Page 1

OWNERS MANUAL FOR

TWO-STAGE

AIR COMPRESSOR

Model No.

L10120H2-2

Specification Chart

Model No.

Horsepower

Voltage/Hertz/Phase

Minimum Branch Circuit Requirement

*Fuse Type

Air Tank Capacity

Approximate Cut-in Pressure

Approximate Cut-out Pressure

SCFM @ 175 PSIG

Magnetic Starter

*A circuit breaker is preferred. Use only a fuse or circuit breaker that is the same rating as

the branch circuit the air compressor is operated on. If the air compressor is connected to

a circuit protected by fuses, use only time delay fuses. Time delay fuses should be

marked "D" in Canada and "T" in the US.

In the unlikely event you should have a problem with this product or if you are missing any parts, it is not necessary

to return it to the store where you purchased it. Simply call our toll free number and talk with our Service

Representative.

240/480V/60 HZ/3 PHASE

Required (Included on Compressor)

L10120H2-2

10

30 Amp

Time Delay

120 Gal. ASME

140 PSIG

175 PSIG

34.2

MGP-SL10120H-2A Rev. 2 1/24/03

OUR OFFICE HOURS ARE FROM

8:00 a.m. to 6:00 p.m. (CST)

MONDAY THROUGH FRIDAY

CALL TOLL FREE 1-800-888-2468

DeVilbiss Air Power Company • 213 Industrial Dr. • Jackson, TN 38301-9615

Page 2

TABLE OF CONTENTS

Page

SAFETY GUIDELINES ................................... 2

WARNING CHART ......................................... 3-5

SPECIFICATIONS .......................................... 6

GLOSSARY .................................................... 6

DUTY CYCLE ................................................ 6

GENERAL INFORMATION ............................ 7

ON-RECEIPT INSPECTION ........................... 7

DESCRIPTION OF OPERATION ................... 8

INSTALLATION AND

BREAK-IN PROCEDURES ............................. 9-12

Location of Air Compressor .......................... 9

Air Compressor Anchoring Methods ............. 9

Wiring Instructions and Diagram ................... 10

Voltage and Circuit Protection ...................... 10

Air Filter Installation ...................................... 11

Break-in Procedures ..................................... 11

Additional Regulators and Controls .............. 11

Lubrication and Oil ....................................... 11

Piping and Diagram ...................................... 12

Page

MAINTENANCE ............................................. 14

SERVICE INSTRUCTIONS ............................. 15-16

Air Filter-Inspection and Replacement .......... 15

Oil-Checking and Changing .......................... 15

Recommended Oils ..................................... 15

Check Valve-Inspection and Replacement ..15-16

Safety Valve-Inspection and Replacement ... 16

Adjusting Belt Tension .................................. 16

Motor Pulley and Flywheel Alignment ........... 17

Additional Service ........................................ 17

STORAGE....................................................... 17

TROUBLESHOOTING GUIDE ...................... 18-21

COMPRESSOR DIAGRAM ............................ 22

COMPRESSOR PARTS LIST ......................... 23

COMPRESSOR PUMP DIAGRAM ................ 24

PUMP PARTS LIST ....................................... 25

SERVICE NOTES ............................................ 26

WARRANTY STATEMENT ............................. 27

OPERATING PROCEDURES ......................... 13

HOW TO ORDER REPAIR PARTS ....... Back Cover

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR

SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols to the right.

Please read the manual and pay attention to these sections.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death of serious injury.

Retain Original Sales Receipt as Proof of Purchase for Warranty Repair Work.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

MGP-SL10120H-2A

2—ENG

Page 3

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS INJURY AND PROPERTY

DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

HAZARD

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN

IT IS NORMAL FOR ELECTRICAL CONTACTS WITHIN THE

MOTOR AND PRESSURE SWITCH TO SPARK.

IF ELECTRICAL SPARKS FROM COMPRESSOR COME INTO

CONTACT WITH FLAMMABLE VAPORS, THEY MAY IGNITE,

CAUSING FIRE OR EXPLOSION.

RESTRICTING ANY OF THE COMPRESSOR VENTILATION

OPENINGS WILL CAUSE SERIOUS OVERHEATING AND

COULD CAUSE FIRE.

UNATTENDED OPERATION OF THIS PRODUCT COULD

RESULT IN PERSONAL INJURY OR PROPERTY DAMAGE.

RISK OF BURSTING

HOW TO PREVENT IT

ALWAYS OPERATE THE COMPRESSOR IN A WELL VENTILATED AREA FREE OF COMBUSTIBLE MATERIALS,

GASOLINE OR SOLVENT VAPORS.

IF SPRAYING FLAMMABLE MATERIALS, LOCATE COMPRESSOR AT LEAST 20 FEET AWAY FROM SPRAY AREA. AN

ADDITIONAL LENGTH OF HOSE MAY BE REQUIRED.

STORE FLAMMABLE MATERIALS IN A SECURE LOCATION

AWAY FROM COMPRESSOR.

NEVER PLACE OBJECTS AGAINST OR ON TOP OF COMPRESSOR. OPERATE COMPRESSOR IN AN OPEN AREA AT

LEAST 12 INCHES AWAY FROM ANY WALL OR OBSTRUC-

TION THAT WOULD RESTRICT THE FLOW OF FRESH AIR TO

THE VENTILATION OPENINGS.

OPERATE COMPRESSOR IN A CLEAN, DRY, WELL VENTILATED

AREA. DO NOT OPERATE UNIT INDOORS OR IN ANY CON-

FINED AREA.

ALWAYS REMAIN IN ATTENDANCE WITH THE PRODUCT

WHEN IT IS OPERATING.

AIR TANK: THE FOLLOWING CONDITIONS COULD LEAD TO A WEAKENING OF THE TANK, AND RESULT IN A

VIOLENT TANK EXPLOSION AND COULD CAUSE PROPERTY DAMAGE OR SERIOUS INJURY.

WHAT CAN HAPPEN

1. FAILURE TO PROPERLY DRAIN CONDENSED WATER

FROM THE TANK, CAUSING RUST AND THINNING OF THE

STEEL TANK.

2. MODIFICATIONS OR ATTEMPTED REPAIRS TO THE TANK.

3. UNAUTHORIZED MODIFICATIONS TO THE UNLOADER

VALVE, SAFETY VALVE, OR ANY OTHER COMPONENTS

WHICH CONTROL TANK PRESSURE.

4. EXCESSIVE VIBRATION CAN WEAKEN THE AIR TANK

AND CAUSE RUPTURE OR EXPLOSION.

DRAIN TANK DAILY OR AFTER EACH USE. IF TANK DEVEL-

OPS A LEAK, REPLACE IT IMMEDIATELY WITH A NEW TANK OR

REPLACE THE ENTIRE COMPESSOR.

NEVER DRILL INTO, WELD, OR MAKE ANY MODIFICATIONS

TO THE TANK OR ITS ATTACHMENTS.

THE TANK IS DESIGNED TO WITHSTAND SPECIFIC OPERATING

PRESSURES. NEVER MAKE ADJUSTMENTS OR PARTS

SUBSTITUTIONS TO ALTER THE FACTORY SET OPERATING

PRESSURES.

HOW TO PREVENT IT

ATTACHMENTS & ACCESSORIES:

EXCEEDING THE PRESSURE RATING OF AIR TOOLS, SPRAY

GUNS, AIR OPERATED ACCESSORIES, TIRES AND OTHER

INFLATABLES CAN CAUSE THEM TO EXPLODE OR FLY

APART, AND COULD RESULT IN SERIOUS INJURY.

FOR ESSENTIAL CONTROL OF AIR PRESSURE, YOU MUST

INSTALL A PRESSURE REGULATOR AND PRESSURE GAUGE

TO THE AIR OUTLET OF YOUR COMPRESSOR. FOLLOW THE

EQUIPMENT MANUFACTURERS RECOMMENDATION AND

NEVER EXCEED THE MAXIMUM ALLOWABLE PRESSURE

RATING OF ATTACHMENTS. NEVER USE COMPRESSOR TO

INFLATE SMALL LOW-PRESSURE OBJECTS SUCH AS

CHILDREN’S TOYS, FOOTBALLS, BASKETBALLS. ETC.

3—ENG

MGP-SL10120H-2A

Page 4

HAZARD

RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN

THE COMPRESSED AIR STREAM CAN CAUSE SOFT TISSUE

DAMAGE TO EXPOSED SKIN AND CAN PROPEL DIRT, CHIPS,

LOOSE PARTICLES AND SMALL OBJECTS AT HIGH SPEED,

RESULTING IN PROPERTY DAMAGE OR PERSONAL INJURY.

RISK TO BREATHING

WHAT CAN HAPPEN

THE COMPRESSED AIR FROM YOUR COMPRESSOR IS NOT

SAFE FOR BREATHING! THE AIR STREAM MAY CONTAIN

CARBON MONOXIDE, TOXIC VAPORS OR SOLID PARTICLES

FROM THE TANK.

HOW TO PREVENT IT

ALWAYS WEAR ANSI Z87.1 APPROVED SAFETY GLASSES

WITH SIDE SHIELDS WHEN USING THE COMPRESSOR.

NEVER POINT ANY NOZZLE OR SPRAYER TOWARD ANY

PART OF THE BODY OR AT OTHER PEOPLE OR ANIMALS.

ALWAYS TURN THE COMPRESSOR OFF AND BLEED PRESSURE FROM THE AIR HOSE AND TANK BEFORE ATTEMPTING

MAINTENANCE, ATTACHING TOOLS OR ACCESSORIES.

HOW TO PREVENT IT

ALWAYS OPERATE AIR COMPRESSOR OUTSIDE IN A CLEAN,

WELL VENTILATED AREA. AVOID ENCLOSED AREAS SUCH AS

GARAGES, BASEMENTS, STORAGE SHEDS, WHICH LACK A

STEADY EXCHANGE OF AIR. KEEP CHILDREN, PETS AND

OTHERS AWAY FROM AREA OF OPERATION.

NEVER INHALE AIR FROM THE COMPRESSOR EITHER

DIRECTLY OR FROM A BREATHING DEVICE CONNECTED TO

THE COMPRESSOR.

SPRAYED MATERIALS SUCH AS PAINT, PAINT SOLVENTS,

PAINT REMOVER, INSECTICIDES, WEED KILLERS, CONTAIN

HARMFUL VAPORS AND POISONS.

RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN

YOUR AIR COMPRESSOR IS POWERED BY ELECTRICITY.

LIKE ANY OTHER ELECTRICALLY POWERED DEVICE, IF IT IS

NOT USED PROPERLY IT MAY CAUSE ELECTRIC SHOCK.

REPAIRS ATTEMPTED BY UNQUALIFIED PERSONNEL CAN

RESULT IN SERIOUS INJURY OR DEATH BY ELECTROCUTION.

ELECTRICAL GROUNDING: FAILURE TO PROVIDE ADEQUATE

GROUNDING TO THIS PRODUCT COULD RESULT IN SERIOUS

INJURY OR DEATH FROM ELECTROCUTION. SEE GROUND-

ING INSTRUCTIONS.

WORK IN AN AREA WITH GOOD CROSS-VENTILATION. READ

AND FOLLOW THE SAFETY INSTRUCTIONS PROVIDED ON

THE LABEL OR SAFETY DATA SHEETS FOR THE MATERIAL

YOU ARE SPRAYING. USE A NIOSH/MSHA APPROVED

RESPIRATOR DESIGNED FOR USE WITH YOUR SPECIFIC

APPLICATION.

HOW TO PREVENT IT

NEVER OPERATE THE COMPRESSOR OUTDOORS WHEN IT IS

RAINING OR IN WET CONDITIONS.

NEVER OPERATE COMPRESSOR WITH COVER COMPONENTS

REMOVED OR DAMAGED.

ANY ELECTRICAL WIRING OR REPAIRS REQUIRED ON THIS

PRODUCT SHOULD BE PERFORMED BY AUTHORIZED

SERVICE CENTER PERSONNEL IN ACCORDANCE WITH

NATIONAL AND LOCAL ELECTRICAL CODES.

MAKE CERTAIN THAT THE ELECTRICAL CIRCUIT TO WHICH

THE COMPRESSOR IS CONNECTED PROVIDES PROPER

ELECTRICAL GROUNDING, CORRECT VOLTAGE AND

ADEQUATE FUSE PROTECTION.

MGP-SL10120H-2A

4—ENG

Page 5

HAZARD

RISK FROM MOVING PARTS

WHAT CAN HAPPEN

MOVING PARTS SUCH AS THE PULLEY, FLYWHEEL AND BELT

CAN CAUSE SERIOUS INJURY IF THEY COME INTO CONTACT

WITH YOU OR YOUR CLOTHING.

ATTEMPTING TO OPERATE COMPRESSOR WITH DAMAGED

OR MISSING PARTS OR ATTEMPTING TO REPAIR COMPRESSOR WITH PROTECTIVE SHROUDS REMOVED CAN

EXPOSE YOU TO MOVING PARTS AND CAN RESULT IN

SERIOUS INJURY.

RISK OF BURNS

WHAT CAN HAPPEN

TOUCHING EXPOSED METAL SUCH AS THE COMPRESSOR

HEAD OR OUTLET TUBES, CAN RESULT IN SERIOUS BURNS.

HOW TO PREVENT IT

NEVER OPERATE THE COMPRESSOR WITH GUARDS OR

COVERS WHICH ARE DAMAGED OR REMOVED.

ANY REPAIRS REQUIRED ON THIS PRODUCT SHOULD BE

PERFORMED BY AUTHORIZED SERVICE CENTER PERSONNEL.

HOW TO PREVENT IT

NEVER TOUCH ANY EXPOSED METAL PARTS ON COMPRESSOR DURING OR IMMEDIATELY AFTER OPERATION. COMPRESSOR WILL REMAIN HOT FOR SEVERAL MINUTES AFTER

OPERATION.

DO NOT REACH AROUND PROTECTIVE SHROUDS OR ATTEMPT

MAINTENANCE UNTIL UNIT HAS BEEN ALLOWED TO COOL.

RISK OF FALLING

WHAT CAN HAPPEN

A PORTABLE COMPRESSOR CAN FALL FROM A TABLE,

WORKBENCH OR ROOF CAUSING DAMAGE TO THE COM-

PRESSOR AND COULD RESULT IN SERIOUS INJURY OR

DEATH TO THE OPERATOR.

RISK OF PROPERTY DAMAGE WHEN TRANSPORTING

COMPRESSOR

(Fire, Inhalation, Damage to Vehicle Surfaces)

WHAT CAN HAPPEN

OIL CAN LEAK OR SPILL AND COULD RESULT IN FIRE OR

BREATHING HAZARD, SERIOUS INJURY OR DEATH CAN RESULT.

OIL LEAKS WILL DAMAGE CARPET, PAINT OR OTHER SURFACES

IN VEHICLES OR TRAILERS.

HOW TO PREVENT IT

ALWAYS OPERATE COMPRESSOR IN A STABLE SECURE

POSITION TO PREVENT ACCIDENTAL MOVEMENT OF THE

UNIT. NEVER OPERATE COMPRESSOR ON A ROOF OR

OTHER ELEVATED POSITION. USE ADDITIONAL AIR HOSE

TO REACH HIGH LOCATIONS.

HOW TO PREVENT IT

ALWAYS PLACE COMPRESSOR ON A PROTECTIVE MAT WHEN

TRANSPORTING TO PROTECT AGAINST DAMAGE TO VEHICLE

FROM LEAKS. REMOVE COMPRESSOR FROM VEHICLE IMMEDIATELY UPON ARRIVAL AT YOUR DESTINATION.

ESW-99 — 9/26/99ESW-99 — 9/26/99

ESW-99 — 9/26/99

ESW-99 — 9/26/99ESW-99 — 9/26/99

5—ENG

MGP-SL10120H-2A

Page 6

SPECIFICATIONS

Refer to cover page for the specifications of your compressor. Use only a fuse or circuit breaker that is the same rating

as the branch circuit the air compressor is operated on. If the compressor is connected to a circuit protected by fuses,

use dual element time delay fuses, as noted in specification chart.

Improper electrical installation of this product

may void its warranty and your fire insurance.

Have circuit wiring performed by qualified personnel such as a licensed electrician who is

familiar with the current national electric code

and any prevailing local electrical codes.

GLOSSARY

CFM:CFM:

CFM: Cubic feet per minute.

CFM:CFM:

SCFM:SCFM:

SCFM: Standard cubic feet per minute; a unit of

SCFM:SCFM:

measure of air delivery.

PSIG: PSIG:

PSIG: Pounds per square inch gauge; a unit of measure

PSIG: PSIG:

of pressure.

ASME:ASME:

ASME: American Society of Mechanical Engineers;

ASME:ASME:

made, tested, inspected and registered to meet the

standards of the ASME.

California CodeCalifornia Code

California Code: Unit may comply with California

California CodeCalifornia Code

Code 462 (l) (2)/(M) (2). Specification/Model Label is on

the side of the tank on units that comply with California

Code.

DUTY CYCLE

Cut-In Pressure:Cut-In Pressure:

Cut-In Pressure: While the motor is off, air tank

Cut-In Pressure:Cut-In Pressure:

pressure drops as you continue to use your accessory.

When the tank pressure drops to a certain low level the

motor will restart automatically. The low pressure at

which the motor automatically re-starts is called “cutin pressure.”

Cut-Out Pressure: Cut-Out Pressure:

Cut-Out Pressure: When you turn on your air com-

Cut-Out Pressure: Cut-Out Pressure:

pressor and it begins to run, air pressure in the air tank

begins to build. It builds to a certain high pressure

before the motor automatically shuts off - protecting

your air tank from pressure higher than its capacity. The

high pressure at which the motor shuts off is called "cutout pressure."

To Lock Out Power:To Lock Out Power:

To Lock Out Power: Place a lock on the line power

To Lock Out Power:To Lock Out Power:

switch so no one else can turn on the power.

All DeVilbiss Air Power manufactured air compressors

should be operated on not more than a 50% duty cycle.

This means an air compressor that pumps more than

50% of one hour, is considered misuse, because the air

MGP-SL10120H-2A

compressor is undersized for the required air demand.

Maximum compressor pumping time per hour is 30

minutes.

6—ENG

Page 7

GENERAL INFORMATION

You have purchased a complete compressor outfit consisting of an air compressor, air tank, electric motor, and

associated controls and instruments. The outfit you have

selected is a stationary model and contains a two stage

air compressor pump.

Your new compressor outfit can be used for operating

paint sprayers, air tools, grease guns, air brushes, caulking guns, sandblasters, inflating tires, etc.

An air pressure regulator is usually necessary for most

applications. An air line filter is normally required for

removal of moisture and oil vapor in compressed air when

a paint spray gun is used.

An in-line lubricator is often required for air tools to prolong

tool life.

ON-RECEIPT INSPECTION

Separate air transformers which combine the functions of

air regulation and/or moisture and dirt removal should

be used where applicable.

A regularly scheduled program of preventive maintenance will help provide the long life that has been

designed into your compressor outfit. Before operating

or performing any maintenance on your compressor, refer

to this manual. To keep your compressor in good working

order, refer to these publications often and perform

preventive maintenance steps as recommended.

Each air compressor outfit is carefully checked before

shipment. With improper handling, damage may result in

transit and cause problems in compressor operation.

Immediately upon arrival, check equipment for both

concealed and visible damages to avoid expenses being

incurred to correct such problems. This should be done

regardless of any visible signs of damage to the shipping

container. Report any damages to carrier and arrange for

inspection of goods immediately.

For the location or a listing of the nearest DeVilbiss Air

Power Authorized Warranty Service Center, call our toll

free number at 1-800-888-2468.

7—ENG

MGP-SL10120H-2A

Page 8

DESCRIPTION OF OPERATION

Drain Valve:Drain Valve:

Drain Valve: At the base of the air tank to drain

Drain Valve:Drain Valve:

condensation at the end of each use.

ON/AUTO-OFF Switch:ON/AUTO-OFF Switch:

ON/AUTO-OFF Switch: Turn this switch ON to

ON/AUTO-OFF Switch:ON/AUTO-OFF Switch:

provide automatic power to the pressure switch and OFF

to remove power.

Air Intake Filter:Air Intake Filter:

Air Intake Filter: This filter is designed to clean air

Air Intake Filter:Air Intake Filter:

coming into the pump. This filter must always be clean

and ventilation openings free from obstructions. See

"Maintenance".

Air Compressor Pump:Air Compressor Pump:

Air Compressor Pump: In two stage compressors, air

Air Compressor Pump:Air Compressor Pump:

is first compressed to an intermediate pressure in the

large bore cylinder, and after passing through an intercooler, the air is further compressed to a higher pressure

in the smaller bore cylinder. This process continues until

the air tank pressure reaches the factory set cutoff

pressure. At that point the pressure switch shuts the

electric motor off.

Check Valve:Check Valve:

Check Valve: When the air compressor is operating,

Check Valve:Check Valve:

the check valve is "open", allowing compressed air to

enter the air tank. When the air compressor reaches

"cut-out" pressure, the check valve "closes", allowing

air pressure to remain inside the air tank.

Pressure Release Valve:Pressure Release Valve:

Pressure Release Valve: The pressure release valve

Pressure Release Valve:Pressure Release Valve:

located on the side of the pressure switch, is designed

to automatically release compressed air from the compressor head and the outlet tube when the air compressor reaches "cut-out" pressure or is shut off. If the air

is not released, the motor will try to start, but will be

unable to. The pressure release valve allows the motor

to restart freely. When the motor stops running, air will

be heard escaping from the valve for a few seconds. No

air should be heard leaking when the motor is running.

Pressure Switch: Pressure Switch:

Pressure Switch: The pressure switch automatically

Pressure Switch: Pressure Switch:

starts the motor when the air tank pressure drops below

the factory set "cut-in" pressure. It stops the motor

when the air tank pressure reaches the factory set "cutout" pressure.

Shut-off Valve:Shut-off Valve:

Shut-off Valve: Turn the knob counterclockwise to

Shut-off Valve:Shut-off Valve:

open the valve and clockwise to close.

Air Tank Safety Valve:Air Tank Safety Valve:

Air Tank Safety Valve: If the pressure switch does not

Air Tank Safety Valve:Air Tank Safety Valve:

shut off the air compressor at its cut-out pressure

setting, the safety valve will protect against high pressure by "popping off" at its factory set pressure (slightly

higher than the pressure switch cut-out setting).

Aftercooler Safety Valve:Aftercooler Safety Valve:

Aftercooler Safety Valve: On two stage compressor

Aftercooler Safety Valve:Aftercooler Safety Valve:

units, safety valve is provided to prevent over-pressurization of the aftercooler. The valve will protect the

aftercooler by "popping off" at its factory set pressure.

Regulator:Regulator:

Regulator: An air pressure regulator or a separate air

Regulator:Regulator:

transformer which combines the functions of air regulation and/or moisture and dirt removal is recommended

for most applications.

Tank Pressure Gauge:Tank Pressure Gauge:

Tank Pressure Gauge: The tank pressure gauge

Tank Pressure Gauge:Tank Pressure Gauge:

indicates the reserve air pressure in the tank. On outfits

with no pressure regulator, this is also the pressure

available at the air outlet.

MGP-SL10120H-2A

8—ENG

Page 9

INSTALLATION AND BREAK-IN PROCEDURES

Location of the Air Compressor

THE PUMP ASSEMBLY DOES NOT PROVIDE ADEQUATE STABILITY OR SUPPORT

FOR LIFTING THE UNIT. IF THE OUTFIT

MUST BE MOVED, USE THE TANK FOR

LIFTING.

This compressor should be permanently mounted in

place on a level floor. Operate the air compressor in a

clean, dry and well ventilated area. The air intake filter

must be kept clear of obstructions which could reduce air

delivery of the air compressor. The air compressor

should be located at least 12" away from walls or other

obstructions that could interfere with the flow of air

through the fan bladed flywheel. The air compressor

crankcase and head are designed with fins to provide

proper cooling.

The flywheel side of the outfit should be placed toward

the wall and protected with a totally enclosed belt guard.

In no case should the flywheel be closer than 12 to 18

inches from the wall or other obstruction that will interfere

with the flow of air through the fan bladed flywheel. The

area should allow space on all sides for air circulation

and for ease of normal maintenance. Keep the outfit

away from areas which have dirt, vapor and volatile fumes

in the atmosphere which may clog and gum the intake

filter and valves, causing inefficient operation. Where this

is not practical a remote air intake is recommended.

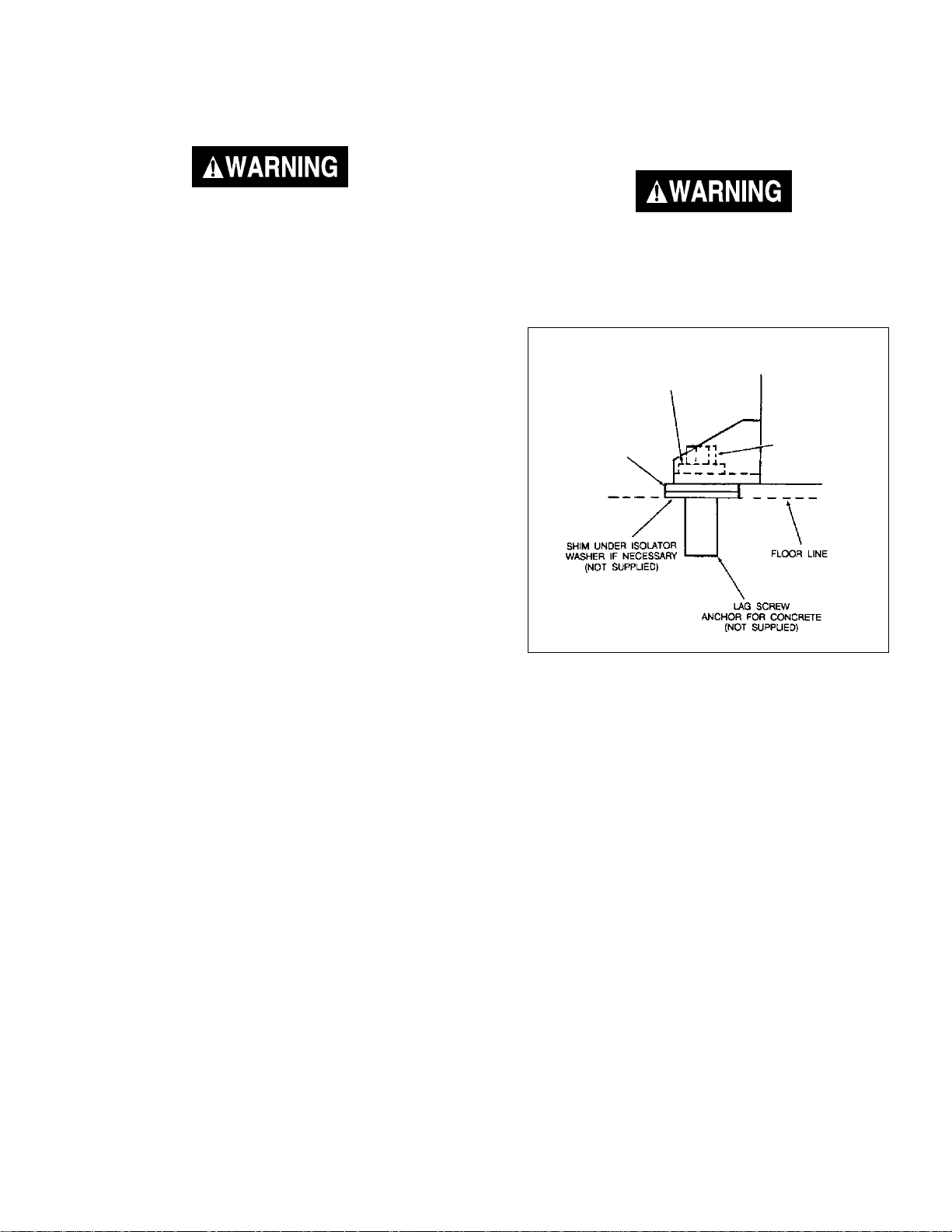

Air Compressor Anchoring

Methods

VIBRATION CAN WEAKEN THE AIR TANK

AND CAUSE AN EXPLOSION. THE COMPRESSOR MUST BE PROPERLY MOUNTED

AS ILLUSTRATED BELOW.

FLAT WASHER

ISOLATOR

WASHER

(supplied)

Anchoring of Horizontal Unit

LAG SCREW

(NOT SUPPLIED)

TORQUE TO

5 TO 10 FT-LB

Note

Where a remote air intake is used, enlarge the size of the air intake piping by

one pipe size for each 10 feet of length.

If humidity is high, an air filter can be installed to

remove excessive moisture. Closely follow instructions packaged with the filter for proper installation. It

must be installed as close as possible to the accessory.

The air compressor should be as near to air outlets as

possible in order to avoid long pipe lines. Do not place

the air compressor where heat is excessive.

9—ENG

Horizontal Units

Horizontal air compressors must be bolted to the floor.

Bolting holes are provided in the base feet. Mount the

air compressor on a solid, level foundation. Support

compressor weight evenly on all four feet. Solid shims

may be used if necessary.

MGP-SL10120H-2A

Page 10

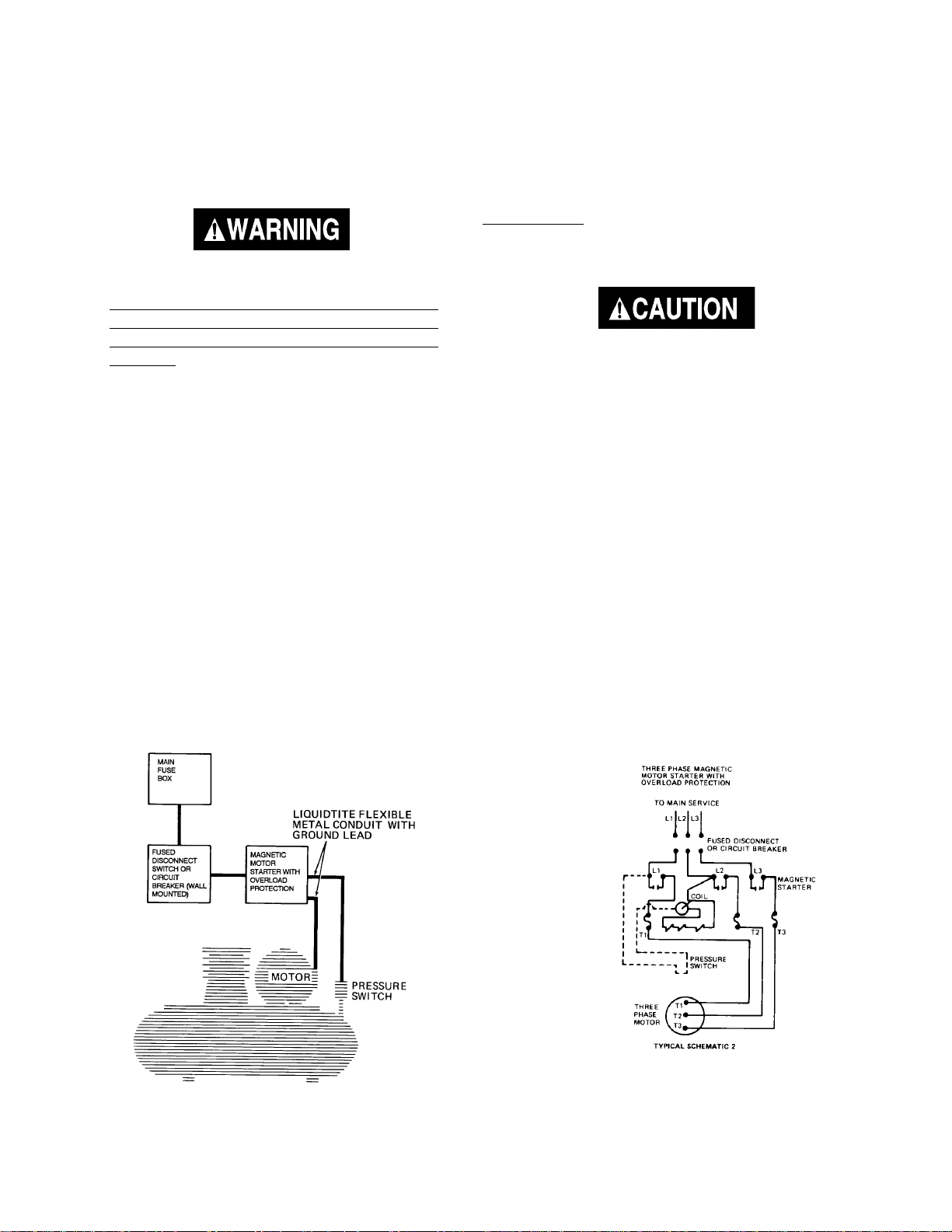

INSTALLATION AND BREAK-IN PROCEDURES

Wiring Instructions

If your compressor unit is not equipped with a plug-in type

power cord, perform electrical wiring according to the

following instructions:

IMPROPER ELECTRICAL GROUNDING CAN

RESULT IN A RISK OF ELECTRICAL SHOCK.

WIRING SHOULD BE DONE BY A LICENSED

ELECTRICIAN IN ACCORDANCE WITH NATIONAL AND LOCAL CODES AND ORDINANCES.

Install the compressor outfit as close to the main power

supply as possible. This practice will avoid using long

lengths of electrical wiring for the power supply which can

cause power loss to the motor. When connecting wires

make sure that:

1.The amperage rating of the electrical box is adequate.

Refer to the Specification Chart (cover page) for your

air compressor outfit.

2.The supply line has the same electrical characteristics

(voltage, cycle, and phase) as motor.

Wiring must be such that full motor nameplate voltage

plus or minus 10%, is available at the motor terminals

during starting. Refer to local codes for recommended

wire sizes for correct wire size and maximum wire run;

undersize wire causes high amp draw and overheating to

the motor.

Electrical wiring must be located away

from hot surfaces such as the compressor

head, compressor cylinder, or compressor outlet tube.

Voltage and Circuit Protection

Refer to The Specification Chart for the voltage and circuit

protection requirements of your compressor. Use only a

fuse or circuit breaker that is the same rating as the branch

circuit the air compressor is operated on. If the compressor

is connected to a circuit protected by fuses, use only dual

element time delay fuses. See Specification Chart.

Wiring of Compressor Units

Typical Wiring of Compressor Units

With more than 80 Gallons Capacity

IF REQUIREDIF REQUIRED

IF REQUIRED

IF REQUIREDIF REQUIRED

Typical schematic subject to all changes as dictated by

local electrical codes and authorities.

NOTE: THESE OUTFITS DO NOT INCLUDE ANY

MGP-SL10120H-2A

WIRING BECAUSE OF VARIOUS

INSTALLATION REQUIREMENTS.

10—ENG

Page 11

INSTALLATION AND BREAK-IN PROCEDURES

Air Filter Installation

To install air filter:

Insert threaded end of the air filter assembly into elbow

and tighten until snug.

Break-In Procedures

Serious damage may result if the following break-in instructions are not

closely followed.

The Break-In Procedure is required when:

A. New compressor is put into service.

B. Check valve is replaced

C. New pump is installed on tank.

1.Recheck compressor wiring. Make sure wires are

secure at all terminal connections. Free all contacts of

loose wire cuttings, etc.

Do not operate compressor without air

filter assembly installed as this will

cause damage to the compressor.

Additional Regulators and

Controls

Since the air tank pressure is usually greater than that

which is needed, a separate regulator is usually employed

to control the air pressure ahead of any individual air driven

device.

Separate air transformers that combine the functions of air

regulation and moisture and dirt removal should be used

where applicable.

Lubrication and Oil

2.Open the air outlet valve fully to permit air to escape

and prevent air pressure build-up in the tank during the

break-in period.

3.Position the fuse disconnect or circuit breaker to the

ON position and, if equipped, turn the ON/AUTO-OFF

switch on the pressure switch to the ON position.

4. Run the compressor for 30 minutes. Make sure the air

outlet, or globe valve, is open and there is no tank

pressure build-up.

5.Check for excessive vibration and noise. Adjust air

compressor belt guard as necessary to eliminate

chatter. Re-adjust or shim the air compressor feet, if

necessary, for proper level.

6. Close the outlet valve and let air compressor pump up

to "cut-out pressure". Turn the air compressor off and

check oil level. Add oil if necessary. Connect air hose

to air outlet adapter.

7. Check all air line fittings and connections/piping for air

leaks by applying a soap solution. Correct as necessary. Even minor leaks can cause this air compressor

to overwork, resulting in premature breakdown or

inadequate performance.

Multi-viscosity motor oils like 10W30, should

not be used in an air compressor. They

leave carbon deposits on critical components, thus reducing performance and compressor life. Use air compressor oil only.

See Maintenance for oil recommendations.

Compressors are shipped without oil. A

small amount of oil may be present in the

pump upon receipt of the air compressor.

This is due to plant testing and does not

mean that the pump contains oil. Do not

attempt to operate in order to check wiring

or for any reason without first adding oil to

the crankcase. Serious damage to the pump

can result from even very limited use without oil. Fill crankcase with recommended

oil before operating.

Remove the oil fill plug and fill the crankcase with recommended oil. Refer to the Service Instructions in this manual

for the specific oil recommended for use in your compressor unit. Replace the oil fill plug. Always fill to middle of

sight glass.

11—ENG

MGP-SL10120H-2A

Page 12

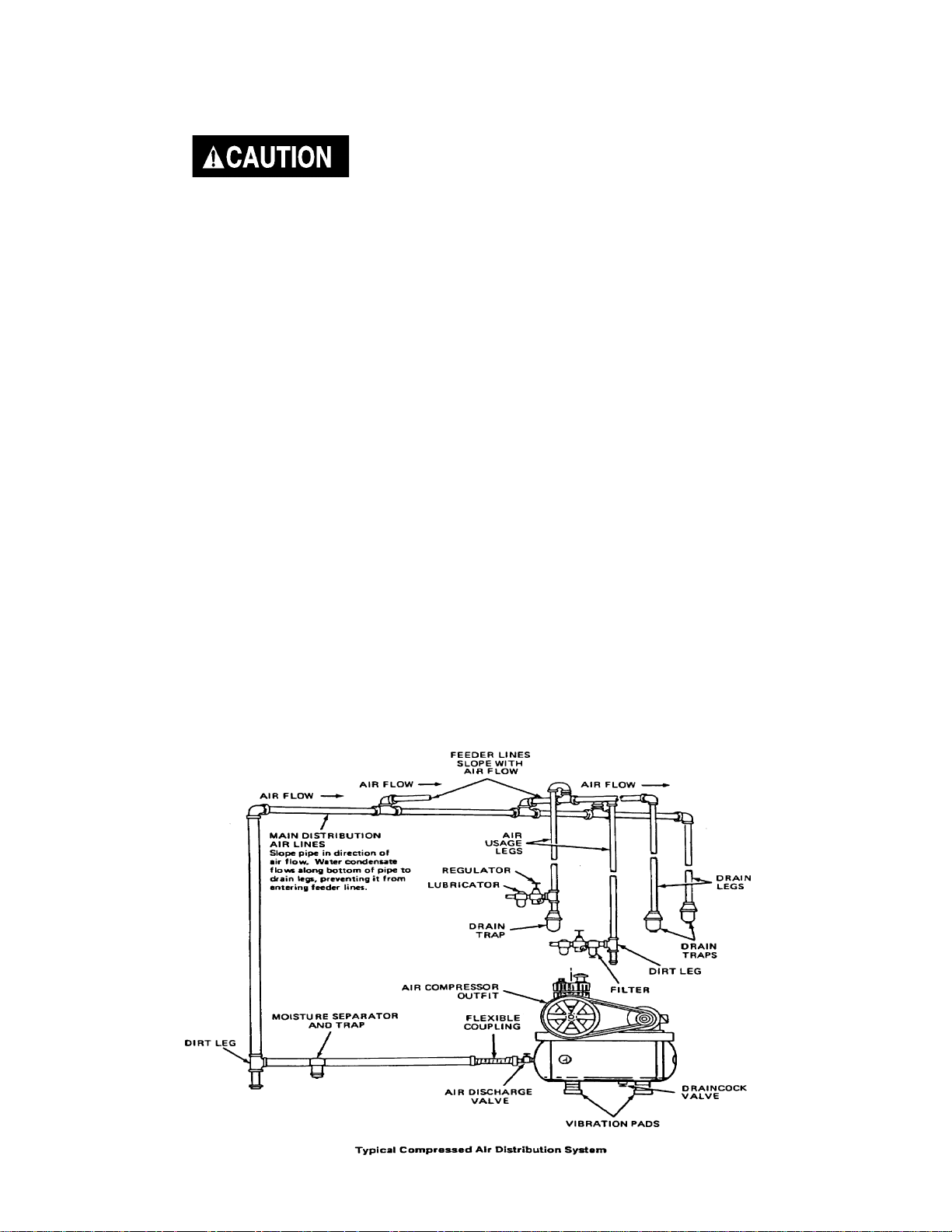

INSTALLATION AND BREAK-IN PROCEDURES

Piping

Plastic or PVC pipe is not designed for use

with compressed air. Regardless of its indicated pressure rating, plastic pipe can burst

from air pressure. Use only metal pipe for

air distribution lines.

NoteNote

Note

NoteNote

Where a remote air intake is used, enlarge the size of the air intake piping by

one pipe size for each 10 feet of length.

A typical compressed air distribution system as shown

below should be of sufficient pipe size to keep the

pressure drop between the supply and point of use to a

minimum. All pipes and fittings used must be certified

safe for the pressures involved. Pipe thread sealant must

be used on all threads, and all joints are to be made up

tight, since small leaks in the piping system are the

largest single cause of high operating costs.

All piping should be sloped to an accessible drain point

and all outlets should be taken from the top of the main

distribution air line so that moisture cannot enter the

outlet.

The main distribution air line should not be smaller than

the compressor air discharge valve outlet. A smaller line

will restrict the flow of air. If piping is over 100 feet long,

or if required air flow will exceed 15 SCFM, use 3/4"

piping.

NoteNote

Note

NoteNote

For underground installation, bury air

lines below the frost line and avoid

pockets where condensation can gather

and freeze. Apply pressure before underground lines are covered to make

sure all pipe joints are free from leaks.

It is recommended that a flexible coupling be installed

between the air discharge valve outlet and main air

distribution line to allow for vibration.

To remove dirt, oil and water, install a separator in the

main distribution line. Install separator a minimum of 5 to

6 feet from compressor to allow the air to cool to room

temperature before passing through the separator. Additional separators or filters may be used depending on the

application.

Liquid water occurs naturally in air lines as a result of

compression. Moisture vapor in ambient air is concentrated when pressurized and condenses when cooled in

downstream air piping. Compressed air dryers reduce

the water vapor concentration and prevent liquid water

formation in compressed air lines. Dryers are a necessary companion to filters, aftercoolers, and automatic

drains for improving the productivity of compressed air

systems.

Water and water vapor removal increases the efficiency

of air operated equipment, reduces contamination and

rusting, increases the service life of pneumatic equipment and tools, prevents air line freeze-ups, and reduces

product rejects. The use of dryers and filters are recommended when these moisture related problems are

reported to our factory or distributor service department.

MGP-SL10120H-2A

12—ENG

Page 13

OPERATING PROCEDURES

1. Before attaching an air hose or accessory, make sure the

outlet valve is in the closed position. On units equipped

with a pressure switch lever make sure the switch is in the

OFF position.

Compressed air from the outfit may contain

water condensation and oil mist. Do not spray

unfiltered air at an item that could be damaged by moisture or oil mist. Some air operated tools or devices may require filtered air.

Read instructions for air tool or device.

2.Attach regulator, hose and accessory. On models

without an air pressure regulator, one must be installed

before using accessories.

TOO MUCH AIR PRESSURE CAUSES A HAZARDOUS RISK OF BURSTING. CHECK THE

MANUFACTURER'S MAXIMUM PRESSURE

RATING FOR AIR TOOLS AND ACCESSORIES.

THE REGULATOR OUTLET PRESSURE MUST

NEVER EXCEED THE MAXIMUM PRESSURE

RATING.

3. Turn the compressor on and allow tank pressure to build.

On units equipped with a pressure switch lever, place the

switch in the ON-AUTO position. The motor will stop

when tank pressure reaches "cut-out pressure".

When You Are Finished:

6. Turn the compressor unit off.

7. Turn the regulator counterclockwise and set the outlet

pressure to zero.

8. Remove the air tool or accessory.

9. Open the regulator and allow the air to slowly bleed

from the tank. Close the regulator when tank pressure

is approximately 20 psi.

10. Open the drain cock valve underneath the tank and

drain water from air tank. Collect the water in a suitable

containter. Continue operating unit until all moisture is

removed from the air tank.

DRAIN TANK DAILY. WATER WILL CONDENSE

IN THE AIR TANK. IF NOT DRAINED, THE WATER WILL CORRODE AND WEAKEN THE AIR

TANK, CAUSING A RISK OF AIR TANK RUPTURE. THE AIR TANK MUST BE DRAINED PROPERLY.

11. After the water has been drained, close the drain cock.

- if the compressor is under continuous use - drain at

least once each day.

4. Open the outlet valve.

5. If an air pressure regulator is in use, open the regulator by

turning it clockwise. Adjust the regulator to the correct

pressure setting. Your outfit is ready for use.

- if the compressor is only used occasionally - drain

after each use.

Note

If drain cock valve is clogged, release air pressure in air tank. The drain cock valve can then

be removed, cleaned and reinstalled.

13—ENG

MGP-SL10120H-2A

Page 14

MAINTENANCE

UNIT CYCLES AUTOMATICALLY WHEN POWER IS ON. DURING MAINTENANCE, YOU COULD BE

EXPOSED TO VOLTAGE SOURCES, COMPRESSED AIR OR MOVING PARTS. PERSONAL INJURIES

CAN OCCUR. DISCONNECT POWER SOURCE AND BLEED OFF ALL AIR TANK PRESSURE BEFORE

DOING ANY MAINTENANCE OR REPAIR. NEVER OPERATE THE UNIT WITH THE BELT GUARD

REMOVED.

To ensure efficient operation and longer life of the air compressor outfit, a routine maintenance schedule should be

prepared and followed. The following routine maintenance schedule is geared to an outfit in a normal working environment

operating on a daily basis. If necessary, the schedule should be modified to suit the conditions under which your

compressor is used. The modifications will depend upon the hours of operation and the working environment. Compressor

outfits in an extremely dirty and/or hostile environment will require a greater frequency of all maintenance checks.

A clean air compressor runs cooler and provides longer service. Clean or blow off fins and any other parts of the air

compressor that collect dust or dirt. Do not place rags, containers or other material on or against the ventilation openings

in the belt guard. Adequate ventilation is necessary to maintain proper air compressor operating temperature.

Routine Maintenance Schedule

Every 8 Hours of Operation

1. Check oil level. Add if necessary.

2. Drain water from the air tank, any moisture

separators or transformers.

Overfilling with oil will cause premature

compressor failure. Do not overfill.

3. Check for any unusual noise and/or vibration.

4. Manually check all safety valves to make sure they

are operating properly.

5. Inspect for oil leaks and repair any leaks found.

6. Clean and inspect the air intake filter; replace if

necessary.

Every 40 Hours of Operation

1. Inspect condition of drive belt; replace if

necessary.

First 100 Hours of Operation

1. Drain and refill compressor crankcase with clean

oil. Refer to Service Instructions for recommended

oils.

2. Increase frequency of oil changes if humidity or

operating conditions are extreme.

Every 160 Hours of Operation

1. Check drive belt tension; adjust if necessary. (Refer

to Service Instructions in this manual.)

2. Inspect air lines and fittings for leaks; correct as

necessary.

3. Check the alignment of the motor pulley to the fly

wheel. If necessary, align to within 1/32 inch on

centerline.

Every 300 Hours of Operation

1. Drain and refill compressor crankcase with clean

oil. Refer to Service Instructions for recommended

oils.

2. Increase frequency of oil changes if humidity or

operating conditions are extreme.

Each Year of Operation (2000 Hours or if a

Problem is Suspected)

Check condition of air compressor pump intake and

exhaust valves. Replace if damaged or worn out.

MGP-SL10120H-2A

14—ENG

Page 15

SERVICE INSTRUCTIONS

Air Filter - Inspection and

Replacement

NOTENOTE

NOTE

NOTENOTE

Keep the air filter clean at all times. Do

not operate the compressor with the air

filter removed.

A dirty air filter will not allow the compressor to operate

at full capacity. Before you use the compressor, check

the air filter to be sure it is clean. If it is dirty, replace it

with a new filter.

Oil - Checking and Changing

Overfilling with oil will cause premature

compressor failure. Do not overfill.

1. Check oil level in compressor crankcase before

each use. The oil level should be to the middle of

the oil sight glass.

2. Replace the oil after initial 100 hours of operation

- thereafter, every 300 hours of operation.

3. Remove the oil fill and drain plugs. Collect the oil

in a suitable container.

4. Replace the oil drain plug and refill the crankcase

with recommended oil. Always fill to middle of sight

glass.

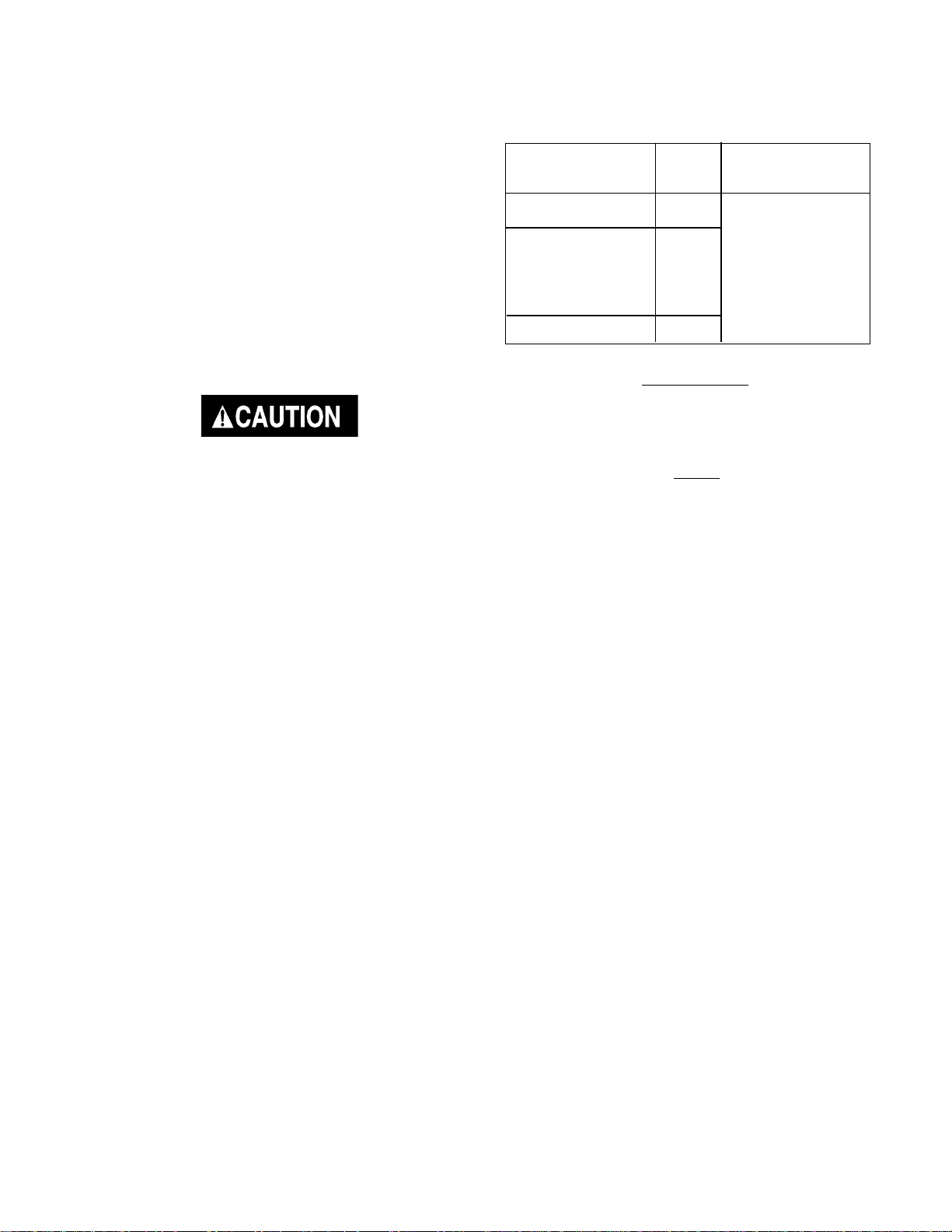

Oil Chart

Room or Ambient

Temperature

Cold Climates - 10º F

Moderate Climates 30º to 80º F

Hot Climates - 80º F

A compressor grade non-detergent oil should be used.

Most automotive detergent oils cause excessive carbon

buildup and should not be used. Please note that all units

run at a constant speed (not start and stop) and should

be lubricated by Rarus 847, Shell turbo 100, or Anderol

synthetic compressor oil. Do not use synthetic oil for the

first 300 hours. All units should be broken in on petroleum based oil.

Oil

Weight

20 Wt.

30 Wt.

40 Wt.

Type

Reciprocating

Non-detergent

petroleum based

compressor rated or

better oil

Check Valve - Inspection and

Replacement

Remove and inspect the check valve at least once a

year or more often if the compressor is heavily used.

Moisture and other contaminants in the hot compressed

air will cause an accumulation of a carbon-like residue

on the working parts. If the valve has heavy carbon

build-up, it should be replaced. Use the following procedure to inspect, clean or replace the check valve.

NoteNote

Note

NoteNote

It is important to maintain the proper oil

level. A low oil level reduces proper cylinder wall lubrication and increases ring

wear.

5. Replace the oil fill plug.

6. Start the compressor outfit and run for several

minutes. Shut the compressor down and check the

oil level. If necessary, add more oil.

1. Turn compressor off and disconnect or lock out

power source.

2. Release air pressure from the air tank.

3. Loosen the top and bottom tube nuts and remove the

outlet tube.

4. Loosen pressure release tube nuts, disconnect from

check valve and move tube aside.

5. Unscrew the check valve with a wrench.

15—ENG

MGP-SL10120H-2A

Page 16

SERVICE INSTRUCTIONS

6. Check that the valve disc moves freely and that the

spring holds the disc in the upper, closed position.

The check valve may be cleaned with a solvent.

7. Apply sealant to the check valve threads. Reinstall

the check valve. Do not overtighten.

8. Replace the outlet tube and tighten top and bottom

nuts. Do not overtighten.

9. Replace the pressure release tube and tighten nuts.

Do not overtighten.

Safety Valve - Inspection and

Replacement

SERIOUS INJURY OR DAMAGE MAY OCCUR

IF PARTS OF THE BODY OR LOOSE ITEMS

GET CAUGHT IN MOVING PARTS. NEVER

OPERATE THE OUTFIT WITH THE BELT

GUARD REMOVED. THE BELT GUARD

SHOULD BE REMOVED ONLY WHEN THE

COMPRESSOR POWER IS DISCONNECTED.

Adjusting Belt Tension

Adjust belt tension as described below.

For compressors with a motor slide mount, adjust belt

tension as follows:

1. Slide motor away from compressor until desired

tension is obtained.

IF THE SAFETY VALVE DOES NOT WORK

PROPERLY, OVER-PRESSURIZATION MAY

OCCUR, CAUSING AIR TANK RUPTURE OR

EXPLOSION. OCCASIONALLY PULL THE

RING ON THE SAFETY VALVE TO MAKE

SURE THAT THE SAFETY VALVE OPERATES FREELY. IF THE VALVE IS STUCK OR

DOES NOT OPERATE SMOOTHLY, IT MUST

BE REPLACED WITH A VALVE HAVING THE

SAME PRESSURE RATING.

The safety valve is set at the factory to a pressure

approximately 15 pounds higher than the rated pressure

of the outfit. If the pressure switch malfunctions and does

not shut off the motor automatically at maximum tank

pressure, the safety valve will protect the air tank against

excessive air pressure by popping off at its preset

pressure.

On two stage compressors, the belt should deflect

1/2" at midway between the pulley and the flywheel.

MGP-SL10120H-2A

2. Tighten two outside cap screws enough to hold the

motor in place for checking pulley and flywheel

alignment.

3. Tighten all four mounting screws to 20-25 ft.-lbs.

16—ENG

Page 17

SERVICE INSTRUCTIONS

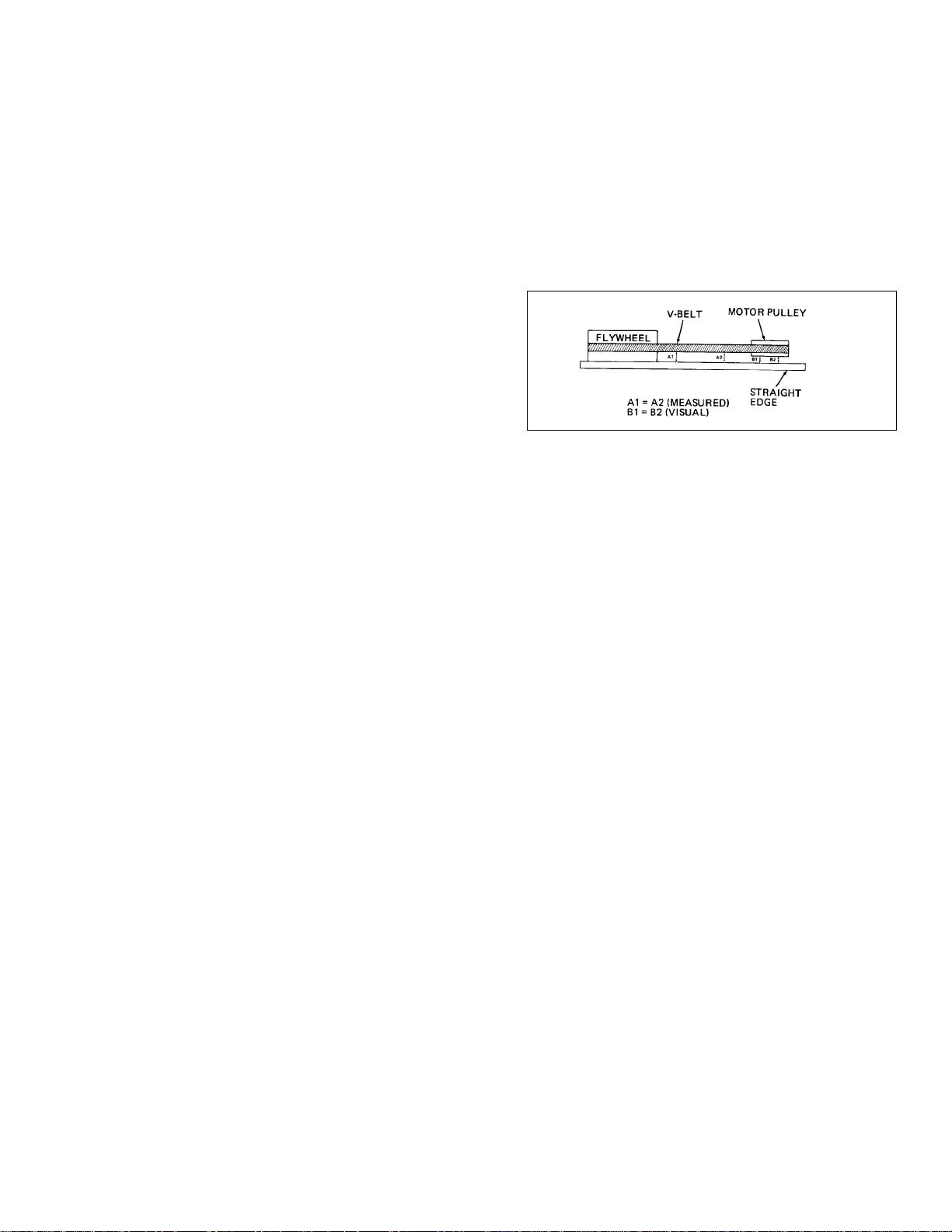

Motor Pulley and Flywheel

Alignment

1. Remove outer beltguard - To remove, loosen and

remove beltguard screws located at top of beltguard.

Insert a flat bladed screwdriver and pry beltguard

apart.

2. Place a straight edge along the outside face of the

compressor flywheel to check alignment of V-belt

grooves. (See figure below for proper alignment.)

3. If the belt grooves aren't aligned, continue with step

4 of this procedure. If the belt grooves are aligned,

continue with step 6 of this procedure.

4. Loosen pulley set screw and adjust pulley until it is in

proper alignment.

5. Tighten pulley set screw to 145-165 in.-lbs.

6. Reinstall belt guard.

Additional Service

Disassembly or service of the air compressor beyond

what is covered in this manual is not recommended.

If additional service is required, contact your nearest

Authorized Warranty Service Center.

STORAGE OF COMPRESSOR OUTFIT

1. Review the Maintenance section on the preceding

pages and perform scheduled maintenance as

necessary. Drain the water from the air tank.

2. Turn compressor off and disconnect or lock out

power source.

3. Remove any air tool or accessory.

4. Protect the electrical cord and/or air hose from

damage (such as being stepped on or run over).

5. Store the compressor in a clean and dry location.

17—ENG

MGP-SL10120H-2A

Page 18

TROUBLESHOOTING GUIDE

PERFORMING REPAIRS MAY EXPOSE VOLTAGE SOURCES, MOVING PARTS OR COMPRESSED AIR

SOURCES. PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY REPAIRS, DISCONNECT

POWER SOURCE FROM THE COMPRESSOR AND BLEED OFF ALL TANK AIR PRESSURE.

PROBLEM

Excessive tank pressure - safety

valve pops off (units with ONAUTO switch).

Excessive tank pressure - safety

valve pops off (units without

ON-AUTO switch).

Air leaks at fittings or hose.

Air leaks at or inside check valve. Def ective or dir ty check valve.

CAUSE CORRECTION

Pressure switch does not shut off motor when compressor reaches “cut-out"

pressure.

Pressure switch "cut-out" too high.

Incorrect wiring connections.

Pressure switch does not shut off motor when compressor reaches "cut-out

pressure".

Incorrect wiring connections.

Tube fittings are not tight enough.

Move the pressure switch lever to the "OFF" position.

If the outfit doesn’t shut off, and the electrical contacts

are welded together, replace the pressure switch.

Contact Service Center to check and adjust, or replace

switch.

See "Wiring of Compressor Units".

Pressure switch must be replaced.

See "Wiring of Compressor Units".

Tighten fittings where air can be heard escaping.

Check fittings with soapy water solution. DO NOT

OVER-TIGHTEN.

A defective check valve results in a constant air leak at

the pressure release valve when there is pressure in the

tank and the compressor is shut off. Remove and clean

or replace check valve. DO NOT OVER-TIGHTEN.

Air leaks at pressure switch release valve during running.

Continuous air relieving from

pressure switch release valve

after shut off.

Air leaks in air tank or at air tank

welds.

Air leak from safety valves. Possible defect in safety valves.

Squealing sound.

Defective pressure switch release valve. Remove and replace the release valve.

Defective check valve. See "Air Leak at Check Valve."

Defective air tank.

Loose belt.

There is no oil in the compressor.

Air tank must be replaced.

DO NOT DRILL INTO, WELD, OR OTHERWISE

MODIFY AIR TANK. IT WILL WEAKEN. THE

TANK CAN RUPTURE OR EXPLODE.

Operate safety valves manually by pulling on ring. If a

valve still leaks, it should be replaced.

Adjust belt tension. (See Belt Replacement.)

Add oil. (See Oil-Checking and Changing)

MGP-SL10120H-2A

18—ENG

Page 19

TROUBLESHOOTING GUIDE

Motor will not run.

CAUSEPROBLEM

Motor overload protection switch has

tripped.

Tank pressure exceeds pressure switch

"cut-in pressure".

Check valve stuck open.

Loose electrical connections.

Possible defective capacitor.

Paint spray on internal motor parts.

Possible defective motor.

Fuse blown, circuit breaker tripped.

CORRECTION

Let motor cool off for 10-15 minutes and overload

protection switch will reset automatically. If the overload still trips, check for defective capacitor.

Motor will start automatically when tank pressure

drops below "cut-in pressure" of pressure switch.

Remove and clean or replace. DO NOT OVERTIGHTEN.

Check wiring connection inside pressure switch and

motor terminal box area.

Contact Service Center for inspection or replacement

if necessary.

Have checked by Service Center. Do not operate the

compressor in the spray area. See Flammable Vapor

Warning.

Have checked by a local Service Center.

1. Check fuse box for blown fuse and replace if

necessary. Reset circuit breaker. Do not use a fuse

or circuit breaker with higher rating than that

specified for your particular branch circuit.

2. Check for proper fuse; only dual element time

delay fuses are acceptable. Use

fuses. Time delay fuses should be marked

"D" in Canada and "T" in the US.

only time delay

Excessive belt wear.

enough air to operate accessories.

Pressure release valve on pressure

switch has not unloaded head pressure.

Loose belt/tight belt.

Loose pulley.

Prolonged excessive use of air. Decrease amount of air usage.Compressor is not supplying

Compressor is not large enough for air

requirement.

Restricted air intake filter.

3. Check for low voltage conditions.

4. Remove check valve and clean or replace if it is

stuck open or closed.

5. Disconnect the other electrical appliances from

circuit or operate the compressor on its own

branch circuit.

On an on/auto pressure switch equipped with a pressure relief valve, bleed the line by pushing the pressure

switch to the OFF position. If valve does not open,

bend the lever until it does. If valve still fails to bleed,

replace the valve assembly.

Adjust belt tension. (See Belt Replacement.)

Check for worn keyway or pulley bore. Also check for

bent motor shaft. Replace parts if necessary.

Check the accessory air requirement. If it is higher than

the CFM or pressure supplied by your air compressor,

you need a larger compressor.

Clean or replace air intake filter. Do not operate the

compressor in the paint spray area.

19—ENG

MGP-SL10120H-2A

Page 20

TROUBLESHOOTING GUIDE

CAUSEPROBLEM

Compressor is not supplying

enough air to operate accessories. (Continued)

Knocking noise.

Excessive oil consumption. Replace the air intake.

Loose belt.

Hole in hose.

Check valve restricted.

Air leaks.

Defective check valve.

Low oil level.

Loose flywheel.

Loose compressor mounting screws.

Belt too tight/too loose.

Carbon build-up.

Restricted air intake.

CORRECTION

Adjust belt tension.

Check and replace if required.

Remove and clean or replace.

Tighten fittings. (See "Air Leaks" section of "Troubleshooting Guide".)

Remove and clean or replace.

Tighten pulley set screw, 145 to 165 in.-lbs.Loose pulley.

Maintain prescribed oil level. Add oil.

Tighten screw, 33 to 37 ft.-lbs.

Check screws. Tighten as required.

Adjust belt tension. (See Belt Replacement.)

Remove the head. Clean the valves and the top of the

piston. (Be sure carbon does not fall into the cylinder.)

Reassemble using new gaskets and torque screws,

117-207 ft.-lbs.

Compressor overheating.

Motor overheating.

Compressor overworked.

Poor quality oil.

The compressor is overworked. Reduce air consumption or add another air compres-

The check valve is restricted.

Dirty compressor. Clean the compressor thoroughly.

High ambient temperature.

Incorrect oil, low oil. See oil recommendation under Maintenance.

Low voltage.

Pressure switch set beyond factory setting.

Belt too tight.

Compressor valves have excessive carbon deposits build-up; restricted check

valve.

Reduce air consumption or add another air compressor to take up some of the load.

Drain pump and replace with correct oil. Refer to

Lubrication and Oil Section.

sor to take up some of the load.

Inspect the check valve. Clean if necessary.

Use remote air intake.

Dirty or defective check valve.Compressor starting against load.

Provide correct voltage. Consult local power company or electrician.

Do not set switch beyond maximum for which outfit

was designed as noted on nameplate.

Adjust for proper tension.

Clean or replace compressor valves or check valve.

MGP-SL10120H-2A

20—ENG

Page 21

TROUBLESHOOTING GUIDE

PROBLEM

Motor overheating.

(Continued)

Water in pump crankcase; oil

appears milky in color.

CAUSE CORRECTION

Too many motor starts per hour. Consult Service Center.

Improper wiring gauge.

Incorrect voltage.

Current style electric motors run relatively hot under normal operating

conditions, with reasonable compressor loading. This condition is normal

and no adjustment is necessary.

Under normal operating conditions, the motor amperage draw will not

exceed the nameplate amperage rating, plus the service factor, as it appears

on the electric motor. If a condition of sustained high amperage exists, refer

to service checks above and/or consult electrician. If cause cannot be isolated

by an electrician, consult with Service Center for additional assistance.

Humid operating conditions.

Unit not reaching proper operating

temperature because the compressor runs infrequently and is oversized

for the air requirement.

Check electrical hookup and installation data or consult electrician.

NOTENOTE

NOTE

NOTENOTE

Relocate compressor outfit, or change oil frequently.

Consult Service Center.

Liquid water or moisture in air

lines.

Condensation forms in air lines when

the warm compressed air coming

from the air tank starts to cool down

as it travels through the air lines.

Install compressed air dryer sized for the flow and

dryness level required.

21—ENG

MGP-SL10120H-2A

Page 22

COMPRESSOR DIAGRAM

MGP-SL10120H-2A

22—ENG

Page 23

COMPRESSOR PARTS LIST

Key Part

No. Number Description

1 Z-BAL-T59S PUMP ASSEMBLY

2 Z-MO-9082 MOTOR

3 Z-D20596 PRESSURE SWITCH ASSEMBLY

4 TIA-4200 SAFETY VALVE

5 Z-GA-360 PRESSURE GAUGE

6 SSV-6-B BALL VALVE

7 AC-0485 BELTGUARD BRACKET (2)

8 PU-2906 MOTOR PULLEY

9 BT-316 BELT (2)

10 AC-0478 CONTACTOR BOX

11 AC-0465 CHECK VALVE

12 AC-0582 3/4" OUTLET TUBE

13 SSP-7815 3/4" NUT/SLEEVE ASSEMBLY (2)

14 AC-0459 1/4" PRESSURE RELIEF TUBE

15 SSP-7811 1/4" NUT/SLEEVE ASSEMBLY

16 CAC-95 MANIFOLD

Part Not Shown

SSF-8131 BELTGUARD NUT (2)

D23000 DRAIN VALVE

AC-0460-1 INSIDE BELTGUARD

AC-0461 OUTSIDE BELTGUARD

SSF-953-ZN BELT GUARD SCREW (2)

23—ENG

MGP-SL10120H-2A

Page 24

COMPRESSOR PUMP DIAGRAM

MGP-SL10120H-2A

24—ENG

Page 25

PARTS LIST

Key Part

No. Number Description

1 BAL-7061400 HEAD

2 BAL-7040050 VALVE PLATE ASSEMBLY

3 BAL-9049011 SAFETY VALVE, AFTERCOOLER

4 AC-0415 FILTER ASSEMBLY

5 AC-0583 FLYWHEEL

6 BAL-1000112 OIL BREATHER ASSEMBLY

7 BAL-9022003 OIL SIGHT GLASS

8 BAL-1000506 OIL PLUG 1/2"

9 BAL-9110022 FLYWHEEL BOLT

10 BAL-9004009 FLYWHEEL WASHER

11 BAL-9049020 SAVETY VALVE, INNERCOOLER

12 K-0589 GASKET KIT

13 K-0590 RING KIT

NOTICE: When ordering repair parts for your Pump Assembly use this page.

25—ENG

MGP-SL10120H-2A

Page 26

SERVICE NOTES

MGP-SL10120H-2A

26—ENG

Page 27

LIMITED WARRANTY

DeVilbiss Air Power Company warrants to the original purchaser who uses the product in a consumer application (personal,

residential or household usage) that all products covered under this warranty are free from defects in material and

workmanship for one year from the date of purchase. All products covered by this limited warranty which are used in

commercial applications (i.e., income producing) are warranted to be free of defects in material and workmanship for 90

days from the date of original purchase. Products covered under this warranty include air compressors, air tools, service

parts, pressure washers, and generators.

DeVilbiss Air Power Company will repair or replace, at DeVilbiss' option, products or components which have failed within

the warranty period. Service will be scheduled according to the normal work flow and business hours at the service center

location, and the availability of replacement parts. All decisions of DeVilbiss Air Power Company with regard to this limited

warranty shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

RESPONSIBILITY OF ORIGINAL PURCHASER (initial User):

• To process a warranty claim on this product, DO NOT return it to the retailer. The product must be evaluated by

an Authorized Warranty Service Center. For the location of the nearest Authorized Warranty Service Center call

1-800-888-2468, 24 hours a day, 7 days a week or visit our web site @ devap.com.

• Retain original cash register sales receipt as proof of purchase for warranty work.

• Use reasonable care in the operation and maintenance of the product as described in the Owners Manual(s).

• Deliver or ship the product to the nearest Authorized Warranty Service Center. Freight costs, if any, must be paid

by the purchaser.

• Air compressors with 60 and 80 gallon tanks will be inspected at the site of installation. Contact the nearest

Authorized Warranty Service Center that provides on-site service calls for service call arrangements.

• If the purchaser does not receive satisfactory results from the Authorized Warranty Service Center, the purchaser should

contact DeVilbiss Air Power Company.

THIS WARRANTY DOES NOT COVER:

• Merchandise sold as reconditioned, used as rental equipment, or floor or display models.

• Merchandise that has become damaged or inoperative because of ordinary wear, misuse*, cold, heat, rain, excessive

humidity, freeze damage, use of improper chemicals, negligence, accident, failure to operate the product in accordance

with the instructions provided in the Owners Manual(s) supplied with the product, improper maintenance, the use of

accessories or attachments not recommended by DeVilbiss Air Power Company, or unauthorized repair or alterations.

* An air compressor that pumps air more than 50% during a one hour period is considered misuse because the air

compressor is undersized for the required air demand.

• Repair and transportation costs of merchandise determined not to be defective.

• Costs associated with assembly, required oil, adjustments or other installation and start-up costs.

• Expendable parts or accessories supplied with the product which are expected to become inoperative or unuseable

after a reasonable period of use, including but not limited to sanding disks or pads, saw and shear blades, grinding

stones, springs, chisels, nozzles, o-rings, air jets, washers and similar accessories.

• Merchandise sold by DeVilbiss Air Power Company which has been manufactured by and identified as the product

of another company, such as gasoline engines. The product manufacturer's warranty, if any, will apply.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM

ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT IS NOT COVERED BY THIS WARRANTY. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

• IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

213 Industrial Drive • Jackson, TN 38301-9615

Telephone: 1-800-888-2468

FAX: 1-800-888-9036

27—ENG

MGP-SL10120H-2A

Page 28

OWNERS MANUAL FOR

TWO-STAGE AIR COMPRESSOR

Model No.

L10120H2-2

Call our Toll Free Number 1-800-888-2468 to obtain the location

of the nearest Authorized Service Center for ordering repair parts and

for warranty repairs.

When ordering repair parts from your local Authorized Service

Center, always give the following information:

• Model number of your product

• Part number and description of the item you

wish to purchase

WARRANTY

This product is covered by the DeVilbiss

one year limited warranty. The warranty

can be found in this General Manual or

is available upon request.

Attach Sales Receipt here.

Retain Original Sales Receipt as

Proof of Purchase for Warranty

Repair Work.

DeVilbiss Air Power Company • 213 Industrial Dr. • Jackson, TN 38301-9615

Page 29

MANUAL DEL

OPERADOR PARA

COMPRESOR DE AIRE

DE DOS ETAPAS

Modelo No.

L10120H2-2

Tabla De Especificaciones

Modelo L10120H2-2

Potencia 10 HP

Voltaje/Ciclaje/Fases 240/480V/60 Hz / trifásico

Requerimiento mínimo del ramal del circuito 30 AMP

* Tipo de fusible "De acción retardada"

Capacidad del Tanque de Aire 120 Gal. ASME

Presión de Arranque Aproximada 140 PSIG

Presión de Corte Aproximada 175 PSIG

SCFM @ 175 PSIG 34,2

Arrancador Magnético Requiere (incluido en el compresor)

*Es preferible un interruptor de circuito. Si el compresor está conectado a un circuito protegido por

fusibles, use sólo fusibles de acción retardada. Los fusibles de acción retardada deben estar marcados

con la letra "D" en Canadá y "T" en EE.UU.

En el poco probable caso que usted tenga un problema con este producto o si le estuviese faltando partes,

no es necesario que lo devuelva a la tienda donde lo compró. Simplemente llame a nuestro teléfono gratuito

y hable con uno de nuestros Representante de Servicio.

NUESTRO HORARIO DE TRABAJO ES DE

8:00 a.m. a 6:00 p.m. (CST - Hora Estándar del Centro)

DE LUNES A SABÁDO

LLAME GRATIS AL 1-800-888-2468

DeVilbiss Air Power Company • 213 Industrial Drive • Jackson, TN 38301-9615

Page 30

TABLA DE CONTENIDOS

Página

PAUTAS DE SEGURIDAD ..................................... 2

TABLA DE ADVERTENCIAS ................................. 3-5

ESPECIFICACIONES .............................................. 6

GLOSARIO .............................................................. 6

CICLO DE TRABAJO .............................................. 6

INFORMACIÓN GENERAL ...................................... 6

INSPECCIÓN AL RECIBIR...................................... 7

DESCRIPCIÓN DE LA OPERACIÓN ....................... 8

INSTALACIÓN Y PROCEDIMIENTOS

PARA EL ASENTAMIENTO ................................ 9-12

Ubicación del Compresor de Aire ........................... 9

Métodos para Anclar el Compresor de Aire ............ 9

Instrucciones y Diagrama para el Cableado ......... 10

Voltaje y Protección del Circuito........................... 10

Instalación del Ensamblaje del Filtro de Aire ........ 11

Procedimientos para el Asentamiento .................. 11

Reguladores y Controles Adicionales ................... 11

Aceite y Lubricación ............................................. 11

Tuberías y Diagrama ............................................. 12

PROCEDIMIENTOS PARA OPERAR ..................... 13

Página

MANTENIMIENTO .................................................. 14

INSTRUCCIONES PARA EL SERVICIO ............ 15-17

Filtro de Aire - Inspección y Reemplazo ................ 15

Aceite - Inspección y Cambio ................................ 15

Aceites Recomendados ......................................... 15

Válvula de Chequeo

- Inspección y Reemplazo ................................ 15-16

Válvula de Seguridad

- Inspección y Reemplazo ..................................... 17

Regulación de la Tensión de la Correa .................. 17

Alineamiento de la Polea del Motor

y de la Polea Volante ............................................. 17

Servicio Adicional .................................................. 17

ALMACENAJE ...................................................... 17

GUÍA PARA DIAGNÓSTICO

DE PROBLEMAS.............................................. 18-21

DIAGRAMA DEL COMPRESOR ........................... 22

LISTA DE PARTES DEL COMPRESOR................ 23

DIAGRAMA DE LA BOMBA COMPRESORA ...... 24

LISTA DE PARTES DE LA BOMBA ...................... 25

NOTAS DE SERVICIO........................................... 26

GARANTÍA ............................................................ 27

CÓMO ORDENAR REPUESTOS Cubierta Posterior

DEFINICIONES DE NORMAS DE SEGURIDAD

Este manual contiene información que es importante que usted conozca y comprenda. Dicha información se relaciona con la protección

de SU SEGURIDAD PERSONAL y LA PREVENCIÓN DE PROBLEMAS PARA SU EQUIPO. A fin de ayudarlo a reconocer dicha

información usamos los símbolos que se muestran a la derecha. Sírvase leer este manual y prestar atención a

PELIGRO

PELIGRO indica una situación de inminente riesgo, la cual, si no

evitada, causará la muerte o lesiones serias.!

ADVERTENCIA

ADVERTENCIA indica una situación potencialmente riesgosa,

que si no es evitada, podría resultar en la muerte o lesiones

serias.

Retenga el recibo original de compra como prueba de la misma para aquellos trabajos de reparación cubiertos por la garantía.

MGP-SL10120H-2A

PRECAUCION indica una situación potencialmente peligrosa, la

cual, si no es evitada, podría resultar en lesiones menores.

PRECAUCION usado sin el símbolo de seguridad de alerta

indica una situación potencialmente riesgosa la que, si no es

evitada, podría causar daños en la propiedad.

2—SP

PRECAUCION

PRECAUCION

Page 31

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

GUARDE ESTAS INSTRUCCIONES

LA OPERACIÓN O EL MANTENIMIENTO INADECUADOS DE ESTE PRODUCTO PODRÍAN OCASIONAR SERIAS LESIONES Y

DAÑOS A LA PROPIEDAD. LEA Y COMPRENDA TODAS LAS ADVERTENCIAS E INSTRUCCIONES DE FUNCIONAMIENTO

ANTES DE UTILIZAR ESTE EQUIPO.

PELIGRO

RIESGO DE EXPLOSIÓN O INCENDIO

¿QUÉ PUEDE OCURRIR?

PARA LOS CONTACTOS ELÉCTRICOS ES NORMAL LA EXISTENCIA DE

CHISPAS ENTRE EL MOTOR Y EL INTERRUPTOR A PRESIÓN.

SI LAS CHISPAS ELÉCTRICAS PROVENIENTES DEL COMPRESOR TOMARAN

CONTACTO CON EMANACIONES DE MATERIALES INFLAMABLES, ELLOS

PODRÍAN ARDER ORIGINANDO INCENDIO O EXPLOSIÓN.

RESTRINGIR CUALQUIERA DE LAS ABERTURAS DE VENTILACIÓN CAUSARÁ

UN SERIO RECALENTAMIENTO Y PODRÍA PRODUCIR UN INCENDIO.

DEJAR DESATENDIDO ESTE PRODUCTO MIENTRAS EL MISMO ESTÁ EN

FUNCIONAMIENTO PUEDE RESULTAR EN LESIONES PERSONALES O DAÑOS

A LA PROPIEDAD.

RIESGO DE EXPLOSIÓN

¿CÓMO PREVENIRLO?

OPERE SIEMPRE EL COMPRESOR EN UN SECTOR BIEN VENTILADO Y LIBRE

DE MATERIALES COMBUSTIBLES, GASOLINA O EMANACIONES DE

SOLVENTE.

EN UN ÁREA DE ROCIADO DE MATERIALES INFLAMABLES, UBIQUE AL

COMPRESOR POR LO MENOS A 6,1M (20 PIES) DE DISTANCIA DEL ÁREA DE

ROCIADO. PODRÍA REQUERIRSE UNA EXTENSIÓN DE LA MANGUERA.

ALMACENE LOS MATERIALES INFLAMABLES EN UNA UBICACIÓN SEGURA,

ALEJADOS DEL COMPRESOR.

JAMÁS COLOQUE OBJETOS APOYADOS O SOBRE EL COMPRESOR. OPERE

EL COMPRESOR EN UN SECTOR ABIERTO, POR LO MENOS A 30 CM (12

PULGADAS) ALEJADOS DE CUALQUIER PARED U OBSTRUCCIÓN QUE

RESTRINJA EL FLUJO DE AIRE FRESCO A LAS ABERTURAS DE VENTILACIÓN.

OPERE EL COMPRESOR EN UN SECTOR LIMPIO, SECO, Y BIEN VENTILADO,. NO

OPERE LA UNIDAD EN ESPACIOS CERRADOS O CUALQUIER ÁREA

CONFINADA.

MANTÉNGASE SIEMPRE ALERTA CADA VEZ QUE EL PRODUCTO ESTE

FUNCIONANDO.

TANQUE DE AIRE: LAS SIGUIENTES CONDICIONES PUEDEN DETERMINAR EL DEBILITAMIENTO DEL TANQUE, Y ORIGINAR

UNA VIOLENTA EXPLOSIÓN DEL MISMO, SIENDO CAUSA DE DAÑOS A LA PROPIEDAD O LESIONES SERIAS.

¿QUÉ PUEDE OCURRIR?

1. DRENAJE INADECUADO DEL AGUA CONDENSADA EN EL TANQUE,

SIENDO LA CAUSA DEL ÓXIDO QUE REDUCE EL ESPESOR DEL TANQUE

DE ACERO.

2. MODIFICACIONES O INTENTO DE REPARACIONES AL TANQUE.

3. MODIFICACIONES NO AUTORIZADAS A LA VÁLVULA DE DESCARGA,

VÁLVULA DE SEGURIDAD O CUALQUIER OTRO COMPONENTE QUE

CONTROLE LA PRESIÓN DEL TANQUE.

4. LA VIBRACIÓN EXCESIVA PUEDE DEBILITAR EL TANQUE DE AIRE Y

CAUSAR SU RUPTURA O EXPLOSIÓN. DICHA VIBRACIÓN EXCESIVA

OCURRIRÁ SI EL COMPRESOR NO ESTÁ ADECUADAMENTE

MONTADO.

AGREGADOS Y ACCESORIOS

EL EXCESO A LOS VALORES DE PRESIÓN ESTABLECIDOS PARA LA

HERRAMIENTAS NEUMÁTICAS, PISTOLAS ROCIADORAS, ACCESORIOS

ACTIVADOS POR AIRE, CUBIERTAS Y OTROS OBJETOS INFLABLES, PUEDE

CAUSAR SU EXPLOSIÓN O SER ARROJADOS, PUDIENDO OCASIONAR

SERIAS LESIONES.

3—SP

DRENE EL TANQUE DIARIAMENTE O DESPUÉS DE CADA USO. SI EL TANQUE

GENERA UNA PÉRDIDA, REEMPLÁCELO INMEDIATAMENTE CON UN NUEVO TANQUE

O REEMPLACE EL COMPRESOR COMPLETO.

JAMÁS PERFORE, SUELDE, O EFECTÚE MODIFICACIÓN ALGUNA AL TANQUE

O SUS ACCESORIOS.

EL TANQUE ESTÁ DISEÑADO PARA RESISTIR PRESIONES OPERATIVAS

ESPECÍFICAS. JAMÁS EFECTÚE AJUSTES O SUSTITUYA PARTES QUE ALTEREN

LAS REGULACIONES DE PRESIÓN ORIGINALES DE FÁBRICA.

PARA UN CONTROL ESENCIAL DE LA PRESIÓN, DEBE USTED INSTALAR UN

REGULADOR Y UN MEDIDOR DE PRESIÓN A LA SALIDA DEL AIRE DE SU

COMPRESOR. SIGA LAS RECOMENDACIONES DE LOS FABRICANTES DE SU

EQUIPO Y JAMÁS EXCEDA LOS VALORES MÁXIMOS DE PRESIÓN PERMITIDOS

PARA LOS ACCESORIOS. JAMÁS USE EL COMPRESOR PARA INFLAR OBJETOS

QUE REQUIEREN POCA O BAJA PRESIÓN, TALES COMO JUGUETES PARA

LOS NIÑOS, PELOTAS DE FÚTBOL, PELOTAS DE BASQUET, ETC.

¿CÓMO PREVENIRLO?

MGP-SL10120H-2A

Page 32

PELIGRO

RIESGO DE OBJETOS ARROJADOS POR EL AIRE.

¿QUÉ PUEDE OCURRIR?

EL CHORRO DE AIRE COMPRIMIDO PUEDE CAUSAR DAÑOS SOBRE LOS

TEJIDOS BLANDOS DE LA PIEL EXPUESTA, Y PUEDE PROPULSAR SUCIEDAD,

ASTILLAS, PARTÍCULAS SUELTAS Y PEQUEÑOS OBJETOS A ALTA VELOCIDAD,

OCASIONANDO DAÑOS A LA PROPIEDAD O LESIONES PERSONALES.

RIESGO DE INHALACIÓN

¿QUÉ PUEDE OCURRIR?

EL AIRE COMPRIMIDO DE SU COMPRESOR ¡NO ES SANO PARA SER

INHALADO! EL CHORRO DE AIRE PUEDE CONTENER MONÓXIDO DE CARBONO,

EMANACIONES TÓXICAS O PARTÍCULAS SÓLIDAS PROVENIENTES DEL TANQUE.

EL ROCIADO DE MATERIALES TALES COMO PINTURA, SOLVENTES,

REMOVEDORES DE PINTURA, INSECTICIDAS, MATA HIERBAS, CONTIENEN

EMANACIONES DAÑINAS Y VENENOSAS.

¿CÓMO PREVENIRLO?

AL UTILIZAR EL COMPRESOR, USE SIEMPRE ANTEOJOS DE SEGURIDAD

Z87.1 APROBADOS, CON PROTECCIÓN LATERAL.

JAMÁS APUNTE NINGUNA BOQUILLA O PULVERIZADOR HACIA PARTES

DEL CUERPO, A OTRAS PERSONAS O ANIMALES.

APAGUE SIEMPRE EL COMPRESOR Y PURGUE LA PRESIÓN DE LA MANGUERA

DEL AIRE Y DEL TANQUE, ANTES DE INTENTAR EL MANTENIMIENTO, EL ACOPLE

DE HERRAMIENTAS O ACCESORIOS.

¿CÓMO PREVENIRLO?

OPERE SIEMPRE EL COMPRESOR DE AIRE EN UNA ZONA EXTERNA, LIMPIA

Y BIEN VENTILADA. EVITE LAS ÁREAS CERRADAS TALES COMO GARAJES,

SÓTANOS, ÁREAS CUBIERTAS DE ALMACENAJE, QUE CARECEN DE CONTINUO

RECAMBIO DE AIRE. MANTENGA ALEJADOS A LO NIÑOS, ANIMALES DOMÉSTICOS

Y OTROS FUERA DEL SECTOR DE OPERACIONES.

JAMÁS INHALE EL AIRE PROVENIENTE DEL COMPRESOR TANTO

DIRECTAMENTE O DESDE UN RESPIRADOR INSTALADO AL COMPRESOR.

TRABAJE EN UN ÁREA CON BUENA VENTILACIÓN CRUZADA. LEA Y SIGA

LAS INSTRUCCIONES DE SEGURIDAD PROVISTAS EN EL RÓTULO O EN LOS

DATOS DE LAS HOJAS DE SEGURIDAD DEL MATERIAL QUE ESTÁ

PULVERIZANDO. USE EL RESPIRADOR APROBADO NIOSH/MSHA DESIGNADO

PARA UTILIZARSE CON SU APLICACIÓN ESPECÍFICA.

RIESGO DE DESCARGA ELÉCTRICA

¿QUÉ PUEDE OCURRIR?

SU COMPRESOR DE AIRE ESTÁ ACCIONADO POR ELECTRICIDAD. COMO

CUALQUIER OTRO DISPOSITIVO ELÉCTRICO IMPULSADO ELÉCTRICAMENTE, SI

NO SE LO UTILIZA ADECUADAMENTE, PODRÍA CAUSARLE UNA DESCARGA

ELÉCTRICA.

LAS REPARACIONES INTENTADAS POR PERSONAL NO CALIFICADO

PODRÍAN OCASIONAR SERIAS LESIONES O LA MUERTE POR

ELECTROCUCIÓN.

CONEXIÓN A TIERRA: DEJAR DE PROVEER UNA ADECUADA CONEXIÓN A

TIERRA A ESTE PRODUCTO PODRÍA OCASIONAR LESIONES SERIAS O LA

MUERTE POR ELECTROCUCIÓN. VER INSTRUCCIONES PARA LA PUESTA A

TIERRA.

MGP-SL10120H-2A

¿CÓMO PREVENIRLO?

JAMÁS OPERE EL COMPRESOR A LA INTEMPERIE CUANDO ESTÁ LLOVIENDO O

EN CONDICIONES DE HUMEDAD.

NUNCA OPERE EL COMPRESOR SIN SUS DEFENSAS O SUS CUBIERTAS

REMOVIDAS O DAÑADAS.

CUALQUIER CONEXIÓN ELÉCTRICA O REPARACIÓN REQUERIDA POR ESTE

PRODUCTO DEBE SER EFECTUADA POR PERSONAL AUTORIZADO DE LOS

SERVICENTROS DE ACUERDO A LOS CÓDIGO ELÉCTRICOS NACIONALES Y

LOCALES.

ASEGÚRESE QUE EL CIRCUITO ELÉCTRICO AL CUAL ESTÁ CONECTADO EL

COMPRESOR, SUMINISTRA APROPIADA CONEXIÓN A TIERRA, TENSIÓN

CORRECTA Y UNA ADECUADA PROTECCIÓN DE FUSIBLES.

4—SP

Page 33

PELIGRO

RIESGO DE PARTES MÓVILES

¿QUÉ PUEDE OCURRIR?

PARTES MOVIBLES TALES COMO LA POLEA, EL VOLANTE Y LA CORREA

PODRÍAN SER LA CAUSA DE SERIAS LESIONES SI ELLAS ENTRARAN EN

CONTACTO CON USTED O SUS ROPAS.

INTENTAR OPERAR EL COMPRESOR CON SUS PARTES DAÑADAS O

FALTANTES, O LA REPARACIÓN DEL COMPRESOR CON SUS PROTECCIONES

REMOVIDAS, PUEDE EXPONERLO A USTED A PARTES MOVIBLES, QUE

PODRÍAN RESULTAR EN LESIONES SERIAS.

RIESGO DE QUEMADURAS

¿QUÉ PUEDE OCURRIR?

TOCAR EL METAL EXPUESTO TAL COMO EL CABEZAL DEL COMPRESOR O

LOS TUBOS DE SALIDA DEL ESCAPE, PUEDEN OCASIONARLE SERIAS

QUEMADURAS.

¿CÓMO PREVENIRLO?

NUNCA OPERE EL COMPRESOR SIN SUS DEFENSAS O SUS CUBIERTAS

REMOVIDAS O DAÑADAS.

CUALQUIER REPARACIÓN REQUERIDA POR ESTE PRODUCTO DEBE SER

EFECTUADA POR PERSONAL AUTORIZADO DE LOS SERVICENTROS.

¿CÓMO PREVENIRLO?

JAMÁS TOQUE PARTES DE METAL EXPUESTAS, EL COMPRESOR DURANTE O

INMEDIATAMENTE DESPUÉS DE LA OPERACIÓN. EL COMPRESOR

PERMANECERÁN CALIENTES POR VARIOS MINUTOS LUEGO DE LA OPERACIÓN.

NO LO CUBRA CON FUNDAS PROTECTORAS O INTENTE EL MANTENIMIENTO

HASTA QUE LA UNIDAD HAYA ALCANZADO SU ENFRIAMIENTO.

RIESGO DE CAIDAS

¿QUÉ PUEDE OCURRIR?

UN COMPRESOR PORTÁTIL PUEDE CAERSE DE LA MESA, EL BANCO DE

TRABAJO O DEL TECHO DAÑANDO AL COMPRESOR Y PUDIENDO RESULTAR

EN SERIAS LESIONES O LA MUERTE DEL OPERADOR.

RIESGO DE DAÑOS A LA PROPIEDAD AL TRANSPORTAR

EL COMPRESOR

(Fuego, inhalación, daño a la superficie de vehículos)

¿QUÉ PUEDE OCURRIR?

EL ACEITE PUEDE DERRAMARSE Y ELLO PODRÍA RESULTAR EN SERIAS

LESIONES O LA MUERTE DEBIDO AL RIESGO DE INCENDIO O INHALACIÓN. EL

DERRAME DE ACEITE DAÑA ALFOMBRAS, PINTURAS U OTRAS SUPERFICIES DE

VEHÍCULOS O REMOLQUES.

¿CÓMO PREVENIRLO?

OPERE SIEMPRE EL COMPRESOR EN UNA POSICIÓN ESTABLE Y SEGURA A

FIN DE PREVENIR EL MOVIMIENTO ACCIDENTAL DE LA UNIDAD. JAMÁS OPERE

EL COMPRESOR SOBRE UN TECHO U OTRA POSICIÓN ELEVADA. UTILICE

MANGUERAS ADICIONALES DE AIRE PARA ALCANZAR POSICIONES ALTAS.

¿CÓMO PREVENIRLO?

DEPOSITE EL COMPRESOR SOBRE UNA ALFOMBRILLA PROTECTORA CUANDO

LO TRANSPORTE, A FIN DE PROTEGER AL VEHÍCULO DE PÉRDIDAS POR GOTEO.

RETIRE EL COMPRESOR DEL VEHÍCULO INMEDIATAMENTE DESPUÉS DE SU

ARRIBO AL DESTINO.

5—SP

MGP-SL10120H-2A

Page 34

ESPECIFICACIONES

Para ver las especificaciones del compresor, referirse a la carátula de este manual. Usar sólo un fusible o interruptor de circuito del

mismo amperaje que el circuito en el cual está operando el compresor de aire. Si el compresor de aire está conectado a un circuito