Page 1

®

The Driving Force in Automation

The Driving Force in Automation

SERVICE MANUAL

MINIATURE

RGD/RGS SERIES INDEX DRIVES

MODELS

40, 50, 70, & 80 RGD/RGS

“WARNING”

This is a controlled document. It is your responsibility to deliver this information to the end user of the CAMCO indexer.

Failure to deliver this, could result in your liability for injury to the user or damage to the machine.

For copies of this manual call your Customer Service Representative 800/645-5207.

“WARNING”

Page 2

TABLE OF CONTENTS

INTRODUCTION..............................................................................................................2

WARNINGS AND CAUTIONS .........................................................................................2

OIL SEAL REMOVAL .......................................................................................................2

SP ARE PARTS KIT..........................................................................................................2

DISASSEMBL Y ................................................................................................................3

REMOVAL OF OUTPUT SHAFT .....................................................................................3

INSPECTION OF CAM FOLLOWERS.............................................................................3

FOLLOWER REMOV AL ...................................................................................................3

REMOVAL OF BEARINGS ..............................................................................................3

INPUT SHAFT/ CAM REMOVAL .....................................................................................4

ASSEMBLY ......................................................................................................................4

PRIOR TO REASSEMBL Y ...............................................................................................4

ASSEMBLING INPUT SHAFT .........................................................................................4

ASSEMBLING OUTPUT SHAFT .....................................................................................5

SETTING CAM.................................................................................................................5

HOW TO ORDER PAR TS................................................................................................7

BALLOONED P ARTS DRAWINGS ..................................................................................8

PARTS LIST.....................................................................................................................9

1

Page 3

INTRODUCTION

This service manual pertains to the disassembly and assembly of CAMCO’s Miniature RGD Series Index

Drives MODELS 40, 50, 70 & 80RGD/RGS.

The manual is to be used in conjunction with the General Service Manual which describes the lubrication and

general maintenance of CAMCO Index Drives.

For your convenience in identifying and ordering spare or replacement parts, a complete Bill of Materials is

included in this manual.

Some users of Index Drives have the facilities and trained personnel to accomplish service repair. You must

determine the extent to which intricate servicing should be done in your facility . When in doubt, CAMCO

recommends that CAMCO trained servicemen make the repairs.

WARNINGS AND CAUTIONS

Statements in this manual proceeded by the words WARNING or CAUTION and printed in italics are very

important. We recommend you take special notice of these during service or repair.

WARNING

Means there is the possibility of personal injury to yourself or others.

CAUTION

Means there is the possibility of damage to the CAMCO unit.

OIL SEAL REMOVAL

The only repair possible without disassembly of the indexer is replacement of oil seals. To remove oil seals, drill

a number of holes into the case of the seal. The seal may then be removed with a pointed tool. Be sure to

remove all metallic chips created during the drilling of removal holes. A new seal may be installed as outlined in

the “Oil Seal Installation Recommendations” section of the “General Service Manual”.

SPARE PARTS KIT

CAMCO offers a Spare Parts Kit for all CAMCO index drive models CAMCO builds. These kits include oil seals,

bearings, shims and cam followers. These are components that will most likely require replacement during

repair of your index drive. CAMCO recommends a Spare Parts Kit be purchased and kept on hand prior to any

disassembly of your CAMCO drive.

A complete list of components supplied in the Spare Parts Kit can be found in the parts list located in the rear

of this manual. The asterisk behind the item number indicates those parts supplied with the Spare Parts Kit.

BEFORE STARTING

Before starting disassembly of your CAMCO unit you should read and review the following instructions. These

provide important information on parts and procedures necessary to successfully complete your repair.

Comply with all Warnings and Cautions.

Read the “Trouble Shooting Guide” section of your “General Service Manual” before disassembling CAMCO

units. CAMCO recommends returning defective equipment for inspection and repair whenever possible.

CAMCO uses Loctite to secure all screws and setscrews. If you encounter a fastener that is difficult to remove,

apply heat to the screw and remove while still warm.

2

Page 4

DISASSEMBLY

1. Remove all accessory equipment such as

clutches, reducers, sprockets, etc.

2. Drain oil and flush with flushing solvent. Retain

any chips or broken pieces that you may find.

These may aid in diagnosis.

3. Remove round access cover. This may be done

by drilling a hole in the cover, threading in a

sheet metal screw, and pulling with pliers.

REMOVAL OF OUTPUT SHAFT.

4.

A. Rotate the input shaft until the output is in

dwell.

B. Remove all upper and lower output bearing

cartridge capscrews.

looseness. It should not exceed .001 inch.Do

not confuse radial loosness with axial endplay .

Endplay will be from .03 to .06 as a normal

condition. If it exceeds .06 it may require

follower replacement.

C. Remove the upper and lower output

cartridge capscrews.

NOTE: Keep the shims with the cartridge. You will

be asked to reinstall or replace with same shim

thickness during assembly .

D. Pull the output bearing thru the cartridge

opening. It may be necessary to tap on the

lower end of the output shaft with a soft

faced hammer to drive the output shaft and

bearing cup out.

5.

INSPECTION OF CAM FOLLOWERS.

NOTE: Generally , followers are replaced as added

insurance against eventual failure.

6.

REPLACEMENT OF CAM FOLLOWERS.

Follower replacement in the field is not

recommended by CAMCO. All follower removal

and replacement must be done at CAMCO. Simply

follow “RETURN FOR REPAIR” instructions in the

“General Service Manual”. CAMCO will provide

quick turnaround on standard follower replacement

or standard follower wheel/shaft assembly

replacement.

This is due to the size of the followers and the tools

required to properly remove and install without

damage to the follower stud or follower wheel.

REMOVAL OF BEARINGS.

7.

A. Remove the output bearing cones from the

output shaft using a small diameter

aluminum bar and hammer. Place the bar

against the protruding edge of the cone and

tap with hammer, working around the

perimeter to prevent binding. Continue this

until the cone is free of shaft.

Inspect followers for damage or radial

3

Page 5

B. Remove any remaining output bearing from

the housing by the same method as

described in step “A”.

8. INPUT SHAFT/CAM REMOV AL.

NOTE: The output shaft must be removed prior to

input shaft removal.

A. Rotate the input shaft and inspect all parts

for wear or damage. Endplay in the input

shaft is not permissible.

B. Match mark both input cartridges relative to

the housing. These must be reinstalled in

the same side and position since they are

eccentric.

C. Remove all input bearing cartridge

capscrews.

D. Tap on end of input shaft to drive the

opposite cartridge from the housing. Then

drive the shaft in the opposite direction for

removal of the remaining cartridge.

NOTE: Keep the shims with their respective

cartriges. You will be asked to reinstall or replace

the same shim thickness during reassembly.

E. Use a wheel puller to remove one bearing

cone from the input shaft.

F. Support the side of the cam where the

bearing was removed and press or drive the

shaft through from the remaining bearing

side. This will remove the remaining

bearing and cam simultaneously.

9. Remove input bearing cups from the cartridges

with a wheel puller, by prying or by drilling and

tapping for jack screws.

10. Press out all oil seals from both input and

output cartridges.

ASSEMBLY

PRIOR TO REASSEMBLY

Clean and deburr all parts before reassembly .

Follow tightening torque and Loc-tite

recommendations as outlined in the General

Service Manual.

1. Use an arbor press to press bearing cups

into input cartridges. Coat outside of cup

and the cartridge bore with anti-sieze

lubricant prior to pressing. Fill cavity of

cartridges with bearing grease

recommended in the “General Service

Manual”.

ASSEMBLING INPUT SHAFT.

2.

A. Use arbor to press cam onto shaft. Be sure

key is installed into shaft. Apply anti-seize

lubricant on shaft and cam bore prior to

pressing.

B. Center cam on shaft.

C. Use an arbor to press bearing cones

ontoshaft. Coat shaft and bearing bore with

anti-sieze lubricant prior to pressing.

D. Install the input cartridges. Be sure to install

the same exact shims or equivalent height

as removed during disassembly.

E. Line up match marks.

F. Tighten cartridge mounting screws.

G. If endplay exists remove an equal amount of

shims from each side until there is a small

amount of drag (1 to 2 inch ozs.) from

preloading the bearings. In rare instances it

may be necessary to remachine the

cartridges if all shims have been removed

and endplay still exists.

4

™

Page 6

H. Loosen the cartridge screws and rotate the

cartridge tops to the most rearward position

attainable within the slots provided in the

cartridges.

3. ASSEMBLING OUTPUT SHAFT

A. Install bearing cones on the output shaft.

Coat the shaft and bore with an anti-sieze

lubricant prior to installation. The bore of

the bearing should be heated prior to

pressing, if a heat gun is available. Tap in

place.

B. Install the bearing cup in the lower output

bore of the housing. Coat bore and cup

with anti-sieze lubricant and tap in place.

C. Position the cam so the dwell rib is facing

the output end of the housing. (Keyways

facing rearward.)

D. Insert the output shaft/follower wheel

assembly into the housing. Be sure the

followers straddle the dwell rib during

insertion.

E. Install the upper output bearing cup in the

housing and the cup with anti-sieze

lubricant and tap into place.

F. Install both lower and upper output cartridges

with the equivalent shim thickness removed

in disassembly .

G. Tighten mounting screws.

H. If endplay exists, remove shims until there is

a small amount of drag from preloading the

bearings. In rare instances it may be

necessary to remachine the cartridges if all

shims are removed and endplay still exists.

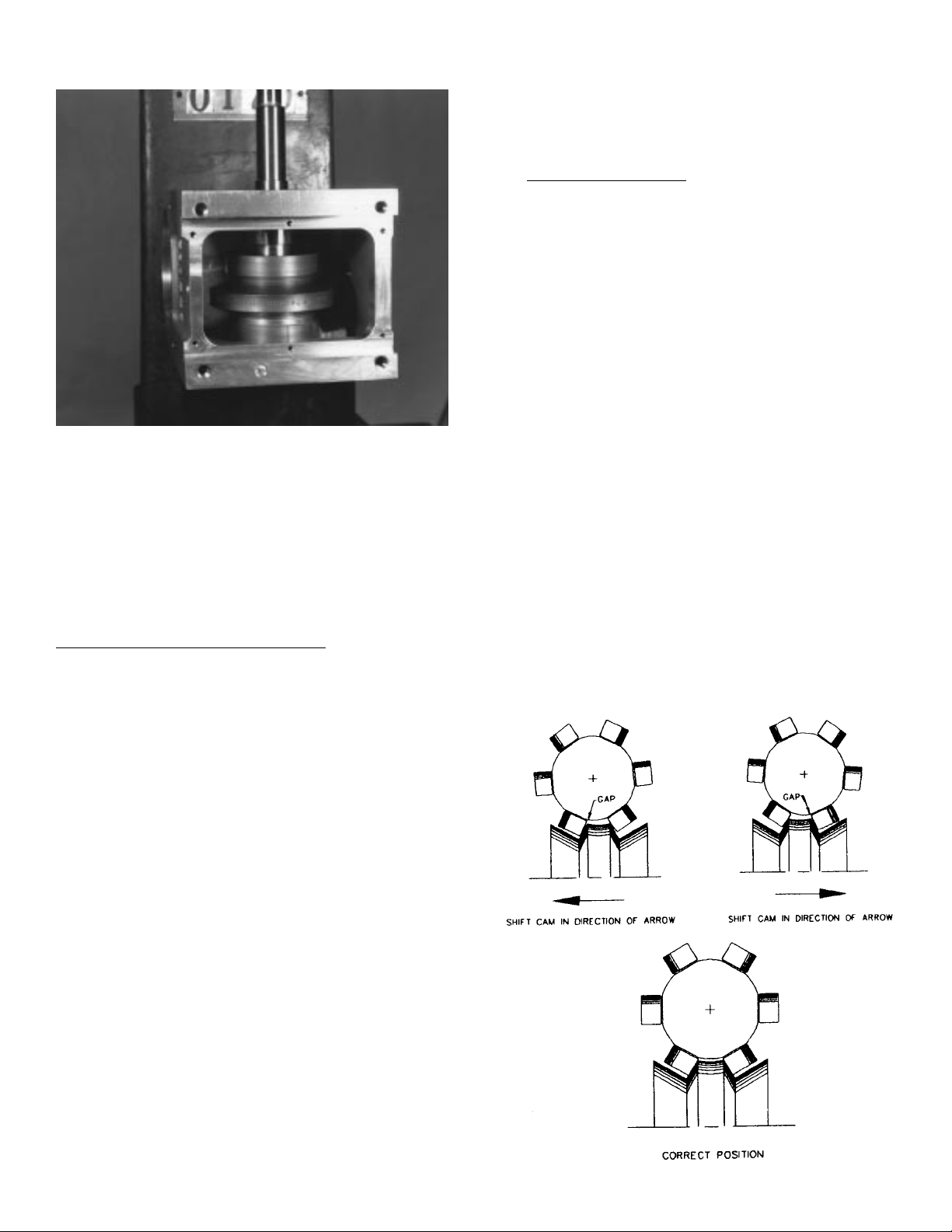

SETTING THE CAM

4.

CAUTION: This mechanism is designed to operate

with adjacent followers in close ontact along their

entire width with the surface of the cam during the

dwell period. Unless this condition is achieved by

proper installation, the mechanism will not transmit

its rated load, and furthermove, serious damage to

the cam and output shaft will occur.

A. Place the cam in dwell (Keyway facing

rearward).

B. Rotate the tops of both input cartridges

toward the output until the cam followers

touch the cam.

C. Shift the cam axially (using shims between

the housing and cartridge) until two

adjacent followers are in full contact with the

cam rib. (This will also require adjustment

to the eccentric cartridges along with the

axial adjustment of the cam).

1.) If there is a gap at the root of the

follower the cam should be shifted

toward the follower.

5

Page 7

2.) If there is a gap at the tip of the follower

the cam should be shifted away from the

follower.

D. Apply “Prussian Blue” to entire cam track.

E. Rotate the cam shaft slowly with a small

handrank to ensure that:

1.) Both rollers are in contact with the cam rib

in dwell. Look for uniform bluing pattern.

2.) The follower is free at center of crossover

track.

3.) You do not encounter unusual resistance

in motion. The bluing pattern should be

fairly uniform from side to side during

motion. If a patch of blueing is worn off the

outside of the cam rib on one side of the

cam and not the other, shift the cam .002

to .005 inches in the direction of the worn

side. Do not overshift the cam or knocking

will occur.

4.) The cam bluing should never be worn off

the leading or exit edges of the cam ribs.

If so this is an indication that the cam is

not adjusted properly.

5.) There should be no looseness in any

dwell. If there is, adjust the eccentric input

cartridges to slightly preload the loosest

dwell.

5. Install a new access cover.Press in flush with

housing.

6. Grease pack the main output bearing with

lubricant specified in the “General Service

Manual”.

7. Install new oil seals as described in the “General

Service Manual”.

8. Fill with lubricant recommended in the “General

Service Manual”. (See oil capacities below)

Oil Capacities

40RGD/RDS = 6 oz.

50RGD/RGS = 16 oz.

70RGD/RGS = 20—24 oz.

80RGD/RGS = 30—38 oz.

CAUTION: Be sure to add the amount shown

above. Too low a level may result in unit failure.

40, 50, 70 & 80

OIL LEVEL CAPACITIES

F. Tighten the input cartridge capscrews and

scribe new match marks on cartridge and

housing.

G. Double check for endplay in output shaft.

Endplay is not permissible in output shaft.

H. Remove the input cartridges (one at a time)

and coat the surface between the shims and

the housing with “General Electric Silicone

Rubber RTV -6” (to insure against leakage) and

reinstall, aligning the match marks, tighten the

screws and dowel in place.

I. Remove the output cartridges (one at a time)

and coat the surface between the shims and

the housing with “General Electric Silicone

Rubber RTV-6” (to insure against leakage and

reinstall, aligning the match marks and tighten

the screws.

Fill Oil to

Center of

Input Shaft.

6

Page 8

HOW TO ORDER P ARTS

Please refer to parts list shown in this manual. This parts list is for a standard Index Drive. If you feel your drive

is nonstandard or you are in doubt you should contact CAMCO Customer Service at (847) 459-5200 and

request a Bill of Material for your specific unit based on serial number. CAMCO maintains records on all units

for a period of ten years.

You may order parts per the standard Bill of Material even if your unit is nonstandard. CAMCO’s order entry

people will review the closed order file based on the following information and supply you with the correct part.

REQUIRED INFORMATION

1. Original purchase order number (if available)

2. Customer name (original purchaser of drive)

3. Model number (located on name plate)

4. Serial number (located on name plate)

5. Approximate date of purchase.

TO ORDER PARTS contact CAMCO “Order Entry Department” Wheeling, Illinois

Phone (847) 459-5200 or Fax (847) 459-3064

A. Describe the parts required and the 14 digit part number as listed in the Standard Bill of Materials or a

Special Bill of Materials pertaining to your unit. State if you are using a Standard or Special bill of

material.

B. Give as much of the above required information as possible.

ON WARRANTY

Replacement parts CAMCO will send freight prepaid via most practical means.

CAMCO will issue a “Returned Material Authorization Number” (RMA#) for the return of defective parts for

inspection. CAMCO will bill customer for repair parts. When inspection of returned parts has been completed

and determined to be a warranty problem, CAMCO will issue a credit to the customer for the repair parts and

freight charges.

ON NON-WARRANTY

Replacement or spare parts, with approved credit, are F.O.B. our plant Wheeling, Illinois.

7

Page 9

40, 50, 70 & 80RGD/RGS

SIDE VIEW

END VIEW

8

Page 10

PARTS LIST FOR 40RGD INDEX DRIVE (STANDARD CONFIGURATION)

1 ......................................................4MD55426001002 Housing

2 ......................................................4MB51870007002 Input Shaft Dbl

........................................................4MA49071007001 Input Shaft Sgl

3 ......................................................4MB51609004006 Output Shaft/Foll Whl 6 Hole 3/8 Foll

........................................................4MB51610004008 Output Shaft/Foll Whl 8 Hole 3/8 Foll

........................................................4MB51611004010 Output Shaft/Foll Whl 10 Hole 1/4 Foll

........................................................4MB51612004012 Output Shaft/Foll Whl 12 Hole 1/4 Foll

4 ......................................................___________ “Cam, (Specify Number Of Stops And “

........................................................ “Index Time, Contact Camco For “

........................................................ “Assistance, Order In Matched Sets)”

5 ......................................................4MB51655003002 “Cart, Output Large “

6 ......................................................4MB51874003001 “Cart, Input”

7 ......................................................4MA51903000000 Bore Plug

8 ......................................................95A51910300000 Shcs M4 X 10mm Lg.

9 ......................................................84D07329470000 Oil Seal C/R 13534

10 ....................................................4MA51916018800 Shim Outp Lg .002

........................................................4MA51916028800 Shim Outp Lg .005

........................................................4MA51916038800 Shim Outp Lg .010

........................................................4MA51916048800 Shim Outp Lg .003

11 .................................................... 86D07328270022 Bearing Cup L68111

12 ....................................................86D07328270021 Bearing Cone L68149

13 ....................................................95A51910300000 Shcs M4 X 10mm Lg.

14 ....................................................86D07328090021 Bearing Cone Lm 12749

15 ....................................................86D07328090022 Bearing Cup Lm12711

16 ....................................................4MA51652003002 “Cart, Output Small “

17 ....................................................4MA51915018800 Shim Outp Sm .002

........................................................4MA51915028800 Shim Outp Sm .005

........................................................4MA51915038800 Shim Outp Sm .010

........................................................4MA51915048800 Shim Outp Sm .003

18 ....................................................95A33042030000 Sss M 3 X 5 Lg (Cone Pt)

19 ....................................................82A49589000000 Cam Follower 3/8 Dia.

........................................................82A49590000000 Cam Follower 1/4 Dia.

20 ....................................................86D07328120021 Bearing Cone Lm11949

21 ....................................................86D07328120022 Bearing Cup Lm11910

22 ....................................................4MA51914018800 Shim 40rgd Inp .002

........................................................4MA51914028800 Shim 40rgd Inp .005

........................................................4MA51914038800 Shim 40rgd Inp .010

........................................................4MA51914048800 Shim 40rgd Inp .003

23 ....................................................95A51911070000 Bhcs M4 X 10mm Lg.

24 ....................................................84D07329480000 Oil Seal C/R 7440

25 ....................................................84D07329540000 Oil Seal C/R 8017

26 ....................................................M04K088 Key 4mm Xq X .88 Lg

27 ....................................................M06K108 Key 6mm Sq X 1.08

28 ....................................................95A33002140000 Plug .12-27 Npt Flush

29 ....................................................__________ Not Used On 40 Rgd/Rgs

30 ....................................................____________ Not Used On 40 Rgd

31 ....................................................__________ Not Used On 40 Rgd/Rgs

32 ....................................................99A44547180000 Service Manual Miniatures

33 ....................................................99A44547010000 General Service Manual

9

Page 11

PARTS LIST FOR 40RGS INDEX DRIVE (STANDARD CONFIGURATION)

1 ......................................................4MD55426001002 Housing

2 ......................................................4MB51870007002 Input Shaft Dbl

........................................................4MA49071007001 Input Shaft Sgl

3 ......................................................4MB51614004006 Output Shaft/Foll Whl 6 Hole 3/8 Dia Sgl

........................................................4MB51615004008 Output Shaft/Foll Whl 8 Hole 3/8 Dia Sgl

........................................................4MB51616004010 Output Shaft/Foll Whl 10 Hole 1/4 Dia Sgl

........................................................4MB51617004012 Output Shaft/Foll Whl 12 Hole 1/4 Dia Sgl

........................................................4MB51899004006 Output Shaft/Foll Whl 6 Hole 3/8 Dia Dbl

........................................................4MB51900004008 Output Shaft/Foll Whl 8 Hole 3/8 Dia Dbl

........................................................4MB51901004010 Output Shaft/Foll Whl 10 Hole 1/4 Dia Dbl

........................................................4MB51902004012 Output Shaft/Foll Whl 12 Hole 1/4 Dia Dbl

4 ......................................................___________ “Cam, (Specify Number Of Stops And “

........................................................ “Index Time, Contact Camco For “

........................................................ “Assistance, Order In Matched Sets)”

5 ......................................................4MB51655003002 “Cart, Output Large “

6 ......................................................4MB51874003001 “Cart, Input”

7 ......................................................4MA51903000000 Bore Plug

8 ......................................................95A51910300000 Shcs M4 X 10mm Lg.

9 ......................................................84D07329470000 Oil Seal C/R 13534

10 ....................................................4MA51916018800 Shim Outp Lg .002

........................................................4MA51916028800 Shim Outp Lg .005

........................................................4MA51916038800 Shim Outp Lg .010

........................................................4MA51916048800 Shim Outp Lg .003

11 .................................................... 86D07328270022 Bearing Cup L68111

12 ....................................................86D07328270021 Bearing Cone L68149

13 ....................................................95A51910300000 Shcs M4 X 10mm Lg.

14 ....................................................86D07328090021 Bearing Cone Lm 12749

15 ....................................................86D07328090022 Bearing Cup Lm12711

16 ....................................................4MA51652003002 “Cart, Output Small “

17 ....................................................4MA51915018800 Shim Outp Sm .002

........................................................4MA51915028800 Shim Outp Sm .005

........................................................4MA51915038800 Shim Outp Sm .010

........................................................4MA51915048800 Shim Outp Sm .003

18 ....................................................95A33042030000 Sss M 3 X 5 Lg (Cone Pt)

19 ....................................................82A49589000000 Cam Follower 3/8 Dia.

........................................................82A49590000000 Cam Follower 1/4 Dia.

20 ....................................................86D07328120021 Bearing Cone Lm11949

21 ....................................................86D07328120022 Bearing Cup Lm11910

22 ....................................................4MA51914018800 Shim 40rgd Inp .002

........................................................4MA51914028800 Shim 40rgd Inp .005

........................................................4MA51914038800 Shim 40rgd Inp .010

........................................................4MA51914048800 Shim 40rgd Inp .003

23 ....................................................95A51911070000 Bhcs M4 X 10mm Lg.

24 ....................................................84D07329480000 Oil Seal C/R 7440

25 ....................................................84D07329540000 Oil Seal C/R 8017 (FOR DBL OUTPUT)

........................................................4MA51904000000 BORE PLUG 1.250 (FOR SGL OUTPUT)

26 ....................................................M04K088 Key 4mm Xq X .88 Lg

27 ....................................................M06K108 Key 6mm Sq X 1.08

28 ....................................................95A33002140000 Plug .12-27 Npt Flush

29 ....................................................__________ Not Used On 40 Rgd/Rgs

30 ....................................................M05K125 Key Metric

31 ....................................................__________ Not Used On 40 Rgd/Rgs

32 ....................................................99A44547180000 Service Manual Miniatures

33 ....................................................99A44547010000 General Service Manual

10

Page 12

PARTS LIST FOR 50RGD INDEX DRIVE (STANDARD CONFIGURATION)

1 ......................................................5MD55427001002 Housing

2 ......................................................5MC52018007002 “Shaft, Input”

3 ......................................................5MC52026004006 Output Shaft/Foll Whl 6 Hole 7/16 Dia.

........................................................5MC52027004006 Output Shaft/Foll Whl 6 Hole 9/16 Dia.

........................................................5MC52025004008 Output Shaft/Foll Whl 8 Hole 7/16 Dia.

........................................................5MC52023004010 Output Shaft/Foll Whl 10 Hole 1/4 Dia.

........................................................5MC52024004010 Output Shaft/Foll Whl 10 Hole 7/16 Dia.

........................................................5MC51673004012 Output Shaft/Foll Whl 12 Hole 1/4 Dia.

4 ......................................................___________ “Cam, (Specify Number Of Stops And “

........................................................ “Index Time, Contact Camco For “

........................................................ “Assistance, Order In Matched Sets)”

5 ......................................................5MB52029003002 “Cart, Output Lg”

6 ......................................................5MB52019003002 “Cart, Input Ecc “

7 ......................................................5MA52057000000 Bore Plug 2.756

8 ......................................................95A33040030000 Shcs M5 X 10

9 ......................................................84D07329560000 Oil Seal C/R 17754

10 ....................................................5MA52009018800 Shim Outp .002 Tk

........................................................5MA52009028800 Shim Outp .005 Tk

........................................................5MA52009038800 Shim Outp .010 Tk

........................................................5MA52009048800 Shim Outp .003 Tk

11 ....................................................86D07328390022 Brg Cup Lm102910

12 ....................................................86D07328390021 Brg Cone Lm 102949

13 ....................................................95A33040030000 Shcs M5 X 10

14 ....................................................86D07328200021 Brg Cone L45449

15 ....................................................86D07328200022 Brg Cup L45410

*.......................................................5MB52020003002 “Cart, Output Sm “

17 ....................................................5MA52010018800 Shim Outp .002 Tk

........................................................5MA52010028800 Shim Outp .005tk

........................................................5MA52010038800 Shim Outp .010 Tk

........................................................5MA52010048800 Shim Outp .003 Tk

18 ....................................................95A33042120000 Sss M4 X 8 Lg Cone Point

........................................................95A33042050000 Sss M3 X 8 Lg Cone Point

19 ....................................................82A49590000000 Cam Follower 1/4 Dia

........................................................82A49591000000 Cam Follower 7/16 Dia

........................................................82A49592000000 Cam Follower 9/16 Dia

20 ....................................................86D07328120021 Bearing Cone Lm11949

21 ....................................................86D07328120022 Bearing Cup Lm11910

22 ....................................................5MA52011018800 Shim Inp .002 Tk

........................................................5MA52011028800 Shim Inp .005 Tk

........................................................5MA52011038800 Shim Inp .010 Tk

........................................................5MA52011048800 Shim Inp .003 Tk

23 ....................................................95A51911110000 Bhcs M5 X 12

24 ....................................................84D07329480000 Oil Seal C/R 7440

25 ....................................................84D07329550000 Oil Seal C/R 11067

26 ....................................................M05K125 Key Metric

27 ....................................................M08K138 Key 8 X 7mm X 1.38 Lg

28 ....................................................95A33002140000 Plug .12-27 Npt Flush

29 ....................................................5MA52182000000 “Spacer, Cam “

30 ....................................................___________ Not Used On 50 Rgd

31 ....................................................___________ Not Used On 50 Rgd/rgs

32 ....................................................99A44547180000 Service Manual Miniatures

33 ....................................................99A44547010000 General Service Manual

11

Page 13

PARTS LIST FOR 50RGS INDEX DRIVE (STANDARD CONFIGURATION)

1 ........................................................... 5MD55427001002 Housing

2 ...........................................................5MC52018007002 “Shaft, Input”

.............................................................5MC52041004006 Output Shaft/Foll Whl 6 Hole 9/16 Dia. Sgl

.............................................................5MC52040004006 Output Shaft/Foll Whl 6 Hole 7/16 Dia. Sgl

.............................................................5MC52039004008 Output Shaft/Foll Whl 8 Hole 7/16 Dia. Sgl

.............................................................5MC52038004010 Output Shaft/Foll Whl 10 Hole 7/16 Dia. Sgl

.............................................................5MC52037004010 Output Shaft/Foll Whl 10 Hole 1/4 Dia. Sgl

.............................................................5MC52042004012 Output Shaft/Foll Whl 12 Hole 1/4 Dia. Sgl

.............................................................5MC52050004006 Output Shaft/Foll Whl 6 Hole 9/16 Dia. Dbl

.............................................................5MC52049004006 Output Shaft/Foll Whl 6 Hole 7/16 Dia. Dbl

.............................................................5MC52048004008 Output Shaft/Foll Whl 8 Hole 7/16 Dia. Dbl

.............................................................5MC52047004010 Output Shaft/Foll Whl 10 Hole 7/16 Dia. Dbl

.............................................................5MC52046004010 Output Shaft/Foll Whl 10 Hole 1/4 Dia. Dbl

.............................................................5MC52051004012 Output Shaft/Foll Whl 12 Hole 1/4 Dia. Dbl

4 ........................................................... ___________ “Cam, (Specify Number Of Stops And “

............................................................. “Index Time, Contact Camco For “

............................................................. “Assistance, Order In Matched Sets)”

5 ........................................................... 5MB52029003002 “Cart, Output Lg”

6 ........................................................... 5MB52019003002 “Cart, Input Ecc “

7 ...........................................................5MA52057000000 Bore Plug 2.756

8 ...........................................................95A33040030000 Shcs M5 X 10

9 ...........................................................84D07329560000 Oil Seal C/R 17754

10 .........................................................5MA52009018800 Shim Outp .002 Tk

.............................................................5MA52009028800 Shim Outp .005 Tk

.............................................................5MA52009038800 Shim Outp .010 Tk

.............................................................5MA52009048800 Shim Outp .003 Tk

11 .........................................................86D07328390022 Brg Cup Lm102910

12 .........................................................86D07328390021 Brg Cone Lm 102949

13 .........................................................95A33040030000 Shcs M5 X 10

14 .........................................................86D07328200021 Brg Cone L45449

15 .........................................................86D07328200022 Brg Cup L45410

*............................................................5MB52020003002 “Cart, Output Sm “

17 .........................................................5MA52010018800 Shim Outp .002 Tk

.............................................................5MA52010028800 Shim Outp .005tk

.............................................................5MA52010038800 Shim Outp .010 Tk

.............................................................5MA52010048800 Shim Outp .003 Tk

18 .........................................................95A33042120000 Sss M4 X 8 Lg Cone Point

.............................................................95A33042050000 Sss M3 X 8 Lg Cone Point

19 .........................................................82A49590000000 Cam Follower 1/4 Dia

.............................................................82A49591000000 Cam Follower 7/16 Dia

.............................................................82A49592000000 Cam Follower 9/16 Dia

20 ......................................................... 86D07328120021 Bearing Cone Lm11949

21 ......................................................... 86D07328120022 Bearing Cup Lm11910

22 .........................................................5MA52011018800 Shim Inp .002 Tk

.............................................................5MA52011028800 Shim Inp .005 Tk

.............................................................5MA52011038800 Shim Inp .010 Tk

.............................................................5MA52011048800 Shim Inp .003 Tk

23 .........................................................95A51911110000 Bhcs M5 X 12

24 .........................................................84D07329480000 Oil Seal C/R 7440

25 .........................................................84D07329550000 Oil Seal C/R 11067 (FOR DBL)

.............................................................5MA52057000000 BORE PLUG 2.756 (FOR SGL)

26 .........................................................M05K125 Key Metric

27 .........................................................M08K138 Key 8 X 7mm X 1.38 Lg

28 .........................................................95A33002140000 Plug .12-27 Npt Flush

29 .........................................................5MA52182000000 “Spacer , Cam “

30 .........................................................M06K162 KEY 6MM SQ X 1.62 LG

31 .........................................................___________ Not Used On 50 Rgd/rgs

32 ......................................................... 99A44547180000 Service Manual Miniatures

33 ......................................................... 99A44547010000 General Service Manual

12

Page 14

PARTS LIST FOR 70RGD INDEX DRIVE (STANDARD CONFIGURATION)

1 ......................................................7MG60152001002 Housing

2 ......................................................7MB60190007002 “Shaft, Input”

3 ......................................................7MB60253004006 Output Shaft/Foll Whl 6 Hole 3/4 Dia.

........................................................7MB60254004006 Output Shaft/Foll Whl 6 Hole 5/8 Dia.

........................................................7MB60255004008 Output Shaft/Foll Whl 8 Hole 5/8 Dia.

........................................................7MB60256004010 Output Shaft/Foll Whl 10 Hole 5/8 Dia.

........................................................7MB60268004012 Output Shaft/Foll Whl 12 Hole 7/16 Dia.

4 ......................................................___________ “Cam, (Specify Number Of Stops And “

........................................................ “Index Time, Contact Camco For “

........................................................ “Assistance, Order In Matched Sets)”

5 ......................................................7MB60176003002 Cap Output Lg

6 ......................................................7MB60164003002 Cart Input Ecc

7 ......................................................7MB60194002002 Cover

8 ......................................................95A33040040000 S.H.C.S. M5 X 12

9 ......................................................84C60165030000 Oil Seal C/R 25420

10 ....................................................7MA60180018800 Shim Outp .002 Tk

........................................................7MA60180028800 Shim Outp .005 Tk

........................................................7MA60180038800 Shim Outp .010 Tk

11-12 ............................................... 86D07328560013 BRG ASSY TIMKEN 32013X 90KA1

13 ....................................................95A33040040000 S.H.C.S. M5 X 12

14 ....................................................86D07328170021 Brg Cone 07100

15 ....................................................86D07328170022 Brg Cup 07196

16 ....................................................7MB60177003002 Cap Output Sm

17 ....................................................7MA60181018800 Shim Outp Sm .002

........................................................7MA60181028800 Shim Outp Sm .005

........................................................7MA60181038800 Shim Outp Sm .010

18 ....................................................95A33042140000 Sss Cone Pt M4x12

........................................................95A33042220000 Sss Cone Pt M5 X 12 Lg

19 ....................................................82A49591000000 Follower 7/32 Dia.

........................................................82C33150010003 Follower 5/8 Dia.

........................................................82C33150020003 Follower 3/4 Dia.

20 ....................................................86D07328230021 Brg Cone Timken Lm 67048

21 ....................................................86D07328230022 Brg Cup Timken Lm 67010

22 ....................................................26B01052018800 Shim Inp .002 Thk

........................................................26B01052028800 Shim Inp .005 Thk

........................................................26B01052038800 Shim Inp .010 Thk

23 ....................................................95A51911100000 Bhcs M5 X 10 Lg

24 ....................................................84C60165010000 Oil Seal C/R 9715

25 ....................................................84C60165020000 Oil Seal C/R 11610

26 ....................................................M06K150 Key 6mm Sq X 1.50 Lg F.S.

27 ....................................................025K187 Key .250 Sq. X 1.87 F .S.

28 ....................................................95A33002130000 Plug .25-18 Npt Flush

29 ....................................................7MA60192009000 Spacer Cam

30 ....................................................______________ Not Used On 70rgd

31 ....................................................______________ Not Used On 70rgd/rgs

32 ....................................................99A44547180000 Service Manual Miniatures

33 ....................................................99A44547010000 General Service Manual

13

Page 15

PARTS LIST FOR 70RGS INDEX DRIVE (STANDARD CONFIGURATION)

1 ......................................................7MG60152001002 Housing

2 ......................................................7MB60190007002 “Shaft, Input”

3 ......................................................7MB60257004006 Output Shaft/Foll Whl 6 Hole 3/4 Dia. Sgl

........................................................7MB60258004006 Output Shaft/Foll Whl 6 Hole 5/8 Dia. Sgl

........................................................7MB60259004008 Output Shaft/Foll Whl 8 Hole 5/8 Dia. Sgl

........................................................7MB60260004010 Output Shaft/Foll Whl 10 Hole 5/8 Dia. Sgl

........................................................7MB60262004006 Output Shaft/Foll Whl 6 Hole 3/4 Dia. Dbl

........................................................7MB60263004006 Output Shaft/Foll Whl 6 Hole 5/8 Dia. Dbl

........................................................7MB60264004008 Output Shaft/Foll Whl 8 Hole 5/8 Dia. Dbl

........................................................7MB60265004010 Output Shaft/Foll Whl 10 Hole 5/8 Dia. Dbl

4 ......................................................___________ “Cam, (Specify Number Of Stops And “

........................................................ “Index Time, Contact Camco For “

........................................................ “Assistance, Order In Matched Sets)”

5 ......................................................7MB60176003002 Cap Output Lg

6 ......................................................7MB60164003002 Cart Input Ecc

7 ......................................................7MB60194002002 Cover

8 ......................................................95A33040040000 S.H.C.S. M5 X 12

9 ......................................................84C60165030000 Oil Seal C/R 25420

10 ....................................................7MA60180018800 Shim Outp .002 Tk

........................................................7MA60180028800 Shim Outp .005 Tk

........................................................7MA60180038800 Shim Outp .010 Tk

11-12 ............................................... 86D07328560013 BRG ASSY TIMKEN 32013X 90KA1

13 ....................................................95A33040040000 S.H.C.S. M5 X 12

14 ....................................................86D07328170021 Brg Cone 07100

15 ....................................................86D07328170022 Brg Cup 07196

16 ....................................................7MB60177003002 Cap Output Sm

17 ....................................................7MA60181018800 Shim Outp Sm .002

........................................................7MA60181028800 Shim Outp Sm .005

........................................................7MA60181038800 Shim Outp Sm .010

18 ....................................................95A33042140000 Sss Cone Pt M4x12

........................................................95A33042220000 Sss Cone Pt M5 X 12 Lg

19 ....................................................82A49591000000 Follower 7/32 Dia.

........................................................82C33150010003 Follower 5/8 Dia.

........................................................82C33150020003 Follower 3/4 Dia.

20 ....................................................86D07328230021 Brg Cone Timken Lm 67048

21 ....................................................86D07328230022 Brg Cup Timken Lm 67010

22 ....................................................26B01052018800 Shim Inp .002 Thk

........................................................26B01052028800 Shim Inp .005 Thk

........................................................26B01052038800 Shim Inp .010 Thk

23 ....................................................95A51911100000 Bhcs M5 X 10 Lg

24 ....................................................84C60165010000 Oil Seal C/R 9715

25 ....................................................84C60165020000 Oil Seal C/R 11610 (FOR DBL OUTPUT ONLY)

26 ....................................................M06K150 Key 6mm Sq X 1.50 Lg F.S.

27 ....................................................025K187 Key .250 Sq. X 1.87 F .S.

28 ....................................................95A33002130000 Plug .25-18 Npt Flush

29 ....................................................7MA60192009000 Spacer Cam

30 ....................................................M08K200 KEY 8X7MM X2LG

31 ....................................................______________ Not Used On 70rgd/rgs

32 ....................................................99A44547180000 Service Manual Miniatures

33 ....................................................99A44547010000 General Service Manual

14

Page 16

PARTS LIST FOR 80RGD INDEX DRIVE (STANDARD CONFIGURATION)

1 ......................................................8MG60210001002 Housing

2 ......................................................8MB60757007002 Shaft Input (W/O Reducer)

........................................................8MC60917007002 Shaft Input (For 180sm)

3 ......................................................8MC60827004006 Output Shaft/Foll Whl 6 Holes 7/8 Dia.

........................................................8MC60828004008 Output Shaft/Foll Whl 8 Holes 3/4 Dia.

........................................................8MC60829004010 Output Shaft/Foll Whl 10 Holes 5/8 Dia.

........................................................8MC60830004012 Output Shaft/Foll Whl 12 Holes 9/36 Dia.

4 ......................................................___________ “Cam, (Specify Number Of Stops And “

........................................................ “Index Time, Contact Camco For “

........................................................ “Assistance, Order In Matched Sets)”

5 ......................................................8MB60772003002 Cap Output Lg

6 ......................................................7MB60164003002 Cart Input Ecc

7 ......................................................8MA63280002002 Cover

8 ......................................................95A33040040000 S.H.C.S. M5 X 12

9 ......................................................84C60165040000 Oil Seal C/R 31510

10 ....................................................8MB60776018800 Shim Outp .002 Tk

........................................................8MB60776028800 Shim Outp .005 Tk

........................................................8MB60776038800 Shim Outp .010 Tk

11-12 ............................................... 86D07328650013 Brg Assy 32016x 92ka1

13 ....................................................95A33004180000 Shcs M6 X 16 Lg

14 ....................................................86D07328350021 Brg Cone Lm 501349

15 ....................................................86D07328350022 Brg Cup Lm501310

16 ....................................................8MB60764003002 Cap Lo Output

17 ....................................................8MA60768018800 Shim Outp .002 Tk

........................................................8MA60768028800 Shim Outp .005 Tk

........................................................8MA60768038800 Shim Outp .010 Tk

18 ....................................................95A33042230000 Sss Cone Pt M5 X16

........................................................95A33042140000 Sss Cone Pt M4 X 12

19 ....................................................82C33150020003 Cam Follower 3/4 Dia.

........................................................82C33150030003 Cam Follower 7/8 Dia.

........................................................82C33150010003 Cam Follower 5/8 Dia.

20 ....................................................86D07328170021 Brg Cone 07100

21 ....................................................86D07328170022 Brg Cup 07196

22 ....................................................26B01052018800 Shim Inp .002 Thk

........................................................26B01052028800 Shim Inp .003 Thk

........................................................26B01052038800 Shim Inp .010 Thk

23 ....................................................95A51911080000 Bhcs M4 X12

24 ....................................................84C60165010000 Oil Seal C/R 9715

25 ....................................................84C60165050000 Oil Seal C/R 14725

26 ....................................................M08K200 Key 8x7mm X2lg

27 ....................................................025K212 Key .250sq X 2.12 Lg

28 ....................................................95A33002130000 Plug .25-18 Npt Flush

29 ....................................................8MA60758009000 Spacer Cam

30 ...................................................._____________ Not Used On 80rgd

31 ....................................................8MC60918009100 Mounting Plate (For 180sm)

32 ....................................................99A44547180000 Service Manual Miniatures

33 ....................................................99A44547010000 General Service Manual

15

Page 17

PARTS LIST FOR 80RGS INDEX DRIVE (STANDARD CONFIGURATION)

1 ......................................................8MG60210001002 Housing

2 ......................................................8MB60757007002 Shaft Input (W/O Reducer)

........................................................8MC60917007002 Shaft Input (For 180sm)

3 ......................................................8MC60831004006 “Output Shaft/Foll Whl (For 6h24, 6h28) Sgl”

........................................................8MC60832004006 Output Shaft/Foll Whl 8h24 Sgl

........................................................8MC60833004010 Output Shaft/Foll Whl 10h20 Sgl

........................................................8MC60834004012 Output Shaft/Foll Whl 12h18 Sgl

........................................................8MC60835004006 “Output Shaft/Foll Whl (For 6h24, 6h28) Dbl”

........................................................8MC60836004008 Output Shaft/Foll Whl 8h24 Dbl

........................................................8MC60837004008 Output Shaft/Foll Whl 10h20 Dbl

........................................................8MC60838004012 Output Shaft/Foll Whl 12h18 Dbl

4 ......................................................___________ “Cam, (Specify Number Of Stops And “

........................................................ “Index Time, Contact Camco For “

........................................................ “Assistance, Order In Matched Sets)”

5 ......................................................8MB60772003002 Cap Output Lg

6 ......................................................7MB60164003002 Cart Input Ecc

7 ......................................................8MA63280002002 Cover

8 ......................................................95A33040040000 S.H.C.S. M5 X 12

9 ......................................................84C60165040000 Oil Seal C/R 31510

10 ....................................................8MB60776018800 Shim Outp .002 Tk

........................................................8MB60776028800 Shim Outp .005 Tk

........................................................8MB60776038800 Shim Outp .010 Tk

11-12 ............................................... 86D07328650013 Brg Assy 32016x 92ka1

13 ....................................................95A33004180000 Shcs M6 X 16 Lg

14 ....................................................86D07328350021 Brg Cone Lm 501349

15 ....................................................86D07328350022 Brg Cup Lm501310

16 ....................................................8MB60764003002 Cap Lo Output

17 ....................................................8MA60768018800 Shim Outp .002 Tk

........................................................8MA60768028800 Shim Outp .005 Tk

........................................................8MA60768038800 Shim Outp .010 Tk

18 ....................................................95A33042230000 Sss Cone Pt M5 X16

........................................................95A33042140000 Sss Cone Pt M4 X 12

19 ....................................................82C33150020003 Cam Follower 3/4 Dia.

........................................................82C33150030003 Cam Follower 7/8 Dia.

........................................................82C33150010003 Cam Follower 5/8 Dia.

20 ....................................................86D07328170021 Brg Cone 07100

21 ....................................................86D07328170022 Brg Cup 07196

22 ....................................................26B01052018800 Shim Inp .002 Thk

........................................................26B01052028800 Shim Inp .003 Thk

........................................................26B01052038800 Shim Inp .010 Thk

23 ....................................................95A51911080000 Bhcs M4 X12

24 ....................................................84C60165010000 Oil Seal C/R 9715

25 ....................................................84C60165050000 Oil Seal C/R 14725 (For Dbl Output Only)

26 ....................................................M08K200 Key 8x7mm X2lg

27 ....................................................025K212 Key .250sq X 2.12 Lg

28 ....................................................95A33002130000 Plug .25-18 Npt Flush

29 ....................................................8MA60758009000 Spacer Cam

30 ....................................................M08K200 Key 8x7mm X2lg

31 ....................................................8MC60918009100 Mounting Plate (For 180sm)

32 ....................................................99A44547180000 Service Manual Miniatures

33 ....................................................99A44547010000 General Service Manual

16

Page 18

99 A44547 18 0000 6/99 0064

Loading...

Loading...