Page 1

Record All Information

for future reference:

Brand:

Purchase Date:

Model #:

Serial #:

Questions? 1-800-888-2468

Register your product online

www.devap.com

CONSUMER SAFETY INFORMATION . .2

SAFETY GUIDELINES/DEFINITIONS . .2

SAFETY INSTRUCTIONS . . . . . . . . . .2-8

ASSEMBLY . . . . . . . . . . . . . . . . . . . .8-13

OPERATION . . . . . . . . . . . . . . . . . .13-16

MAINTENANCE . . . . . . . . . . . . . . .16-17

STORAGE . . . . . . . . . . . . . . . . . . . .17-18

WATTAGE CALCULATIONS . . . . . . .18-20

TROUBLESHOOTING GUIDE . . . . . . .21

WARRANTY . . . . . . . . . . . . . . . . . . . . .22

QUICK FACTS . . . . . . . . . . . . . . . . . . .24

ESPAÑOL . . . . . . . . . . . . . . . . . . . . . . . . . . .25-48

FRANÇAIS . . . . . . . . . . . . . . . . . . . . . .49-72

READ AND SAVE THESE INSTRUCTIONS

Generator

Operator’s Manual

Part No. D26968 Rev. 0

Page 2

2- ENG

D26968

Read Operators Manual. Do not operate equipment until you have read

operators Manual for Safety, Assembly, Operation, and Maintenance

Instructions.

This product may not be equipped with a spark arresting muffler. If the

product is not equipped and will be used around flammable materials,

or on land covered with materials such as agricultural crops, forest, brush, grass, or other

similar items, then an approved spark arrester must be installed and is legally required in the

state of California. It is a violation of California statutes section 130050 and/or sections 4442

and 4443 of the California Public Resources Code, unless the engine is equipped with a spark

arrester, as defined in section 4442, and maintained in effective working order. Spark arrester

are also required on some U.S. Forest Service land and may also be legally required under

other statutes and ordinances.

Engine exhaust contains chemicals known, in certain quantities, to

cause cancer, birth defects or other reproductive harm.

CONSUMER SAFETY INFORMATION

CONSUMER GENERAL AND SERVICE INFORMATION

DO NOT RETURN THIS PRODUCT TO THE RETAILER! FOR SERVICE

OPTIONS CALL: 1-800-888-2468, EXT. 2.

• Please read and follow these instructions for proper use and maintenance.

• Please take the time now to register your generator online at

www.devap.com.

• If you experience any problems and need assistance, please call us at our toll

free number 1-800-888-2468, Monday through Saturday, 8:00 a.m. To 6:00

p.m. C.S.T.

• If repair or service part purchase is required, our many Authorized Warranty

Service Centers are conveniently located and equipped to handle all inwarranty and out-of-warranty service.

• For the location of the nearest Authorized Warranty Service Center call 1800-888-2468, Ext. 2, 24 hours a day, 7 days a week or visit our web site @

devap.com.

• Retain sales receipt as proof of purchase for warranty service.

• Read and understand all safety warnings.

• Do not operate this unit until you have read and understand this Owners

Manual for Safety, Operation, and Maintenance Instructions.

• Do not operate this unit until you have read and understand the Engine

Owners Manual for Safety, Operation, and Maintenance Instructions.

Note: Photographs and line drawings used in this manual are for reference only and

do not represent a specific model.

Page 3

3- ENG

D26968

indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided,may result

in minor or moderate injury

used without the safety alert symbol indicates potentially hazardous

situation which, if not avoided, may result in property damage.

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To

help you recognize this information, we use the symbols below. Please read the manual and

pay attention to these sections.

SAFETY GUIDELINES / DEFINITIONS

IMPORTANT SAFETY INSTRUCTIONS

Improper operation or maintenance of this product could result in

serious injury and property damage. Read and understand all

warnings and operating instructions before using.

RISK OF ELECTROCUTION AND FIRE

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Attempting to

connect generator

directly to the

electrical system

of any building

structure.

Back feeding electricity through

a building’s electrical system to

the outside utility feed lines

could endanger repair persons

attempting to restore service.

Never backfeed electricity

through a structure's electrical

system.

Attempting to connect to the incoming utility service could result

in electrocution.

Restoration of electrical service

while the generator is connected

to the incoming utility could

result in a fire or serious damage

if an isolator switch is not

installed.

Failure to use a double throw

transfer switch when connecting

to a structure's electrical system

can damage appliances and

WILL VOID the manufacturer's

warranty.

To connect to a structure's electrical system in a safe manner,

always have a Double-Throw

Transfer Switch installed by a

qualified electrician and in compliance with local ordinances.

(When installing a DoubleThrow Transfer Switch, a minimum of 10 gauge wiring must

be used.)

Page 4

4- ENG

D26968

Operation of unit

when damaged,

or with guards or

panels removed.

Removal of guarding could

expose electrically charged

components and result in

electrocution.

Do not operate generator with

protective guarding removed.

Improper

connection of

items to

generator.

Exceeding the load capacity of

the generator by attaching too

many items, or items with very

high load ratings to it could

result in overheating of some

items or their attachment wiring

resulting in fire or electrical

shock.

Attempting to use the unit

when it has been damaged, or

when it is not functioning

normally could result in fire or

electrocution.

Read the load rating chart and

instructions in the Wattage Calculation section. Make sure that

the summation of electrical

loads for all attachments does

not exceed the load rating of the

generator.

Do not operate generator with

mechanical or electrical

problem. Have unit repaired by

an Authorized Service Center.

Operation of

generator in rain,

wet, icy, or

flooded

conditions.

Water is an excellent conductor

of electricity! Water which comes

in contact with electrically

charged components can

transmit electricity to the frame

and other surfaces, resulting in

electrical shock to anyone contacting them.

Operate generator in a clean, dry,

well ventilated area. Make sure

hands are dry before touching

unit.

Use of worn,

damaged, undersized or ungrounded extension cords.

Use of ungrounded cordsets

could prevent operation of

circuit breakers and result in

electrical shock.

Always use a cordset having a

grounding wire with an

appropriate grounding plug. DO

NOT use an ungrounded plug.

Use proper size (wire gauge)

cordset for application see chart

in the Assembly section of this

manual.

Contact with worn or damaged

extension cords could result in

electrocution.

Use of undersize extension

cords could result in overheating

of the wires or attached items,

resulting in fire.

Inspect extension cords before

use and replace with new cord if

required.

Placing generator

on or against

highly conductive

surface, such as a

steel walkway or

metal roof.

Place generator on low conductivity surface such as a concrete

slab.

Accidental leakage of electrical

current could charge conductive

surfaces in contact with the

generator.

RISK OF ELECTROCUTION AND FIRE

(Continued)

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

ALWAYS operate generator a

minimum of six feet from any

conductive surface.

Page 5

5- ENG

D26968

RISK OF FIRE

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Improper storage

of fuel

Improperly stored fuel could

lead to accidental ignition. Fuel

improperly secured could get

into the hands of children or

other unqualified persons.

Store fuel in a OSHA approved

container designed to hold

gasoline. Store container in secure location to prevent use by

others.

Attempting to

fill the fuel tank

while the engine

is running.

Gasoline and gasoline vapors

can become ignited by coming

in contact with hot components

such as the muffler, engine

exhaust gases, or from an

electrical spark.

Cigarettes, sparks, fires, or

other hot objects can cause

gasoline or gasoline vapors to

ignite.

Turn engine off and allow it to

cool before adding fuel to the

tank. Equip area of operation

with a fire extinguisher certified

to handle gasoline or fuel fires.

Add fuel to tank in well

ventilated area. Make sure there

are no sources of ignition near

the generator.

Operate generator in a clean, dry,

well ventilated area a minimum of

four feet from any building, object

or wall. DO NOT OPERATE

UNIT INDOORS OR IN ANY

CONFINED AREA.

Materials placed against or near

the generator or operating the

generator in areas where the

temperature exceeds 104° F. ambient (such as storage rooms or

garages) can interfere with its

proper ventilation features causing overheating and possible ignition of the materials or buildings.

Sparks, fire, hot

objects

Inadequate

ventilation for

generator

Tampering with

factory set

engine speed

settings.

Engine speed has been factory

set to provide safe operation.

Tampering with the engine speed

adjustment could result in

overheating of attachments and

could cause a fire.

Spilled fuel and its vapors can

become ignited from hot

surfaces or sparks.

Never attempt to “speed-up”

the engine to obtain more performance. Both the output

voltage and frequency will be

thrown out of standard by this

practice, endangering

attachments and the user.

Use care in filling the tank to

avoid spilling fuel. Make sure

fuel cap is secured tightly and

check engine for fuel leaks

before starting engine. Move

generator away from refueling

area or any spillage before

starting engine. Allow for fuel

expansion. Keep maximum fuel

level ¼ inch below the tip of the

fuel tank. Never refuel with the

engine running.

Overfilling the fuel

tank – fuel

spillage.

Page 6

6- ENG

D26968

RISK OF UNSAFE OPERATION

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Operation of

generator in

careless manner

All sources of energy include the

potential for injury. Unsafe

operation or maintenance of your

generator could lead to serious

injury or death to you or others.

• Review and understand all of

the operating instructions and

warnings in this manual.

• Become familiar with the operation and controls of the

generator. Know how to shut it

off quickly.

• Equip area of operation with a

fire extinguisher certified to

handle gasoline or fuel fires.

• Keep children or others away

from the generator at all times.

RISK OF BREATHING - INHALATION

HAZARD

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Breathing exhaust fumes will

cause serious injury or death.

Operate generator in clean, dry,

well ventilated area. Never

operate unit in enclosed areas

such as garages, basements,

storage, sheds, or in any

location occupied by humans or

animals. Keep children, pets and

others away from area of operating unit.

Gasoline

engines produce

toxic carbon

monoxide

exhaust fumes.

RISK OF INJURY AND PROPERTY

DAMAGE WHEN TRANSPORTING

GENERATOR

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Fire, Inhalation,

Damage to

Vehicle Surfaces

Fuel or oil can leak or spill and

could result in fire or breathing

hazard, serious injury or death

can result. Fuel or oil leaks will

damage carpet, paint or other

surfaces in vehicles or trailers.

If generator is equipped with a

fuel shut-off valve, turn the valve

to the off position before

transporting to avoid fuel leaks.

If generator is not equipped with

a fuel shut-off valve, drain the

fuel from tank before transporting. Transport fuel only in an

OSHA approved container.

Always place generator on a

protective mat when transporting to protect against damage to

vehicle from leaks. Remove

generator from vehicle immediately upon arrival at your destination.

Page 7

7- ENG

D26968

RISK OF UNSAFE OPERATION

(Continued)

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Improper raising or suspending

can cause damage to the

generator.

Always use cables, chains, or

straps rated at 2000 lbs working

load or more to raise or suspend

generator.

Operation of

voltage

sensitive appliances without a

voltage surge

protector

Any gasoline operated

household generator will incur

voltage variations causing

damage to voltage sensitive appliances or could result in fire.

Always use a U.L. listed voltage

sensitive surge protector to

connect voltage sensitive

appliances (TV, computer, stereo, etc.). Failure to use a U.L.

listed voltage surge protector

will void the warranty on your

generator.

Notice: A multiple outlet strip is

not a surge protector. Make sure

you use a U.L. listed voltage

surge protector

Raising or

suspending

generators

equipped with

lift rings

improperly

Generator could fall causing

serious injury or death to you or

others.

Always use proper connecting

procedures as described in this

manual when connecting cables,

chains, or straps for raising or

suspending generators equipped

with lift rings.

Operating

generator while

suspended

Generator will not operate

properly and will cause damage

to the generator and could

cause serious injury or death to

you or others.

Never operate generator while

suspended or in an unlevel

position. Always operate

generate on a flat, level surface.

Contact with hot surfaces, such

as engines exhaust components,

could result in serious burns.

RISK OF HOT SURFACES

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

Contact with hot

engine and

generator

components.

During operation, touch only the

control surfaces of the

generator. Keep children away

from the generator at all times.

They may not be able to recognize the hazards of this

product.

Page 8

8- ENG

D26968

NOTE: This manual is a general manual. Information in this manual may or

may not pertain to your model. Please read carefully.

NOTE: Left and right describes the location of a part with the operator

facing the outlet panel.

ASSEMBLY

Read this manual. Do not attempt to operate equipment

until you have read this Manual for Safety, Operation, and

Maintenance Instructions.

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK OF MOVING PARTS

Never operate generator with

guarding or cover plates

removed. Avoid wearing loose

fitting clothing or jewelry which

could be caught by moving parts.

The generator contains parts

which rotate at high speed during

operation. These parts are

covered by guarding to prevent

injury.

Contact with

moving parts

can result in

serious injury.

RISK FROM LIFTING

The generator is too heavy to be

lifted by one person. Obtain assistance from others before you

try to move it.

Serious injury can result from attempting to lift too heavy an

object.

Lifting a very

heavy object.

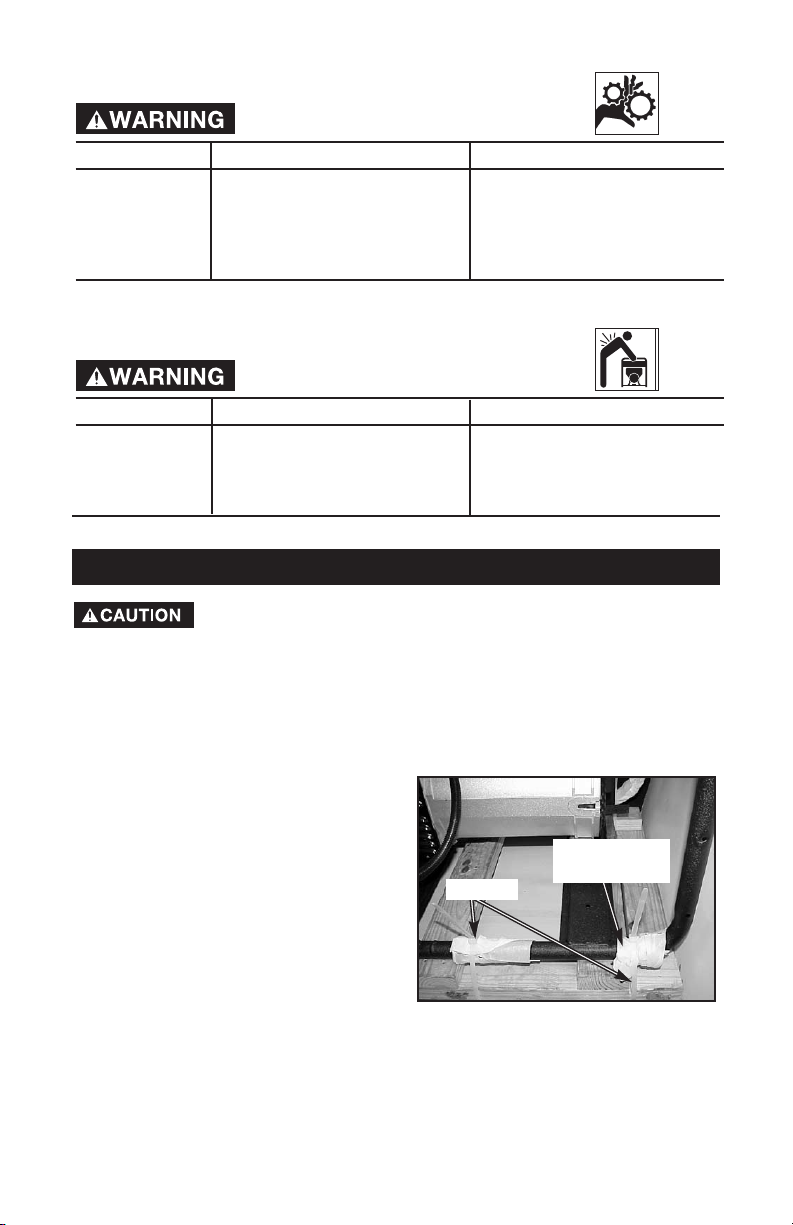

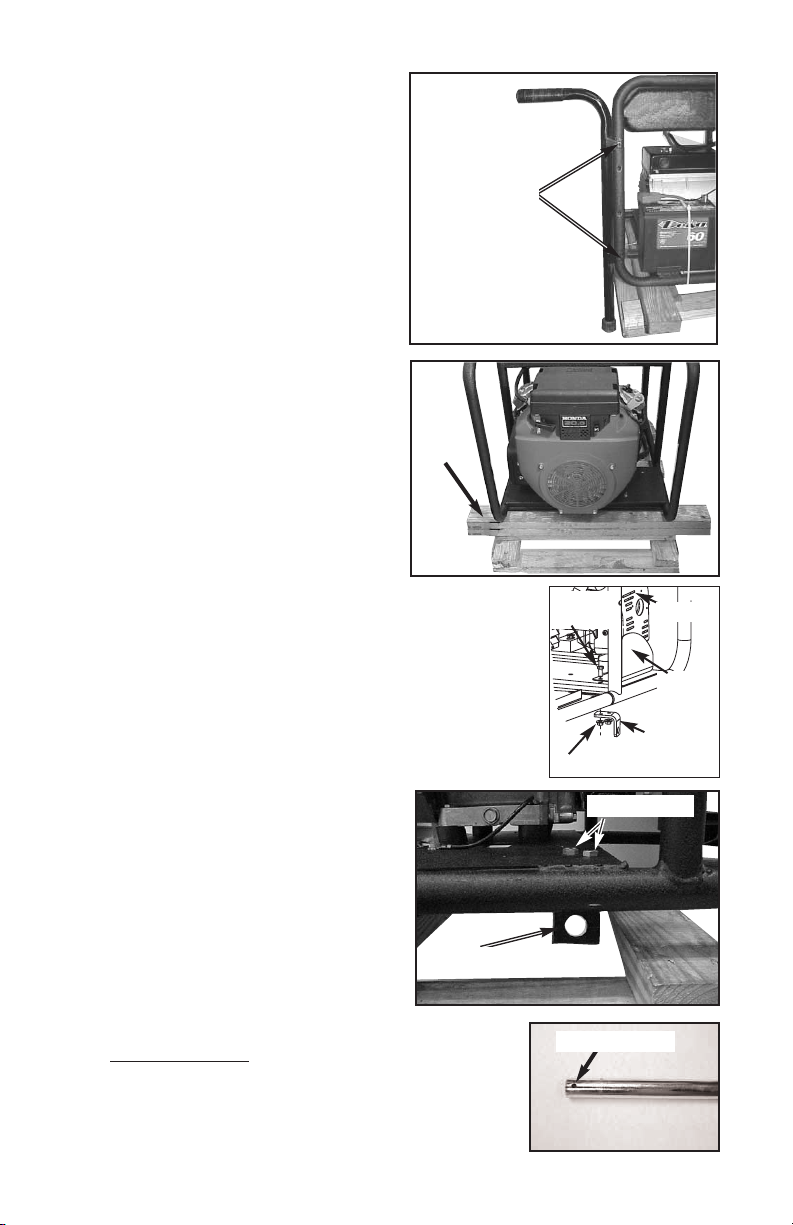

UNPACKING

1. Locate the parts carton and set aside

for later use.

2. Cut wire ties holding generator to

pallet and remove protective

wrapping.

3. Remove all packaging, leaving

generator on pallet.

IMPORTANT: DO NOT remove generator

from pallet.

4. Discard all packaging.

Wire Tie

Protective

Wrapping

Page 9

9- ENG

D26968

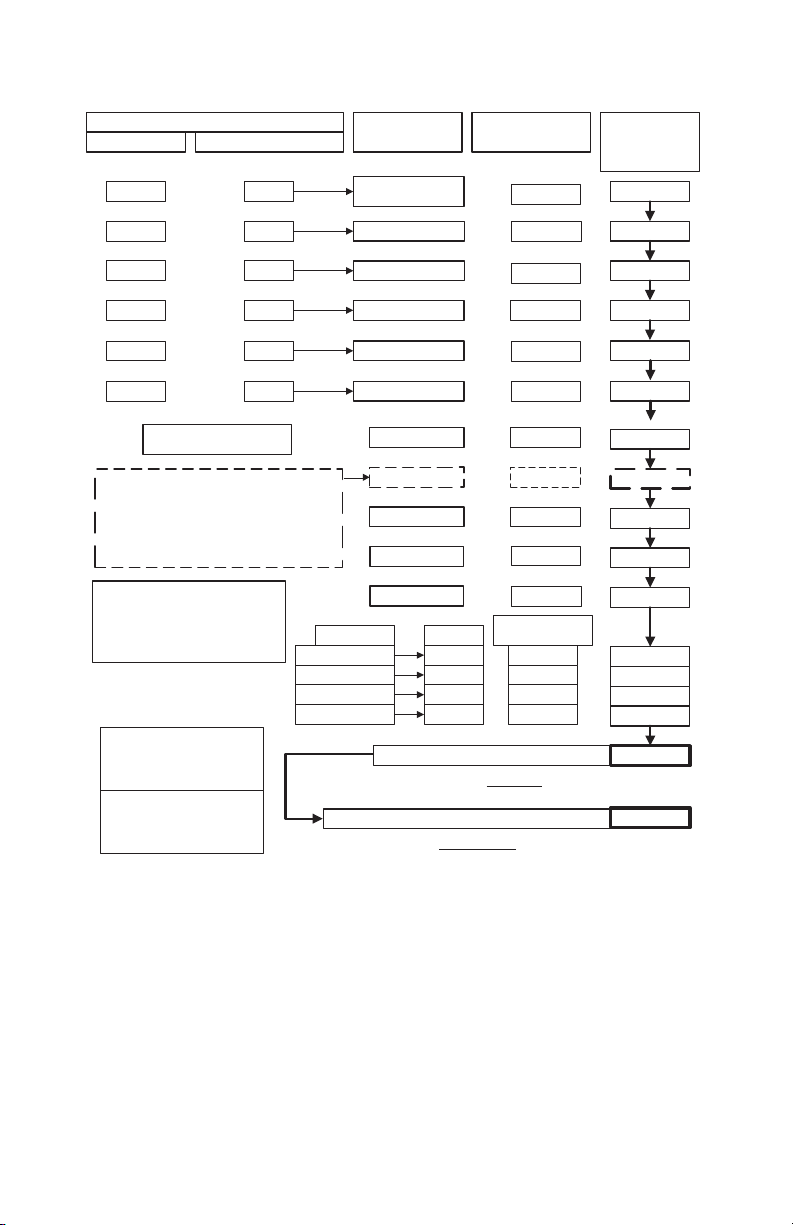

ASSEMBLE WHEEL KIT

Tools needed:

2 - 2x4 at least 30” long

1 - 1/2” socket

1 - 1/2” open end wrench

1 - hammer

1 - pliers

Parts bag contains:

2 - Handle Grips

2 - Handle End Caps

4 - Screws, .313-18X1.75

1 - Cotter Pin

2 - Washers, 5/8" X 1.32 X .09

1 - Flat Steel Washer

2 - Axle Spacer

2 - Cap Screw 5/16-18 X 3/4

6 - Flange Nuts

2 - Wheel Brackets

1 - 5/8” Axle Cap

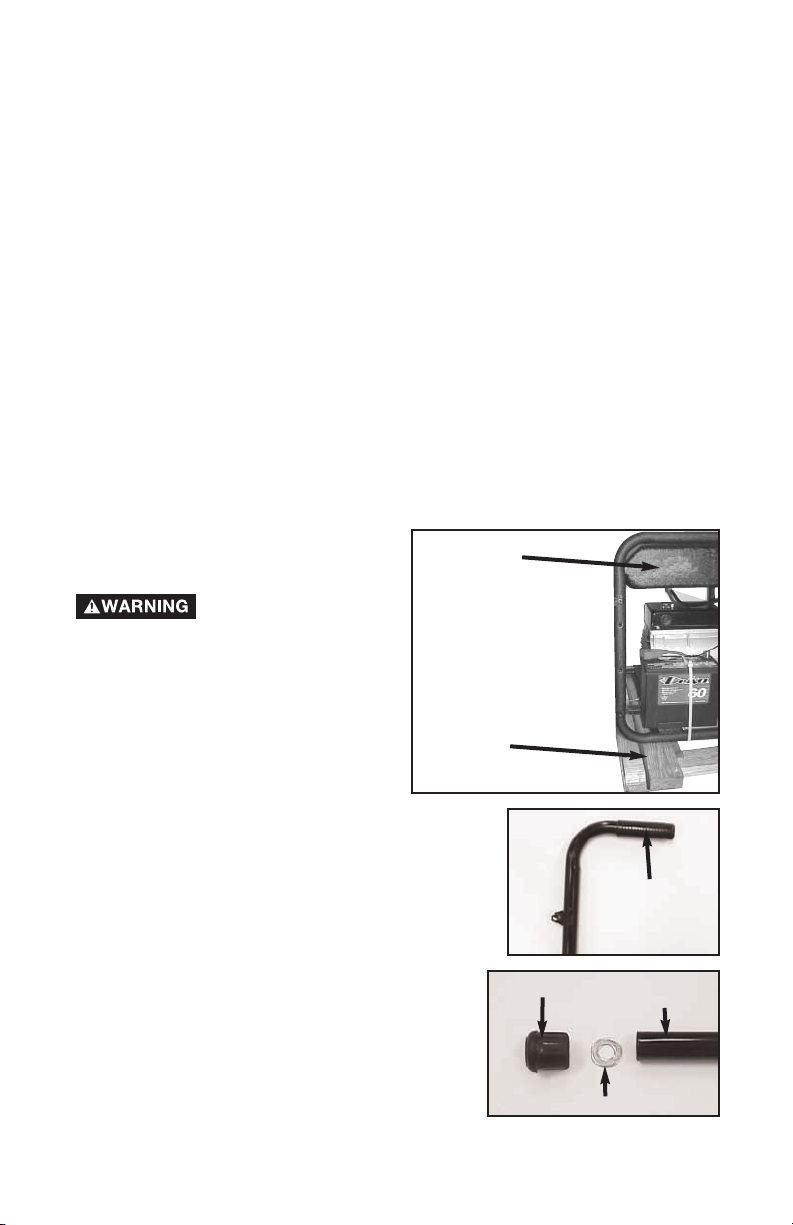

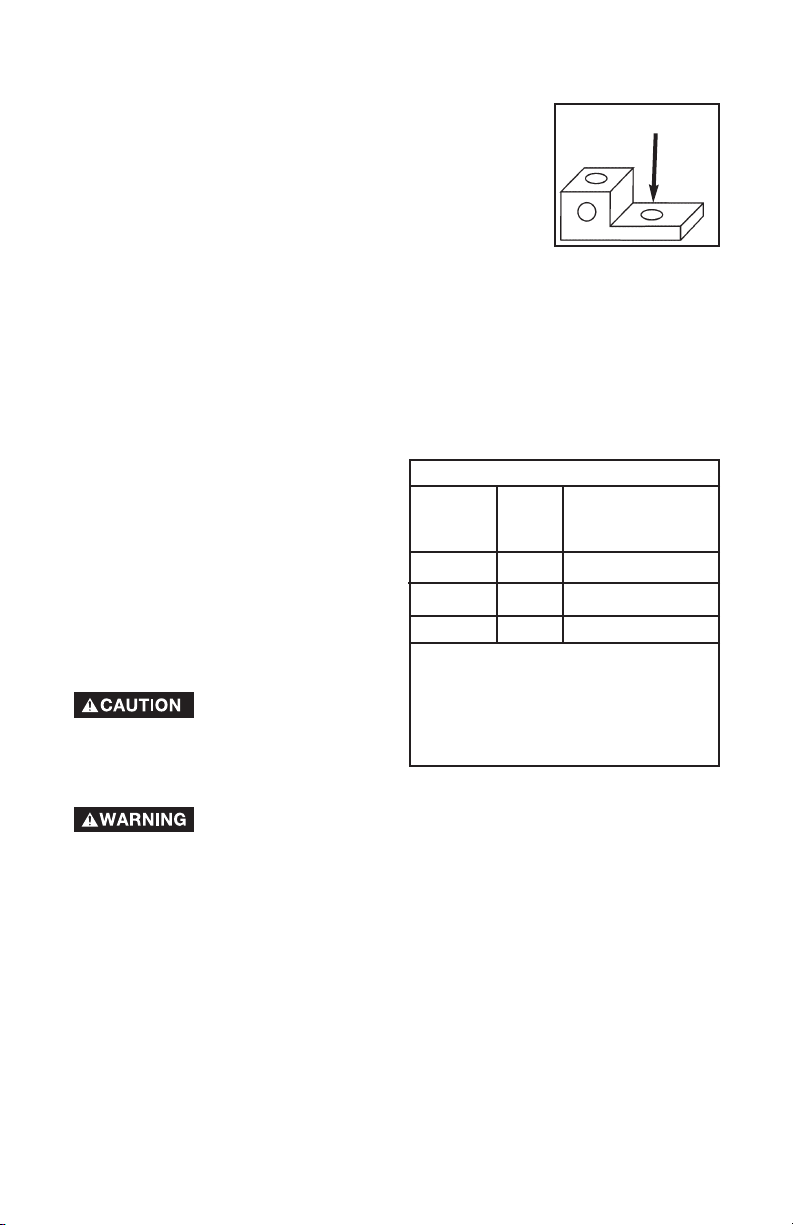

1. Lift the gas tank end of generator

and slide 2x4 between generator

and pallet as shown.

The generator is too

heavy to be lifted by

one person. Obtain assistance from

others before lifting.

2. Place handle grips on handle assemblies.

3. Place one 5/8” washer into the bottom of

each end cap. Push end caps onto the

end of the handle assemblies.

2x4

Gas Tank

Handle Grip

End Cap

5/8” Washer

Handle

Assembly

Page 10

10- ENG

D26968

4. Attach handle assemblies to frame

using four screws and flange nuts.

NOTE: Screw on outside of frame.

NOTE: Do not tighten until all screws

and flange nuts are assembled.

5. Lift generator and remove 2x4.

6. Lift other end of generator and place

two 2x4s between generator and

pallet as shown.

7. On the muffler side of the engine, remove cap screws

and flange nuts holding the heat shield to the frame.

Reassemble cap screws, heat shield, wheel bracket,

and flange nuts and as shown. Tighten securely.

8. On other side, assemble wheel

bracket using cap screws and flange

nuts supplied. Tighten securely.

NOTE: Brackets are placed under frame

with hole facing outward.

9. Using a hammer tap axle cap onto end of axle,

without the hole

.

10. Slide wheel onto axle with valve stem to the

outside.

11. Slide spacer onto axle against wheel.

Cap screws

Wheel Bracket

Hole in Axle

Muffler

Heat

Shield

Cap

Screw

Wheel

Bracket

Flange Nuts

Screws and

Flange Nuts

2x4

Page 11

11- ENG

D26968

12. Slide axle through axle brackets. NOTE: The pallet will need to be

removed before the wheel can be assembled.

13. Lift generator and slide pallet and 2x4s out. NOTE: Generator will tilt.

14. Lift generator and slide spacer, then wheel (with valve stem to the outside)

onto axle.

15. Slide flat steel washer onto axle against wheel.

16. Secure with cotter pin.

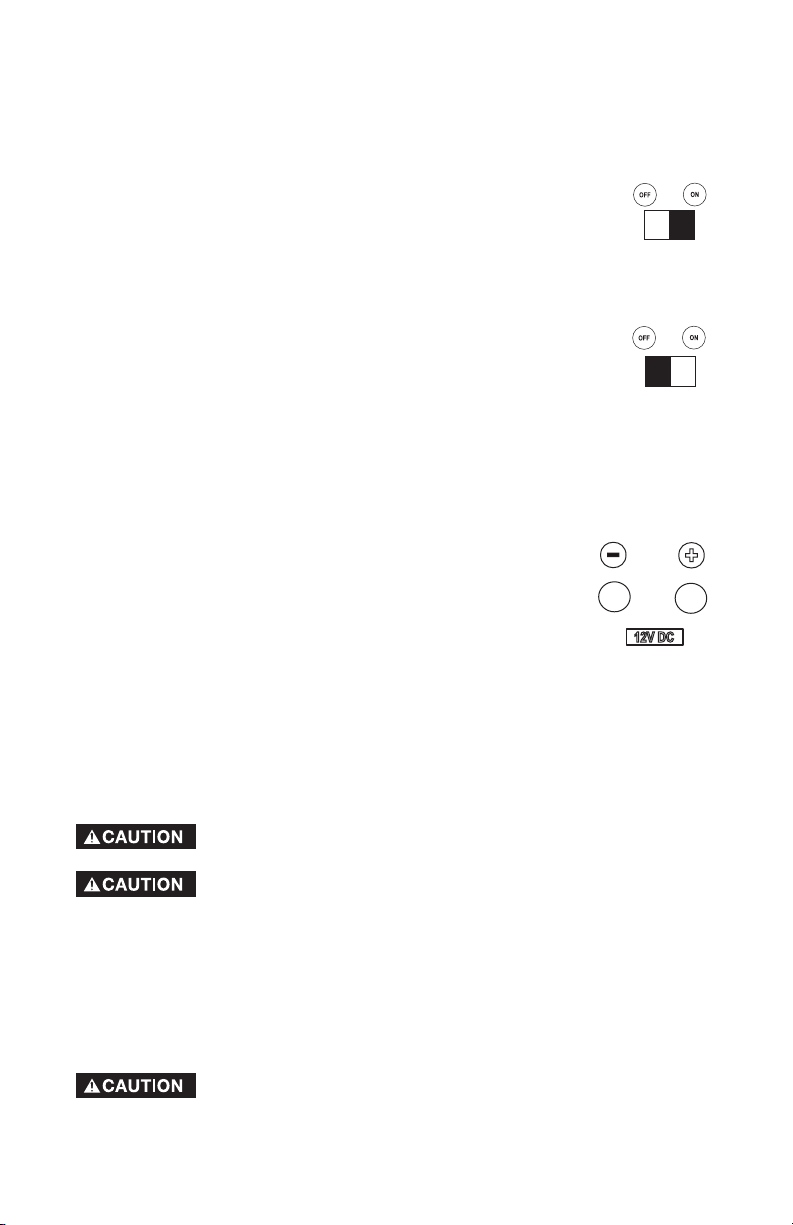

BATTERY INSTALLATION

The generator is equipped with a maintenance free battery.

1. For packaging purposes the black

negative battery cable and battery

were secured with wire ties. Cut

these wire ties.

2. Connect black negative cable to

negative (-) battery post. Tighten

securely. NOTE: Make sure rubber

boot is covering positive (+) battery

terminal.

NOTE: If battery needs to be charged,

follow these instructions.

When charging the

battery, do not smoke.

Keep away from any sparks. The

fumes from the battery acid can cause

an explosion. To prevent explosive

fumes from accumulating do not

charge in an enclosed area.

Sulfuric acid is a

flammable and

explosive chemical that is harmful to

the skin, eyes, and clothing.

To prevent sparks,

disconnect the black

battery cable from the negative (-)

terminal before disconnecting the red positive cable.

1. Remove black negative battery cable from the battery.

2. Remove red positive battery cable from the battery.

3. Use a portable 12 volt battery charger, if needed, to bring battery to full

charge (12.6 at 70ºF.). Refer to the battery charger’s operator’s manual for

the correct procedure. If a battery charger is not available, have an

authorized service center charge the battery.

4. Connect the battery cables.

To Prevent sparks connect the red (positive) cable to the

positive (+) terminal before connecting the black negative

cable.

When transporting unit over extremely rough terrain by

vehicle the battery should be secured.

Positive

Battery

Cable with

rubber boot

Negative

Battery

Cable

Negative

Battery

Cable

Wire Tie

Wire Tie

Page 12

12- ENG

D26968

EXTENSION CORDS

When using an appliance or tool at a

considerable distance from the generator,

a 3-wire extension cord that has a 3blade grounding plug and a 3-slot receptacle that accepts the tool's plug MUST

be used in order to reduce the risk of

electrical shock. A cord of adequate size

must be used. Using the following chart

to determine the minimum wire size required.

An extension cord that

is hot to the touch is

overloaded. Repair or replace

damaged extension cords immediately.

DOUBLE THROW TRANSFER SWITCH

Potential hazards exist when a portable electric generator is

connected to the main electrical supply coming into the house.

It is at that point that the electrical generator could feed back into the utility

company's system causing possible electrocution of workers who are repairing

the electrical lines.

To avoid back feeding of electricity into utility systems, a double-throw transfer

switch must be installed between the generator and utility power. The DoubleThrow Transfer Switch should be installed by a licensed electrician and in compliance with all state and local electrical codes. (When installing a Double-

Throw Transfer Switch, a minimum of 10 gauge wiring must be used.)

The electrician should also install a sub-panel to isolate the circuits you would

want to use during an emergency or electrical power outage. Your generator will

not be large enough to handle the load of all the lights, appliances, TV, etc. at

one time. To select which items to run during the electrical power outage, see

Wattage Calculation section in this manual.

GROUNDING THE GENERATOR

A grounding lug is supplied with the generator for use

when required by local electrical ordinances. Refer to

article 250 of the National Electrical Code to clarify any

needed grounding information. Your local electric company

or a certified electrician should be able to help you with

this information.

Grounding Lug

Extension Cord Wire Gauge Chart

Amperage

Cord

Length

Wire

Gauge

Size

1. When amperage exceeds 20 amp; a

12 gauge extension cord should not

be used for long distances.

2. When amperage exceeds 30 amp; a

10 gauge extension cord should not

be used for long distances.

0 to 100 ft.

0 to 100 ft.

12 ga.

10 ga.

1

Up to 20 amp draw

2

Up to 30 amp draw

0 to 100 ft.

8 ga. Up to 40 amp draw

OBTAINING ELECTRICITY FROM THE GENERATOR

There are basically 2 ways to obtain electricity from a generator:

1. Use of extension cords directly from the generator to the appliance, lights,

tools, etc.

2. Use of a double-throw transfer switch installed directly to the main electrical

supply outside of house.

Page 13

13- ENG

D26968

OTHER LOOSE PARTS

1. Oil is supplied, see engine operator’s manual for correct procedure to add oil

and fuel to engine.

2. The locking plugs maybe used when needed or required.

The locking plugs are to be installed and/or used in

accordance with appropriate local electrical code

regulations. Refer to instructions enclosed with each plug for proper

installation.

3. 12V DC cables to be used with the 12V DC outlets. See Operation section.

IMPORTANT: Before any attempt to start your generator be sure to check

engine oil (See Engine Operator's manual)

KNOW YOUR GENERATOR

Read this General Manual and Safety Rules before operation of your Generator.

Compare the illustration in your parts manual with your generator to familiarize yourself with

the location of various controls and adjustments. Save all manuals for future references.

GENERATOR CAPACITY

IMPORTANT: Exceeding the rated capacity of your generator can result in serious damage

to your generator and connected electrical devices. See the Wattage Calculation section in

this manual to assist you in determining the appliances and tools that can be run with the

wattage capacity of your generator.

CIRCUIT BREAKERS

Each receptacle has a circuit breaker to protect the generator from overloading. If the circuit

breaker trips, unplug all electrical loads from the generator. Let the circuit breaker cool

down. Push circuit breaker button to reset.

LOW OIL SHUTDOWN

Your generator engine is equipped with Low Oil Shutdown. Low Oil Shutdown is

a safety device designed to protect your engine from damage in the event the oil

level in the crankcase is low.

If while the engine is running, the oil gets low, it will automatically shut itself

down and will not restart until the oil is added. If the oil is low before start-up,

the generator will not start until oil is added.

NOTE: The Low Oil Shutdown mechanism is very sensitive. You must fill the

engine to the full mark on the dipstick to inactivate this safety device.

OFF/RUN/START SWITCH

Placed in the start position to start engine and the off position to stop engine.

NOTE: When engine is running switch will remain in the run position.

OPERATION

Page 14

14- ENG

D26968

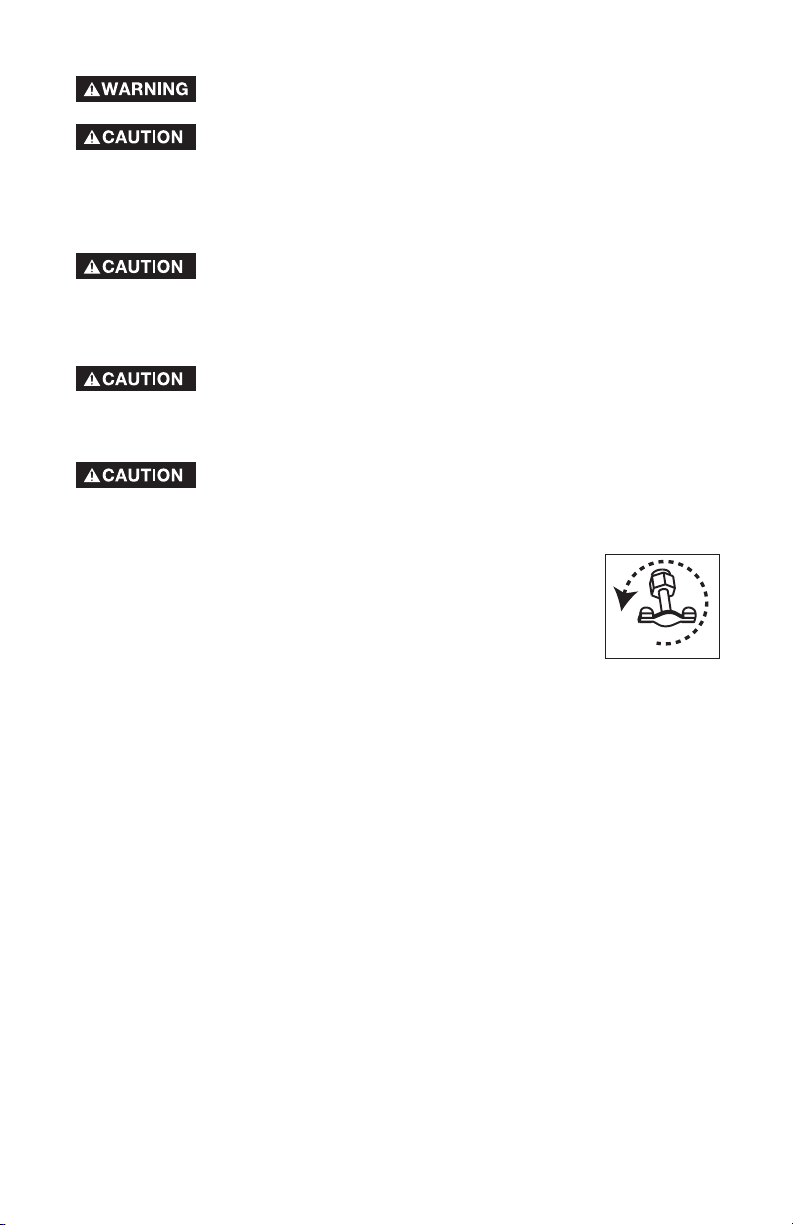

IDLE CONTROL

Choose the correct application.

1. For normal application such as power tools, small electric appliances, light

bulbs, and radios:

Place the idle control switch in the ON position. The generator

will idle down when there is no load. This lowers the engine

noise, saves on fuel consumption, and engine life.

2. Idling down IS NOT recommend on large motors (refrigerators, freezers, etc)

or voltage sensitive electronic equipment (computers, televisions, etc). For

these applications:

Place the idle control switch in the OFF position.

12V DC OUTLET

IMPORTANT: Allow generator to run at no load for 5 minutes upon each initial

start-up to allow engine to stabilize.

IMPORTANT: When the unit is running the battery will charge. DO NOT

connect the 12V DC cables to the generator’s battery.

To charge battery:

1. Using the 12V DC cables supplied, connect the red

positive (+) 12V DC cable to the battery's positive (+)

terminal.

2. Attach the other end of the red positive (+) 12V DC cable

to the generators positive (+) 12V DC outlet.

3. Connect the black negative (-) 12V DC cable to the battery's negative (-)

terminal.

4. Attach the other end of the black negative (-) 12V DC cable to the

generators negative (-) 12V DC outlet.

5. Charge the battery according to battery or equipment manufacturer

recommendations.

BEFORE START UP

This generator has been shipped from the factory without oil in the

crankcase. Operating the unit without oil can damage the engine.

Always check engine oil level before every start. Running engine

low of oil or out of oil could result in serious damage to the engine.

Follow the steps listed below before starting generator:

1. Check engine oil. Refer to the Engine Operator's Manual for correct grade and quantity

of oil.

2. Check fuel level, fill as required. Make sure generator is turned off and has been allowed

time to cool down. Use clean, fresh, regular unleaded gasoline with a minimum of 87

octane. Do not mix oil with gasoline.

Never fill fuel tank completely. Fill tank to 1/2" below the bottom of

the filler neck to provide space for fuel expansion. Wipe any fuel

spillage from engine and equipment before starting engine.

Page 15

15- ENG

D26968

TO START THE ENGINE

Never run engine indoors or in enclosed, poor ventilated

areas, engine exhaust contains carbon monoxide, an

odorless and deadly gas.

1. Open the fuel shut-off valve.

2. Move the choke control located on the engine to "CHOKE"

position. A cold engine may require to be choked longer

than a warm engine.

3. Push ON\OFF\START switch on control panel to the

"START" position to start engine. Hold in "START" position

no longer than 15 seconds per minute when trying to start

engine. Extended cranking can damage the starter motor.

4. When engine starts, gradually move the choke to the "NO Choke" position.

IMPORTANT: Allow generator to run at no load for 5 minutes upon each initial

start-up to allow engine and generator to stabilize.

STOPPING ENGINE

1. Disconnect all electrical loads.

2. Place the ON\OFF\START switch to "OFF" position.

3. Close fuel shut-off valve.

CONNECTING ELECTRICAL LOADS

1. Let engine run and warm up for five minutes after starting with no electrical

load.

Connect loads in the following manner to prevent damage to equipment:

2. Connect inductive load equipment first, inductive loads consist of

refrigerators, freezers, water pumps, air conditioners, or small hand tools.

Connect the items that require the most wattage first. See Wattage Calcu-

lation Section in this manual.

3. Connect the lights next.

Never fill fuel tank indoors. Never fill fuel tank when engine is

running or hot. Do not smoke when filling fuel tank.

Never run engine indoors or in enclosed, poor ventilated areas, engine exhaust contains carbon monoxide, an odorless and deadly

gas.

3. Make sure generator is grounded in accordance with local requirements.

4. All electrical loads MUST be disconnected.

5. Idle control switch must be in the OFF position.

Engine speed has been factory set to provide safe operation.

Tampering with the engine speed adjustment could result in overheating of attachments and could cause a fire. Never attempt to “speed-up” the engine to obtain more performance. Both the output voltage and frequency will be

thrown out of standard by this practice, endangering attachments and the user.

You MUST unplug any load from the generator before starting to

prevent permanent damage to any appliances.

Page 16

16- ENG

D26968

Note 1: Change oil after first two (2) operating hours and every 50 operating

hours thereafter, more often if operated in extreme dusty or dirty conditions.

Note 2: Check oil after 5 hours of operation.

CUSTOMER RESPONSIBILITIES TABLE

MAINTENANCE TASK

Before

each

use

Every 25

Hours of

Every

Season

Every 50

Hours of

Every

Season

Every 100

Hours of

Every

Season

Check Spark Plug

Prepare unit for storage if it is to remain

idle for more than 30 days.

MAINTENANCE

Check oil level

Change oil

Clean Air Filter Assembly

Prepare Unit for Storage

See Note 2

X

See Note 1

X

X

X

GENERAL RECOMMENDATIONS

The warranty of the generator does not cover items that have been subjected to

operator abuse or negligence. To receive full value from the warranty, operator

must maintain the generator as instructed in this manual.

ENGINE MAINTENANCE

Refer to the Engine Operator's manual for service and maintenance of the

engine.

4. Voltage sensitive equipment should be the last equipment connected to the

generator. Plug voltage sensitive appliances such at TV's, VCR's, microwaves, ovens, computers, and cordless telephones into a UL listed voltage

surge protector, then connect the UL listed voltage surge protector to the

generator.

Failure to connect and operate equipment in this sequence

can cause damage to equipment and will void the warranty

on your generator.

Follow the wattage calculation table in the Wattage Calculation section of

this manual. Overloading the generator will cause power fluctuations and

can damage equipment and appliances.

DeVilbiss Air Power Company will only be responsible for damage to

customer's equipment when the generator is determined to be defective.

This determination will only be made by an authorized representative of

DeVilbiss Air Power Company and this decision will be final. DeVilbiss Air

Power Company reserves the right to inspect the electrical connections at

the customer's site of operation and test the generator for proper operation before any determination of liability is made. Failure to maintain the

equipment or wiring for inspection will void any claim for damages by the

customer. DeVilbiss Air Power Company will not be responsible for

equipment damaged as a result of voltage surges, improper operation or

improper installation of the generator.

Page 17

17- ENG

D26968

If you are going to store your generator for more than 30 days, use the

following information as a guide to prepare the generator for storage.

Never store generator with fuel in the tank indoors or in

enclosed, poorly ventilated areas, where fumes can reach

an open flame, spark or pilot light as on a furnace, water heater, clothes

dryer or other gas appliances.

ENGINE PREPARATION

1. Add fuel stabilizer to fuel tank to minimize the formation of fuel gum

deposits during storage.

2. Run engine at least 10 minutes after adding stabilizer to allow it to enter the

fuel system.

3. Next shut off engine.

4. Disconnect the spark plug wire and remove the spark plug.

5. Add one teaspoon of oil through the spark plug hole.

6. Place rag over spark plug hole and pull the recoil a few times to lubricate

the combustion chamber.

7. Replace the spark plug, but do not connect the spark plug wire.

NOTE: If a fuel stabilizer is not used, all gasoline must be drained from the tank

and carburetor to prevent gum deposits from forming on these parts and causing

possible malfunction of the engine.

GENERATOR

• Clean the generator as outlined in the Maintenance Section on this manual.

• Check that cooling air slots and openings on generator are open and

unobstructed.

STORAGE

GENERATOR MAINTENANCE

Your generator should be kept clean and dry at all times. The generator should

not be stored or operated in environments that includes excessive moisture,

dust or any corrosive vapors. If these substances are on the generator, clean

with a cloth or soft bristle brush. Do not use a garden hose or anything with

water pressure to clean the generator. Water may enter the cooling air slots and

could possibly damage the rotor, stator and the internal windings of the gen

head.

GROUND FAULT CIRCUIT INTERRUPTER GFCI RECEPTACLE

MONTHLY: For maximum protection against electrical shock the GFCI should

be tested monthly.

To test:

1. Depress the TEST button. The RESET button should extend. If the RESET

button does not extend, notify a DeVilbiss Air Power Company Authorized

Warranty Service Center.

2. To restore power, depress the RESET button firmly into the GFCI unit until an

audible click is heard. If reset properly, the RESET button is flush with the

surface of the test button. When the button stays in, the power is ON.

Page 18

18- ENG

D26968

BATTERY

• Store battery as described by the battery manufacturer.

NOTE: After storing battery for a long period of time it may lose its charge. If

the battery loses its charge, manually start the engine with the battery connected. The engine will recharge the battery as it runs.

WATTAGE CALCULATIONS

Never exceed the rated capacity of your generator. Serious damage to the

generator or appliance could result from an overload.

1. Starting and running wattage requirements should always be calculated

when matching a generators wattage capacity to the appliance or tool.

2. There are two types of electrical appliances that can be powered by

your generator:

A. Items such as radios, light bulbs, television sets, and microwaves

have a "resistive load". Starting wattage and running wattage are

the same.

B. Items such as refrigerators, air compressors, washer, dryer, and

hand tools that use an electrical motor have an "inductive load".

Inductive load appliances and tools require approximately 2 to 4

times the listed wattage for starting

the equipment. This initial load

only lasts for a few seconds on start-up but is very important when

figuring your total wattage to be used.

C. Always start your largest electric motor first, and then plug in other

items, one at a time.

NOTE: On 120-volt loads the maximum starting wattage should NOT

exceed one half of the rated generator wattage. Example: a 5000 rated

wattage generator = 2500 maximum starting wattage.

IMPORTANT

DETERMINING WATTAGE REQUIREMENTS

Before operating this generator list all of the appliances and/or tools that are

going to operate at the same time. (Then determine the starting wattage

requirements and the running wattage requirements by following example

and/or refer to household wattage calculator.)

1. First total the running wattage of all appliances and/or tools that will be

operated at the same time.

Running W

atts Starting Watts

Example 1:

Lights = 100 Watts 0

Television = 300 Watts 0

Slow Cooker = 250 W

atts 0

TOTAL =650 Watts 0

2. Next the starting wattages of any appliances and/or tools that will start and

stop during operation.

Running W

atts Starting Watts

Example 2:

Small Refrigerator 500 W

atts 2000 Watts

TOTAL =500 Watts 2000 Watts

Page 19

19- ENG

D26968

3. The running wattage of examples 1 & 2 totals 1150 watts. The starting

wattage of the small refrigerator is 2000 watts which is 1500 watts more

than the running watts. Take this difference of 1500 starting watts from the

refrigerator and add to the total running watts of 1150.

Example 3: 1500 Starting Watts

1150 Running W

atts

TOTAL =2650 Total Watts

Generator must have a maximum capacity of at least 2650 watts.

STARTING WATTAGE REQUIREMENTS

1. Some appliances and tools will list on the motor nameplate the starting

and running voltage and amperage requirements. Use the following

formula to convert voltage and amperage to wattage:

Volts X Amp = Watts

Example: 120 volts x 10 amps = 1200 watts

2. To determine the approximate starting wattage requirement for most

appliances and tools with inductive type motors, multiply the wattage that

was calculated by 2 to 4 times to assure adequate generator capacity. If

the nameplate information is not available use the values on the following

chart as a guide.

3. Remember that the starting and running wattage for resistive loads are the

same. (Example: a 100 watt light bulb requires only 100 watts to start.)

Most resistive loads will

be listed in wattage.

Application Guide

3/8” Hand Drill

Jigsaw

(1/3 HP) Airless Sprayer

6” Bench Grinder

Belt Sander

Demolition Hammer

7-1/4” Circular Saw

(Small) Air Compressor

Light Bulb

Home Security

Television

Microwave

Toaster Oven

(5,000 BTU) Portable Heater

Furnace Fan

Refrigerator/Freezer

Sump Pump

Clothes Washer

Water Heater

(30,000 BTU) Air Conditioner

(12V DC) Battery Charger

Radio

Slow Cooker

Electric Blanket

Electric Skillet

Coffee Maker

Small Refrigerator

The wattage ratings

shown are averages actual wattage may vary.

To select the right generator for

your needs, total the wattage of the

items to be run at the same time.

1000

100

250

500

2000

WATTAGE Run Start

3000

4000

5000

6000

7000

8000

9000

10000

Page 20

20- ENG

D26968

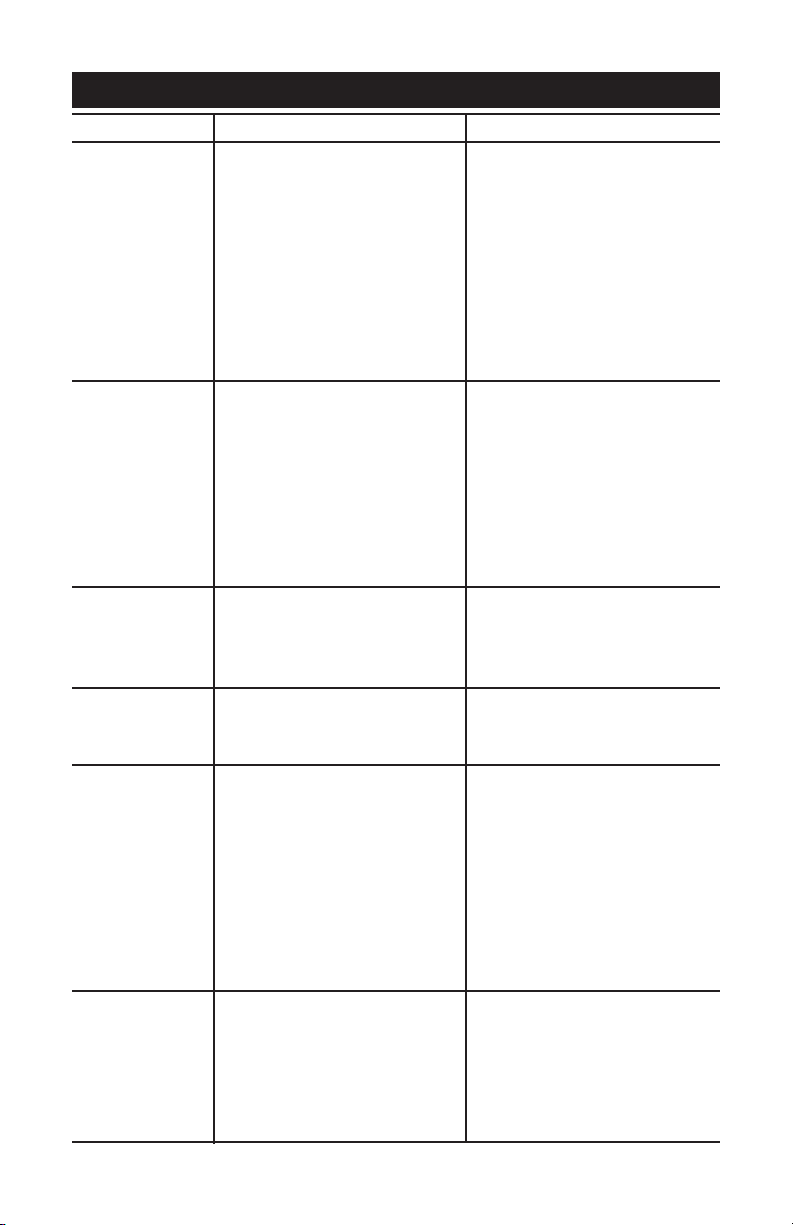

HOUSEHOLD WATTAGE CALCULATOR

DEVICES WITH HIGH STARTING (INDUCTIVE)LOADS

RUN WATTS

800

600

2400

1000

800 3

1000 2

TIMES (X) START FACTOR

x

x

x

x

3

3

3

2

x

x

CAUTION !!

DO NOT CONNECT VOLTAGE SENSITIVE

ELECTRONIC EQUIPMENT (TV SET, COMPUTER,

ETC.) DIRECTLY TO YOUR GENERATOR. IF YOU USE

THE GENERATOR TO POWER SENSITIVE EQUIPMENT

YOU MUST USE A U.L. LISTED VOLTAGE SURGE

PROTECTOR.

NOTICE: FAILURE TO USE A U.L. LISTED VOLTAGE

SURGE PROTECTOR WILL DAMAGE YOUR

EQUIPMENT AND VOID YOUR WARRANTY.

THE IDLE CONTROL MUST BE IN THE

OFF POSITION WHEN OPERATING

LARGE MOTOR LOADS (FREEZERS,

REFRIGERATORS,ETC.) OR VOLTAGE

SENSITIVE ELECTRONIC EQUIPMENT

(TV, COMPUTERS, ETC.)

*FOR PRODUCTS NOT

LISTED REFER TO

CALCULATION

INSTRUCTIONS

**AVERAGE VALUES -

ACTUAL INDIVIDUAL

DEVICE VOLTAGES MAY

BE HIGHER OR LOWER

LIGHTING

60 WATT BULBS

75 WATT BULBS

100 WATT BULBS

300 WATT BULBS

WATTAGE RATING OF YOUR GENERATOR

THIS TOTAL MUST BE GREATER THAN YOUR HOUSEHOLD WATTAGE LOAD

APPLIANCE OR

LOAD DEVICE*

REFRIGERATOR/

FREEZER

SMALL REFRIGERATOR

AIR COND.(ROOM)

SUMP PUMP 1/2 HP

FURNACE FAN 1/3 HP

WELL PUMP 1/2 HP

HOT PLATE

TELEVISION

MICROWAVE

SPACE HEATER

WATER HEATER

WATTS

60

75

100

300

TYPICAL DEVICE

WATTAGE**

=

2400

=

1800

=

7200

2000

=

=

2400

=

2000

=

1500

=

300

800

=

1500

=

4000

=

TIMES NUMBER

OF BULBS

x

x

x

x

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

ELECTRIC LOAD GRAND TOTAL

THIS TOTAL MUST BE LESS THAN YOUR GENERATOR RATING

TOTAL

CAUTION !!

Page 21

21- ENG

D26968

TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

CORRECTION

Engine will not

start

1. Low on fuel or oil.

2. Ignition switch in "Off"

position.

3. Faulty spark plug.

4. Choke in wrong position.

5. Fuel shut-off valve in

closed position

6. Unit loaded during start-

up.

1. Add fuel or oil.

2. Turn to "ON" position

3. Replace spark plug.

4. Adjust choke accordingly.

5. Open fuel shut-off valve.

6. Remove load from unit.

1. Faulty receptacle.

1. Have Service Center

replace.

2. Circuit breaker kicked

out.

2. Depress and reset.

3. Defective capacitor.

3. Have Service Center

replace capacitor.

4. Faulty power cord.

4. Repair or replace cord.

5. GFCI switch breaker

kicked out (if equipped)

5. Depress and reset

7. Spark plug wire loose.

7. Attach wire to spark plug.

No electrical

output

1. Overload

1. Reduce load.

2. Faulty cords or

equipment

2. Check for damaged, bare,

or frayed wires on

equipment. Replace.

Repeated

circuit breaker

tripping

1. Generator overloaded.

1. Reduce load.

2. Insufficient ventilation.

2. Move to adequate supply

of fresh air.

Generator

overheating

1. Faulty solenoid

1. Have Service Center

replace.

2. Faulty idle control switch

2. Have Service Center

replace.

3. Faulty windings in stator

4. Faulty circuit board

5. Faulty wire harness

3. Have Service Center

replace.

4. Have Service Center

replace.

5. Have Service Center

replace.

DC does not

have power

with the

circuit breaker

depressed

1. Faulty rectifier

2. Faulty windings in stator

3. Faulty wire harness

1. Have Service Center

replace.

2. Have Service Center

replace.

3. Have Service Center

replace.

No auto idle

Page 22

22- ENG

D26968

LIMITED WARRANTY

DeVilbiss Air Power Company warrants to the original purchaser who uses the product in a

consumer application (personal, residential or household usage) that all products covered under this

warranty are free from defects in material and workmanship for one year from the date of purchase.

All products covered by this limited warranty which are used in commercial applications (i.e., income

producing) are warranted to be free of defects in material and workmanship for 90 days from the date

of original purchase. Products covered under this warranty include air compressors, air tools, service

parts, pressure washers, and generators.

DeVilbiss Air Power Company will repair or replace, at DeVilbiss' option, products or components

which have failed within the warranty period. Service will be scheduled according to the normal work

flow and business hours at the service center location, and the availability of replacement parts. All

decisions of DeVilbiss Air Power Company with regard to this limited warranty shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

RESPONSIBILITY OF ORIGINAL PURCHASER (initial User):

• To process a warranty claim on this product, DO NOT return it to the retailer. The product must be

evaluated by an Authorized Warranty Service Center. For the location of the nearest Authorized

Warranty Service Center call 1-800-888-2468, Ext. 2, 24 hours a day, 7 days a week or visit our

web site @ devap.com.

• Retain original cash register sales receipt as proof of purchase for warranty work.

• Use reasonable care in the operation and maintenance of the product as described in the Owners

Manual(s).

• Deliver or ship the product to the nearest Authorized Warranty Service Center. Freight costs, if any,

must be paid by the purchaser.

• Air compressors with 60 and 80 gallon tanks will be inspected at the site of installation. Contact

the nearest Authorized Warranty Service Center that provides on-site service calls for service call

arrangements.

• If the purchaser does not receive satisfactory results from the Authorized Warranty Service Center,

the purchaser should contact DeVilbiss Air Power Company.

THIS WARRANTY DOES NOT COVER:

• Merchandise sold as reconditioned, used as rental equipment, or floor or display models.

• Merchandise that has become damaged or inoperative because of ordinary wear, misuse*, cold,

heat, rain, excessive humidity, freeze damage, use of improper chemicals, negligence, accident,

failure to operate the product in accordance with the instructions provided in the Owners Manual(s)

supplied with the product, improper maintenance, the use of accessories or attachments not

recommended by DeVilbiss Air Power Company, or unauthorized repair or alterations.

* An air compressor that pumps air more than 50% during a one hour period is considered

misuse because the air compressor is undersized for the required air demand.

• Repair and transportation costs of merchandise determined not to be defective.

• Costs associated with assembly, required oil, adjustments or other installation and start-up costs.

• Expendable parts or accessories supplied with the product which are expected to become

inoperative or unuseable after a reasonable period of use, including but not limited to sanding

disks or pads, saw and shear blades, grinding stones, springs, chisels, nozzles, o-rings, air jets,

washers and similar accessories.

• Merchandise sold by DeVilbiss Air Power Company which has been manufactured by and identified

as the product of another company, such as gasoline engines. The product manufacturer's

warranty, if any, will apply.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT

MAY RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT IS NOT

COVERED BY THIS WARRANTY. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

• IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL

PURCHASE. Some states do not allow limitations on how long an implied warranty lasts, so the

above limitations may not apply to you.

213 Industrial Drive • Jackson, TN 38301-9615

Telephone: 1-800-888-2468 , Ext. 2

FAX: 1-800-888-9036

Page 23

23- ENG

D26968

NOTES

Page 24

24- ENG

D26968

QUICK FACTS

ALWAYS REFER TO THE MANUALS SUPPLIED WITH THIS UNIT

ENGINE

GAS

ENGINE OIL

WATTAGE

WIRING

BATTERY

VOLT REG.

ENGINE

STORAGE

OPERATION

Use clean, fresh gasoline with a minimum 87 octane rating. Do

not add gasoline during or immediately after use.

Refer to engine owner's manual for oil recommendations.

Most generators are equipped with a low-oil shutdown. If the oil

is low or if the Generator is not level, the engine will not start.

Make wattage calculations before use. Refer to general

operator's manual for further instructions.

Contact an electrician for any wiring instructions. If wiring into a

house, a double-throw transfer switch and a heavy duty cord

set must be used.

Use a standard (12V) lawn and garden battery with a minimum

of 45 A.H. or 210 CCA.

The voltage and frequency are regulated by the rpm's of the

engine. Do not adjust the throttle or governor to achieve higher

performance. This will only alter the factory Pre-set settings

and damage anything connected to the generator.

Be sure a volt/amp surge protector is used when sensitive

electronic equipment is used, such as: televisions, computers,

stereos, and etc… The damage of such equipment without the

use of a protector WILL NOT be covered under warranty.

Do not adjust or attempt maintenance without consulting engine

manual or an authorized engine service center.

Add stabilizer to fuel tank and run engine for 5 minutes before

storage.

When in long term storage, operate the generator every 60 days

for at least 10 minutes with a load on it. This will prevent the

loss of residual magnetism that produces the electricity.

Allow the generator to run 5 minutes at no load for the engine

and the gen head to stabilize.

Make sure the adequate size of extension cord is used. Refer to

the Grounding Instructions/Extension Cord section of the

owners manual.

If the generator is operating equipment that is drawing half of

the rated watts it is considered 50% load. Using all of the rated

watts is considered 100% load.

CALL 1-800-888-2468 EXT 2

TO FIND A LOCAL AUTHORIZED SERVICE CENTER NEAR YOU FOR REPAIRS

AND SERVICE PART PURCHACES

.

Page 25

Registre toda la información para

referencias futuras:

Marca:

Fecha de compra:

Modelo N°

N° de serie

¿Consultas? 1-800-888-2468

Registre su producto en línea en:

www.devap.com

INFORMACIÓN PARA EL CONSUMIDOR . .26

INFORMACIÓN DE SEGURIDAD PARA EL

CONSUMIDOR . . . . . . . . . . . . . . . . . . . . . . . .26

NORMAS DE SEGURIDAD /

DEFINICIONES.. . . . . . . . . . . . . . . . . . . . . . .. 27

IMPORTANTES INSTRUCCIONES DE

SEGURIDAD. . . . . . . . . . . . . . . . . . . . . . . .27-32

INSTALACIÓN . . . . . . . . . . . . . . . . . . . . . ..32-37

INSTRUCCIONES PARA OPERAR . . . . . . .37-40

PROGRAMA DE MANTENIMIENTO . . . .40-41

ALMACENAJE . . . . . . . . . . . . . . . . . . . . . .41-42

INSTRUCCIONES PARA CALCULAR LE

DEMANDA DE POTENCIA . . . . . . . . . . . .42-44

GUÍA DE ANÁLISIS DE PROBLEMAS . . . . .45

GARANTÍA . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

INFORMACION RAPIDA SOBRE

GENERADORES . . . . . . . . . . . . . . . . . . . . . . .48

ENGLISH . . . . . . . . . . . . . . . . . . . . . . . . . . .1-24

FRANÇAISE . . . . . . . . . . . . . . . . . . . . . . . .49-72

LEA Y CONSERVE ESTAS INSTRUCCIONES

Generador

Manual del operador

N° de Pieza D26968 Rev. 0

Page 26

26- SP

D26968

INFORMACIÓN DE SEGURIDAD PARA EL CONSUMIDOR

INFORMACIÓN GENERAL Y DE SERVICIO

NO DEVUELVA ESTE PRODUCTO AL VENDEDOR! PARA OPCIONES DE SERVICIO

LLAME AL 1-800-888-2468, EXT. 2

•¡Sírvase leer y seguir esas instrucciones para el mantenimiento y uso adecuado.

• Tómese un momento ahora para registrar en línea, su generador, en: www.devap.com

• Si experimentara cualquier problema y necesitase asistencia, sírvase llamarnos a nuestro

número telefónico gratuito. 1-800-888-2468 Lunes a sábado entre las 8:00 y las 18:00 hs.

horario central (C.S.T.)

• En caso de requerir el servicio de compra de piezas, nuestros Servicentros autorizados

se encuentran cómodamente ubicados y equipados para ocuparse de todos los

aspectos del servicio correspondientes a la cobertura de su garantía, o para prestarle

servicio si estuviese fuera de ella.

• Para informarse de la ubicación del Servicentro autorizado màs cercano para la atención de

garantías, sírvase llamar al: 1-800-888-2468, Ext 2 durante las 24 hs del día, 7 días a la

semana, o visitar nuestro sitio web @ devap.com.

• Retenga el recibo de venta como prueba de compra para el servicio de garantía.

• Lea y comprenda todas las advertencias de seguridad.

• No opere esta unidad hasta haber leído y comprendido el Manual del propietario para

informarse de las instrucciones de seguridad, operación y mantenimiento.

• No opere esta unidad hasta haber leído y comprendido las instrucciones de seguridad,

operación y mantenimiento del manual del propietario del motor.

Este producto podría no estar equipado con silenciador

apagachispas. Si el producto no estuviese equipado con ello, y

fuera instalado en las cercanías de materiales inflamables, o sobre una superficie cubierta

con materiales tales como restos agriculturales, restos derivados de la forestación,

maleza, u otros ítems similares, en dichas circunstancias deberá instalarse un silenciador

apagachispas, el cual es legalmente requerido por el Estado de California. Resulta una

violación a los estatutos de California, sección 130050 y / o secciones 4442 y 4443 del

Código de recursos Públicos de California, a menos que el motor se encuentre equipado

con un apagachispas, tal como se lo define en la sección 4442, y mantenido en perfecto

estado de funcionamiento. Los apagachispas también son requeridos por el Servicio

Forestal de EE.UU., y podrían ser requeridos legalmente bajo otros estatutos y

ordenanzas.

El escape del motor contiene productos químicos conocidos,

que - en ciertas cantidades - pueden ser causales de cáncer,

defectos de nacimiento u otros daños de gestación.

Lea el Manual del operador . Para su seguridad, armado,

operación, e instrucciones de mantenimiento, no operar el

equipo hasta haber leído el Manual del operador.

Nota: Las fotografías y dibujos utilizados en este manual son solamente para

referencia y no representan ningún modelo en particular.

Page 27

27- SP

D26968

RIESGO DE INCENDIO Y ELECTROCUCIÓN

Intentar conectar el

generador

directamente al

sistema eléctrico de

una edificación.

La alimentación de electricidad por el

sistema eléctrico instalado en la

edificación desde el punto de

entrada del suministro eléctrico

externo podría poner en peligro al

personal de la compañía de servicios

eléctricos que esté tratando de

restaurar el servicio.

Nunca retroalimentar electricidad a

las líneas externas de suministro a

través del sistema eléctrico.

Intentar conectar el generador

directamente a la entrada de la

corriente eléctrica proveniente del

servicio público podría resultar en

electrocución.

De no haber un interruptor aislante

instalado, el restablecimiento del

servicio eléctrico mientras que el

generador esté conectado al servicio

público puede resultar en incendio o

serios daños.

El inclumplimiento en usar el

interruptor de doble transferencia, al

efectuar conexiones a sistemas de

estructuras eléctricas, puede dañar

los artefactos y CANCELARA la

garantía de los fabricantes.

Para conectar el generador al sistema

eléctrico de una edificación en forma

segura, un electricista calificado debe

de instalar un interruptor de

transferencia de doble hoja y cumplir

con todas las ordenanzas locales.

(Cuando se instale un interruptor de

transferencia de doble hoja, es

necesario usar un alambre de

calibre 10 como mínimo.)

Indica una situación de inminente riesgo, la cual, si no es evitada, causará la

muerte o lesiones serias.

Indica una situación potencialmente riesgosa, que si no es evitada,

podría

resultar en la muerte o lesiones serias.

Indica una situación potencialmente peligrosa, la cual, si no es evitada,

podría resultar en lesiones menores o moderadas.

Usado sin el símbolo de seguridad de alerta indica una situación

potencialmente riesgosa la que, si no es evitada, podría

causar daños

en la propiedad.

Este manual contiene información que es importante para que usted sepa y comprenda. Esta

información se relaciona con la protección de SU SEGURIDAD y la PREVENCIÓN DE

PROBLEMAS AL EQUIPO. Para ayudarle a identificar esta información, utilizamos los símbolos

indicados mas abajo. Sírvase leer el manual y prestar atención a los mismos

.

PAUTAS DE SEGURIDAD/DEFINICIONES

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

La operación o el mantenimiento inadecuados de este producto

podría causar serias lesiones y daños a la propiedad. Lea y

comprenda todas las advertencias e instrucciones operativas

antes de su uso.

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

Page 28

28- SP

D26968

Operación del

generador bajo

lluvia, condiciones

de inundación, hielo

o estando mojado.

¡El agua es un excelente conductor

de la electricidad! El agua que entra

en contacto con componentes

cargados eléctricamente, puede

transmitir electricidad al armazón y

otras superficies, resultando en la

electrocución de cualquier persona

que esté en contacto con ellos.

Operar el generador en un área limpia

y bien ventilada. Asegurarse de tener

las manos secas antes de tocar la

unidad.

RIESGO DE INCENDIO Y ELECTROCUCIÓN

(continuación)

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

El contacto con cordones de

extensión gastados o dañados puede

resultar en electrocución.

El uso de cordones de extensión

subdimensionados puede resultar en

el sobrecalentamiento de los cables

o dispositivos conectados al

generador, causando un incendio.

El uso de cordones sin conexión a

tierra puede impedir la operación de

los interruptores de circuito y resultar

en choque eléctrico.

Inspeccionar los cordones de

extensión antes de usarlos y

remplazarlos por nuevos si fuese

necesario.

Usar cables del diámetro (calibre)

apropiado para la aplicación. Ver la

tabla de aplicaciones en la sección

Ensamblaje de este manual.

Use siempre un juego de cables con

conexión a tierra. NO LO UTILICE con

un enchufe sin conexión a tierra.

Uso de cordones

de extensión

dañados,gastados,

subdimensionados

o sin conexión a

tierra.

Colocando el

generador sobre o

contra superficies

altamente

conductivas, tales

como pasillos o

techos de metal.

Conexión

inapropiada de

dispositivos al

generador.

Operación de la

unidad cuando está

dañada o sin los

paneles de

protección.

La fuga accidental de corriente

eléctrica puede cargar superficies

conductoras que estén en contacto

con el generador.

Exceder la capacidad de carga del

generador, conectándole demasiados

artefactos o artefactos que requieren

demasiada potencia; pueden causar

el sobrecalentamiento de ciertos

dispositivos o de su cableado,

causando un incendio o choque

eléctrico.

Intentar usar la unidad cuando está

dañada o cuando no esté

funcionando normalmente, puede

causar un incendio o electroución.

Retirar los paneles protectores

puede exponer componentes

eléctricos y resultar en electrocución.

Colocar el generador en una

superficie de poca conductividad,

tal como una placa de concreto.

Opere SIEMPRE el generador a una

distancia mínima de 1,80 m de

cualquier superficie conductiva.

Leer la tabla de cargas eléctricas e

instrucciones en la sección Cálculo

de Watts. Asegurarse que la suma de

las cargas eléctricas de todos los

artefactos conectados, no exceda la

potencia del generador.

No operar el generador si tuviese

algún problema eléctrico o mecánico.

Hacer reparar la unidad en un Centro

de Servicio Autorizado.

No operar la unidad sin los paneles

de protección en su lugar.

Page 29

29- SP

D26968

RIESGO DE INCENDIO

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

Intentar llenar el

tanque de combustible mientras

el motor está en

funcionamiento.

Chispas, fuego,

objetos calientes

Almacenaje

inapropiado del

combustible.

Ventilación

inadecuada del

generador.

Alterar las

velocidades del

motor prefijadas

en fábrica.

Sobrellenando el

tanque - derrame

del combustible.

La gasolina y los vapores de

gasolina pueden encenderse si

entran en contacto con

componentes calientes tales como

el tubo de escape, gases calientes

salidos de la máquina o chispas

eléctricas.

Los cigarrillos, chispas, fuego u

otros objetos calientes pueden hacer

que la gasolina o los vapores de la

gasolina se enciendan.

El combustible mal almacenado

puede conducir a incendios

accidentales. El combustible

inadecuadamente almacenado

puede llegar a las manos de los

niños o de otras personas no

calificadas.

Los materiales colocados contra el

generador o cerca de éste pueden

interferir con sus dispositivos de

ventilación causando

sobrecalentamiento y posible

encendido de esos materiales. El

regenerador puede sobrecalentarse

si es que se opera en áreas donde la

temperatura ambiental exceda 40°C

(104°F).

La velocidad del motor ha sido fijada

en fábrica para proveer una

operación segura. Alterar la

regulación de la velocidad del motor

puede sobrecalentar los artefactos

conectados y puede causar un

incendio.

El combustible derramado y sus

vapores pueden encenderse por

contacto con superficies calientes o

chispas.

Apagar el motor y permitir que se

enfríe antes de agregar combustible al

tanque. Equipar el área de operación

con un extinguidor de fuegos

certificado para controlar incendios de

gasolina o combustibles.

Agregar gasolina al tanque en áreas

bien ventiladas. Asegurarse que no

haya fuentes de encendido cerca del

generador.

Almacenar la gasolina en un envase

designado para contener gasolina.

Almacenar el envase en lugar seguro

para evitar que otras personas lo

usen.

Operar el generador en un área limpia,

seca, bien ventilada y colocarlo a una

distancia mínima 1,22m (4’) respecto

a cualquier objeto o pared. NO

OPERAR LA UNIDAD EN ESPACIOS

CERRADOS O EN ÁREAS

CONFINADAS.

Nunca intentar “acelerar” el motor

para obtener mayor rendimiento.

Tanto el voltaje de salida como la

frecuencia podrían alterarse, poniendo

en peligro al usuario y a los artefactos

conectados.

Tenga cuidado al llenar el tanque,

evitando derramar combustible.

Asegúrese de colocar la tapa,

asegurarla y verificar el motor por

eventuales pérdidas de combustible

antes de arrancar el motor. Traslade el

generador fuera del área de

reaprovisionamiento de combustible o

de cualquier derramamiento antes de

arrancar el motor. Permita la

expansión del combustible. Mantenga

un máximo nivel de combustible

12,7mm (1/2") por debajo del borde

del tanque de combistible. Jamás

reaprovisione combustible con el

motor en marcha.

Page 30

30- SP

D26968

RIESGO DE OPERACIÓN INSEGURA

RIESGO DE INHALACIÓN PELIGRO PARA LA

RESPIRACIÓN

RIESGO DE LESIONES PERSONALES Y DAÑOS A LA

PROPIEDAD AL TRANSPORTAR EL GENERADOR

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

Incendio,

Inhalación, daños a

las superficies del

vehículo

Las fugas o derrames de los envases

de combustible o aceite pueden

generar riesgos de incendio o a la

respiración, lesiones personales serias

o muerte. Las fugas o derrames de

combustible o aceite dañarán la

alfombra, la pintura y otras superficies

de los vehículos o remolques.

Si la unidad está equipada con una

válvula de cierre de combustible,

mover la válvula a la posición de

“OFF” (Cerrado) cuando se transporte

para evitar fugas de combustible. Si el

generador no estuviese equipado con

una válvula de cierre de combustible,

drenar el combustible del tanque

antes de transportar la unidad.

Transportar combutible únicamente en

envases aprobados por OSHA. Al

transportar el generador, siempre

colocar una alfombrilla protectora

para evitar daños al vehículo por las

fugas. Retirar el generador del

vehículo inmediatamente después de

arribar al lugar de destino.

Los motores a

gasolina producen

gases tóxicos de

escape de

monóxido de

carbono.

Respirar los gases del escape puede

causar daños serios o muerte.

Operar el generador en un área limpia,

seca y bien ventilada. Evitar las áreas

cerradas como los garajes, sótanos,

bodegas, etc. que puedan carecer de

renovación de aire. Nunca operar la

unidad en lugares ocupados por seres

humanos ni animales. Mantener a las

mascotas y niños alejados del área de

operación.

Operación

descuidada del

generador.

Todas las fuentes de energía

conllevan un potencial de riesgo. La

operación del generador sin las

debidas precauciones de seguridad

puede causar lesiones o muerte al

operador o a otras personas.

• Revisar y entender todas las

instrucciones de operación y

advertencias de este manual.

• Familiarizarse con la operación, y

los controles del generador.

Aprender a apagarlo

rápidamente.

• Equipar el área de operación con

un extinguidor de fuegos

certificado para apagar incendios

de gasolina o combustibles.

• Mantener a los niños alejados del

generador en todo momento.

Page 31

31- SP

D26968

RIESGO DE OPERACIÓN INSEGURA

(continuación)

La elevación o su suspensión

inadecuados pueden causarle daño al

generador.

Para levantar o suspender el

generador utilice siempre cables,

cadenas, o cintas estipuladas para

una carga de 907 kg (2000 lbs) o

mayor.

Operación de

equipos sensibles

a las fluctuaciones

de voltaje sin usar

un protector

contra

sobretensiones.

Cualquier generador doméstico a

gasolina incurrirá en fluctuaciones de

voltaje que pueden dañar artefactos

sensibles a las fluctuaciones de

voltaje o causar un incendio.

Siempre usar un protector contra

sobretensiones adecuado para

conectar artefactos sensibles a las

sobretensiones (Televisores,

computadoras, equipos de sonido,

etc.) No usar un protector contra

sobretensiones adecuado,

invalidará la garantía del

generador.

NOTA: Una barra de tomacorrientes

múltiples no es un protector contra

sobretensiones, asegurarse de usar

un protector contra fluctuaciones de

voltaje aprobado.

Levantando o

suspendiendo en

forma

inadecuada los

equipos

generadores con

anillas de

elevación.

El generador puede caer causándole

serias lesiones o la muerte de otros.

Al conectar cables, cadenas o cintas

para elevación o la suspensión de

generadores equipados con anillas

para levantarlos, utilice siempre los

procedimientos de conexión

adecuados, tales como los

descriptos en este manual

Generador en

funcionamiento

mientras se

encuentra

suspendido.

El generador no operará en forma

adecuada; además sufrirá daños, y

puede causarle serias lesiones o la

muerte a usted u otras personas.

Jamás opere el generador mientras

está suspendido o en una posición

desnivelada. Opere siempre el

generador sobre una superficie plana

y nivelada.

RIESGO DE SUPERFICIES CALIENTES

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

Durante la operación del generador

sólo tocar las superficies de control.

Mantener a los niños alejados del

generador en todo momento. Ellos

pueden no conocer los riesgos de

esta máquina.

El contacto con superficies calientes,

tal como los componentes del tubo

de escape, puede causar

quemaduras serias.

Contacto con

componentes

calientes del motor

y generador.

Page 32

32- SP

D26968

NOTA: Éste es un manual general. La información contenida aquí podría no

corresponder al modelo que usted ha comprado. Leer el manual cuidadosamente.

NOTA: Izquierda y derecha describen la ubicación de una parte a la que el operador

debe acceder desde el panel de salida.

INSTALACIÓN

Leer este manual. No intentar operar el equipo hasta haber

leído las instrucciones de seguridad, operación y

mantenimiento de este manual.

RIESGO DE PIEZAS MOVIBLES

Nunca operar el generador sin sus

paneles protectores. Evitar usar ropa

suelta o joyas que pueda atraparse en

las piezas movibles.

El generador tiene piezas que giran a

alta velocidad durante su operación.

Estas piezas están cubiertas por

paneles protectores para evitar

lesiones.

El contacto con

piezas movibles

puede resultar en

lesiones serias.

RIESGO AL LEVANTAR

El generador es muy pesado para ser

levantado por una sola persona,

conseguir ayuda de otros antes de

intentar moverlo por uno mismo.

El intentar levantar un objeto muy

pesado puede causar lesiones serias.

Levantando un

objeto muy

pesado.

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

RIESGO

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

DESEMBALAJE

1. Ubique la caja con partes y póngala aparte

para utilizarla más tarde.

2. Corte las ataduras de alambre que sujetan

el generador a su plataforma y retire su

envoltura de protección.

3. Extraiga todos los elementos de embalaje,

dejando solo al generador sobre la

plataforma.

4. Descarte todo el embalaje.

IMPORTANTE: NO remueva al generador de

su plataforma

Atadura de alambre

Envoltura de

protección

Page 33

33- SP

D26968

ENSAMBLADO DEL JUEGO DE RUEDAS

Herramientas requeridas:

2 - Tirante 2 x 4 de una longitud mínima de 76 cm (30")

1 - Llave de tubo de 1/2"

1 - Llave de extremo abierto de 1/2"

1 - Martillo

1 - Alicates

Partes contenidas en la bolsa:

2 - Manijas agarraderas

2 - Tapones para extremo de manija

4 - Tornillos .313-18x1.75

1 - Perno chavetero

2 - Arandelas, 5/8"X1.32X.09

1 - Arandelas plana de acero

2 - Espaciadores del eje

2 - Tornillos de cabeza cubierta 5/16-18X3/4

6 - Tuercas con pestañas

2 - Soportes de ruedas

1 - Sombrerete del eje de 5/8"

1. Levante el extremo del tanque de

combustible del generador y deslice un

tirante de 2x4 entre el generador y la

plataforma tal como se muestra.

El generador es

demasiado pesado

para ser levantado por una sola persona.

Obtenga ayuda ajena antes de levantarlo.

2. Coloque las agarraderas de las manijas sobre las

mismas.

3. Coloque una arandela de 5/8" en la base de cada

tapón de extremo. Presione los tapones en el extremo

de las manijas.

Tirante

de 2x4

Tanque de

combustible

Agarradera de

la manija

Ta pón del

extremo

Arandela de 5/8"

Manija

Page 34

34- SP

D26968

4. Una las manijas al bastidor utilizando cuatro

tornillos y tuercas con pestañas. NOTA:

Atornille desde el exterior del bastidor.

NOTA: No ajuste hasta que todos los tornillos y

tuercas con pestaña hayan sido ensamblados.