Page 1

SERVICE MANUAL

RITE-TORQ OVERLOAD CLUTCHES

(TORQUE LIMITERS)

SOLUTIONS IN MOTION™

WARNING

This is a controlled document. It is your responsibility to deliver this information to the end user of the

CAMCO/FERGUSON product. Failure to deliver this could result in your liability for injury to the user or damage

to the machine. For copies of this manual call your Customer Service Representative 800-645-5207

Page 2

TABLE OF CONTENTS

General Information...........................................................................................3

Safety.........................................................................................................3

Operating Environment..............................................................................3

Application Recommendations..................................................................4

Requesting Service....................................................................................4

Overview............................................................................................................5

Location Map – RT & RTM Series.............................................................6

Location Map - RTL Series........................................................................7

Specifications.....................................................................................................8

Installation.........................................................................................................9

RT & RTM Series.......................................................................................9

RTL & RTL-FCB Series............................................................................10

Adjustments.....................................................................................................12

RT & RTM Series.....................................................................................12

Spring Sets for RT Clutches................................................................................13

RTL & RTL-FCB Series............................................................................14

Maintenance....................................................................................................15

2

Page 3

General Information

The FERGUSON Torque Limiter is a high quality, precision mechanism. To gain the optimum benefits, the

guidelines described in this manual should be used.

Safety

Read and follow all Warnings and Cautions prior to any service or repair.

1. Read your Overload Clutch Installation-Operation Instructions thoroughly before operating the unit,

for your safety and the protection of your unit.

2. FERGUSON Overload Clutches are designed to protect the Index Drive only and will not protect

against bodily injury.

3. Double check to be sure the power is off and cannot be turned on while working on the equipment.

4. Use extreme caution with jammed or unbalanced loads, which when cleared may set the machine in

motion.

5. Keep all objects such as hands, clothing, and tools away from rotating or moving parts.

6. Use safety glasses or equivalent to protect your eyes.

7. Dowel pins and mounting screws must not protrude from the drive plate or driven member, as the

clutch could become a solid coupling.

8. High humidity, contaminants, or wash down applications may cause rust within the clutch, resulting in

operational failure. Lubricate every six months or more frequently as the application requires.

9. The FERGUSON clutch is not a "FAIL SAFE" device and cannot be used on "overhauling" or

"holding" load applications.

10. When using chain drives, incorporate an idler sprocket to eliminate any slack.

NOTE: The above list includes major safety points to be observed, but should not be

considered as limiting in safety precautions to be followed.

NOTE: In the event the unit is damaged, contact Industrial Motion Control’s Wheeling

factory or your local representative, for replacement.

Operating Environment

This product is intended to operate in a clean environment. Excessive coolant, chips, dust, dirt or debris

can adversely affect its performance and life. If this device does operate in a dirty environment periodic

cleaning must be practiced and careful inspection of seals and accessories is necessary.

3

Page 4

Application Recommendations

1. On applications other than the output of an IMC Index Drive, clutch speeds must not exceed 100

RPM.

2. High humidity, contaminants, or wash down applications may require special protection. If rust forms

within the clutch, it may act as a solid coupling and will not release under overload conditions.

Lubricate every six months or more frequently as the application requires.

3. Use bronze bushings on sprockets, dials, gears or pulleys when used at the high end of the speed

range (100 RPM) to reduce wear.

4. Clutch couplings require accurate shaft alignment of .003" TIR. Insure that a clearance gap is

maintained between the body and the drive plate around the full circumference to the clutch (Type

RT S/S).

5. Use flange mounted clutches and clutch couplings whenever possible. These models provide

superior mounting reliability (Type RT F/F or D).

6. Dowel pins should not protrude from the drive plate or driven members, as they may lock against the

adjacent surface.

7. Do not operate without the detector limit switch electrically disconnecting the prime mover (motor),

as galling of the contacting surfaces may result.

8. On high inertia applications, braking the prime mover is recommended in the dwell cycle of the

INDEX DRIVE to minimize over travel.

9. IMC recommends using limit switches with rated travel not exceeding .008" for actuation.

10. The torque required to re-engage the clutch is usually 25% of the rating. Contact IMC for special

design, anti-friction materials if the clutch is to be used with very low torque settings.

11. Never use the clutch with a torque setting close to the calculated operating torque. Actual torques

may be higher. Torque spring tolerances and coefficients of friction vary with temperature and

application. Allow 130% (1.3 service factor) when applying a FERGUSON clutch.

Requesting Service

Call our Technical Service Department in Wheeling, IL, USA at 800-645-5207 or 847-459-5200 between

8:00AM and 4:30PM CST. When requesting service, always provide the following information:

1. The model number of the torque limiter.

2. A clear description of the problem, including as much detail as possible of the circumstances leading

up to the problem.

4

Page 5

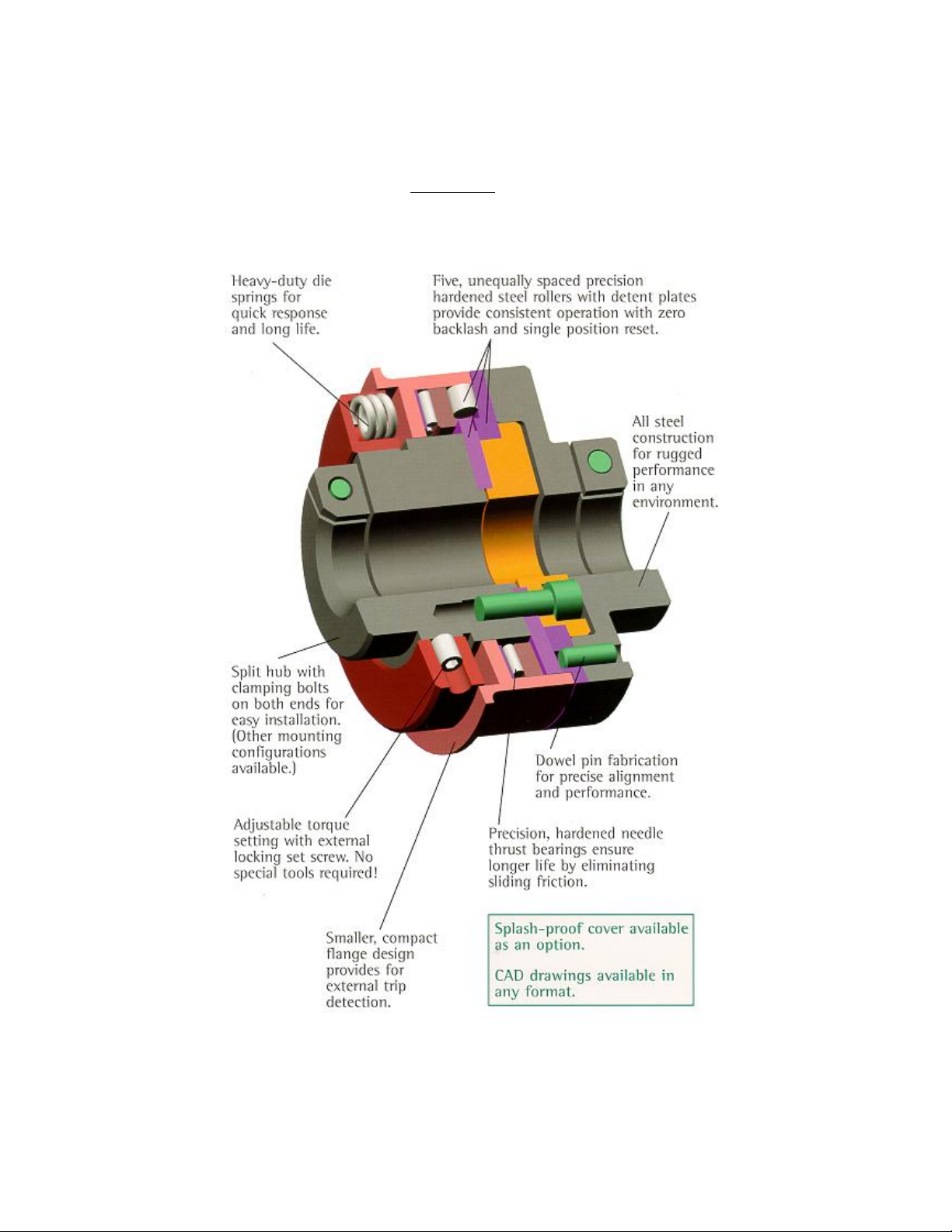

Overview

The drawings contained in this document are for illustrative purposes only. They are not intended to accurately

represent the components and therefore are not to scale. The various models may be different than shown,

depending upon options chosen or the particular configuration.

FIGURE 1

5

Page 6

Location Map – RT & RTM Series

ITEM PART NAME

1 CLUTCH HOUSING – SPLIT CLAMP FOR SHAFT

2 CLUTCH HOUSING – PILOT FOR FLANGE MTG

3 CLAMP SCREW

4 TORQUE ADJUSTING RING NUT

5 LOCKING SET SCREW

6 SPRINGS

7 PRESSURE/TRIP DETECTION RING

8 THRUST RACE – THIN

9 THRUST BEARING

10 THRUST RACE – THICK

11 ROLLER

12 DETENT PLATE SET

13 DOWEL PIN – CLUTCH

14 SCREW – CLUTCH

15 DOWEL PIN – COUPLING

16 SCREW – COUPLING

17 RETAINER

18 COUPLING

19 CLAMP SCREW

S/S S/F F/S F/F

ü ü

ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü ü ü ü

ü

ü

ü ü ü ü

ü

ü

CLUTCH TYPE

ü ü

ü

ü

ü

ü

6

Page 7

Location Map - RTL Series

FIGURE 2

Rite-Torq Number

5 20 60 120

Item No. Part Name Part Number

1 Housing Body 51 201 601 1201

2 End Plate 52 202 602 1202

3 Pressure Ring 53 203 603 1203

4 Actuator Plate 54 204 604 1204

5 Spacer Stud 55 205 605 1205

6 Torque Adj. Screw 56 206 606 1206

7 Locking Nut 57 207 607 1207

8 Thrust Washer 58 208 608 1208

9 Hub 59 209 609 1209

10 Spring 510 2010 6010 12010

11 Needle Bearing 511 2011 6011 12011

12 Thrust Bearing 512 2012 6012 12012

13 Thrust Race 513 2013 6013 12013

14 Oil Seal 514 2014 6014 12014

15 “O” Ring 515 2015 6015 12015

16 Ball 516 2016 6016 12016

17 Locknut 517 2017 6017 12017

18 Hex Head Bolt 518 2018 6018 12018

19 Lock Washer 519 2019 6019 12019

20 Set Screw 520 2020 6020 12020

CHART 1

7

Page 8

Specifications

Model Bore Sizes

RT-3

RTM-3

RT-5

.750-1.250

RTM-5

RT-6

1.000-2.000

RTM-6

RT-8

1.500-2.750

RTM-8

(in.)

(mm)

.500-.750

11,0-19,0

16,0-32,0

25,0-50,0

38,0-63,0

Trip Torque

Range

(in-lb)

(Nm)

100-500

11,3-56,5

500-3500

56,5-339,1

2000-8500

113,0-960,7

2500-12000

452,1-1751,8

Approximate

Weight

(less crating)

(lb)

(kg)

4-6

2-3

13-16

5,9-7,3

28-37

12,7-16,8

51-72

1-32,7

Polar Moment

of Inertia

(lb-in-sec2)

(kgm2)

.019-.024

0,003-0,003

.111-.141

0,013-0,016

.322-.441

0,036-0,05

1.19-1.68

0,130-0,190

Maximum

RPM (See

Installation

Section)

N/A

N/A

N/A

N/A

Limit

Switch

Travel

(in.)

(mm)

0.06

1,5

0.08

1,7

0.09

2,4

0.11

2,9

(in) (in-lb) (lb) (lb-in-sec2)

RTL-5

RTL-5FCB

RTL-20

RTL-20FCB

RTL-60

RTL-60FCB

RTL-120

RTL-120FCB

.750-1.250

(same)

1.00-1.750

(same)

1.000-2.250

(same)

1.500-2.750

(same)

100-150

(same)

400-2000

(same)

1200-6000

(same)

2400-12000

(same)

11

17

20

33

33

60

56

97

.085

0,140

.250

0,437

.624

1,154

1.327

2,500

1800 .073

1200 .092

900 .110

600 .146

(in.)

CHART 2

8

Page 9

Installation

NOTE: Ferguson detent style torque limiters are single positioning, and will re-engage on each

revolution. Avoid continuous tripping as it will cause serious damage to the mechanisms.

NOTE: Use of a limit switch (mechanical or proximity) provided by the user is required to shut down the

power after the initial trip. Ferguson torque limiters are provided with a switch actuating plate or flange

to detect the axial tripping movement. IMC recommends using limit switches with rated travel not to

exceed .008” for actuation.

WARNING:

TORQUE LIMITERS:

• ARE NOT TO BE USED AS A SAFETY DEVICE.

• ARE NOT MEANT TO PROTECT TOOLING.

• SHOULD NOT BE USED FOR OVERHAULING OR LIFTING LOADS SUCH AS VERTICAL CONVEYORS

OR TRUNNION-TYPE FIXTURING.

• SHOULD NOT BE OPERATED MOTOR SPEEDS.

• IF PROPERLY SET, WILL PROTECT THE INTERNAL MECHANISM OF THE INDEX DRIVE.

RT & RTM Series

NOTE: Clutch torque is preset at the factory for application, if known, or the users

request. Final adjustment is required by the user after the load is applied. Adjustment

procedures can be found on page 13 of this manual.

1. RT & RTM Series torque limiters do not have flexible couplings. For shaft/shaft models it is

2. Fit and install key(s) into shaft keyway(s) and hand apply a light coat of anti-seize compound

3. Loosen bolt in clamping hub(s) and slide torque limiter onto driving shaft to required depth.

4. Assemble sprockets, pulleys, etc. onto flange side of shaft/flange or flange/flange torque

necessary to align mating shafts before installation of clutches. Use a dial indicator or

similar instrument.

to shaft surface. (Never Seize® is a brand of such product.)

Tighten bolt in clamp hub securely. Either end of shaft/shaft clutches can be installed on

driving shaft. Slide driven shaft into clutch and tighten bolt in clamping hub securely.

limiter using tapped holes and dowel holes provided by Ferguson. Torque limiter should be

assembled to slow speed shaft of reducers, indexers, etc. for greatest sensitivity. Slide

clutch onto shaft with sprocket side as close as possible to bearing in reducer, etc. Tighten

bolt in clamping hub securely.

5. Mount and adjust limit switch into proper position with clutch trip flange.

6. Turn on power and inspect.

9

Page 10

RTL & RTL-FCB Series

NOTE: Steps 1-8 apply to RTL-FCB type clutch.

1. RTL-FCB (shaft/shaft) torque limiters are furnished with a flexible coupling to tolerate

moderate angular and/or parallel misalignment. The maximum acceptable angular

misalignment is 0.5 degree and maximum acceptable parallel offset is 0.005”.

2. Determine angular alignment by checking the gap between the coupling and the torque

limiter with a ruler, caliper or gauge. The gap should be even all around but not exceed 0.5

degree, as previously mentioned (see Figure 3).

3. Determine parallel alignment by use of a straight edge or indicator. A straight edge should

lie evenly on both members but not to exceed .005” (see Figure 4).

4. Fit key into shaft keyways and hand apply thin coat of anti-seize compound.

5. NOTE: Torque limiter and coupling with maximum bores have shallow keyways.

6. Separate torque limiter & coupling hub by pulling or prying apart (FCB Series only).

7. Mount the torque limiter to the driving or driven shaft on the slow speed side of the reducer

and secure it by tightening the two set screws. The use of Loctite 242 or similar adhesive

on the set screws is recommended.

8. Slide the coupling hub onto the shaft to be connected. Align the studs on the torque limiter

and hub with the holes in the elastomer bushings (Figure 6) in the opposing members and

slide the hub towards the torque limiter until the members are seated together. Align the

shafts per the above tolerances and tighten the coupling hub to the shaft using the furnished

standard QD type bushing.

NOTE: Steps 9-10 apply to basic RTL-type clutch.

9. Assemble the sprocket, pulley, etc. to the torque limiter using the tapped holes provided by

Industrial Motion Control.

CAUTION: SCREW THREAD DEPTH MUST NOT EXCEED THAT LISTED IN CHART 3.

IMPERIAL INSTALLATION SPECIFICATIONS

Model MIN. MAX RPM Travel Thread* B.C. NO. Pilot Dia. Bore

5 100 500 1800 .073 IN. ¼-20X5/8 dp. 3.750 IN. 4 2.500 1.250 IN.

20 400 2000 1200 .092 IN. ¼-20X3/4 dp. 4.875 IN. 6 3.375 1.750 IN.

60 1200 6000 900 .110 IN. 5/16-18X3/4 dp. 6.000 IN. 6 4.000 2.250 IN.

120 2400 12000 600 .146 IN. 3/8-16X1 dp. 7.000 IN. 6 4.750 2.750 IN.

Trip Torque

(IN-LBS)

Max.

Actuator

Plate

Sprocket Mounting

CHART 3

Max.

10

Page 11

METRIC INSTALLATION SPECIFICATIONS

Model MIN. MAX RPM Travel Thread* B.C. NO. Pilot Dia. Bore

5 11,3 56,5 1800 1,85 mm N/A 95,3 mm 4 63,5 mm 31,8 mm

20 58,4 113,0 1200 2,34 mm N/A 123,8 mm 6 85,7 mm 44,5 mm

60 175,2 875,9 900 2,79 mm N/A 152,4 mm 6 101,6 mm 57,2 mm

120 350,4 1751,8 600 3,71 mm N/A 177,8 mm 6 120,7 mm 69,9 mm

Trip Torque

(Nm)

Max.

Actuator

Plate

Sprocket Mounting

Max.

CHART 4

NOTE: RTL & RTL FCB Torque Limiters are built in English dimensions unless otherwise noted. Metric

measures above are approximate conversion from English only.

10. Slide torque limiter onto shaft of reducer, etc. with sprocket side as close as possible to the

bearing of the unit without rubbing. Secure torque limiter in place by tightening the two set

screws provided. Again, the use of Loctite® is recommended. Additional clamping can be

provided by using an arrestor bolt and washer to hold the unit against a shaft shoulder or

clamping collar (see Figure 5).

NOTE: Steps 11-12 apply to both RTL and RTL-FCB clutches.

11. Mount and adjust limit switch into proper position with switch trip plate.

12. Turn on power and inspect.

FIGURE 3 FIGURE 4

FIGURE 6

FIGURE 5

11

Page 12

Adjustments

Torque Adjusting Nut

RT & RTM Series

Locking Set Screw

1. To adjust trip torque, remove locking set screw. Use spanner wrench to adjust nut position.

Turn clockwise to increase torque or counterclockwise to decrease. See Chart 5 for torque

adjustment values.

FIGURE 7

2. Replace locking set screw after achieving required torque.

NOTE: 1) Total torque range in the different models is achieved by a combination of

different spring groups and applied pressure through the adjusting nut. Chart 5 below

show the different torque ranges available for each spring group. When re-ordering,

specify model # (e.g. RT3-6001, etc.) for your required spring range.

NOTE: 2) If a tamper proof setting is desired, apply a permanent adhesive, such as

Loctite® 680, to the set screw after achieving the required trip torque value.

12

Page 13

Spring Sets for RT Clutches

Torque Range Nut Adjustment

RT Clutch Range

RT/RTM3-

6001

RT/RTM3-

6002

RT/RTM3-

6003

RT/RTM3-

6004

RT/RTM5-

6001

RT/RTM5-

6002

RT/RTM5-

6003

RT/RTM6-

6001

RT/RTM6-

6002

RT/RTM6-

6003

RT/RTM8-

6001

RT/RTM8-

6002

*NOTE: Torque per ¼ turn of nut.

1 100 – 175 12 – 20 10 1,13

2 175 – 275 20 – 31 15 1,69

3 250 – 350 28 – 40 20 2,26

4 325 – 500 37 – 56 30 3,39

1 500 – 850 56 – 96 50 5,56

2 800 –1700 90 – 192 100 11,30

3 1600 – 3000 181 – 339 200 22,60

1 1000 – 2700 113 – 305 275 31,07

2 2500 – 5000 282 – 565 525 59,22

3 4000 – 8500 452 – 960 950 107,34

1 4000 – 9500 455 – 1073 600 67,79

2 6000 – 15500 678 – 1750 900 101,69

in-lbs Nm in-lbs* Nm*

CHART 5

13

Page 14

RTL & RTL-FCB Series

NOTE: Trip torque should be less than the maximum the machine can absorb without risk

but great enough to prevent undesirable nuisance tripping due to inertia or starting loads.

Ideally, trip torque should be approximately 40% higher than the operating torque of the

machine.

WARNING: IF THE DRIVE HAS A BRAKE MOTOR, THE TRIP SETTING MUST BE WELL

ABOVE THE BRAKE TORQUE; OTHERWISE WITH A HIGH INERTIA DRIVE, THE CLUTCH MAY

TRIP WHEN THE BRAKE IS APPLIED, ALLOWING THE MACHINE TO RUN UNCONTROLLED

BY THE BRAKE.

FIGURE 8

1. Adjust trip torque (Figure 8) by loosening locknuts.

Approximate Static Trip Torque

Number

Of

Turns

0 500 2000 6000 12000

½ 450 1900 5500 11500

1 375 1700 5000 10500

1 ½ 300 1500 4500 9500

2 225 1300 4000 9000

2 ½ 150 1200 3500 8000

3 100 1000 3000 7000

3 ½ ----- 800 2500 6000

4 ----- 600 2000 5000

4 ½ ----- 500 1700 4500

5 ----- 400 1400 4000

5 ½ ----- ----- 1200 3500

6 ----- ----- ----- 3000

6 ½ ----- ----- ----- 2400

RTL-5 RTL-50 RTL-60 RTL-120

(IN-LBS)

CHART 6

2. Tighten torque adjusting screws all the way down.

3. Back torque adjusting screws off the number of turns in Chart 6 to the desired torque range.

4. Tighten locking nuts to maintain setting.

5. Check the distance between torque adjusting screw heads and locking nuts. All must be the same to insure even spring

compression.

NOTE: All Industrial Motion Control detent clutches are reset by:

1. Turning the power off.

2. Clear jam condition.

3. Rotate machine manually or slow jog until clutch snaps back in the home position. Torque limiter

will re-engage from either direction.

14

Page 15

Maintenance

NOTE: FERGUSON detent torque limiters are factory lubricated and sealed. Unless the unit is

subjected to severe loads, frequent tripping, or harsh environment, replenishment of lubricant is

seldom necessary more often than once a year.

1. Annually disassembly unit, clean and inspect parts. Check bearings and seals and replace if

necessary. Inspect detents and detent plate for wear. If necessary, replace torque limiter.

2. Apply a general-purpose lithium based NLGI grade 2 grease to bearings, thrust washers, detent seats

and track, rubbing surfaces and the threads of adjusting nut or screws.

15

Page 16

1444 S. Wolf Road

Wheeling, IL 60090

USA

ph: 847-459-5200

toll-free: 800-645-5207

fax: 847-459-3064

e-mail: mktg@camcoindex.com

www.camcoindex.com

ISO 9001:2000 registered

This publication is for information purposes only

and should not be considered a binding

description of the product except if confirmed in

writing by Industrial Motion Control, LLC

Sales Office

Camco-Ferguson Michigan

550 Forest Avenue, Unit #14

Plymouth, MI 47170

USA

ph: 734-459-8080

fax: 734-459-8110

European HQ

Ferguson Co., S.A.

33 Parc Industriel

B-1440 Braine-le-Château

Belgium

ph: +32 (0)2 367-1311

fax: +32 (0)2 366-1891

e-mail: sales@ferguson.be

Sales Office

Camco UK Ltd.

432 Perth Avenue

Slough Trading Estate

Slough, Berkshire SL1 4TS

United Kingdom

ph: +44 (0)1753-786-100

fax: +44 (0)1753-786-101

e-mail: sales@camcouk.demon.co.uk

© Industrial Motion Control, LLC 2004

All rights reserved

Printed in U.S.A.

SKU 0108 / Revision 4/04

Loading...

Loading...