Page 1

(rDEmLl

use

manual

&

care

WARNING: FOR YOrJR OWN SAFETY,

REVIEW

This

hd<let is

usgand

tiOns

tlVe

dita

dable service from

care

include

maintenance, maintenarrce

to

assist

provided

your

of

operati(xr,

you

new

in

your

SAFETY

your

lor

DeIUalt

usage,

assuring

saw.

i.... i:i::

:1

..

:

:

-{'

READ THIS MANUAL

OPERATING

RULES

convenience

Saw.

precautions, preven-

and

long life

AND

These

other

and depen-

in the

instruc-

pertinent

BEFORE OPERATING

INSTRUCTIONS

10'

TOOL.

FREQUENTLY.

7739 &

RADIAL

Cat. Nos.7739 &7749

7749

ARM

SAW

Page 2

INDEX

Unpacking,

Setup,and

Specifications.

ElectricalConnectionandGrounding

Rules for

Safer, Operation and Maintenance

MachineControls

Alignment

Operatinglnstructions

TroubleshootingGuides.....

Accessories

UNPACKING AND

SET-UP INSTRUCTIONS

. . . . . . .

. . .

2-3

. . . .3-4

. . . . 4

.......5

....6-12

..... i3-16

.17,18,&2L

..1920

Specilications

Motor

Molor Rating

Full Load

Blade

Arbor Size

Maximum

Maximum

Cros Cut Capacity-

Spindle Dado Cap.-Width

Ripping Capacity-Width

Net weight

Speed.60 cy. AC

0uards

(Upper

and

Standard Elade

Depth of Cut

Depth of Cut

at 45o Eevel

Develops

lower)

1' stock

7739

120V., I

2

3450

254 mm

254 mm

15.9 x

(5/8'xl

76.2 mm

mm

54

330.2 mm

20.6 mm

(13/r6')

527.1 mm

(24.il/16',)

57.6 kg.

(r27

ph

HP

(10')

(10')

38.1

|1')

(3')

(2-ll8')

(13')

rb.)

mm

long

7749

120V.

ZtzHP

3450

mm

254

251 mm

I5.9 x

(5/8'xl

75.2

54 mm

330.2 mm

20.6 mm

(r3lr6')

627.1

(24.1r/16',)

58.5

(r29

I

(10')

(10')

38.1

|1') long

mm

(2

mm

kg.

rb

ph

mm

(3')

I/8')

(13')

)

you

.. .

:

job-tested

screwdrivers from

that

So

120 V

l.

Remove

and legs,

easily

-can

at-the factory, then

your

new

phase

single

table

if

set up

your

tool

Radial

power

boards,

provided,

your

box.

Saw

supply.

from

may

metal

DeWalt Radial

partially

be

knocked

placed

cleats

carton.

Saw, America's most

down for shipment to

in

operation

just

2.

Remove

and remove

upright.

VV49

popular

you.

as

soon as assembled,

guard

box, tip

machine.

radial

power

tool.

The only tools

Handling

all electrical

carton on

Set machine

saw

is minimized

required

are

connections have

I

g

&

il

s

end

because every machine is

the

wrenches

3. Raise

containing

ing handle

move

furnished with the machine

made

been

arm assembly

motor

motor from

box and hardware

assembled

at the factory to

by turning

counter-clockwise,

box.

bag.

to free

Unpack

operate

carton

elevat.

guard

Re-

and

and

on

4. lnsert

into

Head

7. lnstall

long

pointers

tighten

slug and

Rip Lock

as

shown.

pointers

rip

screws

to

screws.

short

and

install

with

provided.

upright

threaded

into

#6-32

Adiust both

position

knob

Roller

r7o"

x

and

5. To rnstall

two

the

remove

Remove

cap rrom its mounted

ol

or

clean

assembty.

Assemble

sir

bag. DO NOT TIGHTEN

THE

motor

set screws

paddle

the shroud beirg

damage wiring. \Yipe

cloth

(5)

screrys

WAY DOWN.

assembly.

on end

to b€ lifted

tlp end

cap mounEqg

the two ma.rntirg

cleats

pnor

to installation

on

provided

p,cition

carelul not

lixed board

2

lirsL

cap

and h€td rn

bact

tienty

srff

screrys.

screwr lift

and

to

arm trac*s with

in the hardware

SCREWS

i

out the

to

position

a

the

phce

disconneit

of motor

with the

f"\

alloy,

end

on toD

ALL

6. Carefully

Replace

to

a

screws securely.

is

end

assembly forward lirmly

cap. The

assembly with no

check the front

tighten these

Retighten

until llush

is no

screws. Paddle

9. lnsert 4

lrame through table

washers,

tighten linger tight.

screws

slide the motor

the end

assembled

caps. Without

end

screws

the

with side

interference

square bolts lrom

lockwashers

securely.

assemblv

cap and

Check to

properly

cap shoukl

apparent

end c:p motrnting

set screws on

must move Ireely.

tighteri

be

in the lront

"Power"

against the tront

mwement

#orrely.

of end cap. Be

between

cleats. Attach llat

and

Then tighten the

into

arm.

mounting

sure the

shroud

rear

and

pull

the motor

stop the motor

skle of end

paddle

]t not.

screws

sure therb

and set

end

and

cap

inside

nuts

and

10

ol

Page 3

guide

10. Assemble

boards,

bracket. lnsert bracket into the slot

provided

eyelet in

screw

thread thumb screw

in

place

until it

fence and spacer

rear

cleats. Hold the

of

and turn the

"pops"

into

CAUTION

into

thumb

place.

11. Place saw blade

row as shown)

cessed side against

arbor

wrenches

place

13.

--'

[tri[ it-eEird rides in the ciririlar

nut securely

guard

over blade

iffi;;r!:Gi,lJiiit'-itie

;;;i;;6;;;;J

iiliit,i,iiecuiety.

blade

t

iustmenti

lor

l-.-#en

removing

p-Jiiiittiioirsiteo

and alignments

(with

between collars

(left-hand

itrE tioni

inj[ltriiitep

lloti

it. Place

direction

blade).

with both

threads).

tilting

*inenui.

uoi!.

the key

ino

marked

ar'

(re-

Tighten

guard

slightly

in

slot

Prace

tnstait

must be

the

in

at

itigneo

with an asterisk

l2.Assemble

knob, dust

except

inner ring

gram.

to clear

motor and

th6

the

the

endcap.

the f aitorv;

the arbor

motor stud

the

ring under

inner

insiide

front

repeated

but d.o

bef

*

(

).

Recommended

your

Radial

B&D Dealer. These accessories

and described

pages

and on

ol

other accessory

any

the moior and

retainer

in reverse.orde.l,tog?!n.?9ces_s-

press

not

operating

ord

ACCESSORIES

Arm

in the B&D DeWalt

19

anti-kickback,

spout

inner retainer

front

per

the Parts

Seat

shaft.

goes

the

with

the

button.

ON

the saw

Blades

and

Saw are

20.

and

CAUTION-The

might be

"*l

and lower

List dia'

g.uard

on.motor so

through

stocked by

the

hook it over

thumbscrew

Your

perlorm

Accessories

are

Catalog

hazardous.

locking

guard

and

hole.ln

the

and

t9.!!9

machlne

the ad-

lor

your

listed

use

.'$S

rable

1.

Securell' laslen

table

er:ensions are a::ached:o::e

1

Shin uncier i:on:

1

Read. unCe:s:a;:d

ELECTRICAL

This tool should

operator

\\'e

from electric

recommend

to do anp.

repairs should

or other

determined

green

this

colored

green

qualified

wire to a

rhe

CONNECTIONS

be

that

re*iring

performed

be

to make a

wire is the

l. Cord-Connected

or breakdown,

resistance for electric current

shock.

equipment-grounding

The

properly

This tool is equipped

plug

must be

installed and

grounding

irame

:o

legs

keep sa* carriage

anci al-* avs

grounded

shock.

you

\E\ ER

the

in

serrice

repair

"grounding"

terminal.

"live"

Tools: In

conduclor

plug-eed

grounded

organizations. Should

local codes and ordinances.

vided

-

installed by a

if it

will not

qualified

the equipment-grouniing

electric shock.

The con,ju;:or

outer surface thai is

the equipment-grounding

ment

of the eieclric cord

necl

Ihe equipmeni-,erounding

ihe ou:let.

iii

eie;::i;ian.

coilciuctortan

*iih

*sreen

conductor.

or

:o ihe Leg

practice

sa\r'.

the

Stand

from creeping

cautions

AND GROUNDING

s

hile in use

dissemble

electrical

onll

ounelf

l

s!'stem.

bf B&D Service

remember

.

*ire.

the

proi'ides

to reduce

*ith

an electric cord

and a

into a

Do not

of a

erent

a

the risk

grounding

matching outlet

accordance

in

modify

have the

Improper

result in a

*ith insulation

without

or

plug

conductor

is

repair or

If

necessar)'. do

or

a sturdy

and

protect

to

tool or

the

Any such

Never

malfunction

path

of

of electric

having an

plug

the

proper

connection

having an

yellou

stripes

not con-

iive

Io a

work

bench using

forward.

operating instructions contained

minal.

the

try

the

or

Use

ing

the

Check

grounding

if in doubt

only 3-wire

plugs

Repair or

Centers

you

be

that the

connect

least

plug.

that

with all

pro-

outlet

of

risk of

is

Grounded,

lA.

supply

a

circuit

This lool

looks like

that

grounding

a

Skitch

adapter

connect

B if a

A. A

illustrated

this

properly

orary adapter

ed outlet

green-colored rigid ear,

adapter

a

cnes

must be connected

properly

Ii ani

1B. Grounded,

a supply circuit

is

repiace-

ter-

volts, inclusive:

has an outlet

that

Sketch

plug

D.

illustrated

provided.

holes

this manual.

within

qualified

a

with

instructions

whether

as to

extension

and 3-pole

replace damaged

receptacles

cord-connected

having

is intended

the one

plug

a

for use

illustrated

that

temporary

in Sketches

plug

to a 2-po1e

grounded

installed

be

be used

outlet

Use

should

can

grounded

is Not for

6

cord-connected

having a

tool

This

that

has a

tool

The

in Sketch

sturdy

Use

electrician

not completely

are

tool

the

that

cords

that accept

worn cord

or

nominal

on a circuit

like

looks

adapter,

B and

receptacle

is

outlet

only

by a

lug, etc.

permanent

to a

box.

in Canada.

nominal

intended

is

like the one

looks

grounding

D. Make

outrigger

properly

is

have

immediately.

intended

tools

less

rating

in Sketch

plug

the

which

C,

as shown

not

available.

a

until

qualified

extending

Adapter

intended

tools

rating

for use

plug

sure

supports

or serviceman

understo-od,

grounded.

3-prong

the

ground-

tool's

for use

than 150

has an

that

The tool

A'

illustrated

like the

looks

may be used

in Sketch

The

properly

ground-

electrician.

from

ground

shown

such as

in Sket-

for use

between

150-250

on a circuit

illustrated

like the

looks

that

the tool

(Con't

is con-

on

if

any

plug.

on

volts.

outlet

has

temp-

The

the

.

on

P.

if

in

to

in

4)

Page 4

ELECTRICAL

nected

plug.

No

tool.

If the

typq

g.f

qualified

tool

should

CONNECTIONS

to

an outlet

adapter

tool must

electric

service

comply

having

is

available

circuit,

personnel;

with

mmurnfr!0b_

\l ol

/t-.-t

eilrm lft-i\ I

mm6

lrc$r

Irf

The

for

RULES

3 rf,tr*s

A.

use

either

lUI

I I

ImBdtul

of

a separate

120

or 240

Volt

FOR

SAFER

OF STATIONARY

l. XEEP

2. REMOVE

3.

4.

5. KEEP CHILDREN

6.

7.

8.

9. WEAR

10.

ll.

12.

13.

14.

15.

16.

17. NEVER

18. CHEICK

19.

2O.NEVER

21.

GUARDS

checking to

tool

before turning

XEEP WORX

accidents.

IX)N"T

USE IN DANGEROUS

tools

in damp

area well lighted.

IN PLACE and in working

ADJUSTING

see that keys

it on.

AREA

or wet locations,

AWAY.

distance from work

MAXE

WORXSHOP

or

by removing

DON'T

FORCE TOOL.

rate

for which

USE RIGHT TOOL.

which it was

PROPER

rings,

bracelets,

Nonslip

contain loirg hair.

ALWAYS

footwear

USE

cutting operation

resistant

SECURE

lenses,

WORX.

It's safer than

tool.

DON'T

times.

OVERREACH.

MAINTAIN

best

and

changing

DISCONNECT

such

REDUCE

sure

safest

accessories.

as blades,

THE

switch is in

area.

starter keys.

was

it

designed.

Don't force

not

designed.

APPAREL.

or other

is recommended.

SAFETY

is

dusty. Everyday

they

are

Use clamps or vise

your

using

TOOLS

WTIH

performance.

TOOLS

bits,

cutters,

RISX

position

off

USE RECOMMENDED

manual

for

cessories may

knock

tipped

guard

determine

function-check

parts,

may

should

DIRECTION

direction

POWER

ONE

should

recommended

cause risk

out

inserts at

STAND

or if the

the arbor hole

ON TOOL.

cutting

tool is

DAMAGED

or other

part

that

that it will

for

alignment

breakage

of

parts,

affect its operation.

properly

be

ofrotation

LEAVE

OFF.

OPERATOR

position

repaired

OF FEED. Feed work

ofthe

TOOL

Don't

leave tool

ONLY. The

the

work.

AND

GROUNDING

the

same

or should

be reconnected

the reconnection

and

all local

B.

15

ampere

after reconnection,

codes

circuit

operition.

OPERATION

POWER

XEYS AND

and adjusting wrenches

CLEAN. Cluttered

KID PROOF with

It will

jewelry

GLASSES. Also

NOT

safety

hand

Keep

CARE. Keep

Follow

before

etc.

OF

UNINTENTIONAI

before

ACCESSORIES.

accessories.

of injury to

Serious injury

unintentionally

PARTS. Before

is

damaged

operate

mounting,

guard

A

replaced.

or

blade or

RUNNING

until it

WRENCHES. Form habit of

ENVIRONMENT.

or

expose them to rain.

All vistors

job

do the

tool or

No loose

get

to

Wear

eyeglasses only have

glasses.

to hold work when

and it frees

proper

footing

instructions

servicing; when

plugging

persons.

may

cause

should be

properly

of moving

and any other

or other

into a

cutter only.

comes

person

same

(con'rtrom

configuration

as the

be used with

for

use on a

different

should be made

ordinances.

and

ffiB

c.

is recommended

TOOLS

order.

are removed

areas and benches invite

should be k@t

padlocks,

better and be safer

attachment to

clothing,

caught in moving

protective

use face or dust mask

both hands

and balance

tools sharp

for lubricating

changing

STARTING. Make

in.

Consult the

The usc of

Use of blades

injury.

could occur if

contacted.

further

use of

carefully

perform

and

parts,

binding of moving

part

that

blade or cutter against the

UNAITENDED.

to

a complete stop.

who

D.

Don't

power

use

Keep work

a safe

master

switches,

job

do a

gloves,

neckties,

covering to

impact

practical.

to operate

and

clean

acccssories

owner's

imprope.r

the tool is

the tool,

checked to

its intended

is damaged

TURN

the

parts.

at all

hair

conditions that

pulls

from

at

with

saw

this

by

thL

the

for

for

and

ac-

p.3)

if

a

MAINTENANCE

l. DO-Protect

2.

DO-Be sure

3. DO-Be

starting

4. DO-Be

collars are

wrenches

5. DO-Keep

6. DO-Use anti-kickback

7. DO-Keep

cleaning with dry

8, DO-Periodically

9. DO-Remove

shaft. Tighten nut

10.

DO-Keep motor

ll. DO-Remove

unauthorized

12. DO-Use

13. DO-Retum

available.

line with

blade

sure all clamp handles

any operation. Push handles

sure blade and

against blade. Tighten

provided.

saw

arm tracks

blade

switch key and

operation.

lower

carriage

l. DON'T-Attempt

2. DON'T-Operate

3. DON'T-Use

blades of larger

4. DON'T-Remove

the workpiece

DON'T-Rip

5.

6. DON'T-OiI

7.

DON'T-Wedge

when

from wrong

or

8. DON'T-Subject

away from dampness.)

9. DON'T-Force

can cause major

10. DON'T-Remove

ll. DON'T-Remove

Tighten nut securely.

12. DON'T-Remove

properly grounded.

it is

13.

DON'T-Remove

The

lower

behind

the fence.

CAUTIONS

GUARD:

l. The

lower

contact with

WITH

THEFRONTORREAR

When

the

rise

up over the

your

keep

2.

Lower

blade

table.

3.

4. The

Replace

Short

cut-off

guard

and the

stops

before

lower

may have

vent

bending.

COMPLETELY

MENT.

5. Catching

can

bc avoided

clears the fence.

6. When

7.

8. To

ripping

rest

on top of the

Do

not use the

size

saw blade.

summarize, when

and when

it is

a help or hindrance.

MOTOR

Your

Sa\y Motor is

protector

If

the

l.

Press

the

2.

After

motor has

pressing

the

motor must

reset,

3. After the

button.

"ON"

guard

bhde

READ THE

TO

blade

the

lower

hands

guards

guide

pieces

blade. If this

removal

blade

to

be raised

BE SURE

the lower

by elevating the

narrow

lower

practical,

OVERLOAD PROTECTION

equipped with

'rtrips"

saw

"OFF" switch button

cooled,

the red

reset

reset

is accomplished,

AND OPERATION

at least a l5 ampere time

rotates

clockwise when facing

and thumb

arbor collars are

Rule

See

blade sharp and

attachment

and bearing

cleaner is recommended.

rocheck alignment.

not

but

securely.

air slots clean and free

guard

at all times.

to full rear

to operate

unless

all clamp handles

anti-kickback

crosscutting.

grease

anything

cutting action.

damage to motor winding.

direction-observe

tracks

arm

against

table top to variable

saw blade

arbor collars and nut when

ground prong

small scraps from

covers thc

FOLLOWING

FOLLOW

guard

side of the blade-BuT

guard

material-thus

out

guards

STOPPED

fence.

be allowed

will

touches

the

of

line of

may

become

fence

frequently.

wood

of

happens

piece.

of

effectiveness

out of the way

THAT POWER

guard

in saw kerfs when

strips, the

Be sure

guard

with

in

doubt about whether

make

a

"dry

and

stops the motor, take

the overload

button.

back to tighten.

arbor nut

16.

properly

arbor collars

set.

guard,

on

surfaces clean

of chips.

store in a safe

after each operation. A return

on anything

diameter than recommended.

but designated voltage.

guard.

from

or motor.

fan

to hold motor

humidity

Stalling or

guard

when

boring.

plug.

from

table with fingers.

side of the

PRECAUTIONS.

WHEN

provide

USING

additional

OFTHE BLADE,

the fence

exposing

may

BEFORE

lower

to use a

a manual-reset

you

If

or material

the

cut!

caught in

become

shut off

is limited

when

MAKING

saw until the

guard

pusher

any accessory

run"

with

and

allow the motor

protector

do not

to cool further

the

saw may

delay fuse.

arbor.

screws are tight

clean and recessed

and nut when

are tight.

partial

Never operate

Pull to loosen.

securely,

and dry. Periodic

place

Adjust

caution tag

shaft.

conditions

stalling of motor

using

teeth when

using both

using rear

to

just

to

it

on

rear shaft.

saw unless

the blade

LOWER

NoT

caught between

setting

IS OFF AND

power

protection

FROM

CoNTACT

being

blade teeth.

prior

kerfs in the

power;

in

bevel operations.

cut, it

Be

wait

until

bevel angle

the

BLADE

AT.IY

ADJUST-

changing the

bottom

may have

stick to

other thart

to

use the lower

type overload

the

following

may

hear

an

before attempting the

be started

saw

of the

to

be raised

feed the work.

the

off

to determine

protector.

steps:

to

cool.

be reset by firmly

audible..click",

pushing

by

before

side of

prevent

reel is

clear

guard.

(keep

from

will

careful,

fence or

lower

blade

pre-

to

set-up

guard

to

correct

guard

the

is

It

IS

if

Page 5

RADIAL-ARM

is due, in

Learn

starting

machine.

part,

to use them by adjusting

to operate it.

are

MACHINE CONTROLS.

to its controls,

and

the machine

All

controls,

and

shown

identified here.

these

well

as

The

are the

versatility

keys to

for

all

the major

as

radial-arm

the

of

successful

its

operations

parts

before

of

the

machine

operation'

actually

radial-arm

COLUMN

GUARD

BASE

GUIDE

FENCE

-

TABLE CLAMP SCREWS

RADIAL

AR

\

M

ELEVATING

HANDLE

/

OPERATING

DUST

HANDLT

SPOUT

ANTI-KICKBACK

ASSEMBLY

BEVEL

GUARD

RETAINER

ONOFF

KEY LOCK

SCALE

CONTROLS

MITER CLAMP

LOWER GUARD

HANDLE

MITER SCALE

LOCK

RIP

YOKE CLAMP HANDLE

RESET

BUTTON

RIGHT HAND

MOTOR ARBOR

SPACER BOARD

Page 6

r

ALIGNMENT

FORE

THE

BUT

OVERALL

WORK

ALIGNMENTS

Your

asterisk (*)

YOKE

The.

of the yoke

play

pushed

this

Its proper

grip

To readjust:

GOING

ALIGNMENT

ALSO

FOR

ENJOYMENT

BENCH,

saw

was

are

to

CLAMP

purpose

between

handle

of

the

(a)

Pull

(b)

Insert

the

(c)

Rotate

counrer-clockwise).

over

(d)

This

accessible

with

back

so

position

yoke.

yoke

adjustor

the

saw

the

of this

and

these

from

rhat

screw

clamp

yoke

1/4hex

ANY

FARTHER

OF

SAFER

APPROPRIATE

OR

OPERATING.

completely

be

made

HANDLE

handle

the

bottom

two p-arts.

the

hand

ir srrikes

for

machine

clamp

handle

driver

downward

adjustor

lug

stop

has

a king

without

wrench

MAKE

TAKE

YOUR

ADJUSTMENT

between

removing,any

NEW

OPERATION.

OF THIS

inspected

you

prior

by

is

provide

to

face

bf

In

grip

of

lhe rear

Be

at final

bolt

the yokel

op..uti6n

forward

the

just

enough

as necessary.

sure

the

with

which

and

operating

legof

setting.

a hex

ii

CERTAIN

TIME

SAW IS

FINE

TABLE,

THESE

tested

to

use.

a friction

the

rollerheaa.

Ii.

the

is

approximaiery

to release

yoke

and the

pass

to

notch

in

hole

part

from

furnished

SAW

IS

OUT

TO

READ

MOST IMPORTANT

THE

TIME

PRODUCT.

OR LEG

UNITS

but

only

lock

rt rr,ouio

position

at any

yo[..

ii

friction

notched

or..

rr,.

(to

loosen,

the

adjustoiii

in the

rhreaded

saw.

wittr

tneidw.

SPENT

NOTE:

STAND,

WILL

FIT

partially

between

aGo

yot,

tt,"

rimc,

it

i; ;;i

is

i;

frfp",

oo;

6.'t.r,

locking

clamp

iugitop"on

ciockwise;

action.

Joiii;on.;

end which

eaJrir-.rt

-'

-trump

NOT

C,NNECTED

THE

NOT

HERE

SECURE

WITH

A NO.

aligned

the

upper

elmiriat"

possible

handle

adiustment.

to the

adjustor.

it

vot".

"

to

p;;;;;i;

can

be made

FOLLOWING

ONLY

WILL

TABLE

SCREWS

R-120I

at the

LEG

factory.

face

uny

ii

to

move

hand

Flex

-

tighten,

is

easily

To

P*WER

IMPORTANT

FOR

MAKING

ADD

CONSIDERABLY

FRAME

OR

BOLTS

STAND

The

alignments preceeded

SoURCE.Now

INSTRUCTIONS.

ACCURATE

OF

UNIT

To

BEFORE

BE.

CUTS,

TO

YOUR

A sTURDY

MAKING

by

an

ADJUSTING

Rr.por"

ffq

plished

'Io

by

adjust:

Loosen

the

set

BEVEL

of

cam

screw (A),

the

CLAMP

bevel

acrion

HANDLE

clamp

of

the

tighten

is

to

clamp

clamp

hold

priting

bolt

the

moror

the

(B),

at any

clamp

then

angle.

p"t

,!'"irrt

retighten

This

set

the

screw.

is

accom-

dial plate.

Page 7

ADJUSTING

ROLLERHEAD

The rollerhead

shield

ball bearings.

and

two

eccentric

all

of

length

pressure

loss

Proper

along

to

it

four

and head

will

of accuracy

adjustment

the arm

contribute

need not

(a)

Wipe

(b)

Bring

(c)

Set in

(d)

Loosen hex

(e)

Insert

shaft

bearing.

required.

(f)

Tighten

position.

bearings

cause

equally to this force.

be removed for

tracks

motor,

"out

Vs" Allen wrench

until the

BEARINGS

is suspended

These

bearing shafts.

should

should roll freely

by

bearings are mounted

in

be

diflicult operation

and

the saw will

will require

at a

constant speed. The front

try to

a force

l.IoTE:

this

adjustment.

with

a clean

yoke,

position.

rip"

nuts on left

dry

and rollerhead

side, front

in recess

bearing

Check the force

the hex

is snugly

lock

nuts while holding

TO ARM

four

special tolerancc,

proper

In

contact with the

but with

and

adlustment thc top and

some

rapid

wear. Too

feed

itsclf into

of 4 to 6 pounds

and rear

the end cap was removed

lint-free

required

cloth.

assemblies

and rear.

at

bottom of

aqainst the

to move

each bcaring

TRACKS

grcased-packed,

on two straight

arm tracks

resistance.

the material

little

Excessive

pressure

to move

bearings

to

the end of arm.

track.

should bc adjusted

shafts and turn

Repeat

the rollelhead.

shaft in its adjusted

double

bearing

for

shafts

bottom radii

their entire

bcaring

will cause

bein-e crosscut.

rollerhead

the

for clarity and

for

bearing

the second

Rcadjust

as

ARM TO

Prior

to readjusting

adjustment

clamp

released

in the

the

arm.

column.

To adjust:

(a)

Loosen

of arm.

(b)

{diust

ti-shten

REMOVING

To make

to

remove

(a)

Remove

held

(b)

Remove

handle.

(c)

Remove

the handle

adjustments

the

COLUMN

the

of the arm

there

and

SHROUD

arm

on

should

the arm

jam

trvo

turning

(B

bolts

jam

nuts

cover, as follorvs:

elevating handle.

by a set

front

end

arm

cover

post.

arm clamp

to column. With

vertical plav

be no

should

nuls

them clockrvise.

for proper

)

(.{)

fir snuelv

in

(A).

in the

arm

it is

&

mirer

Handle is

scre\\'.

cap

bv rotatins

cam check

the arm

on

slLrr at rear

fir

and re-

necessary

clamp

it over

E--'

Cross section

with

shroud removed

''.-

of back

\

of arm

A

ADJUSTING

The

arm

miter

adjust:

Loosen

To

be

Retighten

clamp

latch

made

the

To

(a)

(b)

(c)

ARM

from

ser

tighten

prior

CLAMP

handle

operates

the

0: and

screw

clamp turn

to trying

set screw

(A)

(A).

a

cam that clamps

45:

slots.

on

clamp

clamp

bolt

the

clamp.

(B)

bolt

clockrvise,

)

and releases

in

clamp cam

(Very

little

the arm. and lifts

pivot pin

adjustment

(C).

shouid

Page 8

FC

&-&

MITER

Position

clamp

To

adjust:

(a)

(b)

CLAMP

of

.the

cam

has

Loosen

Turn

contact

trghten

HANDLE

clamp

been

set

screw

the

clamp

casting

set screw.

handle

adjusted.

in pivot

rod

when

POSITION

may

need

pin

so

that

clamped

adjusting

on the

the

clamp

handle

or released.

after

the

rod.

does

not

Re-

ADJUSTING

If

saw

To

noticeable

is

hard

adjust:

(a)

Loosen

and

(b)

Elevate

is

diTculr,

the

easy.

(c)

If

the

proper

jam

(d)

Push

agajnst

their

screws

ADJUSTING

It

is_

necessary

ing

belt

rension.

To

adjust:

(a)

Loosen

(b)

Pull

tension.

(c)

thar

belt

BASE

play

to

elevate,

rear

locknuts

clamp

bolts

and

until

Then

column

adju-stment

against

the

arm.ro

Tighten

to slip

TO

exists

of

lower

righten

.there

tighten

is

Note

the

(Face

slot

nut

the colqmn-

locknuts

or locknuts

lightly.

BELT

to

remove

two

and

excess.ively

then

(A).

loose

the

screws

hold

screws

jump

or

COLUMN

between

the

machine)

and

brass

Adjust

the

arm. If

jam

the

is

no

bolts

in the

is

achieved.

left

side of

the

right.

key

Caution:

may cause

TENSION

the

arm

marked

sprocker

(A)

and

fight

base

from

its pulley.

the

base

base

requires

set screws

lower

the

column

(A)

nuts

play

(A)

but elevation

holding

base,

tighten

Holding

the

slot.

Bring

to remove

excessive

setscrew

cover

to

adjust

(A)

and

bracker

(B)

and

bolt first.

(C)

securelv.

adjustment

the

column

adjustment.

(B).

Loosen

binds

againsr

the

is

jam

the

the setscrews

all rotary

damage.

nuts

bolts

each bolt

play.'Tig:hten

tor!'u'e

the

tim-

(B).

io

apply

belt

may

cause

or if

the

nuts

tam

and elevation

right

side

moderately

place.

in

(A)

until

the

tighten

(B)

lightly

on

thj

set-

of

its

Page 9

*

ADJUSTING

The table

To

align

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j)

Position

under the

the frame..Now.

to this

adjust

over.

touches

locking

top

proceed

Remove the

Elevate

Release

Revolve

Release

and left.

Lower

Bend

down

Move the

and notice

arbor

If the

parallel

If th.ere

provided)

the

table

high point.

one.

two

aeother

the

end

nuts

in

TABLE

surface

the saw

the bevel lock

the arm

and

clearance

to the

end of

must

as follows:

guard,

about 20 turns.

the motor

the miter lock

until the

so that

arm to the

if

there is

top

the

arm.

is a

difference

and adjust

the arbor

you

and

position

Lower

or three nuts

locking

the same

of

the

nut.

arbor.

manner.

TOP PARALLEL

parallel

be

the

lever

until

the arbor is

and locator soyou

your

eye is

right

any change

of

the table.

(distance)

in

follows.

as

will

notice

the

end

the arbor

to get

Loosen

Tighten

with the horizontal plane

blade and the washers

pull

and

end of the

even

and left

is

the

the clearance,

directly over

four

of the arbor

until it touchei

the

table

the lockin_e

the loc[ing

WITH

ARM

the

bevel locating

to

90o

with

and

in the

same over the

(4)

the table.

can movc

arbor is

the highest point

locking

directll:

parallel.

just

the table

push

the roller

distance

remove

the table.

\ow

nut

and push

nut.

over rhe

If required.

of the

from the

over the

top.

between

entire

the four

nuis that hold

mor.e

motor.

pin.

the arm to

table.

hcad

back and forth

the

surface the

spring

on the

nearest

you

the

the

table up

adjust

arm tracks.

right

the

of

end

table. L<-rok

the

locking

mav hai..e

arbor directly

the

table is

(if

pins

cleats to

nut

until ii

the

other

to

CHECK

The

table

"breathe"

Straightness.

:i:^L:

$'ood$

Do

{.

TO

With

and

one

other

saw

set).

^T3,q:

LrrHn

not

use

ADJUSTING

WORK

the

all

clamp-

edge

.edge

blade

If

blade

TABLE

iop

assem-bi1'

and

are affected

TOP

of top-and

ll!:

g

riqulriments.

a level e\cept

BLADE

TOP

arm

in

cross-cur

handles

on

the

table

against

gullets

is

not flat

and

AND

GUIDE

and guide

br:r'arious

Guidi

sanding.

!l'

as a

PERPENDICULAR

position,

lockid place

top parailel

the

flaf

of

not

against

against

FENCE

strip are.checked.for

Lumiditl

rvith

Strip.

.{

alight

slraight

Clamp

variation

edge.

all

latches

a steel square"i:ith

guide

to

the

saiv

teeth

square,

strip

blade

because

adjust

as follows:

conditions,_a

Screws tight,

from perfect

(This

check

engaged

and the

jplace

of

in

tooth

straightness_

ilight

change

sliould

straightness

for

is

straightness,

Norr,:

loosen

before leaving

from

be"checked

of table

(a)

Remove

(b)

Loosen

(c)

Tilt

motor

again

place

bevel pointer.

In

some

center

factory.

the

fac-tory

with'a

top

conditions

square

wili

not levelness

bevel pointer

two

outside

until

blade is

(very

lock

cases

cap

it will

screw in

As all wood products

ro;;i;es

-;,

or straight

not no.rnoiiy

with

the

floor,)

by removing

socket

flrmly)

order

flat

be

head

against

socket

found

to

adjust

edge.

Correction

the

"ff;&

two

screws.

screws.

the

square

head

screws.

necessarv

motoi.

must

be found.

average

and

Re-

to also

Page 10

*

BEYEL

The

bevel

positioned

adiust

li.,osen

*

ADJUSTING

with

the

board

with

the

(

a set

alm

To readjust:

(a)

Loosen

(b)

Loosen

(c)

Lay

the

(d)

Move

which

(e)

If

miter

right

necessary.

(f)

If saw

miter

screw,

(g)

when

ment

Norr:

miter

Do

latch.

SCALE

scale

for

the

CROSS

miter

l"

x

72"

tooth

is

out

of alignment

steel

other

saw

way

saw blade

latch.

adjusting

bladc

latch.

re-engage

saw

screws

not

tighten

is located

vertical

two

latch

if

available)

blade.

arm

clamp

two

set

square

edge

carriage

arm

moves

with

moves

Loosen

travel

in

at

cutting

screws,

CUT

engaged

check

with

handle

screws

on

table

at

0'

cross-cut

and

must

be

toward

screw

screw,

away

right

miter

parallel

is

place

by retightening

adjusting

the

front

pointer

the

move

the

TRAYEL

and.arm

against

cut

with

guide

the

(B)

under

the

top

blade

forward

adjusted.

square

driver

re-engage

from

adjusting

latch.

Check

to square

screws

of

pointer

WITH

clamp

the

a

.

miter

with

as

shown

loosen

miter

square

enough

the

should

guide

steel

fence.

one

arong

as

left

as

screw

and

for

set

motor.

be

to

0 and

GUIDE

handle

strip.

square.

adiusting

edge

against

picture.

in

steel

it

comes

adjusting

letch.

it

comes

ancl

repeat

entire

screws.

to retard

when

at

0

on

tighten.

FENCE

locked,

Cross-cut

If

cut

screws.

guide

square

forward,

screw

check

forward,

tighten

if

necessary.

length,

the

operation

the

motor

the

scale,

place

a

this

is

not

square,

fence

to determine

disengage

and

tighten

and

repeat

disengage

left

adjusting

iock

adjust-

of

is

To

wide

board

and

if

the

MITER

'-.

The

arm

scale.

To

POINTER

miter

positioned

is

adjusr:

Loosen

rotate

DIRECTIONS

1.

Fit

5/ 16"

(This

2.

Fit

large

wrench

3.

While.

use.

downward

and

nut

pointer

the

FOR

wrench

is

holding

a

wrench

possible.

as

holding

will

is

located

for

straight..orr-.ri

rear

screw

scale

to

zero,

REMOVING

into

front

wrench

on

arbor

Allen

wrench

pressure

loosen.

See

at the

located

retighten

end

only.)

nut

as

starionary

of

right

Figure

top

on

the

pointcr

the

on

the

screw.

ARBOR

of

nearl). parallel

NUT

motor

with

hand

on

page

I l,

3.

back

of the

should

top

of

shaft.

to

lirst

lefr

hand,

second rrrench

arm. \\,hen

be

at

the

miter

o.

cn

scale,

the

the

10

Page 11

ADJUSTING

Both

the leading

plane

parallel

against

tion and

front

Now remove

to the

the rear

the

all locks

teeth

back

teeth are

following

teeth

start

same

operation

To

odiust

(a)

Disengage

bevel

(b)

Loosen

(c)

Loosen

tighten

(d)

Retighten

(e)

Recheck

To

odiust

(a)

Disengage

bevel

(b)

Loosen

(c)

Loosen

tighten

(d)

Retighten

(e)

Recheck

After

left

the

motor

make

cuts

and

to the

right

side

of the

blade

the

stock

of the

the front

at the

bottom

with the

when

morks

pin.

right

right

left

as above

when

morks

pin.

right

left

right

lock

as

and

right

to 45"

on

2" x

CROSS.CUT

(HEEL

trailing

arm

tracks.

guide

of

the

and latches

to

clear the

by slidirig

arm.

Examine

prominent

teeth

and

front

of

stock

ore

on

bevel

clamp

and

left

lock

set

screw

set

screw.

lock

nuts

and

by

cutting.

qre

on

bevel

clamp

and

left

lock

set

scre*-

set

scre\\-.

nuts

and

above

by

curting.

adjustments

bevel

cross-cut position

4"

stock

as r.,as

TRAYEL

ADJUSTMENT)

teeth

of

To

check,

fence.

engaged,

stock and

to the right

the cut edge

on the

adiustment

against

the stock

slock

cut

cut

the left

handle.

nuts

about

bevel

clamp

siock

cut

handle,

nuts.

about

berel

clamp handle.

have

been made,

done in

PARALLEL

the

sarv blade

place

with

end

trim

the

before

stock

is

necessary.

and

righi

on

Do not pull

at rear

1./6

turn

handle.

on left

Do

not

1 6

turn and

and

cross-cut

should

a

the

machine

this

stock

rear

teeth remaining

returning

of

the

the rear

travel up

side

of

side:

yoke

of

and

side:

pull

tilt

again

TO

ARM TRACKS

travel

board 4,,

in

by allowing

stock.

If

teeth

(The

and

back.)

guide

the

position.

high

To

cut

To odlust

Now

in the

x

1,, or larger

0o

cross-cut

only the

in

the

cutting

blade marks

are

not

arcs

of the rear

Repeat

fence.

if

or lorv

odiust

(a)

(b)

(c)

(d)

(a)

(b)

(c)

(d)

when

(left.hond

Disengage

bevel

Loosen

Loosen

screws

set screw.

Retighten

and recheck

when

Disengage

bevel

Loosen

Loosen

tighten

Retighten lock

recheck

Go Bqck

same

posi-

the

cut.

head

exactly

this

tooth

in

the rear

pin.

all

by

about

pin.

all

bottom

right

as above

And

of

marks

mqrks

piece

bevel

lock nuts.

equal

lock

as

morks

bevel

lock

and left

again

of the

oppeor

of

siock):

clamp

amounts

l/6

twn

nuts

and

above

by

oppeor

clamp handle.

nuts.

set

screw

set

nuts

and

by cutting

Check

Cross

appear

yoke.

the

on

bofiom

handle.

Do not pull

right

and

tighten

bevel

cutting.

on

about l,u 6 turn

screws.

bevel

clamp

upper

clamp handle

Cut

Adiustments

motor is

side of

and left

bottom

handle

side

of

Do not

and

too

set

eul:

pull

and

.*RIP

SCALE

The

rip

positioned

and

material

)

:

tioned

right.

when

and

when

pointers.

(thickness)

To

adjust:

To

set

the

tion and

you

After

"out

rip"

and

tighten

blade

against

scale

with

toward

"out

The

of

"in

then

ha'e

pointer

the screu's.

PO]NTER

is located

motor

should

the

operator

"in

ripping"

ripping"

pointers

blade

rip

and

set

rhe

done

rhis loosen

equal

the

fence.

on

arbor

be fed

on

are

is

changed.

"out

sa*'

to

Then

Adjust

the right

to*'ard

from

right

it is

called

width

dimensions

the

bortom

adjusrable

pointers,

rip"

blade

at

the

the!

distance

turn

the saw

the

side

of

the

the

column

to left.

"out

rip"

of

and

must

first

predetermined

a

two

screws

between

to

"in

rip"

pointer

radial

it

is

when

and

material

are

located

the

scale

be readjusted

set

the

saw

holding

the

sau.blade

"in

an

rip" position

ro

arm.

when

called

the

motor

on

the

by

use

in

distance

pointer.

the

(C)

zero

11

the

,,in

rip', position,

arbor

is

fed

top

of

the

only

when

an,,out

from

and

and

on

the

motor

is

from

lelt

of the

reference

3auge

rip',

the fence.

Adjust

the fence,

push

scale.

is

posi_

to

scale

posi-

the

the

Page 12

CUTTING

OpuoNer:

protective

a

be

easily

alignment.

front

board

3/q"

brads.

is not necessary to cover

It

KERF

Prior to

material over

replaced as required

Cut a

and secure it to the

Do not

cutting

piece

nail where the saw

A,IARKS

kerf marks

your

table

without disturbing

of V+"

plywood

front board

the spacer

you

may elect

top. This

the

kerfs

material can

same size as

with

countersink

will

be

or back boards.

place

to

the saws

the

located.

-ryqryry-S

!t!lrlt?

E?,Sg

rcset

saw

your

all

After

the table top

you

to

adjustments

the most common

move the saw

ing the elevation.

(a)

Locate

the blade

(b)

Draw the saw

and lower the blade until

(c)

Turn

back.

Plv

(d)

Lower the arm

saw forward to the end

hand.

deep.

(e)

With the saw

the handle

and

handle

ing the

and lock the arm 90" to

the saw on

This will cut the fence

top.

This will cut a

Tighten Rip

pull

presses

yoke

head. You can

direction.

wise

continue

yoke

locator

now

cut

the swing

(Refer

tion.

(l

)

(e)

(h)

the

Once

your

wirh

push

ing

reaches

the

Return sa\\' to

Lock

release

counterclockwise,

the swing line

the fence.

center

and start motor. Using the

the

Lock the

right hand and blade still revoh'ing.

until the

back

(f)

rear

Stop

position

in

j)

(

Return saw to

the

Lock Rip Lock

(k)

release the

move arm to the

will cut

Repeat above

are made

into different

To do so

you

kerf marks.

positions

proceed

should

as follows:

now

This

u'ithout chang-

the fence.

90" to the table.

out to about the

push

and

(saw

still

middle of the

just

grazes

it

roller head all the

the

and lightly score thc

running)

1/4

turn.

the

of the arm with

groove

Lock.

stilI running and

release the

yoke

it with suflicient strength

against

locatcr

rotating the blade until the spring

pin

in the table

the

pin

now rotate

Release

falls into the next

top a

line. The saw

figure 2)

to

1/1r

right

the

cut is complete lock the

turn

hand and with the

yoke

back on the track until the bladc

This will

of the table.

position

pressure

on the bell and

to the outrip

for

outripping.

lock

(clamp

yoke

new trough matches

Motor.

position

and

shown in figure 1 and

behind

start

miter handle

45" right hand miter

a trough

for mitering.

for 45" left hand miter.

in

the table

(Refer

lock

yoke

to figure

your

with

so the

locator

out cf the hole

saw blade in a clock-

the

pressure

the

t/4

is now in

Loosen

Motor.

Stop

shown

groove

turn

the

Rip Lock.

blade

the rip through iu

cut

in figure 1.

1'oke

position.

Loosen rip

handle)

fence.

the

mOtor. With

your

with

left hand still on

your

pin

in

on the bell ancl

hole. You have

"in-rip"

(Refer

clamp handle,

and

,

push

the

motor running

right hand and

position.

(Optional

Stop

cut into

will allorv

Locate

track

ply

top.

wav

Pull thc

your

lelt

i32"

top 7

l)

hancl

right

yoke

clamp

pull-

bell

roller

the

rnounted

known as

posi-

yoke

lock

still revolv-

to fig.

3)

Rip

Lock

rotate

This cuts

lock.

g'ith

the sau'

trough

move to

step)

Motor.

sau'

1'our

cut

This

**-Srl!lllii"

FIGURE

qi6

FIGURE 2

FIGURE

I

&**

"r*

:

3

t2

Page 13

O

OPERATING

INSTRUCTIONS

O

observe

and

comply

with

the

warning

labels

on

the

saw.

WARNING

FOR

YOUR

1.

2.

3.

Wear

Keep

Return

protection.

eye

hands

carriage

operation.

4.

Know

how

5.

6. Do

7.

8.

9.

Use.common

and

Review

Tools"

llg"p

tree-cutting

machine.

jam-ups

Never

workpiece

supported

prevent

ll

the

becomes

free

and re-check

PAI{GER

oraKe tmmec,tately

soon

I_1! ]olgrq

loosen

checked

Never

duced

I

pusher

Use

not

Never

Shut

Make

be

alert.

the

"Maintenance

and

r:* in.

These

or

kickbacks.

perlorm

by

or

any

sawblade

jammed

jam

a

up

Coasting

as

the

switch

developed

the

blade retaining

periodically

cycle

the

which

perform

reach

power

off

no

adjustments

sense,

"Rules

good

tools

and

precautions

any

hand

guided

unexpected

or

-

Turn

without

machine

on

is

tool "on"

will loosen

OWN

MANUAL

out

of

to full

reduce

to

board

for narrow

any

around

before

think

all operations

For

Saler

and

adjustment

accessories

operation

alone).

The

by the

fence

movement.

cutter

power

ofl

first

turning

alignment.

cutting

tools

manual

turned

otf.

during

nut,

and

tightened

and

the

arbor

SAFETY

BEFORE

path

of

saw

rear

risk

of kickback.

operation

moving

clearing

until

Operation

Operation,,

and

alignment;

thaf

will help

,,free

hand"

workpiece

or

supporting

becomes

immediately.

power

Adjust

can

be

hraking

manual

or

therefore

if necessary.

,,off ,'

rapidly,

nut.

READ

OPERATING

blade.

position

work.

freehand.

saw

blade.

a

stall

tool has

through

of

Stationary

sections.

were

designed

reduce

the-possibiliiy

(i.e.

must

always

stalled

as

units

or lower

Never

off. Remove

necessary.

dangerous

to

stop

automatic

the

arbor nut

forces

as

INSTRUCTION

SAW

after

each

jam.

or

stopped.

before

startirg,

power

(See

index)

use

only

sharp,

ior

supporting

Ue

s-otiOty

br tixture

lig

guard

attefipt

workpiece

_

apply the

the tool

braking may

stroJtO

pro_

can

be

crosscut

-

youi

of

the

t6

to

as

U6

type

of

lf

the

complete.stop

excessively,

Read

follow

powershop.

Kickbacks

blade

could

thrown

Never

work

The

correctly

Use

which

Place

rocking.

pusher

A

less

pusher

as shown

It is

catching

brads

arbor nut

using both

through

lor

further

can occur

and the

cause

the workpiece

violently

stand,

adjusted

care when

can rock

the

wood

board

3 inches

board

below.

to change

if

work

may

be used.

or

should

being ripped

anti-kickback

extra

than

easier

TO

NOT

INTO

should

ever loosen,

and re-tighten

wrenches

and

study

the

instructions

when

lence

during

back towards

permit

someone

possible

due to

fingers

to insure

ripping

on

the

saw table

on

the table

should

be

or

so

be made

the

table is

saw

higher

DANGER

AVOID

FEED

CUTTING

FROM

pictorial

the workpiece

a ripping

to

must

proper

used when

between

from

set-up

THIS

allow

the

arbor

provided.

operating

before

type

be ejected

the

operator.

else to

kickbacks.

be kept

operation.

material

and

cause

in

such a manner

tne

clear,

and

than

rear

INJURY

MATERIAL

END

the

blade

nut

securely,

instructions

your

usingf

binds

between

operation.

from

the machine

stand in line

sharp,

free moving

that is

twisted

pinching

as-to

ripping

narrow

UUOe

anO tence).

tablie.

grained

prevent

l/4,

straight

will

DO

TOOL

to

come

but not

which

new

DeWalt

the

Such

action

with

or

bowed

or

binding.

minimizi

work

lumber

lower guard

plywool

to

saw

and

the

and

(i.e.

ihe

and

a

SAME

THICKNESS

AS

WOnx*\

PIECE

Drmension."A"

past

from

The

new

Do not

.

3i

/4

must

be

the

blade

passingundertheantr-kick-back<ievice.

pusher_board

width

of rip

rrp

workpieces

but

new

a

should

such that

short

enough

be

or re-woiked

shorter

13

pre-kerfed

than

b

APPROX

the

workprece

prevEnt-ine

rc

pushei

12, in

prror

board

length.

rs led

;rshd-fi;#

-

-

-

to

use,

mjsi

7-

5.APPROX

comoletelv

for

every

be used.'

Page 14

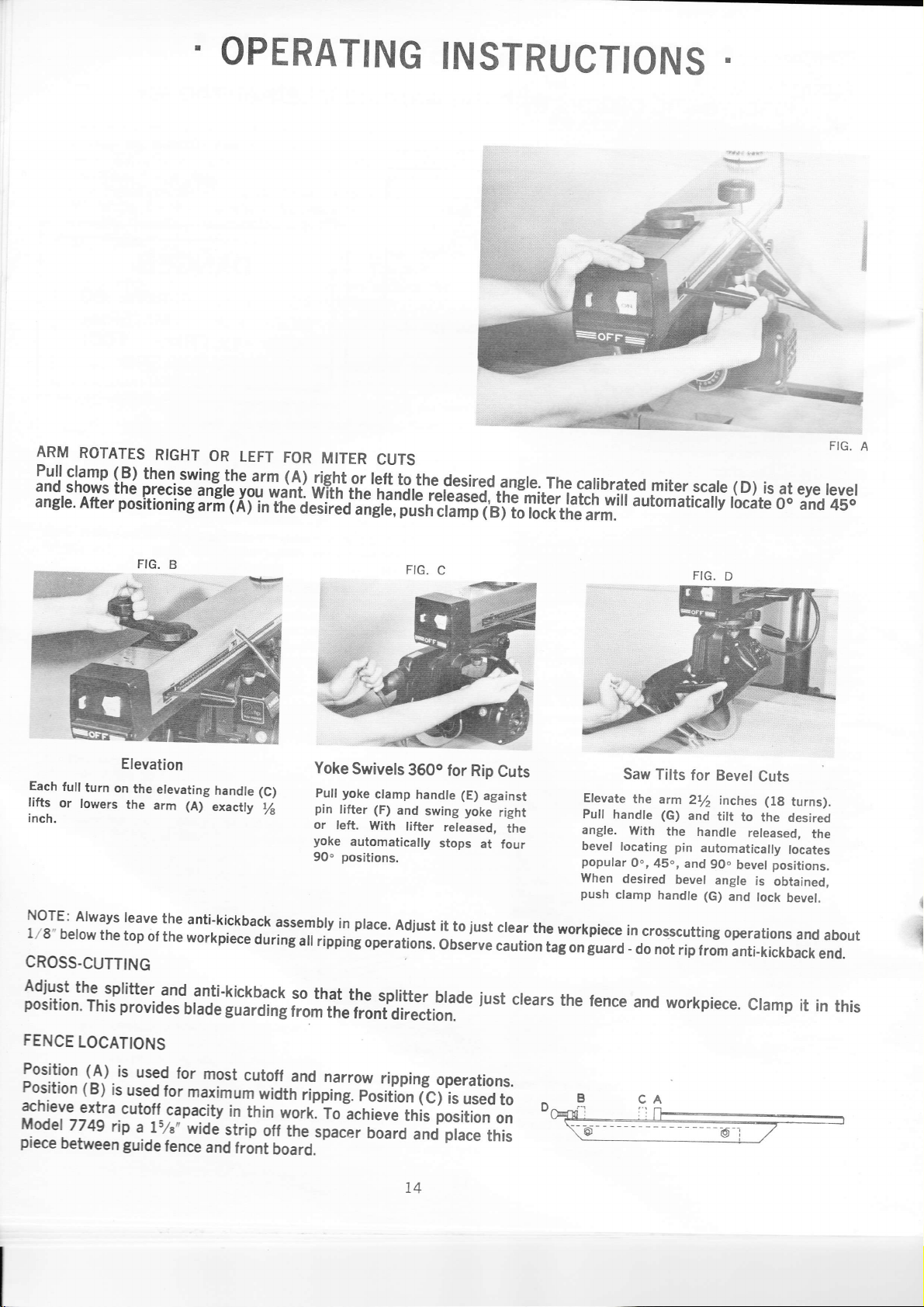

ARM

ROTATES

Pullclamp (B)

and

shows

angre.

After

the

positionine

RIGHT

then

Yilg-lh:,rm

orecise

angtq

arfr'(Ai

OPERATING

OR

LEFT

FOR

MITER

(4).rig.trt.gr

ygg

wa'nt.

wTtrr

ir-ide;i;;a;dE,;;"rr,irliiii

CUTS

left

tii"'iririilrci".i"iiii-tmit";;i;ri-;fiiautomaticary

to

INSTRUCTIONS

the

desired.angle.

el

to rock

The

the

catibrated

arm.

miterscate.(D)

I

rocate

is

at

0o

eye

and

FIG'

tevet

45o

A

Elevation

Each

full

turn

on

lifts

or

lowers

the

the

inch.

NoTE:

1'28"

CROSS.CUTTING

Always

below

the

leave

top

elevating

arm (A)

the

anti'kickback

ol

the

workpiece

handle

exacily

(C)

/s

during

Yoke

puil

pin

or

yoke

90"

assembly

all

ripping

Swivels

yoke

ctamp

tifter (F)

left,

With

automatically

positions.

place.

in

Adiust

operations.

3600

and

lifter

handle

swing

released,

stops

it

observe

for

to

l"1il'Jihil#:"J.il1[t'ilt'i:ff[;:ji,x'.?:,i1,]j;,:,;de

FENCE

Position

Position

achieve

i'!o0"1

piece

LOCATIONS

(A)

(B)

is

extra

7749

rip

between

is

used

used

cutotf

a Ls/e'

guide

ror

most

ror

maximum

capacity

wide

lence

and

cutotf

in

thin

strip

front

and

width

worrl

off

tne'space.

board.

narrow

rippine.

to-acrriere

ripping

posifrJ;l'c)IJuseo

board

ttris

and

operations.

po}iion

prace

t4

Rip

(E)

yoke

iust

Cuts

against

right

at

four

crear

caution

iust

to

on

this

the

the

crears

Elevate

Pull

angle.

bevel

popular

When

push

workpiece

guard

tag

on

the

handle

clamp

rence

Saw

Tilts

the

arm

(G)

With

locating

O",45",

desired

handle

in

crosscutting

-

do not

and

for

Bevel

2t/.

inches

and

the

tilt

handle

pin

automatically

and

90.

bevel

angle

(G)

rip

from

and

operations

anti-kickback

workpiece

Cuts

(lg

to

the

released,

positions.

bevel

is

obtained,

lock

cramp

turns).

desired

the

locates

bevel.

and

it

about

end.

in

{

{

this

Page 15

TYPICAL

RADIAL

(SEE

PAGE

CUTS

ARM

14

FOR

WITH

SAW

FIGURES

A,

A

B,

C, D)

ALWAYS

WEAR

ERATION

{1}'

NOTE

WEAR

DUST

IS

MASK

DUSTY.

r.]]lii.i

It$l

GOGGLES.

IF

OP.

Read

Fig.

guide

.tence,

wrth.the

position,

ctamp

handle.

taDte,

against guide

across

tor

Lb

ryooo.

through

return

saw

The

model

geqsor.y

justa.ble

9t- lhe

necessary

tormtng

repetitive

CROSS

A.

Set

Arm

at

0o

latch

Place

cut

bring

behind

cut

cutting

on

in

lock

lence,

lust

saw

Alter

"Roller

stop

miter

securely

the

not

the

wood.

blade

35OlO

is

available

cross

btade peyon9

to

complete

CUT

at right

tEe

column

arm

material

draw

lar

enough

blade

completirie

guide

Head

lor

use

prevent

to

the

the

cut

operations.

angle

mi6i

slot

with

on

saw

to

comoletelv

fCnce.

Stop"

as

an

position

wh'en

to

the

liiii.

at Oo

ai

wori

blade

sever

cui.

---'

-

ac-

ad_

motion

oer.

Pull

arm

desired

miter.

and

right

clamp

tion

same

clamp

angle

latch

locates

hand

handle

as cross cut.

MITER

handle

shown

on miter

the

angles

to lock.the

adtohatically.

IMPORTANT:

and

popular

arm.

swins into

scaE.

The

lelt

hand

push

Cutfing

ac-

Check

This

position.

RIP

cut

desired,

against

guard

assembly

cut, hold

back

leed

kickback

Lower

operation

machine

on infeed

to

hold

materialfirmly

against

material

device is

Guard

PLOUGH

is

done

Lower

then

guide.

lrom

with

dado

lock

arm. Be

side, lower

material.

down

Feed

side

located.

precautions

dado

head

for

carriase

surE

anti-kickbacli

When

on

evenly.

on

which

page

on

head

Oe*tr ot

sCuretv

to

adiusl

startins

table