Page 1

SB-E-2-243-AE

MSV-512 LVMP SPRAY GUN

OPERATION MANUAL

IMPORTANT: Read and follow all instructions and SAFETY PRECAUTIONS

before using this equipment. Retain for future reference.

SAFETY PRECAUTIONS

This manual contains important information that ALL users should know and understand BEFORE

using the equipment. This information relates to USER SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the following terms to

draw your attention to certain equipment labels and portions of this manual. Pay special attention

to any label or information that is highlighted by one of these terms.:

WARNING

CAUTION Important information that tells how to prevent damage to equipment.

NOTE Information that you should pay special attention to.

FIRE AND EXPLOSION

Solvents and coating materials can be highly flammable or combustible, especially when sprayed.

¾ Work stations must be provided with adequate ventilation/exhaust to prevent the build-up of

flammable vapours.

¾ Smoking and naked flames must not be allowed in the spraying or mixing areas.

¾ Fire extinguishing equipment must be provided in the spraying and mixing areas.

Users must comply with all local and national codes of practice and insurance company requirements

governing ventilation, fire precautions, operation maintenance and housekeeping of work stations.

HALOGENATED HYDROCARBON SOLVENTS – for example 1,1,1-Trichloroethane and Methylene

Chloride can chemically react with aluminum and galvanised or zinc coated parts and cause an

explosion hazard. Read the label and data sheet of the material you intend to spray.

This equipment, as supplied, is suitable for use with Halogenated Hydrocarbons and the user must

ensure that all other equipment in the system is also suitable for use with these materials. DO NOT

SPRAY MATERIALS CONTAINING THESE SOLVENTS EXCEPT WITH EQUIPMENT

SPECIFICALLY DISIGINATED BY THE MANUFACTURER AS BEING SUITABLE FOR SUCH USE.

STATIC ELECTRICITY – is generated by fluid moving through pipes and hoses. A static spark,

capable of igniting certain solvents and coating materials, could be produced by high fluid flow rates.

To prevent the risk of fire or explosion, earth continuity to the spray equipment and object being

sprayed should be maintained.

PERSONAL PROTECTIVE EQUIPMENT

TOXIC VAPOURS – When sprayed, certain materials may be poisonous, create irritation or otherwise

be harmful to health. Always read carefully all labels and safety/performance data for the material

being sprayed and follow any recommendations. IF IN DOUBT, CONSULT THE MATERIAL

SUPPLIER.

Important information to alert you to a situation that might cause serious injury or

loss of life if instructions are not followed.

SAFETY WARNING

− 1 −

Page 2

¾ The use of respiratory protective equipment is recommended at all times when spraying. The

type of respiratory protective equipment used must be compatible with the material being

sprayed and the level of concentration.

¾ Always wear eye protection when spraying or cleaning the equipment.

¾ Gloves must be worn for spraying or cleaning the equipment when certain coating materials and

solvents are used.

TRAINING

Personnel should be given adequate training in the safe use and maintenance of this equipment.

Training courses on all aspects of the equipment are available. For details contact your local

representative. The instructions and safety precautions contained in this literature and the literature

supplied with the coating material should be read and understood before the equipment is used.

MISUSE

¾ All spray guns project particles at high velocity and must never be aimed at any part of the body.

¾ Never exceed the recommended safe working pressures for any of the equipment used.

¾ The fitting of non-recommended or non-original accessories or spare parts may create hazardous

conditions.

¾ Before dismantling the equipment for cleaning or maintenance, all pressures, air and material,

must be isolated and released.

The disposal of non-metallic materials must be carried out in an approved manner. Burning may

generate toxic fumes. The removal of waste solvents and coating materials must be carried by an

authorized local waste disposal service.

The materials used in the construction of this equipment are (bearing in mind the warning on

Halogenated Hydrocarbon) solvent resistant enabling the equipment to be cleaned using gun

cleaning machines. However, this equipment must not be left inside the gun cleaning machine for

prolonged period of time after the automatic cleaning cycle has been completed

The solvents used in the gun cleaning machine should be regularly checked to insure that the

equipment is not flushed through with contaminated material. Follow the recommendations of the

machine manufacturer.

NOISE LEVENLS

The continuous A-weighted sound pressure level of this spray gun may exceed 85 dB(A) depending

on the air cap/nozzle set-up being used. Sound levels are measured using an impulse sound level

meter and analyser, when the gun is being used in a normal spraying application. Details of actual

noise levels produced by the various air cap/nozzle set-ups are available on request.

DESCRIPTION

MSV-512 has been developed aiming at high transfer efficiency. The most merit of this gun is that

fine atomization and high transfer efficiency can be obtained with less air consumption comparing

with the existing guns. LVMP stands for Low Volume Medium Pressure; Low Volume means low air

consumption and Medium Pressure means medium atomization air pressure.

CAUTION:

MSV-512 LVMP gun is suitable for almost all of general paint except for high corrosive and high

abrasive paint. If these paint may be used, thorough cleaning must be done frequently. Also, the

replacement of the parts will be more frequent. Please ask the supplier for advice if you have any

doubt of the paint.

− 2 −

Page 3

A

MODEL

Example:

MSV-512-805-DFX

Basic part number

Air Caps: 805

807 GD (0.7mm)

Fluid Tip size: DFX (1.1mm)

DFW (1.6mm)

SPECIFICATION

Maximum Air Pressure: 0.9Mpa (9 bar)

Maximum Fluid Pressure: 1.4Mpa (14 bar)

Weight: 470g

Air Inlet Thread: G1/4

Fluid Inlet Thread: G3/8 (standard)

G1/4 (optional)

Fluid Supply: Pressure Feed

Air Consumption: 278L/min. (Air Cap Pressure 0.20Mpa)

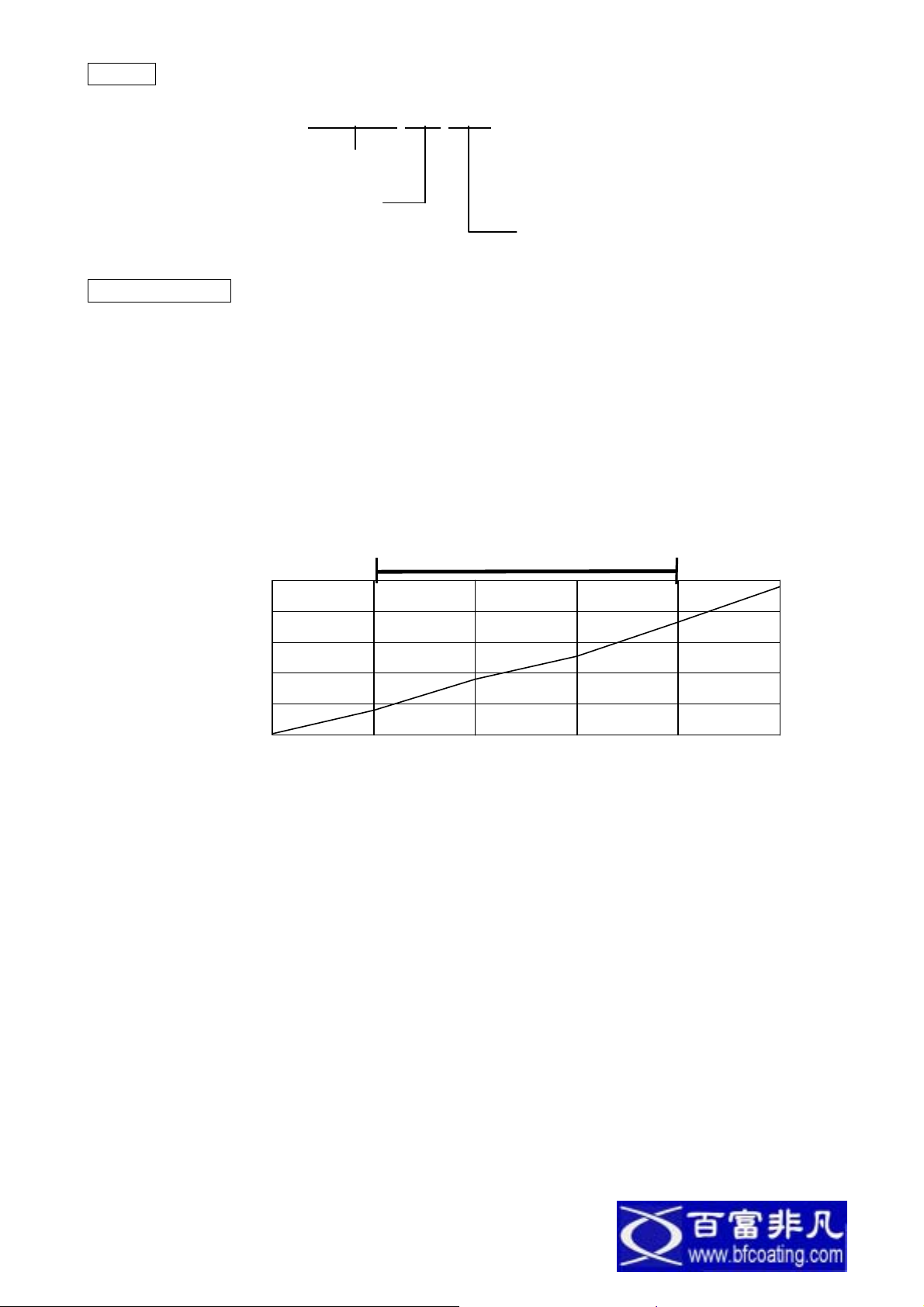

805,807 Air Cap Pressure & Air Consumption L/min.

Recommended Applicable Range

L/min.

ir Cap Pressure

(

Gun Inlet Pressure

400

350

300

250

278

200

150

0.07MPa 0.11MPa 0.16MPa 0.20MPa 0.24MPa 0.28MPa

)

(0.10MPa)

(0.15MPa) (0.20MPa) (0.25MPa) (0.30MPa) (0.35MPa)

− 3 −

Page 4

PARTS LIST

No. CODE NO. PART NUMBER DESCRIPTION Q’TY

1 804277 MSG-368 Retaining Ring 1

2 Refer to Chart 2 Air Cap 1

3 805118 SSG-8182-K5 O-Ring 1

4 Refer to Chart 2 Fluid Tip 1

5 803791 JGD-14-K5 Seal Kit of (5) 1

6 803833 JGHV-450-46-50 Baffle 1

7 803932 JGS-72-K10 Gasket Kit of (10) 2

8 803561 JGA-17 Gun Body Bushing 1

9 Refer to Chart 2 Needle 1

10 804342 MBD-19-K5 Spring Kit of (5) 1

11 804270 MSG-16 Adjusting Screw 1

12 805277 SST-8453-K5 Circlip Kit of (5) 1

13 SSG-8190-K5 O-Ring Kit of (5) 1

14 804274 MSG-498 Pattern Valve Assy 1

15 803929 JGS-431 Air Valve Stem 1

16 803936 JGV-262-K5 Spring Kit of (5) 1

17 803910 JGK-449 Air Valve Assy 1

18 803855 JGV-463 Needle Packing (2 pcs.) 1

19 806286 34411-122-K3 Needle Packing Nut Kit of (3) 1

20 803916 JGS-108-1 Trigger 1

21 805281 JGX-46-K10 Circlip Kit of (10) 1

22 803567 JGX-45-K5 Trigger Bearing Stud Kit of (5) 1

24 JGA-132 Plug 1

25 MSG-21 Air Connector 1

26 MSG-11 Fluid Nipple G 3/8 1

804456 MSG-11-1/4 Fluid Nipple G 1/4 (Optional) 1

− 4 −

Page 5

Chart 2 Air Cap, Fluid Tip and Needle Combination

Air Cap Lapped Set (Tip & Needle)

Part Number

AV-1239-805 802447

AV-1239-807 802449

Code No.

Part Number Size (mm)

JGA-4046-DFX 1.1

JGA-4046-DFW 1.6

JGA-4046-GD 0.7

JGA-4046-DFX 1.1

JGA-4046-DFW 1.6

JGA-4046-GD 0.7

Material

Supply

Pressure

Pressure

INSTALLATION/OPERATION

NOTE: The air supplied to spray gun must be cleaned air which any water, oil and solid material

removed. To set up the Mist Separator and Air Transformer near the gun is recommended.

As LVMP gun consumes less air, it is not necessary to use thicker hose compare to HVLP gun.

CAUTION: Adjust Needle Packing (18) before start using new gun. Tighten the Packing Nut (19)

gradually and then to adjust the needle moving smoothly, untighten a little where the Needle (9) is not

well pulled back

The Air Cap Pressure is set at 0.2MPa when Gun Inlet Pressure is 0.25MPa. It is recommended

to check the Air Cap Pressure just in case with the Air Cap Test Kit which is available separately.

The recommended spray distance is 150〜200mm. If the spray distance is too far, good result does

not appear. Also, in order to get uniform finishing, the spray gun should be hold vertically toward the

painting surface.

To adjust the fluid delivery, keep the needle full open, not tightening the Adjusting Screw, so that the

delivery can be adjusted at the material supply line. It leaves the abrasion of the Fluid Tip (4) and the

Needle (9) the minimum.

The paint should be filtered through 60〜90 mesh filter before use.

MAINTENANCE

Daily lubrication and cleaning is necessary to maintain the best condition of the gun.

NOTE: Clean the spray gun after used with clean solvent and empty the inside of the hose.

To clean the fluid passage, after removing extra paint, through the appropriate solvent and flush down

the residual paint. When blowing the paint inside the hose and the gun back to pressure tank by

pressuring, follow the following procedure:

Release the pressure in the tank and loosen the lid a little, then make one rotation to loosen the

Retaining Ring (1), which presses the gun cap. Press the point of the gun with cloth and pull the

Trigger (20). The atomizing air then flows back to the fluid hose and the paint in the hose is flushed

back to the tank.

CAUTION: To clean the gun body, wipe exterior with solvent dampened cloth. Do not submerge the

gun body in solvent as any solids may get into the air passage and cause troubles.

− 5 −

Page 6

CAUTION: The air cap can be immersed in solvent for cleaning. If orifices are clogged, use a broom

straw or toothpick to remove obstruction. Never use a steel wire or hard instrument. This will

damage

air cap and result in a distorted spray pattern.

NOTE: Do not immerse any plastic parts in solvent for long time.

CAUTION: Lubrication

Do not lubricate to any portions where not instructed

Lubricate one drop of Gun Lube SSL-10 daily to the following portions.

Lubricate regularly, Trigger Bearing Stud (22), Air Valve Stem (15) where it enters the valve body and

the

Needle (9) where it enters the Packing Nut (19).

When installing Air Cap (2), make sure no foreign materials adhered on Retaining Ring (1) and thread

of

Baffle (6) and then oil one drop of Gun Lube SSL-10.

Apply non-silicone grease lightly on Needle Spring (10) and Air Valve Spring (16).

Do not apply to much grease as it may clog the air passage.

Lubricate daily to the following portions. For lubrication, SSL-10 Gun Lube is recommended.

A) Trigger Bearing Stud

B) Needle Packing

C) Thread of Pattern Valve

Thread of Adjusting Screw

D) Retaining Ring

E) Air Valve Stem

REPLACEMENT OF PARTS

CAUTION: Be careful not to touch the point of Needle (9) as it is sharp.

When removing Fluid Tip (4), Adjust Screw (11) and Needle Spring (10) should also be removed and

Needle (9) should be withdrew or retreated. Turn the Pattern Valve (14) fully counter-clockwise

Tools should be 1/2” offset wrench, box wrench or DeVilbiss wrench WR-103, do NOT use open wrench

or adjustable wrench.

Recommended torque of fluid tip is 24~27N.m.

To replace Fluid Inlet Nipple and Air Inlet Nipple (25), apply LOCKTIGHT 242 and tighten.

Recommended torque 20N・m.

− 6 −

Page 7

SERVICE CHECK

Normal spray pattern

PROBLEM CAUSE CORRECTION

Will not spray. No pressure to gun.

Improper spray pattern

Jerky or fluttering spray

Fluid leaking from

needle packing nut (19).

Dripping from fluid tip. Worn or damaged fluid tip or

Screw (11) not properly adjusted.

A, B. Material build up on the air

cap or fluid tip.

C, D. Wrong material or material

too thick.

Insufficient material in the tank or

an obstruction in the line.

Gun material passage plugged.

Worn needle packing (18).

Loose or damaged fluid tip.

Loose needle packing nut (19).

Worn or stuck needle packing

(18).

needle.

Stuck needle packing (18) or

needle (9).

Tight packing nut (19).

Loose adjust screw (11).

Check air and material lines.

Adjust.

A, B. Clean the air cap or fluid tip.

C, D. Adjust material pressure or

thin material.

Fill tank or clean obstruction.

Clean.

Replace.

Tighten or replace.

Tighten.

Replace or lubricate.

Replace.

Lubricate.

Adjust.

Tighten.

− 7 −

Page 8

ACCESSORIES

PART NUMBER CODE NO. DESCRIPTION

KB-555 800223 Pressure Cup (2 Quart)

AD-404-J 800029 Adapter (1/4 NPS M, 3/8 NPS F)

WR-103 800314 Wrench

SSL-10 805153 Gun Lube

42884-214-K5 806472 Cleaning Brush Kit of 5

KK-5033-805 Air Cap Test Kit

KK-5033-807 Air Cap Test Kit

− 8 −

Loading...

Loading...