maLetenir son #quitibre en tout temps et

de mieux maftriser !'outi/ dans des situations impr6vues.

* Utiliser le materiel de s#curite approprie; toujours porter des

lunettes de protection. Porter un masque anti-poussieres, des

chaussures antid_rapantes, un casque de s_curit_ ou des pro-

tecteurs aud,#'ifsIorsque /a situation le requiert.

UT_LISAT_ON ET ENTRETIEN DE L'OUT_L

* Fixer et soutenir Fouvrage sur une plate-forme stable au moyen

d'une butte fixe ou de tout autre diepositif eemb]ab]e; t'ouvrage

est instabie lorsqubn le retient manuellement ou qu'on t'appuie cen-

tre le corps, ce qd pou_rait faire perdre la mai_'risede Ibuti/.

* Ne pas forcer I'outi] ni Futiliser pour des travaux autres que

ceux pour lesquels il a et# con_u. Pour obtenir de meiileurs

r_sultats et pr_venir les risques de biessure, laisser !'out,;!couper

la vitesse pour laquefle it a #t# con_u.

Page 14

* Nepasutiliser Foutil Iorsque Finterrupteur de marche-arr_t ne

fonctionne pas; tout out/t qui ne peut _tre command_ au moyen

de I'interrupteur est dangereux et duit _tre r_par_.

* Debrancher le bloc-piles de Fouti] ou mettre Finterrupteur en

position de verroui]]age ou d'arr6t avant d'effectuer un

reglage, de changer ]es aeeessoiree ou de ranger Foutil; cee

mesures de s_curit_ preventives _duisent les risques de d_mar-

rage accidenteL

* Lorsqu'on n'ut#ise pas Foutii, le ranger here de ]a portee des

enfants ou des personnes non qualifiees; les out/ls sent dan-

gereux entre/es mains de personnes inexperiment_es.

* Lorsqu'on n'utilise pas le bloc-piles, le ranger _tF6cart des

objets meta]]iques tels que ]es trombones, tes pibces de mon-

naie, les c/_s, /es claus, les v/s ou autres pet/ts objets susceptibles

de conduire l'_tectflcit_ entre les barnes et d'occasionner aLesides

courts-circuits suscept/bles de provoquer des _tinceh'es, des

brOlures ou un incendie.

* BienentretenirFoutil;s'assurerqu'ilsoittoujoursbienpropre

et aiguise. Les outils bien entretenus et dent les bards sent bien

tranc,#ants sent mains suscept/btes de rester coinc_s et sent plus

fac/les a maftr/ser.

* Verifier ]es pieces mobiles afin de s'assurer qu'eltes soient

bien alignees et qu'ellee ne reetent pas coincees; verifier

egalement lee pieces afin de s'assurer qu'il n'y ait aueun bris

ni aucune autre condition susceptible de nuire au ben fonc-

tionnement de FoutiL Paire r_parer I'out/l si ce demier est endom-

mag_ avant de s'en servir a nouveau, car les accidents sent sou-

vent causes par des out/ls mal entretenus.

* N'uti]iser que lee accessoires recommand#s par le fabdcant

pour le mod#le coneerne; un accessuire destin# a un outil part/-

culier pourrait devenir dangereux Iorsqu'fl est u_.qis_avec un autre.

ENTRET_EN

* L'outil doit _tre entretenu ou r6par6 par ]e personnel qua]ifie

seulement; toute maintenance effectu_e par une personne non

quat/fl_e peut entraiber des risques de blessure.

12

* Lore de Fentretien, n'utiiiser que des pieces de reehange iden-

tiques et suivre lee directives de ]a section .Entretien. du

present manuel afin de pr_ven/r les risques de choc _lectrique ou

de blessure.

R_gles de s_curit_ specJfiq_e

* ToBit Fouti] par lee surfaces isoleee prevues acette fin

Iorsque Foutil risque d'entrer en contact avec des ills caches,

car de tets contacts peuvent mettre les pieces m_taHiques de I'out//

sous tension, engendrant des risques de choc _tectrique.

iiAVERTtSSEMENT : Certains outils _lectr/ques, tels que les

sab/euses, les scies, tes meuies, /es perceuses ou certains autres out-

i/s de construction, peuvent souiever de la poussibre contenant des

produits chim/ques suscept/bfes d'entrafner /e cancer, des malforma-

tions cong_nitales ou pouvant _tre nodfs pour le systeme repmduct/tt

Parmi ces produits chimiques, on retrouve :

* le plomb clans les peintures a base de plomb,

* ta silice crLsta///ne dans les briques et le ciment et autres pm-

duits de magonnerie,

* /'arsenic et /e chrome darts le bois de sciage ayant subi un

traitement chimique.

Le _isque assoc/_ 9 de relies expositions peut varier selon la

fr_quence avec laque//e on effect_e ces travaux. Pour r_duire /'expo-

sit/on 9 de tels produits, fl faut travaifler clans un endroit bien ventil_ et

ut/t/ser I'equipement de s_curit_ appropri_ tel un masque anti-pous-

sieres sp_cialement congu pour flitter tes particuies m/cmscopiques.

* E:viter tout contact prolonge avecla poussiere soulevee par

cot oudl ou autres outils eleetriques. Porter des v#tements de

protection et nettoyer ]es parties exposees du corps avec de

Feau savonneuee. S'assurer de bien se prot_ger afin d'_viter

d'absorber par la boucbe, los yeux ou la peau des produits chim-

iques noch%

iiAVERTISSEMENT : Cet outil peut produire et r_pandre de la pous-

sibre susceptible de causer des dommages s_rieux et permanents au

systeme respiratoire. Toujours uti!iser un apparefl respiratoire ami-

poussieres appmuv_ par le N/OSH ou t'OSHA. Diriger les particuies

darts le sens oppos_ du visage et du corps.

Page 15

_kM/SE EN GARDE : Lorsqu'il n'est pas utilise, coucher /'outil

sur une surface stable ou il ne risque pas de causer une chute.

Certains outi,tsdot_s d'un bloc-piles volumineux peuvent demeurer en

position vertica/e sur teur bloc-piles, mais peuvent _galement @'reren-

vers_s facilemenL

* L'_tiquette appos_e sur/'outil peut affic,her lee symboles sdvants.

Voici les symbofes et leurs d6finitions :

V............ volts

Hz ..........hertz

min ........minutes

.... ___ courant continu

[] .......... construction

de classe l/

..........borne de terre

sppm ......surface de sciage

par minute

A ............ amperes

W ............ watts

_ ..........courant altematif

no ............ aucune option 9 vide

.../min ......tours OUmouvements

altemailts par minute

Z¢ .......... symbole d'avertissement

#mportantes cenMgnes de s6cudt_

cencernant lee Mec-pi#es

L'oufii fonctionne sur un bloc-piles DEWALT de 12, de 14,4 ou de 18

volts. Lorsqu'on commande des bloc-piles de rechange, on dolt indi-

quer le num6ro de catalogue et la tension requise. Les bloc-plies b,

dur6e prolong6e durent 25 % plus Iongtemps que les bloc-piles

standard.

REMARQUE : bien que !'outil puisse fonctionner au moyen de I'un ou

I'autre des deux types de bloc-piles, on dolt s'assurer d'en choisir un

de tension appropri6e. Comme Ies piles perdent leur charge lente-

ment Iorsqu'elles ne sont pas placSes dans le chargeur, il est

pr6f6rable de les laisser a cet endroit en tout temps.

Le b!oc-piles n'est pas compl_tement charg6 Iorsqu'on le sort de la

baste. Avant d'utiliser Ie bloc-piles et Ie chargeur, Iire Ies consignes de

s_curit6 ci-dessous. Puis suivre la m6thode de chargement indiqu6e.

LIRE TOUTES LES CONSIGNES

* Ne pas Mcinerer le bloc_piles m_me s'H eet tree endommage eu

comp/etement use. h'risque d'expleser si on tejette au feu.

* H peut y avoir une legere fuite de fiquide en provenance des

616merits du b/ecopiles dane des conditions d'utiflsation ou

des temperatures extremes. Ceci n'est pas un signe de

d_faitlance. Cependant, si te sceau d'_tanch_it_ ext_ieur est bris_

et si le tiquide entre en cem_ct avec ta peau :

a. la laver rapidement au savon eta/'eau ;

b. neutrahser avec un acide doux, comme du jus de dtron ou du

vinaigre ;

c. si /e liquide des piles entre en contact avec les yeux, lee rincer

9 /'eau claire pendant au mains 10 minutes et consdter

immediatement un medecin. (Remarque d'ordre medical : Le

/iqu/de est une solution compos_e 9 25-35% d'hydroxyde de

potassium.)

* Ne pas transporter de b/ocsopHes de rechange dane eon tab/ier

ou see poches, ni dane des beZtes a outils contenant d'autree

objets en metal Le bloc-piles peurrait #tre endommag_ par un

court-circuit qui risquerait d'entrafner de graves br_lures ou un

incendie.

Ne charger lee blocs-piles que dans lee chargeurs D_WALT_

* NE PAS _clabousserni irnmerger clans/'eau ou d'autres liquides.

Ne pas ranger ou utiffser _'outi_ et _e b_oc-pfles dane des

endroits o# la temperature peut atteindre ou d#passer 40 -°C

(105°F), par exemple, dans lee cabanens ou lee bgtiments

metaHiques, en etc.

_€DANGER : On ne dolt en aucun cas tenter d'ouvrir/e bloc-piles. Si

son barrier est fissur# ou endommag#, ne pas insurer le bloc clans te

chargeur au risque de subir un choc #/ectrique ou une #tectrocution.

Les blocs-piles endommag#s doivent #tre retoum#s a un centre de

service oL_ils semnt recycles.

13

Page 16

REMARQUE:uncapuchonestfoumiaveclapiieenvue

d'etreutiJis6chaqueloisqu'onretirecettedernJerede!'outiI

ouduchargeurenvuedelarangeroudelatransporter;

enleverIe capuchonavantde remettreIa piledansle

chargeuroudansI'outil.

_AVERTtSSEMENT: s'assurer, au moment de ranger ou de

transporter la pile, qu'aucun objet metallique n 'entre en contact

avec les homes a decouvert de la pile. Par exempte, it faut _viter

de placer une pile sans capuchon clans un tabfier, une poche, une

boi_'ea outits ou un firoir (etc.) contenant des objets tels que des ctous,

des v/s ou des c/_s, car ta pile pou_rait causer un court-circuit et

s'endommager, ou risquer de provoquer des brOlures ou un incendie.

_MISE EN GARDE : Le bloc-pries dolt _tre so!idement fix4 a/'outri;

tout bloc-piles qui n'est pas bien fixe a /'ourit risque de causer des

blessures.

Sceau RBRC Mc

Le sceau RBRC Mcde Ia Rechargeable Battery Recycling

Corporation appos6 sur la pile au nickei-cadmium (ou le

bloc-piles) indique que Ies coots de recyclage de ce

dernier a Ja fin de sa vie utile ont dej& 6t6 pay6s par

DEWALT. En certains endroits, Ia mise au rebut ou aux ordures munic-

ipales des piles au nickel-cadmium est iII6gale; le programme de

<<RBRC >> constitue donc une solution des plus pratiques et

6cologiques.

La <<RBRC >>,en collaboration avec DEWALT et d'autres utilisateurs

de plies, a mis sur pied des programmes aux E_tats-Unis dans Ie but

de faciliter la collecte des piles d6charg6es. DEWALT encourage sos

utiIisateurs a participer a son programme de protection de I'environ-

nement et de conservation des ressources naturelJes en retoumant

Jespiles usag6es a un centre de service DEWALT autoris6 ou chez un

d6positaire Iocal afin qu'eIles puissent 6tre recycl6es. On pout en

outre se renseigner aupr6s d'un centre de recydage Jocai pour con-

naitre d'autres sites Jesacceptant.

14

impertantes consignes de s_cuHt_

CO_CeR'Et_nt _eS C_1i3E_e_##'S

CONSERVER CES CONStGNES : Ce manuel confient des consignes

de s_curit4 importantes pour los chailgeurs.

* Avant d'udliser le chargeur, Iire toutes les consignes et tousles

marquages de s#cufit_ sur le chargeur, /e bloc-plies et /e produit

utilisant le bloc-pries.

ZcDANGER : Les bomes de charge re_oivent une tension de 120

volts. Ne pas los touctler avec des objets conducteurs, au risque de

subir un choc _lectrique ou une 41ectmcufion.

_AVERTISSEMENT : Ne laisser aucun fiquide s'infiltrer dans le

chargeu£ Cela risque d'entrainer un c,hoc _lectrique.

/&MISE EN GARDE : Pour r_duire les risques de blessures, ne

charger que les piles au nickel-cadmium rechargeables DEWALT Les

autres types de pries risquent d'_clater, et d'entra_ner ainsi des

b/essures et des dommages.

_MtSE EN GARDE : Dans certains cas, lorsque le chargeur est

branche clans la source d'alimentation, il est possible que des corps

4trangers court-circuitent les contacts de charge a nu a/'/nt_r/eur du

chargeu_ Les corps 4trangers conducteurs, notamment ta tafi_ed'acier,

le papier d'aluminium ou toute accumulation de particu/es m#talliques,

doivent _tre tenus a distance des cavit4s du chargeur. On dolt toujours

d#brancher le chargeur de la source d'alimentation lorsqu'i/ n'y a pas

de bloc-pries clans la cavitY. D_brancher le chargeur avant de tenter de

/e nettoyer.

* NE PAS tenter de charger le bloc-piles avec un chargeur autre

que ceux du pr#sent manuel Le c,hargeur et le bloc-piles sont

sp#cifiquement con_us pour #tre ufi/is#s conjointement.

* Cos chargeurs ne sont census que pour charger des piles

rechargeables D_WALT. Tout autre usage peut entrah_er un

incendie, un choc 4lectrique ou une #lectrccurion.

. Ne pas exposer le chargeur a la pMie ni a la neige.

* Tirer sur la fiche et non sur le cordon pour debrancher le

chargeur. AinsL on risque moins d'endommager la fiche et le

cordon d'alimentafion #lectrique.

Page 17

* S'aeeurer que le cordon eet poeitionne de fa_on a emp_cher

qu'on ne le pietine ou qu'on ne tr6buche deseue, ou bien qu'i]

soit expose a des contraintes ou des dommages quelconques.

* On utilieera une rallonge eeulement si c'est absolument

neceesaire. Une raftonge inadequate peut entra,;ner un incendie,

un choc _lectrique ou une _lectmcution.

* Pour des raisons de securit6, ]a rallonge dolt comporter un

diametre de fil (AWG ou American Wire Gauge) approprie. Plus

le num#ro de jauge du fil est petit, plus la capacit# du cgble est

grande ; par exemple, un num6ro de jauge 9gal a 16 correspond 9

une capac/t_ plus grande qu'un num_ro de jauge _gal 9 18.

Lorsqubn ufltise plusieurs rallonges pour obtenir la longueur totale,

on dolt s'assurer que les ills de chacune d'elles sent au moins du

calibre minimum n6cessaire.

Calibre de fil minimum recommande pour lee rallongee

Longueur totale de la rallonge

25 pi 50 pi 75 pi 100 pi 125 pi 150 pi 175 pi

7,6m 15,2m 22,9m ;-_0,5m f:_A,1m 45,7m 53,;_m

CaBibre AWG

18 18 16 16 14 14 12

* Ne poser aueun objet cur le chargeur et ne pae poser ]e

chargeur sur une surface non rigide risquant d'obstruer les

prises d'air et d'entra[ner ainei une surchauffe interne de

I'appareiL Placer te chargeur a l'_cart de route source de chaleur.

flest a_r6 par des fentes dans le haut et le bas du bo,;tier.

* Ne pae ut#ieer ]e chargeur ei le cordon d'a]imentation ou ]a

fiche eont endommages. -- Les l_ire remplacer imm_diatement.

* Ne pas utiliser le chargeur s'i] a re_u un coup violent, si on Fa

#chapp6 ou s'g a et6 endommage d'une fa_on quelconque. On

dolt alors !'apporter a un centre de service autoris_.

* Ne pae demonter le chargeur ; il taut plut_t I'apporter a un

centre de service autorise s'# requiert de ]'entretien ou dee

reparations. Un r_assemblage inad6quat risque d'entra,;ner un

choc _lectrique, une _lectrocution ou un incendie.

* Debrancher le chargeur avant detenter tout nettoyage. On reduit

ainsi lee fisques de chocs electriques. Le seul falt d'enlever le bloc-

piles ne _du'it pas ces fisques.

* NE JAMAIS tenter de raccorder dec:_chargeurs l'un 9 l'autre.

* Le chargeur est con_u pour _tre aliment# par un courant

electfique domeetique normal (120 volts). Ne tentez pas de

I'alimenter au moyen de route autre tension. Cela ne s'apptique

pas au chailgeur pour poste mobile.

UtJlisa_r_ d_ _ede T_ne.U_¢ _c

Automatiq_e

Le mode Tune-up _c automatique _qailibre Ies diff_rents _t_ments du

bloc-piles afin de lai permettre de fonctionner & pleine capacite. Les

blocs-piles do!vent _tre mis au point chaque semaine ou apres 10

cycles de charge/dScharge, ou quand ils n'offrent plus Ie m_me

rendement. Pour utiliser le mode Tune-Up _c Automatique, p{acer le

bloc-piles dans le chargeur pendant une p_riode d'au moins huit

heares. Le chargeur execute les cycles suivants.

1. Le voyant ioug÷ clignotela en continu, ce qui il_dique que le cycle

de charge d'une dur_e d'une heure est amorc_.

2. Lorsque le cycle de charge d'une dur_e d'une heure est terrainS,

le voyant reste allum_ continuellement et ne clignote plus. Cela

indique que Ie bloc est enti_rement charg_ et peat _tre utilis_.

3. Lorsque le bloc demeure dans le chargeur apres la p_riode de

charge initiale de une heure, Ie chargeur passe en mode Tune-

Up_cAutomatique. Ce mode se maintient pendant huit heares ou

jusqu'a ce que les diff_rents _I_ments de Ia pile soient _quilibr_s.

Le bloc-piles est pr_t a _tre utiIis& et peat _tre retir_ en tout temps

au coats du mode Tune-Up Me.

4. Une lois que Ie mode Tune-Up _c automatique est termin_, le

chargeur passe en charge de maintien ; le voyant s'_teint quand le

mode Tune-Up _c automatique est terminS.

CO_SEBVEB CES CO_S_G_ES

POUB UT_L#SAT#O_ ULTEB#EUBE

15

Page 18

FIG. 1

Fenctiennement du voyant

CHARGEMENT OU

BLOC=PILES ................................ Him

CHARGE A BLOC .......................

RETABDEMENT BLOC=PILES

BEIVIPLACEB LE BLOC=PILES,,= @ ® O O • • ® • O ® O O • • ® O @O O O

SOURCE D'ALIMENTATION

INADEQUATE ............................... • @ Q Q • @ @ • Q • @ • Q Q

Chargeurs

L'outil utilise un chargeur DEWALT de 12.0, 14.4, ou 18 volts. Les piles

peuvent _tre charg6es au moyen d'un chargeur DEWALT d'une heure

ou de 15 minutes, ou d'un chargeur pour v6hicules de 12 volts.

S'assurer de lire toutes les consignes de s_curit_ avant d'utiliser Ie

chargeur. Consulter le diagramme apparaissant sur la couverture

arri_re du present guide afin de v_rifier la compatibilit_ du chargeur

avec le bloc-pile.

M_thede de charge

1. Brancher le chargeur a une prise de courant appropri_e avant

d'insSrer Ie bloc-piles.

2. Ins&rer Ie bloc-piles dans Ie chargeur, tel qu'ilIustr8 a la Figure 1,

en s'assurant de bien I'enfoncer. Le voyant rouge (recharge)

clignotera continuelIement, ce qui indique que le cycle de charge

est amorc_,

3, Le bloc-pibs est completement charg6 Iorsque le voyant rouge

reste allum6 continuellement, Le bloc-piles est alors compl6tement

charg6 et on peut I'utiliser ou Ie Iaisser darts le chargeur,

AMtSE EN GARDE : La tension pr_sente aux bomes de charge est

de 120 volts. Ne pas les toucher avec des objets conducteurs. Danger

de choc _lectrique ou d'_/ectrocut/on.

Indicate.rs de charge

Certains chargeurs sont con?us pour d_tecter certains problemes

pouvant aIt6rer le fonctionnement des blocs-pibs. Les problemes sont

signal6s par Ie dignotement rapide du voyant rouge. Si cela se produit,

r6introduire Ie bIoc-pibs darts le chargeur. Si le probleme persiste,

essayer un autre bloc-piIes pour d6terminer si le chargeur est en bon

6tat. Si Ia charge du nouveau bloc-pibs se fait sans probleme, le bloc

originaI est d6fectueux et iIfaut le retourner & un centre de service ou

un site de coibcte pour qu'il soit recyct6. Si I'indication de panne

persiste avec Ie nouveau bloc-piles, faire tester le chargeur a un centre

de service autoris6.

RETARDEMENT- BLOC=PILES CHAUD/FROID

Certains chargeurs sont munis d'une fonction de retardement en raison

d'un bloc-plies chaud/froid : Iorsque le chargeur d_tecte une pile

chaude, il d6clenche automatiquement un retardement -- bloc-piles

chaud, interrompant lacharge jusqu'& ce que la pile ait refroidL Lorsque

les piles sont refroidies, Ie chargeur passe automatiquement en mode

de chargement du bloc. Cette fonction permet de maximiser la vie utile

des piles. Lorsque le chargeur est en mode de retardement en raison

du bloc-piles chaud, le voyant rouge clignote en _mettant

alternativement des signaux de Iumiere longs et brefs.

SOURCE D'ALIMENTATION tNADE_QUATE

Certains chargeurs comportent un indicateur de source d'alimentation

d6fectueuse. Lorsque le chargeur est utilis6 avec certaines sources

16

Page 19

d'alimentationportatives,commedes g6n6ratricesou des

convertisseursc.c.-c.a,11peutcesserdefonctionnertemporairement;

letemoinrougeemettantabetsunclignotementsconstituede

deuxsignauxrapidessuivisd'unepause.Celaindiquequelasource

d'alimentatJonesthorslimites.

BLOC-PILESLAJSSE_BANSLECNARGEUB

OnpeutlaJsserlechargeuretlebloc-pilesbranch6saveclevoyant

rougeallure6Jnd6finiment.Lechargeurmaintiendralebloc-piles

comptetementcharge.

NOTA: Unbloc-pilessed_chargelentementhorsduchargeur.S'i!

n'6taitpasa!iment6parlachargedemaintien,11faudraitpeut-&trele

chargerdenouveauavantdeI'utiliser.Unbloc-pilespeut_galementse

dSchargerlentementsionIelaissedansunchargeurquin'estpas

branch6aunesourcedecourantc.a.appropri6e.

BLOOSoP_LESFAIBLES:Leschargeurspeuventegalement d_tecter

si des piles sont faibles. Celles-c[ sont utilisables mais on ne dolt pas

s'attendre _ ce qu'e!les offrent le m&me rendement. Pour signaler qu'un

bloc-piles est faible, le chargeur emet huit bips rapides environ 10

secondes apres qu'on y a ins6r8 Ie bloc. Le chargeur commence

ensuite _ charger Ies piles jusqu'a Ieur capacit8 maximale dans les

circonstances.

Remarques i_pertantes sur la charge

1, Pour une dur@ede vie maxirnale et un rendement optimal, Ie bloc-

piles doit @trecharg6 _ une temp6rature ambiante de 65 a 75 °F

(18 a 24 °C). NE PAS charger le bloc-piles _ une temp6rature

[nf6rieure b.+40 °F(+4,5 °C) ou superieure _ +105 °F (+40,5 °C).

II s'agit d'une mesure de pr6caution importante pour @viter des

dommages s6rieux au bloc-piles.

2. Le chargeur st le bloc-piles peuvent devenir chauds au toucher

pendant le chargement. II s'agit d'une condition normale, qu[

n'indique pas Ia pr@sence d'un probleme.

3. S[ le bloc-piles ne se recharge pas correctement :

a. V@rifierle courant a Ia prise en branchant une lampe ou un autre

appare[I @lectrique.

b. V@rifier si Ia prise est raccord6e & un interrupteur qu[ coupe le

courant Iorsque I'on 6teint I'6clairage.

c. Placer Ie chargeur et Ie bloc-piles a un endroit o_ Ia temp@rature

de !'air ambiant est d'environ 65 _ 75 °F (18 a 24 °C)

d. S'[I y a touiours des problemes de charge, emmener I'outil, le

bloc-piles etIe chargeur a un centre de service local.

4. Le bloc-piles doit 6tre recharg& Iorsqu'[I ne produit plus

suffisamment de puissance pour des travaux qui @taient

auparavant effectu6s sans difficult@.CESSER I'utilisation dans ces

conditions. Suivre Ia m@thode de charge. On peut @galement

charger un bloc-piles partiellement decharg& sans que cela n'ait

d'incidence n@gativesur Ie bloc-piles.

5. Dans certains cas, Iorsque le chargeur est branch@ a Ia source

d'aiimentation, 11est possible que des corps etrangers court-

circuitent les contacts de charge _ nu a !'int@rieurdu chargeur. Les

corps @trangersconducteurs, notamment Ia laine d'acier, le papier

d'aluminium ou toute accumulation de particules m_talliques,

doivent etre tenus a distance des cavites du chargeur. On doit

toujours d_brancher le chargeur de la source d'alimentation

Iorsqu'[I n'y a pas de bloc-piles dans la cavitY. D_brancher le

chargeur avant de tenter de Ie nettoyer.

6. Ne pas congeler ni [mmerger le chargeur dans I'eau ou un Iiquide

quelconque.

ZCAVERTIBBEMENT : Ne /aisser aucun fiquide s'infiltrer clans /e

chargeu_ Ce/a risque d'entra_ner un choc 41ectrique. Pour facititer le

refroidissement des piles apr_s /'usage, _viter de placer le chargeur

ou le bloc-piles 9 la chaleur, comme dana un cabanon m_ta_;qqueou

darts une remorque non isol_e.

AMiBE EN GARDE : On ne dolt en aucun cas tenter d'ouvfir le bloc-

piles. Si le bo/tier de p/astique du bloc-plies se bfise ou se fissure,/e

rapporter 9 un centre de service pour le recycle_

17

Page 20

FIG. 2

FONCTIONNEMENT

Montage e* d_montage du blocopJles

REMARQUE : S'assurer que Iebloc-piles soit completement charg6.

Pour Hnstaller darts Bapoignee de I'outiB,aligner la base de I'outil

avec I'encoche situ6e & I'int_rieur de Ja poign6e (Fig. 2) et glisser le

bloc-piles fermement dans la poign_e jusqu'a ce qu'on entende un

d6clic indiquant qu'il est bien enclench6, tei qu'illustr6 & la Figure 2A.

Pour retirer le bloc-piles hors de m'outil, appuyer sur Ies boutons de

d_gagement et tirer fermement Ie bloc-piles hers de la poign_e, puis

I'insSrer dans le chargeur selon les directives darts la section

<<Chargeur >>du pr6sent manuel.

interrupfteur de vitesse variable

Pour mettre Voutil en marche, appuyer sur I'[nterrupteur. Pour

I'arr_ter, ret&cher I'interrupteur. Cet out[I est dot6 d'un re&can[sine de

freinage. Le mandrin cesse de toumer aussit6t que I'interrupteur est

completement rel&ch_. L'interrupteur a vitesse variable permet de

s_lect[onner la v[tesse qu[ convient le m[eux & une appI[cafion

parficul[ere. Plus on appu[e sur I'[nterrupteur, plus I'outiI tourne

rapidement. Utiliser I'outil &des vitesses plus basses pour amorcer le

per£age de trous sans coup de pointeau, pour le per£age des m_taux,

du plastique ou de la c_ramique, pour v[sser ou pour toute application

exigeant un couple &lev_. Les v[tesses plus _lev_es conviennent mieux

FIG. 3 , Enfoncer pour la Enfoncer pour la (

rotation arriere rotation avant

au per_age du bois et des compositions de bois ou pour I'utilisation

d'accessoires de pongage et de polissage. Pour assurer a I'outil une

dur_e de vie maximale, n'utiliser la vitesse variable que pour amorcer

le per cage de trous ou pour Ia boulonnerie.

NOTA : L'utilisation prolong6e & des vitesses variables n'est pas

recommand_e. Cette pratique doit 8tre 8vitae car elle risque

d'endommager I'interrupteur.

Bouten de co_mande avant.arri_re

Le bouton de commande avant-arriere d6termine lesens de rotation de

I'outi! et sert 6galement de bouton de verrouillage. Pour s_lectionner la

rotation avant, rel&cher I'interrupteur et enfoncer le bouton de

commande avant-arriere qu[ se trouve du c6t_ droit de I'outiL Pour

s_lectionner Ia rotation arri_re, enfoncer Ie bouton de commande

avant-arri_re qui se trouve du c6t8 gauche de I'outiL Lorsqu'il est pIac_

au centre, le bouton de commande verrouille I'outil en position d'arr_t.

Avant de changer la position du bouton de commande, veilIer

rel&cher d'abord I'interrupteur.

NOTA : Lorsque I'on utilise !'outil pour la premiere lois apres avoir

chang_ Ie sens de rotation, iI est possible qu'un d_clic se fasse

entendre au d_marrage. Ce bruit est normal et n'indique pas la

presence d'un probl_me.

18

Page 21

Collier de r_glage de couple (fig° 4)

Le collier de r6glage de couple est marqu6 a FIG. 4

I'aide de chiffres et d'un symbole repr6sentant

un foret. Faire tourner Ie collier jusqu'a ce que

le r6gIage d_sir8 se trouve sur le dessus de

I'outil (fig. 4). Ces marques sont fournies afin

de permettre de s6Iectionner avec pr6cision le

couple deserrage. Plus le hombre indiqu6 sur

le collier est 61ev6, plus Ie couple est 61ev6 et

plus la dimension de la piece de boulonnerie

visser peut @treimportante. Pour verrouiller

I'embrayage afin d'ex@cuter des op@rations de

pergage, faire tourner le collier iusqu'au

symbole repr6sentant un foret.

NOTA : Lorsque Ia perceuse tournevis est utilis6e pour percer des

trous, s'assurer que le cotlier de r6glage de couple est tourn6 de fagon

que le symbole repr@sentant un foret soit align@avec la Iigne au centre

sur le dessus de I'outil, a defaut de quoi I'embrayage glissera Iorsque

I'on tentera de percer.

Engrenage _ double ga_e (figo 5)

La caract_ristique d'engrenage &double gamme de la FIG.5_

pergeuse-tournevis permet de changer de rapport afin

d'obtenir une plus grande polyvalence. Pour

s6tectionner le rSglage de basse vitesse et de couple

&leve, mettre I'outil hors tension et attendre qu'il

s'arrSte. Faire glisser Ie bouton de changement de

rapport vers I'avant (vers Ie mandrin), comme le

montre Ia fig. 5. Pour sSIectionner le r_glage de haute

vitesse et de faibte couple, mettre I'outil hors tension B

et attendre qu'iI s'arrSte. Faire glisser Ie bouton de

changement de rapport vers I'arriere (dans le sens

oppos_ au mandrin).

NOTA : Ne pas changer de rapport Iorsque I'outil fonctionne. Si le

changement de rapport ne se produit pas, s'assurer que le bouton de

19

changement de rapport est compl_tement pouss_ vers I'avant ou vers

I'arriere.

Mandrin _ mancbon unique sans ci_

L'outil est dot6 d'un mandrin sans fil & rnanchon rotatif afin de permet-

tre a I'utilisateur de manipuier Ie mandrin d'une seule main. Pour ins6r-

er une meche ou tout autre accessoire, suivre les _tapes d_crites ci-

dessous :

1. Verrouiiler Finterrupteur & g&chette en position d'arr_t, tel que

decrit.

2. Saisir la pattie arri_re du mandrin d'une main et utiiiser I'autre

pour retenir fermement I'outil. Faire tourner Ie manchon vers la

gauche, iusqu'& ce que I'ouverture soit assez grande pour

recevoir I'accessoire.

3. Ins6rer I'accessoire sur environ 19 mm (3/4 po) dans Ie mandrin

et te serrer fermement en tournant le manchon vers Ia droite d'une

main et en utilisant I'autre pour tenir I'outil. L'outil est muni d'un

m_canisme de verrouiliage automatique de la broche permettant

d'ouvrir et de fermer le mandrin d'une seule main.

Utiiisation co_e perceuse

Tourner Ie collier iusqu'au symbole repr6sen!ant un foret, hstaller et

serrer Ie foret d6sir6 darts le mandrin. A I'aide du bouton de

changement de rapport, s61ectionner Ia gamme de vitesse et de couple

d@sir6equi convient &I'op6ration planifi@e. Pour le percage, suivre les

directives suivantes afin d'obtenir Ies meilleurs r@sultatspossibles.

PER(_AGE

1=N'employer que des forets bien aff0t_s. Pour Ie BOIS, utiliser des

forets h@Iicoidaux, des forets a trois poin!es, des forets de tari@re

moteur ou des scies &trous. Pour les METAUX, utiliser des forets

h@licoYdaux en acier rapide ou des scies & trous. Pour Ia

MA(_ONNERE (brique, ciment, blocs de b@ton, etc.), utiliser des

forets a pointe au carbure.

2. S'assurer que le mat@riau qui doit @tre perc@est ancr@ ou fix@

solidement. Si le mat@riauest mince, I'appuyer sur un "bloc de bois"

pour @viterde I'endommager.

Page 22

3.Toujoursexercerunepressionenlignedroiteparrapportauforet.

ExercersuffisammentdepressionpourfairemordreIeforetmais

nepasappuyer&I'excSspour8viterdebloquerlemoteuroude

faired6vierleforet.

4.TenirfermementlaperceuseensaisissantIapoign_ed'unemain

etenpla£antI'autremainsurlapartieinf_rieuredubloc-pileafin

demaTtriserlatorsiondeI'outiL

5.SlLAPERCEUSESEBLOQUE,le^probl_meestgen6ralement

attribuable&unesurcharge.RELACHERIMMEDIATEMENT

UNTERRUPTEUR,retirerteforetdutrouperc8etd&terminerla

causedublocage.NEPASAPPUYERDEFACONRE_PE_TE_E

SURL'INTERRUPTEURPOURTENTERDESUPPRIMERLE

BLOCAGECARCETTEPRATIQUEPEUTENDOMMAGERLA

PERCEUSE.

6.Pour&viterunblocageIorsqueI'outiltentedetraverserlemat6riau,

r_duireIapressionexerc&esurlaperceuseafinqueleforetperce

lentementladerni_repattiedutrou.

7.Fairetournertaperceusepourretirerleforetdutrouperc&.Cette

pratiqueempScheleforetdesecoincer.

8.DansIecasdesperceuses&vitessevariable,iln'estpasn&cessaire

demarqueraupointeaulecentredutrou&percer.DSbuterabasse

vitessepouramorcerIetrou,puisacc_I6rerenenfoncantdavantage

I'interrupteurIorsqueIetrouestsuffisammentprofondpour

emp6cherIeforetdesortir.Unefoisletrouamorc&,fairefonctionner

laperceuse&lavitessemaximale.

Per_age du bois

Le bois peut 8tre perc& a I'aide des m_mes forets h&licoTdaux utilis_s

pour les m_taux. Ce type de foret peut surchauffer s'il n'est pas retir6

fr6quemment du trou afin de d&gager lescopeaux des goujures. Pour les

trous de grande dimension, utiliser un foret a bois a basse vitesse. Si le

bois est susceptible de faire des &ctats, placer un bloc de bois a I'arri_re.

Per_age des _taux

Pour percer des m6taux, utiliser un lubrifiant de coupe. Cette consigne

ne s'applique pas b.la fonte ni au laiton, qui doivent _tre perc&s &sec.

Les meilleurs Iubrifiants sont I'huile de coupe sulfur6e et I'huile de

saindoux; la graisse de bacon peut &galement faire I'affaire=

Per_age de la ma_onneHe

Utiliser un foret a maconnerie a pointe au carbure a basse vitesse.

Exercer une force uniforme sur la perceuse mais ne pas appuyer

I'exces pour &viter de faire craquer les mat6riaux friables. Une &mission

de poussi_re rSguli_re indique que lavitesse est appropri_e.

Utilisatien comme teurnevis

_, I'aide du bouton de changement de rapport qui se trouve sur le

dessus de I'outiI, sSlectionner Ia gamme de vitesse et de couple

d&sir&e qui convient &I'op&ration ptanifiSe.

Ins&rer I'accessoire de fixation d&sir8 darts le mandrin, comme pour un

foret quelconque. Faire quelques essais sur une piece inutilisable ou

un endroit qui n'est pas apparent afin de d_terminer la position

appropri&e du collier d'embrayage.

CAPAC_TES MAXIMALES RECOMMANDEES

DC727, DC728 DC759

BOIS 1 1/2 po 1 1/2po

ACIER 3/8 po 1/2 po

BENTON 3/16 po 1/4 po

2O

_ettoya_e

_M/SE EN GARDE : Au moins ut_e lois par semaine, mettre /e

moteur en marche et souffler la poussiere et la salet# hors des #vents

au moyen d'un pulv#r]sateur 9 air sec; on doit porter des iut_ettes de

s#curit# pour effectuer cette tgche. On peut nettoyer les pi_ces

extemes en ptastique au moyen d'un /inge humide et de d#tergent

dos,x. Bien que ces pieces soient tres r#sistantes aux solvants, NE

JAMAIS ut#'iser ces demiers.

_ETHODE DE NETTOYAGE DU CHARGEUR

_AVERT/SSEMENT : D_braneher le c,_argeur de /a prise e.a.

(eourant a/tematif) avant d'en effectuer /e nettoyage. E/it*f_iner/a sa/et_

Page 23

et/agraissede/asurfaceext_rieureduchargeuraumoyend'untinge

ou d'une brosse deuce non m4tallique. Ne pas utLUserd'eau ou de

solutions de nettoyage.

AccessoJres

Des accessoires recommand6s pour I'utilisation avec I'outiI sent

disponibles moyennant un suppl6ment aupres du centre de sewice

autoris6 local

Pour obtenir de I'aide afin de Iocatiser un accessoire particulier,

communiquer avec DEWALT IndustriaE Tool Co., 701 East Joppa Road,

Baltimore, MD 21286 ou composer le 1 800 4-DEWALT. (1 800 433-

9258).

AMISE EN GARDE : fl peut _tre dangereux dbhH'iser des acces-

soires autres due ceux recommand#s.

R_paratiens

Pour assurer Ia SE_CUR,TE_et la F,AB,L,TE_ du produit, les centres de

service certifi6s ou autres services de r6paration comp6tents doivent

effectuer les r6parations, !'entretien et le r6glage (y compris I'inspection

et Ie remplacement des balais) en utilisant touiours des pieces de

rechange identiques.

Garantie ii_it_ de trois arts

DEWALT r_parera, sans frais, tout produit d6fectueux cause par un

d6faut de mat6riel ou de fabrication pour une p6riode de trois arts &

compter de la date d'achat. La pr6sente garantie ne couvre pas les

pieces dent la d6fectuosit6 a 6t6 caus6e par une usure normale ou

Fusage abusif de Foutil. Pour obtenir de ptus amples renseignements

sur les pieces ou Ies r6parations couvertes par la pr6sente garantie,

visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-DEVv'ALT). Cette garantie ne s'applique pas aux accessoires et ne

vise pas les dommages caus6s par des r6parations effectu6es par un

tiers. Cette garantie conf6re des droits 16gaux particuliers _ I'acheteur,

mais celui-ci pourrait aussi b6n6ficier d'autres droits variant d'un 6tat

ou d'une province a Fautre.

En plus de la pr6sente garantie, les outils DEWALT sent couverts par

notre :

CONTFtAT D'ENTRETJEN GRATUJT D'UN AN

DEWALT entretiendra l'outiJ et remptacera les pi6ces us6es au cours

d'une utiiisation normale et ce, gratuitement, pendant une p6riode

d'un an a compter de la date d'achat, et la

GARANTIE DE REMBOURSEI_ENT DE 90 JOURS