Page 1

WARNING

This is a controlled document. It is your responsibility to deliver this information to the end user of the

CAMCO/FERGUSON product. Failure to deliver this could result in your liability for injury to the user or damage

to the machine. For copies of this manual call your Customer Service Representative 800-645-5207.

The Driving Force in Automation

INTERMITTOR

®

ROLLER DIAL INDEX DRIVES

Installation & Service Manual

Page 2

INTRODUCTION

This manual is supplied to aid in the installation and maintenance of your Fergusonbrand index drive.

When contacting Industrial Motion Control, please have the serial number of your unit

available. This number can be found on the serial number tag.

To determine the model number and the ratio of a Ferguson reducer, refer to the tag

which is located on the reducer housing. If the reducer is by another manufacturer,

refer to that manufacturer's nametag located on the reducer housing.

Unit configurations, reducer mounting positions, and hand of cam nomenclature can

be found inside the back cover of this manual. These will aid in describing your unit.

Industrial Motion Control provides factory rebuild or repair services at our centrally

located Wheeling, IL facility. Industr ial Motion Control can also provide technicians or

engineers for field service calls worldwide.

If you have any questions or problems, please feel free to contact our

Technical Service Department at:

1-800-645-5207 or 1-847-459-5200, FAX: 1-847-459-3064,

or EMAIL: techservice@camcoindex.com.

If you need to contact a sales representative in your area, you can log on to our web

site: www.camcoindex.com and go the section labeled "Find a local Rep" to find the

sales office that is nearest to you.

At Industrial Motion Control, it is our policy to provide the highest quality products that

meet or exceed our customer's requirements. In order to achieve this commitment,

Industrial Motion Control has documented its policies and procedures to be in

compliance with ISO-9001.

INTRODUCTION

Page 3

1

Table of Contents

Section Page

1. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

1.1. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3

1.3. Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4. Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.5. Requesting Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.6. Returning a Unit for Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5,6

2.1. Intermittor Location Map & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2. Reducer Location Map & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

5. Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-14

5.1. FSC…Ferguson Slip Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-14

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.1. Using Correct Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.2. Changing Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16,17

8. Repair and Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-28

8.1. Cam Follower Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-20

8.2. Oil Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21,22

8.3. Reducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-25

9. Things to Avoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

REFERENCE: Unit configurations, Reducer Mtg Positions, Hand of Cam Drawing . . . . . .27

Page 4

2

SECTION 1: General Information

The Industrial Motion Control (IMC) Intermittor is engineered and manufactured to very high tolerances

which necessitate careful inspection and maintenance.

Some users of indexing drives have the facilities and trained personnel to accomplish service repair.You

must determine the extent to which intricate servicing should be done in your own facility.When in doubt,

IMC recommends that IMC trained servicemen make the repairs.

1.1. Warranty - Products are warranted as follows:

1.1.1. Our products are warranted for one (1) year from the date of shipment to be free

from defects in workmanship and materials.The foregoing warranty is exclusive

and in lieu of all other warranties, whether written or orally expressed or implied

and there are no warranties of merchantability or fitness for particular use.

1.1.2. Our obligation under the foregoing is limited to replace free of charge, including the

lowest transportation cost, but not including installation or any other charges, any

part that our inspection shows to be defective provided that the part was properly

installed, suitably maintained and not subject to misuse or abuse, and further

provided that the defective parts are retur ned to our plant within one (1) year after

delivery by us.Wr itten permission for such return must first be obtained from IMC.

A complete explanation is required of the alleged defects and circumstances.

1.2. Safety – Read and follow all Warnings and Cautions pr ior to any service or repair.

1.2.1. Intermittors should not be started and stopped at high speed during the transfer

phase of the cam. This can cause serious damage to the Intermittor and reduce

the cam follower life. For cycling during setup or jog mode, speed must be

reduced to 25% of the normal operating speed. The use of an E-stop for

purposes other than emergencies is not recommended. A cycle stop button should

be incorporated into the system controls. Please consult Industrial Motion Control’s

Wheeling factory for additional information.

1.2.2. Always disconnect power and lockout the source before working on these units.

1.2.3. All input and output connections should be backlash free. Use friction lock type

shaft couplings such as taper lock bushings, split and clamped hubs, etc., in the

input and output drive train. There should be no loose keys, set screws, etc.

Page 5

3

SECTION 1: General Information (continued)

1.2.4. Reducers should be of minimum backlash variety and directly coupled with a

backlash-free connection. If line shafts are used, they must be sized for severe

reversing loads.

1.2.5. When using chain drives, incorporate an idler to eliminate any slack. (Do not use

spring-loaded idlers.) As the cam motion stops and starts, any slack in the drive

changes sides. It is necessary to maintain a constant speed of the input shaft.

Loose belts or chains will cause inertial over-run, causing distorted acceleration

and deceleration characteristics which may cause damage to the unit. Belts and

chains must be sized for severe reversing loads.

1.2.6. Ferguson does not provide guarding for moving parts, such as dials, handwheels,

switch cams, etc.Numerous pinch points do exist on this equipment and the

possibility exists of being struck by a moving part. Since this product is expected to

become part of a fur ther developed machine, it is the customer’s responsibility to

add safety fencing, guarding, light curtains or other protection devices, as

necessary, to protect personnel and property.

NOTE: In the event the unit is damaged, contact Industrial Motion Control’s

Wheeling factory or your local representative, for proper reconditioning or

repair (see sections 1.5 Requesting Service or 1.6 Returning a Unit for Repair).

1.3. Operating Environment –This machine is intended to operate in a clean environment.

Excessive coolant, chips, dust dirt or debris can adversely affect its performance and life.

If this machine does operate in a dirty environment periodic cleaning must be practiced

and careful inspection of seals and accessories is necessary.

1.3.1. For extended storage, remove vents and fill with proper oil. (Refer to section 6)

1.4. Ordering Replacement Parts – When ordering parts, always provide the following

information:

1.4.1. The serial number shown on the nameplate.

1.4.2. The part name and/or the description listed in the manual.

1.4.3. The part numbers shown on the bill of material or assembly drawings.

Page 6

4

SECTION 1: General Information (continued)

1.5. Requesting Service – Call our Technical Service Department in Wheeling, IL at

1-800-645-5207 or 847-459-5200 between 8:00AM and 4:00PM CST.When requesting

service, always provide the following information:

1.5.1. The serial number shown on the nameplate. (Refer to Inside Front Cover)

1.5.2. A clear description of the problem, including as much detail as possible of the

circumstances leading up to the problem.

1.6. Returning a Unit for Repair – Please contact the Repair Department in Wheeling,

Illinois at (847) 459-5200 for a "Return Material Authorization" Number (RMA#).

The following information is required of a unit for repair, conversion or warranty.

1. Purchase order number

2. Customer name

3. Customer billing address

4. Customer shipping address

5. Person to contact, upon inspection, with delivery and price.

6.Telephone number

7. Model number (located on name plate)

8. Serial number (located on name plate)

9. Description of defects, problems or circumstances.

The IMC Repair Department will assess repairs by phone and estimate inspection fees or

repair costs.

Non-warranty inspection fees will vary depending on the size of the unit and optional

equipment mounted.These fees apply only if customer decides not to repair or replace

subject unit.

Please return IMC equipment only (remove sprockets, pulleys, etc).This will reduce the

amount of disassembly time (saving customer cost on labor) and will provide faster

evaluation for quoting price and delivery of repair or conversion. Oil must be drained

before shipping.

Package unit to protect it from weather or damage during shipping. Place the

(RMA#) on the outside of the packaging for prompt service.

Ship Warranty units via surface freight collect. Ship Non-Warranty units to IMC

transportation prepaid. IMC will not accept collect shipments on non-warranty repairs

Ship to: Industrial Motion Control, LLC

1444 South Wolf Road

Wheeling, Illinois 60090 - USA

Page 7

5

SECTION 2: Overview

The sketches contained in this document are for illustrative purposes only. They are intended to

represent standard components and may not be shown to scale. The various models may be different

than shown, depending upon options chosen or the particular configuration of a unit.

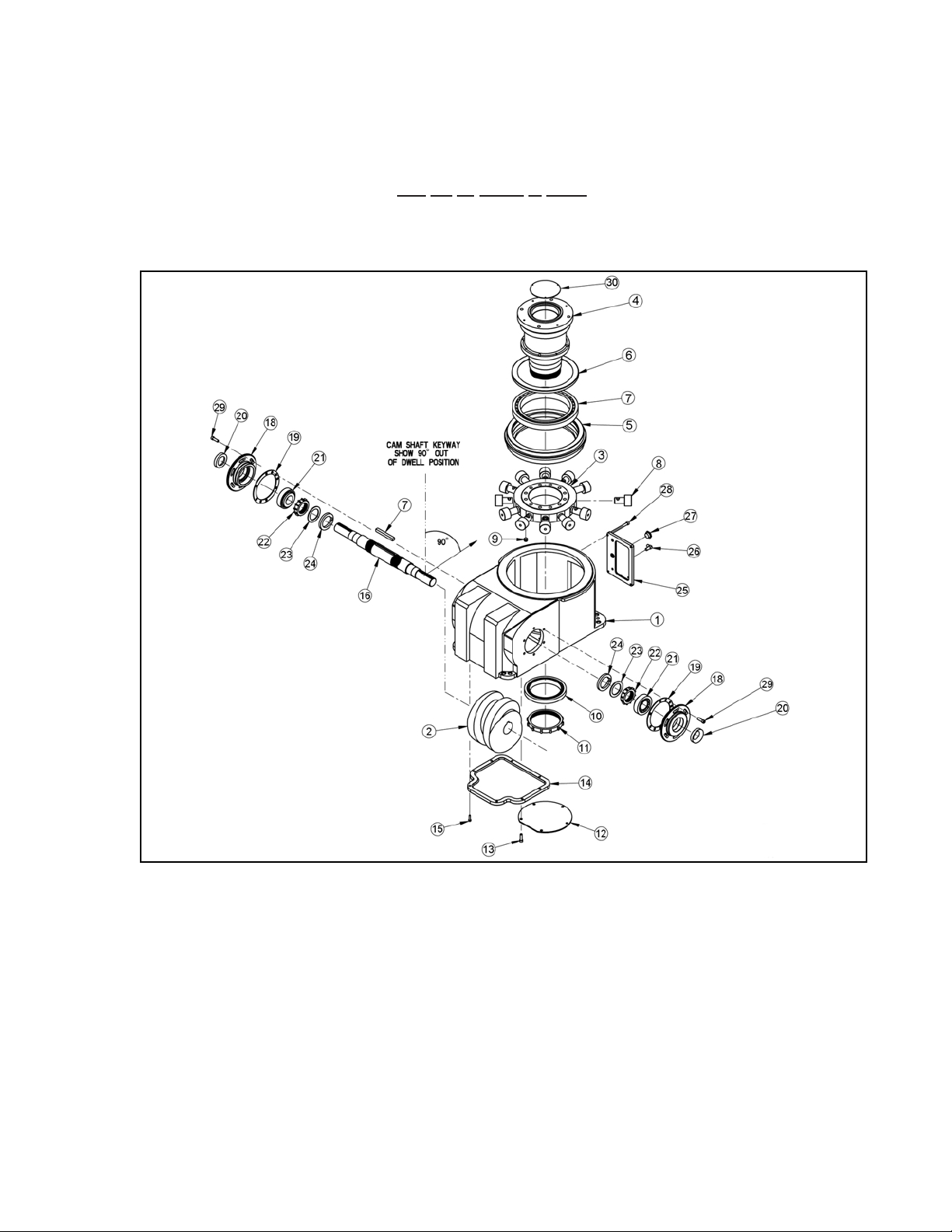

2.1. Intermittor Location Map

FIGURE 1

Intermittor Parts List

1. Housing

2. Cam

3. Roller Gear Hub

4. Roller Gear (Output) Shaft

5. Bearing Ring &

Spacer Shims

6. Oil Seal

7. Timken Bearing

8. Cam Followers

9. Locking Set Screw

10. Bottom Timken Bearing

11. Locknut & Washer

12. Bottom Cover for

Output Shaft

13. Cap Screws

14. Bottom Housing Cover

15. Cap Screws

16. Cam (Input) Shaft

17. Drive Key (Cam)

18. Eccentric Bushing

19. Shim Pack

20. Oil Seal

21. Timken Bearing

22. Locknut

23. Lockwasher

24. Cam Spacer – not required

for all drive codes

25. Front Access Cover

26. Air Vent

27. Pipe Plug

28. Cap Screws

29. Cap Screws

30. Top Cover

Page 8

6

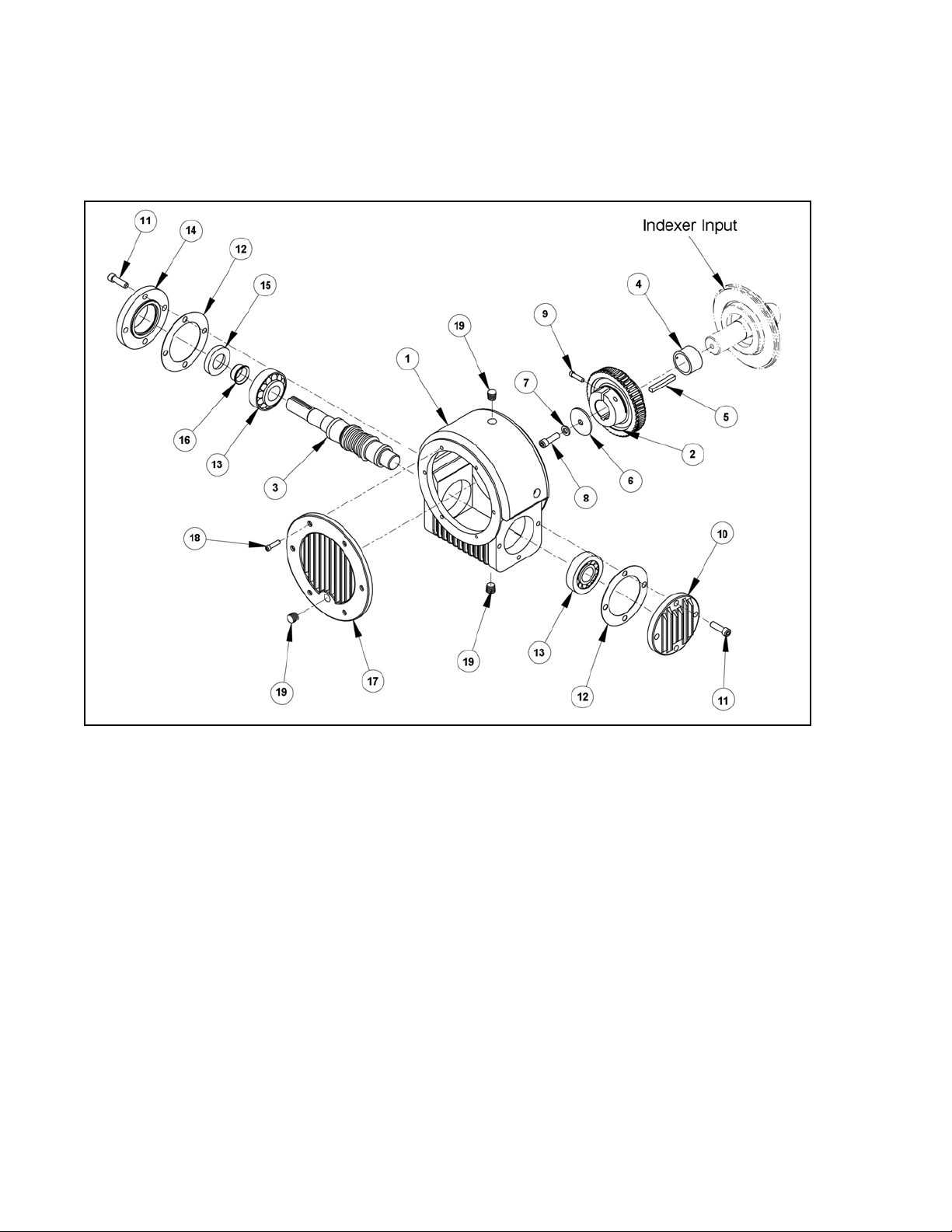

SECTION 2: Overview (continued)

2.2. Ferguson Reducer Location Map

FIGURE 2

1. Housing

2. Ring Gear (& separate spider

for some units)

3. Pinion Worm Gear

4. Gear Spacer

5. Key for Indexer Shaft

6. Arrestor Washer

7. Lockwasher

8. Cap Screw Keeper

9. Cap Screw for Clamping Hub

10. Closed End Cap

11. Cap Screws

12. Shim Pack

13. Timken Bearing

14. Open End Cap

15. Oil Seal

16. Wear Sleeve

17. Cover Plate

18. Cap Screws

19. Oil Plugs

Ferguson “R” Series Reducer Parts List

Page 9

7

SECTION 3: Specifications

Model

Standard Reducer

Standard AC Motor

with Air Clutch/Brake

Standard 180 Volt DC Motor

Output Shaft Torque Limiter

Input Shaft Torque Limiter

Lubrication Capacity

Main Oil Sump (Gallons)

3

Lubrication Capacity

Gear Reducer

3

Unit Weight (LBS)

2

Unit Weight with Reducer (LBS)

2

Unit Weight with Motor/Reducer Pkg. (LBS)

2

1

90 V olt DC.

2

Weights are approximate, less crating.

3

Refer to section on lubrication for specifications of lubricants. Amounts are approximate for standard

HM-1 position only. Actual capacities may vary by other mounting positions or drive codes. Always

check oil level site glass or plugs before topping off or refilling.

122

123

242

243

362

363

481

482

722

723

R300

R400

R400

R500

R500

R600

R600

R700

R700

R800

MDB625

With 1 HP

MDB875

With 2 HP

MDB875

With 2 HP

MDB1125

With 5 HP

MDB1125

With 5 HP

MDB1125

With 5 HP

N/A

N/A

N/A

N/A

1 HP

1

1.5 HP

1.5 HP

2.0 HP

N/A

N/A

N/A

N/A

N/A

N/A

DTL10

DTL10

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

R3FSC

R4FSC

R4FSC

R5FSC

R5FSC

R6FSC

R6FSC

R7FSC

R7FSC

R8FSC

4 GAL.

4 GAL.

8 GAL.

9 GAL.

14 GAL.

15 GAL.

33 GAL.

33 GAL.

42 GAL.

44 GAL.

2.5 QTS.

1.5 GAL.

1.5 GAL.

2.5 GAL.

2.5 GAL.

3.7 GAL.

3.7 GAL.

6.5 GAL.

6.5 GAL.

10.5 GAL.

200

450

800

1000

1500

2500

4750

6000

8750

10000

250

550

875

1150

1650

2700

4950

6300

10000

10500

300

625

975

1300

1800

3000

5250

6650

10500

11050

CHART 1

Page 10

8

SECTION 4: Installation

These units are manufactured to meet a specific set of design parameters.Any change to the load,

size of dial, or speed of the camshaft may require a size change. No change can be made without

affecting other performance characteristics of the unit and, therefore, should not be done without

consulting the factory.

4.1. To install the unit:

4.1.1. Rotate input shaft so cam is in center of dwell (see Figure 3).

4.1.2. Mount the Intermittor into position on a rigid base and secure with the largest size

bolts that will fit through the mounting holes.

4.1.3. Align the Intermittor with respect to the station positions before tightening bolts and

doweling. Use a dial indicator or other appropriate tool to insure alignment.

4.1.4. Tighten all mounting bolts securely and uniformly.

FIGURE 3

Page 11

9

SECTION 4: Installation (continued)

4.1.5. Install dowels.

4.1.5.1. Use a commercially available straight dowel of the appropriate size.

4.1.5.2. Drill a hole into the base to a depth of at least 1-1/2 times the diameter

of the dowel. Use a drill the same size as the pilot holes in the indexer

housing.

4.1.5.3. Line ream housing and base for press fit with dowel pin.

4.1.5.4. Install dowel pins into position.Leave some material exposed to

facilitate removal in the future, or use threaded dowel pins.

4.1.6. Check the oil level of the sump and gear reducer prior to operating the unit.

4.1.6.1. Pay particular attention if the oil level is too high. If a unit has been idle

for some time since its manufacture, condensation may be present. If

condensation is noticed, the oil should be drained, the unit thoroughly

cleaned and re-filled with oil (see Chart 1 in Section 3 for capacities).

NOTE: If shot pins or leader guide pins in dies are used, the cam

should have been manufactured with a dwell relief in the cam.

If severe tangential or vertical loads exist, an anvil may be

required. For further information, consult your local Industrial

Motion Control Representative or the Technical Sales Department

at 1-800-645-5207 or 847-459-5200.

4.1.6.2. The unit’s sump must be filled with SAE 90 EP Gear or equivalent

meeting MIL-PRF-2105E and API Service Classification GL5 or GL6

before operation (see Chart 1 in Section 3 for capacities). An example

of this oil is Mobilube HD 80W-90. For extreme applications, use

Mobilube HD 85W-140 (consult your local representative to determine if

your application is extreme).

4.1.6.3. Bronze Gear Reducer oil must be SAE140 Steam Cylinder Oil meeting

AGMA #8 Compound, MIL SPEC, MIL-L-15016A;symbol 3150

(see Chart 1 in Section 3 for capacities). (Or manufacturer’s specified

oil if not a Ferguson manufactured reducer.)

4.1.6.4. Be sure optional controller is properly fused – refer to vendor’s manual.

Page 12

10

SECTION 4: Installation (continued)

4.1.7. Check the adjustment of the switch cam if your unit has this option. To insure unit

stops in dwell, see Figure 3.

4.1.7.1. A standard roller gear indexer is shown in Figure 3 with a Brake Cam &

Limit Switch shown with the keyway in the center of the dwell period. It

is necessary to phase the Brake Cam such that the input shaft of the

indexer stops during the dwell period of the index cycle while leaving

enough of the dwell period for the input shaft to accelerate to full speed

before leaving the dwell period.

4.1.7.2. If the indexer has a drive code which causes multiple indexes per

camshaft revolution (i.e. X2, X3, etc… drive codes), additional lobe(s) on

the Brake Cam are required. The lobes will be equally spaced.

Therefore, phasing the one lobe of the Brake Cam to one dwell period

on the indexing cam will, in most cases, cause the other lobes to be

correctly phased with the other dwell periods.

NOTE: Controllers are normally shipped loose and brake cam /

limit switches are mounted to the unit. However, neither are set or

adjusted at the factory. Limit switch and cam must be set to initiate

the stopping cycle. Controller must be set for the load & speed of

the application per instruction in the vendor’s manual.

NOTE: The switch and brake cam commonly provided to initiate

the stop cycle can not be used to indicate “on station.” A second

switch and brake cam should be ordered for this purpose.

Page 13

11

SECTION 5: Adjustments

The Intermittor is a solid mechanical, backlash-free mechanism.There are no adjustments required on

the Intermittor during installation unless it is furnished with a torque limiting device or a motor drive

package equipped with speed control. After the Intermittor has been installed and set up with the users’

load in place, it will be necessary to check these items for proper adjustment & settings.

NOTE: Drive should be in center of dwell and dowel pinned to base before installing dial, as

previously mentioned in 4.1.1. & 4.1.5.4.

5.1. FSC… Ferguson Slip Clutch Location Map

FIGURE 4

1. Housing

3. Body & Cone

4. Thrust Bearing

5. Silicon Spring

6. Adjusting Nut

7. Guide Pin

8. Spool

9. Ball Plunger

10. Liner Bushing

11. Setscrew

12. Pipe Plug

Page 14

12

SECTION 5: Adjustments (continued)

5.1.1. Clutch Adjustment Description

The clutch must be adjusted to prevent any slippage during normal operation to

prevent shock loading. It should also not be adjusted so tight as to be able to

damage the indexer during a jam or overload. However, it is best to err on the side

of being tighter than required. The proper setting for the clutch is determined by

gradually tightening the clutch adjusting nut until the clutch no longer slips in either

direction during a complete, fully loaded index cycle at normal speed.

5.1.2. Shut-off Spool Use & Adjustment

The shut-off spool (number 8, Figure 4) is attached to body (number 3, Figure 4)

by means of shallow round threads in body (number 3, Figure 4) and a ball

plunger (number 9, Figure 4) in spool (number 8, Figure 4). When the clutch is

operating normally (i.e. not slipping), there is no relative movement between spool

(number 8, Figure 4) and main body (number 3, Figure 4) and the remainder of the

clutch, including the spool (number 8, Figure 4) driven by pin (number 7, Figure 4).

This relative rotation causes the spool to move along the screw threads on the

body (number 3, Figure 4). The spool will move to the left or to the right,

depending on the rotation of the clutch. This lateral movement of the spool is

intended to activate a limit switch arm located in the center groove in the spool.

The "tripped" limit switch should be electrically connected to the controls to stop

the operation of the motor driving the indexer.

5.1.3. Resetting Procedure

To recover from a jam or overload in which the clutch has slipped sufficiently to

displace the shut-off spool:

Manually disconnect the power to the drive motor to prevent an accidental start-up

(use O.S.H.A.approved lockout procedures), clear the cause for the overload.

Then simply push or pull the spool (number 8, Figure 4) on the main body

(number 3, Figure 4) to the thread engagement which is closest to the center

position on the threaded portion of the body (number 3, Figure 4). Check the limit

switch circuitry for proper operating conditions. The indexer can now be powered

up and production resumed.

Page 15

13

SECTION 5: Adjustments (continued)

5.1.4. Clutch Adjustment Procedure

CAUTION: OPERATIING THE INDEXER WITH THE CLUTCH NOT ADJUSTED

CAN CAUSE IMMEDIATE AND SEVERE DAMAGE TO THE INTERNAL

COMPONENTS OF THE INDEXER.

a. Loosen cone point setscrew (number 11, figure 4).

b. Insert pins of spanner (figure 6) into holes of adjusting nut (number 6, figure 4),

and turn nut clockwise one notch in the adjusting nut. This will tighten the clutch.

NOTE: For heavy indexing loads or clutches on large units, it may be

necessary to increase the length of the spanner wrench to gain more leverage.

If clutch has not been adjusted for a long period of time, it may be necessary

to turn the nut counter-clockwise several turns, and tap the face of housing

(number 1, figure 4) towards the indexer with a rubber mallet to separate

(loosen) the tapers. Take note of the number of loosening turns so the

adjusting nut can be re-tightened to its original position.

c. Re-tighten setscrew (number 11, figure 4) making sure it engages in adjusting

nut (number 6, figure 4) to prevent damage to screw threads.

NOTE: If setscrew (number 11, figure 4) is accidentally tightened on threaded

portion of adjusting nut (number 6, figure 4), it will raise a burr. Failure to

remove this burr will cause shearing of threads and jamming of nut of housing

(number 1, figure 4). To remove burr, remove setscrew (number 11, figure 4)

and rotate adjusting nut counter-clockwise until burr is in center of tapped hole

in housing (number 1, figure 4). Use a hand electric drill that fits freely into the

tapped hole. Drill into the adjusting nut (number 6, figure 4) sufficiently to

remove the burr.

There are (2) setscrews (number 11, figure 4). They are positioned so one

screw is half way between the slots in the nut when the other screw engages

the slot in the nut. This is to allow for fine adjustment of the clutch. DO NOT

use both screws at the same time as one screw will not be over a slot and will

cause damage to the screw threads.

FIGURE 5

Page 16

14

SECTION 5: Adjustments (continued)

d. Apply power to the unit and check for clutch slippage.

NOTE: When clutch is not slipping, entire clutch will rotate as a single unit.

When clutch is slipping body (number 3, Figure 4) will not rotate with the other

parts of the clutch. Small amounts of clutch slippage can be difficult to

determine. To aid in providing if the clutch is slipping, use a grease pencil or

felt tip marker and draw a line across face of nut (number 6, Figure 4) and

along body (number 3, Figure 4). If clutch is slipping, the line on nut (number 6,

Figure 4) and body (number 3, Figure 4) will move relative to each other.

DO NOT LET CLUTCH SLIP ANY LONGER THAN NECESSARY OR

CLUTCH MAY HEAT UP RESULTING IN UNPREDICTABLE OPERATION

AFTER IT COOLS.

e. Repeat steps a through d until there is positively no clutch slippage.

5.1.5. Lubrication:

a. Clutches are grease packed at the factory and should not require additional

lubrication. If clutch is subject to consistent slippage and heating, remove pipe

plug (number 9, Figure 4) and insert your standard grease fitting, lubricate with

Lithium EP grease. Do not use air pressure gun!

Page 17

15

SECTION 6: Maintenance

6.1. Correct Lubricants – For the protection of the unit use only lubricants meeting the

specifications shown below in Chart 2. If you have any questions about a particular

lubricant feel free to call us at 1-800-422-8936.

6.2. Changing Oil

6.2.1. All parts are oil splash lubricated except for isolated areas where grease fittings

will be supplied.

6.2.2. Maintain oil to the midpoint of the sight gauge or oil level & fill plug.

NOTE:The orientation of your unit will determine the exact quantity of oil

required.

6.2.3. Drain, flush and fill the unit in intervals of 2400 hours or at least yearly. If drive

operates at speeds above 300 RPM or at temperatures above 140 degrees F.,

increase oil change frequency to 6 months or 1200 hours intervals.

6.2.4. Service all grease fittings on 1-month intervals or every 200 hours of operation.

NOTE: In the majority of the applications, grease fittings are not supplied

since oil splash supplies the lubrication. Should grease be specified use

Lithium No.2.

Indexer Oil: Use SAE 90 EP Gear oil or equivalent meeting MIL-PRF-2105E and

API Service Classification GL5 or GL6. For example, Mobilube HD 80W-90

Capacity: See specifications in Chart 1 for your model.

Gear Oil: Bronze Gear Reducer oil requires SAE 140 Steam Cylinder Oil,

meeting AGMA #8 Compound, MIL SPEC.MIL-L-15016A; symbol 3150

(Or manufacturer’s specified oil if not a Industrial Motion Control

manufactured reducer.)

Capacity: See specifications in Chart 1 for your model.

CHART 2

Page 18

16

SECTION 7: Troubleshooting

TROUBLESHOOTING GUIDE

Symptom Cause Solution

Backlash at output shaft Worn/damaged followers Replace

(in dwell)

Tight Stations Bent cam followers Replace; inspect holes in roller

(torque required to rotate gear shaft

cam shaft through tight

station is more than 1 1/2

times the loose station)

Pitting of cam follower Incorrect oil Replace cam followers and fill

outer race/cam track surface unit with correct oil

Fine magnetic metallic particles Steel and iron worn from Flush out when replacing oil

in oil; appear bronze color bearing roller ends and cages

when in oil and cams surface (this is a

normal condition)

REDUCER:

Excessive Backlash A. End play in worm shaft Contact Technical Services at

800-645-5207 or 847-459-5200.

B. Loose gear on camshaft. Contact Technical Services at

800-645-5207 or 847-459-5200.

Overheating in Excess of 210°F A.Worm-shaft bearings Contact Technical Services at

pre-load. 800-645-5207 or 847-459-5200.

B. Incorrect alignment of Contact Technical Services at

worm and gear. 800-645-5207 or 847-459-5200.

C. Excessive worm speed. Reduce worm speed.

Page 19

17

SECTION 7: Troubleshooting (continued)

TROUBLESHOOTING GUIDE

Symptom Cause Solution

OIL LEAKS AT:

Seals Worn or damaged seal Replace seal; polish shaft

and/or shaft surface

Shims Damaged shim Replace; apply “Loctite Aviation

Grade Sealant” to both sides

Cap Screws Shim damaged between screw Replace gasket or shim;apply

hole and interior of housing “Loctite Aviation Grade

Sealant” to both sides

Holes drilled through Remove screw, apply

“Loctite Threadlocker” and

re-install

Cover joints Inadequate sealant Remove, clean and

reassemble with silicone

rubber sealant

Oil service pipe fittings Not properly sealed Remove, clean and reinstall

with “Loctite Teflon Pipe

Sealant”

NOTE: In the event that damage is found, it is recommended that the unit be returned to the

factory for repair or that an Industrial Motion Control Serviceman make or supervise repairs in

your plant. Proper alignment and adjustment of the components are essential to their

performance and life.

Page 20

18

SECTION 8: Repair and Replace

8.1 Cam Follower Replacement

8.1.1. Rotate camshaft to mid-dwell position. (See Figure 3)

8.1.2. Drain oil and remove front access cover.

8.1.3. Stand unit on end and remove bottom access cover to expose cam follower stud

locking fastener.

8.1.4. Determine cam follower design for your unit, and refer to the following instructions

(Figures 6 through 9). Then continue with step #8.1.5. below.

8.1.5. Clean sealant from access cover(s) and surfaces on housing.

8.1.6. Install access cover(s) with silicon rubber sealant, and tighten screws evenly.

8.1.7. Refill with oil.

Page 21

19

SECTION 8: Repair and Replace (continued)

FOLLOWER NO. F-50 THROUGH F-400

DISASSEMBLY:

Remove setscrew and pull cam follower

from hole using a draw hammer secured

in tapped hole.

ASSEMBLY:

Clean the follower stud hole in the roller

gear hub and inspect for elongation,

which could cause backlash by failing to

support the stud at the top.

Place a socket head screw in pull hole

and strike its head - do not strike the

follower end cap when installing.

Apply a light coat of assembly grease to a new cam follower, orient so the setscrew and seat are in

line and install lightly against shoulder.

FOLLOWER NO. FM-50; FM-62; FM-75

DISASSEMBLY:

Remove jam nut, setscrew, follower and

nylon plug.

ASSEMBLY:

Clean the follower stud hole in the hub

and inspect for an out-of-round condition,

which could cause backlash by failing to

support the stud at the top.

Apply a light coat of assembly grease to

a new cam follower and install it firmly

against seat; loosen and retighten. Install

new nylon plug and tighten setscrew and

jam nut in place.

FIGURE 7

FIGURE 6

Page 22

20

FOLLOWER NO. FM-100 & FS100 - FS-400

DISASSEMBLY:

Remove locknut, setscrew and follower.

ASSEMBLY:

Clean the follower and stud hole in the

roller gear hub and inspect for

elongation, which could cause backlash

by failing to support the stud at the top.

Apply a light coat of assembly grease to

a new cam follower and install it firmly

against seat; loosen and retighten.

Install setscrew, tighten sufficiently to mark follower stud with setscrew point and remove setscrew.

Remove cam follower and drill a setscrew seat at the marked position deeply enough to make seat

diameter equal to setscrew diameter.

Clean cam follower, coat with grease and install firmly against seat; check that the drilled seat lines up

with the setscrew hole. Assemble setscrew and locknut and tighten firmly.

SECTION 8: Repair and Replace (continued)

FIGURE 8

FOLLOWER NO. 5202M; 5204T; 5304M; 5306M

DISASSEMBLY:

Remove flat head screw,

bearing cap and outer race

of follower.

Remove outer and inner race.

(If inner race is tight on the

stud, drive a wedge between

the flanged end and the roller

gear hub to remove it.)

ASSEMBLY:

Clean stud and bearing cap and apply light coat of assembly grease to stud; install inner race firmly

against hub; install outer race with identifying numbers on outboard side; install bearing cap over

locating pins and tighten in place with self locking flat head cap screw.

FIGURE 9

Page 23

21

SECTION 8: Repair and Replace (continued)

8.2. Oil Seal Replacement

8.2.1. Remove oil seals by drilling a number of holes into the seal case.The seal may

then be removed with a pointed tool.Be sure to remove all metallic chips created

during the drilling of removal holes.

8.2.2. Check dimensions – to be sure that shaft and bore diameters match those

specified for the seal selected.

8.2.3. Check seal – for damage that may have occurred prior to installation.A sealing lip

that is turned back, cut or otherwise damaged should be replaced.

8.2.4. Check bore – to see that the leading edge is deburred, a rounded corner or

chamfer should be provided.

8.2.5. Check shaft – remove surface nicks, burrs and grooves and look for spiral machine

marks that can damage the seal lip.

8.2.6. Check shaft end – remove burrs or sharp edges.The shaft end should be

chamfered.

8.2.7. Check splines and keyways – smooth any sharp edges and when necessary

protect the seal lip with an assembly sleeve or shim stock. Round the edges of the

spline or keyway as much as possible and lubricate with a hard, fibrous grease.

8.2.8. Check seal direction – make sure that the new seal faces in the same direction as

the original. Generally, the lip faces the lubricant or fluid to be sealed.

8.2.9. Pre-lubricate the sealing element before installation by wiping with lubricant

being retained.

8.2.10.Use the correct installation tool – press fitting tools should have an outside

diameter .010” smaller than the bore size. If possible, the center of tool should be

relieved so that pressure is applied only at the O.D.

8.2.11. Use proper dr iving force – where possible, an arbor press; otherwise, a dead blow

hammer to avoid popping the spring out of the seal. NEVER HAMMER DIRECTLY

ON THE SURFACE OF THE SEAL.

Page 24

22

SECTION 8: Repair and Replace (continued)

8.2.12. Bottom out the tool or seal – to avoid cocking of the seal in the bore. This also

positions the seal correctly on the shaft.

8.2.13. Check for parts interference – from other machine parts that might rub against the

seal causing friction and damaging heat.

8.3. Reducers

Typical Ferguson “R” Series Reducer

FIGURE 10

Page 25

23

SECTION 8: Repair and Replace (continued)

8.3.1. “R” Series (Ferguson) Reducers

NOTE: The “R” Series reducer is a double enveloping worm gear type with

components manufactured to Industrial Motion Control’s specifications by

selected vendors. The worm and gear are provided in matched sets with

minimal backlash and installed in housings of IMC’s design.

The identifying number of a reducer consists of the letter “R” followed by a

number and a two-digit number (i.e. R4 15). The “4” indicates the center-tocenter distance between the worm and the gear; the “15” reflects the

reduction ratio. In this example, the ratio is 15:1.

8.3.1.1. Component Removal

8.3.1.1.1. Worm Shaft.

8.3.1.1.1.1. Drain oil and remove cover plate.

8.3.1.1.1.2. Record the distance between the worm bear ing shoulder

on the splined end of the shaft (opposite the single

extension end of the shaft) to the finished bore on the

cover side (see Figure 10).

8.3.1.1.1.3. Remove screws and worm bearing caps, keeping each set

of shims with their respective bearing caps.

8.3.1.1.1.4. Tap the wor m shaft back and forth axially to move the outer

race of the supporting bearings out of position.

8.3.1.1.1.5. Shaft the worm to the side of the housing, clear of the

gear. Remove the worm through the bearing bore in the

housing.

Page 26

24

SECTION 8: Repair and Replace (continued)

NOTE: Worm must be dropped before attempting to remove the gear.

8.3.1.1.2. Gear

8.3.1.1.2.1. Remove the worm as described above.

8.3.1.1.2.2. Record the distance from the finished face of the housing

to the unmarked face of the gear (see Figure 10).

8.3.1.1.2.3. Remove screw and washer retaining gear, if applicable.

8.3.1.1.2.4. Loosen the screw clamp on the split hub side of the gear.

8.3.1.1.2.5. Remove the gear. Tapped holes in the end of the gear hub

may be utilized in conjunction with a puller.

8.3.1.1.3. Component Replacement

NOTE: If both worm and gear were removed from the housing,

the gear must be replaced before the worm shaft is installed

8.3.1.1.3.1. The correct relationship of the worm and gear must be

maintained when reassembling the components. Regardless

of the actual position of the reducer unit on the roller gear

drive or Intermittor housing, you must imagine that the worm

is over the gear and that you are viewing the worm from the

single extension end (the end opposite of the splines on the

worm shaft) with the unmarked face of the gear to your right.

Maintain this relationship between components when

installing the gear on the roller gear camshaft.

Page 27

25

SECTION 8: Repair and Replace (continued)

8.3.1.1.3.2. The distance from the finished face of the housing to the

unmarked face of the gear, noted at the time of

disassembly, must be duplicated, either by grinding the

adjusting spacer or adding shims (see Figure 10).

8.3.1.1.3.3. Tighten the clamp screw in the split hub of the gear and

assemble the gear retaining screw and washer, if such

were provided as part of the factory installation.

8.3.1.1.3.4. Press cones of the tapered bear ings onto the worm shaft

and insert the worm shaft in the housing.

8.3.1.1.3.5. Assemble bearing cups, shims and caps and establish

pre-load, 2 IN-LBS, .003 SHIM. Adjust shims under bearing

cups until the dimension between the worm bearing

shoulder and the finished housing bore, as recorded at the

time of disassembly, is duplicated (see Figure 10).

NOTE: Do not discard any of the shims. Make

adjustments in pre-load by shifting shims from one

bearing cup to the other.

8.3.1.1.3.6. Replace cover plate and refill with oil. Refer to Chart 1 & 2

for quantity and specification.

Page 28

26

SECTION 9: THINGS TO AVOID

An Industrial Motion Control Indexer is a relatively simple mechanism using an input shaft

mounted cam to drive roller followers on the output hub. While simple in concept, the precision

nature of the indexer requires that it must be used within design constraints.The indexer is, after

all, just a mechanical device. In this regard there are several situations which should be avoided

to protect your warranty and maximize indexer life.

Off-center loading, such as might be seen when a large press is used in conjunction with

an indexer, requires a back-up suppor t anvil under the dial. The bearings of an indexer are

very heavy duty, but their life will be shortened dramatically by unsupported, asymmetr ical

loading.The support anvil is typically designed with .001” of clearance under the dial and is

strong enough to carry the full load of the asymmetrical load. Consult Industrial Motion

Control Technical Sales Department at 1-800-645-5207 or 847-459-5200 for assistance in all

asymmetrical load situations.

E-Stop Usage should be limited to emergency situations only. E-Stops should not be used

to jog an indexer. The E-Stop function causes extreme load conditions inside the indexer by

virtue of the instantaneous stopping of significant weights. This is not unlike driving a car

into a brick wall. Excessive use of the E-Stop will significantly shorten the life of the indexer.

Starting and Stopping while in the motion profile of the cam will also put high loading

on the indexer’s inter nal components. Should it be necessary to stop/star t the indexer in

any position other than the dwell of the cam, it is best to reduce motor speed to avoid

overloading the unit.

Shock Loading may also lead to problems. Shock loading typically occurs when there is

looseness in the input drive train or where the output load is not stable.

This condition will eventually damage either the indexer’s followers or cam. Overload

devices, that are not set correctly, are sometimes a source of this condition. Chain dr ives or

loose timing belt drives are also potentials.

Machine Jams, like E-Stops, put excessive loading on an indexer. While the impact of jams

is minimized by the use of overload devices, it is always best to track the occurrence of jams

and, when possible, rectify the condition that led to the jam.

A high jam frequency will shorten indexer life.

Friction from any source adds to the load of an indexer. This can include cam driven

mechanisms and/or additional, ancillary devices driven off the indexer’s drive shaft or output.

Extreme build-up of contamination or other sources of interference adds to the frictional load.

Ferguson indexers handle frictional loads very well, but the loading must be evaluated in terms

of the indexer’s overall capacity to ensure that the life of the equipment will not be compromised.

IMPROPER LUBRICATION CAN RESULT IN IMMEDIATE CATASTROPHIC FAILURE

OF THE UNIT .

Contact Industrial Motion Control Technical Sales Department (1-800-645-5207 or

847-459-5200) or your local Sales Engineer for assistance when evaluating the

above conditions.

Page 29

27

UNIT CONFIGURATIONS, REDUCER MOUNTING POSITIONS, HAND OF CAM

Page 30

© Industrial Motion Control, LLC 2003 All rights reserved

This publication is for information purposes only and should not be considered a binding Printed in U.S.A.

description of the product except if confirmed in writing by Industrial Motion Control, LLC. SKU 0106 / Revision 7/1/03

Michigan Office

550 Forest Avenue Unit #14

Plymouth, Ml 48170

USA

ph: 734-459-8080

fax: 734-459-8110

UK Office

432 Perth Avenue

Slough Trading Estates

Slough, Berkshire SL14TS

England

ph: 44-1-753-786100

fax: 44-1-753-786101

Belgium Office

33 Parc Industriel

BI 440 Braine-le-Château

Brussels, Belgium

ph: 322-367-1311

fax: 322-366-1891

Industrial Motion Control, LLC 1444 S. Wolf Road, Wheeling, IL 60090 Phone: 847-459-5200 Fax: 847-459-3064

www.camcoindex.com www.ferguson-co.com

The Driving Force in Automation

Loading...

Loading...