Page 1

Electric Pressure Washer

Record All Information and attach sales

receipt here for future reference:

Purchase Date:__________________________

Serial #: ________________________________

Questions? 1-800-888-2468

Learn more about your pressure washer,

get answers to frequently asked questions,

and register on line at

www.excellpressurewasher.com

Model VR1600E

Table of Contents

Safety Guidelines/Definitions..................2

Consumer Saftey Information ................2

Important Safety Instructions ..............2-6

Specifications ..........................................6

Carton Contents ......................................7

Assembly Instructions .............................7

Operating Instructions ......................8-13

Maintenance .................................... 14-15

IMPORTANT

Please make certain that the person who is to use this equipment carefully

reads and understands these instructions before operating.

Accessories ...........................................15

Repairs ...................................................15

Storage ..................................................16

Trouble Shooting Guide ........................17

Warranty.................................................18

Français ........................................... 19-36

Español ............................................ 37-55

Part No. A17913 Rev. 0 5/10/06

Page 2

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand.

This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

Indicates an

situation which, if not avoided, will

result in death or serious injury.

which, if not avoided, could result in

death or serious injury.

reproductive harm. Wash hands after handling.

imminently hazardous

which, if not avoided, may result in

minor or moderate injury.

Indicates a potentially

hazardous situation

indicates a potentially hazardous

situation which, if not avoided, may

result in property damage.

This product contains chemicals, including lead, known to the

State of California to cause cancer, and birth defects or other

Indicates a potentially

hazardous situation

Used without the

safety alert symbol

IMPORTANT SAFETY INSTRUCTIONS

Do not operate this unit until you have read and understand

Instructions.

RISK OF EXPLOSION OR FIRE

• Use of acids, toxic or cor ro sive

chemicals, poisons, in sec ti cides, or

any kind of flam ma ble solvent with

this product could re sult in se ri ous

injury or death.

• Restricting any of the pressure

washer ventilation openings will

cause serious overheating and

could cause fire.

this Operators Manual for Safety, Operation, and Maintenance

READ AND SAVE THESE INSTRUCTIONS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Do not spray flammable liquids.

• Never place objects against or on

top of pressure washer. Operate

pressure washer in an open area at

least 12 inches away from any wall

or obstruction that would restrict

the flow of fresh air to the ventilation

openings.

RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Some clean ing fluids con tain substanc es which could cause injury to

skin, eyes or lungs.

A17913

• Use only clean ing fluids spe cif i cal ly

rec om mend ed for high-pressure

washers. Fol low manufacturers

recommendations. Do not use

chlorine bleach or any other

corrosive compound.

2- ENG

Page 3

RISK OF FLUID INJECTION AND LACERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Your pressure washer operates at

fluid pressures and velocities high

enough to penetrate human and

animal flesh, which could result in

amputation or other serious injury.

Leaks caused by loose fittings or

worn or damaged hoses can result

in injection injuries. DO NOT TREAT

FLUID INJECTION AS A SIMPLE

CUT! See a physician immediately!

• Inspect the high-pressure hose

regularly. Replace the hose

immediately if it is damaged,

worn, has melted from contacting

the engine, or shows any signs

of cracks, bubbles, pinholes, or

other leakage. Never grasp a highpressure hose that is leaking or

damaged.

• Never touch, grasp or attempt to

cover a pinhole or similar water

leak on the high-pressure hose.

The stream of water IS under high

pressure and WILL penetrate skin.

• Never place hands in front of noz zle.

• Direct spray away from self and

others.

• Make sure hose and fit tings are

tightened and in good condition.

Never hold onto the hose or fittings

during op er a tion.

• Do not allow hose to contact muf fler.

• Never attach or remove wand

or hose fittings while sys tem is

pressurized.

• Injuries can result if system pressure

is not reduced before attempting

maintenance or disassembly.

• To relieve sys tem pres sure, place

on/off switch in off position, turn off

water sup ply, and pull gun trigger

until water stops flowing.

• Use only hoses and accessories

rated for pressure higher than your

pressure washer's PSI.

RISK OF INJUR Y FROM SPRAY

WHAT CAN HAPPEN HOW TO PREVENT IT

• High-velocity fluid spray can cause

objects to break, propelling particles

at high speed.

• Light or unsecured objects can

become hazardous projectiles.

• Always wear ANSI-approved Z87.1

safety glasses. Wear protective

clothing to protect against

accidental spraying.

• Never point wand at or spray people

or animals.

• Always secure trigger lock when

wand is not in service to prevent

accidental operation.

• Never permanently secure trigger in

pull-back (open) position.

3 - ENG

A17913

Page 4

RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe op er a tion of your pressure

wash er could lead to se ri ous in ju ry

or death to you or others.

• Do not use chlorine bleach or any

other corrosive compound.

• Be come fa mil iar with the op er a tion

and con trols of the pressure washer.

• Keep operating area clear of all

persons, pets and obstacles.

• Do not operate the product when

fatigued or under the influence of

alcohol or drugs. Stay alert at all

times.

• Never defeat the safety fea tures of

this prod uct.

• Never leave wand unattended while

unit is running.

• Pressure washer pump contains

moving parts. Contact with moving

parts can cause serious injury.

• Never operate machine with pump

guard removed.

• Do not op er ate machine with

missing, broken or un au tho rized

parts.

• The spray gun/wand is a powerful

clean ing tool that could look like a

• Keep chil dren away from the

pressure washer at all times.

toy to a child.

• Reactive force of spray will cause

gun/wand to kickback, and could

cause the op er a tor to slip or fall

or misdirect the spray. Im prop er

control of gun/wand can re sult in

in ju ries to self and others.

• Do not over reach or stand on an

unstable support.

• Do not use pressure washer while

standing on a ladder.

• Grip gun/wand firmly with both

hands. Expect the gun to kickback

when triggered.

RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Con tact with hot sur fac es, such as

engines exhaust com po nents, could

result in se ri ous bur n.

A17913

• During op er a tion, touch only the

control surfaces of the pres sure

washer. Keep children away from

the pres sure washer at all times.

They may not be able to recognize

the haz ards of this product.

4- ENG

Page 5

RISK OF CHEMICAL BURN

WHAT CAN HAPPEN HOW TO PREVENT IT

• Use of acids, toxic or cor ro sive

chemicals, poisons, in sec ti cides, or

any kind of flam ma ble solvent with

this product could re sult in se ri ous

injury or death.

• Do not use ac ids, gasoline, kero sene, or any other flammable

materials in this product. Use only

household de ter gents, cleaners and

degreasers recommended for use in

pres sure washers.

• Wear pro tec tive clothing to protect

eyes and skin from con tact with

sprayed materials.

RISK OF

ELEC TRI CAL SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• Water spray di rect ed at elec tri cal

outlets or switch es, or ob jects connect ed to an elec tri cal circuit, could

re sult in a fatal electrical shock.

• This product is powered by electricity. It contains and sprays water and

other conductive liquids. Improper

operation could result in electrocution.

• Unplug any elec tri cal ly op er at ed

product before attempting to clean

it. Direct spray away from electric

out lets and switches.

• Always connect cordset to a properly grounded and polarized electrical circuit. Your cordset is equipped

with a Ground Fault Circuit

Interrupter (GFCI) for your personal protection.

• The Ground Fault Circuit Interrupter

(GFCI) will not function properly

unless connected to a fully grounded electrical circuit!

• Extension cords can lead to electri-

• If damaged, the entire cordset

assembly must be replaced by an

authorized service center. Refer to

Grounding Instructions.

• Do not use with extension cords.

cal shock.

RISK OF

INJURY FROM LIFTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result from

attempting to lift too heavy an

object.

• The pressure washer is too heavy

to be lifted by one person. Obtain

assistance from others before lifting.

The powerful spray from your pressure washer is capable

of causing damage to surfaces such as wood, glass,

automobile paint, auto striping and trim, and delicate objects such as

fl owers and shrubs. Before spraying, check the item to be cleaned to

assure yourself that it is strong enough to resist damage from the force of

the spray. Avoid the use of the concentrated spray stream except for very

strong surfaces like concrete and steel.

READ AND SAVE THESE INSTRUCTIONS

5 - ENG

A17913

Page 6

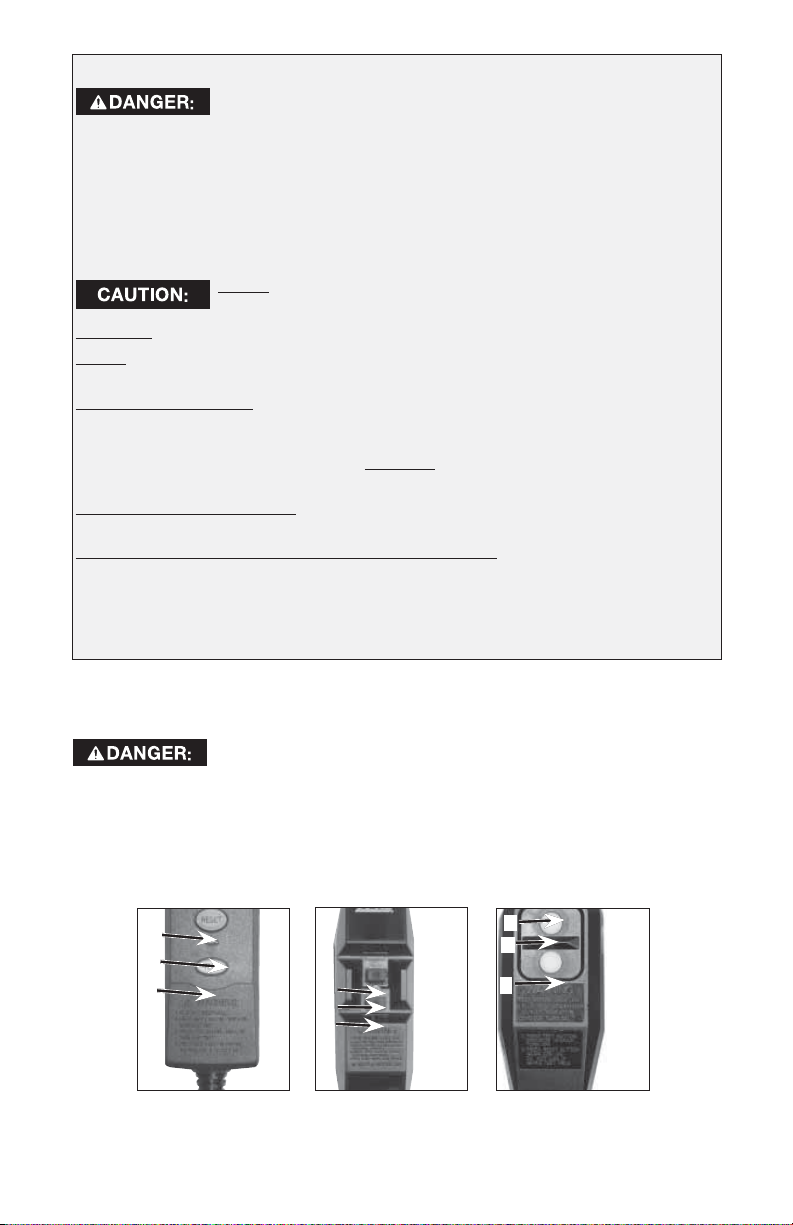

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or breakdown, grounding

provides a path of least resistance for electric current to reduce the risk of electric

shock. This product is equipped with a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in accordance with all local codes

and ordinances.

Improper connection of the equipment-grounding

qualifi ed electrician or service personnel if you are in doubt as to whether

the outlet is properly grounded. Do not modify the plug provided with

the product-if it will not fi t the outlet, have a proper outlet installed by a

qualifi ed electrician. Do not use any type of adapter with this product.

operating pressure washer.

EXTENSION CORDS

Use additional length of high pressure hose instead of extension cords to avoid

voltage drop and power loss to the motor, and to prevent overheating. DO NOT

USE EXTENSION CORDS. NOTE: The use of additional length of high pressure

hose will lower the pressure washer's psi below 1600.

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

This pressure washer is provided with a ground fault circuit interrupter (GFCI)

built into the plug of the power supply cord. This device provides additional

protection from the risk of electric shock. Should replacement of the plug or

cord become necessary, use only identical replacement parts that include GFCI

protection.

conductor can result in risk of electrocution. Check with a

To prevent overloading circuit, do not operate any other

electrical device connected to the same circuit while

SPECIFICATIONS

Model VR1600E

PSI Max* 1600 (11031.6 kPa)

Operating PSI 1440 (9859.5 kPa)

GPM Max* 1.5

Operating GPM 1.35

* Water flow and maximum pressure ratings determined in accordance with

PWMA standard PW101.

A17913

6- ENG

Page 7

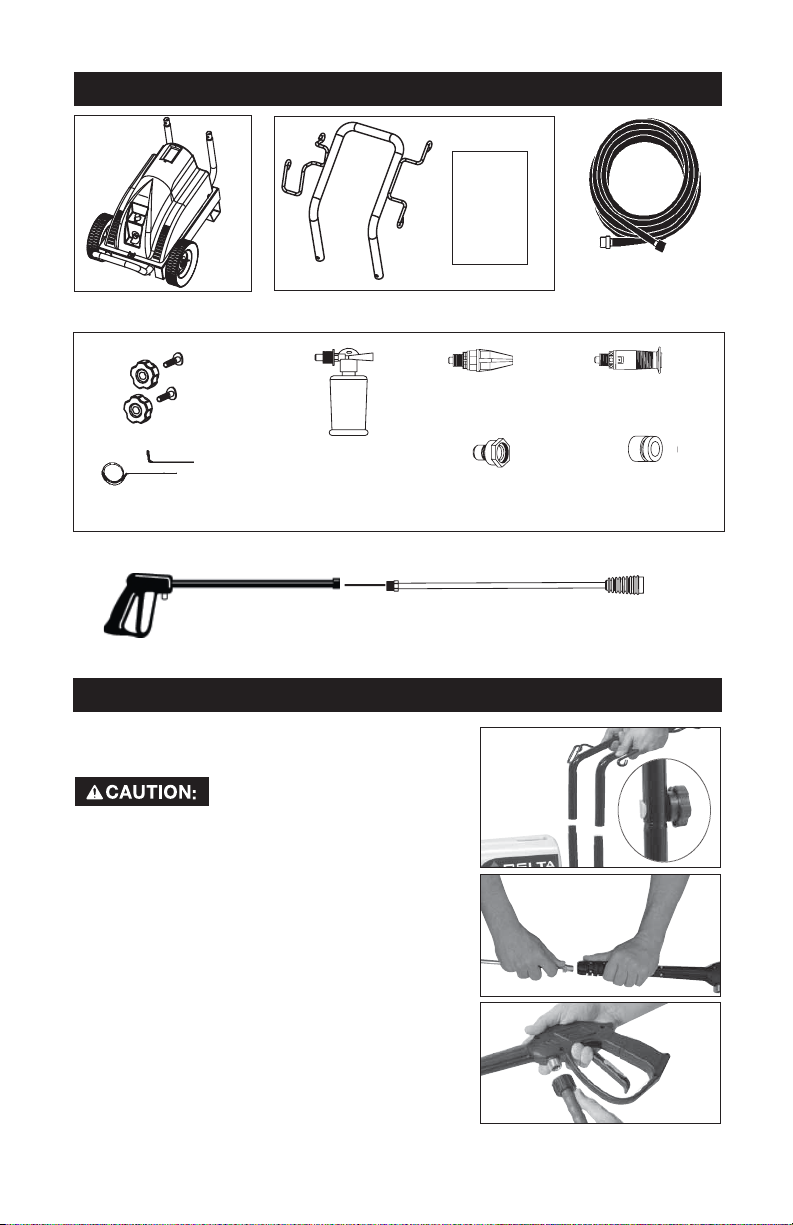

Motor, Frame, and

Wheel Assembly

Knobs

CARTON CONTENTS

English/

Spanish/

French

Operation

Manual

Handle

Bagged Handle

High Pressure

Hose

Rotary Nozzle

Saddle Bolts

Chemical

Nozzle Cleaning

application unit

Kit

Spray Gun

Quick-connect adapter

Parts Bag

ASSEMBLY INSTRUCTIONS

1. Place handle assembly onto frame and

connect handle to frame.

Risk of personal injury. Avoid

handle and frame when assembling to prevent

pinching.

2. Connect spray wand to gun. Tighten

securely.

3. Attach high pressure hose to gun. Tighten

se cure ly .

placing hands between

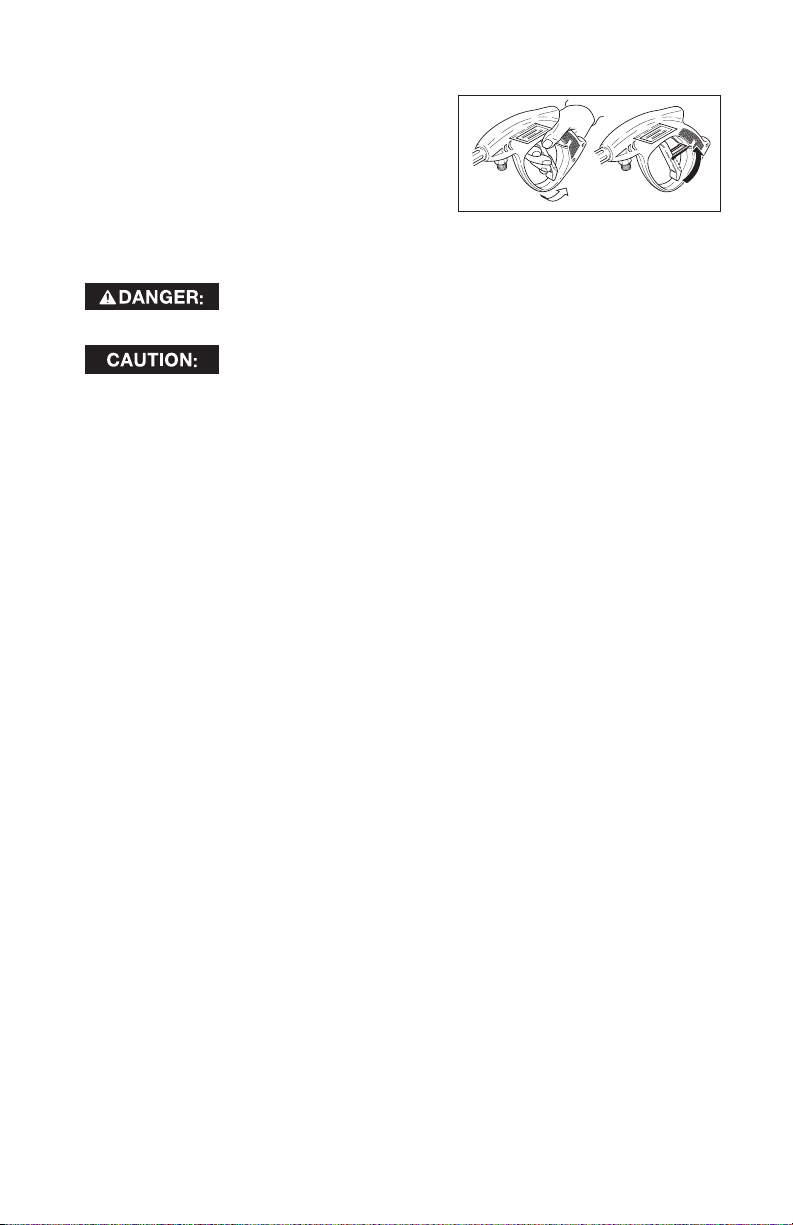

Variable Spray Nozzle

Quick-connect

Spray Wand

7 - ENG

A17913

Page 8

OPERATING INSTRUCTIONS

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with the

location of various controls and adjustments. Save this manual for future reference.

Spray

High Pressure Hose

Spray

Wand

with

Variable

Spray

Nozzle

Water

outlet

Gun

Electric

Cord

Motor

ON-OFF

switch

Motor

Water

inlet with

filter

High Pressure Pump

Quick-connect adapter

Quick-connect

Cleaning Solution

application unit

Rotary Nozzle

BASIC ELEMENTS OF A PRESSURE WASHER

High Pressure Pump (located inside the shroud): Increases the pressure of the

water supply.

Motor (located inside the shroud): Drives the high pressure pump.

High Pressure Hose: Carries the pressurized water from the pump to the gun and

wand.

Spray Gun: Connects with wand to control water flow rate, direction, and

pressure.

Spray Wand With Variable Spray Nozzle: Spray nozzle adjusts from a narrow

jet stream to a fan jet spray. The spray can be adjusted by twisting the nozzle

clockwise and/or counterclockwise.

Rotary Nozzle: increases cleaning efficiency by allowing you to cover more area

while using a concentrated spray pattern.

Cleaning Solution Application Unit: Used to apply cleaning solutions, see How

To Use Cleaning Solution Application Unit in this section.

PRESSURE WASHER TERMINOLOGY

Ground Fault Circuit Interrupter Protection (GFCI): This washer is provided with

a ground fault circuit interrupter (GFCI) built into the plug of the power supply

cord. This device provides additional protection from the risk of electric shock.

Should replacement of the plug or cord become necessary, use only identical

replacement parts that include GFCI protection.

A17913

8- ENG

Page 9

Total Stop System: This unit is equipped with a total stop system. When the

trigger is released the motor is shut off automatically. When the trigger is pressed

again the motor will au to mat i cal ly start. The time between release and en gagement must not be less than 4-5 seconds. DO NOT leave the unit in automatic

stop mode for more than 15 minutes.

PSI: Pounds per Square Inch. The unit of measure for water pressure. Also used

for air pressure, hydraulic pressure, etc.

GPM: Gallons Per Minute. The unit of measure for the flow rate of water through

the pressure washer.

CU: Cleaning Units. GPM multiplied by psi.

Water Supply: All pressure washers must have a source of water. The minimum

requirements for a water supply are 20 psi and 5 gallons per minute.

HOW TO USE

IMPORTANT: Read and understand how to use the pressure washer before

operating.

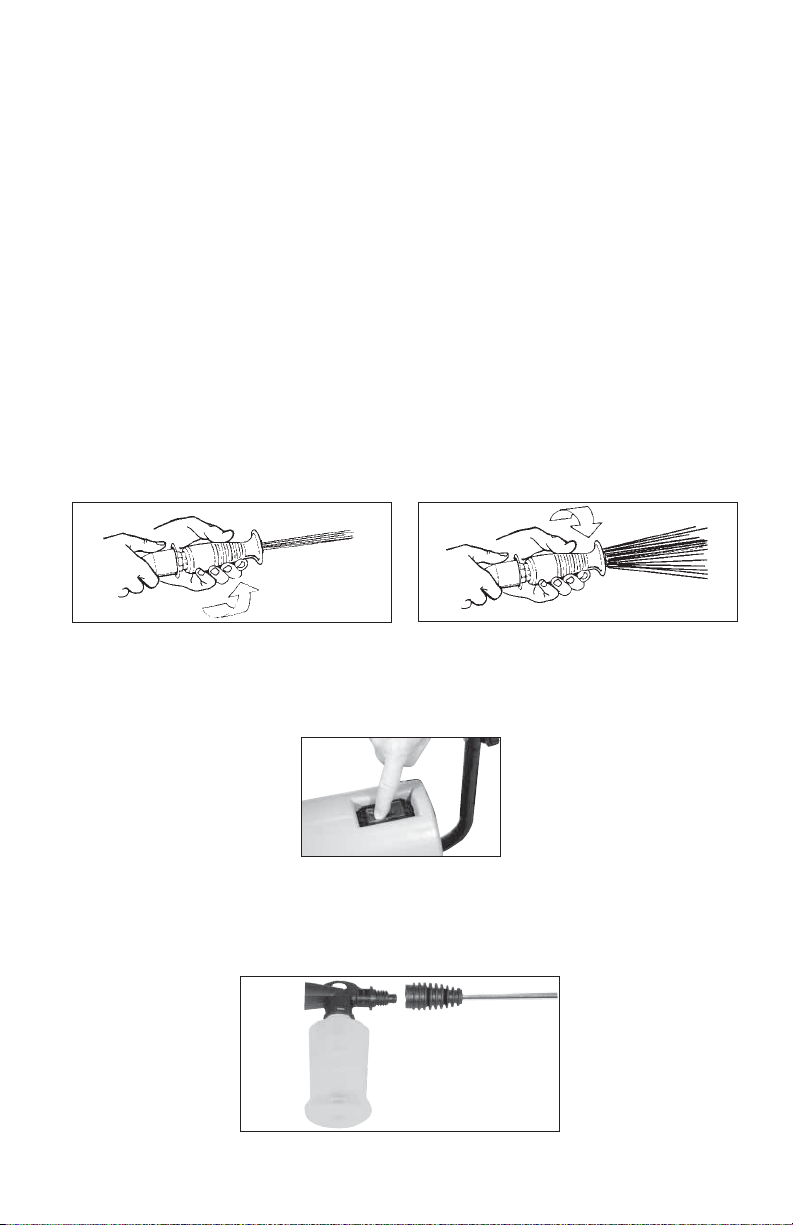

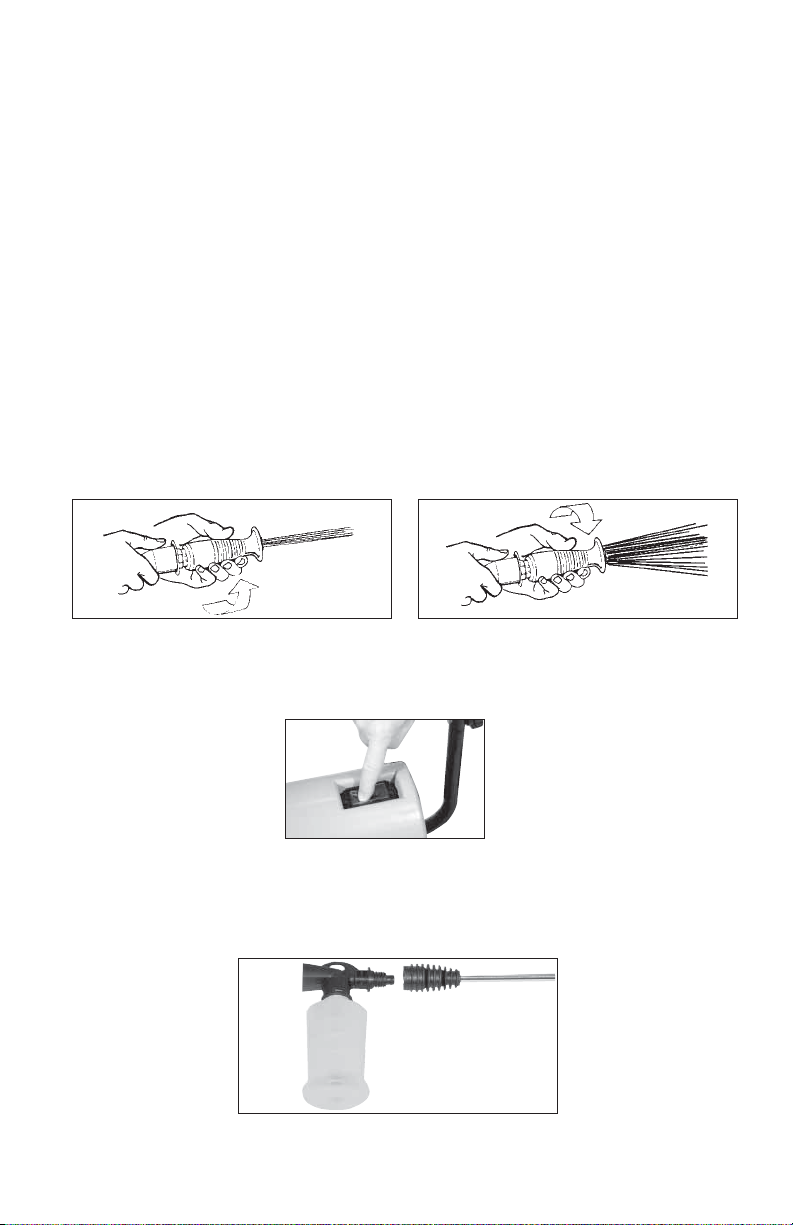

HOW TO USE SPRAY WAND

The nozzle at the end of the wand can be rotated to change from narrow jet

stream to fan jet, as shown.

jet stream

fan spray

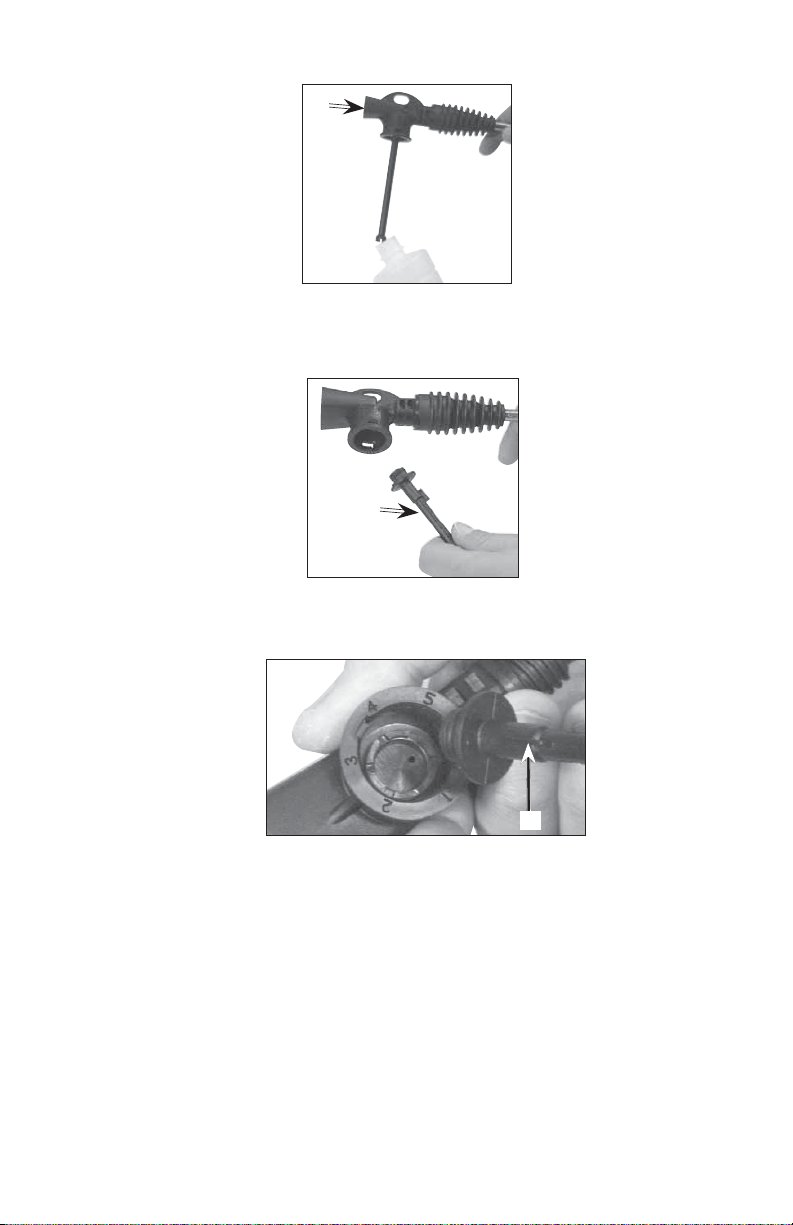

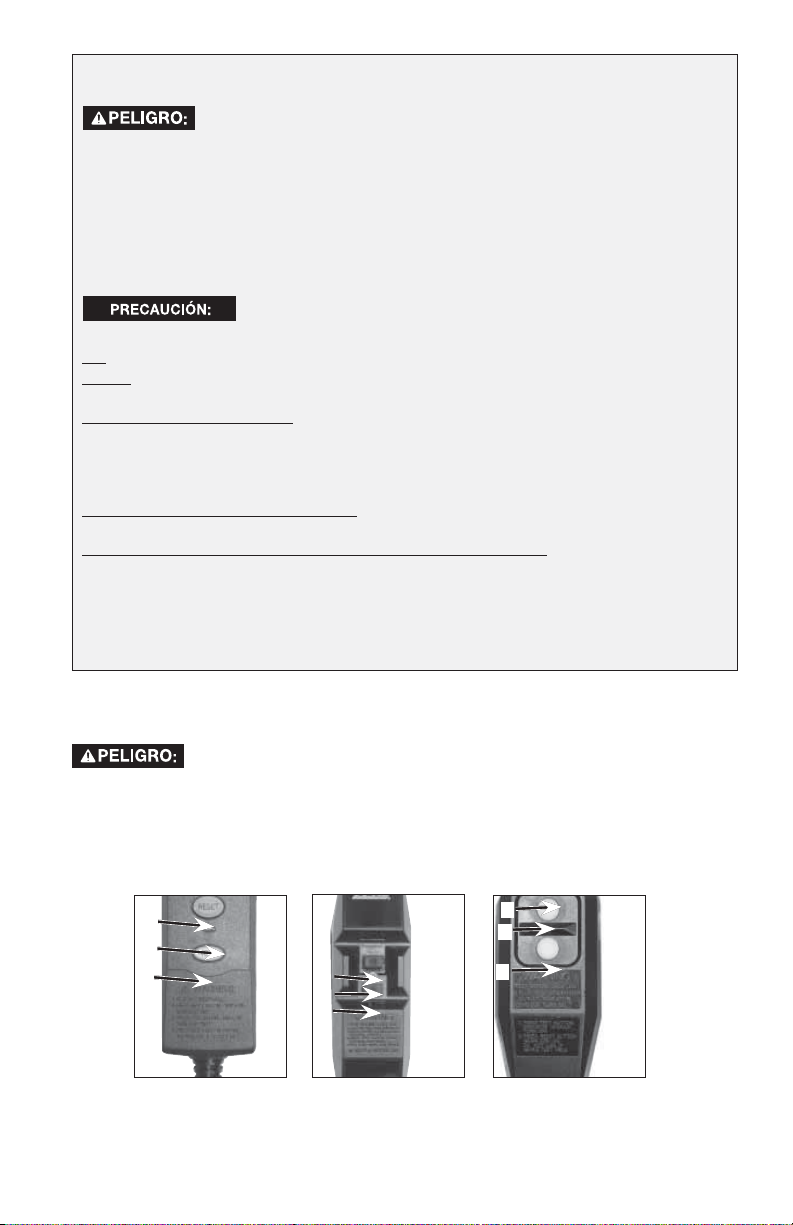

HOW TO USE THE CLEANING SOLUTION APPLICATION UNIT

NOTE: Use only soaps and cleaning solutions designed for pressure washer

use. Do not use bleach.

1. Place the ON-OFF switch in the OFF position.

2. Turn off the water supply.

3. Attach cleaning solution application unit to wand as shown and tighten

securely. Grasp end of nozzle and turn until cleaning solution application unit

is oriented correctly.

9 - ENG

A17913

Page 10

4. Remove the cleaning solution application tank from the application nozzle.

a

5. Soap mixture pressure can be adjusted by adjusting the pipe located in the

cleaning solution application nozzle (a).

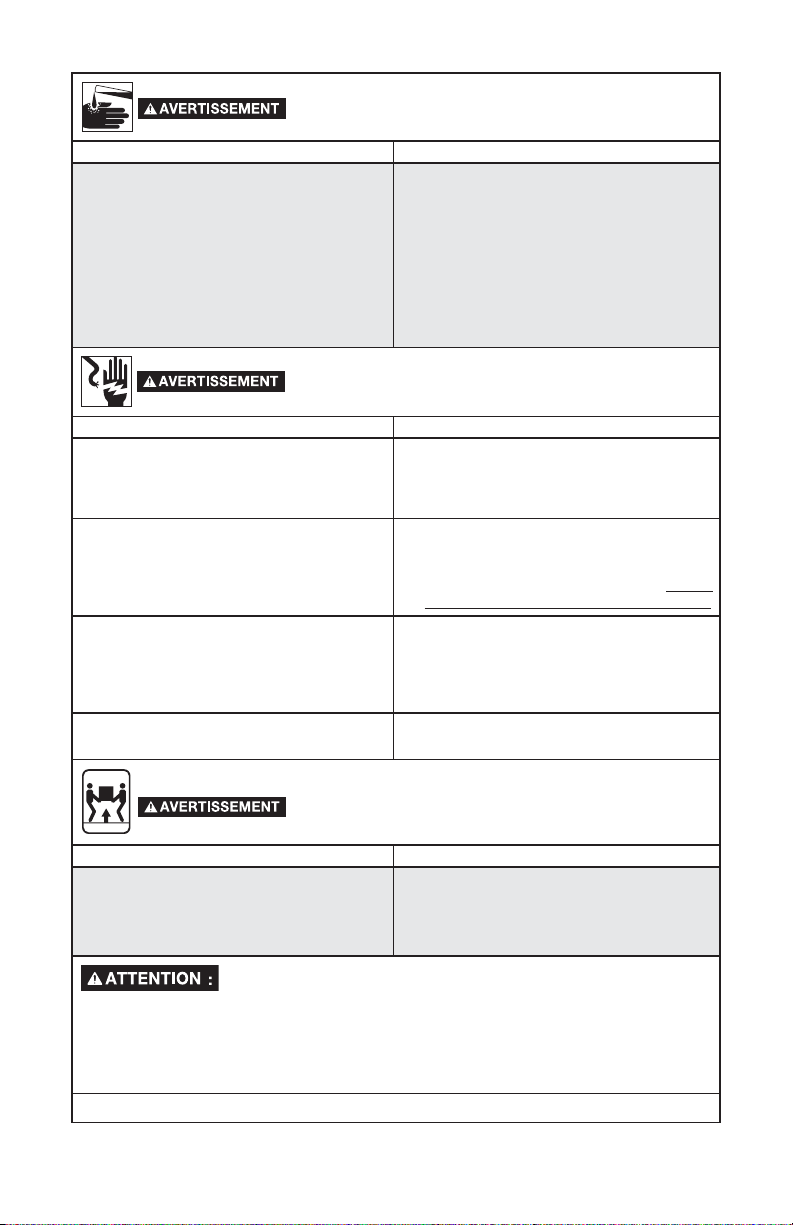

a. Pull pipe (b) from cleaning solution application nozzle.

b

b. Position the notch (c) on the pipe to the desired soap mixture

1-6, 1 being the highest and 6 being the lowest.

c

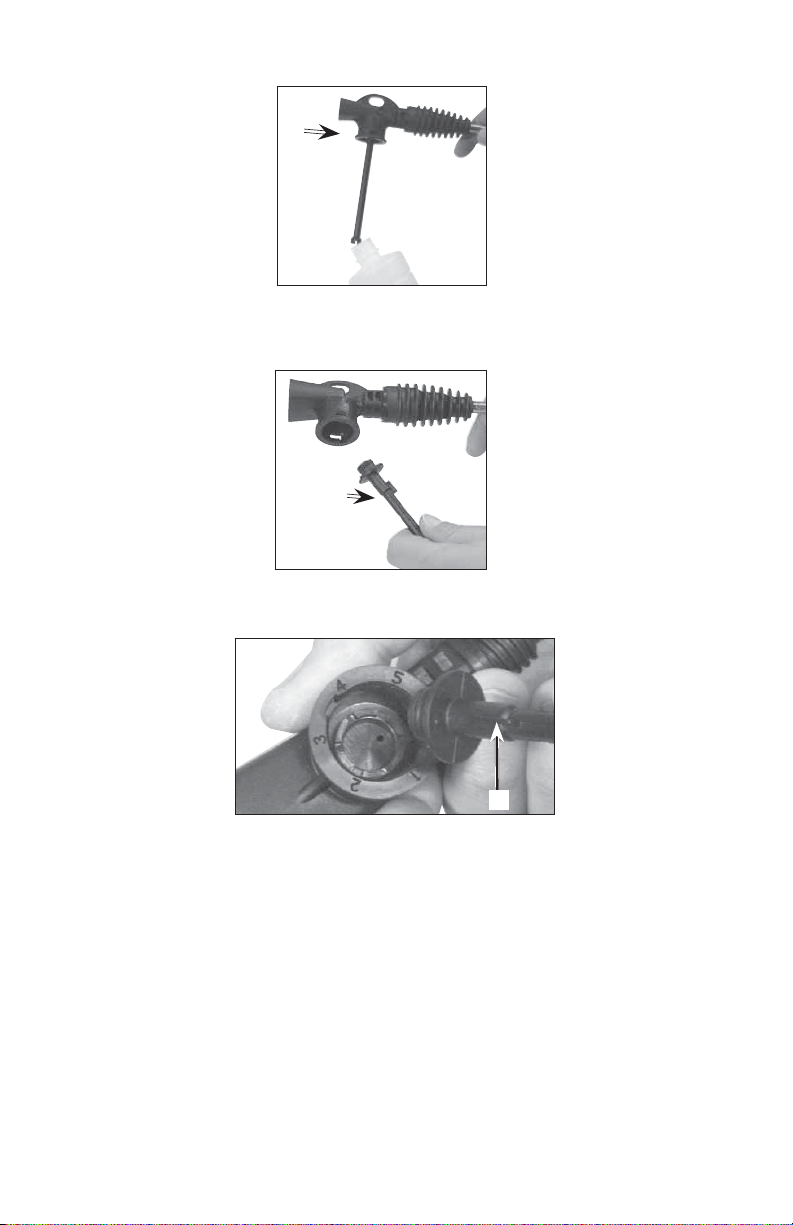

c. Press pipe into position.

6. Fill application tank with detergent.

7. Push cleaning solution application tank onto cleaning solution application

nozzle. Turn to lock into place.

8. See Before Starting and Starting Your Pressure Washer paragraphs in

this section to continue.

A17913

10- ENG

Page 11

READ AND UNDERSTAND ALL W ARNINGS BEFORE STARTING UNIT

Risk of fluid injection and laceration. When using the high

pressure setting, DO NOT allow the high pressure spray to

come in contact with unprotected skin, eyes, or with any pets or animals. Serious injury can occur.

Your washer operates at fluid pressures and velocities high enough to

penetrate human and animal flesh, which could result in amputation or other

serious injury. Leaks caused by loose fittings or worn or damaged hoses can

result in injection injuries. DO NOT TREAT FLUID INJECTION AS A SIMPLE

CUT! See a physician immediately!

Never pull water supply hose to move pres sure washer. This

could damage hose and/or pump inlet.

DO NOT use hot water, use cold water only.

Never turn water supply off while pressure washer motor is running or damage

to pump will result.

This unit is equipped with an automatic stop mode. When the trigger is

released the motor is shut off automatically. When the trigger is pressed again

the motor will automatically start. The time between release and engagement

must not be less than 4-5 seconds. DO NOT leave the unit in automatic stop

mode for more than 15 minutes.

Stand on a stable surface and grip gun/wand firmly with both hands. Expect

the gun to kick when triggered.

This product is intended for intermittent use only. Operate pressure washer

one hour or less in a 2 hour period.

For outdoor use only. Store indoors.

If you do not understand these precautions please call 1-866-422-4286 to

speak to a service representative for further instructions.

BEFORE STARTING

1. Move pressure washer to level ground.

2. Make sure the ON/OFF switch is in the OFF position

To reduce the risk of electrocution, keep all connections

Do not use if cord is damaged.

3. Plug the unit into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances. See the

GROUNDING paragraph.

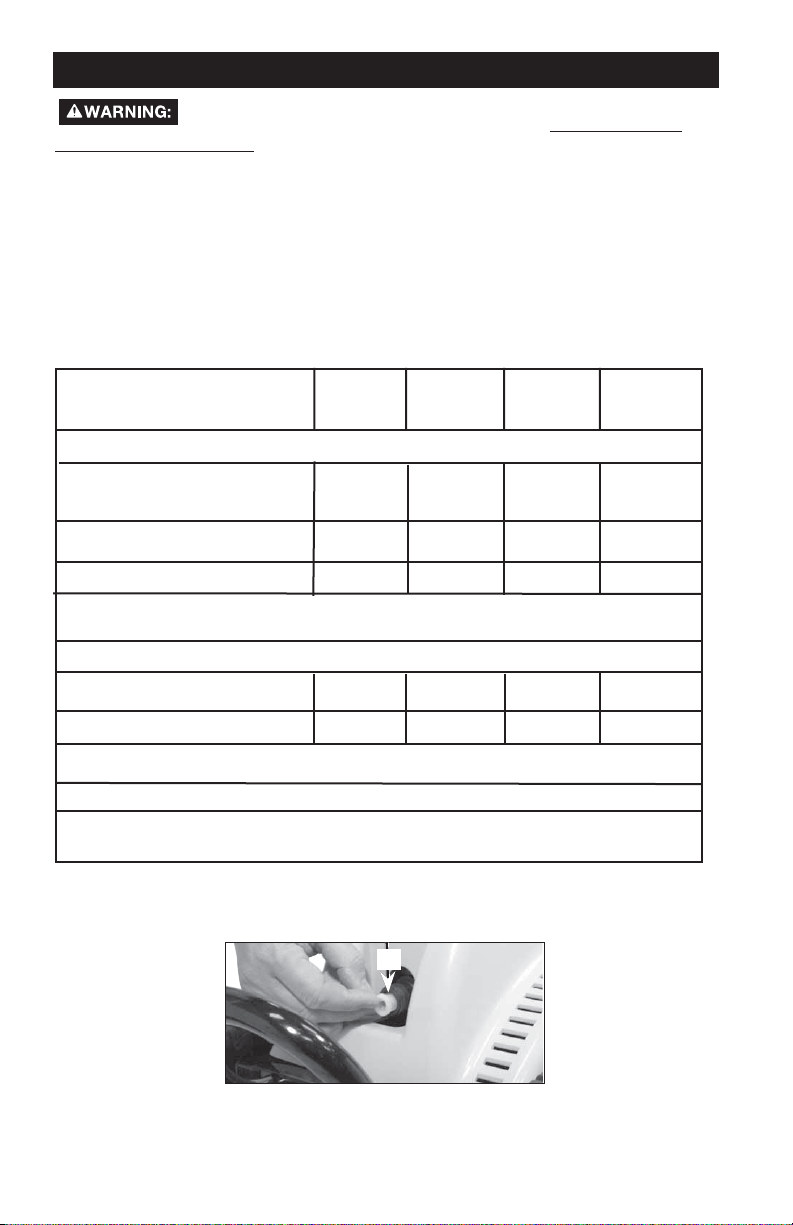

4. Press reset button and indicator light (a) will appear. You will have one of

the following GFCI switches shown below.

c

a

b

dry and off the ground. Do not touch plug with wet hands.

a

c

c

a

b

b

11 - ENG

A17913

Page 12

5. Test GFCI switch before each use, to test:

a. Press test button (b), indicator light will disappear.

c. Press reset button (c) to use unit. If indicator light does not reappear

DO NOT use unit, see troubleshooting guide.

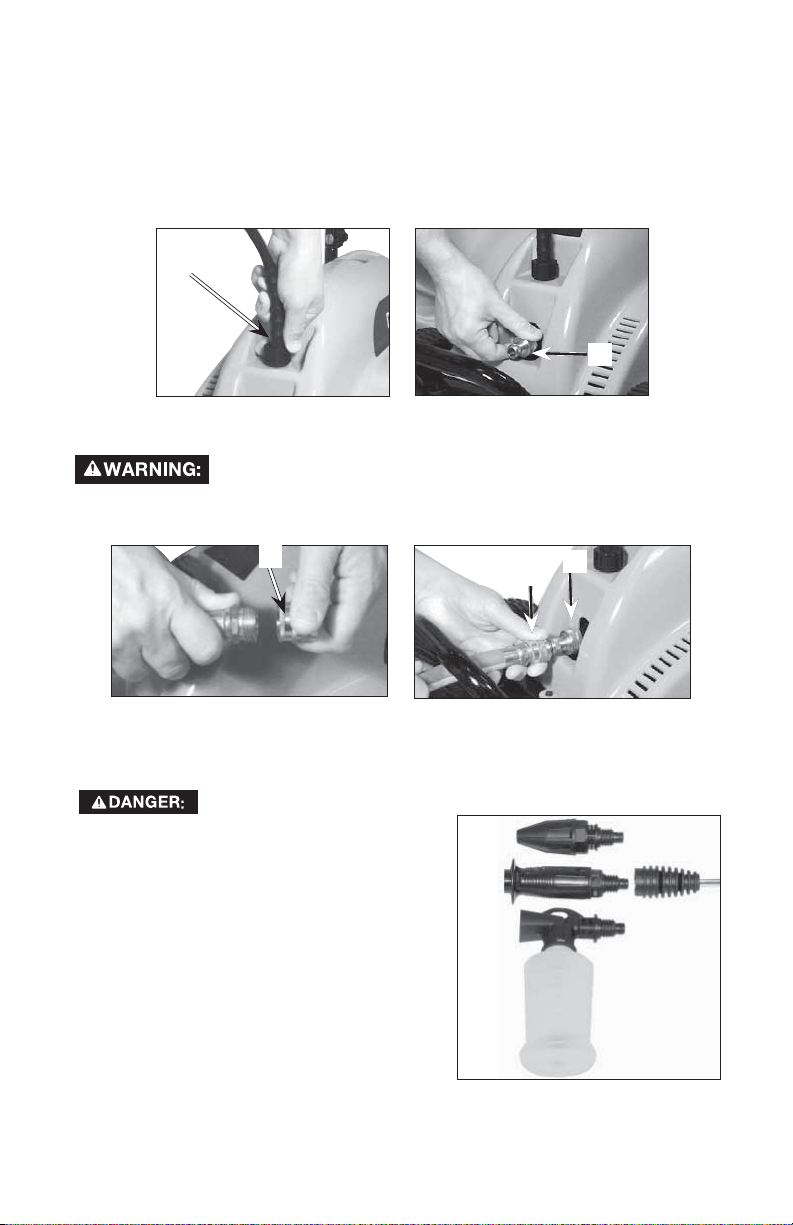

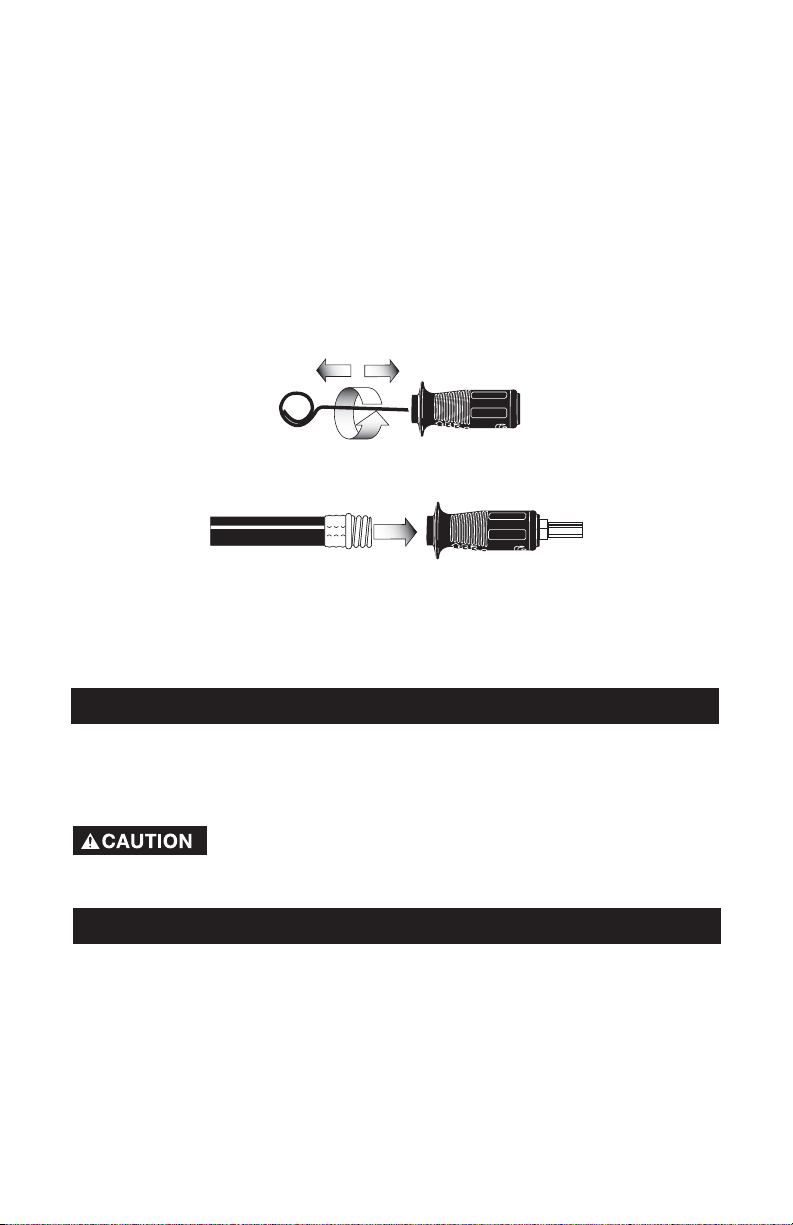

6. Con nect the high pressure hose (i) to the water outlet on the unit. The

water outlet is marked OUT.

7. Assemble quick-connect adapter (k) to water inlet.

i

k

8. Connect the quick-connect (j) to the water supply hose.

Risk of property damage.

To reduce the possibility of

contamination always protect against backflow when

connected to a potable water system.

9. Connect quick-connect (j) to quick connect adapter (k) at the water inlet.

j

k

j

NOTE: The water supply must provide a minimum of 5 gallons per minute.

10. Make sure high pressure hose and water supply hose are securely

connected.

Risk of fluid injection and laceration. Always relieve sys tem

pres sure before changing

accessories. Place on/off switch in off

a

position, turn off water sup ply, and pull gun

trigger until water stops fl owing.

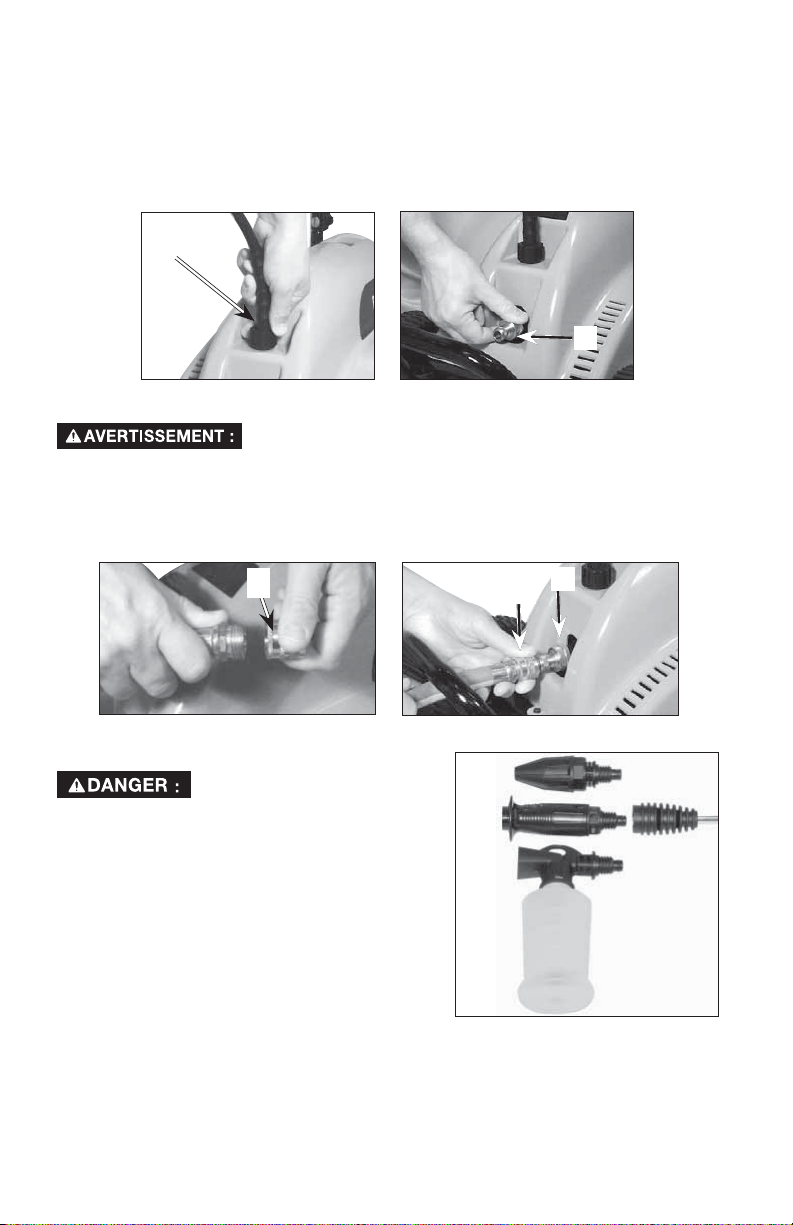

11. Connect the desired nozzle to spray

wand. To connect rotary (a) and variable

spray nozzle (b), turn clockwise until it

b

c

snaps into place. To remove nozzle, turn

nozzle counter clockwise to remove. To

connect chemical application unit (c)

see How To Use Cleaning Solution

Application Unit in this section.

12. Turn water supply on.

A17913

12- ENG

Page 13

STARTING

NOTE: Make sure water supply is turned

on.

1. Disengage the safety catch as shown.

Depress trigger to allow air to escape

and to discharge residual pressure in the

pipes.

2. With the trigger depressed, place the

ON-OFF switch in the On position. When starting motor, always keep the

trigger depressed.

Risk of fluid injection and laceration. Always engage the

cause accidental spraying.

unit off to prevent damage to the unit and see the troubleshooting guide

for instructions.

trigger lock when gun is not in use. Failure to do so could

Risk of property damage. If after running unit for a few

minutes it does not maintain steady water pressure, turn

RECOMMENDED CLEANING

• On vertical surfaces, work from the bottom upwards.

• Let the detergent sit for 1-2 minutes, DO NOT allow detergent to dry.

• To rinse detergent, apply the high pressure jet, keeping the nozzle at least

10 inches from the surface, work from the bottom up.

SHUTTING DOWN YOUR PRESSURE WASHER

1. Place the ON-OFF switch in the OFF position.

2. Turn off water supply.

3. Pull trigger on spray gun to relieve any water pressure in hose or spray gun.

4. Disconnect water supply hose from water inlet.

5. Disconnect high pressure hose from outlet.

6. If cleaning solution application unit was used, rinse cleaning solution

application tank and nozzle thoroughly.

13 - ENG

A17913

Page 14

MAINTENANCE

When performing maintenance, you may be exposed to hot

serious injury or death!

Before performing any maintenance or repair, unplug unit from power

source, let motor cool and release all water pressure.

To ensure efficient operation and longer life of your pressure washer, a routine

maintenance schedule should be prepared and followed. If the pressure washer is

used in unusual conditions, such as high-temperatures or dusty conditions, more

fre quent maintenance checks will be required.

Any maintenance or repair not listed should be performed by an Authorized

Warranty Service Center.

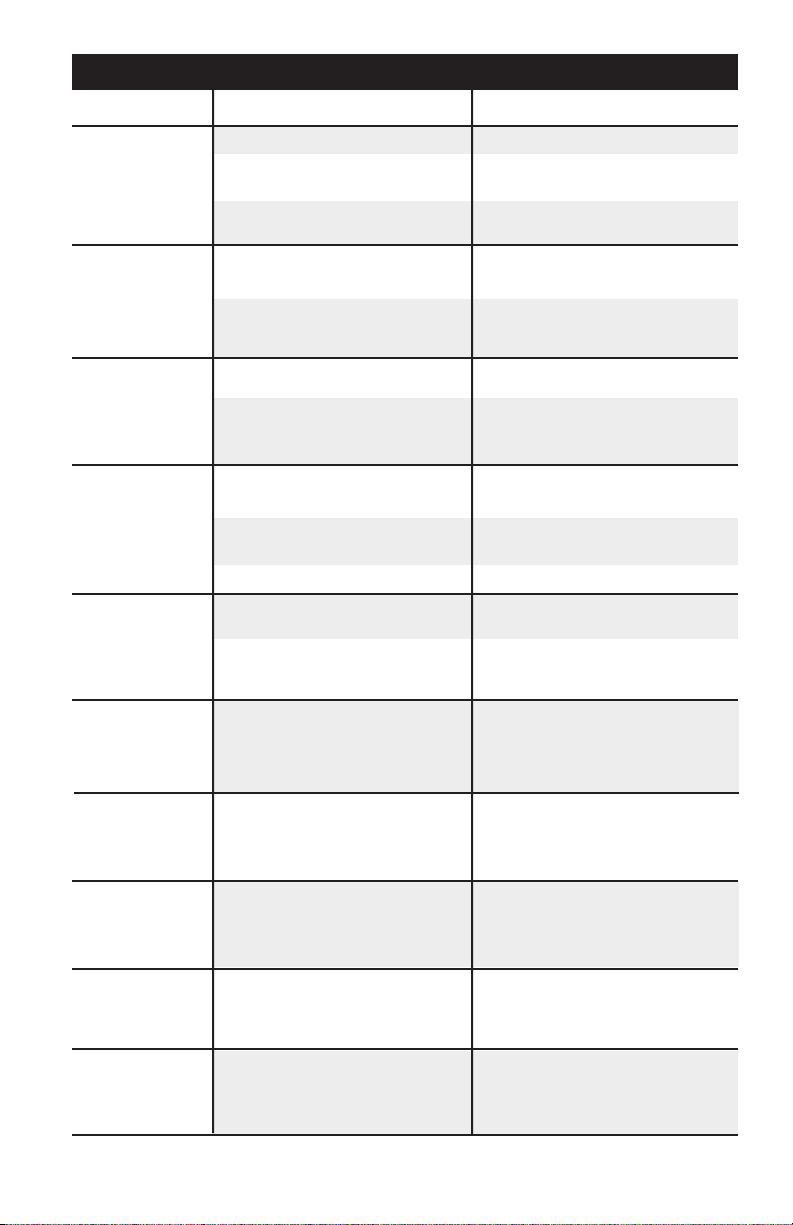

CUSTOMER RESPONSIBILITIES TABLE

MAINTENANCE TASK

PRESSURE WASHER

check high pressure hose for

leaks

check soap and chemical

hose and filter

check gun and wand for leaks

prepare for storage

HIGH PRESSURE PUMP

check/clean suction filter

surfaces, water pressure, or moving parts that can cause

Before

each use

Every 25

hours or

yearly

Every 50

hours or

yearly

Every 100

hours or

yearly

X

X

X

Prepare unit for storage if it is to remain idle for longer

than 30 days

X

check/change oil

*

* This pump does not require oil

MOTOR

Clean motor after each use. Using a cloth remove debris from motor. DO NOT

use water to clean motor.

SUCTION FILTER

1. Check and clean the suction filter (b) after every 50 hours of use.

b

A17913

14- ENG

Page 15

NOZZLE CLEANING

If the nozzle becomes clogged with foreign matter, such as dirt, excessive

pressure may develop. If the nozzle becomes partially clogged or restricted, the

pump pressure will pulsate. Clean the nozzle immediately using the nozzle kit

supplied and the following instructions:

1. Place the ON/OFF switch in the OFF position and turn off the water supply.

2. Unplug unit from power source

3. Pull trigger on gun handle to relieve any water pressure.

4. Disconnect the wand from the gun.

5. Clean the nozzle using the nozzle cleaner provided or a straightened paper

clip. Insert into the nozzle end and work back and forth until ob struc tion is

re moved.

6. Direct water supply into nozzle end to backflush loosened particles for 30

seconds.

7. Plug unit into appropriate outlet.

8. Reassemble the nozzle to the wand. Tighten securely to prevent leaks.

9. Reconnect wand to gun and turn on water supply.

10. Start pressure washer and place wand into high pressure setting to test.

ACCESSORIES

Recommended accessories for use with your pressure washer are available

for purchase from your local retailer or authorized service center. If you need

assistance in locating any accessory for your tool, please call

visit our website

branded accessories rated equal to or greater than the rating of the pressure

washer.

www.excellpressurewasher.com.

The use of any other accessory not recommended for

use with this tool could be hazardous. Use only EXCELL

1-800-888-2468 or

REPAIRS

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment

should be performed by an Authorized Warranty Service Center. Always use identical

replacement parts. For the location of the nearest Authorized Warranty Service

Center call 1-800-888-2468 or visit our website www. excellpressurewasher .com.

15 - ENG

A17913

Page 16

STORAGE

1. Drain all water from high pressure hose, coil it, and store it in cradle of the

pressure washer handle.

2. Drain all water from spray gun and spray wand by holding spray gun in a

vertical position with nozzle end pointing down and squeez ing trigger. Store

in gun/hose holder.

3. Store chemical hose, high pressure hose, spray gun, and spray wand so

they are protected from dam age, such as being run over.

It is recommended that you follow these steps to protect the internal seals of the

pressure washer when STORING THE UNIT FOR MORE THAN 30 DAYS AND/OR

WHEN FREEZING TEMPERATURES ARE EXPECTED.

*RV antifreeze needs to be run through the pump as outlined in the steps below.

4. Obtain a funnel, six ounces of *RV antifreeze, and approximately 36 inches

of garden hose with a male hose connector attached to one end.

Risk of property damage. Use only RV antifreeze. Any other

an ti freeze is corrosive and can damage pump.

5. Connect the quick-connect (j) to the garden hose.

j

6. Connect 36 inch length of hose to water inlet of pump.

7. Add *RV antifreeze to hose as shown.

8. Place the ON-OFF switch in the On position then Off position until an ti-

freeze comes out of high pressure hose con nec tion of pump.

9. Remove garden hose from water inlet of pump.

* Windshield washer fluid may also be used

A17913

16- ENG

Page 17

PROBLEM

Motor will not

start and there

is no humming

sound

Power

source circuit

continues to

trip or blow

fuses

TROUBLE SHOOTING GUIDE

CAUSE

Pressure washer not plugged in.

“RESET” button on GFCI not

pushed.

Circuit breaker has tripped or fuse

is blown.

Too much load already on circuit.

Using an extension cord.

Plug in pressure washer.

Push “RESET” button.

Reset breaker or replace fuse.

Reduce load on circuit.

Try another 15 amp circuit.

DO NOT use extension cords.

CORRECTION

Motor hums but

will not start

No or low

pressure

Excess noise

Pressure

fluctuates without open ing gun

GFCI switch indicator light does

not appear after

depressed

GFCI test fails

Unit does not

maintain steady

water pressure

Unit continues

to trip GFCI

switch

Using an extension cord.

Supply voltage below required

minimum.

Low water supply.

High pressure hose is too long.

Worn nozzle.

Restricted, insufficient water

supply, or air in the water line.

Water temperature is too high.

Water leak in high pressure fittings,

hose, or gun.

Circuit breaker has tripped or fuse

is blown.

Circuit breaker has tripped or fuse

is blown.

Nozzle clogged Clean nozzle, if unit still does not

Nozzle clogged

DO NOT use extension cords.

Check the voltage of the main

supply line.

Water supply must be at least 5

GPM @ 20 psi.

Use high pressure hose under

100 feet.

Replace nozzle.

Check supply hose, faucet, and

inlet screen.

Do not use water from a hot

water source, use water only from

a cold water faucet.

Replace hose or gun. If problem

continues take to authorized

service center.

Reset breaker or replace fuse. If

indicator light still does not appear

have receptacle checked by a

qualified electrician.

Reset breaker or replace fuse. If

indicator light still does not appear

have receptacle checked by a

qualified electrician.

maintain steady water pressure,

turn unit off and contact customer

service at 1-866-422-4286

Clean nozzle, if unit still does not

maintain steady water pressure,

turn unit off and contact customer

service at 1-866-422-4286

17 - ENG

A17913

Page 18

LIMITED WARRANTY

ONE YEAR LIMITED WARRANTY ON PRODUCT COMPONENTS EXCLUDING IC2 PUMP

Black & Decker (U.S.) Inc. warrants to the original purchaser that the frame, wheels,

gun, hose, wand, spray nozzle(s) and other components (excluding the IC2 pump) of the

Excell pressure washers covered under this warranty are free from defects in material and

workmanship for one year from the date of purchase.

TWO YEAR LIMITED WARRANTY ON IC2 PUMP

Black & Decker warrants to the original purchaser that the IC2 pump of the Excell pressure

washers covered under this warranty is free from defects in material and workmanship

for two years from the date of purchase. The two year limited warranty applies to the IC2

pump only.

Black & Decker will repair or replace, at Black & Decker option, products or components

which have failed within the above warranty periods. Service will be scheduled according

to the normal work fl ow and business hours at the service center location, and the

availability of replacement parts. All decisions of Black & Decker with regard to this limited

warranty shall be fi nal.

This warranty gives you specifi c legal rights, and you may also have other rights which

vary from state to state.

RESPONSIBILITY OF ORIGINAL PURCHASER (Initial User):

• To process a warranty claim on your Excell pressure washer, return it to the place of

purchase.

• Retain original cash register sales receipt as proof of purchase for warranty work.

• Use reasonable care in the operation and maintenance of the product as described in

the Owners Manual(s).

THIS WARRANTY DOES NOT COVER:

• Merchandise sold as reconditioned, used as rental equipment, or fl oor or display

models.

• Merchandise that has become damaged or inoperative because of ordinary wear,

misuse, cold, heat, rain, excessive humidity, freeze damage, use of improper

chemicals, negligence, accident, failure to operate the product in accordance with the

instructions provided in the Owners Manual(s) supplied with the product, improper

maintenance, the use of accessories or attachments not recommended by Black &

Decker, or unauthorized repair or alterations.

• Repair and transportation costs of merchandise determined not to be defective.

• Costs associated with assembly, required oil, adjustments or other installation and

start-up costs.

• Expendable parts or accessories supplied with the product which are expected to

become inoperative or unusable after a reasonable period of use, including but not

limited to springs, nozzles, o-rings, washers, and similar accessories.

• Merchandise sold by Black & Decker which has been manufactured by and identifi ed

as the product of another company, such as gasoline engines. The product

manufacturer’s warranty, if any, will apply.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR

EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION

OF THE PRODUCT IS NOT COVERED BY THIS WARRANTY. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

• IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM

THE DATE OF ORIGINAL PURCHASE. Some states do not allow limitations on how

long an implied warranty lasts, so the above limitations may not apply to you.

A17913

18- ENG

Page 19

Registre toda la información y adhiera

el comprobante de compra aquí para

referencia futura.

Fecha de compra:_______________________

N° de serie: ____________________________

¿Consultas? 1-800-888-2468

Familiarícese con su lavadora a presión,

obtenga respuesta rápida a las preguntas

más frecuentes

y regístrela en línea en:

www.excellpressurewasher.com

Laveuse à pression

Modèle VR1600E

Table des matières

Mesures de sécurité/Définitions……… ........20

Mesures de sécurité importantes ...........20-24

Fiche technique ..............................................24

Contenu de la boîte .......................................25

Instructions d’assemblage ............................25

Instructions d’utilisation ........................... 26-31

Entretien ....................................................32-33

Accessoires ....................................................33

Réparations ....................................................33

Entreposage ...................................................34

Guide de dépannage .....................................35

Garantie ..........................................................36

English ........................................................1-18

Español .....................................................37-55

IMPORTANT

Assurez-vous que toute personne qui utilisera cet équipement lise

attentivement ces instructions avant de l’utiliser.

N° de pièce A17913 Rev. 0 5/10/06

Page 20

MESURES DE SÉCURITÉ - DÉFINITIONS

Ce guide contient des renseignements importants que vous deviez bien saisir. Cette

information porte sur VOTRE SÉCURITÉ et sur LA PRÉVENTION DE PROBLÈMES

D'ÉQUIPEMENT. Afi n de vous aider à identifi er cette information, nous avons utilisé

les symboles ci-dessous. Veuillez lire attentivement ce guide en portant une attention

particulière à ces symboles.

Indique un danger

pas évité, causera de graves blessures

ou la mort.

danger qui, s’il n’est pas évité, pourrait

causer de graves blessures ou la mort.

cancérigènes et pouvant entraîner des anomalies congénitales et d'autres dangers

relatifs à la reproduction. Se laver les mains après la manipulation de l'appareil.

imminent qui, s'il n'est

s'il n'est pas évité, peut causer des

blessures mineures ou moyennes.

Indique la

possibilité d’un

possibilité d’un danger qui, s’il n’est pas

évité, peut causer des dommages à la

propriété.

Ce produit contient des produits chimiques, dont du

plomb, reconnus par l'État de la Californie comme étant

Indique la possibilité

d'un danger qui,

Sans le symbole

d’alerte. Indique la

MESURES DE SÉCURITÉ IMPORTANTES

Lisez le Guide de l’utilisateur. Ne tentez pas d’utiliser cet

l’assemblage, l’utilisation et l’entretien de ce Guide de l’utilisateur.

RISQUE D'EXPLOSION OU D'INCENDIE

appareil avant d’avoir lu les directives sur la sécurité,

LISEZ ET CONSERVEZ CES INSTRUCTIONS

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• L'utilisation d'acides, de produits chimiques

toxiques ou corrosifs, de poisons,

d'insecticides ou de toute sorte de solvant

inflammable dans ce produit pourrait

provoquer des blessures graves ou la mort.

• Une restriction de toute ouverture de

ventilation de la laveuse à pression

causera une surchauffe importante et

risque de causer un incendie.

RISQUE D'ASPHYXIE

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Certains liquides nettoyants contiennent

des substances pouvant provoquer des

blessures à la peau, aux yeux ou au

système respiratoire.

A17913

• Ne pas vaporiser des liquides

inflammables.

• Ne jamais placer des objets contre

ou sur la laveuse à pression. Utiliser

la laveuse à pression dans un endroit

ouvert, à une distance minimum de

30 cm (12 po) de tout mur ou de toute

obstruction qui pourrait restreindre le

débit d'air frais vers les ouvertures de

ventilation.

• Utiliser uniquement des liquides

nettoyants spécialement recommandés

pour les laveuses haute pression. Suivre

les recommandations des fabricants.

Ne pas utiliser de produit à blanchir au

chlore ou tout autre composé corrosif.

20- FR

Page 21

RISQUE D'INJECTION ET DE LACÉRATION

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Votre laveuse haute pression fonctionne

à des pressions de liquides et des

vitesses suffisamment élevées pour

pénétrer la peau de l'homme et

animale, ce qui pourrait se solder par

une amputation ou autre blessure

grave. Des fuites provoquées par des

raccords lâches ou des tuyaux usés ou

endommagés peuvent se solder par

des blessures par injection. NE PAS

TRAITER UN INJECTION DE LIQUIDE

COMME UNE SIMPLE COUPURE !

Consulter un médecin immédiatement !

• Inspecter périodiquement le tuyau haute

pression. Remplacer immédiatement

le tuyau s'il est endommagé, usé, s'il a

fondu en contact avec le moteur ou s'il

démontre un signe de fissure, des bulles,

des trous d'épingle ou tout autre fuite.

Ne jamais saisir untuyau haute pression

quifuit ou est endommagé.

• Ne jamais toucher, saisir ou essayer de

couvrir un trou minuscule ou tout autre

fuite similaire sur le tuyau haute pression.

Le jet d'eau EST sous haute pression et

PÉNÈTRERA la peau.

• Ne jamais mettre les mains

devantl'embouchure.

• Éloigner le jet, ne pas le diriger vers soimême ou autrui.

• S'assurer que le tuyau et les raccords

sont serrés et en bon état. Ne jamais

s'agripper au tuyau ou aux raccords en

cours de fonctionnement.

• Ne pas mettre le tuyau en contact avec

le silencieux.

• Ne jamais attacher ou retirer le tube ou

les raccords du tuyau avec le système

sous pression.

• Il y a risque de blessures si la pression

n'est pas réduite avant d'essayer

de procéder à un entretien ou un

démontage.

•

Pour dégager la pression de l'appareil, placer

l'interrupteur marche/arrêt « ON/OFF » dans la

position « OFF », couper l'alimentation d'eau

et enfoncer la détente jusqu'à ce que l'eau

arrête de s'écouler.

• Utiliser uniquement des tuyaux et

accessoires classés pour des pressions

plus élevées que le PSI de la laveuse

haute pression.

RISQUE DE BLESSURE PAR JET

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Un jet de liquide à haute vitesse peut

briser des objets et projeter les éclats à

haute vitesse.

• Des objets légers ou mal fixés peuvent

se transformer en projectiles dangereux.

• Toujours porter des lunettes de sécurité

conformes à la norme ANSI Z87.1 Porter

des vêtements protecteurs pour se

protéger de jets accidentels.

• Ne jamais diriger la lance ou le jet vers

une personne ou des animaux.

• Toujours fixer solidement le verrou de

la détentelorsque le tube pulvérisateur

est inutilisé pour empêcher tout

fonctionnement accidentel.

• Ne jamais fixer, de façon permanente, la

détente en position arrière (ouverte).

21 - FR

A17913

Page 22

RISQUE D'UTILISATION DANGEREUSE

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Une utilisation dangereuse de la laveuse

haute pression pourrait provoquer de

graves blessures, voire son propre

décès ou celle d'autres personnes.

• Ne pas utiliser de produit à blanchir au

chloreou tout autre composé corrosif.

• Se familiariser ave le fonctionnement

et les commandes de la laveuse haute

pression.

• Tenir la zone de travail exempte de

toutes personnes, animaux et obstacles.

• Ne pas utiliser le produit en cas de

fatigue ou sous l'emprise d'alcool ou de

drogues. Rester vigilant en tout temps.

• Ne jamais rendre inopérant les

caractéristiques de sécurité du produit.

• Ne jamais laisser le tube pulvérisateur

sans surveillance lors du fonctionnement

de l'appareil.

• La pompe de la laveuse à pression

contient des pièces mobiles. Le contact avec des pièces mobiles peut

causer des blessures graves.

• Le pistolet et le tube de pulvérisation sont

des outils de nettoyage puissants qui

• Ne jamais utiliser l'appareil lorsque le

protecteur de la pompe est enlevé.

• Ne pas utiliser l'appareil avec des pièces

manquantes, brisées ou non autorisées.

• Garder la laveuse haute pression hors de

portée des enfants en tout temps.

ressemblent à un jouet pour un enfant.

• Le pistolet et le tube de pulvérisation

réagissent à la pression du jet et

provoqueront un effet de rebond

qui pourrait faire glisser, ou tomber,

l'opérateur ou rediriger le jet. Une

maîtrise imparfaite du pistolet et de la

lance peut provoquer des blessures à

soi même et à autrui.

• Ne pas trop tendre les bras ou se tenir

debout sur une surface instable.

• Ne pas utiliser une laveuse haute

pression debout sur une échelle.

• Saisir solidement à deux mains

le pistolet/tube de pulvérisation.

S'attendre à un effet de rebond lors de

l'enclenchement de la détente.

ATTENTION SURFACES CHAUDES

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Le contact de surfaces chaudes comme

les composants d'échappement moteur,

pourrait provoquer des brûlures graves

• En cours de fonctionnement, ne toucher

que les surfaces de commande de la

laveuse haute pression. Tenir en tout

temps les enfants à l'écart de la laveuse

haute pression. Ils n'ont pas assez de

jugement pour reconnaître les dangers

inhérents au produit.

A17913

22- FR

Page 23

RISQUE DE BRÛLURE CHIMIQUE

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• L'utilisation d'acides, de produits

chimiques toxiques ou corrosifs,

de poisons, d'insecticides, ou de tout

type de solvant inflammable avec le

produit risque de se solder par des

blessures graves, voire la mort.

• Ne pas utiliser d'acides, d'essence,

de kérosène ou tout autre matériel

inflammable avec ce produit.

Utiliser uniquement des détergents

domestiques, des nettoyants et

dégraissants recommandés pour les

laveuses haute pression.

• Porter des vêtements protecteurs pour

protéger les yeux et la peau contre le

contact avec les matériaux sous pression.

RISQUE DE

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Un jet en direction de prises électriques

ou d'interrupteurs ou tout objet branché

à un circuit électrique pourrait se solder

par un choc électrique..

• Ce produit est alimenté par électricité. Il

contient et vaporise de l'eau ainsi que des

liquides conducteurs. Une utilisation inappropriée peut entraîner une électrocution.

• Le disjoncteur de fuite à la terre (DFT) ne fonctionnera pas de manière appropriée, à moins

qu'il ne soit branché à un circuit électrique

entièrement mis à la terre.

•

Les rallonges peuvent entraîner des

chocs électriques.

RISQUE DE BLESSURE EN SOULEVANT LE PRODUIT

CE QUI PEUT SE PRODUIRE COMMENT L'ÉVITER

• Essayer de soulever un objet trop

lourd peut se solder par de graves

blessures.

CHOC ÉLECTRIQUE

• Débrancher tout produit fonctionnant

à l'électricité avant d'essayer de le

nettoyer. Éloigner le jet des prises

électriques et interrupteurs.

•

Toujours brancher l'ensemble de cordon

d'alimentation dans un circuit électrique polarisé

et mis à la terre de façon appropriée. L'ensemble

de cordon d'alimentation est équipé d'un disjoncteur de fuite à la terre (DFT) pour votre protection.

• Si l'ensemble de cordon d'alimentation est

endommagé, il doit être remplacé au complet

dans un Centre de service après-vente autorisé. Consulter les instructions sur la mise à la

terre.

•

Ne pas utiliser avec des rallonges.

• La laveuse haute pression est trop

lourde pour être soulevée par une

seule personne. Demander de l'aide

avant de la soulever.

Le puissant jet de la laveuse à pression est capable

la peinture d'automobiles, les garnitures d'auto ainsi que les objets délicats tels

que les fleurs et arbustes. Avant de vaporiser, vérifiez l'objet à nettoyer afin de

vous assurer qu'il est assez robuste pour résister à la puissance du jet sans subir

de dommages. Évitez d'utiliser le jet à débit concentré sauf pour des surfaces très

résistantes telles que le béton ou l'acier.

d'endommager les surfaces fragiles telles que le bois, le verre,

LISEZ ET CONSERVEZ CES INSTRUCTIONS

23 - FR

A17913

Page 24

INSTRUCTIONS DE MISE À LA TERRE

Ce produit doit être mis à la terre. S'il ne fonctionne pas de manière appropriée ou s'il subit une

panne, une bonne mise à la terre fournit une voie de moindre résistance pour le courant électrique

afin de réduire le risque de chocs électriques. Ce produit est doté d'un cordon avec conducteur

de mise à la terre de l'équipement et d'une fiche de mise à la terre. La fiche doit être branchée

dans une prise de courant appropriée qui a été installée et mise à la terre conformément à tous les

codes électriques et ordonnances locaux.

Un branchement inapproprié du conducteur de mise à la terre de

un électricien qualifié ou un technicien de service si vous avez des doutes

concernant la mise à la terre appropriée de votre appareil. Ne modifiez pas la fiche

fournie avec le produit ; si elle ne s'insère pas facilement dans la prise de courant,

faites installer une prise de courant appropriée par un électricien qualifié. N'utilisez

aucun type d'adaptateur avec ce produit.

de la laveuse haute pression.

l'équipement peut entraîner un risque d'électrocution. Consultez

Pour prévenir une surcharge de circuit, ne pas utiliser d’autre

dispositif électrique relié au même circuit lors du fonctionnement

RALLONGES

Utilisez un boyau à haute pression plus long au lieu de rallonges électriques afin d'éviter une

chute de tension et une perte de puissance du moteur et pour empêcher toute surchauffe.

N'UTILISEZ PAS DE RALLONGES.

REMARQUE : L'utilisation d'un boyau à haute pression plus long, réduira la puissance de la

laveuse à pression à une valeur inférieure à 1600 psi.

PROTECTION PAR DISJONCTEUR DE FUITE À LA TERRE

Cette laveuse à pression est dotée d'un disjoncteur de fuite à la terre (DFT) qui est

incorporé dans la fiche du cordon d'alimentation. Ce dispositif offre une protection

supplémentaire contre le risque de chocs électriques. Si vous devez remplacer la fiche

ou le cordon, utilisez seulement des pièces identiques avec une protection par DFT.

FICHE TECHNIQUE

Modèle

VR1600E

PSI Max* 1600 (11031,6 kPa)

PSI en Fonctionnement

GPM Max* 1,5 (5,7 L/min)

GPM en Fonctionnement

* Débit d'eau et limites maximales de pression déterminés en conformité avec la

norme PW101 de la PWMA américaine.

A17913

1440 (9859.5 kPa)

1,35 (5,1 L/min)

24- FR

Page 25

CONTENU DE LA BOÎTE

Guide de

l’utilisateur

en anglais,

espagnol et

français

Poignée

Ensemble de moteur,

châssis et roues

Boutons

Trousse de nettoyage

de la buse

Boulons

de selle

Unité d'application

de produit chimique

Pistolet de vaporisation

Poignée dans un sac

Buse rotative

Adaptateur à

connexion rapide

Sac de pièces

Lance de vaporisation

INSTRUCTIONS D'ASSEMBLAGE

1. Placez l’ensemble de poignée sur le châssis et

attachez la poignée au châssis.

Risque de blessures corporelles.

module et le cadre pour éviter de se pincer les mains.

2. Attachez la lance au pistolet et bien serrer.

3. Attachez le boyau à haute pression au pistolet et

bien serrer.

Ne pas placer les mains entre le

Boyau à haute

pression

Buse de vaporisation

variable

Raccord à

connexion

rapide

25 - FR

A17913

Page 26

INSTRUCTIONS D'UTILISATION

LISEZ CE GUIDE DE L’UTILISATEUR ET TOUTES LES MESURES DE SÉCURITÉ AVANT

D’UTILISER CET APPAREIL. Comparez les illustrations avec votre appareil afi n de vous

familiariser avec l’emplacement des commandes et des réglages. Conservez ce guide pour

les références futures.

Pistolet de

vaporisation

Cordon

d'alimentation

électrique

Interrupteur

marche/arrêt

du moteur

Moteur

Lance de

vaporisation

avec buse de

vaporisation

variable

Boyau à

haute

pression

Sortie

d'eau

Entrée

d'eau

avec

filtre

Pompe à haute pression

Adaptateur à connexion rapide

Raccord à connexion rapide

Unité

d'application

de solution

de nettoyage

Buse rotative

ÉLÉMENTS DE BASE D’UNE LAVEUSE À PRESSION

Pompe à haute pression (située à l’intérieur du bouclier)-: Augmente la pression de la source

d’eau.

Moteur (située à l’intérieur du bouclier) : Entraîne la pompe à haute pression.

Boyau à haute pression : Achemine l'eau pressurisée de la pompe jusqu'au pistolet et à la lance.

Pistolet de vaporisation : S'attache à la lance pour régler le débit d'eau, la direction et la pression.

Lance de vaporisation avec buse de vaporisation variable : La buse s'ajuste d'un jet

étroit à un jet en éventail. Le jet de vaporisation peut être réglé en tournant la buse dans le

sens des aiguilles d'une montre et/ou dans le sans contraire.

Buse rotative - La buse rotative augmente l'efficacité de nettoyage en vous permettant de

couvrir une surface plus grande tout en utilisant un jet de vaporisation concentré.

Unité d'application de solution de nettoyage - Cette unité est utilisée pour appliquer la

solution de nettoyage. Consultez la partie intitulée « Utilisation de l'unité d'application de

solution de nettoyage » de cette section.

TERMINOLOGIE DES LAVEUSES À PRESSION

Disjoncteur de fuite à la terre (DFT) : Cette laveuse à pression est dotée d'un disjoncteur

de fuite à la terre (DFT) qui est incorporé dans la fiche du cordon d'alimentation. Ce

dispositif offre une protection supplémentaire contre le risque de chocs électriques. Si vous

devez remplacer la fiche ou le cordon, utilisez seulement des pièces identiques avec une

protection par DFT.

A17913

26- FR

Page 27

Système d'arrêt total : Cet appareil est doté d'un système d'arrêt total. Lorsque la détente

est relâchée, le moteur s'arrête automatiquement. Lorsqu'on appuie sur la détente, le moteur

se remet automatiquement en marche. Le temps entre le relâchement et le réengagement

ne peut pas être inférieur à 4 ou 5 secondes. Ne laissez pas l'appareil en mode d'arrêt

automatique pendant plus de 15 minutes.

psi : Livres par pouce carré. Une unité de mesure de pression d'eau. Également utilisé pour

la pression d'air, la pression hydraulique, etc.

GPM : Gallons par minute. L'unité de mesure du débit d'eau dans la laveuse à pression.

CU : Unités de nettoyage. gal./min x psi.

Source d'eau : Toutes les laveuses à pression ont besoin d'une source d'eau. Les

exigences minimums pour la source d'eau sont de 20 psi et de 19 litres (5 gallons) à la

minute.

UTILISATION

IMPORTANT : Lisez attentivement la section sur l'utilisation de la laveuse à pression

avant d'utiliser l'appareil.

UTILISATION DE LA LANCE DE VAPORISATION

La buse à l'extrémité de la lance peut être tournée pour choisir un jet étroit ou un jet en

éventail, tel qu'illustré.

Jet étroit

Jet en éventail

UTILISATION DE L'UNITÉ D'APPLICATION DE SOLUTION DE

NETTOY AGE

REMARQUE : N'utilisez que des solutions de nettoyage conçues pour l'usage dans une

laveuse à pression. N'utilisez jamais de l'eau de Javel.

1. Réglez l'interrupteur marche/arrêt à la position d'arrêt « OFF ».

2. Fermez le robinet de la source d'eau.

3. Attachez l'unité d'application de solution de nettoyage à la lance tel qu'illustré et

serrez-la bien. Saisissez l'extrémité de la buse et tournez-la jusqu'à ce que l'unité

d'application de solution de nettoyage soit orientée correctement.

27 - FR

A17913

Page 28

4. Retirez le réservoir d'application de solution de nettoyage de la buse d'application.

a

5. La pression du jet du mélange de savon peut être réglée en réglant le tuyau situé dans

la buse d'application de solution de nettoyage (a).

a. Tirez le tuyau (b) de la buse d'application de solution de nettoyage.

b

b. Positionnez l'encoche (c) du tuyau au niveau de mélange de savon désiré

(1 à 6) ; 1 est le mélange le plus élevé et 6 est le mélange le plus faible.

c

c. Poussez le tuyau à sa position originale.

6. Remplissez le réservoir d'application avec un détergent.

7. Poussez le réservoir d'application de solution de nettoyage sur la buse d'application

de solution de nettoyage. Tournez pour le verrouiller en place.

8. Consultez les paragraphes intitulés « Avant le démarrage » et « Démarrage de la

laveuse à pression » de cette section pour continuer.

A17913

28- FR

Page 29

LISEZ ATTENTIVEMENT TOUS LES AVERTISSEMENTS AVANT DE METTRE

L'APPAREIL EN MARCHE.

Risque d'injection de liquide et de lacération. Lorsque vous avez réglé

vaporisation à haute pression atteindre la peau nue, les yeux ou les animaux. Cela risque de

provoquer des blessures graves.

Votre laveuse à pression fonctionne à une pression et à une vitesse suffisamment élevées

pour faire pénétrer le fluide dans la peau de personnes ou d'animaux et causer des

blessures graves ou la nécessité d'une amputation. Une fuite causée par des raccords

desserrés ou par un boyau usé ou endommagé peut aboutir à une blessure par injection.

NE TRAITEZ PAS L'INJECTION D'UN FLUIDE COMME UNE SIMPLE COUPURE !

Consultez immédiatement un médecin !

de la pompe.

N'utilisez PAS d'eau chaude. Utilisez seulement de l'eau froide.

Ne fermez jamais le robinet de la source d'eau lorsque le moteur de la laveuse à pression

est en marche puisque cela risque d'endommager la pompe.

Cet appareil est doté d'un mode d'arrêt automatique. Lorsque la détente est relâchée,

le moteur s'arrête automatiquement. Lorsqu'on appuie sur la détente, le moteur se

remet automatiquement en marche. Le temps entre le relâchement et le réengagement

ne peut pas être inférieur à 4 ou 5 secondes. NE laissez PAS l'appareil en mode d'arrêt

automatique pendant plus de 15 minutes.

Tenez-vous sur une surface stable et saisissez le pistolet/la lance fermement avec les

deux mains. Attendez-vous à ressentir un contre-coup lors du déclenchement.

Ce produit a été conçu pour un fonctionnement intermittent seulement. N'utilisez la

laveuse à pression que pendant une heure ou moins dans une période de 2 heures.

Uniquement pour utilisation extérieure. Le ranger à l’intérieur.

Si vous ne comprenez pas ces mises en garde, veuillez nous téléphoner au

1-866-422-4286 et communiquer avec un représentant du service à la clientèle pour

obtenir de plus amples instructions.

l'appareil à la position de haute pression, NE laissez PAS le jet de

Ne tirez jamais sur le boyau d'alimentation d'eau pour déplacer la

laveuse à

pression. Cela risque d'endommager le boyau et/ou l'entrée

AVANT LE DÉMARRAGE

1. Placez la laveuse à pression sur une surface de niveau.

2. Assurez-vous que l'interrupteur marche/arrêt est à la position d'arrêt « OFF ».

Afin de réduire le risque d'électrocution, assurez-vous que toutes les

pas à la fiche avec des mains humides. N'utilisez pas le cordon s'il est endommagé.

3. Branchez l'appareil dans une prise de courant appropriée qui a été installée et mise à la

terre conformément à tous les codes et ordonnances locaux. Consultez le paragraphe

sur la MISE À LA TERRE.

4. Appuyez sur le bouton de rétablissement et le voyant lumineux (a) s'illuminera. Un des

interrupteurs à DFT montrés ci-dessous sera présent sur votre équipement.

connexions demeurent sèches et qu'elles ne sont pas par terre. Ne touchez

c

a

b

c

a

b

29 - FR

a

c

b

A17913

Page 30

5. Vérifiez le DFT avant chaque utilisation :

a. Appuyez sur le bouton d'essai (b) et le voyant lumineux s'éteindra.

b. Appuyez sur le bouton de rétablissement (c) pour utiliser l'appareil. Si le voyant

6. Branchez le boyau à haute pression (i) à la sortie d'eau de l'appareil. La sortie d'eau est

7. Posez l'adaptateur à connexion rapide (k) à l'entrée d'eau.

lumineux ne s'illumine pas de nouveau, N'utilisez PAS l'appareil. Consultez le

guide de dépannage.

identifiée par le mot « OUT ».

i

k

8. Posez le raccord à connexion rapide (j) au boyau d'alimentation d'eau.

Pour réduire la possibilité de contamination, toujours protéger

d’apport en eau potable.

9. Posez le raccord à connexion rapide (j) à l'adaptateur à connexion rapide (k), situé à

l'entrée d'eau.

REMARQUE : La source d'alimentation d'eau doit avoir un débit minimum de 19 litres par

minute (5 gallons par minute).

le système contre les refoulements s’il est raccordé au système

j

k

j

10. Assurez-vous que le boyau à haute pression et le boyau d'alimentation d'eau sont bien

connectés.

Risque d'injection de liquide et de

le système avant de changer un accessoire. Déplacer

l’interrupteur marche/arrêt en position d’arrêt, fermer

l’alimentation d’eau et appuyer sur la détente du

pistolet jusqu’à évacuation complète de l’eau.

11. Connectez la buse désirée à la lance. Pour

connecter la buse rotative (a) ou la buse de

vaporisation variable (b), tournez la buse dans

le sens des aiguilles d'une montre jusqu'à ce

qu'elle s'enclenche. Pour retirer la buse, tournezla dans le sens contraire des aiguilles d'une

montre. Pour connecter l'unité d'application de

produit chimique (c), consultez la partie intitulée

« Utilisation de l'unité d'application de solution de nettoyage » de cette section.

12. Ouvrez le robinet de la source d'eau.

A17913

lacération. Toujours décompresser

30- FR

a

b

c

Page 31

DÉMARRAGE DE LA LAVEUSE À PRESSION

REMARQUE : Assurez-vous que la source d'alimentation d'eau est ouverte.

1. Désengagez le verrou de sûreté, tel qu indiqué.

Appuyez sur la détente pour libérer l'air et pour

dégager la pression résiduelle dans les tuyaux.

2. Tout en appuyant sur la détente, réglez

l'interrupteur marche/arrêt à la position de marche

« ON ». Continuez à appuyer sur la détente lors

du démarrage du moteur.

Risque de blessure par jet. Verr ouiller la détente lorsque le pistolet

n'est pas utilisé pour empêcher une pulvérisation accidentelle.

Risque de dommages à la propriété. Si, après avoir utilisé

d'eau uniforme, arrêtez l'appareil pour éviter de l'endommager et consultez le guide de

dépannage pour obtenir des instructions.

l'appareil pendant plusieurs minutes, il ne conserve pas une pression

NETTOYAGE RECOMMANDÉ

• Pour nettoyer une surface verticale, commencez en bas et continuez vers le haut.

• Laissez le détergent travailler pendant 1 à 2 minutes, mais N'ATTENDEZ PAS jusqu'à

ce que le détergent soit sec.

• Pour rincer le détergent, utilisez le jet à haute pression, tout en maintenant la buse à

une distance minimum de 25 cm (10 po) de la surface à nettoyer et en travaillant du

bas en haut.

ARRÊT DE LA LAVEUSE À PRESSION

1. Réglez l'interrupteur marche/arrêt à la position d'arrêt « OFF ».

2. Fermez le robinet de la source d'alimentation d'eau.

3. Appuyez sur la détente du pistolet de vaporisation pour dégager toute pression d'eau

dans le boyau ou dans le pistolet.

4. Débranchez le boyau d'alimentation d'eau de l'entrée d'eau.

5. Débranchez le boyau à haute pression de la sortie.

6. Si vous avez utilisé l'unité d'application de solution de nettoyage, rincez bien le

réservoir d'application de solution de nettoyage et la buse.

31 - FR

A17913

Page 32

ENTRETIEN

Lorsque vous effectuez de l'entretien, vous pouvez être

aux pièces en mouvement qui peuvent causer des blessures graves ou la mort !

Avant d'effectuer tout entretien ou toute réparation, débranchez l'appareil de la sour ce

d'alimentation, laissez le moteur refroidir et dégagez toute la pression d'eau.

Afin d'assurer le bon fonctionnement et une durée de vie prolongée de votre laveuse à

pression, vous devez préparer et suivre un calendrier d'entretien régulier. Si votre laveuse à

pression est utilisée dans un environnement défavorable, tel qu'à des températures élevées

ou des conditions poussiéreuses, les vérifications d'entretien doivent être exécutées plus

souvent..

Confier tout entretien ou réparation non précisé(e) à un centre de réparation sous garantie

autorisé.

TABLEAU DES RESPONSABILITÉS DU CLIENT

TACHE D’ENTRETIEN

LAVEUSE À PRESSION

Vérification du boyau à haute

pression pour déceler des fuites

Vérification du boyau de

savon/produit chimique et du

filtre

Vérification du pistolet et de la

lance pour déceler des fuites

Préparation pour l’entreposage

POMPE À HAUTE

PRESSION

vérifier/nettoyer le filtre de

succion

Vérification/changement de

l’huile

* Cette pompe ne requiert pas d'huile.

MOTEUR

Nettoyez le moteur après chaque utilisation. Utilisez un chiffon pour enlever le débris du

moteur. NE nettoyez JAMAIS le moteur avec de l'eau.

exposé à des surfaces chaudes, à l'eau sous pression, ou

Avant

chaque

utilisation

X

X

X

Préparez l’appareil pour l’entreposage s’il ne sera pas

utilisé pendant 30 jours ou plus.

X

*

Toutes les

25 heures ou

annuellement

Toutes les

50 heures ou

annuellement

Toutes les

100 heures ou

annuellement

FILTRE DE SUCCION

1. Vérifiez et nettoyez le filtre d'aspiration (b) après toutes les 50 heures d'utilisation.

b

A17913

32- FR

Page 33

NETTOYAGE DE LA BUSE

Si la buse devient obstruée par des matériaux étrangers comme la poussière, une pression

excessive peut se développer. Si la buse devient partiellement obstruée ou le débit est

restreint, la pression de la pompe commencera à pulser. Nettoyez la buse immédiatement

en vous servant de la trousse de nettoyage de buse fournie et en suivant les directives

suivantes :

1. Réglez l'interrupteur marche/arrêt à la position d'arrêt « OFF » et fermez le robinet

de la source d'alimentation d'eau.

2. Débranchez l'appareil de la source d'alimentation électrique.

3. Appuyez sur la détente du pistolet afin de dégager l’eau sous pression.

4. Détachez la lance du pistolet.

5. Nettoyez la buse en vous servant du dispositif de nettoyage fourni ou d'un trombone redressé

en ligne droite. Insérez-le dans l'extrémité de la buse et déplacez-le dans un mouvement d'allerretour pour libérer l'obstruction.

6. Dirigez la source d'eau dans la buse et rincez les particules libérées pendant 30 secondes.

7. Branchez l'appareil dans une prise électrique appropriée.

8. Réassemblez la buse à la lance. Serrez fermement afin d'empêcher des fuites.

9. Attachez la lance au pistolet et ouvrez le robinet de la source d'eau.

10. Démarrez la laveuse à pression et réglez la lance à la position de haute pression pour

l'essayer.

ACCESSOIRES

Les accessoires recommandés pour la laveuse haute pression peuvent être achetés auprès

du distributeur local ou d’un centre de réparation autorisé. Pour toute assistance en matière

d’accessoire convenant à l’outil acheté, composer le numéro suivant : 1-800-888-2468 ou

consulter notre site Web www.excellpressurewasher.com.

l’utilisation de tout autre accessoire non recommandé avec

accessoires de marque EXCELL de classement égal ou supérieur à celui de la laveuse

haute pression.

cet outil pourrait s’avérer dangereuse. Utiliser uniquement des

RÉPARATIONS

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations, l’entretien et les

réglages doivent être réalisés par un centre de réparation sous garantie autorisé. Toujours

utiliser des pièces de rechange identiques. Pour connaître l’emplacement du centre de

réparation sous garantie autorisé le plus près, composer le 1-800-888-2468 ou consulter

notre site Web www.excellpressurewasher.com

33 - FR

A17913

Page 34

ENTREPOSAGE

1. Vidangez toute l'eau du boyau à haute pression, enroulez-le et rangez-le dans le

berceau de la poignée de la laveuse à pression.

2. Vidangez toute l'eau du pistolet et de la lance. Pour ce faire, maintenez le pistolet

en position verticale, en dirigeant la buse vers le bas, et appuyez sur la détente du

pistolet. Rangez ces pièces dans le porte-pistolet/boyau.

3. Entreposez le boyau de produit chimique, le boyau à haute pression, le pistolet de

vaporisation et la lance en les protégeant contre les dommages, surtout les dommages

causés en roulant sur ces pièces.

Nous vous recommandons de suivre les étapes ci-dessous pour protéger les joints

d'étanchéité internes de la laveuse à pression LORSQUE VOUS DEVEZ ENTREPOSER

L'APPAREIL PENDANT PLUS DE 30 JOURS ET(OU) LORSQUE DES TEMPÉRATURES DE

GEL SONT PRÉVUES.

* Vous devez passer de l'antigel pour véhicules récréatifs à travers la pompe, tel que stipulé

dans les étapes ci-dessous.

4. Obtenez un entonnoir, 177 ml (6 oz) d'antigel pour véhicules récréatifs, un boyau

d'arrosage d'une longueur d'environ 91 cm (36 po) doté d'un raccord mâle à une

extrémité.

Risque de dommages à la propriété. Utiliser uniquement de l’antigel

endommager la pompe.

5. Branchez le raccord à connexion rapide (j) au tuyau d'arrosage.

pour véhicule récréatif. Tout autre antigel est corrosif et peut

j

6. Connectez le boyau d'arrosage de 91 cm (36 po) à l'orifice d'entrée de la pompe.

7. Ajoutez l’antigel pour véhicules récréatifs, tel qu'illustré.

8. Placez l'interrupteur marche/arrêt «ON/OFF» à la position «ON» et ensuite à la

position «OFF» jusqu'à ce que l'antigel sorte de la connexion de haute pression de la

pompe.

9. Retirez le tuyau d'arrosage de l'orifice d'entrée de la pompe.

* Vous pouvez également utiliser du liquide de lave-glace

A17913

34- FR

Page 35

PROBLÈME

Le moteur ne

démarre pas et il

n'y a aucun bruit

de bourdonnement

Le circuit

d'alimentation

électrique coupe

souvent ou fait

sauter les fusibles

Le moteur

bourdonne mais ne

démarre pas

Aucune pression

ou basse pression

GUIDE DE DÉPANNAGE

CAUSE SOLUTION

La laveuse à pression n'est pas

branchée.

Le bouton de rétablissement

« RESET» du DFT n'est pas enfoncé.

Le disjoncteur est déclenché ou le

fusible est sauté.

Une charge trop élevée sur le circuit.

Utilisation d'une rallonge électrique.

Utilisation d'une rallonge électrique.

La tension d'alimentation est inférieure à

la valeur minimum.

Alimentation d'eau insuffisante.

Le boyau à haute pression est trop long.

Buse usée.

Branchez la laveuse à pression.

Appuyez sur le bouton de

rétablissement «RESET».

Réinitialisez le disjoncteur ou remplacez

le fusible.

Réduisez la charge sur le circuit.

Essayez un autre circuit de 15 A.

NE PAS utiliser des rallonges

électriques.

NE PAS utiliser des rallonges

électriques.

Vérifiez la tension de la conduite

principale d'alimentation.

La source d'eau doit avoir un débit

minimum de 19 litres ou 5 gal./min à 20

psi.

Utilisez un boyau à haute pression d'une

longueur inférieure à 30 m (100 pi) .

Remplacez la buse.

Bruit excessif

La pression subit

des fluctuations

sans avoir ouvert le

pistolet

Le voyant lumineux

de l'interrupteur à

DFT ne s'illumine

pas après

l'enfoncement.

L'essai du DFT a

échoué

L'appareil ne

conserve pas une

pression d'eau

uniforme

L'appareil

déclenche

continuellement

l'interrupteur à

DFT

Source d'alimentation d'eau restreinte

ou insuffisante, ou de l'air dans la

conduite d'eau.

La température de l'eau est trop élevée.

Fuite d'eau au niveau des raccords à

haute pression, du boyau ou du pistolet.

Le disjoncteur est déclenché ou le

fusible est sauté.

Le disjoncteur est déclenché ou le

fusible est sauté.

Buse obstruée

Buse obstruée

Vérifiez le boyau d'alimentation d'eau, le

robinet et l'écran d'entrée.

N'utilisez pas l'eau d'une source

d'alimentation d'eau chaude ; n'utilisez

que de l'eau d'un robinet d'eau froide.

Remplacez le boyau ou le pistolet. Si le

problème continue, apportez l'appareil à

un centre de service autorisé.

Réinitialisez le disjoncteur ou remplacez le fusible. Si le voyant lumineux

ne s'illumine toujours pas, demandez à

un électricien qualifié de vérifier la prise

électrique.

Réinitialisez le disjoncteur ou remplacez le fusible. Si le voyant lumineux

ne s'illumine toujours pas, demandez à

un électricien qualifié de vérifier la prise

électrique.

Nettoyez la buse. Si l'appareil ne

conserve toujours pas une pression

d'eau uniforme, arrêtez l'appareil et

contactez le service à la clientèle au

1-866-422-4286

Nettoyez la buse. Si l'appareil ne

conserve toujours pas une pression

d'eau uniforme, arrêtez l'appareil et

contactez le service à la clientèle au

1-866-422-4286

35 - FR

A17913

Page 36

GARANTÍA LIMITADA

LOS COMPONENTES DEL PRODUCTO TIENEN GARANTÍA LIMITADA DE UN AÑO, A

EXCEPCIÓN DE LA BOMBA DE IC2

Durante un año a partir de la fecha de compra, Black & Decker (U.S.) Inc. le garantiza al

comprador original que el armazón, las ruedas, la pistola, la manguera, la varilla, la/s boquilla/s

del pulverizador y otros componentes (salvo la Bomba de IC2) de las lavadoras a presión Excell

cubiertas por esta garantía están libres de defectos en los materiales y en la mano de obra.

GARANTÍA LIMITADA DE DOS AÑOS PARA LA BOMBA DE IC2

Durante dos años a partir de la fecha de compra, Black & Decker . le garantiza al comprador

original que la Bomba de IC2 de las lavadoras a presión Excell cubiertas por esta garantía está

libre de defectos de material y mano de obra. La garantía limitada de dos años sólo se aplica a

la Bomba de IC2.

Black & Decker reparará o reemplazará, según su criterio, los productos o componentes que

hayan fallado dentro de los períodos de garantía mencionados. El servicio se programará de

acuerdo con el fl ujo y las horas de trabajo normales del centro de mantenimiento y está sujeto a

la disponibilidad de los repuestos. Todas las decisiones que Black & Decker tome con respecto

a esta garantía limitada serán defi nitivas.

Esta garantía le concede derechos legales específi cos; pueden existir otros derechos que

varían según el estado.

RESPONSABILIDAD DEL COMPRADOR ORIGINAL (usuario inicial):

• Para procesar un reclamo por la garantía de su lavadora a presión Excell, devuélvala al

lugar de compra.

• Conserve el recibo de venta original emitido por la caja registradora como prueba de

compra para el trabajo que deberá realizarse en virtud de la garantía.

• Opere y mantenga los productos con el cuidado adecuado, como se describe en el/los

Manual/es del cliente.

ESTA GARANTÍA NO CUBRE:

• La mercadería vendida como reacondicionada, usada como equipo de alquiler o

modelos de piso o en exhibición.

• La mercadería que se haya dañado o no funcione a causa de desgaste común, uso

indebido, frío, calor, lluvia, humedad excesiva, daño por congelamiento, utilización

de productos químicos inadecuados, negligencia, accidente, uso del producto de

modo contrario a las instrucciones del Manual del cliente que se suministra con el

producto, mantenimiento inapropiado, empleo de accesorios o complementos no

recomendados por Black & Decker, o reparaciones o modifi caciones no autorizadas.

• El costo de la reparación y el transporte de la mercadería que se haya defi nido como

no defectuosa.

• Los costos asociados con el ensamblado, la lubricación, los ajustes necesarios y

otros gastos de instalación y puesta en marcha.

• Las piezas prescindibles o los accesorios suministrados con el producto que dejarán

de funcionar o serán inutilizables tras un período de uso razonable, incluidos, entre

otros, resortes, boquillas, anillos de pistón, arandelas y accesorios similares.

• La mercadería que haya vendido Black & Decker pero que otra compañía haya

fabricado e identifi cado como su producto, por ejemplo, los motores de nafta. Se