Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DeWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DP2800

Pressure Washer

Laveuse à pression

Lavadora a presión

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Page 2

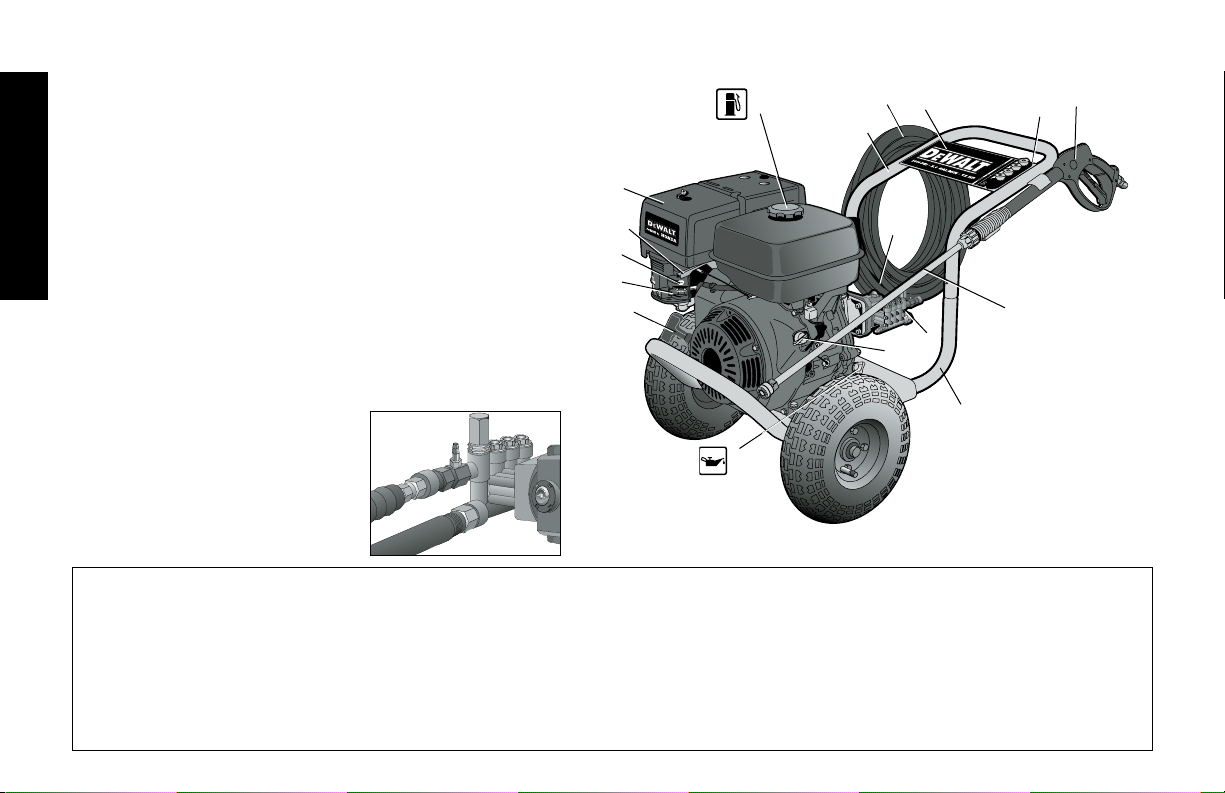

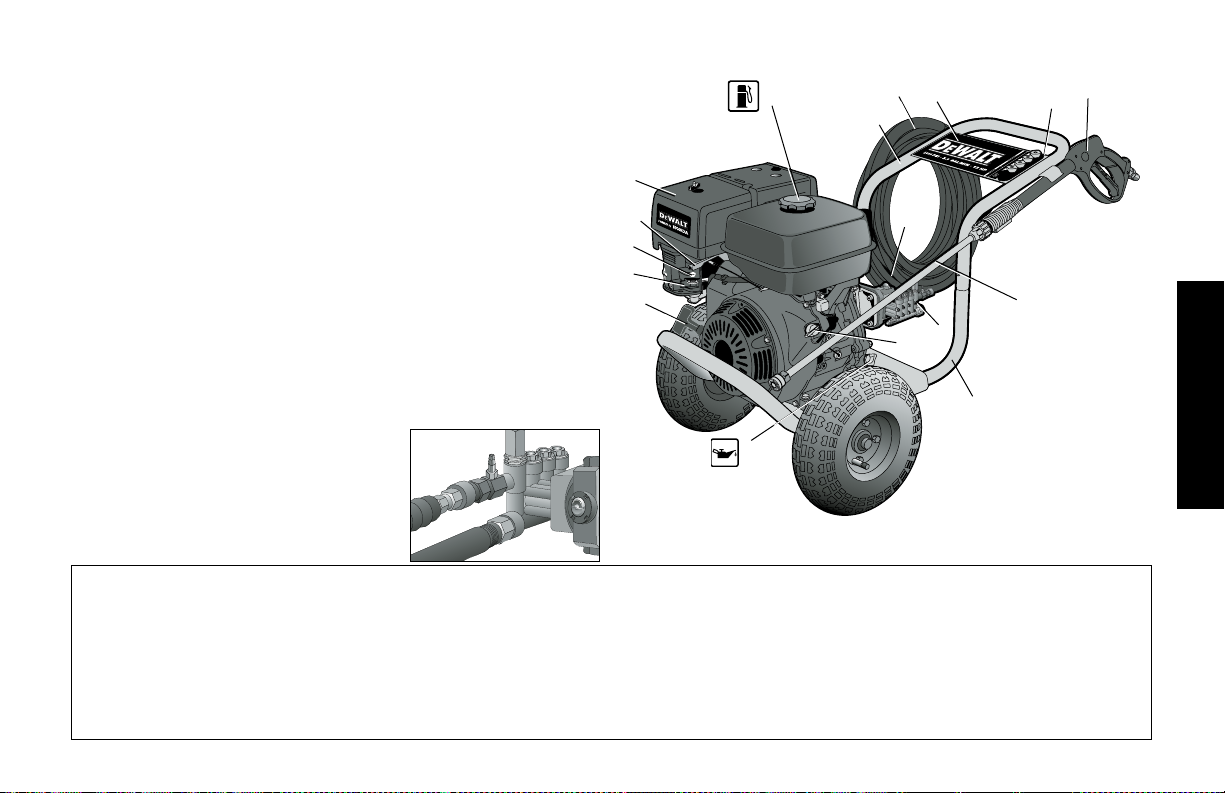

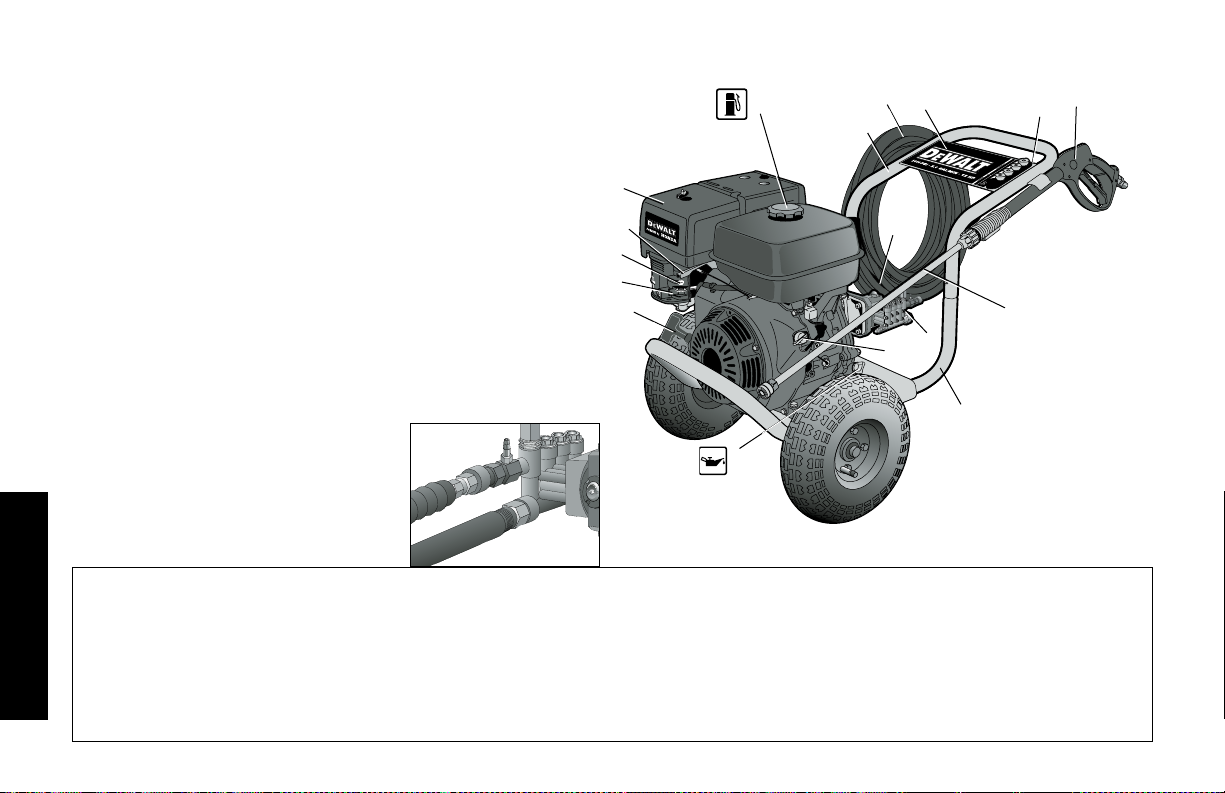

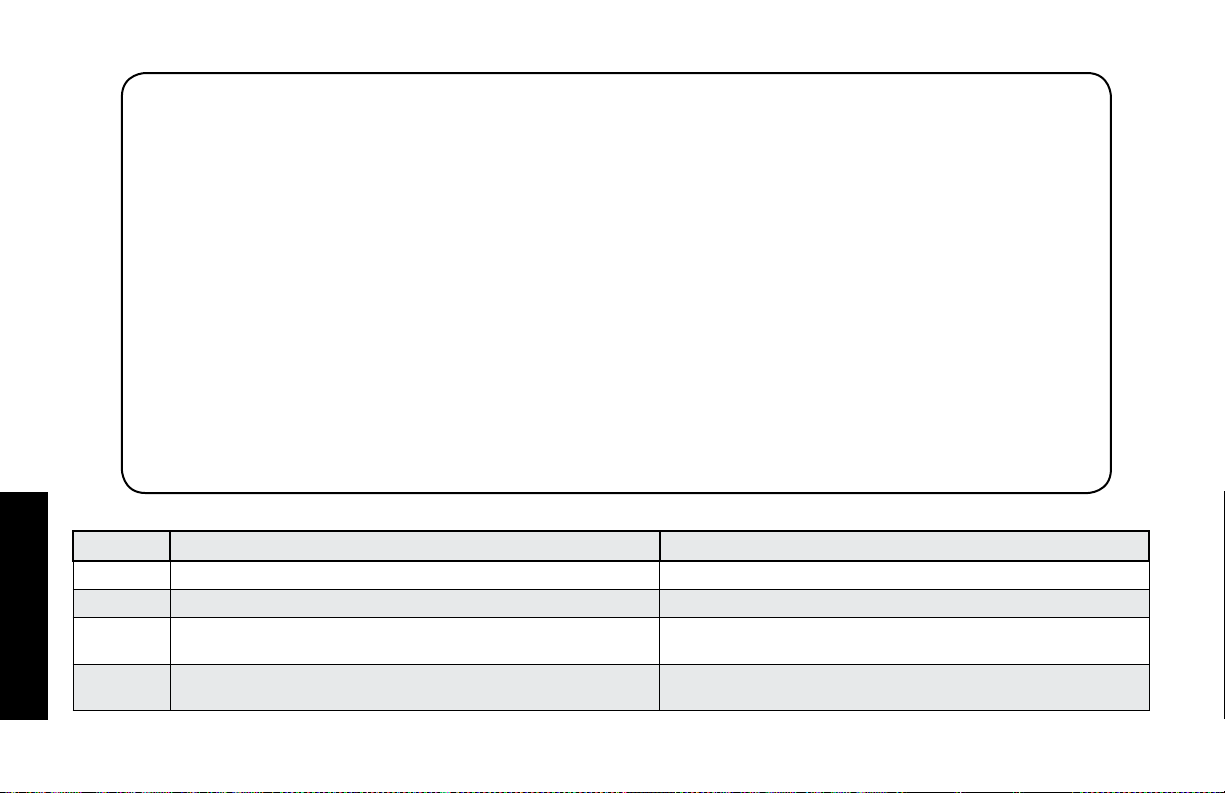

DP2800 PRESSURE WASHER

A. Handle assemble

B. Frame

C. High-pressure hose

D. Spray gun

E. Quick-connect

English

spray wand

F. Panel assembly

G. Nozzle holder

H. High-pressure pump

oil plug

ENGINE

Refer to the engine instruction manual for location

and operation of other engine controls.

I. Engine dipstick/oil plug

J.

High-pressure pump

K.

Engine

L. Choke control

M. Starter grip

N. Fuel valve lever

O. Engine switch

P. Gas cap

Q. Throttle control lever

Pump Specifications

CAT 3DX29GSI

Oil: Use DP70

Oil Capacity: 8.5 oz. (251 ml)

Specifications

K

L

N

FIG. 1

Q

M

C

P

A

I

F

H

J

O

B

D

G

E

MODEL WEIGHT HEIGHT WIDTH LENGTH PSI MAX* OPERATING

GPM MAX* OPERATING

PSI

DP2800

97 lbs 26.5" 23" 40" 2800 2520 3.0 2.7 Honda 6.5

* Water flow and maximum pressure ratings determined in accordance with PWMA standard PW101.

2

GPM

ENGINE

Hp GX200

Page 3

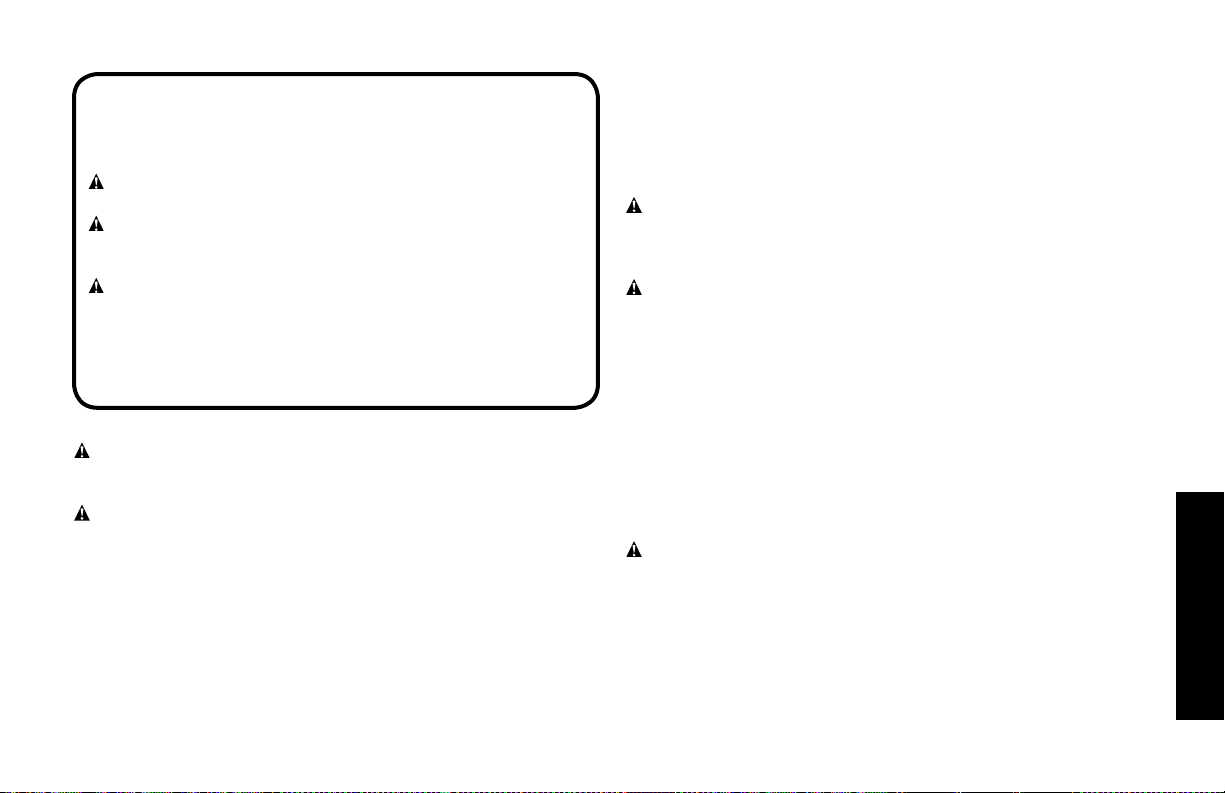

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

CAUTION:

indicates a potentially hazardous situation which, if

not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT

THIS OR ANY DeWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DeWALT (1-800-433-9258)

Used without the safety alert symbol

Important Safety Instructions

WARNING: Do not operate this unit until you read and understand

this instruction manual and the engine instruction manual for safety,

operation and maintenance instructions.

WARNING: When using this product basic precautions should

always be followed, including the following:

1. Read all instructions before using the product.

2. To reduce the risk of injury, close supervision is necessary when

a product is used near children.

3. Know how to stop the product and bleed pressures quickly. Be

thoroughly familiar with the controls.

4. Stay alert – watch what you are doing.

5. Do not operate the product when fatigued or under the influence

of alcohol or drugs.

6. Keep operating area clear of all persons.

7. Do not overreach or stand on unstable support. Keep good

footing and balance at all times.

8. Follow the maintenance instructions specified in the manual.

DANGER: RISK OF INJECTION OR SEVERE INJURY. KEEP

CLEAR OF NOZZLE. DO NOT DIRECT DISCHARGE STREAM AT

PERSONS. THIS PRODUCT IS TO BE USED ONLY BY TRAINED

OPERATORS.

WARNING: This product may not be equipped with a spark-

arresting muffler. If the product is not equipped and will be used

around flammable materials or on land covered with materials such

as agricultural crops, forest, brush, grass or other similar items, then

an approved spark arrester must be installed and is legally required

in the state of California. It is a violation of California statutes

section 130050 and/or sections 4442 and 4443 of the California

Public Resources Code, unless the engine is equipped with a spark

arrester, as defined in section 4442, and maintained in effective

working order. Spark arresters are also required on some U.S.

Forest Service land and may also be legally required under other

statutes and ordinances.

WARNING: This product contains chemicals, including lead,

known to the State of California to cause cancer, and birth

defects or other reproductive harm. Wash hands after handling.

SAVE THESE INSTRUCTIONS

English

3

Page 4

DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spilled gasoline and it’s

English

vapors can become ignited

from cigarette sparks,

electrical arcing, exhaust

gases and hot engine

components such as

the muffler.

• Heat will expand fuel in the

tank which could result in

spillage and possible fire

explosion.

• Operating the pressure

washer in an explosive

environment could

result in a fire.

• Materials placed against or

near the pressure washer

can interfere with its proper

ventilation features causing

overheating and possible

ignition of the materials.

• Shut off engine and allow

it to cool before adding fuel

to the tank.

• Use care in filling tank to

avoid spilling fuel. Move pres

sure washer away

from fueling area before

starting engine.

• Keep maximum fuel level

1/2" (12.7 mm) below

bottom of filler neck

to allow for expansion.

• Operate and fuel equipment

in well-ventilated areas free

from obstructions. Equip

areas with fire extinguisher

suitable for gasoline fires.

• Never operate pressure

washer in an area containing

dry brush or weeds.

• Muffler exhaust heat can

damage painted surfaces,

melt any material sensitive

to heat (such as siding,

plastic, rubber, vinyl or the

pressure hose, itself), and

damage live plants

• Imprope

lead to accidental ignition.

-

Fuel improperly secured

could get into the hands of

children or other unqualified

persons.

• Use of acids, toxic or

corrosive chemicals,

poisons, insecticides, or any

kind of flammable solvent

with this product could result

in serious injury or death.

DANGER: RISK TO BREATHING (ASPHYXIATION)

• Breathing exhaust fumes

will cause serious injury

or death! Engine exhaust

contains carbon monoxide,

an odorless and deadly gas.

rly stored fuel could

WHAT CAN HAPPEN HOW TO PREVENT IT

.

• Always keep pressure washer

a minimum of 4' (1.2 m) away

from surfaces (such as

houses, automobiles or

live plants) that could be

damaged from muffler

exhaust heat.

• Store fuel in an OSHAapproved container, in a

secure location away from

work area.

• Do not spray flammable

liquids.

• Operate pressure washer in

a well-ventilated area. Avoid

enclosed areas such as

garages, basements, etc.

• Never operate unit in a

location occupied by

humans or animals.

4

Page 5

RISK TO BREATHING (ASPHYXIATION) CONTINUED

• Some cleaning fluids

contain substances which

could cause injury to skin,

eyes or lungs.

DANGER: RISK OF FLUID INJECTION AND LACERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Your pressure washer

operates at fluid pressures

and velocities high enough to

penetrate human and

animal flesh, which could

result in amputation or

other serious injury. Leaks

caused by loose fittings or

worn or damaged hoses can

result in injection injuries.

DO NOT TREAT FLUID

INJECTION AS

A SIMPLE CUT! See a

physician immediately!

• Use only cleaning fluids

specifically recommended

for high-pressure washers.

Follow manufacturers

recommendations. Do not

use chlorine bleach or any

other corrosive compound.

• Inspect the high-pressure

hose regularly. Replace

the hose immediately if it is

damaged, worn, has melted

from contacting the engine,

or shows any signs of cracks,

bubbles, pinholes, or other

leakage. Never grasp a

high-pressure hose that

is leaking or damaged.

• Never touch, grasp or attempt

to cover a pinhole or similar

water leak on the highpressure hose. The stream

of water IS under high

pressure and WILL

penetrate skin.

• Never place hands in front

of nozzle.

• Direct spray away from self

• Injuries can result if system

pressure is not reduced

before attempting

maintenance or

disassembly.

and others.

• Make sure hose and fittings

are tightened and in good

condition. Never hold onto

the hose or fittings during

operation.

• Do not allow hose to contact

muffler.

• Never attach or remove wand

or hose fittings while system

is pressurized.

• To relieve system pressure,

shut off engine, turn off water

supply and pull gun trigger

until water stops flowing.

•

Use only accessories rated

equal to or higher than the

rating of the pressure washer.

English

5

Page 6

DANGER: RISK OF INJURY FROM SPRAY

WHAT CAN HAPPEN HOW TO PREVENT IT

• High-velocity fluid spray

can cause objects to break,

English

propelling particles at high

speed.

• Light or unsecured objects

can become hazardous

projectiles.

• Always wear ANSI-approved

Z87.1 safety glasses. Wear

protective clothing to protect

against accidental spraying.

• Never point wand at or spray

people or animals.

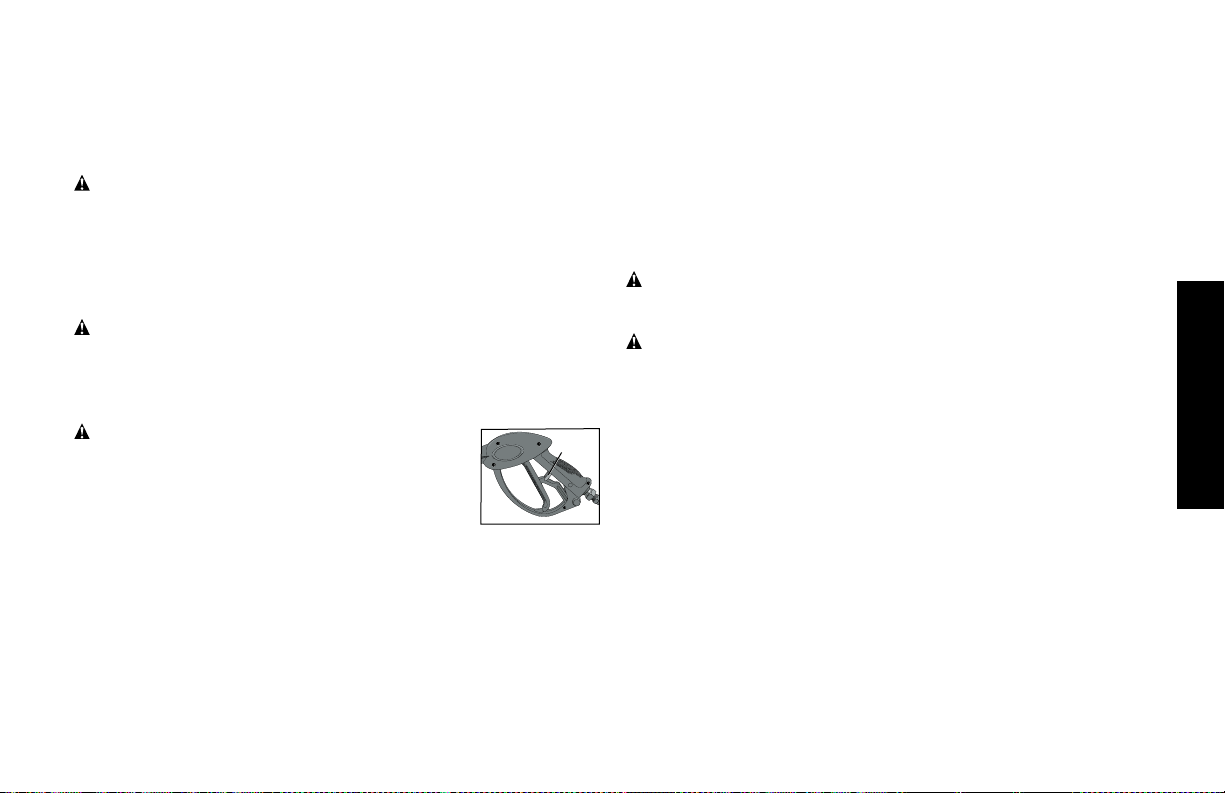

• Always secure trigger lock

when wand is not in service

to prevent accidental

operation.

• Never permanently secure

trigger in pull-back (open)

position.

DANGER: RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe operation of your

pressure washer could lead

to serious injury or death to

you or others.

• Do not use chlorine

bleach or any other

corrosive compound.

• Become familiar with the

operation and controls of

the pressure washer.

• Keep operating area clear

of all persons, pets and

obstacles.

• Do not operate the product

when fatigued or under the

influence of alcohol or drugs.

Stay alert at all times.

• Never defeat the safety

features of this product.

• Do not operate machine

with missing, broken or

unauthorized parts.

• Never leave wand

unattended while unit

is running.

6

Page 7

DANGER: RISK OF UNSAFE OPERATION (CONTINUED)

• If proper starting procedure

is not followed, engine can

kickback causing serious

hand and arm injury.

• The spray gun/wand is

a powerful cleaning tool

that could look like a toy

to a child.

• Reactive force of spray

will cause gun/wand to

kickback, and could cause

the operator to slip or fall

or misdirect the spray.

Improper control of gun/

wand can result in

injuries to self and

others.

• If engine does not start after

two pulls, squeeze trigger

of gun to relieve pump

pressure. Pull starter cord

slowly until resistance is felt.

Then pull cord rapidly to

avoid kickback and prevent

hand or arm injury.

• Keep children away from the

pressure washer at all times.

• Do not overreach or stand

on an unstable support.

• Do not use pressure washer

while standing on a ladder.

• Grip gun/wand firmly with

both hands. Expect the

gun to kickback when

triggered.

DANGER: RISK OF INJURY OR PROPERTY DAMAGE WHEN

TRANSPORTING OR STORING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Fuel or oil can leak or spill

and could result in fire or

breathing hazard. Serious

injury or death can result.

Fuel or oil leaks will damage

carpet, paint or other

surfaces in vehicles

or trailers.

English

• If pressure washer is

equipped with a fuel shut-off

valve, turn the valve to the

OFF position before transporting to avoid fuel leaks. If pressure washer is not equipped

with a fuel shut-off valve, drain

the fuel from tank before transporting. Only transport fuel in

an OSHA-approved container.

Always place pressure washer

on a protective mat when

transporting to protect against

damage to vehicle from leaks.

Remove pressure washer

from vehicle immediately upon

arrival at your destination.

7

Page 8

WARNING: RISK OF BURSTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Over inflation of tires could

English

result in serious injury and

property damage.

• Use a tire pressure gauge

to check the tires pressure

before each use and while

inflating tires; see the tire sidewall for the correct tire pressure.

NOTE:

Air tanks,

compressors and similar

equipment used to inflate

tires can fill small tires similar

to these very rapidly. Adjust

pressure regulator on air

supply to no more than the

rating of the tire pressure.

Add air in small increments

and frequently use the tire

gauge to prevent over

inflation.

WARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Contact with hot surfaces,

such as engines exhaust

components, could result in

serious burn.

WARNING: RISK OF CHEMICAL BURN

WHAT CAN HAPPEN HOW TO PREVENT IT

• Use of acids, toxic or

corrosive chemicals, poisons,

insecticides, or any kind of

flammable solvent with this

product could result in serious injury or death.

• During operation, touch

only the control surfaces

of the pressure washer.

Keep children away from

the pressure washer at all

times. They may not be able

to recognize the hazards of

this product.

• Do not use acids, gasoline,

kerosene, or any other

flammable materials in this

product. Use only household

detergents, cleaners and

degreasers recommended

for use in pressure washers.

• Wear protective clothing

to protect eyes and skin

from contact with sprayed

materials.

8

Page 9

WARNING: RISK OF

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spray directed at electrical

outlets or switches, or objects

connected to an electrical

circuit, could result in a

fatal electrical shock.

WARNING: RISK OF

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result

from attempting to lift too

heavy an object.

ELECTRICAL SHOCK

• Unplug any electrically

operated product before

INJURY FROM LIFTING

attempting to clean it. Direct

spray away from electric

outlets and switches.

• The pressure washer is too

heavy to be lifted by one

person. Obtain assistance

from others before lifting.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

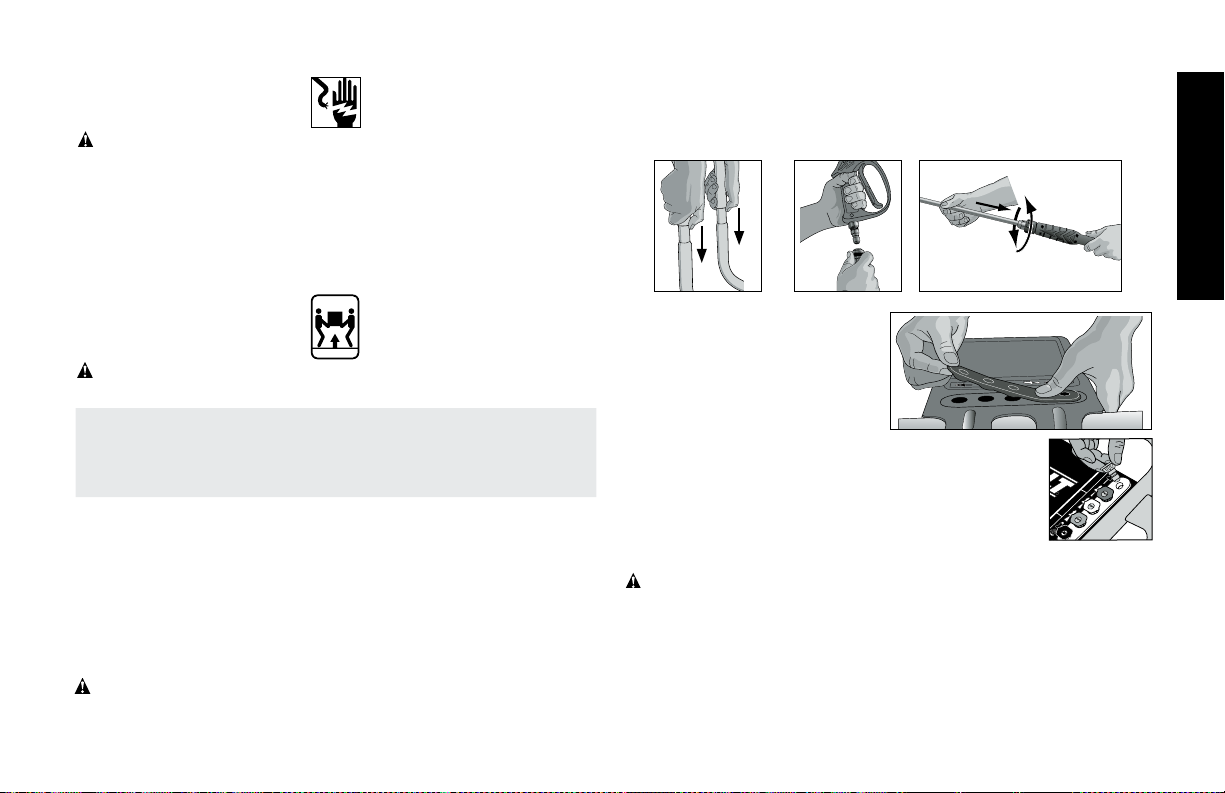

INSTALLATION

Pressure Washer Assembly (Fig. 1)

1. Place handle assembly (A) onto frame, depress the snap

buttons, and slide the handle assembly onto the frame (B) until

snap buttons are secured in place.

CAUTION: Risk of personal injury. Avoid placing hands between

handle and frame when assembling to prevent pinching.

2. Attach high-pressure hose (C) to spray gun (D). Make sure it is

secure.

3. Connect wand (E) to spray gun. Make sure connection is

secure.

4. Place the nozzle holder (G)

onto the panel assembly (F)

and push each nozzle holder

into place.

5. Remove the five colored

quick-connect nozzles from

the plastic bag and insert

them into correct grommet on the nozzle holder.

Nozzles are color coded to match colored

nozzles on panel assembly.

NOTE:

The high-pressure pump was filled with oil

at the factory. Always check oil level before using

(refer to Maintenance for more information).

WARNING: Risk of bursting.

the tires pressure before each use and while inflating tires; see the tire

sidewall for the correct tire pressure.

Air tanks, compressors and similar equipment used to inflate

NOTE:

tires can fill small tires similar to these very rapidly. Adjust pressure

regulator on air supply to no more than the rating of the tire pressure.

Add air in small increments and frequently use the tire gauge to prevent over inflation.

Use a tire pressure gauge to check

English

9

Page 10

OPERATION

Pressure Adjustments

The pressure setting is preset at the factory to achieve optimum pressure and cleaning. To lower the pressure, follow these instructions.

1. Back away from the surface to be cleaned. The further away you

are, the less the pressure will be on the surface to be cleaned.

2. Change to the 40˚ nozzle (white). This nozzle delivers a less

English

powerful stream of water and a wider spray pattern. Refer to

Spray Wand Nozzles

CAUTION:

DO NOT attempt to increase pump pressure. A higher

.

pressure setting than the factory set pressure may damage pump.

3. Reduce the speed of the gasoline engine (RPM). Slow the

engine down and the water pressure will go down with it.

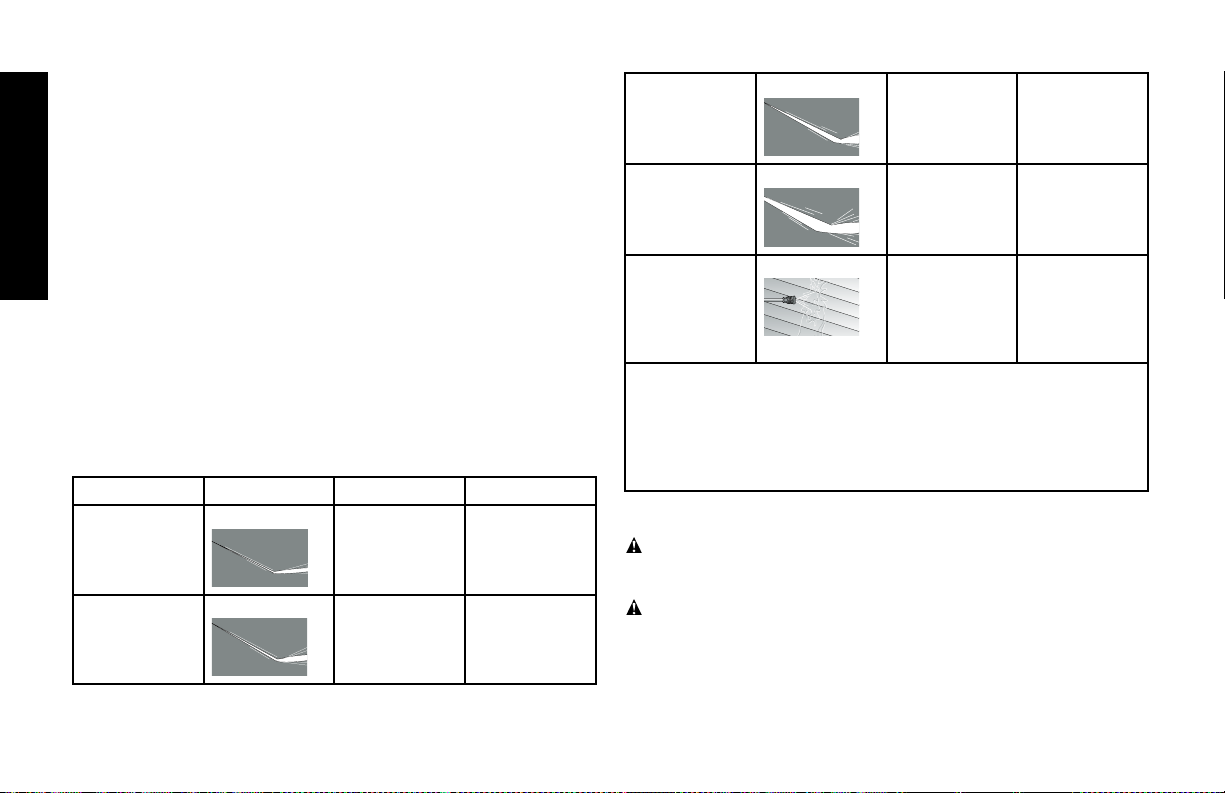

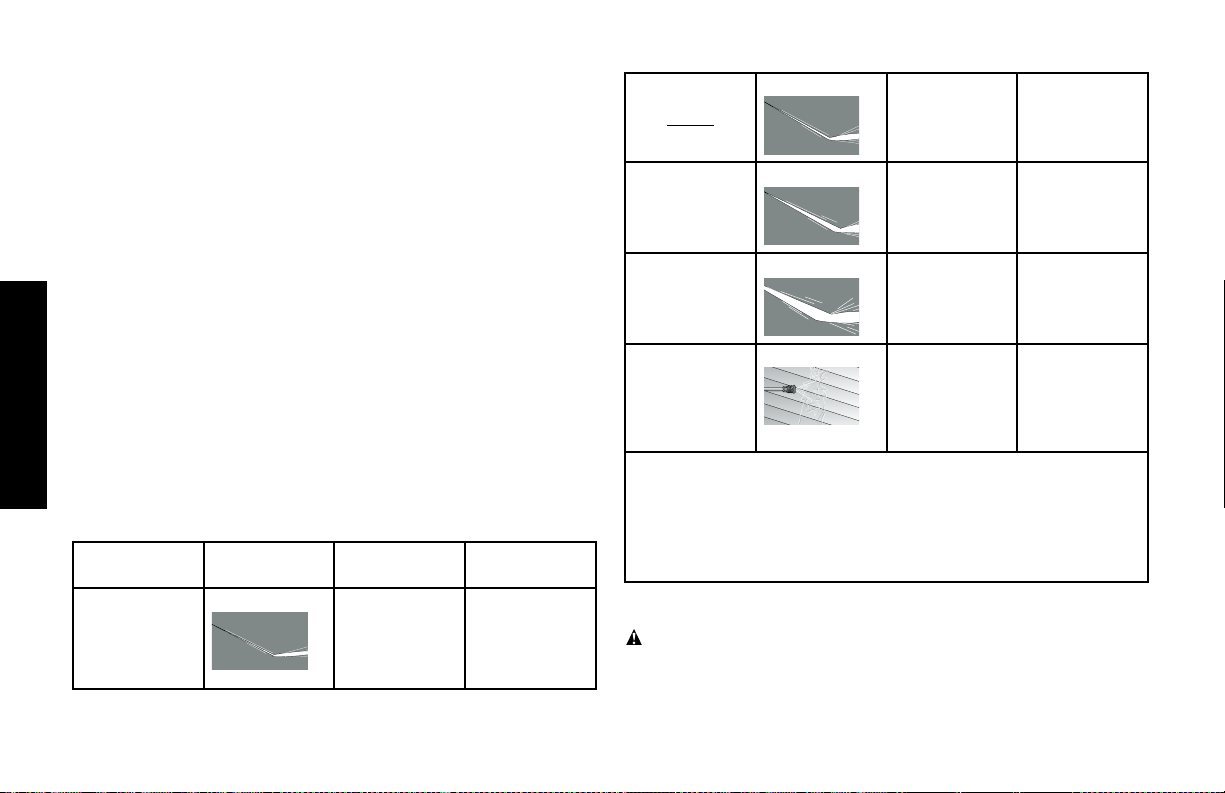

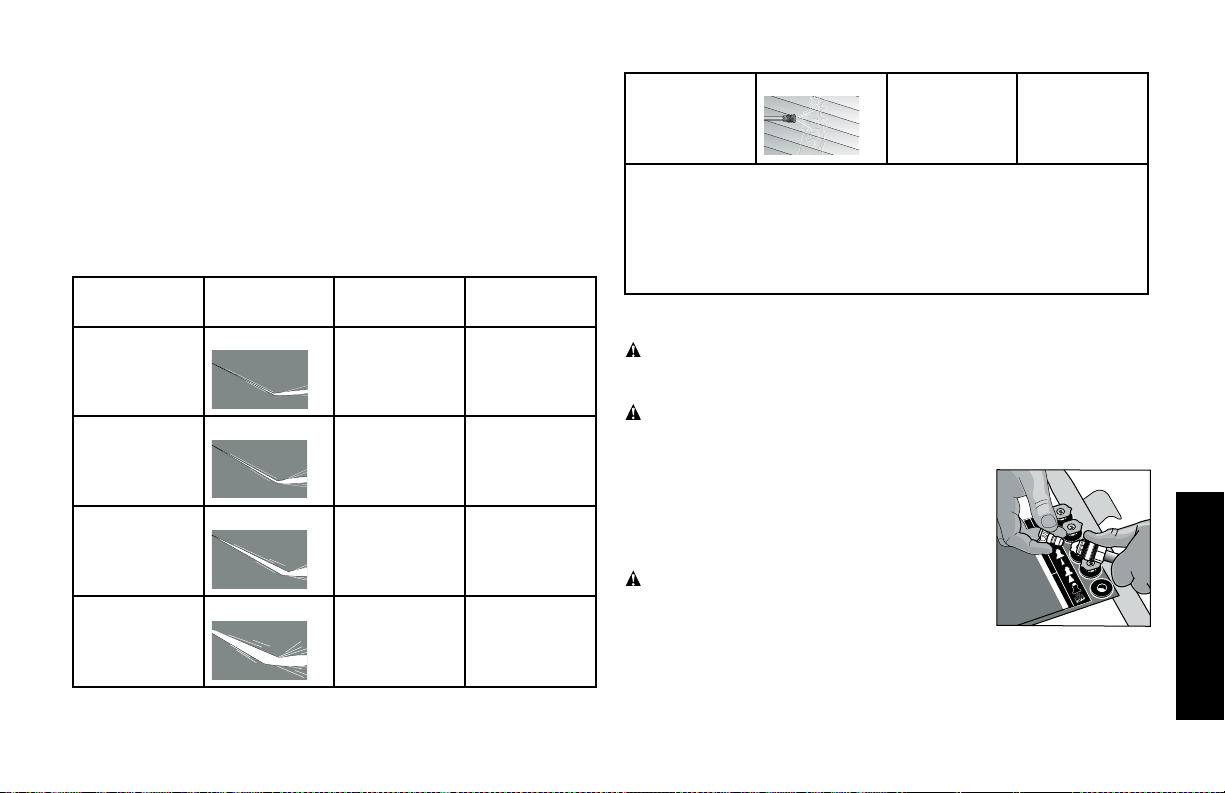

Spray Wand Nozzles (Fig. 1)

The nozzles for the spray wand are stored in the nozzle holder (G) on

the panel assembly (F). Colors on the panel identify nozzle location

and spray pattern. Refer to the following chart to choose the correct

nozzle for the job to be performed.

Nozzle Color Spray Pattern Uses Surfaces*

Red

Yellow

0˚ powerful

pinpoint for

very intense

cleaning

15˚ intense

cleaning of

small areas

metal or

concrete;

DO NOT use

on wood

metal, concrete

or wood

Green

White

Black

˚

25

40˚

low pressure applies cleaning

intense

cleaning of

larger areas

covers wide

areas of

cleaning

solutions

metal, concrete

or wood

metal, concrete,

wood or vinyl

metal, concrete,

wood or vinyl

* CAUTION: The high-pressure spray from your pressure washer

is capable of causing damage to surfaces such as wood, glass,

automobile paint, auto striping and trim, delicate objects such

as flowers and shrubs. Before spraying, check the item to

be cleaned to assure yourself that it is strong enough to resist

damage from the force of spray.

CHANGING NOZZLES ON SPRAY WAND

DANGER: Risk of fluid injection. Do not direct discharge stream

toward persons, unprotected skin, eyes or any pets or animals.

Serious injury will occur.

WARNING: Flying objects could cause risk of serious injury. DO

NOT attempt to change nozzles while pressure washer is running.

Turn engine off before changing nozzles.

10

Page 11

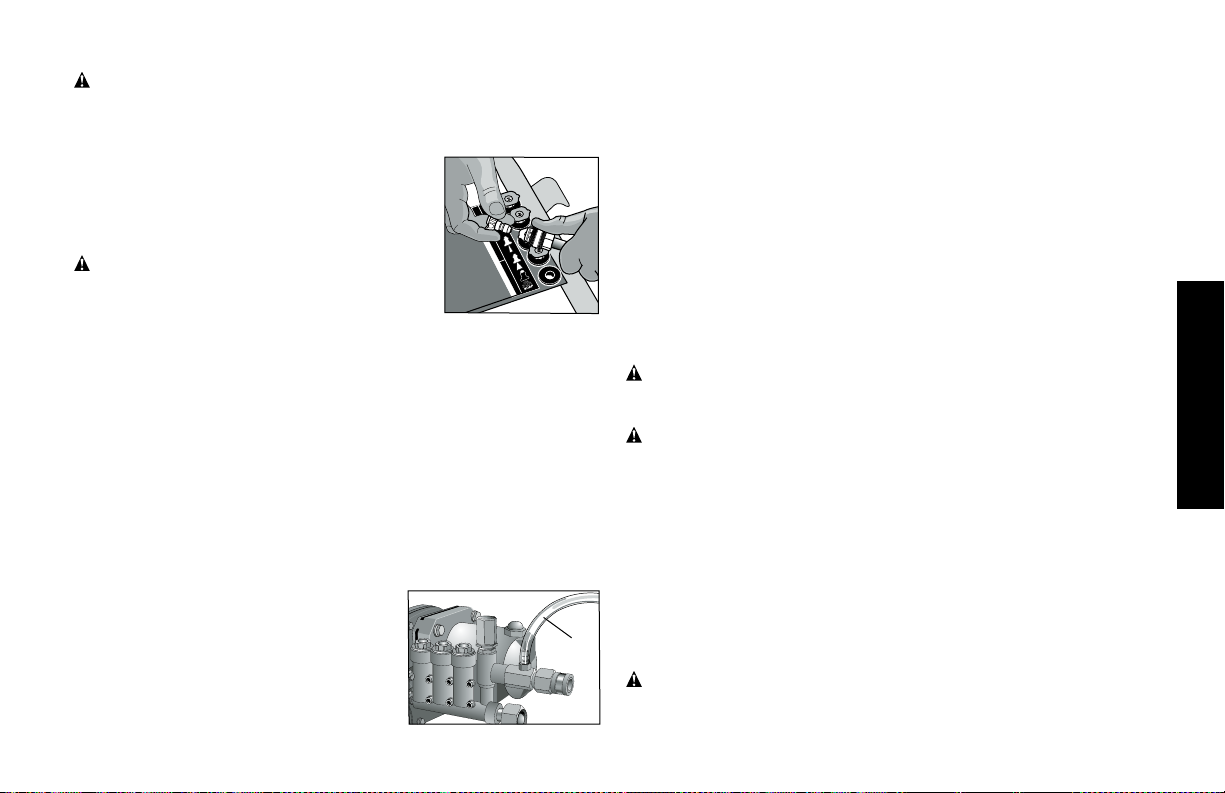

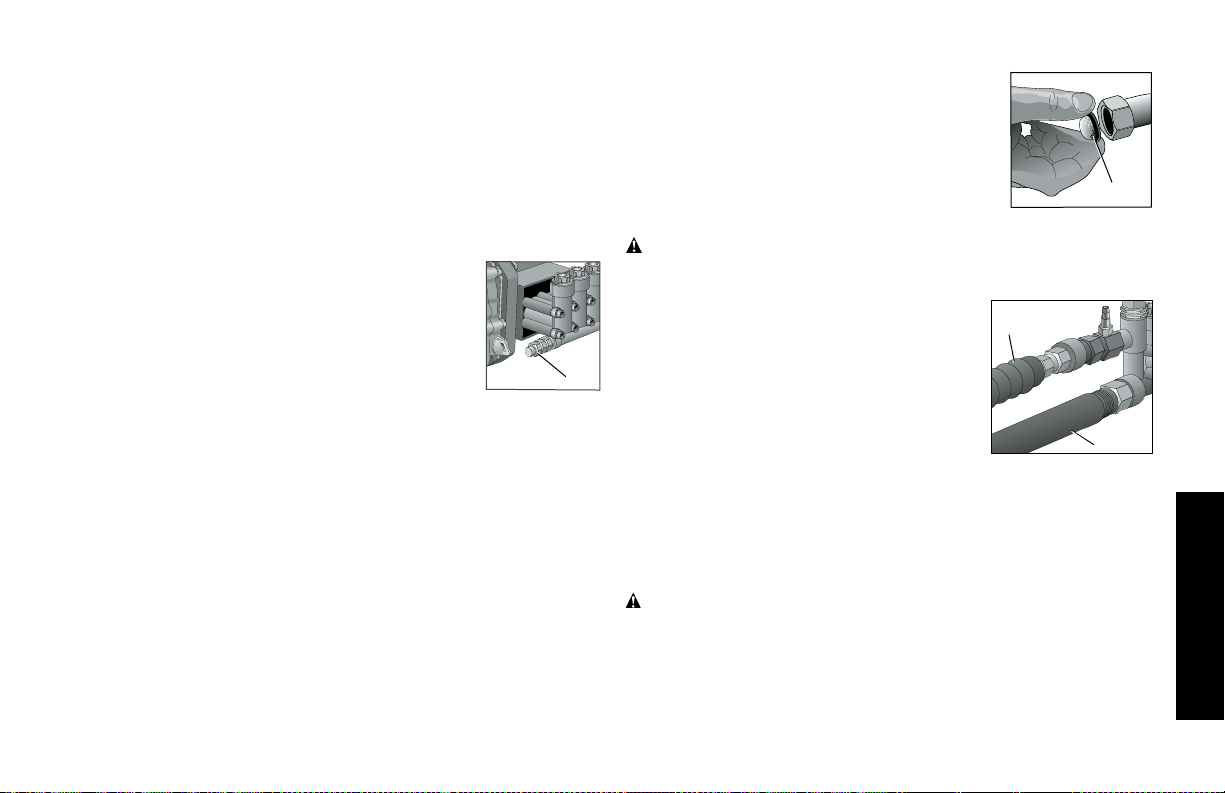

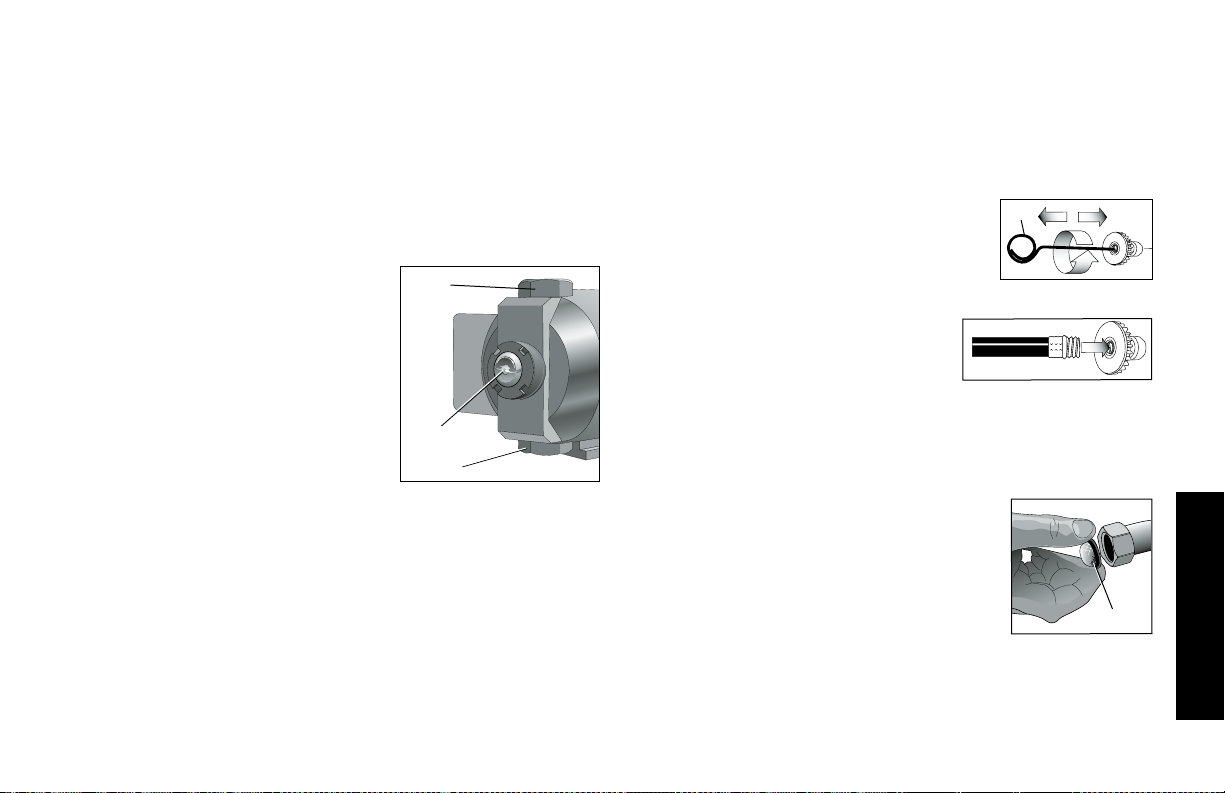

1. Pull quick-connect coupler back and insert

nozzle.

2. Release quick-connect coupler and

twist nozzle to make sure it is secure in

coupler.

WARNING: Flying object could cause risk

of serious injury. Ensure nozzle is completely

inserted in quick-connect socket and quickconnect snap ring is fully engaged (forward)

before squeezing gun trigger.

Chemicals and Cleaning Solvents

Applying chemicals or cleaning solvents is a low-pressure operation.

Use only soaps and chemicals designed for pressure washer

NOTE:

use. Do not use bleach.

TO APPLY CHEMICALS AND SOLVENTS

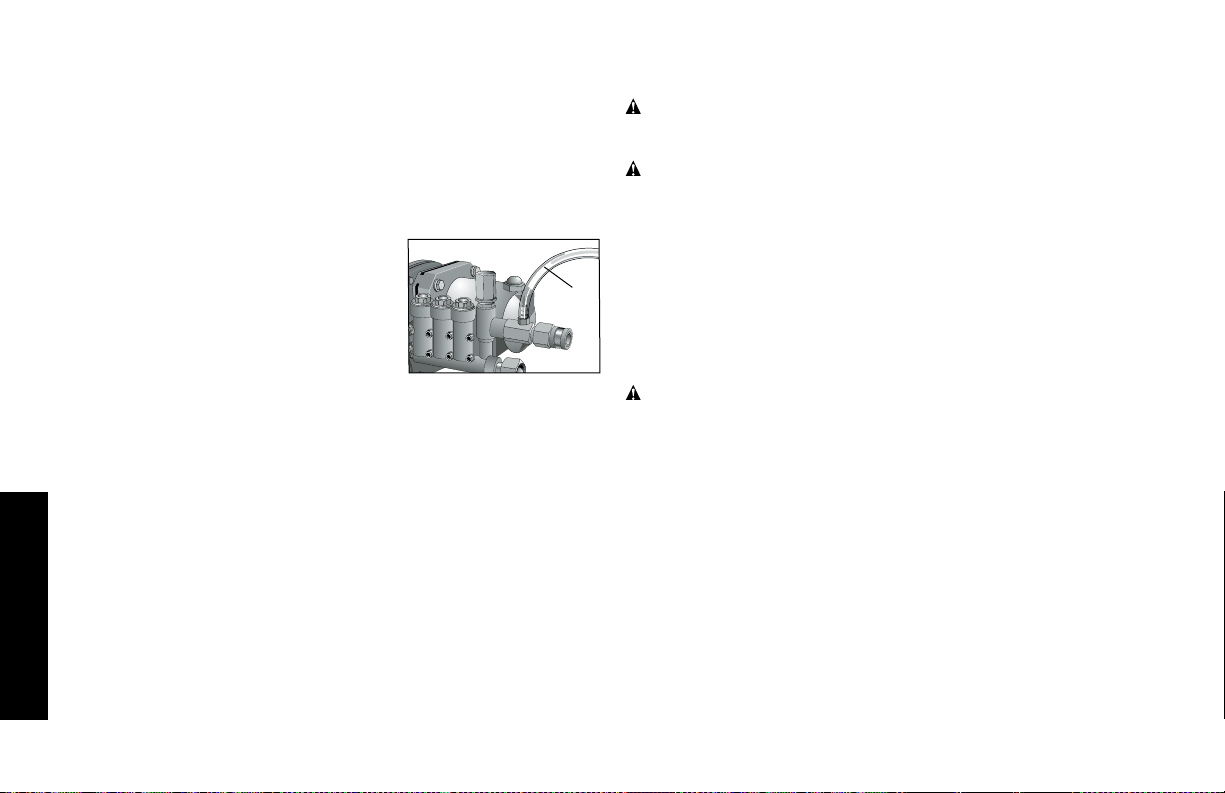

1. Press chemical hose (S) onto barbed

fitting located near high pressure hose

connection of pump as shown.

2. Place the other end of chemical hose

with filter on it into the container holding

chemical/cleaning solution.

NOTE: For every 7 gallons of water

pumped 1 gallon of chemical/cleaning solution will be used.

3. Install low-pressure (black) nozzle into quick connect fitting of spray

wand, refer Spray Wand Nozzles.

4. After use of chemicals,

water and draw clean water through chemical injection system

to rinse system thoroughly. If chemicals remain in the pump it

could be damaged. Pumps damaged due to chemicals will not be

covered under warranty.

place chemical hose into container of clean

S

Chemicals and soaps will not siphon when spray wand is in the

NOTE:

high-pressure setting.

Starting

WARNING: To reduce the risk of injury, read the pressure washer

instruction manual and the engine instruction manual before starting

pressure washer.

DANGER: Risk of fluid injection and laceration. When using the high-

pressure setting, DO NOT allow the high-pressure spray to come in

contact with unprotected skin, eyes, or with any pets or animals. Serious

injury will occur.

• Your washer operates at fluid pressures and velocities high

enough to penetrate human and animal flesh, which could result

in amputation or other serious injury. Leaks caused by loose fittings or worn or damaged hoses can result in injection injuries.

DO NOT TREAT FLUID INJECTION AS A SIMPLE CUT! See a

physician immediately!

WARNING: Risk of fire, asphyxiation and burning. NEVER fill fuel tank

when engine is running or hot. Do not smoke when filling fuel tank.

• NEVER

• NEVER run engine indoors or in enclosed, poorly ventilated

•

CAUTION: NEVER pull water supply hose to move pressure washer.

This could damage hose and/or pump inlet.

•

fill fuel tank completely. Fill tank to 1/2" (12.7 mm) below

bottom of filler neck to provide space for fuel expansion. Wipe any

fuel spillage from engine and equipment before starting engine.

areas. Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

DO NOT let hoses come in contact with very hot engine

muffler during or immediately after use of your pressure

washer. Damage to hoses from contact with hot engine

surfaces will NOT be covered by warranty.

DO NOT use hot water, use cold water only.

English

11

Page 12

• NEVER turn water supply off while pressure washer engine is

running or damage to pump will result.

•

DO NOT stop spraying water for more than two

minutes at a time. Pump operates in bypass

mode when spray gun trigger is not pressed.

When the temperature inside the pump rises

too high the thermal relief valve (T) will open

English

and release a gush of water in an effort to lower

the temperature inside the pump. The thermal

relief valve will then close. If pump is left in bypass mode for

more than two minutes internal components of the pump can

be damaged.

START-UP PROCEDURE

1. In a well-ventilated outdoor area, add fresh, high-quality, unleaded

gasoline with a pump octane rating of 86 or higher. Do not overfill.

Wipe up spilled fuel before starting the engine. Refer to engine

instruction manual for correct procedure.

2. Check engine oil level. Refer to the engine instruction manual for

correct procedure.

3. Connect the water hose to the water source. Turn the water source

on to remove all air from the hose. When a steady stream of water

is present, turn the water source off.

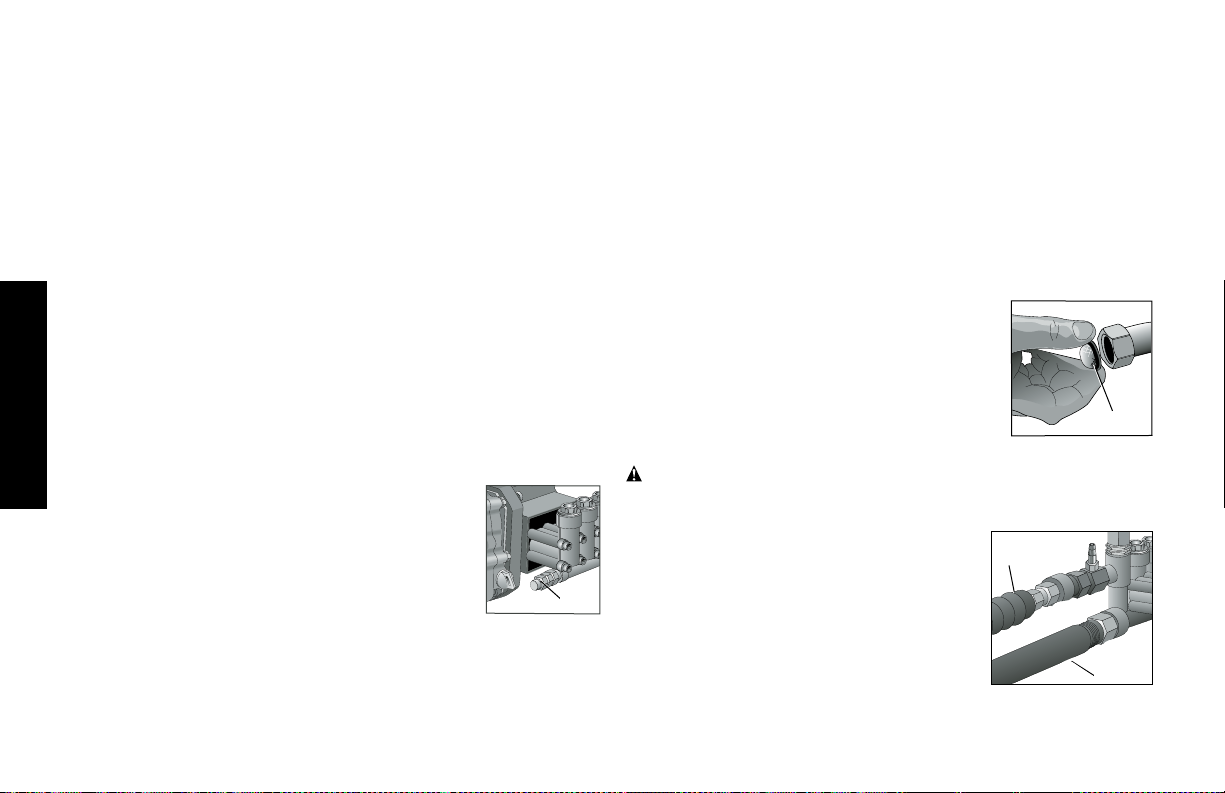

4. Verify the filter screen (U) is in water inlet of

pump. The cone side faces out.

5. Connect the cold water source (V) to pump

inlet.

NOTE: Water source must provide a minimum

of 5 gallons per minute at 20 PSI.

WARNING: To reduce the possibility of con-

tamination always protect against backflow when connected to a

potable water system.

6. Connect high-pressure hose (C) to pump

outlet.

7. If applying a chemical or cleaning solution,

C

refer to Chemicals and Cleaning

Solvents.

8. Turn the water source on.

CAUTION: Risk of property damage. Failure

to do so could cause damage to the pump.

T

9. Remove all air from the pump and high pressure hose by depress-

V

ing trigger until a steady stream of water is present.

10. Start engine. Refer to the engine instruction manual for correct

procedure.

WARNING: Risk of unsafe operation. If engine does not start

after two pulls, squeeze trigger of gun to relieve pump pressure. Pull

starter cord slowly until resistance is felt. Then pull cord rapidly to

avoid kickback and prevent hand or arm injury.

11. Depress trigger on gun to start water flow.

WARNING: Risk of unsafe operation. Stand on a stable

surface and grip gun/wand firmly with both hands. Expect the gun to

kickback when triggered.

12. Release trigger to stop water flow.

DANGER: Risk of injury from spray. Engage the

trigger lock (W) when gun is not in use to prevent

W

accidental spraying.

13. Adjust spray for the task being performed by

changing quick connect nozzle. Refer to Spray

Wand Nozzles

U

Shutting Down

.

1. If chemicals were applied, place the chemical hose into a

container of clean water and draw clean water through chemical

injection system to rinse system thoroughly.

12

Page 13

CAUTION: Risk of property damage Failure to do so could cause

damage to the pump.

2. Turn engine off. Refer to the

CAUTION:

while pressure washer engine is running or damage to pump will

result.

3. Turn water source off.

4. Pull trigger on spray gun to relieve any water pressure in hose or

5. Refer to Storage

Risk of property damage. NEVER turn water supply off

spray gun.

for proper storage procedures.

engine instruction manual.

MAINTENANCE

WARNING: Risk of burning. When performing maintenance, you

may be exposed to hot surfaces, water pressure or moving parts that

can cause serious injury or death.

WARNING: Risk of fire. Always disconnect, spark plug wire, let the

engine cool and release all water pressure before performing any

maintenance or repair. The engine contains flammable fuel. Do not

smoke or work near open flames while performing maintenance.

To ensure efficient operation and longer life of your pressure washer,

a routine maintenance schedule should be prepared and followed.

If the pressure washer is used in unusual conditions, such as high

temperatures or dusty conditions, more frequent maintenance

checks will be required.

Engine

Consult the engine instruction manual for the manufacturer's recommendations for any and all maintenance.

The pressure washer frame is equipped with an oil drain

NOTE:

hole to help make changing the engine oil easier.

Pump

NOTE: The pump was filled with oil at the factory.

1. Change pump oil after the first 10 hours of operation and every

250 hours thereafter.

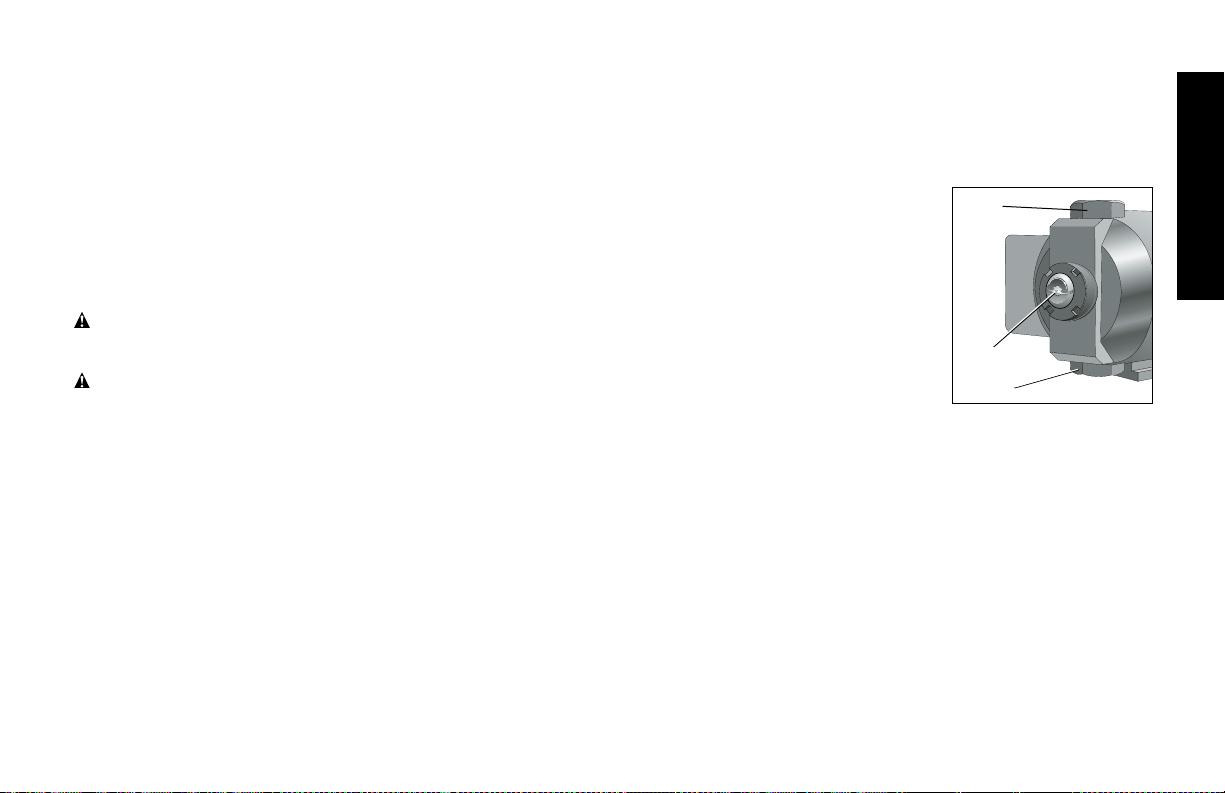

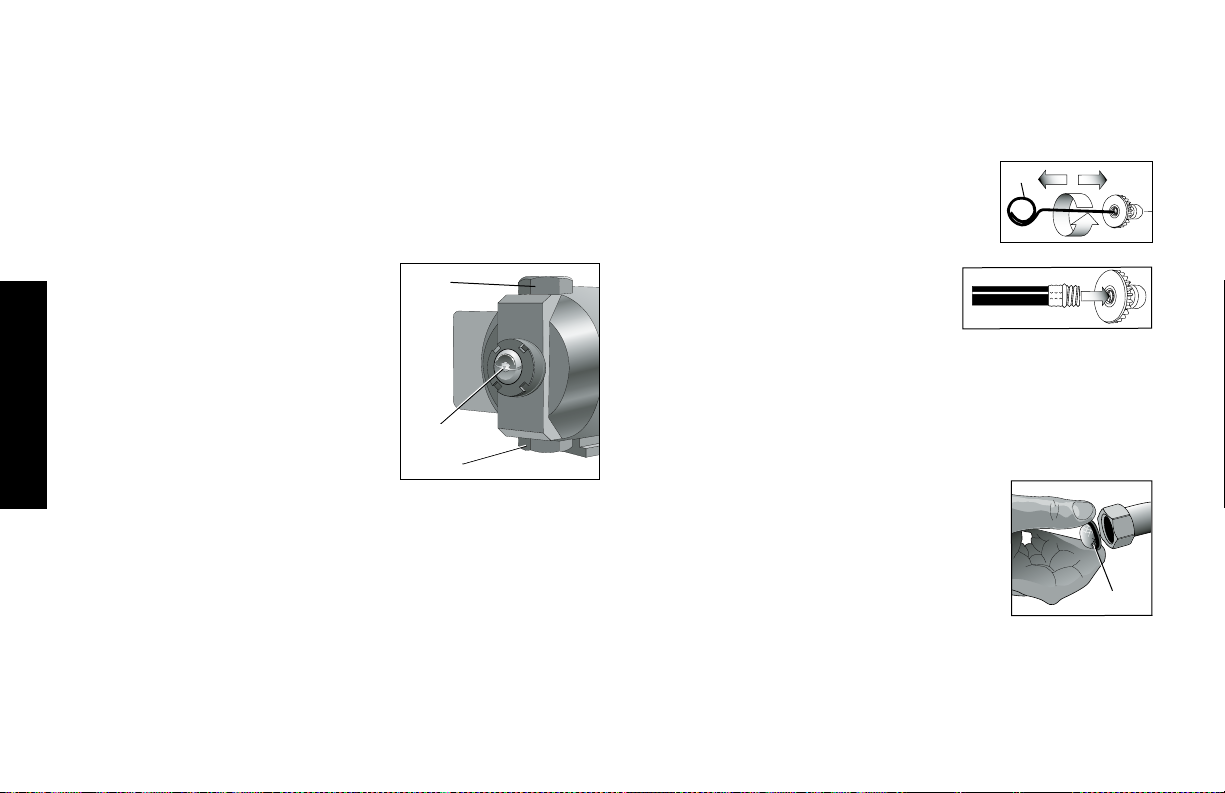

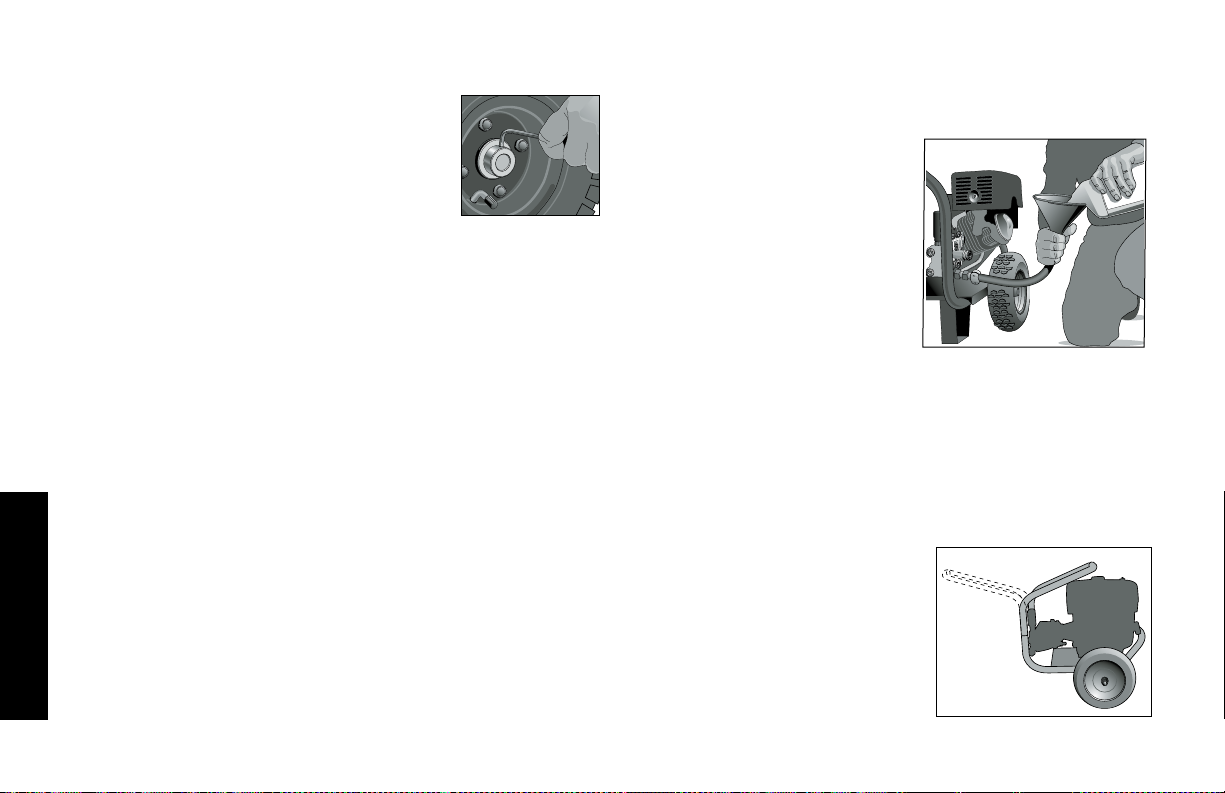

TO CHECK OIL

1. The oil level should come to the dot in

the middle of the sight glass (X).

HOW TO CHANGE

PUMP OIL

1. Loosen pump oil fill plug (H).

2. Place a container under the oil drain

plug (Y).

3. Remove pump oil drain plug.

4. After oil is drained, replace oil drain

plug. Tighten securely.

5. Remove pump oil plug and fill with 8.5 oz. (251 ml) of DP70 pump

oil. If DP70 is not available use 30W non-detergent oil.

6. Replace pump oil plug and tighten securely.

Nozzle Cleaning

If the nozzle becomes clogged with foreign materials, such as dirt,

excessive pressure may develop. If the nozzle becomes partially

clogged or restricted, the pump pressure will pulsate. Clean the

nozzle immediately using the nozzle kit supplied and the following

instructions:

1. Shut off the pressure washer and turn off the water supply.

2. Pull trigger on gun handle to relieve any water pressure.

H

X

Y

English

13

Page 14

3. Disconnect the spray wand from the gun.

4. Remove the high-pressure nozzle from

the spray wand. Remove any obstructions

with the nozzle cleaning tool (Z) provided

and back flush with clean water.

5. Direct water supply into spray wand to

back flush loosened particles for 30

English

seconds.

6. Reassemble the nozzle to the wand.

7. Reconnect spray wand to gun then turn on water supply.

8. Start pressure washer an

setting to test.

d place spray wand into high pressure

Z

To Clean the Water Inlet Filter

This filter screen (U) should be checked

periodically and cleaned if necessary.

1. Remove the filter screen (U) by grasping

the end and removing it from water inlet of

pump.

2. Clean filter by flushing it with water on both

sides.

3. Reinsert filter into water inlet of pump. Cone

side faces out.

NOTE:

Do not operate pressure washer without filter properly

installed.

To Remove Tires

1. Using a 1/8" hex head wrench loosen set

screw in hub collar.

2. Slide hub collar from axle and remove the

tire.

STORAGE

Engine

Consult the engine instruction manual for the manufacturer's

recommendations for storage.

Pump

The manufacturer recommends using a pump protector/winterizer,

such as DP80 when storing the unit for more than 30 days and/or

when freezing temperatures are expected. DP80 is availabe at the

store where the pressure washer was purchased. If a pump protector/

winterizer is not available, RV antifreeze or windshield washer fluid

needs to be run through the pump as outlined in the steps below.

Using a pump protector/ winterizer, RV antifreeze or wind-

NOTE:

shield washer fluid is to provide proper lubrication to the internal

seals of the pump regardless of temperature or environment.

1. Obtain a funnel, 6 oz. (172 ml) of RV antifreeze or windshield

washer fluid, and 16–36" (91 cm) of garden hose with a male

hose connector attached to one end.

CAUTION: Risk of property damage. Use only RV antifreeze. Any

U

other antifreeze is corrosive and can damage pump.

2. Disconnect spark plug wire.

3. Connect length of garden hose to water inlet of pump.

4. Add RV antifreeze or windshield

washer fluid to hose as shown.

5. Pull engine starter rope slowly

several times until antifreeze/

washer fluid comes out of highpressure hose connection of

pump.

6. Remove garden hose from

water inlet of pump.

7. Reconnect spark

plug wire.

14

Page 15

Pressure Washer

1. Drain all water from highpressure hose, coil it and store it

in cradle of the pressure washer

handle.

2. With nozzle pointed down and

the spray gun and wand in a

vertical position, squeeze trigger

to drain all water from spray gun

and wand. Store in gun holder.

3. Store chemical hose so it is protected from damage.

4. If space

shown.

CAUTION: Risk of personal injury. Avoid placing hands between

handle and frame when assembling to prevent pinching.

is needed, handles may be removed and attached as

ACCESSORIES

Recommended accessories for use with your tool are available for

purchase from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, please contact DeWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

MD 21286, call 1-800-4-D

site www.dewalt.com.

CAUTION: The use of any other accessory not recommended for

use with this tool could be hazardous. Use only accessories rated

equal to or higher than the rating of the pressure washer.

eWALT (1-800-433-9258) or visit our web-

SERVICE INFORMATION

Please have the following information available for all service calls:

Model Number ____________ Serial Number ___________

Date and Place of Purchase ____________________________

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by a DeWALT factory service

center, a DeWALT authorized service center or other qualified

service personnel. Always use identical replacement parts.

Limited Warranty

DeWALT pressure washers are warranted for one year from the

date of purchase. DeWALT will repair, without charge, any defects

due to faulty materials or workmanship. For further detail of

warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-DeWALT (1-800-433-9258). This

warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces. The product’s engine is covered by the

engine manufacturer’s warranty.

LATIN AMERICA:

Latin America. For products sold in Latin America, see country specific warranty information contained either in the packaging, call the

local company or see website for warranty information.

This warranty does not apply to products sold in

English

15

Page 16

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DeWALT for a free

replacement.

English

16

Page 17

Glossary

Bypass mode: Allows water to re-circulate within pump when the gun trigger is not pulled.

English

Chemical hose:

and Cleaning Solvents

Chemical injection system:

effectiveness.

Choke control:

CU:

Cleaning Units. GPM multiplied by PSI. (GPM x PSI = CU)

Fuel valve lever: Opens/closes connection between fuel tank and carburetor.

GPM: Gallons Per Minute. The unit of measure for the flow rate of water.

PSI:

Pounds per Square Inch. The unit of measure for water pressure. Also used for air pressure,

hydraulic pressure, etc.

Quick-connect spray wand: Allows the user to quickly change out high-pressure nozzles. Refer

to Spray Wand Nozzles.

Thermal relief valve

release a gush of water in an effort to lower the temperature inside the pump. The valve will then

close.

Water supply: All pressure washers must have a source of water. The minimum requirements for a

water supply are 20 PSI and 5 gallons per minute.

Feeds cleaning agents into the pump to mix with the water. Refer to Chemicals

.

Mixes cleaners or cleaning solvents with water to improve cleaning

Opens and closes carburetor choke valve.

: When the temperature inside the pump rises too high the valve will open and

17

Page 18

English

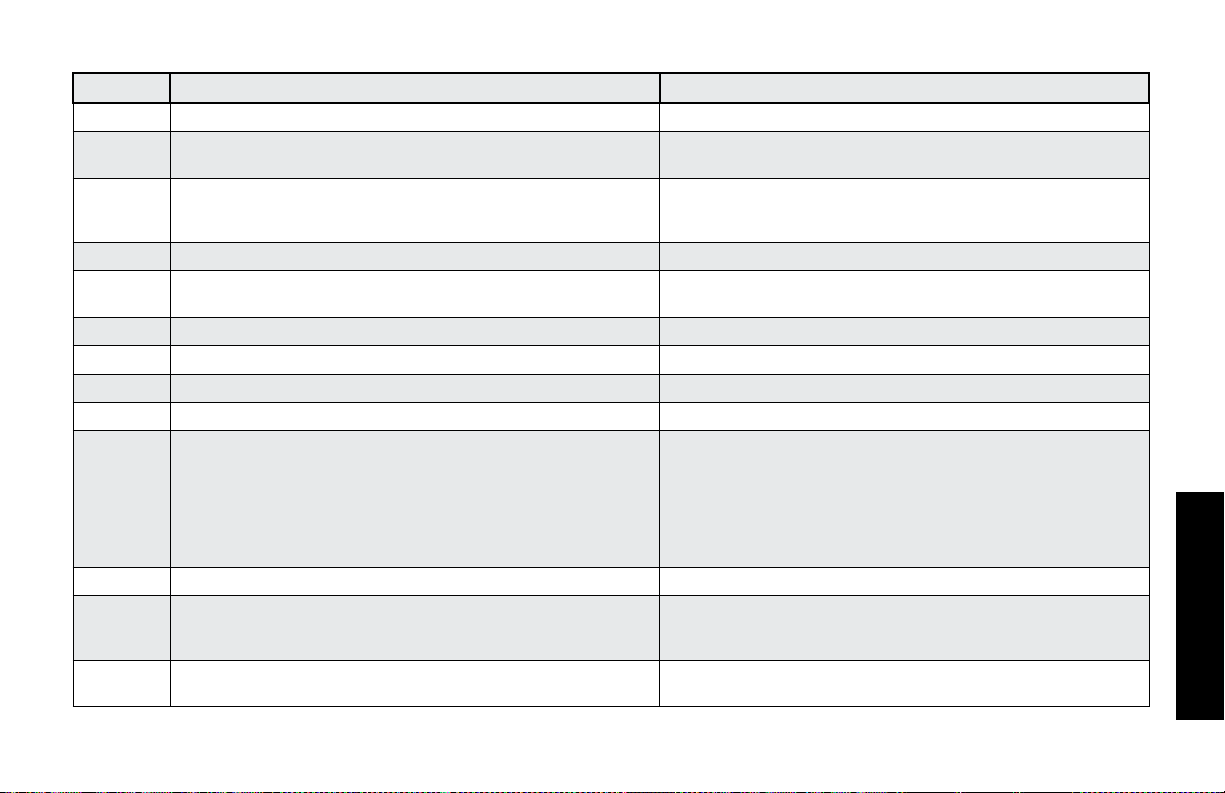

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The

operator or maintenance personnel can perform some corrective actions, and others may require the assistance of a

qualified DeWALT technician or your dealer.

Problem Code

Engine will not start ......................................................................................................1, 2, 3, 4, 5, 6, 7, 8

(refer to the engine's instruction manual for further engine troubleshooting)

No or low pressure (initial use) .....................................................................................9, 10, 11, 12, 13, 14, 15, 16

Will not draw chemicals .................................................................................................16, 17, 18, 19, 20, 21

No or low pressure (after period of normal use) ...........................................................22, 23, 24

Water leaking at gun/spray wand connection ...............................................................25, 26

Water leaking at pump ..................................................................................................25, 26, 27, 28

Oil leaking at pump ........................................................................................................29, 30, 31, 32, 33, 34, 35

Pump Pulsates ..............................................................................................................12

18

Page 19

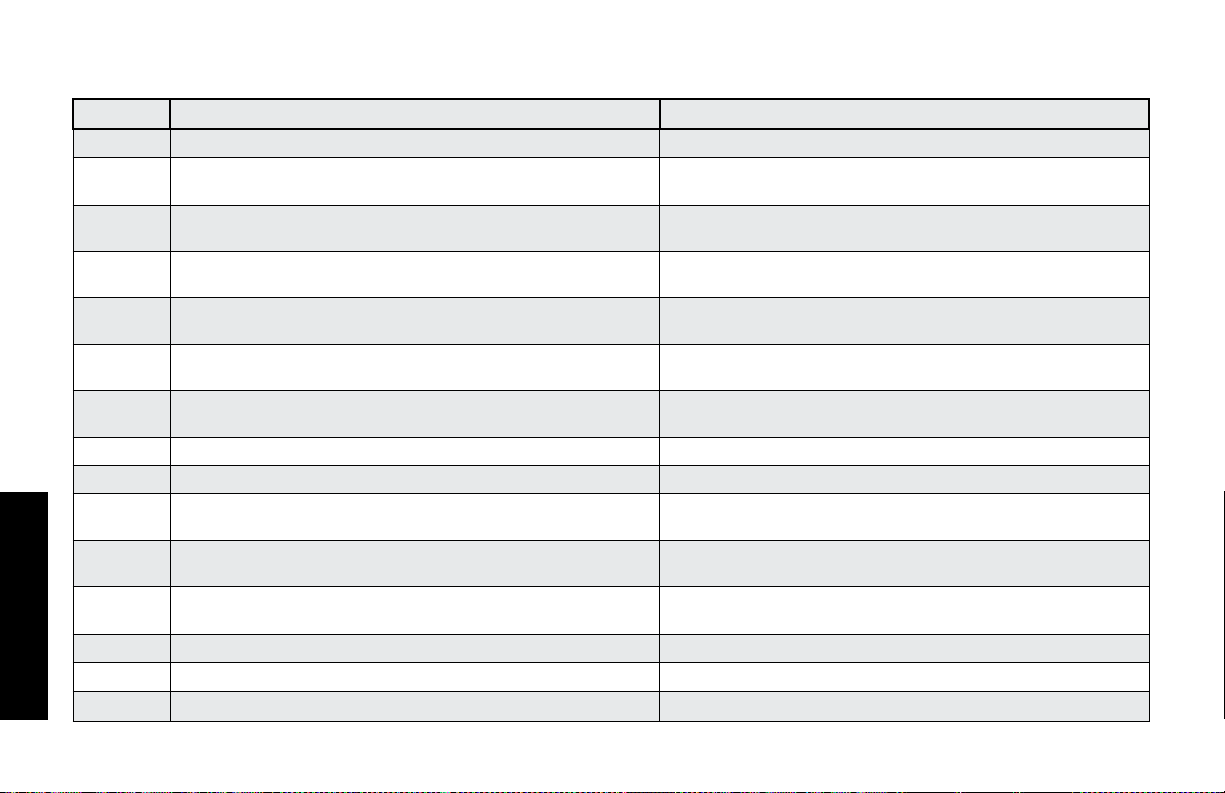

Troubleshooting Codes

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

1 No fuel. Add fuel.

2 Low oil. Add required amount of oil.

3 Pressure builds up after two pulls on the recoil starter or after

4 Choke lever in the NO CHOKE position. Move choke to the CHOKE position.

5 Spark plug wire not attached. Attach spark plug wire.

6 Engine ON/OFF switch in OFF position. Place engine ON/OFF switch in ON position.

7 Choke lever in the CHOKE position on a hot engine or an engine

8 Fuel valve closed. Move the fuel valve lever to the OPEN position.

9 Spray wand not in high pressure. See Spray Wand Nozzles under Operation.

10 Low water supply. Water supply must be at least 5 GPM @ 20 PSI.

11 Leak at high-pressure hose fitting. Repair leak. Apply sealant tape if necessary.

12

13 Water filter screen clogged. Remove and clean filter.

14 Air in hose. Turn off the engine, then the water source. Disconnect the

15 Choke lever in the CHOKE position. Move choke to the NO CHOKE position.

16 High-pressure hose is too long. Use high-pressure hose under 100 feet (30.48 m). Lengthen water

initial use.

that has been exposed to thermal heat for a long period of time.

Nozzle obstructed. See Nozzle Cleaning under Maintenance.

Squeeze gun trigger to relieve pressure.

Move choke to the NO CHOKE position.

water source from the pump inlet and turn the water source

on to remove all air from the hose. When there is a steady

stream of water present, turn water source off. Reconnect

water source to pump inlet and turn on water source. Squeeze

trigger to remove remaining air.

supply hose instead of high-pressure hose.

English

19

Page 20

(Troubleshooting Codes cont.)

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

17 Spray wand not in low pressure. See Spray Wand Nozzles under Operation.

18 Chemical filter clogged. Clean filter.

English

19 Chemical screen not in cleaning solution. Make sure end of chemical hose is fully submerged into cleaning

20

21 Worn seal or packing. Have parts cleaned or replaced by authorized service center.

22 Chemical build up in chemical injector. Have replaced by an authorized service center.

23 Worn or obstructed valves. Have replaced by authorized service center.

24

25 Worn or broken o-ring. Check and replace.

26

27 Piston packings worn. Have replaced by authorized service center.

28

29

30 Loose drain plug. Tighten.

31 Worn drain plug o-ring Check and replace.

32

33 Pump overfilled. Check for correct amount.

34 Incorrect oil used. Drain and fill with correct amount and type of oil.

35 Vent plug is clogged. Clean vent plug; blow air through it to remove any blockage. If

Chemical too thick. Dilute chemical. Chemical should be the same consistency as water.

Worn unloader piston. Have replaced by authorized service center.

Loose hose connection. Tighten.

Pump head or tubes damaged from freezing. Have replaced by authorized service center.

Oil seals worn. Have replaced by authorized service center

Worn fill plug o-ring. Check and replace.

solution.

problem persists, replace plug.

20

Page 21

LAVEUSE HAUTE PRESSION, MODÈLE DP2800

A. Module de poignée

B. Cadre

C. Tuyau haute pression

D. Pistolet de pulvérisation

E. Tube de pulvérisation à

changement rapide

F. Panneau

G. Porte-buse

H. Jauge graduée/Bouchon du

réservoir d’huile de la pompe

haute pression

I. Jauge bouchon du réservoir

d’huile du moteur

J. Pompe haute pression

K. Moteur

L. Commande d’étrangleur

M. Poignée de démarrage

N. Levier de la soupape à

essence

O. Interrupteur moteur

P. Bouchon du réservoir

d’essence

Q. Levier de contrôle de

l’étrangleur

FIG. 1

K

Q

L

N

M

C

P

A

F

H

J

O

MOTEUR

Se reporter au mode d’emploi du moteur pour l’emplacement et

B

l’utilisation des commandes moteur.

Caractéristiques

I

techniques de la pompe

CAT 3DX29GSI

Huile : Utiliser du DP70

Volume d’huile : 251 ml (8,5 onces)

Fiche technique

MODÈLE POIDS HAUTEUR LARGEUR LONGUEUR PSI MAX* PSI EN

DP2800 44,0 kg

(97 lb)

67,3 cm

(26,5 po)

58,4 cm (23

po)

101,6 cm

(40 po)

2800

(19306 kPa)

FONCTIONNEMENT

2520

(17375 kPa)

* Débit d’eau et limites maximales de pression déterminés en conformité avec la norme PW101 de la PWMA américaine.

GPM MAX * GPM EN

3,0

(11,4 L/min)

FONCTIONNEMENT

2,7

(10,2 L/min)

G

E

D

Français

MOTEUR

Honda 6,5

Hp GX200

21

Page 22

Définitions : lignes directrices en

matière de sécurité.

Les définitions ci-dessous décrivent le niveau de danger pour

chaque mot-indicateur employé. Veuillez lire le mode d’emploi et

porter une attention particulière à ces symboles.

DANGER : indique une situation dangereuse imminente qui, si

elle n’est pas évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dan-

gereuse qui, si elle n’est pas évitée, pourrait causer la mort ou des

blessures graves.

MISE EN GARDE : indique une situation potentiellement dan-

gereuse qui, si elle n’est pas évitée, peut causer des blessures

mineures ou modérées.

MISE EN GARDE :

indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée, peut se solder par des dommages à la propriété.

EN CAS DE QUESTIONS OU DE COMMENTAIRES SUR

Français

CET OUTIL OU SUR TOUT AUTRE OUTIL DeWALT,

APPELEZ-NOUS SANS FRAIS AU NUMÉRO SUIVANT :

1 (800) 4-DeWALT (1 (800) 433-9258)

utilisé sans le symbole d’alerte de sécurité,

Directives de sécurité importantes

AVERTISSEMENT : ne pas utiliser l’appareil avant d’avoir lu et com-

pris le mode d’emploi, et celui du moteur, et l’intégralité des directives

de sécurité, d’utilisation et d’entretien.

AVERTISSEMENT : lors de l’utilisation du produit, toujours mettre

en pratique des précautions de base, notamment les suivantes :

1. Lire toutes les directives avant d’utiliser le produit.

2. Pour réduire les risques de blessures, exercer une étroite surveil

lance pour l’utilisation du produit à proximité d’enfants.

3. Apprendre à arrêter le produit et à purger la pression rapidement.

Se familiariser à fond avec les commandes.

4. Être vigilant – Surveiller le travail effectué.

5. Ne pas utiliser le produit en cas de fatigue ou sous l’emprise

d’alcool ou de drogues.

6. S’assurer que personne ne se trouve dans la zone de travail.

7. Ne pas trop tendre les bras ou se tenir sur une surface instable.

Bien conserver son équilibre et une position stable en permanence.

8. Suivre les directives d’entretien décrites dans le mode d’emploi.

DANGER : RISQUE D’INJECTION OU DE BLESSURE GRAVE.

S’ÉLOIGNER DE LA BUSE. NE PAS DIRIGER LE JET EN DIRECTION

DE PERSONNES. CE PRODUIT NE DOIT ÊTRE UTILISÉ QUE PAR

DES OPÉRATEURS FORMÉS.

AVERTISSEMENT : il est possible que le produit ne soit pas doté

d’un silencieux avec pare-étincelles. Si le produit n’en est pas équipé

et qu’il est destiné à être utilisé près de matières inflammables ou

sur un terrain cultivé ou couvert d’arbres, arbustes, herbes ou autres

matières similaires, alors l’installation d’un pare-étincelles homologué

est obligatoire et exigée par la loi dans l’État de Californie. Le produit

sans cet équipement viole la législation californienne, section 130050

et/ou sections 4442 et 4443 du California Public Resources Code,

à moins que le moteur ne soit muni d’un pare-étincelles comme

stipulé à la section 4442 et tenu en bon état de fonctionnement. Les

pare-étincelles sont exigés sur certaines terres du Service des forêts

américain et peuvent être également exigés par d’autres législations

ou ordonnances.

AVERTISSEMENT : ce produit contient des produits chimiques,

dont du plomb, reconnus par l’État de la Californie comme étant

cancérigènes et pouvant entraîner des anomalies congénitales

et d’autres dangers relatifs à la reproduction. Se laver les mains

-

après la manipulation de l’appareil.

CONSERVER CES DIRECTIVES

22

Page 23

DANGER : RISQUE D’EXPLOSION OU D’INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Les cigarettes, étincelles, arc électrique, gaz

d’échappement et des parties

chaudes du moteur telles

qu’un silencieux peuvent

enflammer l’essence déversée et ses vapeurs.

• Le combustible du réservoir

se dilate sous l’effet de la

chaleur et pourrait se solder

par un déversement et un

incendie ou une explosion.

• Le fonctionnement de la

laveuse haute pression dans

un milieu explosif pourrait se

solder par un incendie.

• Éteindre le moteur et le lais

ser refroidir avant de remplir

le réservoir d’essence

• Être attentif et éviter de

déverser de l’essence lors

du remplissage du réservoir.

Éloigner la laveuse haute

pression de la zone de ravitaillement avant de démarrer

le moteur.

• Laisser environ 127 mm

(1/2 po) de dégagement

sous le bord du goulot de

remplissage pour permettre

l’expansion de l’essence.

• Utiliser et faire le plein

d’essence de l’équipement

dans des zones bien dégagées de tout obstacle. Installer

un extincteur adéquat dans

les zones de travail pour combattre les incendies à base

d’essence.

• Du matériel déposé contre

ou près de la laveuse haute

pression peut interférer avec

les fonctionnalités d’aération

de l’équipement et pro-

-

voquer une surchauffe et

l’allumage du matériel (risque

d’incendie).

• La chaleur de l’échappement

du silencieux peut endommager des surfaces peintes,

faire fondre tout type de

matériel sensible à la chaleur

(comme du revêtement extérieur, plastique, caoutchouc,

vinyle ou même le tuyau

haute pression) et nuire aux

plantes vivantes.

• De l’essence mal entreposée

pourrait provoquer un allumage (incendie) accidentel.

Ranger l’essence de façon

sécuritaire pour en empêcher

l’accès aux enfants et à

toutes autres personnes non

qualifiées.

• L'utilisation d'acides, de

produits chimiques toxiques

ou corrosifs, de poisons,

d'insecticides ou de toute

sorte de solvant inflammable

dans ce produit pourrait provoquer des blessures graves

ou la mort.

23

• Ne jamais utiliser la laveuse

haute pression dans une

zone avec arbustes ou broussailles secs.

• Toujours éloigner la laveuse

haute pression d’au moins

1,2 m (4 pi) de toutes sur

faces (telles que desmaisons,

voitures, ou des plantes

vivantes) qui pourraient être

endommagées par la chaleur

s’échappant du silencieux.

• Entreposer l’essence dans un

contenant homologué par la

Loi sur la santé et la sécurité

du travail dans un emplacement sécuritaire loin de la

zone de travail.

• Ne pas vaporiser des liquides

inflammables.

-

Français

Page 24

DANGER : RISQUE D’ASPHYXIE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Respirer les vapeurs

d’échappement provoquera de graves blessures

voire, un décès ! Les gaz

d’échappement des moteurs

contiennent du monoxyde de

carbone, un gaz inodore et

mortel.

• Certains liquides nettoyants

contiennent des substances

pouvant provoquer des bles-

Français

sures à la peau, aux yeux ou

au système respiratoire.

• Utiliser la laveuse haute pres

sion dans une zone bien

aérée. Éviter les endroits clos

comme les garages, les soussols, etc.

• Ne jamais utiliser l’appareil

dans un endroit habité par

des hommes ou des an

maux.

• Utiliser uniquement des

liquides nettoyants spécialement recommandés pour

les laveuses haute pression.

Suivre les recommandations

des fabricants. Ne pas utiliser

de produit à blanchir au chlore

ou tout autre composé corrosif.

DANGER : RISQUE D’INJECTION ET DE LACÉRATION

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

-

• Votre laveuse haute pression

fonctionne à des pressions

de liquides et des vitesses

suffisamment élevées pour

pénétrer la peau de l’homme

et animale, ce qui pourrait

se solder par une amputation ou autre blessure grave.

Des fuites provoquées par

des raccords lâches ou des

tuyaux usés ou endommagés peuvent se solder

par des blessures par injection. NE PAS TRAITER UN

INJECTION DE LIQUIDE

COMM UNE SIMPLE

COUPURE ! Consulter un

médecin immédiatement !

• Inspecter périodiquement

le tuyau haute pression.

Remplacer immédiatement

le tuyau s’il est endommagé,

usé, s’il a fondu en contact

avec le moteur ou s’il démontre un signe de fissure, des

bulles, des trous d’épingle

ou tout autre fuite. Ne jamais

saisir untuyau haute pression

quifuit ou est endommagé.

• Ne jamais toucher, saisir

ou essayer de couvrir un

trou minuscule ou tout autre

fuite similaire sur le tuyau

haute pression. Le jet d’eau

EST sous haute pression et

PÉNÈTRERA la peau.

• Ne jamais mettre les mains

devantl’embouchure.

• Éloigner le jet, ne pas le

diriger vers soi-même ou

autrui.

24

Page 25

RISQUE D’INJECTION ET DE LACÉRATION (SUITE)

• S’assurer que le tuyau et les

raccords sont serrés et en

bon état. Ne jamais s’agripper

au tuyau ou aux raccords en

cours de fonctionnement.

• Ne pas mettre le tuyau en

contact avec le silencieux.

• Ne jamais attacher ou retirer

le tube ou les raccords du

tuyau avec le système sous

pression.

• Il y a risque de blessures si

la pression n’est pas réduite

avant d’essayer de procéder

à un entretien ou un démontage.

• Pour décompresser le sys

tème, éteindre le moteur,

fermer l’approvisionnement en

eau et enclencher la détente

du pistolet jusqu’à l’arrêt complet de l’écoulement d’eau.

•

Utiliser uniquement des

accessoires de classement

égal ou supérieur à celui de

la laveuse haute pression.

DANGER : RISQUE DE BLESSURE PAR JET

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Un jet de liquide à haute

vitesse peut briser des objets

et projeter les éclats à haute

vitesse.

-

• Des objets légers ou mal

fixés peuvent se transformer

en projectiles dangereux.

• Toujours porter des lunettes

de sécurité conformes à la

norme ANSI Z87.1 Porter

des vêtements protecteurs

pour se protéger de jets

accidentels.

• Ne jamais diriger la lance ou le

jet vers une personne ou des

animaux.

• Toujours fixer solidement le

verrou de la détentelorsque

le tube pulvérisateur est

inutilisé pour empêcher tout

fonctionnement accidentel.

• Ne jamais fixer, de façon

permanente, la détente

enposition arrière (ouverte).

Français

25

Page 26

DANGER : RISQUE D’UTILISATION DANGEREUSE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Une utilisation dangereuse

de la laveuse haute pression

pourrait provoquer de graves

blessures, voire son propre

décès ou celle d’autres personnes.

Français

• Ne pas utiliser de produit

à blanchir au chloreou tout

autre composé corrosif.

• Se familiariser ave le fonc

tionnement et les commandes

de la laveuse haute pression.

• Tenir la zone de travail

exempte de toutes personnes,

animaux et obstacles.

• Ne pas utiliser le produit

en cas de fatigue ou sous

l’emprise d’alcool ou de

drogues. Rester vigilant en

tout temps.

• Ne jamais rendre inopérant

les caractéristiques de sécurité du produit.

• Ne pas utiliser l’appareil avec

des pièces manquantes, brisées ou non autorisées.

• Ne jamais laisser le tube pul

vérisateur sans surveillance

lors du fonctionnement de

l’appareil.

• Suivre la procédure de

démarrage correcte pour

éviter l’effet de rebond moteur

qui provoquerait ainsi une

blessure grave à la main ou

au bras.

-

• Le pistolet et le tube de pulvérisation sont des outils de

nettoyage puissants qui ressemblent à un jouet pour un

enfant.

• Le pistolet et le tube de

pulvérisation réagissent à

la pression du jet et provoqueront un effet de rebond

qui pourrait faire glisser,

ou tomber, l’opérateur ou

rediriger le jet. Une maîtrise

imparfaite du pistolet et de

la lance peut provoquer des

-

blessures à soi même et à

autrui.

• Si le moteur ne démarre pas

après deux tentatives, appuyer sur la détente du pistolet

pour décompresser la pompe.

Tirer délicatement la corde du

démarreur jusqu’à obtention

d’une résistance. Puis tirer

rapidement sur celui-ci pour

éviter l’effet de rebond moteur

et empêcher toute blessure à

la main ou au bras.

• Garder la laveuse haute

pression hors de portée des

enfants en tout temps.

• Ne pas trop tendre les bras

ou se tenir debout sur une

surface instable.

• Ne pas utiliser une laveuse

haute pression debout sur

une échelle.

• Saisir solidement à deux

mains le pistolet/tube de

pulvérisation. S’attendre

à un effet de rebond lors

de l’enclenchement de la

détente.

26

Page 27

DANGER : RISQUE DE BLESSURE OU DE DOMMAGE À LA

PROPRIÉTÉ LORS DU TRANSPORT OU DU RANGEMENT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Il y a risque de fuite ou de

déversement d’essence ou

d’huile qui pourrait se solder par un incendie ou des

problèmes respiratoires, des

blessures graves, voire la

mort. Des fuites d’essence

ou d’huile endommageront

les tapis, peinture ou toutes

autres surfaces de véhicules

ou de remorques.

• Si la laveuse haute pression

est dotée d’une soupape

d’arrêt, FERMER la soupape

d’arrêt avant le transport pour

éviter toute fuite d’essence.

S’il n’y a pas de soupape

d’arrêt, purger l’essence du

réservoir avant le transport.

Transporter l’essence uniquement dans un contenant

homologué par la Loi sur

la santé et la sécurité du

travail . Toujours installer la

laveuse haute pression sur

un revêtement protecteur lors

du transport pour protéger le

véhicule de tout dommage de

fuites. Retirer immédiatement

la laveuse haute pression du

véhicule dès l’arrivée à destination.

AVERTISSEMENT : RISQUE D’ÉCLATEMENT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Des pneus surgonflés

pourraient provoquer des

blessures graves et des

dommages à la propriété.

• Utiliser un manomètre pour

vérifier la pression des pneus

avant chaque utilisation et lors

du gonflage; consulter le flanc

de pneu pour obtenir la pression correcte.

des réservoirs d’air, des

compresseurs et d’autres

appareils similaires utilisés

pour gonfler les pneus peuvent remplir de petits pneus

à ces pressions très rapidement. Régler le régulateur de

pression d’air à une pression

moindre que celle indiquée

sur le pneu. Ajouter l’air par

petite quantité et utiliser

fréquemment le manomètre

pour empêcher un surgonflage.

REMARQUE :

Français

27

Page 28

AVERTISSEMENT : ATTENTION SURFACES CHAUDES

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Le contact de surfaces

chaudes comme les composants d’échappement

moteur, pourrait provoquer

des brûlures graves

• En cours de fonctionnement,

ne toucher que les surfaces

de commande de la laveuse

haute pression. Tenir en tout

temps les enfants à l’écart de

la laveuse haute pression. Ils

n’ont pas assez de jugement

pour reconnaître les dangers

inhérents au produit.

Français

AVERTISSEMENT : RISQUE DE BRÛLURE CHIMIQUE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• L’utilisation d’acides, de

produits chimiques toxiques

ou corrosifs, de poisons,

d’insecticides, ou de tout type

de solvant inflammable avec

le produit risque de se solder

par des blessures graves,

voire la mort.

AVERTISSEMENT : RISQUE DE CHOC ÉLECTRIQUE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Un jet en direction de prises

électriques ou d’interrupteurs

ou tout objet branché à un

circuit électrique pourrait se

solder par un choc électrique.

• Ne pas utiliser d’acides,

d’essence, de kérosène ou

tout autre matériel inflammable avec ce produit. Utiliser

uniquement des détergents

domestiques, des nettoyants

et dégraissants recommandés

pour les laveuses haute pression.

• Porter des vêtements pro

tecteurs pour protéger les

yeux et la peau contre le contact avec les matériaux sous

pression.

• Débrancher tout produit fonc

tionnant à l’électricité avant

d’essayer de le nettoyer.

Éloigner le jet des prises électriques et interrupteurs.

-

-

28

Page 29

AVERTISSEMENT : RISQUE DE BLESSURE EN SOULEVANT

LE PRODUIT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Essayer de soulever un objet

trop lourd peut se solder par

de graves blessures.

• La laveuse haute pression

est trop lourde pour être soulevée par une seule personne.

Demander de l’aide avant de

la soulever.

CONSERVER CES DIRECTIVES POUR

UN USAGE ULTÉRIEUR

INSTALLATION

Assemblage de la laveuse haute

pression (Fig. 1)

1. Insérer le module de la poignée (A) dans le cadre, enfoncer les

boutons pression et glisser le module de poignée dans le cadre

(B) jusqu’à ce que les boutons soient solidement fixes.

MISE EN GARDE : risque de blessures corporelles. Ne pas

placer les mains entre le module et le cadre pour éviter de se pincer

les mains.

2. Assembler le tuyau haute pression (C) au pistolet de pulvérisa

tion (D). S’assurer que les deux pièces sont bien fixées.

3. Brancher le tube de pulvérisation (E) au pistolet de pulvérisation.

S’assurer que le raccord soit bien fixe.

4. Installer le porte-buse (G) sur

e panneau (F) et enfoncer

chaque porte-buse en position.

5. Retirer du sac plastique les

cinq buses colorées à

changement rapide et les

insérer dans l’anneau correspondant sur le

porte-buse. Les couleurs des buses correspondent aux couleurs sur le panneau.

AVERTISSEMENT : risque d’éclatement. Utiliser

un manomètre pour vérifier la pression des pneus

avant chaque utilisation et lors du gonflage; consulter le flanc de pneu pour obtenir la pression correcte.

REMARQUE : des réservoirs d’air, des compresseurs et d’autres

appareils similaires utilisés pour gonfler les pneus peuvent remplir

de petits pneus à ces pressions très rapidement. Régler le régulateur

de pression d’air à une pression moindre que celle indiquée sur le

pneu. Ajouter de l’air par petite quantité et utiliser fréquemment le

manomètre pour empêcher un surgonflage

Français

29

Page 30

FONCTIONNEMENT

Réglages de la pression

Le paramètre de pression est prédéfini en usine pour optimiser

la pression et le nettoyage. Pour diminuer la pression, suivre ces

directives.

1. S’éloigner de la surface à nettoyer. Plus on s’éloigne, moins il y

aura de pression sur la surface à nettoyer.

2. Installer la buse de 40° (blanche). La buse de 40° produit un

jet d’eau moins puissant et pulvérise sur une plus grande

superficie. Se reporter à la section Buses du tube de pulvéri-

sation.

MISE EN GARDE :

pompe. Un réglage de pression plus élevé que la valeur de consigne

réglée en usine peut endommager la pompe.

3. Réduire la vitesse du moteur à essence (régime). La réduction

du régime moteur diminuera la pression de l’eau.

Buses du tube de pulvérisation (Fig. 1)

Français

Les buses du tube de pulvérisation sont rangées dans le porte-buse

(G) sur le panneau (F). Les couleurs sur le panneau identifient la position de la buse et l’angle de pulvérisation. Se reporter au tableau suivant pour sélectionner la bonne buse pour le travail souhaité.

Couleur de la

buse

Rouge Rouge

NE PAS essayer d’augmenter la pression de la

Angle de

pulvérisation

0˚ jet puissant

Utilisations Surfaces*

en un seul

point pour un

nettoyage très

en profondeur

métal ou béton ;

NE PAS utiliser

sur le bois

Jaune

Vert

Blanc

Noir

15˚ nettoyage en

˚

25

40˚

basse pression applique des

profondeur de

petites surfaces

nettoyage en

profondeur

de grandes

surfaces

pour de

grandes

superficies de

nettoyage

solutions de

nettoyage

métal, béton ou

bois

métal, béton ou

bois

métal, béton,

bois ou vinyle

métal, béton,

bois ou vinyle

* MISE EN GARDE : le jet sous haute pression de la laveuse

haute pression est capable d’endommager des surfaces comme

le bois, le verre, les peintures d’automobiles, les garnitures

d’automobiles, les objets délicats comme les fleurs et les arbustes.

Avant de pulvériser, vérifier l’article à nettoyer et s’assurer qu’il est

suffisamment solide pour résister à la puissance du jet.

CHANGEMENT DES BUSES SUR LE TUBE DE

PULVÉRISATION

DANGER : risque d’injection de liquides. Ne pas diriger le jet en

direction de personnes, sur la peau et les yeux sans protection ou

sur des animaux. Une blessure grave se produira.

30

Page 31

AVERTISSEMENT : la projection d’objets pourrait provoquer de

graves blessures. NE PAS essayer de changer de buse lorsque la

laveuse haute pression est en fonctionnement. Éteindre le moteur

avant de changer de buse.

1. Pousser vers l’arrière le coupleur à

branchement rapide et insérer la buse.

2. Relâcher le coupleur et tourner la buse

pour s’assurer de la bonne fixation de

celle-ci.

AVERTISSEMENT : la projection d’objets

pourrait provoquer de graves blessures.

S’assurer que la buse est complètement

insérée sur la douille du dispositif de

branchement rapide et quele joint de blocage est complètement

engagé (vers l’avant) avant d’appuyer sur la détente du pistolet de

pulvérisation.

Produits chimiques et solvants de

nettoyage

Utiliser la basse pression pour l’application de produits chimiques

pour de solvants de nettoyage. REMARQUE : utiliser uniquement

des savons et des produits chimiques conçus pour l’utilisation avec

laveuse haute pression. Ne pas utiliser de produit à blanchir au

chlore.

APPLICATION DE PRODUITS CHIMIQUES ET SOLVANTS

1. Insérer l’extrémité du tuyau pour

produit chimique (S) dans le raccord

cannelé situé près du raccord du

tuyau haute pression de la pompe

comme indiqué.

2. Déposer l’autre extrémité du tuyau,

avec filtre, dans le contenant qui contient la solution chimique/nettoyante.

S

REMARQUE :

de solution chimique/nettoyante utilisé.

3. Insérer la buse de basse pression (noire) sur le raccord à

branchement rapide du tube de pulvérisation, se reporter à la

section

4. Après l’utilisation de produits chimiques, déposer le tuyau

pour produits chimiques dans un contenant d’eau fraîche et la

pomper dans le système de pulvérisation pour bien le nettoyer.

La présence de résidus de produits chimiques dans la pompe

risquerait de l’endommager. Les dommages provoqués par les

produits chimiques ne seront pas couverts par la garantie.

REMARQUE :

aspirés si le tube de pulvérisation est réglé à haute pression.

l’appareil pompera 7 litres d’eau pour chaque litre

Buses du tube de pulvérisation.

les produits chimiques et les savons ne seront pas

Démarrage

AVERTISSEMENT : afin de réduire le risque de blessures, lire le

mode d’emploi de la laveuse haute pression avant de la mettre en

marche.

DANGER : risque d’injection de liquide et de lacération Lors du

fonctionnement à haute pression, veiller à ce que le jet à haute pression N’ENTRE PAS EN CONTACT avec la peau et les yeux sans

protection ou avec des animaux. Une blessure grave se produira.

• La laveuse haute pression fonctionne à des pressions de

liquides et des vitesses suffisamment élevées pour pénétrer

la peau humaine et animale, ce qui pourrait se solder par une

31

amputation ou autres blessures graves. Des fuites provoquées

par des raccords lâches ou des tuyaux usés ou endommagés

peuvent se solder par des blessures par injection. NE PAS

TRAITER UNE INJECTION DE LIQUIDE COMME UNE

SIMPLE COUPURE ! Consulter un médecin immédiatement !

AVERTISSEMENT : risque d’incendie, d’asphyxie et de brûlure.

NE JAMAIS faire le plein du réservoir avec le moteur en marche ou

chaud. Ne pas fumer lors du plein d’essence.

Français

Page 32

• NE JAMAIS remplir le réservoir au complet. Laisser environ

12,7 mm (1/2 po) de dégagement sous le bord du goulot de

remplissage pour permettre l’expansion de l’essence. Essuyer

toute trace d’essence du moteur et de l’équipement avant de

démarrer le moteur.

• NE JAMAIS utiliser le moteur à l’intérieur ou dans un espace

clos peu aéré. Les gaz d’échappement des moteurs contiennent du monoxyde de carbone, un gaz inodore et mortel.

• NE PAS laisser les tuyaux entrer en contact avec le silencieux

chaud en cours de fonctionnement ou immédiatement après

l’utilisation de la laveuse haute pression. Les dommages aux

tuyaux suite à un contact avec les surfaces chaudes du moteur,

NE SONT PAS couverts par la garantie.

MISE EN GARDE :

NE JAMAIS tirer sur le tuyau d’approvisionnement

en eau pour déplacer la laveuse haute pression. Cette action risque

d’endommager le tuyau ou l’arrivée d’eau de la pompe.

• NE PAS utiliser d’eau chaude. Utiliser uniquement de l’eau

froide.

Français

• NE JAMAIS fermer l’arrivée d’eau lors du fonctionnement de

la laveuse haute pression, cela endommagera la pompe.

• NE PAS cesser la pulvérisation d’eau pour

une période de plus de deux minutes à

chaque fois. La pompe fonctionne en mode de

dérivation lorsque la détente du pistolet de

pulvérisation n’est pas engagée. Lorsque la

température à l’intérieur de la pompe dépasse

un certain seuil (température élevée), une

soupape de surpression thermique (T) s’ouvre et relâche un

jet d’eau pour essayer d’abaisser la température à l’intérieur

de la pompe. La soupape de surpression thermique se fermera par la suite. Il y a risque d’endommagement des composants internes de la pompe si elle demeure en mode de

dérivation pour plus de deux minutes.

PROCÉDURE DE DÉMARRAGE

1. Dans une zone extérieure bien aérée, faire l’appoint d’essence

avec de l’essence fraîche et de bonne qualité, d’indice d’octane

de 86 ou plus. Ne pas remplir plus que nécessaire. Essuyer toute

trace d’essence avant de démarrer le moteur. Se reporter au mode

d’emploi du moteur pour connaître la procédure correcte.

2. Vérifier le niveau d’huile. Se reporter au mode d’emploi du moteur

pour connaître la procédure correcte.

3. Raccorder le tuyau d’eau à l’approvisionnement d’eau. Faire couler

de l’eau dans le tuyau pour retirer toute bulle d’air. Dès que le jet

d’eau est constant, fermer l’approvisionnement d’eau.

4. Vérifier le filtre grillagé (U) dans l’admissiond’eau

de la pompe. La face conique fait face à

l’extérieur.

5. Raccorder l’approvisionnement d’eau froide (V)

à l’admission de la pompe.

REMARQUE :

l’approvisionnement d’eau doit

être d’au moins 19 l/min (5 gpm) à une pression

de 1,4 bar (20 PSI).

AVERTISSEMENT : pour réduire la possibilité de contamination,

toujours protéger le système contre les refoulements s’il est raccordé au système d’apport en eau potable.

6. Raccorder le tuyau haute pression (C) à la

sortiede la pompe.

C

7. Lors de l’utilisation d’une solution de produit

T

chimique ou de nettoyant, se reporter à la

section

Produits chimiques et solvants

de nettoyage.

8. Ouvrir l’approvisionnement en eau.

MISE EN GARDE : risque de dommages à la

propriété. Négliger de suivre cette directive pourrait endommager la

pompe.

32

U

V

Page 33

9. Retirer toute trace de bulles d’air de la pompe et du tuyau haute

pression en appuyant sur la détente jusqu’à l’obtention d’un jet

d’eau constant.

10. Démarrer le moteur. Se reporter au mode d’emploi du moteur

pour connaître la procédure correcte.

AVERTISSEMENT : risque d’utilisation dangereuse Si le moteur

ne démarre pas après deux tentatives, appuyer sur la détente du

pistolet pour décompresser la pompe. Tirer lentement la corde du

démarreur jusqu’à obtention d’une résistance. Puis tirer rapidement

sur celui-ci pour éviter l’effet de rebond moteur et empêcher toute

blessure à la main ou au bras.

11. Enfoncer la détente du pistolet pour activer le jet d’eau.

AVERTISSEMENT : risque d’utilisation dangereuse Se tenir sur

une surface stable et saisir solidement le pistolet/le tube avec les

deux mains. S’attendre à un effet de recul lorsque la détente du

pistolet de pulvérisation est engagée.

12. Relâcher la détente pour arrêter le jet d’eau.

DANGER : risque de blessure par jet. Verrouiller

la détente (W) lorsque le pistolet n’est pas utilisé

pour empêcher une pulvérisation accidentelle.

13. Régler le jet selon le travail à effectuer en

changeant la buse à branchement rapide. Se

reporter à la section Buses du tube de pulvé-

risation.

W

Mise à l’arrêt de l’appareil

1. En cas d’utilisation de produits chimiques, déposer le tuyau pour

produits chimiques dans un contenant d’eau fraîche et la pomper dans le système de pulvérisation pour bien le nettoyer.

MISE EN GARDE :

suivre cette directive pourrait endommager la pompe.

2. Éteindre le moteur. Se reporter au mode d’emploi du moteur.

risque de dommages à la propriété Négliger de

MISE EN GARDE : risque de dommages à la propriété. NE JAMAIS

fermer l’arrivée d’eau lors du fonctionnement de la laveuse haute

pression, cela endommagerait la pompe.

3. Fermer l’approvisionnement en eau.

4. Enfoncer la détente du pistolet de pulvérisation pour décom

presser la pression dans le tuyau ou le pistolet de pulvérisation.

5. Se reporter à la section Rangement pour les bonnes procédures

d’entreposage.

ENTRETIEN

AVERTISSEMENT : risque de brûlure. Lors d’un entretien, il y a

présence de surfaces chaudes, d’eau à pression élevée et de pièces

mobiles qui peuvent provoquer des blessures graves ou un décès.

AVERTISSEMENT : risque d’incendie. Avant tout entretien ou

réparation, toujours débrancher le fil de la bougie, laisser refroidir le

moteur et décompresser toute pression d’eau. Le moteur contient

un combustible inflammable. Ne pas fumer ou travailler près de

flammes nues lors d’un entretien.

Veuillez préparer et suivre un calendrier d’entretien de routine pour

assurer un fonctionnement efficace et prolonger la vie de la laveuse

haute pression. En cas d’utilisation de l’appareil dans des conditions

anormales, telles que des températures élevées ou des conditions

poussiéreuses, effectuer des vérifications de contrôle plus fréquentes.

Moteur

Consulter le mode d’emploi du moteur pour connaître les

recommandations du fabricant concernant toutes les procédures

d’entretien.

REMARQUE :

d’un orifice de vidange d’huile pour faciliter la vidange.

le cadre de la laveuse haute pression est pourvu

-

Français

33

Page 34

Pompe

REMARQUE : le plein d’huile de la pompe a été fait en usine.

1. Changer l’huile de la pompe après les premières dix heures

d’utilisation et par la suite, à toutes les 250 heures.

VÉRIFICATION DU NIVEAU D’HUILE

1. Le niveau d’huile devrait atteindre le point au milieu de la jauge

visuelle (X).

MÉTHODE DE VIDANGE DE L’HUILE DE LA POMPE

1. Desserrer la jauge bouchon du réservoir d’huile de la pompe (H).

2. Déposer un contenant sous l’orifice

de vidange de l’huile (Y).

3. Retirer le bouchon de l’orifice de

vidange.

4. Une fois la vidange terminée, revisser

le bouchon. Serrer solidement.

5. Retirer la jauge bouchon du réservoir

Français

d’huile de la pompe et remplir avec

251 ml (8,5 onces) de lubrifiant pour

pompe DP70. Si le lubrifiant DP70 n’est pas disponible, utiliser

du 30W non corrosif.

6. Replacer la jauge bouchon du réservoir d’huile de la pompe

et serrer solidement.

Nettoyage des buses

En cas d’obturation de la buse avec une matière étrangère (saletés

par exemple), une pression excessive peut se développer. En cas

d’obturation ou de restreinte partielle de la buse, la pression de

la pompe pulsera. Nettoyer immédiatement la buse à l’aide de la

trousse de nettoyage fournie. Suivre les directives suivantes :

H

X

Y

1. Éteindre la laveuse haute pression et fermer l’arrivée d’eau.

2. Enfoncer la détente du pistolet de pulvérisation pour décom

presser toute pression d’eau.

3. Débrancher le tube de pulvérisation du pistolet.

4. Retirer la buse haute pression du tube de

pulvérisation. Retirer toute trace

d’obstruction à l’aide de l’outil de nettoyage de buse (Z) fourni puis rincer à l’eau

fraîche en sens contraire.

5. Diriger l’arrivée d’eau dans le tube de

pulvérisation pendant 30 secondes

pour évacuer les particules détachées.

6. Replacer la buse sur le tube de pulvérisation.

7. Rebrancher le tube de pulvérisation au pistolet puis ouvrir

l’arrivée d’eau.

8. Démarrer la laveuse haute pression et sélectionner la pression

élevée pour tester le pistolet de pulvérisation.

Z

Nettoyage du filtre de l’admission d’eau

Vérifier régulièrement le filtre grillagé (U) et le

nettoyer au besoin.