Page 1

®

The Driving Force in Automation

OVERLOAD CLUTCHES

FOR INDEX DRIVES

“WARNING”

This is a controlled document. It is your responsibility to deliver this information to the end user of the CAMCO indexer.

Failure to deliver this, could result in your liability for injury to the user or damage to the machine.

For copies of this manual call your Customer Service Representative 800/645-5207.

“WARNING”

Page 2

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

SAFETY INSTRUCTIONS

1. Read your Overload Clutch InstallationOperation Instructions thoroughly before

operating the unit, for your safety and the

protection of your unit.

2. CAMCO Overload Clutches are designed to

protect the Index Drive only and will not

protect against bodily injury.

3. Double check to be sure the power is off

and cannot be turned on while working on

the equipment.

4. Use extreme caution with jammed or unbalanced loads, which when cleared may set

the machine in motion.

5. Keep all objects such as hands, clothing,

tools away from rotating or moving parts.

6. Use safety glasses or equivalent to protect

your eyes.

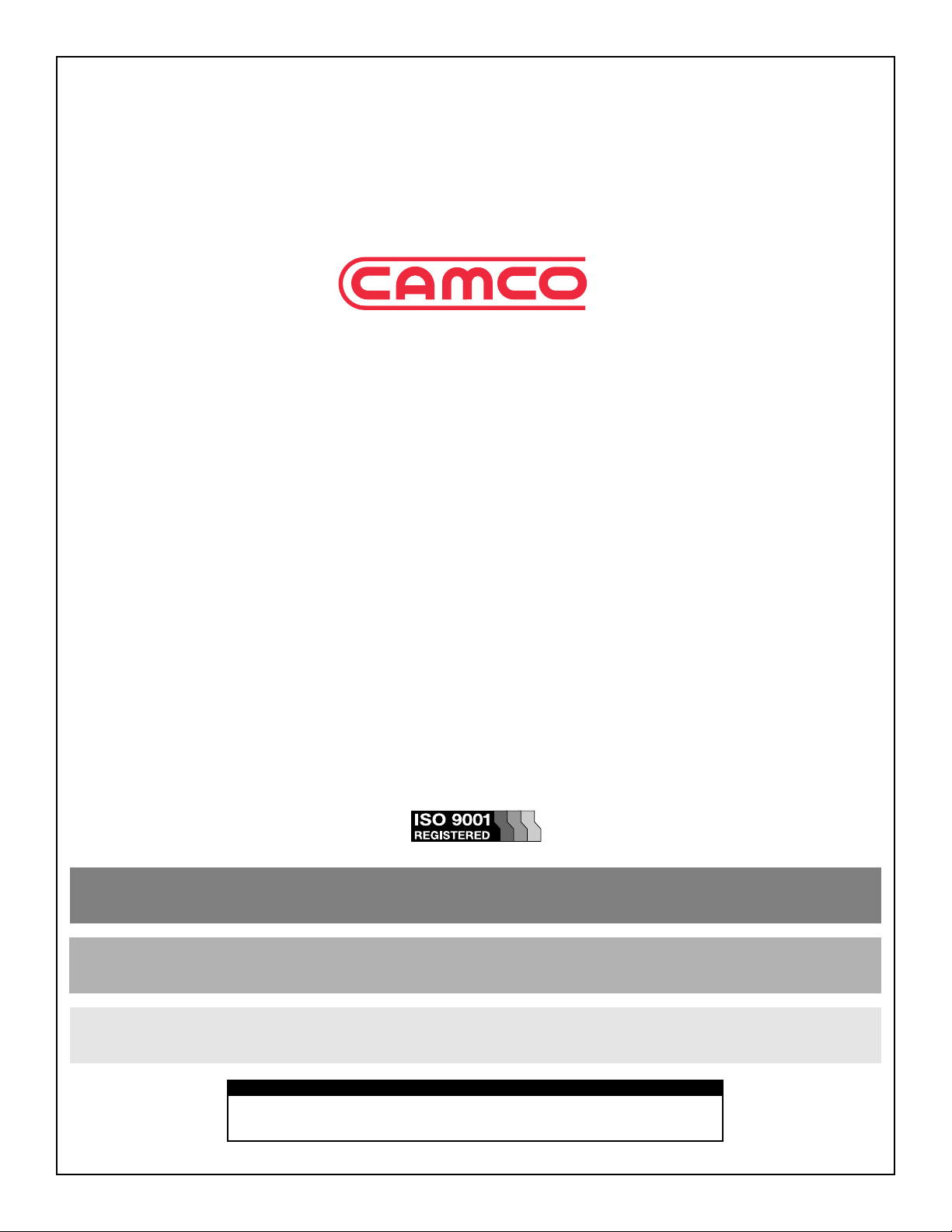

Fig.1

SWITCH NORMALLY

CLOSED

DETECTOR

PLATE

7. Dowel pins and mounting screws must not

protrude from the drive plate or driven

member as the clutch could become a solid

coupling.

8. High humidity, contaminants, or wash down

applications may cause rust within the

clutch, resulting in operational failure.

Lubricate every six months or more frequently as the application requires.

9. The CAMCO clutch is not a "FAIL SAFE"

device and cannot be used on "overhauling"

or "holding" load applications.

The above list includes major safety points to

be observed, but should not be considered as

limiting in safety precautions to be followed.

OPERATING PRINCIPLE

CAMCO Overload Clutches are designed

for mounting on the output member of the

CAMCO Index Drive. An Index Drive is essentially a variable ratio speed reducer. Each index

provides an incremental output to input torque

ratio, which may range from 1:1 in the center of

the motion, to as high as 1000:1 in the beginning or end of the motion. As output torque

equals input torque times the ratio, a clutch

mounted on the input side provides no protection at the beginning or end of the motion.

DRIVING

POSITION,

TYPICAL FOR

EACH PLUNGER

Fig.2

OVERLOAD POSITION,

DETECTOR PLATE IS

MOVED AXIALLY TOW ARD

SWITCH BY TRAVEL OF

PLUNGERS

BODY

DRIVE PLATE

PLUNGER

DRIVE PLATE

SWITCH OPEN

WITHIN 0.008"

DEFLECTION OF

DETECTOR PLATE

PLUNGER

DRIVE PLATE

CAMCO Overload Clutches provide zero

backlash, high rigidity, low inertia and are

specifically designed to be used in conjunction

with CAMCO Index Drives.

Power is transmitted from the Index Drive

through the body of the CAMCO Overload

Clutch. The body contains spring loaded

tapered plungers that engage in mating tapered seats in the drive plate. (See Fig. 1.)

Torque settings are determined by the pressure

the calibrated springs "seat" the plungers.

When an overload occurs, which exceeds the

torque setting of the clutch, the breakaway

friction between the tapered plunger and the

tapered seat, forces the plungers outward from

their seats. The movement of the plungers

elevates the detector plate, actuating the limit

switch. (See Fig. 2.)

The CAMCO Overload Clutch always resets in

its original position, making it an excellent

choice on applications that must remain

registered or timed.

2

Page 3

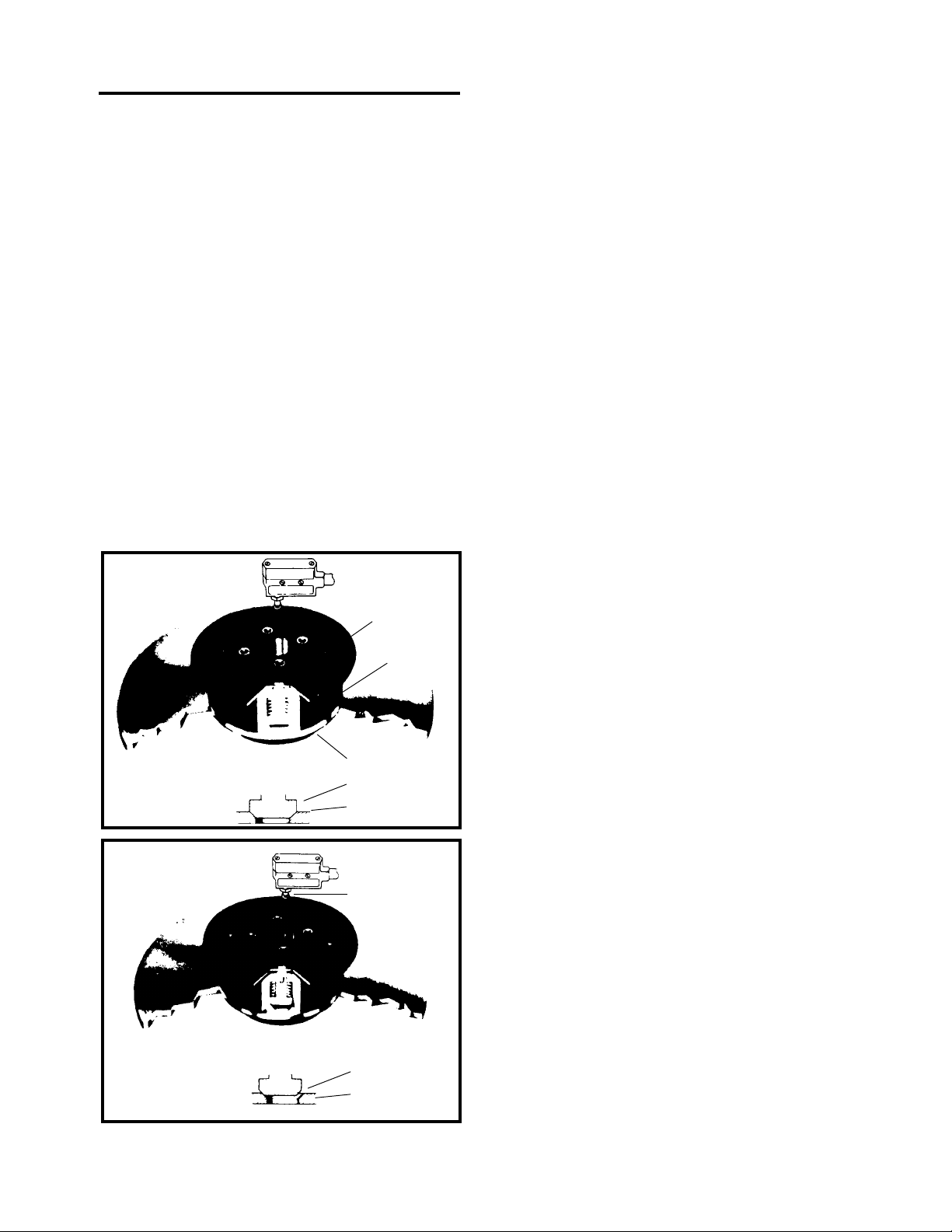

CLUTCH TYPES

CAMCO clutches are designed to meet specific application

requirements. They are available in five basic designs.

.39C

2.3C

6.0C

11C

25C

41C

.39FC

2.3FC

6.0FC

11FC

25FC

41FC

.39F

2.3F

6.0F

11F

25F

41F

140F

TYPE C

•Clamped Hub

•Clamped Body

• Shrink Disc

A clutch coupling which can be mounted on Index Drives

without output flanges. They provide a positive, rigid

connection between two shafts.

TYPE FC

•Flange Mounted Body

•Clamped Hub

• Shrink Disc

These clutch couplings flange mount to the ouput shaft

of the Index Drive and provide a keyed-clamped hub

connection to the driven shaft.

TYPE F

LIMIT SWITCH

•Shaft Mounted Body

The type F Clutch flange mounts to

the output shaft of the Index Drive

and provides a mounting surface for a

dial plate, sprocket, gear, etc., resulting in a rigid, compact and accurate

connection to the driven member.

MOUNTING A

DRIVEN MEMBER MAY BE DIAL

PLATE, SPROCKET, GEAR, ETC.

LIMIT SWITCH

LIMIT SWITCH

DRIVEN MEMBER MAY BE DIAL

PLATE, SPROCKET,

GEAR, ETC.

LIMIT

SWITCH

MOUNTING B

.39S

2.3S

6.0S

11S

25S

41S

2.8D

4.0D

7.8D

18D

31D

32D

61D

130D

TYPE S

•Shaft Mounted

•Clamped Body

• Shrink Disc

The combination of a key and clamped

hub construction provides rigid and

backlash-free shaft connections. The

Type S clutch is designed to mount on

MOUNTING A

DRIVEN MEMBER MAY BE DIAL PLATE,

SPROCKET, GEAR, ETC.

LIMIT

SWITCH

Index Drives without flanges.

TYPE D

•Flange Mounted

These units are designed to mount on CAMCO Index

Drives featuring large output mounting surfaces. The dial

plate rests directly on the Index Drive output flange,

providing the ultimate in stability and accuracy.

3

DRIVEN MEMBER MAY BE DIAL PLATE,

SPROCKET, GEAR, ETC.

MOUNTING B

LIMIT SWITCH

Page 4

INSTALLATION AND REMOVAL

INSTRUCTIONS FOR SHRINK DISCS

Shrink Discs are supplied ready for installation. However, prior to tightening of locking

screws it is necessary to remove wooden

spacers located between outer collars, which

are used during shipment of Shrink Discs.

INSTALLATION

Important: Never tighten locking screws

before shaft installation, since inner ring of

Shrink Discs as well as hub can be permanently contracted even at relatively low

tightening torques.

Outer Collars

Hub

Inner Ring

Metrix Hex Head Locking Screws

DIN 931, Grade 10.9

IMPORTANT!

Carefully Clean

Shaft & Hub Bore

& Keep Free of Any

Lubricant

Shaft

1 Clean hub O.D. and Shrink Disc bore and

lightly lubricate hub O.D. before assembly

of Shrink Disc on hub.

2 Carefully clean shaft and hub bore from

any lubricant prior to mounting hub onto

shaft. THIS STEP IS VERY IMPORTANT,

since it will greatly affect the torque

transmitting capability of a Shrink Disc

connection.

3 After checking correct position of Shrink

Disc and hub, handtighten 3 or 4 equally

spaced locking screws and make sure that

outer collars of Shrink Disc are in a parellel

position. Afterwards handtighten rest of

locking screws.

4 Use torque wrench and equally tighten all

screws one after another in a clock or

counterclockwise sequence by approx.

1/4 turns (even if initially some screws will

require a very low tightening torque) until

specified tightening torque MA is reached.

NOTE: To compensate for bolt setting

during installation, a 5% higher than

specified tightening torque is recommended for final tightening round.

5 Reset torque wrench and make sure that

no screw will turn at specified tightening

torque M

.

A

NOTE: It is not necessary to check tightening

torque again after installation is completed or

equipment has been in operation.

REMOVAL

1. Loosen locking screws in several stages by

using approx. 1/2 turns, following either a

clock or counterclockwise sequence till Shrink

Disc can be moved on hub. DO NOT remove

locking screws completely.

2. Make sure any rust buildup in front of hub

is removed before hub is pulled from shaft.

RE-INSTALLATION OF SHRINK DISC

In relatively clean operating conditions, Shrink

Discs can be re-used without prior cleaning.

Severe conditions, however, require thorough

cleaning and re-lubrication with the following

or similar lubricants:

Tapers of inner rings and outer collar

bores: Molykote 3321 R-spray or

Molykote G RAPlD-spray or paste

Screwthreads and head contact area:

Multipurpose grease like Molykote BR-2

Damaged O-rinqs should be replaced.

LOCKING SCREW-TIGHTENING TORQUES "MA"

screw size M5 M6 M8 M10 M12 M16 M20 M24 M27

s mm 8 10 13 17 19 24 30 36 41

MA [Nm] 5 12 30 59 100 250 490 840 1250

MA [ft.-lbs] 3.6 8.7 22 44 74 185 362 620 922

4

Page 5

SHRINK DISC COUPLINGS

IFOR RIGID SHAFT CONNECTIONS- TRANSMIT TORQUES &

BENDING MOMENTS- PERMIT AXIAL & ANGULAR TIMING

SHRINK DISC (PREFERABLY USE UNITS WITH INTEGRATED HUB STOP) REFER

TO SHRINK DISC SPECIFICATION TABLE FOR SELECTION OF SHRINK DISC TO

MEET YOUR TORQUE & SHAFT SIZE REQUIREMENTS. CONSULT WITH US IF A

BENDING MOMENT HIGHER THAN 25% OF RATED TORQUE HAS TO BE

TRANSMITTED.

COUPLING SLEEVE CAN BE SUPPLIED BY BIKON CORP. USE

MATERIAL WITH A YEILD POINT OF AT LEAST 36000 PSI FOR LIGHT

DUTY APPLICATIONS, BUT AISE 1045 (OR BETTER) FOR MEDIUM DUTY

APPLICATIONS.

SEE SHRINK DISC SPECIFICATION TABLE FOR DIMENSIONS "L" & 'e"

CHAMFER

OPTIONAL RECESS

ON SLEEVE O.D.

ONLY IF SHRINK

DISCS WITH

INTEGRATED HUB

STOPS ARE USED

≥ 15˚

RECOMMENDED SLEEVE DIMENSIONS FOR

SHRINK DISC COUPLINGS USING SERIES 01

& SERIES 03 SHRINK DISC SIZE 140 &

LARGER

SHRINK DISC U V SERIES 01 SERIES 03

SIZE

140 5/8 1/8 8.00 9.00

145 thru 155 5/8 1/8 8.38 9.50

160 thru 175 7/8 1/8 9.00 10.50

180 thru 200 7/8 3/16 11.00 12.63

220 7/8 3/16 12.25 14.38

240 1 3/16 13.25 15.38

260 1 3/16 14.00 16.63

280 1-1/4 1/4 15.50 18.25

300 1-1/4 1/4 16.25 18.50

320 1-1/4 1/4 16.25 19.00

340 1-1/2 1/4 17.75 21.00

350 & 360 1-1/2 1/4 18.25 21.25

380 & 390 1-1/2 5/16 18.75 22.25

420 1-3/4 5/16 21.00 24.75

440 & 460 1-3/4 3/8 22.25 26.25

480 & 500 1-3/4 3/8 23.75 28.25

REQUIRED

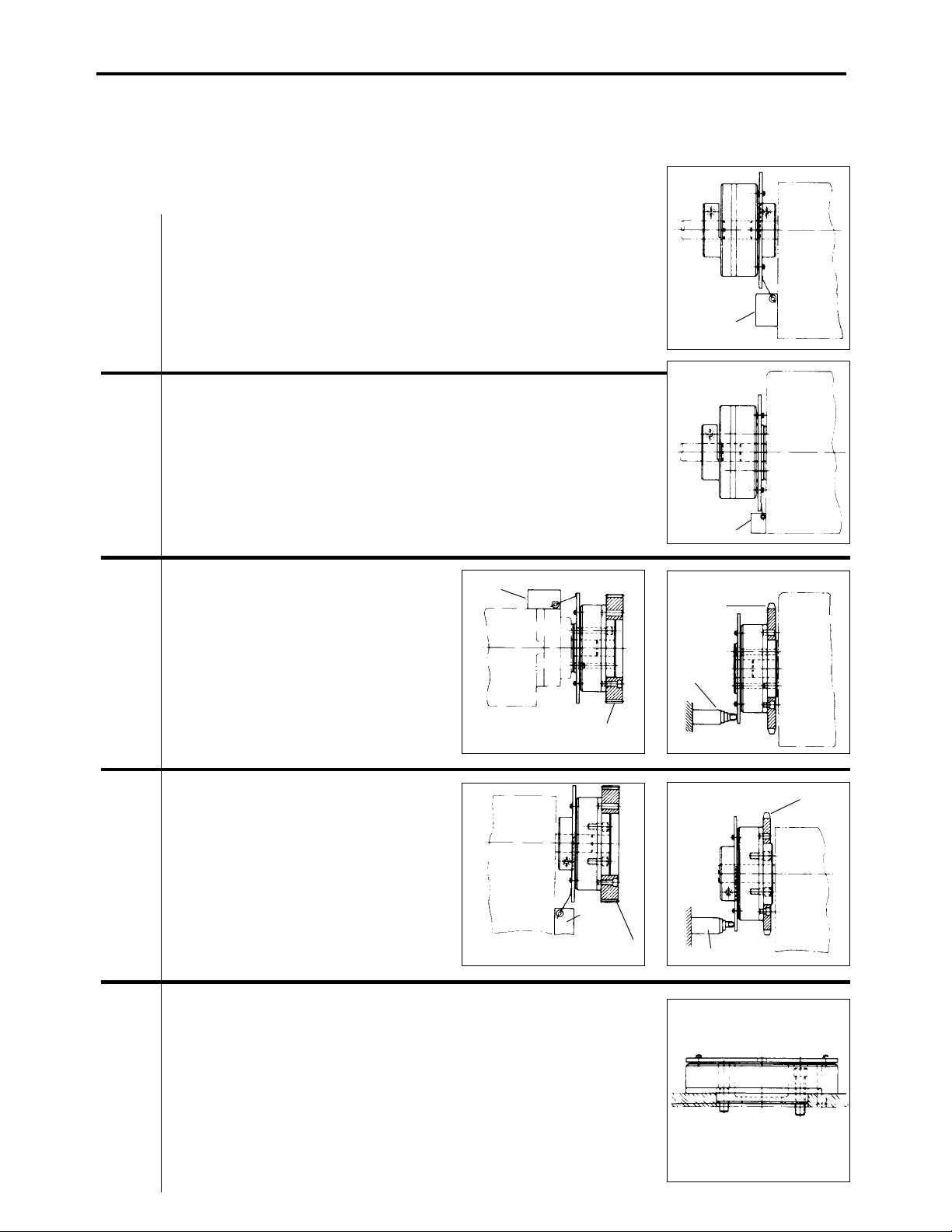

ASSEMBLIES CLUTCH TYPE

(FIG. 3) C FC F S

HUB ➊➊

FLANGE PLATE ∑∑∑∑

TYPES C, FC AND F, S

CLUTCHES

DRIVE PLATE ∏∏∏∏

BODY (S, C) ππ

DETECTOR PLATE ∫∫∫∫

BODY (F, FC) ❻❻

PLUNGERS ❼ ❼❼❼

SPRINGS ΩΩΩΩ

DOWEL PIN

➊

HUB (NOT USED ON F, S)

∑

FLANGE PLATE FOR F & S (ONLY)

RETAINER RING FOR C & FC (ONLY)

DRIVE PLATE

OR

∏

❼

PLUNGER

Ω

SPRING

Fig.3

INSTALLATION INSTRUCTIONS TYPES C AND FC CLUTCH COUPLINGS

ASSEMBLY INSTRUCTIONS

See Fig. 3 for required assemblies

Important: To obtain maximum accuracy in

positioning the DRIVEN MEMBER, the INDEX

DRIVE "CAM SHAFT" must be in the EXACT

CENTER OF DWELL position. See CAMCO

drawing applicable to the Index Drive Model.

1. Insert PLUNGERS ❼ into SPRlNGS Ω and

install the assemblies in the BODY pockets. Test for free movement of the plungers.

Lightly lubricate the body pockets, springs

and plungers with Mobilgrease 77 or

equivalent.

Caution: Do not overlubricate. Heavy

lubrication may prevent clutch disengagement.

2. Install the FLANGE PLATE ∑ into the

DRIVE PLATE ∏ Lightly lubricate both

sides of the DRIVE PLATE and the machined face of the BODY with

Mobilgrease 77 or equivalent.

❻

F, FC BODY

∫

DETECTOR PLATE

MOUNTING SCREWS

π

S, C BODY

OR

5

Page 6

3. Align the PLUNGERS with the tapered

seats in the DRIVE PLATE.

5. Place BODY with the PLUNGERS face

down on a solid surface.

4. Type C Clutch COUPLING: Insert mounting

screws through the FLANGE PLATE into

the tapped holes in the BODY π . Alternately tighten the screws until the flange

plate is seated on the BODY.

4A.Type FC Clutch COUPLING: Insert the

mounting screws through the BODY ❻ and

FLANGE PLATE into the tapped holes in

the INDEX DRIVE flange. Alternately tighten

the screws until the FLANGE PLATE is

seated on the BODY.

5. Assemble the DETECTOR PLATE ∫ on the

clutch BODY and secure both the DETECTOR PLATE and the PLUNGERS with the

detector mounting screws.

6. Install the assembled clutch on the output

shaft or flange of the INDEX DRIVE.

7. Press the dowel pins in the HUB ➊ until

they protrude approximately .125" beyond

the machined face of the HUB.

8. Insert the HUB mounting screws through

the HUB into the tapped holes in the

DRIVE PLATE. Tighten the HUB mounting

screws.

9. Drive the dowel pins flush with the HUB

shoulder.

WARNING: Hub mounting screws and

dowel pins must not protrude from the

drive plate as they may lock against the

adjacent surface, making the clutch

inoperative.

10. Place driven shaft in HUB ➊. The respective shafts should not protrude from the

face of the HUB or the FLANGE PLATE.

Tighten clamp screws.

11. Note: Shafts must be aligned within .003"

TIR, and there must be an airgap between

the DRIVE PLATE and CLUTCH BODY of

.004" to .01". Check clearances with a

shim or feeler gauge throughout the full

diameter of the clutch.

Warning: Excessive misalignment will

cause the coupling to lock.

12. Test for proper torque setting.

DISASSEMBLY INSTRUCTIONS

(Types C and FC)

1. Remove HUB mounting screws and separate the HUB from the CLUTCH. (Resistance may be caused by the dowel pins.)

2. Type C Clutch: Remove output shaft clamp

screws.

2A. Type FC Clutch: Remove mounting screws.

3. Remove the clutch from the index drive.

6. Remove DETECTOR MOUNTING screws

which will release the PLUNGER assemblies.

Warning: The plunger assemblies are

spring loaded and under tension. Bodily

injury could result if the plunger assemblies

are not retained against a solid surface.

INSTALLATION INSTRUCTIONS TYPES

F AND S CLUTCHES

ASSEMBLY INSTRUCTIONS

See Fig. 3 for required assemblies

Important: To obtain maximum accuracy in

positioning the DRIVEN MEMBER, the lNDEX

DRIVE "CAM SHAFT" must be in the EXACT

CENTER OF DWELL position. See CAMCO

drawing applicable to the Index Drive Model.

1. Insert PLUNGERS ❼ into SPRINGS Ω and

install the assemblies in the BODY pockets. Test tor free movement of the plungers.

Lightly lubricate the body pockets, springs

and plungers with Mobilgrease 77 or

equivalent.

Caution: Do not overlubricate.

Heavy lubrication may prevent clutch

disengagement.

2. Install the FLANGE PLATE ∑ into the

DRIVE PLATE ∏. Lightly lubricate both

sides of the DRIVE PLATE and the machined face of the BODY with Mobilgrease

77 or equivalent.

3. Align the PLUNGERS with the tapered

seats in the DRIVE PLATE.

4. Type S Clutch: Insert mounting screws

through the FLANGE PLATE into the

tapped holes in the BODY π . Alternately

tighten the screws until flange plate is

seated on the BODY.

4A.Type F Clutch: Insert mounting screws

through the BODY ❻ and FLANGE PLATE

into the tapped holes in the INDEX DRIVE

flange. Alternately tighten the screws until

the FLANGE PLATE is seated on the BODY.

5. Assemble the DETECTOR PLATE ∫ on the

clutch BODY and secure both the DETECTOR PLATE and the PLUNGERS with the

detector mounting screws.

Note: Type F Clutch only. If alternate

assembly, with the clutch BODY mounted

on the INDEX DRIVE flange is required,

reassemble as follows:

Remove the mounting screws. Insert the

mounting screws through the FLANGE

PLATE first, and then the BODY, into the

tapped holes in the INDEX DRIVE flange.

4. Type C Clutch: Remove mounting screws.

6

Page 7

Warning: Do not remove the detector

mounting screws as they must retain the

plunger assembly.

6. Install the assembled clutch on the output

shaft or flange of the INDEX DRIVE.

7. Prepare the DIAL, SPROCKET or DRIVEN

MEMBER with a center hole and mounting

holes to mate with the tapped holes in the

DRIVE PLATE. (Refer to CAMCO assembly

drawings.)

8. Install DIAL or DRIVEN MEMBER and

check if it is free to rotate.

9. Tighten DIAL mounting screws. Disengage

clutch and test for clearance between the

DRIVE PLATE and BODY (approximately

.002"). The center hole of the DIAL must

also clear the FLANGE PLATE.

WARNING: Dial mounting screws must not

protrude from the drive plate as

they may lock against the adjacent

surface making the clutch inoperative.

10. Remove the flange plate and

dial-drive plate assembly.

Caution: Do not loosen the dial

screws.

(BODY TO INDEX DRIVE MOUNTING

11. Using the DRIVE PLATE as a "Jig,"

drill and ream the DIAL dowel holes.

Deburr all holes.

12. Install dowel pins through the DIAL

into the DRIVE PLATE.

Warning: Dowel pins must not protrude

from the drive plate as they may lock

against the adjacent surface, making the

clutch inoperative.

13. Reassemble the FLANGE PLATE and DIALDRIVE PLATE assembly to the clutch

BODY.

14. Test for proper torque setting.

Note: For added reliability and/or high

speed operation, a bronze bushing may be

inserted between the DIAL PLATE and the

FLANGE PLATE. Special bronze flange

plates are also available from CAMCO.

DISASSEMBLY INSTRUCTIONS

(Types F and S)

1. Remove DIAL mounting screws.

2. Remove DIAL or other driven member by

tapping under the DIAL to overcome dowel

pin friction.

3. Type S Clutch: Remove output shaft clamp

screws.

3A.Type F Clutch: Remove mounting screws.

4. Remove the clutch from the index drive.

5. Type S Clutch: Remove mounting screws.

6. Place BODY with the PLUNGERS face

down on a solid surface.

7. Remove DETECTOR MOUNTING

screws which will release the PLUNGER

assemblies.

Warning: The plunger assemblies are

spring loaded and under tension. Bodily

injury could result if the plunger assemblies

are not retained against a solid surface.

WARNING

High humidity, contaminants or wash down applications may cause rust within the clutch resulting in

operational failure. Lubricate every six months or

more frequently as the applications require.

CAMCO CLUTCHES are precision assemblies and

should not be modified. Modification of the clutch

will VOID THE CAMCO WARRANTY.

DETECTOR PLATE

MOUNTING SCREW

DOWEL PIN

FLANGE)

∏

DRIVE PLATE

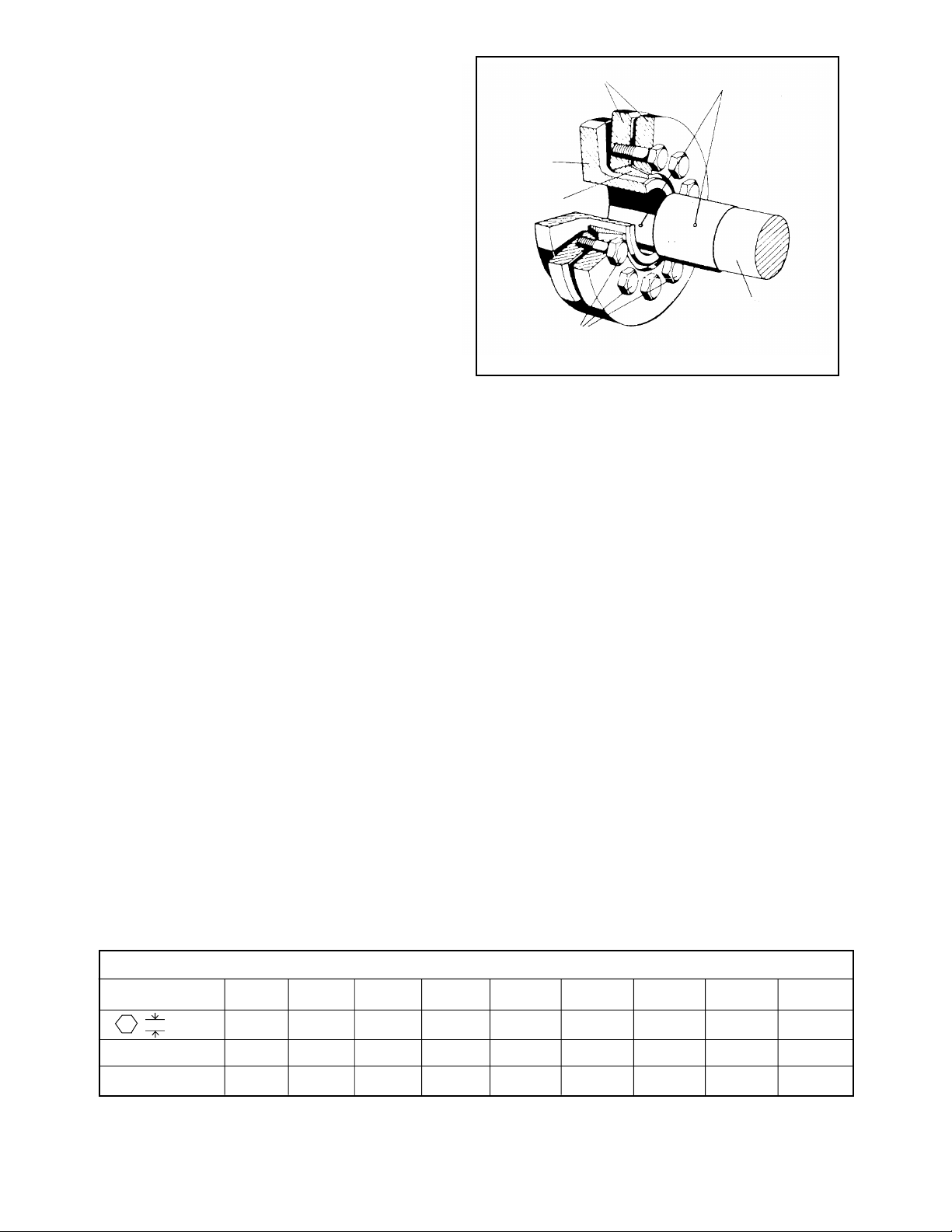

Fig.4

TYPE D CLUTCH

➊

DETECTOR

PLATE

BODY

MOUNTING

SCREW

∑

BODY

π

SPRING

∫

PLUNGER

DOWEL PIN

(DRIVE PLATE TO

DIAL PLATE

BODY MOUNTING SCREW

SPRING

PLUNGER

DRIVE PLATE

D

CLUTCH PILOT (INDEX

DRIVE)

C

LIMIT SWITCH

INSTALLATION INSTRUCTIONS TYPE D

OVERLOAD CLUTCH FOR DIAL PLATE

APPLICATIONS

ASSEMBLY INSTRUCTIONS

See Fig. 4 and Fig. 5

Important: To obtain maximum accuracy in

positioning the DIAL PLATE, the INDEX DRIVE

"CAM SHAFT" must be in the EXACT CENTER

OF DWELL position. See CAMCO drawing

applicable to the Index Drive Model.

1. Lubricate output shaft and dial mounting

surface of the INDEX DRIVE with

Mobilgrease 77 or equivalent.

2. Prepare the DIAL with center hole as

required. (Refer to CAMCO assembly

drawings.)

3. Place the DIAL on the output mounting

flange of the INDEX DRIVE and check if it is

free to rotate.

Note: Dowel pins are factory installed

when the clutch is supplied with the INDEX

DRIVE.

7

DETECTOR PLATE

BODY

DOWEL PIN

(BODY TO INDEX DRIVE MOUNTING

FLANGE)

A

DIAL PLATE

B

MOUNTING FLANGE (INDEX DRIVE)

DOWEL PIN

(DRIVE PLATE

TO DIAL PLATE)

ALTERNATE OVERLOAD DETECTION METHOD

(DETECTOR ROD SUPPLIED BY CUSTOMER

Fig.5

Page 8

4. Install dowel pins in the INDEX DRIVE

mounting flange to insure proper positioning to the clutch BODY.5. Insert BODY ∑

into DRIVE PLATE ∏ and through the

center hole of the DIAL.

Note: Do not assemble SPRINGS, PLUNGERS or DETECTOR PLATE on the BODY.

6. Attach the clutch BODY to the INDEX

DRIVE output mounting flange with the

body mounting screws.

Note: A .002" minimum to .004" maximum

clearance gap must exist between the

DRIVE PLATE and the BODY, around the

full circumference of the clutch.

7. Clearance Procedure (See Fig. 5)

A. Measure dimension "A" (bottom

surface to BODY to bottom

surface of BODY detent).

B. Measure dimension "B" (top surface

of DRIVE PLATE to top surface of

dutch pilot).

C. Subtract "B" from "A".

D. If less than .002", add shim at surface

"C" (between clutch pilot and

bottom surface of BODY)

to obtain clearance

gap of .002" to .004".

E. If greater than .004" grind BODY,

(between DRIVE PLATE and DIAL

PLATE) to obtain clearance gap of

.002" to .004".

8. Remove BODY. Insert PLUNGERS ∫ into

SPRINGS π and install the assemblies in

the BODY pockets. Test for free movement

of the plungers. Lightly lubricate the body

pockets, springs and plungers with

Mobilgrease 77 or equivalent.

Caution: Do not overlubricate.

Heavy lubrication may prevent clutch

disengagement.

9. Align the PLUNGERS with tapered seats in

the DRIVE PLATE ∏. Re-install BODY.

10. Rotate the DIAL PLATE to desired position.

Place .010" shim stock between the BODY

and the DRIVE PLATE and alternately

tighten body mounting screws, clamping

the DIAL PLATE. Shim stock should be

placed at 90° intervals.

Caution: Do not cock the plunger.

The plungers must retract evenly into the

clutch body.

11. Using the BODY and DRIVE PLATE as a

"JIG," drill and ream the DIAL PLATE dowel

holes. Theholes should not go completely

through the DIAL PLATE. DIAL PLATE

dowel pins should be .125" shorter than

the combined thickness of the DIAL and

DRIVE PLATES.

12. Disassemble, deburr and clean all parts.

Remove .010" shim stock.

13. Dowel pin

the DRIVE PLATE to the DIAL PLATE.

Note: Dowel pins are factory installed when

the CLUTCH and DIAL PLATE are supplied

with the INDEX DRIVE.

Warning: Dowels pins must not protrude from

the DRIVE PLATE or DIAL PLATE as they may

lock against the adjacent surtace, making the

clutch inoperative.

14. LIGHTLY lubricate the DRIVE PLATE and

mating surtace of the clutch BODY with

Mobilgrease 77 or equivalent.

15. Assemble complete clutch. Alternately tighten

body mounting screws following the procedures in instruction #10.

16. Assemble the DETECTOR PLATE ➊ on the

clutch BODY and secure both the DETECTOR

PLATE and the PLUNGERS with the detector

mounting screws.

17. Check it DIAL PLATE can be disengaged.

18. Test tor proper torque setting. The clutch

should disengage within 10% to the nameplate torque rating.

Note: All clutches are torque tested by

CAMCO prior to shipment.

DISASSEMBLY INSTRUCTIONS (TYPE D)

1. Remove DETECTOR MOUNTING screws

which will release the PLUNGER assemblies.

2. Alternately loosen and remove the BODY

mounting screws.

Warning: The plunger assemblies are spring

loaded and under tension. Bodily injury could

result if the plunger assemblies are not released slowly by the body mounting screws.

3. Remove the clutch BODY.

Note: It may be necessary to tap under the

DIAL PLATE to overcome the friction caused

by the dowel pins that register the body to the

mounting flange.

4. Clean and inspect all parts tor wear.

5. Lubricate per assembly instructions 1, 8,and

14.

WARNING

High humidity, contaminants or wash down

applications may cause rust within the clutch

resulting in operational failure. Lubricate every

six months or more frequently as the applications

require.

8

Page 9

CAMCO CLUTCHES are precision assemblies

and should not be modified. Modification of the

clutch will VOID THE CAMCO WARRANTY.

APPLICATION RECOMMENDATIONS

1. Clutch operation in dusty or corrosive environments may require special preparation.

Contact CAMCO for special modifications.

2. On applications other than the output of a

CAMCO Index Drive, clutch speeds must

not exceed 100 RPM.

3. High humidity, contaminants, or wash

down applications may require special

protection. If rust forms within the clutch, it

may act as a solid coupling and will not

release under overload conditions. Lubricate every six months or more frequently

as the application requires.

Caution: Lubricate the spring pockets with

a light film to grease. Heavy lubrication of

the spring pocket may lock the plunger, due

to hydraulic pressure, preventing clutch

disengagement.

4. Use bronze bushings on sprockets, dials,

gears or pulleys when used at the high end

of the speed range (100 RPM) to reduce

wear. Special bronze flange plates are

available.

5. Clutch couplings require accurate shaft

alignment of .003" TIR. Insure that a clearance gap is maintained between the body

and the drive plate around the full circumference to the clutch (Type FC, C).

6. Use flange mounted clutches and clutch

couplings whenever possible. These

models provide superior mounting reliability (Type D, F, FC).

7. Dowel pins should not protrude from the

drive plate or driven members, as they may

lock against the adjacent surface.

8. Do not operate without the detector limit

switch, electrically disconnecting the prime

mover (motor), as galling of the contacting

surfaces may result.

9. On high inertia applications, braking the

prime mover is recommended, in the dwell

cycle of the INDEX DRIVE, to minimize over

travel.

10. CAMCO recommends using limit switches

with rated travel not exceeding .008" for

actuation.

9. On high inertia applications, braking the

prime mover is recommended, in the dwell

cycle of the INDEX DRIVE, to minimize over

travel.

10. CAMCO recommends using limit switches

with rated travel not exceeding .008" for

actuation.

11. The torque required to re-engage the clutch

is usually 25% of the rating. Contact

CAMCO for special design, anti-friction

materials if the clutch is to be used with

very low torque settings.

12. Never use the clutch with a torque setting

close to the calculated operating torque.

Actual torques may be higher. Torque

spring tolerances and coefficients of friction

vary with temperature and application.

Allow 130% (1.3 service factor) when

applying a CAMCO clutch.

9

Page 10

10

Page 11

11

Page 12

99A45938000000 USA 6/99 0136

Loading...

Loading...