Page 1

®

The Driving Force in Automation

SERVICE MANUAL

TABLE TOP SERIES

1.5 LINK, 2.0 LINK, 3.0 LINK,

4.5 LINK, & 6.0 LINK

HEAVY DUTY SERIES

6.0 LINK & 9.0 LINK

“WARNING”

This is a controlled document. It is your responsibility to deliver this information to the end user of the CAMCO indexer.

Failure to deliver this, could result in your liability for injury to the user or damage to the machine.

For copies of this manual call your Customer Service Representative 800/645-5207.

“WARNING”

Page 2

T ABLE OF CONTENTS

INTRODUCTION ............................................................................................ 2

GENERAL DESCRIPTION ............................................................................ 2

WARNING AND CAUTIONS .......................................................................... 3

SPARE PARTS KIT ........................................................................................ 3

BEFORE STARTING...................................................................................... 3

CONVEYOR LUBRICATION INFORMATION................................................ 4

GENERAL .......................................................................................... 4

LUBRICATION OF SPROCKET BEARINGS ..................................... 4

LUBRICATION OF PRECISION LINKS ............................................. 4

CHAIN OR IDLER LUBRICATION ..................................................... 5

LINE SHAFT LUBRICATION.............................................................. 5

GENERAL MAINTENANCE LUBRICATION ...................................... 5

OIL SEAL INSTALLATION RECOMMENDATIONS........................................ 5

CHANGING OF PRECISION LINK CAM FOLLOWERS ............................... 6

LINK PIN FOLLOWERS................................................................................. 6

LINK SUPPORT FOLLOWERS .......................................................... 6

CONVEYOR TENSION SETTING.................................................................. 8

GENERAL INFORMATION................................................................. 8

CONVEYOR RE-TENSIONING.......................................................... 8

HOW TO ORDER PARTS............................................................................... 9

T ABLE TOP

1.5 LINK ASSY................................................................................. 10

1.5 LINK ASSY PARTS LIST............................................................ 11

2.0 LINK ASSY................................................................................. 10

2.0 LINK ASSY PARTS LIST............................................................ 11

3.0 LINK ASSY................................................................................. 10

3.0 LINK ASSY PARTS LIST............................................................ 11

4.5 LINK ASSY................................................................................. 12

4.5 LINK ASSY PARTS LIST............................................................ 13

6.0 LINK ASSY................................................................................. 12

6.0 LINK ASSY PARTS LIST............................................................ 13

HEAVY DUTY

6.0 LINK ASSY................................................................................. 14

6.0 LINK ASSY PARTS LIST............................................................ 15

9.0 LINK ASSY................................................................................. 14

9.0 LINK ASSY PARTS LIST............................................................ 15

Page 3

INTRODUCTION

This service manual pertains to the disassembly and assembly of CAMCO’s 1.5 link, 2.0 link, 3.0

link, 4.5 link, and 6.0 link “Table Top” Precision Link Conveyors and CAMCO’s 6.0 and 9.0 “HeavyDuty” Precision Link Conveyors.

The CAMCO Precision Link Conveyor comes in two types: “over and under” and “carousel”. Both

are driven by a CAMCO Index Drive containing cam followers and a precision ground cam. Inspection and service on the Index Drives is covered in a separate Service Manual for the specific

model Index Drive.

This manual is to be used in conjunction with the "General Service Manual" which describes the

lubrication and general maintenance of CAMCO Index Drives.

Drawings of the various size links are included in this manual. The procedures in this manual

reference the item numbers of these drawings.

Also included is a complete Bill of Materials for your convenience in identifying and ordering spare

or replacement parts.

Some users of CAMCO’s Precision Link Conveyors have the facilities and trained personnel to

accomplish service repair. You must determine the extent to which intricate servicing should be

done in your facility. When in doubt, CAMCO recommends that CAMCO trained serviceman make

the repairs.

GENERAL DESCRIPTION

The CAMCO Precision Link Conveyor is a precision mechanical device that requires no internal

adjustment during its expected service life when operated within rated loads and speeds.

All CAMCO Precision Link Conveyors employ the “link on link” design, meaning all links are identical to each other and can be used for fixture mounting, rather than the “link on spacer bar” design

which permits only every other link to be used for fixture mounting.

The connection of the two links consists of a precision ground link pin (2) with precision needle

bearings (1 and 6) in each link ear.

The ends of pins (2) are fitted with precision link pin followers (3) which ride in the main frame

guides and support the loads on the face of the link as well as restricting face “in and out” movement.

Each link is furnished with link support cam followers (10) to support loads and eliminate any

movement between the link and conveyor main frame.

2

Page 4

WARNINGS AND CAUTIONS

Statements in this manual preceded by the words WARNING or CAUTION and printed in italics

are very important. We recommend you take special notice of these during service or repair.

WARNING: Means there is the possibility of personal injury to yourself or others.

CAUTION:

Means there is the possibility of damage to the CAMCO unit.

SPARE P AR TS KIT

CAMCO offers a Spare Parts Kit for all CAMCO Precision Link Conveyors. These kits include link

pin, needle bearings, followers, locknuts, shims and retaining rings required to rebuild (one) link

assembly. These are components that will most likely require replacement during repair of your

Conveyor. CAMCO recommends several Spare Parts Kits be purchased and kept on hand to

insure against “down time” in the event of damage to the link components.

Individual components may be purchased in any quantity by specifying the part numbers, as noted

in the Bill of Materials provided in this service manual.

BEFORE ST ARTING

Before starting disassembly of your CAMCO unit you should read and review the following instructions. These provide important information on parts and procedures necessary to successfully

complete your repair.

Comply with all

Read the “Trouble Shooting Guide” section of your “General Service Manual” before disassem-

bling CAMCO units. CAMCO recommends returning defective equipment for inspection and repair

whenever possible.

Warnings and Cautions.

CAMCO uses Loctite to secure all screws and setscrews. If you encounter a fastener that is

difficult to remove, apply heat to the screw and remove while still warm.

3

Page 5

CONVEYOR LUBRICA TION INFORMA TION

GENERAL

The following is a recommendation for “Clean”

Environment “Moderate” Loading and “30”

Cycles per min.

Lubrication of the CAMCO’s Precision Link

Conveyors is largely dependent upon Work

Environment, Conveyor Loading and Cycle

Rate, therefore a “standard” lube interval can-

Lubrication should be done at Take-Up end of

the conveyor with the link in dwell and the motor

stopped.

not be established but instead should be determined by the Customer based on the above

conditions.

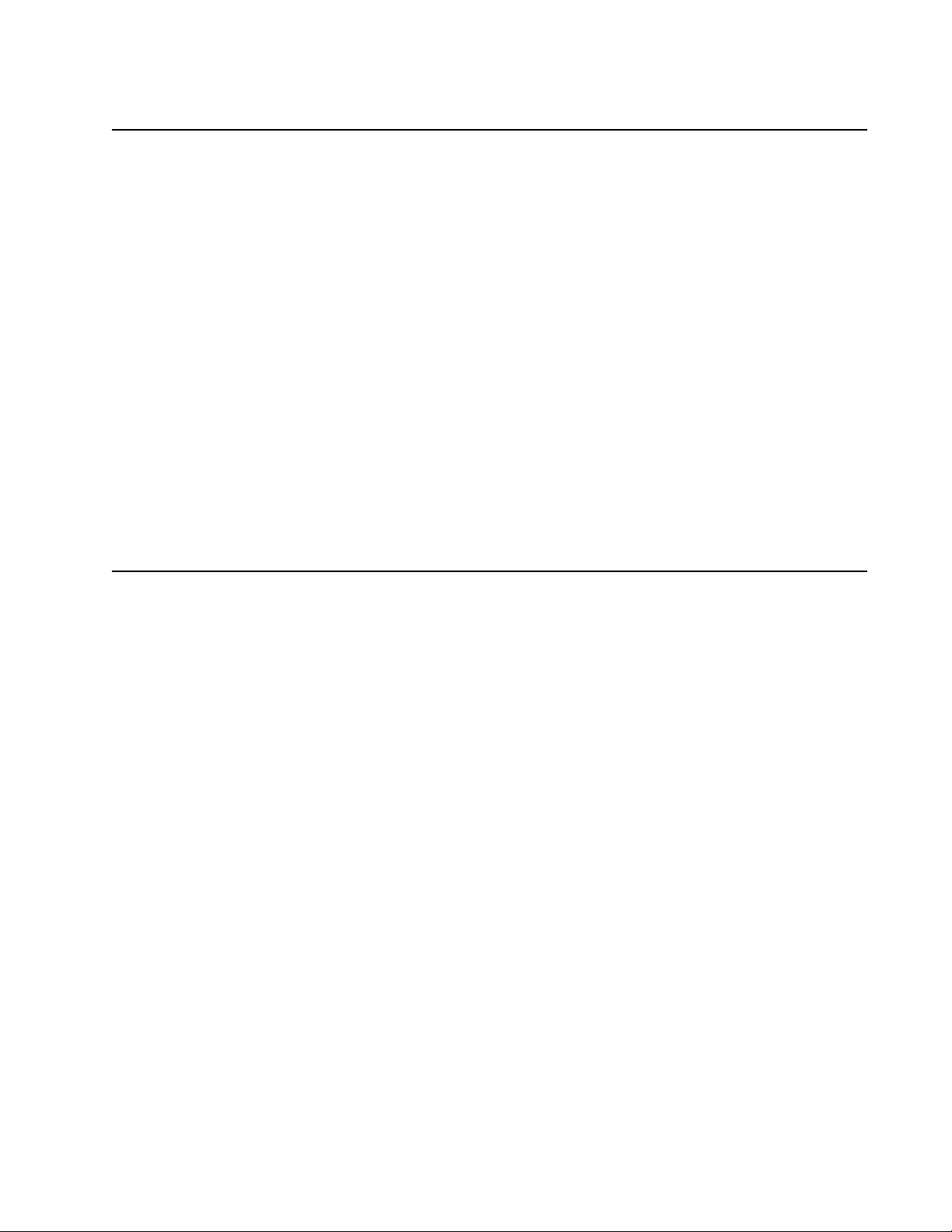

LINK SIZE INTERVAL TYPE OF LUBRICANT LOCATION

9" LINK

HEAVY DUTY

6" LINK

TABLE TOP

AND

6" LINK

HEAVY DUTY

4 1/2" LINK

TABLE TOP

3" LINK

TABLE TOP

2000 HOURS

2000 HOURS

2000 HOURS

LUBED FOR LIFE

LITHIUM SOAP GREASE

#1 CONSISTENCY

LITHIUM SOAP GREASE

#1 CONSISTENCY

LITHIUM SOAP GREASE

#1 CONSISTENCY

STANDARD LUBE FITTING

AT BOTH ENDS OF LINK

PIN AND LINK FACE

STANDARD LUBE FITTING

AT BOTH ENDS OF LINK

PIN AND LINK FACE

NEEDLE LUBE FITTING

AT BOTH ENDS OF LINK

PIN AND LINK FACE

2" LINK

TABLE TOP

1 1/2" LINK

TABLE TOP

LUBED FOR LIFE

1000 HOURS LIGHT MACHINE OIL

LUBRICATION OF SPROCKET

BEARINGS

The flange bearings supporting the Sprocket/

Input Shaft should be lubricated, approx. every

2000 working hours, with NGLI #3 bearing

grease.

LUBRICATION OF PRECISION

LINKS

Followers equipped with lube fitting should be

given a shot of Lithium Soap grease having a

#1 consistency at least once every 2000 hours

of operation, or 6 months, whichever is less.

In order to lubricate the link support followers

(10), it may be necessary to remove any mounting fixtures or tooling which may have been

added by the machine builder other than

OIL CAN APPLICATION

BETWEEN THE LINK AND

FOLLOWER AT BOTH

ENDS OF LINK PIN

CAMCO, if provisions have not been made to

access these lube fittings.

To lubricate the link pin followers (3), the conveyor drive should be placed in dwell, at which

time the lube fittings can be accessed through

the holes provided in the straight or radical

guides. Index once and repeat the procedure

until all the links have been lubricated.

NOTE: Both top and bottom guide rails (car-

ousel), and left and right guide rails

(over and under) have the lube access

holes. Both should be lubricated.

NOTE: If only one access hole is provided in

each side, it may be necessary to

hand crank the reducer until the lube

fittings appear. Repeat this procedure

until all links have been lubricated.

4

Page 6

CHAIN OR IDLER LUBRICA TION

LINE SHAFT LUBRICA TION

All idlers (chain or belt) are supplied with a

grease fitting and should be lubricated at least

once a month. Roller chains are used in some

applications to drive the line shaft or provide

power to optional equipment such as indexers,

oscillators, pick and place units, etc. These

chains should be brushed periodically with a

light machine oil. Timing belts do not require

any lubrication.

OIL SEAL INST ALLA TION RECOMMENDA TIONS

We recommend that all seals be replaced

anytime the device is being disassembled

whether they are damaged of not, as most

damage to oil seals occurs at assembly when

recommended practice for seal installation is

generally not followed.

1.

Check dimensions to be sure that shaft and

bore diameters match those specified for

the seal selected.

2.

Check seal for damage that may have

occurred prior to installation. A sealing lip

that is turned back, cut or otherwise damaged should be replaced.

3.

Check bore to see that leading edge is

deburred. A rounded corner or chamfer

should be provided.

4.

Check shaft and remove surface nicks,

burrs and grooves and look for spiral machine marks that can damage the seal lip.

5.

Check shaft end and remove burrs or sharp

edges. Where the installation requires the

shaft seal against the sealing lip, the shaft

end should be chamfered.

On conveyors supplied with a line shaft or

power take-off shaft, provisions have been

made in the support bearings of these shafts for

periodic lubrication. These bearings are to be

greased at least once every 500 hours of

operation with EXXON Andok “C” or equivalent

NGLI #4 bearing grease.

GENERAL MAINTENANCE

LUBRICA TION

The general condition of all unpainted components should be observed periodically and

given a light spray of machine oil as required to

retard rust.

the edges of the spline or keyway as much

as possible and lubricate with a hard,

fibrous grease.

7.

Check seal direction making sure that the

new seal faces in the same direction as the

original. Generally, the lip faces the lubricant or fluid to be sealed.

8.

Prelubricate the sealing element before

installation by wiping with lubricant being

retained.

9.

Use correct installation tool — press fitting

tools should have an outside diameter

0.010" smaller than the bore size. If possible, center of tool should be relieved so

that pressure is applied only at the OD.

10.

Use proper driving force, where possible an

arbor press; otherwise, a dead blow hammer to avoid popping the spring out of the

seal. NEVER HAMMER DIRECTLY ON

THE SURFACE OF THE SEAL.

11.

Bottom out the tool or seal to avoid cocking

the seal in the bore. This also positions the

seal correctly on the shaft.

6.

Check splines and keyways for sharp edges

and protect the seal lip with an assembly

sleeve or shim stock. If not available, round

12.

Check for parts interference from other

machine parts that might rub against the

seal to cause friction and damaging heat.

5

Page 7

CHANGING OF PRECISION LINK CAM FOLLOWERS

The changing of cam followers on CAMCO

Precision Link Conveyors is done by two methods, depending upon which follower is worn.

The procedure for changing the link pin followers (3) is different from the procedure for the

link support followers (10). (See Pages 12 to

15).

The following will describe the steps required

for each procedure:

LINK PIN FOLLOWERS

(See Pages 12 to 15)

1. Remove the radial guides from the drive

end of the conveyor.

2. Index the conveyor until the worn link pin

followers (3) are exposed at the end of the

conveyor.

3. Remove the retaining ring (4) holding

follower (3) on pin (2).

If a pedestal mount is used, the four

"forward-most” screws used to mount the

base to the main frame will be the take-up

cam locking screws.

On a heavy duty base design, clearance

holes will be provided to locate and access

these screws. It may also be necessary, on

a heavy duty base, to loosen the three end

support block mounting screws, located on

the bottom of the conveyor frame at the

extreme end.

3. Once the locking screws have been loosened, remove the round access cover for

the tension adjusting screw and back off the

tensioning screws two turns. Refer to

Figure 1.

4. Remove the worn or damaged follower (3)

and replace.

CAUTION: If shims (5) are used between

the link (9) and follower (3),

be sure to replace before

installing new follower.

5. Repeat until all worn or damaged followers

are replaced.

LINK SUPPORT FOLLOWERS

1. Remove the radial guides at the take-up

end of the conveyor.

2. Loosen the take-up cam locking screws (4

per side) located in slotted holes in the main

frame portion of the conveyor. These are

located on both sides of the fitted key

section of the take-up cam.

The slots should be obvious on both sides

of the “over and under” conveyor. The slots

should be obvious on the top of the “carousel” conveyor but may be more difficult to

locate on the bottom due to the base

mounting.

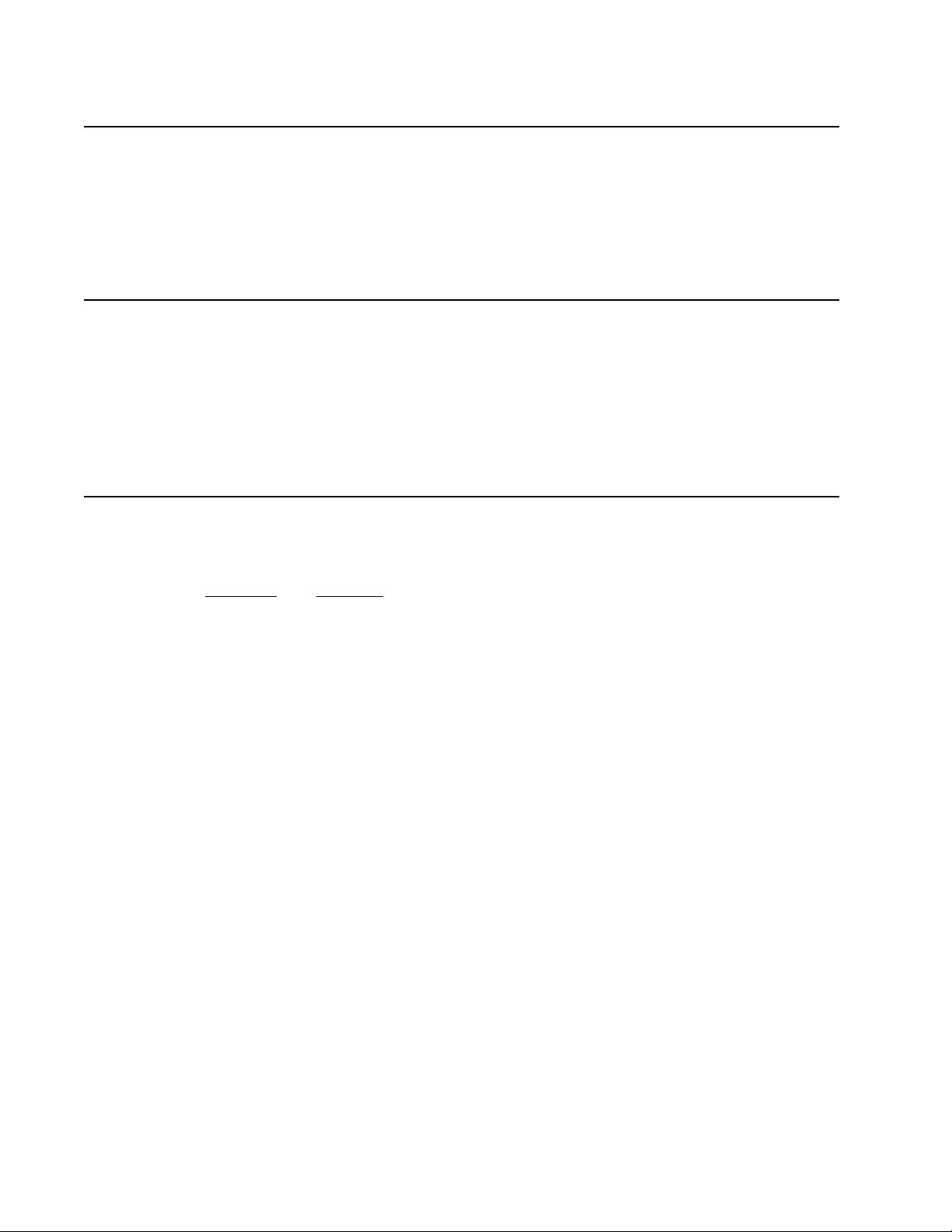

Fig. 1. Removing link.

4. At this time, it will be possible to force the

take-up end towards the drive end enough

to provide slack in the link chain.

5. Hand crank the index drive input reducer

until the suspect link is positioned on the

radial end of the take-up cam.

6. Remove retaining rings (4) on the link pins

of the link to be removed.

6

Page 8

7. Remove followers (3) and if equipped, shims

(5) from one side only. If equipped with

shims (5), retain for reassembly.

8. 9.0 LINK: Loosen the clamping collars (8)

on the link pins of the link to be removed.

9. Pull pins (2) with remaining followers (3)

through all four ears of the link connection.

10. Once the link has been removed, place the

link on a work bench and remove the follower locknut (11).

11. Using a soft aluminum bar, drive out the

worn follower (10).

12. Press in a new follower (10) and install a

new locknut (11). (If equipped, be sure to

install a new grease fitting (12) in the follower stud for future lubrication.)

13. Place link back into position so that alignment of the link ears will permit insertion of

the link pin (2).

14. Insert pins (2) through all four ears of the

link connection.

WARNING:

Use caution when pulling chain

for section removal. The chain

should be held back so that a

runaway condition does not

occur. This can happen when

the weight of the chain outside

the conveyor overcomes the

friction of the chain still inside

the conveyor and all the links

feed out uncontrollably.

18. If other links are to be removed it will be

necessary to hand crank the drive (due to

the lack of chain tension) until the link to be

removed is exposed at the take-up end.

Repeat Steps 5 through 14 as many times

as required to replace all worn followers.

WARNING:

Use caution when pulling chain

for section removal. The chain

should be held back so that a

runaway condition does not

occur. This can happen when

the weight of the chain outside

the conveyor overcomes the

friction of the chain still inside

the conveyor and all the links

feed out uncontrollably.

15. 9.0 LINK: Secure clamping collars (8)

against the inside of the ears.

16. Reinstall followers (3) and, if equipped,

shims (5).

17. Reinstall retaining rings (4) on the link pins.

NOTE: When rebuilding all links, the chain can

be removed in large sections by

breaking the chain at the drive end as

well as the take-up end. Pull a manageable length of chain out from takeup end. It is recommended that links

be reassembled in same order as

received from CAMCO. Number links

before disassembly.

19. When all followers are changed, re-tension

the chain as described in “Conveyor Tension

Setting”.

7

Page 9

CONVEYOR TENSION SETTING

GENERAL INFORMATION

To maintain and guarantee accuracy and

performance of the conveyor, CAMCO utilizes a

unique “chordal action compensating CAM”.

This CAM arrangement is state of the art in

precision link conveyor design. Spring actuated

tensioned conveyors utilizing either tail shaft or

secondary tensioning were rejected by CAMCO

because of the contribution to indexing inaccuracies.

Once the conveyor is properly tensioned at the

factory, no further adjustment is required in the

field for the duration of expected follower lift.

We are including instructions for adjustments,

should it become necessary to replace followers, or if the tension is lost because of extraordinary conditions (i.e., EXTREME THERMAL

EXPANSION). It is recommended that CAMCO

factory be consulted prior to starting with the

actual adjustment. Failure to do so may void all

warranties for the conveyor.

CONVEYOR RE-TENSIONING

1. Read section in general information regarding warranty.

2. Remove the radial guides at the take-up

end of the conveyor.

3. Loosen the take-up cam locking screws (4

per side) located in slotted holes in the main

frame portion of the conveyor. These are

located on both sides of the fitted key

section of the take-up cam.

The slots should be obvious on both sides

of the “over and under” conveyor. The slots

should be obvious on the top of the “carousel” conveyor but may be more difficult to

locate on the bottom due to the base

mounting.

On a heavy duty base design, clearance

holes will be provided to locate and access

these screws. It may also be necessary, on

a heavy duty base, to loosen the three end

support block mounting screws, located on

the bottom of the conveyor frame at the

extreme end.

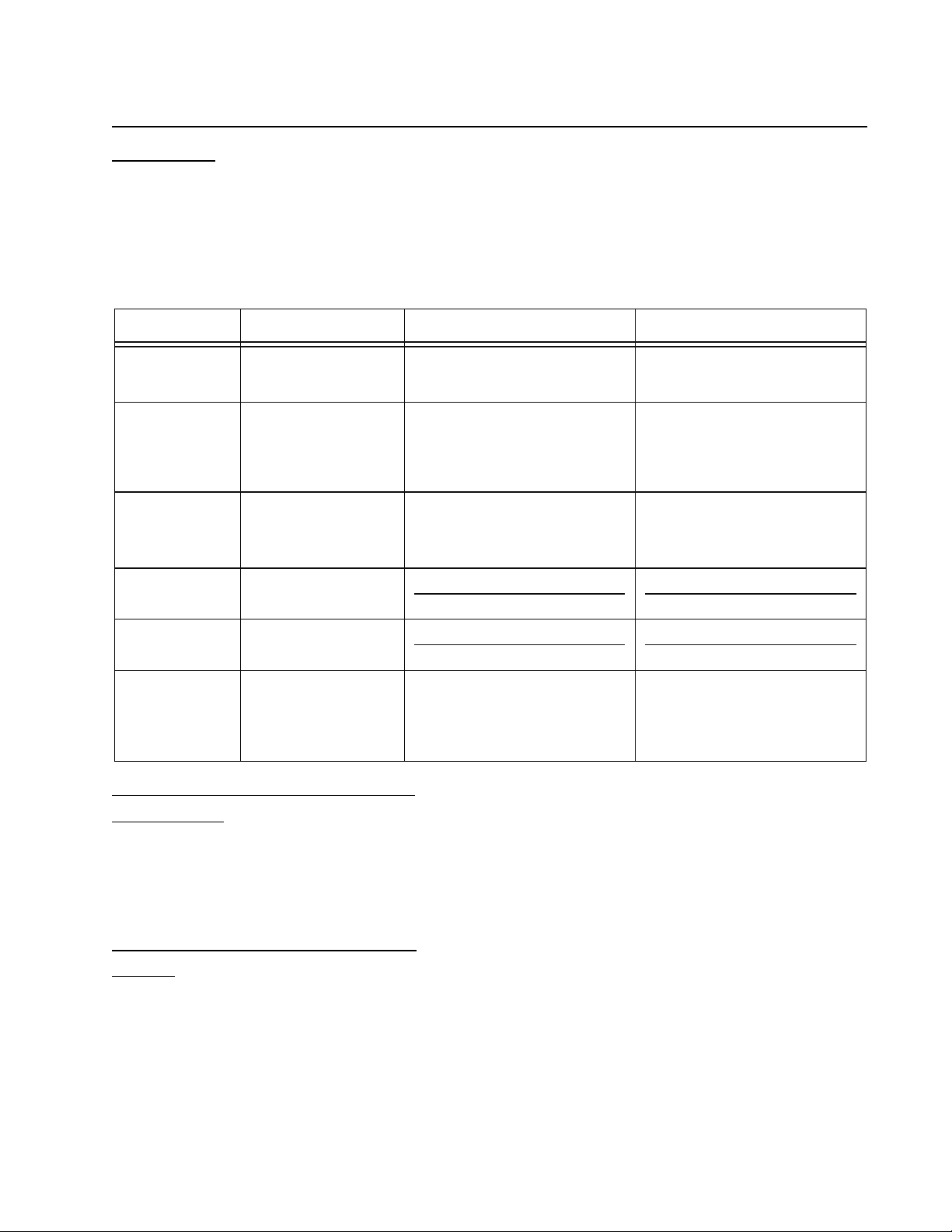

4. Once the locking screws have been loosened, remove the round access cover for

the tension adjusting screw. Refer to

Figure 2.

Fig. 2. Conveyor re-tensioning.

5. Hand crank the index drive input reducer

until a link pin follower is positioned at the

high point of the take-up cam (point “A” as

shown in Figure 2).

6. Slowly tighten the tensioning screws, an

equal amount, until it becomes impossible to

turn the link pin cam follower, at point “A”, by

hand. At this point, it will still be easy to turn

the follower using pliers. If it is difficult with

pliers, you have overtightened.

7. Be sure that the followers at both ends of

the link pin have approximately. the same

loading. It is important to adjust the take-up

screws equally.

8. Tighten locknuts and locking screws (4 per

side).

If a pedestal mount is used, the four

"forward-most” screws used to mount the

base to the main frame will be the take-up

cam locking screws.

9. Re-install the radial covers and tension

screw access cover.

8

Page 10

HOW TO ORDER P AR TS

Please refer to parts list shown in this manual. This parts list is for a standard Link Assy. If you

feel your link is nonstandard or you are in doubt, you should contact CAMCO Customer Service at

(847) 459-5200 and request a Bill of Material for your specific unit based on serial number.

CAMCO maintains records on all units for a period of ten years.

You may order parts per the standard Bill of Material even if your unit is nonstandard. CAMCO’s

order entry people will review the closed order file based on the following information and supply

you with the correct part.

REQUIRED INFORMA TION

1. Original purchase order number (if available)

2. Customer name (original purchaser of conveyor)

3. Model number (located on name plate)

4. Serial number (located on name plate)

5. Approximate date of purchase.

TO ORDER PARTS contact CAMCO "Order Entry Department" Wheeling, Illinois

Phone (847) 459-5200 or FAX #847-459-3064

A. Describe the parts required and the 14 digit part number as listed in the Standard Bill of Materi-

als or a Special Bill of Materials pertaining to your unit. State if you are using a Standard or

Special bill of material.

B. Give as much of the above required information as possible.

ON WARRANTY

Replacement parts CAMCO will send freight prepaid via practical means.

CAMCO will issue a "Returned Material Authorization Number" (RMA#) for the return of defective

parts for inspection. CAMCO will bill customer for repair parts. When inspection of returned parts

has been completed and determined to be a warranty problem, CAMCO will issue a credit to the

customer for the repair parts and freight charges.

ON NON-WARRANTY

Replacement or spare parts, with approved credit, are sent F.O.B. our plant Wheeling, Illinois.

9

Page 11

T ABLE TOP

1.5 LINK ASSY

2.0 LINK ASSY

10

3.0 LINK ASSY

Page 12

T ABLE TOP

PARTS LIST FOR 1.5 LINK ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION

1 ....................86A33185000000....................NEEDLE BEARING

2 .................... 40A40656000000 ....................GROUND LINK PIN

3 ....................82B08417090002....................LINK SUPPORT FOLLOWER

4 .................... 95A43089040000....................RETAINING RING

5 ....................95A39287000000....................SHIM

6 ....................86A39288000000....................NEEDLE BEARING

7 ....................NOT USED

8 ....................NOT USED

9 ....................M3B46434000000...................1.5 LINK

10 .................. 82A46437000000....................LINK SUPPORT FOLLOWER

11...................95A26008160000....................LOCKNUT

12 ..................NOT USED

PARTS LIST FOR 2.0 LINK ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION

1 ....................86A433550000 .......................NEEDLE BEARING

2 .................... 37B43349000000 ....................GROUND LINK PIN

3 ....................82A34952000000....................LINK SUPPORT FOLLOWER

4 .................... 95A43089060000....................RETAINING RING

5 ....................NOT USED

6 ....................86A433550000 .......................NEEDLE BEARING

7 ....................NOT USED

8 ....................NOT USED

9 .................... M4C55877000000...................2.0 LINK

10 .................. 82A43363000001....................LINK SUPPORT FOLLOWER

11...................95A26008130000....................LOCKNUT

12 ..................NOT USED

PARTS LIST FOR 3.0 LINK ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION

1 ....................86A433550000 .......................NEEDLE BEARING

2 .................... 37B43349000000 ....................GROUND LINK PIN

3 ....................82A34952000000....................LINK SUPPORT FOLLOWER

4 .................... 95A43089060000....................RETAINING RING

5 ....................NOT USED

6 ....................86A433550000 .......................NEEDLE BEARING

7 ....................NOT USED

8 ....................NOT USED

9 ....................37C55878000000....................3.0 LINK

10 .................. 82A43363000001....................LINK SUPPORT FOLLOWER

11...................95A26008130000....................LOCKNUT

12 ..................NOT USED

11

Page 13

T ABLE TOP

7

4

4.5 LINK ASSY

3

2

6

12

11

10

1

5

9

6.0 LINK ASSY

12

Page 14

T ABLE TOP

PARTS LIST FOR 4.5 LINK ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION

1 ....................86A45309000000....................NEEDLE BEARING

2 .................... M2B45289000000...................GROUND LINK PIN

3 ....................82J27323000000 ....................LINK SUPPORT FOLLOWER

4 .................... 95A33031160000....................RETAINING RING

5 ....................95A503780000000..................SHIM

6 ....................86A45309000000....................NEEDLE BEARING

7 .................... 95A45308000000 ....................LUBE FITTING

8 ....................NOT USED

9 .................... M2C55900000000...................4.5 CLOSED LINK

10 .................. 82A43363000001....................LINK SUPPORT FOLLOWER

11...................95A26008130000....................LOCKNUT

12 .................. 95A45308000000....................LUBE FITTING

PARTS LIST FOR 6.0 LINK ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION

1 ....................86A56824000000....................NEEDLE BEARING

2 .................... M5B55985000000...................GROUND LINK PIN

3 ....................82J27323000000 ....................LINK SUPPORT FOLLOWER

4 .................... 95A33031160000....................RETAINING RING

5 ....................86A22870030000....................SHIM

6 ....................86A56824000000....................NEEDLE BEARING

7 .................... 95A45308000000 ....................LUBE FITTING

8 ....................NOT USED

9 .................... M5D55975000000...................6.0 CLOSED LINK

10 .................. 82J30354000000 ....................LINK SUPPORT FOLLOWER

11...................95A26008020000....................LOCKNUT

12 .................. 95A45308000000....................LUBE FITTING

13

Page 15

HEAVY DUTY

7

3

5

1

2

9

10

11

12

4

6.0 LINK ASSY

6

8

9.0 LINK ASSY

14

Page 16

HEAVY DUTY

PARTS LIST FOR 6.0 LINK ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION

1 ....................86J21967000000 .................... NEEDLE BEARING

2 .................... 40K31509009999 ....................GROUND LINK PIN

3 ....................82J27323000000 ....................LINK SUPPORT FOLLOWER

4 .................... 95A33031160000....................RETAINING RING

5 ....................86A29049030000....................SHIM

6 ....................86J21967000000 .................... NEEDLE BEARING

7 .................... 95A33004020000 ....................LUBE FITTING

8 .................... 99J26434000000 ....................CLAMPING COLLAR

9 .................... 41C52528000000 ....................6.0 CLOSED LINK (ALUM)

9 .................... 41C52529000000....................6.0 CLOSED LINK (C.I.)

10 ..................82J30354000000 ....................LINK SUPPORT FOLLOWER

11 .................. 95A26008020000....................LOCKNUT

12 .................. 95A33004030000....................LUBE FITTING

PARTS LIST FOR 9.0 LINK ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION

1 ....................86J21967000000 .................... NEEDLE BEARING

2 .................... 40K31509009999 ....................GROUND LINK PIN

3 ....................82J27323000000 ....................LINK SUPPORT FOLLOWER

4 .................... 95A33031160000....................RETAINING RING

5 ....................86A29049030000....................NOT USED

6 ....................86J21967000000 .................... NEEDLE BEARING

7 .................... 95A33004020000 ....................LUBE FITTING

8 .................... 99J26434000000 ....................CLAMPING COLLAR

9 .................... 40C52670000000 ....................9.0 CLOSED LINK (ALUM)

9 .................... 40C52673000000....................9.0 CLOSED LINK (C.I.)

10 ..................82J30354000000 ....................LINK SUPPORT FOLLOWER

11 .................. 95A26008020000....................LOCKNUT

12 .................. 95A33004030000....................LUBE FITTING

15

Page 17

NOTES

16

Page 18

USA 6/99 0074

Loading...

Loading...