Page 1

Record All Information

for future reference:

Brand:

Purchase Date:

Model #:

Serial #:

Questions? 1-800-888-2468

Register your product online

www.devap.com

CONSUMER SAFETY INFORMATION . .2

SAFETY GUIDELINES/DEFINITIONS . . .2

SAFETY INSTRUCTIONS . . . . . . . . . .2-8

SPECIFICATIONS . . . . . . . . . . . . . . . . . .8

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . .9

OPERATION . . . . . . . . . . . . . . . . . . .10-12

MAINTENANCE . . . . . . . . . . . . . . . .13-17

STORAGE . . . . . . . . . . . . . . . . . . . . . . .18

WATTAGE CALCULATIONS . . . . . . .19-21

TROUBLESHOOTING GUIDE . . . . . . . .22

AVAILABLE REPAIR PARTS . . . . . . . . .23

WARRANTY . . . . . . . . . . . . . . . . . . . . . .24

ESPAÑOL . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-48

FRANÇAIS . . . . . . . . . . . . . . . . . . . . . . .49-72

READ AND SAVE THESE INSTRUCTIONS

Operator’s

Manual

Part No. A04669 Rev. 1 01/19/05

Page 2

2- ENG

A04669

Read Operators Manual. Do not operate equipment until you have read

operators Manual for Safety, Assembly, Operation, and Maintenance

Instructions.

This product is equipped with a spark arresting muffler. It is a violation of

California statutes section 130050 and/or sections 4442 and 4443 of the

California Public Resources Code, unless the engine is equipped with a spark arrester, as

defined in section 4442, and maintained in effective working order. Spark arrester are also

required on some U.S. Forest Service land and may also be legally required under other

statutes and ordinances.

Engine exhaust contains chemicals known, in certain quantities, to cause

cancer, birth defects or other reproductive harm.

CONSUMER GENERAL AND SERVICE INFORMATION

• Please read and follow these instructions for proper use and maintenance.

• Please take the time now to register your generator online at www.devap.com.

• If you experience any problems and need assistance, please call us at our toll free

number 1-800-888-2468, Monday through Saturday, 8:00 a.m. To 6:00 p.m.

C.S.T.

• If repair or service part purchase is required, our many Authorized Warranty

Service Centers are conveniently located and equipped to handle all in-warranty

and out-of-warranty service.

• For the location of the nearest Authorized Warranty Service Center call

1-800-888-2468, 24 hours a day, 7 days a week or visit our web site at

www.devap.com.

• Retain sales receipt as proof of purchase for warranty service.

• Read and understand all safety warnings.

• Do not operate this unit until you have read and understand this Owners Manual

for Safety, Operation, and Maintenance Instructions.

CONSUMER SAFETY INFORMATION

DO NOT RETURN THIS PRODUCT TO THE RETAILER! FOR SERVICE OPTIONS

CALL: 1-800-888-2468

Page 3

Operation of

generator in rain,

wet, icy, or

flooded

conditions.

Water is an excellent conductor

of electricity! Water which comes

in contact with electrically

charged components can

transmit electricity to the frame

and other surfaces, resulting in

electrical shock to anyone contacting them.

Operate generator in a clean, dry,

well ventilated area. Make sure

hands are dry before touching unit.

3- ENG

A04669

indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

indicates a potentially hazardous situation which, if not avoided,may result in minor

or moderate injury

used without the safety alert symbol indicates potentially hazardous situation

which, if not avoided, may result in property damage.

This manual contains information that is important for you to know and understand. This

information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS.

To help you recognize this information, we use the symbols below. Please read the manual and

pay attention to these sections.

SAFETY GUIDELINES / DEFINITIONS

IMPORTANT SAFETY INSTRUCTIONS

Improper operation or maintenance of this product could result in serious injury

and property damage. Read and understand all warnings and operating

instructions before using.

RISK OF ELECTROCUTION AND FIRE

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Attempting to

connect generator

directly to the

electrical system

of any building

structure.

Back feeding electricity through

a building’s electrical system to

the outside utility feed lines

could endanger repair persons

attempting to restore service.

Never backfeed electricity through a

structure's electrical system.

Page 4

4- ENG

A04669

Operation of unit

when damaged,

or with guards or

panels removed.

Removal of guarding could

expose electrically charged

components and result in

electrocution.

Do not operate generator with protective guarding removed.

Improper

connection of

items to

generator.

Exceeding the load capacity of

the generator by attaching too

many items, or items with very

high load ratings to it could

result in overheating of some

items or their attachment wiring

resulting in fire or electrical

shock.

Attempting to use the unit

when it has been damaged, or

when it is not functioning

normally could result in fire or

electrocution.

Read the load rating chart and instructions in the Wattage Calculation section. Make sure that the

summation of electrical loads for all

attachments does not exceed the

load rating of the generator.

Do not operate generator with mechanical or electrical problem. Have

unit repaired by an Authorized Service Center.

Use of worn,

damaged, undersized or ungrounded extension cords.

Use of ungrounded cordsets

could prevent operation of

circuit breakers and result in

electrical shock.

Always use a cordset having a

grounding wire with an appropriate

grounding plug. DO NOT use an ungrounded plug.

Use proper size (wire gauge)

cordset for application see chart in

the Assembly section of this

manual.

Contact with worn or damaged

extension cords could result in

electrocution.

Use of undersize extension

cords could result in overheating

of the wires or attached items,

resulting in fire.

Inspect extension cords before use

and replace with new cord if required.

Placing generator

on or against

highly conductive

surface, such as a

steel walkway or

metal roof.

Place generator on low conductivity surface such as a concrete slab.

Accidental leakage of electrical

current could charge conductive

surfaces in contact with the

generator.

RISK OF ELECTROCUTION AND FIRE

(Continued)

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

ALWAYS operate generator a minimum of six feet from any conductive surface.

Page 5

5- ENG

A04669

RISK OF FIRE

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Improper storage

of fuel

Improperly stored fuel could lead

to accidental ignition. Fuel

improperly secured could get into

the hands of children or other

unqualified persons.

Store fuel in a OSHA approved

container designed to hold

gasoline. Store container in secure

location to prevent use by others.

Attempting to

fill the fuel tank

while the engine

is running.

Gasoline and gasoline vapors can

become ignited by coming in

contact with hot components

such as the muffler, engine

exhaust gases, or from an

electrical spark.

Cigarettes, sparks, fires, or other

hot objects can cause gasoline or

gasoline vapors to ignite.

Turn engine off and allow it to cool

before adding fuel to the tank.

Equip area of operation with a fire

extinguisher certified to handle

gasoline or fuel fires.

Add fuel to tank in well ventilated

area. Make sure there are no

sources of ignition near the

generator.

Operate generator in a clean, dry,

well ventilated area a minimum of

four feet from any building, object

or wall. DO NOT OPERATE UNIT

INDOORS OR IN ANY CONFINED

AREA.

Materials placed against or near the

generator or operating the generator in areas where the temperature

exceeds 104° F. ambient (such as

storage rooms or garages) can interfere with its proper ventilation

features causing overheating and

possible ignition of the materials or

buildings.

Sparks, fire, hot

objects

Inadequate

ventilation for

generator

Tampering with

factory set

engine speed

settings.

Engine speed has been factory

set to provide safe operation.

Tampering with the engine speed

adjustment could result in

overheating of attachments and

could cause a fire.

Spilled fuel and its vapors can

become ignited from hot surfaces

or sparks.

Never attempt to "speed-up" the

engine to obtain more performance. Both the output voltage

and frequency will be thrown out of

standard by this practice,

endangering attachments and the

user.

Use care in filling the tank to avoid

spilling fuel. Make sure fuel cap is

secured tightly and check engine

for fuel leaks before starting

engine. Move generator away from

refueling area or any spillage

before starting engine. Allow for

fuel expansion. Keep maximum

fuel level ¼ inch below the tip of

the fuel tank. Never refuel with the

engine running.

Overfilling the fuel

tank – fuel

spillage.

Page 6

6- ENG

A04669

RISK OF UNSAFE OPERATION

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Operation of

generator in

careless manner

All sources of energy include the

potential for injury. Unsafe

operation or maintenance of your

generator could lead to serious

injury or death to you or others.

• Review and understand all of the

operating instructions and

warnings in this manual.

• Become familiar with the operation and controls of the

generator. Know how to shut it

off quickly.

• Equip area of operation with a

fire extinguisher certified to

handle gasoline or fuel fires.

• Keep children or others away

from the generator at all times.

RISK OF BREATHING - INHALATION

HAZARD

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Breathing exhaust fumes will

cause serious injury or death.

Operate generator in clean, dry,

well ventilated area. Never operate

unit in enclosed areas such as

garages, basements, storage,

sheds, or in any location occupied

by humans or animals. Keep children, pets and others away from

area of operating unit.

Gasoline

engines produce

toxic carbon

monoxide

exhaust fumes.

RISK OF INJURY AND PROPERTY

DAMAGE WHEN TRANSPORTING

GENERATOR

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Fire, Inhalation,

Damage to

Vehicle Surfaces

Fuel or oil can leak or spill and

could result in fire or breathing

hazard, serious injury or death

can result. Fuel or oil leaks will

damage carpet, paint or other

surfaces in vehicles or trailers.

If generator is equipped with a fuel

shut-off valve, turn the valve to the

off position before transporting to

avoid fuel leaks. If generator is not

equipped with a fuel shut-off valve,

drain the fuel from tank before

transporting. Transport fuel only in

an OSHA approved container.

Always place generator on a

protective mat when transporting

to protect against damage to

vehicle from leaks. Remove

generator from vehicle immediately

upon arrival at your destination.

Page 7

7- ENG

A04669

RISK OF UNSAFE OPERATION

(Continued)

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Improper raising or suspending

can cause damage to the

generator.

Always use cables, chains, or

straps rated at 2000 lbs working

load or more to raise or suspend

generator.

Operation of

voltage

sensitive appliances without a

voltage surge

protector

Any gasoline operated household

generator will incur voltage

variations causing damage to

voltage sensitive appliances or

could result in fire.

Always use a U.L. listed voltage

sensitive surge protector to

connect voltage sensitive

appliances (TV, computer, stereo,

etc.). Failure to use a U.L. listed

voltage surge protector will void

the warranty on your generator.

Notice: A multiple outlet strip is not

a surge protector. Make sure you

use a U.L. listed voltage surge protector

Raising or

suspending

generators

equipped with

lift rings

improperly

Generator could fall causing

serious injury or death to you or

others.

Always use proper connecting procedures as described in this

manual when connecting cables,

chains, or straps for raising or

suspending generators equipped

with lift rings.

Operating

generator while

suspended

Generator will not operate

properly and will cause damage to

the generator and could cause

serious injury or death to you or

others.

Never operate generator while suspended or in an unlevel position.

Always operate generate on a flat,

level surface.

Contact with hot surfaces, such

as engines exhaust components,

could result in serious burns.

RISK OF HOT SURFACES

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Contact with hot

engine and

generator

components.

During operation, touch only the

control surfaces of the generator.

Keep children away from the generator at all times. They may not be

able to recognize the hazards of

this product.

Page 8

8- ENG

A04669

SPECIFICATIONS

MODEL GM1000

HORSE POWER 2.4

RATED/SURGE WATTS 1000/1250

VOLTAGE 120V

AMPERAGE 8.3 A

PHASE SINGLE

HERTZ 60 Hz

ENGINE SPEED 3600 RPM

MAX. AMBIENT TEMP. 104° F

FUEL CAPACITY 1.2 GALLON

RUN TIME @ 50%/100% 8/6 HOURS

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK OF MOVING PARTS

Never operate generator with

guarding or cover plates removed.

Avoid wearing loose fitting clothing

or jewelry which could be caught by

moving parts.

The generator contains parts which

rotate at high speed during

operation. These parts are covered

by guarding to prevent injury.

Contact with

moving parts

can result in

serious injury.

RISK FROM LIFTING

This generator is heavy and lifting it

may require assistance.

Serious injury can result from attempting to lift a heavy object.

Lifting a heavy

object.

A portable generator can fall from a

table, workbench, or roof causing

damage to the generator and could

result in serious injury or death.

Always operate generator in a

stable secure position to prevent

accidental movement of the unit.

Never operate generator on a roof

or other elevated position.

HAZARD

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK OF FALLING

A portable

generator can

fall from an

elevated

position causing

equipment

damage or

serious injury.

Page 9

9- ENG

A04669

NOTE: Left and right describes the

location of a part with the operator

facing the outlet panel.

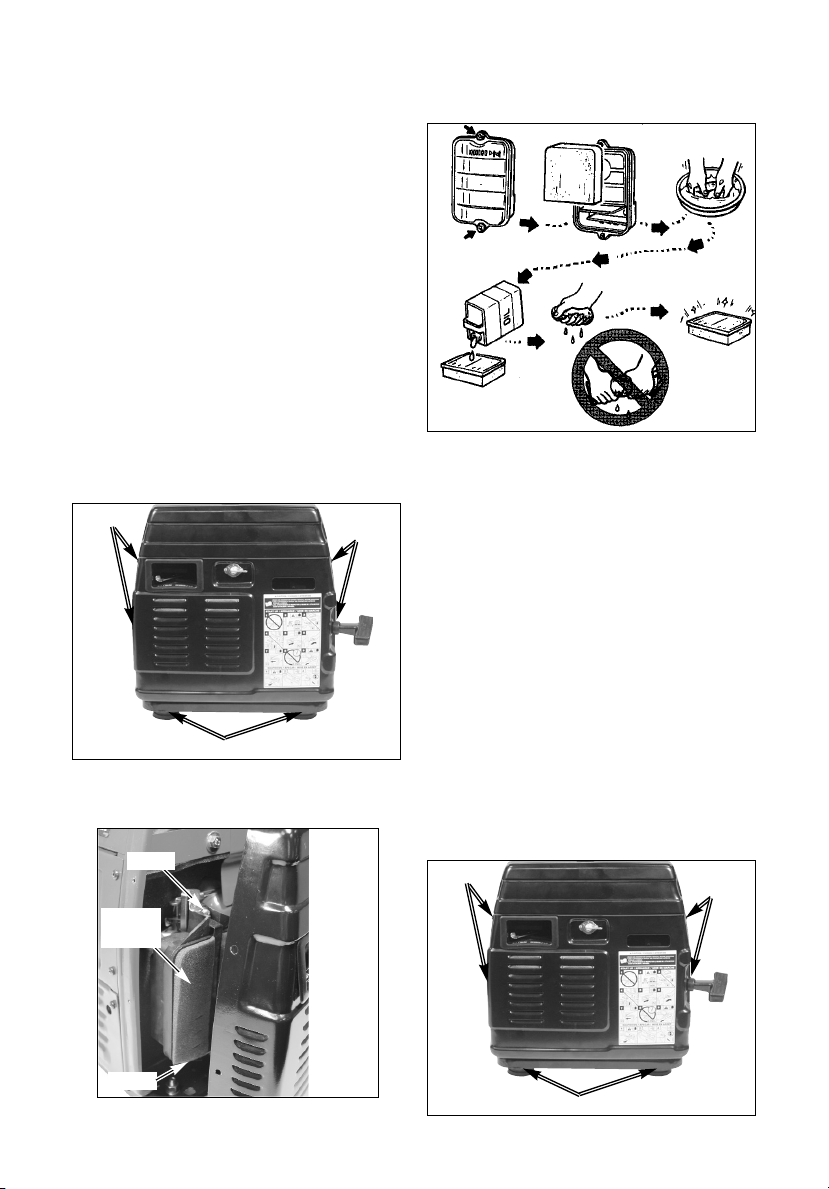

REMOVE GENERATOR FROM

CARTON

• Open carton from top.

• Locate and remove the handle kit.

• Assemble the handle to the top of

the generator using the screwdriver

and screws supplied. Save the

screwdriver and spark plug wrench

for future use.

• Carefully lift generator from carton.

GROUNDING THE GENERATOR

A grounding screw is supplied on the

generator for use when required by local

electrical ordinances. Refer to article 250

of the National Electrical Code to clarify

any needed grounding information. Your

local electric company or a certified

electrician should be able to help you

with this information.

ASSEMBLY

Read this manual. Do

not attempt to operate

equipment until you have read this

Manual for Safety, Operation, and

Maintenance Instructions.

EXTENSION CORDS

When using an appliance or tool at a

considerable distance from the

generator, a 3-wire extension cord that

has a 3-blade grounding plug and a

3-slot receptacle that accepts the tool's

plug MUST be used in order to reduce

the risk of electrical shock. A cord of

adequate size must be used. Using the

following chart to determine the

minimum wire size required.

Extension Cord Wire Gauge Chart

Amperage

Cord

Length

Wire

Gauge

Size

An extension cord

that is hot to the

touch is overloaded. Repair or

replace damaged extension cords

immediately.

DO NOT connect this

generator to the main

electrical supply coming into a house.

Up to 10

amp draw

14 ga.0 to

100 ft.

Page 10

10- ENG

A04669

OPERATION

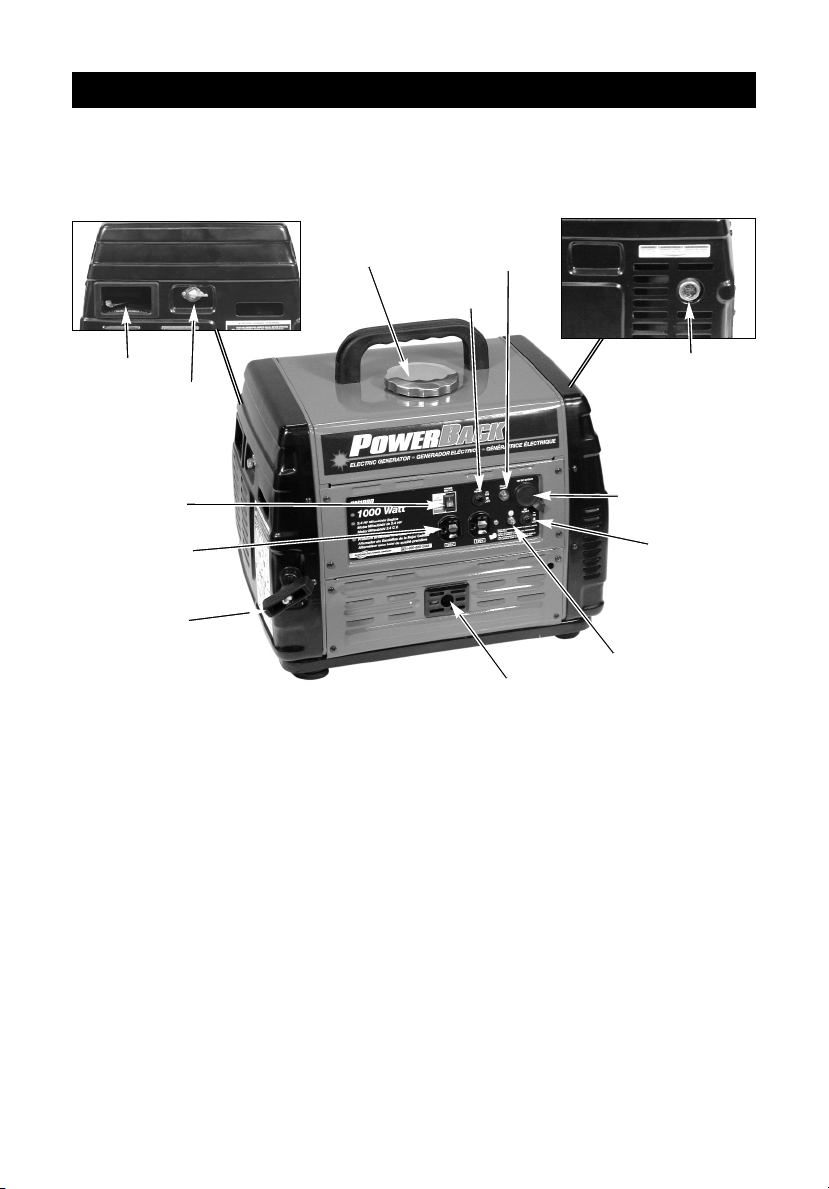

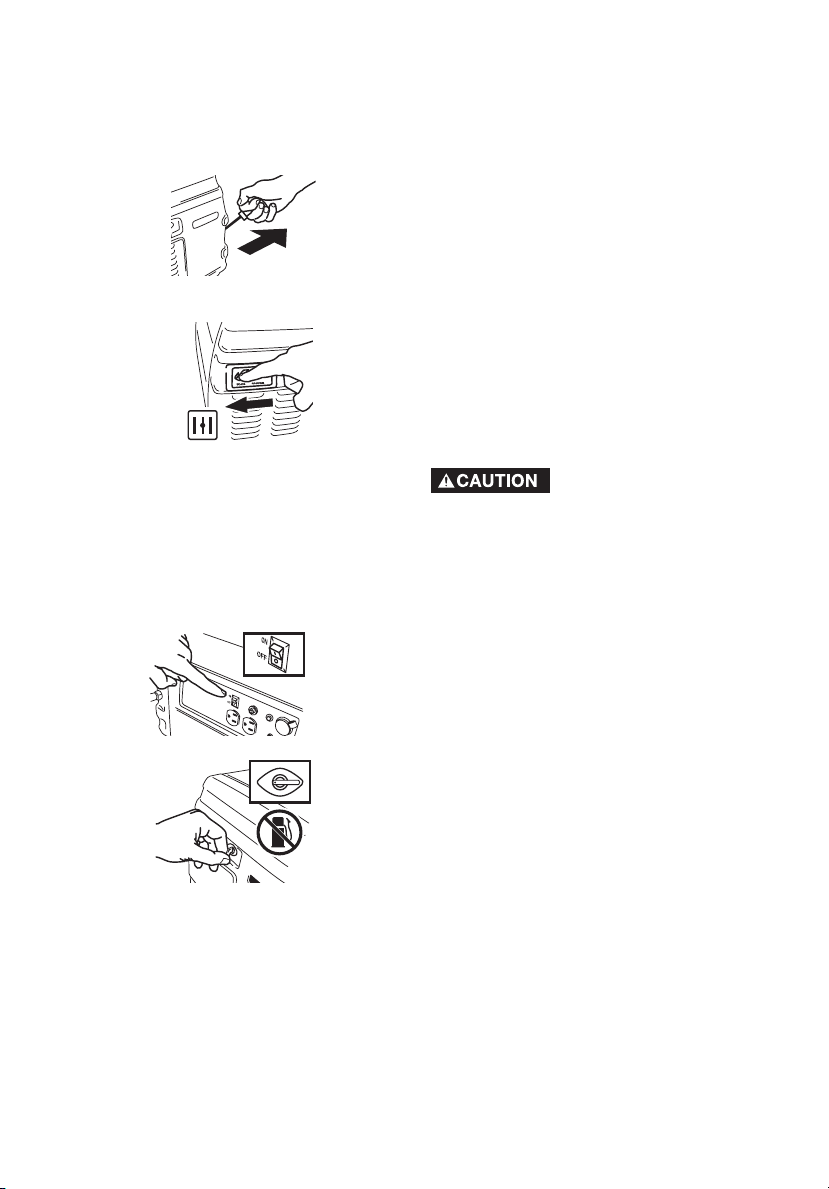

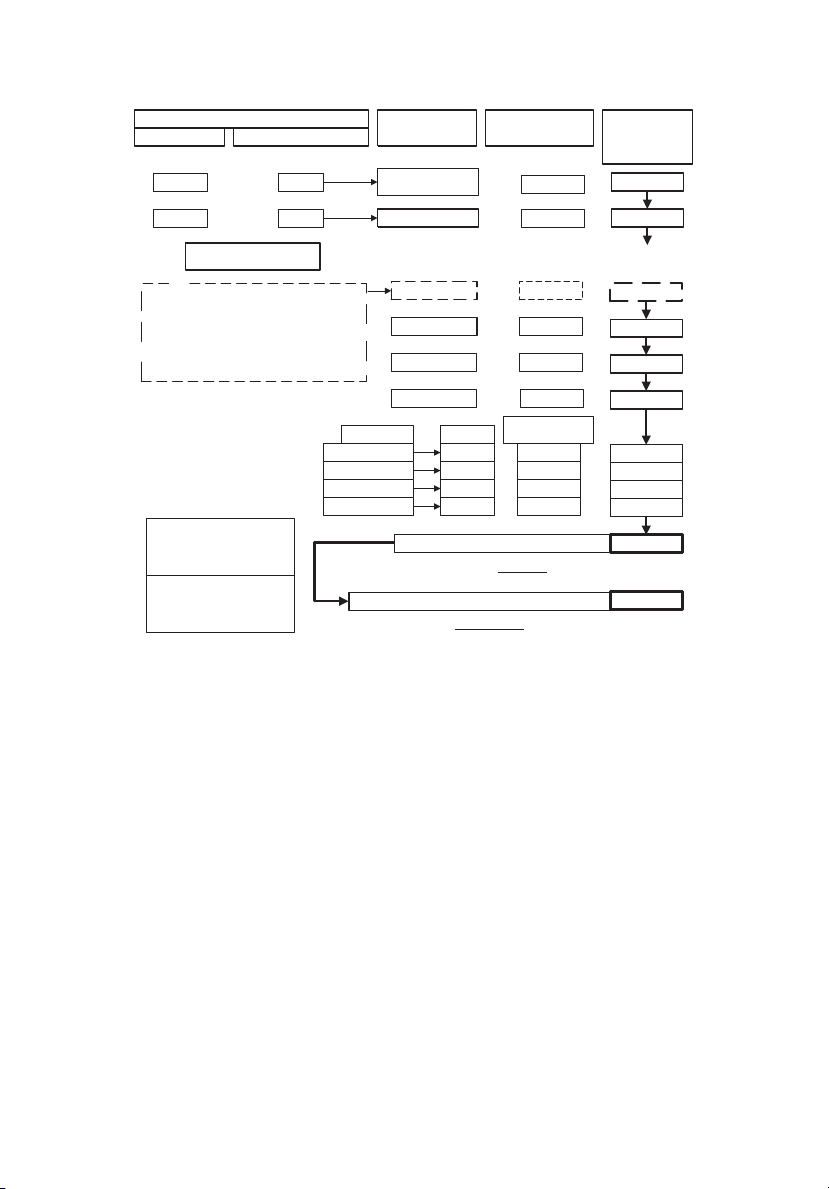

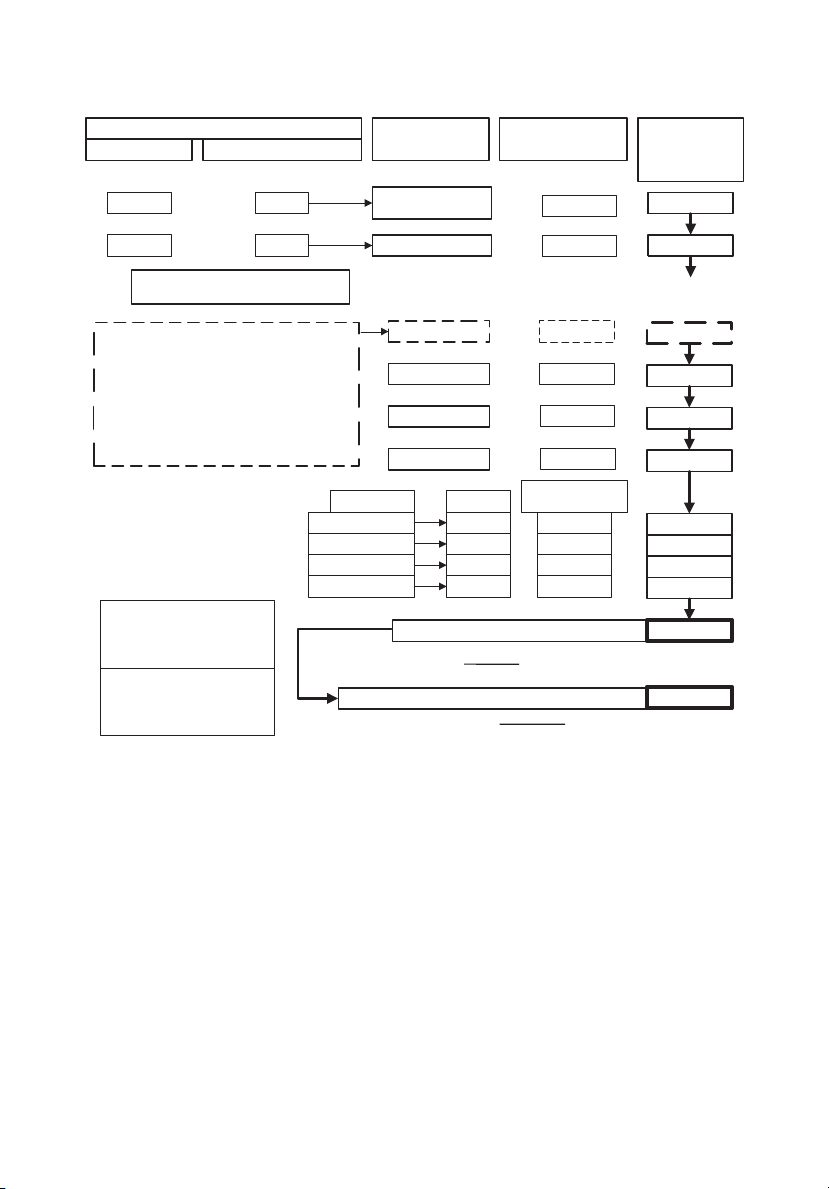

1. Engine On/Off Switch - Enables

and disables the ignition system.

2. Pilot Lamp - Indicates voltage is

being provided by generator.

3. 12V DC Outlet - Supplies voltage

to 12V DC appliances. NOTE: This

outlet is for operating 12V DC

appliances only, DO NOT use this

outlet to charge batteries.

4. Grounding Screw- This is the

attachment point for a ground wire

to an external earth ground.

5. Receptacle- 120V duplex supplies

voltage to 120V appliances.

6. Fuel Cap - Fill the fuel tank with

clean, fresh, unleaded gasoline with

a pump octane rating of 87 or

higher.

7. Circuit Breakers -

Each receptacle

has a circuit breaker to protect the generator from overloading. If the circuit

breaker trips, unplug all electrical loads

from the generator. Let the circuit breaker cool down. Push circuit breaker

button to reset.

8. Oil Fill - Fill the crankcase with

SAE 10W-30 oil.

9. Muffler Exhaust

10. Fuel Valve Lever - Opens and

closes the connection between the

fuel tank and the carburetor.

11. Choke- Opens and closes the

choke valve in the carburetor.

12. Recoil Starter

KNOW YOUR GENERATOR

Read this General Manual and Safety Rules before operation of your Generator. Compare

the illustration in your parts manual with your generator to familiarize yourself with the location of

various controls and adjustments. Save all manuals for future references.

Muffler

Exhaust (9)

Choke (11)

Fuel Valve

Lever (10)

Oil Fill (8)

12V DC

Outlet (3)

DC Circuit

Breaker (7)

Grounding

Screw (4)

Pilot

Lamp (2)

Engine

On/Off

Switch (1)

Receptacle (5)

AC Circuit

Breakers (7)

Fuel Cap (6)

Recoil

Starter (12)

Page 11

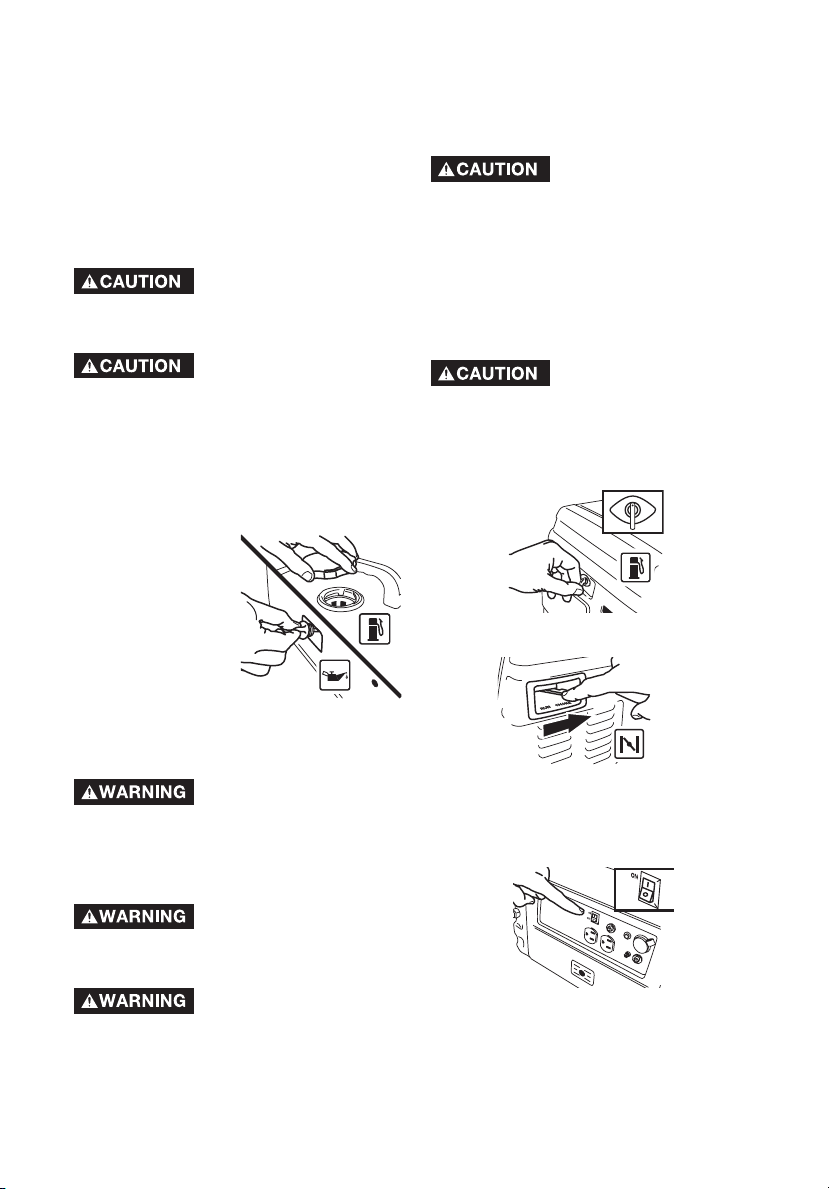

TO START THE ENGINE

1. Open the fuel shut-off valve lever.

2. Move the choke control located to

CHOKE position.

NOTE: No choke is required on warm

engines. Make sure choke is in the RUN

position on warm engine starts.

3. Move the engine ON/OFF switch to

the ON position.

11- ENG

A04669

GENERATOR CAPACITY

IMPORTANT: Exceeding the rated capacity

of your generator can result in serious damage

to your generator and connected electrical

devices. See the Wattage Calculation section

in this manual to assist you in determining the

appliances and tools that can be run with the

wattage capacity of your generator.

BEFORE START UP

This generator has been

shipped from the factory

without oil in the crankcase. Operating the

unit without oil can damage the engine.

Always check engine oil

level before every start.

Running engine low of oil or out of oil could

result in serious damage to the engine.

Follow the steps listed below before starting

generator:

1. Check engine oil. See the Maintenance

section for correct procedure.

2. Check fuel level,

fill as required.

Make sure generator is turned off

and has been

allowed time to

cool down. Use

clean, fresh, regular unleaded

gasoline with a

minimum of 87 octane. Do not mix oil

with gasoline.

Never fill fuel tank

completely. Fill tank to

1/2" below the bottom of the filler neck to

provide space for fuel expansion. Wipe

any fuel spillage from engine and

equipment before starting engine.

Never fill fuel tank

indoors. Never fill fuel

tank when engine is running or hot. Do

not smoke when filling fuel tank.

Never run engine

indoors or in enclosed,

poor ventilated areas, engine exhaust

contains carbon monoxide, an odorless

and deadly gas.

3. Make sure generator is grounded in

accordance with local requirements.

4. All electrical loads MUST be

disconnected.

Engine speed has been

factory set to provide

safe operation. Tampering with the engine

speed adjustment could result in overheating of attachments and could cause a fire.

Never attempt to "speed-up" the engine to

obtain more performance. Both the output

voltage and frequency will be thrown out of

standard by this practice, endangering attachments and the user.

You MUST unplug any

load from the generator

before starting to prevent permanent damage to any appliances.

ON

OFF

OFF

Page 12

12- ENG

A04669

CONNECTING ELECTRICAL

LOADS

1. Let engine run and warm up for five

minutes after starting with no

electrical load.

IMPORTANT: If engine speed or voltage

fluctuates with a load below 250 Watts,

move the choke control to the half

choke position.

4. Grasp handle on rope starter and

pull slowly until resistance is felt. Let

the rope rewind slowly. Pull rope

with a rapid full arm stroke. Let rope

rewind slowly. Repeat if necessary.

5. When engine starts, gradually move

the choke to the RUN position.

IMPORTANT: Allow generator to run at

no load for five minutes upon each initial

start-up to allow engine and generator

to stabilize.

STOPPING ENGINE

1. Disconnect all electrical loads.

2. Turn engine ON/OFF switch to

"OFF" position.

3. Close fuel shut-off valve lever.

Connect loads in the following manner

to prevent damage to equipment:

2. Connect inductive load equipment

first; inductive loads consist of

small hand tools and some small

appliances. Connect the items that

require the most wattage first. See

Wattage Calculation Section in this

manual.

3. Connect the lights next.

4. Voltage sensitive equipment should

be the last equipment connected to

the generator. Plug voltage sensitive

appliances such as TV's, VCR's,

microwaves, and cordless

telephones into a UL listed voltage

surge protector, then connect the

UL listed voltage surge protector to

the generator.

Failure to connect and

operate equipment in

this sequence can cause damage to

equipment and will void the warranty

on your generator.

Follow the wattage calculation table in

the Wattage Calculation section of this

manual. Overloading the generator

will cause power fluctuations and can

damage equipment and appliances.

DeVilbiss Air Power Company will only

be responsible for damage to

customer's equipment when the

generator is determined to be

defective. This determination will only

be made by an authorized

representative of DeVilbiss Air Power

Company and this decision will be

final. DeVilbiss Air Power Company

reserves the right to inspect the

electrical connections at the

customer's site of operation and test

the generator for proper operation

before any determination of liability is

made. Failure to maintain the

equipment or wiring for inspection will

void any claim for damages by the

customer. DeVilbiss Air Power

Company will not be responsible for

equipment damaged as a result of

voltage surges, improper operation or

improper installation of the generator.

ON

OFF

Page 13

13- ENG

A04669

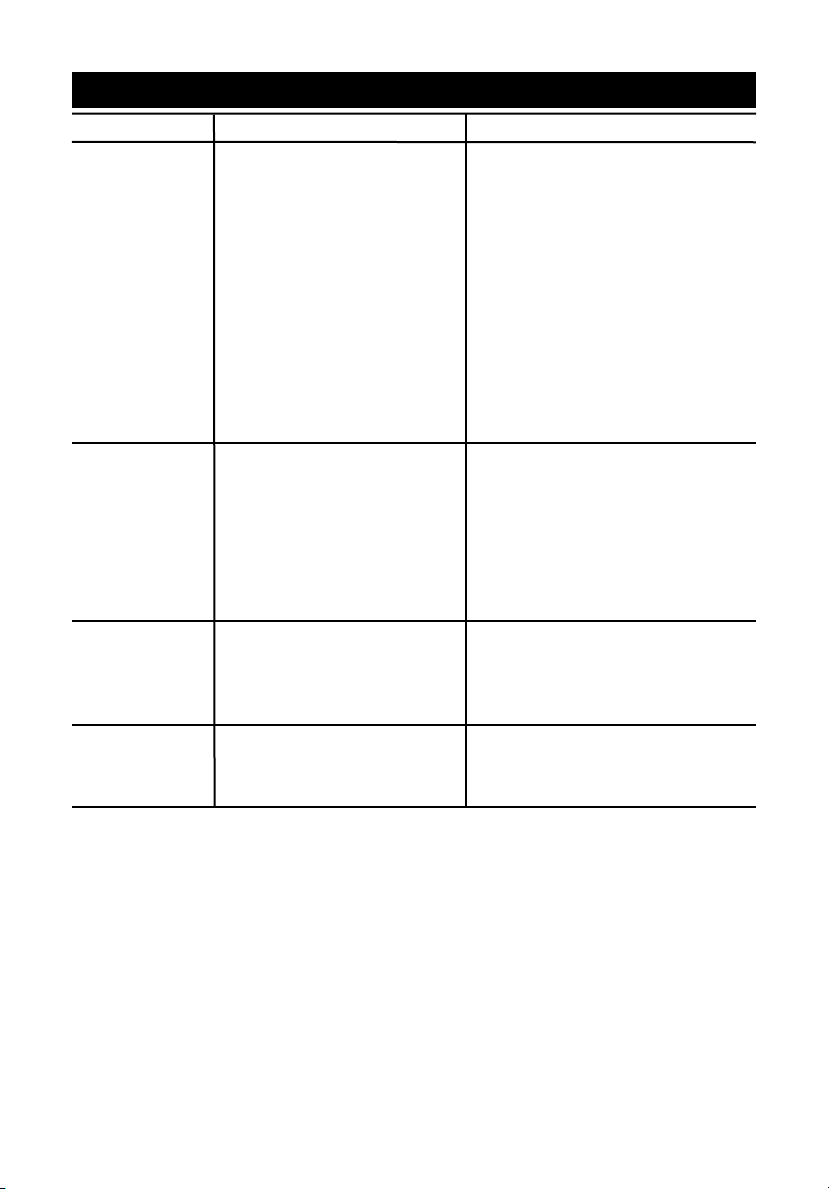

Note 1: Change oil after first two (2) operating hours and every 50 operating hours

thereafter, more often if operated in extremely dusty or dirty conditions.

Note 2: Check oil after 5 hours of operation.

Note 3: Every 100 hours of operation or once a year.

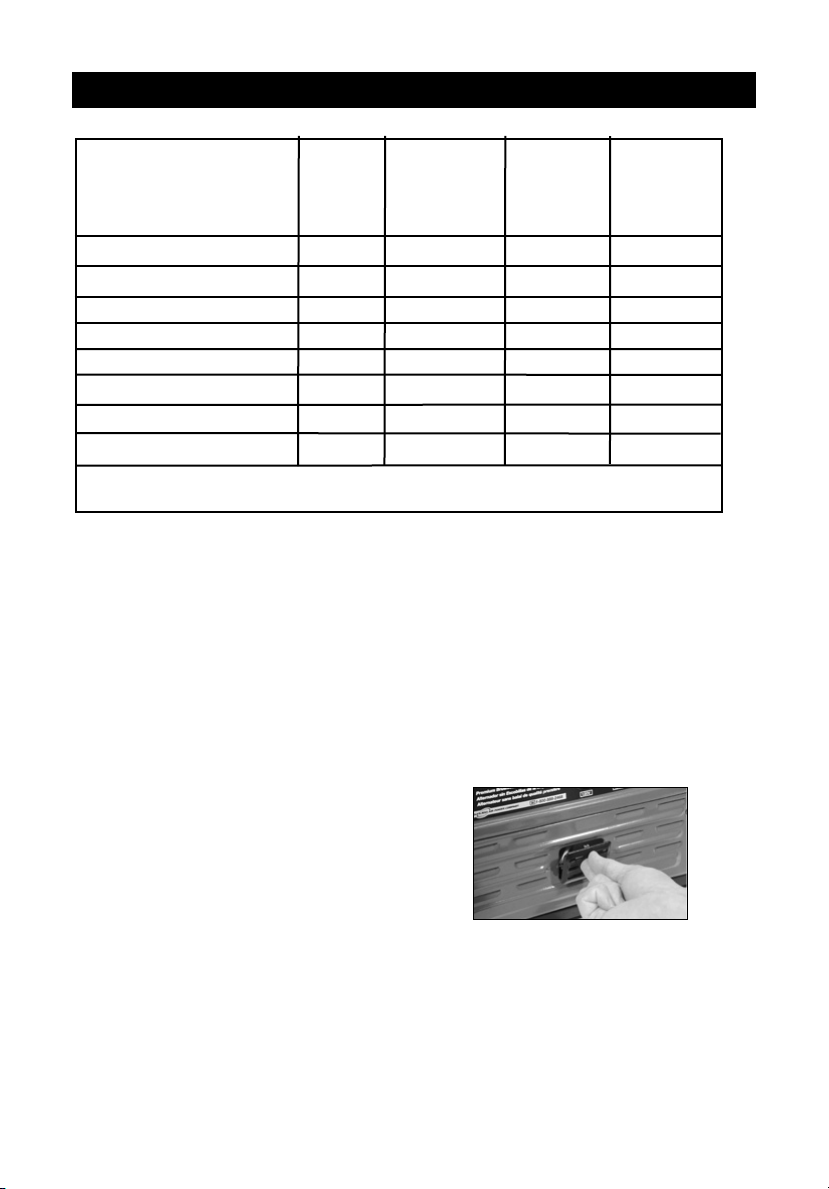

CUSTOMER RESPONSIBILITIES TABLE

MAINTENANCE TASK

Before

each

use

Every 25

Hours of

Every

Season

Every 50

Hours of

Every

Season

Every 100

Hours of

Every

Season

Check Spark Plug

Prepare unit for storage if it is to remain

idle for more than 30 days.

MAINTENANCE

Check oil level

Change oil

Clean Air Filter Assembly

Prepare Unit for Storage

See Note 2

X

See Note 1

X

X

See Note 3

Clean Fuel Valve Bowl

X

Clean Fuel Filter

X

Clean Fuel Tank Filter

X

Clean Muffler Screen

X

GENERAL RECOMMENDATIONS

The warranty of the generator does not

cover items that have been subjected to

operator abuse or negligence. To

receive full value from the warranty,

operator must maintain the generator as

instructed in this manual.

GENERATOR MAINTENANCE

Your generator should be kept clean and

dry at all times. The generator should

not be stored or operated in

environments that include excessive

moisture, dust or any corrosive vapors. If

these substances are on the generator,

clean with a cloth or soft bristle brush.

Do not use a garden hose or anything

with water pressure to clean the generator. Water may enter the cooling air slots

and could possibly damage the rotor,

stator and the internal windings of the

gen head.

ENGINE

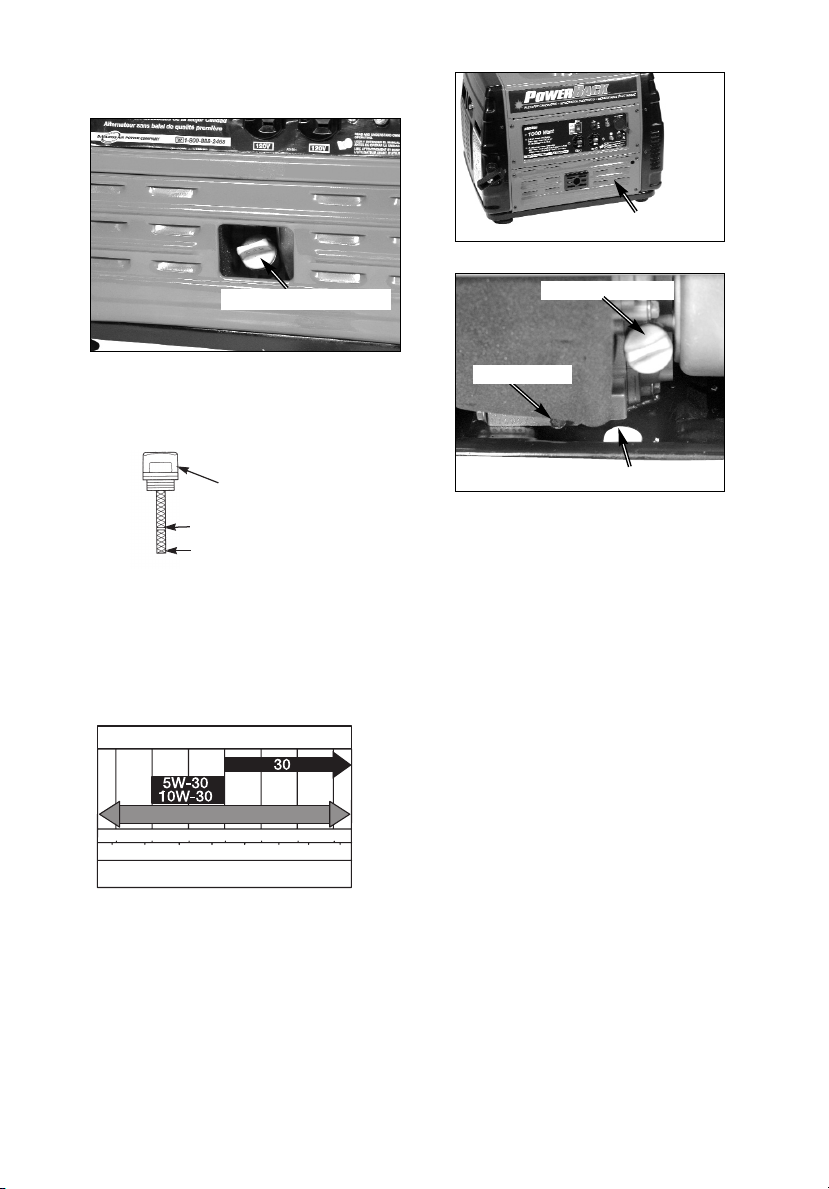

To Check Oil

1. Shut down engine and place on a

level surface.

2. Remove the oil filler cap/dipstick

cover.

Page 14

3. Remove filler cap/dipstick.

4. Place a suitable container under the

oil drain hole in the frame.

5. Remove the drain plug and allow

the engine oil to drain into the

container.

NOTE: Please dispose of used motor oil

in a manner that is compatible with the

environment. It is recommended to take

used oil in a sealed container to your local

recycling center or service station for

reclamation. Do not throw it in the trash

or pour it on the ground or down a drain.

6. Replace oil drain plug.

7. With the engine in a level position,

fill to the edge of the oil filler hole

with the SAE 10W-30 oil.

NOTE: Other viscosities shown in the

chart in the "To Check Oil" paragraph

may be used.

8. Replace the oil filler cap/dipstick

securely.

To Change Oil

Drain the engine oil when the engine is

warm. Warm oil drains quickly and

completely.

1. Stop engine as described in the

Operation section.

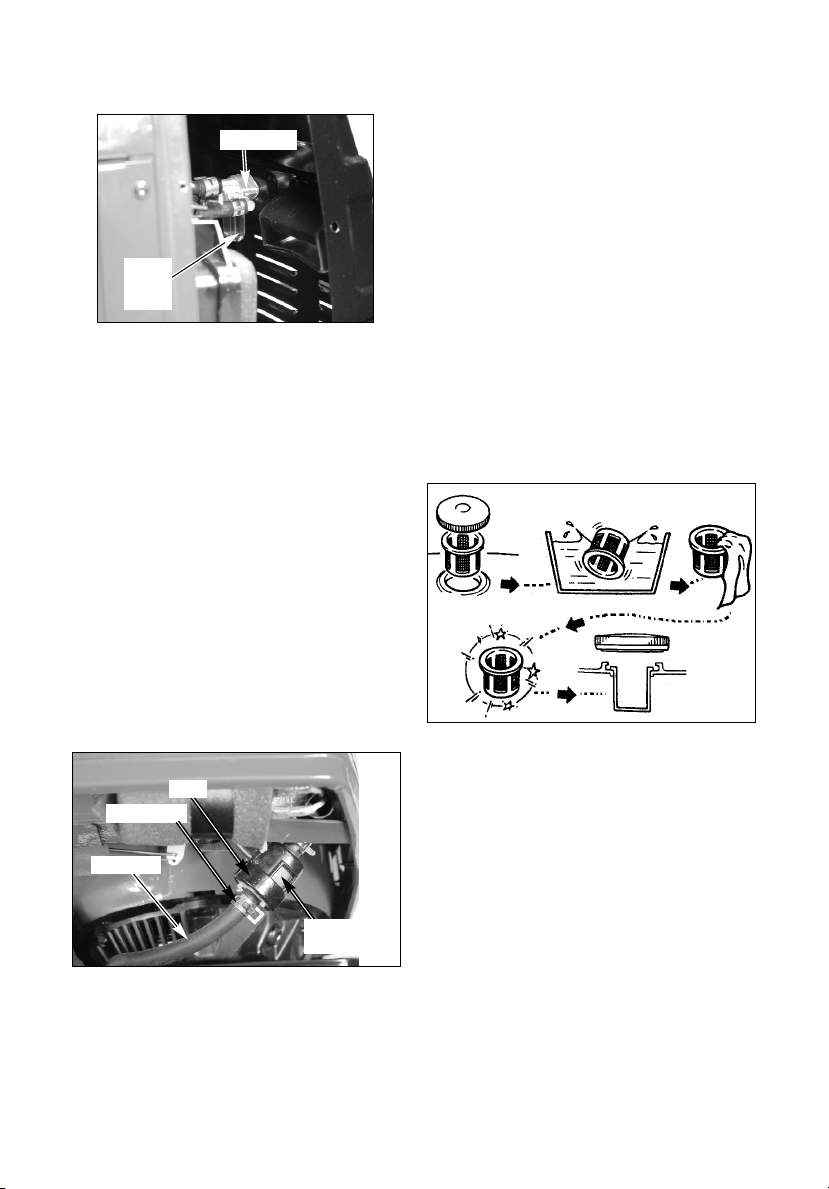

2. Remove the bottom panel on the

control panel side of the unit.

Remove Bottom Panel

Filler Cap/Dipstick

Oil Drain Plug

Oil Drain Hole

14- ENG

A04669

3. Remove the oil filler cap/dipstick

and wipe it clean.

4. Insert and remove the filler

cap/dipstick without screwing it into

the filler neck. Check the oil level

shown on the dipstick.

5. If the oil level is low, fill to the edge

of the oil filler hole with the SAE

10W-30 oil.

NOTE: Other viscosities shown in the

chart may be used when the average

temperature in your area is within the

recommended range.

Oil Filler cap/dipstick

Oil Filler

Cap/Dipstick

Upper Limit

Lower Limit

SAE Viscosity Grades

**

*

Synthetic 5W-30, 10W-30

-20 0 20 40 60 80 100

F

-30 -20 -10 0 10 20 30 40

C

STARTING TEMPERATURES RANGE

ANTICIPATED BEFORE NEXT OIL CHANGE

32

Page 15

15- ENG

A04669

Air Filter

A dirty air cleaner will restrict air flow to

the carburetor and cause poor engine

performance. Inspect the filter each time

the engine is operated. Clean the filter

more frequently if the engine is operated

in very dusty areas.

NOTICE: Operating the engine without a

filter will allow dirt to enter the engine,

causing rapid engine wear. This type of

damage is not covered under the

warranty.

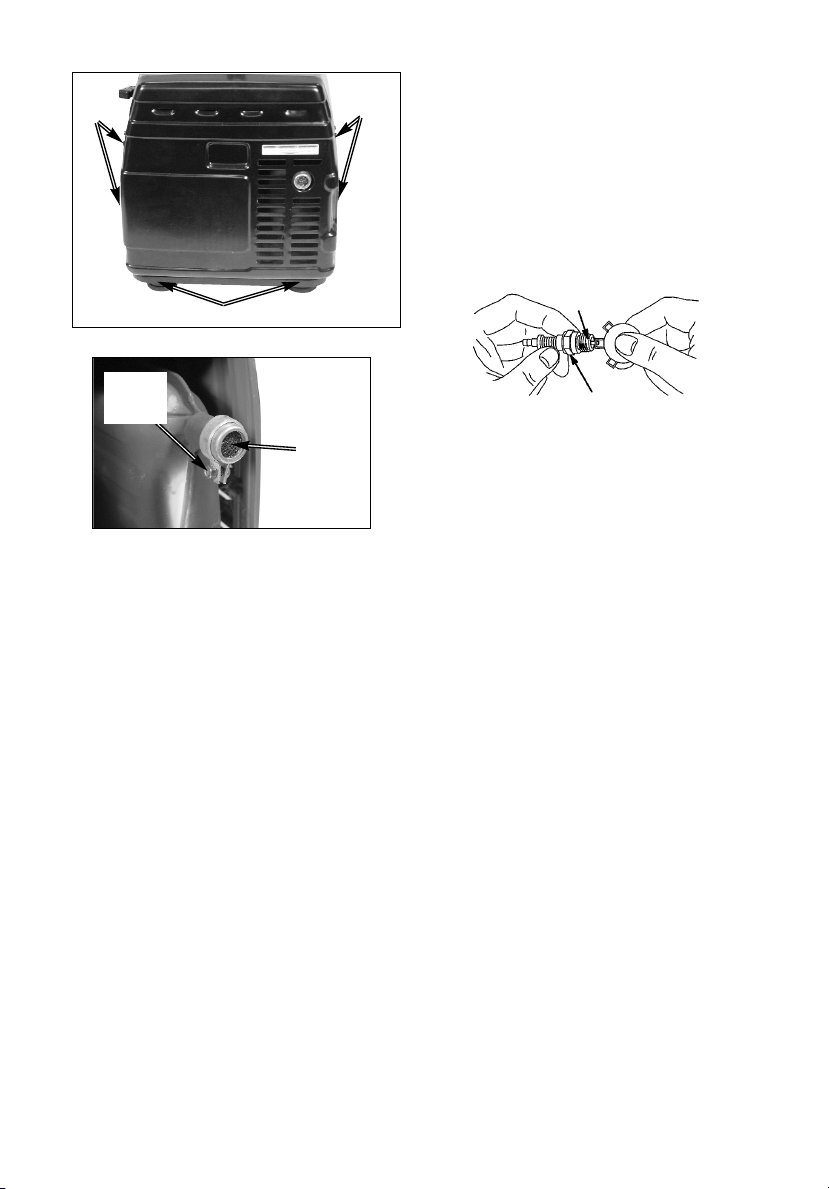

Cleaning

1. Remove the four screws securing

the sides of the panel and the two

fasteners with isolators securing the

bottom of the panel. Carefully

remove the panel noting that the

fuel filter and recoil starter will be

attached to the panel.

2. Remove the screws holding the

foam element in place.

Screws

Screws

Fasteners with isolators

3. Wash element in liquid detergent

and water. Air dry thoroughly.

4. Add clean engine oil to element and

press out excess, DO NOT wring or

twist element.

5. Replace element and secure in

place.

6. Replace and secure panel.

Screw

Screw

Foam

Element

Fuel Valve Bowl

Cleaning

1. Stop engine as described in the

Operation section.

2. Place the fuel valve lever in the OFF

position.

3. Remove the four screws securing

the sides of the panel and the two

fasteners with isolators securing the

bottom of the panel. Carefully

remove the panel noting that the

fuel filter and recoil starter will be

attached to the panel.

Screws

Screws

Fasteners with isolators

Page 16

Muffler Screen

Cleaning

1. Stop engine as described in the

Operation section.

2. On the exhaust end of the unit,

remove the four screws securing

the sides of the panel and the two

fasteners with isolators securing the

bottom of the panel. Carefully pull

panel away from the unit noting the

insulation is attached to the panel.

16- ENG

A04669

Fuel Tank Filter

Cleaning

1. Stop engine as described in the

Operation section.

2. Remove gas cap and remove the

fuel tank filter.

3. Clean with solvent. Wipe off excess

solvent and replace fuel tank filter

into tank.

Fuel Filter

NOTE: It is recommended to run all the

gasoline from the tank before changing

or cleaning the fuel filter.

1. Stop engine as described in the

Operation section.

2. Place the fuel valve lever in the OFF

position.

3. Remove the recoil end panel as

described in the Fuel Valve Bowl

paragraph.

4. The fuel line can be removed from

the fuel filter cover by squeezing the

fuel clamp and sliding it up the fuel

line.

5. After removing the fuel line unscrew

the cap on the fuel filter cover.

NOTE: Do not loose rubber washer

from fuel filter cover cap.

Fuel Filter

Cover

4. Unscrew and remove the fuel valve

bowl.

5. Clean and replace fuel valve bowl.

Tighten securely.

6. Replace and secure panel.

Fuel Valve

Fuel

Valve

Bowl

4. Replace gas cap.

Fuel Clamp

Cap

Fuel Line

6. The fuel filter can now be removed

to clean or replace.

7. Place new or cleaned filter into

cover.

8. Press rubber washer into fuel filter

cap and screw cap into fuel filter

cover body.

9. Reconnect fuel line.

10. Replace and secure panel.

Page 17

3. Remove the muffler screen.

4. Clean the muffler screen using a

wire brush.

5. Replace muffler screen and secure

in place.

6. Replace and secure panel.

17- ENG

A04669

Screws

Screws

Fasteners with isolators

Muffler

Screen

Remove

Screw

and Nut

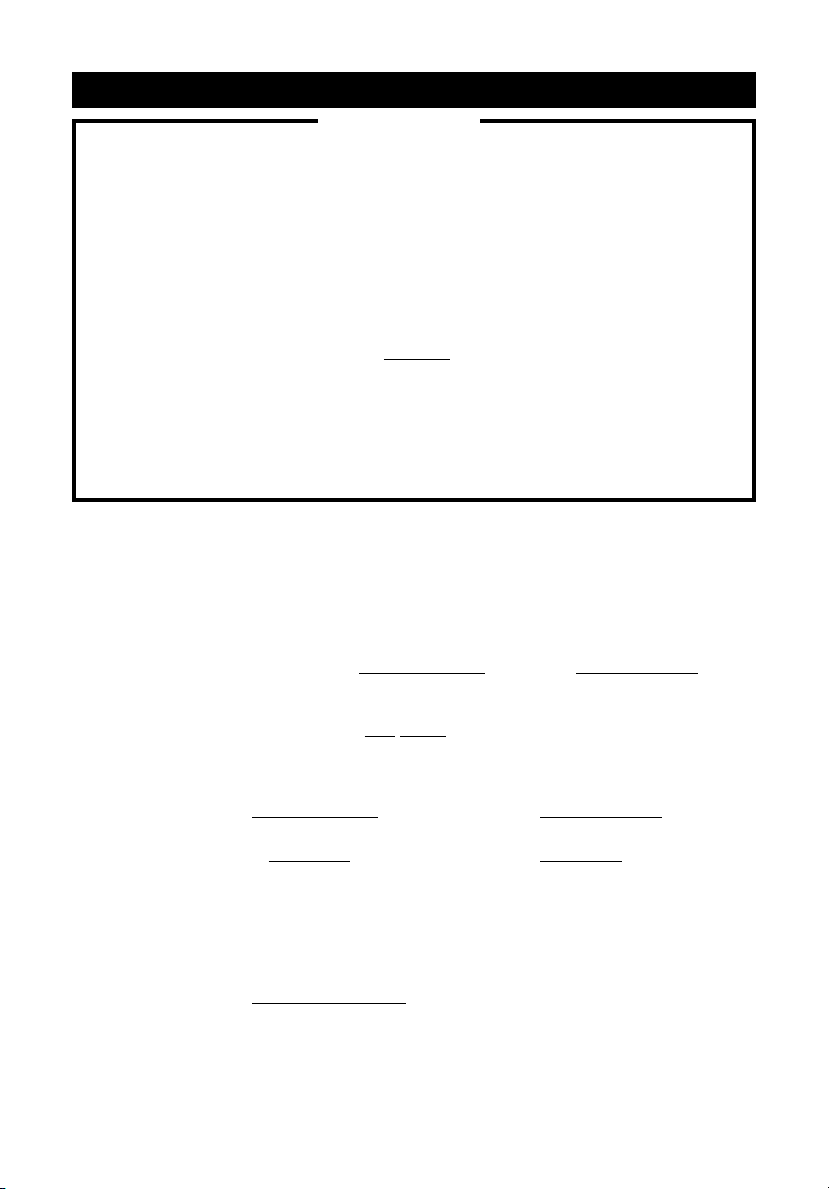

Replace Spark Plug

Change the spark plug every 100 hours

of operation or once each year,

whichever comes first. This will help your

engine to start easier and run better.

NOTE: Use the spark plug wrench and

screwdriver supplied to remove spark

plug. The spark plug is found under the

top panel opposite the controls.

Resistor

.030" (0.76 MM)

Wire Gauge

NOTE:

Standard spark plug: BPR4ES (NGK)

Spark Plug Gap: 0.7-0.8 mm

(0.028 -0.031 in)

Page 18

18- ENG

A04669

If you are going to store your generator

for more than 30 days, use the following

information as a guide to prepare the

generator for storage.

Never store generator

with fuel in the tank

indoors or in enclosed, poorly ventilated areas, where fumes can reach

an open flame, spark, or pilot light as

on a furnace, water heater, clothes

dryer, or other gas appliances.

ENGINE PREPARATION

1. Add fuel stabilizer to fuel tank to

minimize the formation of fuel gum

deposits during storage.

2. Run engine at least 10 minutes after

adding stabilizer to allow it to enter

the fuel system.

3. Shut off engine.

4. Disconnect the spark plug wire and

remove the spark plug.

5. Add one teaspoon of oil through the

spark plug hole.

STORAGE

6. Place rag over spark plug hole and

pull the recoil a few times to

lubricate the combustion chamber.

7. Replace the spark plug, but do not

connect the spark plug wire.

NOTE: If a fuel stabilizer is not used, all

gasoline must be drained from the tank

and carburetor to prevent gum deposits

from forming on these parts and causing

possible malfunction of the engine.

IMPORTANT: If gasoline is removed

from the tank, oil needs to be added to

prevent rust from forming in the tank:

1. Pour a cup of SAE 10W-30 oil into

the gas tank.

2. With assistance from another

person, shake or roll the unit so the

oil covers the complete gas tank.

3. Drain off excess oil.

GENERATOR

• Clean the generator as outlined in

the Maintenance Section on this

manual.

• Check that cooling air slots and

openings on generator are open

and unobstructed.

Page 19

19- ENG

A04669

WATTAGE CALCULATIONS

Never exceed the rated capacity of your generator. Serious damage to the

generator or appliance could result from an overload.

1. Starting and running wattage requirements should always be calculated when

matching a generators wattage capacity to the appliance or tool.

2. There are two types of electrical appliances that can be powered by your

generator:

A. Items such as radios, light bulbs, television sets, and microwaves have a

"resistive load". Starting wattage and running wattage are the same.

B. Items such as hand tools that use an electrical motor have an "inductive

load". Inductive load appliances and tools require approximately 2 to 3

times the listed wattage for starting

the equipment. This initial load only

lasts for a few seconds on start-up but is very important when figuring

your total wattage to be used.

C. Always start your largest electric motor first, and then plug in other

items, one at a time.

NOTE: On 120-volt loads the maximum starting wattage should NOT exceed

1250 watts.

IMPORTANT

DETERMINING WATTAGE REQUIREMENTS

Before operating this generator list all of the appliances and/or tools that are going

to operate at the same time. (Then determine the starting wattage requirements and

the running wattage requirements by following example and/or refer to household

wattage calculator.)

1. First total the running wattage of all appliances and/or tools that will be

operated at the same time.

Running W

atts Starting Watts

Example 1:

Lights = 100 Watts 0

Television = 300

Watts 0

TOTAL = 400 Watts 0

2. Next the starting wattages of any appliances and/or tools that will start and

stop during operation.

Running W

atts Starting Watts

Example 2:

Blender 400 W

atts 800 Watts

TOTAL = 400 Watts 800 Watts

3. The running wattage of examples 1 & 2 totals 800 watts. The starting wattage

of the blender is 800 watts which is 400 watts more than the running watts.

Take this difference of 400 starting watts from the blender and add to the total

running watts of 800.

Example 3: 400 Starting Watts

800 Running W

atts

TOTAL =1200 Total Watts

Generator must have a maximum capacity of at least 1200 watts.

Page 20

20- ENG

A04669

STARTING WATTAGE

REQUIREMENTS

1. Some appliances and tools will list

on the motor nameplate the

starting and running voltage and

amperage requirements. Use the

following formula to convert

voltage and amperage to wattage:

Volts X Amp = Watts

Example: 120 volts x 10 amps =

1200 watts

2. To determine the approximate

starting wattage requirement for

most appliances and tools with

inductive type motors, multiply the

wattage that was calculated by 2 to

3 times to assure adequate

generator capacity. If the

nameplate information is not available use the values on the

following chart as a guide.

3. Remember that the starting and

running wattage for resistive loads

are the same. (Example: a 100

watt light bulb requires only 100

watts to start.) Most resistive loads

will

be listed in wattage.

Application Guide

To select the right generator for your

needs, total the wattageof the items to

be run at the same time.

Run

Electric Appliance

3/8" Hand Drill

Jigsaw

Contractor

Light Bulb

Small Fan

Radio

Home Security

ReliefRecreational

Television

Emergency

Hair Dryer

Microwave

12V DC Battery Charger

Radio

Slow Cooker

Electric Blanket

Electric Skillet

Coffee Maker

Blender

The wattage ratings shown are averages.

Wattage requirements may vary with different

brands of appliances.

Start

Wattage

100

250

500

1000

1500

Page 21

21- ENG

A04669

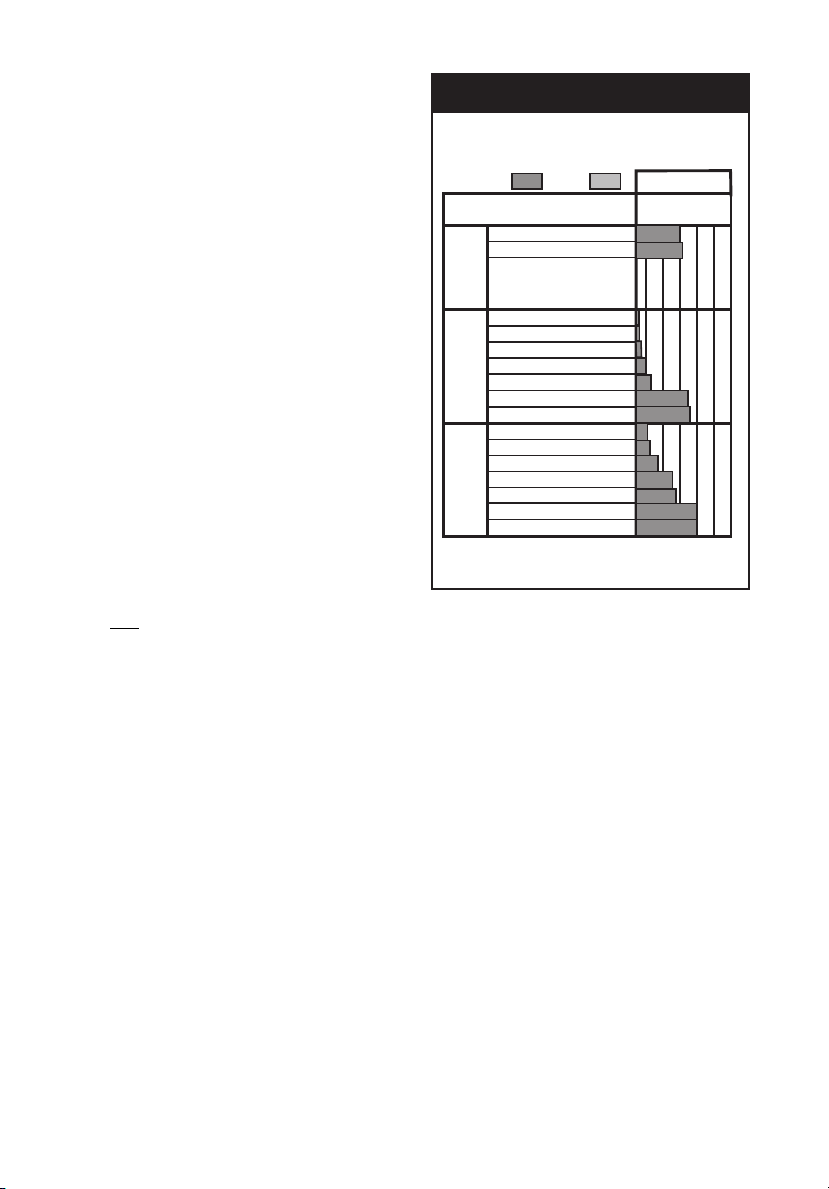

HOUSEHOLD WATTAGE CALCULATOR

DEVICES WITH HIGH STARTING (INDUCTIVE)LOADS

RUN WATTS

500

400

TIMES (X) START FACTOR

x

x

2

2

CAUTION !!

DO NOT CONNECT VOLTAGE SENSITIVE ELECTRONIC

EQUIPMENT (TV SET, COMPUTER, ETC.) DIRECTLY TO

YOUR GENERATOR. IF YOU USE THE GENERATOR TO

POWER SENSITIVE EQUIPMENT YOU MUST USE A U.L.

LISTED VOLTAGE SURGE PROTECTOR.

NOTICE: FAILURE TO USE A U.L. LISTED VOLTAGE

SURGE PROTECTOR WILL DAMAGE YOUR

EQUIPMENT AND VOID YOUR WARRANTY.

*FOR PRODUCTS NOT

LISTED REFER TO

CALCULATION

INSTRUCTIONS

**AVERAGE VALUES -

ACTUAL INDIVIDUAL

DEVICE VOLTAGES MAY

BE HIGHER OR LOWER

LIGHTING

60 WATT BULBS

75 WATT BULBS

100 WATT BULBS

300 WATT BULBS

WATTAGE RATING OF YOUR GENERATOR

THIS TOTAL MUST BE GREATER THAN YOUR HOUSEHOLD WATTAGE LOAD

APPLIANCE OR

LOAD DEVICE*

CORDED HAND

TOOL

BLENDER

TELEVISION

MICROWAVE

HAIR DRYER

SMALL FAN

WATTS

60

75

100

300

TYPICAL DEVICE

WATTAGE**

=

1000

=

800

=

300

800

=

800

=

42

=

TIMES NUMBER

OF BULBS

x

x

x

x

=

=

=

=

=

=

=

=

=

=

ELECTRIC LOAD GRAND TOTAL

THIS TOTAL MUST BE LESS THAN YOUR GENERATOR RATING

TOTAL

CAUTION !!

Page 22

22- ENG

A04669

TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

CORRECTION

Engine will not

start

1. Low on fuel or oil.

2. Engine On/Off switch in

Off position.

3. Faulty spark plug.

4. Choke in wrong position.

5. Fuel valve lever in closed

position

6. Unit loaded during

start-up.

1. Add fuel or oil.

2. Place in the ON position

3. Replace spark plug.

4. Adjust choke accordingly.

5. Open fuel valve lever.

6. Remove load from unit.

1. Faulty receptacle.

1. Have Service Center replace.

2. Circuit breaker kicked

out.

2. Depress and reset.

3. Defective capacitor.

3. Have Service Center replace

capacitor.

4. Faulty power cord.

4. Repair or replace cord.

7. Spark plug wire loose.

7. Attach wire to spark plug.

No electrical

output

1. Overload

1. Reduce load.

2. Faulty cords or

equipment

2. Check for damaged, bare, or

frayed wires on equipment.

Replace.

Repeated

circuit breaker

tripping

1. Generator overloaded.

1. Reduce load.

2. Insufficient ventilation.

2. Move to adequate supply of

fresh air.

Generator

overheating

8. Fuel line clogged.

8. Clean fuel line and fuel filter.

9. Faulty ignition system.

9. Consult a Service Center.

Page 23

23- ENG

A04669

AVAILABLE REPAIR PARTS

Part No. Description

Z-A05449 Fuel Cap

Z-A05451 Air Filter

Z-A05453 Fuel Shut Off Valve

Z-A05454 Fuel Filter

Z-A05458 Control Panel Assembly

Z-A05459 Generator Assembly

Z-A05460 Engine Assembly

Z-A05455 Oil Fill Cap

Z-A05457 Spark Arrestor

Z-A05456 Capacitor

Page 24

LIMITED WARRANTY

DeVilbiss Air Power Company warrants to the original purchaser who uses the product in a consumer

application (personal, residential or household usage) that all products covered under this warranty are free

from defects in material and workmanship for one year from the date of purchase. All products covered by

this limited warranty which are used in commercial applications (i.e., income producing) are warranted to be

free of defects in material and workmanship for 90 days from the date of original purchase. Products

covered under this warranty include air compressors, air tools, service parts, pressure washers, and

generators.

DeVilbiss Air Power Company will repair or replace, at DeVilbiss' option, products or components which

have failed within the warranty period. Service will be scheduled according to the normal work flow and

business hours at the service center location, and the availability of replacement parts. All decisions of

DeVilbiss Air Power Company with regard to this limited warranty shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

RESPONSIBILITY OF ORIGINAL PURCHASER (initial User):

• To process a warranty claim on this product, DO NOT return it to the retailer. The product must be

evaluated by an Authorized Warranty Service Center. For the location of the nearest Authorized Warranty

Service Center call 1-800-888-2468, 24 hours a day, 7 days a week or visit our web site @ devap.com.

• Retain original cash register sales receipt as proof of purchase for warranty work.

• Use reasonable care in the operation and maintenance of the product as described in the Owners

Manual(s).

• Deliver or ship the product to the nearest Authorized Warranty Service Center. Freight costs, if any, must

be paid by the purchaser.

• Air compressors with 60 and 80 gallon tanks will be inspected at the site of installation. Contact the

nearest Authorized Warranty Service Center that provides on-site service calls for service call

arrangements.

• If the purchaser does not receive satisfactory results from the Authorized Warranty Service Center, the

purchaser should contact DeVilbiss Air Power Company.

THIS WARRANTY DOES NOT COVER:

• Merchandise sold as reconditioned, used as rental equipment, or floor or display models.

• Merchandise that has become damaged or inoperative because of ordinary wear, misuse*, cold, heat,

rain, excessive humidity, freeze damage, use of improper chemicals, negligence, accident, failure to

operate the product in accordance with the instructions provided in the Owners Manual(s) supplied with

the product, improper maintenance, the use of accessories or attachments not recommended by

DeVilbiss Air Power Company, or unauthorized repair or alterations.

* An air compressor that pumps air more than the recommended duty cycle during a one hour period

may be considered misuse.

• Repair and transportation costs of merchandise determined not to be defective.

• Costs associated with assembly, required oil, adjustments or other installation and start-up costs.

• Expendable parts or accessories supplied with the product which are expected to become inoperative or

unusable after a reasonable period of use, including but not limited to sanding disks or pads, saw and

shear blades, grinding stones, springs, chisels, nozzles, o-rings, air jets, washers and similar

accessories.

• Merchandise sold by DeVilbiss Air Power Company which has been manufactured by and identified as

the product of another company, such as gasoline engines. The product manufacturer's warranty, if any,

will apply.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY

RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT IS NOT COVERED

BY THIS WARRANTY. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

• IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL

PURCHASE. Some states do not allow limitations on how long an implied warranty lasts, so the above

limitations may not apply to you.

213 Industrial Drive • Jackson, TN 38301-9615

Telephone: 1-800-888-2468

FAX: 1-800-888-9036

A04669

24- ENG

Page 25

25- SP

A04669

Lea el manual del operador. No opere el equipo hasta haber leído las

instrucciones Seguridad, Operación y Mantenimiento en el Manual del

Operador.

Esta unidad no está equipada con un cortachispas en el tubo de

escape. Operar esta unidad en California constituye una violación de

las secciones 130050 y/o 4442 y 4443 a menos que esté provista de un

cortachispas de acuerdo a lo definido en la sección 4442 y que esté en buen estado de

funcionamiento. El cortachispas también se requiere en algunas tierras del Servicio Forestal

del Gobierno de los EE.UU. y también puede requerirse bajo otros estatutos y ordenanzas.

Los gases que escapan de esta unidad contienen químicos, que en

ciertas cantidades, se conoce que causan cáncer, defectos de

nacimiento u otras lesiones reproductivas.

INFORMACIÓN GENERAL Y DE SERVICIO PARA EL CONSUMIDOR

• Lea y siga estas instrucciones para el uso y mantenimiento apropiado.

• Tómese el tiempo ahora para registrar su generador en www.devap.com.

• Si se le presenta cualquier problema o nedcesita asistencia, llámenos gratis al

1-800-888-2468, de lunes a sábado de 8:00 a.m. a 6:00 p.m. Hora Estándar

del Centro.

• Si requiere servicio o comprar un repuesto, cualquiera de nuestros muchos

Servicentros Autorizados para Garantía convenientemente ubicados están

equipados para proveer todos los servicios amparados por la garantía o fuera de

ella.

• Para información sobre la ubicación del Servicentro Autorizados para Garantía

más cercano, llame gratis a nuestra línea 1-800-888-2468 las 24 horas de los 7

días de la semana o visite nuestro sitio web: www.devap.com.

• Para el servicio de garantía, conserve el comprobante de pago por la compra.

• Lea y entienda todas las advertencias de seguridad.

• No opere esta unidad sin antes haber leido y comprendido todas las

instrucciones de seguridad, operación y mantenimiento de este manual.

INFORMACIÓN DE SEGURIDAD PARA EL CONSUMIDOR

¡NO DEVUELVA ESTA UNIDAD AL LUGAR DONDE LA COMPRÓ! PARA LAS

OPCCIONES DE SERVICIO, LLAME AL 1-800-888-2468

Page 26

26- SP

A04669

La operación inapropiada de esta unidad puede causar lesiones serias y

daños a la propiedad. Lea y entienda todas las advertencias de

seguridad e instrucciones de operación antes de usar esta unidad.

Operación de un

generador bajo

lluvia, ambientes

mojados, con

hielo o

condiciones

inundadas.

¡El agua es un excelente

conductor de la electricidad! El

agua que entra en contacto con

componentes cargados de

electricidad puede transmitir la

electricidad al bastidor y a otras

superficies causando choque

eléctrico a cualquiera que esté en

contacto con ellos.

Opere el generador en un área

limpia, seca y bien ventilada.

Asegúrese de tener las manos

secas antes de tocar la unidad.

Indica una situación peligrosa inminente que si no se evita causará muerte o

lesiones serias.

Indica una situación potencialmente riesgosa que si no se evita puede causar

lesiones serias o muerte.

Indicates a potentially hazardous situation which, if not avoided,may result in

minor or moderate injury

Usado sin el símbolo de alerta indica una situación potencialmente riesgosa

que si no se evita puede causar daños materiales.

Este manual contiene información que es importante que usted sepa y entienda. Esta

información se relaciona con la protección de SU SEGURIDAD y la PREVENCIÓN DE

PROBLEMAS AL EQUIPO. Para ayudarle a entender esta información usamos los siguientes

símbolos. Por favor leer este manual y prestar atención especial a estas secciones.

PAUTAS DE SEGURIDAD - DEFINICIONES

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

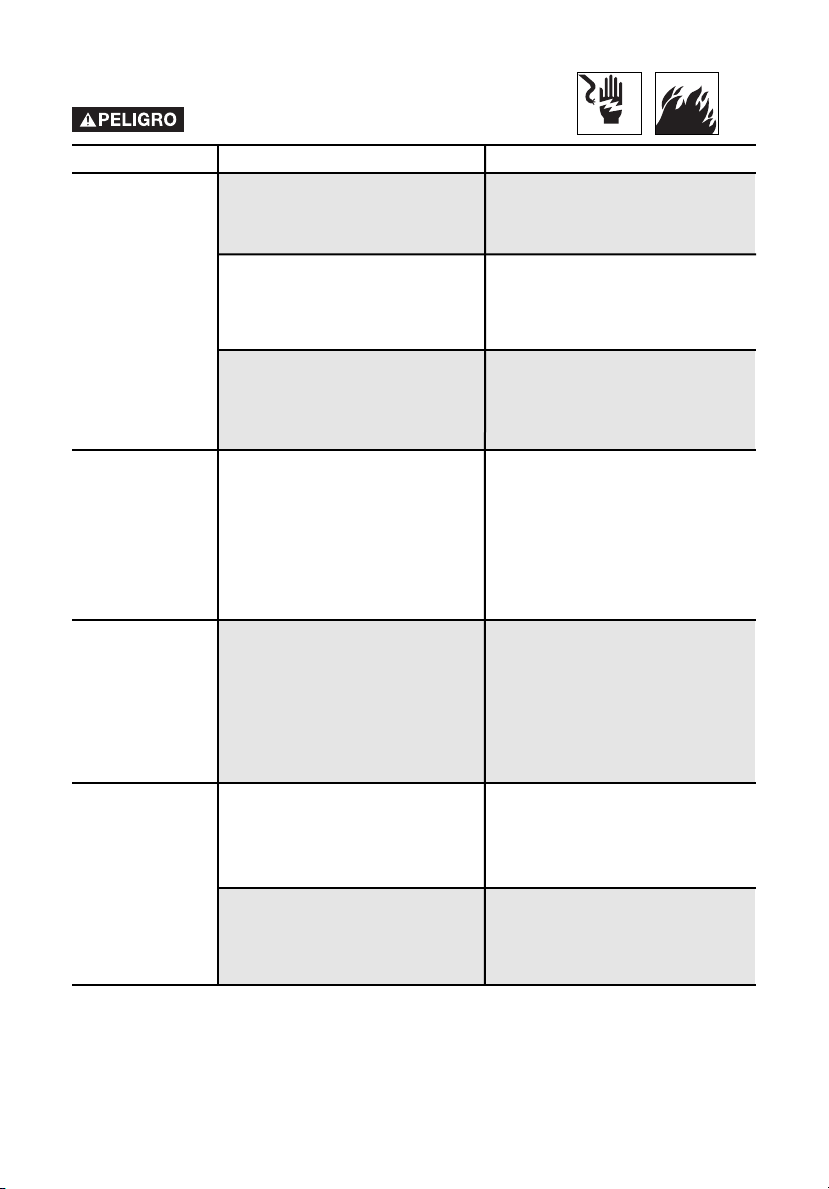

RIESGO DE ELECTROCUCIÓN E INCENDIO

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

Intento de

conectar el

generador

directamente al

sistema eléctrico

de cualquier

construcción.

Retroalimentar electricidad por

el sistema eléctrico de una

construcción hacia la red publica

puede poner en peligro a las

personas que estén tratando de

restaurar el servicio.

Nunca retroalimente electricidad al

sistema eléctrico de una edificación.

Page 27

27- SP

A04669

Operación de la

unidad dañada o

sin las cubiertas

o paneles

protectores.

La remoción de las cubiertas

protectoras puede exponer los

componentes con carga

eléctrica y causar

electrocución.

No opere el generador sin las

cubiertas protectoras.

Conexión

inadecuada de

artefactos al

generador.

Exceder la capacidad de salida

de un generador conectándole

demasiados artefactos o

artefactos de gran demanda

puede hacer que algunos de

éstos se recalienten, que su

cableado se incendie o cause

choque eléctrico.

Intentar usar la unidad dañada

o cuando no funciona

normalmente, puede causar

incendio o electrocución.

Lea la cartilla de Demandas de

Carga e Instrucciones en la sección

Cálculo de Wataje. Asegúrese que

la suma total del wataje de todos

los artefactos eléctricos

conectados al generador no

exceda la capacidad de salida del

generador.

No opere el generador si tiene

problemas mecánicos o eléctricos.

Haga reparar la unidad en un

servicentro autorizado.

Uso de

cordones de

extensión

gastados,

dañados, subdimensionados

o no

conectados a

tierra.

El uso de cordones de extensión

sin conexión a tierra puede evitar

que los interruptores de circuito

se abran y causar choque

eléctrico.

Siempre use un cordón que tenga

un alambre para conexión a tierra y

enchúfelo a un tomacorriente con

conexión a tierra. NO USE un

enchufe sin conexión a tierra.

Use un cordón con alambres del

calibre adecuado para el uso que

se le va a dar. Refiérase a la

cartilla en la sección Ensamblaje de

este manual.

El contacto con cordones de

extensión gastados o dañados

puede causar electrocución.

El uso de cordones de extensión

subdimensionados puede causar

recalentamiento de los alambres

o artefactos conectados,

causando un incendio.

Inspeccione los cordones de

extensión antes de usarlos y

cámbielos por nuevos si se

requiere.

Colocación de un

generador sobre

o contra una

superficie

altamente

conductiva como

una pasarela de

acero o un techo

de metal.

Coloque el generador sobre una

superficie de baja conductividad,

como un piso de concreto.

SIEMPRE opere un generador a

una distancia mínima de 1,80m. (6')

de cualquier superficie conductiva.

La fuga accidental de corriente

eléctrica puede cargar las

superficies conductivas en

contacto con el generador.

RIESGO DE ELECTROCUCION E INCENDIO

(Continuación)

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

Page 28

28- SP

A04669

RIESGO DE INCENDIO

Almacenaje

inapropiado del

combustible.

El combustible mal almacenado

puede conducir a un incendio

accidental. El combustible

guardado en un lugar inseguro

puede caer en manos de los niños

u otras personas no calificadas.

Guarde el combustible en un

contenedor diseñado para gasolina

aprobado por OSHA. Guarde el

contenedor en un lugar seguro para

evitar su uso por otras personas.

Intento de llenar

el tanque de

combustible

con el motor

funcionando.

La gasolina y sus vapores pueden

incendiarse al hacer contacto con

componentes calientes como el

motor, su escape o sus gases o

una chispa eléctrica.

Los cigarrillos, chispas, fuegos u

otros objetos calientes pueden

hacer que la gasolina o sus

vapores se inflamen.

Apague el motor y espere a que se

enfríe antes de echarle

combustible al tanque. Provea al

área de operación con un extintor

de incendios certificado para

gasolina u otros incendios de

combustibles.

Llene el tanque con combustible

en un área bien ventilada.

Asegúrese que no existan fuentes

de encendido cerca del generador.

Opere el generador en un lugar

limpio, seco y bien ventilado y

alejado por lo menos 1,2m (4') de

cualquier construcción, objeto o

pared. NO OPERE EL

COMPRESOR EN INTERIORES NI

EN ÁREAS CONFINADAS.

Los materiales colocados contra o

cerca del generador o su operación

en áreas con temperatura

ambiental superior a 40°C (104°F)

(como en bodegas de

almacenamiento o garajes) pueden

interferir con sus dispositivos de

ventilación, causar recalentamiento

y un probable incendio de los

materiales o la edificación.

Chispas, fuego,

objetos calientes.

Ventilación

inadecuada

para el

generador.

Alteración de la

graduación de

velocidad del

motor hecha en

fábrica.

La velocidad del motor se ha

graduado en fábrica para proveer

una operación segura. Adulterar

esta graduación puede causar

recalentamiento de los artefactos

conectados y un incendio.

El combustible derramado y sus

vapores pueden incendiarse por

contacto con superficies

calientes o chispas.

Nunca intente "acelerar" el motor

para obtener mayor rendimiento.

Tanto el voltaje como la frecuencia

de la corriente de salida se saldrán

de la norma y pondrán en peligro

los artefactos conectados y

también al usuario.

Tenga cuidado al llenar el tanque para

evitar derramar combustible. Antes de

arrancar el motor, cerciórese que la tapa

del tanque de combustible esté ajustada

en forma segura, revise que el motor no

tenga fugas de combustible y aleje la

unidad del lugar donde se le llenó de

combustible o de cualquier derrame.

Deje lugar en el tanque para la expansión

del combustible. Mantenga el nivel

máximo del combustible 2,5cm (1")

debajo de la boca de llenado del tanque.

Nunca rellene combustible con el motor

encendido.

Sobrellenado de

combustible en el

tanque. Derrame

de combustible.

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

Page 29

29- SP

A04669

RIESGO DE OPERACIÓN INSEGURA

La operación del

generador en

forma

descuidada.

Todas las fuentes de energía

tienen el potencial de causar

lesiones. La operación o

mantenimiento inseguro del

generador puede conducir a

lesiones serias o muerte del

operador o de otros.

• Lea y comprenda todas las

operaciones de instrucción y

advertencias en este manual.

• Familiarícese con la operación y

los controles del generador; y

como apagarlo en forma rápida.

• Provea al área de operación con

un extintor de incendios

certificado para incendios de

gasolina o combustibles.

• Mantenga a los niños y a otras

personas alejadas del generador

en todo momento.

RIESGO A LA RESPIRACIÓN O

INHALACIÓN

Respirar los gases del escape

puede causar lesiones serias o

muerte.

Opere el generador en un área

limpia, seca y bien ventilada; nunca

lo opere en áreas cerradas como

garajes, sótanos, almacenes,

casetas, cobertizos ni en lugares

ocupados por seres humanos o

animales. Mantenga a los niños y

las mascotas alejados del área de

operación.

Los motores a

gasolina

producen

monóxido de

carbono toxico

por los gases

del escape.

RIESGO DE LESIONES Y DAÑOS A LA

PROPIEDAD AL TRANSPORTAR EL

GENERADOR

Incendio,

inhalación,

daños a las

superficies del

vehículo.

El combustible o el aceite se

pueden fugar o derramarse y

causar un incendio o riesgo a la

respiración, lesiones serias o

muerte. Estas fugas pueden

dañar las alfombras, pintura y

otras superficies de los vehículos

o remolques.

Si el generador está equipado con

una válvula de cierre de combustible,

ciérrela antes de transportar la unidad

y evitar así las fugas. Si el generador

no tiene una válvula de cierre de

combustible, drene el combustible del

tanque antes de transportar la unidad.

Transporte el combustible únicamente

en un contenedor aprobado por

OSHA. Siempre coloque el generador

sobre una alfombra protectora

cuando lo transporte para así evitar

daños al vehículo por las fugas.

Desmonte el generador del vehículo

inmediatamente que llegue a su

destino.

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

Page 30

30- SP

A04669

RIESGO DE OPERACIÓN INSEGURA

(Continuación)

El izaje, levantamiento o

suspensión inapropiada, puede

causar daños al generador.

Para elevar o suspender un

generador Siempre use cables,

cadenas o eslingas con capacidad

para 900 Kg. (2000 Lb.) de carga o

más.

Operación de

artefactos

sensibles a

sobrecargas de

voltaje sin un

protector de

sobrecargas.

Cualquier generador de corriente

a gasolina doméstico incurrirá en

variaciones de voltaje que causen

daño a artefactos sensibles a

estas variaciones o pueden

causar incendio.

Para operar artefactos sensibles a

las variaciones de voltaje (TV,

computadoras, estéreos, etc.)

siempre conéctelos a un protector

de sobrecargas de voltaje

certificado por U.L. Si no se usa

un protector de sobrecarga de

voltaje certificado por U.L., se

anulará la garantía del generador.

Nota: Una barra de tomacorrientes

múltiples no es un protector de

sobrecargas. Asegúrese de usar

un protector de sobrecargas de

voltaje certificado por U.L.

Izaje o

levantamiento

inapropiado de

generadores

provistos de

anillos de

levantamiento.

El generador se podría caer y

causar lesiones serias o muerte a

usted o a otras personas.

Siempre siga los procedimientos

de conexión apropiados descritos

en este manual cuando se

conecten cables, cadenas o

eslingas para elevar o suspender

generadores equipados con anillos

de levantamiento.

Operating

generator while

suspended.

El generador no funcionará

apropiadamente, se dañará y

podría causarle lesiones serias o

muerte a usted o a otros.

Nunca opere un generador

mientras esté suspendido o en una

posición desnivelada. Siempre

opere el generador sobre una

superficie plana nivelada.

El contacto con superficies

calientes como los componentes

del escape del motor, puede

causar quemaduras serias.

RIESGO DE SUPERFICIES CALIENTES

Contacto con

componentes

calientes del

motor y del

generador.

Durante la operación, sólo toque

las superficies de control del

generador. Mantenga a los niños

alejados del generador en todo

momento. Ellos pueden no

reconocer los riesgos de esta

máquina.

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

Page 31

31- SP

A04669

ESPECIFICACIONES

MODELO: GM1000

CABALLAJE: 2,4

TAJE CAPACIDAD/SOBRECARGA: 1000/1250

VOLTAJE: 120V

AMPERAJE: 8,3A

FASES: 1 (UNA)

CICLOS: 60 HZ

VELOCIDAD DEL MOTOR: 3600 RPM

TEMPERATURA AMBIENTAL MÁXIMA: 40°C (104°F)

CAPACIDAD DE COMBUSTIBLE: 4,5 L (1,2 GALONES)

TIEMPO DE OPERACIÓN A 50%/100%: 8/6 HORAS

RIESGO DE PIEZAS MOVIBLES

Nunca opere el generador sin las

guardas o cubiertas protectoras.

Evite usar ropa o joyas sueltas que

puedan atraparse en las piezas

movibles.

El generador contiene piezas que

rotan a alta velocidad durante su

operación. Estas piezas están

cubiertas con guardas protectoras

para evitar lesiones.

Las piezas

movibles

pueden causar

lesiones serias.

RIESGOS POR LEVANTAMIENTO

Este generador es pesado y se

requiere ayuda para levantarlo.

El intento de levantamiento de

objetos pesados puede causar

lesiones serias.

Levantamiento

de objetos

pesados.

Un generador portátil puede caerse

de una mesa, banco de trabajo o

techo dañándose y pudiendo

causar lesiones serias o muerte.

Siempre opere el generador en una

posición estable y segura para

evitar movimientos accidentales de

la unidad. Nunca opere el

generador sobre un techo ni otra

posición elevada.

RIESGO

RIESGO DE CAÍDA DE OBJETOS

Un generador

portátil puede

caerse de una

posición

elevada y

dañarse o

causar lesiones

serias.

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

RIESGO

¿QUÉ PUEDE SUCEDER?

¿CÓMO EVITARLO?

Page 32

32- SP

A04669

NOTA: Las indicaciones de izquierda

y derecha describen la ubicación de

las piezas con el operador mirando al

panel de salida.

EXTRACCIÓN DEL GENERADOR

DE SU CAJA

• Abra la caja por arriba.

• Ubique y extraiga el juego del

manubrio.

• Instale el manubrio en la parte

superior del generador con el

entornillador y los tornillos

suministrados. Conserve el

entornillador y la llave para bujías

para uso futuro.

• Levante el generador

cuidadosamente para sacarlo de la

caja.

CONEXIÓN DEL GENERADOR A

TIERRA

El generador viene provisto de un tornillo

para conectarlo a tierra donde las

ordenanzas locales lo requieran. Para

mayor información sobre las

necesidades de conexión a tierra,

refiérase al artículo 250 del Código

Eléctrico Nacional (EE.UU.). La

compañía de suministro eléctrico local o

un electricista calificado pueden

ayudarle con esta información.

ENSAMBLAJE

Lea este manual.

No intente operar

esta unidad hasta haber leído las

instrucciones de seguridad,

operación y mantenimiento

contenidas en este manual.

CORDONES DE EXTENSIÓN

Para reducir el riesgo de choque

eléctrico, cuando opere un artefacto o

herramienta eléctrica a una distancia

considerable del generador, DEBE usar

un cordón de extensión de 3 alambres

con enchufe de 3 espigas para conexión

a tierra y con un tomacorriente de 3

ranuras que acepte el enchufe del

artefacto o herramienta. Debe usarse un

cordón de las dimensiones adecuadas.

Refiérase a la cartilla a continuación para

determinar las dimensiones mínimas de

los alambres requeridos.

Calibres de Alambres de

Cordones de Extensión

Amperaje

Largo

del

Cordón

Calibre del

Alambre

Un alambre de

extensión que se

sienta caliente al tacto, está

sobrecargado. Repare o cambie los

cordones de extensión dañados

inmediatamente.

No conecte este

generador a la

entrada del suministro eléctrico de la

casa.

Hasta 10 amperios

de demanda

14

0 a 30m

(100')

Page 33

33- SP

A04669

OPERACIÓN

1. Interruptor: Activa y desactiva el sistema

de encendido.

2. Luz piloto: Indica que el generador está

proveyendo voltaje.

3. Tomacorriente de 12V CD: Suministra

voltaje de corriente directa de 12 voltios a

los artefactos. NOTA: Este tomacorriente

es tan sólo para operar artefactos de

corriente directa de 12 voltios. NO es para

cargar baterías.

4. Tornillo para conexión a tierra: Este es el

punto donde se conecta el alambre para

conexión a tierra externa.

5. Tomacorriente: Tomacorriente doble para

proveer voltaje a artefactos de 120V.

6. Tapa de combustible: Cuando se llene el

tanque de combustible use gasolina sin

plomo, limpia y fresca de un surtidor de 87

octanos o más.

7. Interruptores de circuito: Cada

tomacorriente tiene un interruptor de

circuito para proteger el generador contra

sobre demandas. Si éste se abre (salta),

desconecte todos los artefactos

enchufados al generador. Espere que el

interruptor de circuito de enfríe y oprima

su botón de reactivación.

8. Toma de aceite: Rellene el carter con

aceite SAE10W-30.

9. Tubo de escape

10. Palanquita de la válvula de

combustible: Abre y cierra la conexión

entre el tanque de combustible y el

carburador.

11. Estrangulador (choke): Abre y cierra la

válvula de estrangulamiento del

carburador.

12. Cordón arrancador

FAMILIARÍCESE CON EL GENERADOR

Lea este manual general y las reglas de seguridad antes de operar el generador.

Compare las ilustraciones de las piezas en este manual con las del generador para

familiarizarse con la ubicación de los diversos controles y regulaciones. Conserve

todos los manuales para referencia futura.

Salida del

escape (9)

Estrangulador

(choke) (11)

Palanquita de

la válvula de

combustible

(10)

Toma de aceite (8)

Tomacorriente de

12V CD (3)

Interruptor

de circuito

de CD (7)

Tornillo para

conexión a

tierra (4)

Luz

piloto (2)

Interruptor (1)

Tomacorriente

de 110V CA (5)

Interruptor de

circuito de CA (7)

Tapa del tanque

de combustible (6)

Cordón

arrancador

(12)

Page 34

34- SP

A04669

PARA ARRANCAR EL MOTOR

1. Abra la válvula de corte de combustible

moviendo la palanquita.

2. Mueva la palanca de estrangulamiento

(choke) a la posición cerrada

NOTA: Si el motor está caliente, no se

requiere mover la palanca de

estrangulamiento (choke) a la posición

cerrada. Asegúrese que esta palanca esté

en la posición de operación cuando se

arranque un motor que esté caliente.

3. Mueva el interruptor a la posición de

encendido "ON"

CAPACIDAD DEL GENERADOR

IMPORTANTE: Exceder la capacidad del

generador puede causar daños serios al

generador y a los artefactos eléctricos

conectados. Vea la sección Cálculo de

Wataje en este manual para ayudarle a

determinar los artefactos y herramientas que

puede hacer funcionar con la capacidad del

wataje de su generador.

ANTES DE COMENZAR

Este generador se ha

despachado de fábrica

sin aceite en el carter. Operar la unidad sin

aceite puede dañar el motor.

Siempre revise el nivel

del aceite antes de

comenzar. Operar el motor con poco o nada

de aceite puede causar daños serios al motor.

Siga los pasos a continuación antes de

arrancar el generador:

1. Revise el aceite del motor. Refiérase a la

sección Mantenimiento en este manual

para el procedimiento correcto.

2. Revise que el

combustible esté al

nivel requerido.

Asegúrese que el

generador esté

apagado y que se

haya esperado

suficiente tiempo

para que se enfríe. Use gasolina regular

limpia, fresca sin plomo de mínimo 87

octanos. No mezcle aceite con la gasolina.

Para dejar suficiente

espacio para la

expansión del combustible, nunca llene el

tanque completamente, sólo hasta 13mm

(1/2") por debajo del cuello de la toma.

Limpie el combustible que pueda haberse

derramado del motor y el equipo antes de

arrancar el motor.

Nunca llene el

tanque en ambientes

interiores. Nunca llene el tanque cuando el

motor esté funcionando o caliente. No fume

al llenar el tanque de combustible.

Nunca haga

funcionar el motor

en interiores ni en áreas cerradas o con

poco ventilación porque los gases del

escape del motor contienen monóxido de

carbono y otros gases inodoros mortales.

3. Asegúrese que el generador esté

conectado a tierra de acuerdo a los

reglamentos locales.

4. DEBE desconectar todos los artefactos.

La velocidad del motor

se ha regulado en la

fábrica para proveer una operación segura.

La alteración de la velocidad del motor

puede causar sobrecalentamiento de los

artefactos conectados e incendio. Nunca

intente "acelerar" el motor para obtener

mayor rendimiento. Tanto el voltaje como

la frecuencia de la corriente de salida se

saldrán de la norma y harán peligrar los

artefactos conectados y al usuario.

Para evitarle daños

permanentes a

los

artefactos conectados al generador, DEBE

desenchufarlos del generador antes de

arrancarlo.

ON

OFF

OFF

Page 35

35- SP

A04669

4. Agarre el mango de la cuerda del

arrancador y tire de él lentamente hasta

sentir una resistencia. Deje que la

cuerda se enrolle lentamente. Tire la

cuerda en forma rápida y firme. Deje que

la cuerda se enrolle lentamente. Repita

si fuese necesario.

5. Cuando el motor arranque, mueva

gradualmente la palanquita del

estrangulador (choke) a la posición

abierta.

IMPORTANTE: Después de cada arranque

inicial, permita que el generador funcione sin

carga por 5 minutos para que el motor y el

generador se estabilicen.

APAGADO DEL MOTOR

1. Desconecte todos los artefactos que

están enchufados al generador.

2. Apague el motor moviendo el interruptor

a la posición "OFF".

3. Cierre la válvula de corte de combustible

moviendo la palanquita.

CONEXIÓN DE ARTEFACTOS

ELÉCTRICOS

1. Deje que el motor funcione y se caliente

por 5 minutos sin carga después de

arrancar.

IMPORTANTE: Si la velocidad del motor o el

voltaje fluctuasen con una demanda menor a

250 watts, mueva el control de

estrangulamiento (choke) a la posición del

medio. Conecte los artefactos de la

siguiente forma para evitarle daños al

equipo.

2. Conecte los equipos con carga inductiva

primero. Estos son herramientas

eléctricas de mano y algunos artefactos

domésticos pequeños. Conecte primero

los que demandan mayor wataje. Vea la

sección Cálculo de Wataje en este

manual.

3. Luego conecte las luces.

4. Los equipos sensibles a las variaciones

de voltaje deben conectarse al generador

al final. Estos son los televisores,

videograbadoras, hornos de microondas

y teléfonos inalámbricos que deben

conectarse a un protector de sobrecarga

de voltaje aprobados por U.L., el que a

su vez se conecta al generador.

Si no enchufa los

artefactos al generador

en la secuencia indicada, puede dañar los

artefactos y el generador y se anularán las

garantías.

Siga lo indicado en la cartilla en la sección

Cálculo de Wataje de este manual.

Sobrecargar el generador con mayor

demanda hará fluctuar el voltaje del

generador y puede dañar los equipos o

artefactos conectados a éste. DeVilbiss

Air Power Company sólo será responsable

por daños al equipo del cliente cuando se

determine que el generador está

defectuoso. Esta determinación sólo la