Pressure Washer

Operation Manual

for model WD1600E

Part No. D28921 Rev. 0 3/17/03

IMPORTANT

Please make certain that the person who is to use this equipment

carefully reads and understands these instructions before operating.

Record All Information

for future reference:

Purchase Date:

Model #:

Serial #:

Questions? 1-800-888-2468

Learn more about your pressure

washer and register on line at

www

.devap.

com

2- ENG

D28921

1.0 SAFETY AND OPERATION RULES

INDEX

1.0 SAFETY AND OPERATION RULES . page 2

2.0 SAFETY FEATURES . . . . . . . . . . . . page 8

3.0 INSTALLATION . . . . . . . . . . . . . . . . page 9

3.1 HIGH PRESSURE HOSE . . . . . page 9

3.2 WATER CONNECTION . . . . . . . page 9

3.3 POWER SUPPLY

CONNECTION . . . . . . . . . . . . . page 9

4.0 OPERATING INSTRUCTIONS . . . . page 10

4.1 START-UP PROCEDURE . . . . page 10

4.2 HIGH PRESSURE/

LOW PRESSURE . . . . . . . . . . page 11

4.3 ADJUSTABLE SPRAY

NOZZLE . . . . . . . . . . . . . . . . page 12

4.4 HIGH PRESSURE/

TURBO SPRAY . . . . . . . . . . . page 12

4.5 USE OF CHEMICAL . . . . . . . . page 13

4.6 CLEANING TECHNIQUES . . . page 13

4.7 END OF OPERATION . . . . . . . page 14

5.0 USER MAINTENANCE . . . . . . . . . page 14

5.1 CONNECTIONS . . . . . . . . . . . page 14

5.2 NOZZLE . . . . . . . . . . . . . . . . . page 14

5.3 LUBRICATION . . . . . . . . . . . . page 15

5.4 WATER SCREEN . . . . . . . . . . page 15

5.5 COOLING SYSTEM . . . . . . . . page 15

6.0 MOVING AND STORAGE

INSTRUCTIONS . . . . . . . . . . . . . . page 15

6.1 AFTER EXTENDED STORAGE page 15

7.0 TROUBLESHOOTING . . . . . . . . . page 16

8.0 REPLACEMENT PARTS AND

ACCESSORIES . . . . . . . . . . . . . . page 18

9.0 TECHNICAL DATA . . . . . . . . . . . . page 18

Indicates an imminently

hazardous situation which,

if not avoided, will

result in death or

serious injury.

Indicates a potentially

hazardous situation which,

if not avoided, could result in death or

serious injury.

Indicates a potentially

hazardous situation which, if

not avoided, may

result in minor or

moderate injury.

Used without the safety alert

symbol indicates a

potentially hazardous situation which, if not

avoided, may result in pr

operty damage.

This manual contains information that is important for you to know and understand. This

information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the symbols below. Please

read the manual and pay attention to these symbols.

Read Operation Manual. Do not operate equipment until you have

read Operation Manual for Safety, Assembly, Operation, and Mainte-

nance Instructions.

3- ENG

D28921

• Water spray directed at electrical outlets or

switches, or objects connected to an electrical

circuit, could result in a fatal electrical shock.

• Unplug any electrically operated product before

attempting to clean it. Direct spray away from

electric outlets and switches.

• This product is powered by electricity. It contains

and sprays water and other conductive liquids.

Improper operation could result in electrocution.

• The Ground Fault Circuit Interrupter (GFCI) will

not function properly unless connected to a

fully grounded electrical circuit!

• Extension cords can lead to electrical shock.

• Always connect cordset to a properly

grounded and polarized electrical circuit. Your

cordset is equipped with a Gr

ound Fault Circuit

Interrupter (GFCI) for your personal

protection.

• Do not touch plug or outlet with wet hands

• If damaged, the entire cordset assembly must be

replaced by an authorized service center. Refer

to Grounding Instructions.

• Do not use with extension cords.

RISK OF

ELECTRICAL SHOCK

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Some cleaning fluids contain substances which

could cause injury to skin, eyes, or lungs.

• Use only cleaning fluids specifically recom-

mended for high pressure washers. Follow

manufacturers recommendations. Do not use

chlorine bleach or any other corrosive

compound.

RISK OF EXPLOSION OR FIRE

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

Do not use acids, gasoline, kerosene, or any other

flammable materials in this product. Use only

household detergents, cleaners, and degreasers

recommended for use in Pressure Washers. Work

in a well ventilated area.

Use of acids, unapproved chemicals, or flammable

solvents with this product could cause injury or

death.

Restricting any of the pressure washer

ventilation openings will cause serious

overheating and could cause fire.

Never place objects against or on top of

pressure washer. Operate pressure washer in

an open area at least 12 inches away from any

wall or obstruction that would restrict the flow of

fresh air to the ventilation openings.

RISK TO BREATHING

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

4- ENG

D28921

• Your washer operates at fluid pressures and

velocities high enough to penetrate human and

animal flesh, which could result in amputation or

other serious injury. Leaks caused by loose fittings

or worn or damaged hoses can result in injection

injuries. DO NOT TREAT FLUID INJECTION AS A

SIMPLE CUT! See a physician immediately!

RISK TO FLUID INJECTION

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Injuries can result if system pressure is not

reduced before attempting maintenance or

disassembly.

• To relieve system pressure, place on/off switch in

off position, turn off water supply, and pull gun

trigger until water stops flowing.

• Use only hose and high pressure accessories

rated for pressure higher than your pressure

washer's p.s.i.

• Never place hands in front of nozzle.

• Do not direct discharge stream at persons or

animals.

• Make sure hose and fittings are tightened and in

good condition. Never hold onto the hose or

fittings during operation.

• Do not operate pressure washer with worn or a

braided hose.

• Never attach or remove wand or hose fittings

while system is pressurized.

RISK OF

CHEMICAL

BURN

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Do not use acids, gasoline, kerosene, or any

other flammable materials in this product. Use

only household detergents, cleaners and

degreasers recommended for use in pressure

washers.

• Wear protective clothing to protect eyes and

skin from contact with sprayed materials.

• Use of acids, toxic or corrosive chemicals,

poisons, insecticides, or any kind of flammable solvent with this product could result in

serious injury or death.

• Unsafe operation of your pressure washer

could lead to serious injury or death to you or

others.

• Do not use chlorine bleach or any other

corrosive compound.

• Become familiar with the operation and controls of the pressure washer.

• Keep operating area clear of all persons,

pets, and obstacles.

• Do not operate the product when fatigued or

under the influence of alcohol or drugs. Stay

alert at all times.

• Never defeat the safety features of this product.

• Never leave wand unattended while unit is

running.

• Know how to stop product and bleed

pressure quickly.

RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN

HOW TO PREVENT IT

DANGER

5- ENG

D28921

• Reactive force of spray will cause gun/wand to

move, and could cause the operator to slip or

fall, or misdirect the spray. Improper control of

gun/wand can result in injuries to self and

others.

• Do not overreach or stand on an unstable

support. Grip gun/wand firmly with both

hands. Expect the gun to kick when triggered.

• The spray gun/wand is a powerful cleaning

tool that could look like a toy to a child.

• Keep children away from the pressure

washer at all times.

• Unsafe operation of your pressure washer

could lead to serious injury or death to you or

others.

• Avoid accidental starts. Move switch on unit to

"OFF" position before connecting or

disconnecting cord to electrical outlets.

• Never carry your pressure washer by the cord.

Do not pull on the cord to disconnect from the

outlet.

• To prevent damage, the cord should not be

crushed, placed next to sharp objects or near a

heat source.

• Disconnect power plug from the outlet when not

in use and prior to the detaching of the high

pressure hose.

• Never tie knots or kink the high pressure hose as

damage could result.

• Prior to starting the pressure washer in cold

weather, be sure ice has not formed in any part

of the equipment.

• To minimize the amount of water getting into the

pressure washer, the unit should be placed as far

as possible from the cleaning site during

operation.

• Pressure washer pump contains moving parts.

Contact with moving parts can cause serious

injury.

• Never operate machine with pump guard

removed.

• Do not operate machine with missing,

broken, or unauthorized parts.

• Contact with hot surfaces could result in serious burn.

• During operation, touch only the control

surfaces of the pressure washer. Keep children

away from the pressure washer at all times.

They may not be able to recognize the hazards

of this product.

RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK OF HOT

SURFACES

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

DANGER

6- ENG

D28921

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the risk of electric shock. This product is equipped with

a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and grounded in accordance with all local codes

and ordinances.

Improper connection of the equipment-grounding conductor can result in a

risk of electrocution. Check with a qualified electrician or service person if

you are in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the product - if it will not fit the outlet installed by a qualified electrician. Do

not use any type of adapter with this product.

DANGER

The powerful spray from your pressure washer is capable of causing damage

to surfaces such as wood, glass, automobile paint, auto striping and trim, and

delicate objects such as flowers and shrubs. Before spraying, check the item to be cleaned to

assure yourself that it is strong enough to resist damage from the force of the spray. Avoid the

use of the concentrated spray stream except for very strong surfaces like concrete and steel.

SAVE THESE INSTRUCTIONS

• High velocity fluid spray can cause objects to

break, propelling particles at high speed.

• Light or unsecured objects can become

hazardous projectiles.

RISK OF INJURY FROM SPRAY

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Always wear ANSI approved Z87 safety

glasses.Wear protective clothing to protect

against accidental spraying.

• Never point wand at, or spray people or

animals.

• Always secure trigger lock when wand is not in

service to prevent accidental operation.

• Never permanently secure trigger in pull back

(open) position.

7- ENG

D28921

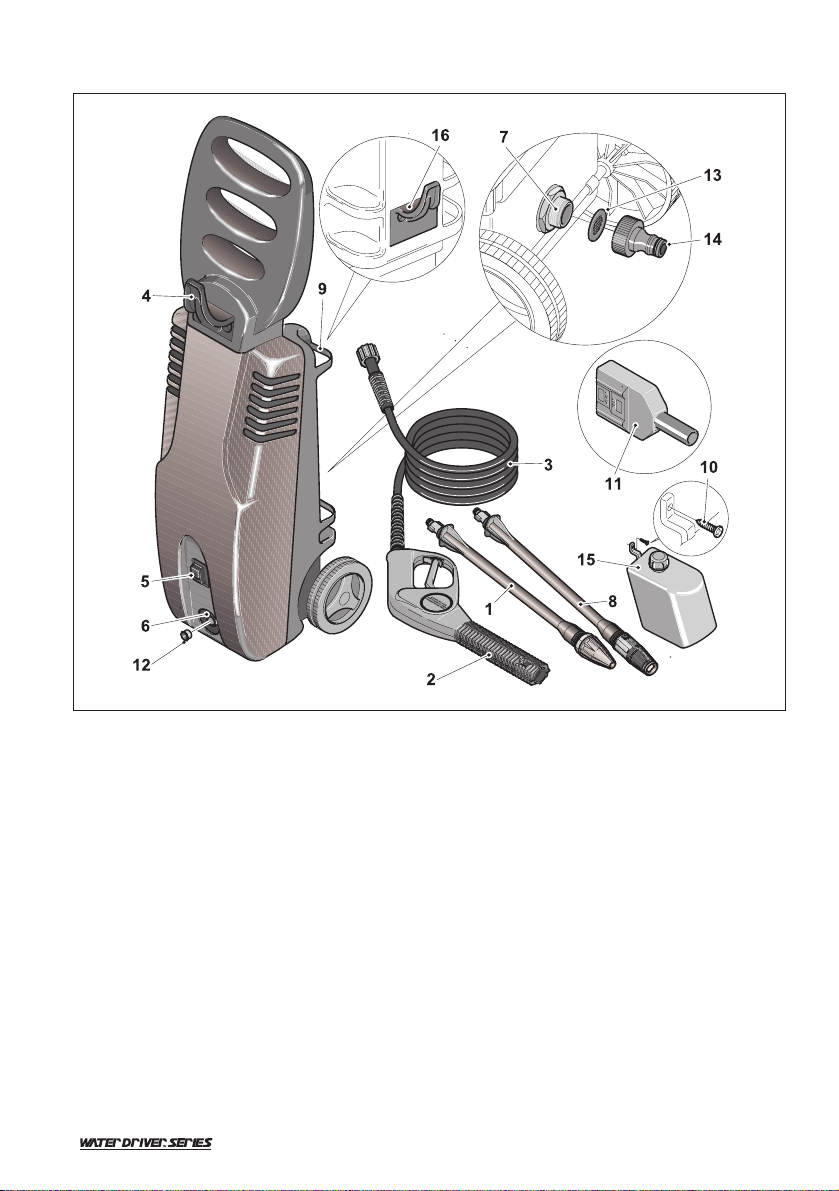

PARTS DRAWING

PARTS LIST

1 Wand with Rotary Nozzle Head

2 Spray Gun

3 High-Pressure Hose

4 Holder For High-Pressure Hose

5 ON/OFF Switch

6 High-Pressure Hose Connector

7 Threaded Water Inlet

8 Wand with Variable Nozzle Head

9 Holder for Accessories

10 Screw (Chemical Solution Reservoir)

11 Electrical GFCI Plug

12 Water Plug

13 Screen Filter

14 Garden Hose Inlet Nipple with Quick Connector

15 Chemical Solution Reservoir

16 Holder for Power Cable

8- ENG

D28921

2.0 SAFETY FEATURES

The pressure washer is equipped with a stop device which will sense when the trigger on the gun

is released. It will open the power circuit to the motor and cause the pressure washer to stop.

The pressure washer is also equipped with a main power ON/OFF switch

located on the unit. It should always be moved to the off position when the

pressure washer is not being used to prevent possible injury or damage.

MOTOR OVERLOAD

The electric motor in this pressure washer is equipped with an overload protection device which

will automatically shut off the motor in the event the motor draws excessive current or overheats.

The device will automatically reset itself and resume normal operation after a short period of time.

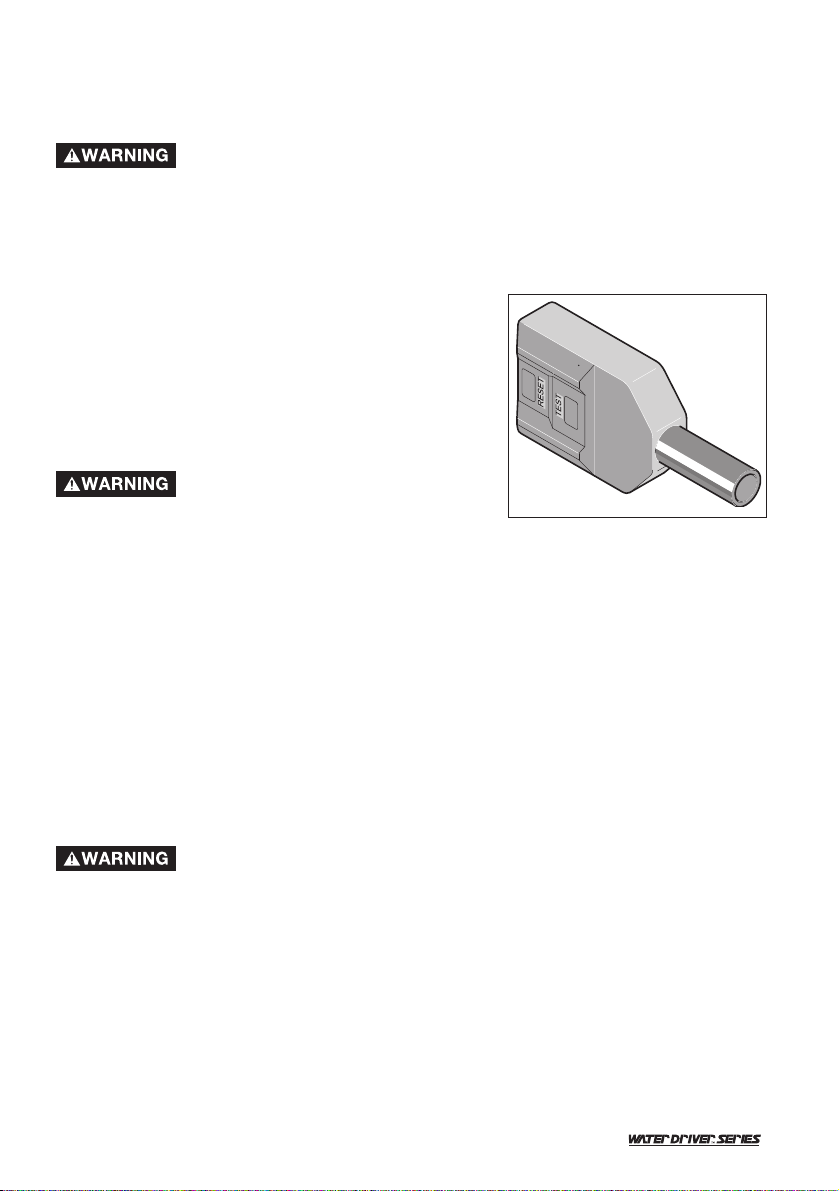

GROUND-FAULT CIRCUIT-INTERRUPTER PROTECTION

This pressure washer is provided with a ground-fault circuitinterrupter (GFCI) built into the plug of the power supply cord.

This device provides additional protection from the risk of

electric shock. Should replacement of the plug or cord

become necessary, use only identical replacement parts that

include GFCI protection.

EXTENSION CORDS

extension cords are not recommended

unless they are plugged into a groundfault circuit-interrupter found in circuit boxes or protected

receptacles.

Use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole cord

connectors that accept the plug from the product.

Use only extension cords that are intended for outdoor use. These extension cords are identified

by a marking “Acceptable for use with outdoor appliances; store indoors while not in use”.

Use only extension cords having an electrical rating higher than the rating of the product.

Do not use damaged extension cords. Examine extension cord before using and replace if

damaged.

Do not abuse extension cord and do not yank on any cord to disconnect. Keep cord away from

heat and sharp edges. Always disconnect the extension cord from the receptacle before

disconnecting the product from the extension cord.

When using an extension cord, observe the specification below:

Cable Length Wire Gauge

Up to 50 ft. 14 AWG

50 to 100 ft. 12 AWG

To reduce the risk of electrocution, keep all connections dry and off the

ground. Do not touch plug with wet hands.

9- ENG

D28921

3.3 POWER SUPPLY CONNECTION

The pressure washer is factory-equipped with an electrical cord and a Ground Fault Circuit

Interrupter (GFCI) power plug.

This cord should only be connected to an electrical outlet installed in accordance with local safety

regulations.

NOTE: The power supply must be 120v, 60hz and a minimum 15 amp circuit.

Test GFCI before each use. DO NOT use pressure washer if test below fails.

GFCI Test Procedures:

1. Plug GFCI into power receptacle

2. Press reset button

3. Press test button.

4. Press reset button again for use.

NOTE: The GFCI must be reset each time the pressure washer is connected to an electrical outlet.

Reset by simply pushing the reset button on the GFCI power plug.

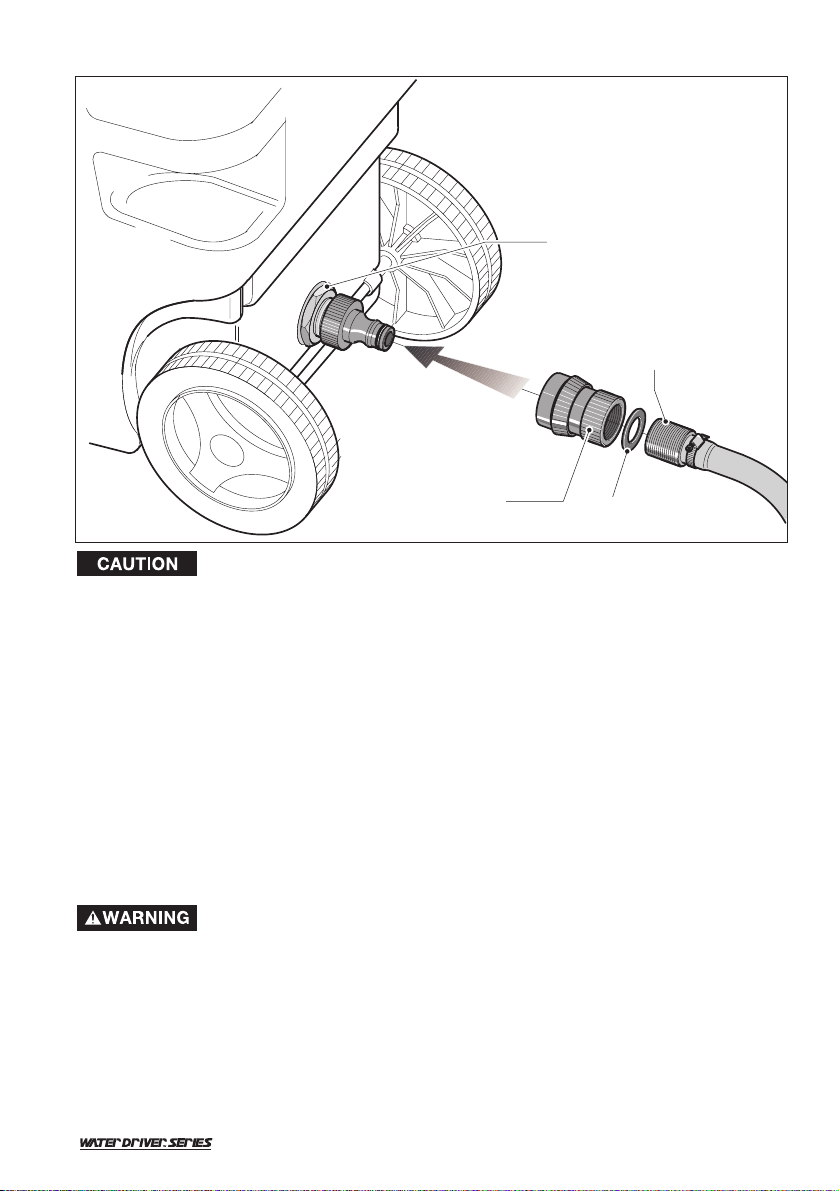

WATER CONNECTION

Proper water connection.

3.0 INSTALLATION

3.1 HIGH PRESSURE HOSE

Remove and discard the water plug (12 parts list) before attaching the high pressure hose by

carefully inserting the fitting with the o-ring into the high pressure outlet and tighten the threaded

nut by hand.

3.2 WATER CONNECTION

Before connecting, run water through the garden hose (not supplied) to flush out any foreign

matter. Attach garden hose to the pressure washer water inlet connection.

Fig. 1

Machine Inlet

Quick Connector

Garden Hose

Gasket

10- ENG

D28921

A. Connect only to properly grounded outlet. Do not remove grounding pin.

B. Inspect cord before using. Do not use if cord is damaged.

C. Keep all connections dry and off the ground.

D. Do not touch plug with wet hands.

E. The pressure washer is provided with a ground-fault circuit interrupter built into the power

plug. If replacement of the plug or cord is needed, use only identical replacement parts.

Contact Customer Service for proper replacement parts.

Extension cords are not recommended unless they are plugged into a receptacle protected by a

ground fault circuit interrupter. Any extension cord used should be 14 AWG and no longer than 50

feet to prevent excessive voltage loss. Use only extension cords intended for outdoor use. These

extension cords are identified by a marking “Acceptable for use with outdoor appliances; store

indoors when not in use”.

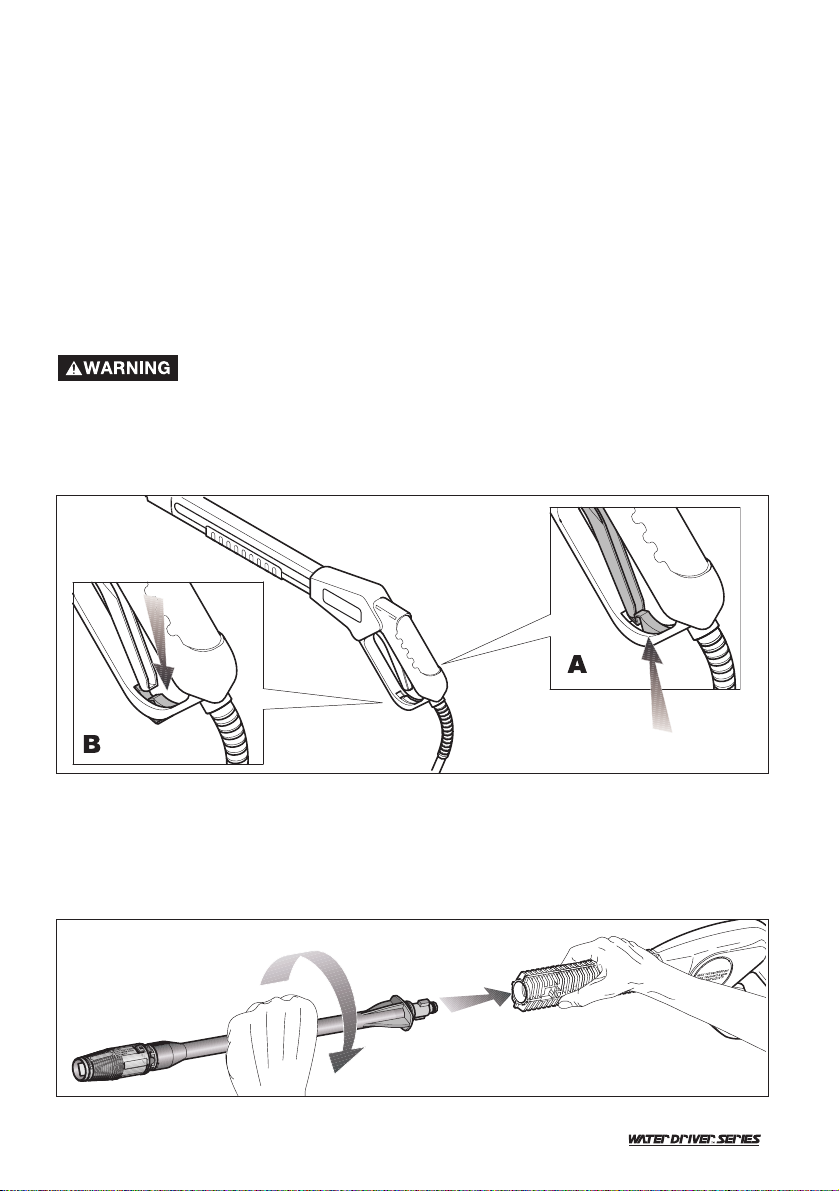

4.1 START-UP PROCEDURE

1. Make sure water supply is connected and turned on.

2. Make sure the unit is plugged in and the GFCI HAS BEEN RESET.

3. Release gun safety if locked.

4.0 OPERATING INSTRUCTIONS

Risk of injection or injury. Do not direct discharge stream at persons.

A. Safety lock “locked”

B. Safety lock “unlocked”

4. To allow air to escape from the hose, squeeze trigger on the gun until there is a steady stream

of water.

5. Remove any dirt or foreign matter from the gun outlet and the male connector of the wand.

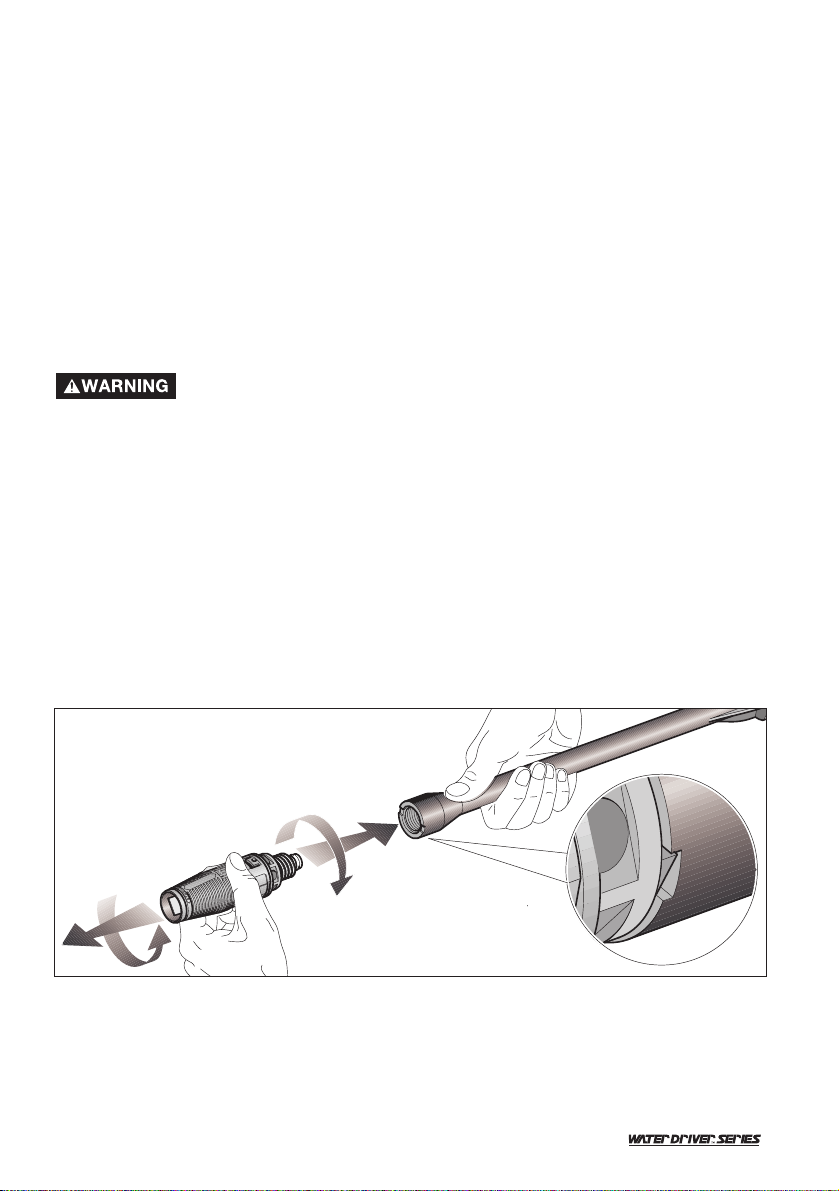

6. Insert the requested wand into the gun’s quick connect coupling by pushing firmly and twisting

wand ¼ of a turn to lock into place.

NOTE: Make sure wand is locked.

11- ENG

D28921

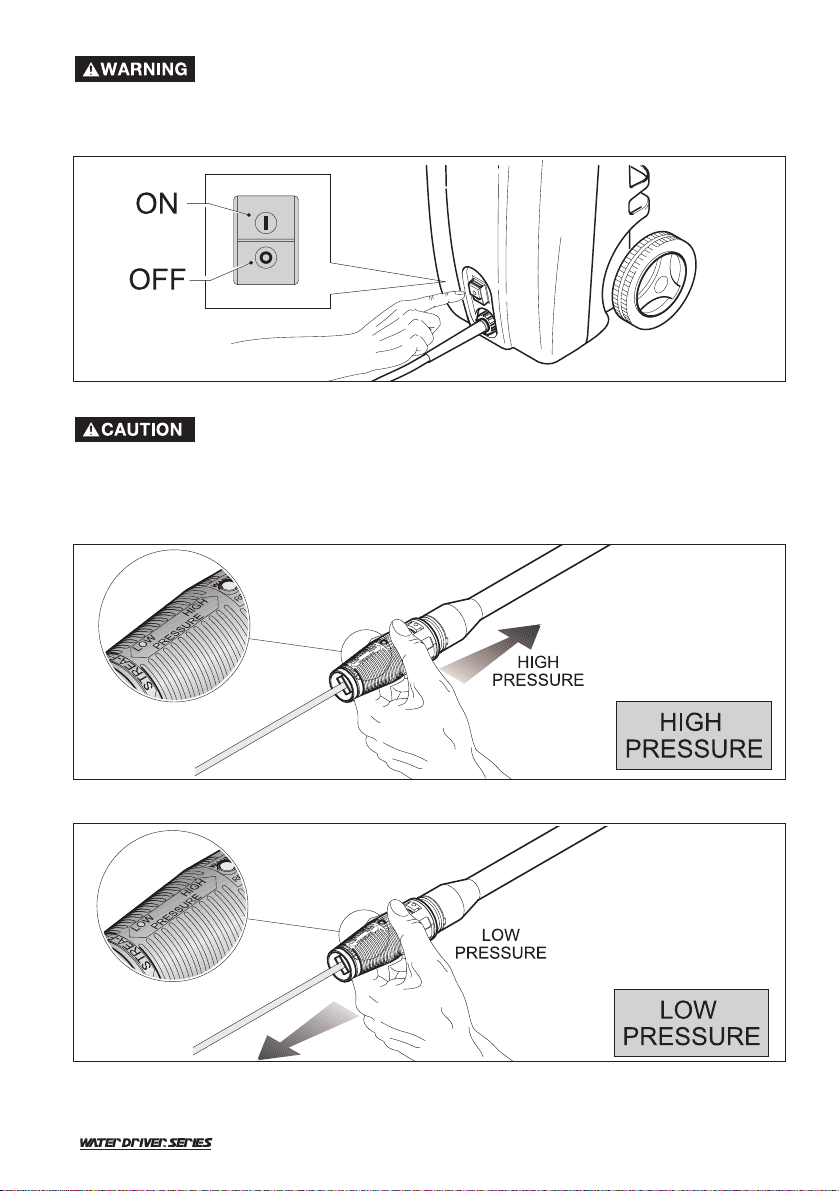

7 Squeeze trigger on the spray gun

8 Press the on/off button to start pressure washer

if the wand is not securely locked into place, it could be ejected under

high pressure when operating the gun, possibly causing injury or damage.

When low-pressure is required, grasp collar and slide collar and nozzle away from the gun.

4.2 HIGH PRESSURE/LOW PRESSURE

Do not move the nozzle to adjust pressure while the trigger is squeezed.

The high pressure nozzle position is intended for cleaning. When high pressure is required, grasp

collar and slide the collar and nozzle toward the gun.

NOTE: Make sure the collar is pulled to the extreme rear position to lock the nozzle in the high

pressure position.

12- ENG

D28921

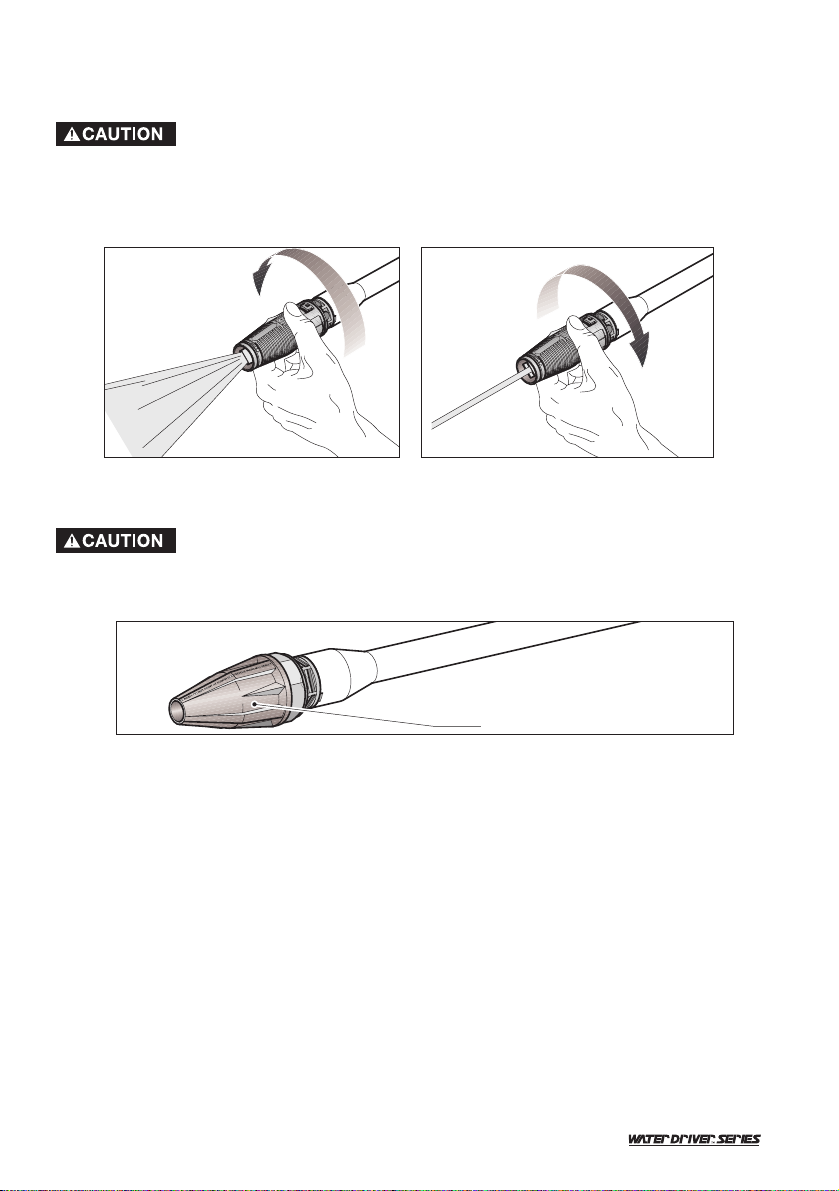

4.3 ADJUSTABLE SPRAY NOZZLE

The adjustable spray nozzle can adjust spray from fan to pencil point in both the high and low

pressure positions. The spray is adjusted by turning the nozzle.

The pencil point spray adjustment is very aggressive. We recommend that

for most cleaning applications, a twenty degree (20°) spray angle be used

to avoid damage to the surface being sprayed.

NOTE: The pressure of the spray on the surface you are cleaning increases as you move the wand

closer to the surface.

To increase angle to a fan spray, turn counterclockwise

To decrease angle to pencil point spray, turn clockwise

4.4 HIGH PRESSURE/TURBO SPRAY

Do not move the nozzle to adjust pressure.

The high pressure rotary nozzle position is intended for maximum cleaning effect. Keep the spray

lance min. 6” to 8” away from the cleaning surface at all times.

Rotary Spray

13- ENG

D28921

4.6 CLEANING TECHNIQUES

When cleaning with the pressure washer, some cleaning tasks can be solved with water alone, but

for most tasks it is advantageous to use a detergent. A detergent ensures a quick soaking of the

dirt allowing the high pressure water to penetrate and remove the dirt more effectively.

The low pressure position provides a gentle application of chemicals. This position is also

recommended to rinse a surface after wax application or for other applications which require the

low pressure of a garden hose. Low pressure is the equivalent of a garden hose set at the lowest

output to properly apply chemical. FOR CHEMICAL APPLICATION, SLIDE COLLAR ACCORDING

TO SECTION 4.2.

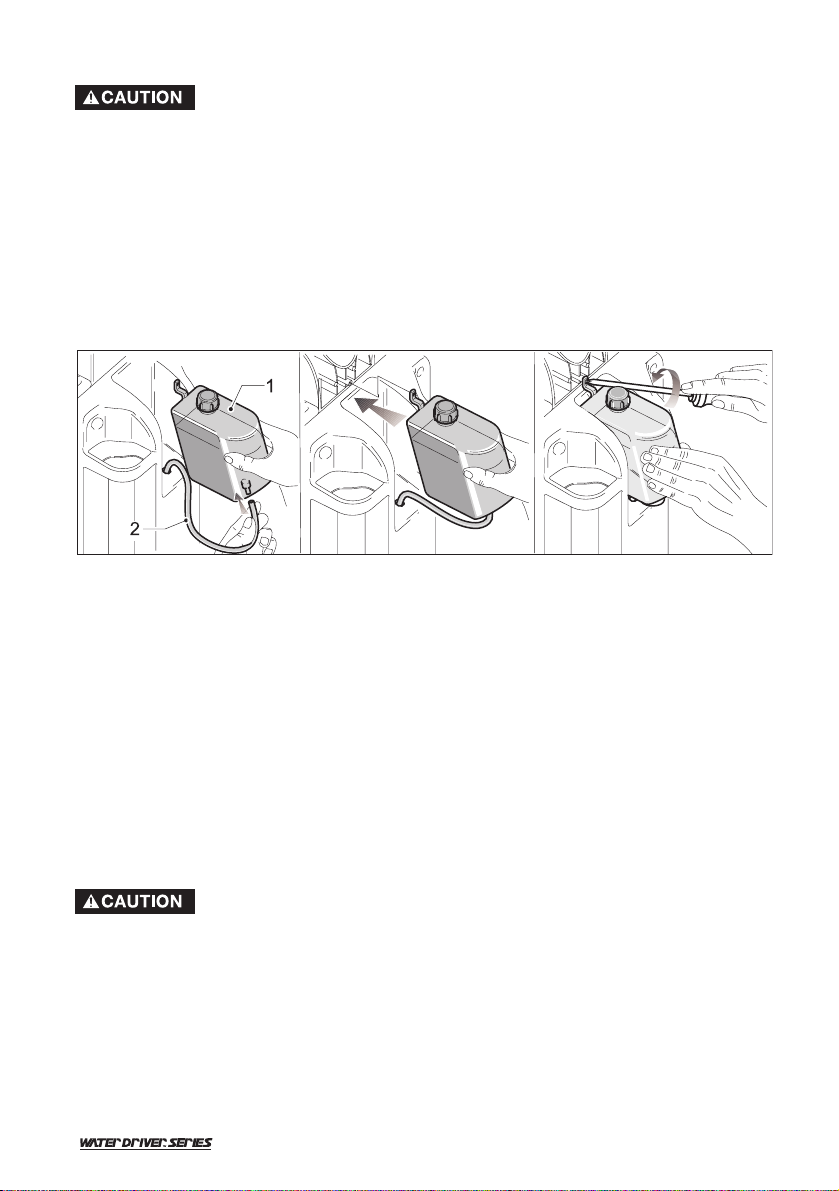

4.5 USE OF CLEANING CHEMICALS

only use cleaning chemicals recommended for pressure washers.

1 Insert the relevant suction tube (2) beneath the chemical solution reservoir.

2 Fill the reservoir (1) with suitable cleaning solution.

3 Insert the chemical solution reservoir into the relative compartment in the rear part of the

machine

4 Secure the chemical solution reservoir with the screw provided

5 Move the adjustable nozzle forward to the low pressure position by sliding collar toward the

nozzle. The chemical will automatically be mixed with the water and discharged through the

nozzle.

NOTE: When the adjustable nozzle is moved to the high pressure position, chemical will not be

discharged.

APPLICATION OF SOAP DEGREASER

1. Apply the solution to a DRY work surface. NOTE: WETTING THE SURFACE FIRST IS NOT

RECOMMENDED, AS IT DILUTES THE DETERGENT AND REDUCES ITS CLEANING ABILITY.

On a vertical surface, apply horizontally from side to side starting from the bottom to avoid

streaking.

2. Allow chemical to remain on the surface for a short time before rinsing

Damage may occur to painted surface if chemical is allowed to dry on the

surface. Wash and rinse a small section at a time. Avoid working on hot

surfaces or in direct sunlight.

3. Rinse with clean water under high pressure. On a vertical surface, first rinse from the bottom

up, then rinse from the top down. Hold nozzle 6 to 8 inches from the work surface at a 45°

angle using the flat spray as a peeling tool rather than a scrub brush.

NOTE: Insure that the chemical injection system is completely clean prior to switching from one

chemical to another.

14- ENG

D28921

APPLICATION OF LIQUID VEHICLE WAX

1. Immediately after cleaning, apply Pressure Washer Liquid Vehicle Wax using low pressure.

Pour wax into chemical solution reservoir.

2. Apply the wax sparingly in an even layer. Apply to wet surfaces from the bottom up for even

distribution and to avoid streaking.

3. Rinse off the surplus wax. NOTE – IF SURPLUS WAX IS NOT REMOVED, A HAZY FINISH

MAY RESULT.

4. Wipe dry to reduce water spotting.

4.7 END OF OPERATION

When you have completed use of the chemical injection system, remove tube from container,

continue to run in low pressure position and flush clean water through the chemical tank until it is

thoroughly cleaned. NOTE: Failure to clean properly will cause the injection system to become

clogged and inoperable.

l Stop the unit by pressing the ON/OFF button to the "OFF" position.

l Disconnect electrical plug.

l Turn off water and depressurize unit by squeezing trigger.

Turn off water supply and squeeze trigger to depressurize the unit. Failure

to do so could result in personal injury due to discharge of high pressure

water.

l Disconnect the high pressure discharge hose and the water inlet hose.

5.2 NOZZLE

The high pressure/low pressure adjustment of the nozzle should be lubricated regularly.

Clogging of the nozzle causes the pump pressure to be too high and cleaning is immediately

required.

1. Separate the nozzle from the wand

2. Clear the nozzle.

5.0 MAINTENANCE

5.1 CONNECTIONS

Connections on Pressure Washer hoses, gun and spray wand should be cleaned regularly and

lubricated to prevent leakage and damage to the o-rings.

3. Flush the nozzle backwards with water

4. Reconnect the nozzle to the wand

NOTE: Completely screw the nozzles on the wand up to the complete lock. (see picture)

Restart the pressure washer and depress the trigger on the spray gun. If the pressure is still too

high, repeat above items 1-4.

15- ENG

D28921

6.0 MOVING AND STORAGE INSTRUCTIONS

Always store your pressure washer in a location where the temperature will

not fall below 32°F. The pump in this machine is susceptible to permanent

damage if frozen. FREEZE DAMAGE IS NOT COVERED BY THE WARRANTY.

If you must store your pressure washer in a location where the temperature is below 32°F, you can

minimize the chance of damage to your machine by utilizing the following procedure:

1. Stop the pressure washer and detach supply hose and high pressure hose.

2. Squeeze the trigger of the discharge gun to drain all water from the wand and hose.

3. Restart the pressure washer and let it run briefly (about 5 seconds) until water no longer

discharges from the high pressure outlet.

6.1 AFTER EXTENDED STORAGE

Scale deposits may form in the pump when it is not used for some time.

This causes the motor to run stiff or it may not start up at all.

Remove scale deposits from the piping.

l Connect machine to water supply and rinse thoroughly with water. Do not plug unit into

electrical outlet.

To avoid electrical overloading turn the motor shaft by hand.

5.4 WATER SCREEN

The pressure washer is equipped with a water inlet screen to protect the pump.

If the screen is not kept clean, the flow of water to the pressure washer will

be restricted and the pump may be damaged.

5.3 LUBRICATION

The pressure washer is designed with a permanent lubrication system. Conventional oil check and

oil changes are not necessary.

NOTE: IN CASE OF OIL LEAKAGE, CONTACT CUSTOMER SERVICE DEPARTMENT

CONCERNING REPAIR. A SMALL AMOUNT OF OIL LEAKAGE IS NORMAL.

l To clean inner water screen, remove quick connect and remove the filter screen from the

pump inlet. (see page 4, item 13)

l Backflush screen to clean

l Replace screen and quick connect immediately to prevent any foreign matter from entering the

pump.

Do not damage the screen while removing or cleaning. Any foreign

particles entering the pump may damage the pump.

5.5 COOLING SYSTEM

The air vents, located in and around the pressure washer, must be kept clean and free of any

obstructions to ensure proper air cooling of the motor during operation.

prevent water from penetrating the vents of the pressure washer to

minimize the risk of damage to the machine and to reduce the risk of shock

to the operator.

16- ENG

D28921

7.0 TROUBLESHOOTING

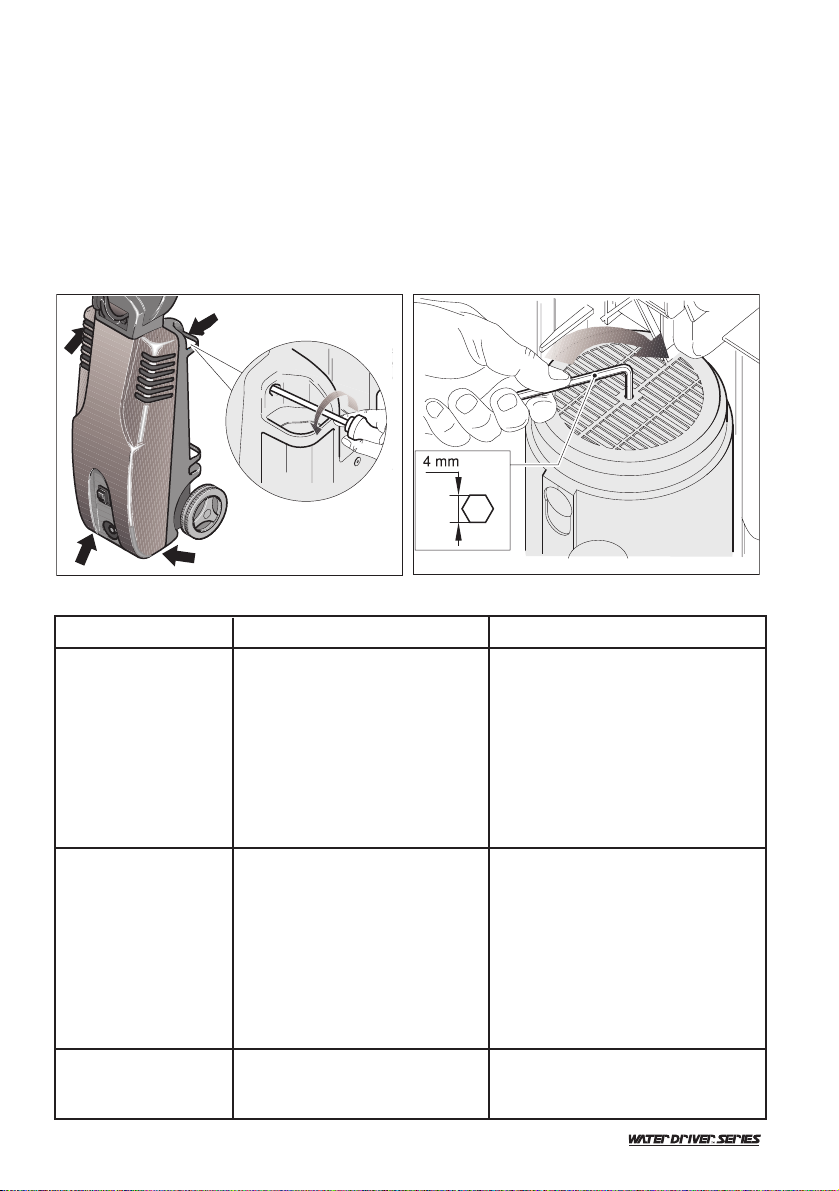

Proceed as follows:

l Disconnect unit from electrical outlet.

l Remove cover (Fig. A)

l Insert a suitable hexagon socket wrench (size 4 mm.) through the middle opening in the fan

cover and into the hexagon socket in the motor shaft.

l Turn the motor shaft clockwise by hand several times (Fig. B)

l Remove hexagon socket wrench

l Install cover

l Plug unit into electrical outlet

l Switch on machine with spray gun open.

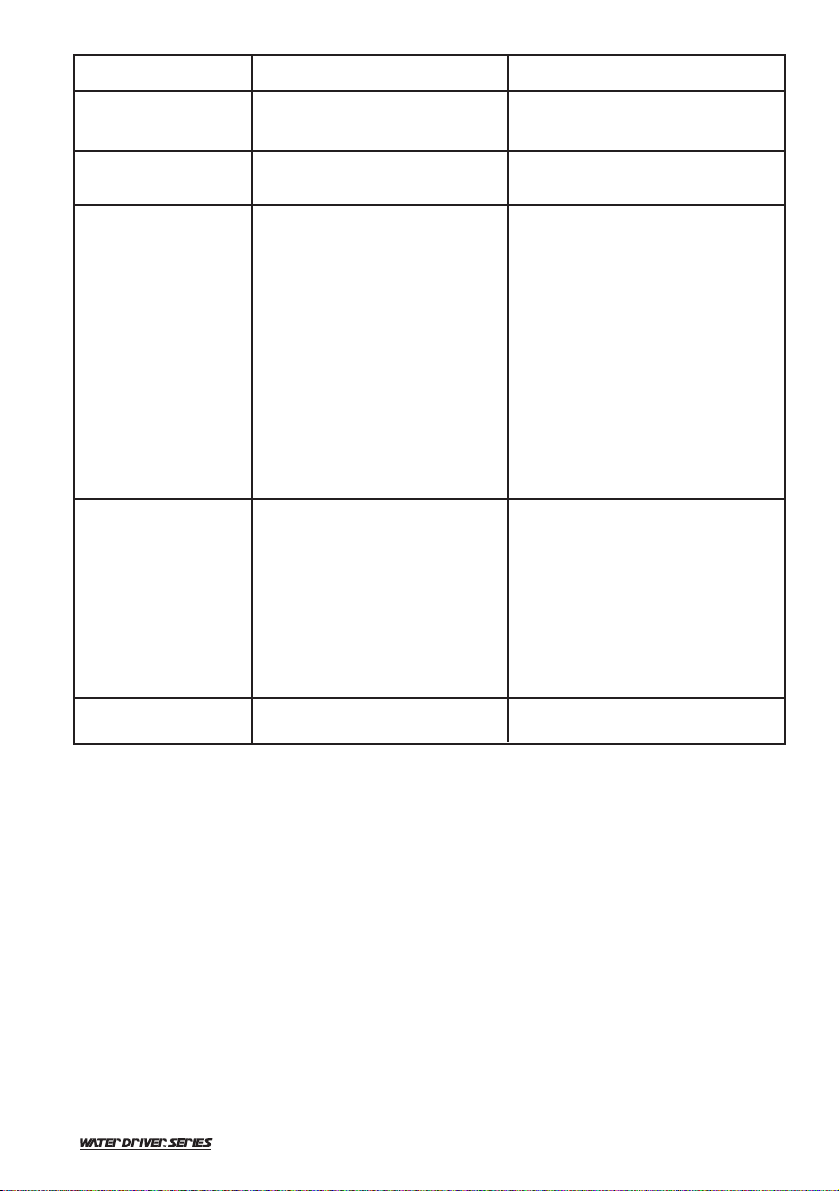

Motor will not start or

stops while operating

GFCI tripped or not reset Turn off unit. Press GFCI reset

button firmly after it has been

connected to the electrical supply

Circuit breaker tripped or fuse

blown in circuit fuse box

Disconnect all other loads on the

same circuit and reset circuit breaker

or replace fuse

Loose or disconnected plug Reconnect plug

Tripped pressure washer

circuit breaker

Allow to cool and restart unit

Circuit breaker trips or

fuse blown in fuse box

Circuit Overload Check that the circuit is rated 15

amps or greater. Disconnect all

loads on the circuit

Extension cord too long or

wire size too small

Use proper extension cord as

recommended in Operator's Manual

Nozzle partially blocked

Clean nozzle as instructed in

Section 5.2

Excessive pressure

Reduce pressure by using pressure

adjustment knob

GFCI trips repeatedly

Incorrect voltage See Section 3.3

Internal short Call Customer Service Department

PROBLEM

POSSIBLE CAUSE

CORRECTION

Fig. A

Fig. b

17- ENG

D28921

Water or oil leaking

from bottom of pump

A small amount of leakage is

normal

If excessive leaking occurs call

Customer Service Department

Bypass valve not operating

properly

Call Customer Service Department

Faucet closed

Open faucet

Unit has been stored in freezing

temperatures

Thaw out unit completely including

hose, gun, and wand

No intake of chemicals

Injection tube not securely

inserted into pressure washer

Push firmly into machine

Tube cracked or split Replace tubing

Pressure increases

when gun is closed

Motor running but

pump not building

maximum pressure or

has irregular pressure

Water inlet screen clogged

Clean screen. See section 5.4

Air in pump

Let pressure washer run with gun

open and wand removed until

steady stream of water is released.

Adjustable pressure knob not

set to maximum position

Set to maximum position. See

Section 4.2

Suction or discharge valves

clogged or worn out

Call Customer Service Department

By-pass valve not operating

effectively

Call Customer Service Department

Wrong Nozzle setting Switch nozzle to low pressure

Injection tube strainer clogged Clean strainer

Dried chemicals in injector Dissolve by running warm water

through the injection tube

Gun safety lock engaged Release safety lock

Trigger will not move

PROBLEM

POSSIBLE CAUSE

CORRECTION

Nozzle Blocked Clean Nozzle. See Section 5.2

18- ENG

D28921

9.0 TECHNICAL DATA

Pump pressure 1600 psi MAX.

Operation Pressure

Electrical requirement 120V, 13 Amps, 60 Hz

Electrical cord 35 ft.

High Pressure Hose 23 ft.

Flow Rate at 1600 psi 1.6 gpm

Minimum Amperage source 15 amp

Pressure of inlet water 20 - 100 psi

Injection rate 2 - 4%

Inlet Water Cold Tap Water

Nozzle Spray Angle

High Pressure 0 - 60°

Nozzle Spray Angle

Low Pressure 0 - 90°

Turbo Nozzle Spray 30°

Manufacturing Tolerances (+-10%) on stated performances.

8.0 REPLACEMENT PARTS AND ACCESSORIES

THE FOLLOWING LIST OF ACCESSORIES AND REPLACEMENT PARTS ARE AVAILABLE

PLEASE CONTACT CUSTOMER SERVICE FOR MORE INFORMATION 1-800-888-2468

Code

Description

D28936 Detergent Tank

D28937 Detergent Tank Cap

D28939 Handle

D28940 Hubcap

D28941 Wheel

D28942 Locknut

D28943 Hose

D28944 Suction Fliter

D28945 Gun with hose

D28946 Multi-Reg Nozzle

D28947 Rotating Nozzle

D28949 Switch

D28950 Axle

D28921 Manual

19- ENG

D28921

Please Call Us First.

If there are missing or damaged parts,

DO NOT RETURN THIS PRODUCT TO THE STORE.

Our Customer Service Department

is available to help with any problems

and operational questions.

Our toll free number

1-800-888-2468

SEE OUR WEB SITE FOR REPLACEMENT AND OR MISSING PARTS

www.devap.com

20- ENG

D28921

DeVilbiss Air Power Company warrants to the original purchaser who uses the product in a consumer

application (personal, residential or household usage) that all products covered under this warranty are free from

defects in material and workmanship for one year from the date of purchase. All products covered by this limited

warranty which are used in commercial applications (i.e., income producing) are warranted to be free of defects

in material and workmanship for 90 days from the date of original purchase. Products covered under this

warranty include air compressors, air tools, service parts, pressure washers, and generators.

DeVilbiss Air Power Company will repair or replace, at DeVilbiss' option, products or components which have

failed within the warranty period. Service will be scheduled according to the normal work flow and business

hours at the service center location, and the availability of replacement parts. All decisions of DeVilbiss Air

Power Company with regard to this limited warranty shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

RESPONSIBILITY OF ORIGINAL PURCHASER (initial User):

• To process a warranty claim on this product, DO NOT return it to the retailer. The product must be evaluated

by an Authorized Warranty Service Center. For the location of the nearest Authorized Warranty Service Center

call 1-800-888-2468, 24 hours a day, 7 days a week or visit our web site @ devap.com.

• Retain original cash register sales receipt as proof of purchase for warranty work.

• Use reasonable care in the operation and maintenance of the product as described in the Owners Manual(s).

• Deliver or ship the product to the nearest Authorized Warranty Service Center. Freight costs, if any, must be

paid by the purchaser.

• Air compressors with 60 and 80 gallon tanks will be inspected at the site of installation. Contact the nearest

Authorized Warranty Service Center that provides on-site service calls for service call arrangements.

• If the purchaser does not receive satisfactory results from the Authorized Warranty Service Center, the

purchaser should contact DeVilbiss Air Power Company.

THIS WARRANTY DOES NOT COVER:

• Merchandise sold as reconditioned, used as rental equipment, or floor or display models.

• Merchandise that has become damaged or inoperative because of ordinary wear, misuse*, cold, heat, rain,

excessive humidity, freeze damage, use of improper chemicals, negligence, accident, failure to operate the

product in accordance with the instructions provided in the Owners Manual(s) supplied with the product,

improper maintenance, the use of accessories or attachments not recommended by DeVilbiss Air Power

Company, or unauthorized repair or alterations.

* An air compressor that pumps air more than 50% during a one hour period is considered misuse because

the air compressor is undersized for the required air demand.

• Repair and transportation costs of merchandise determined not to be defective.

• Costs associated with assembly, required oil, adjustments or other installation and start-up costs.

• Expendable parts or accessories supplied with the product which are expected to become inoperative or

unusable after a reasonable period of use, including but not limited to sanding disks or pads, saw and shear

blades, grinding stones, springs, chisels, nozzles, o-rings, air jets, washers and similar accessories.

• Merchandise sold by DeVilbiss Air Power Company which has been manufactured by and identified as the

product of another company, such as gasoline engines. The product manufacturer's warranty, if any, will

apply.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT

FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT IS NOT COVERED BY THIS

WARRANTY. Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

• IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE. Some states do

not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

213 Industrial Drive • Jackson, TN 38301-9615

Telephone: 1-800-888-2468

FAX: 1-800-888-9036

LIMITED WARRANTY

Manual de funcionamiento

para el modelo WD1600E

Pieza No. D28921 Rev. 0 3/17/03

Lavadora a presión

IMPORTANTE

Asegúrese de que la persona que va a usar esta herramienta lea

cuidadosamente y comprenda estas instrucciones antes de utilizarla.

Registre toda la información para

referencias futuras:

Fecha de compra:

Modelo N°

N° de serie

¿Consultas? 1-800-888-2468

Para conocer más su lavadora a

presión y registrarla en línea visite:

www.devap.com

22-SP

D28921

1.0 NORMAS OPERATIVAS Y DE SEGURIDAD

ÍNDICE

1.0 NORMAS OPERATIVAS Y DE

SEGURIDAD . . . . . . . . . . . . . . . . . . . pag. 22

2.0 CARACTERÍSTICAS RELATIVAS

A LA SEGURIDAD . . . . . . . . . . . . . . pag. 28

3.0 INSTALACIÓN . . . . . . . . . . . . . . . . . . pag. 29

3.1 MANGUERA DE

ALTA PRESIÓN . . . . . . . . . . . . . pag. 29

3.2 CONEXIÓN DEL AGUA . . . . . . . . pag. 29

3.3 EMPALME DE LA

ALIMENTACIÓN ELÉCTRICA . . . . pag. 29

4.0 INSTRUCCIONES DE USO . . . . . . . . . pag. 30

4.1 PROCEDIMIENTO DE

PUESTA EN MARCHA . . . . . . . . . pag. 30

4.2 CHORRO DE

ALTA PRESIÓN / TURBO . . . . . . pag. 31

4.3 BOQUILLA CHORRO

REGULABLE . . . . . . . . . . . . . . . . pag. 32

4.4 CHORRO DE

ALTA PRESIÓN / TURBO . . . . . . . pag. 32

4.5 USO DE PRODUCTOS

QUÍMICOS . . . . . . . . . . . . . . . . . . pag. 33

4.6 TÉCNICAS DE LIMPIEZA . . . . . . . pag. 33

4.7 FINALIZACIÓN

DE LA OPERACIÓN . . . . . . . . . . . pag. 34

5.0 MANUTENCIÓN USUARIO . . . . . . . . . pag. 34

5.1 CONEXIONES . . . . . . . . . . . . . . . pag. 34

5.2 BOQUILLA . . . . . . . . . . . . . . . . . . pag. 34

5.3 LUBRICACIÓN . . . . . . . . . . . . . . pag. 35

5.4 FILTRO AGUA . . . . . . . . . . . . . . . pag. 35

5.5 SISTEMA DE REFRIGERACIÓN . . pag. 35

6.0 MANIPULACIÓN Y

ALMACENAMIENTO . . . . . . . . . . . . . pag. 35

6.1 DESPUÉS DE UN ALMACENAMIENTO . .

PROLONGADO . . . . . . . . . . . . . . . . . pag. 35

7.0 LOCALIZACIÓN DE LAS

AVERÍAS . . . . . . . . . . . . . . . . . . . . . . pag. 36

8.0 PIEZAS DE REPUESTO Y

ACCESORIOS . . . . . . . . . . . . . . . . . . pag. 38

9.0 DATOS TÉCNICOS . . . . . . . . . . . . . . pag. 38

Indica una situación de

inminente riesgo, la cual, si

no es evitada, causará la muerte o lesiones

serias.

Indica una situación

potencialmente

riesgosa, que si no es evitada, podría resultar

en la muerte o lesiones serias.

Indica una situación

potencialmente

peligrosa, la cual, si no es evitada, podría

resultar en lesiones menores o

moderadas.

Usado sin el símbolo de

seguridad de alerta indica

una situación potencialmente riesgosa la que,

si no es evitada, podría causar daños en la

propiedad.

Este manual contiene importante información para que usted sepa y comprenda. Dicha

información se relaciona con la protección de SU SEGURIDAD Y LA PREVENCIÓN DE

PROBLEMAS AL EQUIPO. Para ayudarlo a reconocer esa información, utilizamos los símbolos

indicados más abajo. Sírvase leer el manual y prestar atención a dichos símbolos.

Lea el Manual de funcionamiento . Para su seguridad, armado,

funcionamiento e instrucciones de mantenimiento, no haga funcionar

el equipo hasta haber leído el Manual de funcionamiento.

23- SP

D28921

RIESGO DE DESCARGA ELÉCTRICA

RIESGO

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

Un chorro de agua dirigido a tomacorrientes, interruptores

eléctricos u objetos conectados a un circuito eléctrico, puede

ocasionar una electrocución fatal.

Este producto está impulsado por electricidad.

Contiene y pulveriza agua y otros líquidos conductivos.

Su operación inadecuada podría ser causa de

electrocución.

El disyuntor diferencial, que protege ante la falta de

conexión a tierra (GFCI), no funcionará adecuadamente a

menos que su conexión eléctrica se encuentre hecha a un

circuito adecuadamente conectado a tierra.

• Los cordones de extensión pueden provocar choques

elécticos.

Conecte siempre el cableado a un circuito

polarizado a tierra. Su cableado viene equipado con

un interruptor difer

encial (GFCI) que protege su

seguridad personal ante la ausencia de conexión

a tierra.

No toquen el enchufe o la toma con las manos

mojadas.

En caso de estar dañado, deberá sustituirse el

conjunto completo del cableado, por medio de un

servicentro autorizado. Refiérase a las instrucciones

de conexión a tierra.

No usar con cordones de extensión.

• Desenchufe cualquier producto eléctrico en

funcionamiento antes de intentar limpiarlo. Dirija el

rociado alejado de salidas eléctricas e interruptores.

• Algunos fluidos para limpieza contienen sustancias que

pueden lesionar la piel, los ojos o los pulmones

.

• Use solamente fluidos para limpieza

específicamente recomendados para lavadoras

a alta presión. Siga las recomendaciones del

fabricante. No usar blanqueador de cloro ni

compuesto corrosivo alguno.

RIESGO DE EXPLOSIÓN O INCENDIO

RIESGO

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

RIESGO DE INHALACIÓN

RIESGO

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

No utilice ácidos, gasolina, querosén o cualquier

otro material inflamable en este producto. Utilice

únicamente detergentes, limpiadores y

desengrasantes recomendados para el uso en

lavadoras a presión. Trabaje en una zona bien

ventilada.

La utilización de ácidos, productos químicos no

aprobados o solventes inflamables en este producto

puede ocasionar lesiones o la muerte.

La restricción a cualquiera de las aberturas de

ventilación de la lavadora a presión, ocasionará un

serio recalentamiento y podría ser causa de incendio.

Jamás coloque objetos apoyados o encima de

la lavadora a presión. Opere la lavadora a

presión en una zona abierta; sepárela - por lo

menos - 30 centímetros (12 pulgadas) de

cualquier pared u obstrucción que pudiese

restringir el flujo del aire fresco a las aberturas

de ventilación.

24-SP

D28921

• Su lavadora opera a presiones de fluido y velocidades

elevadas, capaces de penetrar el tejido humano y

animal; ello podría determinar una amputación u otras

lesiones serias. Las pérdidas causadas por

conexiones flojas o gastadas, o mangueras dañadas

pueden determinar lesiones por inyección. ¡NO

TRATE A LA INYECCIÓN DE FLUIDO COMO A UN

SIMPLE CORTE! ¡Vea a un médico

inmediatamente!

• Jamás coloque su mano delante de la boquilla.

• No dirija el chorro de descarga a personas ni

animales.

• Asegúrese que las mangueras y acoples estén

ajustados y en buenas condiciones. Jamás agarre de

la boquilla o los acoples durante la operación.

• No opere la lavadora a presión con una manguera

gastada o erosionada.

• Jamás conecte o desconecte la varilla rociadora o los

acoplamientos mientras el sistema esté presurizado.

RIESGO DE INYECCIÓN DE FLUIDO

RIESGO

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

•

Para liberar la presión del sistema, coloque el interruptor

on/off en la posición "off", cierre el suministro de agua, y

mantenga apretado el gatillo hasta que el agua deje de

fluir.

• Use solamente boquillas y accesorios para alta presión

clasificados para una presión más elevada que los psi

de su lavadora.

• Si no se reduce la presión antes de intentar el

mantenimiento o el desarmado, ello podría ser causa

de lesiones.

• El uso de ácidos, productos químicos tóxicos o

corrosivos, venenos, insecticidas o cualquier

clase de solventes inflamables con este producto,

puede ocasionar una seria lesión o la muerte.

• No utilice en este producto ácidos, gasolina,

kerosén, o cualquier otro material inflamable.

Utilice únicamente detergentes caseros,

limpiadores y desengrasantes recomendados para

el uso en lavadoras a presión.

Use atuendo de protección adecuado para la

preservación de sus ojos y piel, del contacto con

los materiales rociados.

RIESGO DE QUEMADURA QUÍMICA

RIESGO

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

RIESGO DE OPERACIÓN INSEGURA

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

RIESGO

• No use soluciones cloradas ni cualquier otro

compuesto corrosivo.

• Familiarícese con la operación y controles de la

lavadora a presión.

• Mantenga la zona de operaciones libre de personas,

animales domésticos y obstáculos.

• No opere el producto si está fatigado o bajo la

influencia del alcohol o drogas. Manténgase alerta en

todo momento.

• Jamás desactive los mecanismos de seguridad de

este producto.

• Jamás deje la varilla rociadora desatendida mientras

la unidad esté funcionando.

• Infórmese cómo detener el equipo y rápidamente

purgar la presión.

• La operación insegura de su lavadora a presión

puede ocasionar lesiones serias o la muerte a

usted u otras personas.

25- SP

D28921

• Las bombas de las lavadoras a presión contienen

partes expuestas en movimiento. El contacto con

dichas partes en movimiento puede ocasionar

serias lesiones.

• Jamás opere la máquina sin la protección de la

bomba.

• No opere la máquina con partes faltantes, rotas

o desautorizadas.

RIESGO DE OPERACIÓN INSEGURA

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

RIESGO

• Eviten encendidos accidentales. Coloquen el

interruptor en OFF antes de conectar o

desconectar el cable eléctrico a una toma.

• No utilicen el cable para mover la

hidrolimpiadora de alta presión. No tirar del cable

para desconectar el equipo de la toma.

• Con el fin de evitar daños, el cable no debe ser

aplastado, no debe ser colocado cerca de

objetos cortantes ni de fuentes de calor.

• Desconecten el enchufe eléctrico de la toma

cuando no está en uso e, igualmente, antes de

desconectar la manguera de alta presión.

• Hay que utilizar exclusivamente las mangueras y

los lanzadores de la hidrolimpiadora de alta

presión.

• En las estaciones frías, antes de poner en

funcionamiento la hidrolimpiadora, controlen que

no se haya formado hielo en la misma.

• Para reducir al máximo la cantidad de agua que

podría entrar en la hidrolimpiadora de alta

presión, durante el uso, colocarla lo más lejos

posible de la zona que debe ser limpiada.

• Párese sobre una superficie estable y sostenga

firmemente el mango de la pistola/varilla

rociadora con ambas manos. Prevea el retroceso

de la pistola cuando apriete el gatillo.

• En todo momento, mantenga alejados a los

niños de la lavadora a presión.

• La operación insegura de su lavadora a presión

puede ocasionar lesiones serias o la muerte a

usted u otras personas.

• La pistola/varilla rociadora es una poderosa

herramienta de limpieza que un niño puede

imaginar como un juguete.

• La fuerza reactiva del rociado determinará que la

pistola/varilla rociadora se mueva y podría ser la

causa de que el operador se resbale, caiga, u

oriente el rociador hacia una dirección errónea. El

control inadecuado de la pistola/varilla puede

ocasionar lesiones a uno mismo u otras personas.

• El contacto con superficies calientes, puede

ocasionar serias quemaduras.

• Durante la operación, toque solamente las

superficies de control de la lavadora a presión.

Mantenga a los niños alejados en todo momento

de la lavadora a presión. Ellos podrían no darse

cuenta de los riesgos de este producto.

RIESGO DE SUPERFICIES CALIENTES

RIESGO

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

26-SP

D28921

ISTRUCCIONES PARA LA PUESTA A TIERRA.

Este equipo debe poseer la puesta a tierra. En caso de funcionamiento defectuoso o de avería, la

puesta a tierra suministra un recorrido de resistencia mínima para la corriente eléctrica con el fin de

reducir el riesgo de sacudidas. El equipo está dotado de un cable que incluye un conductor y

enchufe de tierra. El enchufe debe ser introducido en una toma apropiada, instalada en modo

idóneo y con puesta a tierra según lo establecido por las leyes y disposiciones locales.

Una conexión impropia entre el equipo y el conductor de tierra puede

provocar sacudidas eléctricas. Si tienen dudas sobre la idónea puesta

a tierra de la toma, consulten con un electricista o con un encargado de la manutención. No

modifiquen el enchufe suministrado con el equipo; en caso contrario, adapten la toma

instalada con la ayuda de un electricista cualificado. No utilicen adaptadores para este

equipo.

• El rociado de los líquidos a alta velocidad puede

causar la rotura de algunos objetos proyectando

sus partículas a altas velocidades.

• Los objetos livianos o que no estén sujetos se

pueden convertir en proyectiles peligrosos.

•

Siempre usar anteojos de seguridad que cumplan

con la norma Z87 de ANSI. Siempre usar ropa

especial para protegerse del rociado.

• Nunca apuntar la varilla rociadora ni dirigir el

rociado a personas ni animales.

• Para evitar que se accione accidentalmente

siempre enganchar el seguro del gatillo cuando la

varilla rociadora no esté en uso.

• Nunca fijar el gatillo permanentemente en la

posición de abierto (open).

RIESGO DE LESIONES POR EL ROCIADO

RIESGO

QUÉ PUEDE OCURRIR

CÓMO PREVENIRLO

El chorro poderoso de su lavadora a presión es capaz de causar daño a

superficies tales como la madera, vidrio, pintura del automóvil, guardas rayadas,

adornos y objetos delicados tales como flores y arbustos. Antes de rociar,

verifique el ítem que debe ser lavado para asegurarse que el mismo es suficientemente fuerte como para

resistir el daño de la fuerza del rociado. Evite el uso del chorro concentrado excepto para superficies muy

fuertes, tales como concreto y acero.

CONSERVAR ESTAS INSTRUCCIONES

27- SP

D28921

DISEÑO PIEZAS

LISTA PIEZAS

1 Lanzador con Boquilla de Cabezal Rotatorio

2 Pistola

3 Tubo de alta presión

4 Porta-manguera alta presión

5 Interruptor ON/OFF

6 Conector manguera alta presión

7 Entrada agua

8 Lanzador con Boquilla Variable

9 Porta-accesorios

10 Tornillo (Depósito del liquido detergente)

11 Enchufe eléctrico con Interruptor diferencial automático de seguridad

12 Tapón agua

13 Filtro

14 Entrerrosca con conexión rápida

15 Depósito del liquido detergente

16 Portacable alimentación

28-SP

D28921

2.0 CARACTERÍSTICAS RELATIVAS A LA SEGURIDAD

La hidrolimpiadora de presión está dotada de un dispositivo de stop que detecta cuándo está

desenganchado/suelto el gatillo de la pistola. Abre el circuito eléctrico al motor y bloquea la

hidrolimpiadora de presión.

La hidrolimpiadora de presión está también dotada de un interruptor

eléctrico principal ON/OFF. Cuando la hidrolimpiadora no está en uso,

es necesario que dicho interruptor esté colocado siempre en OFF para prevenir posibles

accidentes o daños.

SOBRECARGA DEL MOTOR

El motor eléctrico de la hidrolimpiadora posee un dispositivo de protección contra la sobrecarga

que bloquea automáticamente el motor en el caso de exceso de corriente o en el caso de

recalentamiento.

El dispositivo se resetea automáticamente y reactiva las

condiciones normales de funcionamiento después de un

breve período.

PROTECCIÓN CON INTERRUPTOR DIFERENCIAL

AUTOMÁTICO DE SEGURIDAD

La hidrolimpiadora está dotada de un interruptor diferencial

automático de seguridad (GFCI) montado en el enchufe del

cable de alimentación eléctrica. Dicho dispositivo suministra

una protección adicional contra el riesgo de sacudidas. Si

fuere necesario substituir el enchufe o el cable, utilicen

exclusivamente repuestos similares provistos de protección

GFCI.

EXTENSIONES

No se aconseja el uso de extensiones si éstas no están conectadas a

un interruptor diferencial automático de seguridad, puesto en cajas

del circuito o en tomas protegidas.

Utilicen exclusivamente extensiones de 3 conductores que posean enchufes con puesta a tierra de

3 polos y conectores tripolares aptos para el enchufe del equipo. Usen exclusivamente extensiones

para uso exterior. Dichas extensiones están marcadas por la frase “Aptas para uso exterior: si no las

utilizan, colóquenlas en un lugar reparado”.

Usen solamente extensiones con una potencia eléctrica superior a la potencia nominal del equipo.

No utilicen extensiones dañadas. Antes del uso, controlen la extensión y si está dañada

substitúyanla. No la usen en modo incorrecto y no tiren del cable para desenchufar. Tengan a las

extensiones lejos de fuentes de calor y de ángulos cortantes. Antes de desconectar el equipo de la

extensión, desconecten siempre esta última de la toma.

Cuando se utilizan extensiones, respeten las siguientes características:

Longitud cable Calibres cable

Hasta 50 pies 14 AWG

De 50 a 100 pies 12 AWG

Para reducir la posibilidad de que el cable sea fulminado, mantengan

la extensión seca y fuera de tierra. No toquen el enchufe con las

manos mojadas.

29- SP

D28921

CONEXIÓN DEL AGUA

Unión del agua apropriada

Fig. 1

Agujero admisión máq

Conexión rápida

Manguera flexible jardín

Guarnición

3.0 INSTALACIÓN

3.1 TUBO DE ALTA PRESIÓN

Extraer y desechar el tapón del agua (lista piezas de repuesto 12) antes de conectar el tubo de

alta presión, introduciendo cuidadosamente la unión mediante el O-ring adentro de la salida de

alta presión y apretando manualmente la tuerca roscada.

3.2 CONEXIÓN DEL AGUA

Antes de efectuar la conexión, haga correr el agua en la manguera jardín (no incluida en el

suministro) para hacer salir los materiales extraños. Conecten la manguera jardín a la unión del

agujero de introducción de la hidrolimpiadora de alta presión.

3.3 ENLACE DE LA ALIMENTACIÓN ELÉCTRICA

La hidrolimpiadora está dotada de serie de un cable eléctrico y de un enchufe de alimentación con

interruptor diferencial automático de seguridad (GFCI). El cable deberá ser conectado únicamente

a una toma eléctrica instalada en conformidad con las normativas locales de seguridad.

NOTA: La corriente eléctrica deberá ser de 120V, 60 Hz con un circuito de por lo menos 15 amp.

Controlen el interruptor diferencial automático de seguridad (GFCI)

antes del uso. No utilicen la hidrolimpiadora si el control efectuado da

un resultado negativo.

Procedimiento para controlar el GFCI:

1. Conectar el GFCI en la toma de alimentación

2. Presionar RESET

3. Presionar el botón TEST. Aparecerá un indicador de color rojo en RESET

4. Presionar nuevamente RESET antes del uso

NOTA: El GFCI debe ser reseteado todas las veces que se conecta la hidrolimpiadora a una toma

eléctrica.

30-SP

D28921

A. Conecten sólo a una toma con una puesta a tierra idónea. No extraigan el enchufe de tierra

B. Controlen el cable antes del uso. Si está dañado, no lo utilicen.

C. Mantengan secas y fuera de tierra todas las conexiones

D. No toquen el enchufe con las manos mojadas

E. La hidrolimpiadora es suministrada con un interruptor diferencial automático de seguridad

instalado en el enchufe de alimentación. Si es necesario substituir el enchufe o la toma, usen

sólo piezas de repuesto del mismo tipo. Para una substitución correcta, contacten la Oficina

de Asistencia Clientes.

No se aconseja el uso de extensiones si no están introducidas en una toma protegida por el

interruptor diferencial automático de seguridad. Cualquier extensión utilizada debe ser del tipo

14AWG y la longitud no debe superar los 50 pies con el fin de prevenir una excesiva dispersión de

tensión. Utilicen sólo extensiones para uso exterior. Tales extensiones están señaladas con la

siguiente frase: “Idóneas para uso exterior; almacenar en lugar cerrado cuando no es utilizada.”

4.0 INSTRUCCIONES DE USO

Riesgo de penetración o de daños. NO descarguen el flujo sobre las

personas.

4.1 PROCEDIMIENTO DE PUESTA EN MARCHA

1. Asegúrense de que la alimentación del agua esté conectada.

2. Asegúrense de que el enchufe del equipo esté conectado y que el GFCI HAYA SIDO

RESETEADO.

3. Liberen la seguridad de la pistola si está bloqueada.

A. Bloqueo de seguridad “cerrado”

B. Bloqueo de seguridad “abierto”

4. Con el fin de permitir la salida de aire de la manguera, aprieten el gatillo de la pistola hasta

que salga un flujo regular por la boquilla.

5. Extraigan la suciedad o los materiales extraños de la salida de la pistola y del conector blando

del lanzador.

6. Introduzcan el lanzador en la unión rápida empujando enérgicamente y luego girando el

lanzador de ¼ de vuelta para bloquearlo en su sede.

NOTA: Asegúrense de que el bloqueo de seguridad esté cerrado.

31- SP

D28921

Cuando se requiere alta presión, sostener y hacer desplazar la abrazadera/brida y la boquilla lejos

de la pistola.

Si el lanzador no está bien bloqueado en su sede, cuando se utiliza la

pistola, podría ser expulsada debido a la alta presión, provocando

daños y perjuicios.

7 Presionen el gatillo en la pistola de chorro

8 Presionen la tecla ON/OFF para poner en marcha la hidrolimpiadora.

4.2 ALTA PRESIÓN / BAJA PRESIÓN

No desplacen la boquilla para regular la presión cuando el gatillo está

presionado.

La posición de la boquilla de alta presión (baja presión) es ideal para la limpieza. Cuando se

requiere presión alta, sostener y hacer desplazar la abrazadera/brida y la boquilla hacia la pistola.

NOTA: Asegúrense de que la abrazadera/brida esté toda atrás para cerrar la boquilla en la posición

de baja presión.

32-SP

D28921

Para disminuir el ángulo del chorro de la punta de “lápiz”, giren hacia la derecha.

Chorro Rotatorio

4.3 BOQUILLA CHORRO REGULABLE

La boquilla de chorro regulable, permite regular el chorro desde el ventilador hasta la punta del

“lápiz” tanto en posición de alta como de baja presión. El chorro se regula girando la boquilla

La regulación del chorro de la punta del lápiz puede dar resultados

“agresivos/corrosivos”. Aconsejamos utilizar para la mayor parte de las

aplicaciones de limpieza, un ángulo de chorro de veinte grados (20°) para no dañar las

superficies donde se necesita utilizar el chorro.

NOTA: La presión del chorro sobre la superficie que están limpiando aumenta en proporción al

acercamiento del lanzador sobre la superficie misma.

Para aumentar el ángulo de un chorro de ventilador, giren hacia la izquierda.

4.4 CHORRO DE ALTA PRESIÓN / TURBO

No actúen sobre la boquilla para modificar la presión.

La posición de la boquilla rotatoria de alta presión está diseñada para obtener el mejor resultado

de limpieza. Siempre mantener el lanzador de chorro a una distancia de 15 a 20cm (6" a 8") de la

superficie que desea limpiar.

33- SP

D28921

4.6 TÉCNICAS DE LIMPIEZA

Cuando se procede a la limpieza con la hidrolimpiadora, se pueden efectuar diferentes

operaciones sólo con el agua; en muchos casos, sin embargo, es conveniente utilizar también un

detergente. El uso de un detergente asegura un tratamiento inmediato de la suciedad, permitiendo

al agua con alta presión penetrar y eliminar eficazmente la suciedad. La posición de baja presión

suministra una aplicación delicada del producto químico. Recomendamos esta posición también

para enjuagar una superficie después de la aplicación de cera y de otras aplicaciones que

requieran la baja presión de una manguera de jardín. La baja presión equivale a una manguera de

jardín programada en el rendimiento más bajo para aplicar en modo correcto el producto químico.

PARA APLICACIONES CON PRODUCTOS QUÍMICOS, HAGAN DESPLAZAR LA

ABRAZADERA/BRIDA COMO ESPECIFICADO EN LA SECCIÓN 4.2.

4.5 USO DE PRODUCTOS QUÍMICOS

use tan solo productos químicos específicos para hidrolimpiadoras de

alta presión.

1 Inserte el tubo de aspiración (2) en su toma en el estanque

2 Rellene el estanque con detergente específico

3 Asiente el estanque con la solución química en su lugar adecuado en la parte posterior de la

máquina.

4 Asegure el estanque por medio del tornillo suministrado.

5 Muevan la boquilla regulable hacia la posición de baja presión haciendo desplazar la

abrazadera/brida hacia la boquilla. El producto químico será mezclado inmediatamente con el

agua y descargado a través de la boquilla.

NOTA: cuando la boquilla está ajustada para la erogación de alta presión, el producto químico no

será aspirado desde su estanque.

APLICACIÓN DE DESENGRASANTE A BASE DE JABÓN

1. Apliquen la solución de jabón de la hidrolimpiadora sobre una superficie de trabajo SECA.

NOTA: NO SE ACONSEJA MOJAR LA SUPERFICIE ANTES, PUESTO QUE DILUYE EL DE-

TERGENTE Y REDUCE SU CAPACIDAD DE LIMPIEZA. Ante la presencia de una superficie

vertical, apliquen el jabón horizontalmente comenzando por la parte baja para evitar estriados.

2. Antes de enjuagar, dejen el producto químico sobre la superficie durante un breve lapso de

tiempo.

Si se deja secar el jabón, las superficies pintadas podrían dañarse. Laven

y sequen una pequeña sección por vez. No trabajen sobre superficies

calientes o bajo la luz directa del sol.

3. Enjuaguen con agua limpia y con alta presión. Sobre las superficies verticales, comiencen a

enjuagar antes desde la parte baja hacia la parte alta y luego viceversa. Tengan la boquilla a

6/8 pulgadas de la superficie de trabajo con un ángulo de 45° utilizando el chorro turbo como

si fuera una herramienta para pelar en lugar de cepillo de acero.

NOTA: Asegúrense que el sistema de inyección de productos químicos esté completamente limpio

antes de cambiar productos químicos.

34-SP

D28921

APLICACIÓN DE LA CERA

1. Después de haber limpiado, apliquen la cera con la hidrolimpiadora regulada sobre la baja

presión. Coloquen la cera dentro el depósito del liquido detergente.

2. Apliquen la cera en un estrato uniforme. Apliquen sobre superficies mojadas desde abajo

hacia arriba, para distribuirla uniformemente y para evitar los estriados.

3. Eliminen el exceso de cera del aparato de baja presión. NOTA: SI EL EXCESO DE CERA NO

ES EXTRAÍDO, SE PUEDE OBTENER UN RESULTADO OPACO.

4. Efectúen el secado para reducir las manchas de agua.

4.7 FINALIZACIÓN DE LA OPERACIÓN

Cuando habrán concluido la utilización del sistema de inyección de productos químicos, extraigan

la manguera del recipiente, hagan funcionar aún a baja presión y hagan pasar agua limpia por el

depósito del liquido detergente hasta que esté completamente limpio. NOTA: La falta de una

limpieza a fondo puede provocar una obturación en el sistema de inyección y será inutilizable.

l Detengan el equipo presionando el botón on/off.

l Desconecten la toma eléctrica.

l Cierren el agua y depresuricen el equipo presionando el gatillo.

Cierren la alimentación del agua y presionen el gatillo para

depresurizar el equipo. La falta de depresurización puede provocar

daños a las personas debido a la descarga del agua de alta presión.

l Desconecten la manguera de descarga de la alta presión y la manguera de introducción del

agua.

3. Laven abundantemente con agua hacia la parte trasera de la boquilla.

4. Conectar nuevamente la boquilla al lanzador

NOTA: Atornillar completamente las boquillas en el lanzador hasta cerrar completamente (ver

dibujo)

Hacer arrancar nuevamente la hidrolimpiadora y bajar el gatillo de la pistola de chorro. Si la

boquilla está aún bloqueada o parcialmente bloqueada, repitan dichas operaciones desde el punto

1 hasta el punto 4.

5.0 MANUTENCIÓN

5.1 CONEXIONES

Las conexiones a mangueras, la pistola y el lanzador de chorro de la hidrolimpiadora, deberían ser

limpiados regularmente y lubricados para prevenir las pérdidas y la rotura de los o-rings.

5.2 BOQUILLA

El dispositivo de regulación de la alta/baja presión de la boquilla debe ser lubricado con

regularidad.

La obturación de la boquilla provoca el aumento de la presión de la bomba y, con toda

probabilidad, la distorsión de la forma del chorro. Se requiere una limpieza inmediata.

1. Separar la boquilla del lanzador

2. Limpien la boquilla.

35- SP

D28921

5.4 FILTRO DE AGUA

La hidrolimpiadora está dotada de un filtro de introducción de agua para proteger la bomba.

Si no se mantiene limpio el filtro, el flujo del agua hacia la

hidrolimpiadora se ve limitado y la bomba puede dañarse.

l Para limpiar el filtro más interno del agua, remuevan la conexión rápida y el filtro plástico de la

toma de la bomba (verla página 20, pos. 13).

l El filtro de retorno del flujo debe estar limpio.

l Remplacen de inmediato el filtro y la unión rápida para evitar que entre material extraño en la

bomba.

No dañen el filtro cuando lo extraen y limpian. Cualquier partícula

extraña que pudiera entrar en las bombas, podría dañarla.

5.5 SISTEMA DE REFRIGERACIÓN

Los respiraderos de aire colocados en la hidrolimpiadora y a su alrededor, deben ser mantenidos

limpios de cualquier obstrucción para garantizar la refrigeración del motor con aire limpio durante

el uso.

Eviten que el agua penetre en los respiraderos de la hidrolimpiadora

para que el riesgo de dañar la máquina sea mínimo y para reducir el

peligro de sacudida eléctrica al operador.

5.3 LUBRICACIÓN

La hidrolimpiadora ha sido creada con un sistema de lubricación permanente. No son necesarios

controles convencionales ni la substitución de aceites.

NOTA: EN EL CASO DE PÉRDIDA DE ACEITE, CONTACTEN AL SERVICIO CLIENTES DE LA

SOCIEDAD HD POWERWASHER, SECCIÓN REPARACIONES. UNA PEQUEÑA PÉRDIDA DE

ACEITE ES NORMAL.

6.0 MANIPULACIÓN Y ALMACENAMIENTO

Almacenen la hidrolimpiadora en un local cuya temperatura no

descienda por debajo de los 32°F. En el caso de congelamiento, la bomba

de este equipo está sujeta a daño permanente. LOS DAÑOS PROVOCADOS POR EL HIELO

NO ESTÁN CUBIERTOS POR LA GARANTÍA.

Si almacenan la hidrolimpiadora en un local donde la temperatura es inferior a los 32°F, pueden

disminuir el riesgo de daño del equipo siguiendo el siguiente procedimiento:

1. Detengan la hidrolimpiadora y desconecten la manguera de alimentación y la de alta presión.

2. Presionen el gatillo de la pistola de descarga para hacer salir toda el agua del “lanzador” y de

la manguera.

3. Pongan nuevamente en marcha la hidrolimpiadora y déjenla en funcionamiento durante un

breve período (unos 5 segundos) hasta que saldrá el agua por la salida de la alta presión.

6.1 DESPUÉS DE UN ALMACENAMIENTO PROLONGADO

Cuando no es utilizada durante mucho tiempo, se podrían formar en la bomba depósitos

calcáreos.

Ello podría implicar que el motor no funcione correctamente o que directamente no funcione.

Extraigan los depósitos calcáreos de la tubería.

l Conecten la máquina a la alimentación del agua y enjuaguen. No introduzcan el enchufe en el

conector principal.

Para evitar la sobrecarga eléctrica, giren el eje motor manualmente.

36-SP

D28921

Efectúen las siguientes operaciones:

l Desconecten el enchufe del conector principal.

l Extraigan el revestimiento de paneles (Fig.A)

l Introduzcan una llave de casquillo hexagonal apropiada (4 mm) a través de la apertura central

en la tapa del ventilador y en el alojamiento hexagonal en el eje motor.

l Giren algunas veces a mano el eje motor en sentido retrógrado (Fig.B)

l Saquen la llave de casquillo hexagonal

l Vuelvan a montar el revestimiento de paneles

l Introduzcan el enchufe del conector principal en la caja de la toma de corriente

l Enciendan el aparato con la pistola de chorro abierta

7.0 LOCALIZACIÓN DE LAS AVERÍAS

El motor no arranca o

se detiene durante el

funcionamiento

El GFCI salta o no resetea Apagar el equipo. Presionar la teda

Reset del GFCI después de haberlo

conectada al alimentador eléctrico.

El interruptor del circuito se

desconecta o los fusibles

están quemados en la caja de

fusibles

Desconectar todas las demás

cargas sobre el mismo circuito y

resetear el interruptor de circuito o

cambiar los fusibles

El interruptor de circuito de la

hidrolimpiadora ha saltado

Dejar enfriar descansar el equipo

Boquilla parcialmente

bloqueada

Limpien la boquilla como indicado

en la sección 5.2

Controlen que el circuito esté

regulado en 15 o más amp.

Desconecten todas las cargas del

circuito.

Extensión demasiado larga o

dimensión del cable

demasiado pequeña

Presión excesiva Reducir la pressión con la manopla

de regulación

PROBLEMAS

CAUSAS PROBABLES

SOLUIÓN

Enchufe flojo o no conectado

Reconectar el enchufe

L’interruptor de circuito

salta o están

quemados los fusibles

en la caja de fusibles

Sobrecarga circuito

Usen una extensión idónea como

aconsejado en el Manual del

Operador

Fig. A

Fig. b

37- SP

D28921

El GFCI se desconecta

continuamente

Voltaje equivocado Véase sección 3.3

Una pequeña pérdida es

normal

Si la pérdida es excesiva, hay que

contactar la Oficina de Asistencia

Clientes

Cortocircuito interior

Llamen a la Oficina de Asistencia

Clientes

La válvula de bypass no

funciona correctamente

Llamen a la Oficina de Asistencia

Clientes

El motor gira pero la

bomba no suministra

la máxima presión o

tiene una persión

irregular

Aire en la bomba Dejen en funcionamiento la

hidrolimpiadora con la pistola

abierta y el “lanzador” desplazado

hasta que se obtenga un flujo de

agua regular

La manopla de regulación de

la presión no se coloca en la

posición máxima

Calibrar en la posición máxima.

Véase sección 4.2

Hay pérdidas de agua

y aceite desde el

fonda de la bomba

Cuando la pistola está

cerrada aumenta la

presión

Grifo cerrado

Abran el grifo

El equipo ha sido almacenado

a temperaturas muy frias

Descongelar completamente el

equipo, incluidos las mangueras, la

pistola y el lanzador

La pantalla de indroducción

agua está obturada

Limpien la pantalla. Véase sección

5.4

Dirigrise a la Oficina de Asistencia

Clientes

Enderecen la manguera

Pliegues de la manguera de

jardín

Consulten con la Oficina de

Asistencia Clientes

Válvulas de aspiración o de

descargo obturadas o fuera de

uso

La válvula by-pass no funciona

correctamente

PROBLEMAS

CAUSAS PROBABLES

SOLUIÓN

No se obtiene la

introducción de

productos químicos

La manguera de inyección no

está conectada correctamente

a la hidrolimpiadora

Empujen con fuerza en el equipo

La manguera está arruinada o

rota

Cambiar

Regulación equivocada de la

boquilla

Desconecten la boquilla para bajor

la presión

El filtro de la manguera está

tapado

Limpiar el filtro

Los productos químicos se

han secado en el inyector

Disolver haciendo correr agua

corriente en la manguera de

inyección

Está conectado el bloqueo de

seguridad de la pistola

Desenganchen el bloqueo de

seguridad

El gatillo no se mueve

La boquilla está bloqueada Limpiar - Véase sección 5.2

38-SP

D28921

9.0 DATOS TÉCNICOS

Código Descripción

D28936 Tanque de Detergente

D28937 Tapa del Tanque de Detergente

D28939 Asa

D28940 Tapacubo

D28941 Rueda

D28942 Contratuerca

D28943 Manguera

D28944 Filtro de Succión

D28945 Pistola con Manguera

D28946 Boquilla de Regulación Múltiple

D28947 Boquilla Rotatoria

D28949 Interruptor

D28950 Eje

D28921 Manual

8.0 PIEZAS DE REPUESTO Y ACCESORIOS

ESTÁN A DISPOSICIÓN LOS ACCESORIOS Y LAS PIEZAS DE REPUESTO PRESENTADOS EN LA

SIGUIENTE LISTA

PARA MAYORES INFORMACIONES CONTACTEN EL SERVICIO CLIENTES 1-800-888-2468

Presión bomba 1600 psi MAX

Presión de uso man.

Necesidades de electricidad 120V, 13 Amp., 60 Hz

Cable eléctrico 35 pies

Manguera alta presión 23 pies

Capacidad a 1600 psi 1.6 gpm

Fuente mínima de amperaje 15 Amp.

Presión del agua de introducción de 20 a 100 psi

Caudal de inyección 2 - 4%

Agua de introducción Agua fría de grifo

Alta presión del ángulo del

chorro de la boquilla 0- 60°

Baja presión del ángulo del

chorro de la boquilla 0 – 90°

Chorro boquilla turbo 30 grados

39- SP

D28921

Llámennos inmediatamente

Si faltan piezas o hay piezas dañadas,

NO MANDEN SU EQUIPO AL ALMACÉN

Nuestra Oficina Asistencia Clientes

está siempre disponible para ayudarles para resolver cualquier problema

o para cuestiones operativas

Nuestro numero gratuito interurbano es

1-800-888-2468

VISITEN NUESTRO SITIO WEB PARA SUSTITUCIONES Y/O PARTES FALTANTES

www.devap.com

40-SP

D28921

GARANTÍA LIMITADA

DeVilbiss Air Power Company garantiza al comprador original que utilice este producto para uso personal (uso

personal, residencial o doméstico) que todos los productos cubiertos bajo esta garantía están libres de defectos en

materiales y mano de obra durante un año, a partir de la fecha de su compra. Todos los productos cubiertos por esta

garantía limitada que sean utilizados para usos comerciales (por ej. aquellos que produzcan utilidades) quedan

garantizados libres de defectos en materiales y mano de obra durante, 90 días a partir de la fecha de su compra original.

Los productos cubiertos bajo esta garantía incluyen compresores de aire, herramientas neumáticas, partes de servicio,

lavadoras a presión y generadores.

DeVilbiss Air Power Company reparará o reemplazará, a opción de DeVilbiss, productos o componentes que hayan

fallado dentro del periodo de garantía. El servicio será programado de acuerdo al flujo y al horario normal de trabajo del

domicilio del servicentro, y a la disponibilidad de piezas de reemplazo. Todas las decisiones de DeVilbiss Air Power

Company relacionadas con esta garantía limitada serán definitivas.

Esta garantía le otorga derechos legales específicos, aunque también usted podría tener otros derechos que podrán

variar entre estados.

RESPONSABILIDAD DEL COMPRADOR ORIGINAL (Usuario inicial):

• Para procesar un reclamo de garantía sobre este producto, NO lo devuelva al comercio vendedor. El producto

deberá ser evaluado por un servicentro autorizado para la atención de garantías. Para informarse de la ubicación

más cercana del servicentro autorizado para atención de garantías llame al 1-800-888-2468, que atiende 24 horas

diarias, los 7 días de la semana o visite nuestro sitio Web en devap.com .

• Retenga el recibido de venta original, como comprobante de su compra, para obtener la atención de su garantía.

• Mantenga un cuidado razonable en la operación y mantenimiento del producto, de acuerdo a lo descripto en

el(los) Manual(es) del propietario.

• Entregue o envíe el producto al servicentro autorizado para atención de garantías más cercano. Los costos de